Page 1

Contents

Electrical system 11

ELECTRICAL SYSTEM ................................ 2

PROTECTION AND SAFETY

REQUIREMENTS ......................................... 3

Preventative measures.............................. 3

CONNECTORS ............................................. 4

Moisture-proof connectiors ...................... 4

POWER CONSUMPTION ............................. 5

SIZING FUSES AND CABLES AND

VOLTAGE LOSS........................................... 7

CENTRAL ELECTRIC UNIT ......................... 8

Extra central electric unit (accessories/

bodywork) .................................................. 9

FACTORY-FITTED WIRING........................ 10

Factory-fitted wiring in cab ..................... 11

EXTRA CONTROL BOX ............................. 17

JUNCTION BOX IN FRAME ....................... 18

PLACE FOR OPTIONAL ELECTRICAL

ACCESSORIES IN TOPLINE CAB ............ 19

POWER TAKE-OFFS IN COMBINATION

WITH OPTICRUISE .................................... 20

EDC ............................................................. 21

Hand throttle (normal) ............................. 22

Limited hand throttle ............................... 22

Raised idling speed ................................. 23

Fixed engine speed ................................. 23

Example of setting three fixed engine

speeds ...................................................... 24

Torque limitation ...................................... 25

Factory-fitted wiring for FM/AM radio ....13

Factory-fitted wiring for CB radio .......... 13

Factory-fitted wiring for cell phone........ 13

Factory-fitted extra voltage converter

24/12 V ...................................................... 13

Factory-fitted wiring for electrically

operated rear-view mirrors ..................... 13

Connecting extra lights ........................... 14

Power socket in cab ................................ 14

Extra direction indicators ....................... 14

Extra brake light lamps ........................... 14

Electrical items for front-mounted

equipment ................................................ 15

Speed limiter ............................................ 26

Engine stop .............................................. 26

External control of engine speed ........... 27

ADR............................................................. 28

Bodywork on ADR-equipped vehicle .....28

SWITCHES ................................................. 29

APPENDIX:

Wiring diagrams manual

Connection diagrams sheets 1-4

© Scania CV AB 2003

1

Page 2

Electrical system 11

ELECTRICAL SYSTEM

This chapter provides general information about

the electrical system in the Scania 4 series which is

relevant to bodywork.

Supplementing this chapter as attachments are

Manual: Wiring diagram with list of components

and Basic electrical systems.

For further information about components,

diagrams, etc. contact a Scania dealer.

For further information concerning the illustration,

see the Manual: Wiring diagram attachment.

2

© Scania CV AB 2003

Page 3

PROTECTION AND SAFETY REQUIREMENTS

Preventative measures

When working on the electrical system

Detach the battery earth lead and fit a line fuse

between the negative battery terminal and the

chassis in order to avoid accidents in the case of

short circuit.

In and under the instrument panel, close to hot air

ducts, temperatures can reach 90 °C. Always use

cables which resist at least 105 °C in the cab.

Electronic control units and components for such

things as ABS, Opticruise and automatic gearboxes

can be sensitive to heat during oven drying after

painting and to current during such things as arc

welding. Prevent damage as follows:

Electrical system 11

When oven-drying

See Chapter 2 Painting

When arc welding

See Chapter 2 General recommendations for

bodywork section Welding, general.

When charging

Vehicle system voltage must not exceed 30 volts.

This means that jump starting should only be

carried out using batteries in order to prevent a

voltage surge which could damage electronic

components.

Protection against transients

Solenoid valves can give rise to high transients

when the ignition switch is turned off. For this

reason, always use solenoid valves with transient

protection.

The electrical system can cope with transients up to

150 V.

Batteries

The batteries should be trickle-charged to avoid

deterioration while the vehicle is under bodywork

construction.

If the specific gravity of the electrolyte falls too

low, sulphation of the lead plates will result and lead

to a drastic reduction of battery life and capacity.

See Chapter 2 General recommendations for

bodywork section Batteries.

© Scania CV AB 2003

3

Page 4

Electrical system 11

CONNECTORS

A standard electrical system contains about 200

connectors of different shape and material.

When working on the electrical system, changing

or adding components, it is important to use the

same types of connector in order to avoid the risk

of causing interference.

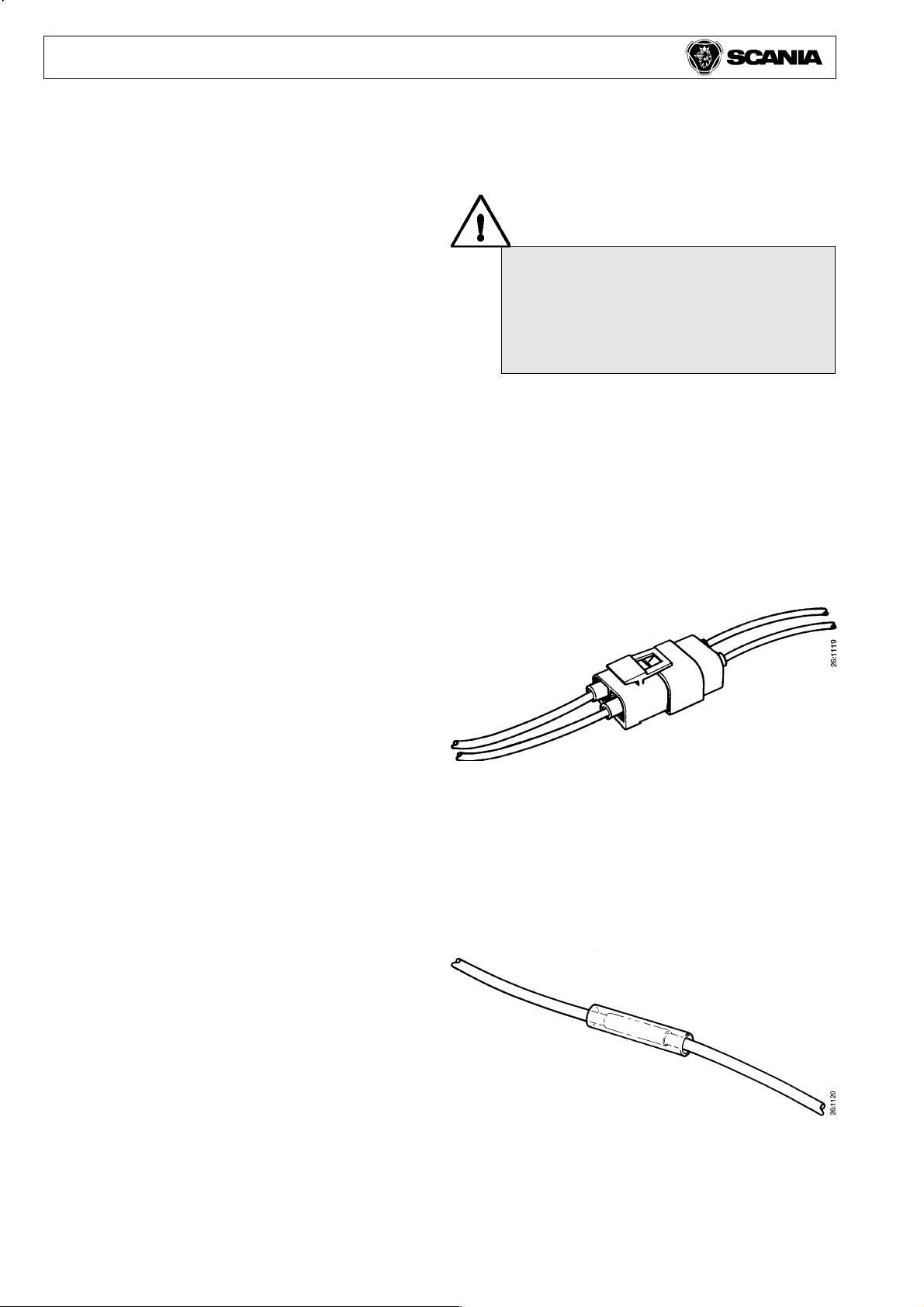

Moisture-proof connectiors

The Scania spare parts department can supply a

number of different types of moisture-proof

connector. Some examples are given below.

Moisture-proof, moulded connectors with 1 m of

1.5 mm2 cable.

Part No.

389202 Female connector, 2-pole with cable

389203 Male connector, 2-pole with cable

1117327 Cable with female terminal, red

1117328 Cable with female terminal, black

1117329 Cable with male terminal, red

1117330 Cable with male terminal, black

Many connectors have a double latching

mechanism for cable terminals.

It is important to release or secure the

double latching mechanism after

changing or adding connectors.

Splice connector

Use splice connector part No. 341333 for splicing

cable 1-2.6 mm2. This is wound with vulcanising

tape part No. 380128 and cover tape part No.

380129.

Alternatively, use a splice connector with adhesive

lined heat shrink tubing.

Part No. 1112499 0.75 mm

1112500 2.5 mm

1112501 3-6 mm

4

2

2

2

© Scania CV AB 2003

Page 5

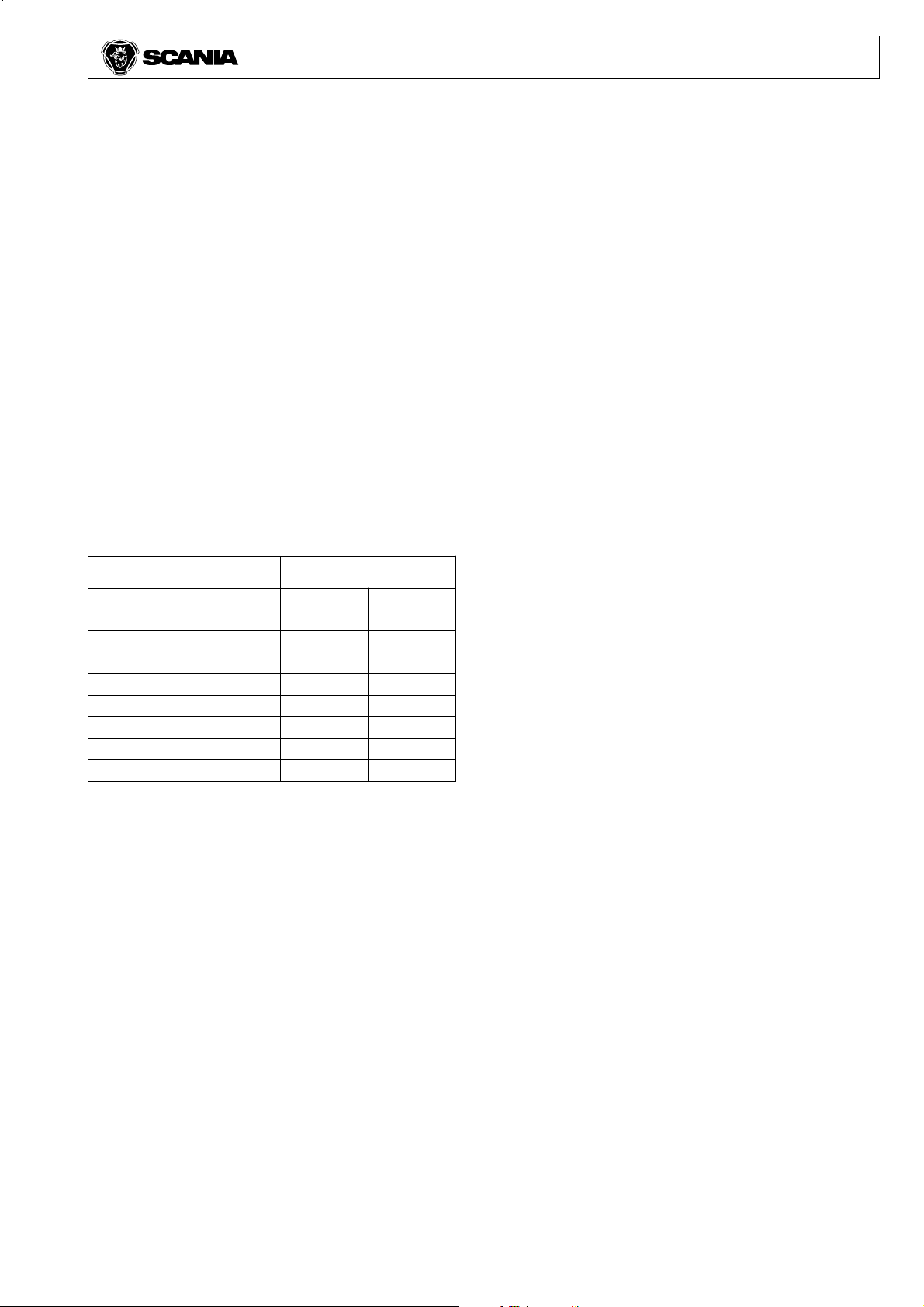

POWER CONSUMPTION

Batteries, alternator and current consumption must be

matched to each other. There should be a charging

equilibrium.

Alternator capacity should be matched to current

consumption so that battery damage is avoided.

The time aspect is important. The current taken from

the batteries must restored within a day or two.

What is the driving cycle like? Frequent starting and

lengthy idling periods will not charge up the batteries

as efficiently as long-haul runs. The alternator generates less current at low engine speeds.

Some examples are given below.

Electrical system 11

Engine speed

(rpm)

500 30 42

600 40 58

700 46 68

800 50 76

1000 56 82

1200 60 88

1600 64 92

Temperature is also important. A battery is much

less able to accept a charge at low temperatures. To

achieve charging balance the alternator should have

an overcapacity of about 15-25 A. In general, it

could be said that an overcapacity of about 15 A

suffices for a vehicle driven over long distances

without stopping (e.g. long-haul runs) while an

overcapacity of about 25 A is needed for a vehicle

making frequent stops (e.g. a delivery van).

Alternator

65A

(A)

90A

(A)

To check whether the alternator has sufficient

capacity, obtain the total current consumption using

the tables below and then add the overcapacity.

Note that this is a very approximate calculation.

© Scania CV AB 2003

5

Page 6

Electrical system 11

To avoid shortening the useful life of the batteries,

the radio position on the ignition switch should be

used whenever possible for supplying power. In the

drive position the entire electrical system is

engaged, which increases current consumption and

with it a bigger drain on the battery.

Normal power consumption, truck

Electric fuel injection 1 x 5 A = 5 A

Main beam headlights 2 x 3 A = 6 A

Rear lights 4 x 0.25 A = 2 A

Front position lights 2 x 0.25 A = 0.5 A

Width marker lights 2 x 0.25 A = 0.5 A

Instrument illumination 20-30 x 0.05 A = 1.5 A

Fan motor 1 x 5 A = 5 A

Windscreen wipers 1 x 4 A = 4 A

Air dryer 1 x 3 A = 3 A

Radio ( std ) 1 x 2 A = 2 A

Normal power consumption, trailer

Rear lights 4 x 0.5 A = 2 A

Side marker lights 8 x 0.5 A = 4 A

Width marker lights 2 x 0.25 A = 0.5 A

Box interior lighting 4 x 2 A = 8 A

Guide values for extra equipment

Operating

time

Extra lights 2-4 x 3 A = 6-12 A 50%

Side marker lights 4-6 x 0.5 A = 2-3 A 100%

Roof lighting, external 1 x 4 A = 4 A 50%

Loading lights 2 x 4 A = 8 A 50%

Electrically-heated seats 2 x 2.5 A = 5 A 25%

Electrically-heated mirrors 2 x 2 A = 4 A 25%

Refrigerator 1 x 2 A = 2 A 60%

Extra cab heaters: 25%

a) Engine cab heater (Webasto) = 6 A

b) Cab heater (Eberspächer) = 3 A

c) Short stop heater = 4 A

Retarder (Electric) 1 x 100-200 A = 100-200 A 5-10 %

Battery heater 1 x 10 A = 10 A 25-50 %

Tail lift 1 x 100 A = 100 A ----

6

© Scania CV AB 2003

Page 7

SIZING FUSES AND CABLES AND VOLTAGE LOSS

Calculate how many amps are consumed when

extra equipment is connected in order to size the

fuses and cables.

Use the following equation:

I = P/U

I = Current in amps (A)

P = Power in watts (W)

U = Voltage (V)

If two of P, U and I are known, the third can be

calculated as follows:

Electrical system 11

U = P/I, I = P/U, P = U x I

Example

Power P = 200 W

Voltage U = 24 V

I = 200 W / 24 V = 8.3 A

The calculated total current through a fuse should

not exceed 60 % of the amp rating.

Sizing cables

Current, power and the distance to the load

determine the cross-section of the conductor.

Current Power Cross-section

10 A 200W 0.75-1 mm

15 A 400W 1.5 mm

20 A 500W 2.5 mm

25 A 650W 4.0 mm

40 A 850W 6.0 mm

50 A 1200W 10.0 mm

2

2

2

2

2

2

Always use the correct fuse. An

oversized fuse can cause fire in the

electrical system.

If cables are long, it may be necessary to use a

thicker cable to reduce voltage loss.

Normally, a voltage loss of 5 % (1.2 V) is acceptable.

Voltage loss in copper conductors is calculated

using the following formula:

U = I x (0.0175 x L) / A

Cables outside the cab should be at least 1.5 mm

2

These values are based on the heat generated in the

cable with continuous current.

© Scania CV AB 2003

U = Voltage loss (V).

I = Current in amps (A).

L = Length of cable.

A = Cross-section of conductor (mm2).

7

Page 8

Electrical system 11

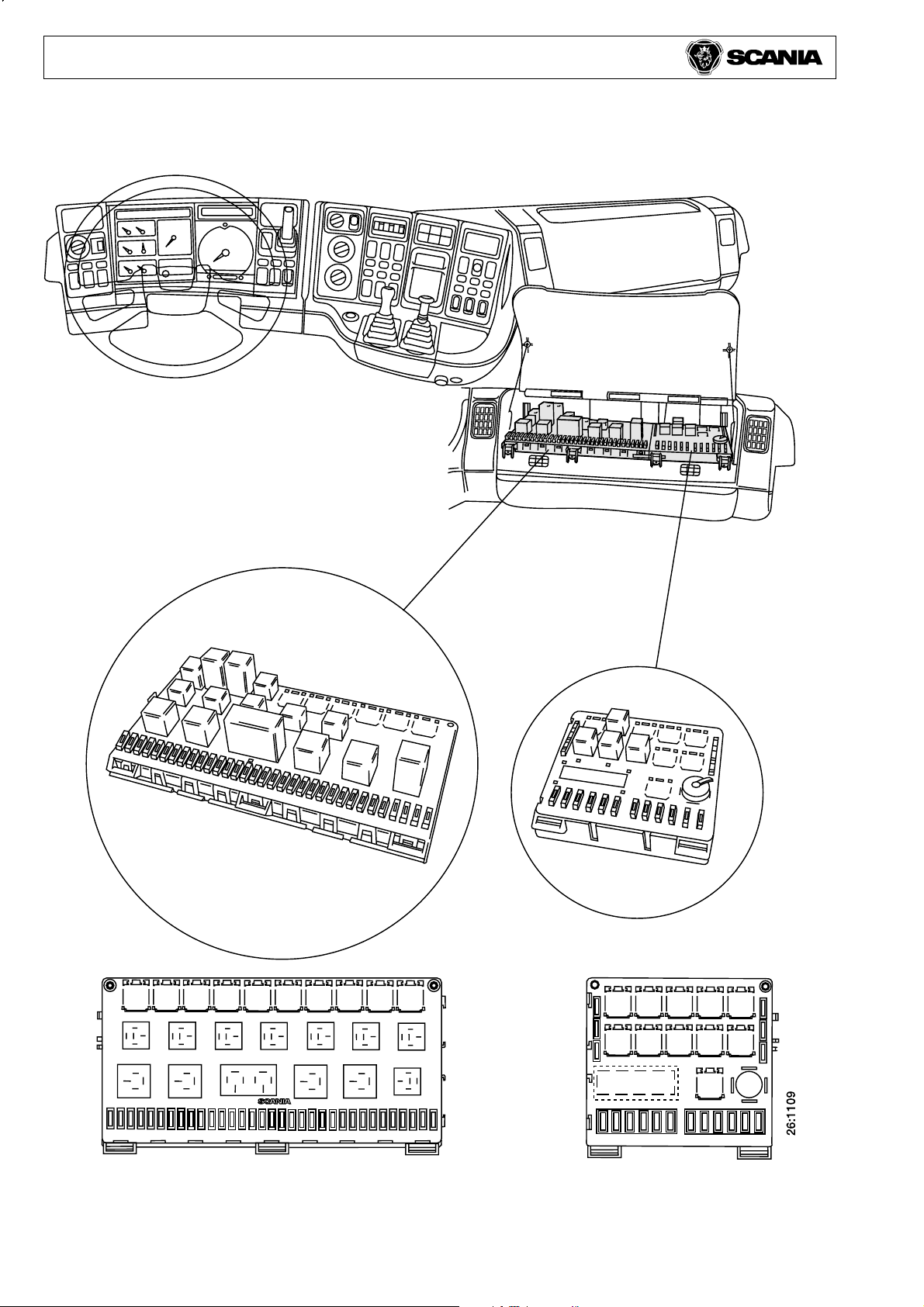

CENTRAL ELECTRIC UNIT

Central electric unit Extra central electric unit

(accessories/bodywork)

8

© Scania CV AB 2003

Page 9

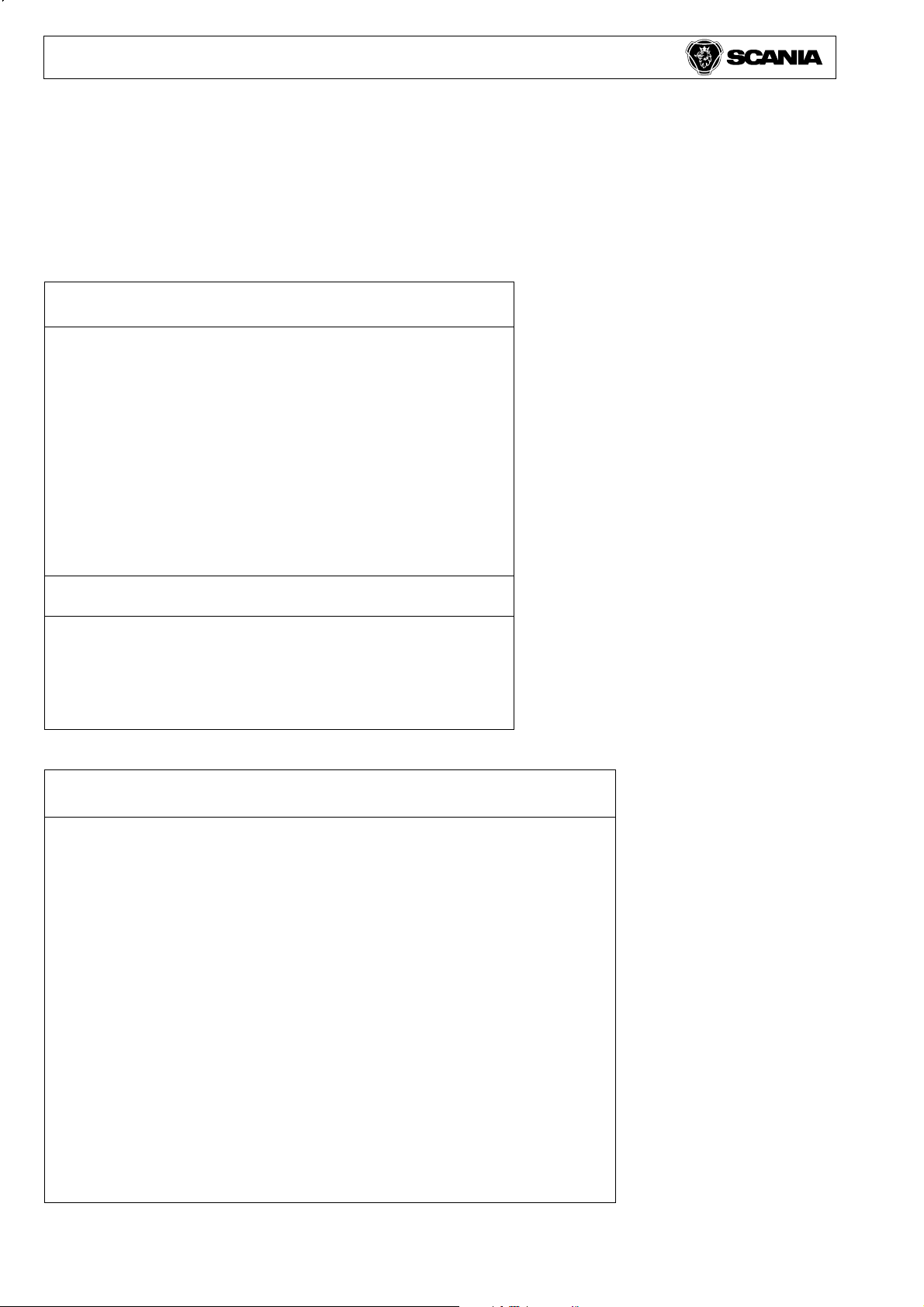

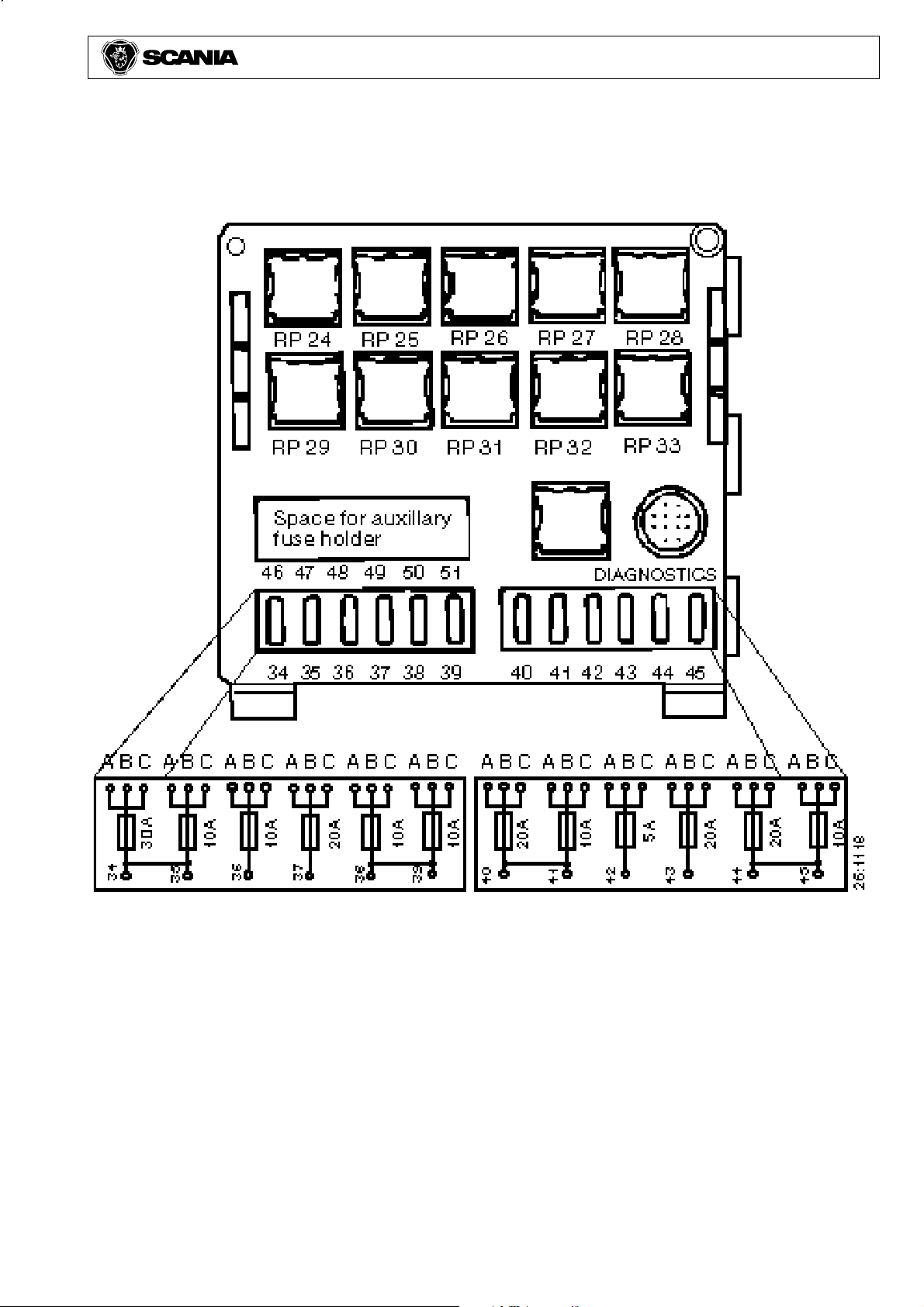

Extra central electric unit (accessories/bodywork)

Electrical system 11

The extra central electric unit can have a varying

number of positions occupied from factory,

depending on what extra equipment, such as fuel/

battery heater and flame start, is fitted.

Extra fuse holder for positions 46-51, part number

1320852.

Extra relay holder, 9-pole, part number 1320851.

© Scania CV AB 2003

9

Page 10

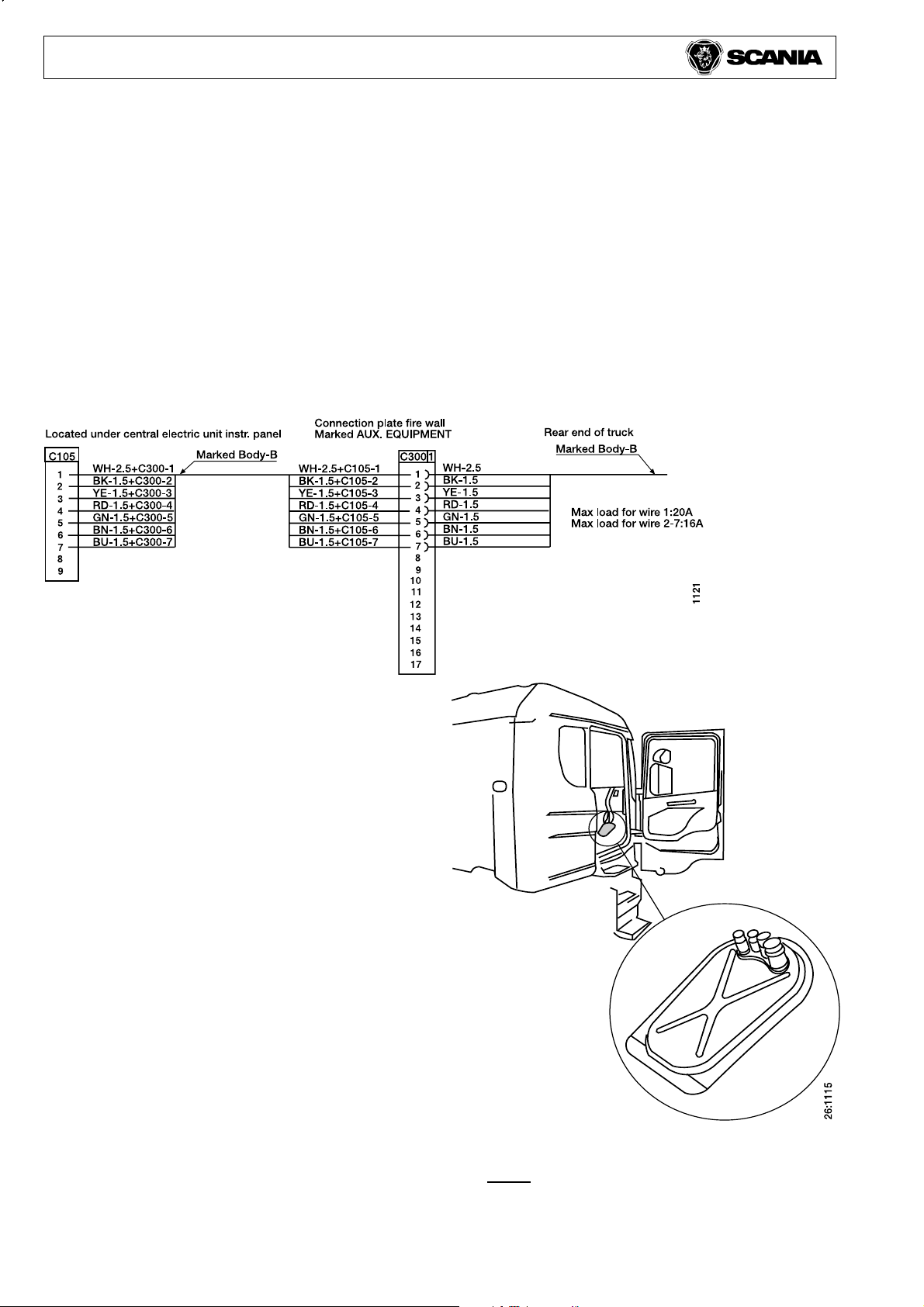

Electrical system 11

FACTORY-FITTED WIRING

With the exception of tractors, all vehicles can be

ordered with a seven-core cable running from the

cab to the rear end of the frame. Via a connector in

the bulkhead marked C300 this cable is wired to a

white connector marked C105 located under the

central electric unit and terminates without a

connector about 1 metre behind the junction box at

the rear end of the frame.

The cable is of ADR design on vehicles ordered

with ADR.

Cable cross- Colour Max. load

section area

1 2.5 mm

2 1.5 mm

3 1.5 mm

4 1.5 mm

5 1.5 mm

6 1.5 mm

7 1.5 mm

2

2

2

2

2

2

2

white 20 A

black 16 A

yellow 16 A

red 16 A

green 16 A

brown 16 A

blue 16 A

Suitable connector housing for C105: part. no. 813556

Suitable round female terminals

Cable cross-section: 1.5 mm

Cable cross-section: 2.5 mm

2

part no. 813925

2

part no. 813927

If the 7-core cable is not enough, or if it is

necessary to route cables to the cab of tractor units,

there are four lead-throughs of varying diameter in

the floor on the passenger side.

Cable lead-throughs

Note: The floor panel is illustrated upside

down to show the rubber plugs.

10

© Scania CV AB 2003

Page 11

Factory-fitted wiring in cab

It is important to consider what optional wiring is required before ordering the

truck as it is complicated to add wiring in the cab, especially in the roof.

All cabs are fitted with prerouted cables for connection of the following

equipment:

- High-mounted working lights on rear wall.

- Rotating beacon mounted either on the rear wall or roof

(Topline only on rear wall).

- Sign lighting.

- Spotlights under exterior sun visor.

- Electric sunroof.

- Interior background lighting.

- FM/AM radio.

- Electrically adjustable rear-view mirrors.

Electrical system 11

For most of the above equipment all connections are made in the roof shelf switch

panel with the exception of external parts of the equipment.

However, in the case of the FM/AM radio, the roof shelf and some trim must be

removed and modified. Fitting is made considerably easier with the radio

prewiring option (see below).

In the case of the electrically adjustable rear-view mirrors, only the cable

harnesses between the cab and doors contain the cables for this equipment.

Mounting is much easier with the pre-wiring option for electrically adjustable

rearview mirrors (see below).

The following optional equipment is also available for all cabs from factory:

- Fully fitted sign lighting.

- Fully fitted spotlights (2) in exterior sun visor.

- Fully fitted spotlights/foglights (2) in the bumper.

- Fully fitted electric sunroof.

- Fully fitted interior background lighting.

- Wiring for FM/AM radio, 12 V.

- Fully fitted FM/AM radio, 12 V.

- Fully fitted Scania Alert. (Only in combination with radio wiring or fully fitted

FM/AM radio).

- Wiring for CB radio.

- Wiring for cell phone.

- Wiring for electrically adjustable rear-view mirrors (enables fitting of

electrically adjustable mirrors on both driver and passenger sides).

- Fully fitted electrically adjustable rear-view mirror on passenger side.

- Electrics for front mounted equipment

© Scania CV AB 2003

11

Page 12

Electrical system 11

Seven holes for electrical equipment are predrilled in

the roof panel.

1. An aerial is fitted for the radio or radio prewiring

options. If neither option has been selected the hole

is plugged but an aerial cable is fitted between the

hole and the radio outlet in the roof shelf.

2. Cable grommet and cables for upper position

marker lights. A connector housing for fitting upper

spotlights is available for connection behind the

cable grommet. Wiring is available as a spare part.

3. An aerial cable for the roof shelf is fitted behind

the rubber plug if the prewiring for CB radio option

is selected.

4. Hole with rubber plug.

5. Wiring behind rubber plug for rotating beacon and

work lighting. Three-core cable (common earth

lead)

6. Wiring behind rubber plug for sign lighting and

rotating beacon. (Not Topline.)

7. If the mobile telephone prewiring option is

selected, an aerial bracket with connected cable

which ends in the dashboard is fitted, rolled up at

the A pillar on the drivers side.

Note: The drawing is in mirror image for right-hand

drive trucks.

12

© Scania CV AB 2003

Page 13

Electrical system 11

Factory-fitted wiring for FM/AM radio

Cable harness for radio equipment, radio bracket, radio panel and 24/12V-4A

voltage converter fitted in the roof shelf. Radio aerial mounted on roof panel,

including factory-fitted 75-ohm impedance aerial cable connected to the radio

outlet in the roof shelf.

Fitted speakers, each with 4-ohm impedance, nominal 30 W and maximum 40 W

output, as follows:

Normal sleeper cabs: Three speakers fitted in the roof shelf.

Topline: Total of four speakers, two fitted in the roof shelf and one in each rear

corner panel.

Factory-fitted wiring for CB radio

One extra radio bracket, extra voltage converter 24/12 V as below and prerouted

12 V cables are fitted in the roof shelf above the windscreen.

Prerouted aerial cable, impedance 50 ohm, between the plug in the roof and the

roof shelf. One extra speaker, impedance 4 ohm and max. output 20 W, fitted in

the centre of the roof shelf.

Factory-fitted wiring for cell phone

An extra 24/12V voltage converter as below, mounted in the roof shelf.

A 12 V socket visible mounted in the roof shelf switch panel.

A bracket with a 12 V socket fitted in the inner side panel under the bunk on the

passenger side.

An aerial bracket on the cab roof with connected aerial cable which ends in the

dashboard, rolled up at the A pillar on the drivers side.

Factory-fitted extra voltage converter 24/12 V

The extra voltage converter is mounted in the roof shelf when the prewiring

option is selected for either CB radio, mobile telephone or both.

The voltage converter, which is connected directly to the battery and not

controlled by the ignition switch, can be loaded with 12V-15A, i.e. 200 W.

Factory-fitted wiring for electrically operated rear-view mirrors

Cable harness fitted in the instrument panel, to the central electric unit and to both

door bridge cables.

Prewiring makes it easy to add electrically adjustable mirrors, either only on the

passenger side or on both sides.

© Scania CV AB 2003

13

Page 14

Electrical system 11

Connecting extra lights

Extra lights can not be connected directly to the light

switch but must be controlled from an output on the

main beam relay.

See attachment Manual: Wiring diagram.

Power socket in cab

A 12 V and a 24 V socket are normally located in the

dashboard on the passenger side. Versions with two

24 V sockets also occur.

With the mobile telephone prewiring option selected,

two 12 V sockets are fitted additionally.

(See under prewiring for mobile telephone.)

Extra direction indicators

The flasher relay, see attachment Manual: Wiring

diagram, has three circuits - vehicle front/side,

vehicle rear/side and trailer, with protection against

overloading and a warning function for bulb filament

failure.

When a lamp blows, the driver is warned as below.

The indicator lamp goes out if:

- A lamp at the front has blown

- The last lamp at the rear has blown

The indicator lamp for the trailer goes out if the last

lamp on the trailer blows.

Note: The system must not be loaded with more than:

eight 21 W bulbs on each side of the vehicle.

Three lamps are factory fitted. For bodywork there is

capacity for two lamps in the rear/side circuit and

three lamps in the trailer circuit.

If more or stronger lamps are connected, the overload

protection activates when the hazard lights are

switched on and they stop flashing.

The overload protection is reset by turning the starter

switch to 0.

Extra brake light lamps

The brake light circuit must not be loaded with more

than eight 21 W lamps.

If the circuit is overloaded, the life of the brake light

relay is reduced.

See attachment Manual: Wiring diagram.

FLASHER RELAY 24V

2+1....3+1....3x21W

9 L 31 30 30 15 R RT

LT L 31 30 30 15 R RT

LA LF C HWL HW C2 RF BR

1234567 8

1122

14

© Scania CV AB 2003

Page 15

Electrical items for front-mounted equipment

Vehicles prepared for front-mounted equipment can,

in addition to brackets (see section Equipment

mounted at the front in Chapter 7 Other bodywork

equipment) also be prepared with electrical items

such as switches and cable harnesses.

This electrical preparation consists of three parts:

1. Switch for plough lights on instrument panel.

The switch is marked S65 and fitted in the upper

part of panel E, see attachment Manual: Wiring

diagram, on vehicles without pressure gauge for

axle weight and in the lower part on vehicles with

pressure gauge.

Part numher of the switch is 1391312.

Part number of the switch decal is 1390521.

Electrical system 11

2. Wiring harness in the instrument panel.

The wiring harness is fitted from switch S65 to the

central electric unit. Part number of the wiring

harness is 1391313.

3. Wiring harness from central electric unit to underside of service panel.

Trucks with P and R cabs have four contacts fitted

behind the service panel.

On trucks with T-cab those contacts are to be found

under the service step on the passenger side. The

contacts are marked C364, C365, C366 and C367.

They contain the following signals:

C364 - Signals for main beam, dipped beam, position

light and direction indicators on the left side.

C365 - Signals for main beam, dipped beam, position

light and directon indicators on the right side.

C366 - Signals for position light on front-mounted

equipment, left side.

C367 - Signals for position light on front-mounted

equipment, right side.

There are also four sealing plugs to use whenever the

contacts are not in use. These plugs should always be

used to prevent the contacts from corrosion.

© Scania CV AB 2003

15

Page 16

Electrical system 11

Suitable contacts to use for connection to C364 and

C365 are:

Part number 815641 - Socket (male)

815635 - Socket (female)

Suitable contacts to use for connection to C366 and

C367 are:

Part number 815638 - Socket (male)

815632 - Socket (female)

Other parts:

Part number

815840 Cable connector type casing (7 per

contact)

815838 Cable connector type pin (7 per contact)

1354883 Both for C364 and C365 (cable diameter

4,2-6,5 mm)

1354885 Both for C364 and C365 (cable diameter

6,2-9 mm)

814776 Both for C366 and C367 (cable diameter

4,2-6,5 mm)

815832 Both for C366 and C367 (cable diameter

6,2-9 mm)

Vehicles with front-mounted equipment may also need

extra switches and joysticks for manoeuvring.

A panel equipped with two extra switches and two

joysticks is obtainable ex works or can be purchased

as an accessory. This panel screws onto the regular

instrument panel below the parking brake lever.

Part number Part name Quantity

1384610 Switch panel 1

1113490 Joystick (4-way) 2

1390308 Mounting frame 1

1371214 Switch 2

815161 Screw 4

1115794 Decal set 1

16

© Scania CV AB 2003

Page 17

EXTRA CONTROL BOX

An extra control box fitted to the rear of the vehicle can be useful

when handling loads (vehicle with air suspension).

Connection between connectors C78 and C163 is the most suitable.

C78 is located below the central electric unit. See attachment

Manual: Wiring diagram. Use a cable cross-section of 0.75 mm2.

Also fit a two-way switch as shown in the illustration.

Electrical system 11

C78

1

2

3

4

C78

1 Red

2 Black

3 Yellow

4 Green

15L

31

ELC 20

ELC

21

C163

1

2

3

4

A

1 Control box

2 Extra control box

A Two-way switch

1

2

3

1

M

2

M

P

O

T

4

S

1

1

M

2

M

P

O

T

S

105 893

2

© Scania CV AB 2003

17

Page 18

Electrical system 11

JUNCTION BOX IN FRAME

The junction box at the rear of the frame is located

either on the last crossmember or on the frame

web, depending on the type of vehicle.

Left-hand rear light is connected to positions

1, 2, 3, 4, 6.

Right-hand rear light is connected to positions

1, 2, 3, 5, 7.

Side marker lights are connected to positions 4, 5.

Trailer cable 24S is connected to positions 1, 2.

Trailer cable 24N is connected to positions

3, 4, 5, 8, 9, 10.

Differential lock is connected to positions 11, 12.

See also chapter 14 Bodywork adaptations BWA

section Trailer connections.

18

© Scania CV AB 2003

Page 19

PLACE FOR OPTIONAL ELECTRICAL ACCESSORIES IN TOPLINE CAB

Our Topline cabs have two storage compartments on

the rear wall and one compartment on each side wall.

Electrical system 11

If you wish to use one or more of these spaces to fit

a TV, microwave, CD changer etc., the hatch must

be removed.

The rear part of the compartment is left in position

to protect the cab insulation.

In order to fit extra equipment, a frame must be

manufactured which uses the four screws securing

the compartment.

There is a space above compartment A which can

be used for a small TV or CD changer.

When making the frame for this space, use the top

two screws in compartment A and the bracket just

above on the roof.

When compartments B-C are used, standing space

in the cab is limited with the upper bunk folded

out.

Good ventilation round optional accessories is

essential due to the risk of fire. Exercise care

when clamping wiring harnesses and always use

rubber grommets at lead-throughs.

All extra equipment in these spaces

must be fitted so that it cannot become

detached in an accident.

© Scania CV AB 2003

19

Page 20

Electrical system 11

POWER TAKE-OFFS IN COMBINATION WITH OPTICRUISE

The Opticruise is programmed to engage and

disengage gears at the torque level which is best for

the gearbox.

If power take-offs, or other equipment, which can

be engaged and disengaged during operation and

which increase torque considerably more than

normal wear, are coupled, the Opticruise must

receive a signal in order to compensate for the

increased torque.

The Opticruise control unit has two different inputs

to handle different types of power take-off / load.

The inputs are active at +24 V.

THE INPUTS MUST ONLY BE ACTIVE

WHEN THE LOAD IS COUPLED.

EK/ED Power take-off

This input, pin 9 on the control unit, must be used

for engine-driven (independent of clutch) power

take-offs. The Opticruise can compensate for an

extra torque take-off of maximum 200 Nm during

operation.

Torque compensation can only be made for one

power take-off or one extra load.

Prewired connections

EK / ED

The cable between S31 and the control unit is

always fitted. If EK / ED is opted for, it is

connected to the base for S31. Otherwise, it is not

connected.

The cable between the power take-off and S31 is

only fitted if the power take-off has been opted for.

EG

Both cables are fitted as standard and the cable to

S30 is connected.

EG Power take-off

This input, pin 50 on the control unit, must be used

for gearbox-driven (independent of clutch) powertake offs.

With this input activated, it is not possible to

change gear while driving. Changing gear with the

power take-off engaged can damage the gearbox.

However, it is possible to engage a gear when the

vehicle is stationary in order to allow range operation with the power take-off active.

Several power take-offs or other equipment which

require gear locking can use this input. However,

when several signals are connected at the same

time, they must be connected so that no conflict

arises with potential differences.

20

© Scania CV AB 2003

Page 21

EDC

Electrical system 11

Trucks equipped with EDC (Electronic Diesel

Control) have a number of prewired functions to

facilitate crane operation and the like.

The prewired functions are:

- Hand throttle

- Limited hand throttle

- Raised idling speed

- Fixed engine speed

- Torque limitation

- Speed limiter (vehicles with coordinator)

- Engine stop

- External control of engine speed

The connections are made at the factory and cables are

routed to a 5-pin connector marked C107 under the

central electric unit.

On vehicles with a coordinator the connector is of 6pin type and labelled C271. It has the same location

under the central electric unit and both connectors are

blue. In both cases the housings are complete

assemblies with corresponding connectors ex works.

- Cable terminal for C107, part no. 199950

- Cable terminal for C271, part no. 815886

1 Control unit (may be located elsewhere)

2 Throttle pedal sensor

3 Brake pedal switches

4 Clutch pedal switch

5 Control for cruise control

6 Tachograph (speed)

7 Diagnostics switch with lamp

8 Indicator lamp

9 Power supply relay

10 Diagnostics socket for PC

The functions are engaged by earthing

different combinations of certain pins on

the connector.

Use a cable cross-section area of 0.75 mm2.

1 Violet

2Grey

3 Brown

4 Green

5 White

6 Yellow (only C271)

© Scania CV AB 2003

21

Page 22

Electrical system 11

Hand throttle (normal)

The hand throttle is used to set the desired engine

speed during crane operation and the like. Setting is

carried out using the cruise control switches. The hand

throttle can be used when the vehicle is stationary or

when driving at low speeds, max. 10 km/h.

Engine speed can be set anywhere between 500 and

2000 rpm.

See vehicle Operators manual.

Limited hand throttle

The limited hand throttle basically works in the same

way as the normal hand throttle. The difference is that

engine speed (between 700 and 2000 rpm) and torque

(between 200 Nm and maximum) can be limited to

protect equipment connected to the power take-off.

It is also possible to select whether the throttle pedal

is to be active or disengaged. These options are

programmed by the Scania workshop. The desired

engine speed, up to the programmed rpm, is set with

the cruise control switches. The function is activated

by earthing connector pin 1.

See also vehicle Operators manual.

22

© Scania CV AB 2003

Page 23

Raised idling speed

Minimum engine rpm can be selected using the

raised idling speed function. Idling speed can be

increased in this way for such purposes as filling

the compressed air system or warming up the

engine. The function is also useful on vehicles with

a cement mixer.

Engine speed (500-800 rpm) is set with the cruise

control switches and is not disengaged by

activating the brake pedal, clutch pedal, exhaust

brake or retarder. The set engine speed can be

stored in the memory.

The function is activated by earthing pin 5.

See also vehicle Operators manual.

Fixed engine speed

Fixed engine speed means that the driver cannot

alter engine speed with either the throttle pedal or

the cruise control switches. This can be used when

precision is important.

Engine speed (600-2000 rpm) and maximum

torque (200-2000 Nm) are programmed by the

Scania workshop.

The function is activated by earthing pins 1 and 5.

See also vehicle Operators manual.

Electrical system 11

© Scania CV AB 2003

23

Page 24

Electrical system 11

Example of setting three fixed engine speeds

Certain types of bodywork equipment require one or

more different engine speed levels.

Examples showing how up to three different fixed

engine speeds can be set are given below.

The cruise control switch must be in the ON position

for these settings to function correctly.

Engine speed 1

Setting engine speed 1, say 750 rpm, using the

Raised idling speed function.

This function can be used between 500 and 800 rpm.

Engine speed 2

Setting engine speed 2, say 1100 rpm, using the

Limited hand throttle function.

This function can be used between 700 and 2000 rpm.

Engine speed 3

Setting engine speed 3, say 1400 rpm, using the

Fixed engine speed function.

This function can be used between 600 and 2000 rpm.

Engine speed settings 1 and 2 can be set/adjusted by

the driver using the cruise control switches. See

vehicle Operators Manual.

Engine speed setting 3 is to be programmed at a

Scania workshop.

24

© Scania CV AB 2003

Page 25

Torque limitation

The EDC unit can be programmed for three different levels of torque limitation. These are chosen

by earthing pins 3 and 4 in different combinations.

The function can be combined with engine speed

control.

Torque limitation 1

With Torque limitation 1 engaged the engines

torque curve is peaky. It then feels as though

pulling power increases when engine speed drops,

e.g. on uphill gradients.

The function is activated by earthing pin 4.

Torque limitation 2

With Torque limitation 2 engaged the torque is

limited to 700 Nm at engine speeds up to

1000rpm. At higher engine speeds the torque limit

is slightly lower.

Electrical system 11

Nm

107 461

r/min

Nm

The function is used on vehicles with a torque

converter and manual gearbox. Engagement can be

arranged so that the function is active when the

clutch pedal is depressed. That is to protect the

clutch from overheating, such as when pulling

heavy loads.

The function is activated by earthing pin 3.

Torque limitation 3

With Torque limitation 3 a torque curve with early

breakaway is obtained. Torque limitation starts at

1000 rpm and stops at 1400 rpm. This function can

be used as an alternative to the engine speed

control function Limited hand throttle to protect

a power take-off, for instance.

With this function it is also possible to reprogram

the torque curve to suit your own requirements.

This is done at a Scania workshop.

The function is activated by earthing pins 3 and 4.

107 387

r/min

Nm

107 388

r/min

© Scania CV AB 2003

25

Page 26

Electrical system 11

Speed limiter

Vehicles having the 6-pin connector C271 also

have an additional function, speed limitation. This

can be used for example on refuse collection trucks

with an external platform and can be engaged when

someone is standing on the platform. The speed

limiting function is independent of the regular

cruise control and can be used as a complementary

system to it.

The default speed is 70km/h but it can be changed

at a Scania workshop. The function is activated by

earthing pin 6.

This function is also included on vehicles with unit

injectors (PDE) and EDCMS6. The function is then

activated by applying current (+24 V) to pin H-6 of

connector C112 at the cab lead-through.

See attachment Manual: Wiring diagram.

Cable terminal for C112.

Part no. 815 844

Use a cable cross-section area of 0.75 mm2.

You can see whether or not the vehicle has a

coordinator by looking at the diagnostics panel. If it

does have a coordinator there will be a switch as

shown in the illustration. In addition, the switch

lamp comes on for a few seconds when power is

turned on with the ignition switch.

Engine stop

With the engine stop function the engine can be

stopped quickly if, for instance, an accident occurs

during crane operation.

When the engine stop button is pressed, pin 2 of

connector C107/271 is earthed and the engine

immediately stops if the vehicle is stationary. If the

stop is activated while the vehicle is in motion,

engine speed drops to idling but the engine is not

shut down. This is in order to retain servo

assistance for power steering.

26

© Scania CV AB 2003

Page 27

External control of engine speed

General

The speed of EDC engines can be regulated with the

cruise control. It can be operated from outside the

vehicle with an extra control unit connected to the

vehicle by an extension cable. The connection below

ensures that external control of engine speed is only

possible when the parking brake is applied.

Connection of the extra control unit is shown in

wiring diagram no. 16:04-57, part number 1 712 468,

which can be ordered from your Scania dealer.

Proceed as follows

1. Connection of the extra control unit is via pins 8

and 9 of connector C23 (a 9-pin connector located

on the cable nearest the cruise control switch

assembly).

Electrical system 11

2. Connect an extra cable to pin 9 which leads to a

new connector for the extra control unit. This

should be located in the front cab wall.

3. Transfer the existing cable connected to pin 8 of

connector C 23 to pin 30 of a new relay (part no.

1 391 322) mounted in the central electric unit.

4. Run a new cable from pin 8 of connector C 23 to

pin 87A of the relay and a cable from pin 87 of the

relay to the new connector for the external control

unit.

5. Power for the new relay is supplied via fuse, as

shown in the wiring diagram, with switch (part no.

1 488 066) and a cable to connector C 56 (under

the central electric unit), terminal block R pin 3

(signal when the parking brake is applied).

6. The external control unit must be arranged

according to the schematic so that only one

function at a time can be activated. The tolerance

of the resistors should be ±1%.

7. The external control units connection cable should

be twisted with 30-40 turns per metre to avoid

electrical interference in the system.

8. A motor stop should be mounted adjacent to the

external control unit.

© Scania CV AB 2003

27

Page 28

Electrical system 11

ADR

Scania supplies chassis equipped in conformity

with applicable international ADR regulations.

The chassis are supplied with equipment and

certification for the relevant ADR category (AT,

EXII, EXIII, FL and OX), which means that no

modification of ADR related components/systems

shall be made to the chassis in connection with

bodywork assembly unless so required by national

laws and regulations.

Bodywork on ADR-equipped vehicle

The following applies to the connection of extra

equipment on an ADR classified chassis:

- All bodywork/modification affecting ADR must

be approved by the vehicle inspection authority

in the country of registration.

- Conversion of a non-ADR chassis may be

carried out in consultation with a Scania

distributor and the relevant national authority.

To facilitate official approval the use of genuine

Scania ADR parts is recommended.

- An ADR-classified cable is available for the

electrical connection of bodywork. See the

section entitled Factory-fitted wiring in this

chapter.

- The workshop or bodywork builder is

responsible for ensuring that bodywork/

modification complies with ADR requirements.

28

© Scania CV AB 2003

Page 29

SWITCHES

Tag axle lift (air suspension) 353623 Interior lighting 353625

Electrical system 11

Electric sunroof 353628

Socket 353642

Power take-off (dependent on parking brake)

353638

Short stop heater, Central lock

(Topline from upper bunk)

353646

Interior lighting (Topline),

Air horn 383744

© Scania CV AB 2003

Robson drive 1115426

29

Page 30

Electrical system 11

Retarder 1350317TC 1347592

Rheostat (light level) 1350547

Speed limiter with cruise control

1357244

Front foglight 1352114

Opticruise (selection of driving mode)

1357375

30

Mechanical air suspension

1367546

Rheostat (instrument illumination)

1371210

© Scania CV AB 2003

Page 31

Electrical system 11

Differential lock (all wheel drive) 1371213

Instrument panel

1371215

Differential lock / Power take-off 1488071

Instrument panel

1371216

Tag axle lift (leaf spring) 1405631

Rear foglight, Scania Alert,

High-level work lights on rear wall 1488067

© Scania CV AB 2003

Electric windows 1413146

Electrically heated rear-view mirror, Sign lighting,

Interior background lighting, Spotlights, Rotating

beacon 1488066

31

Page 32

Electrical system 11

4x4/6x6 with ABS

1488070

Electrically adjustable mirror on passenger side

1361023

Electrically adjustable mirrors for both driver

and passenger sides 1380910

32

© Scania CV AB 2003

Loading...

Loading...