Page 1

Application

NYBA-182

ACME-258

ACME-220

NYBA-197-10

NYBA-197-20

YBA-519-1

TOOL-20-1

The AV-608 linkage adapter kit is designed to t the

Schneider Electric AV-607-1 linkage kit or the M400A,

M800A and M1500A Forta actuators to the

discontinued 1-1/2” and 2” VB-9XXX valves.

Features

• Compatible with Schneider Electric VB-9XXX 1-1/2”

and 2” valves and SmartX or M400A, M800A and

M1500A Forta actuators

• Kit contains necessary parts for either application

AV-608

Adapter for AV-607-1

Schneider Electric SmartX Linkage,

M400A, M800A and M1500A Forta Actuators, and

VB-9XXX 1-1/2” and 2” Valves

General Instructions

Schneider Electric

F-27234-5 October 2 014

Page 2

Applicable Literature

F-Number Description Audience Purpose

F-27599

F-26642

F-26644

F-26645

F-26742

F-26748

F-26749

F-27215

F-27082

F-26646

F-26752

F-11366 Valve Selection Chart Steam (two-way valves only)

F-11080 Valve Selection Chart Water

F-13755 CA-28 Control Valve Sizing

F-27234 AV-811 Forta to Globe valve adapter kit

F-26080 EN-205 Water System Guidelines

M400A (VB), M800A (VB) and M1500A (VB) Forta

Actuator General Instructions

MA40-704X, MA4X-707X, MA4X-715X Schneider

Electric Spring Return Two-Position SmartX Actuators

General Instructions

MF4X-7XX3 Schneider Electric Spring Return Floating

SmartX Actuator General Instructions

MS4X-7XX3 Schneider Electric Spring Return

Proportional SmartX Actuator General Instructions

MA40-717X Spring Return Direct Coupled SmartX

Actuator General Instructions

MS40-717X Schneider Spring Return Direct Coupled

SmartX Actuator General Instructions

MF40-7173 Schneider Electric Spring Return Direct

Coupled SmartX Actuator General Instructions

MF41-6153/MS41-6153 Series Non-spring return Rotary

Electronic Damper Actuators General Instructions

AV-607-1, AV-609-1 Schneider Electric SmartX Linkages

for 1-1/2” to 6” Globe Valves General Instructions

MX4X-7XXX, MX4X-6XXX Series Schneider Electric

SmartX Actuator Selection Guide

VX-7000 and VX-9000 Series Linked Globe Valve

Assemblies and MX4X-7XXX and MX4X-6XXX Series

Actuator/Linkage Assemblies with Schneider Electric

SmartX Actuators, Selection Guide

– Sales Personnel

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

Describes the actuator’s features,

specications, and possible applications.

Provides step-by-step mounting

instructions and wiring instructions for the

actuator/linkage assemblies.

Describes the linkages’ specications and

possible applications. Provides step-bystep mounting instructions for the actuator/

linkage assemblies.

Provides actuator specications and part

number cross referencing of phased out

actuators with the new Schneider Electric

direct-coupled actuators.

Provides features, specications,

mounting dimensions, and other criteria

useful to the selection of linked globe valve

assemblies and actuator/linkage

assemblies with Schneider Electric

SmartX actuators.

Provides charts, equations, and diagrams

to assist in the conguration of valve

system applications. TOOL-150, valve

sizing slide rule may be purchased

separately

Provides information on how to install the

adapter on globe valves up to 2”.

Describes Schneider Electric’

recommended water treatment practices.

2

Schneider Electric

F-27234-5 October 2 014

Page 3

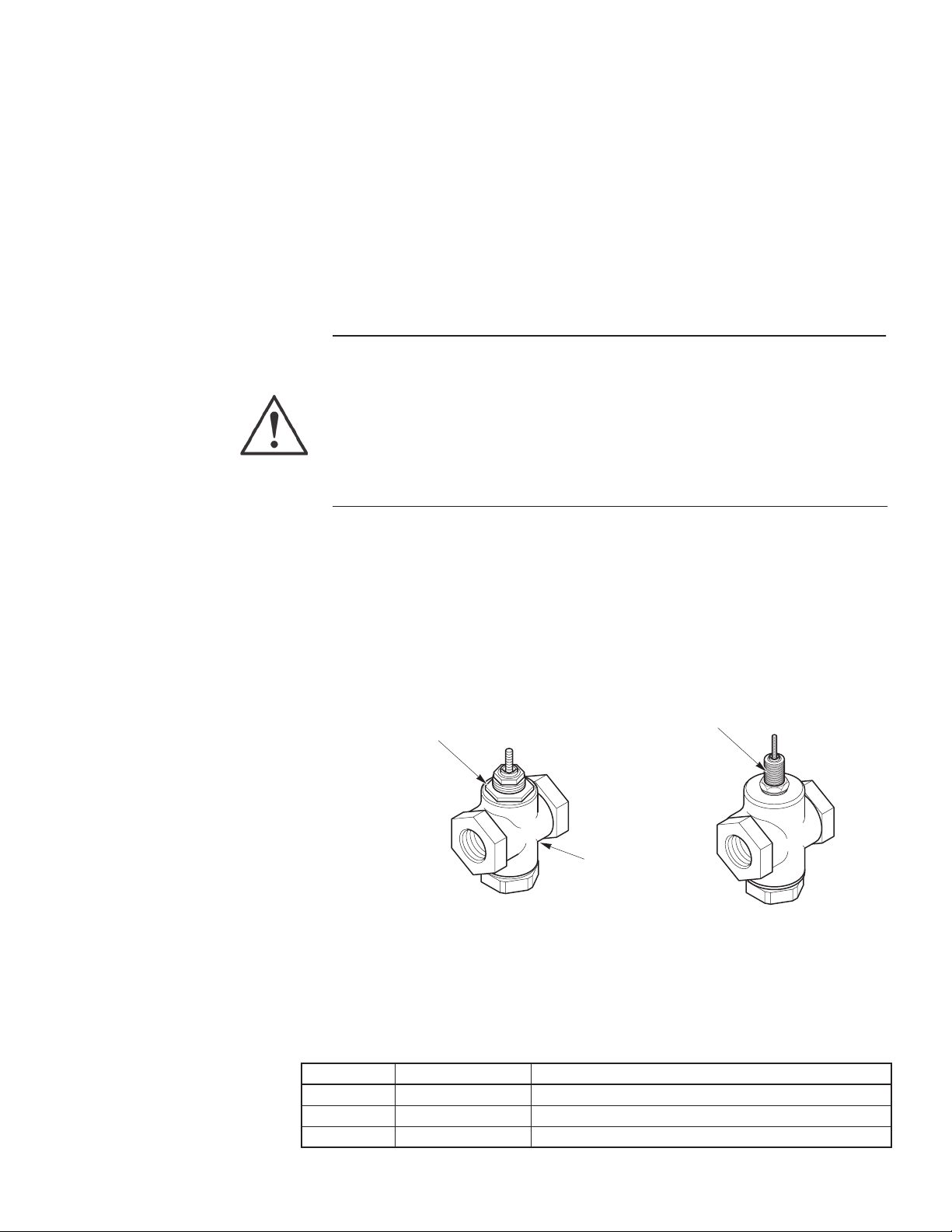

Style A VB-9XXX

1-1/2" and 2"

(40 and 50 mm)

valve body

Style B VB-9XXX

1-1/2" and 2"

(40 to 50 mm)

valve body

Valve Mounting Nut

Globe style

body

1-3/8" high, 1" diameter

threaded bonnet

INSTALLATION

3

Inspection

Requirements

General Installation

Inspect package for damage. If damaged, notify carrier immediately. If undamaged, open

the package and inspect for obvious damage. Return damaged products.

• Training: Installer must be a qualied, experienced technician.

• Tools (not provided):

– Measuring scale graduated in 1/16””increments

– Two 5/16” open-end wrenches or TOOL-20-1 for jam nuts

– 3/4 to 2” spanner wrench for linkage adapter

– 1-3/8” open-end wrench for valve adapter

– 1-5/8” open-end wrench for valve mounting nut

– Vise grip or pliers

– Appropriate power supply (see the applicable actuator General Instructions sheet

for power requirements)

Warning: Electrical shock hazard! Contact with live circuits can result in severe injury or

death.

• Disconnect the power supply (line power) at the breaker or fuse before and during

installation of an actuator to prevent electric shock and equipment damage.

• Make all connections in accordance with the wiring diagram and in accordance with

national and local electrical codes. Use copper conductors only.

Failure to observe these warnings can result in severe injury or death and can damage the

equipment.

The AV-608 kit contains parts for the AV-607 linkage and Schneider Electric jackscrew style

actuators. Save the unused parts and instructions for other applications.

Allow at least 5” (127 mm) above the actuator or actuator/linkage assembly for removal and

reattachment to the installed valve.

Valve Styles

Identify the valve body and follow the specic instructions on the following pages.

• Style A valve bodies were discontinued in August, 1997

• Some style B valve bodies were discontinued in 1994 (date code 9404)

Figure-1 Valve Body Identication.

Table-1 Model Chart – Valve Bodies

Model Type Description

VB-921X 2-Way stem up open Seat on bottom, closed when stem down

VB-922X 2-Way stem up closed Seat on top, closed when stem up

VB-931X 3-Way mixing Seat on top and bottom, one inlet closed when stem up or down

Schneider Electric

F-27234-5 October 2 014

Page 4

Mounting AV-607-1

Linkage to Valve Body

1 Install two YBA-519-1 jam

nuts on the valve stem,

3/16" from the top of the

valve stem and lock

together using TOOL-20-1

or 5/16" open-end

wrenches. The second

nut enables you to hold or

rotate the valve stem if

necessary.

AV-607-1 Linkage

To attach the linkage to the valve body, refer to the subsection that applies to the specic

valve body.

AV-607-1 Linkage and Style A Valve Bodies

1. Remove any previously installed actuator and linkage parts.

2. Assemble the linkage to the valve, according to Figure-2.

Note: If necessary for ease of assembly, remove the actuator from the linkage.

2 Raise the valve

stem to the full

up position.

3 Install the NYBA-197-10

Adapter into the rack end

and tighten with a 5/8"

open-end wrench.

4

5 Rotate the linkage, fully

engaging the stem until

the NYBA-197-10

contacts the jam nuts.

6 Lock the nuts securely

against the adapter using

TOOL-20-1 or 5/16"

open-end wrenches.

7 While holding the valve

mounting nut, rotate the

entire linkage, threading

the mounting nut onto the

NYBA-182 Adapter.

4 Install the NYBA-182

Adapter into the bottom of

the rack housing and

tighten with a 3/4 to 2"

spanner wrench.

8 Orient the linkage on the

valve as desired and then

using TOOL-37 or an

1-5/8" open-end wrench,

lock the assembly into

place.

9 Rotate the pinion shaft with pliers

in both directions, confirming the

seats are reached for close off. If

necessary, remove the linkage

cover with a Torx screwdriver and

observe the rack. The valve seats

should control the stroke, not the

linkage cover or rack teeth.

If stem up closed valves do not

seat, increase the stroke by

returning to Step 1 and lowering

the two jam nuts on the stem as

needed.

Figure-2 Assembling the AV-607-1 Linkage Onto a Style A Valve Body.

Schneider Electric

F-27234-5 October 2 014

Page 5

1 Install two YBA-519-1 jam

nuts on the valve stem,

3/16" from the top of the

valve stem and lock

together using TOOL-20-1

or 5/16" open-end

wrenches. The second

nut enables you to hold or

rotate the valve stem if

necessary.

2 Install one ACME-220

Adaptor with the hexagon

down onto the valve

bonnet as far as possible.

For stem up closed

valves, back the valve

adapter up three full

turns.

3 Raise the valve

stem to the full

up position.

4 Install the NYBA-197-20

Adapter into the rack end

and tighten with a 5/8"

open-end wrench.

5 Install the NYBA-182

Adapter into the bottom of

the rack housing.

6 Install one ACME-220

Adapter into the

NYBA-182 in the rack

housing and tighten with

an 1-3/8" open-end

wrench.

7 Rotate the linkage, fully

engaging the stem until

the NYBA-197-20

contacts the jam nuts.

If the valve stem rotates,

use a 5/16" open-end

wrench to turn the stem

into the adapter.

8 Lock the nuts securely

against the adapter using

TOOL-20-1 or 5/16"

open-end wrenches.

9 Rotate the entire linkage,

threading it onto the valve

bonnet, fully engaging the

bottom ACME-220

Adapter.

10 Orient the linkage on the

valve as desired and then

using an 1-3/8" open-end

wrench, lock the

assembly into place with

the bottom ACME-220

11 Rotate the pinion shaft with pliers

in both directions, confirming the

seats are reached for close off. If

necessary, remove the linkage

cover with a Torx screwdriver and

observe the rack. The valve seats

should control the stroke, not the

linkage cover or rack teeth.

If stem up closed valves do not

seat, increase the stroke by

backing the assembly up and

then back the bottom ACME-220

Adapter up additional turns as

shown in Step 2.

AV-607-1 Linkage and Style B Valve Bodies

5

1. Remove any previously installed actuator and linkage parts.

2. Assemble the linkage to the valve, according to Figure-3.

Note: If necessary for ease of assembly, remove the actuator from the linkage.

Schneider Electric

F-27234-5 October 2 014

Figure-3 Assembling the AV-607-1 Linkage Onto a Style B Valve Body.

Page 6

Mounting M400A,

M800A and M1500A

Forta Actuators to

Valve Body

Install one YBA-519-1 jam nut

1

to the bottom of stem thread.

M400A , M800A and M1500A Forta Style Actuators

To mount the actuator to the valve body, refer to the subsection that applies to the specic

valve body.

M400A, M800A and M1500A Forta and Style A Valve Bodies

1. Remove any previously installed actuator and linkage parts.

2. Assemble the new linkage to the valve, according to Figure-4.

Then install stem extension, from AV-811

2

kit, to bottom of thread on stem and

lock together using TOOL-20 or 5/16

open-end wrench.

Tighten

6

Install theAV-811 assembly (make sure

3

the mounting adapter bottoms out on

top of the valve bonnet) tighten the valve

actuator nut to the mounting adapter.

Tighten

4

Push valve stem to full down position

Mount Forta actuator to stem extension slot

5

and bolt the U-clamp to the mounting adapter.

Manual override may be required to align

U-clamp assembly. See AV-811 documentation

for further mounting detail.

Figure-4 Assembling the Forta Actuator Onto a Style A Valve Body.

Schneider Electric

F-27234-5 October 2 014

Page 7

M400A, M800A and M1500A Forta Actuators and Style B Valve Bodies

Mount Forta actuator to stem extension slot

and bolt the U-clamp to the mounting adapter.

U-clamp assembly. See AV-811 documentation

Tighten the ACME-220 to the mounting adapter.

1. Remove any previously installed actuator and linkage parts.

2. Assemble the new linkage to the valve, according to Figure-5.

Install one YBA-519-1 jam nut

1

to the bottom of stem thread.

Install one ACME-220 adapter with

3

hexagon down onto the valve bonnet

as far as possible without tightening.

Then install stem extension, from AV-811

2

kit, to bottom of thread on stem and

lock together using TOOL-20 or 5/16

open-end wrench.

Tighten

7

Install the AV-811 mounting adapter to the

4

ACME-220. Make sure the mounting adapter

bottoms out on the top of the valve bonnet.

Tighten

Push valve stem to full down position

5

6

Manual override may be required to align

for further mounting detail.

Figure-5 Assembling the Forta Actuator onto a Style B Valve Body.

Schneider Electric

F-27234-5 October 2 014

Page 8

Schneider Electric

F-27234-5 October 2 014

© 2014 Schneider Electric. All rights reserved.

Loading...

Loading...