Page 1

Property of American Airlines

Scania Engine

Page 2

Important information

WARNING!

IMPORTANT!

Serious risk of injury

When working on the engine, for example when adjusting drive belts and the clutch, or when changing the

oil, it is important not to start the engine. The engine could be damaged, but more importantly there is a

serious risk of injury.

For this reason, always secure the starting device or disconnect a battery cable before working on the engine.

This is especially important if the engine has a remote starter or automatic starting.

This warning symbol and text can be found next to those inspection points where it is particularly important

to bear in mind the risk of injury.

Operator's manual

DC13

XPI

Industrial engine

en-GB 2 397 828

Issue 2.1

The owner is responsible for making sure that inspection is carried out on time and in accordance with the

instructions.

The owner must entrust the maintenance, renewal and repair of emission-related components and systems

to a qualified workshop or person.

Property of American Airlines

Page 3

Start-up Report – Warranty

When the start-up report has been filled in and

sent to Scania, you have a 1-year warranty from

the date of entry into service. Fill in the particulars below as well. This can make things easier if

you need to contact a workshop for example.

Engine serial number

Date of entry into service

User's name and address

Signature

Engine type

Variant

Engine type and variant are indicated on the engine data plate.

Property of American Airlines

OPM 200 en-GB 2

©

Scania CV AB 2014, Sweden

Page 4

Start-up Report – Warranty . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Environment and safety . . . . . . . . . . . . . . . . . . 5

Environmental responsibility . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings and advisories . . . . . . . . . . . . . . . . . 6

Certification . . . . . . . . . . . . . . . . . . . . . . . . . 11

Scania engines engine warranty for industrial

engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Emission control systems warranty. . . . . . . . 12

Emission control system warranty statement 12

California emission control warranty statement

16

Your warranty rights and obligations . . . . . . 16

Manufacturer's warranty coverage . . . . . . . . 16

Owner's warranty responsibilities . . . . . . . . . 16

SCR catalytic converter . . . . . . . . . . . . . . . . . 17

Engine data plate . . . . . . . . . . . . . . . . . . . . . . . 19

Component identification . . . . . . . . . . . . . . . . 20

SCR system . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Starting and running . . . . . . . . . . . . . . . . . . . . 23

Checks before running . . . . . . . . . . . . . . . . . 23

Starting the engine . . . . . . . . . . . . . . . . . . . . 23

Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine shutdown . . . . . . . . . . . . . . . . . . . . . . 27

Checks after running . . . . . . . . . . . . . . . . . . . 27

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Engines with few hours of operation . . . . . . 29

Cleaning the engine. . . . . . . . . . . . . . . . . . . . 29

Inspection interval . . . . . . . . . . . . . . . . . . . . . 30

Lubrication system . . . . . . . . . . . . . . . . . . . . . 31

Oil grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Oil analysis . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Checking oil level . . . . . . . . . . . . . . . . . . . . . 32

Changing the oil . . . . . . . . . . . . . . . . . . . . . . 33

Labels for top-up engine oil grade . . . . . . . . 34

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cleaning the centrifugal oil cleaner . . . . . . . 35

Operational testing . . . . . . . . . . . . . . . . . . . . 40

Renewing the oil filter. . . . . . . . . . . . . . . . . . 41

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . 42

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Checking coolant level . . . . . . . . . . . . . . . . . 46

Checking antifreeze and corrosion inhibitor . 47

Antifreeze and corrosion inhibitor . . . . . . . . 48

Changing coolant . . . . . . . . . . . . . . . . . . . . . 49

Cleaning the cooling system . . . . . . . . . . . . . 51

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Reading the vacuum indicator. . . . . . . . . . . . 54

Renewing the filter element . . . . . . . . . . . . . 54

Renewing the safety cartridge. . . . . . . . . . . . 55

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

General information on the XPI fuel system 56

Property of American Airlines

Checking fuel level . . . . . . . . . . . . . . . . . . . .56

Renewing the fuel filter . . . . . . . . . . . . . . . . .57

Bleeding the fuel system . . . . . . . . . . . . . . . .61

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . .62

Checking the drive belt . . . . . . . . . . . . . . . . .62

Checking for leaks . . . . . . . . . . . . . . . . . . . . .64

Checking and adjusting the valve clearance .64

Renewing the reductant filter . . . . . . . . . . . . .67

Cleaning the reductant tank filler filter . . . . .69

Cleaning the reductant tank ventilation filter .69

Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Composition of the fuel . . . . . . . . . . . . . . . . .69

Sulphur content of fuel. . . . . . . . . . . . . . . . . .70

Temperature dependency of the fuel . . . . . . .72

Reductant for SCR . . . . . . . . . . . . . . . . . . . . . .73

Responsibility and quality requirements . . . .73

Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Preparing the engine for storage . . . . . . . . . . .75

Handling the engine . . . . . . . . . . . . . . . . . . . .75

Preservative coolant . . . . . . . . . . . . . . . . . . . .76

Preservative fuel . . . . . . . . . . . . . . . . . . . . . . .76

Preservative oil . . . . . . . . . . . . . . . . . . . . . . . .77

Preparations for storage . . . . . . . . . . . . . . . . .77

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . .80

General data . . . . . . . . . . . . . . . . . . . . . . . . . .80

Lubrication system . . . . . . . . . . . . . . . . . . . . .80

Injection system . . . . . . . . . . . . . . . . . . . . . . .81

Cooling system . . . . . . . . . . . . . . . . . . . . . . . .81

Intake system . . . . . . . . . . . . . . . . . . . . . . . . .81

Electrical system . . . . . . . . . . . . . . . . . . . . . .81

Scania Assistance . . . . . . . . . . . . . . . . . . . . . . .82

OPM 200 en-GB 3

©

Scania CV AB 2014, Sweden

Page 5

Introduction

Note:

This Operator's Manual describes the operation

and inspection of Scania industrial engines.

The engines are direct-injection, liquid-cooled,

four-stroke, turbocharged diesel engines. Certain

engines are also equipped with an SCR system

for emission control.

The engines are available with different output

and engine speed settings. The normal output

setting of the engine (performance code) is indicated on the engine data plate.

Only standard components are described in the

operator's manual. Information about special

equipment is contained in instructions from the

various manufacturers.

Introduction

To ensure the maximum performance and the

longest service life for the engine remember the

following:

• Read through the Operator's Manual before

starting to use the engine. Even regular users

of Scania engines will get new information

from the Operator's Manual.

• Always follow the inspection instructions.

• Read the section on safety carefully.

• Get to know your engine so that you know

what it can do and how it works.

• Always contact a workshop with qualified

personnel for inspection and repair.

The information in this manual was correct at the

time of going to press. Scania reserves the right

to make alterations without prior notice.

Property of American Airlines

OPM 200 en-GB 4

©

Scania CV AB 2014, Sweden

Page 6

Environment and safety

WARNING!

IMPORTANT!

Note:

Environment

Environment and safety

Environmental responsibility

Scania develops and produces engines that are as

environmentally-friendly as possible. Scania has

made major investments in the reduction of

harmful exhaust emissions in order to fulfil the

environmental requirements in force in almost

every market.

At the same time, we have been able to maintain

a high level of performance and operating economy for Scania Industrial and Marine Engines.

To maintain these throughout the entire service

life of the engine, it is important for the user to

follow the instructions on running, inspection

and fuel and lubricating oil as outlined in the Operator's Manual.

Other green initiatives taken include ensuring

that, following inspection and repair, waste that

is harmful to the environment (for example oil,

fuel, coolant, filters and batteries) is disposed of

accordance with the applicable environmental

requirements.

Safety

Different types of advisory

Warning!

All advisories preceded by Warning! are very

important. They warn of serious faults and incorrect operation that could lead to personal injury.

Example:

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

Important!

Advisories preceded by Important! warn of

faults and incorrect operation that could lead to

equipment being damaged. Example:

For Scania to guarantee that the engine corresponds to its certified configuration, and take responsibility for any damage and injuries that

occur, inspection must be carried out as above.

The following pages contain a summary of the

safety precautions to be complied with when operating and inspecting Scania engines. The

equivalent text can also be found under the relevant inspection point.

To prevent damage to the engine and to ensure

that it runs optimally, follow the instructions in

the warnings and advisories.

If the instructions are not followed, the warranty

can cease to apply.

Property of American Airlines

Note:

Advisories preceded by Note: refer to information important to ensure the best possible operation and functionality. Example:

Leave the engine off for at least 1 minute before

checking the oil level.

Environment

This Operator’s Manual contains specially highlighted text with instructions to help protect the

environment during inspection. Example:

Use a container to avoid spillage.

OPM 200 en-GB 5

©

Scania CV AB 2014, Sweden

Page 7

Environment and safety

WARNING!

WARNING!

WARNING!

WARNING!

IMPORTANT!

Warnings and advisories

Smoking

Smoking is prohibited

• in the vicinity of flammable or explosive material, e.g. fuel, oils, batteries, chemicals

• when refuelling and in the vicinity of the filling station

• when working on the fuel system

Safety precautions for running the

engine

Daily inspection

Always carry out a visual inspection of the engine and engine compartment before starting the

engine or when the engine has been switched off

after operation.

Refuelling

Never overfill the fuel tank as the fuel needs

space to expand. Also ensure that the filler cap is

properly closed.

During refuelling there is a risk of fire and explosion. The engine must be switched off and smoking is prohibited.

Hazardous gases

Only start the engine in a well ventilated area.

The exhaust gases contain carbon monoxide and

nitrogen oxides, which are toxic.

If it is run in an enclosed space, there should be

an effective device to extract exhaust gases and

crankcase gases.

This inspection should be done to detect fuel, oil

or coolant leaks, or anything else that may require corrective action.

Fuel

Use only fuel recommended in the workshop

manual.

The wrong fuel grade can cause breakdowns or

stoppages by causing the injection system to

malfunction. This can cause damage to the engine and, possibly, personal injury.

Property of American Airlines

Starter lock

If the control panel is not fitted with a starter

lock, the engine compartment should be locked

to prevent unauthorised personnel from starting

the engine. Alternatively, a lockable master

switch or battery master switch can be used.

OPM 200 en-GB 6

©

Scania CV AB 2014, Sweden

Page 8

Environment and safety

WARNING!

WARNING!

WARNING!

WARNING!

WARNING!

Environment

Starter gas

Never use starter gas or similar agents to help

start the engine. This can cause an explosion in

the intake manifold and possible injury.

Running

The engine must not be run in environments

where there is a risk of explosion, as all of the

electrical or mechanical components can generate sparks.

Approaching a running engine always poses a

safety risk. Parts of the body, clothes or dropped

tools can get caught in rotating parts such as the

fan and cause injury. For personal safety all rotating parts and hot surfaces must be fitted with

guards.

Batteries

The batteries contain and form oxyhydrogen gas,

particularly during charging. Oxyhydrogen gas

is flammable and highly explosive.

There must be no smoking, naked flames or

sparks near the batteries or the battery compartment. Incorrect connection of a battery cable or

jump lead can cause a spark, which can cause the

battery to explode.

Chemicals

Most chemicals such as glycol, anti-corrosive

agents, preservative oils and degreasing agents,

are hazardous to health.

Some chemicals, such as preservative oil, are

also flammable.

Safety precautions for handling materials

Fuel and lubricating oil

All fuels and lubricants as well as many chemicals are flammable. Always follow the instructions on the relevant packaging.

The work must be carried out on a cold engine.

Fuel leaks and spillage on hot surfaces can cause

fire.

Store used rags and other flammable materials

safely so as to avoid spontaneous combustion.

Property of American Airlines

Always follow the safety precautions on the relevant packaging.

Store chemicals and other materials which are

hazardous to health in approved containers,

marking them clearly and storing them where

they are inaccessible to unauthorised persons.

Always hand in leftover and used chemicals to

an authorised waste disposal contractor.

OPM 200 en-GB 7

©

Scania CV AB 2014, Sweden

Page 9

Environment and safety

WARNING!

WARNING!

WARNING!

WARNING!

Reductant

Reductant (AdBlue/DEF) is used in the reductant

tank on engines equipped with an SCR system.

Avoid contact with the skin.

If reductant comes in contact with the skin: Wash

with soap and plenty of water. If reductant

splashes in the eyes: Rinse immediately with

plenty of water. Contact a doctor if it is ingested

or causes skin irritations.

Safety precautions for inspection

and repair

Switch off the engine

Always switch off the engine before carrying out

inspections and repairs, unless otherwise indicated.

Hot surfaces and fluids

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are exhaust manifolds, turbochargers, oil sumps, hot

coolant and oil in pipes and hoses.

Lift the engine out

Always use the engine lifting eyes. Always

check that lifting devices are in good condition

and are designed to lift the weight.

Optional equipment on the engine can change

the centre of gravity. This means that it may be

necessary to use additional lifting devices to balance the engine correctly and lift it safely.

Make it impossible to start the engine: Remove

any starter key, or cut the power using the main

power switch or battery master switch and lock

them.

Fix a warning plate somewhere appropriate,

showing that work is being carried out on the engine.

Working with a running engine always poses a

safety risk. Parts of the body, clothes or dropped

tools can get caught in rotating parts and cause

injury.

Property of American Airlines

Never work underneath a suspended engine!

OPM 200 en-GB 8

©

Scania CV AB 2014, Sweden

Page 10

Environment and safety

WARNING!

Environment

IMPORTANT!

IMPORTANT!

WARNING!

Environment

Batteries

The batteries contain highly corrosive sulphuric

acid. Take care to protect your eyes, skin and

clothes when charging or handling batteries.

Wear protective gloves and goggles.

If sulphuric acid comes in contact with the skin:

Wash with soap and plenty of water. If it gets in

your eyes: Rinse immediately with plenty of water and seek medical attention.

Always hand in used batteries to an authorised

waste disposal contractor.

Electrical system

Electric welding

When carrying out welding work on and near the

engine, disconnect the battery and alternator

leads. Pull out the multi-pin connector for the engine control unit as well.

Connect the welding clamp close to the component to be welded. The welding clamp must not

be connected to the engine, or so that the current

can cross a bearing.

When welding is finished:

1.

Connect the alternator and control unit cables first.

2.

Then connect the batteries.

Lubrication system

The engine must be switched off and the power

disconnected using the master switch or battery

master switch before working on the electrical

system. External power supplies to extra equipment on the engine must also be disconnected.

Scania recommends that Scania spare parts are

used for the fuel and electrical systems. Scania

spare parts are designed to minimise the risk of

fire and explosion.

Property of American Airlines

Hot oil can cause burns and skin irritation. Wear

protective gloves and goggles when changing

hot oil.

Make sure that there is no pressure in the lubrication system before starting work on it.

The oil filler cap must always be in place when

starting and running the engine to prevent oil being ejected.

Always hand in used oil to an authorised waste

disposal contractor.

OPM 200 en-GB 9

©

Scania CV AB 2014, Sweden

Page 11

Cooling system

WARNING!

Environment

WARNING!

WARNING!

Never open the coolant filler cap when the engine is hot. Hot coolant and steam may spray out

and cause burns.

If the cap has to be opened do it slowly and carefully to release the pressure before removing the

cap. Wear gloves as the coolant is still very hot.

Always hand in used coolant to an authorised

waste disposal contractor.

Environment and safety

Fuel system

Always wear protective goggles when testing injectors. Fuel escaping at high pressure can penetrate tissues and cause serious injury.

Scania recommends that Scania spare parts are

used for the fuel and electrical systems. Scania

spare parts are designed to minimise the risk of

fire and explosion.

Before starting

Ensure that all guards are in place before starting

the engine. Ensure that no tools or other objects

have been left on the engine.

The air filter must be fitted before starting the engine. Otherwise there is a risk of objects being

sucked into the compressor impeller or of injury

if you come into contact with the air filter.

Property of American Airlines

OPM 200 en-GB 10

©

Scania CV AB 2014, Sweden

Page 12

Certification

IMPORTANT!

An emissions certified engine fulfils the emissions requirements for a particular range of application.

On each emissions certified engine there is a label which shows which requirements the engine

fulfils. Scania guarantees that each such engine

fulfils the emissions requirements for the range

of application for which it is certified.

The following are required for the certified engine to fulfil the emissions requirements once it

has been taken into service:

• Inspection is to be carried out in accordance

with the instructions in this Operator's Manual.

• The inspection and repair of injection equipment are to be carried out by a qualified

workshop or person.

• The engine may only be modified with equipment that has been approved by Scania.

• Seals may be broken and setting data edited

only once approval has been granted by Scania. Modifications may be made by authorised personnel only.

• Modifications affecting the exhaust and intake systems must be approved by Scania.

Environment and safety

Otherwise, the instructions in the Operator's

Manual for the running and inspection of the engine shall apply. The safety precautions should

be observed.

For Scania to guarantee that the engine corresponds to its certified configuration, and take responsibility for any damage and injuries that

occur, inspection must be carried out as above.

Property of American Airlines

OPM 200 en-GB 11

©

Scania CV AB 2014, Sweden

Page 13

Scania engines engine warranty for industrial engines

IMPORTANT!

Scania engines engine warranty for industrial engines

Emission control systems warranty

Only applicable to engines used in the U.S.A.

Table of Contents

General warranty provisions 12

Warranty period 12

Parts covered by the Warranty 13

General warranty limitations 14

Specific warranty exclusions 15

Customer support 15

in the engine manufacturer's application for

certification.

Where a warrantable condition exists, Scania

will repair your heavy-duty off-road engine at no

cost to You including diagnosis, parts, and labor.

Warranty period

This warranty shall apply for one of the following periods, whichever occurs first:

• 3,000 hours of operation as determined by a

device to measure hours of use, or

• Five years

Each engine is equipped with a device to measure hours of use. If that device fails to account for

hours of use due to defects in materials or workmanship, the engine shall be warranted for a period of five years. The warranty period shall

begin on the date the engine is delivered to the

first ultimate purchaser who, in good faith, purchases the engine for purposes other than imminent resale.

Emission control system warranty statement

General warranty provisions

The emission control systems of your new Scania Engines (“Scania”) industrial diesel engine

were designed, built and tested using genuine

parts, and were certified as being in conformity

with federal emission control regulations. Scania

warrants to the original owner, and to each subsequent owner, of a new Scania industrial diesel

engine (“You”) that the engine:

1.

Was designed, built and equipped so as to

conform at the time of sale with all applicable regulations under Section 213 of the

Clean Air Act, 42 U.S.C. § 7547, for their

full useful life and designed, built and

equipped so as to conform with all applicable

regulations adopted by the California Air Resources Board pursuant to its authority under

Chapters 1 and 2, Part 5, Division 26 of the

California Health and Safety Code, and;

2.

Is free from defects in material and workmanship which would cause such engine to

fail to conform to applicable regulations for

its warranty period or otherwise cause the

failure of a warranted part to be identical in

all material respects to the part as described

Property of American Airlines

The Warranty on emission-related

parts shall be interpreted as follows:

1.

Any warranted part which is not scheduled

for replacement as required maintenance in

Scania's written instructions for maintenance

and use of the engine by owner shall be warranted for the warranty period defined above.

If any such part fails during the period of

warranty coverage, it shall be repaired or replaced by the engine manufacturer according

to Subsection (4) below. Any such part repaired or replaced under the Warranty shall

be warranted for the remaining warranty period.

2.

Any warranted part which is scheduled only

for regular inspection in Scania's written instructions for maintenance and use of the engine by owner shall be warranted for the

warranty period defined above. A statement

in such written instructions to the effect of

“repair or replace as necessary” shall not reduce the period of warranty coverage. Any

such part repaired or replaced under warranty shall be warranted for the remaining warranty period.

OPM 200 en-GB 12

©

Scania CV AB 2014, Sweden

Page 14

Scania engines engine warranty for industrial engines

Any warranted part which is scheduled for

3.

replacement as required maintenance in Scania's written instructions for maintenance

and use of the engine by owner shall be warranted for the period of time prior to the first

scheduled replacement point for that part. If

the part fails prior to the first scheduled replacement, the part shall be repaired or replaced by the engine manufacturer according

to Subsection (4) below. Any such part repaired or replaced under warranty shall be

warranted for the remainder of the period

prior to the first scheduled replacement point

for the part.

4.

Repair or replacement of any warranted part

under the warranty provisions of this article

shall be performed at no charge to the owner

at a warranty station.

5.

Notwithstanding the provisions of Subsection (4) above, warranty services or repairs

shall be provided at all manufacturer distribution centers that are franchised to serve the

subject engines.

6.

The owner shall not be charged for diagnostic labor that leadsto the determination that a

warranted part is in fact defective, provided

that such diagnostic work is performed at a

warranty station.

7.

The engine manufacturer shall be liable for

damages to other engine components proximately caused by a failure under warranty of

any warranted part.

8.

Throughout the engine's warranty period defined above, the engine manufacturer shall

maintain a supply of warranted parts sufficient to meet the expected demand for such

parts.

9.

Any replacement part, as defined in Section

1900(b), Title 13 of the California Code of

Regulations, may be used in the performance

of any maintenance or repairs and must be

provided without charge to the owner. It is

not necessary for replacement parts to be the

same brand or by the same manufacturer as

the original part sold with the engine. Such

Property of American Airlines

use shall not reduce the warranty obligations

of the engine manufacturer.

10.

Add-on or modified parts, as defined in Section 1900(b), Title 13 of the California Code

of Regulations, that are not exempted by the

California Air Resources Board may not be

used. The use of any non-exempted add-on

or modified parts shall be grounds for disallowing a warranty claim made in accordance

with this article. The engine manufacturer

shall not be liable under this article to warrant failures of warranted parts caused by the

use of a non-exempted add-on or modified

part.

11.

The Executive Officer of the California Air

Resources Board may request, and in such

case, the engine manufacturer shall provide,

any documents which describe that manufacturer's warranty procedures or policies.

Parts covered by the Warranty

The following is a list of parts considered to be

part of the Emission Control Systems covered by

the Emission Warranty for Scania industrial engines which were built to conform to federal and

California emission control regulations:

1.

Fuel injection system.

2.

Air induction system.

3.

Exhaust manifold system.

4.

Smoke puff limiter (included in ECU).

5.

Oil filler cap.

6.

EGR system (when applicable):

a)

Cooler.

b)

EGR valve.

7.

Exhaust brake (when applicable).

8.

NOx sensors:

a)

NOx sensor, engine out.

b)

NOx sensor, tail pipe.

9.

DOC (when applicable).

10.

SCR system:

a)

DEF tank.

b)

DEF tank level, temperature and quality

sensors.

c)

DEF hose.

d)

DEF injector.

e)

DEF injector pressure and temperature

sensors.

f)

Evaporator.

g)

SCR catalyst inlet temperature sensor.

h)

SCR catalyst including the ammonia-slip

catalyst.

i)

SCR control unit (EEC3).

OPM 200 en-GB 13

©

Scania CV AB 2014, Sweden

Page 15

Scania engines engine warranty for industrial engines

IMPORTANT!

WARNING!

Miscellaneous items used in the above sys-

11.

tem:

a)

Electronic control unit (ECU), sensors,

wiring harnesses.

b)

Hoses, belts, connectors, assemblies,

clamps, fittings tubing, sealing gaskets or

devices and mounting hardware.

c)

Pulleys, belts and idlers.

d)

Emission control information label.

This list does not include all expendable maintenance parts.

• Expendable emission related parts requiring

scheduled maintenance are warranted until

their first scheduled replacement point.

• Emission related parts scheduled for inspection and replacement only as necessary are

not considered expendable and if repaired or

replaced under warranty shall be warranted

for the remaining warranty period.

See Specific Warranty Exclusions below.

Receipts covering the performance of regular

maintenance should be retained in the event

questions arise concerning maintenance. The receipts should be transferred to each subsequent

owner of the engine with the emission warranted

engine. Scania cannot, however, deny warranty

solely for the lack of receipts or for your failure

to ensure the performance of all scheduled maintenance.

The Warranty covers the cost of diagnosis, repair

and replacement parts and services of warranted

components and systems performed by an authorized Scania distributor or dealer using genuine Scania parts. You may elect to have

maintenance, replacement or repair of these

components and systems performed by any repair establishment or individual without invalidating the Warranty.

The use of other than Scania replacement parts

also does not invalidate the warranty on other

components unless such parts cause damage to

warranted parts. However, the cost of such services or parts will not be covered by the Warranty.

General warranty limitations

To retain the dependability of the exhaust emission control originally built into your Scania industrial diesel engine, it is essential that the

engine is installed according to Scania installation instructions and emission certificates. Your

engine is designed to operate on diesel fuel only.

Use of any other fuel may result in your engine

no longer operating in compliance with state or

federal emissions requirements. The use of alternative fuels shall not void the warranties on any

engine certified to use such fuel.

In addition, as the engine owner, You are responsible for the performance of all scheduled maintenance listed in your owner's manual, and all

necessary repairs, on your new Scania industrial

diesel engine. Scania may deny a warranty claim

if the engine or part has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

Property of American Airlines

You are responsible for initiating the warranty

process. The California Air Resources Board

suggests that You present your heavy-duty offroad engine to an authorized Scania dealer as

soon as a problem exists. The warranty repairs

should be completed by the dealer as expeditiously as possible.

Use of replacement parts which are not of equivalent quality may impair the effectiveness of

emission control systems. Accordingly, it is recommended that only Scania repair or replacement parts be used for maintenance, repair or

replacement of emission control systems.

If other than Scania parts are used for maintenance, repair or replacement, the owner should

obtain assurance that such parts are warranted by

their manufacturer to be equivalent to genuine

Scania parts.

OPM 200 en-GB 14

©

Scania CV AB 2014, Sweden

Page 16

Scania engines engine warranty for industrial engines

Specific warranty exclusions

This warranty does not cover:

1.

.Malfunctions in any part caused by any of

the following: misuse, abuse, improper adjustments, modifications, alteration, tampering, disconnection, improper or inadequate

maintenance, or use of fuels not recommended for the engine as described in the Operator's Manual.

2.

Engine installation, including cooling system, intake system and exhaust system installation, that is not completed in

accordance with the Scania installation instructions and emissions certificate for this

engine type.

3.

Damage resulting from accidents, acts of nature or other events beyond the control of

Scania.

4.

The replacement of expendable maintenance

items such as filters, hoses, belts, oil, thermostat, exhaust system and coolant made in

connection with scheduled maintenance services once these parts have been replaced.

5.

Replacement items which are not genuine

Scania parts or not authorized by Scania.

6.

Inconvenience, loss of use of the engine or

commercial loss.

7.

Any engine on which the actual use cannot

be accurately determined due to a failure of

the device to track hours of use unrelated to

defects in materials or workmanship.

8.

Any engine operating outside the United

States.

Customer support

In the event that You do not receive the warranty

service to which You believe You are entitled

under the Warranty, or if You need additional

support or information concerning the Warranty,

please contact:

Scania USA, Inc.

Address: 121 Interpark Blvd, suite 1002, 78216,

San Antonio, Texas

Mailing address: 121 Interpark Blvd, suite

1002, 78216, San Antonio, Texas

Telephone: +1 210 403 0007

Fax: +1 210 403 0211

E-mail: contact@scaniausainc.com

California customers shall also be furnished a

copy of the California Emission Control Warranty Statement applicable to each new Scania engine purchased.

Property of American Airlines

OPM 200 en-GB 15

©

Scania CV AB 2014, Sweden

Page 17

California emission control warranty statement

California emission control

warranty statement

Your warranty rights and obligations

The California Air Resources Board is pleased to

explain the emission control system warranty on

your 2015 engine. In California, new heavy-duty

off-road engines must be designed, built and

equipped to meet the State's stringent anti-smog

standards. Scania CV AB must warrant the

emission control system on your engine for the

periods of time listed below provided there has

been no abuse, neglect or improper maintenance

of your engine.

Your emission control system may include parts

such as the fuel injection system and the air induction system. Also included may be hoses,

belts, connectors and other emission-related assemblies.

Where a warrantable condition exists,

Scania CV AB will repair your heavy-duty offroad engine at no cost to you including diagnosis, parts and labor.

Owner's warranty responsibilities

• As the off-road engine owner, you are responsible for the performance of the required

maintenance listed in your owner's manual.

Scania CV AB recommends that you retain

all receipts covering maintenance on your

off-road engine, but Scania CV AB cannot

deny warranty solely for the lack of receipts

or for your failure to ensure the performance

of all scheduled maintenance.

• As the off-road engine owner, you should

however be aware that Scania CV AB may

deny you warranty coverage if your off-road

engine or a part has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

• Your engine is designed to operate on ultra

low-sulfur diesel fuel only. Use of any other

fuel may result in your engine no longer operating in compliance with California's emissions requirements.

• You are responsible for initiating the warranty process. The ARB suggests that you present your off-road engine to a Scania CV AB

dealer as soon as a problem exists. The warranty repairs should be completed by the

dealer as expeditiously as possible.

Manufacturer's warranty coverage

The 2015 heavy-duty off-road engines are warranted for a period of five years or 3,000 hours,

whichever occurs first. If any emission-related

part on your engine is defective, the part will be

repaired or replaced by Scania CV AB.

Property of American Airlines

If you have any questions regarding your warranty rights and responsibilities, you should contact Scania U.S.A. Inc +1-210-403-0007.

OPM 200 en-GB 16

©

Scania CV AB 2014, Sweden

Page 18

SCR catalytic converter

WARNING!

SCR catalytic converter

The SCR catalytic converter contains vanadium

pentoxide, a chemical known to the State of California to cause cancer.

The SCR catalytic converter is fitted in the silencer and does not constitute a health hazard

during normal use and handling.

When carrying out work on the SCR catalytic

converter which may result in exposure to dust,

safety precautions must be taken. Such work includes, for example, opening the silencer machining and scrapping the SCR catalytic

converter.

Safety precautions when working on the SCR

system.

• Inhalation: If dust is inhaled, the person

should be provided with fresh air immediately. Seek medical attention

• Eye contact: Rinse eyes with water immediately. If irritation persists, seek medical attention.

• Skin contact: Wash with water and soap. Remove contaminated clothes.

• Ingestion: If large amounts have been ingested, drink plenty of water and induce vomiting. Seek medical attention

Environmental hazards

• Vanadium pentoxide is toxic to water organisms and can cause detrimental long term effects to water environment.

Environmental protection measures

• The SCR catalytic converter is a manufactured article that contains vanadium pentoxide, a hazardous substance. Before disposing

of, or scrapping, a spent SCR catalytic converter, it should be tested for any hazardous

characteristics (ignitability, corrosivity, reactivity, acute hazardousness, and toxicity), as

those categories are described in 22 CCR §

66261.30. If the spent SCR catalytic converter exhibits hazardous characteristics and is

being disposed of, it will be considered by the

State of California to be a hazardous waste

subject to Title 22, California Code of Regulations. Before disposing of hazardous waste,

review and follow all pertinent federal and

California requirements.

• Vanadium pentoxide is a listed commercial

chemical product - P120 - pursuant to 22

CCR § 66261.33(e). According to the State of

California, commercial chemical products

that are discarded or intended to be discarded

are hazardous wastes and are subject to all

provisions of Title 22, California Code of

Regulations. Before disposing of vanadium

pentoxide, review and follow all pertinent

federal and California requirements.

• If the SCR catalytic converter is opened for

maintenance, any dust spillages from the catalyst should be collected and tested for the

presence of vanadium pentoxide prior to

proper disposal. Dust spillages should also be

tested for any hazardous characteristics (ignitability, corrosivity, reactivity, acute hazardousness, and toxicity), as those categories

are described in 22 CCR § 66261.30, prior to

proper disposal. If the dust contains either vanadium pentoxide or exhibits hazardous characteristics and is being disposed of, it will be

considered by the State of California to be a

hazardous waste subject to Title 22, California Code of Regulations. Before disposing of

hazardous waste, review and follow all pertinent federal and California requirements.

Property of American Airlines

OPM 200 en-GB 17

©

Scania CV AB 2014, Sweden

Page 19

SCR catalytic converter

WARNING!

• Do not dispose of the spent SCR catalytic

converter or its constituent parts into any waterways, storm drains or sanitary sewers.

The SCR catalytic converter contains vanadium

pentoxide, a chemical known to the State of California to cause cancer.

Additional considerations when working on the

SCR system

• Carry out work on the SCR catalytic converter in all well ventilated area. Use protective

goggles and gloves if there is any risk of

splashing or spraying of reductant or coolant.

• When engine is running, the exhaust system

parts can reach such high temperatures that

there is a risk of personal injury. Make sure

that the exhaust system temperature has decreased to a suitable level before starting to

work.

• The SCR system is heated by water from the

engine cooling system. The cooling system

runs at overpressure and when the engine is

hot the coolant is hot. Do not open any hoses

without first stopping the coolant flow in the

hose.

• A P3 type respirator/filter mask or a type

FFP3 fine dust musk, protective goggles and

gloves should be used for any work where

there is a risk of exposure to dust from the

SCR catalytic converter.

• Use a disposable overall and dispose of it

properly after machining.

• Eating, drinking or smoking while working is

not permitted.

• Any dust from the SCR catalytic converter

should be removed using a vacuum cleaner

with microfilter to minimize exposure.

• Make sure that the work surface is cleaned after completed work; Vacuum first then swab.

• Make sure you clean your hands after working with SCR catalytic converter to avoid ingestion.

• Work done on the SCR catalytic converter

may generate waste considered by the State

of California to be a hazardous waste subject

to Title 22, California Code of Regulations.

Before disposing of hazardous waste, review

and follow all pertinent federal and California

requirements.

Property of American Airlines

OPM 200 en-GB 18

©

Scania CV AB 2014, Sweden

Page 20

Engine data plate

Made by

Type

Engine No

Output. kW rpm.

DC13 070A

6950106

331

Ty p e a p pr o va l No :

e 5 x 97 / 68 L Ax 2 00 4 /2 6 x0 14 2 x0 0

2100

319 989

Example of an engine data plate

The engine data plate indicates, in the form of a

code, the engine type, its size and applications.

The engine EU type approval for exhaust emissions is indicated under Output, where applicable.

The engine serial number is stamped onto the top

of the cylinder block at the front right.

Example: DC13 070A

DC Supercharged diesel engine with air-cooled charge air cooler.

13 Displacement in whole dm3.

070 Performance and certification code. The code indicates, together

with the application code, the normal gross engine output.

A Code for application. A means for general industrial use.

Engine data plate

Property of American Airlines

OPM 200 en-GB 19

©

Scania CV AB 2014, Sweden

Page 21

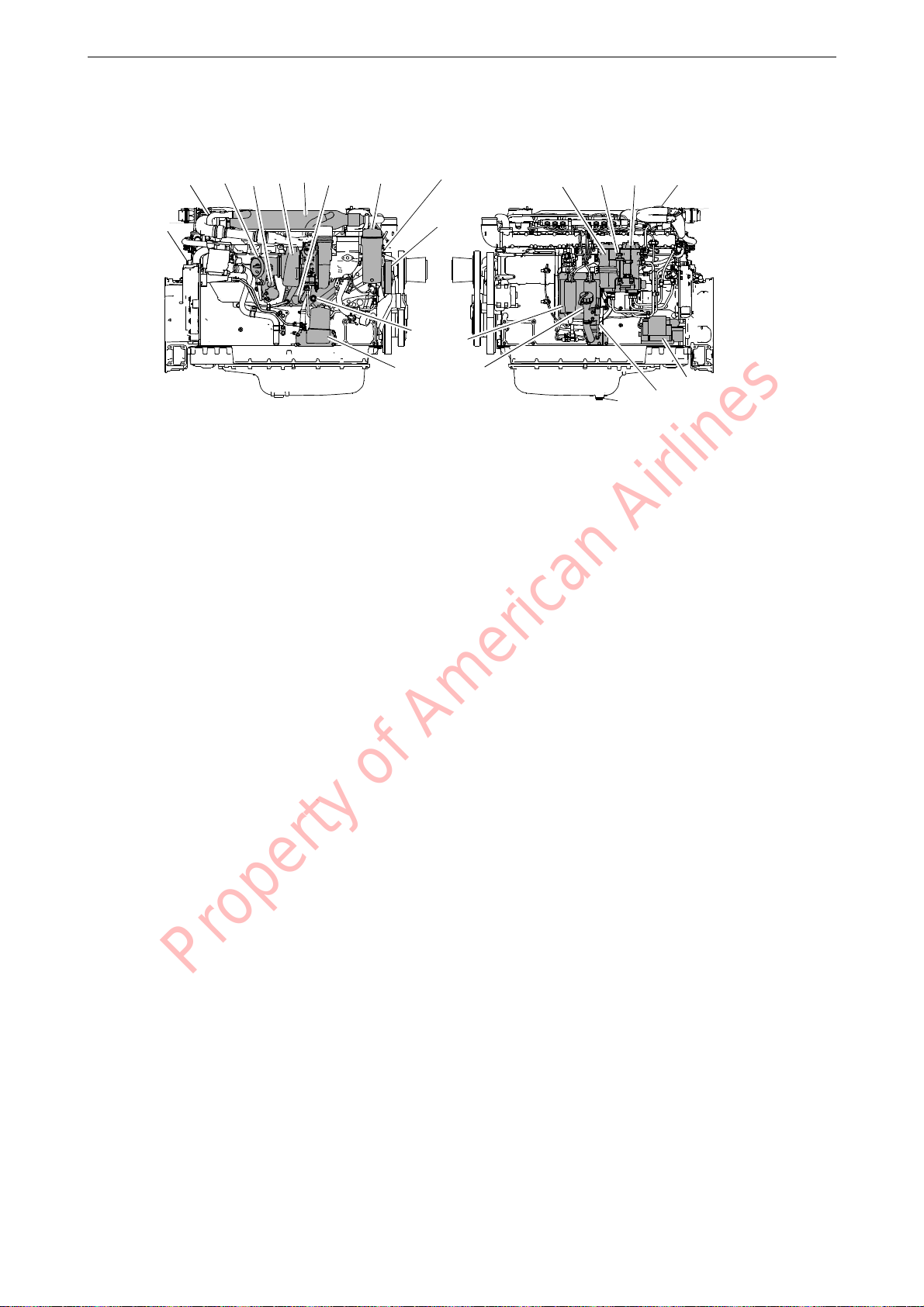

Component identification

336 872

1

2 3 4 5 6 7 8 9

10

11

12 13

14

15 16 17 13

18

1920

The illustration shows a normal version of a DC13 engine. The engine ordered may have different equipment

Component identification

1.

Engine data plate

2.

EGR valve

3.

Exhaust brake

4.

Actuator

5.

Turbocharger

6.

EGR cooler

7.

Oil cooler

8.

Oil filter

9.

Engine serial number on the cylinder

block

10.

Coolant pump

11.

Draining coolant

12.

Centrifugal oil cleaner

13.

Oil filler

14.

Engine control unit

15.

Water separating prefilter for fuel

16.

Hand pump for fuel

17.

Fuel filter

18.

Starter motor

19.

Oil dipstick

20.

Oil plug

Property of American Airlines

OPM 200 en-GB 20

©

Scania CV AB 2014, Sweden

Page 22

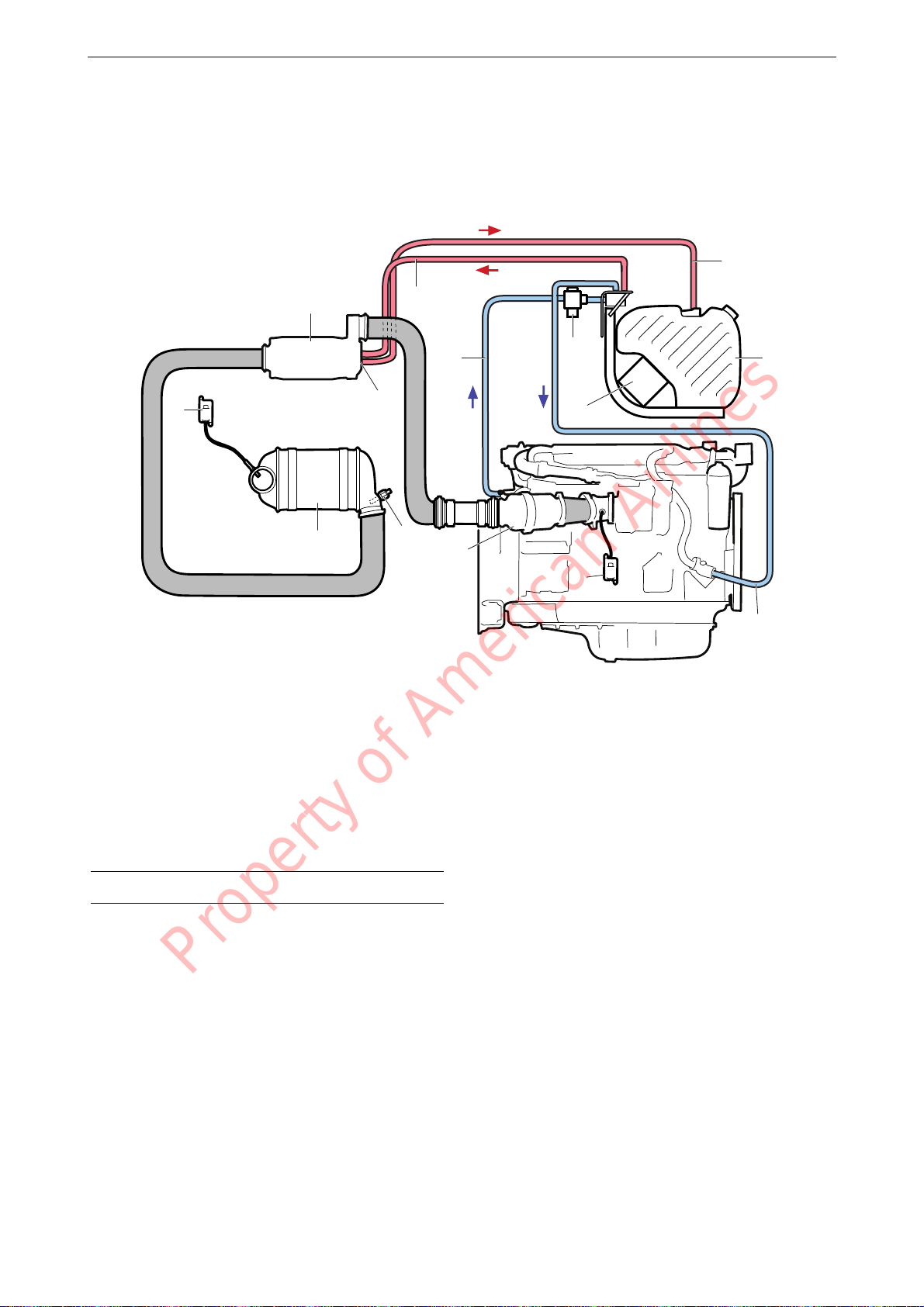

SCR system

6

11

5

9

4

13

3

8

7

10

2

12

1

14

336 907

The illustration provides an overview of SCR

system components.

Component identification

1.

Evaporator

2.

Pressure line for reductant

3.

Coolant hose for tank and pump heating

4.

Coolant valve

5.

Reductant return line

6.

Reductant tank

7.

Reductant pump and control unit

1. DC13 084/085/087/089A only.

2. DC13 084/087/089A only.

Property of American Airlines

8.

Coolant hose, return from tank and pump heating

9.

NOx sensor with control unit

10.

Oxidation catalytic converter

11.

Exhaust gas temperature sensor

12.

SCR catalytic converter

13.

NOx sensor with control unit

14.

Reductant doser

1

2

OPM 200 en-GB 21

©

Scania CV AB 2014, Sweden

Page 23

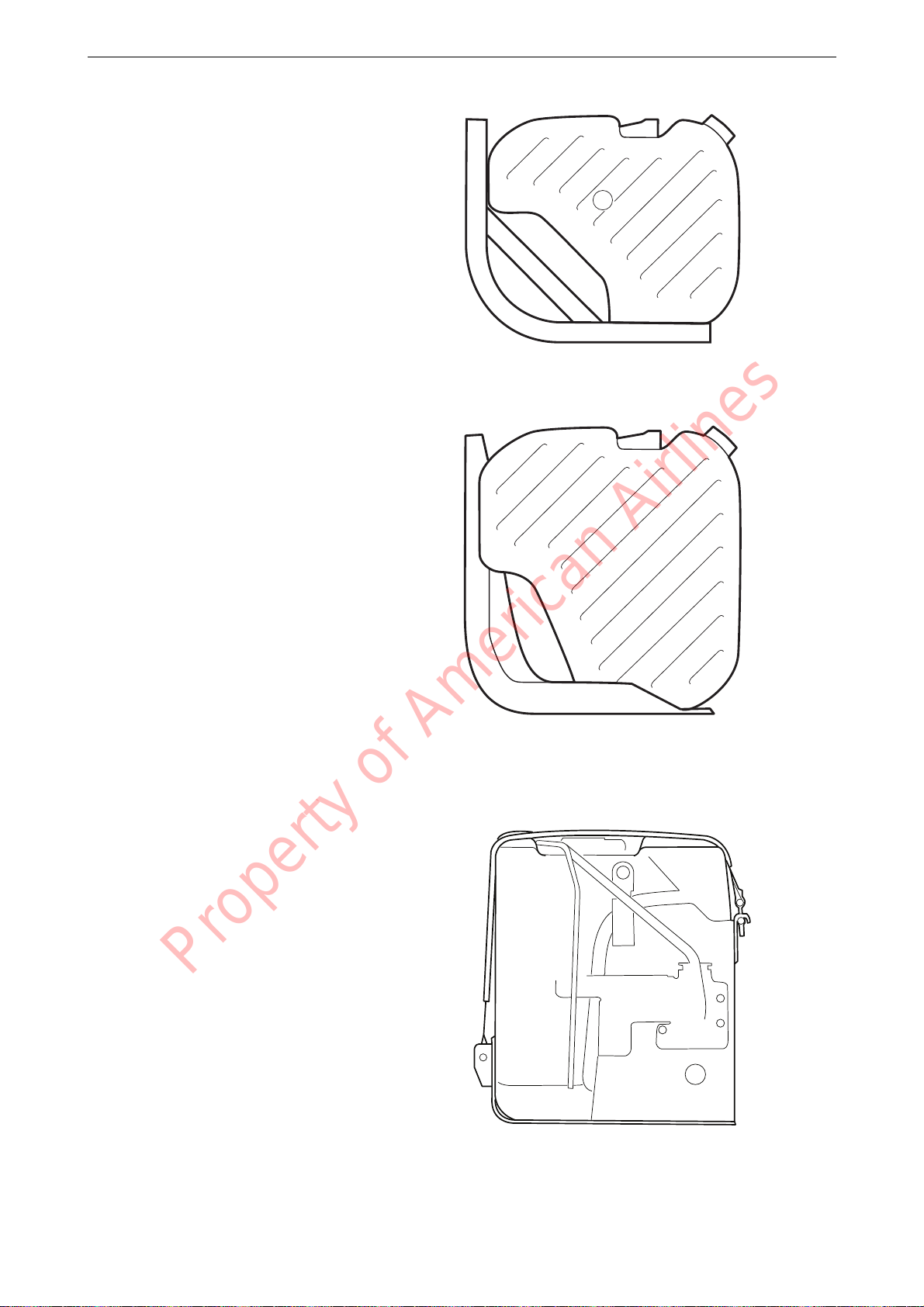

Reductant tank

319 991

38 litres (10 US gallons)

319 992

60 litres (15.8 US gallons)

340 426

69 litres (18.2 US gallons)

The reductant tank comes in 3 sizes. The volumes indicated for each tank are filling volumes.

The total volume is approx. 10 litres (2.6 US gallons) greater.

A filler filter with magnet is fitted in the reductant tank to prevent the reductant from becoming

contaminated when topping up. The filler filter

with magnet is used when topping up at a filling

station.

A filler filter without a magnet is also supplied

for use when manually topping up reductant.

Component identification

OPM 200 en-GB 22

Property of American Airlines

©

Scania CV AB 2014, Sweden

Page 24

Starting and running

Note:

WARNING!

WARNING!

WARNING!

IMPORTANT!

When the engine is started for the first time, carry out the inspection points listed under First

start-up in the inspection schedule. See the Inspection section.

Always check the following before running:

• oil level

• coolant

• fuel level

• electrolyte level in batteries

• state of charge of the batteries

• condition of the drive belt

• the level in the reductant tank, if the engine is

equipped with an SCR system.

Starting and running

3.

If the engine has a battery master switch:

Switch on the power by means of the battery

master switch.

4.

Start the engine.

If the fuel tank has been run dry or if the engine

has not been used for a long time, bleed the fuel

system.

Never use starter gas or similar agents to help

start the engine. An explosion may occur in the

intake manifold with a risk of personal injury.

Only start the engine in a well ventilated area.

When the engine is run in an enclosed space,

there must be effective devices to extract exhaust

gases and crankcase gases.

Running the engine without reductant in the reductant tank violates emissions legislation and

will damage the SCR system.

Checks before running

Carry out a daily inspection as described in the

inspection schedule prior to operation. See the

Inspection section.

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

Starting the engine

For environmental reasons the Scania engine has

been developed to be started with a low fuel feed.

Using unnecessarily large amounts of fuel when

starting the engine always results in emissions of

unburnt fuel.

Property of American Airlines

The starter motor must only be cranked twice for

30 seconds at a time. After that, it must rest for at

least 5 minutes before the next attempt to start it.

Starting at low temperatures and at

high altitudes

Take the local environmental requirements into

account. Use a fuel heater and engine heater to

avoid starting problems and white smoke.

Scania recommends that an engine heater should

be used if the engine will be used at temperatures

below -10°C or at an altitude of more than 2,000

metres.

A low engine speed and a moderate load on a

cold engine limits white smoke, gives better

combustion and warms up the engine more

quickly than warming it up with no load.

Avoid running it longer than necessary at idling

speed.

1.

Open the fuel cock if fitted.

2.

Disengage the engine.

OPM 200 en-GB 23

©

Scania CV AB 2014, Sweden

Page 25

Starting and running

319 562

Symbol for low reductant level

Running

Check instruments and warning lamps at regular

intervals.

Engine speed range

600-750 rpm Low idling. Engine idling is controlled by the engine management system.

Low idling up to 2,100 rpm Engine operating speed range. Controlled by the engine management sys-

tem.

2,100-2,600 rpm Unsuitable operating speed, but a slightly higher engine speed than the nor-

mal maximum operating speed may occur when load is low or negative.

2,600-3,000 rpm Prohibited engine speed.

Emission control

The system provides a warning if there are faults

on the SCR system or if the level of reductant in

the reductant tank is too low. In the case of some

faults, for example if doser cooling is not working, the torque is reduced.

Reaction at low reductant level

Reductant

level

20% Constant

10% Flashing Torque is reduced by

0% Flashing rap-

1. Applies only to engines that are certified according to Tier

4.

The engine resumes normal torque after reductant has been filled to a level of at least 20%.

Warning

lamp

light

idly

Torque reduction

1% per minute to

70% of the highest

torque

Torque is reduced to

0% (low idling)

within 2-10 minutes

Property of American Airlines

1

OPM 200 en-GB 24

©

Scania CV AB 2014, Sweden

Page 26

Reaction to fault in SCR system

IMPORTANT!

Note:

319 563

Symbol for fault in SCR system

Starting and running

Time Warning

lamp

Fault detect-edConstant

light

After 30

minutes

After 4 hours Flashing rap-

1. Applies only to engines that are certified according to Tier

4.

Once the fault has been remedied and the engine

control unit has received an indication that it is

working, torque returns to the normal level.

If a new fault occurs within 40 hours of operation

since the first fault, the warning lamp will come

on. After 30 minutes of operation, the warning

lamp will flash rapidly and torque will be reduced to 0% (low idling) within 30 minutes.

Flashing Torque is reduced by

idly

Torque reduction

1% per minute to

70% of the highest

torque

Torque is reduced to

0% (low idling)

within 2-10 minutes

1

If the torque has been reduced to 0% (low

idling), the engine control unit does not detect

that the SCR system is functioning again. A service technician must then reset the system so that

the torque returns to the normal level.

The torque reduction applies only to engines that

are certified according to Tier 4.

Property of American Airlines

OPM 200 en-GB 25

©

Scania CV AB 2014, Sweden

Page 27

Starting and running

IMPORTANT!

Note:

Coolant temperature

Normal coolant temperature during operation is

80-90°C/176-194°F.

Alarm levels are set in the engine control unit.

The default setting for the lowest and highest

limit values for high coolant temperature are

95°C/203°F and 105°C/221°F respectively.

The following function is standard as alarm for

high coolant temperature:

• Alarm and torque reduction at the lowest limit value.

Depending on the engine configuration, the following alarm functions may also be available:

• Alarm only.

• Alarm and engine shutdown at the highest

limit value.

• Alarm, torque reduction at the lowest limit

value and engine shutdown at the highest limit value.

• Alarm and engine shutdown at the highest

limit value with the possibility of engine shutdown override control.

• Alarm, torque reduction at the lowest limit

value and engine shutdown at the highest limit value, with the possibility of engine shutdown override control.

If run for extended periods under an extremely

light load, the engine may have difficulty in

maintaining the coolant temperature. At an increased load the coolant temperature rises to the

normal value.

Oil pressure

Information about the normal oil pressure and

lowest permitted oil pressure is contained in the

section headed Technical Data.

The engine management system has the following alarm levels:

• At an engine speed below 1,000 rpm and an

oil pressure below 0.7 bar/10.2 psi.

• At an engine speed above 1,000 rpm and an

oil pressure below 2.5 bar/36.3 psi for longer

than 3 seconds.

The following function is standard as alarm for

incorrect oil pressure:

• Alarm and torque reduction by 30%.

Depending on the engine configuration, the following alarm functions may also be available:

• Alarm only.

• Alarm and engine shutdown.

• Alarm and engine shutdown override control.

High oil pressure (above 6 bar/87 psi) is normal

when starting a cold engine.

Charging indicator lamp

If the lamp comes on during operation:

• Check and adjust the alternator drive belts as

described under the corresponding inspection

point. See the Inspection section.

An excessively high coolant temperature can

damage the engine.

Property of American Airlines

OPM 200 en-GB 26

©

Scania CV AB 2014, Sweden

If the charging indicator lamp is still on, this

could be due to an alternator fault or a fault in the

electrical system.

Belt transmission

When the belt transmission is new, it may make

a squeaking noise when running. The noise is

normal and disappears after 50-100 hours of operation.

The noise does not affect the service life of the

belt transmission.

Page 28

Starting and running

Note:

IMPORTANT!

WARNING!

IMPORTANT!

Engine shutdown

1.

Run the engine without a load for a few minutes if it has been run continuously with a

heavy load.

2.

Switch off the engine.

The battery voltage must remain on for a few

seconds after the 15 voltage is switched off so

that the control units can store the values and

switch to standby mode.

10 prohibited engine shutdowns will cause a

torque reduction (70% of fuel quantity). Reset

the engine by switching it off correctly once.

There is risk of post boiling and of damage to the

turbocharger if the engine is switched off without cooling.

The power must not be switched off before the

engine has stopped.

If the engine is equipped with a battery master

switch and an SCR system, the SCR system must

run for a while after the ignition has been

switched off to allow it to cool down. During this

period the power must not be cut using the battery master switch.

Checks after running

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are exhaust manifolds, turbochargers, oil sumps, hot

coolant and oil in pipes and hoses.

1.

Check that the power supply has been cut.

2.

Top up the fuel tank. Make sure that the filler

cap and the area round the filler opening are

clean to avoid contamination of the fuel.

3.

Top up the reductant tank. Make sure that the

filler cap and the area round the filler opening are clean to avoid contamination of the

reductant.

4.

If there is a risk of freezing, the cooling system must contain enough glycol.

5.

If the temperature is below 0°C/32°F: Prepare for the next start by connecting the engine heater (if fitted).

Check the coolant level following the first start.

Top up if necessary.

Property of American Airlines

OPM 200 en-GB 27

©

Scania CV AB 2014, Sweden

Page 29

Inspection

WARNING!

XL

6000

S

5500

M

5000

S

4500

L

4000

S

3500

M

3000

S

2500

L

2000

S

1500

M

1000

S

500

313 153

IMPORTANT!

The inspection programme covers a number of

points that are divided into the following sections:

• Lubrication system

• Cooling system

• Air cleaner

• Fuel system

• Miscellaneous

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

Inspection

On delivery a Scania engine is optimised for its

application. However, regular inspection is necessary to:

• prevent unplanned stops

• extend the service life of the engine

• maximise the long-term emission performance of the engine

• give the best possible operating economy.

The inspection programme includes the following inspections:

• S inspection: Minimum basic inspection.

• M inspection: More extensive inspection.

• L inspection: Includes nearly all inspection

points.

• XL inspection: Includes all inspection points.

During a period, the sequence is S-M-S-L-S-MS-L-S-M-S-XL.

Property of American Airlines

OPM 200 en-GB 28

©

Scania CV AB 2014, Sweden

Page 30

Engines with few hours of op-

IMPORTANT!

WARNING!

Environment

312 152

Clean within the marked area

eration

On engines with few hours of operation, inspection must be carried out annually or every 5

years.

Stand-by generator sets and the like that are not

used regularly should be test run and checked in

accordance with the manufacturer's instructions.

The following inspection points must be carried

out once the engine has been warmed up to operating temperature.

1.

Checking oil level.

2.

Checking coolant level.

3.

Checking vacuum indicator.

4.

Checking fuel level.

5.

Checking for engine leaks.

Inspection

Cleaning the engine

The engine must be cleaned before starting work.

Clean the engine with hot water. Also use a degreasing agent, if necessary.

Avoid spraying water on the engine control unit,

see illustration.

Beware of hot water! Use suitable protective

equipment.

Property of American Airlines

The washing water must be disposed of in compliance with the relevant national and international regulations.

OPM 200 en-GB 29

©

Scania CV AB 2014, Sweden

Page 31

Inspection interval

Daily First time at Interval (hours) At least

first start 500 500 1,000 2,000 6,000 annu-

S M L XL

Lubrication system

Checking oil level

Changing the oil

Cleaning the centrifugal oil

cleaner

Renewing the oil filter

Cooling system

Checking coolant level

Checking coolant antifreeze or

corrosion protection

Cleaning the cooling system and

changing coolant

Air cleaner

Reading the vacuum indicator

Renewing the filter element

Renewing the safety cartridge X

Fuel system

Checking fuel level

Renewing the fuel filter

Miscellaneous

Checking the drive belt

Checking for leaks X X X

Checking and adjusting the

valve clearance

Renewing the reductant filter X X X

Cleaning the reductant tank filler

filter

Cleaning the reductant tank ventilation filter

1 More often if required.

Property of American Airlines

X X

X X

X

X X

1

X

1

X

1

X

X

X

X

X

X

1

1

1

1

X

X

X

X

X

1

1

1

X

1

1

X X X X X

X X X

1

X

1

X

1

X

1

X

X

X

1

X

X

X

X

X

X

1

1

Inspection

every

ally

5

years

1

X

1

1

X

1

X

X

X

X

X

X

1

X

X

OPM 200 en-GB 30

©

Scania CV AB 2014, Sweden

Page 32

Lubrication system

Oil grade

What is Scania LDF?

Scania LDF stands for the Scania Long Drain

Field test standard. Approved Scania LDF oils

have been carefully selected after extensive testing. The approval is only granted to the highest

quality engine oils available on the market.

Recommended oil

Scania Oil LDF

Scania Oil LDF-2

Scania Oil LDF-3

Scania Oil E7

Lubrication system

The engine oil must fulfil the following quality

requirements:

• ACEA E5/API CI-4

• ACEA E7/API CI-4+ for fuel with maximum

15 ppm sulphur content (0.0015%)

• For engines not run on low-sulphur fuel, the

TBN (Total Base Number) should be at least

12 (ASTM 2 896).

• Oils with a low ash content (ACEA E9/API

CJ4) are not recommended.

Check with your oil supplier that the oil meets

these requirements.

If the engine is used in areas of the world where

lubricating oil with ACEA or API classification

is not available, the oil grade must be measured

in actual operation. In this case contact the nearest Scania workshop.

For operation at extremely low outdoor temperatures: Consult your nearest Scania representative

on how to avoid starting difficulties.

Viscosity class Outdoor temperature

SAE 20W-30 -15 °C (5 °F) - +30 °C (86 °F)

SAE 30 -10 °C (14 °F) - +30 °C (86 °F)

SAE 40 -5 °C (23 °F) - > +45°C (113°F)

SAE 50 0 °C (32 °F) - > +45°C (113°F)

SAE 5W-30 < -40°C (-40°F) - +30 °C (86 °F)

SAE 10W-30 -25 °C (-13 °F) - +30 °C (86 °F)

SAE 15W-40 -20 °C (-4 °F) - > +45°C (113°F)

OPM 200 en-GB 31

Property of American Airlines

©

Scania CV AB 2014, Sweden

Page 33

Oil analysis

Note:

312 506

2

1

To be able to extend the oil change intervals using an oil analysis, Scania LDF-2 and LDF-3 oils

must be used.

Oil companies can offer analysis of the engine

oil.

The following conditions must remain fulfilled

when the oil is changed.

• Viscosity at 100°C (212°F): max. ±20% of

original value of the fresh oil.

• TBN (in accordance with ASTM D4739): >

3.5

• TBN (in accordance with ASTM D4739): >

TAN (in accordance with ASTM D664)

• Soot (DIN 51452): < 3%

Such analysis measures the oil's TBN (Total

Base Number), TAN (Total Acid Number), fuel

dilution, water content, viscosity and the quantity of particles and soot in the oil.

Lubrication system

The result of a series of analyses is used as the

basis for establishing a suitable oil change interval.

If the conditions are changed, a new oil analysis

programme must be carried out to establish new

change intervals.

Checking oil level

Checking the oil level with the engine

switched off

Leave the engine off for at least 1 minute before

checking the oil level.

1.

Remove the oil dipstick (1) and check the oil

level. The correct level is between the minimum and maximum marks on the oil dipstick.

2.

Top up with more oil (2) when the oil level is

at or below the lower mark.

Information on the correct oil type is found under

the heading Oil grade.

Property of American Airlines

OPM 200 en-GB 32

©

Scania CV AB 2014, Sweden

Page 34

Changing the oil

Note:

WARNING!

Environment

Note:

314 603

Max. 45 litres (11.9 US gallons)

Min. 39 litres (10.3 US gallons)

314 602

Max. 34 litres (9 US gallons)

Min. 28 litres (7.4 US gallons)

Renew the oil filter and clean the centrifugal oil

cleaner when changing oil.

• Hot oil can cause burns and skin irritation.

Wear protective gloves and goggles when

changing hot oil.

• Make sure that there is no pressure in the lubrication system before starting work on it.

• The oil filler cap must always be in place

when starting and running the engine to prevent oil being ejected.

Lubrication system

Use a container to avoid spillage. Used oil must

be disposed of as specified in national and international law.

Change oil more often if the engine is subjected

to particularly demanding operation, such as a

dusty environment, or if deposits in the centrifugal oil cleaner are thicker than 28 mm (1.1 in).

1.

Unscrew the oil plug and drain the oil when

the engine is hot.

In certain engines the oil is pumped out by

means of a bilge pump.

2.

Clean the magnet on the oil plug.

3.

Refit the oil plug.

4.

Top up with oil.

5.

Check the level on the oil dipstick.

Property of American Airlines

OPM 200 en-GB 33

©

Scania CV AB 2014, Sweden

Page 35

Maximum angles of inclination during opera-

30°

30°

30° 30°

30°

25°

25°

30°

343 843

336 492

The illustration shows the label for oil grade Scania

LDF-2.

tion

Maximum permissible angles during operation

vary, depending on the type of oil sump; see illustration.

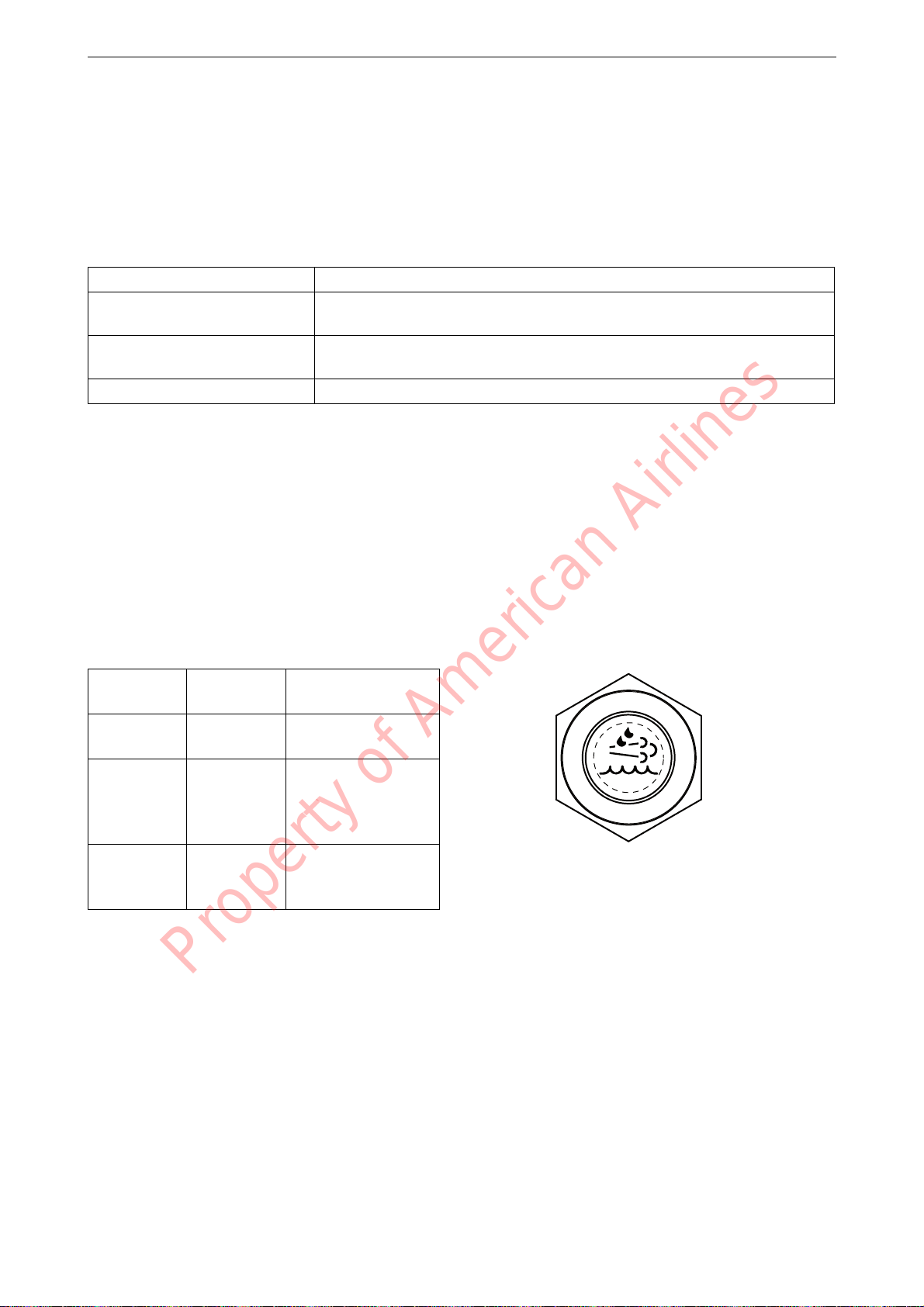

Labels for top-up engine oil grade

When changing oil it is important to use the correct engine oil grade.

Lubrication system

The oil filler cap must be clearly marked with a

label showing the top-up oil grade.

If the label is missing or the engine oil grade is

changed, a new label must be fitted.

Parts

Oil grade Colour Part No.

Scania LDF-2 Blue 2 132 424

Scania LDF-3 Red 2 132 426

Scania LDF Grey 2 269 345

ACEA E7 White 2 132 425

Property of American Airlines

OPM 200 en-GB 34

©

Scania CV AB 2014, Sweden

Page 36

Cleaning the centrifugal oil

WARNING!

Note:

IMPORTANT!

x 1.5

133 315

x 1.5

M20

133 316

cleaner

When cleaning the centrifugal oil cleaner there

will be some dirt deposits in the rotor cover. If

this is the case, this indicates that the rotor is

working. If it is not working, the cause must be

established immediately.

If the dirt deposit exceeds 28 mm at the recommended intervals, the rotor cover should be

cleaned more often.

The oil may be hot. Carefully remove the cover

from the centrifugal oil cleaner.

Lubrication system

1.

Clean the cover. Unscrew the nut securing

the outer cover.

2.

Let the oil run out from the rotor.

3.

Lift out the rotor. Wipe off the outside. Undo

the rotor nut and unscrew it about 1.5 turns to

protect the bearing.

Take care not to damage the rotor shaft.

4.

If the rotor nut is difficult to get loose, turn

the rotor upside down and fasten the rotor nut

in a vice. Turn the rotor counterclockwise

1.5 turns by hand or use an M20 nut, see illustration.

The rotor must not be put in a vice. Never strike

the rotor cover. This may cause damage resulting

in imbalance.

Property of American Airlines

OPM 200 en-GB 35

©

Scania CV AB 2014, Sweden

Page 37

Remove the rotor cover by holding the rotor

133 317

127 878

5.

in both hands and tapping the rotor nut

against the table. Never strike the rotor directly as this may damage its bearings.

Lubrication system

6.

Remove the strainer from the rotor cover. If

the strainer is stuck, insert a screwdriver between the rotor cover and strainer and carefully prise them apart.

Property of American Airlines

OPM 200 en-GB 36

©

Scania CV AB 2014, Sweden

Page 38

Remove the paper insert and scrape away

333 044

333 037

7.

any remaining dirt deposits inside the rotor

cover. If the deposits are thicker than 28 mm,

the centrifugal oil cleaner must be cleaned

more often.

Lubrication system

8.

Wash the parts.

9.

Inspect the 2 nozzles on the rotor. Ensure that

they are not blocked or damaged. Renew any

damaged nozzles.

10.

Check that the bearings are undamaged.

Property of American Airlines

OPM 200 en-GB 37

©

Scania CV AB 2014, Sweden

Page 39

Fit a new paper insert on the inside of the ro-

Note:

1

2 3 4

337 178

127 881

11.

tor cover. Fit the strainer onto the rotor.

Lubrication system

12.

Fit the strainer onto the rotor.

13.

Fit a new O-ring by sliding it over the strainer.

14.

Refit the rotor cover. Make sure that the Oring is seated correctly on the inside.

15.

Screw the rotor nut back on by hand.

16.

Check that the shaft is not loose. Secure with

thread-locking fluid 561 200 if it is loose.

First clean thoroughly using a suitable solvent. Tighten the rotor shaft using socket

wrench 99 520. Tightening torque 27 Nm.

Take care not to damage the rotor shaft.

Property of American Airlines

OPM 200 en-GB 38

©

Scania CV AB 2014, Sweden

Page 40

Refit the rotor and rotate it by hand to make

127 882

127 883

15 Nm

17.

sure it rotates easily.

Lubrication system

18.

Renew the O-ring on the cover of the oil

cleaner housing and fit the cover. Tighten the

lock nut to 15 Nm.

Property of American Airlines

OPM 200 en-GB 39

©

Scania CV AB 2014, Sweden

Page 41

Operational testing

333 039

Operational testing need only be carried out if it

is suspected that the centrifugal oil cleaner is not

working properly. For example, if there is an abnormally small amount of deposit in the centrifugal oil cleaner in relation to the distance driven.

The rotor rotates very fast and should continue to

turn when the engine has stopped.

1.

Run the engine until it is warm.

2.

Stop the engine and listen for noise coming

from the rotor. Use your hand to feel if the

filter housing is vibrating.

3.

If the filter housing is not vibrating, dismantle and check the centrifugal oil cleaner.

Lubrication system

Property of American Airlines

OPM 200 en-GB 40

©

Scania CV AB 2014, Sweden

Page 42

Renewing the oil filter

IMPORTANT!

IMPORTANT!

312 503

312 502

Clean the centrifugal oil cleaner when renewing

the oil filter.

Otherwise, the oil filter will be blocked and resistance in the filter will increase. If this happens,

an overflow valve in the filter retainer opens and

lets the oil pass without being filtered.

1.

Unscrew the filter cover with a socket

wrench with hexagon driver e.g. 36 mm

socket 588 475.

Lubrication system

Do not use an adjustable spanner or other open

tool as there is risk of damaging the filter cover.

2.

Lift out the filter housing cover with filter element. The filter housing will drain automatically once the filter has been removed.

3.

Detach the old filter from the cover by holding the cover and carefully tapping the entire

filter element against something hard. Remember that there will be oil splashes.

4.

Fit the new filter and tighten the filter cover

to 25 Nm (18 lbf ft).

Property of American Airlines

OPM 200 en-GB 41

©

Scania CV AB 2014, Sweden

Page 43

Cooling system

WARNING!

Note:

Coolant

Ethylene glycol can be fatal if ingested and can

cause skin irritation and eye damage.

The coolant recommended by Scania is a mixture of water with antifreeze and corrosion inhibitor (ethylene glycol). The coolant has several

characteristics which are important for the operation of the cooling system:

• Corrosion inhibitor

• Antifreeze

• Increases the boiling point

Cooling system

The coolant should always contain 35-55% by

volume of antifreeze and corrosion inhibitor so

that the coolant properties ensure that the coolant

works correctly.

The coolant should be changed when the cooling

system is cleaned: every 6,000 hours or at least

every 5 years. Refer to Changing coolant.

Property of American Airlines

OPM 200 en-GB 42

©

Scania CV AB 2014, Sweden

Page 44

Coolant resistance to cold

312 505

2

1

3

°C

B A

-50

-40

-30

-20

-16

-10

0

10020 30 40 50

%