Page 1

Application

CLOSED

OPEN

CLOSED

OPEN

CLOSED

OPEN

CLOSED

OPEN

CLOSED OPEN

CLOSED

OPEN

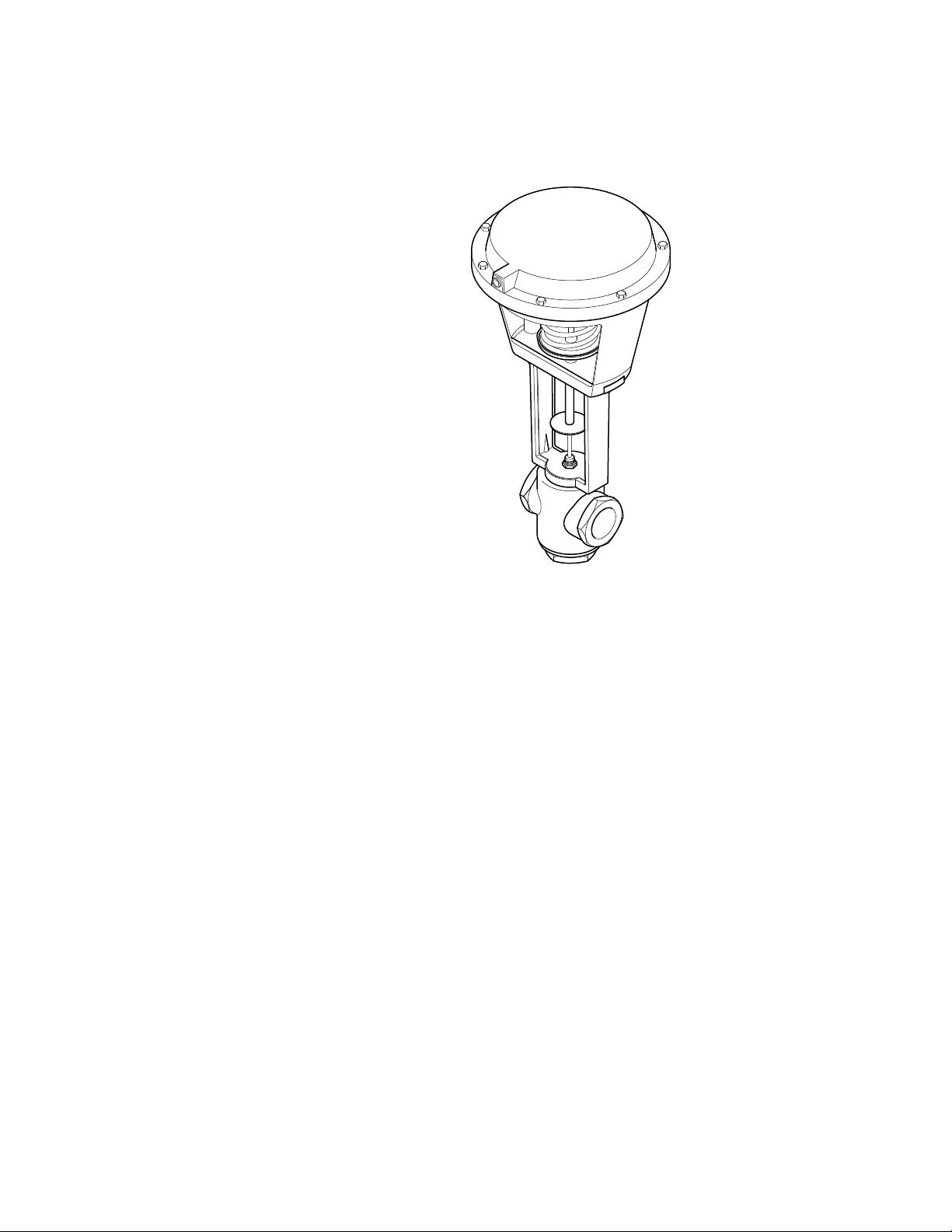

The AV-430 valve linkage is used to field assemble MK-66X1, MK-68X1, and MK-6911 actuators to applicable 1/2" to 6" two-way and three-way valve bodies.

Features

• Die cast aluminum mounting bracket

• Valve position indication is provided as a standard

f

eature

AV-430

Valve Linkage for Pneumatic Actuators

General Instructions

Applicable Literature

• Environmental Controls Cross-Reference Guide,

F-23638

• Environmental Controls Reference Manual,

F-21683

• Environmental Controls Application Manual,

F-21335

• Pneum,atic Products Catalog, F-27383

• Environmental Controls Valve Selection Guide,

F-26094

• EN-205 Water System Guidelines, F-26080

Printed in U.S.A. 11/10 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 2

SPECIFICATIONS

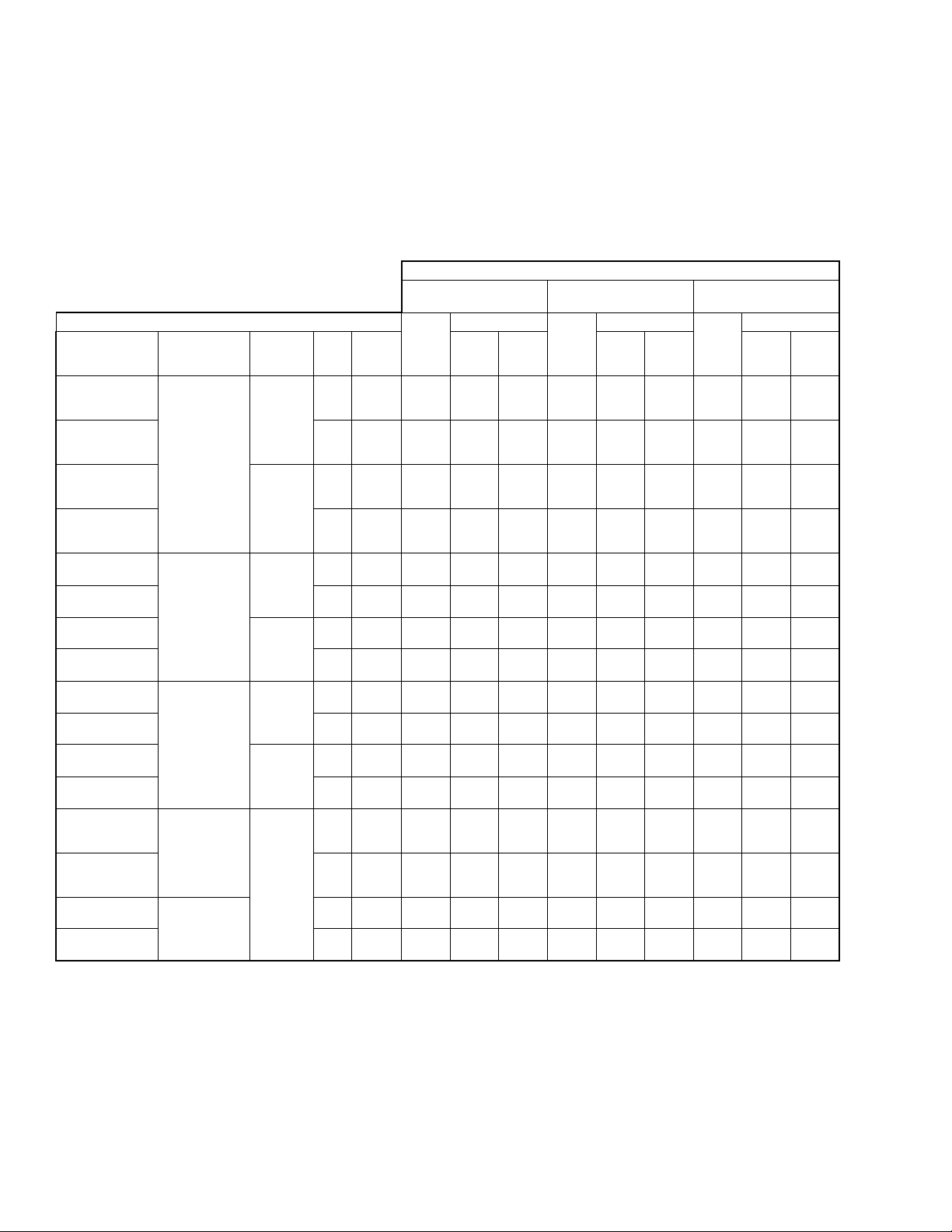

Close-Off Pressure Rating

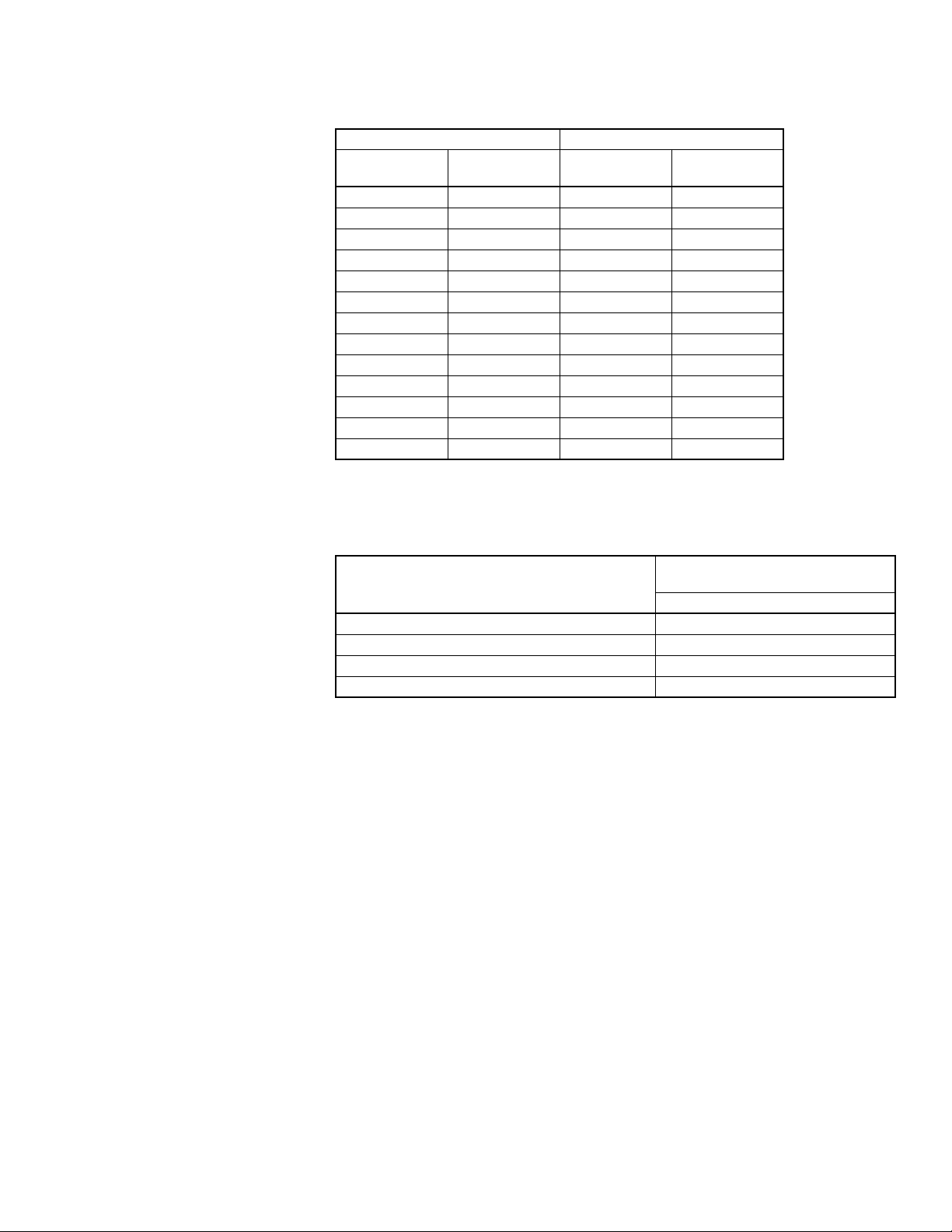

Refer to Table-1 and Table-2 to make sure the valve and actuator are compatible with each

other, and that the close-off rating is adequate for the application. Refer to Ta b le - 3 and

Ta bl e -4 for listings of obsolete valves and their corresponding actuators that used the

AV-430 valve linkage. Verify that the valve body differential pressure is in compliance with

the limitations specified for the valves being used with MM-400/500 actuators. Refer to

Environmental Controls Valve Selection Guide, F-26094 for detail information.

Table-1 Selection and Close-Off Ratings for Current VB-7XXX Valves.

Actuator

MK-6601

VALVE BODY INFORMATION

Valve Bo dy Pa rt

Number

VB-7213-0-4-10

VB-7214-0-4-10

VB-7215-0-4-10

VB-7213-0-4-11

VB-7214-0-4-11

VB-7215-0-4-11

VB-7223-0-4-10

VB-7224-0-4-10

VB-7225-0-4-10

VB-7223-0-4-11

VB-7224-0-4-11

VB-7225-0-4-11

VB-7253-0-4-10

VB-7253-0-4-11 40 2" —

VB-7263-0-4-10

VB-7263-0-4-11 40 2"

VB-7273-0-4-10

VB-7273-0-4-11 40 2" —

VB-7283-0-4-10

VB-7283-0-4-11 40 2"

VB-7313-0-4-10

VB-7314-0-4-10

VB-7315-0-4-10

VB-7313-0-4-11

VB-7314-0-4-11

VB-7315-0-4-11

VB-7323-0-4-10

VB-7323-0-4-11 40 2"

a

Close-Off Pressures for 3-Way Valves are Determined as Follows:

The value for SU is the “A” port close-off pressure, and is based on the pressure at “A” port minus the pressure at “B” port.

The value for SD is the “B” port close-off pressure, and is based on the pressure at “B” port minus the pressure at “A” port.

b

Supply Air Pressure, psig (kPa).

Description

2-Way, FNPT,

Union Sweat,

and

R

p

2-Way, FNPT

Stainless Steel

Tr i m & Te f l on

Disc

2-Way, FNPT

Stainless Steel

Tr i m

3-Way, Mixing

FNPT,

Union Sweat,

and R

p

3-Way, Diverting

FNPT

Normal

Posi tion

(SU)

Open

Closed

Open

Closed

Open

Closed

Flow B to

AB

C

Size

v

28 1-1/2" —

40 2" —

28 1-1/2"

40 2"

28 1-1/2" —

28 1-1/2"

28 1-1/2" —

28 1-1/2"

28 1-1/2"

41 2"

28 1-1/2"

Stem

Up

40

(276)

20

(138)

40

(276)

20

(138)

40

(276)

20

(138)

50

(345)

50

(345)

250

(1725)

250

(1725)

Stem Down

b

15

(104)

160

(1104)

90

(621)

— —

— —

160

(1104)

90

(621)

— —

— —

160

(1104)

90

(621)

— —

— —

150

(1034)

150

(1034)

250

(1725)

250

(1725)

20

(138)

250

(1725)

160

(1104)

250

(1725)

160

(1104)

250

(1725)

160

(1104)

250

(1724)

250

(1724)

250

(1725)

250

(1725)

CLOSE-OFF PRESSURE, psi (kPa)

Actuator

MK-6611

Stem Down

Stem

b

Up

—

—

85

(586)

50

(345)

—

—

85

(586)

50

(345)

—

—

85

(586)

50

(345)

100

(689)

100

(689)

250

(1725)

250

(1725)

b

15

(104)

115

(794)

60

(414)

— —

— —

115

(794)

60

(414)

— —

— —

115

(794)

60

(414)

— —

— —

100

(689)

100

(689)

250

(1725)

250

(1725)

20

(138)

230

(1587)

125

(862)

230

(1587)

125

(862)

230

(1587)

125

(862)

230

(1586)

230

(1586)

250

(1725)

250

(1725)

b

a

Actuator

MK-6621

Stem Down

Stem

170

(1173)

(586)

170

(1173)

(586)

170

(1173)

(586)

180

(1241)25(172)

180

(1241)25(172)

250

(1725)

250

(1725)

Up

—

—

85

—

—

85

—

—

85

15

(104)

30

(207)

15

(104)90(621)

— —

— —

30

(207)

15

(104)90(621)

— —

— —

30

(207)

15

(104)90(621)

— —

— —

250

(1725)

—

b

20

(138)

160

(1104)

160

(1104)

160

(1104)

150

(1034)

150

(1034)

250

(1725)

250

(1725)

b

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 3

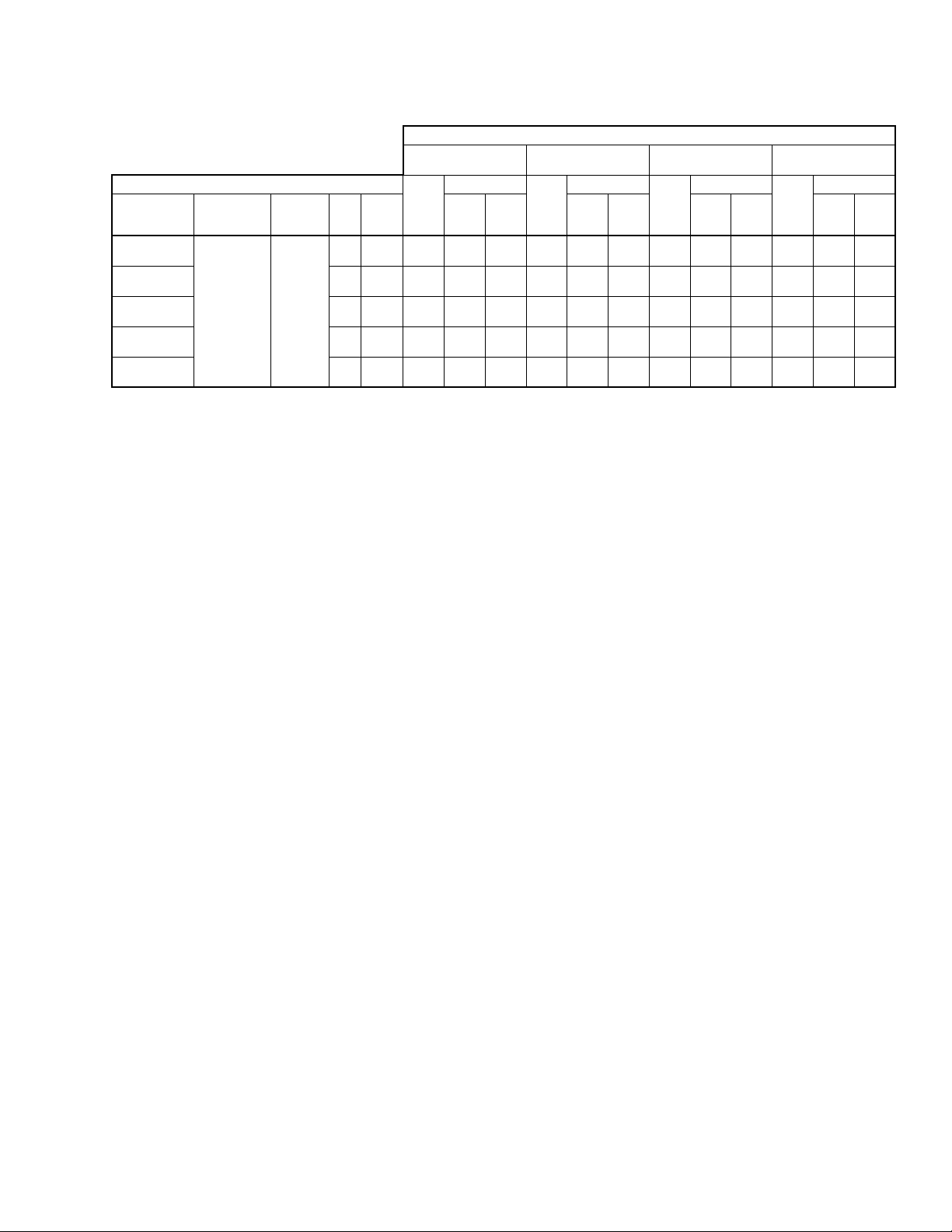

Refer to Table-2 to make sure the valve and actuator are compatible with each other, and

that the close-off rating is adequate for the application.

Table-2 Selection and Close-Off Ratings for Current VB-9XXX Valves.

Actuator

MK-6821

Stem Down

b

15

(104)

125

(862)

125

(862)

a

CLOSE-OFF PRESSURE, psi (kPa)

Actuator

MK-6801

VALVE BODY INFORMATION

Valve Body

Part N umber

VB-9323-0-4-12

Description

Normal

Position

(SU)

C

v

75 2-1/2"

Stem

Size

VB-9323-0-4-13 95 3"

3-Way,

VB-9323-0-4-14 180 4" — — — — — — — — —

Diverting, 125

psi, Flanged

Flow B to

AB

Up

125

(862)

125

(862)

Stem Down

b

15

(104)

125

(862)

125

(862)

20

(138)

125

(862)

125

(862)

b

Stem

Up

125

(862)

125

(862)

Actuator

MK-6811

Stem Down

b

15

(104)

125

(862)

125

(862)

20

(138)

125

(862)

125

(862)

Stem

b

Up

125

(862)

125

(862)

VB-9323-0-4-15 220 5" — — — — — — — — —

VB-9323-0-4-16 275 6" — — — — — — — — —

a

Close-Off Pressures for 3-Way Valves are Determined as Follows:

The value for SU is the “A” port close-off pressure, and is based on the pressure at “A” port minus the pressure at “B” port.

The value for SD is the “B” port close-off pressure, and is based on the pressure at “B” port minus the pressure at “A” port.

b

Supply Air Pressure, psig (kPa).

20

(138)

125

(862)

125

(862)

Stem

b

Up

— — —

— — —

125

(862)

125

(862)

125

(862)

Actuator

MK-6911

Stem Down

b

15

(104)

125

(862)

125

(862)

125

(862)

20

(138)

125

(862)

125

(862)

125

(862)

b

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 3

Page 4

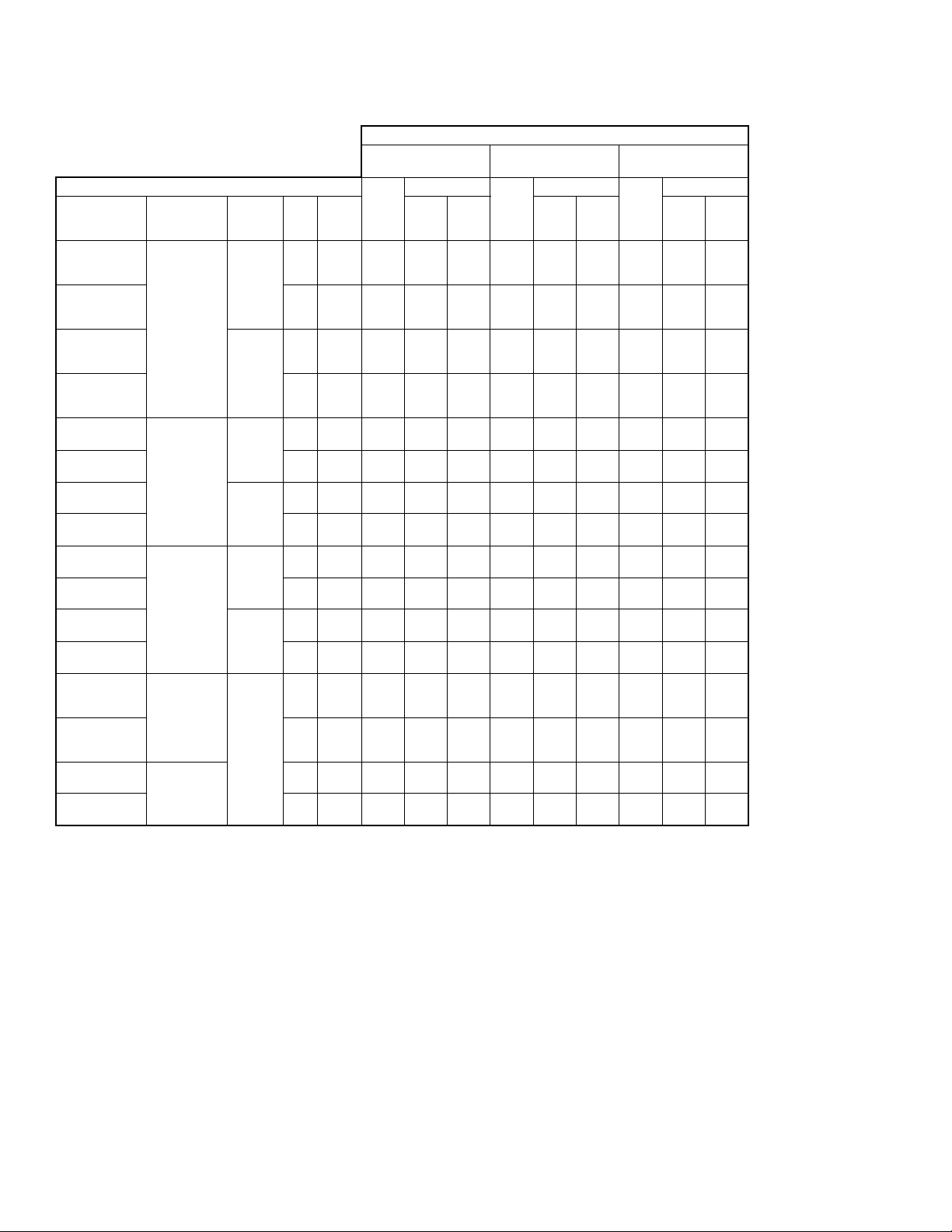

Refer to Table-3 for a listing of obsolete valves and their corresponding actuators that used

the AV-430 valve linkage.

Table-3 Selection and Close-Off Ratings for Obsolete Valves.

CLOSE-OFF PRESSURE, psi (kPa)

Actuator

MK-6801

VALVE BODY INFORMATION

Valve Body

Part Number

VB-9213-0-4-10

VB-9214-0-4-10

VB-9215-0-4-10

VB-9213-0-4-11

VB-9214-0-4-11

VB-9215-0-4-11

VB-9223-0-4-10

VB-9224-0-4-10

VB-9225-0-4-10

VB-9223-0-4-11

VB-9224-0-4-11

VB-9225-0-4-11

VB-9253-0-4-10

Description

2-Way, FNPT,

Union Sweat,

and R

p

Normal

Position

(SU)

Open

Closed

CvSize

25 1-1/2" —

40 2" —

25 1-1/2"

40 2"

25 1-1/2" —

Stem

(276)

(138)

Open

VB-9253-0-4-11 40 2" —

VB-9263-0-4-10

VB-9263-0-4-11 40 2"

VB-9273-0-4-10

2-Way, FNPT

Stainless Steel

Tr i m & Te f lo n

Disc

Closed

25 1-1/2"

(276)

(138)

25 1-1/2" —

Open

VB-9273-0-4-11 40 2" —

VB-9283-0-4-10

VB-9283-0-4-11 40 2"

VB-9313-0-4-10

VB-9314-0-4-10

VB-9315-0-4-10

VB-9313-0-4-11

VB-9314-0-4-11

VB-9315-0-4-11

VB-9323-0-4-10

VB-9323-0-4-11 42 2"

a

Close-Off Pressures for 3-Way Valves are Determined as Follows:

The value for SU is the “A” port close-off pressure, and is based on the pressure at “A” port minus the pressure at “B” port.

The value for SD is the “B” port close-off pressure, and is based on the pressure at “B” port minus the pressure at “A” port.

b

Supply Air Pressure, psig (kPa).

2-Way, FNPT

Stainless Steel

Tr im

3-Way, Mixing

FNPT,

Union Sweat,

and R

p

3-Way,

Diverting

FNPT

Closed

Flow B to

AB

25 1-1/2"

33 1-1/2"

55 2"

30 1-1/2"

(276)

(138)

(1304)85(586)

(1304)85(586)

(1725)

(1725)

Up

40

20

40

20

40

20

29

29

250

250

Stem Down

b

15

20

(104)

(138)

160

90

(621)

250

(1725)

160

(1104)

(1104)

— —

— —

160

90

(621)

250

(1725)

160

(1104)

(1104)

— —

— —

160

90

(621)

250

(1725)

160

(1104)

(1104)

— —

— —

160

(1104)60(414)60(414)

160

(1104)60(414)60(414)

250

250

250

(1725)

250

(1725)

(1725)

(1725)

Stem

b

Up

—

—

85

(586)

50

(345)

—

—

85

(586)

50

(345)

—

—

85

(586)

50

(345)

250

(1725)

250

(1725)

Actuator

MK-6811

Stem Down

b

15

(104)

115

(794)

60

(414)

— —

— —

115

(794)

60

(414)

— —

— —

115

(794)

60

(414)

— —

— —

250

(1725)

250

(1725)

Stem

b

20

230

125

Up

—

—

(138)

(1587)

(862)

170

(1173)

85

(586)

230

125

230

125

—

—

170

(1173)

85

(586)

—

—

170

(1173)

(1587)

(862)

(1587)

(862)

85

(586)

130

105

(897)

(724)14(97)85(586)

130

105

(897)

(724)14(97)85(586)

250

250

250

(1725)

250

(1725)

(1725)

(1725)

a

Actuator

MK-6821

(1725)

(1725)

Stem Down

b

15

20

(104)

(138)

30

160

(207)

(1104)

15

(104)90(621)

— —

— —

30

160

(207)

(1104)

15

(104)90(621)

— —

— —

30

160

(207)

(1104)

15

(104)90(621)

— —

— —

250

250

(1725)

250

250

(1725)

b

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 5

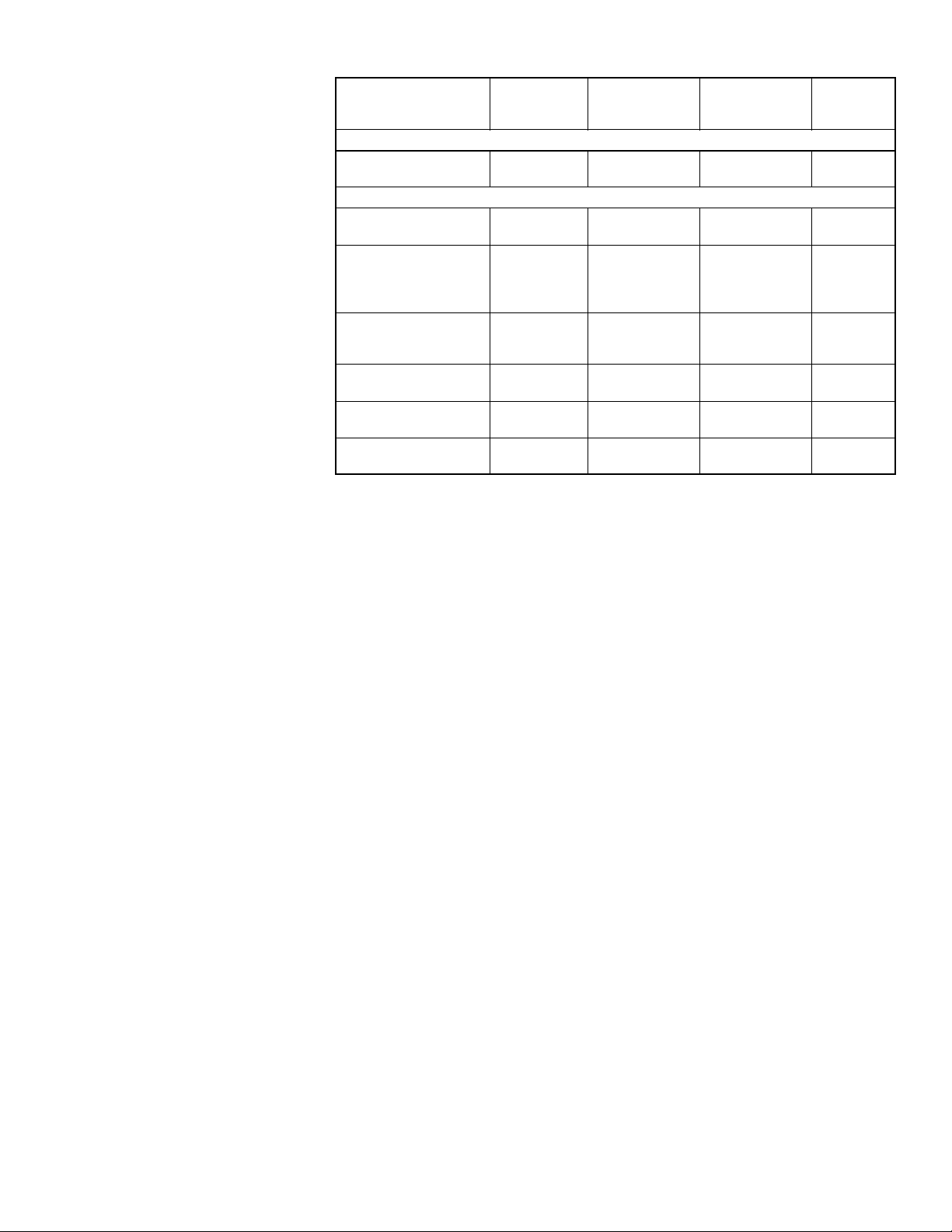

Refer to Table-4 for a listing of obsolete valves and their corresponding actuators that used

the AV-430 valve linkage.

Table-4 Obsolete Valves and Corresponding Actuators Using Valve Linkage AV-430.

Valve Data Actuator Series

Part Number

Series

VB-202 1/2" to 2" Ye s No

VB-202 2-1/2" to 4" Ye s No

VB-212 1/2" to 2" Ye s No

VB-252 1/2" to 2" Ye s No

VB-252 2-1/2" to 4" Ye s No

VB-304 1/2" to 2" Ye s No

VB-304 2-1/2" to 4" Ye s No

VB-804 1/2" to 2" Ye s No

VB-804 2-1/2" to 4" Ye s No

VB-807 1/2" to 2" Ye s No

VB-817 1/2" to 2" Ye s No

VB-817 2-1/2" to 3" Ye s No

VB-817 4" to 6" No Ye s

Sizes MK-68X1 MK-6911

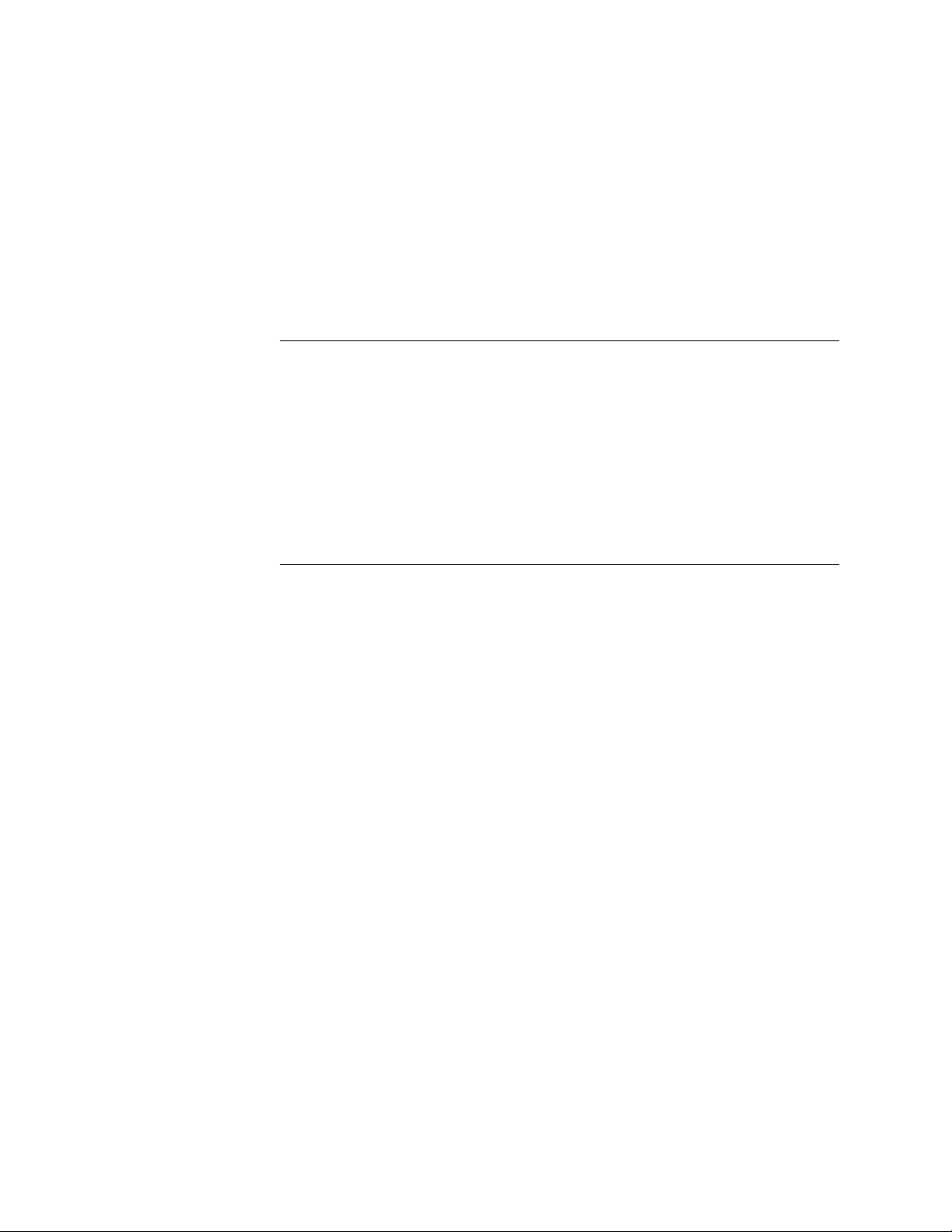

Temperature Restrictions

Required Components

Verify that the temperature of the media in the valve and the ambient temperature at the

actuator do not exceed the values shown in Tab le - 5 .

Table-5 Restrictions on the Maximum Ambient Temperature for the Actuators.

Maximum Temperature

of Media in the Valve

(Check Ratings of the Valve)

366° F (180° C) 100° F (37° C)

340° F (171° C) 100° F (37° C)

281° F (138° C) 160° F (71° C)

250° F (121° C) 220°F (104° C)

a

Maximum allowable ambient temperature for the actuator.

Maximum Ambient

Temperature for Actuators

MK-68X1, MK-66X1 or MK-6911

a

Factory assemblies of valve and actuator combinations are available for several of the

selections listed in

Ta bl e -1 and Ta bl e -2 . Consult the Pneumatic Products Catalog, F-

27383 or Environmental Controls Valve Selection Guide, F-26094 for availability.

Actuator and valve combinations not available as factory assemblies must be purchased

separately, along with the appropriate valve linkage kit.

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 5

Page 6

INSTALLATION

Inspection Inspect the package for damage. If damaged, notify the appropriate carrier immediately. If

undamaged, open the package and inspect the device for any obvious damage. Return

damaged products.

Requirements • Parts:

– See Ta bl e - 6 for parts selection for the AV-430 valve linkage.

• Tools (not provided):

– Appropriate wrenches for stem extensions, locknuts, packing nuts, and bracket nuts.

– Appropriate screw driver for actuator mounting screws.

– TOOL-37, 1-5/8" open-ended wrench with a maximum thickness of 3/16"

• Training:

– Installer must be a qualified, experienced technician.

Caution:

• Avoid locations where excessive moisture, corrosive fumes, or vibration are present. Do

not insulate above actuator mounting nut trapping moisture.

• Install all two-way valves so that they close against the flow. An arrow on the valve body

or a tag indicates the proper flow direction.

• Always install three-way mixing valves with two inlets and one outlet.

• Always install three-way diverting valves with one inlet and two outlets.

• Do not install the actuator below the center line of the valve. For steam applications only,

mount the actuator above the valve body at 45° from vertical.

• When selecting a location, allow sufficient room for accessories and for servicing the

actuator.

Mounting 1. Actuators can be mounted in any upright position above the center line of a valve body.

2. When selecting a location, allow sufficient room for accessories and for service of the product.

3. Maintain proper flow direction when installing all globe and radiator-type valves. Flow direction is indicated by an arrow on the valve body or by information on the attached tag.

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 7

Table-6 Parts Selection for the AV-430 Valve Linkage.

Valve Body

Description

1/2" to 2"

(VB-7XXX)

1/2" to 1-1/4"

(obsolete VB-9XXX)

1-1/2" to 2"

(VB-202, -212, -252,

-304, -804,

obsolete VB-9XXX)

2-1/2" to 4"

(VB-202, -252,

-304, -804)

1/2" to 3"

(VB-817)

2-1/2" and 3"

(VB-9323)

4" to 6"

(VB-817, VB-9323)

a

Included with the valve body.

Required

Locknut

1/4" and 1/2"

1/4" and 1/2"

1/4"

3/8"

3/8"

3/8"

3/8"

Required

Stem Extension

Current Valves

Long for

1/4" Stem

Obsolete Valves

Long for

1/4" Stem

Medium for

1/4" Stem

Short for

3/8" Stem

Short for

3/8" Stem *

Short for

3/8" Stem

Short for

3/8" Stem

a

Required

Indicator Plate

With 1/2"

Diameter Hole

With 1/2"

Diameter Hole

With 1/4"

Diameter Hole

With 3/8"

Diameter Hole

With 3/8"

Diameter Hole

With 3/8"

Diameter Hole

With 3/8"

Diameter Hole

Required

Scale

Length

1/2"

1/2"

1"

1"

1"

1"

1-1/2"

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 7

Page 8

ASSEMBLY PROCEDURE

OPEN

CLOSED

OPEN

CLOSED

Actuator Piston Stem *

Connecting Pin

OPEN/CLOSED Decal

(1/2" Long)

(See Table-7 for Orientation)

Valve Body *

Hex Mounting Nut

Stem Locknut (1/4")

Indicator Locknut (1/2")

Indicator Plate

(1/2" Hole)

Stem Extension

(1/4", Long)

* Not included with AV-430 Linkage Kit

Mounting Bracket

(NYBA-6)

Install AV-430 Valve Linkage onto 1-1/2" and 2" VB-7XX3, VB-7XX4, and VB-7XX5 Valve Bodies

1. Thread the mounting bracket onto the hex head mounting nut on the valve body. See Figure-1.

2. Position the mounting bracket, then tighten the mounting nut against it, using a 1-5/8" open-ended wrench with a maximum thickness of 3/16" (TOOL-37).

Note: Install the mounting bracket in such a position as to make the wiring or piping of the

actuator convenient.

Figure-1 Assembly of MK-66X1 Series Actuators onto 1-1/2" and 2" VB-7XX3, VB-7XX4,

and VB-7XX5 Series Valve Bodies.

3. Select the required stem extension, stem locknut, and indicator plate, according to Ta bl e -6 .

4. Thread the stem locknut onto the valve stem. Continue threading the locknut until it is positioned near the bottom of the exposed valve stem.

5. Position the indicator plate onto the valve stem.

6. Thread the stem extension well down onto the valve stem.

7. Position the actuator onto the mounting bracket.

8. Secure the actuator, using the two bolts provided. For a view of the completed assembly, see Figure-2.

9. Adjust the stem height according to the instructions in the Adjustments section.

10. Tighten the stem locknut against the stem extension to secure the stem extension in position on the valve stem.

8 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 9

11. Apply the OPEN/CLOSED decal (which features a 1/2" scale length) onto the mounting

Assembly shown prior to

final adjustments.

bracket. See Tab le - 7 for the orientation of the decal.

Figure-2 Typical MK-66X1 Series Actuator Using the AV-430 Valve Linkage.

Table-7 Orientation of OPEN/CLOSED Decal on Mounting Bracket.

Valve Body Label Orientation

2-Way, Stem-Up, Open VB-721X

VB-921X, VB-202, VB-212

2-Way, Stem-Up, Closed

VB-722X

VB-922X, VB-252

3-Way, Mixing

VB-731X

VB-931X, VB-304, VB-804

3-Way, Diverting

VB-7323

VB-9323, VB-817

"OPEN" at Bottom Indicates Inlet Port “A” Is Open

"OPEN" at Bottom Indicates Outlet Port “U” Is Open

"OPEN" End Towards Actuator

"CLOSED" End Towards Actuator

Orientation Depends on Application:

"OPEN" at Top Indicates Inlet Port "B" Is Open

Orientation Depends on Application:

"OPEN" at Top Indicates Outlet Port “L” Is Open

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 9

Page 10

Install AV-430 Valve Linkage onto Obsolete 1-1/2" and 2" VB-9XX3 and

OPEN

CLOSED

OPEN

CLOSED

Actuator Piston Stem *

Connecting Pin

OPEN/CLOSED Decal

(1" Long)

(See Table-7 for Orientation)

Style A Valve Body *

Hex Mounting Nut

Stem Locknut (1/4")

Indicator Plate

(1/4" Hole)

* Not included with AV-430 Linkage Kit

Stem Extension

(1/4", Medium Length)

Bolt

(MK-68X1 Series)

Mounting Bracket

(NYBA-6)

VB-9XX4 Valve Bodies

1. Install the mounting bracket onto a Style A valve body as follows:

a. Thread the mounting bracket onto the hex head mounting nut. See Figure-3.

b. Position the mounting bracket, then tighten the mounting nut against it, using a

1-5/8" open-ended wrench with a maximum thickness of 3/16" (TOOL-37).

Note: Install the mounting bracket in such a position as to make the wiring or piping of the

actuator convenient.

Figure-3 Assembly of MK-68X1 Series Actuators with Style A 1-1/2" and 2" VB-9XX3 and

VB-9XX4 Series Valve Bodies.

2. Install the mounting bracket onto a Style B valve body as follows:

a. Remove the bracket nut from the valve body.

b. Position the mounting bracket onto the valve body. See Figure-4.

c. Replace and tighten the bracket nut onto the valve body to secure the mounting

bracket.

10 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 11

OPEN

CLOSED

OPEN

CLOSED

Connecting Pin

Bracket Nut

OPEN/CLOSED Decal

(1" Long)

(See Table-7 for Orientation)

Style B Valve Body *

Bolt

(MK-68X1 Series)

Stem Locknut

(1/4")

Indicator Plate

(1/4" Hole)

Stem Extension

(1/4", Medium Length)

Actuator Piston Stem *

* Not included with AV-430 Linkage Kit

Mounting Bracket

(NYBA-6)

Figure-4 Assembly of MK-68X1 Series Actuators with Style B 1-1/2" and 2" VB-9XX3 and

VB-9XX4 Series Valve Bodies.

3. Select the required stem extension, stem locknut, and indicator plate, according to Ta bl e -6 .

4. Thread the stem locknut onto the valve stem. Continue threading the locknut until it is positioned near the bottom of the exposed valve stem.

5. Position the indicator plate onto the valve stem.

6. Thread the stem extension well down onto the valve stem.

7. Install the actuator onto the mounting bracket as follows:

MK-68X1 Series Actuators

a. Position the actuator onto the mounting bracket.

b. Secure the actuator, using the two bolts provided. For a view of the completed

assembly, see

Figure-5.

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 11

Page 12

8. Adjust the stem height according to the instructions in the Adjustments section.

9. Tighten the stem locknut against the stem extension to secure the stem extension in position on the valve stem.

10. Apply the OPEN/CLOSED decal (which features a 1" scale length) onto the mounting

bracket. See

Ta bl e -7 for the orientation of the decal.

Figure-5 Typical MK-68X1 Series Actuator Using the AV-430 Valve Linkage.

12 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 13

Install AV-430 Valve Linkage onto VB-202, -212, -252, -304, -804, -807, and

OPEN

CLOSED

OPEN

CLOSED

Connecting Pin

Indicator Plate

(1/4" Hole)

OPEN/CLOSED Decal

(See Table-6 for Length)

(See Table-7 for Orientation)

Valve Body *

Bolt

(MK-68X1 Series

and MK-6911)

Bracket Nut *

Packing Nut *

Stem Locknut

(1/4")

Stem Extension

(1/4", Medium Length)

Actuator Piston Stem *

* Not included with AV-430 Linkage Kit

Mounting Bracket

(NYBA-6)

-817 (1-1/2" to 2") Valve Bodies

1. Install the mounting bracket onto the valve body as follows:

a. Remove the packing nut and the bracket nut from the valve body.

Note: Install the mounting bracket in such a position as to make the wiring or piping of the

actuator convenient.

b. Position the mounting bracket onto the valve body. See Figure-6.

c. Replace and tighten the bracket nut and packing nut onto the valve body to secure

the mounting bracket.

Figure-6 Assembly of MK-6800 Series Actuators with VB-202, -212, -252,

-304, -804, -807, -817, and VB-9323 (1-1/2" to 2") Series Valve Bodies.

2. Select the required stem extension, stem locknut, and indicator plate, according to Ta bl e -6 .

3. Thread the stem locknut onto the valve stem. Continue threading the locknut until it is positioned near the bottom of the exposed valve stem.

4. Position the indicator plate onto the valve stem.

5. Thread the stem extension well down onto the valve stem.

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 13

Page 14

6. Install the actuator onto the mounting bracket as follows:

MK-68XX and MK-6911 Series Actuators

a. Position the actuator onto the mounting bracket.

b. Secure the actuator, using the two bolts provided. For a view of the completed

assembly, see Figure-5.

7. Adjust the stem height according to the instructions in the Adjustments section.

8. Tighten the stem locknut against the stem extension to secure the stem extension in position on the valve stem.

9. Apply the OPEN/CLOSED decal onto the mounting bracket. Refer to Ta bl e - 6 for the required scale length. See Ta b le - 7 for the orientation of the decal.

Install AV-430 Valve Linkage onto VB-202, -212, -252, -304, -804, -807, -817, and VB-9323 (2-1/2" to 6") Series Valve Bodies

1. Install the mounting bracket onto the valve body as follows:

a. Remove the packing nut and the bracket nut from the valve body.

Note: Install the mounting bracket in such a position as to make the wiring or piping of the

actuator convenient.

b. Position the mounting bracket onto the valve body. See Figure-7.

c. Replace and tighten the bracket nut and packing nut onto the valve body to secure

the mounting bracket.

2. Select the required stem extension, stem locknut, and indicator plate, according to Ta bl e -6 .

3. Thread the stem locknut onto the valve stem. Continue threading the locknut until it is positioned near the bottom of the exposed valve stem.

4. Position the indicator plate onto the valve stem.

5. Thread the stem extension well down onto the valve stem.

6. Install the actuator onto the mounting bracket as follows:

MK-68X1 Series Actuators

a. Position the actuator onto the mounting bracket.

b. Secure the actuator, using the two bolts provided. For a view of the completed

assembly, see Figure-5.

7. Adjust the stem height according to the instructions in the Adjustments section.

8. Tighten the stem locknut against the stem extension to secure the stem extension in position on the valve stem.

9. Apply the OPEN/CLOSED decal onto the mounting bracket. Refer to Ta bl e - 6 for the required scale length. See Ta b le - 7 for the orientation of the decal.

14 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 15

OPEN

CLOSED

OPEN

CLOSED

Connecting Pin

Indicator Plate

(3/8" Hole)

OPEN/CLOSED Decal

(See Table-6 for Length)

(See Table-7 for Orientation)

Valve Body *

Bolt

(MK-68X1 Series

and MK-6911)

Bracket Nut *

Packing Nut *

Stem Locknut

(3/8")

Stem Extension

(3/8", Short Length)

Actuator Piston Stem *

* Not included with AV-430 Linkage Kit

Mounting Bracket

(NYBA-6)

Figure-7 Assembly of MK-68X1, and MK-6911Series Actuators with VB-202,

-212, -252, -304, -804, -817, and

VB-9323 (2-1/2" to 6") Series Valve Bodies.

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 15

Page 16

Adjustments For VB-202, VB-212, VB-7213, VB-7253, VB-7273, VB-9213, VB-9253, and

VB-9273 Valve Bodies (2-Way, Normally Open)

Adjust the stem height as follows:

1. Apply supply air pressure to the actuator so

2. Push the valve stem down completely so that the valve disc is seated against the bottom

v

alve seat.

3. Turn the stem extension only until the hole in the stem extension aligns with the hole in the actuator piston.

4. Turn the stem extension two full rotations upward, into the actuator piston.

5. Remove air pressure (actuator in the retract position) and insert the connecting pin into

the ali

gned holes in the stem extension and actuator piston.

For VB-252, VB-304, VB-804, VB-817, VB-7223, VB-7263, VB-7283, VB-7323, VB-9223, VB-9263, VB-9283, VB-9313, and VB-9323 Valve Bodies (2-Way, Normally Closed and 3-Way)

Adjust the stem height as follows:

1. Without applying power, make sure the actuator is in the fully retracted position.

2. Make sure the valve stem is pulled completel

against the top valve seat.

3. Turn the stem extension only until the hole in the stem extension aligns with the hole in the actuator piston.

4. Turn the stem extension two full rotations downward, away from the actuator piston.

5. Apply air pressure to put the actuator in the fully extended position and insert the connecting pin into the aligned holes in the stem extension and actuator piston.

that the actuator piston shaft is fully extended.

y up, so that the valve disc is seated

For VB-7213, VB-7253, and VB-7273 Valve Bodies (2-Way, Normally Open)

Adjust the stem height as follows:

1. Without applying air, make sure the actuator is in fully re

2. Make sure the valve stem is pulled completely up (Full Open Position).

3. Turn the stem extension until the hole in the stem extension aligns with the hole in the actuator piston.

4. Insert the connecting pin into the aligned holes in the stem extension and actuator piston.

tracted position.

16 © Copyright 2010 Schneider Electric All Rights Reserved. F-19072-13

Page 17

CHECKOUT

Actuator

Coupling Line

9/16"

(14.2 mm)

Valve Body

Coupling Line

1-1/64" (25.8 mm)

Maximum Width of Bracket is 3-1/16" (77.8 mm)

7"

(177.8 mm)

5-9/16"

(141 mm)

(1-1/4" - 16 Internal Threads)

MAINTENANCE

FIELD REPAIR

DIMENSIONAL DATA

When assembly is completed, operate the actuator full-stroke several times to verify valve

close-off and the performance of the assembly.

The actuator linkage requires no maintenance.

Regular maintenance of the total system is recommended to assure sustained, optimum

performance.

None. Replace an inoperative actuator linkage with a functional unit.

Figure-8 Dimensions of the Valve Linkage Mounting Bracket.

F-19072-13 © Copyright 2010 Schneider Electric All Rights Reserved. 17

Page 18

On October 1st, 2009, TAC became the Bui ldings bu siness of its pa rent company Schn eider Electric. This document reflect s the vi sual identity of Schneider Electric,

however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be c han ged to reflect appropr iate

corpo rate bra nd ch a nges.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-19072-13

Loading...

Loading...