Page 1

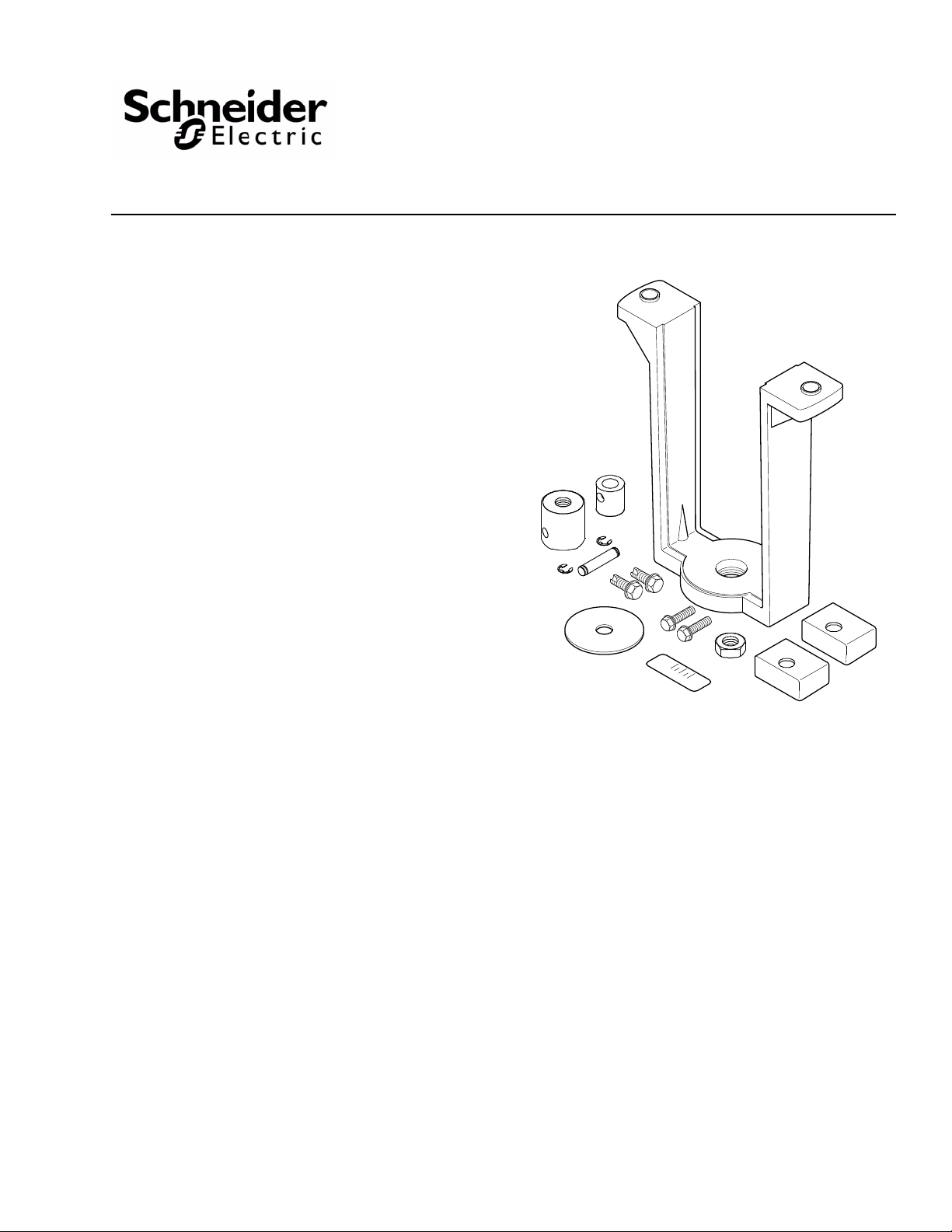

Application

CLOSED OPEN

CLOSED OPEN

The AV-496 valve linkage kit is used to field assemble

MK-88XX and MK-89XX series actuators to 2½ inch

through 6 inch VB-9XXX series valve bodies, except

VB-9323.

Features

• Die cast aluminum mounting bracket.

• Valve position indication provided as standard.

AV-496

Valve Linkage for MK-88XX

and MK-89XX Actuators

General Instructions

Applicable Literature

• Cross-Reference Guide, F-23638

• Reference Manual, F-21683

• Application Manual,F-21335

• Pneumatic Products Catalog, F-27383

• AK-42309-500 Positive Positioner Pneumatic Relay

Gene

ral Instructions, F-22909

• EN-205 Water System Guidelines, F-26080

Printed in U.S.A. 6-10 © Copyright 2010 Schneider Electric All Rights Reserved. F-21663-5

Page 2

SPECIFICATIONS

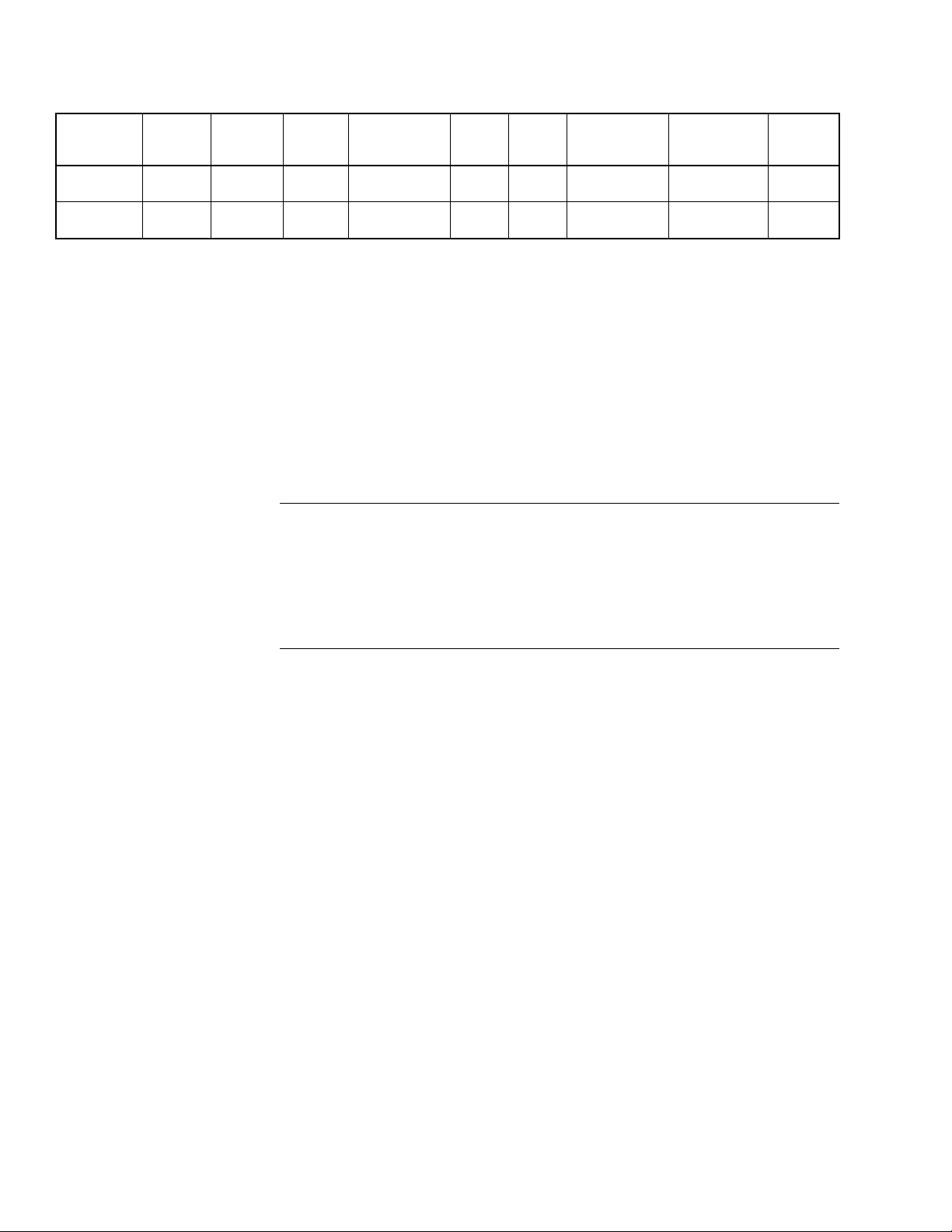

Table-1 AV-496 Valve Linkage Component Selection.

Valve Body

2-1/2 to 4”

VB-9XXX

5 & 6”

VB-9XXX

a

Except VB-9323 series valves.

a

Actuator Lock Nut Spacers Stem Adapters

MK-88XX 1/2” —

MK-89XX 1/2” 2

2 for

1/2” stem

2 for

1/2” stem

Stem

Link

Shaft

1 2

1 2

E-rings

Mounting

Bracket Bolts

2

1-1/4” long

2

2-1/4” long

Indicating

Plate

1 with

1/2” hole

1 with

1/2” hole

Scale

Length

1”

(25.4mm)

2”

(50.8mm)

INSTALLATION

Inspection Inspect the package for damage. If damaged, notify the appropriate carrier immediately. If

undamaged, open the package and inspect the device for obvious damage. Return any

damaged products.

Requirements • Tools:

– Open end wrench, 3/4 inch

– Slotted screw driver

– Scale for measuring the gap between valve stem and actuator shaft

• Training: Installer must be a qualified, experienced technician

Caution:

• Avoid locations where excessive moisture, corrosive fumes, or vibration is present.

• Install all two-way valves so that they close against the flow. An arrow on the valve body

or a tag indicates the proper flow direction.

• Always install three-way mixing valves with two inlets and one outlet.

• Do not install the actuator below the center line of the valve. For steam applications

mount the actuator above the valve body at 45° from vertical.

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-21663-5

Page 3

Linkage Kit Installation

Two-way Normally Open VB-9213 2½” through 6” Valve Bodies

Warning: 2½” through 6” valve bodies date coded before 8603 must have valve packing

nut removed and replaced [replace packing nut — tighten four (4) turns] along with the

bracket nut. Before removing packing nut, isolate the valve body using shutoff valves or

depressurize system to zero gauge and drain piping. System pressure could cause packing

parts to blow out with potential of bodily injury and/or water damage.

1. Push the valve stem completely down.

2. Remove bracket nut from valve body. Refer to Figure-1.

3. Place mounting bracket onto valve body and secure it in place with the bracket nut.

4. Thread the stem lock nut all the way down the valve stem.

5. Place the indicator plate on the valve stem.

6. Install an E-ring on one end of stem link shaft (pin). Insert the pin through the holes of the valve stem adapter.

7. Thread the valve stem adapter onto the valve stem until the stem touches the pin. Back

the adapter off ½ turn (counterclockwise) and remove the pin.

8. Secure the valve stem adapter, the AK-42309-500 spring arm (if required), and the

indicator plate into place with the stem lock nut. Refer to

Note: For actuator/valve assemblies that require a positive positioner, refer to

AK-42309-500, Positive Positioner Pneumatic Relay General Instructions, F-22909,

for details.

Figure-1.

9. Select the actuator (MK-88XX or MK-89XX series). For actuators details refer to

MK-8800 Series, MK-8900 Series, Pneumatic Valve Actuators General

Instructions, F-21662.

10. Thread actuator shaft adapter onto the actuator shaft as far as it will turn. Refer to Table-1 for required AV-496 components.

1 1. Using the appropriate bolts attach the selected actuator to the mounting bracket. Refer

Table-1. If MK-89XX series actuator is selected, install the spacers before attaching

to

the actuator to the bracket. Refer to Figure-1.

12. Turn actuator shaft adapter (counterclockwise) until the distance between the surface

of the two adapters is 1.100” (for 5” and 6” valves with 2” stroke) or 0.100” (for 2-1/2” to

4” valves with 1” stroke). Use a scale or caliper to measure the distance.

13. Raise the valve stem to slide the valve stem adapter into the actuator shaft adapter.

14. Align the holes on both sides of the adapter assembly.

15. Insert the stem link shaft (pin) through the holes and place the second E-ring on the other end to secure the assembly.

16. Align the top indication marker of the OPEN/CLOSE decal with the indicator plate. Affix

the OPEN/CLOSE decal to the mounting bracket. Refer to

17. Linkage assembly is complete. Refer to Figure-2 and Figure-3.

Figure-1.

F-21663-5 © Copyright 2010 Schneider Electric All Rights Reserved. 3

Page 4

Actuator Piston*

Stem

Vertical View of

Actuator Shaft Adapter

Spacer (2) for

MK-89XX Series

Actuators Only

Valve

Stem

Adaptor

Indicator

Plate

Mounting Bolt (2)

for MK-8900 Series

Stem

Lock Nut

Mounting

Bracket

E-Ring (2)

Stem Link Shaft

Mounting Bolt (2)

for MK-8800 Series

CLOSED

OPEN

OPEN

CLOSED

Decal

*Packing Nut

*Bracket Nut

*Valve Body

*Not Included with AV-496.

Actuator Shaft

Adapter

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-21663-5

Figure-1 AV-496 Valve Linkage Kit Components.

Page 5

Linkage Kit Installation (Continued)

Two-way Normally Closed VB-9223 2½” through 6” and

Three-way Mixing VB-9313 2½” through 6” Valves Bodies

Warning: 2½” through 6” valve bodies date coded before 8603 must have valve packing

nut removed and replaced [replace packing nut — tighten four (4) turns] along with the

bracket nut. Before removing packing nut, isolate the valve body using shutoff valves or

depressurize system to zero gauge and drain piping. System pressure could cause packing

parts to blow out with potential of bodily injury and/or water damage.

1. Push the stem completely down.

2. Remove the bracket nut from valve body. Refer to Figure-1.

3. Place the mounting bracket onto the valve body and secure it in place with the bracket nut.

4. Thread the stem lock nut all the way down the valve stem.

5. Place the indicator plate on the valve stem.

6. Install an E-ring on one end of the stem link shaft (pin). Insert the pin through the hole on the valve stem adapter.

7. Thread the valve stem adapter onto the valve stem until the stem touches the pin. Back

the adapter off ½ turn (counterclockwise) and remove the pin.

8. Secure the valve stem adapter, the AK-42309-500 spring arm (if required), and the

indicator plate into place with the stem lock nut. Refer to

Note: For actuator/valve assemblies that require a positive positioner, refer to

AK-42309-500, Positive Positioner Pneumatic Relay General Instructions, F-22909,

for details.

Figure-1.

9. Select the actuator (MK-88XX or MK-89XX series). For actuators details refer to

MK-8800 Series, MK-8900 Series, Pneumatic Valve Actuators General

Instructions, F-21662.

10. Thread the actuator shaft adapter onto the actuator stem as far as it will turn. Refer to Table-1 for required AV-496 components.

1 1. Using the appropriate bolts attach the selected actuator to the mounting bracket. Refer

to Table-1. If MK-89XX series actuator is selected install the spacers before attaching

the actuator to the bracket. Refer to Figure-1.

12. Raise the valve stem completely up, so that the disc rest against the top seat.

13. Turn the actuator shaft adapter counterclockwise until the holes on the adapters are aligned.

14. Screw the actuator shaft adapter 1½ turns further clockwise onto the actuator shaft.

15. Apply air pressure to actuator until the holes on the adapters are aligned.

16. Insert the stem link shaft (pin) through the holes and place the second E-ring on the other end to secure the assembly.

17. Release pressure to actuator and allow valve assembly to spring return to the closed position.

18. Align the top indication marker of the OPEN/CLOSE decal with the indicator plate. Affix

the OPEN/CLOSE decal to the mounting bracket. Refer to

19. Linkage assembly is complete. Refer to Figure-2 and Figure-3.

Figure-1.

MAINTENANCE The actuator linkage requires no maintenance. Regular maintenance of the total system is

recommended to assure sustained optimum performance. Hard water leaves abrasive

deposits and reduces component life. T o maximize valve life, consult EN-205 Water System

Guidelines, F-26080.

F-21663-5 © Copyright 2010 Schneider Electric All Rights Reserved. 5

Page 6

Figure-2 MK-8800 Series Actuator Valve Assembly.

Figure-3 MK-8900 Series Actuator Valve Assembly.

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-21663-5

Page 7

F-21663-5 © Copyright 2010 Schneider Electric All Rights Reserved. 7

Page 8

On Oc tober 1st, 2009, TAC bec am e the Bui ldings bus iness of its parent company Schneider Electr ic. This docum ent r eflects the visual ident ity of Schneider El ectric,

ho wever there rem ains referenc es to TAC as a corporat e brand in the body c opy. As e ach document is updated, the body copy will be changed to reflect appropriate

corpo rate br a nd ch a nges.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-21663-5

Loading...

Loading...