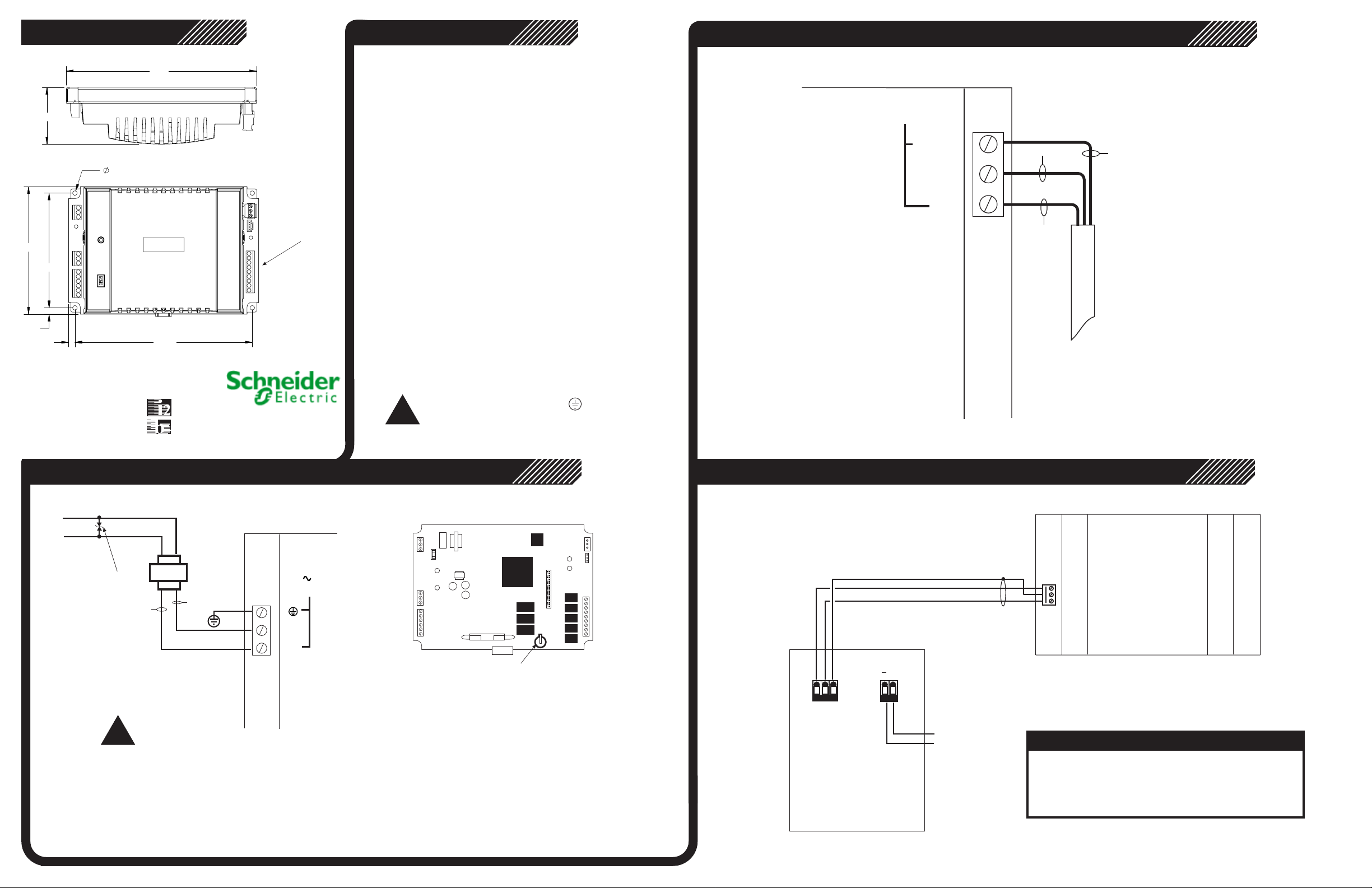

Schneider Electric 850 Series Installation Instructions

Mechanical

8.16

Wiring Rules

These modules are intended for installation within the enclosure

of another product.

Do not remotely ground any part of the input sensor wiring.

RS-485 Connection

850 Series Module

5.47

.27

2.44

4.920

7

.2

.187 THRU

To ensure proper

relay operation, do

not mount controller

with this (right-hand)

edge facing down.

7.610

850 Series Installation

b

3

30-3001-808 Rev G

Remote grounds connected to the return terminal could make

the system operate incorrectly or damage the equipment.

The signal return is not true earth ground. It is an electronic

reference point necessary to interpret the sensor properly.

For reliable input operation, follow these input wiring guidelines:

· Never lay wires across the surface of a printed circuit board.

· Wires should never be within 1 in. or 25 mm of any component

on a printed circuit board.

· Use shielded input wire.

· Terminate the shield of the input wires at one end of the run

only—preferably at the end where your I/O module is located.

· Be careful when stripping wire not to drop small pieces of wire

inside the cabinet.

· Don’t run your input wiring in the same conduit with AC power.

· Don’t run your input wiring in the same conduit with your

output wiring.

Grounding the Controller

To insure proper operation of the controller, it is imperative that it be connected

to a good earth ground. It is important that this connection be made as close to

the module as possible.

Caution: Earth ground ( ) must be

!

connected to avoid module damage.

RS-485

SHLD 24

Black (-)

23

-

+

22

White (+)

Shield

RS-485 Cable

AC Power & Battery Backup Connection Smart Sensor Bus Interface (IN5 & SPWR)

AC Line

Power

24 VAC Step-Down

X2

Transformer

White or

Green

Optional Varistor

choose a voltage rating appropriate to the

input voltage applied. i.e 130V or 250V

Black

X1

!

Use care when attaching power

wiring to these connectors.

They are not to be used as a strain relief.

The connectors cannot withstand

excessive bending or flexing.

Use a separate transformer for each unit installed.

850 Series Module

AC POWER

24 VAC

20 VA

50/60 HZ

1

23N

L

BATTERY

BATTERY ENABLE INFORMATION

During shipment, an insulating plastic tab is inserted under

the clip on the battery to prevent it from draining prior to

installation. To activate the battery, this tab must be removed.

Remove the top of the plastic case to access the board.

(SPWR)

(RET)

(IN3)

SMART SENSOR

INF

+

RS-485 +

RS-485 -

850 Series Module

SPWR

RET

IN5

DETAILED PROGRAMMING & TECHNICAL INFORMATION

Refer to the following documents:

i2 Controller Technical Reference, 30-3001-861

b3 and b4920 Controller Technical Reference, 30-3001-862

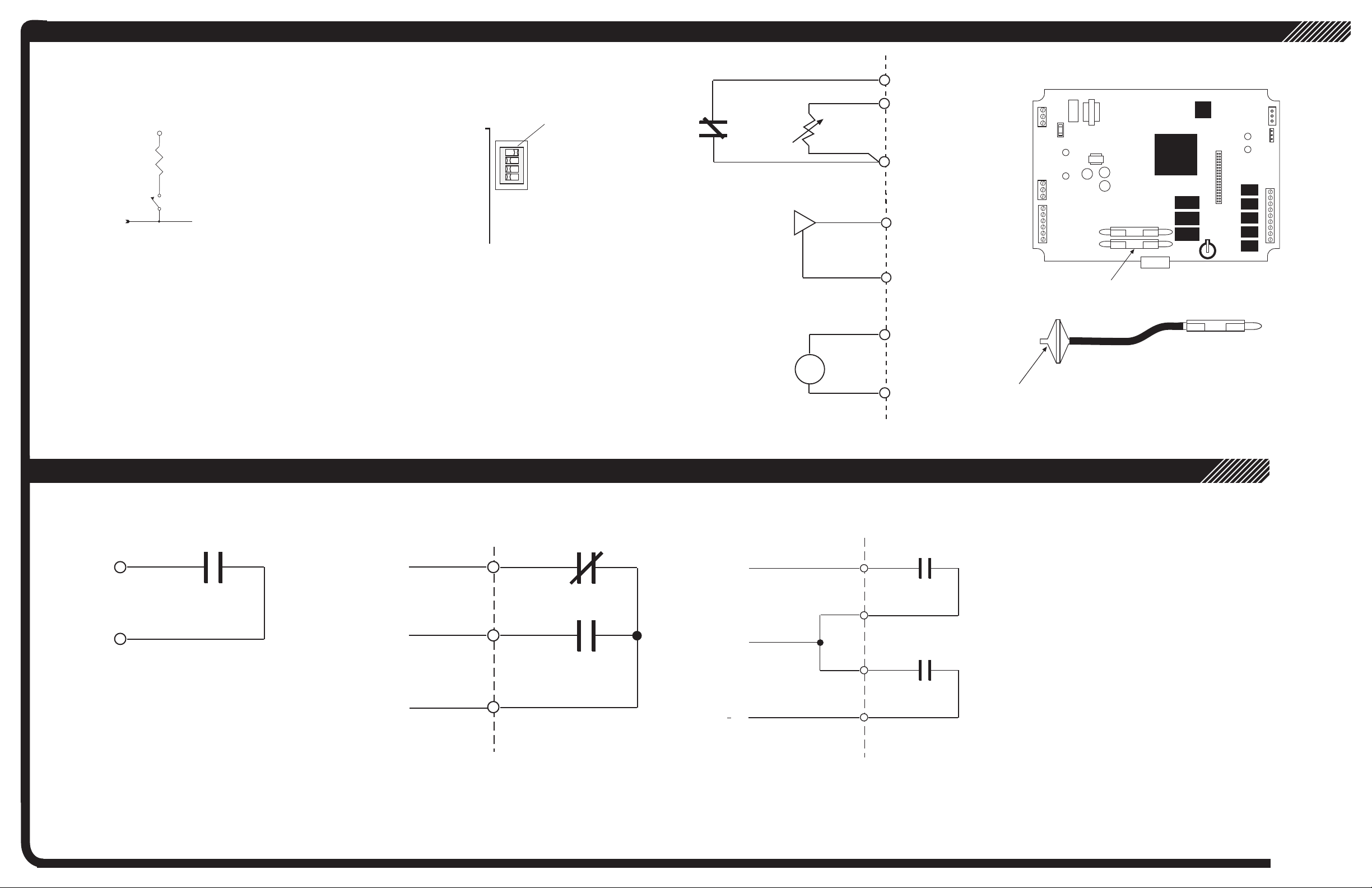

Inputs

INPUT

VREF

Each input includes a reference

resistor that may be disabled.

10K

Switch shown in

‘disabled’ OFF position

Accessing the Reference Resistor Switch

Switch shown in

led Position

710IN 1

8

IN 2

9

RET

IN 3

11

IN 4

12

RET

OFF

1 2 3 4

ON

O N

Enab

1

2

3

4

Contact

Closure

Digital Logic

Signal

+

V

-

Thermistor

DC Voltage

IN x

IN x

Reference

Resistor = ON

RET

IN x

Reference

Resistor = OFF

RET

IN x

Reference

Resistor = OFF

RET

Airflow Sensor Input

Input #7

Input #8

AIR FLOW SENSOR(s)

Filter

Side Marked “IN”

Airflow Sensor

P

1

(mar

ked on sensor case)

Outputs

Digital Form A Output

OUT x

OUT x

Output Rating: 24 V

AC @ 3 A

30 VDC @ 3A

- ON

+ ON

Common

Tristate Output

OUT 1 NC

OUT 1 NO

OUT 1 COM

Max DC Input Voltage = 5V

Tristate from 2 Form A Outputs

+ ON

Common

ON

Using Two Outputs to make

FORM K

OUT x

GND

GND

OUT x

Adjacent output pairs:

OUT1 and OUT2

OUT2 and OUT3

can be combined to form a standard Tri-state output.

The outputs are electrically connected as shown in the

schematic for the built-in Tri-state output.

Configure the output point of the first point of a pair

(i.e., OUT1 of the pair OUT1 and OUT2) with an

Electrical Type of Tri-state.

Loading...

Loading...