Page 1

PowerLogic

Multi-Circuit Meters

Configuration Guide

TM

Series EM4800

Page 2

PowerLogic

DANGER

WARNING

01/2011

TM

EM4800 Series 930-112-01-B.00

Hazard Categories and Special

Symbols

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service or maintain it.

The following special messages may appear throughout this bulletin or on

the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal injury if

the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in minor or moderate injury.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially

hazardous situation which, if not avoided, can result in property damage.

NOTE: Provides additional information to clarify or simplify a

procedure.

PLEASE NOTE Electrical equipment should be installed, operated, serviced, and maintained

only by qualified personnel. No responsibility is assumed by Schneider

Electric for any consequences arising out of the use of this material.

© 2011 Schneider Electric All Rights Reserved

Page 3

930-112-01-B.00 PowerLogic

01/2011

TM

EM4800 Series

Copyright © 2011. Schneider Electric. All Rights Reserved.

Schneider Electric is the holder of all intellectual property rights, including

copyrights, in and to this software, except for specific software components

integrated herein which are used under license from Triacta Power Inc., and

Microsoft Corp.

This software is protected under copyright law and international treaties.

Unauthorized reproduction or distribution of this software, or any portion or

component thereof, in any form, is strictly prohibited and may be prosecuted

to the fullest extent permissible under the law resulting in severe civil and

criminal penalties.

© 2011 Schneider Electric All Rights Reserved

Page 4

PowerLogic

TM

EM4800 Series 930-112-01-B.00

01/2011

© 2011 Schneider Electric All Rights Reserved

Page 5

930-112-01-B.00 PowerLogic

01/2011 Table of Contents

TM

EM4800 Series

Table of Contents

POWERLOGIC CONFIGURATION TOOL..................................................1

System Set-up and Description ..................................................................1

Configuration and Programming ...........................................................1

Display Navigation .................................................................................4

Normal Mode .................. ... .............................................................. 4

Diagnostics Mode ............................................................................ 4

Communications Connections ...............................................................5

Network Connection Ethernet Requirements ..................................6

Configuring the Meters .................................................... ... .........................7

Login ......................................................................................................7

Connecting to a Meter ...........................................................................8

Unit Field Configuration Tab ................................................................10

Report Parameters ........................................ ... .............................12

Manufacturing Tab .............................................................................. 18

Meter Points (Circuits) Tab ........................................ ... .......................19

Meter Point Configuration ..............................................................19

Badge Numbering ..........................................................................20

Pulse Probes Tab ................................................................................22

Completing the Meter Configuration .................................................... 23

© 2011 Schneider Electric All Rights Reserved

i

Page 6

PowerLogic

TM

EM4800 Series 930-112-01-B.00

Table of Contents 01/2011

© 2011 Schneider Electric All Rights Reservedii

Page 7

930-112-01-B.00 PowerLogic

01/2011 PowerLogic configuration tool

TM

EM4800 Series

POWERLOGIC CONFIGURATION

TOOL

This document describes how to configure the PowerLogic EM4800 Series

meter (PowerLogic EM4833, EM4880 and EM4805 meters), using the

PowerLogic configuration tool. It includes the following configuration tool

information:

• “System Set-up and Description” on page 1

• “Configuration and Programming” on page 1

• “Display Navigation” on page 4

• “Communications Connections” on page 5

• “Configuring the Meters” on page 7

• “Login” on page 7

• “Connecting to a Meter” on page 8

• “Unit Field Configuration Tab” on page 10

• “Manufacturing Tab” on page 18

• “Meter Points (Circuits) Tab” on page 19

• “Pulse Probes Tab” on page 22

• “Completing the Meter Configuration” on page 23

This documentation is intended for those responsible for configuring the

PowerLogic EM4833, EM4880 and EM4805 meters.

System Set-up and Description The configuration tool supports the PowerLogic EM4833, EM4880 and

EM4805 meters.

Depending on how the meters are installed and configured, they can meter

8, 12, or 24 individual meter points. The PowerLogic EM4833, EM4880 and

EM4805 meters are designed for residential, commercial, and industrial use

and display the power and consumption readings for each measurement

point.

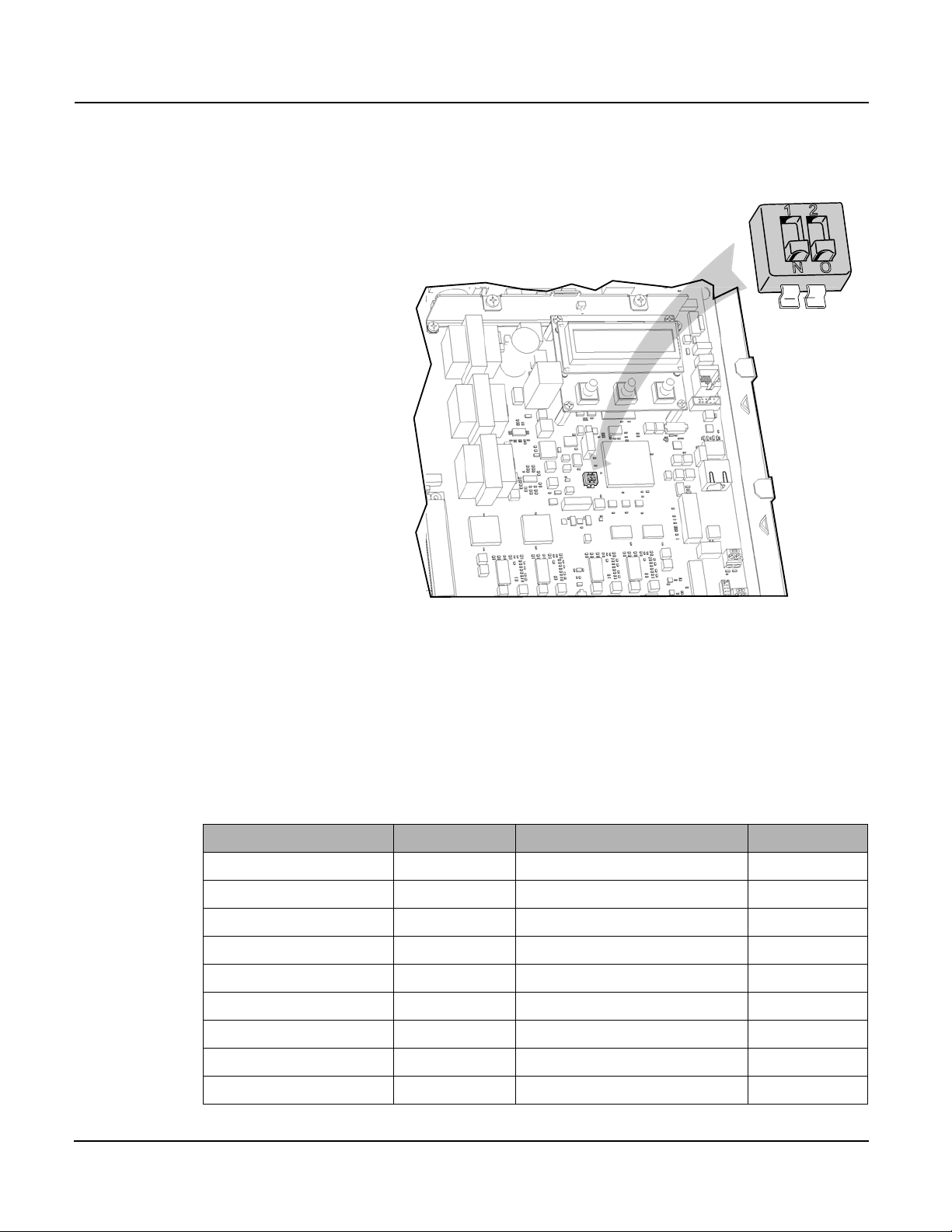

Configuration and Programming The configuration tool is used to set any of the programmable parameters of

the PowerLogic EM4800 Series meter. The combination of the configuration

tool and the state of the meter programming switches determine which

parameters can be set or changed. As shown in Figure 1, the programming

switches are two-position DIP switches labeled SW1, and are located inside

the meter cover below the Display button. To enable meter configuration,

both switches must be physically set to the ON (down) position (default).

© 2011 Schneider Electric All Rights Reserved

1

Page 8

PowerLogic

"SW1"

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

Figure 1: Programming Switch location

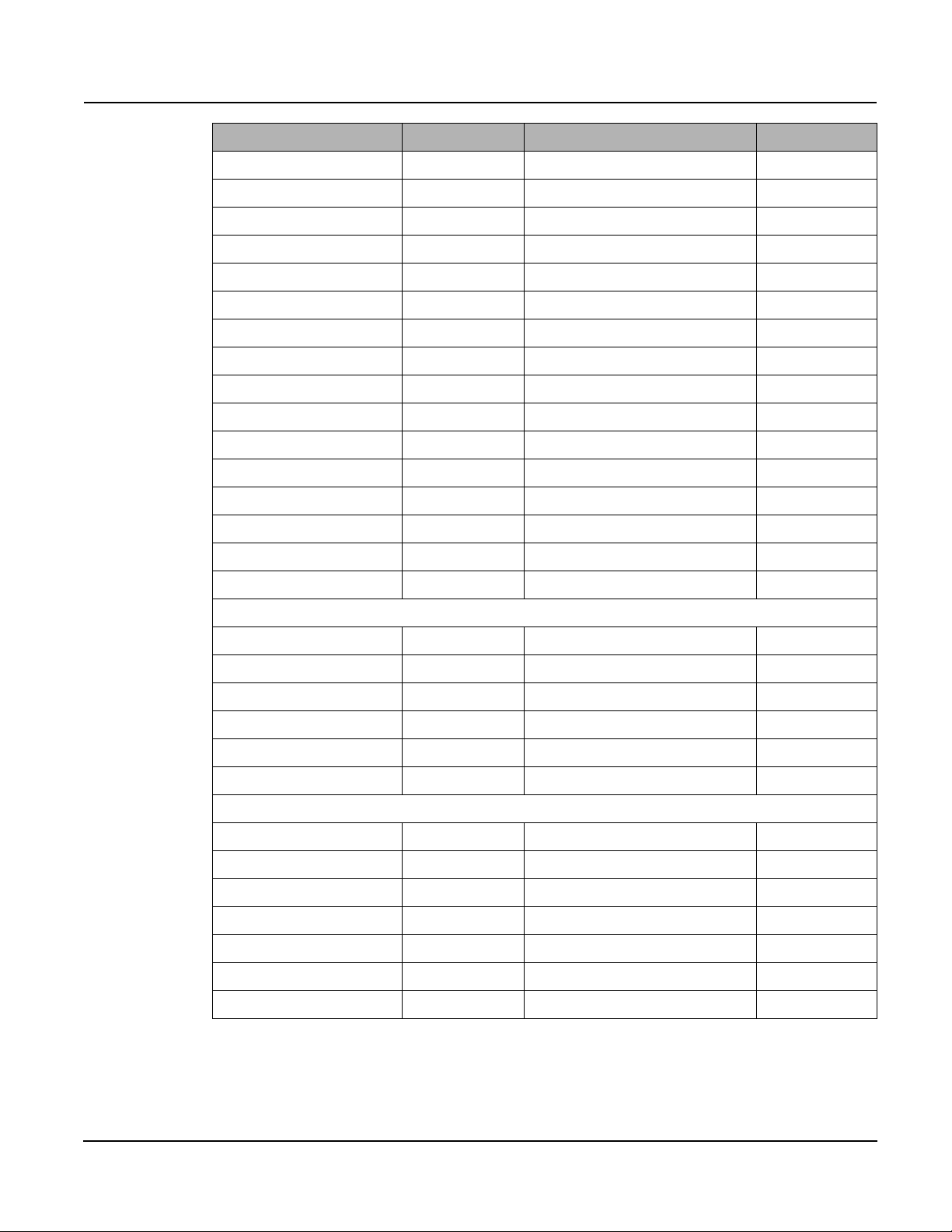

Table 1 lists the programming capabilities associated with each parameter in

combination with the programming switches. After the meter has been

programmed, the programming switches can be turned OFF to prevent

tampering with metering parameters.

Parameter Read access Write access Activation time

Meter name Configuration tool Configuration tool Immediate

Badge number Configuration tool Configuration tool Immediate

Phone number Configuration tool Configuration tool Immediate

Alternate phone number Configuration tool Configuration tool Immediate

AT string Configuration tool Configuration tool Immediate

Host upload directory Configuration tool Configuration tool Immediate

Host download directory Configuration tool Configuration tool Immediate

Host IP address Configuration tool Configuration tool Immediate

PPP user name Configuration tool Configuration tool Immediate

Table 1: Programming access to meter parameters

© 2011 Schneider Electric All Rights Reserved2

Page 9

930-112-01-B.00 PowerLogic

TM

EM4800 Series

01/2011 PowerLogic configuration tool

Parameter Read access Write access Activation time

PPP password Configuration tool Configuration tool Immediate

FTP user name Configuration tool Configuration tool Immediate

FTP password Configuration tool Configuration tool Immediate

Daily report interval start time Configuration tool Configuration tool Immediate

Daily report interval end time Configuration tool Configuration tool Immediate

Report period Configuration tool Configuration tool Immediate

Report interval in minutes Configuration tool Configuration tool Immediate

PT ratio Configuration tool Configuration tool + prog. switch ON Immediate

Default IP address Configuration tool Configuration tool Immediate

Default netmask Configuration tool Configuration tool Immediate

Default gateway Configuration tool Configuration tool Immediate

Reset dial readings No Access Configuration tool + prog. switch ON Immediate

Send PC time No Access Configuration tool Immediate

Programming switch state Configuration tool No Access Immediate

MAC address Configuration tool No Access Immediate

Report types Configuration tool Configuration tool Immediate

Manufacturing

Serial number Configuration tool No Access N/A

Part number Configuration tool No Access N/A

Model number Configuration tool Configuration tool + prog. switch ON After reset

Revision Configuration tool No Access

Firmware revision Configuration tool No Access N/A

Build number Configuration tool No Access

Meter and probe points

Name Configuration tool Configuration tool After reset

CT 1 current Configuration tool Configuration tool + prog. switch ON After reset

CT 2 current Configuration tool Configuration tool + prog. switch ON After reset

CT 3 current Configuration tool Configuration tool + prog. switch ON After reset

CT 1 phase Configuration tool Configuration tool + prog. switch ON After reset

CT 2 phase Configuration tool Configuration tool + prog. switch ON After reset

CT 3 phase Configuration tool Configuration tool + prog. switch ON After reset

© 2011 Schneider Electric All Rights Reserved

3

Page 10

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

Display Navigation The display on the front of the meter provides status information for each

circuit, and general information for metering. The PowerLogic EM4800 meter

has three buttons for navigating: a Display button, and left and right arrow

buttons. The display has a normal and a diagnostics mode.

Normal Mode

In Normal mode, the Display button scrolls through the information for each

meter. The left and right arrow buttons select the previous or next meter

points respectively. The following information is available:

• Real Energy Delivered kWh D

• Real Energy Received kWh R

• Real Power Watts

• Reactive Energy Delivered KVarhD

• Reactive Energy Received KVarhR

• Reactive Power Var

In Normal mode, the right and left arrow buttons scroll the display from meter

points 1 to 8, 1 to 12, or 1 to 24, depending on your configuration.

Diagnostics Mode

Diagnostics mode is accessed by pressing and holding the Display button for

5 seconds. In Diagnostics mode, pressing the Display button will scroll

through the following additional information:

• Send data command

• CT Primary value and Real Power Watts per phase

• Voltage per phase

• Local IP address

• Reset factory default IP address command

• Date and time (UTC)

In Diagnostics mode, the right and left arrow buttons scroll the display from

meter 1 through N. When the local IP address is shown on the LCD, use the

right and left arrow buttons to scroll through the following information:

• Remote host server IP address

• Time server IP address

• Default IP address

• Default NetMask

• Default gateway

• PPP user name

• Phone number

• AT command string

• Alternate phone number

• Unit serial number

• Firmware build number

• Ethernet port MAC address

• Firmware revision

• Potential transformer ratio

© 2011 Schneider Electric All Rights Reserved4

Page 11

930-112-01-B.00 PowerLogic

DANGER

01/2011 PowerLogic configuration tool

TM

EM4800 Series

Communications Connections If you are configuring the meter at the installation site, see the PowerLogic

EM4800 Series Meter Installation Guide for instructions on connecting the

power. Power connections vary depending on whether the meter is

configured for single-phase or three-phase operation.

If you are pre-configuring the meter in the shop, only Phase A, Neutral, and

protective earth connections are required to power up the PowerLogic

EM4800 Series meter for configuring.

The PowerLogic EM4800 Series Configuration Tool communicates with the

PowerLogic meters through an Ethernet network connection. A network

connection can be accomplished in two ways: either Direct using an Ethernet

crossover cable, or by connecting to a LAN (Local Area Network).

NOTE: If you are attempting to use the list function, the PC being used

to configure the device MUST be on the same network segment as the

PowerLogic meters to be configured. The connect function will allow

the user to find the PowerLogic meters on or off the same segment,

however you must know the correct IP address of the unit being

modified.

Direct Connection Ethernet Requirements

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow

safe electrical work practices. See NFPA 70E.

• This equipment must only be installed and serviced by qualified

electrical personnel.

• Turn off all power supplying this equipment before working on or

inside equipment.

• Always use a properly rated voltage sensing device to confirm

power is off.

• Replace all devices, doors and covers before turning on power to

this equipment.

• The meters must be connected to the sense voltage and control

voltage through a properly rated disconnect.

Failure to follow these instructions will result in death or serious

injury.

© 2011 Schneider Electric All Rights Reserved

To connect a PC directly to the PowerLogic EM4800 Series meter:

1. Disconnect power from the meter with the installed breaker or

disconnecting device. Use a properly rated voltage sensing device to

confirm power is off.

2. Remove the outer cover.

3. If you are changing parameters that require the programming switch to

be on, remove the inner cover and ensure the programming switches

are in the ON position.

4. Re-install the inner cover.

5. Remove the local LAN Ethernet cable if present and connect the CAT 5

Ethernet cross-over cable between the PC and the PowerLogic

EM4800 Series meter.

6. Restore power to the meter.

5

Page 12

PowerLogic

DANGER

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

7. Assign the PC a static IP address such that the first three segments are

the same as the default IP address, and the last segment is different

from the default IP address. For example, 169.254.0.xxx, where xxx

differs from the last segment of the default IP address.

8. Configure the meter. See “Configuring the Meters” on page 7 for

configuration instructions.

9. Remove power. Use a properly rated voltage sensing device to confirm

power is off.

10. If you wish to lock the configuration parameters, remove the inner cover

and move the programming switches (SW1) to the OFF (up) position.

11. Re-install the inner cover.

12. Connect the LAN Etherent cable if present.

13. Re-install the outer cover.

14. Restore power.

NOTE: All PowerLogic EM4800 Series meters have a default IP

address of 169.254.0.10 in the absence of a DHCP service.

Network Connection Ethernet Requirements

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow

safe electrical work practices. See NFPA 70E.

• This equipment must only be installed and serviced by qualified

electrical personnel.

• Turn off all power supplying this equipment before working on or

inside equipment.

• Always use a properly rated voltage sensing device to confirm

power is off.

• Replace all devices, doors and covers before turning on power to

this equipment.

• The meters must be connected to the sense voltage and control

voltage through a properly rated disconnect.

Failure to follow these instructions will result in death or serious

injury.

To connect the PowerLogic EM4800 Series meter to the network:

1. Turn off power to the meter with the installed breaker or disconnecting

device. Use a properly rated voltage sensing device to confirm power

is off.

2. Remove the outer cover.

3. If you are changing parameters that require the programming switch to

be on, remove the inner cover and ensure the programming switches

are in the ON position.

4. Re-install the inner cover.

5. Using a CAT 5 Ethernet patch cable, connect the meter to a local

Ethernet switch.

6. Re-install the outer cover.

© 2011 Schneider Electric All Rights Reserved6

Page 13

930-112-01-B.00 PowerLogic

01/2011 PowerLogic configuration tool

TM

EM4800 Series

7. Restore power. When control power is restored, the meter will receive

an IP address from a local DHCP server. This IP address can be

viewed from the Diagnostics menu.

NOTE: To use a static IP address, have your local network

administrator assign the desired IP address to the MAC address of the

meter in the DHCP server configuration. To display the MAC address,

see “Display Navigation” on page 4.

Configuring the Meters The PowerLogic EM4800 Series configuration tool is available on the CD

shipped with each unit, and is used to configure all programmable

parameters listed in Table 1.

Login Use the following procedure to log in to the meter.

1. Establish an Ethernet network connection with the meter using one of

the methods descirbed in “Communications Connections” on page 5.

2. Ensure the programming switches are in the ON position. The

programming switches are two-position DIP switches labeled SW1, and

are located inside the meter cover below the Display button. To enable

meter configuration, both switches must be physically set to the ON

position. When both switches are in the OFF position, meter

configuration is disabled.

3. Start the configuration tool by entering “PowerLogic” as the User

Name, and “E4800” as the Password (see Figure 2). Click Ok.

Figure 2: Login screen

4. The main window displays as shown in Figure 3.

© 2011 Schneider Electric All Rights Reserved

7

Page 14

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

Figure 3: Configuration tool main window

Connecting to a Meter The configuration tool automatically detects and lists the PowerLogic meters

on the same network segment as the PC. The configuration tool can also be

used with meters on a different network.

To connect to a meter on the same network:

1. Click Unit in the menu ba r, then se lect List from the drop-down menu.

The Discovered Units window appears, displaying a list of meters

available for configuration. See Figure 4.

© 2011 Schneider Electric All Rights Reserved8

Page 15

930-112-01-B.00 PowerLogic

01/2011 PowerLogic configuration tool

TM

EM4800 Series

Figure 4: Discovered Units dialog box

2. Select the Load Unit Configuration check box, then click Ok. The

main configuration tool window appears populated with the current

programming information for the selected meter. See Figure 5.

3. Proceed to “Unit Field Configuration Tab” on page 10.

To connect to a meter on a different networ k:

1. Click Unit in the menu bar, then select Connect from the drop-down

menu. The Connect to Unit window appears. See Figure 5.

Figure 5: Connect function window

2. Enter the IP address of the meter to be configured, then click Connect.

The configuration tool main window appears populated with the current

programming information for the selected meter. See Figure 6.

3. Proceed to “Unit Field Configuration Tab” on page 10.

© 2011 Schneider Electric All Rights Reserved

9

Page 16

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

Figure 6: Main configuration window with configured parameters

Unit Field Configuration Tab Use Table 2 to set meter configuration parameters in the Unit Field

Configuration tab.

© 2011 Schneider Electric All Rights Reserved10

Page 17

930-112-01-B.00 PowerLogic

TM

EM4800 Series

01/2011 PowerLogic configuration tool

Table 2: Unit Field Configuration tab parameters

Field Parameter Description

Unit Field Configuration Current IP Address The current IP address for the unit .This parameter is read only and cannot

Mac Address The current MAC address for the unit. This parameter is read only and

be changed by the user.

cannot be changed by the user.

Revision The revision number of the unit.

Default IP Configuration IP Address The default IP address. This parameter is configured when DHCP has

been disabled, or DHCP services are not available on the network.

Netmask The default subnet mask. This parameter is configured when DHCP has

Gateway The default gateway. This parameter is configured when DHCP has been

been disabled, or DHCP services are not available on the network.

disabled, or DHCP services are not available on the network.

DNS Primary The primary domain name server. This parameter is configured when

DHCP has been disabled, or DHCP services are not available on the

network.

DNS Secondary The secondary domain ame server. This parameter is configured when

DHCP has been disabled, or DHCP services are not available on the

network.

DHCP Enabled If DHCP is not enabled, the meter uses the Default IP Configuration

parameters. If DHCP is enabled, the meter uses the IP configuration

parameters provided by the network DHCP service.

Report See “Report Parameters” on

page 12

Main Meter PT Ratio The main meter potential transformer ratio. This is an internal multiplier

used by the meter for external potential transformers. External PTs can be

used with a PT ratio of 1 if the billing system will apply the PT muliplier.

Use a PT Ratio of 1 with no external PTs.

Modem Phone # The phone number of your internet service provider’s PPP service.

Alternate Phone # An alternate phone number of your internet service provider’s PPP service.

AT String AT command string to customize modem operation. Default string is ATX3,

Wait for Dial Tone Do not enable this parameter if the line has a broken dial tone due to a

do not wait for dial tone.

message waiting feature.

Host Server IP Address The IP address or domain name of the FTP server for data storage.

Upload Directory The sub-directory used for data reporting within the root directory. The root

directory is determined by the FTP user name and the FTP server

configuration. The FTP account must have write access to this directory.

Download Directory The sub-directory used by the meter to retrieve configuration updates. The

FTP account must have read access to this directory..

FTP Login User Name The user name for the FTP account.

Password The password for the FTP account.

PPP Login User Name The user name for the PPP account. This is only required if using dial-up

Password The password for the PPP account. This is only required if using dial-up

reporting.

reporting.

NTP Host (Time Server) IP Address The IP address of the NTP server that provides timing to the meter.

© 2011 Schneider Electric All Rights Reserved

11

Page 18

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

Report Parameters

The Report section in the main configuration window has three tabs:

• the Period tab allows the user to configure when the reports are

generated and the interval at which data is collected. Figure 7 shows

the Period tab, and Table 3 lists the configuration parameters within the

tab.

• the Types tab allows the user to configure the types of reports that are

generated, and to define the metering parameters that are to be logged

on an interval basis. Figure 8 shows the Types tab, and Table 4 lists the

configuration parameters within the tab.

• the Real Time Interval tab allows the user to configure real time

reporting daily, or at a specified regular interval in minutes. It allows the

user to define how often the meter is to send interval data to a server.

This setting works independently from the Period tab setting. Figure 9

shows the Real Time Interval tab, and Table 5 lists the configuration

parameters within the tab.

• the Power Factor tab allows the user to configure the type of power

factor calculation and the display format for leading vs. lagging power

factor. Figure 10 shows the Power Factor tab, and Table 6 lists the

configuration parameters within the tab.

• the BACnet tab allows the user to configure the BACnet Device ID.

Figure 11 shows the BACnet tab, and Table 7 lists the configuration

parameters within the tab.

© 2011 Schneider Electric All Rights Reserved12

Page 19

930-112-01-B.00 PowerLogic

01/2011 PowerLogic configuration tool

TM

EM4800 Series

Figure 7: Period tab in the Report section

© 2011 Schneider Electric All Rights Reserved

Table 3: Period tab configuration parameters

Parameter Description

Interval in Minutes The interval at which data is collected.

13

Page 20

PowerLogic

TM

EM4800 Series 930-112-01-B.00

PowerLogic configuration tool 01/2011

Figure 8: Types tab in the Report section

Table 4: Types tab configuration parameters

Parameter Description

Watt Hours Delivered Interval/Register

Watt Hours Received Interval/Register

VAR Hours Delivered Interval/Register

VAR Hours Received Interval/Register

VA Hours Interval/Register

Voltage

Pulses

These types of records can be enabled

by selecting the check box.

© 2011 Schneider Electric All Rights Reserved14

Page 21

930-112-01-B.00 PowerLogic

01/2011 PowerLogic configuration tool

TM

EM4800 Series

Figure 9: Real Time Interval tab in the Report section

© 2011 Schneider Electric All Rights Reserved

Table 5: Real Time Interval tab configuration parameters

Parameter Description

Daily Enables daily real time reporting by

Start Time When daily reporting is enabled, you

End Time When daily reporting is enabled, you

Minutes Enables real time reporting every x

selecting the radial button. The unit

defaults to daily reporting and sends

the data file at a randomly selected

time within the report window.

can set the reporting period start time.

can set the reporting period end time.

number of minutes by selecting the

radial button and entering the interval

in miuntes.

15

Page 22

PowerLogic

TM

EM4800 Series 930-112-01-B.00

PowerLogic configuration tool 01/2011

Figure 10: Power Factor tab in the Report section

Table 6: Power Factor tab configuration parameters

Parameter Description

Format

IEEE

IEC

Method of Calculation

You can set the display format to IEC

or IEEE by selecting the radial button.

This sign indicates leading (+) or

lagging (-) power. The direction of

active power is not indicated.

The sign (+ or -) indicates the direction

of active power and provides an

additional indicator for capacitive or

inductive (leading or lagging) power.

You can set the power factor method of

calculation to Arithmetic or Vector by

selecting the radial button.

© 2011 Schneider Electric All Rights Reserved16

Page 23

930-112-01-B.00 PowerLogic

TM

EM4800 Series

01/2011 PowerLogic configuration tool

Figure 11: BACnet tab in the Report section

© 2011 Schneider Electric All Rights Reserved

Table 7: BACnet tab configuration parameters

Parameter Description

BACnet Device ID

You can set the BACnet device ID by

entering a 4-digit numeric ID.

17

Page 24

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

Manufacturing Tab The Manufacturing tab allows the user to define the metering configuration

for the PowerLogic meters.The meters support the configurations listed in

Table 8.

Table 8: List of supported metering configurations

PowerLogic EM4805 PowerLogic EM4833 PowerLogic EM4880

EM480510-1P-12 EM483310-1P-12 EM488010-1P-12

EM480510-1P-24 EM483310-1P-24 EM488010-1P-24

EM480510-2P-12 EM483310-2P-12 EM488010-2P-12

EM480510-2P-24 EM483310-2P-24 EM488010-2P-24

EM480510-3P-08 EM483310-3P-08 EM488010-3P-08

To view the manufacturing information for a specific meter, select a model

number from the Model # pull-down list shown in Figure 12. The part

number, revision number and serial number for the selected model will be

shown.

Figure 12: Manufacturing tab

© 2011 Schneider Electric All Rights Reserved18

Page 25

930-112-01-B.00 PowerLogic

01/2011 PowerLogic configuration tool

TM

EM4800 Series

Meter Points (Circuits) Tab The Meter Points (Circuits) tab contains the configuration information for

each of the metering points. It shows the number of elements used, the

phase, the current ratings, and the user-defined identification string for each

meter point. Default information is entered when the metering configuration

is selected in the Manufacturing Tab (see “Manufacturing Tab” on page 18).

Meter Point Configuration

The current rating and phase assignment for each meter point can be

configured individually, by meter, or all at once. The configuration in all three

cases does not take effect until the new settings have been sent to the meter

(see “Completing the Meter Configuration” on page 23).

To change the current rating and phase assignment for an individual meter

point:

1. Select one probe at a time from the Meter Points (Circuits) List. The

selected probe number will appear in the middle pane beside Probe,

and its assigned Current and Phase are shown beneath it. See Figure

13.

2. To change the Current, enter the required number. To change the

Phase, select the required phase type from the pull-down list.

Figure 13: Meter Points configuration screen

© 2011 Schneider Electric All Rights Reserved

19

Page 26

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

To change the current rating for all meter points assigned to a meter:

1. Select a meter from the Meter Points (Circuits) List. The selected

meter will appear in the Name field of the middle pane. See Figure 13.

2. In the Alter Current for Probes pane, enter the desired value

referenced to the CT primary rating in the Current field, and click on

Change Probes in Selected Meter.

To change the current rating for all meter points assigned to all meters:

1. In the Alter Current for Probes pane, enter the desired value

referenced to the CT primary rating in the Current field, and click on

Change all Probes in all Meters. See Figure 13.

Badge Numbering

Each meter point can be configured with a name defined by the user. The

meter point name, known as the badge number, can be up to 13

alphanumeric characters in length. The Badge Numbering pane allows the

user to set two types of badge numbers:

• sequential, which assigns a badge number to each meter point after the

prefix (for example CORP-00000001 to CORP-00000012)

• grouped by meter, which uses a base prefix to designate the meter,

then assigns a sequential badge number suffix to each meter point

assigned to that meter (for example CORP-00001-01 to

CORP-00001-12)

The configuration tool provides examples before the badge number is

assigned to the meter. In the Badge Numbering pane shown in Figure 14,

the following fields and buttons are provided for assigning badge numbers:

• Prefix field - an alphanumeric field that prefixes the number field.

• Badge Number field - a numeric field that becomes part of the prefix

for meter points assigned to that meter, or the first number in the

sequence to be assigned to individual meter points.

• Badge Number Width field - a numeric field that defines the number of

digits in the badge number field. Zeroes (0) are automatically entered

at the beginning of the badge number field until the total number of

digits in the badge number field equals the number of digits defined in

the badge number width field.

• Incremental badge numbers button - selecting this button assigns a

sequential badge number for each meter point

• Single badge number button - selecting this button assigns one badge

number prefix followed by a numeric suffix for each meter point

assigned to that meter.

• Assign Badge Numbers button - selecting this button implements the

badge numbering defined by the user in the previous fields.

• Reset Dial Readings button - selecting this button resets all registers

for all energy types and pulse counts to zero. This function takes effect

immediately and does not require a send action.

• Send PC Time button - selecting this button configures the meter with

the current PC time and UTC. This function takes effect immediately

and does not require a send action. This function can be used when

access to the network time service is not available.

© 2011 Schneider Electric All Rights Reserved20

Page 27

930-112-01-B.00 PowerLogic

TM

EM4800 Series

01/2011 PowerLogic configuration tool

Figure 14: Badge Numbering pane

© 2011 Schneider Electric All Rights Reserved

21

Page 28

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

Pulse Probes Tab The Pulse Probes tab contains the configuration information for each pulse

input. It shows the measurement type in units for each input, and the scale

factor applied to the collected pulse counts. Figure 15 shows the Pulse

Probes tab of the main configuration tool window.

To configure a pulse probe:

1. Select a pulse probe from the Probe List.

2. Select a measurement type from the Type pull-down list.

3. Enter a value in the Scale Factor field.

NOTE: The scale factor only changes the pulse values in the TR3

report.

Figure 15: Pulse Probes tab

© 2011 Schneider Electric All Rights Reserved22

Page 29

930-112-01-B.00 PowerLogic

01/2011 PowerLogic configuration tool

TM

EM4800 Series

Completing the Meter Configuration Once you have defined all of the configurable parameters, the PowerLogic

EM4800 Series meter is ready to be programmed.

To complete the meter configuration:

1. Click Unit in the menu bar, then select Save from the drop-down menu.

See Figure 16.

Figure 16: Saving the configuration settings

© 2011 Schneider Electric All Rights Reserved

23

Page 30

PowerLogic

PowerLogic configuration tool 01/2011

TM

EM4800 Series 930-112-01-B.00

2. Click Unit in the menu bar, then select Send from the drop-down menu

to transmit the configuration settings from your PC to the selected

PowerLogic EM4800 Series meter. The confirmation message File

loaded successfully! should appear in the bottom left corner of the

window. See Figure 17.

Figure 17: Sending the configured settings to the meter

© 2011 Schneider Electric All Rights Reserved24

Page 31

930-112-01-B.00 PowerLogic

TM

EM4800 Series

01/2011

© 2011 Schneider Electric All Rights Reserved

Page 32

PowerLogic

TM

EM4800 Series

Configuration Guide

Schneider Electric USA

Power Monitoring and Control

295 Tech Park Drive, Suite 100

Lavergne, TN 37086 USA

1-888-SquareD

(1-888-778-2733)

www.us.SquareD.com

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences ari sing out of

the use of this material.

930-112-01-B.00 © 2011 Schneider Electric All Rights Reserved

01/2011

Loading...

Loading...