Page 1

Product information PI 54

Machining unit 0.5.030.xxx

Slide unit 0.2.200.xxx

2009-10-23

Page 2

Page 3

®

Table of Contents

Machining Unit

Brief Description.............................................................................................................................4

Technical Data .................................... .... ... .... ... .... ... .... ... .... ....... ... .... ... .... ... .... ... .... ... ...... ..............6

Dimensions.....................................................................................................................................7

Precision...................................................................................................................... ...................8

Installation Options........................................................ ... .... ... ....... .... ... ....... .... ... .... ....... ................9

Application Examp les...................................................................................................................10

Slide Unit

Brief Description...........................................................................................................................12

Technical Data .................................... .... ... .... ... .... ... .... ... ....... .... ... .... ... .... ... .... ... ....... .... ..............14

Dimensions...................................................................................................................................15

Installation Options........................................................ ... .... ... ....... .... ... ....... .... ... .... ....... ..............16

Table of Contents

Spindle heads

Features..................................................................................................................... ..................18

Spindle Heads 0° Selection..........................................................................................................19

Admissible Loads.........................................................................................................................20

Spindle Heads 90° Selection........................................................................................................21

Precision...................................................................................................................... .................22

Ordering details

Machining Unit..............................................................................................................................23

Spindle Heads....................................................................................................................... .......24

Slide Unit......................................................................................................................................25

NOTE:

The information contained in this product information is based on the

knowledge available at the time of printing. We expressly reserve the right to make changes which occur in line with

continuous development.

Our guarantee demands observance of the information provided in the project planning instructions!

PI_54_e_09-09-22.fm

PI 54 e

3

Page 4

Brief Description

Machining Unit

Brief description of machining unit

Machining units are used particularly for machining stations of transfer lines,

revolving transfer machines and for turning machines.

Features

• Prepared for high-power servomotors

• High torque capacity .

• Protection of all tool spindles against swarf and cooling lubricant by

labyrinth seals supported by sealing air

• Cooling lubricant supply

– externally by the spindle head housing or

– internally by the tool spindle (suitable for dry running)

– Minimal quantity lubrication (optional)

• Universal installation

• Expansion of the application areas of your machine

• Other versions on request

®

4

PI 54 e

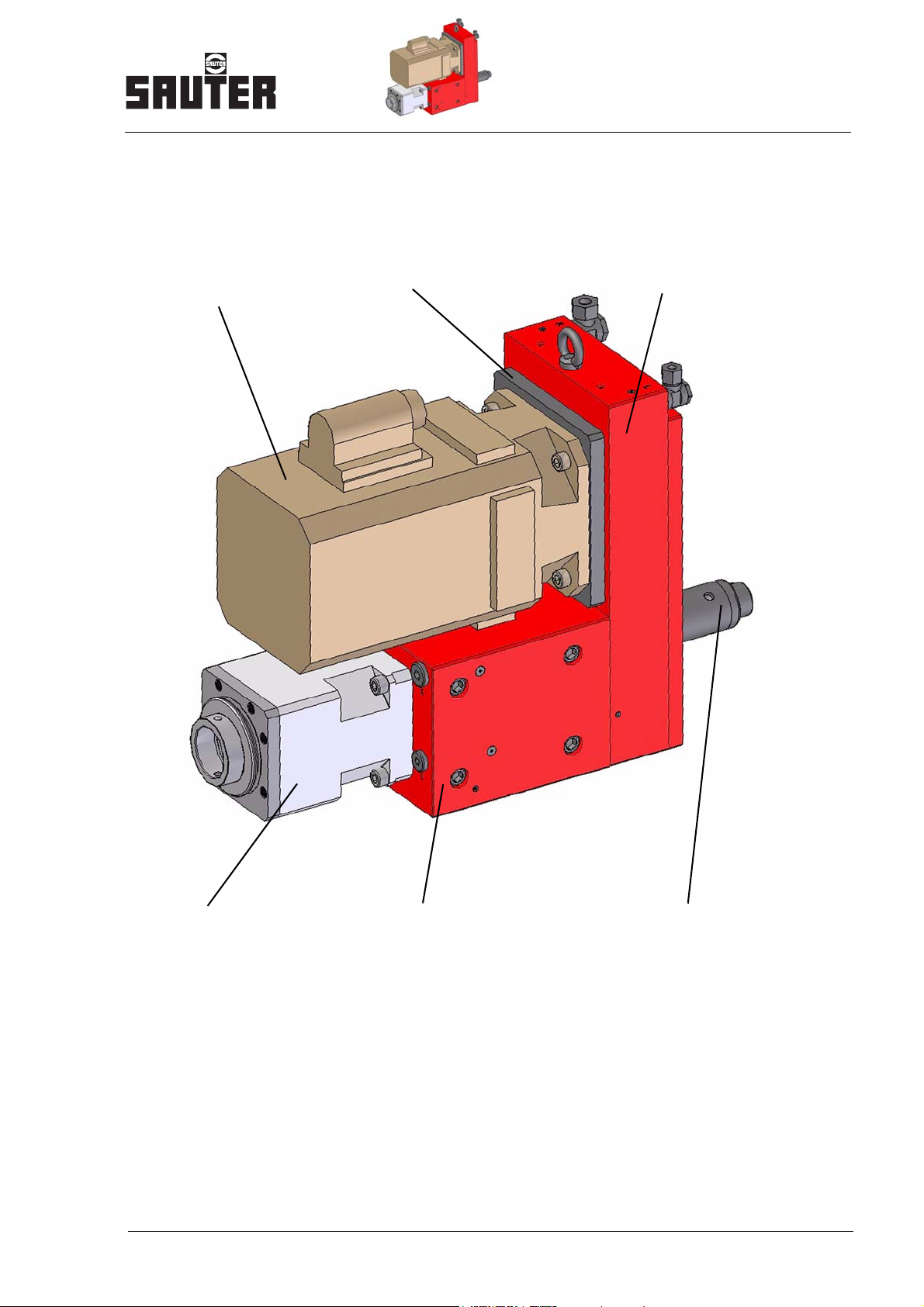

Page 5

®

Brief Description

Machining Unit

Drive motor

- provided by customer -

Motor flange

Machining Unit

Spindle head

1.) e.g. Deublin, GAT, etc.

Screw-on surfaces

- on both sides -

PI 54 e

Cooling lubricant

rotary feed-through

- provided by customer -

1)

5

Page 6

Technical Data

Machining Unit

Technical Data of Machining Unit

Series Size

Machining unit 0.5.030.0xx 06

Max. permitted drive speed

Max. permitted drive torque

1.)

3.)

Max. permitted output torque Nm 150

Max. permitted drive rating kW 12

Transmission ratio

Mass

(machining unit without motor and without spindle head)

2.)

(Options)

Operating pressure

Sealing air bar 0.4 - 0.8 (filtering <5µm) Cooling lubricant

• for external supply through the spindle head housing bar <

• for internal supply through the tool spindle bar <

• for minimal quantity lubrication bar On request

Recommended drive motors

SIEMENS 1FT6 086

rpm

Torque

Power

n

max

M

max 60% DC

P

max 60% DC

Mass kg 26

FANUC Alpha 30 / 4000HVis

rpm

Torque

Power

n

max

M

max 60% DC

P

max 60% DC

Mass kg 23

For this purpose SAUTER spindle

heads

-1

min

Nm 100

i = n

1/n2

2,4 (1,0 / 1,5 / 2,0)

kg 70

25 (filtering <100µm)

100 (filtering <50µm)

-1

min

Nm 35

kW 12

-1

min

Nm 38

kW 12

0.5.934.1..

0.5.934.2..

6000

6000

4000

®

1.) Higher rpm on request

2.) Other transmissions on request.

is the admissible peak load for the gearbox.

3.) M

adm

The torque must be reduced to the indicated value on the motor inverter. Also consider the gear ratio.

The usable performance data depends on the performance characteristic of the motor type used.

The permitted torque can be used for shock-free machining. For high-shock machining – e.g. cutter head milling, etc. –

the drive torque must be reduced considerably to prevent an overload of the gearbox.

6

PI 54 e

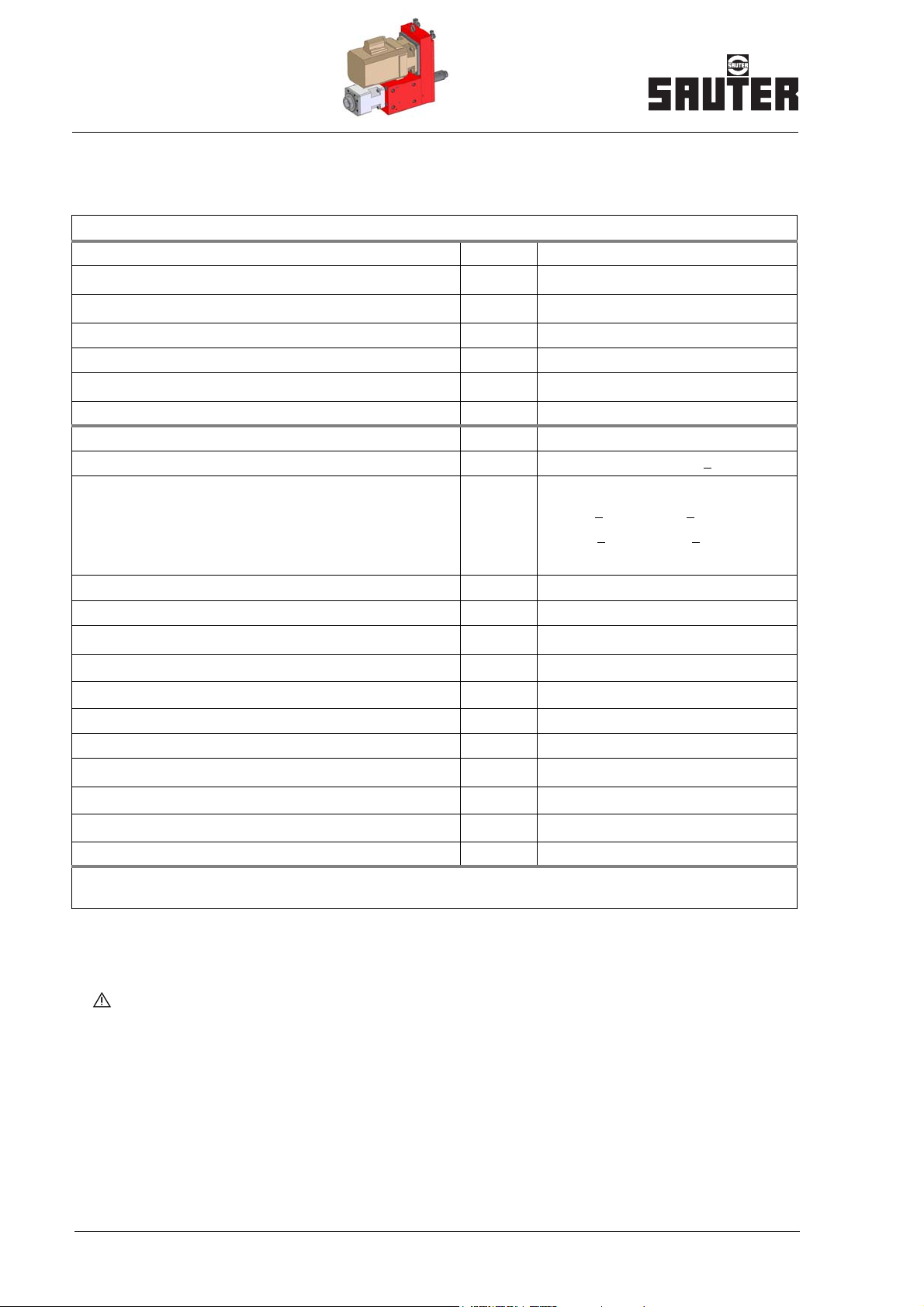

Page 7

®

Dimensions of Machining Unit

Dimensions

Machining Unit

Cooling lubricant connection (external)

Series Size

Machining unit 0.5.030.0xx 06

mm 187

mm 77

mm 360,5

mm 78

mm depending on transmission ratio

mm 88

mm 176

mm depending on motor manufacturer and motor type

mm depending on spindle head length

mm 87,5

mm 146

mm 72

M12

mm 20

mm 28

mm 120

mm 45

mm 45

M

B

C

D

E

F

G

H

L

K

max.

U

T

SG

SL

Y

X

Z

W

PI 54 e

7

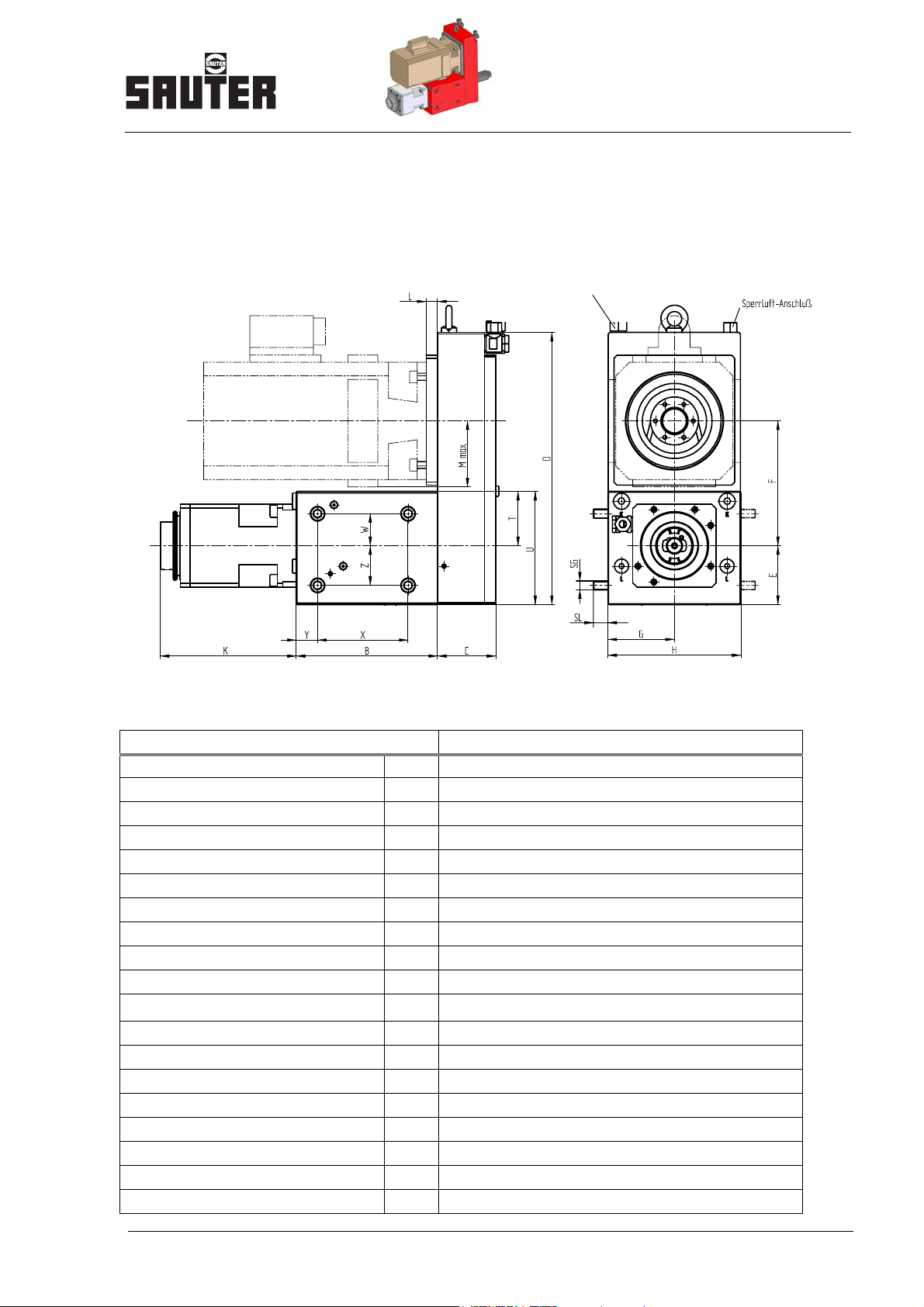

Page 8

Precision

Machining Unit

Precision of Machining Unit

®

Positioning accuracy

• Spindle head location hole

- Positioning accuracy

- Bore tolerance H6

Spindle head contact surface

To determine the positioning accuracy of the tool tip, the accuracy of the spindle head and

tools must also be considered

8

PI 54 e

Page 9

®

Installation options

Installation options

Adjustment part s for inst allatio n on the head turret 0.5.32 0.xxx with tool hold er in accordanc e with D IN 6988 1

Installation option 1

42

Installation option 2

NG 140

Alignment device

Tool holder - adapter

-without height adjustment-

76

PI 54 e

NG 140

Tool holder - adapter

-with manual height adjustmentStroke ± 11 mm

9

Page 10

Application examples

Application examples:

Head turret 0.5.320.xxx

®

Slide unit 0.2.201.036

Other installation options on request

10

PI 54 e

Page 11

Notes

®

Notes

PI 54 e

11

Page 12

Brief Description

Slide Unit

Brief description of slide unit

These slide units are particularly suitable for accommodating machining units.

Installation is e.g. on a bidirectional head turret.

Features

• Slide unit designed as a compact dovetail guide.

• Central lubrication connection.

• Cooling lubricant supply via the interface DIN 69881.

• Slide position via motor encoder.

• Expansion of the application area of your machine.

• Quick installation by precision quick-change system. (e.g. SPEEDY metec)

• High repeating accuracy by alignment device.

• Other versions on request.

®

12

PI 54 e

Page 13

®

Brief Description

Slide Unit

Drive motor -

provided by

-customer-

Central terminal box

-option -

Attachment drilling pattern

for machining unit

Alignment device

Central lubrication

connection

Slide Unit

PI 54 e

13

Page 14

Technical Data

Slide Unit

Technical Data of Slide Unit

Series Size

Slide unit 0.2.200.0xx 25

Gearing ratio i 1 Gradient of the ball roller spindle mm 5 Adm. rapid feed rate m/min 10 Working stroke mm ±100 Adm. feed force kN 1

®

Adm. motor drive speed

min

-1

2000

Adm. motor drive torque Nm 3

Length measuring system

Motor

encoder

Achievable positioning accuracy µm 10

(slide unit without machining unit, without spindle head and without motor)

Mass

kg 125

Recommended drive motors

SIEMENS 1FK7 042

1.)

Speed

1.)

Torque

with brake

n

max

M

max 60% DC

min

-1

3000

Nm 3,2

Mass kg 5,4

FANUC Alpha 2 / 5000 is

FANUC Alpha 2 / 5000 HVis

1.)

Speed

1.)

Torque

with brake

with brake

n

max

M

max 60% DC

min

-1

5000

Nm 2,6

Mass kg 3,8

1.)

Limit motor to adm. values of the slide unit.

14

PI 54 e

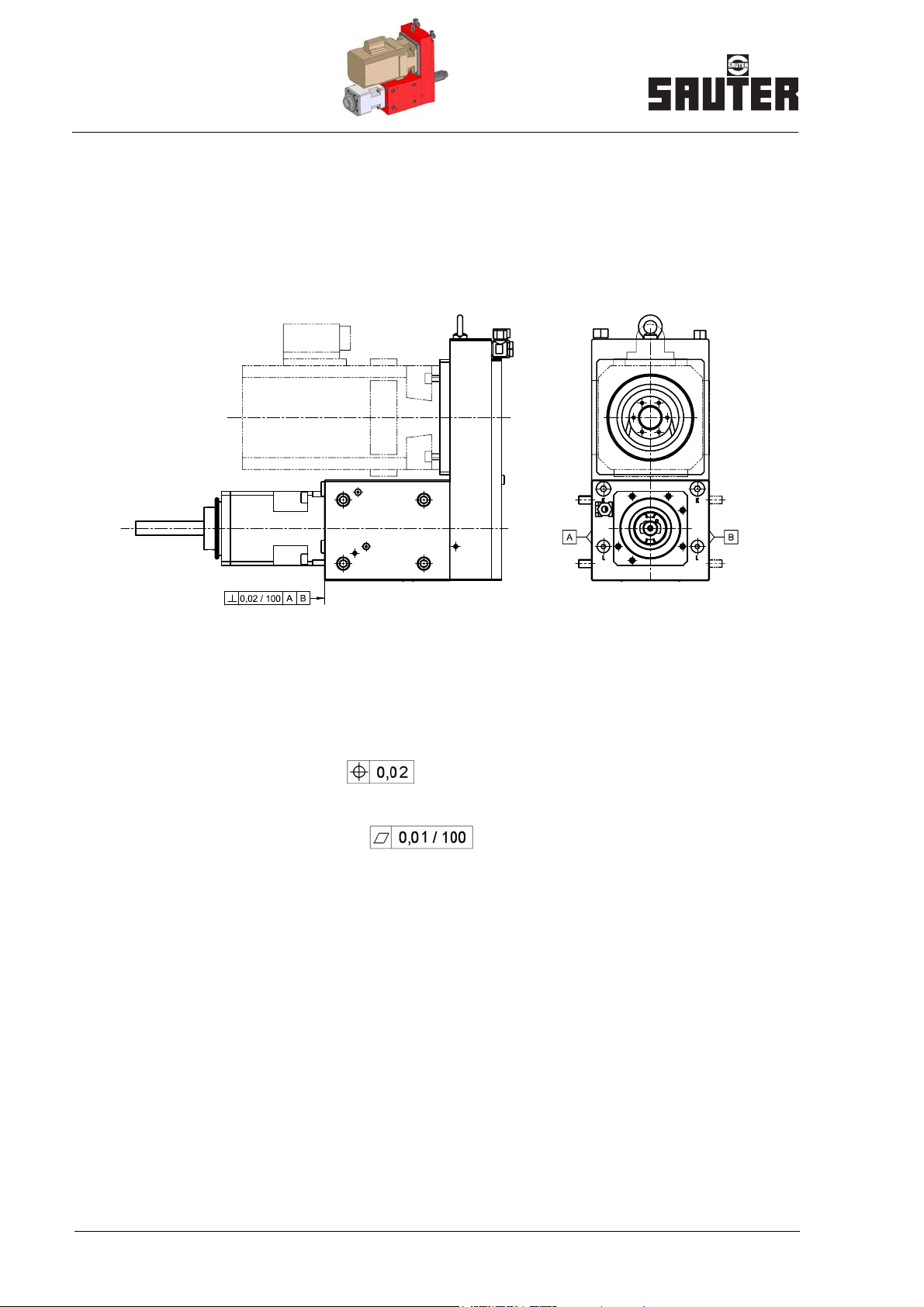

Page 15

®

Dimensions

Slide Unit

Series Size

Slide unit 0.2.200.0xx

B

C

D

H

±H

M

Y

X

R (Grid)

Z

W

mm 108

mm 130

mm 260

mm 228

mm 100

mm 542

mm 105

mm 120

mm 30

mm 90

mm 45

25

PI 54 e

15

Page 16

®

Installation options

Adjustment parts for installation on the head turret 0.5.320.xxx with tool holder

Installation options

Central terminal box

- Option -

Cable carrier

- Option -

NG 140

KSS supply from

head turret

KSS output to the

machining Unit

in accordance

with DIN 69881

Tool holder - adapter

with quick-change system

42

0

0

3

16

PI 54 e

Page 17

Notes

®

Notes

PI 54 e

17

Page 18

Features of the Spindle

Spindle heads of series 0.5.934.xxx

®

Features

• Bearing assembly via precision spindle bearings in -O- or tandem-O-arrangement,

moderate preload

• Service life grease lubrication

• Wear-free labyrinth seal with sealing air support

• Cooling lubricant supply:

– externally by the spindle head housing or

– internally by the tool spindle

• Ve ry high concentricity and degree of balance

• Tool holder in the spindle: for HSK/Mapal clamping system

• Transmission i = 1

Options

• Special tool holders

• Spindle bearings (selection):

– for high speed

– for high load

– for special requests

• Other options on request:

• Spindle heads with transmission i

– Multi-spindle drill heads

.

.

.

‡

1

18

PI 54 e

Page 19

®

Spindle head 0° selection 0.5.934.xxx

Shaft diameter

D

Tool

holder

Arrangement of

1)

bearings

Size Length

HSK 50-C < O > 106 138 HSK 63-C < O > 106 138

60

HSK 63-C << O > 106 138 HSK 63-C << O > 106 180 HSK 63-C << O >> 106 -

1)

Including clamping unit from Mapal, type KS..-07 clamping unit and guard ring.

Spindle head 0° selection

L

Application recommendation:

Bearing arrangement << O > – for higher loads.

Internal cooling lubricant supply – suitable for dry running.

PI 54 e

19

Page 20

0

Admissible Loads

Permitted axial force during drilling

®

Characteristic no.

Bearing

arrangement

Nominal

bearing service life

L

1 Standard 4000 2 Tandem 4000 3 Standard 8000 4 Tandem 8000

7,00

6,00

5,00

4,00

ax

F [kN]

3,00

2,00

1,00

0,00

1000

Permitted transverse force during milling

h

2000

[h]

0.5.934.106

3000

n [1/min]

4000

5000

2

4

1

3

600

Characteristic no.

Bearing arrange-

ment

1 Tandem Long

3 Standard Standard 4 Tandem Long 5 Tandem Standard 6 Standard Standard

Bearing spac-

ing

L

[mm]

W

802 Tandem Standard

160

L

W

20

PI 54 e

Page 21

®

Spindle head 90° selection

Spindle head 90°

selection

Shaft diameter

Tool holder

1)

Arrange-

D

bearings

for collet

DIN 6499-40

for collet

DIN 6499-40

60

HSK 63-C

HSK 63-C

HSK 63-C

1)

Including clamping unit from Mapal, type KS..-07 clamping unit and guard ring.

2) High speeds in short time operation only. (= 10% DC - 5 min.)

1) 2)

1) 2)

1) 2)

<< O >> 206 - - -

0.5.934.xxx

Size L1 L2 B

ment of

<< O > 206 - 160 118

<< O > 206 - 250 118

<< O > 206 70 160 0 << O > 206 70 250 0

Operating pressure for cooling lubricant for internal and external supply: p

Internal cooling lubricant supply – suitable for dry running.

Other versions of tool holding system, bearing types, etc. on request.

PI 54 e

= 25 bar.

max

21

Page 22

Precision

Precision - Spindle Head

– Spindle with HSK tool holder

– Bearing quality P2 = ABEC 9

Spindle head 0°

®

Spindle head 90°

Dimensions in mm

22

PI 54 e

Page 23

®

Ordering details

++49 (0) 7123-926-190

++49 (0) 123-926-0

info@sauter-feinmechanik.com

Sauter Feinmechanik GmbH

Postfach 1551

D-72545 Metzingen

Germany

Firma:

Straße:

PLZ, Ort:

Name:

Tel.:

Fax:

E-Mail:

SAUTER machining unit 0.5.030.0xx

Ordering details Possible configurations Your selection Installation position Size: 06 06 Drive motor used See page 6

Transmission

i= n1/n2 = 1.0 / 1.5 / 2.0 / 2.4

Features:

Machining type

Tapping

Special requirements:

e.g. cutting depth, drill diameter, feed values

Quantity: ........

Drilling

Milling

PI 54 e

23

Page 24

Ordering details

SAUTER spindle heads 0.5.934.xxx

Ordering details Possible configurations Your selection Size: 06 Tool holder: HSK 50

HSK 63

including Mapal clamping

unit

Special

®

Bearing spacing/bearing arrangement:

Standard / -O-

Standard / Tandem -O-

Standard / Special

Long / Tandem -O-

Long / Special

= .....

Application features: Drilling

Milling

n

M

max

= .....

d

Other ......

Transmission: i = ....

Special requirements: Sketch is enclosed

Quantity: .......

SAUTER slide unit 0.2.200.xxx

Ordering details Possible configura-

tions

Your selection Installation position

Size: 025

min

Nm

-1

Working stroke

Drive motor used

Quantity: .........

24

+ 100

See page 14

PI 54 e

Loading...

Loading...