Page 1

ProWORX 32

Programming Software for PLCs

User Guide

372 SPU 780 01EMAN Version 1.0

31003882 00

Page 2

2

372 SPU 780 01EMAN May 2002

Page 3

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

About the Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Chapter 1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Welcome to ProWORX 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing ProWORX 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Logging in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Authorizing ProWORX 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

The ProWORX 32 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ProWORX 32 Client Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tracking Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ProWORX 32 Toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contacting Schneider Electric. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 2 Working with Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Creating a New Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Selecting a Controller Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Converting Ladder Logic Databases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Using the ProWORX Server to Manage ProWORX 32 Projects. . . . . . . . . . . . . 35

Working with a ProWORX 32 Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using Emulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Instructions Supported in Emulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Adding Emulation Instruction Solve Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Documentation Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Using the Documentation Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Importing and Exporting ProWORX 32 Documentation . . . . . . . . . . . . . . . . . . . 55

Protected Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Using Search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Address Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

The Knowledge Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

372 SPU 780 01EMAN May 2002 3

Page 4

Chapter 3 Communications Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Connecting to a Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Communications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configuring Modbus Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Modbus Communications by Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configuring Modbus Plus Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Configuring Ethernet Gateway Communications. . . . . . . . . . . . . . . . . . . . . . . . . 72

Configuring TCP/IP Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Network Explorer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Chapter 4 Configuring a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Controller Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Controller Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

‘General’ Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

‘Ports’ Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

‘Loadables’ Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Loadable Library Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 5 Working with Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Initializing Logic in a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Reading From a Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Writing to a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Transferring Memory Contents to Controller EEPROM. . . . . . . . . . . . . . . . . . . . 94

Transferring the Flash RAM Executive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Transferring Memory Contents to Micro Flash RAM . . . . . . . . . . . . . . . . . . . . . . 96

Transferring Internal Flash or PCMCIA to Controller Flash. . . . . . . . . . . . . . . . . 97

Starting and Stopping Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

PLC Status Viewer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Analyze Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Chapter 6 Configuration Extensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Configuration Extensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Compact Phase II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Data Protect Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Quantum Hot Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

IO Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

IO Scanner Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Peer Cop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Peer Cop Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Profibus Extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Profibus Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

S980 Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

SY/MAX Extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

TCP/IP Extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

4 372 SPU 780 01EMAN May 2002

Page 5

Quantum VME Bus Extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Chapter 7 Using the Logic Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Logic Editor Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Logic Editor Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Hotkey Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Using the Logic Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Working with Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Working with Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Configurable Mnemonics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

ISA Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Diagnostic Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Sweep (Online Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Setting Bookmarks in Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Hardware Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Segment Scheduler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Equation Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Mathematical Equations in Equation Networks. . . . . . . . . . . . . . . . . . . . . . . . . 156

Mathematical Operations in Equation Networks. . . . . . . . . . . . . . . . . . . . . . . . 158

Mathematical Functions in Equation Networks. . . . . . . . . . . . . . . . . . . . . . . . . 161

Chapter 8 Using the Traffic Cop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Traffic Cop Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Working with Drops and Racks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Working with Slots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Online Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

I/O Drawing Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Materials List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Chapter 9 Using the Data Watch Window . . . . . . . . . . . . . . . . . . . . . . . .175

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Data Watch Window Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Trend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Trend - Mode Functionality Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Track Logic Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Track Traffic Cop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Instruction Editor / Terminal Block Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Instruction / Terminal Block Editor Display Scripts . . . . . . . . . . . . . . . . . . . . . . 194

Display Script Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Display Script Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Register Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

372 SPU 780 01EMAN May 2002 5

Page 6

PID Tuner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

DRUM Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Importing and Exporting Data Watch Window Data. . . . . . . . . . . . . . . . . . . . . . 207

Chapter 10 Working with the ASCII Editor . . . . . . . . . . . . . . . . . . . . . . . . 209

ASCII Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Chapter 11 Working with Macros. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Macros. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Using Macros in Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Chapter 12 ProWORX 32 Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

BM85 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

BootP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Compare Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

I/O Drawing Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

The Ping Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

MBP Stat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Chapter 13 ProWORX 32 Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Chapter 14 ProWORX 32 Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Using the ProWORX 32 Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Audit Trail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Chapter 15 Schneider Alliances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Using the Schneider Alliances Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Using the Script Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Using Script Editor Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Appendix A I/O Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

800. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

A120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Compact TSX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Micro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Momentum M1 and INTERBUS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Quantum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Sy/Max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

6 372 SPU 780 01EMAN May 2002

Page 7

Appendix B Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

B.1 General Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Isolating Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Manual Procedure List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Modbus Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Stopcode Error Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

B.2 Status Words for S901 and S908 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

ASCII Message Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Cable A Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Cable B Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Communication Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Controller State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Controller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

EOL (End of Logic) Pointer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Global Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

S911 Hot Standby Status (S908) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Local Drop Communications Errors (S908). . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Machine Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Module Health. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Number of Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Status Word Pointer Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

RIO Time-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Run/Load/Debug Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

S901/J200 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

S908 Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Stopcode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Appendix C Editing .DIF Files with Microsoft Excel. . . . . . . . . . . . . . . . . .303

Editing .DIF files with Microsoft Excel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

372 SPU 780 01EMAN May 2002 7

Page 8

8 372 SPU 780 01EMAN May 2002

Page 9

Safety Information

§

Important Information

NOTICE Read these instructi ons carefully , and look a t the equipm ent to become fa miliar with

the device before trying to install, operate, or maintain it. The following special

messages may appear th roug hout thi s docu menta tion or on the equi pment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symb ol to a Danger or Warning safety labe l indicates

that an electrical hazard exists, which will result in personal injury if the

instructions are not foll owed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will

result in death, serious in ju ry , or equipment damage.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result

in death, serious injury , or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result

in injury or equipment d am age.

372 SPU 780 01EMAN May 2002 9

Page 10

Safety Information

PLEASE NOTE Electrical equipment should be serviced only by qualified personnel. No responsi-

bility is assumed by Schneider El ect ric for an y cons equen ces ari sing o ut of the u se

of this material. Thi s document is not intende d as an instruction manual for untrained

persons.

© 2002 Schneider Electric All Rights Reserved

10

372 SPU 780 01EMAN May 2002

Page 11

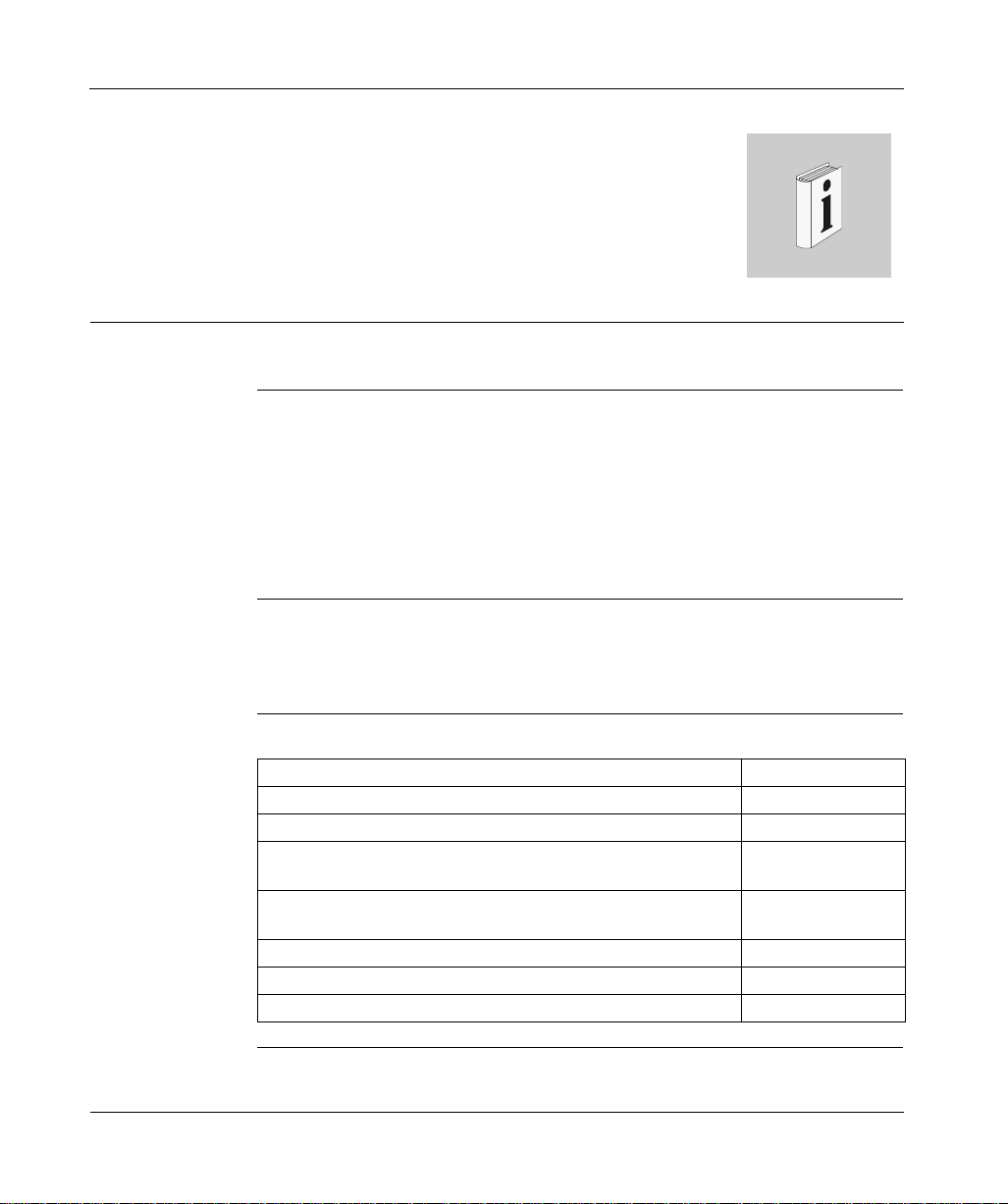

About the Book

At a Glance

Document Scope This manual describes how to install, c onf igu r e a nd us e Pro WO RX 32 and all of its

components.

To find out about any changes to the manual after this version was published,

consult our web site at public.modicon.com.

Terms and Abbreviations

Numbers are written according to international practice as well as according to

approved SI (System International d’Unites) presentation; each thousand is

separated by a space, along with use of the decimal point, e.g., 12 345.67

Validity Note This document applies to the installation and use of ProWORX 32 in Windows 98,

Windows Me, Windows XP, Windows NT 4.0, and Windows 2000 environments and

ProWORX Server in Windows XP, Windows NT 4.0, and Windows 2000

environments.

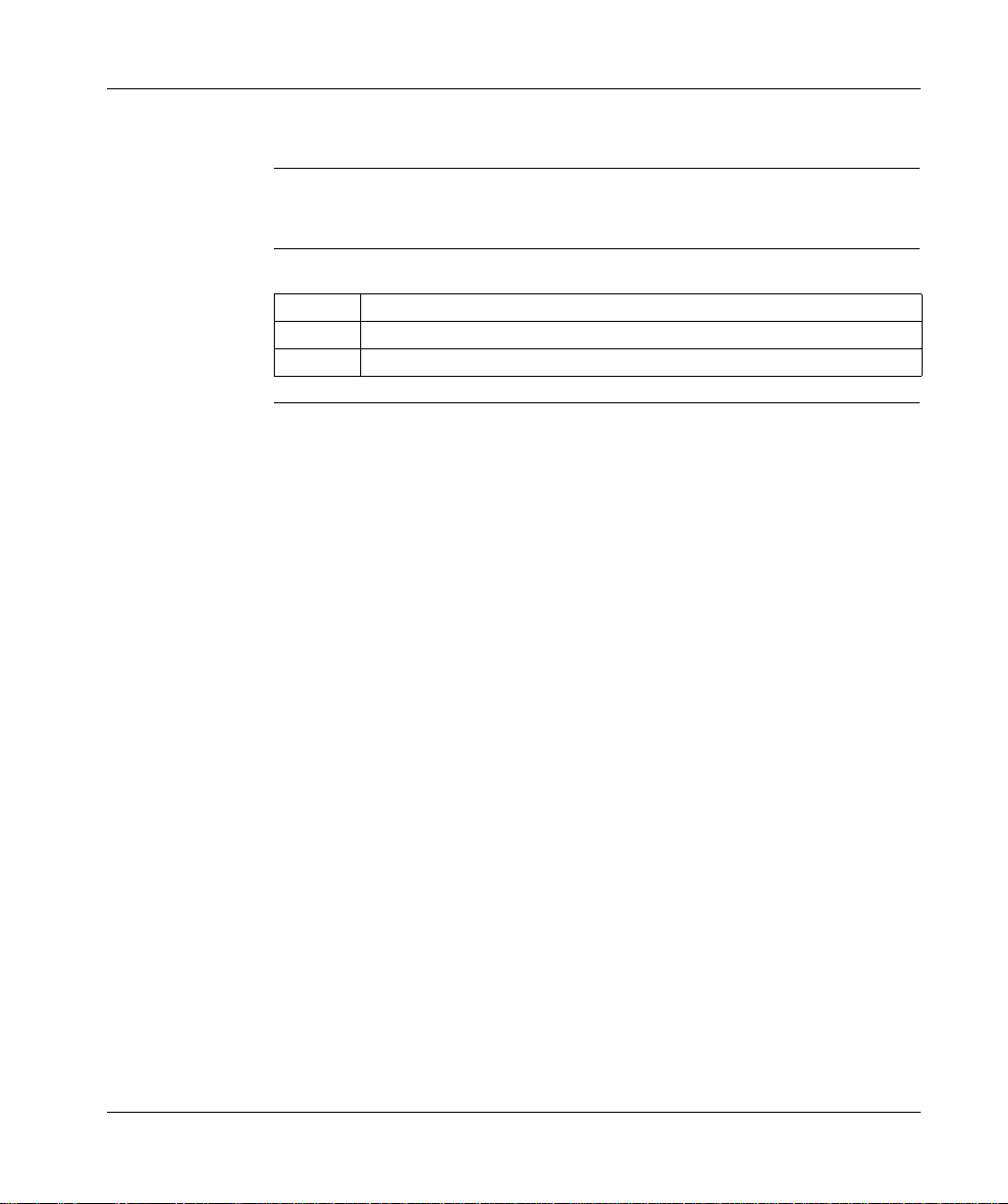

Related

Documents

Title of Documentation Reference Number

Modicon Ladder Logic Block Library 840 USE 101 00

Modicon Modbus Plus PCI-85 Interface Adapter 890 USE 162 00

Modicon Quantum Hot Standby System Planning and Installation

Guide

Modicon TSX Quantum Automation Series Hardware Reference

Guide

TSX Momentum I/O Base User Guide 870 USE 002 00

Modicon A120 Series I/O Modules User Guide 890 USE 109 00

BM85 Bridge Multiplexer User’s Guide 890 USE 103 00

840 USE 106 00

840 USE 100 00

372 SPU 780 01EMAN May 2002 11

Page 12

About the Book

Product Related

Warnings

Schneider Electric assumes no res po ns ibi lit y for an y errors that may appear in this

document. If you have any suggestions for improvements or amendments or have

found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electron ic

or mechanical, including photocopying, without the express written permission of

Schneider Electric. All rights reserved. Copyright 2002.

User Comments We welcome your comments about this document. You can reach us by e-mail at

TECHCOMM@modicon.com

12

372 SPU 780 01EMAN May 2002

Page 13

Getting Started

Welcome to ProWORX 32

About this

Manual

Getting Started

with

ProWORX 32

What’s in this

Chapter?

This manual is a guide for operating ProWORX 32. It does not contain information

about specific controllers, I/O cards, or ladder logic instructions. For further

hardware and ladder logic info rma tio n, go to the ProWO R X 32 on -li ne he lp syste m.

This chapter guides you through starting out with ProWORX 32.

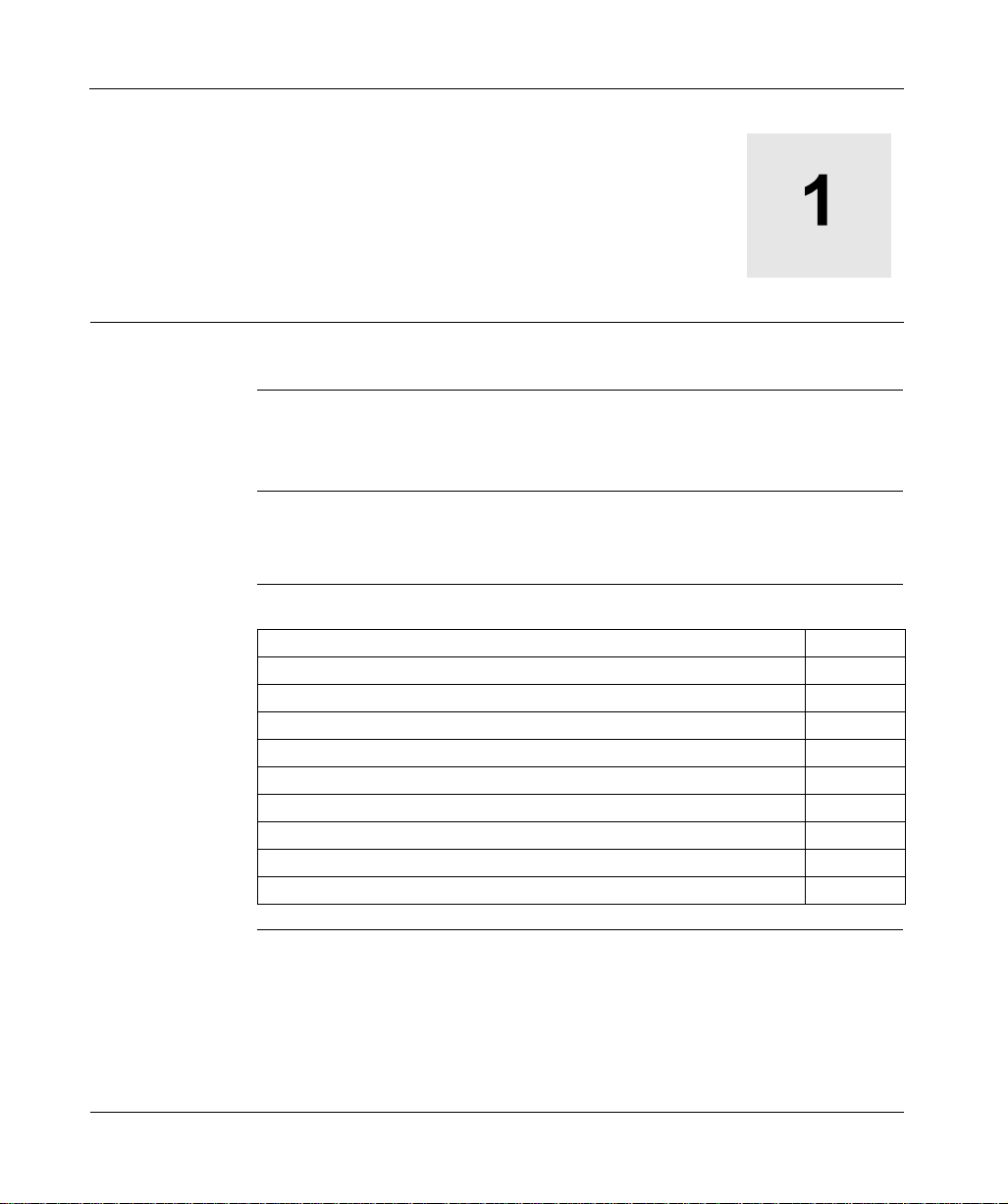

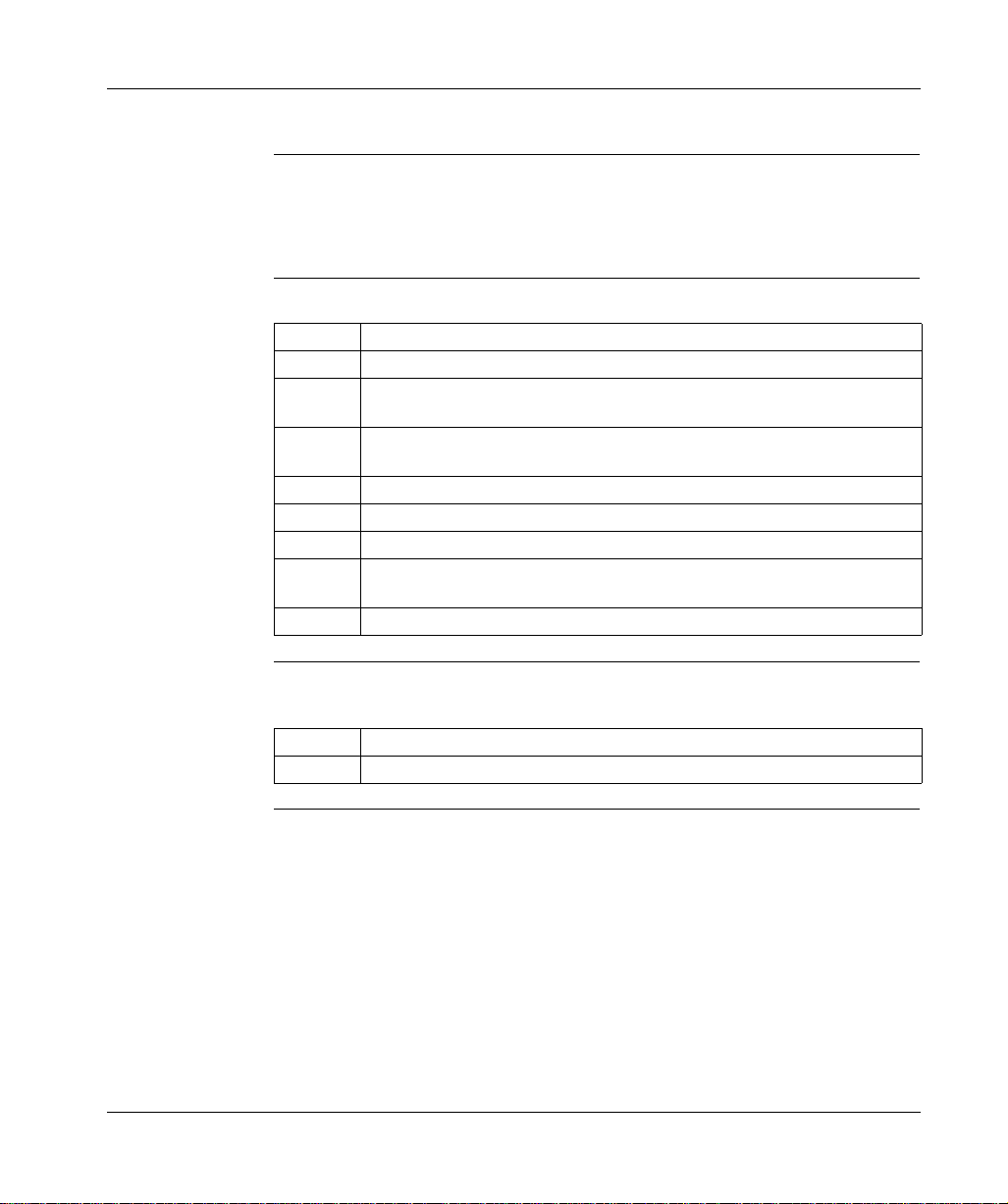

This chapter contains the following topics:

Topic Page

System Requirements 14

Installing ProWORX 32 15

Logging In 16

Authorizing ProWORX 32 17

The ProWORX 32 Environment 19

ProWORX 32 Client Security 20

Tracking Help 22

ProWORX 32 Toolbar 23

Contacting Schneider Electric 26

372 SPU 780 01EMAN May 2002 13

Page 14

Getting Started

System Requirements

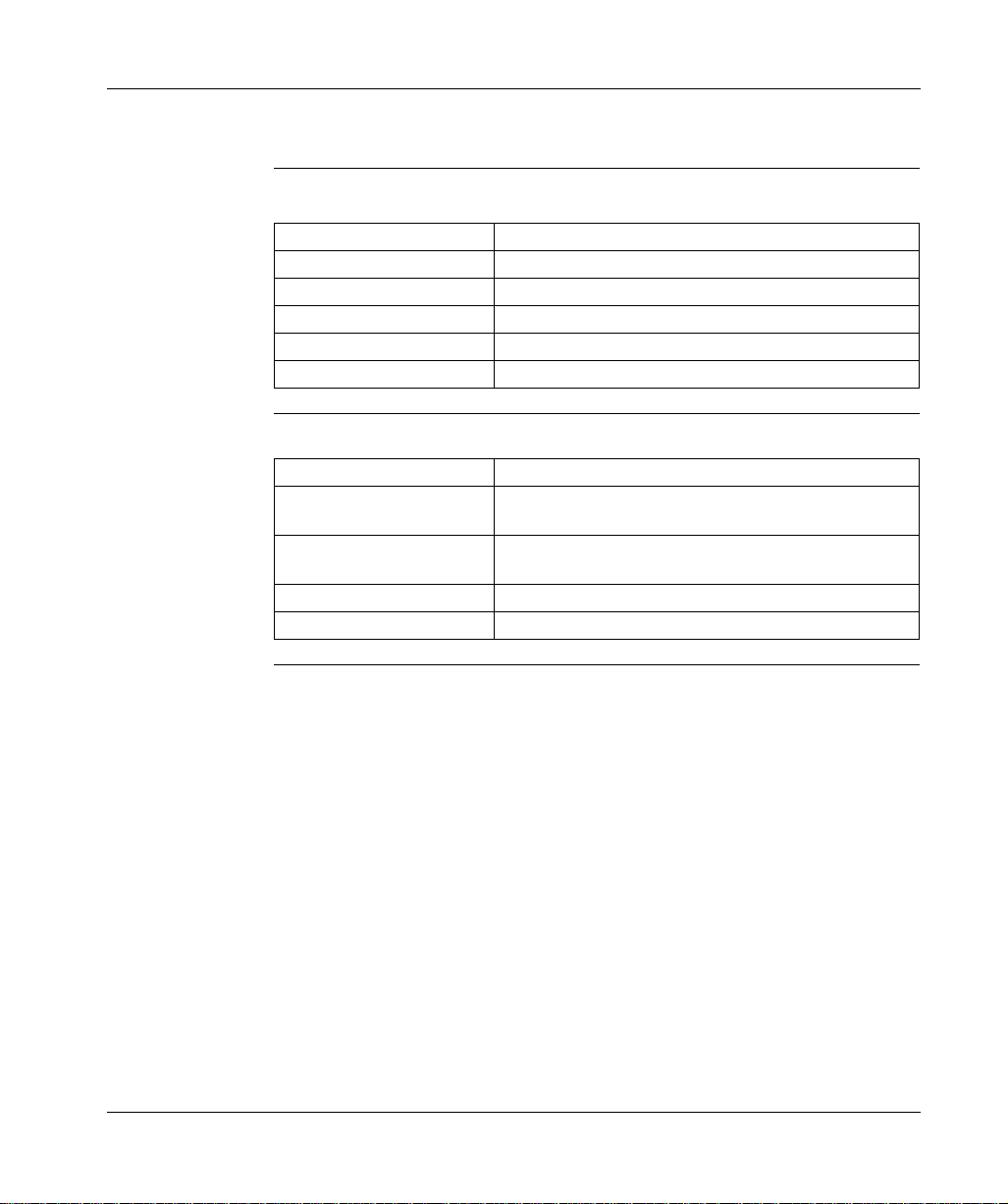

Hardware

Requirements

Software

Requirements

Hardware:

Hardware Requirement

Processor P200

Memory 128 MB

Hard Disk Space (Available) 200 MB

Installation Media Type CD

Display 256 color VGA or higher

Software:

Software Requirement

ProWORX 32 Client Operating Systems

ProWORX Server - Operating

Systems

Microsoft Internet Explorer Version 5.0 or higher.

Microsoft MDAC Version 2.5 or higher.

Windows 98, Windows NT (Version 4.0, SP5 or higher),

Windows 2000, Window Me, and Windows XP.

Windows NT (Version 4.0, SP5 or higher), Windows 2000,

and Windows XP.

14

372 SPU 780 01EMAN May 2002

Page 15

Installing ProWORX 32

Getting Started

Installing

ProWORX 32

Modifying or

Repairing the

ProWORX 32

Installation

Uninstalling

(Removing)

ProWORX 32

ProWORX 32 requires the installation of MDac version 2.5 or great er and Internet

Explorer 5.0 or greater. Install the MDac software from the ProWORX 32 installation

CD, and ensure that you have a compatible version of Internet Explorer prior to

installing ProWORX 32. Then, to install ProWORX 32:

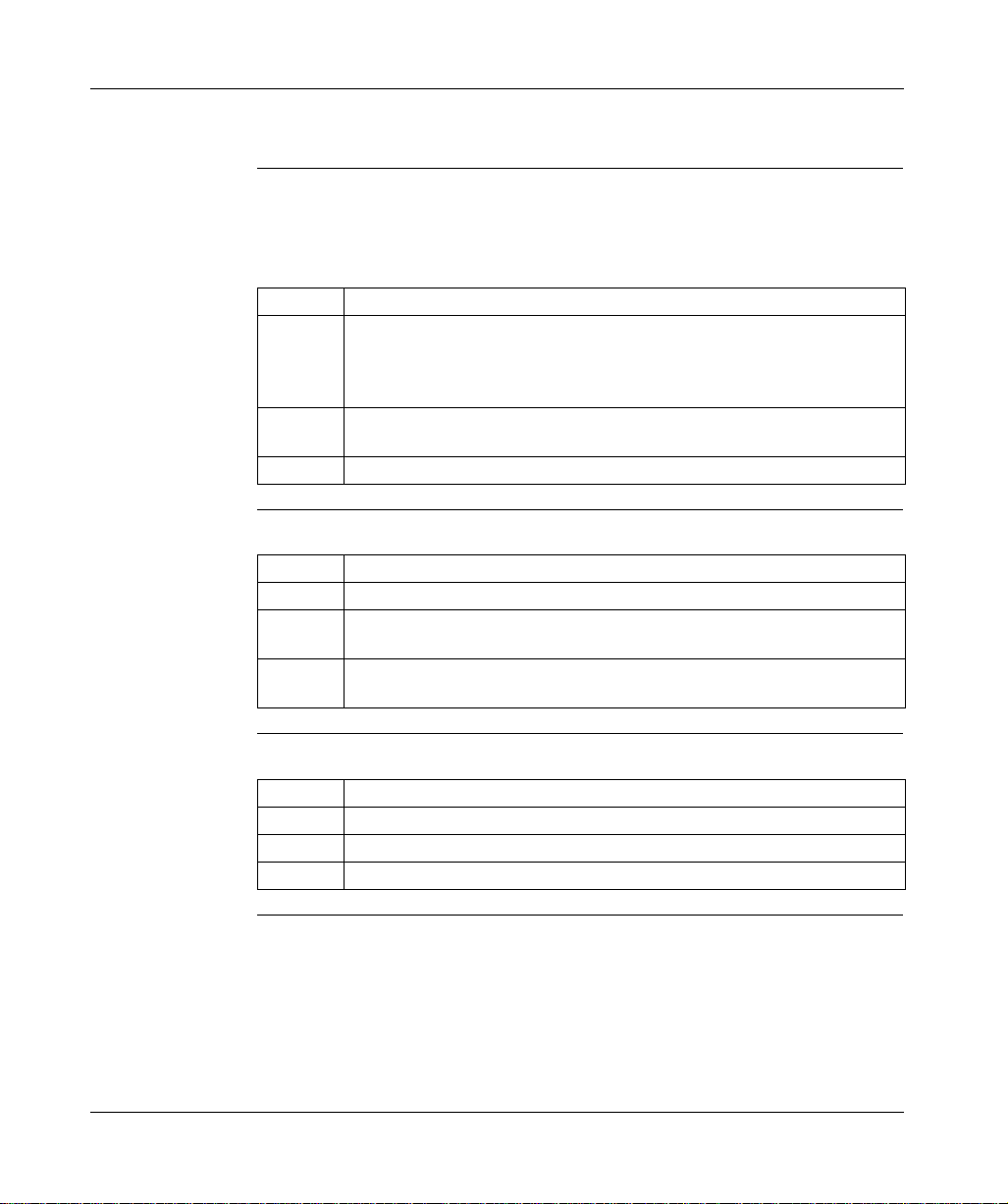

Step Action

1 Insert the ProWORX 32 CD into your CD-ROM drive. The ProWORX 32

installation screen should automatically load. If the ProWORX installation

program does not automatically load, you can open the installation in Windows

Explorer at CD Rom Drive

2 Select the Language you want to install ProWORX 32 in. (English, French,

German, Spanish.)

3 Follow the on-screen instructions to complete the installation of ProWORX 32.

→ Setup.exe.

If you have already installed ProWORX 32:

Step Action

1 Insert the ProWORX 32 CD into your CD-ROM drive.

2 Select Modify to add new components, or remove already installed components.

Click Next and follow the on-screen instructions.

3 Select Repair to reinstall all components installed by the previous setup. Click

Next and follow the on-screen instructions.

If you have already installed ProWORX 32:

Step Action

1 Insert the ProWORX 32 CD into your CD-ROM drive.

2 Select Remove to uninstall all installed components.

3 Click Next and follow the on-screen instructions.

372 SPU 780 01EMAN May 2002 15

Page 16

Getting Started

Logging In

The ProWORX 32

Login Screen

Logging In to the

ProWORX 32

Server

Logging Out of

the ProWORX 32

Server

When opening ProWORX 32 you are pro mpted with the ProWORX 32 Login sc reen.

If you are using project s that reside on a server or you w ant to communicate through

the server, enter the login informa tion and click Login. If you are us ing onl y projec ts

that reside on the client, click Bypass.

To access th e login screen from within ProWORX 32:

Step Action

1 In the ProWORX 32 menu, select File

2 Enter the user name and password that your system administrator has given you

in the Name and Password fields.

3 Select your method of communicating with the server from TCP/IP and Modbus

Plus.

4 Enter the address of the server in the Server Address field.

5 Enter the timeout (seconds) in the Timeout field.

6 If you have selected TCP/IP, enter the port number in the Port Number field.

7 If you have selected Modbus Plus, enter the adapter number in the Adapter

Number field.

8 Click Login.

→ Login.

Closing ProWORX 32 c li ent lo gs y ou out of the server or to l og ou t w hile remaining

in ProWORX 32:

Step Action

1 From the ProWORX 32 menu, select File

→ Logout.

16

372 SPU 780 01EMAN May 2002

Page 17

Authorizing ProWORX 32

Getting Started

Opening the

Authorization

Program

Using the

Authorization

Wizard

From the Windows Start menu:

Step Action

1 Select Programs

→ ProWORX 32 → Authorization.

After opening the authorization wizard:

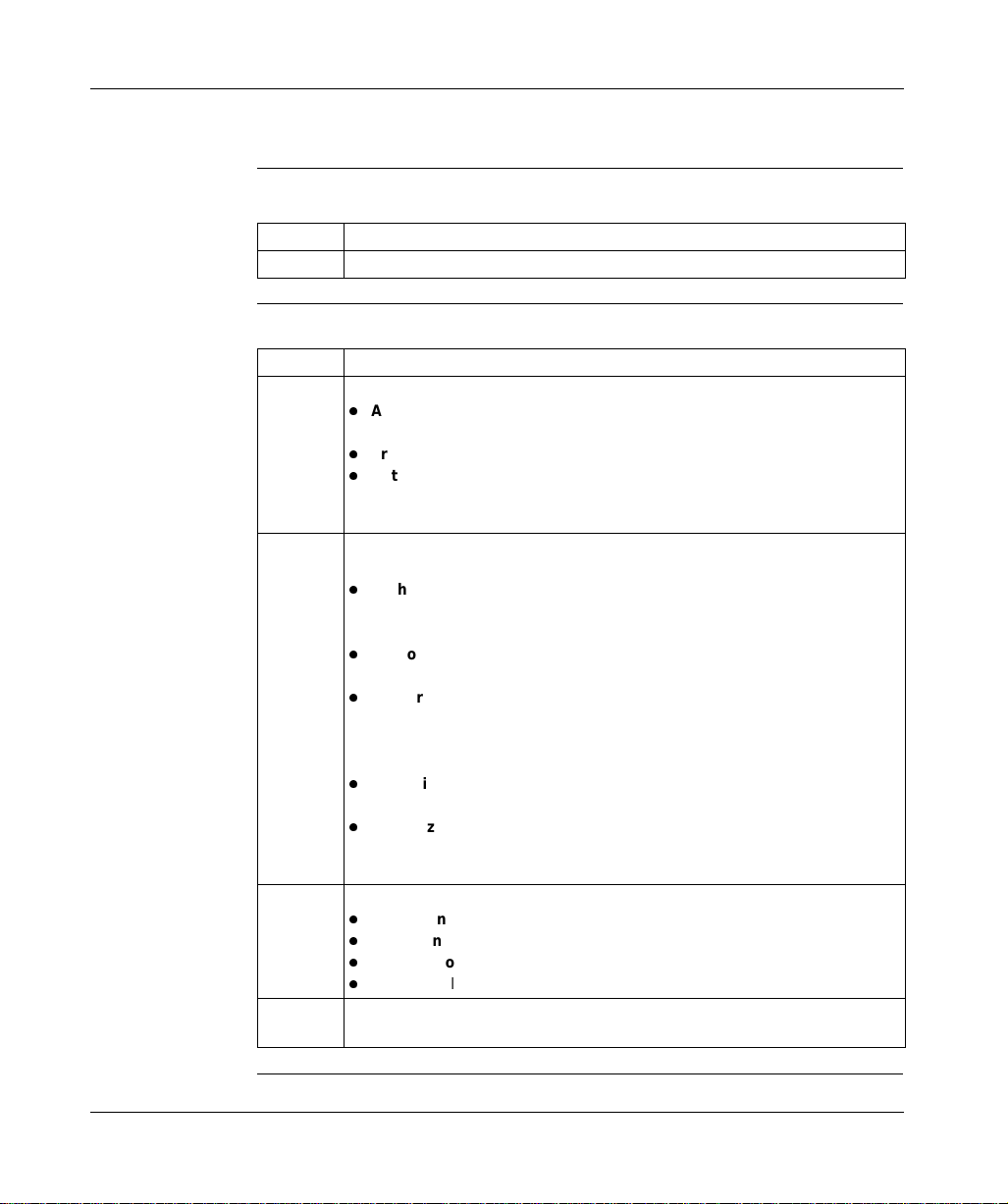

Step Action

1 Select which task you would like to perform:

l

Authorize this PC: Sets up the PC you are currently using to run ProWORX

32.

l

Transfer Authorization: Transfers authorization from one PC to another.

l

Enter received code: If already registered, you are taken directly to the

Entering Authorization Code screen.

When you have made a selection, click Next.

2 Select which method you would prefer to authorize ProWORX 32 by, and click

Next:

l

Authorize by Phone: A message box is displayed containing a customer

support phone number and the customer support hours of operation. Click

OK to return to the authorization application.

l

Authorize by Fax: A fax page is printed containing the information you have

entered and a number to send the fax to.

l

Authorize by Multi-User License Diskette: This option is used strictly for

uncopyprotected versions in which a diskette has been provided by

Schneider Electric. The contents of the diskette will be transferred onto your

machine.

l

Authorize by Email: An email is sent to customer support containing the

information you have entered.

l

Authorize by W e b: You will be directed to a web page at the Schneider

Electric web site where the information that you have entered will be

displayed and an authorization number will be generated for you.

3 Select which product you want to authorize and click Next:

l

Online Only Client: Access to online only portions of ProWORX 32.

l

Lite Client: Access to Momentum, Compact, and Micro controllers only.

l

Full Development Client: Full access to all features of ProWORX 32.

l

Server: Full access to the ProWORX Server.

4 Enter all of your personal information in the User Information screen and click

Next. If you would like to view our privacy policy, click Privacy Policy.

372 SPU 780 01EMAN May 2002 17

Page 18

Getting Started

Moving

Authorization

Entering the

Authorization

Number

After selecting Transfer Authorization in Step One:

Step Action

1 Insert a diskette into your PC diskette drive.

2 Select which transaction you want to complete and click Next:

l

Transfer authorization from computer to diskette.

l

Transfer authorization from diskette to computer.

After receiving an authorization number:

Step Action

1A Code Entry Number and a Computer ID are created automatically

2 Enter the Authorization Number provided to you by customer support and click

Next.

3 To complete your ProWORX 32 authorization, click Finish.

18

372 SPU 780 01EMAN May 2002

Page 19

Getting Started

The ProWORX 32 Environment

Overview ProWORX 32 is organized i n s uch a w ay tha t the info rma tion you need at any time

is readily accessible through the ProWORX 32 main interface.

Setting

ProWORX 32

Properties

From the My Computer right-click menu in the Navigation panel:

Step Action

1 Select Properties.

2 Select the Environment tab.

3 Set the following ProWORX 32 Environment parameters:

4 Auto Monitor/Logout: When selected with Logout, the Online Network Editor

closes after the specified amount of inactive time. When selected with Monitor,

the Online Network Editor closes after the specified amount of inactive time and

Monitor mode is activated.

5 Prompt For Read When Exiting Online: Displays a prompt to perform a read

after switching out of online mode.

6 Compare To Project On Attach: Displays a prompt to perform a compare when

switching to online mode.

7 Enable Audit Trails : Audit trails and the log book are viewable.

8 Automatically Update Used Tables Online: When going online, the used

tables are automatically updated.

9 Enable Scrolling Nav igation Panel: When this option is selected, the

navigation panel shrinks showing only the panel’s border. To see the navigation

panel, hover your mouse over the border and the navigation panel expands.

10 Instruction Toolbar: See ProWORX 32 Toolbar, p. 23.

372 SPU 780 01EMAN May 2002 19

Page 20

Getting Started

ProWORX 32 Client Security

Overview Security allows an administrator to disable features of ProWORX 32.

Setting Security

for a Client

From the My Computer right-click menu in the Navigation panel:

Step Action

1 Select Security Settings to open the Client Security dialog.

2 To set and confirm the administrative password, enter the password into the

Password and Confirm Password boxes.

3 To set the rights that users have while running ProWORX 32 on this specific PC,

select rights from the Enabled Functionality group of rights. See User Rights

below for more information.

4 Click OK to confirm changes. Click Close to exit.

20

372 SPU 780 01EMAN May 2002

Page 21

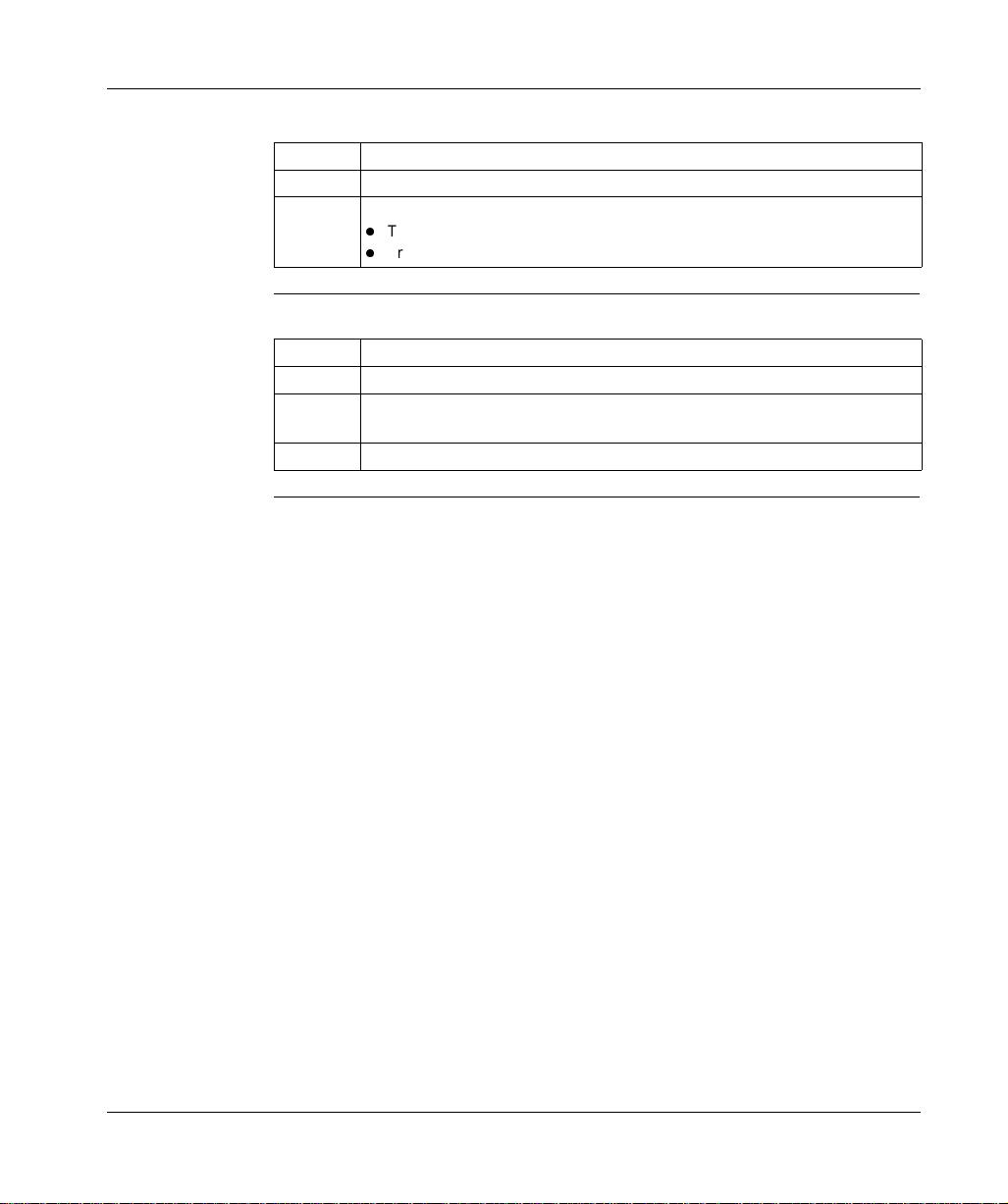

User Rights User rights descriptions:

User Rights Descriptions

Controller Configuration The ability to change the controller configuration, or change

Traffic Cop The ability to edit in the traffic cop.

Communications The ability to change the communications setup including the

Logic The ability to edit logic.

Forcing The ability to force contacts and coils.

Insert The ability to insert cells, rows, columns, and networks.

Delete The ability to delete cells, rows, columns, and networks.

Sweep The ability to enter sweep mode.

Data Editors The ability to enter any of the data editors, If deselected, the

Extended Memory The ability to edit extended memory registers.

Protected Registers The ability to set ranges of 4xxxx addresses that are

Configuration Extensions The ability to edit the configuration extensions.

ASCII Messages The ability to edit the ASCII messages.

Search The ability to use the search feature.

Read The ability to read from the controller.

Write The ability to write to the controller.

Start/Stop The ability to start or stop the controller.

Clear Audit Trails The ability to remove all audit trail and logbook entries.

Getting Started

controller type.

controller’s address.

user is unable to change register data.

uneditable. See Setting Protected Registers for more

information.

372 SPU 780 01EMAN May 2002 21

Page 22

Getting Started

Tracking Help

Overview Tracking help is a brief desc ription or overv iew of the editor, ins tructions, or I/O card

that is curr ently selected in ProWORX 32.

Using Tracking

Help

From the ProWORX 32 menu:

Step Action

1 Select View

2 To see more information about the current tracking help topic, press F1.

→ Tracking Help to open the tracking help window.

22

372 SPU 780 01EMAN May 2002

Page 23

Getting Started

ProWORX 32 Toolbar

Overview The ProWORX 32 toolbar holds all of the icon buttons that can be used to access

features, utilities, and tools needed to properly use ProWORX 32s development

capabilities.

Using the

Toolbar

Customizing the

Instruction

Toolbar

Handle

ProWORX 32 Toolbar

From the ProWORX 32 toolbar right-click menu:

Step Action

1 To add a toolbar, select a toolbar to add from the list. A toolbar that is displayed

is denoted by a check .

2 To remove a toolbar, select a toolbar to remove from the list.

3 To move a selected toolbar within the ProWORX 32 toolbar area, select the

toolbars handle, and drag and drop the toolbar to its desired location.

4 To customize the toolbars, click Customize. To view help concerning toolbar

customizing please refer the Windows help file, Windows Start Menu

In the project navigation panel:

Step Action

1 From the project right-click menu, select Properties.

2 Select the Environment tab.

3 Scroll to the number of the button (1-14) you would like to change in the Button

Number field. eg. 1 = the leftmost button, 14 = the rightmost button.

4 Enter the name of the instruction to be placed on the toolbar in the Button Text

field.

→ Help.

372 SPU 780 01EMAN May 2002 23

Page 24

Getting Started

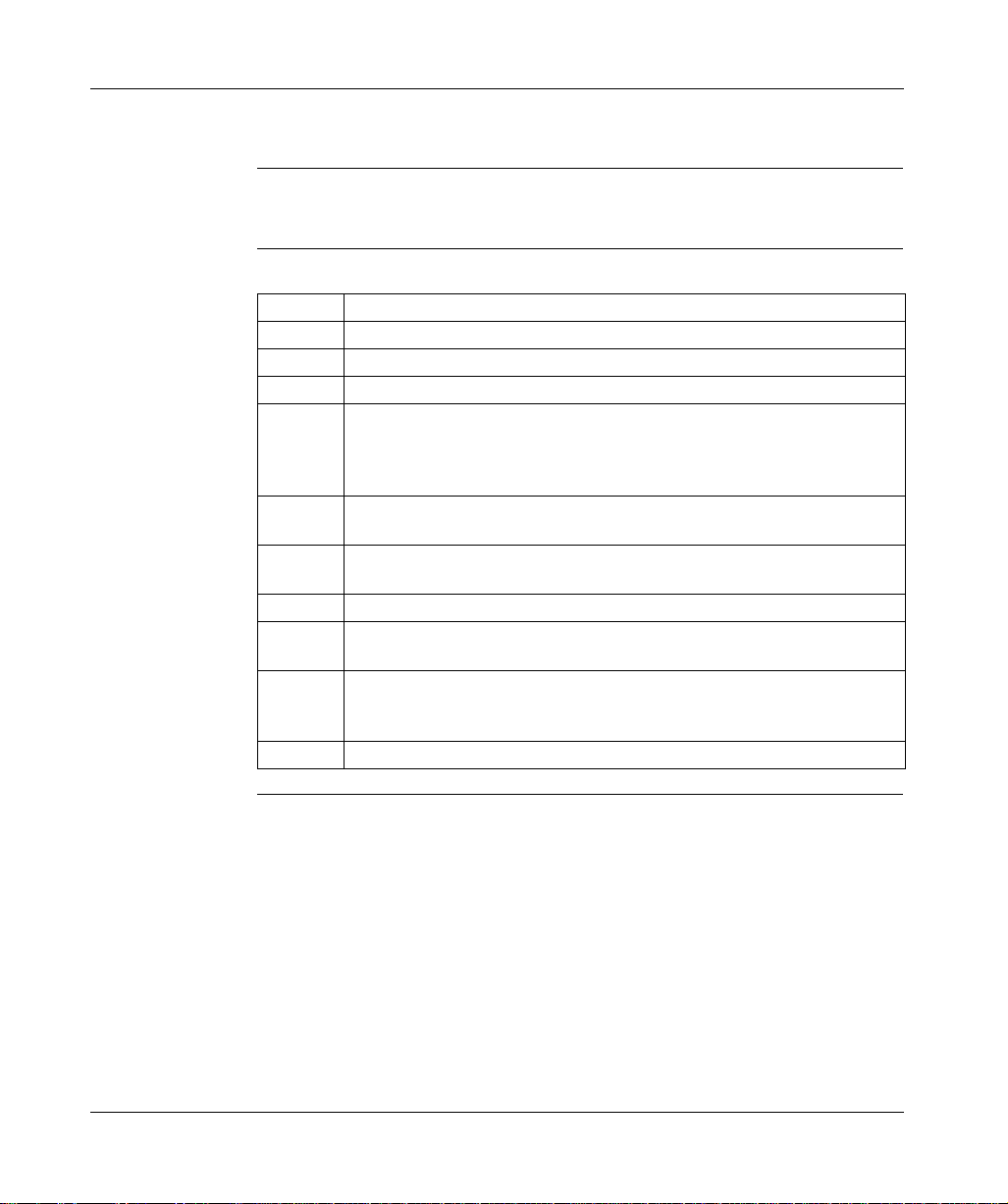

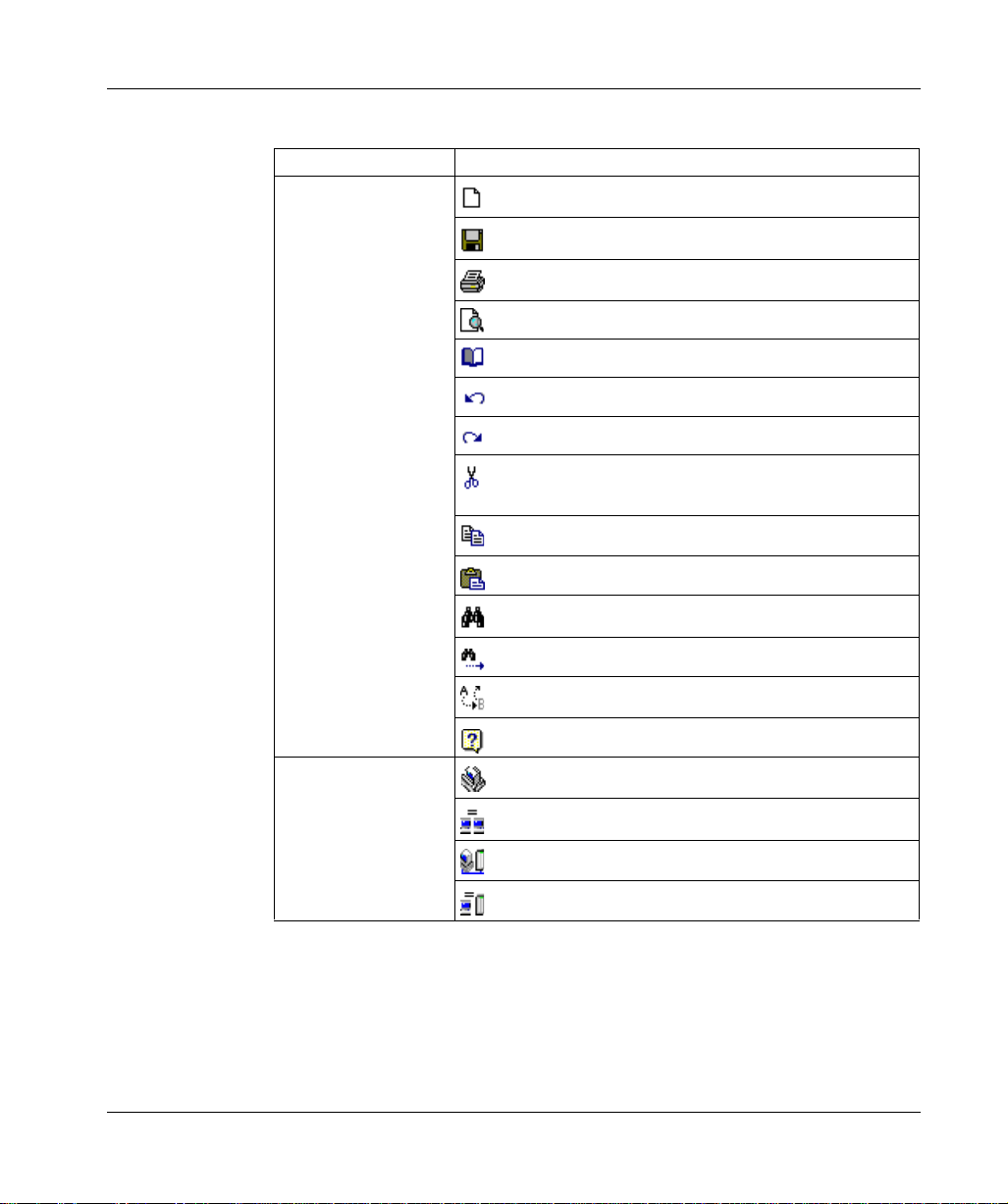

Toolbar Listing Default toolbars and items:

Toolbar Item

Standard Toolbar

(CTRL+X)

- Create a New Project

- Save the Active Project

- Print the Active Project

- Open Print Preview

- Open Report Setup

- Undo the most recent action (CTRL+Z)

- Repeats the most recent action

- Cut the current selection and copy to the system clipboard

- Copy the current selection to the system clipboard (CTRL+C)

- Paste data from system clipboard to selected area (CTRL+V)

- Open the Search window (CTRL+F)

24

Control Toolbar. See

Working with a

ProWORX 32 Project,

p. 36

- Repeat the last Search operation (SHIFT+F4)

- Find and Replace (CTRL+H)

- Open Help (F1)

- Take project offline

- Take project to emulation

- Take project online

- Take project to combined mode

372 SPU 780 01EMAN May 2002

Page 25

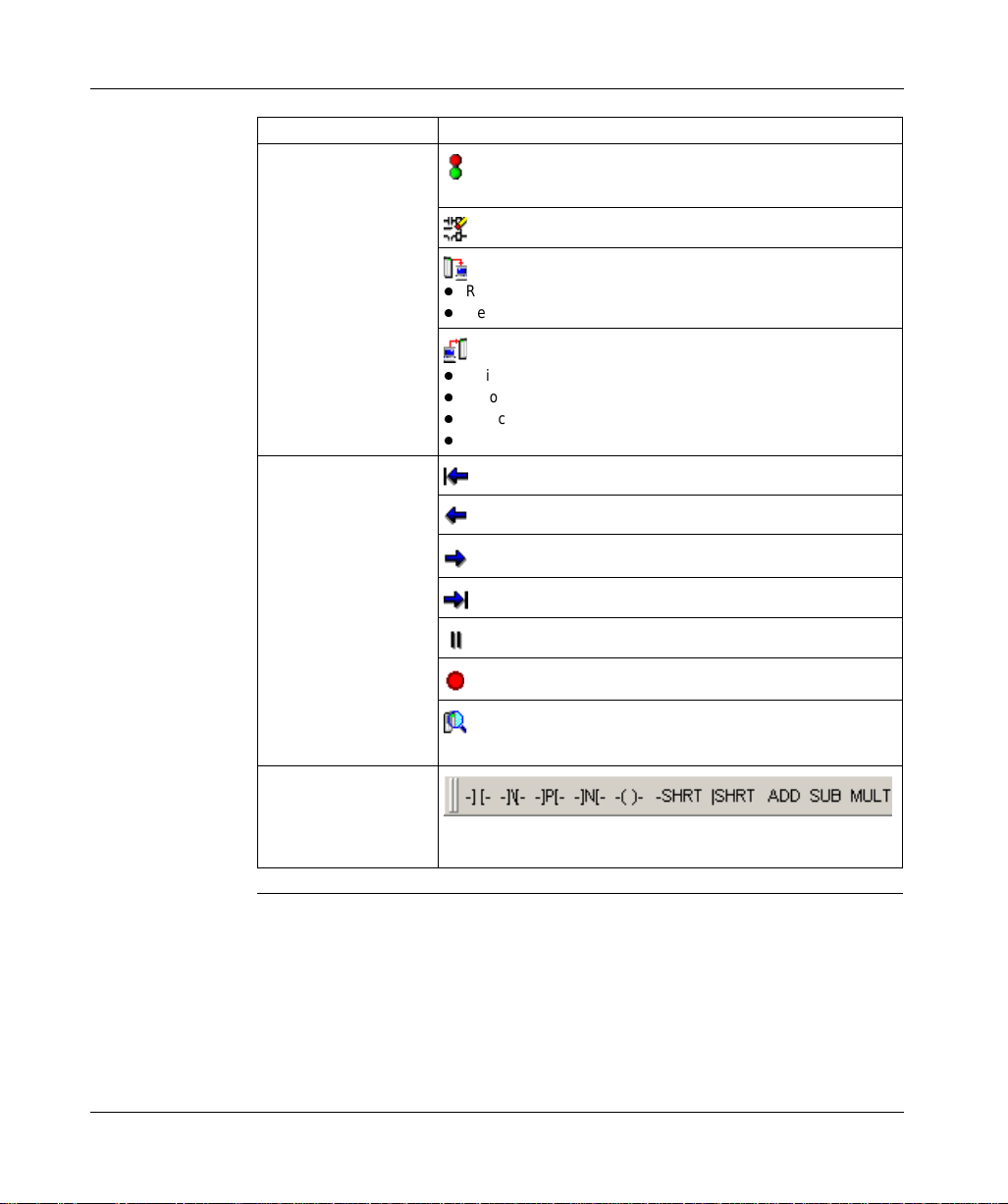

Toolbar Item

Online Control Toolbar

p. 98.

l

l

l

l

l

l

DWW Log Toolbar

Getting Started

- Start/Stop controller. See Starting and Stopping Controllers,

- Initialize logic. See Initializing Logic in a Controller, p. 90.

- Read from controller. See Reading From a Controller, p. 91.

Read

Read extended memory

- Write to controller. See Writing to a Controller, p. 92.

Write logic

Relocate logic and data

Relocate logic only

Write extended memory

- First record

- Previous record

- Next Record

- Last record

- Pause/Resume

- Record

- Toggle between logging real-time data from a controller and

logging stored

Instruction Toolbar

- A user-defined set of instructions. Clicking an instruction adds it

to the logic editor at the cursor.

372 SPU 780 01EMAN May 2002 25

Page 26

Getting Started

Contacting Schneider Electric

Contact

Information

Support

Guidelines

Customer support is available to registered Schneider Electric users.

If you have a question about ProWORX 32 and can’t find the answer in the

ProWORX 32 Help system or the User ’s Guid e, contact our Custom er Servic e staff

for assistance. You can reach Schneider’s Customer Support department by

Internet, phone, fax, or mail:

Schneider Electric

One High Street

North Andover, MA 01845

Internet: http://public.modicon.com/

E-mail: customercentral@schneiderautomation.com

Support Hotline: (888) 266-8705

Telephone: (978) 794-0800

Fax: (978) 975-9301

To help us assist you quickly, we sugge st yo u have the fol lowing inf ormati on read y:

l

The version and serial number of your copy of ProWORX 32. To find this

information, select About on the Help menu.

l

What you were doing when the p roblem occu rred, whether you can repe at it, and

any error messages you recei ve d.

l

Your version of Windows. To find this information in Windows ME, 98, 95, 2000

or NT 4.x: click Start, then Settings. Select Control Panel. When the Control

Panel window opens, double-click System. When the System window opens,

select the General tab. Your version of Windows is listed under the heading

System.

l

Information about your computer, inclu ding its processor type, memory, hard

drive size, video card type, and I/O boards.

26

372 SPU 780 01EMAN May 2002

Page 27

Working with Projects

At a Glance

Overview ProWORX 32 holds information about each of your controllers in a project. The

project stores:

l

The controller’s configuratio n

l

Ladder logic

l

Descriptors of the controller and ladder logic

l

Project properties

l

Data trends

l

Compare results

372 SPU 780 01EMAN May 2002 27

Page 28

Working with Projects

What’s in this

Chapter?

This chapter contains the following topics:

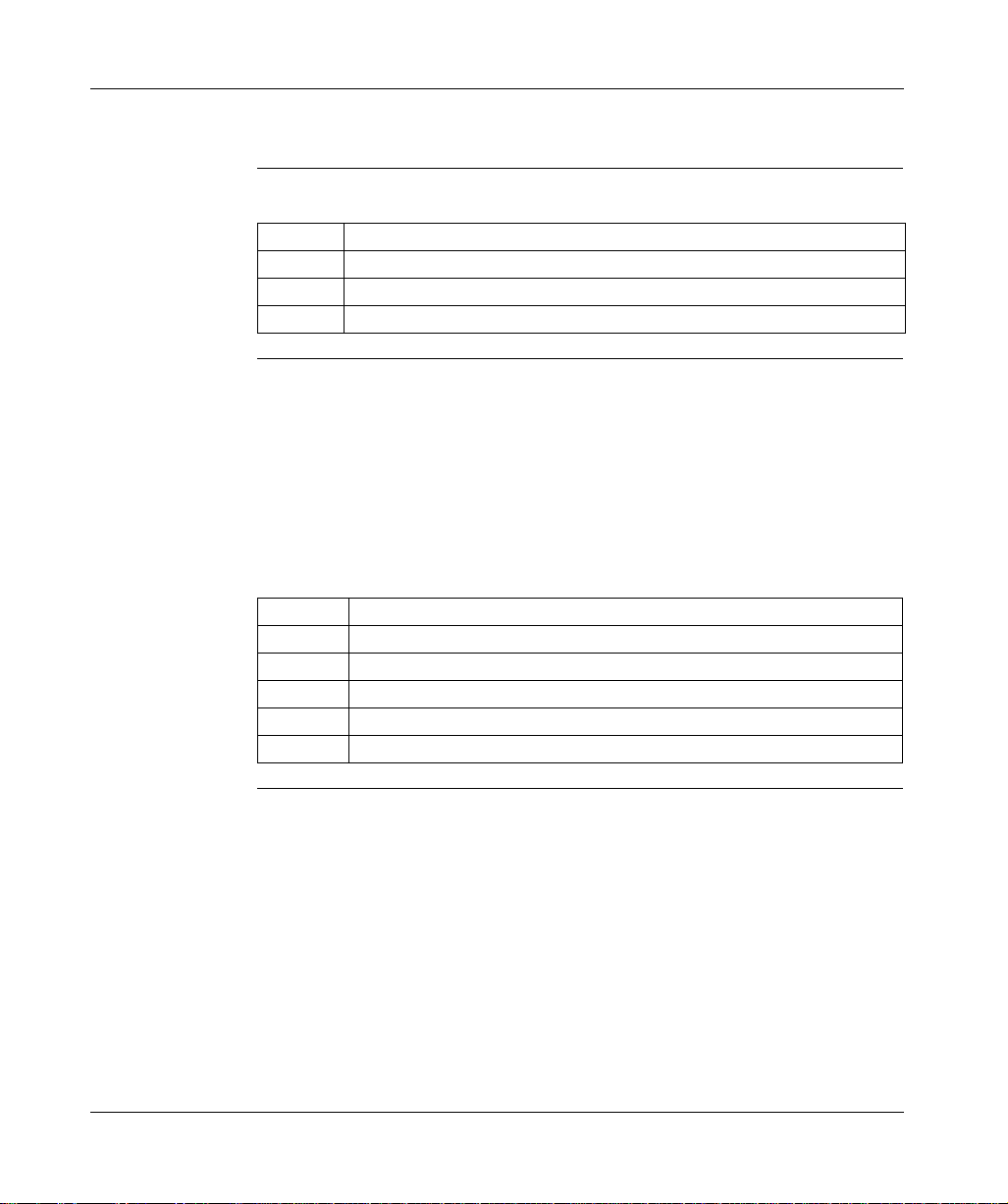

Topic Page

Creating a New Project 29

Selecting a Controller Type 31

Converting Ladder Logic Databases 34

Using the ProWORX Server to Manage ProWORX 32 Projects 35

Working with a ProWORX 32 Project 36

Using Emulation Mode 39

Instructions Supported in Emulation Mode 45

Adding Emulation Instruction Solve Support 46

Documentation Editor 51

Using the Documentation Editor 53

Importing and Exporting ProWORX 32 Documentation 55

Protected Registers 58

Using Search 59

Address Used 60

The Knowledge Base 62

28

372 SPU 780 01EMAN May 2002

Page 29

Creating a New Project

Working with Projects

Creating a New

Project

From the ProWORX 32 tool bar:

Step Action

1 Click File

2 Enter a project name in the New Project Name box.

3 Click OK. The New Project Wizard appears.

→ New.

Overview The Project Configuration Wizard steps you through creating new default projects

and modify existing projects in ProWORX 32. The configuration wizard guides you

through a series of easy to understand steps to set up a project. Each step

configures an important area of the project.

Each screen in the wizard has a caption stating which step you are currently

completing. Also, each screen has a diagram and description detailing what the

current step involves.

The standard wizard buttons are:

Button Function

Help Displays context-sensitive help pertaining to the current step.

Cancel Exits the wizard and no new project is created or no changes are saved.

Back Returns the wizard to the previous step.

Next Advances the wizard to the next step.

Finish Completes the wizard and creates a new project or saves the changes.

372 SPU 780 01EMAN May 2002 29

Page 30

Working with Projects

Step 1 - Select

Creation Method

Select a path to create a new project:

Path Description

Online to Controller This option sets up a project enough to go online to a controller.

The first step configures the parameters used to communicate

with the desired controller. This step encapsulates

communications setup; use of this step is identical to the Project

communications setup dialog. Click Next to display the Finish

step. Click Finish to go online to the desired controller.

Select Controller Type This step allows you to set up the controller type. For more

information, see Selecting a Controller Type, p. 31.

Base on Existing Project This option creates a project based on an existing project. First,

select an existing Project from the list of projects on the local

computer. ProWORX 32 creates a copy of the project and uses

it as the base for the new project. ProWORX 32 initializes the

logic and clears the traffic cop of the new project. ProWORX 32

then displays a communications setup step to configure

communications to the desired controller. On the finish step

click Finish to complete the new project creation.

Read from Controller This option creates a project based on a read of the program

from an existing controller. ProWORX 32 displays a

communications setup step to configure communications to the

desired controller. On the Finish step click Finish. ProWORX

32 reads the contents of the controller into a new default project.

Use as a Macro When selecting any offline options, you can click the Use as

Macro checkbox to create a macro-enabled database. For more

information, see Macros, p. 214.

30

372 SPU 780 01EMAN May 2002

Page 31

Selecting a Controller Type

Working with Projects

Selecting a

Controller Type

This step includes two drop dow n lists to se lect a contro ller. To the ri ght of the drop

down lists is a detailed description of the currently selected controller. Displayed

below the controlle r selection dr op down list are pictures of the I/O type(s) supported

by the current controller.

To select a controller:

Step Action

1 Select a controller family from the Pick a Controller Family drop-down box:

Compact, Micro, Momentum, 38x/48x, 484 Replacement, 68x/78x, 984ABX,

Atrium, Other, Quantum, or VME.

2 Select the desired controller from the Pick a Controller drop-down box. The list

of controllers depends on which controller family you selected in Step 1.

3 Click Next to continue.

372 SPU 780 01EMAN May 2002 31

Page 32

Working with Projects

Controller

Details

The controller details available depends on the controller you have selected in the

previous step. Set the available controller details:

Controller Detail Description

Executive Cartridge Cartridges which determine the controller’s instruction set.

Select the one installed in your controller. The Executive

Cartridge is available for some 38x, 48x, 68x and Quantum

controllers.

Memory Pack The amount of both Extended and User Logic memory in the

controller. Select the amount installed in your controller.

Available on a variety of x80 and 984 A/B controllers.

Extended Memory Additional mem ory providing 6xxx x registers. Selec t the

amount installed in your controller. Available on a variety of

x80 and 984 A/B controllers.

Built-in XMRD/XMWT Select Yes or No. The built-in extended memory functions

option is only available for the 984AS908.

User Logic Memory available for ladder logic. Select the amount of

memory you want to use for ladder logic from the total amount

available in your controller. Available on a variety of x80 and

984 A/B controllers.

S908 Size Select either 512 or 1024 (1k) input and output points per drop.

Available for most 68x and 78x controllers.

Micro I/O Mode Micro controllers only. Select:

l

Single: The controller is independent, not in a parent/child

relationship.

l

Parent: The controller is the parent in a parent/child

relationship.

l

Child: The controller is the child in a parent/child

relationship.

Available for "Brick" controllers from the Micro 311/0 to the

Micro 612/4.

32

Click Next when you have set the controller details.

372 SPU 780 01EMAN May 2002

Page 33

Working with Projects

Communications

Setup

To select a communications mode:

Step Action

1 Select a communications tab: Modbus, Modbus Plus, Gateway, or TCP/IP.

2 Set the communications-specific properties as desired. For more information

see Communications Overview, p. 66.

3 If your project will communicate with a controller via the ProWORX server, click

the Use server to communicate check box.

4 Click Next to continue.

Finish The finish step displays a summary of the selected controller type. Click Finish to

perform the operations set up in the previous steps. When the progress number

reaches 100% the wizard closes. The newly created project appears in the project

navigation tree.

372 SPU 780 01EMAN May 2002 33

Page 34

Working with Projects

Converting Ladder Logic Databases

Overview Old ladder logic databases created in 484, 884, ProWORX, ProWORX Plus,

ProWORX NxT, Modsoft, and Concept can be imported into the new format of

ProWORX 32. By importing a database using the ProWORX 32 convert function,

your logic, documentation, configuration, and other relevant areas of your project

are converted directly into ProWORX 32.

Converting a

Database

From the ProWORX 32 menu:

Step Action

1 Select File

appears.

2 Select a database to convert from the following database types:

l

l

l

l

l

l

3 When you have selected a database, click Open to start the conversion process.

4 To cancel the conversion, click Cancel in the Conversion Status dialog.

5 Click OK in the Conversion complete dialog to return to ProWORX 32.

→ Import Database. The Select Database to Convert dialog

484 databases - *.CF4

884 databases - *.CF8

Old ProWORX databases - *.CF9, *.DCF

Modsoft databases - *.CFG

Concept databases - *.ASC

ProWORX Plus/NxT databases - *.DCF

34

372 SPU 780 01EMAN May 2002

Page 35

Working with Projects

Using the ProWORX Server to Manage ProWORX 32 Projects

Overview The ProWORX Server is an application used to store and manage ProWORX 32

projects. The following project transactions can occur between a ProWORX 32

client, and the ProWORX Se rver. For more in formation about the ProWORX Server,

see ProWORX 32 Server, p. 239.

In the project navi gation panel of the ProWORX 32 client, fro m the projec t right-click

menu:

Transaction Result

Select Get from Server. The selected project is copied to your local PC. If you

plan to make changes to a project it is recommended

that you get the project from the server with a lock.

Select Get from Server with Lock. The selected project is copied to your local PC. You

have sole access and editing capabilities for a project

when it is locked out to your PC.

Select Put to Server. When you have finished making changes or you want

to add a project to the server, use the Put to Server

function. This function creates a copy of the project on

the server.

Select Unlock Project. The project is unlocked so that other clients can

check it out of the server.

372 SPU 780 01EMAN May 2002 35

Page 36

Working with Projects

Working with a ProWORX 32 Project

Projects in

Offline Mode

Taking a Project

Offline

Projects in

Online Mode

Taking a Project

Online

To work with a controll er offline, you must cre ate a p r oje ct for i t. Th is pro jec t s tore s

the controller’s traffic cop and configuration information, its ladder logic, and

descriptors of the controller and ladder logic. As you work in offline mode, editors

modify this data. Because the offline editors are not connected directly to the

controller, changes made in it do not take effect immediately. Instead, when you

have finished progra mming, you c an write all your ch anges to th e controll er at once.

From the project right-click menu in the Navigation panel:

Step Action

1 Select Project State

→ Offline.

To work with a controller online, select a project, and changes its mode to online.

ProWORX 32 then attaches to that controller with the communications settings

provided. The online editors read ladder logic, traffic cop information, register

contents, and the controller’s configuration directly from the controller and

ProWORX 32 writes back to it. Chang es mad e in the onl ine mo de take ef fect in the

controller immediately, but don’t appear in its project until you read from the

controller.

From the project right-click menu in the Navigation panel:

Step Action

1 Select Project State

→ Online.

Projects in

Emulation Mode

Taking a Project

to Emulation

36

To work with a controller in emulation mode, you first make sure that the project is

in offline mode. Bringing a project into emulation mode allows you to emulate the

solving of logic without needing a controller. From emulation mode, you can view the

solving of logic, and the changing of register data. Use the online controls to start

and stop the emulator. For more information, see Using Emulation Mode, p. 39.

From the project right-click menu in the Navigation panel:

Step Action

1 Select Project State

→ Emulation.

372 SPU 780 01EMAN May 2002

Page 37

Working with Projects

Projects in

Combined Mode

Taking a Project

to Combined

Mode

Setting the

Project

Properties

Combined mode is a comb ina t io n of off lin e and online modes. When a pr oj ec t is in

combined mode, it attaches to the controller specified by the communication

settings. All work done in th e edi tors a re mad e dire ctly to the cont roller. Work d one

in the logic edi tor, traf fic c op, an d regi ster e ditors ar e also s aved back to th e proj ect

file, so there is no immediate need to read from the co ntro lle r to upda te t he proj ect

file with all of the changes.

From the project right-click menu in the Navigation panel:

Step Action

1 Select Project State

→ Combined.

From the project right-click menu in the Navigation panel:

Step Action

1 Ensure that the project is selected in the navigation panel. The currently selected

project is denoted by its name being part of the ProWORX screen’s title bar.

2 Select Properties.

3 Select the Project tab.

4 Configure the project properties. See Project Properties Descriptions below.

5 Click OK to save changes.

372 SPU 780 01EMAN May 2002 37

Page 38

Working with Projects

Project

Properties

Description

Property descriptions:

Property Description

Detailed Project Name Enter the detailed description of the current project.

Project Enter a name (brief description) for the current project.

Client Enter the name of the project’s client if applicable.

Author Enter the name of the project author.

6 Digit Addressing When On, sets all addressing to six digits, allowing

ProWORX 32 to enter and display constants greater than

9999. Auto is the default, which sets addressing to five digits

unless the controller has addresses configured that require

six.

Maximum Decimal Value Restricts registers to a decimal value of either 9999 (default)

or 65535.

Enable Symbols Enables or disables symbolic addressing.

Save to Flash on Exit of Online If the controller supports flash memory, selecting this

feature will save the controllers contents to memory on exit

of online.

Online Update Rate Adjust how fast ProWORX 32 polls the controller for

information when online and running. The faster the update

rate, the more accurate the data displayed. But, as the

update rate is increased, the performance of the software

is reduced.

38

372 SPU 780 01EMAN May 2002

Page 39

Working with Projects

Using Emulation Mode

Overview The emulation funct ion is used to test th e integrity of t he logic in a proj ect without the

need of a PLC. Emulation mode allows you to check discrete states and register

contents, and test your logic in a "safe" environment.

Taking a Project

to Emulation

Setting up

Emulation

Setting

Emulation

Properties

In the project navigation panel:

Step Action

1 From the project right-click menu, select Project State

→ Emulation.

Before you test your logic, set the default states, or values into the emulator, so

when you use the Load command, you can debug your database file using the

states you have pres et. Disc retes m ay be s et to OFF , ON, Enabl ed, Disable d OFF,

or Disabled ON. Register values may be set to Decimal, Hexadecimal, Binary,

ASCII, or Floating Point.

From the project right-click menu in the Project Navigation Panel:

Step Action

1 Select Properties. The properties window appears.

2 In the Properties window, select the Emulation tab.

372 SPU 780 01EMAN May 2002 39

Page 40

Working with Projects

Setting the

Default Address

Data Values

You can toggle discretes or transfer values to arrays of registers during emulation

when setting states or register contents on a state or value.

Step Action

1 In the Emulation Properties tab, enter an address or a range or addresses in the

format (axxxx-axxxx) in the Address Range field.

2 If you have entered an analog address range, enter a value in the Data Value

field. If you have entered a discrete address range, select a data value (Off, On,

Enables, Disabled Off, Disabled On) from the Data Value drop-down list.

3 If you have entered an analog address range, select a radix for the address

range from the Radix drop-down list.

Note: Floating point only works with two registers. All others can be set to work

on ranges of addresses.

4 Click OK to save the changes and return to ProWORX 32.

5 To load the default address values while in Emulation mode, select Emulation

→

Load Default Address Values from the logic editor right-click menu.

40

372 SPU 780 01EMAN May 2002

Page 41

Working with Projects

Setting

Instructions with

Loopback

You can toggle discretes or transfer values to arrays of registers during emulation

when setting states or register contents based on a state or value. To edit the

loopback table, in the Emulation Properties tab:

Step Action

1 Enter the address where you want the loopback in the Ctrl Address field.

Control Address - The instruction address in the logic that is checked for a

condition while the logic is being emulated and Loopback is enabled.

2 Enter the state or value of the address in the Condition field.

Condition - The state or value of the Control discrete or analog. If the condition

of the Control’s address is true, the Loopback stores a new value or triggers a

new state in a Destination range of addresses.

3 Select the numeric system you want to enter your Condition in from the Radix

drop-down list.

4 Enter the number of scans you want the Condition to be monitored by before

being updated (0 to 65535) in the Scan Delay field.

Scan Delay - You may not want the Loopback function to immediately update

the Destination when a condition becomes true. By setting Scan Delay, you can

set the number of scans for which the Condition must remain true before the

Destination is updated.

5 Enter the address range by typing a the start and end addresses, separated by

a dash, in the Destination field. If there is only one Destination for that control

condition, enter only one address.

Destination - The Destination is the range of addresses to be driven when the

Loopback Control Condition is true.

6 For discrete destinations, select On or Off from the Data Value drop-down list.

Data Value - The Data Value is the new state or value to be placed in a

Destination address range when the Loopback Control Condition is true.

7 Select the numeric system you want to enter your Destination in from the Radix

drop-down list.

8 Click OK to save the changes and return to ProWORX 32.

9 To load the loopback table while in Emulation mode, select Emulation

Loopback Table from the logic editor right-click menu.

10 To enable or disable loopback while in Emulation mode, select Emulation

Loopback Enabled from the logic editor right-click menu.

→ Load

→

372 SPU 780 01EMAN May 2002 41

Page 42

Working with Projects

Adjusting Scan

Time

Starting

Emulation

Setting the Solve

Mode

Setting the Solve

Mode to Sweep

In the Emulation Properties tab:

Step Action

1 Enter a scan time rate between 1 and 999 in the Scan Time field.

Note: This option does not speed up or slow down the emulator’s solving time.

It only affects how fast the timers increment.

2 Click OK to save the changes and return to ProWORX 32.

From the project navigation panel:

Step Action

1 To start emulation, select Online Commands

2 Set the emulator’s solve mode in the Start/Stop dialog. See Setting the Solve

Mode for more information.

3 To start emulation in continuous solve mode, click Start.

→ Start/Stop.

Several solve modes are available to assist in emulating logic. You can set

Emulation to stop solving following any number of full sweeps, after a particular

network is solved, when a breakpoint is reached or to stop when certain logical

conditions are true or n ot true. You ca n change th e solve m ode by sel ecting Online

Commands → Start/Stop and selecting a sol ve mode radio b utton at anytim e when

emulation is in a stopped state.

In the start/stop dialog:

Step Action

1 Select the Sweep radio button.

2 Enter the number of times you want the logic to be solved before stopping in the

Number of Scans to Sweep field.

3 To the Spacebar to run another sweep.

Solving by

Network

42

In the start/stop dialog:

Step Action

1 Select the Network radio button.

2 Logic is solved network-by-network in order of networks, starting at segment

one, network one. Press the Spacebar to solve the next network.

372 SPU 780 01EMAN May 2002

Page 43

Working with Projects

Solving by

Instruction

Solving to a

Breakpoint

In the start/stop dialog:

Step Action

1 Select the Instruction radio button.

2 Logic is solved instruction-by-instruction in order of instructions, starting at

segment one, network one, cell (1,1). Press the Spacebar to solve the next

instruction.

In the start/stop dialog:

Step Action

1 Select the Break radio button. Select one of the following break types:

2 To set a break when a particular value is reached in a register, select Register

radio button. Enter the address in the Address field and a data value in the

Value field.

3 To set a break when a discrete value turns on or off, select the Discrete radio

button. Enter the address in the Address field and select Off to On or On to Off

in the Value field.

4 To set a break when the solve reaches a certain instruction type in logic, select

the Instruction radio button. Select the instruction to break at from the

Instruction drop-down list.

5 To set a break when a specific address is reached in logic, select the Address

radio button. Enter the address to break at in the Address field.

6 To break at the breakpoints set in the breakpoint table, select the Breakpoint

radio button. For more information on setting breakpoints, see Setting Emulator

Breakpoints.

7 Logic is solved in order until it comes to the first breakpoint at which point it stops.

To continue solving logic until the next breakpoint, press the Spacebar.

Setting Emulator

Breakpoints

372 SPU 780 01EMAN May 2002 43

In the logic editor while in Emulation mode;

Step Action

1 To set a breakpoiont at the cursor in the logic editor, select Emulation

Breakpoint from the right-click menu.

2 To delete a breakpoint, select Emulation

click menu. Select the row of the breakpoint that you want to delete and click

Delete. Click Close to exit the Breakpoint Table.

→ Breakpoint Table from the right-

→

Page 44

Working with Projects

Stopping

Emulation

From the project navigation panel:

Step Action

1 To stop emulation, select Online Commands

2 Click Stop.

→ Start/Stop.

44

372 SPU 780 01EMAN May 2002

Page 45

Working with Projects

Instructions Supported in Emulation Mode

Overview Following is an alphabetical list of instructions support by ProWORX 32 1.0

emulation mode.

Instruction Instruction Instruction Instruction

AD16 DV16 NBIT SKP

ADD EMTH (1-37) NC SRC H

AND FIN NCBT SU16

BCD FOUT NO SUB

BLKM FTOI NOBT T.01

BLKT IBKR NTC T->R

BROT IBKW OR T->T

CMPR ICMP PTC T0.1

CNR ITOF R->T T1.0

COMP JSR RBIT TBLK

CONV LAB RET TEST

CR MATH RTTI TTR

DCTR MBIT RTTO UCTR

DIV MSTR (reg read/write SBIT XOR

DMTH MU16 SCIF

DRUM MULT SENS

372 SPU 780 01EMAN May 2002 45

Page 46

Working with Projects

Adding Emulation Instruction Solve Support

Overview ProWORX 32 has the capabili ty of allowing adva nced users to add instruction so lve

support for the ProWORX emulator.

Creating an

Emulation

Solve File

Using a text editor:

Step Action

1 Create a blank .ESF file in the ProWORX\32\EmulatorInst\ directory.

2 Name your .ESF file the same as the instruction that is to be solved. E.g.: The

ADD instruction’s emulation solve file would be named ADD.ESF.

Note: Do not use spaces in your emulation solve file name.

46

372 SPU 780 01EMAN May 2002

Page 47

Working with Projects

Instruction Solve

File Function

Parameters

Parameter Descriptions

Variable Description

Network The network number where instruction is located.

Row The row in logic where instruction is located.

Col The column in logic where instruction is located.

TopTyp The address type of the top node of the instruction (valid values: 0, 1, 3, 4, 8

for constants).

TopVal The address offset of the top node of the instruction (valid values: 0 - 65535).

TopLen The number of addresses the top node uses.

MidTyp The address type of the middle node of the instruction (valid values: 0, 1, 3,

4, 8 for constants).

MidVal The address offset of the middle node of the instruction (valid values: 0 -

65535).

MidLen The number of addresses the middle node uses.

BotTyp The address type of the bottom node of the instruction (valid values: 0, 1, 3,

4, 8 for constants).

BotVal The address offset of the bottom node of the instruction (valid values: 0 -

65535).

BotLen The number of addresses the bottom node uses.

UctrNum Used only for UCTR instructions.

DctrNum Used only for DCTR instructions.

Spare3 Spare parameter.

Note: All parameters must appear in the instruction subroutine decl arat ion .

372 SPU 780 01EMAN May 2002 47

Page 48

Working with Projects

Emulation Solve

File API Calls

API Call Description

Power Flow Calls

GetPowerFlow(Network, Row, Col, PowerState)

SetPowerFlow(Network, Row, Col, 1)

Single Discrete State Calls

GetSingleDiscreteState(RefTyp, RefVal, State)

SetSingleDiscreteState(RefTyp, RefVal, 1)

Single Discrete History Calls

GetSingleDiscreteHistory(RefTyp, RefVal, History)

SetSingleDiscreteHistory(RefTyp, RefVal, State)

Single Discrete Disabled Calls

GetSingleDiscreteDisabled(RefTyp, RefVal, Disabled)

SetSingleDisabledState(RefTyp, RefVal, Disabled)

Single Register Data Calls

GetSingleRegisterData(RefTyp, RefVal, Data)

SetSingleRegisterData(RefTyp, RefVal, Data)

Group Discrete Calls

GetGroupDiscreteState(RefTyp, RefVal, NumGroups, State(), Disabled())

SetGroupDiscreteState(RefTyp, RefVal, NumGroups, State())

SetGroupDisabledState(RefTyp, RefVal, NumGroups, Disabled())

Power flow calls are used to:

l

Determine whether an instruction

should be solved (using

GetPowerFlow)

l

To pass along powerflow to the next

cell (using SetPowerFlow)

l

To activate an error condition (using

SetPowerFlow)

Power flow calls can be used to either

get or set a particular cell in logic.

Depending on the instruction being

solved, the row and col variables are

used to access a particular cell within

the 7 row x 11 column matrix.

Single discrete state calls are used to

get or set the state of a 0xxxx or 1xxxx

address. The State will return with 0 for

Off or 1 for On. When calling the Set,

use either 0 for Off or 1 for On.

Single discrete history calls are used to

get or set the history of a 0xxxx or 1xxxx

address. The history will return with 0 for

Off or 1 for On. When calling the Set,

use either 0 for Off or 1 for On.

Single discrete disabled calls are used

to get or set the disabled status of a

0xxxx or 1xxxx address. The disabled

status will return with 0 for Enabled or 1

for Disabled. When calling the Set, use

either 0 for Enabled or 1 for Disabled.

Single register data calls are used to get

or set the data value of a 3xxxx or 4xxxx

address. Valid range for data is 0 to

65535.

Group discrete calls are similar to the

single calls except 16 discretes per

group are received or set at one time.

The arrays must contain data for as

many groups as are specified.

48

372 SPU 780 01EMAN May 2002

Page 49

API Call Description

Group Register Calls

GetGroupRegisterData(RefTyp, RefVal, NumGroups, Data())

SetGroupRegisterData(RefTyp, RefVal, NumGroups, Data())

Group register calls are similar to the

single calls except that a group of

registers are received or set at one time.

The Data array must contain data for as

many groups as are specified.

Working with Projects

372 SPU 780 01EMAN May 2002 49

Page 50

Working with Projects

Emulation Solve

File Content

Example

ADD.ESF File Content Example:

Sub ADDINST (Network, Row, Col, TopTyp, TopVal, TopLen,

MidTyp, MidVal, MidLen, BotTyp, BotVal, BotLen, Spare1,

Spare2, Spare3)

dim State,TData,MData,Bdata

’is top input powered?

call LLEmulator.GetPowerFlow(Network,Row,Col-1,State)

If State<>0 then

’ get the value of top node

If (TopTyp=3) or (TopTyp=4) then

call LLEmulator.GetSingleRegisterData(TopTyp,TopVal,TData)

Else

TData=TopVal

End if

’get the value of middle node

If (MidTyp=3) or (MidTyp=4) then

call LLEmulator.GetSingleRegisterData(MidTyp,MidVal,MData)

Else

MData=MidVal

End if

BData=TData+Mdata

’overflow

If BData>9999 then

BData=BData-10000

call LLEmulator.SetPowerFlow(Network,Row,Col,1)

End if

’set value into bottom node

call LLEmulator.SetSingleRegisterData(BotTyp,BotVal,BData)

End if

End Sub

50

Note: Only emulation solve files for instructions currently not supported by the

Emulator are checked for by ProWORX 32. You cannot edit built-in instructions.

372 SPU 780 01EMAN May 2002

Page 51

Working with Projects

Documentation Editor

Overview The documentation editor, the defaulted bottom-left editor, allows you to see and

edit documentatio n for a ddress es and T raffi c Cop items . It ho t-track s item s tha t are

selected in the many of the edit ors, incl uding th e data wat ch win dow and tra ffic cop .

To open the documentation editor, select View → Documentation from the

ProWORX 32 menu

There are three sections of the documentation editor: Edit, Summary, and Traffic

Cop. To switch between sections, select the corresponding radio button at the top

of the documentation editor.

Opening the

Documentation

Editor Properties

Window

In the navigation tree:

Step Action

1 Ensure the project folder is expanded and right-click the current project’s folder.

2 Select Properties from the right-click menu.

3 Select the Documentation tab in the properties window.

372 SPU 780 01EMAN May 2002 51

Page 52

Working with Projects

Documentation

Editor Properties

These properties are found in the Properties window under the Documentation tab:

Property To set: Function

Total

Number of

Descriptor

Lines

Number of

Visible

Descriptor

Lines

Supported

Fields

In the Total Number of

Descriptor Lines box enter a

number between 3 and 9 or use

the arrow keys to increase or

decrease the number.

In the Number of Visible

Descriptor Lines box enter a

number between 1 and the Total

Number of Descriptor Lines

value or use the arrow keys to

increase or decrease the

number.

In the Supported Field s frame,

select the check boxes that you

want displayed.

The descriptor field is a multi-line field that

can be set from 3 lines to 9 lines of

documentation. This preference forces the

editor to edit only the set number of lines of

the descriptor.

The descriptor field is a multi-line field that

can be set from 3 lines to 9 lines of

documentation. This preference forces the

editor to display only the number of lines of

the descriptor that are set.

If a check box is unchecked, the

corresponding field will never be displayed.

If a check box is checked, the field will be

displayed as long as dependant properties

are set correctly.

E.g. If Symbols are disabled for the project,

the symbol field will not be displayed even

though the check box is checked.

52

372 SPU 780 01EMAN May 2002

Page 53

Using the Documentation Editor

Working with Projects

Edit Mode

Overview

Customizing the

Edit Mode Fields

Using the Edit

Mode

Using the Singleline Mode

The edit mode is a completely cu stomizable and ed itable visual re presentation of the

current project documentation. The edit mode hot-tracks items currently selected in

ProWORX 32 including instructions, I/O cards, and addresses in the Data Watch

Window.

In the documentation editor:

To: Function

Move a field Click the field’s handle and drag it to the area of the

window that you would like the field moved to.

Resize a field Click and drag the field’s handle.

Minimize or maximize a field Click the field’s handle.

Enter an address into the Reference box to view the a ddress es do cume ntatio n. T o