Page 1

PowerLogic

Multi-Circuit Meters

930-112-01-D.00

11/2013

TM

Series EM4000/EM4800

Page 2

Page 3

Safety Information

Important Information

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service or maintain it.

The following special messages may appear throughout this manual or on

the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates that

an electrical hazard exists which will result in personal injury if the instructions are

not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Please note

WARNING indicates a potentially hazardous situation which, if not avoided, can

result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, can

result in minor or moderate injury.

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this signal word.

Electrical equipment should be installed, operated, serviced and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

Page 4

Notices

FCC Part 15 Notice

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures.

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

FCC Part 68 Notice

This equipment complies with Part 68 of the FCC rules and the requirements

adopted by the Administrative Council for Terminal Attachments (ACTA). On the

side of this equipment is a label that contains, among other information, a product

identifier in the format US: AAAEQ##TXXXX. If requested, this number must be

provided to the telephone company.

This equipment uses the following Universal Service Order Codes (“USOC”) jacks:

RJ11.

A plug and jack used to connect this equipment to the premises wiring and

telephone network must comply with the applicable FCC Part 68 rules and

requirements adopted by the ACTA. A compliant telephone cord and modular plug

or compliant modular jack is provided with this product.

The REN is used to determine the number of devices that may be connected to a

telephone line. Excessive RENs on a telephone line may result in the devices not

ringing in response to an incoming call. In most but not all areas, the sum of RENs

should not exceed five (5.0). To be certain of the number of devices that may be

connected to a line, as determined by the total RENs, contact the local telephone

company. The REN for this product is part of the product identifier that has the

format US: AAAEQ##TXXXX. The digits represented by ## are the REN without a

decimal point (e.g., 03 is a REN of 0.3).

If this equipment, Digital Power Meter with Internal Modem, causes harm to the

telephone network, the telephone company will notify you in advance that service

may be temporarily discontinued. When advance notice is not practical, the

Page 5

telephone company will notify you as soon as possible. You will also be advised of

your right to file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations

or procedures that could affect the operation of this equipment. If this happens, the

telephone company will provide advance notice in order for you to make necessary

modifications to maintain uninterrupted service.

If you experience trouble with this equipment, Digital Power Meter with Internal

Modem, please contact Schneider Electric at 615-287-3400. If this equipment is

causing harm to the telephone network, the telephone company may request that

you disconnect this equipment until the problem is resolved.

There are no user serviceable parts in this equipment.

Connection to party line service is subject to state tariffs. Contact the state public

utility commission, public service commission or corporation commission for

information.

If your premises has specially wired alarm equipment connected to the telephone

line, ensure that the installation of this Digital Power Meter with Internal Modem

does not disable your alarm equipment. If you have questions about what will

disable alarm equipment, consult your telephone company or a qualified installer.

Network Compatibility Notice for the Internal Modem

The internal modem in meters equipped with this option is compatible with the

telephone systems of most countries in the world, with the exception of Australia

and New Zealand. Use in some countries may require modification of the internal

modem’s initialization strings. If problems using the modem on your phone system

occur, please contact Schneider Electric Technical Support.

Page 6

Page 7

930-112-01-D.00 PowerLogic

11/2013 Table of Contents

TM

EM4000/EM4800 Series

Table of Contents

PowerLogic configuration tool ..................................................................... 1

System Set-up and Description ............................................................. 1

Configuration and Programming...................................................... 1

Display Navigation........................................................................... 3

Communications Connections ......................................................... 5

Configuring the Meters .......................................................................... 7

Login................................................................................................ 7

Connecting to a Meter ..................................................................... 8

Unit Field Configuration Tab.......................................................... 10

Manufacturing Tab......................................................................... 19

Meter Points (Circuits) Tab............................................................ 21

Pulse Probes Tab .......................................................................... 24

Completing the Meter Configuration .............................................. 26

User notes ................................................................................................. 29

©2013 Schneider Electric All Rights Reserved

i

Page 8

PowerLogic

TM

EM4000/EM4800 Series 930-112-01-D.00

Table of Contents 11/2013

©2013 Schneider Electric All Rights Reservedii

Page 9

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

PowerLogic configuration tool

This document describes how to configure the PowerLogic EM4000/EM4800

Series meters, using the PowerLogic configuration tool. It includes the following

configuration tool information:

• “System Set-up and Description” on page 1

• “Configuration and Programming” on page 1

• “Display Navigation” on page 3

• “Communications Connections” on page 5

• “Configuring the Meters” on page 7

• “Login” on page 7

• “Connecting to a Meter” on page 8

• “Unit Field Configuration Tab” on page 10

• “Manufacturing Tab” on page 19

• “Meter Points (Circuits) Tab” on page 21

• “Pulse Probes Tab” on page 24

• “Completing the Meter Configuration” on page 26

This documentation is intended for those responsible for configuring the

PowerLogic meters.

System Set-up and Description

The configuration tool supports the following PowerLogic meters

• PowerLogic EM4000 Series: PowerLogic EM4033 and EM4080 meters

• PowerLogic EM4800 Series: PowerLogic EM4805, EM4833, and EM4880

meters

Depending on how the meters are installed and configured, they can meter 8, 12, or

24 individual meter points. The PowerLogic meters are designed for residential,

commercial, and industrial use and display the power and consumption readings

for each measurement point.

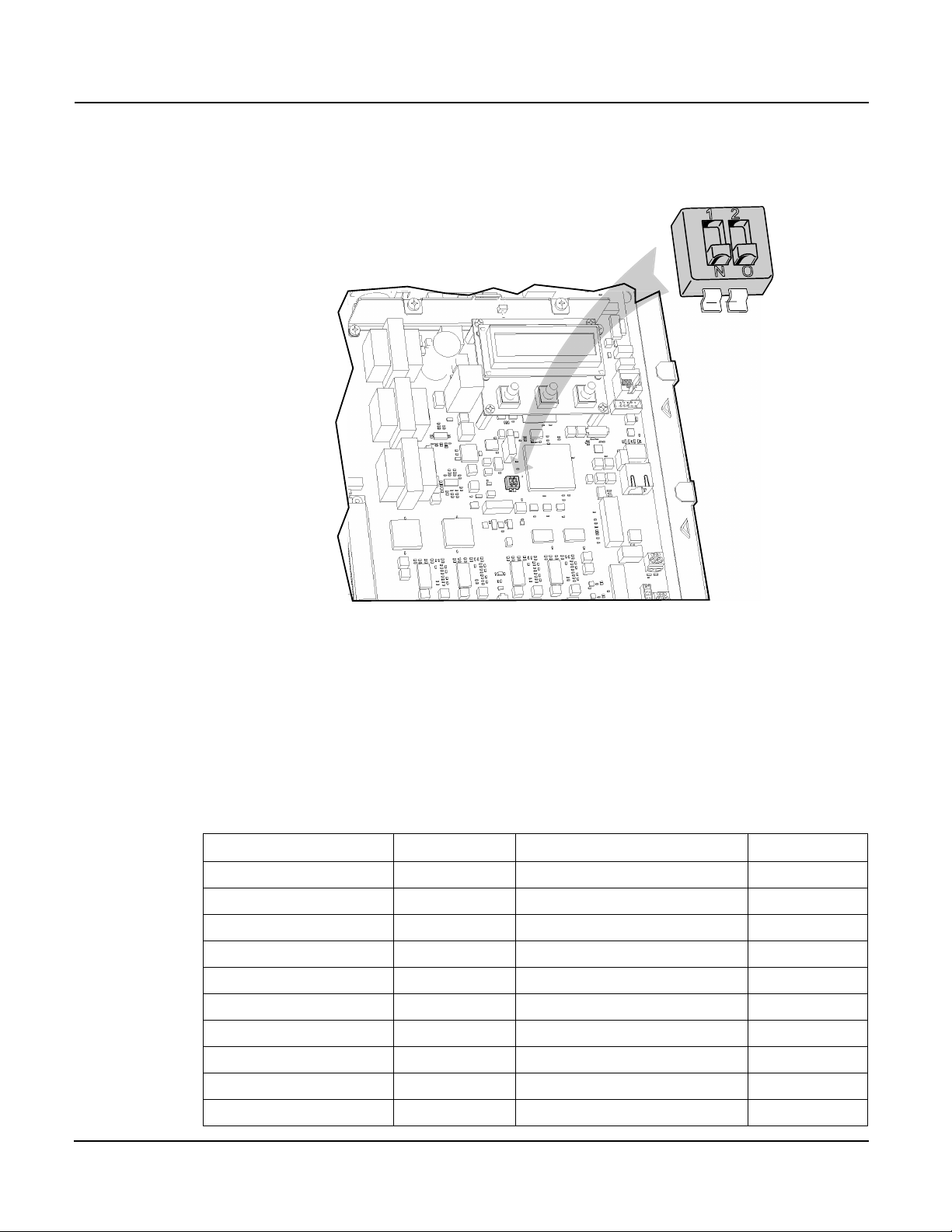

Configuration and Programming

The configuration tool is used to set any of the programmable parameters of the

PowerLogic EM4000/EM4800 Series meter. The combination of the configuration

tool and the state of the meter programming switches determine which parameters

can be set or changed. As shown in Figure 1, the programming switches are

two-position DIP switches labeled SW1, and are located inside the meter cover

below the Display button. To enable meter configuration, both switches must be

physically set to the ON (down) position (default).

©2013 Schneider Electric All Rights Reserved 1

Page 10

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

"SW1"

11/2013

Figure 1: Programming Switch location

Table 1 lists the programming capabilities associated with each parameter in

combination with the programming switches. After the meter has been

programmed, the programming switches can be turned OFF to prevent tampering

with metering parameters.

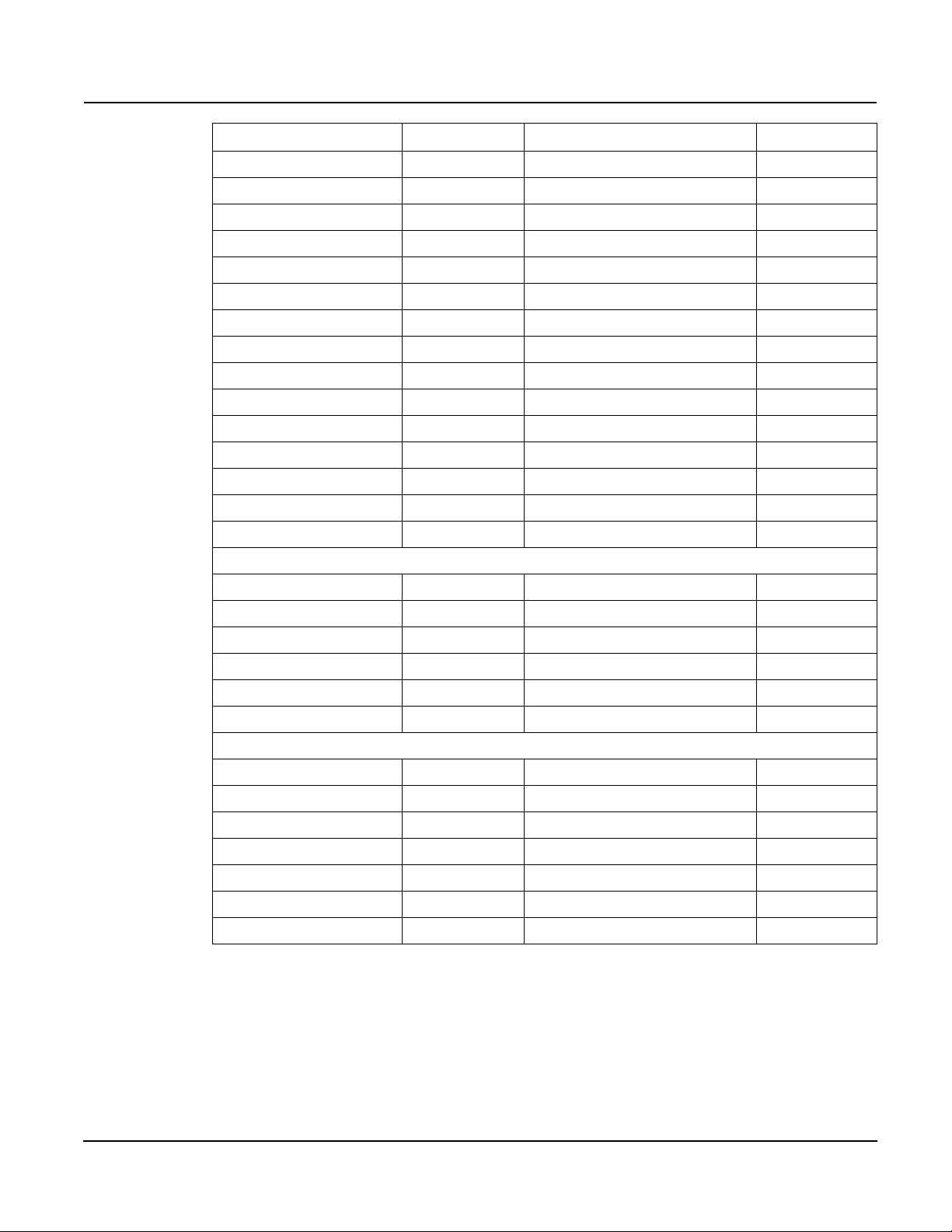

Table 1: Programming access to meter parameters

Parameter Read access Write access Activation time

Meter name Configuration tool Configuration tool Immediate

Badge number Configuration tool Configuration tool Immediate

Phone number Configuration tool Configuration tool Immediate

Alternate phone number Configuration tool Configuration tool Immediate

AT string Configuration tool Configuration tool Immediate

Host upload directory Configuration tool Configuration tool Immediate

Host download directory Configuration tool Configuration tool Immediate

Host IP address Configuration tool Configuration tool Immediate

PPP user name Configuration tool Configuration tool Immediate

PPP password Configuration tool Configuration tool Immediate

2 ©2013 Schneider Electric All Rights Reserved

Page 11

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Parameter Read access Write access Activation time

FTP user name Configuration tool Configuration tool Immediate

FTP password Configuration tool Configuration tool Immediate

Daily report interval start time Configuration tool Configuration tool Immediate

Daily report interval end time Configuration tool Configuration tool Immediate

Report period Configuration tool Configuration tool Immediate

Report interval in minutes Configuration tool Configuration tool Immediate

PT ratio Configuration tool Configuration tool + prog. switch ON Immediate

Default IP address Configuration tool Configuration tool Immediate

Default netmask Configuration tool Configuration tool Immediate

Default gateway Configuration tool Configuration tool Immediate

Reset dial readings No Access Configuration tool + prog. switch ON Immediate

Send PC time No Access Configuration tool Immediate

Programming switch state Configuration tool No Access Immediate

MAC address Configuration tool No Access Immediate

Report types Configuration tool Configuration tool Immediate

Manufacturing

Serial number Configuration tool No Access N/A

Part number Configuration tool No Access N/A

Model number Configuration tool Configuration tool + prog. switch ON After reset

Revision Configuration tool No Access

Firmware revision Configuration tool No Access N/A

Build number Configuration tool No Access

Meter and probe points

Name Configuration tool Configuration tool After reset

CT 1 current Configuration tool Configuration tool + prog. switch ON After reset

CT 2 current Configuration tool Configuration tool + prog. switch ON After reset

CT 3 current Configuration tool Configuration tool + prog. switch ON After reset

CT 1 phase Configuration tool Configuration tool + prog. switch ON After reset

CT 2 phase Configuration tool Configuration tool + prog. switch ON After reset

CT 3 phase Configuration tool Configuration tool + prog. switch ON After reset

Display Navigation

The display on the front of the meter provides status information for each circuit,

and general information for metering. The PowerLogic meter has three buttons for

navigating: a Display button, and left and right arrow buttons. The display has

a normal and a diagnostics mode.

©2013 Schneider Electric All Rights Reserved 3

Page 12

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Normal Mode

In Normal mode, the Display button scrolls through the information for each meter.

The left and right arrow buttons select the previous or next meter points

respectively. The following information is available:

• Real Energy Delivered kWh D

• Real Energy Received kWh R

• Real Power Watts

• Reactive Energy Delivered kVarhD

• Reactive Energy Received kVarhR

• Reactive Power Var

• Peak Demand PeakW (Watts)

In Normal mode, the right and left arrow buttons scroll the display from meter points

1 to 8, 1 to 12, or 1 to 24, depending on your configuration.

Diagnostics Mode

Diagnostics mode is accessed by pressing and holding the Display button for 5

seconds. In Diagnostics mode, pressing the Display button will scroll through the

following information in addition to the Normal mode data:

• Send data command

• CT Primary value and Real Power (Watts) per phase

• Current (Amps) per phase

• Power Factor (pf) per phase

• Phase angle (Degrees) per phase

• Voltage per phase

• Local IP address

• Reset factory default IP address command

•Verify

• Badge #

• Date and time (UTC)

In Diagnostics mode, the right and left arrow buttons scroll the display from meter 1

through N. When the local IP address is shown on the LCD, use the right and left

arrow buttons to scroll through the following information:

• Remote host server IP address

• Time server IP address

• Default IP address

• Default NetMask

• Default gateway

• PPP user name

• Phone number

• AT command string

• Alternate phone number

• Unit serial number

• Firmware build number

4 ©2013 Schneider Electric All Rights Reserved

Page 13

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

• Ethernet port MAC address

• Firmware revision

• Potential transformer ratio

Communications Connections

If you are configuring the meter at an installation site, see the PowerLogic EM4000

Series Meter Installation Guide or the PowerLogic EM4800 Series Meter

Installation Guide for instructions on connecting the power. Power connections vary

depending on whether the meter is configured for single-phase or three-phase

operation.

If you are pre-configuring the meter in the shop, only Phase A, Neutral, and

protective earth connections are required to power up the meter for configuring.

The PowerLogic EM4000/EM4800 Series Configuration Tool runs on a Windows

PC and communicates with the PowerLogic meters through an Ethernet network

connection. A network connection can be accomplished in two ways: either Direct,

or by connecting to a LAN (Local Area Network).

Direct Connection Ethernet Requirements

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow

safe electrical work practices. See NFPA 70E.

• This equipment must only be installed and serviced by qualified

electrical personnel.

• Turn off all power supplying this equipment before working on or

inside equipment.

• Always use a properly rated voltage sensing device to confirm

power is off.

• Replace all devices, doors and covers before turning on power to

this equipment.

• The meters must be connected to the sense voltage and control

voltage through a properly rated disconnect.

Failure to follow these instructions will result in death or serious

injury.

To connect a PC directly to the PowerLogic meter:

1. Disconnect power from the meter with the installed breaker or disconnecting

device. Use a properly rated voltage sensing device to confirm power is off.

2. Remove the outer cover.

3. If you are changing parameters that require the programming switch to be on,

remove the inner cover and ensure the programming switches are in the ON

position.

4. Re-install the inner cover.

5. Remove the local LAN Ethernet cable if present and connect the CAT 5

Ethernet cable between the PC and the PowerLogic meter. If the PC does not

have auto-crossover detection, an Ethernet crossover cable will be required.

6. Restore power to the meter.

©2013 Schneider Electric All Rights Reserved 5

Page 14

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

7. Assign the PC a static IP address such that the first three segments are the

same as the default IP address, and the last segment is different from the

default IP address.

For example, 169.254.0.xxx, where xxx differs from the last segment of the

default IP address.

Enter 255.255.255.0 into the subnet mask field.

For Windows 7 users, you must enter the IP address of the meter into the

Default Gateway field.

8. Configure the meter. See “Configuring the Meters” on page 7 for configuration

instructions.

9. Remove power. Use a properly rated voltage sensing device to confirm power is

off.

10.If you wish to lock the configuration parameters, remove the inner cover and

move the programming switches (SW1) to the OFF (up) position.

11.Re-install the inner cover.

12.Connect the LAN Ethernet cable if present.

13.Re-install the outer cover.

14.Restore power.

NOTE: All PowerLogic meters have a default IP address of 169.254.0.10 in the

absence of a DHCP service.

Network Connection Ethernet Requirements

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow

safe electrical work practices. See NFPA 70E.

• This equipment must only be installed and serviced by qualified

electrical personnel.

• Turn off all power supplying this equipment before working on or

inside equipment.

• Always use a properly rated voltage sensing device to confirm

power is off.

• Replace all devices, doors and covers before turning on power to

this equipment.

• The meters must be connected to the sense voltage and control

voltage through a properly rated disconnect.

Failure to follow these instructions will result in death or serious

injury.

To connect the PowerLogic meter to the network:

1. Turn off power to the meter with the installed breaker or disconnecting device.

Use a properly rated voltage sensing device to confirm power is off.

2. Remove the outer cover.

3. If you are changing parameters that require the programming switch to be on,

remove the inner cover and ensure the programming switches are in the ON

position.

6 ©2013 Schneider Electric All Rights Reserved

Page 15

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

4. Re-install the inner cover.

5. Using a CAT 5 Ethernet patch cable, connect the meter and the PC to a local

Ethernet switch.

6. Re-install the outer cover.

7. Restore power. When control power is restored, the meter will receive an IP

address from a local DHCP server. This IP address can be viewed from the

Diagnostics menu.

NOTE: To use a static IP address, have your local network administrator assign

the desired IP address to the MAC address of the meter in the DHCP server

configuration. To display the MAC address, see “Display Navigation” on page 3.

Configuring the Meters

The PowerLogic EM4000/EM4800 Series configuration tool is available on the CD

shipped with each unit, and is used to configure all programmable parameters

listed in Table 1.

NOTE: Disable any firewall software on your PC before attempting to connect to

a meter using the configuration tool.

Login

Use the following procedure to log in to the meter.

1. Establish an Ethernet network connection with the meter using one of the

methods described in “Communications Connections” on page 5.

2. Ensure the programming switches are in the ON position. The programming

switches are two-position DIP switches labeled SW1, and are located inside the

meter cover below the Display button. To enable meter configuration, both

switches must be physically set to the ON position. When both switches are in

the OFF position, meter configuration is disabled.

3. Start the configuration tool by entering “PowerLogic” as the User Name, and

“E4800” as the Password (see Figure 2). Click Ok.

Figure 2: Login screen

4. The main window displays as shown in Figure 3.

©2013 Schneider Electric All Rights Reserved 7

Page 16

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Figure 3: Configuration tool main window

Connecting to a Meter

The configuration tool automatically detects and lists the PowerLogic meters on the

same network segment as the PC. The configuration tool can also be used with

meters on a different network.

8 ©2013 Schneider Electric All Rights Reserved

Page 17

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

To connect to a meter on the same network:

1. Click Unit in the menu bar, then select List from the drop-down menu. The

Discovered Units window appears, displaying a list of meters available for

configuration. See Figure 4.

Figure 4: Discovered Units dialog box

2. Select the Load Unit Configuration check box, then click Ok. The main

configuration tool window appears populated with the current programming

information for the selected meter. See Figure 5.

3. Proceed to “Unit Field Configuration Tab” on page 10.

To connect to a meter on a different network:

1. Click Unit in the menu bar, then select Connect from the drop-down menu. The

Connect to Unit window appears. See Figure 5.

Figure 5: Connect function window

©2013 Schneider Electric All Rights Reserved 9

Page 18

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

2. Enter the IP address of the meter to be configured, then click Connect. The

configuration tool main window appears populated with the current

programming information for the selected meter. See Figure 6.

3. Proceed to “Unit Field Configuration Tab” on page 10.

Figure 6: Main configuration window with configured parameters

Unit Field Configuration Tab

Use Table 2 to set meter configuration parameters in the Unit Field Configuration

tab.

10 ©2013 Schneider Electric All Rights Reserved

Page 19

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Table 2: Unit Field Configuration tab parameters

Field Parameter Description

Unit Field Configuration Current IP Address The current IP address for the unit .This parameter is read only and cannot be

Mac Address The current MAC address for the unit. This parameter is read only and cannot be

Revision The revision number of the unit.

Default IP Configuration IP Address The default IP address. This parameter is configured when DHCP has been disabled,

Netmask The default subnet mask. This parameter is configured when DHCP has been

Gateway The default gateway. This parameter is configured when DHCP has been disabled, or

DNS Primary The primary domain name server. This parameter is configured when DHCP has been

DNS Secondary The secondary domain name server. This parameter is configured when DHCP has

DHCP Enabled If DHCP is not enabled, the meter uses the Default IP Configuration parameters. If

Report See “Report Parameters” on page 12

Main Meter PT Ratio The main meter potential transformer ratio. This is an internal multiplier used by the

Modem Phone # The phone number of your internet service provider’s PPP service.

Alternate Phone # An alternate phone number of your internet service provider’s PPP service.

changed by the user.

changed by the user.

or DHCP services are not available on the network.

disabled, or DHCP services are not available on the network.

DHCP services are not available on the network.

disabled, or DHCP services are not available on the network.

been disabled, or DHCP services are not available on the network.

DHCP is enabled, the meter uses the IP configuration parameters provided by the

network DHCP service.

meter for external potential transformers. External PTs can be used with a PT ratio of

1 if the billing system will apply the PT multiplier.

Use a PT Ratio of 1 with no external PTs.

AT String AT command string to customize modem operation. Default string is ATX3, do not wait

Wait for Dial Tone Do not enable this parameter if the line has a broken dial tone due to a message

Host Server IP Address The IP address or domain name of the FTP server for data storage.

Upload Directory The sub-directory used for data reporting within the root directory. The root directory

Download Directory The sub-directory used by the meter to retrieve configuration updates. The FTP

FTP Login User Name The user name for the FTP account.

Password The password for the FTP account.

PPP Login User Name The user name for the PPP account. This is only required if using dial-up reporting.

Password The password for the PPP account. This is only required if using dial-up reporting.

NTP Host (Time Server) IP Address The IP address of the NTP server that provides timing to the meter.

for dial tone.

waiting feature.

is determined by the FTP user name and the FTP server configuration. The FTP

account must have write access to this directory.

account must have read access to this directory..

©2013 Schneider Electric All Rights Reserved 11

Page 20

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Report Parameters

The Report section in the main configuration window has six tabs:

• Intervals tab allows the user to configure the recording interval at which meter data is

collected, and the demand interval for which demand readings are calculated. Figure 7

shows the Intervals tab, and Table 3 lists the configuration parameters within the tab.

• Types tab allows the user to define the metering data parameters that are to be logged

on each recording interval, then reported per the Reporting Schedule. Figure 8 shows

the Types tab, and Table 4 lists the configuration parameters within the tab.

• Reporting Schedule tab allows the user to configure how often the meter is to send

recording interval data to a server. Figure 9 shows the Reporting Schedule tab, and

Table 5 lists the configuration parameters within the tab.

• Calculations & Format tab allows the user to configure the type of power factor

calculation and the display format for leading vs. lagging power factor. Figure 10 shows

the Calculations & Format tab, and Table 6 lists the configuration parameters within the

tab.

• BACnet tab allows the user to configure the BACnet Device interface. Figure 11 shows

the BACnet tab, and Table 7 lists the configuration parameters within the tab.

• Comms tab allows the user to configure the communications module and change the

Meter Utility Password. Figure 12 shows the Comms tab, and Table 8 lists the

configuration parameters within the tab.

Figure 7: Intervals tab in the Report section

Table 3: Intervals tab configuration parameters

Parameter Description

Recording Interval in Minutes The interval at which meter data is collected.

Demand Interval Setup

Block Demand Select Block Demand calculation for demand data.

Sliding Window Demand Select Sliding Window Demand calculation for demand data.

12 ©2013 Schneider Electric All Rights Reserved

Page 21

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Parameter Description

Demand Interval in Minutes The size of the block demand window in minutes (select from the

Number of Sub-intervals The number of recording sub-intervals that make up the sliding

pull-down menu).

demand interval (select from the pull-down menu).

Example: Selecting a Recording Interval of 5 minutes with Sliding Window

Demand enabled and 3 Sub-intervals, creates a demand calculation every

5 minutes based on the previous 15 minutes. This is the common demand

measurement used by North American utilities when billing for Demand.

NOTE: To activate the Demand Interval Setup settings, Peak Demand must be

enabled (

) in the Types tab (see Figure 8).

Figure 8: Types tab in the Report section

©2013 Schneider Electric All Rights Reserved 13

Page 22

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Table 4: Types tab configuration parameters

Parameter Description

Watt Hours Delivered Interval/Register These types of records can be enabled by

Watt Hours Received Interval/Register

VAR Hours Delivered Interval/Register

VAR Hours Received Interval/Register

VA Hours Interval/Register

Present Demand

Peak Demand

Peak Current

Voltage

Pulses

selecting () the check box.

NOTE: If parameters are grayed out, they are not available on the variant or

firmware revision of the meter being configured.

14 ©2013 Schneider Electric All Rights Reserved

Page 23

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Figure 9: Reporting Schedule tab in the Report section

Table 5: Reporting Schedule tab configuration parameters

Parameter Description

Daily (default) Enables daily real time reporting.

Start Time When daily reporting is enabled, select the reporting period start time.

End Time When daily reporting is enabled, select the reporting period end time.

Minutes Enables real time reporting every x number of minutes by selecting the

The unit sends the data file at a randomly selected time within the

report window specified by the start and end time .

radial button and entering the interval in minutes.

NOTE: When selecting a Daily report schedule, the Start Time must occur

before the End Time within the midnight to midnight 24-hour time period.

©2013 Schneider Electric All Rights Reserved 15

Page 24

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Figure 10: Calculations & Format tab in the Report section

Table 6: Calculations & Format tab configuration parameters

Parameter Description

Power Factor

Sign Format IEEE In the display, the sign (+ or -) indicates leading (+) or

IEC (default) In the display, the sign (+ or -) indicates the direction

Method of Calculation Arithmetic Selects the arithmetic method for calculating Power

Vector (default) Selects the vector method for calculating Power

lagging (-) power. The direction of active power is not

indicated.

of active power. Lead or lag indicates capacitive or

inductive power.

Factor.

Factor

16 ©2013 Schneider Electric All Rights Reserved

Page 25

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Figure 11: BACnet tab in the Report section

Table 7: BACnet tab configuration parameters

Parameter Description

Device ID Set the BACnet device ID by entering a a numeric ID between 0 and

Network Port The BACnet specific port number for this device (default is 47808).

BBMD Timeout Enter the amount of time (seconds) required for connection to a BACnet

BBMD Address Enter the address of the BBMD device that controls all devices in the

Description A user selectable description of the device (default is Power Meter)

Vendor ID BACnet Vendor Identification number (default is 10)

Vendor Name Schneider Electric (default)

Software Version The software version of the PowerLogic product (fixed).

UTC Offset Fixed at 0

Location A user selectable description of the physical location of the unit (default is

Object Name PowerHawk Meter (default)

4194303.

network.

BACnet network.

Unknown).

©2013 Schneider Electric All Rights Reserved 17

Page 26

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Figure 12: Comms tab in the Report section

18 ©2013 Schneider Electric All Rights Reserved

Page 27

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Table 8: Comms tab configuration parameters

Parameter Description

Parameters

Comms Option Modem Selecting Modem configures the communications

None Selecting None disables the communications

RTU Adapter Selecting RTU Adapter configures the

RTU comms config Enter the RTU serial port parameters as a string

Modbus base address Enter the Modbus RTU address for this device (1

Utility Password

Current Password The default meter Utility Password is listed here

Enter new password To change the password, enter the new password.

Enter new password again To confirm, re-enter the new password.

module as a dial-up modem for remote reporting

via a phone line.

module interface

communications module as a Modbus

RS422/RS485 serial interface.

with the following selections: baud rate (19200 or

9600), number of bits (8), number of start bits (1),

number of stop bits (1), parity type (e – even, n –

none

Example: 19200,8,1,e (default)

to 255)

whenever the Configuration Tool is started or

when a configuration is uploaded from a meter.

If the Utility Password for the meter is not the

default password, enter the Current Password

here to change metering specific parameters or to

change the password again.

NOTE: The Modbus and RTU Adapter Comms Option parameters are valid only

when a Modem module or an RTU adapter module is present.

The RTU Adapter parameters apply only to Modbus RTU communications.

There are no configuration options when Modbus over TCP/IP is used.

NOTE: : The meter Utility Password is used to control access to changing the

metering specific parameters in the PowerLogic meter. The following

parameters and functions cannot be changed or activated unless the correct

Utility Password is entered before sending the new config to the meter:

PT Ratio

CT Current and Phase

Reset Dial Readings

Model Number

Change Password

All other parameters and functions can be changed or accessed without

entering the correct Utility Password for the meter being configured.

Manufacturing Tab

The Manufacturing tab allows the user to define the metering configuration for the

PowerLogic meters. The meters support the configurations listed in Table 9.

©2013 Schneider Electric All Rights Reserved 19

Page 28

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Table 9: List of supported PowerLogic metering configurations

EM4033xx EM4080xx EM4805xx EM4833xx EM4880xx

EM4033xx-1P-12 EM4080xx-1P-12 EM4805xx-1P-12 EM4833xx-1P-12 EM4880xx-1P-12

EM4033xx-1P-24 EM4080xx-1P-24 EM4805xx-1P-24 EM4833xx-1P-24 EM4880xx-1P-24

EM4033xx-2P-12 EM4080xx-2P-12 EM4805xx-2P-12 EM4833xx-2P-12 EM4880xx-2P-12

EM4033xx-2P-24 EM4080xx-2P-24 EM4805xx-2P-24 EM4833xx-2P-24 EM4880xx-2P-24

EM4033xx-3P-08 EM4080xx-3P-08 EM4805xx-3P-08 EM4833xx-3P-08 EM4880xx-3P-08

To view the manufacturing information for a specific meter, select a model number

from the Model # pull-down list shown in Figure 13. The part number, revision

number and serial number for the selected model will be shown.

Figure 13: Manufacturing tab

20 ©2013 Schneider Electric All Rights Reserved

Page 29

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Meter Points (Circuits) Tab

The Meter Points (Circuits) tab contains the configuration information for each of

the metering points. It shows the number of elements used, the phase, the current

ratings, and the user-defined identification string for each meter point. Default

information is entered when the metering configuration is selected in the

Manufacturing Tab (see “Manufacturing Tab” on page 19).

Meter Point Configuration

The current rating and phase assignment for each meter point can be configured

individually, by meter, or all at once. The configuration in all three cases does not

take effect until the new settings have been sent to the meter (see “Completing the

Meter Configuration” on page 26).

To change the current rating and phase assignment for an individual meter point:

1. Select one probe at a time from the Meter Points (Circuits) List. The selected

probe number will appear in the middle pane beside Probe, and its assigned

Current and Phase are shown beneath it. See Figure 14.

2. To change the Current, enter the required number. To change the Phase,

select the required phase type from the pull-down list.

Figure 14: Meter Points configuration screen

©2013 Schneider Electric All Rights Reserved 21

Page 30

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

To change the current rating for all probes assigned to a meter point:

1. Select a meter from the Meter Points (Circuits) List. The selected meter will

appear in the Name field of the middle pane. See Figure 14.

2. In the Alter Current for Probes pane, enter the desired value referenced to the

CT primary rating in the Current field, and click on Change Probes in Selected

Meter.

To change the current rating for all probes assigned to all meter points:

1. In the Alter Current for Probes pane, enter the desired value referenced to the

CT primary rating in the Current field, and click on Change all Probes in all

Meters. See Figure 14.

Badge Numbering

Each meter point can be configured with a name defined by the user. The meter

point name, known as the badge number, can be up to 13 alphanumeric characters

in length. The Badge Numbering pane allows the user to set two types of badge

numbers:

• sequential, which assigns a badge number to each meter point after the prefix

(for example CORP-00000001 to CORP-00000012)

• grouped by meter, which uses a base prefix to designate the meter, then

assigns a sequential badge number suffix to each meter point assigned to that

meter (for example CORP-00001-01 to CORP-00001-12)

The configuration tool provides examples before the badge number is assigned to

the meter. In the Badge Numbering pane shown in Figure 15, the following fields

and buttons are provided for assigning badge numbers:

• Prefix field - an alphanumeric field that prefixes the number field.

• Badge Number field - a numeric field that becomes part of the prefix for meter

points assigned to that meter, or the first number in the sequence to be

assigned to individual meter points.

• Badge Number Width field - a numeric field that defines the number of digits in

the badge number field. Zeroes (0) are automatically entered at the beginning of

the badge number field until the total number of digits in the badge number field

equals the number of digits defined in the badge number width field.

• Incremental badge numbers button - selecting this button assigns a sequential

badge number for each meter point

• Single badge number button - selecting this button assigns one badge number

prefix followed by a numeric suffix for each meter point assigned to that meter.

• Assign Badge Numbers button - selecting this button implements the badge

numbering defined by the user in the previous fields.

22 ©2013 Schneider Electric All Rights Reserved

Page 31

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Figure 15: Badge Numbering pane

Reset Buttons

• Reset Dial Readings button - selecting this button resets all registers for all

energy types and pulse counts to zero. This function takes effect immediately

and does not require a send action.

• Send PC Time button - selecting this button configures the meter with the

current PC UTC and local time. This function takes effect immediately and does

not require a send action. This function can be used when access to the network

time service is not available.

©2013 Schneider Electric All Rights Reserved 23

Page 32

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

• Adjust Dial Reading button - selecting this button allows the operator to set all

of the following energy type registers to the same fixed initial value:

• Delivered Watt Hours

• Received Watt Hours

• Delivered VAR Hours

• Received VAR Hours

• VA Hours

This function takes effect immediately and does not require a send action.

• Reset Demand Reading button - selecting this button resets the Peak Demand

register for all meter points to zero. This function takes effect immediately and

does not require a send action.

Pulse Probes Tab

The Pulse Probes tab contains the configuration information for each pulse input.

It shows the measurement type in units for each input, and the scale factor applied

to the collected pulse counts. Figure 16 shows the Pulse Probes tab of the main

configuration tool window.

To configure a pulse probe:

1. Enable () Pulses in the Types tab of the Report section in the Unit Field

Configuration tab. See Figure 8 on page 13.

NOTE: The Pulse Probe settings are not active unless Pulses are enabled in

the Types tab.

2. Select a pulse probe from the Probe List.

3. Select a measurement type from the Type pull-down list.

4. Enter a value in the Scale Factor field.

NOTE: This scale factor only changes the pulse values in the TR3 report. The

pulse count in the device web page is not scaled.

24 ©2013 Schneider Electric All Rights Reserved

Page 33

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

Figure 16: Pulse Probes tab

©2013 Schneider Electric All Rights Reserved 25

Page 34

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

Completing the Meter Configuration

Once you have defined all of the configurable parameters, the PowerLogic meter is

ready to be programmed.

To complete the meter configuration:

1. Click Unit in the menu bar, then select Save from the drop-down menu. See

Figure 17.

Figure 17: Saving the configuration settings

26 ©2013 Schneider Electric All Rights Reserved

Page 35

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

2. Click Unit in the menu bar, then select Send from the drop-down menu to

transmit the configuration settings from your PC to the selected PowerLogic

meter. The confirmation message File loaded successfully! should appear in

the bottom left corner of the window. See Figure 18.

Figure 18: Sending the configured settings to the meter

©2013 Schneider Electric All Rights Reserved 27

Page 36

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

28 ©2013 Schneider Electric All Rights Reserved

Page 37

930-112-01-D.00 PowerLogicTM Series EM4000/EM4800

11/2013

User notes

©2013 Schneider Electric All Rights Reserved 29

Page 38

PowerLogicTM Series EM4000/EM4800 930-112-01-D.00

11/2013

30 ©2013 Schneider Electric All Rights Reserved

Page 39

Page 40

PowerLogicTM Series EM4000/EM4800

Multi-Circuit Meters

Schneider Electric

35 rue Joseph Monier

92500 Rueil-Malmaison, France

www.schneider-electric.com

PowerLogic is a trademark or registered trademark of Schneider Electric in France, the USA and

other countries. Other trademarks used are the property of their respective owners.

This product must be installed, connected and used in compliance with prevailing standards

and/or installation regulations. As standards, specifications and designs change from time to time,

always ask for confirmation of the information given in this publication.

930-112-01-D.00 11/2013

©2013 All Rights Reserved

Loading...

Loading...