Schneider Electric 871EC Installation and Maintenance

Instruction MI 611-150

August 2020

871EC Electrodeless Conductivity

Sensors and Accessories

Installation and Maintenance

MI 611-150 – August 2020

2

Contents

Figures...........................................................................................................................................5

Tables ............................................................................................................................................ 7

Important Information..................................................................................................................9

Please Note .................................................................................................................................9

1. Introduction ............................................................................................................................ 11

Reference Documents ...............................................................................................................12

Electrical Certifications .............................................................................................................13

Sensor Identification .................................................................................................................13

Standard Specifications..............................................................................................................14

Wetted Parts.........................................................................................................................14

Cable....................................................................................................................................14

Mounting.............................................................................................................................14

Electromagnetic Compatibility (EMC).................................................................................14

Sensor Measurement Limits, Materials, Temperature Limits, Pressure Limits, and

Temperature Compensator ...................................................................................................15

Sensor Applications...................................................................................................................17

Sensor Cell Factors ....................................................................................................................20

Sensor Model Code...................................................................................................................21

2. Sensor Installation and Accessories ..........................................................................................23

Installation Precautions .............................................................................................................23

Notes For Small Bore Sensor Types ...........................................................................................24

O-Ring Seals for Small Bore Sensors .........................................................................................25

O-Ring Seals for Large Bore Sensors..........................................................................................25

Ball Valve Assembly Installation ................................................................................................26

Installing the Ball Valve Assembly Into the Process ...............................................................27

Connecting the Sensor to the Insertion Shaft Assembly........................................................28

Installing the Insertion Shaft Into the Ball Valve...................................................................29

Removing and Replacing a Sensor.............................................................................................31

Flange Installation.....................................................................................................................32

Flange Specifications ............................................................................................................32

Installation Procedure with a Flange .....................................................................................33

Bushing Installation (Sensor Types -TF, -SP, -NL, -HP, -PN, -PX, -PP, and -PT).......................34

3

MI 611-150 – August 2020 Contents

Bushing Specifications..........................................................................................................34

Installation Procedure with a Bushing...................................................................................35

Tri-Clamp Flange Installation....................................................................................................35

In Situ Installation ....................................................................................................................36

In-Line Installation ...................................................................................................................38

Junction Box Installation...........................................................................................................39

Mounting.............................................................................................................................39

Wiring..................................................................................................................................39

3. Maintenance............................................................................................................................ 41

Troubleshooting ........................................................................................................................41

Checking for Sensor Magnetization...........................................................................................42

Sensor Resistance Check............................................................................................................43

Appendix A. Temperature Compensation and Conductivity Reference Data............................... 45

4

Figures

1 Sensor Identification ...........................................................................................................13

2 Sensor Types -SP, -HP, -PP, -PT, -NL, -TF, -PN, and -PX O-Ring Seals ..............................25

3 Sensor Types -LB, -UT, -RE, -BW, -EV, and -AB O-Ring Seals ...........................................25

4 Ball Valve Assembly.............................................................................................................27

5 Assembly of Shaft Bushing to Sensor...................................................................................28

6 Preassembly of Shaft Assembly ............................................................................................28

7 Ball Valve Assembly Shaft Installation and Removal............................................................30

8 Typical Flange Installation...................................................................................................33

9 Typical Bushing Installations...............................................................................................35

10 Tri-Clamp Flange Installation..............................................................................................35

11 Typical In Situ Installation ..................................................................................................37

12 Typical In-Line Installation .................................................................................................38

13 Junction Box Wiring...........................................................................................................40

14 Sensor Magnetization Check...............................................................................................42

15 Sensor Cable Resistances .....................................................................................................43

5

MI 611-150 – August 2020 Figures

6

Tables

1 Sensor Applications - Standard Temperature PEEK - up to 120°C (250°F) .........................17

2 Sensor Applications - High Temperature PEEK - up to 200°C (392°F)...............................18

3 Sensor Applications - Non-PEEK Version ...........................................................................19

4 Sensor Cell Factors ..............................................................................................................20

5 Patch Cables........................................................................................................................22

6 Ball Valve Assembly Specifications.......................................................................................26

7 Flange Specifications ...........................................................................................................32

8 Hex Head Bushing Specifications........................................................................................34

9 Minimum Pipe Diameters...................................................................................................38

10 Troubleshooting ..................................................................................................................41

11 Approximate Conductivity Values of Common Solutions ...................................................45

7

MI 611-150 – August 2020 Tab l es

8

Important Information

!!!

Read these instructions carefully and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may

appear throughout this manual or on the equipment to warn of potential hazards or to call

attention to information that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal injury

if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING

WAR NI NG indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury.

Please Note

Electrical equipment should be installed, operated, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of

this material.

A qualified person is one who has skills and knowledge related to the construction, installation,

and operation of electrical equipment and has received safety training to recognize and avoid the

hazards involved.

9

MI XXX-XXX – Month 2019 Important Information

10

1. Introduction

!!!

!

The 871EC Sensors are used with 875EC Intelligent Analyzers, 870ITEC Intelligent

Transmitters, 873EC and 873AEC Analyzers, and 870EC Transmitters. Sensors are available in a

number of configurations and materials suitable for a variety of conditions.

The sensors measure an induced current in a loop of solution. Their patented proprietary design

comprises two or three toroidally wound coils encapsulated within the sensor which is immersed

in the solution. An ac signal, applied to one toroidal coil, induces a current in the second coil that

is directly proportional to the conductance of the solution.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

An electrical shock hazard may be present under sensor fault conditions when the sensor is

located in process fluids at electrical potentials above 30 V rms or 60 V dc. To help prevent

electrical shock hazard, remove the sensor from the process or de-energize power to the process

prior to performing maintenance on the transmitter or analyzer.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Electrical shock potential can be detected while the sensor is in a potentialized solution by

removing the analyzer/transmitter field-terminal compartment cover and measuring between

each of the sensor leads and ground with a voltmeter. If a potential above 30 V rms or 60 V dc is

detected, an electrical shock hazard is present.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Certain units described in this instruction contain electrical shock hazard potential.

Maintenance should be performed by qualified personnel only. During maintenance, remove

power to avoid severe injury or death.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

When performing maintenance, wear appropriate, protective clothing including protective

goggles. Escaping chemicals under pressure can cause severe injury including blindness.

Failure to follow these instructions will result in death or serious injury.

11

MI 611-150 – August 2020 1. Introduction

!!!

!

WARNING

RISK OF IMPROPER INSTALLATION

Use care when connecting and disconnecting high pressure service connections. Use proper

gloves and follow the recommended procedures to avoid severe injury to personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

When processing hazardous liquids, follow the recommended procedures. Failure to do so could

result in injury to personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

EQUIPMENT OPERATION HAZARD

Use only recommended replacement parts. Substitution parts could result in damage to

equipment, damage to the process, and/or injury to personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Be careful to avoid touching exposed circuits and components. Potential shock hazards are

present.

Failure to follow these instructions will result in death or serious injury.

Reference Documents

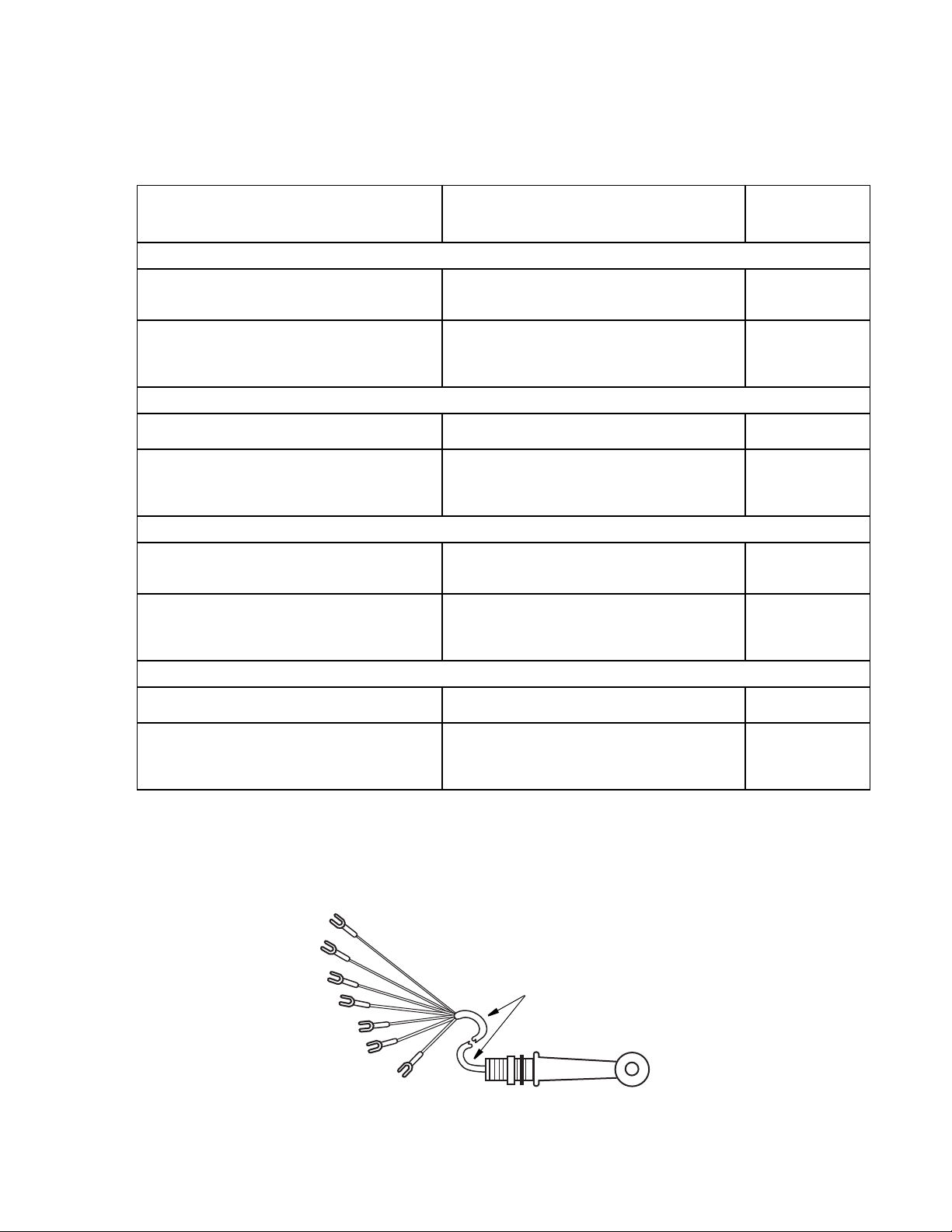

Document Document Description

MI 611-156 Instruction – 870EC Transmitters (Electrodeless Conductivity)

MI 611-167 Instruction – 873EC Electrochemical Analyzers

MI 611-193 Instruction – 873AEC Ace Series Electrochemical Analyzers

MI 611-212 Instruction – 870ITEC Intelligent Electrochemical Transmitters

MI 611-220 Instruction – Electrodeless Conductivity System Calibration Examples

MI 611-224 Instruction – 875EC Intelligent Electrochemical Analyzers

DP 611-011 Dimensional Print – 871EC Electrodeless Conductivity Sensors

DP 611-092 Dimensional Print – Flanges (316 ss) used with 871CC, 871EC, 910, 920, and 1210 Conductivity

DP 611-105 Dimensional Print – Universal Mounting Bushing used with 871CC, 871EC, 910, 920, and 1210

DP 611-142 Dimensional Print – Ball Valve Assembly for Electrodeless Conductivity Sensors (871EC-PN and PX)

DP 611-155 Dimensional Print – Ball Valve Assembly for Electrodeless Conductivity Sensors (871EC-SP, -HP,

TI 612-005 Electrodeless Conductivity, Toroidal Magnets and the Procedure of Degaussing

Sensors

Conductivity Sensors

-PP, -PT, -NL, and -TF)

12

1. Introduction MI 611-150 – August 2020

MODEL AND DATE CODE LABELS

Electrical Certifications

The following information shows which analyzers and transmitters can be used with a certified

871EC Sensor.

Testing Laboratory,

Type of Protection, and

Area Classification Application Conditions

CSA Certifications - 875EC Analyzer with 871EC Sensors

CSA ordinary locations. Temperature Class T4A, Ta = 85°C maximum

ambient. Connect to 875EC Transmitter per MI

611-206.

CSA nonincendive, Class I, Division 2, Groups A,

B, C, D; suitable for

Class II, Div. 2, Groups E, F, G; and

Class III, Div. 2.

CSA Certifications - 873EC and 873AEC Analyzers with 871EC Sensors

CSA ordinary locations. Connect to 873EC and 873AEC Analyzer per MI

CSA nonincendive, Class I, Division 2, Groups A,

B, C, D; suitable for

Class II, Div. 2, Groups F, G; and

Class III, Div. 2.

FM Approvals - 875EC Analyzer with 871EC Sensors

FM ordinary locations. Temperature Class T4A, Ta = 75°C maximum

FM nonincendive, Class I, Division 2, Groups A,

B, C, D; suitable for

Class II, Div. 2, Groups F, G; and

Class III, Div. 2.

FM Approvals - 873EC Analyzer with 871EC Sensors

FM ordinary locations. Connect to 873EC Analyzer per MI 611-206. 873EC-...FGZ-.

FM nonincendive, Class I, Division 2, Groups A,

B, C, D; suitable for

Class II, Div. 2, Groups F, G; and

Class III, Div. 2.

Temperature Class T4A, Ta = 85°C maximum

ambient. Connect to 875EC Transmitter per MI

611-206.

611-206.

Connect to 873EC and 873AEC Analyzer per MI

611-206.

ambient. Connect to 875EC Transmitter per MI

611-206.

Temperature Class T4A, Ta = 75°C maximum

ambient. Connect to 875EC Transmitter per MI

611-206.

Connect to 873EC Analyzer per MI 611-206. 873EC-...FNZ-.

Electrical

Safety Design

Code

875EC-..C-.

875EC-..C-.

873EC-...CGZ-.

873EC-...CNZ-.

873EC-...CNZ-.

875EC-..F-.

875EC-..F-.

873EC-...FNZ-.

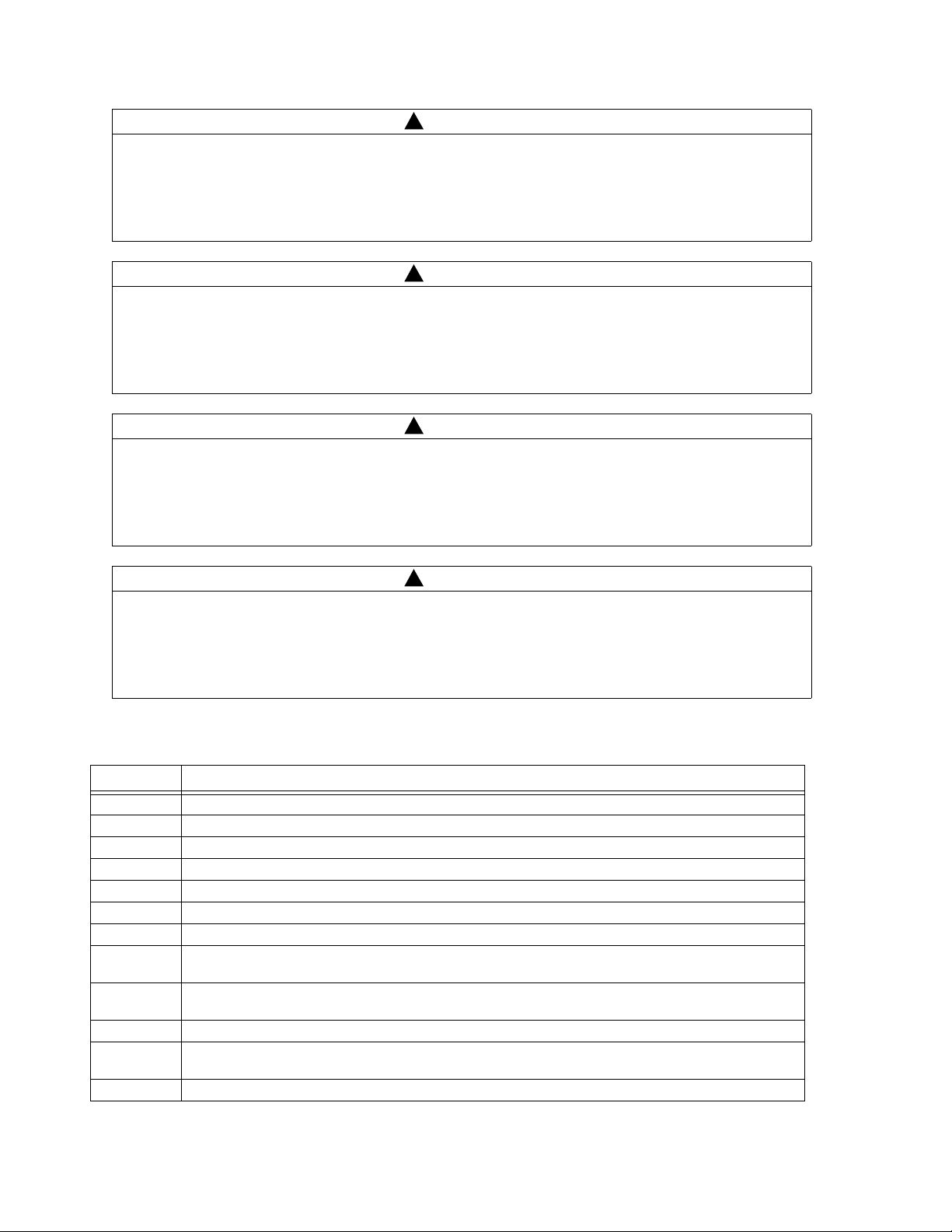

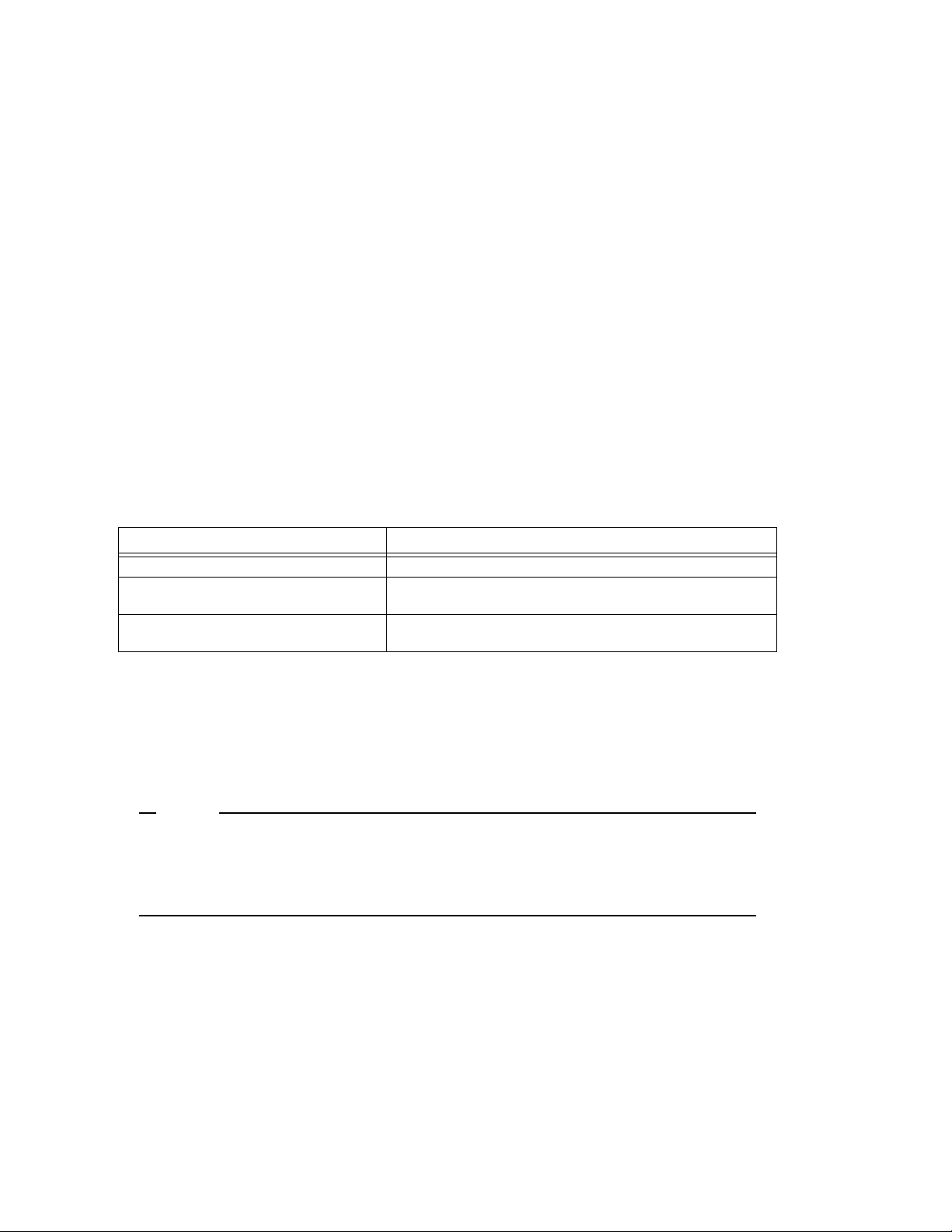

Sensor Identification

Figure 1. Sensor Identification

13

MI 611-150 – August 2020 1. Introduction

NOTE

Standard Specifications

A sensor can be identified by the model code located on both ends of the sensor cable (see

Figure 1). Refer to “Sensor Applications” on page 17 for sensor application information.

Wetted Parts

See “Sensor Measurement Limits, Materials, Temperature Limits, Pressure Limits, and

Temperature Compensator” on page 15.

Cable

Integral, 6 m (20 ft) multi-shielded cable with the following jacket material:

♦ For -SP, -NL, -TF, -RE, -LB, and -EV; irradiated polyolefin jacket

♦ For -HP, -BW, and -UT; PTFE jacket

Mounting

Pipe thread types supplied with various sensors are listed below.

Sensor Type Pipe Thread Type

871EC-REO, -BWO, -LBO, -UTO 3/4-14 NPT (National Pipe Thread), Tapered

871EC-SPO, -HPO, -PPO, -PTO, -NLO,

-SP7, -HP7, -PT7, -PP7

871EC-TF2, -TF3, -TF7, -EV3, -PN3,

-PXO, -AB3,

3/4-14 NPSM (National Straight Pipe Thread for Free Fitting

Mechanical Joints) truncated to 0.990/0.975 in O.D.

3/4-14 NPT (National Pipe Thread), Tapered

Insertion Mounting: Sensors are used with threaded bushings or flanges that form a process seal

against the sensor O-ring.

In situ Mounting: Mate to a user-supplied 3/4-in coupling and length of DN20 or 3/4-in pipe.

Ball Valve Mounting: Sensors are used with ball valve assemblies that contain connections for

mating to the sensor.

When mounting in-line, install the sensors (centered) in the following minimum pipe

sizes to avoid pipe wall effects:

For -SP, -HP, -PP, -PT, -NL, -TF, -PN, and -PX; DN 80 (3 in)

For -RE, -BW, -LB, -UT, -EV, and AB; DN 150 (6 in)

Electromagnetic Compatibility (EMC)

The 871EC Electrodeless Conductivity Sensor complies with the requirements of the European

EMC Directive 89/336/EEC when its cable is connected through rigid metal conduit as

recommended for 873EC*, 873AEC*, and 875EC Analyzers, and 870ITEC Transmitters.

(*220 V ac, 240 V ac metal enclosures only)

14

Loading...

Loading...