Page 1

Rackmount 3.5-kW Air Conditioning Unit

User Manual

ACRMD4KI-1, ACRMD4KI-2, ACRMD4KI-3

990-6186-001

Release Date: 06/2019

www.schneider-electric.com

Page 2

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Page 3

Table of Contents

Safety............................................................................................................5

Important Safety Instructions — SAVE THESE INSTRUCTIONS....................5

Safety During Installation and Operation.......................................................6

General Information....................................................................................9

Document Overview ...................................................................................9

Equipment Disposal ....................................................................................9

Receiving and Inspecting the Unit ..............................................................10

Storing the Unit Before Installation ............................................................. 10

Unpacking the Unit ................................................................................... 11

Moving the Unit ........................................................................................ 11

Intended Use ........................................................................................8

Original Instructions ..............................................................................9

Save These Instructions ........................................................................9

Manual Updates ...................................................................................9

Cross-Reference Symbol Used in This Manual........................................9

Abbreviations .......................................................................................9

General Information ..............................................................................9

Please Recycle...................................................................................10

Waste Electrical and Electronic Equipment (WEEE) Disposal.................10

Filing a Claim......................................................................................10

Unit Overview ............................................................................................ 12

Introduction..............................................................................................12

Equipment Guidelines ............................................................................... 13

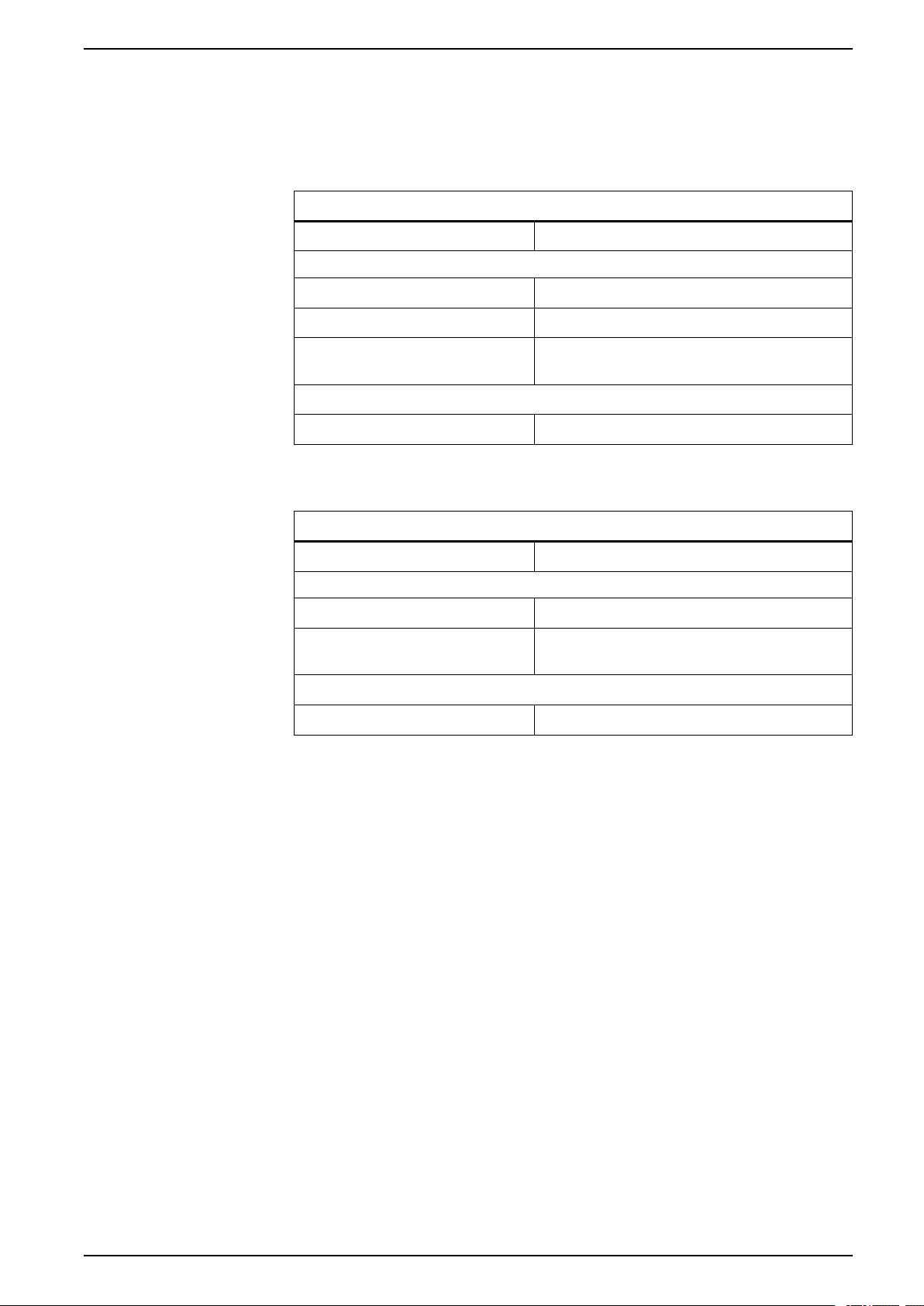

Working Conditions and Environmental Limits.......................................13

Standard Features and Options .................................................................14

Standard Features ..............................................................................14

Optional Features ............................................................................... 15

Technical Data....................................................................................15

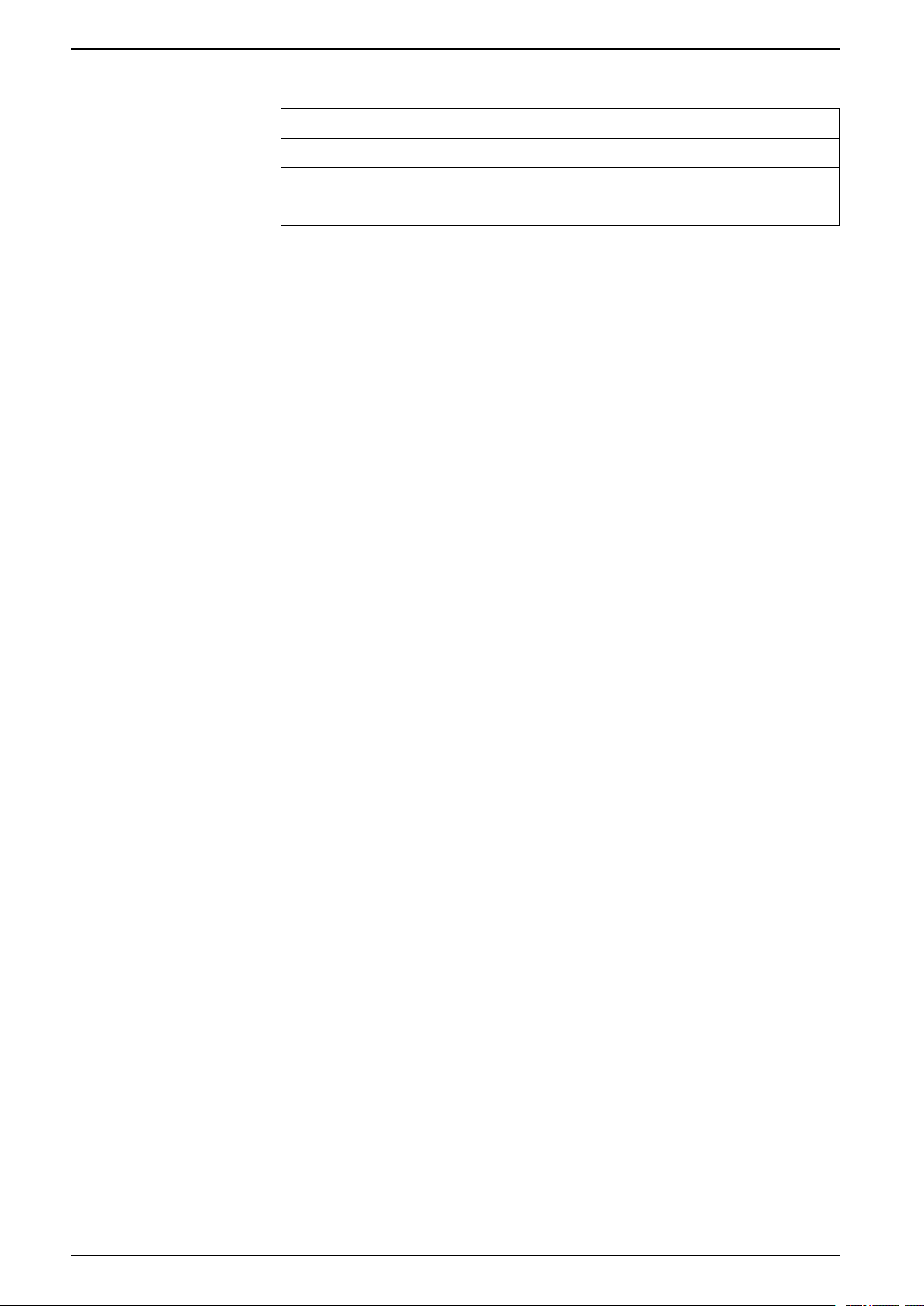

Dimensions and Weights.........................................................................17

Indoor Unit ............................................................................................... 17

Outdoor Units ........................................................................................... 17

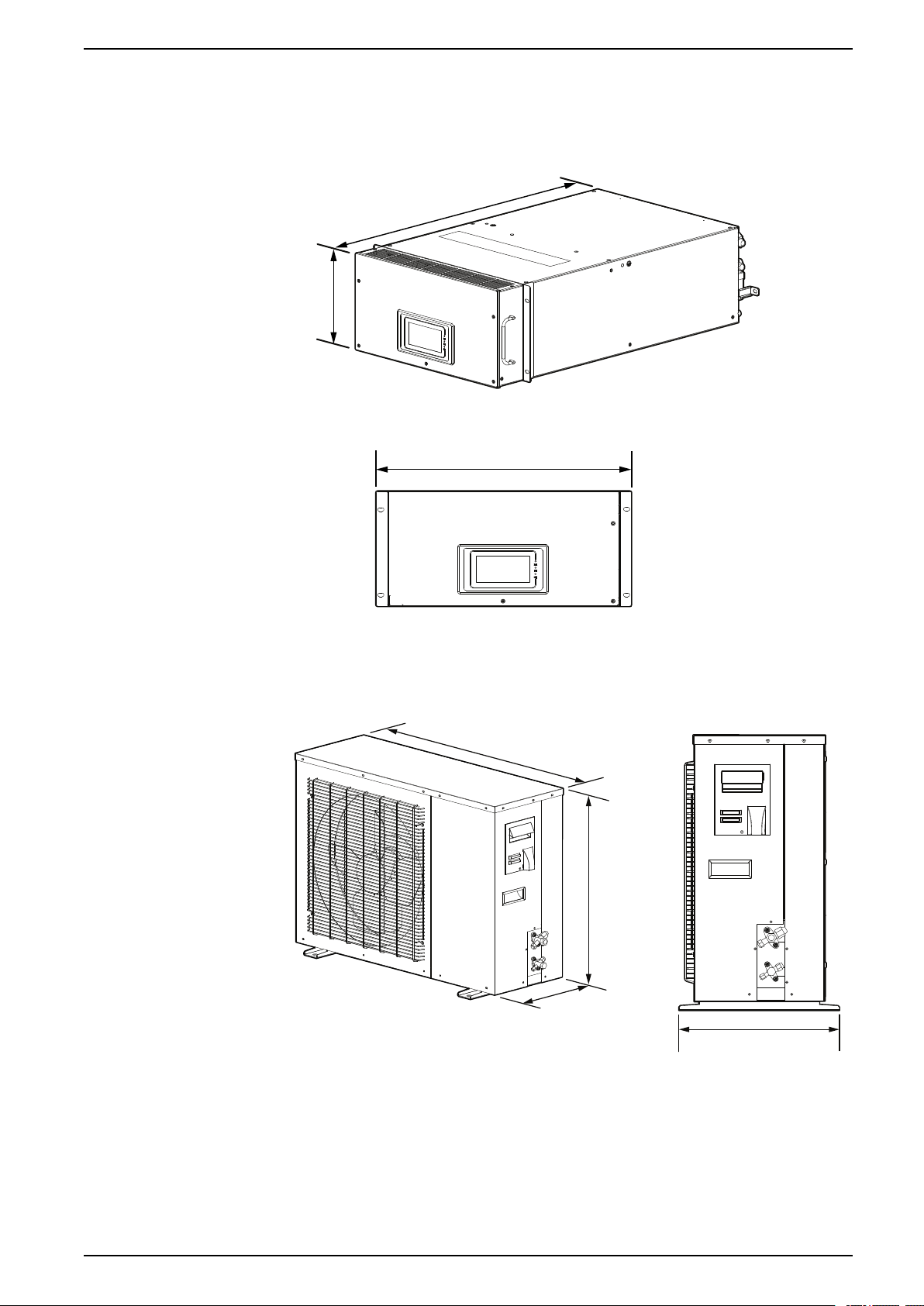

Weight .....................................................................................................18

Service Clearance .................................................................................... 18

Airflow Clearance .....................................................................................18

Access Locations ..................................................................................... 19

Component Identification......................................................................... 20

Inventory..................................................................................................20

External Components ............................................................................... 20

Indoor Unit ......................................................................................... 20

Outdoor Unit ....................................................................................... 21

Internal Components ................................................................................ 22

Indoor Unit ......................................................................................... 22

Outdoor Unit ....................................................................................... 23

Installation..................................................................................................24

Site Preparation ....................................................................................... 24

Incoming Power Supply Requirements ................................................. 24

Before You Start .......................................................................................24

990-6186-001 3

Page 4

Positioning Units....................................................................................... 25

Panel Removal .........................................................................................26

Indoor Unit ......................................................................................... 26

Outdoor Unit ....................................................................................... 27

Display Interface....................................................................................... 28

Mechanical Connections ...........................................................................28

Installing the Indoor Unit in the Rack.....................................................28

Installing the Outdoor Unit ................................................................... 29

Piping Kit Application .......................................................................... 30

Refrigerant Piping ...............................................................................31

Drain Connection ................................................................................36

Electrical Connections .............................................................................. 37

Wire Cross-Section Ratings................................................................. 38

Connection Interface................................................................................. 39

Charging the Refrigeration System ............................................................42

Leak Detection ...................................................................................42

Vacuum Pumping................................................................................43

Calculating the Refrigerant Charge.......................................................44

Charging the Refrigerant ..................................................................... 45

Commissioning..........................................................................................46

Start-Up Inspection Checklist ....................................................................46

Electrical Inspection Checklist ................................................................... 47

Mechanical Inspection Checklist ................................................................ 48

Operation ...................................................................................................49

Using the Display......................................................................................49

Maintenance .............................................................................................. 56

Preventive Maintenance............................................................................56

4 990-6186-001

Page 5

Safety

Safety

Important Safety Instructions — SAVE THESE INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar

with it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will

result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this

symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990-6186-001 5

Page 6

Safety During Installation and Operation

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the

equipment.

• Replace all devices, doors, and covers before turning on power to this

equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• If the power supply cord is damaged, it must be replaced by an equivalent

cord or assembly available from the manufacturer or its service agent.

Failure to follow these instructions will result in death or serious injury.

WARNING

Safety

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the

equipment for foreign objects before closing the doors and starting the

equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

• The equipment is heavy. For safety purposes, adequate personnel must be

present when moving this item.

• The load must always be solidly anchored to the bearing element of the

lifting equipment and means of transport.

• No one should be near the suspended load, nor in the working area of the

crane, forklift, truck, or any other lifting equipment or means of transport.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

6 990-6186-001

Page 7

Safety

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

This equipment is not to be operated or installed by persons with reduced

physical, sensory, or mental capabilities, or persons lacking experience or

knowledge unless they have been given supervision or instruction. Children are

not to operate or play on or around this equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

HAZARD FROM UNPROTECTED OUTPUT

Apply circuit protection to all outputs.

Failure to follow these instructions can result in injury or equipment

damage.

CAUTION

HAZARD TO EQUIPMENT OR PERSONNEL

Do not operate your air conditioner in a wet room such as a bathroom or laundry

room.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

STATIC ELECTRICITY HAZARD

Circuit boards contained within this unit are sensitive to static electricity. Use

one or more electrostatic-discharge devices while handling the board.

Failure to follow these instructions can result in equipment damage.

NOTICE

DAMAGE FROM EXPOSURE

Leaving the equipment uncovered and exposed to possible damage from the

environment will void the factory warranty.

Failure to follow these instructions can result in equipment damage.

NOTICE

DAMAGE TO REFRIGERATION CIRCUIT

• Make sure the compressor has been pre-heated for at least 24 hours in the

event the system is not in operation for an extended period of time.

Failure to follow these instructions can result in equipment damage.

990-6186-001 7

Page 8

Intended Use

Safety

NOTICE

DAMAGE TO EQUIPMENT

• If the power supply cord is damaged, it must be replaced by the

manufacturer.

• An all-pole disconnection device that has at least 3-mm clearances in all

poles and has a leakage current that may exceed 10 mA, the residual

current device (RCD) having a rated residual operating current not

exceeding 30 mA, and disconnection must be incorporated in the fixed

wiring in accordance with the wiring rules.

• Type and rating of fuses: glass tube 250 V, 3.15 A

Failure to follow these instructions can result in equipment damage.

The cooling units provide air conditioning within the limits and methods described

in this manual. This equipment must be installed and applied in accordance with

the instructions provided. No modifications may be made to the units or their parts

without explicit written consent from Schneider Electric. Any mechanical or

electrical modification voids factory warranty.

8 990-6186-001

Page 9

General Information

General Information

Document Overview

Original Instructions

These are the original instructions provided by the manufacturer.

Save These Instructions

This manual contains important instructions that must be followed during

installation, operation, and maintenance of the cooling unit.

Manual Updates

Schneider Electric™policy is one of continuous technological innovation and the

company reserves the right to amend any data herein without prior notice. The

images shown in this manual are for descriptive purposes only and they may differ

from specific models that are selected.

NOTE: Unit images and component identification information are examples

only. The final configuration of the unit may change according to the different

options.

Check for updates to this manual on the Schneider Electric Web site,

www.schneider-electric.com/support. Select the Download Documents and

Software link under the Support tab and enter the manual part number or SKU

for your equipment in the search field. See the back cover of this manual for the

part number.

Cross-Reference Symbol Used in This Manual

See another section of this document or another document for more

information on this subject.

Abbreviations

The following abbreviations and terms are used in this manual:

• CFD: Computational fluid dynamics

• EXV: Electronic expansion valve

• PTC: Positive Temperature Coefficient

Equipment Disposal

General Information

• This air-conditioning unit contains fluorinated greenhouse gases.

• Installation, servicing, maintenance, and repair of this unit must be performed

by qualified personnel.

• Un-installation and recycling of the product must be performed by qualified

personnel.

• When the unit is checked for leaks, proper record keeping of all checks is

strongly recommended.

990-6186-001 9

Page 10

Please Recycle

The shipping materials are recyclable. Save them for later use, or dispose of them

appropriately.

Waste Electrical and Electronic Equipment (WEEE) Disposal

Schneider Electric products comply with international directives on

the Restriction of Hazardous Substances (RoHS) in electronic and

electrical equipment and the disposal of Waste Electrical and

Electronic Equipment (WEEE). Dispose of any waste electronic or

electrical equipment with the appropriate recycling center. Contact

Schneider Electric for assistance.

Receiving and Inspecting the Unit

The cooling unit is packaged in a wooden crate or anchored to a pallet and

covered with transparent film.

Upon delivery, check that the unit is intact and immediately notify the carrier in

writing of any damage that can be attributed to careless or improper

transportation. Check for any damage on the area upon which the display

interface is mounted.

General Information

In case of shipping damage, do not operate the cooling unit. Keep all packaging

for inspection by the shipping company and contact Schneider Electric

Corporation.

Filing a Claim

If damage is identified on receipt of the equipment, note the damage on the bill of

lading and file a damage claim with the shipping company. Contact Schneider

Electric Worldwide Customer Support at one of the numbers listed on the Web

page on the back page of this manual for information on how to file a claim with

the shipping company. The shipping claim must be filed at the receiving end of the

delivery.

NOTE: In case of shipping damage, do not operate the equipment. Keep all

packaging for inspection by the shipping company and contact Schneider

Electric.

Storing the Unit Before Installation

DAMAGE FROM EXPOSURE

Leaving the equipment uncovered and exposed to possible damage from the

environment will void the factory warranty.

NOTICE

Failure to follow these instructions can result in equipment damage.

The storage environment for the series AC should comply with GB4798.1-2005.

Item Requirements

Storage environment Indoor, clean (without dust)

Ambient humidity

Ambient temperature

10 990-6186-001

15–85%RH (without condensation)

–20 to 52℃ (–4 to 129.2°F)

Page 11

General Information

75°

105°

na91282-30

Unpacking the Unit

Move the unit near its final position before unpacking it for inspection.

The unit is packed with corrugated paper. Remove all packing materials on site.

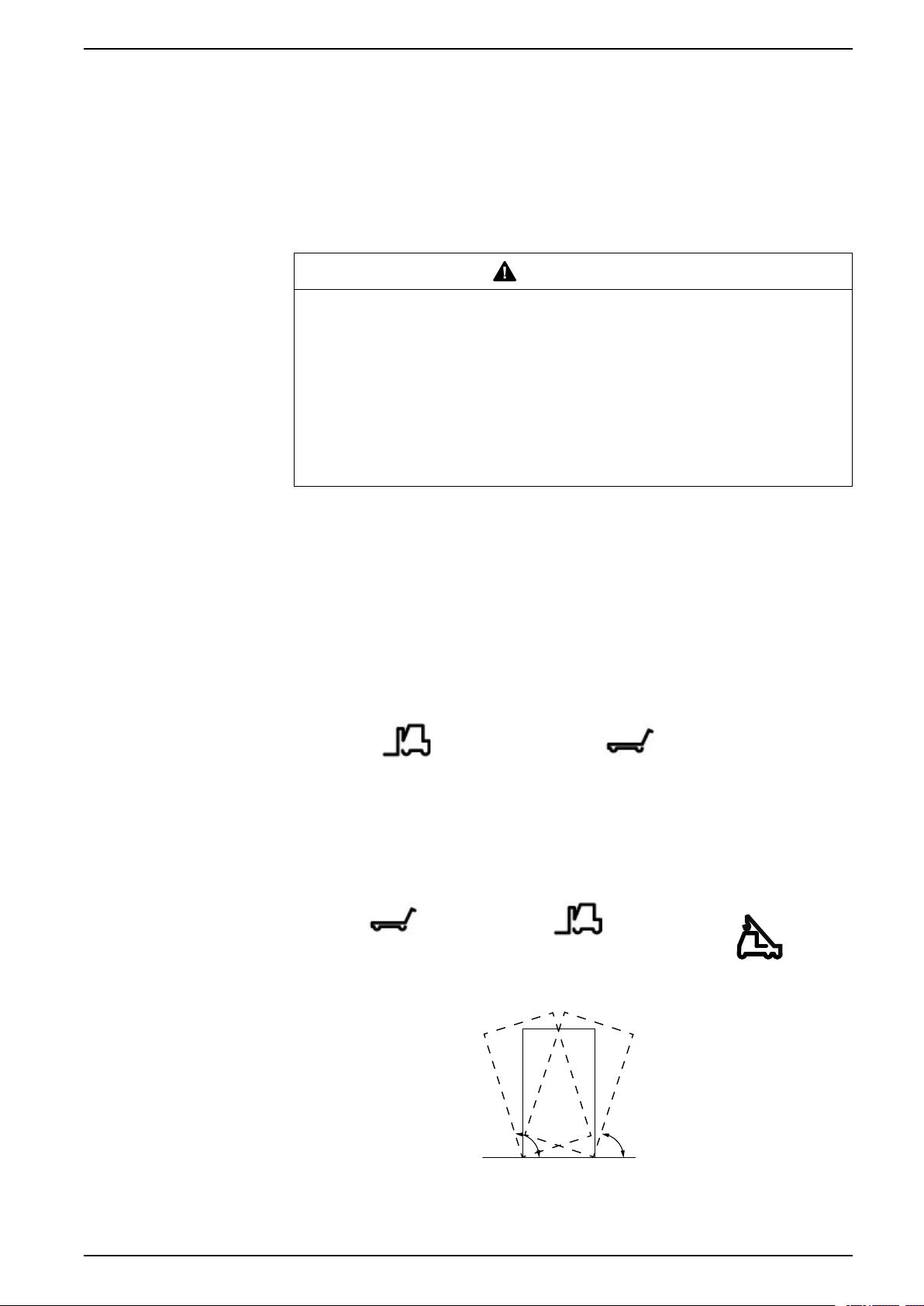

Moving the Unit

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

• The equipment is heavy. For safety purposes, adequate personnel must be

present when moving this item.

• The load must always be solidly anchored to the bearing element of the

lifting equipment and means of transport.

• No one should be near the suspended load, nor in the working area of the

crane, forklift, truck, or any other lifting equipment or means of transport.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Indoor Unit

Outdoor Unit

Lifting and transporting the units must be carried out by qualified personnel as

described in this manual.

Use all relevant safety standards to prevent any possible damage to people or

objects.

The cooling unit is packaged in a carton. The recommended tools for moving and

installing the equipment include the following:

Forklift Pallet Jack

The condensing unit is packaged in a carton. The recommended tools for moving

and installing the equipment include the following:

Pallet Jack Forklift Crane

Keep the inclination of the outdoor unit within 75–105 degrees.

990-6186-001 11

Page 12

Unit Overview

Introduction

This AC unit series, an air conditioning system of precision environmental control

in a server cabinet, provides precise temperature control, safety and reliability,

high energy efficiency design, and remote monitoring.

This series also features efficient refrigeration, high reliability, high sensible-heat

factor, intelligent monitoring, rapid installation, convenient maintenance, and

compact structure. R410A refrigerant is used as required internationally for

environmental protection.

Precise Temperature Control

This series of air conditioners has a temperature control of up to ±2.0°C (3.6°F).

Intelligent microprocessing control monitors any change in the server cabinet and

responds with control processing in advance rather than reacting to the change of

the environment at that time.

Safety and Reliability

Unit Overview

Keep the unit running 24 hours a day to keep it reliable. The advanced

microprocessing system of the units automatically adjusts machine operation and

reduces faults. Automatic alarms and diagnostics aid in maintenance and

servicing to help protect the unit and prolong the life of the unit.

High Energy Efficiency Design

The DC brushless, axial flow, centrifugal fan features minimal vibration, low noise,

and high reliability. The high-efficiency, finned-tube heat exchanger greatly

improves the heat exchange efficiency. The loop developed and verified to a

specific model ensures each loop is uniformly distributed and the heat exchanger

is fully used.

Remote Monitoring

Remote monitoring includes an RS485 interface and Modbus protocol.

• Telemetry Function: Remotely read the return and supply air temperature,

humidity of return, and working state of the unit.

• Remote Function: Remotely read the open and close state, high or low

temperature and return air humidity, and normal or failure fan state.

Cooling Control

• Temperature Control Function

◦ Indoor temperature controls system

• Cooling Regulation Function

◦ Variable-speed compressor

◦ Cooling output range of 25–100% (16–90Hz)

• Temperature

◦ Regulated temperature range of 19–30°C (66.2–86.0°F)

◦ Adjustable temperature ±2.0°C (3.6°F)

12 990-6186-001

Page 13

Unit Overview

Equipment Guidelines

Working Conditions and Environmental Limits

Indoor Unit

Limit Working Conditions

Power Supply

Room Conditions

Temperature

Humidity

Maximum Altitude

Storage Conditions

Temperature

Outdoor Unit

Limit Working Conditions

Power Supply

Ambient Conditions

Temperature

Maximum Altitude

200–240 V~, 1 Ph, 50 Hz

16–43℃ (60.8–109.4°F)

15%–65%RH (without condensation)

1000 m (3281 ft), de-rated for more than

1000 m (3281 ft)

–20 to 52℃ (–4.0 to 129.2°F)

200–240 V~, 1 Ph, 50 Hz

–35.0 to 45.0°C (–31.0 to 113.0°F)

1000 m (3281 ft), de-rated for more than

1000 m (3281 ft)

Storage Conditions

Temperature

–20 to 52℃ (–4.0 to 129.2°F)

990-6186-001 13

Page 14

Standard Features and Options

Standard Features

Indoor Unit

Feature Description

Unit Overview

Evaporator

EXV The EXV improves the control precision and response

Fan

Controller The unit controller features power recovery and fault

Filter

The finned tube heat exchanger with high-efficiency

internal thread copper pipes, hydrophilic foil, CFD flow

field analysis, and optimal matching improve the heat

transfer efficiency.

speed for precision cooling while the system is stable to

save energy.

The DC fan is continuously variable in speed and can

quickly respond to heat loads. It features high airflow,

high efficiency, long service life, and low noise.

warning. It has a terminal block connection interface.

The aluminum air filter provides a clean air supply.

Outdoor Unit

Feature Description

Compressor The inverter-driven compressor adjusts the refrigerating

capacity. The frequency conversion control technology of

the compressor and the air supply temperature control of

the unit enable the unit to flexibly adjust the refrigerating

capacity under different heat loads, to provide a constant

supply of air temperature, and reduce air temperature

fluctuations. The running frequency of the compressor

may be minimized under low thermal load conditions to

ensure that the supply air temperature of the unit does not

drop too low, and the compressor can be prevented from

frequent start and stop to improve the efficiency and

reliability of the unit and avoid condensation resulting from

too low supply air temperature.

Fan

Condenser Efficient finned-tube heat exchanger with hydrophilic fins

14 990-6186-001

An axial flow, low-noise fan blade features wide voltage

range and high reliability. The fan has multi-level air flow

control, which improves the operation stability of the unit.

does not retain dust and is easy to clean and maintain.

Page 15

Unit Overview

Optional Features

Feature Description

Tube The copper tube includes threaded joints, bell nuts, and

insulation material for the outer package. The tube is sturdy,

does not corrode easily, and withstands high temperature

and high pressure.

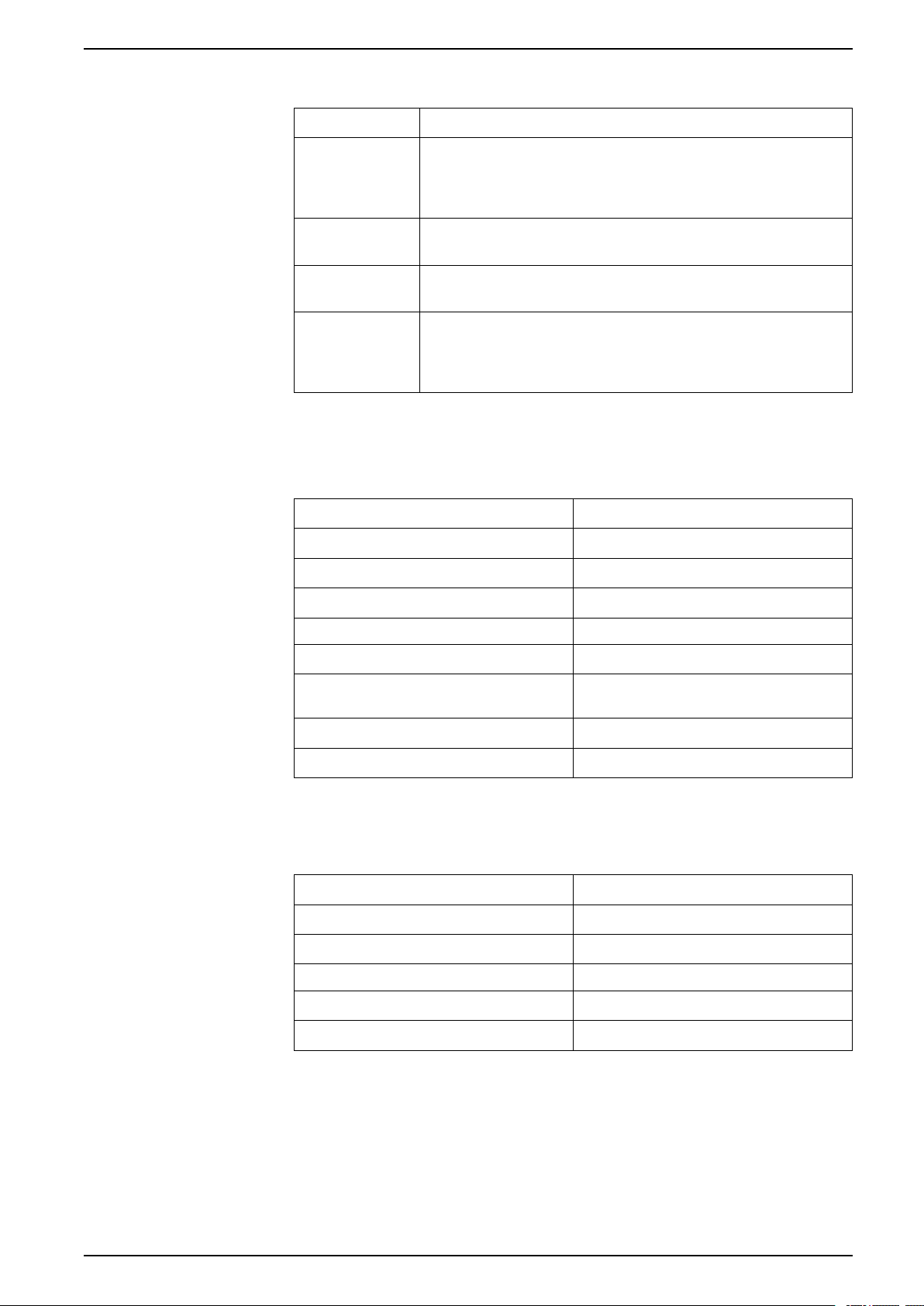

Technical Data

Condensate

Drain Pump

Low Ambient

Temperature Kit

Positive

Temperature

Coefficient

The low noise DC brushless water pump has a lift that

reaches 5 meters (16.4 ft).

The low ambient temperature kit provides the capability to

operate in temperatures below –15°C (–5°F).

The structure is compact and the heating is uniform.

The PTC heater installed in the indoor unit is used for heat

compensation when the IT load is low.

(PTC) Heater

Indoor Unit

Total Cooling Capacity 3.6 kW (12,300 BTU/hr)

Sensible Cooling Capacity* 3.5 kW (11,900 BTU/hr)

Rated Power Input 200–240 V~, 1 Ph, 50 Hz

Rated Air Volume

Number of Fans 1

IDU Fan Input Power 0.43 kW

700 m

3

/h (410 SCFM)

Size of Liquid Pipe/Air Pipe

9.52/12.7 mm (0.37/0.50 in.)

Connection

Energy Efficiency Ratio (EER) 2.5

Sound Pressure Level 62.5 dB(A)

*Data at 35°C (95°F) RAT, 23%RH, outdoor air temperature 35°C (95°F)

Outdoor Unit

Heat Exchange 6.3 kW

Rated Air Volume

1700 m

Input Power 1.00 kW

Number of Fans 1

Number of Compressors

1

Sound Pressure Level 51.5 dB(A)

3

/h (1000 SCFM)

990-6186-001 15

Page 16

Refrigerant

Unit Overview

Refrigerant Type

R410A

Refrigerant Charge 1.65 kg (58.2 oz)

CO

Equivalent 3.445 tonnes (7594.9 lb)

2

GWP

2088

16 990-6186-001

Page 17

Dimensions and Weights

FRONT OF UNIT

484 (19.1)

218

(8.6)

752 (29.6)

na6186-02a

856 (33.7)

617

(24.3)

296 (11.7)

359 (14.1)

na91282-31a

Dimensions and Weights

Indoor Unit

NOTE: Display interface is optional.

Outdoor Units

990-6186-001 17

Page 18

Weight

600 mm (24 in.)

600 mm (24 in.)

na91282-33a

≥2 m

(≥6.5 ft)

≥0.5 m

(≥1.5 ft)

≥0.5 m

(≥1.5 ft)

≥0.5 m

(≥1.5 ft)

na91282-34a

Dimensions and Weights

Service Clearance

Unit

Indoor unit

Outdoor unit 48 kg (105.8 lb)

Operating Weight – kg (lb)

26 kg (57.3 lb)

Airflow Clearance

18 990-6186-001

Page 19

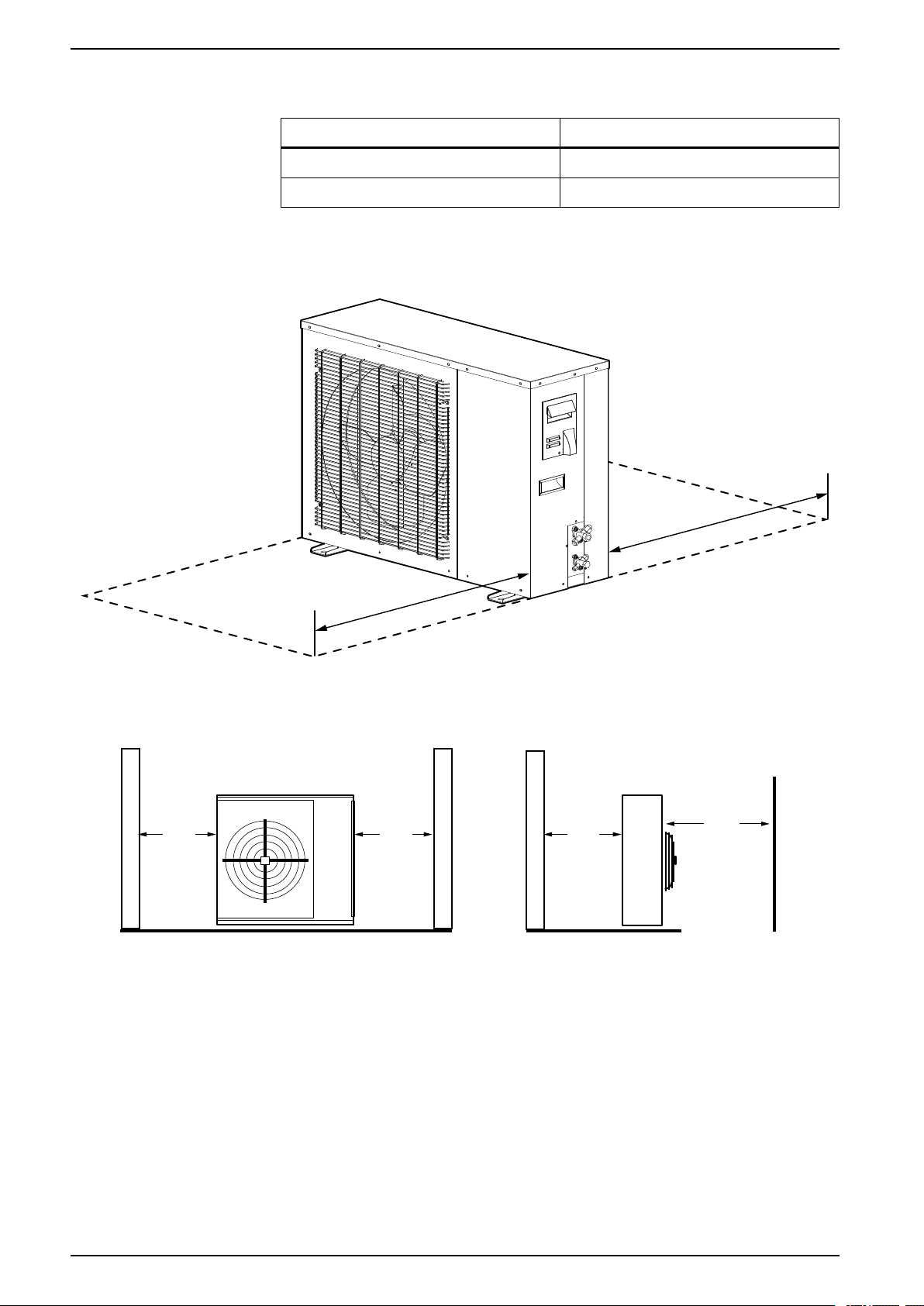

Dimensions and Weights

63 (2.5)

68 (2.7)

40 (1.6)

15 (0.6)

121 (4.8)

175 (6.9)

na91282-35a

Access Locations

Indoor Unit

Item Description

Suction line valve

Liquid line valve

Condensate drain line

990-6186-001 19

Page 20

Component Identification

na6186-03a

na6186-04a

Inventory

Component Identification

Item Description

External Components

Indoor Unit

Quantity

Indoor unit 1

Outdoor unit

Mounting bracket 2

M4x12 screw 2

Condensate drain hose 1

Hose clamp 1

1

Item Description Item Description

Mounting flange Mounting bracket (field installed)

Grille Condensate drain line

Suction line valve

Liquid line valve

20 990-6186-001

Handle

Display interface (field installed)

Page 21

Component Identification

na91282-37a

Outdoor Unit

Item Description

Electrical panel access cover

Suction line valve

Liquid line valve

Mounting support

Fan protection grille

990-6186-001 21

Page 22

Internal Components

na6186-05a

Indoor Unit

Component Identification

Item Description Item Description

Supply air temperature sensor

Electronic expansion valve (EXV) Air filter

Centrifugal fan

Connection access box Suction line temperature sensor

Condensate drain pan

Evaporative coil Electric heater

22 990-6186-001

Temperature and humidity sensor

Isolated data repeater

Electrical box

Page 23

Component Identification

na91282-59a

Outdoor Unit

Item Description Item Description

Accumulator High pressure sensor

Filter Discharge temperature sensor

Suction temperature sensor

Low pressure sensor

Service port Compressor

High pressure switch

Electronic expansion valve (EXV)

Electrical panel

990-6186-001 23

Page 24

Installation

Site Preparation

Follow these guidelines to prepare the site for installation.

• Moisture proof and insulate the room to ensure the normal functioning of the

environmental control system inside the room.

• Use polyethylene film for the moisture barrier on the ceilings and walls.

• Use moisture-proof paints on the concrete walls and floor.

• Minimize the entry of the outdoor air into the IT space as outdoor air may

increase heating, cooling, and humidification and dehumidification loads of

the system. Maintain intake of outdoor air below 5% of the circulating air.

• Fully enclose all doors and windows with minimized gaps.

Incoming Power Supply Requirements

Installation

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

• The main power requirement is 200–240 V/50 Hz.

• Ensure the electrical connection of the unit allows for the total load of the unit

and its optional components. The difference between external static pressure

of the unit and that of a standard unit may lead to changes in its input power

and current. For the total input power and the total current, see the

nameplate.

• The incoming power wire must have a circuit breaker of enough capacity with

a contact opening distance of at least 3 mm (0.11 in.).

• Provide each unit with an independent power supply with power supply cut-off

and over-current protection devices.

• Before wiring, ensure the power supply conforms to the specified value on the

nameplate.

• Keep the wires away from the cooling line and the moving parts of the

compressor, fan, and motor.

Before You Start

The outdoor unit has been charged with refrigerant in the factory, and the indoor

unit has been filled with a nitrogen holding charge. If you need to check the gas,

do the following:

NOTE: Outdoor unit model ACRMD4KI-3 is not charged with refrigerant in the

factory.

1. Open the shutoff valve.

2. Press the needle valve side of the service valve and check for gas ejection.

3. Connect a pressure gauge to get an accurate reading.

24 990-6186-001

Page 25

Installation

Positioning Units

Outdoor Unit

CAUTION

HAZARD FROM SHARP EDGES

Many metal parts have sharp edges. Be careful and wear protective gloves and

clothing when working around and inside the equipment.

Failure to follow these instructions can result in injury or equipment

damage.

CAUTION

DAMAGE TO EQUIPMENT OR PERSONNEL

Use concrete or a supporting frame to build a base for the unit. Allow for the

floor strength, drainage treatment, duct, and wiring. Insufficient strength may

cause the unit to drop resulting in injury or equipment damage.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

EQUIPMENT DAMAGE RISK

Install the unit in an area that is protected from adverse conditions such as an

oil source (including engine oil), salt (in a marine region), and sulfide gases

(near a hot spring or refinery).

Failure to follow these instructions can result in equipment damage.

Select a location for the installation that adheres to the following guidelines:

• Does not take in hot air from the unit or another unit.

• Allows enough clearance space for maintenance.

• Has no obstacles in the air exhaust and draft ducts of the outdoor unit to stop

airflow.

• Provides good ventilation to help the unit exchange heat.

• Has sufficient strength to bear the weight of the unit and its vibration during

operation.

• Does not have dirt, oil, salt, or sulfide gases.

• Is able to drain rainwater and defrost water.

• Is not susceptible to flammable gas. If any flammable gas leaks and

accumulates around the unit, an explosion may occur.

• Is not subject to direct blow of a strong breeze or typhoon. Install rainproof,

snowproof, and sunproof equipment if possible.

The floor and wall may cause vibration and noises depending on the installation

conditions. Adopt anti-vibration measures such as anti-vibration pad or bumper

bracket.

990-6186-001 25

Page 26

Panel Removal

na91282-60a

na91282-61a

na91282-38a

Indoor Unit

Installation

Electrical Box Access

1. Remove the filter.

2. Remove the electrical panel screws.

3. Slide the electrical box out of the unit.

26 990-6186-001

Page 27

Installation

na91282-62a

na91282-63a

Outdoor Unit

Electrical Panel Access

External Panel

990-6186-001 27

Page 28

Display Interface

na6186-06a

See the installation sheet provided with the display interface for

installation instructions.

Mechanical Connections

Installing the Indoor Unit in the Rack

The air conditioner is a cabinet refrigeration product that is installed in the

standard cabinet of a machine room.

NOTE: Some components not shown for easier viewing.

1. Install the optional rail kit in the cabinet where the unit is to be installed.

See the installation instructions in the rail kit.

2. Slide the cooling unit into the rack on the rails.

Installation

3. Attach the front mounting flanges to the vertical mounting rails in the rack with

the cage nuts and washers provided with the rack.

4. Attach the rear of the unit to the vertical mounting rails with the supplied

mounting brackets and the cage nuts and washers provided with the rack.

NOTE: These may not be necessary to support the unit if the rail kit is

installed.

28 990-6186-001

Page 29

Installation

na6186-07a

M10 FOUNDATION BOLT

15-MM-THICK (0.06-IN.-THICK)

VIBRATION PAD

Installing the Outdoor Unit

SHARP EDGES

Do not touch the fins of the heat exchanger with bare hands.

Failure to follow these instructions can result in injury or equipment

damage.

When installing the outdoor unit, follow these guidelines:

• Concrete or a supporting frame should be used to build a base for the unit.

• The outdoor unit should be attached to the frame with M10 bolts at each

• Vibrations and noise from the unit may be transmitted to the structure when it

CAUTION

When building the base, allow for the floor strength, drainage treatment

(drainage water will outflow from the unit when it is in operation), and duct and

wiring. Insufficient strength may cause the unit to fall.

corner of the mounting base of the outdoor unit.

is in operation. Use anti-vibration pads or a similar measure to prevent

transmission of vibrations and noise.

990-6186-001 29

Page 30

Piping Kit Application

ACAC10042

ACAC10043 ACAC10044

na91282-72a

Installation

Three piping kits are available as options for use with the cooling unit:

• ACAC10042: Top piping

• ACAC10043: Bottom piping under the raised floor

• ACAC10044: Bottom piping under the rack

30 990-6186-001

Page 31

Installation

DIAMETER

na7154a

Refrigerant Piping

Piping Connection

The maximum equivalent piping length between the indoor and outdoor units is 20

m (65.6 ft). The maximum vertical difference for the outdoor unit above or below

the indoor unit is 5 m (16.4 ft). The table below outlines pipe sizes for field piping.

Tube

Liquid line

Gas line

Refrigerant R410A piping (minimum

Size

Ø9.52 mm (3/8 in.)

Ø12.7 mm (1/2 in.)

0.8 mm (0.03 in.)

thickness)

The minimum thickness of the piping specified in the instructions is based on

drawn tube of copper and copper alloys (GB/T1527-2006). The thickness and

material of pipes used must be able to withstand a pressure of 4.15 MPa (602 psi)

in accordance with applicable laws.

If the unit is in an environment of severe corrosion, increase the thickness of the

pipe by at least 0.2 mm (0.008 in.).

If the piping has a reduced thickness from bending and tensioning, increase its

wall thickness accordingly.

Refer to the sizes in the table for processing the bell mouth of copper piping.

OD OD Size

Metric British R410A

Ø6.35 mm

Ø9.52 mm

Ø12.70 mm

Ø15.88 mm

Ø19.05 mm

1/4 in. 9.1 mm (0.36 in.)

3/8 in. 13.2 mm (0.52 in.)

1/2 in. 16.6 mm (0.65 in.)

5/8 in. 19.7 mm (0.78 in.)

3/4 in. 24.0 mm (0.94 in.)

990-6186-001 31

Page 32

See the table for the corresponding flare nut specifications.

DIAMETER

na7255a

Installation

OD

Metric British

Ø 6.35 mm

Ø 9.52 mm

Ø 12.70 mm

Ø 15.88 mm

Ø 19.05 mm

OD Size

1/4 in.

17.0

3/8 in. 22.0

1/2 in. 24.0

5/8 in.

3/4 in.

27.0

36.0

32 990-6186-001

Page 33

Installation

na91282-66a

FLARE

NUT

FLARE

NUT

COPPER

PLUG

COPPER

PLUG

na91282-67a

FLARE NUT

CUSTOMER PIPING

(FIELD SUPPLIED)

na91282-68a

Copper Pipe Connection

1. Remove and keep the flare nuts and remove and discard the copper plugs

from the liquid line and suction line connections.

2. Connect the pipes from the selected pipe kit (ACAC10042, ACAC10043, or

ACAC10044) to the liquid and suction lines.

NOTE: Make sure the piping does not inhibit removal of the electrical box.

990-6186-001 33

3. Use a flaring tool to connect the customer piping (field supplied) to the flare

nut.

NOTE: Make sure the flare nut is on the piping before using the flaring

tool on the customer piping.

4. Route the customer piping through the cabinet and connect the flare nuts to

the customer-piping side of the pipe kit.

NOTE: Pipe kit ACAC10044 is shown.

Page 34

Installation

PIPING

KIT

FLARE NUT

FLARE NUT

CUSTOMER PIPING

(FIELD SUPPLIED)

na91282-69a

FLARE

NUT

FLARE

NUT

COPPER

PLUG

COPPER

PLUG

na91282-70a

FLARE NUT

CUSTOMER PIPING

(FIELD SUPPLIED)

na91282-68a

5. Remove and keep the flare nuts and remove and discard the copper plugs

from the liquid line and suction line connections.

6. Use a flaring tool to connect the customer piping (field supplied) to the flare

nut.

NOTE: Make sure the flare nut is on the piping before using the flaring

tool on the customer piping.

34 990-6186-001

7. Connect the flare nuts to the suction and liquid lines of the outdoor unit.

Page 35

Installation

FLARE

NUT

FLARE

NUT

CUSTOMER PIPING

(FIELD SUPPLIED)

CUSTOMER PIPING

(FIELD SUPPLIED)

na91282-71a

OD

Ø6.35 mm

(1/4 in.)

Ø9.52 mm

(3/8 in.)

Ø12.7 mm

(1/2 in.)

Ø15.88 mm

(5/8 in.)

Ø19.05 mm

(3/4 in.)

Tightening Torque Tightening Angle

14–18 N·m

60°–90°

(10.33–13.28 ft-lb)

35–42 N·m

60°–90°

(25.81–30.98 ft-lb)

50–57.5 N·m

30°–60°

(36.88–42.41 ft-lb)

75–80 N·m

30°–60°

(55.32–59.00 ft-lb)

100–140 N·m

20°–35°

(73.76–103.26 ft-lb)

Brazing Copper Pipes

1. Use a neutral flame to braze and control the ratio of oxygen to acetylene (O2:

C

=1.0–1.2). Heat the base metal 20–25 mm (0.78–0.98 in.) from the flame

2H2

core given that the highest temperature is 2–3 mm (0.7–0.11 in.) from the

flame core (for reference only).

2. Fill the copper pipe with nitrogen to eliminate air. An oxide film may lead to

blockage of the expansion valve, filter, or other system components.

3. Maintain the flow of nitrogen at 10–20 l (2.64–5.28 gal) per minute with a

pressure regulating valve.

4. Fill with nitrogen until the pipe is completely cooled down.

Insulating Refrigerant Pipes

Insulate the refrigerant pipes with closed cell foam insulation of sufficient

thickness to cover the liquid pipe and the suction line. Improper insulation

materials or installation methods may cause condensation to drip from the

refrigerant pipes.

990-6186-001 35

Page 36

Drain Connection

CONDENSATE

DRAIN HOSE

HOSE

CLAMP

na91282-76a

Installation

1. Attach the condensate drain hose to the drain connection of the unit with the

hose clamp.

2. Route the condensate drain hose out of the unit or connect it to the

condensate drain pump.

See the condensate drain pump Installation Sheet.

36 990-6186-001

Page 37

Installation

Electrical Connections

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the

equipment.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

ELECTRICAL HAZARD

Overcurrent protection for all incoming power feeds must be provided by the

customer. See unit nameplate for equipment ratings.

DANGER

DANGER

Failure to follow these instructions will result in death or serious injury.

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

ELECTRICAL FIRE HAZARD

Use copper conductor wiring only.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

The following electrical connections are required in the field:

• Power connection of the indoor unit (H05VV-F 3 x 1.0 mm

• Power connection of the outdoor unit (H05VV-F 3 x 1.5 mm

• Communication lines between the indoor and outdoor units (PLTC 2 x 0.5

• Remote monitoring line of the unit

Before connecting the circuit, determine the input power voltage with a voltmeter,

and turn the power off. Use PVC insulated copper wires or rubber insulated

copper wires for the connecting wires of the indoor and outdoor units. The crosssectional area must meet the maximum requirements for load of the unit and its

components. Secure all wiring: Connecting wires of the indoor and outdoor units

must be fixed on clips.

2

cable)

mm

NOTE: A and B need to be distinguished when connecting.

2

cable)

2

cable)

990-6186-001 37

Page 38

Wire Cross-Section Ratings

na7256a

a

b

c

d

a

b

c

d

Installation

Wire Area

4 mm

6 mm

2

2

2

2

2

2

1.0 mm

1.5 mm

2.5 mm

10 mm

Maximum Current

8 A

11 A

15 A

20 A

25 A

35 A

Do not connect the same power terminal with two wires of different diameters.

When connecting to the terminal block, use a needle-shaped terminal with an

insulation sleeve. Ensure the terminal connection to the wires is acceptable.

Item Description

Wires (cross copper wires of over 0.5 mm2)

Insulating material

Shielding layer (requires more than 95% shielding

effectiveness)

Outer layer protection (PVC)

38 990-6186-001

Page 39

Installation

L N

L3 N SV L1

A3

B3

A6

V+

B6

V-

PE

RS485+

RS485-

RS485+

RS485-

F1

F2

W1

W2

P1

P2

na6186-08a

Connection Interface

Connection interfaces include the total power input interface and the remote

communication interface of the unit.

Indoor Unit

See the installation sheets provided with the accessories for more

information.

Item Description Item Description

Controller communication connections

(RS485+, RS485–, RS485+, RS485–)

Fire/smoke alarm connection (F1, F2) Power supply connection (L, N, GND)

Leak sensor connection (W1, W2) Communication connection to the

Condensate drain pump

communication connection (P1, P2)

Condensate drain pump power supply

connection (L3, N)

Low temperature kit connection

• Solenoid valve (SV)

• High pressure control and heater

(L1)

Ground (GND)

outdoor unit (A3, B3)

Display interface connection (A6, B6)

24-VDC power supply (V+, V-, PE)

990-6186-001 39

Page 40

Installation

na91282-73a

na6186-09a

1. Remove the cover from the connections box.

2. Remove the communication position connectors from the electrical box to

make connections easier.

3. Route the power connections through the cable strain reliefs and make the

connections in the unit.

4. Route the communication connections through the cable strain reliefs and

make the connections to the position connectors.

5. Replace the communication position connectors.

6. Replace the cover.

40 990-6186-001

Page 41

Installation

na91282-75a

Outdoor Unit

Item Description

Power supply connection (L, N, GND)

Communication connection to indoor unit (Ain, Bin)

1. Remove the electrical panel cover.

See Panel Removal, page 26.

2. Route cables through the cable strain reliefs and make the unit connections.

3. Replace the electrical panel cover.

990-6186-001 41

Page 42

Charging the Refrigeration System

DAMAGE TO EQUIPMENT

Follow the procedures and tables outlined in this manual to charge the

refrigerant if the piping exceeds the standard length.

Failure to follow these instructions can result in equipment damage.

Indoor and outdoor units are all provided with service valves. Connect the service

valves to pipes for immediate system leak detection, vacuum pumping, and

refrigerant filling procedures.

NOTE: Indoor units and outdoor unit model ACRMD4KI-3 are not pre-charged

with refrigerant in the factory.

Leak Detection

Method One

1. Fill the service valve with nitrogen to increase pressure to 2.8 MPa (406 psi)

and 4.15 MPa (601 psi) for refrigerant R410A.

2. Apply soapy water at the connecting joints or welding joints of pipes for leak

detection.

3. Repair leak sources and maintain the pressure for more than six hours to

ensure that the pressure is not decreased.

4. The low side of the compound gauge cannot be connected to the system.

Installation

NOTICE

Method Two

1. Fill with the refrigerant and stop when the pressure gauge indicates 0.3 MPa

(43 psi).

2. Fill with nitrogen and stop when the pressure gauge indicates 2.8 MPa (406

psi) and 4.15 MPa (601 psi) for refrigerant R410A.

3. Use an HFC electronic leak detector to detect the leak. Use the bubble gas

leak testing method.

42 990-6186-001

Page 43

Installation

INDOOR UNIT

LOW

HIGH

TO OUTDOOR UNIT

TO OUTDOOR UNIT

LIQUID PIPE

GAS PIPE

na91282-40a

Vacuum Pumping

1. Exhaust the high pressure nitrogen in the system.

2. Connect the three flexible pipes of the compound pressure gauge to the

corresponding joints of the service valve and the vacuum pump.

3. Start the vacuum pump and maintain the pressure inside the system below

650 Pa (0.09 psi). Do not start the unit until the pipeline for vacuum pumping

is turned off.

Item Description

Ball valve

Service port

Compound pressure gauge

Check valve

Vacuum pump

990-6186-001 43

Page 44

Calculating the Refrigerant Charge

When leaving the factory, the outdoor units that have been filled with refrigerant in

the factory have enough refrigerant required to cover 5 m (49 ft) of pipe. If the

actual length of the pipe exceeds 5 m (49 ft), add more refrigerant for the

additional length. Outdoor unit model ACRMD4KI-3 needs to be charged with 1.65

kg (3.64 lb) of R410A refrigerant for the initial 5 m (49 ft).

Installation

Liquid Pipe

Specifications – mm

Ø22.23

Ø19.05

Ø15.88

Ø12.7

Ø9.52

Ø6.35

R410A Refrigerant – g/

m (lb/ft)

350 (0.24)

260 (0.17) L2

180 (0.12)

120 (0.08)

70 (0.05)

45 (0.03)

Actual Pipe Length

L1

L3

L4

L5

L6

The refrigerant to be added is calculated on the basis of the length and thickness

of the lengthened pipe. The formula is: refrigerant to be added (kg) = 0.35 x L1 +

0.26 x L2 + 0.18 x L3 + 0.12 x L4 + 0.07 x L5 + 0.045 x L6.

If the calculated result is less than 0.1 kg, round it to 0.1 kg. For example, if the

calculated result is 28.62 kg, then add 28.7 kg as the charge amount.

44 990-6186-001

Page 45

Installation

INDOOR UNIT

LOW

HIGH

TO OUTDOOR UNIT

TO OUTDOOR

UNIT

LIQUID PIPE

GAS PIPE

SCALE

SCALE

na91282-41a

Charging the Refrigerant

1. Open the gas and liquid valves of the indoor and outdoor units.

2. If the filling tank for R410A does not have siphons, invert it.

3. Measure the filling amount with an electronic scale to prevent excessive

filling.

Fill the gas pipe and the liquid pipe with liquid refrigerant at the same time. If

the pressure is too large to fill the refrigerant, fill the refrigerant with a

compressor during the test run.

Item Description

Cylinder with siphon

Ball valve

Service port

Compound pressure gauge

Refrigerant tank

990-6186-001 45

Page 46

Commissioning

After installation, verify that all components are working properly and the

equipment is ready to begin operation.

Start-Up Inspection Checklist

The start-up inspection ensures that the equipment is operating properly after the

initial start-up. This inspection verifies that all modes of operation are working

correctly and the cooling unit is ready for normal operation.

Ensure that

The power core model of the outdoor and indoor units is correct.

The fan and motor of the indoor unit are working normally.

The fan and motor of the outdoor unit are working normally.

Communication lines are correctly connected.

Commissioning

The condensate pipe of the indoor unit is unblocked and the water seal

installation is correct.

The equipment is properly grounded and insulation is correct (10

megohm).

The indoor and outdoor units have power supply in line with the

nameplate, and the input voltage is not too high or too low.

The system has no leaks.

The main menu shows no fault after the unit is powered on.

Parameters on the manual operator are correctly set.

After the unit is started, the safety device does not trip.

The air-out temperature of the unit is within its normal range.

The air-out or air-return speed of the unit is within its normal range.

The unit has no abnormal sound and its components have no abnormal

vibration.

The unit can operate normally by setting the switch mode and its

components work accordingly.

After a Long Shutdown

If the outdoor unit is restarted after a long shutdown, energize it for at least 8 hours

before restarting the compressor.

46 990-6186-001

Page 47

Commissioning

Electrical Inspection Checklist

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the

equipment.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

DANGER

WARNING

The electrical inspection verifies that all electrical connections are secure and

correct and that the equipment is properly grounded.

Ensure that

The power core model of the outdoor and indoor units is proper.

Incoming voltages match the phase and voltage rating on the

nameplate.

Electrical wiring complies with local and national codes and regulations.

The equipment is properly grounded and insulation is correct (10

megohm).

Electrical connections are tight, including contactors, terminal blocks,

controllers, switches, relays, auxiliary devices, and field connections.

Circuit breakers are correct and securely attached to the DIN rail.

Communication lines are correctly connected.

990-6186-001 47

Page 48

Mechanical Inspection Checklist

HAZARD TO EQUIPMENT OR PERSONNEL

• The equipment is shipped from the factory with a nitrogen holding charge.

Remove the nitrogen holding charge using the service ports located on the

internal refrigerant piping.

• Improperly installed piping may result in improper operation and possible

damage to the cooling unit or surrounding equipment.

Failure to follow these instructions can result in injury or equipment

damage.

The mechanical inspection verifies that all mechanical components and

connections are secure and tight and ready for start-up.

Ensure that

Clearance space around the unit is appropriate.

The fan and motor of the indoor unit are working normally.

Commissioning

CAUTION

The fan and motor of the outdoor unit are working normally.

The units are placed upright and fasteners used for installation are

locked.

Pipes connecting the indoor and outdoor units are installed.

The drain pipe of the indoor unit is connected.

The condensate pipe of the indoor unit is unblocked and the water seal

installation is correct.

All copper pipe joints are fastened.

The system has no leaks.

Fasteners for transport are removed.

Transport materials, structure materials, and tools inside or around the

equipment are removed.

48 990-6186-001

Page 49

Operation

2019-03-20

16:11

na91282-01a

Manufac

turer

ON/OFF

Input/

Output

Setpoint User

Mainten

ance

Air outlet temperature 0.0°C

Air return temperature 0.0°C

Air return humidity 0.0°C

Operating mode Refrigeration/cooling

2019-03-20

16:11

V1

Presss the appropriate button to turn the

unit on or o.

na91282-03b

ON

OFF

U:01

2019-03-20

16:11

IDU Controller

Operating

Parameters

ODU Controller

Operating

Parameters

Historical Data

Historical

Alarms

na91282-05a

2019-03-20

16:11

I1

A01-EC fan 0.0 V

IDU expansion valve steps 0

na91282-43b

Operation

Using the Display

Main Interface

Description

Press the buttons on the Main Interface screen to access the

following functions:

• Alarm

• ON/OFF

• Input/Output (Operating Parameters)

• Setpoint

• User

• Maintenance

• Manufacturer

Turning the Unit ON/OFF

Description

Path: Main Interface > ON/OFF

Screen

Screen

Path: Main Interface > Input/Output > IDU Controller Operating

Parameters

This screen provides information about the A01–EC fan and the IDU

expansion valve steps.

Operating Parameters–IDU Controller

Description

Screen

990-6186-001 49

Page 50

Operating Parameters–IDU Controller

2019-03-20

16:11

I2

Digital input

Fire alarm / Remote ON/OFF ON

High level switch of pump ON

Water on the oor ON

na91282-44a

2019-03-20

16:11

I3

na91282-45a

Air out temperature °C

Coil Inlet temperature °C

Coil outlet temperature °C

Air return temperature °C

Air return humidity

2019-03-20

16:11

I4

Digital input

Serious alarm ON

Common alarm ON

Condensation pump ON

PTC heater ON

IDU fan ON

SV of low temperature kit ON

na91282-46a

Main fan 0.0 h

#

1 Compressor runtimes 0.0 h

I5

na91282-47a

2019-03-20

16:11

Operation

Description

Digital input:

ON-No alarm

OFF-Alarm

Temperature and humidity parameters

Parameters for alarms, pump, heater, fan, and low temperature kit

Screen

Fan and compressor run time

50 990-6186-001

Page 51

Operation

2019-03-20

16:11

IDU Controller

Operating

Parameters

ODU Controller

Operating

Parameters

Historical Data

Historical

Alarms

na91282-05a

2019-03-20

16:11

A10

na91282-16b

#1 ODU parameter

Operation frequency 0 Hz

Ambient temperature 0.0°C

Suction temperature 0.0°C

Exhaust temperature 0.0°C

System low pressure 0.0 Bar

System high pressure 0.0 Bar

2019-03-20

16:11

IDU Controller

Operating

Parameters

ODU Controller

Operating

Parameters

Historical Data

Historical

Alarms

na91282-05a

Historical Data

na91282-17b

100

75

50

25

0

9:28 9:40 9:52 10:04 10:16 10:28

2019-03-20 2019-03-20 2019-03-20 2019-03-20 2019-03-20 2019-03-20

Operating Parameters–ODU Controller

Description

Path: Main Interface > Input/Output > ODU Controller Operating

Parameters

Temperature parameters

Operating Parameters–Historical Data

Description

Screen

Screen

Path: Main Interface > Input/Output > Historical Data

Historical Humidity Data

990-6186-001 51

Page 52

Operating Parameters–Historical Alarms

2019-03-20

16:11

IDU Controller

Operating

Parameters

ODU Controller

Operating

Parameters

Historical Data

Historical

Alarms

na91282-05a

Historical Alarm

Time Date

A

larm Message

na91282-02b

2019-03-20

16:11

na91282-18b

Air return temp.: 35°C

Air outlet temp.: 22°C

Minimum humidity: 15°C

Maximum humidity: 80°C

na91282-19a

Please enter your password

****

Password error.

CancelConrm

2019-03-20

16:11

P1

na91282-20b

Language English

PTC Heater YES

Condensation pump YES

Condensation pump alarm UNIT OFF

Operation

Description

Path: Main Interface > Input/Output > Historical Alarms

Path: Main Interface > Input/Output > Historical Alarms > Alarm

Press and hold Clear Alarm to clear alarms.

Setpoint

Description

Screen

Screen

Path: Main Interface > Setpoint

The password for the Setpoint screen is 1000.

Item

Air return temperature

Air outlet temperature

Minimum humidity

Maximum humidity

Default

35°C

22°C

15°C

80°C

User

Description

Path: Main > User > User Password

The default user password is 1000.

Password error displays if a wrong password is entered.

Enter the password within 5 seconds after the password error.

Screen

Item

Language

PTC Heater YES NO

Condensation pump NO YES

Condensation pump alarm UNIT OFF

52 990-6186-001

Default Option

Chinese

English

ALARM

Page 53

Operation

2019-03-20

16:11

P2

na91282-21b

Air outlet temperature limit

Maximum 27°C

Minimum 13°C

Air return temperature limit

Maximum 42°C

Minimum 16°C

2019-03-20

16:11

P3

na91282-22b

Air return temperature alarm

High temperature 45°C

Return humidity alarm

Low humidity 15%

High humidity 95%

Air outlet temperature alarm

Low temperature 8°C

High temperature 32°C

2019-03-20

16:11

Date

Time

Touch Screen

Sound

ON/OFF

P4

na91282-23b

BMS control YES

Modbus address 0

Comunication speed 9600

New user password 0

User

Item

Air outlet temperature limit

Maximum

Minimum

Air return temperature limit

Maximum

Minimum

Item

Air outlet temperature limit

High temperature

Return humidity alarm

Low humidity

High humidity

Description

Default

27°C 0–35°C

13°C 0–20°C

42°C 0–50°C

16°C 0–35°C

Default

45°C 0–50°C

15% 0–95%

95% 0–100%

Screen

Range

Range

Air outlet temperature alarm

Low temperature

High temperature

Item

8°C 0–13°C

32°C 0–25°C

Default

Range

BMS control YES NO

Modbus address 0 0–255

Communication speed 9600 4800/9600/19200

New user password 1000 0–65535

Press Date Time to show the date and time.

Press Touch Screen Sound to turn the sound on or off.

990-6186-001 53

Page 54

Maintenance

2019-03-20

16:11

F1

Outlet temperature o 19°C

IDU board version SE_IDC_EN 1.3

ODU board version SE_ODC_EN 1.3

HMI version SE_HMIC_EN 1.3

na91282-28b

Touch Screen

Sound ON/OFF

Restart Touch

Screen

Alarm Sound

ON/OFF

2019-03-20

16:11

F2

na91282-48a

Manual operation NO

Serious alarm Auto OFF

Common alarm Auto OFF

Condensation pump Auto OFF

PTC heater Auto OFF

IDU fan Auto OFF

SV low temperature kit Auto OFF

2019-03-20

16:11

F3

na91282-49a

IDU fan speed Auto 0.0V

IDU EEV steps Auto 0

2019-03-20

16:11

F4

na91282-50a

Modify run hours

IDU fan hours reset NO

#1 Compressor hours reset NO

Threshold running hours alarm

IDU fan 0.0 h

2019-03-20

16:11

F5

na91282-51a

Probe setting

Air outlet temperature 0.0°C

Coil inlet temperature 0.0°C

Coil outlet temperature 0.0°C

Air return temperature 0.0°C

Air return humidity 0.0%

2019-03-20

16:11

Clear

History

Alarm

Clear

History

Date

Download

Alarm to

U Disk

Download

Date to

U Disk

F6

na91282-52a

New maintenance password 0

Operation

Description

Path: Main > Maintenance

IDU board version: SE_IDC_EN1.3

ODU board version: SE_ODC_EN1.3

HMI version: SE_HMIC_EN 1.3

Item

Default

Range

Outlet temperature for unit off 19°C 14–24°C

Select YES for manual operation.

Select Manual and ON from the drop-down lists.

IDU maintenance information

Screen

IDU maintenance information

IDU maintenance information for temperature and humidity

Press the appropriate buttons to clear and download alarm or date.

54 990-6186-001

Page 55

Operation

2019-03-20

16:11

Conguration

Management

TimingParameters

na91282-53a

Default value NO

New manufacturer password 0

2019-03-20

16:11

na91282-54a

BMS Network Standard

DI1 Function selection Fire/Smoke

Condensation pump alarm NO

Water on oor NO

Maintenance alarm YES

2019-03-20

16:11

na91282-55a

Maximum speed of EC/DC fan 0.0 V

Minimum speed of EC/DC fan 0.0 V

Failure speed of EC/DC fan 0.0 V

Dehumidifying speed EC/DC fan 0.0 V

2019-03-20

16:11

na91282-56a

Delay time to stop fan 5 seconds

Delay alarm low/high temperature 30 seconds

Delay alarm condensation pump 5 seconds

Delay alarm output 10 seconds

Manufacturer

Description

Path: Main > Manufacturer

Enter a new manufacturer password.

Path: Main > Manufacturer > Configuration Management

Item

Default Option

BMS Network Standard Custom

DI1 Function selection

Fire/Smoke

Remote

Condensation pump alarm NO YES

Water on floor NO YES

Maintenance alarm

YES NO

Path: Main > Manufacturer > Parameters

Screen

Item

Maximum speed of EC/DC fan

Maximum speed of EC/DC fan

Default

10

10

Failure speed of EC/DC fan 10

Dehumidifying speed of EC/DC fan

5

Path: Main > Manufacturer > Timing

Item

Delay time to stop fan

Default

5 seconds

Delay alarm low/high temperature 30 seconds

Delay alarm condensation pump 5 seconds

Delay alarm output 10 seconds

990-6186-001 55

Page 56

Maintenance

Preventive Maintenance

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the

equipment.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

HAZARD TO EQUIPMENT OR PERSONNEL

Maintenance

DANGER

WARNING

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Perform the following maintenance check list.

Prepared By: ________________________________

Model Number: ______________________________

Serial Number: ______________________________

Date: ______________________________________

56 990-6186-001

Page 57

Maintenance

Electrical Maintenance

Perform visual inspection and processing of electrical connections.

Perform a total electrical insulation test. Find the non-conforming

contacts for processing. Disconnect the control switch or air switch

during the test to avoid any damage to the control device from high

voltage.

Statically detect whether each contactor is pulled in flexibly without

jamming.

Remove dust from the electrical and control components with a brush

or dry compressed air.

Check for arcing or burn marks on the contacts. Replace the contactor if

necessary.

Fasten each electrical connection terminal.

Check whether the quick connector is in good contact and replace the

terminal if necessary.

Check the appearance of the adapter and test its output voltage for the

indoor and outdoor units.

Control Maintenance

Check the output connection from the control interface board to each

contactor and the input connection of the high and low voltage

switches, and filter plug switch. Replace the plug terminal immediately if

it is loose or has bad contacts.

Replace the control fuse (or air switch), control board, and other

electrical components if necessary.

Perform visual inspection and simple function testing of the control segment for

processing.

Check for obvious aging on the surface of the control interface board

and the display control board.

Remove the dust and dirt on the control components and control boards

with a brush and an electronic dedusting agent.

Check and fasten the I/O plug interface of the control interface board,

including the connection between the display control board and the

control interface board and the connection between the control

interface board and the temperature and humidity sensor board.

Check the specifications and aging of the control wire and the power

wire and replace if necessary.

Check and calibrate the readings of the temperature and humidity

sensor with an instrument of high measuring accuracy. Select relative

humidity control as the humidity control mode.

Clean the air filter net. Place on a hard surface and gently tap to remove

heavy particles. If necessary, wash the filter with a neutral detergent in

warm water and dry it before re-installation.

Use a vacuum cleaner and a nylon brush to clean the dust and other

debris on the surface of the heat exchanger. If a compressed air source

is available, use the compressor to spray the dust off the surface.

Regularly check the motor, impeller, and other components of the fan. If

necessary, consult the manufacturer for more details.

Before operating the unit, ensure the drainage pipe is not blocked.

990-6186-001 57

Page 58

Worldwide Customer Support

Customer support for this or any other product is available at no charge in any of the

following ways:

• Visit the Schneider Electric Web site to access documents in the Schneider

Electric Knowledge Base and to submit customer support requests.

- www.schneider-electric.com (Corporate Headquarters)

Connect to localized Schneider Electric Web sites for specific countries, each of

which provides customer support information.

- www.schneider-electric.com/support/

Global support searching Schneider Electric Knowledge Base and using

esupport.

• Contact the Schneider Electric Customer Support Center by telephone or e-mail.

Local, country-specific centers: go to www.schneider-electric.com/support/

contactwww.schneider-electric.com > Support > Operations around the

world for contact information.

For information on how to obtain local customer support, contact the representative

or other distributors from whom you purchased your product.

Page 59

Page 60

Schneider Electric (China) Co., Ltd Shanghai Pu Dong Branch

4F Building 9, No 3000 Long Dong Avenue, 201203

Pu Dong, Shanghai

People’s Republic of China

www.schneider-electric.com

As standards, specifications, and design change from time to time,

please ask for confirmation of the information given in this publication.

© 2019 – 2019 Schneider Electric. All rights reserved.

990-6186-001

Loading...

Loading...