Universal Automation

A call for change

exchange.se.com

UNIVERSAL AUTOMATION

The IT world has moved

on from proprietary

operating systems.

Now it’s industry’s turn.

The future of industry is wide open

™

Schneider Electric

calling it universal automation and it will forever change the way we automate operations.

believes the time is right for a bold move in industrial automation. We’re

Universal automation is the world of plug-and-produce automation software components

(think app store) enabled by the IEC 61499 standard.

We believe “open automation” as it exists today is not open enough. We believe

interoperable and portable application software is an essential enabler for

next-generation industries.

We believe broad adoption of universal automation will unleash a wave of unbounded

innovation and usher in a new era of à la carte automation where cost/performance is

optimized by integrating best-of-breed components without regard to vendor.

We believe industrial enterprises will embrace this ever-growing automation app

marketplace to realize step-change improvements in eciency and sustainability we

could only dream of a decade ago.

And we believe businesses will thrive with universal automation that fluidly adapts to our

changing world to better transform humanity through the food we eat, the technology we

use, the products we consume, the work we do, and the environment we live in.

This is NOT business as usual.

Life is On | Schneider Electric 2

UNIVERSAL AUTOMATION

Executive Summary

Current industrial automation system architecture has done a good job of advancing industry to

where we are today, but to fully realize the promise of the Fourth Industrial Revolution, we need to

fundamentally change our technology model.

It is time to release the constraints we have learned to accept: Big engineering efforts, lack of

modularization, and barriers that inhibit adaptability and bog down innovation.

We can create step-change operational improvements with an open, standard-based architecture

and a plug-and-produce application ecosystem capable of keeping up with the speed of doing

business in the digital world.

Will you be part of the universal automation future?

Life is On | Schneider Electric 3

UNIVERSAL AUTOMATION

À la Carte Automation

A digital world

We are now living in a true digital economy. Technological innovations and the internet have

forever changed how the business of the world gets done.

At the same time, the recent pandemic and resulting global economic disruption has served

as a “wake up call” for industrial enterprises to no longer postpone much-needed operational

advancements in automation and digitalization. Even established companies that were once

perceived to be immune from market fluctuations are finding themselves challenged by

unprecedented global dynamics and by newcomers who are embracing digital technologies

to create agile businesses that better serve the modern world.

No one company can navigate these conditions alone. Persisting in this new world requires an

extended ecosystem of partners collaborating to succeed. It’s time for universal automation.

For manufacturing enterprises, the epidemic has

simply exposed problems and risks that already

existed. As such, it might force industry to undertake

much needed reforms to automation, digitalization

and logistics processes and systems.”

Control Engineering, 2020

Life is On | Schneider Electric 4

UNIVERSAL AUTOMATION

What future do we want?

In a digital world, industrial organizations thrive by seamlessly adapting to ever-changing market

conditions on both the supply and demand sides. By embracing innovative technologies along

with sustainability goals, companies can easily accommodate new business opportunities while

also conserving energy and natural resources.

• Operations respond fluidly and cost-effectively to evolving market demands, to real-time

price fluctuations in energy and raw materials, and to highly dynamic and greatly shortened

product lifecycles.

• Plants and processes are fully optimized for efficiency, reliability, productivity, and

sustainability, supported by a flexible, intrinsically cybersecure digital automation platform.

• Manual tasks are fully automated freeing the industrial workforce to use intuitive technology

and easy to understand analytics to make smart, real-time decisions that create

unprecedented business value.

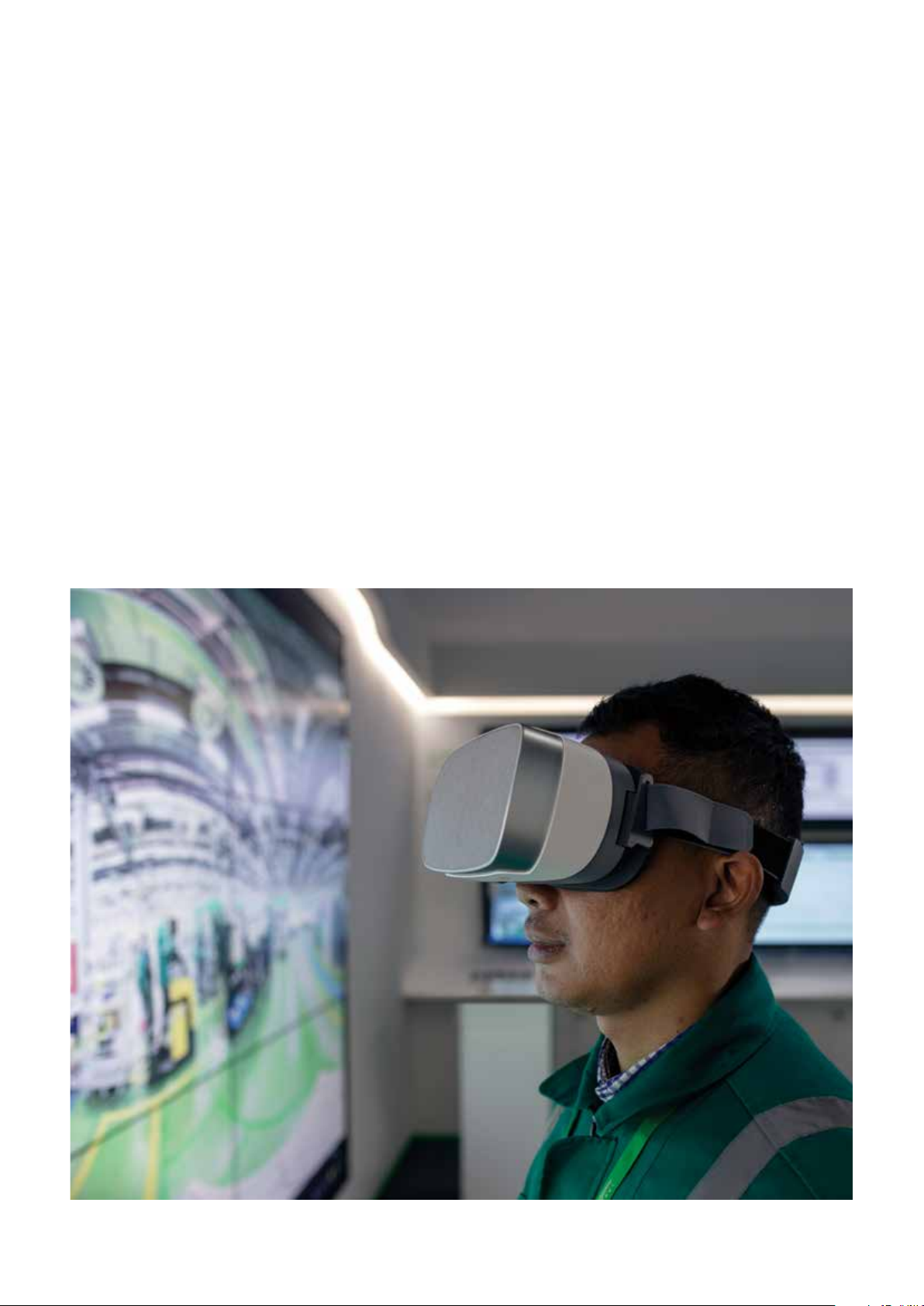

• Innovations such as augmented reality, remote management tools, and predictive maintenance

ensure that plants and processes are ready for 100% effectiveness. Return on OpEx and

CapEx spend is quickly realized.

Life is On | Schneider Electric 5

UNIVERSAL AUTOMATION

Today, companies need to be able to respond to

volatile demand, uncertain supply and constrained

capacity. But as we look beyond the pandemic,

they must also be able to respond to demanding

customers who will look for individualized and

sustainable products. If anything, this volatility has

highlighted the need for digital transformation and

industry 4.0.”

Forbes, 2020

Life is On | Schneider Electric 6

UNIVERSAL AUTOMATION

Constraints Are More

Historical than Technical

Time for change

The incentive to take the leap into the industry of the future is compelling. So, what is stopping

us from unleashing the full power of digital technology and achieving this new level of industrial

enterprise excellence? Surprisingly, the constraints are more historical and psychological

than technical.

In simple terms, proprietary automation systems make it difficult for companies to address digital

age challenges.

Over the last 50 years, little has changed in the fundamentals of how industrial automation systems

are designed, implemented, and operated. They have served us well and taken us this far in

industrial advancement, but digital innovation is limited without truly open automation systems

supporting portable application software. Some constraints include:

1. Automation applications written for one system will not easily run on another. This makes it

costly and difficult for industrial organizations to innovate, so changes are slow and the ability

to integrate revolutionary approaches is limited.

2. Lack of reference implementations for standards creates architectural challenges that lead

to isolated islands of control and inefficiencies. Integrating these islands into a holistic plant

architecture requires a great deal of application engineering, extra hardware, and additional

layers of software in order to build a coordinated plant automation and control system.

The added layers of interfaces contribute to lower reliability, increased unplanned downtime,

and higher costs.

3. Proprietary systems are not designed to take advantage of the recent and rapid changes

in IT. For precisely this reason, they inhibit manufacturers from realizing the full promise of

digital transformation.

Life is On | Schneider Electric 7

UNIVERSAL AUTOMATION

End Users Demand Open

Open benefits everyone

The pressure to adopt open automation is mounting for stakeholders across all corners of industr y.

End users are beginning to see proprietary automation systems as a barrier to growth and a cost,

rather than an enabler and source of profit.

Many organizations recognize that next-generation industrial automation must be interoperable

and break free from the proprietary locked-in model we have now. A few examples are:

Open Process Automation Forum, NAMUR, and OPC Foundation.

Moving from a proprietary world to universal automation not only benefits end users, but it also

gives those willing to innovate an edge in the race for new value built on software innovation.

Universal automation will create a market for proven-in-use software components that bring unique

values to users and new revenues for vendors.

Life is On | Schneider Electric 8

UNIVERSAL AUTOMATION

Apps Solve Specic

Problems at Low Cost

Lessons from IT

In the IT world, standardized, open operating systems like Linux stimulate an active, broad

ecosystem of developers to create a rich and expansive portfolio of portable, innovative, and

cost-effective software solutions and services that solve very specific business problems.

This paradigm does not exist in the industrial automation world today.

It’s natural for traditional industrial automation vendors to resist change. The concepts of

“interoperable” and “portable” drive against their longstanding business models. But the same

dynamics led to the demise of mainframe computer manufacturers who continued to bundle

software due to what now appears to be market-denial and misguided hubris.

Held hostage by risk-aversion

Vendors benefiting from a proprietary model may argue that building systems based on best-ofbreed components from multiple vendors increases risk, but the reality is just the opposite:

1. Risk is reduced when an end user can benefit from the domain expertise of multiple authorities

with broad and deep competence in a given field, as well as the fresh perspectives from

up-and-coming innovators that challenge the status quo.

2. Proven-in-use software components running on a standards-based system are not only more

reliable but also more easily expanded and adapted for future use. By contrast, customprogrammed proprietar y systems are expensive to maintain and difficult to upgrade.

3. In the IT-world, the approach of using reference implementations eliminates the risk associated

with interpreting written standards and accelerates the creation of de-facto industry standards

with broad support. Open-source Linux has been used for years in mission-critical applications

and is supported by an extensive ecosystem.

The reality is that system integrators/EPC’s are already building solutions with components from

different vendors. It’s just a lot more difficult than it needs to be.

Strategically, traditional automation suppliers who reevaluate their unique value-add to reinvent

their business model will be in stronger competitive positions in the digital world.

As automation systems become more flexible and capable of providing increased end user

value, a virtuous cycle will be created where investment in automation systems will increase.

New business models will be enabled, new customers reached, and new markets ser ved.

Life is On | Schneider Electric 9

UNIVERSAL AUTOMATION

Plug-and-Produce

What will it take?

Fully digitalizing the manufacturing and process industries will require open automation systems

that support:

• Cost-effective and flexible interoperability with enterprise IT systems across the full lifecycle—

from design to operations.

• Applications that can be built using proven-in-use software components, regardless of the

underlying hardware on which the software will run. This reduces cost and time to market while

increasing return-on-investment, flexibility, and overall functionality.

It will take two steps to get there:

1. Create an IEC 61499 standardized automation layer across vendors, in the same

way that Linux has standardized operating systems across computers.

2. Leverage the standard automation layer to enable an ecosystem of developers

to create a rich and expansive portfolio of portable, innovative automation apps

(software components) that solve specific challenges at low cost.

Universal automation will allow OEMs, integrators, and end users to build automation solutions

by plugging together best-of-breed apps using low-code graphical tools. In industry, we call this

plug-and-produce.

Much in the same way that consumers can easily access the latest mobile phone technologies and

apps, industrial stakeholders, will be able to experience ease-of-use at lower costs through much

simpler, less labor intensive behind-the-scenes integration.

Life is On | Schneider Electric 10

UNIVERSAL AUTOMATION

IEC 61499 Enables

Universal Automation

We have the proven technology

The IEC 61499 standard extends and enhances the IEC 61131-3 standard. It solves the problems

of ensuring por tability, configurability, and interoperability of application software across vendors

and, at the same time, software and hardware independence. IEC 61499 defines a high-level

system design language for distributed information and control systems. It is the technical

foundation of universal automation because it:

1. Enables automation applications to be built using portable, proven-in-use software

components, independent of the underlying automation hardware.

2. Allows the user to distribute the application to any system hardware architecture of choice—

highly distributed, centralized, or both—all with little programming effort. Hardware targets can

be as small as instruments and actuators or as large as powerful edge computers.

3. Supports mainstream software best practices making it easy to create automation applications

that interoperate with IT systems. Native IT convergence and easy portability will drive a

long-term shift from low-value programming of proprietary controllers to high-value plug-andproduce automation systems using proven-in-use automation software components.

IEC 61499 already runs on today’s PC-based platforms and IPCs, as well as modern edgecomputing devices such as Raspberry Pis. Driven by demand from end user organizations,

the trend towards such open hardware platforms continues to accelerate.

Life is On | Schneider Electric 11

UNIVERSAL AUTOMATION

Better than Business

as Usual

Unprecedented opportunity

This new, universal automation world, with IEC 61499-enabled digitization at its center, will surpass

business-as-usual on multiple levels:

1. “Lot size of one” supersedes mass production. The tradition of large, centralized

manufacturing plants only capable of churning out mass produced products halfway around

the world will be replaced with smaller, more distributed manufacturing plants, closer to the

consumer, capable of producing highly customized, affordable products that are fast and cost

effective to deliver. In such a world, the product doesn’t exist until the consumer defines what

it should be. Manufacturers benefit from dramatic reductions in finished goods and work-inprogress inventory throughout the supply chain, delivering output only to paying customers

who are lined up and ready to consume the goods.

2. Step change improvements in efficiency, agility, and sustainability. Advanced

technologies such as artificial intelligence and machine learning will improve real-time control

of critical business, operating, and sustainability variables with unprecedented precision. Selfconfiguring, self-healing, fast-retooling systems will make it easy for industrial companies to

keep up with the speed and requirements of doing business in the digital age.

3. Minimization of workforce “brain drain.” As the Baby Boomer generation retires, the

potential loss of knowledge is lessened with the advent of systems that learn and improve over

time. As the next generation takes over, software-based automation systems are a more natural

fit to this Digital Native population. The next wave of the workforce won’t be control engineers.

They will be data engineers focused on controlling the process to generate positive business

outcomes and performance.

4. IT/OT convergence is strengthened. A common standard serves as a natural point of

convergence between the physicality of OT and the digital perspective of IT where realtime data is used to make precise business and operating adjustments to improve financial

performance. In addition, supporting multiple programming languages to create a new

generation of portable and interoperable code means that an automation application designed

to run on one manufacturer’s system could also run on another’s. Moreover, automation

engineering can be fast-tracked by wrapping and reusing existing systems.

5. Software plays a leading role. Customer requirements will not be addressed with new

hardware but will require the intelligent application of software-based technologies to address

OT problems. This digital paradigm will provide unprecedented operational capabilities and

support new business opportunities for all industrial stakeholders.

Life is On | Schneider Electric 12

UNIVERSAL AUTOMATION

It Takes an Ecosystem

Universal automation

What will it take for next-generation industrial businesses to thrive?

The proprietary industrial automation architectures that most enterprises currently rely on

constrain innovation, needlessly increase total cost of ownership, and inhibit the adoption of

IT-based advancements. Businesses cannot evolve quickly enough to match the market dynamics

of the digital world.

But why? Next-generation manufacturing and process operations do not have to be centered

around an automation system architecture at all. Instead, the automation system should only

be an open platform tool that is used to implement new manufacturing and production models.

The confluence of digitization and the IEC61499 standard now make it possible.

The IEC 61499 standard is the technical enabler for a plug-and-produce approach to industrial

automation. Adoption of a standardized automation layer, common across vendors, will provide

limitless opportunities for growth and modernization across industry.

The age of plug-and-produce universal automation apps is upon us.

We no longer must live with the constraints we have learned to accept in industrial automation, but

no one company can accomplish all that Industr y 4.0 promises on their own. Persisting in this new

world requires an extended ecosystem of partners collaborating to succeed.

Will you be part of the universal automation future?

For more information

• 5 ways IEC 61499 is liberating Industrial Automation

• Bailing out of the Mainframe Industry

• Coronavirus will force manufacturers to enhance automation, digitalization

• IEC 61499: The Industrial Automation Standard for Portability that

Unleashes Industry 4.0

• Is IEC 61499 the missing link for Industr y 4.0?

• NAMUR

• OPC Foundation

• Open Process Automation Forum

• The Changing Definition of “Good Enough” Automation

• The Missing ‘Industry 4.0/Digitalization’ Link

• The Time for Industry 4.0 Is Now

Life is On | Schneider Electric 13

Learn more about Universal Automation

exchange.se.com

Schneider Electric

35 rue Joseph Monier

92500 Rueil Malmaison

France

©2020 S chneider Electr ic. All Rights Res erved . Schneid er Electr ic | Life Is O n are trad emarks a nd the propert y of Schneider Elect ric SE, its subsidiaries, and aff iliated co mpanies. All othe r

trade marks are the property o f their re spective owners . • 998 -21066 447_GMA

Loading...

Loading...