Page 1

63230-300-212

Instruction Bulletin

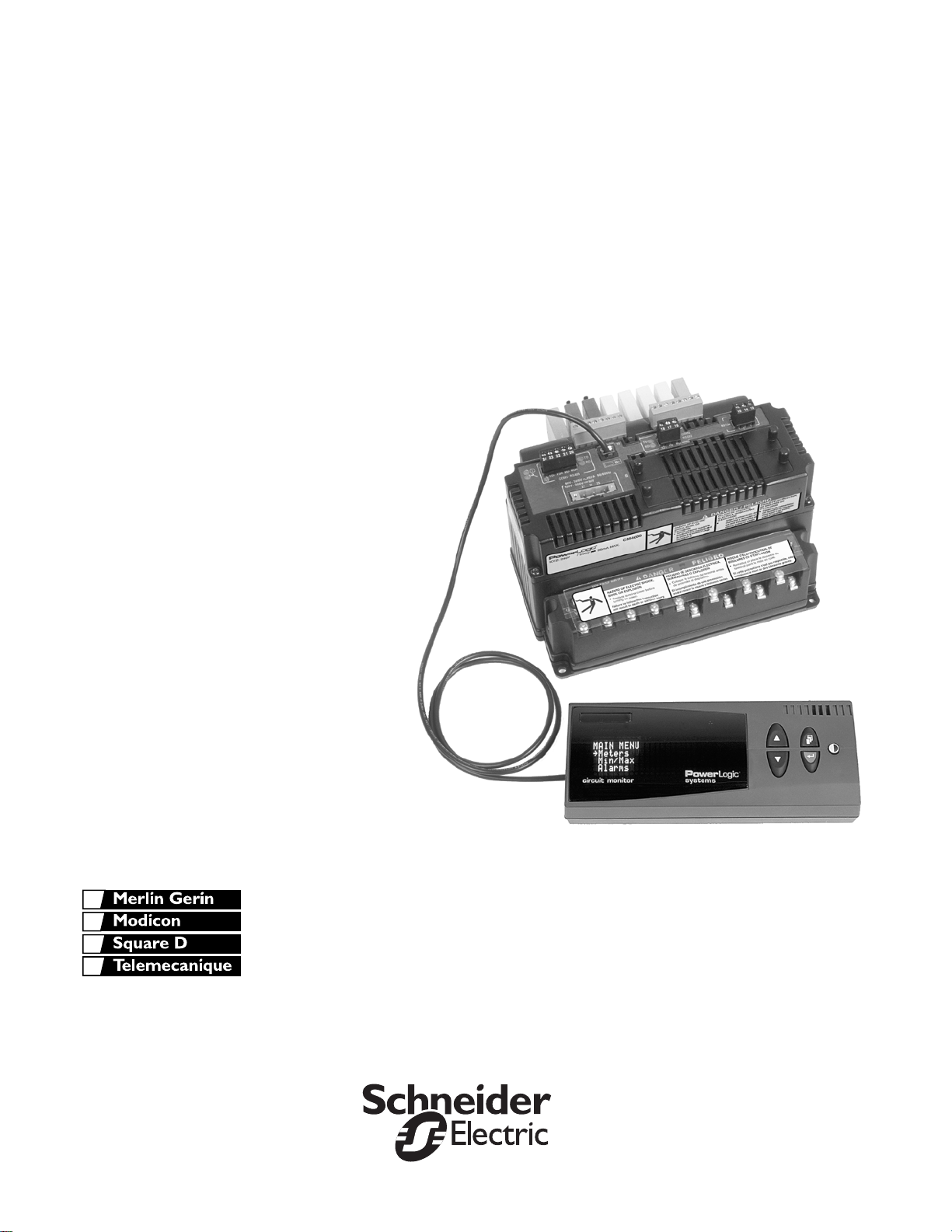

POWERLOGIC®Circuit Monitor

Series 4000

Reference Manual

Retain for future use

April 2001

Page 2

NOTICE

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service, or maintain

it. The following special messages may appear throughout this bulletin or on

the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal injury if

the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not

avoided, can result in death or serious injury.

PLEASE NOTE

Class A FCC Statement

CAUTION

CAUTION indicates a potentially hazardous situation which, if not

avoided, can result in minor or moderate injury.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially

hazardous situation which, if not avoided, can result in property damage.

NOTE: Provides additional information to clarify or simplify a procedure.

Electrical equipment should be installed, operated, serviced, and maintained

only by qualified personnel. This document is not intended as an instruction

manual for untrained persons. No responsibility is assumed by Square D for

any consequences arising out of the use of this manual.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designated to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

© 2000 Schneider Electric All Rights Reser ved

Page 3

63230-300-212 POWERLOGIC® Circuit Monitor Series 4000 Reference Manual

April 2 001 Contents

CONTENTS

CONTENTS ................................................ I

LISTOFFIGURES ..........................................VII

LISTOFTABLES ...........................................IX

CHAPTER 1—INTRODUCTION ................................1

CHAPTERCONTENTS .......................................1

WHATISTHECIRCUITMONITOR? .............................2

AccessoriesandOptionsfortheCircuitMonitor .................3

Features................................................4

TOPICSNOTCOVEREDINTHISBULLETIN ......................4

FIRMWARE ................................................5

CHAPTER 2—SAFETY PRECAUTIONS ..........................7

CHAPTER 3—OPERATION ....................................9

CHAPTERCONTENTS .......................................9

OPERATINGTHEDISPLAY ..................................10

HowtheButtonsWork ....................................10

DisplayMenuConventions ................................11

SelectingaMenuOption ..............................11

Changing a Value ....................................11

MAINMENUOVERVIEW .....................................12

CONFIGURING THE CIRCUIT MONITOR USING THE

SETUPMENU .............................................13

SettingUptheDisplay ....................................13

SettingUptheCommunications ............................14

SettingtheDeviceAddress ............................14

RS-485, RS-232, and Infrared Port Communications Setup . . . 15

EthernetCommunicationsCard(ECC)Setup ..............16

SettingUptheMeteringFunctionsoftheCircuitMonitor .........16

SettingUpAlarms .......................................18

CreatingaNewCustomAlarm ..........................19

SettingUpandEditingAlarms ..........................21

SettingUpI/Os .........................................23

Selecting I/O Modules . ...............................23

ConfiguringI/OModules ...............................25

SettingUpPasswords ....................................27

AdvancedSetupFeatures .................................28

CreatingCustomQuantitiestobeDisplayed ...............28

CreatingCustomScreens .............................31

Viewing Custom Screens ..............................34

AdvancedMeterSetup ................................34

RESETTINGMIN/MAX,DEMAND,ANDENERGYVALUES .........37

VIEWINGMETEREDDATA ...................................38

ViewingMeteredDatafromtheMetersMenu ..................38

Viewing Minimum and Maximum Values from the

Min/MaxMenu ..........................................39

© 2001 Schneider Electric All Rights Reserved

i

Page 4

POWERLOGIC® Circuit Monitor Series 4000 Reference Manual 63230-300-212

Contents April 2001

VIEWINGALARMS ..........................................41

ViewingActiveAlarms ....................................42

View and Acknowledging High Priority Alarms .................42

VIEWINGI/OSTATUS .......................................43

READINGANDWRITINGREGISTERS ..........................44

PERFORMINGAWIRINGERRORTEST ........................45

Running the Diagnostics Wiring Error Test . . ..................46

CHAPTER 4—METERING CAPABILITIES .......................51

CHAPTERCONTENTS ......................................51

REAL-TIMEREADINGS ......................................52

MIN/MAXVALUESFORREAL-TIMEREADINGS ..................53

PowerFactorMin/MaxConventions .........................54

VARSignConventions ................................55

DEMANDREADINGS........................................56

Demand Power Calculation Methods . ........................57

BlockIntervalDemand ................................57

SynchronizedDemand ................................59

DemandCurrent ........................................59

DemandVoltage ........................................59

ThermalDemand ........................................60

PredictedDemand .......................................60

PeakDemand ..........................................61

GenericDemand ........................................61

InputPulseDemandMetering ..............................62

ENERGYREADINGS ........................................64

POWERANALYSISVALUES..................................66

CHAPTER 5—INPUT/OUTPUT CAPABILITIES . ..................69

CHAPTERCONTENTS ......................................69

I/OOPTIONS ..............................................70

DIGITALINPUTS ...........................................71

DEMANDSYNCHPULSEINPUT ..............................72

ANALOGINPUTS ...........................................73

AnalogInputExample ....................................74

RELAYOUTPUTOPERATINGMODES .........................75

MECHANICALRELAYOUTPUTS ..............................77

Setpoint-controlledRelayFunctions .........................78

SOLID-STATEKYZPULSEOUTPUT ...........................78

2-WirePulseInitiator .....................................79

3-WirePulseInitiator .....................................79

CALCULATINGTHEKILOWATTHOUR-PER-PULSEVALUE.........80

ANALOGOUTPUTS .........................................81

AnalogOutputExample ...................................82

ii

© 2001 Schneider Electric All Rights Reser ved

Page 5

63230-300-212 POWERLOGIC® Circuit Monitor Series 4000 Reference Manual

April 2 001 Contents

CHAPTER 6—ALARMS . .....................................83

CHAPTERCONTENTS ......................................83

ABOUTALARMS ...........................................84

AlarmsGroups ..........................................84

Setpoint-DrivenAlarms ...................................85

Priorities ...............................................87

AlarmLevels ...........................................87

CUSTOMALARMS..........................................88

SETPOINT-CONTROLLEDRELAYFUNCTIONS ..................88

TypesofSetpoint-ControlledRelayFunctions .................89

SCALEFACTORS ..........................................91

SCALINGALARMSETPOINTS ................................92

ALARMCONDITIONSANDALARMNUMBERS ...................93

CHAPTER 7—LOGGING . ....................................99

CHAPTERCONTENTS ......................................99

ALARMLOG ..............................................100

AlarmLogStorage ......................................100

DATALOGS ..............................................100

Alarm-DrivenDataLogEntries ............................101

OrganizingDataLogFiles ................................101

DataLogStorage.......................................101

MIN/MAXLOGS ...........................................102

Min/MaxLog ..........................................102

IntervalMin/Max/AverageLog .............................102

IntervalMin/Max/AverageLogStorage ..................103

MAINTENANCELOG .......................................103

© 2001 Schneider Electric All Rights Reserved

MEMORYALLOCATION ....................................104

CHAPTER 8—WAVEFORM AND EVENT CAPTURE .............107

CHAPTERCONTENTS .....................................107

TYPES OF WAVEFORM CAPTURES . . ........................108

Steady-stateWaveformCapture ...........................108

InitiatingaSteady-stateWaveform......................108

DisturbanceWaveformCapture ...........................108

Adaptive Waveform Capture ..............................109

100ms rms Event Recording ..............................110

SETTING UP THE CIRCUIT MONITOR FOR AUTOMATIC EVENT

CAPTURE................................................111

Setting Up Alarm-Triggered Event Capture . ..................111

SettingUpInput-TriggeredEventCapture ...................111

WAVEFORM STORAGE . ...................................111

HOW THE CIRCUIT MONITOR CAPTURES AN EVENT ...........112

iii

Page 6

POWERLOGIC® Circuit Monitor Series 4000 Reference Manual 63230-300-212

Contents April 2001

CHAPTER 9—DISTURBANCE MONITORING . . .................113

CHAPTERCONTENTS .....................................113

ABOUTDISTURBANCEMONITORING.........................114

CAPABILITIES OF THE CIRCUIT MONITOR DURING AN EVENT . . .117

USING THE CIRCUIT MONITOR WITH SMS TO PERFORM

DISTURBANCEMONITORING ...............................118

UNDERSTANDING THE ALARM LOG . . . .......................119

CHAPTER 10—MAINTENANCE AND TROUBLESHOOTING . ......121

CHAPTERCONTENTS .....................................121

CIRCUIT MONITOR MEMORY . . .............................123

UpgradingMemoryintheCircuitMonitor ....................123

IDENTIFYINGTHEFIRMWAREVERSION ......................124

VIEWINGTHEDISPLAYINDIFFERENTLANGUAGES ............124

CALIBRATION OF THE CURRENT/VOLTAGE MODULE (CVM) . . . .124

GETTING TECHNICAL SUPPORT ............................124

TROUBLESHOOTING ......................................125

APPENDIX A—ABBREVIATED REGISTER LISTING . ............127

CONTENTS ..............................................127

ABOUTREGISTERS .......................................127

HOWPOWERFACTORISSTOREDINTHEREGISTER...........128

HOWDATEANDTIMEARESTOREDINTHEREGISTER .........129

REGISTERLISTING ........................................130

APPENDIXB—USINGTHECOMMANDINTERFACE .............181

CONTENTS ..............................................181

OVERVIEWOFTHECOMMANDINTERFACE ...................182

IssuingCommands .....................................183

I/OPOINTNUMBERS ......................................186

OPERATINGOUTPUTSFROMTHECOMMANDINTERFACE ......187

USING THE COMMAND INTERFACE TO CHANGE CONFIGURATION

REGISTERS ..............................................187

CONDITIONALENERGY ....................................188

CommandInterfaceControl ...............................188

Digital Input Control . . . ..................................188

INCREMENTAL ENERGY . ..................................189

UsingIncrementalEnergy ................................189

SETTINGUPINDIVIDUALHARMONICCALCULATIONS ..........190

CHANGINGSCALEFACTORS ...............................191

iv

© 2001 Schneider Electric All Rights Reser ved

Page 7

63230-300-212 POWERLOGIC® Circuit Monitor Series 4000 Reference Manual

April 2 001 Contents

GLOSSARY ..............................................193

INDEX...................................................197

© 2001 Schneider Electric All Rights Reserved

v

Page 8

POWERLOGIC® Circuit Monitor Series 4000 Reference Manual 63230-300-212

Contents April 2001

vi

© 2001 Schneider Electric All Rights Reser ved

Page 9

63230-300-212 List of Figures

April 2 001

LIST OF FIGURES

Figure 3–1: Arrowonthedisplayscreen........................ 10

Figure 3–2: Displaybuttons.................................. 10

Figure 3–3: Partsofamenu ................................. 11

Figure 3–4: MenuoptionsontheMainMenu .................... 12

Figure 3–5: Menusthatcanbepasswordprotected............... 27

Figure 3–6: PerformingresetsfromtheResetmenu .............. 37

Figure 3–7: Viewing metered data on the Meters and Min/Max

menus......................................... 38

Figure 3–8: ViewAlarmsmenu............................... 41

Figure 3–9: DiagnosticsMenuaccessedfromtheMainMenu....... 44

Figure 3–10: Wiring Error Test option on the Diagnostics menu. ...... 45

Figure 4–1: Powerfactormin/maxexample ..................... 54

Figure 4–2: Reactive Power—VARsignconvention............... 55

Figure 4–3: BlockIntervalDemandExamples ................... 58

Figure 4–4: ThermalDemandExample......................... 60

Figure 4–5: PredictedDemandExample........................ 60

Figure 4–6: Channel pulse metering example. . .................. 63

Figure 4–7: Reactiveenergyaccumulatesinfourquadrants ........ 65

Figure 5–1: Demandsynchpulsetiming........................ 72

Figure 5–2: Analoginputexample............................. 74

Figure 5–3: Two-wirepulsetrain.............................. 79

Figure 5–4: Three-wirepulsetrain............................. 79

Figure 5–5: Analogoutputexample............................ 82

Figure 6–1: Samplealarmlogentry ........................... 86

Figure 6–2: How the circuit monitor handles setpoint-driven alarms. . . 86

Figure 6–3: Two alarms set up for the same quantity with different

pickup and dropout set points 87

Figure 7–1: Memoryallocationexample....................... 104

Figure 7–2: MemoryallocationinSMS........................ 105

Figure 8–1: Event capture initiated from a high-speed input. . ...... 112

Figure 9–1: A fault can cause voltage sag on the whole system. . . . . 115

Figure 9–2: Waveform showing voltage sag, which was caused by a

remote fault and lasted five cycles. 115

Figure 9–3: OnboardFilestab............................... 118

Figure 9–4: OnboardAlarms/Eventstab....................... 118

Figure 9–5: Eventlogentriesexample ........................ 119

Figure 9–6: Samplealarmlogentry .......................... 119

Figure 10–1: Memorychiplocationinthecircuitmonitor ........... 123

Figure A–1: Bitsinaregister................................ 128

Figure A–2: Powerfactorregisterformat....................... 128

Figure B–1: CommandInterfacePointerRegisters............... 182

Figure B–2: Identifying I/Os for the command interface............ 186

Figure B–3: IncrementEnergyExample ....................... 189

© 2001 Schneider Electric All Rights Reserved

vii

Page 10

List of Figures 63230-300-212

April 2001

viii

© 2001 Schneider Electric All Rights Reserved

Page 11

63230-300-212 List of Tables

April 2 001

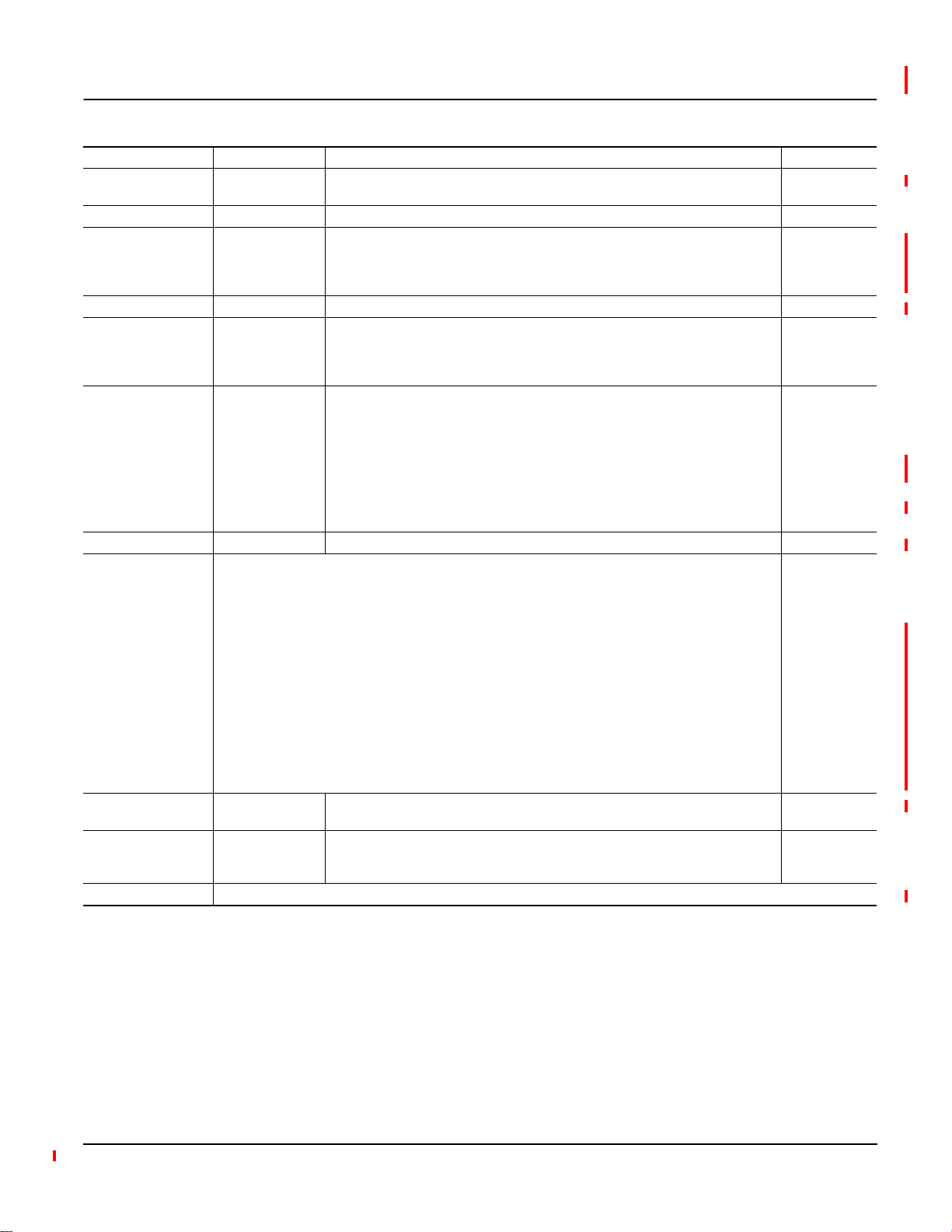

LIST OF TABLES

Table 1–1: SummaryofCircuitMonitorInstrumentation ............ 2

Table 1–2: Circuit Monitor Parts, Accessories, and Custom Cables . . . 3

Table 3–1: FactoryDefaultsfortheDisplaySettings.............. 14

Table 3–2: OptionsforCommunicationsSetup.................. 15

Table 3–3: OptionsforMeterSetup........................... 17

Table 3–4: OptionsforCreatinganAlarm ...................... 20

Table 3–5: OptionsforEditinganAlarm ....................... 22

Table 3–6: I/ODescriptions ................................. 24

Table 3–7: OptionsforPasswordSetup........................ 27

Table 3–8: OptionsforCustomQuantities...................... 30

Table 3–9: Available Default Quantities ........................ 33

Table 3–10: OptionsforAdvancedMeterSetup .................. 36

Table 3–11: Read/WriteRegisterOptions....................... 44

Table 3–12: Wiring Error Messages............................ 48

Table 4–1: One-Second, Real-Time Readings Samples ........... 52

Table 4–2: 100msReal-TimeReadings ....................... 53

Table 4–3: DemandReadings............................... 56

Table 4–4: EnergyReadings ................................ 64

Table 4–5: PowerAnalysisValues............................ 68

Table 5–1: I/ O Extender Options ............................. 70

Table 5–2: Sample register readings for analog inputs ............ 74

Table 5–3: Sample register readings for analog output ............ 82

Table 6–1: Scale Groups ................................... 91

Table 6–2: ScaleGroupRegisterNumbers..................... 92

Table 6–3: ListofDefaultAlarmsbyAlarmNumber .............. 94

Table 6–4: AlarmTypes.................................... 96

Table 7–1: Values Stored in Maintenance Log ................. 103

Table 8–1: Available Resolutions for Disturbance Waveform

Captures...................................... 108

Table 8–2: Available Resolutions for Adaptive Waveform

Captures...................................... 109

Table 8–3: 100ms rms Quantities ........................... 110

Table 9–1: Capability of the circuit monitor to measure electromagnetic

phenomena . .................................. 117

Table 10–1: Troubleshooting . . . ............................. 125

Table A–1: DateandTimeFormat........................... 129

Table A–2: DateandTimeByteExample...................... 129

Table A–3: AbbreviatedRegisterList......................... 130

Table A–4: AbbreviatedRegisterListforI/OStatus.............. 166

Table A–5: Registers for Alarm Position Counters . . . ............ 173

Table A–6: Spectral Components ............................ 178

Table B– 1: Locationofthecommandinterface ................. 182

Table B– 2: CommandCodes............................... 183

Table B– 3: RegistersforHarmonicCalculations ................ 190

© 2001 Schneider Electric All Rights Reserved

ix

Page 12

List of Tables 63230-300-212

April 2001

x

© 2001 Schneider Electric All Rights Reserved

Page 13

63230-300-212 Chapter 1—Introduction

C

April 2 001 Chapter Contents

CHAPTER 1—INTRODUCTION

This chapter offers a general description of the Series 4000 Circuit Monitor,

tells how to best use this bulletin, and lists related documents.

HAPTER CONTENTS

CHAPTERCONTENTS .......................................1

WHATISTHECIRCUITMONITOR? .............................2

AccessoriesandOptionsfortheCircuitMonitor .................3

Features................................................4

TOPICSNOTCOVEREDINTHISBULLETIN ......................4

FIRMWARE ................................................5

© 2001 Schneider Electric All Rights Reserved

1

Page 14

Chapter 1—Introduction 63230-300-212

W

What is the Circuit Monitor? April 2001

HAT IS T HE CIRCUIT MONITOR?

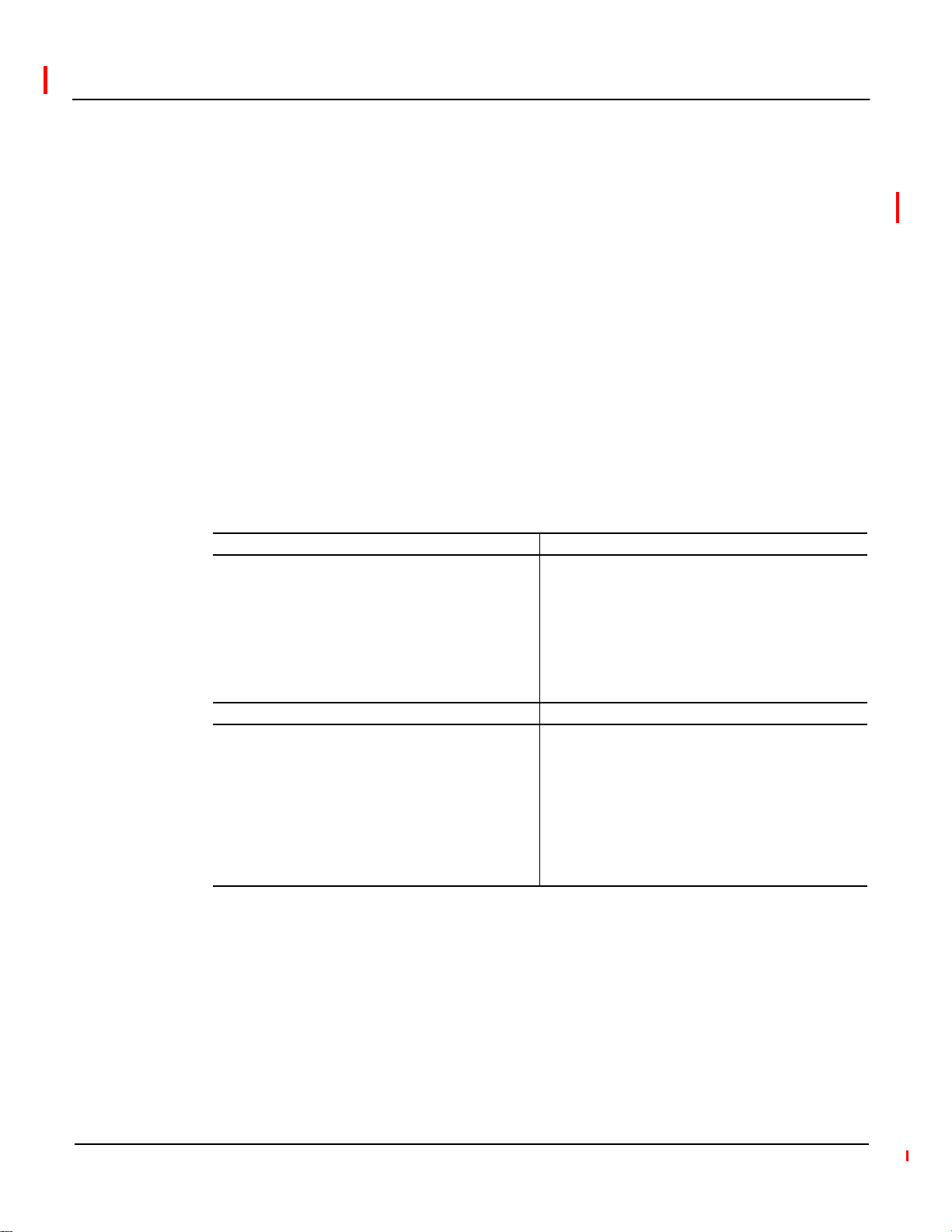

Table 1–1: Summary of Circuit Monitor Instrumentation

• Current (per phase, N, G, 3-Phase)

• Voltage ( L–L, L–N, N–G, 3-Phase)

• Real Power (per phase, 3-Phase

• Reactive Power (per phase, 3-Phase)

• Apparent Power (per phase, 3-Phase)

• Power Factor (per phase, 3-Phase)

• Frequency

• Temperature (internal ambient)

• THD (current and voltage)

• K-Factor (per phase)

• Demand Current (per phase present, 3-Phase avg.)

• Demand Voltage (per phase present, 3-Phase avg.)

• Average Power Factor (3-Phase total)

• Demand Real Power (per phase present, peak)

• Demand Reactive Power (per phase present, peak)

• Demand Apparent Power (per phase present, peak)

• Coincident Readings

• Predicted Power Demands

The circuit monitor is a multifunction, digital instrumentation, data acquisition

and control device. It can replace a variety of meters, relays, transducers and

other components. The circuit monitor can be located at the service entrance

to monitor the cost and quality of power, and can be used to evaluate the

utility service. When located at equipment mains, the circuit monitor can

detect voltage-based disturbances that cause costly equipment downtime.

The circuit monitor is equipped with

RS-485 and RS-232 communications for

integration into any power monitoring and control system. However, System

Manager™ software (

SMS)fromPOWERLOGIC, which is written specifically

for power monitoring and control, best supports the circuit monitor’s

advanced features.

The circuit monitor is a true rms meter capable of exceptionally accurate

measurement of highly nonlinear loads. A sophisticated sampling technique

enables accurate, true rms measurement through the 255th harmonic. You

can view over 50 metered values plus extensive minimum and maximum data

from the display or remotely using software. Table 1–1 summarizes the

readings available from the circuit monitor.

Real-Time Readings Energy Readings

• Accumulated Energy, Real

• Accumulated Energy, Reactive

)

DemandReadings Power Analysis Values

• Accumulated Energy, Apparent

• Bidirectional Readings

• Reactive Energy by Quadrant

• Incremental Energy

• Conditional Energy

• Crest Factor (per phase)

• Displacement Power Factor (per phase, 3-Phase

• Fundamental Voltages (per phase)

• Fundamental Currents (per phase)

• Fundamental Real Power (per phase)

• Fundamental Reactive Power (per phase)

• Harmonic Power

• Unbalance (current and voltage)

• Phase Rotation

• Harmonic Magnitudes & Angles (per phase)

• Sequence Components

)

2

© 2001 Schneider Electric All Rights Reserved

Page 15

63230-300-212 Chapter 1—Introduction

April 2 001 What is the Circuit Monitor?

Accessories and Options for the Circuit Monitor

The circuit monitor has a modular design to maximize its usability. In addition

to the main meter, the circuit monitor has plug-on modules and accessories,

including:

• Current/voltage module (CVM). A standard part of the circuit monitor is

the current/voltage module where all metering data acquisition occurs.

• Remote display . The optional remote 4-line display is available with a

back-lit liquid crystal display (LCD) or a vacuum fluorescent display (VFD).

The VFD model includes an infrared port that can be used to

communicate directly with the circuit monitor from a laptop and can be

used to download firmware, which keeps the circuit monitor up to date with

the latest system enhancements.

• I/O Extender. The I/O extender, located on the side of the circuit monitor,

enables you to “plug in” up to 8 industry-standard inputs and outputs.

Several preconfigured combinations are available, or you can create a

custom configuration.

• Digital I/O Card. You can further expand the I/O capabilities of the circuit

monitor by adding a digital I/O card (4 inputs and 4 outputs). This card fits

into one of the option slots on the top of the circuit monitor.

• Ethernet Communications Card. The Ethernet communications card

provides an Ethernet port that accepts a 100 Mbps fiber optic cable or a

10/100 Mbps UTP and provides an RS-485 master port to extend the

circuit monitor communications options. This card is easily installed into

option slot A on the top of the circuit monitor.

Table 1–2 lists the circuit monitor parts and accessories and their associated

instruction bulletins.

Table 1–2: Circuit Monitor Parts, Accessories, and Custom Cables

Description Part Number Document Number

Circuit Monitor CM4000 63230-300-200

Current/Voltage Module CVM 63230-301-200

VFD Display with infrared (IR) port and proximity sensor CMDVF

LCD Display CMDLC

Optical Communications Interface (for use with the VFD display only) OCIVF 63230-306-200

I/O Extender Module

with no preinstalled I/ Os, accepts up to 8 individual I/O modules with a

maximum of 4 analog I / Os

with 4 digital inputs (32 Vdc), 2 digital outputs ( 60 Vdc),

1 analog output (4–20 mA), and 1 analog input (0–5Vdc)

with 4 analog inputs (4–20 mA) and 4 digital inputs (120 Vac) IOX0404

with 8 digital inputs (120 Vac) IOX08

Digital I/O Card

Field installable with 4 digital inputs (120 Vac), 3 (10 A) relay outputs (120Vac),

1 pulse output (KYZ)

Ethernet Communications Card with

100 Mbps fiber or 10/100 Mbps UTP Ethernet port and 1 RS-485 master port

Optical Communications Interface OCIVG 63230-306-200

Memory Expansion Kit (16 MB and 32 MB kits)

For parts list of individual inputs and outputs, see Table 5–1onpage70.

IOX

IOX2411

IOC44 63230-303-200

ECC21 63230-304-200

CM4MEM16M

CM4MEM32M

63230-305-200

63230-302-200

63230-300-205

© 2001 Schneider Electric All Rights Reserved

3

Page 16

Chapter 1—Introduction 63230-300-212

Topics Not Covered in This Bulletin April 2001

Table 1–2: Circuit Monitor Parts, Accessories, and Custom Cables

63230-204-316

CM4 Mounting Adapters CM4MA

4-ft display cable (1.2 m) CAB-4

12-ft display cable (3.6 m) CAB-12

30-ft display cable (9.1 m) CAB-30

10-ftRS-232cable(3m) CAB-106

For parts list of individual inputs and outputs, see Table 5–1onpage70.

63230-300-206

63230-305-201

N/A

Features

Some of the circuit monitor’s many features include:

• True rms metering to the 255th harmonic

• Accepts standard CT and PT inputs

• 600 volt direct connection on metering inputs

• Certified ANSI C12.20 revenue accuracy and IEC 687.2 class revenue

accuracy

• High accuracy—0.04% current and voltage

• Min/max readings of metered data

• Power quality readings—THD, K-factor, crest factor

• Real-time harmonic magnitudes and angles to the 63rd harmonic

• Current and voltage sag/ swell detection and recording

• Downloadable firmware

• Easy setup through the optional remote display (password protected)

where you can view metered values

• Setpoint-controlled alarm and relay functions

• Onboard alarm and data logging

• Wide operating temperature range –25° to 70°C

• Modular, field-installable digital and analog I/O modules

• Flexible communications—RS-485 and RS-232 communications are

standard, optional Ethernet communications card available with fiber optic

connection

• Two option card slots for field-installable I/O and Ethernet capabilities

• Standard 8MB onboard logging memory (field upgradable to 16 MB, 32

MB, and higher

• CT and PT wiring diagnostics

• Revenue security with utility sealing capability

TOPICS NOT COVERED IN THIS BULLETIN

4

Some of the circuit monitor’s advanced features, such as onboard data logs

and alarm log files, can only be set up over the communications link using

SMS. SMS versions 3.12 and higher support the CM4000 device type.This

circuit monitor instruction bulletin describes these advanced features, but

does not tell how to set them up. For instructions on using

SMS online help and the

SMS-3000 Setup Guide,

which is available in

SMS,refertothe

English (63220-060-200), French (63220-060-201), and Spanish (63220060-202). For information about related instruction bulletins, see Table 1–2

on page 3.

© 2001 Schneider Electric All Rights Reserved

Page 17

63230-300-212 Chapter 1—Introduction

April 2 001 FirmwAre

FIRMWARE

This instruction bulletin is written to be used with firmware version 11.000 or

higher. See “Identifying the Firmware Version” on page 124 for instructions

on how to determine the firmware version.

© 2001 Schneider Electric All Rights Reserved

5

Page 18

Chapter 1—Introduction 63230-300-212

FirmwAre April 2001

6

© 2001 Schneider Electric All Rights Reserved

Page 19

63230-300-212 Chapter 2—Safety Precautions

April 2 001

CHAPTER 2—SAFETY PRECAUTIONS

This chapter contains important safety precautions that must be followed

before attempting to install, service, or maintain electrical equipment.

Carefully read and follow the safety precautions outlined below.

DANGER

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

• Only qualified workers should install this equipment. Such work

should be performed only after reading this entire set of instructions.

• NEVER work alone.

• Before performing visual inspections, tests, or maintenance on this

equipment, disconnect all sources of electric power. Assume that all

circuits are live until they have been completely de-energized, tested,

and tagged. Pay particular attention to the design of the power

system. Consider all sources of power, including the possibility of

backfeeding.

• Turn off all power supplying this equipment before working on or

inside.

• Always use a properly rated voltage sensing device to confirm that all

power is off.

• Beware of potential hazards, wear personal protective equipment,

carefully inspect the work area for tools and objects that may have

been left inside the equipment.

• Use caution while removing or installing panels so that they do not

extend into the energized bus; avoid handling the panels, which could

cause personal injury.

• The successful operation of this equipment depends upon proper

handling, installation, and operation. Neglecting fundamental

installation requirements may lead to personal injury as well as

damage to electrical equipment or other property.

• Before performing Dielectric (Hi-Pot) or Megger testing on any

equipment in which the circuit monitor is installed, disconnect all input

and output wires to the circuit monitor. High voltage testing may

damage electronic components contained in the circuit monitor.

© 2001 Schneider Electric All Rights Reserved

Failure to follow these instructions will result in death or

serious injury.

7

Page 20

Chapter 2—Safety Precautions 63230-300-212

April 2001

8

© 2001 Schneider Electric All Rights Reserved

Page 21

63230-300-212 Chapter 3—Operation

April 2 001 Chapter Contents

CHAPTER 3—OPERATION

This chapter tells how to set up the circuit monitor from the display only.

Some advanced features, such as configuring the onboard logs of the circuit

monitor, must be set up over the communications link using

SMS instruction bulletin and online help file for instructions on setting up

advanced features not accessible from the display.

SMS. Refer to the

CHAPTER CONTENTS

CHAPTERCONTENTS .......................................9

OPERATINGTHEDISPLAY ..................................10

HowtheButtonsWork ....................................10

DisplayMenuConventions ................................11

SelectingaMenuOption ..............................11

Changing a Value ....................................11

MAINMENUOVERVIEW .....................................12

CONFIGURING THE CIRCUIT MONITOR USING THE SETUP MENU . 13

SettingUptheDisplay ....................................13

SettingUptheCommunications ............................14

SettingtheDeviceAddress ............................14

RS-485, RS-232, and Infrared Port Communications Setup . . . 15

EthernetCommunicationsCard(ECC)Setup ..............16

SettingUptheMeteringFunctionsoftheCircuitMonitor .........16

SettingUpAlarms .......................................18

CreatingaNewCustomAlarm ..........................19

SettingUpandEditingAlarms ..........................21

SettingUpI/Os .........................................23

Selecting I/O Modules . ...............................23

ConfiguringI/OModules ...............................25

SettingUpPasswords ....................................27

AdvancedSetupFeatures .................................28

CreatingCustomQuantitiestobeDisplayed ...............28

CreatingCustomScreens .............................31

Viewing Custom Screens ..............................34

AdvancedMeterSetup ................................34

RESETTINGMIN/MAX,DEMAND,ANDENERGYVALUES .........37

© 2001 Schneider Electric All Rights Reserved

VIEWINGMETEREDDATA ...................................38

ViewingMeteredDatafromtheMetersMenu ..................38

Viewing Minimum and Maximum Values from the Min/Max Menu . . 39

VIEWINGALARMS..........................................41

ViewingActiveAlarms ....................................42

View and Acknowledging High Priority Alarms . . . ..............42

VIEWINGI/OSTATUS .......................................43

READINGANDWRITINGREGISTERS..........................44

PERFORMINGAWIRINGERRORTEST ........................45

Running the Diagnostics Wiring Error Test . ...................46

9

Page 22

Chapter 3—Operation 63230-300-212

Operating the Display April 2001

OPERATING THE DISPLAY

MAIN MENU

Meters

Min/Max

View Alarms

How the But tons Work

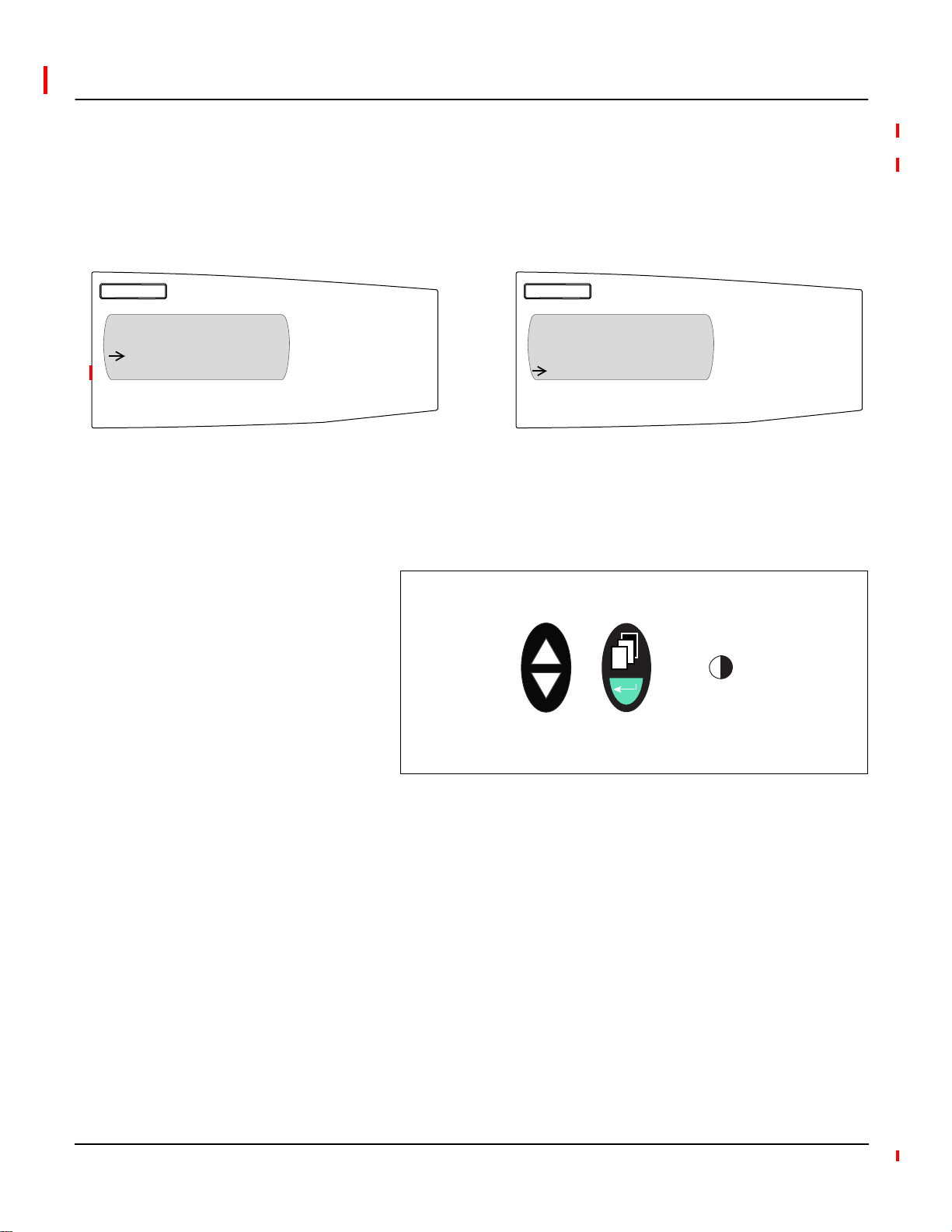

The display shows four lines of information at a time. Notice the arrow on the

left of the display screen. This arrow indicates that you can scroll up or down

to view more information. For example, on the Main Menu you can view the

Resets, Setup, and Diagnostics menu options only if you scroll down to

display them. When at the top of a list, the arrow moves to the top line. When

the last line of information is displayed, the arrow moves to the bottom as

illustrated in Figure 3–1.

MAIN MENU

Resets

Setup

Diagnostics

Figure 3–1: Arrowon the display screen

The buttons on the display let you scroll through and select information, move

from menu to menu, and adjust the contrast. Figure 3–2 shows the buttons.

Menu button

Arrow buttons

Contrast button

Enter button

Figure 3–2: Display buttons

The buttons are used in the following way:

• Arrow buttons. Use the arrow buttons to scroll up and down the options

on a menu. Also, when a value can be changed, use the arrow buttons to

scroll through the values that are available. If the value is a number,

holding the arrow button down increases the speed in which the numbers

increase or decrease.

• Menu button. Each time you press the menu button, it takes you back one

menu level. The menu button also prompts you to save if you’ve made

changes to any options within that menu structure.

• Enter button. Use the enter button to select an option on a menu or select

a value to be edited.

• Contrast button. Press the contrast button to darken or lighten the

display. On the LCD model, press any button once to activate the back

light.

10

© 2001 Schneider Electric All Rights Reserved

Page 23

63230-300-212 Chapter 3—Operation

April 2 001 Operating the Display

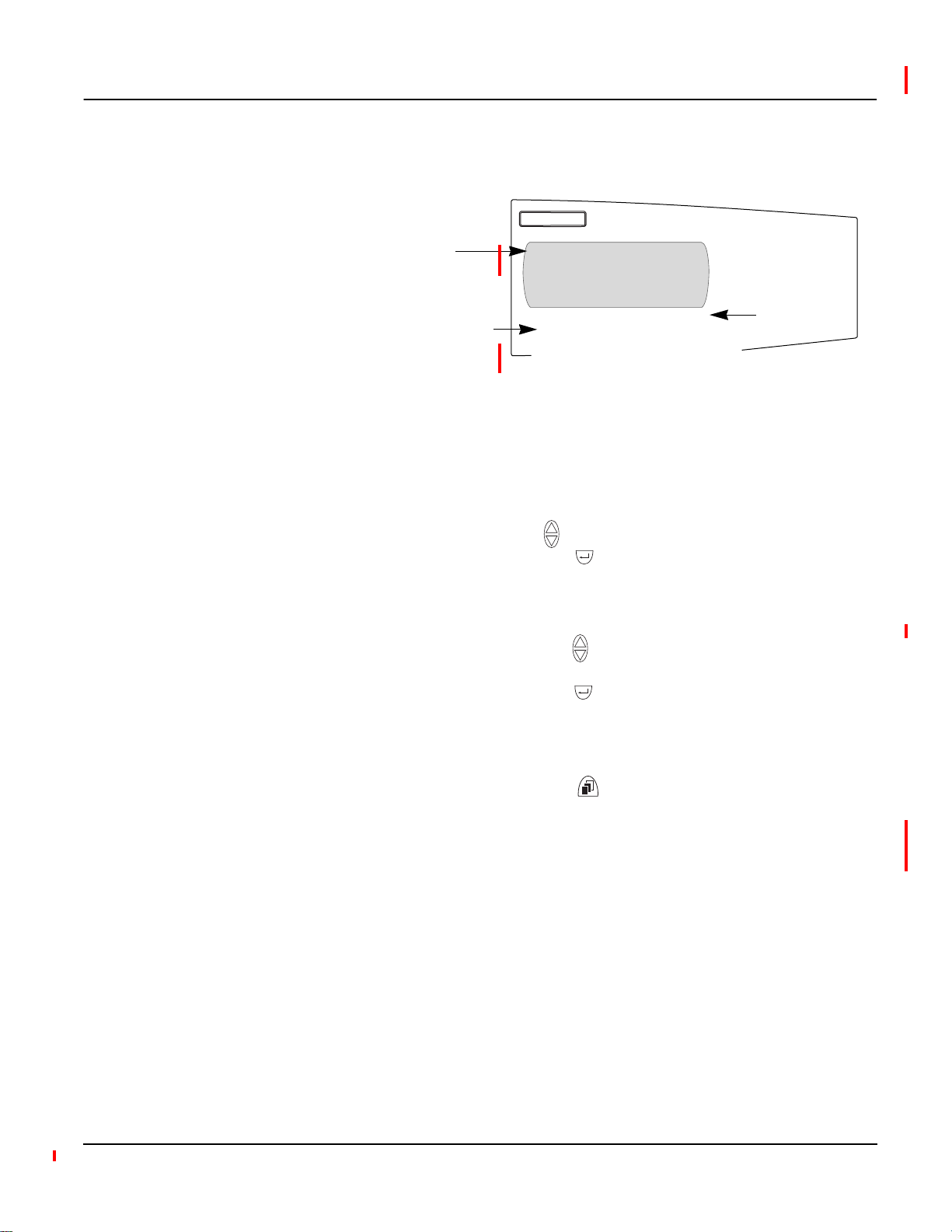

Display Menu Conventions

Selecting a Menu Option

This section explains a few conventions that were developed to streamline

instructions in this chapter. Figure 3–3 shows the parts of a menu.

Menu

DISPLAY

Language English

Date MM/DD/YYYY

Time Format 2400hr

Menu Option

VFD Sensitivity 3

Display Timer 1 Min

Value

Custom Quantity

Custom Screen

Figure 3–3: Parts of a menu

Each time you read “select” in this manual, choose the option from the menu

by doing this:

1. Press the arrows to highlight the menu option.

2. Press the enter button to select that option.

Changinga Value

To change a value, the procedure is the same on every menu:

1. Use the arrow buttons to scroll to the menu option you want to

change.

2. Press the enter button to select the value. The value begins to blink.

3. Press the arrow buttons to scroll through the possible values. To select

the new value, press the enter button.

4. Press the arrow buttons to move up and down the menu options. You can

change one value or all of the values on a menu. To save the changes,

press the menu button until the circuit monitor displays:

“Save changes? No”

NOTE: Pressing the menu button while a value is blinking will return that

value to its most current setting.

5. Press the arrow to change to “Ye s, ” then press the enter button to save

the changes.

© 2001 Schneider Electric All Rights Reserved

11

Page 24

Chapter 3—Operation 63230-300-212

Main Menu Overview April 2001

MAIN MENU OVERVIEW

MAIN MENU

Meters

Min/Max

View Alarms

I/O Display

Resets

Setup

Diagnostics

METERS

Summary

Powe r

Power Quality

Energy

Power Demand

Current Demand

Custom

MIN / MAX

Current

Voltage

Frequency

Powe r

Power Factor

THD

VIEW ALARMS

Active Alarms List

High Priority Log

I/O DISPLAY

Digital Inputs

Analog Inputs

Digital Outputs

Analog Outputs

RESETS

Energy

Demand

Min/Max

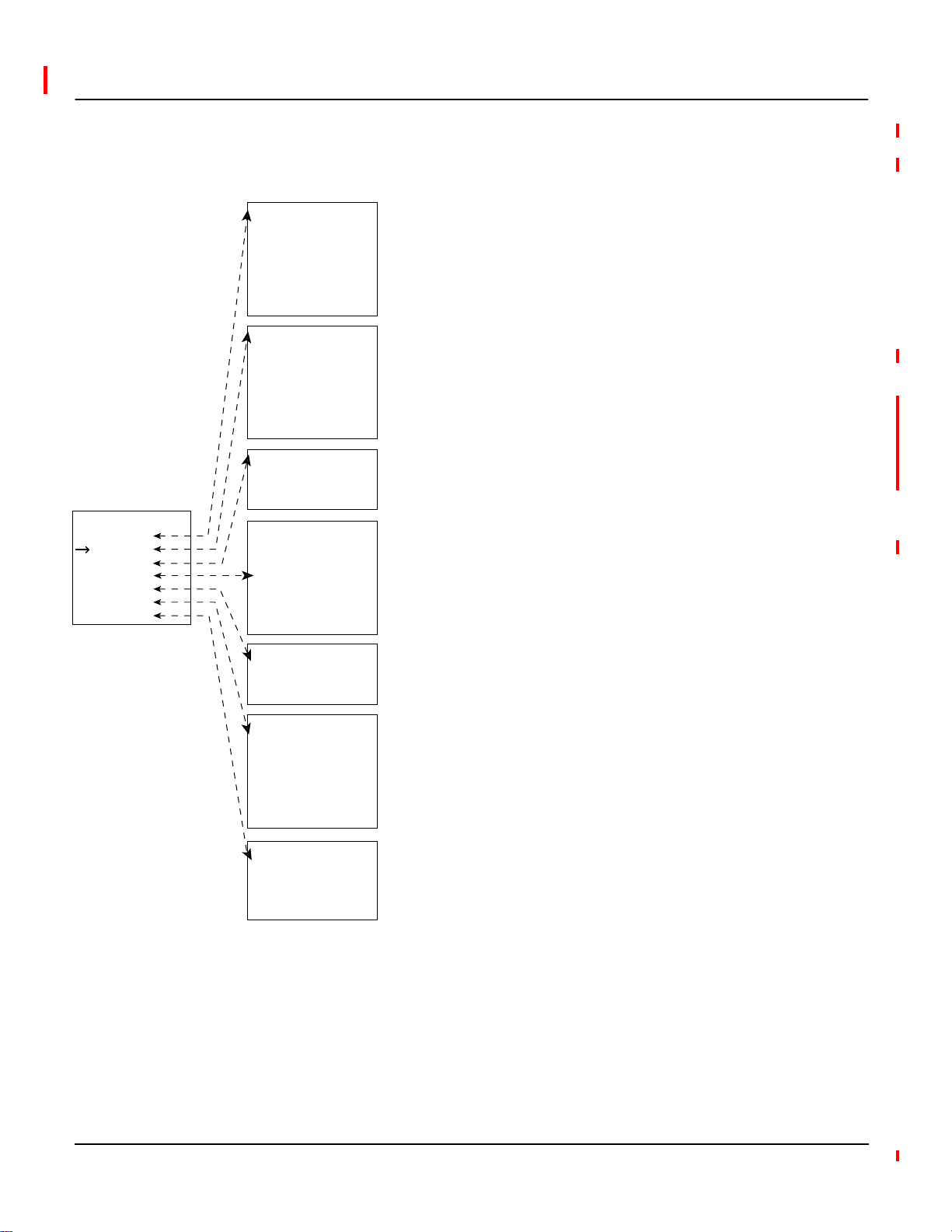

The Main Menu on the display contains the menu options that you use to set

up and control the circuit monitor and its accessories and view metered data

andalarms.Figure3–4 on the left shows the options on the Main Menu. The

menus are briefly described below:

• Meters. This menu lets you view metered values that provide information

about power usage and power quality.

• Min/Max. This menu lets you view the minimum and maximum metered

values since the last reset of the min/max values with their associated

dates and times.

• View Alarms. This menu lets you view a list of all active alarms,

regardless of the priority. In addition, you can view a log of high priority

alarms, which contains the ten most recent high priority alarms.

• I/O Display. From this menu, you can view the designation and status of

each input or output. This menu will only display the I/Os present, so you

might not see all of the available menu items if you do not have a particular

I/O installed.

• Resets. This menu lets you reset energy, peak demand, and minimum/

maximum values.

• Setup. From this menu, you define the settings for the display such as

selecting the date format to be displayed. Creating custom quantities and

custom screens are also options on this menu. In addition, use this menu

to set up the circuit monitor parameters such as the CT and PT ratios. The

Setup menu is also where you define the communications, alarms, I/Os

and passwords.

• Diagnostics. From this menu, you can initiate the wiring error test. Also,

use this menu to read and write registers and view information about the

circuit monitor such as its firmware version and serial number.

SETUP

Date & Time

Display

Communications

Meter

Alarm

I/O

Passwords

DIAGNOSTICS

Meter Information

CVM Information

Read/Write Regs

Wiring Error Test

Figure 3–4: Menuoptions on the Main Menu

12

© 2001 Schneider Electric All Rights Reserved

Page 25

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using the Setup Menu

CONFIGURINGTHE CIRCUIT MONITOR USING THE SETUP MENU

Setting Up the Display

Before you can access the Setup menu from the Main Menu, you must enter

the Setup password. Thedefault password is 0. To change the password, see

“Setting Up Passwords” on page 27. The Setup menu has the following

options:

• Date & Time

• Display

• Communications

• Meter

• Alarm

• I/O

• Passwords

Each of these options is described in the sections that follow.

Setting up the display involves, for example, choosing a date and time format

that you want to be displayed. To set up the display, follow these steps:

1. From the Main Menu, select Setup > Display.

The Display Setup menudisplays. Table 3–1 describes the options on this

menu.

DISPLAY

Language English

Date MM/DD/YYYY

Time Format AM/PM

VFD Sensitivity 2

Display Timer 5

Custom Quantity

Custom Screen

© 2001 Schneider Electric All Rights Reserved

2. Use the arrow buttons to scroll to the menu option you want to change.

3. Press the enter button to select the value.The value begins to blink. Use

the arrow buttons to scroll through the available values. Then, press the

enter button to select the new value.

4. Use the arrow buttons to scroll through the other options on the menu, or

if you are finished, press the menu button to save.

13

Page 26

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

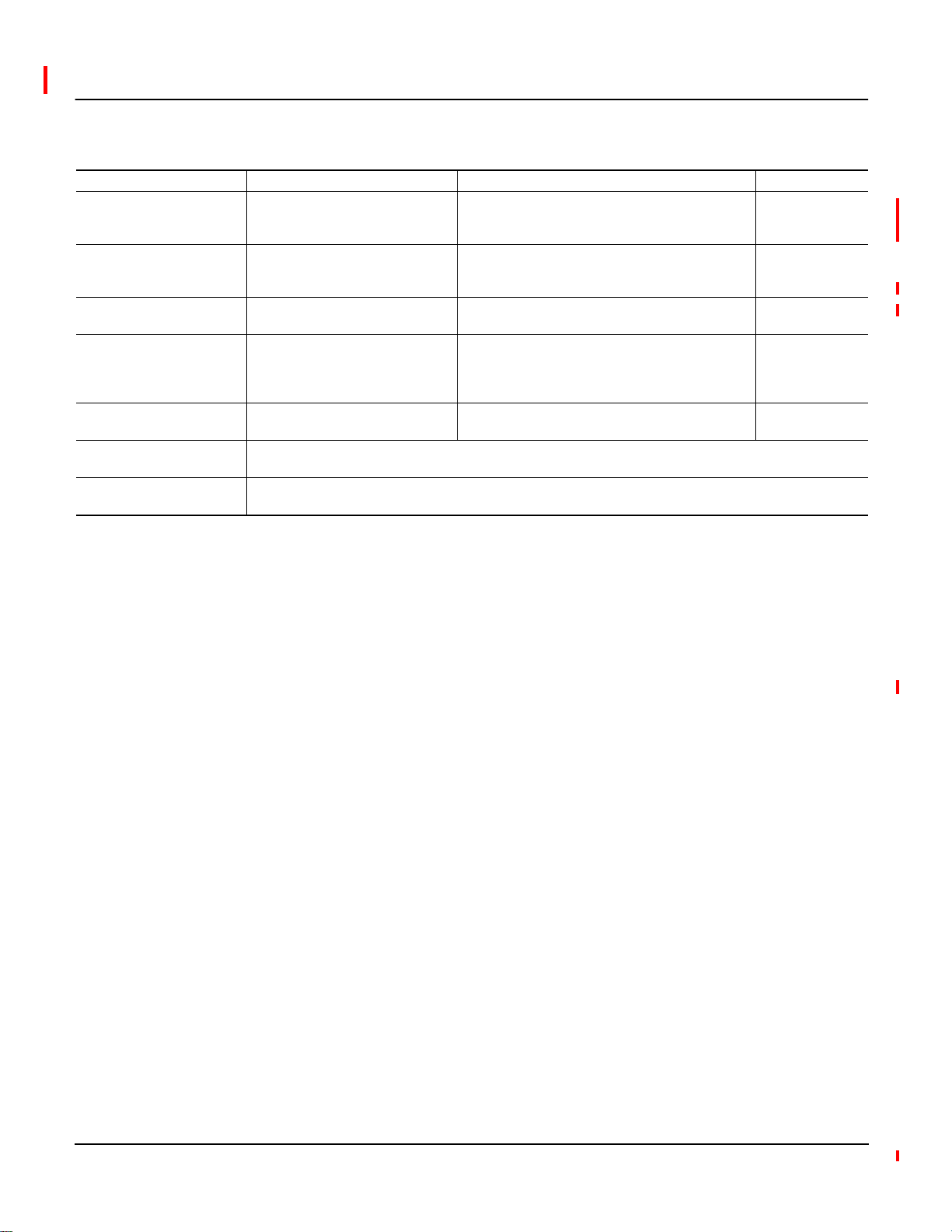

Table 3–1: Factory Defaults for the Display Settings

Option Available Values Selection Description Default

Language English

Francais

Espanol

Date MM/DD/YYYY

YYYY/MM/DD

DD/MM/YYYY

Time Format 2400hr

AM/PM

VFD Sensitivity Off

1=0–6ft(0–15 m)

2=0–12 ft (0–31 m)

3=0–20 ft (0–51 m)

Display Timer 1, 5, 10, or 15 minutes Number of minutes the display remains illuminated

Custom Quantity Creating custom quantities is an advanced feature that is not required for basic setup. To learn more about this

feature, see “Creating Custom Quantities to be Displayed” on page 28.

Custom Screen Creating custom screens is an advanced feature that is not required for basic setup. To learn more about this

feature, see “Creating Custom Screens” on page 31.

Language used by the display. English

Data format for all date-related values of the circuit

monitor.

Time format can be 24-hour military time or 12-hour

clock with AM and PM.

Sensitivity value for the proximity sensor (for the VFD

display only).

after inactivity.

MM/DD/YYYY

2400hr

2

5

Setting Up the Communications

Setting the Device Address

The Communications menu lets you set up the following communications:

•

RS-485

monitor and other

RS-232

•

the circuit monitor and a host device, such as a

Infrared Port

•

computer (available only on the

•

Ethernet Options

communications for daisy-chain communication of the circuit

RS-485 devices.

communications for point-to-point communication between the

PC or modem.

communications between the circuit monitor and a laptop

VFD display).

for Ethernet communications between the circuit

monitor and your Ethernet network when an Ethernet Communications

Card (

ECC)ispresent.

Each of these options is described in the sections that follow.

Each

POWERLOGIC device on a communications link must have a unique

device address. The term communications link refers to 1–32

POWERLOGIC

compatible devices daisy-chained to a single communications port. If the

communications link has only a single device, assign it address 1. By

networking groups of devices,

POWERLOGIC systems can support avirtually

unlimited number of devices.

14

© 2001 Schneider Electric All Rights Reserved

Page 27

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

RS-485, RS-232, and Infrared Port Communications Setup

To se t up RS-485, RS-232, or the infrared port communications, set the

address, baud rate, and parity. Follow these steps:

1. From the Main Menu, select Setup > Communications.

The Communications Setup screen displays.

COMMUNICATIONS

RS-485

RS-232

Infrared Port

Ethernet Option

NOTE: You can set up infrared communications only if the circuit monitor

is equipped with a VFD display. Also, you can set up Ethernet

communications only if the circuit monitor is equipped with an

ECC

card.

2. From the Comms Setup menu, select the type of communications that

you are using. Depending on what you select, the screen for that

communications setup displays, as shown below.Table 3–2 describes the

options on this menu.

RS-485

Protocol Modbus

Address 1

Baud Rate 9600

Parity Even

3. Use the arrow buttons to scroll to the menu option you want to change.

4. Press the enter button to select the value.The value begins to blink. Use

5. Use the arrow buttons to scroll through the other options on the menu, or

Table 3–2: Options for Com munications Setup

Option Available Values Selection Description Default

Protocol

Address 1–255 Device address of the circuit monitor.

Baud

Rate

RS-232

Protocol Modbus

Address 1

Baud Rate 9600

Parity Even

INFRARED PORT

Protocol Modbus

Address 1

Baud Rate 9600

Parity Even

the arrow buttons to scroll through the available values. Then, press the

enter button to select the new value.

if you are finished, press the menu button to save.

MODBUS

JBUS

1200

2400

4800

9600

19200

38400

Select MODBUS or JBUS protocol. MODBUS

See “Setting the Device Address” on

page 14 for requirements of device

addressing.

Speed at which the devices will

communicate. The baud rate must

match all devices on the

communications link.

1

9600

© 2001 Schneider Electric All Rights Reserved

15

Page 28

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

Table 3–2: Options for Communications Setup

Parity Even, Odd, or

None

Parity at which the circuit monitor will

communicate.

Even

EthernetCommunications Card (ECC) Setup

Setting Up the Metering Functions of the Circuit Monitor

Ethernet communications is available only if you have an optional Ethernet

Communications Card (

ECC) that fits into slot A on the top of the circuit

monitor. See “Option Cards” on page 28 in Chapter 4—Installation of the

installation manual for more information. To set up the Ethernet

communications between the circuit monitor and the network, refer to

instruction bulletin no. 63230-304-200 provided with the

ECC.

To set up the metering within the circuit monitor, you must configure the

following items on the Meter setup screen for basic setup:

• CT and PT ratios

• System type

• Frequency

The power demand method, interval and subinterval, and advanced setup

options are also accessible from the Meter Setup menu, but are not required

for basic setup if you are accepting the factory defaults already defined in the

circuit monitor. Follow these steps to set up the circuit monitor:

1. From the Main Menu, select Setup > Meter.

The Meter setup screen displays. Table 3–3 describes the options on this

menu.

METER

Ø CT Primary 5

Ø CT Secondary 5

N CT Primary 5

N CT Secondary 5

PT Pri Scale x1

PT Primary 120

PT Secondary 120

Sys Type 3Ø4W3CT

Required for

basic setup

Frequency (Hz) 60

Pwr Dmd Meth Slide

Pwr Dmd Int 15

Pwr Dmd Sub Int 1

Advanced

2. Use the arrow buttons to scroll to the menu option you want to change.

3. Press the enter button to select the value. The value begins to blink. Use

the arrow buttons to scroll through the available values. Then, press the

enter button to select the new value.

4. Use the arrow buttons to scroll through the other options on the menu, or

if you are finished, press the menu button to save.

16

© 2001 Schneider Electric All Rights Reserved

Page 29

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

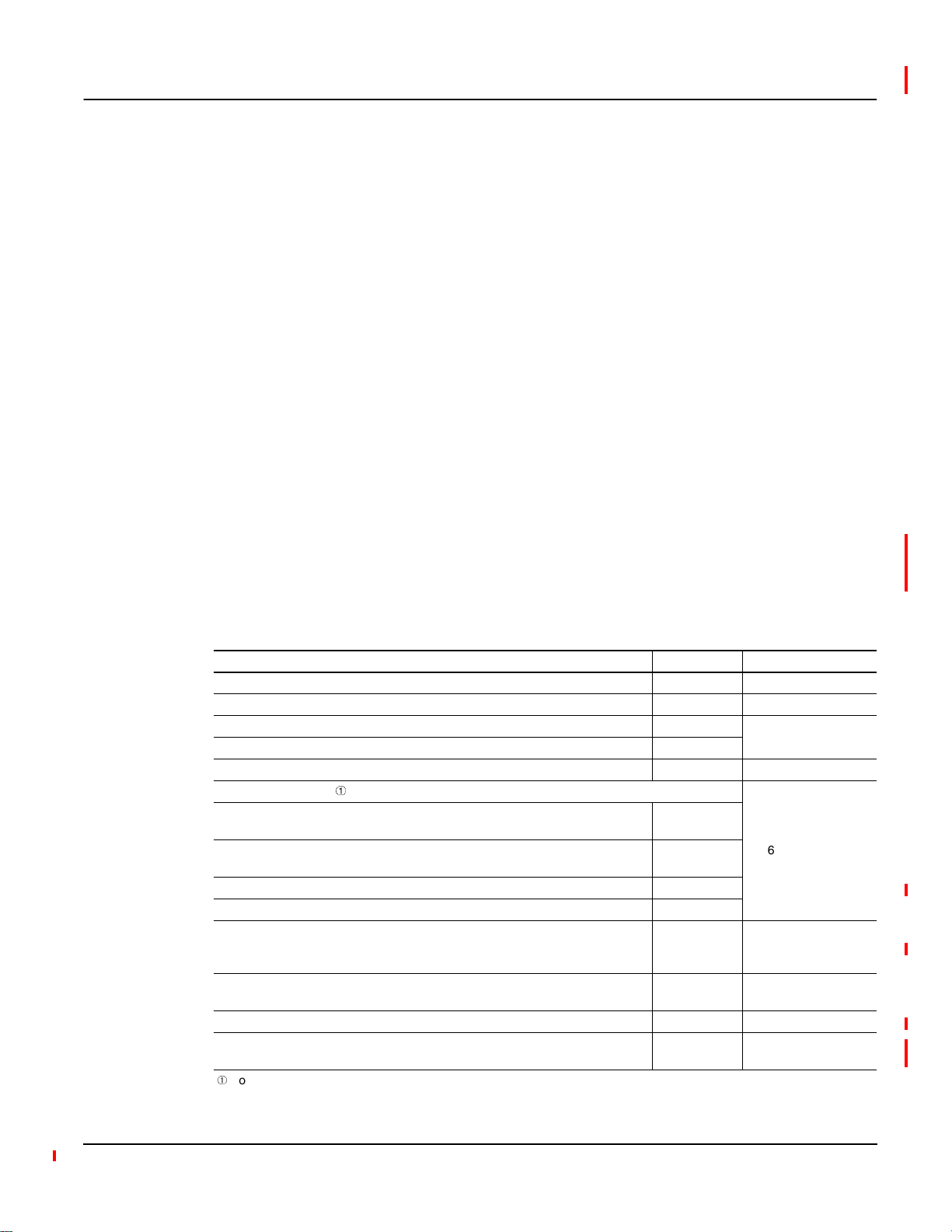

Table 3–3: Options for Meter Setup

Option Available Values Selection Description Default

CT Primary 1–32,767 Set the rating for the CT primary. The circuit monitor supports two primary CT

ratings: one for the phase CTs and the other for the neutral CT.

CT Secondary 1 or 5 Set the rating for the CT secondaries. 5

PT Pri Scale x1

x10

x100

No PT

PT Primary 1–32,767 Set the rating for the PT primary. 120

PT Secondary 100

110

115

120

Sys Type 3Ø3W2CT

3Ø3W3CT

3Ø4W3CT

3Ø4W4CT

3Ø4W3CT2PT

3Ø4W4CT2PT

Frequency (Hz) 50, 60, or 400 Hz Frequency of the system. 60

Pwr Dmd Meth Select the power demand calculation method. The circuit monitor supports several methods to calculate

average demand of real power. See “Demand Power Calculation Methods” on page 57 for a detailed

description.

Slide—Sliding Block Demand

Slave—Slave Block Demand

Therm—Thermal Demand

RComms—Command-Synchronized Rolling Block Demand

Comms—Command-Synchronized Block Demand

RInput—Input-Synchronized Rolling Block Demand

Input—Input-Synchronized Block Demand

RClock—Clock-Synchronized Rolling Block Demand

Clock—Clock-Synchronized Block Demand

RBlock—Rolling Block Demand

Block—Fixed Block Demand

IncEngy—Synch to Incremental Energy Interval

Pwr Dmd Int 1–60 Power demand interval—set the time in minutes in which the circuit monitor

Pwr Dmd Sub Interval 1–60 Power demand subinterval—period of time within the demand interval in which the

Advanced See “Advanced Meter Setup” on page 34 in this chapter for more information.

Set the value to which the PT Primary is to be scaled if the PT Primary is larger

than 32,767. For example, setting the scale to x10 multiplies the PT Primary

number by 10.

For a direct-current installation, select “No PT.”

Set the rating for the PT secondaries. 120

3Ø3W2CT is system type 30

3Ø3W3CT is system type 31

3Ø4W3CT is system type 40

3Ø4W4CT is system type 41

3Ø4W3CT2PT is system type 42

3Ø4W4CT2PT is system type 43

Set the system type. A system type code is assigned to each type of system

connection. See Table 5–2 on page 38 of the installation manual for a description

of system connection types.

calculates the demand.

demand calculation is updated. Set the subinterval only for methods that will

accept a subinterval. The subinterval must be evenly divisible into the interval.

5

x1

3Ø4W3CT (40)

Slide

15

N/A

© 2001 Schneider Electric All Rights Reserved

17

Page 30

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

Setting Up Alarms

This section describes how to setup alarms and create your own custom

alarms. For a detailed description of alarm capabilities, see Chapter 6—

Alarms on page 83. The circuit monitor can detect over 100 alarm

conditions, including over/under conditions, status input changes, phase

unbalance conditions, and more. Some alarms are preconfigured and

enabled at the factory. See “Factory Defaults” on page 11 in Chapter 3—

Getting Started of the installation manual for information about

preconfigured alarms. You can edit the parameters of any preconfigured

alarm from the display.

For each alarm that you set up, do the following:

• Select the alarm group that defines the type of alarm:

—

Standard speed

alarms have a detection rate of one second and are

useful for detecting conditions such as over current and under voltage.

Up to 80 alarms can be set up in this group.

—

High speed

alarms have a detection rate of 100 milliseconds and are

useful for detecting voltage sags and swells that last a few cycles. Up

to 20 alarms can be set up in this group.

—

Disturbance monitoring

alarms have a detection rate of one cycle and

are useful for detecting voltage sags and swells. Up to 20 alarms can

be set up in this group.

—

Digital

alarms are triggered by an exception such as the transition of a

status input or the end of an incremental energy interval. Up to 40

alarms can be set up in this group.

—

Boolean

alarms have a detection rate of the alarms used as inputs.

They are used to combine specific alarms into summary alarm

information.

• Select the alarm that you want to configure. Keep the default name or

enter a new name with up to 15 characters.

• Enable the alarm.

• Assign a priority to the alarm. Refer to “Viewing Alarms” on page 41 for

information about the alarm priority levels.

• Define any required pickup and dropout setpoints, and pickup and dropout

time delays (for standard, high speed, and disturbance alarm groups only,

refer to “Setpoint-Driven Alarms” on page 85 in Chapter 6—Alarms).

18

© 2001 Schneider Electric All Rights Reserved

Page 31

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

Creating a New Custom Alarm

In addition to editing an alarm, you can also create new custom alarms by

performing two steps:

1. Create the custom alarm.

2. Setup and enable the new alarm.

To use custom alarms, you must first create a custom alarm and then set up

the alarm to be used by the circuit monitor. Creating an alarm defines

information about the alarm including:

• Alarm group (standard, high speed, disturbance, digital, or boolean)

• Name of the alarm

• Type (such as whether it alarms on an over or under condition)

• Register number of the value that will be alarmed upon

To create an alarm, follow these steps:

1. From the Main Menu, select Setup > Alarm > Create Custom.

The Create Custom screen displays.

CREATE CUSTOM

Standard 1 sec

High Speed 100ms

Disturbance <1cycle

Digital

Boolean

2. Select the Alarm Group for the alarm that you are creating:

• Standard—detection rate of 1 second

• High Speed—detection rate of 100 millisecond

• Disturbance—detection rate of less than 1 cycle

• Digital—triggered by an exception such as a status input or the end of

an interval

• Boolean—triggered by condition of alarms used as inputs

The Select Position screen displays and jumps to the first open position

in the alarm list.

SELECT POSITION

*43 Over THD Vbc

*44 Over THD Vca

45

3. Select the position of the new alarm.

The Alarm Parameters screen displays.

© 2001 Schneider Electric All Rights Reserved

19

Page 32

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

ALARM PARAMETERS

Lbl: Over THD Vbc

Type Over Val

Qty THD Vbc

Ta b le 3 –4 on page 20 describes the options on this menu.

Table 3–4: Options for Creating an Alarm

Option Available Values Selection Description Default

Label—name of the alarm. Press the down arrow button to scroll through the alphabet. The lower

Lbl Alphanumeric

Selectthetypeofalarmthatyouarecreating.

Note: For digital alarms, the type is either ON state, OFF state, or Unary to describe the state of the digital input. Unary

is available for digital alarms only.

Over Val—over value

Over Pwr—over power

Over Rev Pwr—over reverse power

Under Val—under value

Ty p e

Qty

Under Pwr—under power

Phs Rev—phase reversal

Phs Loss Volt—phase loss, voltage

Phs Loss Cur—phase loss, current

PF Lead—leading power factor

PF Lag—lagging power factor

Binary

Time of Day

See Table 6–4 on page 96 for a description of alarm types.

For standard or high speed alarms this is the quantity to be evaluated. While selected, press the arrow buttons to scroll

through the following quantity options: Current, Voltage, Demand, Unbalance, Frequency, Power Quality, THD,

Harmonics, Temperature, Custom, and Register. Pressing the enter key while an option is displayed will activate that

option’s list of values. Use the arrow keys to scroll through the list of options, selecting an option by pressing the enter key.

Unary is a special type of alarm used for ”end of” digital alarms. It does not apply to setting up alarms for digital inputs.

case letters are presented first, then uppercase, then numbers and symbols. Press the enter button

to select a letter and move to the next character field. To move to the next option, press the menu

button.

—

Undefined

Undefined

20

4. Press the menu button until “Save Changes? No” flashes on the display.

Select Yes with the arrow button, then press the enter button to save the

changes. Now, you are ready to set up the newly created custom alarm.

© 2001 Schneider Electric All Rights Reserved

Page 33

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

Setting Up and Editing Alarms

To set up a newly created custom alarm for use by the circuit monitor, use the

Edit Parameters option on the Alarm screen. You can also change

parameters of any alarm, new or existing. For example, using the Edit option

you can enable or disable an alarm, change its priority, and change its pickup

and dropout setpoints.

Follow these instructions to set up or edit an alarm:

1. From the Main Menu, select Setup > Alarm > Edit Parameters.

The Edit Parameters screen displays.

EDIT PARAMETERS

Standard 1 sec

High Speed 100ms

Disturbance <1cycle

Digital

Boolean

2. Select the Alarm Group:

• Standard

• High Speed

• Disturbance

• Digital

• Boolean

The Select Alarm screen displays.

SELECT ALARM

*01 Over Ia

02 Over Ib

03 Over Ic

NOTE: If you are setting up or editing a digital alarm, alarm names such

as Breaker 1 trip, Breaker 1 reset will display instead.

3. Select the alarm you want to set up or edit.

The Edit Alarm screen with the alarm parameters displays. Table 3–5

describes the options on this menu.

EDIT ALARM

Lbl:Over Ia

Enable No

Priority None

Setpoint Mode Abs

Pickup 0

PU Dly seconds 0

Dropout 0

DO Dly seconds 0

© 2001 Schneider Electric All Rights Reserved

21

Page 34

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

NOTE: If you are setting up or editing a digital alarm, fields related to

pickup and dropout are not applicable and will not be displayed.

4. Use the arrow buttons to scroll to the menu option you want to change,

then edit the alarm options.

5. When you are finished with all changes, press the menu button until

“Save Changes? No” flashes on the display. Select Yes with the arrow

button, then press the enter button to save the changes.

NOTE: An asterisk next to the alarm in the alarm list indicates that the

alarm is enabled.

Table 3–5: Options for Editing an Alarm

Option Available Values Selection Description Default

Label—name of the alarm assigned to this position. Press the down arrow button

Lbl Alphanumeric

Enable

Priority

Setpoint Mode

Pickup 1–32,767

PU Dly

Seconds

Dropout 1–32,767

DO Dly

Seconds

Ye s

No

None

Low

Med

High

Abs

Rel

Pickup Delay

1–32,767

Dropout Delay

1–32,767

to scroll through the alphabet. The lower case letters are presented first, then

uppercase, then numbers and symbols. Press the enter button to select a letter

and move to the next character field. To move to the next option, press the menu

button.

Y

Select

preconfigured alarms, the alarm may already be enabled.

Select

Low

the active alarm in the list of high priority alarms. To view this list from the Main

Menu, select Alarms > High Priority Alarms. For more information, see “Viewing

Alarms” on page 41.

Selecting Abs indicates that the pickup and dropout setpoints are absolute values.

Rel indicates that the pickup and dropout setpoints are a percentage of a running

average, the relative value, of the test value.

When you enter a delay time, the number is multiples of time. For example, for

standard speed the time is 2 for 2 seconds, 3 for 3 seconds, etc. For high speed

alarms, 1 indicates a 100 ms delay, 2 indicates a 200 ms delay, and so forth. For

disturbance the time unit is 1 cycle. See “Setpoint-Driven Alarms” on page 85 for

an explanation of pickup and dropout setpoints.

to make the alarm available for use by the circuit monitor. On

N

to makes the alarm function unavailable to the circuit monitor.

is the lowest priority alarm.

High

is the highest priority alarm and also places

Name of the alarm

assigned to this position.

Depends on individual

alarm.

Depends on individual

alarm.

Depends on individual

alarm.

22

© 2001 Schneider Electric All Rights Reserved

Page 35

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

Setting Up I/Os

Selecting I/O Modules

TosetupanI/O,youmustdothefollowing:

1. Install the I/O option module following the instructions provided with the

product.

2. Use the display to select which

IOX option is installed.

3. Use the display to configure each individual input and output. You can

also use

SMS to configure inputs and outputs.

NOTE: After selecting which IOX option is installed, you can’t configure the

module until you have saved the changes. After saving the changes, you then

can configure the inputs and outputs.

For a description of I/O options, see Chapter 5—Input/Output Capabilities

on page 69. To view the status of an I/O, see “Viewing I/O Status” on page

43. You need to know the position number of the I/O to set it up. See “I/O Point

Numbers” on page 186 to determine this number. To set up an I/O, follow

these steps:

1. From the Main Menu, select Setup.

The password prompt displays.

2. Select your password. The default password is 0.

The Setup menu displays.

SETUP

Date & Time

Display

Communications

Meter

Alarm

I/O

Passwords

© 2001 Schneider Electric All Rights Reserved

3. Select I/O.

TheI/OSetupmenudisplays.

I/O

KYZ

I/O Extender

NOTE: Other option modules will be displayed in the I/O menu if they

are installed

4. Select the I/O option that you have installed. In this example, we selected

the I/O Extender.

23

Page 36

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

The I/O Extender Setup menu displays.

I/O EXTENDER SETUP

Select Modules

Configure Modules

5. Select the Select Modules menu option.

The IOX Select Modules menu displays.

IOX SELECT MODULES

IOX-08

IOX-0404

IOX-2411

Custom

6. If you have the IOX-08, IOX-0404, or IOX-2411, select the option you

have installed. A pound sign (#) appears next to the option to indicate that

the circuit monitor has recognized the module. If you installed individual

custom I/Os, select Custom on the IOX Select Modules menu.

The Custom Extender menu displays.

CUSTOM

Position 1 DI120AC

Position 2 AI420

Position 3 DI120AC

Position 4 AI420

Position 5 DI120AC

Position 6 AI420

Position 7 DI120AC

Position 8 AI420

7. Select the position in which the I/O is installed. Then, select which I/O

module is located in that position using the arrow keys to scroll through

the available I/Os. The individual I/Os are described in Table 3–6.

Table 3–6: I/O Descriptions

I/O Name Description

DigitalI/Os

DI32DC 32 Vdc input (0.2ms turn on) polarized

DI120AC 120 Vac input

DO120AC 120 Vac output

DI240AC 240 Vac input

DO60DC 60 Vdc output

DO200DC 200 Vdc output

24

© 2001 Schneider Electric All Rights Reserved

Page 37

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

Table 3–6: I/O Descriptions

I/O Name Description

DO240AC 240 Vac output

Analog I/Os

AI05 0to5Vdcanaloginput

AI420 4 to 20 mA analog input

AO420 4 to 20 mA analog output

8. Press the menu button until “Save Changes? No” flashes on the display.

Select Yes with the arrow button, then press the enter button to save the

changes.

Configuring I/O Modules

After selecting the I/O modules used with your circuit monitor, you can

configure the I/O modules. Follow the steps below to configure the inputs and

outputs for the I/O module you selected.

1. From the Main Menu, select Setup.

The password prompt displays

2. Select your password. The default password is 0.

The Setup menu displays.

SETUP

Date & Time

Display

Communications

Meter

Alarm

I/O

Passwords

3. Select I/O.

TheI/OSetupmenudisplays.

I/O

KYZ

I/O Extender

© 2001 Schneider Electric All Rights Reserved

4. Select the I/O option that you have installed. In this example, we selected

the I/O Extender.

25

Page 38

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

The I/O Extender Setup selection menu displays.

I/O EXTENDER SETUP

Select Modules

Configure Modules

5. Select the Configure Modules menu option.

The IOX Setup menu displays according to the IOX previously selected.

In this example the IOX Custom Setup menu displays.

IOX CUSTOM SETUP

Position 1

Position 2

Position 3

Position 4

Position 5

Position 6

Position 7

Position 8

ANALOG INPUT SETUP

Lbl: Analog In C02

Type 4-20mA Input

I/O Point # 36

Multiplier 1

Lower Limit 400

Upper Limit 2000

6. Select the position in which the I/O is installed.

The I/O module’s setup menu displays based on the type of module

installed in the selected position.

ANALOG OUTPUT SETUP

Lbl: Analog OutC04

Type 4-20mA Output

I/O Point # 38

Reference Reg 100

Lower Limit 400

Upper Limit 2000

NOTE: For a description of the I/O options displayed above, refer to

Chapter 5—Input/Output Capabilities

DIGITAL INPUT SETUP

Lbl: Dig In C01

Type 120Vac Input

I/O Point # 35

Mode Normal

DIGITAL OUTPUT SETUP

Lbl: Dig Out C03

Type 120 Vac Output

I/O Point # 37

Mode Normal

Pulse Const ****

Timer (secs) 0

Control External

Associate Alarm

on page 69.

26

© 2001 Schneider Electric All Rights Reserved

Page 39

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

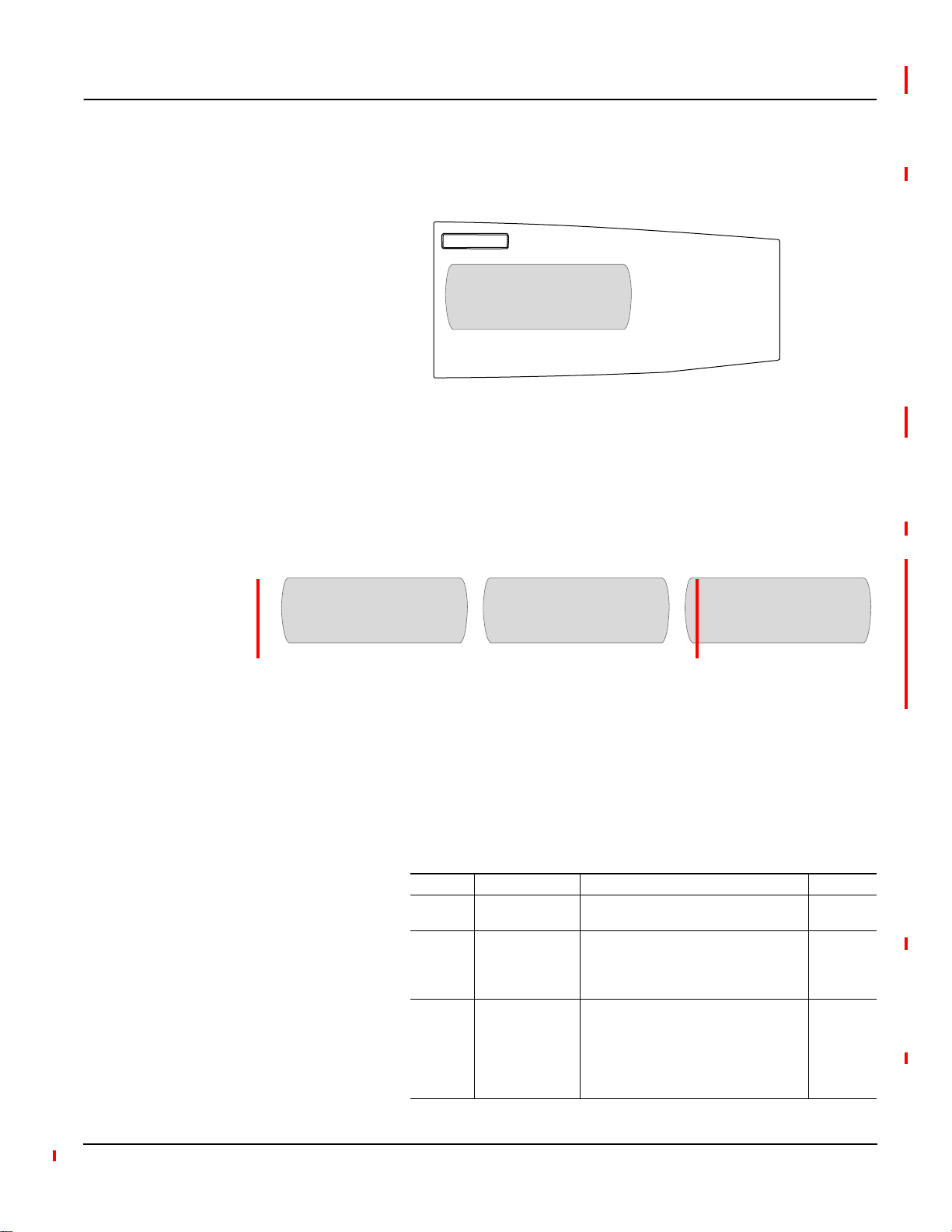

Setting Up Passwords

MAIN MENU

Meters

Min/Max

View Alarms

I/O Display

Resets

Setup

Diagnostics

Passwords can be set

up for Resets, Setup,

and Diagnostics menus

METERS

Summary

Powe r

Power Quality

Energy

Power Demand

Amp Demand

Custom

MIN/MAX

Amps

Volts

Frequency

Powe r

Power Factor

THD

VIEW ALARMS

Active Alarms

High Priority Alarms

I/O DISPLAY

Digital Inputs

Analog Inputs

Digital Outputs

Analog Outputs

RESETS

Energy

Demand

Min/Max

SETUP

Display

Communications

Meter

Alarm

I/O

Passwords

DIAGNOSTICS

Meter Information

CVM Information

Read/Write Regs

Wiring Error Test

A password is always required to access the following menus from the

Main Menu:

• Resets (a separate password can be set up for Energy/Demand Reset

and Min/Max Reset)

• Setup

• Read/Write Regs on the Diagnostics Menu

The default password is 0. Therefore, when you receive a new circuit monitor,

the password for the Setup, Diagnostics, and Reset menu is 0. If you choose

to set up passwords, you can set up a different password for each of the four

menus options listed above.

To set up a password, follow these instructions:

1. From the Main Menu, select Setup.

The password prompt displays.

2. Select 0, the default password.

The Setup menu displays.

SETUP

Date & Time

Display

Communications

Meter

Alarm

I/O

Passwords

3. Select Passwords.

The Password Setup menu displays. Table 3–7 describes the options.

PASSWORDS

Setup 0

Diagnostics 0

Engy/Dmd Reset 0

Min/Max Reset 0

Figure 3–5: Menus that can be

password protected

© 2001 Schneider Electric All Rights Reserved

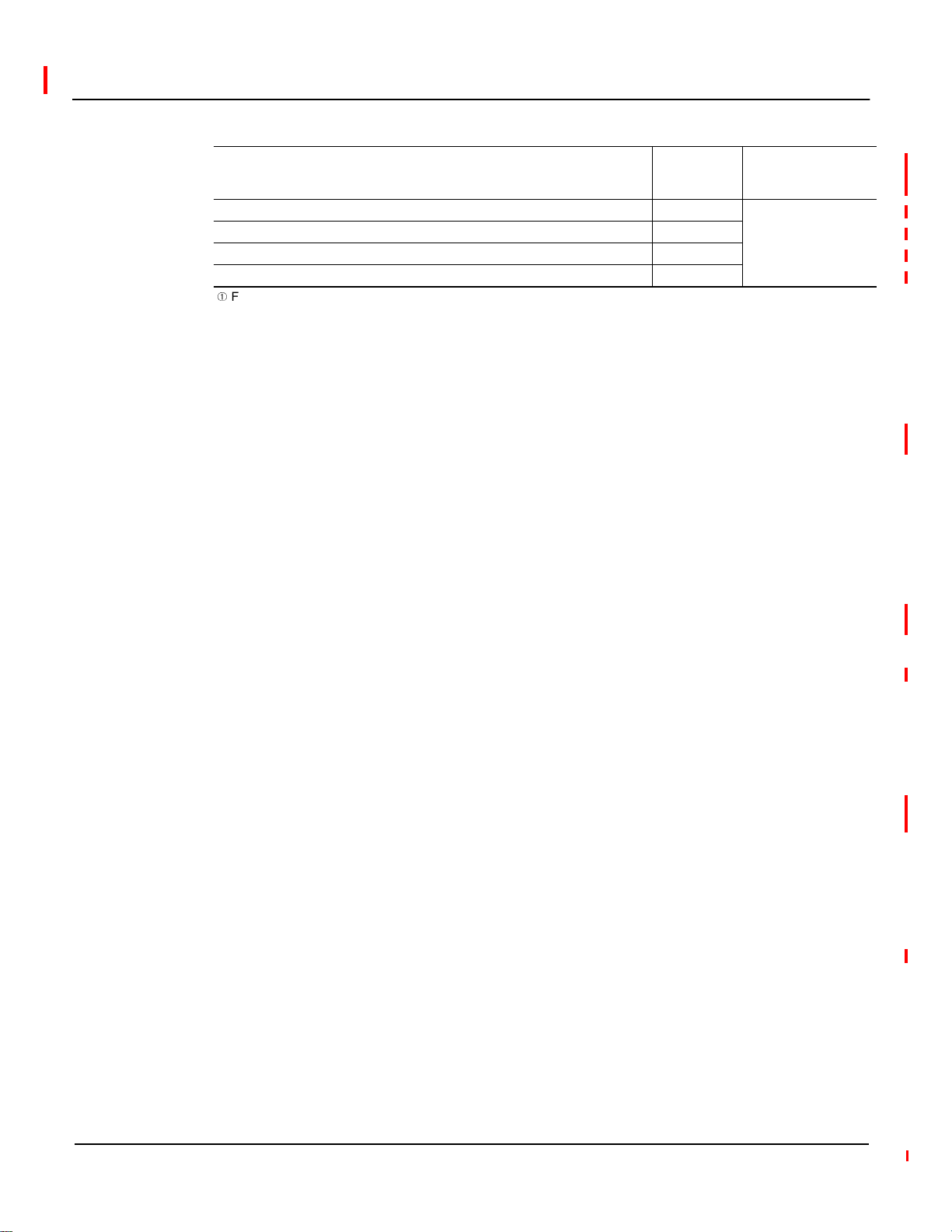

Table 3–7: Options for Password Setup

Option Available Values Description

EnterapasswordintheSetupfieldtocreate

Setup 0–9998

Diagnostics 0–9998

a password for the Setup option on the Main

Menu.

Enter a password in the Diagnostics field to

create a password for the Diagnostics option

on the Main Menu.

27

Page 40

Chapter 3—Operation 63230-300-212

Configuring the Circuit Monitor Using The Setup Menu April 2001

Table 3–7: Options for Password Setup

Enter a passwordin the Engy/DmdReset field

Engy/Dmd

Q

Reset

Min/Max Reset

QThe word “Locked” appears next to a reset option that is inaccessible. If all of the

reset opt ions are locked, “Locked” will appear next to the Resets option in the Main

Menu, and the Resets menu will be inaccessible.

Q

0–9998

0–9998

to create a password for resetting Energy and

Demand. These options appear on the Reset

menu, and they can also be locked. See

“Advanced Meter Setup” on page 34 for

instructions.

Enter a password in the Min/Max Reset field

to create a password for resetting the Min/

Max, which appears on the Reset menu. This

optioncanalsobelocked.See“Advanced

Meter Setup” on page 34 for instructions.

Advanced Setup Features

Creating Custom Quantities to be Displayed

The features discussed in this section are not required for basic circuit

monitor setup, but can be used to customize your circuit monitor to suit your

needs.

Any quantity that is stored in a register in the circuit monitor can be displayed

on the remote display. The circuit monitor has a list of viewable quantities

already defined such as average current, power factor total, and so forth. In

addition to these predefined values, you can define custom quantities that

can be displayed on a custom screen. For example, if your facility uses

different types of utility services such as water, gas, and steam, you may want

to track usage of the three services on oneconvenient screen. To dothis, you

could set up inputs to receive pulses from each utility meter, then display the

scaled register quantity.

For the circuit monitor display, custom quantities can be used to display a

value. Don’t confuse this feature with

quantities are used to add new parameters which

functions.

new

into

SMS custom quantities are defined, for example, when you add a

POWERLOGIC-compatible device to SMS or if you want to import data

SMS from another software package. You can use the SMS custom

SMS custom quantities. SMS custom

SMS can use to perform

quantitiesin custom tables and interactivegraphics diagrams, but you cannot

use circuit monitor display custom quantities in this way.

that you define for display from the circuit monitor are not available to

Custom quantities

SMS

They must be defined separately in SMS.

.

28

To use a custom quantity, perform these tasks:

1. Create the custom quantity as described in this section.

2. Create a custom screen on which the custom quantity can be displayed.

See “Creating Custom Screens” on page 31 in the following section. You

can view the custom screen by selecting from the Main Menu, Meters >

Custom. See “Viewing Custom Screens” on page 34 for more

information.

To create a custom quantity, follow these steps:

1. From the Main Menu, select Setup.

The password prompt displays.

© 2001 Schneider Electric All Rights Reserved

Page 41

63230-300-212 Chapter 3—Operation

April 2 001 Configuring the Circuit Monitor Using The Setup Menu

2. Select your password. The default password is 0.

The Setup menu displays.

SETUP

Date & Time

Display

Communications

Meter

Alarm

I/O

Passwords

3. Select Display.

The Display Setup menu displays.

DISPLAY

Language English

Date MM/DD/YYYY

Time Format AM/PM

VFD Sensitivity 2

Display Timer 5 Min

Custom Quantity

Custom Screen

4. Select Custom Quantity.

The Custom Quantity Setup screen displays.

© 2001 Schneider Electric All Rights Reserved

CUSTOM QUANT SETUP

Custom Quantity 1

Custom Quantity 2

Custom Quantity 3

Custom Quantity 4

Custom Quantity 5

Custom Quantity 6

Custom Quantity 7

Custom Quantity 8

Custom Quantity 9

Custom Quantity 10

5. Select a custom quantity.

29

Page 42

Chapter 3—Operation 63230-300-212