Page 1

PI 36.3 e – Product Information

Disk-type tool turret

without tool drive

Series

tool drive

with

0.5.680.1xx

2003-11-19

Series

10/2003

0.5.673.2xx/0.5.676.2xx

0.5.675.1xx

Page 2

Page 3

Content

Disk-type tool turret series 0.5.680.1xx

without tool drive

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Admissible loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Fluid rotary transmission feed-through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Disk-type tool turret 0.5.673.2xx/0.5.676.2xx

with axial tool drive

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Alternate configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Disk-type tool turret 0.5.675.1xx

with radial tool drive

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Motor arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Type key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ordering details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Request the following if needed: Planning instructions PA 36.3 e

NOTE:

The information given in this product information is based on the details available at the time

of printing. We explicitly reserve the right to make changes arising out of

the continuous further development of the product.

3PI 36.3 e

Page 4

Turret series 0.5.680.1xx

Description

Disk-type tool turret 0.5.680.1xx

These turrets are suitable for use on turning machines for forward as well as reverse

machining. Their exclusive hydraulic action means they are highly suitable for heavy-duty

use in series manufacture.

Turret series without tool drive – 0.5.680.1xx

with axial tool drive – 0.5.673.xxx

– 0.5.676.xxx

with radial tool drive – 0.5.675.xxx

Features:

} Drive with hydraulic positioning motor for fast bidirectional positioning

} High degree of stability due to high locking forces

} Hydraulically activated locking with triple Hirth serration

} Simple hydraulic supply

} Absolute positioning control – does not require moving to reference point

} Not affected by collisions due to the low kinetic energy of the drive and fastening snap

ring groove for the tool disk

} Directly controllable with machine controller or with SAUTER control unit EK 501

} Connection with centralised lubricating system to ensure extremely high service and

usage life

} Can be installed in any position

Options:

• Block-shaped housing or with flange fitting form for especially high degree of

rigidity

• Attachment of plate coolers when especially high thermal stability requirements

demand water cooling

• Central rotary feed-through for fluid-actuated tools and a high-pressure

cooling lubricating device

• Attachment of transfer elements for switching sensors in tool disk

• Attachment of sensors to monitor cutting force

• Turret with y-axis slide feed unit

• and many more features

4 PI 36.3 e

Page 5

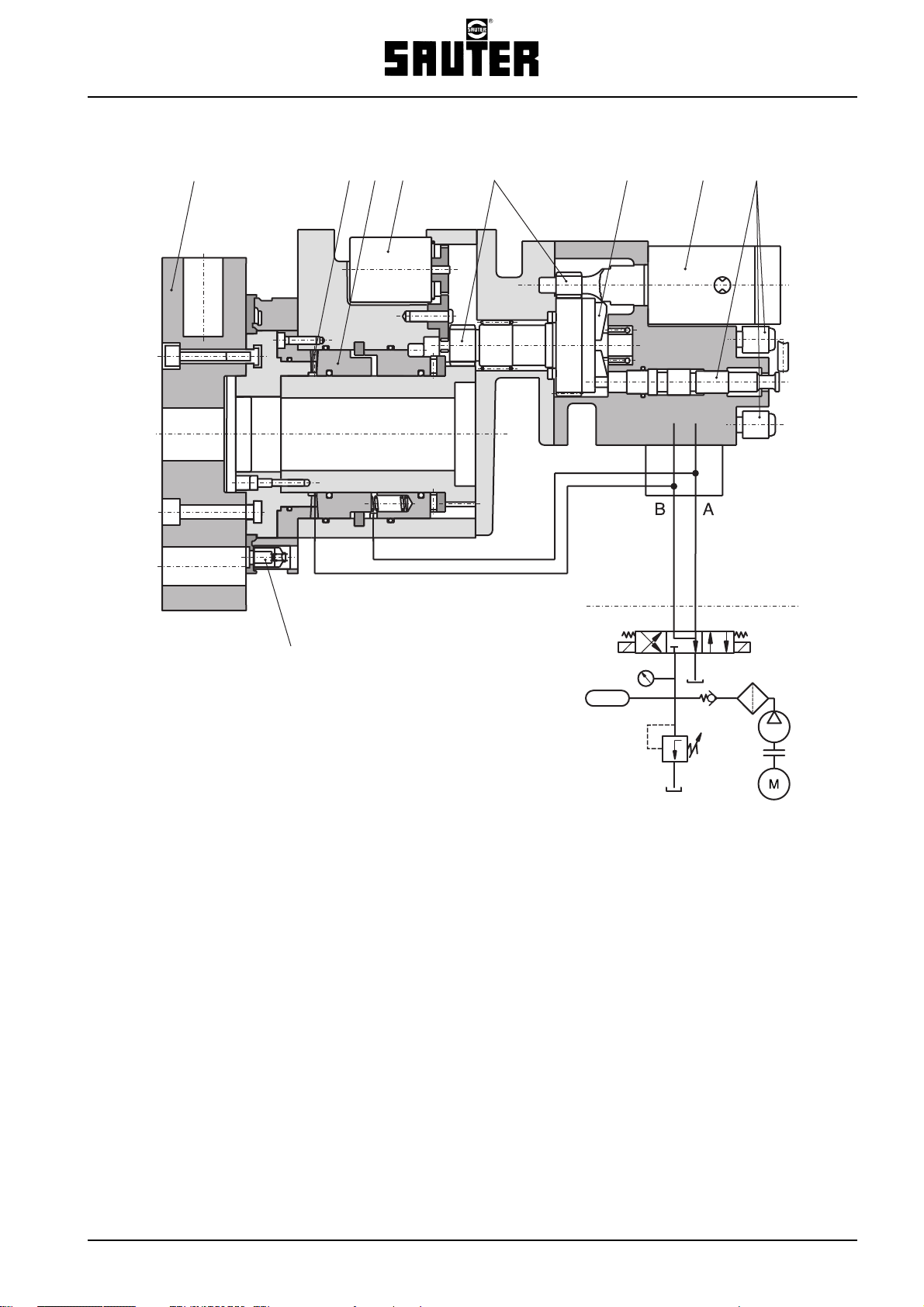

Turret series 0.5.680.1xx

Description

7

8

6

5

4

3

2

1

9

1 Control vaves

2 Hydraulic drive motor

3 Radial cam

4 Spur wheel gear

5 Electrical position transmitter

6 Locking piston

7 Hirth serration

8 Tool disk

9 Cooling lubricant valve

5PI 36.3 e

Page 6

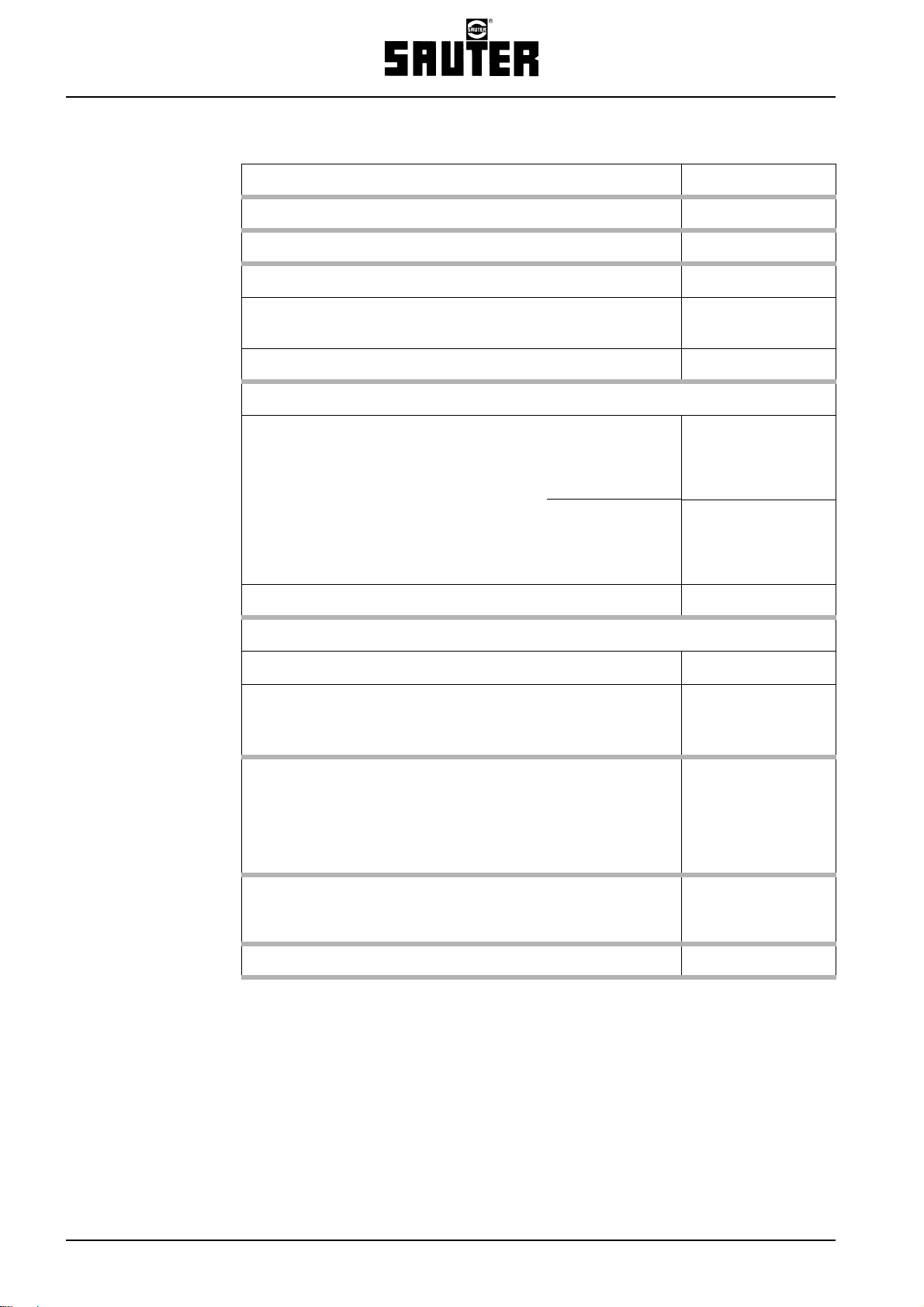

Turret series 0.5.680.1xx

Technical Data

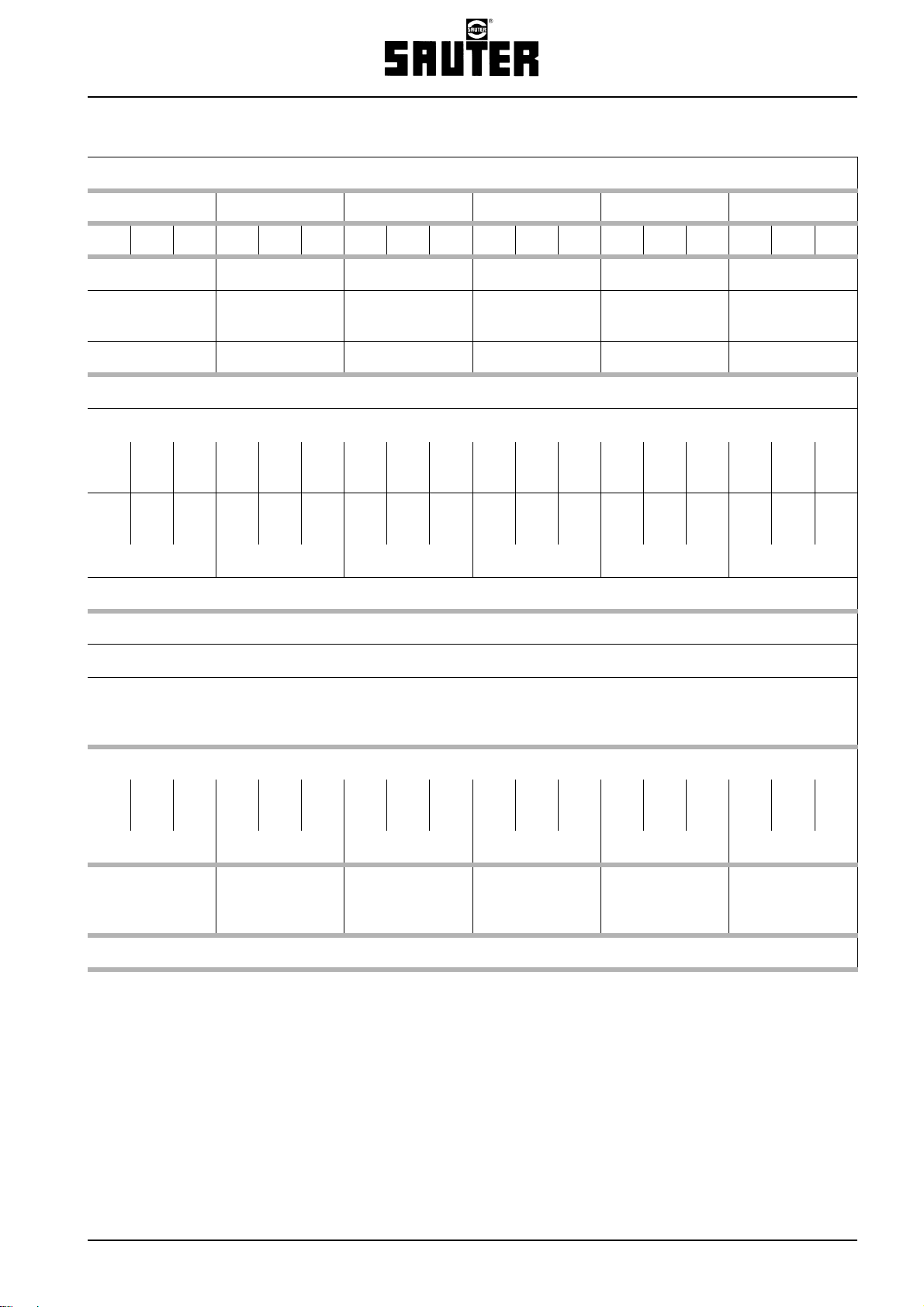

Series

Disk-type tool turret 0.5.680.1xx

Number of switching positons

Admissible tangential load (locked turret) kNm

• Admissible mass moment of inertia of Standard load stage

tooling (tool disk and holder) High load load stage

kgm

kgm

Admissible unbalanced mass due to tooling Nm

Indexing times

1.)

Rotating tool disk

• Incl. accelerating and braking Standard load stage

per partial step 45°/30°/22.5° High load load stage

• Without accelerating and braking Standard load stage

per additional partial step 45°/30°/22.5° High load load stage

s

s

Turret unlockedor locked s

Adm. Indexing freqency (median switching angle ϕ

=90°) min

m

Operating pressure

Hydraulics ± 10 % bar

Cooling lubricant

• With medium pressure valve

2.)

• With central high pressure lubricant device

bar

bar

2

2

-1

Fluid absorption volume

• Rotating tool disk Standard load stage

per partial step 45°/30°/22.5° High load load stage

Turret unlocked or locked cm

Mass

Turret (incl. drive motor) m

Tool disk and tooling m

adm.

Adm. ambient temperature °C

1.) Conditions: Fluid supply has to be sufficiently dimensioned.

Please comply with notes in PA 36.3!

Turret has to be at operating temperature.

With max. unbalanced tooling, the rotation times are changed by max. ± 15%.

See planning instructions PA 36.3 for notes on determining the total switching time.

2.) Also suitable for min. cooling lubricant volumes when using special valve.

cm

cm

kg

kg

3

3

3

6 PI 36.3 e

Page 7

Turret series 0.5.680.1xx

Technical Data

Size

12 16 20 25 32 40

812168121681216812168

3.)

12

3.)

16 8

0.7 1.3 3.2 6.3 12.5 25

1.2

2.5

2.5

5.0

5.0

10

12.5

32

25

63 140

16 32 63 125 200 320

0.21

0.26

0.16

0.24

0.16

0.19–0.16

0.11

0.17–0.12

0.26

0.30

0.19

0.28

0.20

0.22–0.18

0.13

0.19–0.14

0.30

0.38

0.21

0.31

0.24

0.29–0.22

0.15

0.21–0.16

0.46

0.57

0.33

0.46

0.36

0.43

0.22

0.31

0.26

0.30

0.17

0.23

0.52

0.92

0.46

0.82

0.38

0.31

0.68

0.55 1.0 0.72 0.58

0.31

0.23

0.55

0.42 0.83 0.56 0.42

0.11 0.14 0.20 0.30 0.50 0.80

no limitations

50

3.)

12

3.)

16

5 .. 25 Filtering 100 µm

100 Filtering 25 µm

46753150–3746753150–3750803455–4081

12754854063

4.)

4.)

100

160681105080 254 170 127

12 28 42 65 114 165

38

40

50

80

70

160

110

250

190

400

10 ... 40

3.) Delivered with 24 switching positions.

4.) Comply with the fineness of the filter required for the utilised tools, e.g. spindle heads with internal cooling lubricant supply.

380

630

7PI 36.3 e

Page 8

Turret series 0.5.680.1xx

Admissible loads

Primary cutting force ±F

(turning forward)

(Fx, Fz)

y

Size 16

Size 12

Size 20

Size 25

Size 40

Size 32

Primary cutting force ±F

(turning backward)

Size 12

(Fx, Fz)

y

Size 16

Size 40

Size 32

Size 25

Size 20

Feed force +F

(drilling forward)

Size 12

z

Size 16

Size 20

Size 25

Size 40

Size 32

Feed force –F

z

Transverse force +F

Size 16

Size 12

x

Size 40

Size 32

Size 25

Size 20

Note: The diagrams apply to static loads.

Significantly lower values have to be used with shock loads (discontinous cutting).

8 PI 36.3 e

Page 9

Turret series 0.5.680.1xx

Dimensions

Turret geometry with

block form or fitted flange housing upon

request

Series Size

Disk-type tool

turret 0.5.680.1xx

12

16 20 25 32 40

right left

A 63 80 100 125 160 200

B 120 133 138T 153 182 226

C 175 215 255 318 396 470

D 80 65 85 100 125 160 200

E 65 80 85 100 125 160 200

Ø F 90 120 145 182 220 300

G 8 x M8 8 x M8 11 x M10 11 x M12 15 x M12 22 x M12

H 128 138 155 190 220 341

I M8 M10 M12 M16 M20 M24

K 324041526270

Ø L 70 90 110 120 150 200

M 385 428 460 508 550 670

N 192 192 210 262 312 442

O 85 100 106 125 158 198 245

P 100 85 106 125 158 198 245

Ø Q 175 215 255 318 396 470

Dimensions in mm

9PI 36.3 e

Page 10

Turret series 0.5.680.1xx

Precision/fluid rotary feed-through

Precision

Repeating accuracy

(Multiple move to a switching position from the same direction)

Indexing precision

(Multiple move to a switching position from different direction)

Fluid rotary feed-through

All turrets are deliverable with central fluid rotary feed-through:

• “Uncontrolled” variation – fluid supply in all switching positions,

e.g. for sealing air, for gripper activation, and similar actions

• “Controlled” variation – fluid supply to one switching position,

e.g. for KSS, autom. tool changes, and other functions

A maximum of three supply lines are routed through the centre of the turret.

Operating pressure P

= 100 bar (standard)

adm.

10 PI 36.3 e

Page 11

Axial tool drive

Description

Disk-type tool turret 0.5.673.xxx/0.5.676.xxx

with axial tool drive

These turrets feature a modular construction and consist of the following:

• Basic turret series 0.5.680.1xx and

• decentralised tool drive for

individually switchable axial tools

for forwardmachining.

The tool coupling can alternatively be supplied for spindle heads with or without the patented spindle locking system.

This means that the tools are either connected after positioning the drive spindle or after searching.

– When conducting search run with small – positioning with controls is not required

number of revolutions per minute electromagnetically activated coupling

or

– after positioning the drive spindle – shortest switching time

Hydraulically activated coupling

Suitable spindle heads

Coupling

process

with

Small number of

revolutions

Spindle positioning 0.5.676.2xx yes 0.5.941.xxx

Spur wheel

drive

turret

series

0.5.673.2xx no 0.5.921.xxx

Tool drive

motor

Spindle locking

system

spindle head type

SAUTER

Tool

disk

Tool

Sliding coupling

Coupling wheel

The tool drive motor drives the coupling wheel via the spur wheel gear incorporated in the gearbox casing. The drive

motor can be located at the side of the turret opposite the working position or above the turret casing, depending on the

application.

Basic turret

11PI 36.3 e

Page 12

Axial tool drive

Performance data/motor recommendation

Performance data for the tool coupling

The gearbox is designed for the performance data given below for the

tool coupling. The actually available performance data depend on the utilised

drive motor (see below).

Series

Disk-type tool turret 0.5.673.xxx/676.xxx

Gearbox performance data

Adm. drive rating

Adm. torque

Adm. rpm

Gear ratio

7.)

2.)

1.) 3.)

1.)

P

M

n

adm.

adm.

adm.

Nm

min

i

kW

-1

Recommended drive motors

Siemens servomotor,

Type 1 FT 6..

Max. torque

Max. rpm

Indramat servomotor,

Max. torque

Max. rpm

6.)

6.)

Type MKD..

6.)

6.)

4.)

Nm

min

Nm

min

-1

-1

Fanuc spindle motor, Type Alpha..

Max. torque

Max. rpm

1.) The values are reference values for short-term operation. Higher rpms generate more heat and noise.

2.) Torque limitation at motor converter required!

The listed torque values apply to smooth machining (such as thread-cutting).

In the case of machining with severe shock loads (e.g. face milling and similar operations), it is necessary

to reduce the motor drive torque by 50% or more.

3.) Higher rpms upon request.

4.) With absolute value encoder for turret series 0.5.676.xxx

5.) Spindle motor

6.) At tool coupling 40% WT – 10 min

7.) i = 1.5 only with turret series 0.5.676.xxx

6.)

6.)

Nm

min

-1

12 PI 36.3 e

Page 13

Axial tool drive

Performance data/Drive motors

Size

12 16 20 25 32 40

6

20

6000

8

32

5000

10

63

4000

12.5

100

4000

16

160

3200

16

160

3200

~1.5 1.0 1.0 ~1.5 1.0 ~1.5 1.0 ~1.5 1.0 ~1.5 1.0

..062

-AK..

12.5

4500

..064

-AK..

14

6000

..084

-AK..

28

5000

3000

..071 B ..090 B ..112 B

15

4000

14

6000

α 1.5

11

6000

22

5000

2600

α 2 α 3 α 6 α 8 α 8

25

5000

4000

..86 - AH..

58

60

55

40

4000

42

4000

40

4000

..102

-AH..

58

3200

2AD

100 C

78

4000

..105

1PH7

-AF

68

4000

5.)

..112C 2AD 100D..

68

4000

56

4000

-107..

125

3200

108

3200

5.)

120

3200

..105

-AF

68

3200

5.)

72

3200

5.)

1PH7

-107..

125

3200683200

2AD 100D..

108

3200723200

120

3200

Adm. relative working time – Reference values for gears –

..105

-AF..

5.)

Favourable

conditions

Adm. rpm

Unfavourable

conditions

Adm. drive rating

Working time WT – 10 min

Example for size 20:

Tool coupling = 3000 min

n

adm.

⇒ n

Tool coupling

= 4000 min

= 75% n

-1

-1

adm.

⇒ Working time 40% - 10 min (max. 4 min ON – min. 6 min OFF)

13PI 36.3 e

Page 14

Axial tool drive

Alternate configurations

Motor arrangement possible

in position 9°° or 12°°

Working

position

d

1

Tool arrangement:

(Depicted

turret arrangement "right”)

8 pos. – 1 graduated circle

12 pos. – 2 graduated circles 12 pos. – 1 graduated circle

16 pos. – 2 graduated circles 16 pos. – 1 graduated circle

14 PI 36.3 e

쏹 Position with tool drive

쎻 Position w/o tool drive

Page 15

Alternate configurations

Axial tool drive

Alternate configurations

Coupling profile

Turret

Size

12 +98.54 / -17

16 +117. 4 / -25

20 +155 / 0

25 +198 / -70

Working

position

X / Y

+100 / 0

+142.5 / 0

Motor

position

9°°

9°°

9°°

0.5.673.2xx 0.5.676.2xx

DIN 5480-

W10x0.8

+100/0 9°° –

9°°

+125 / -25

+135 / 0

+150 / 0

+150 / 0

+170 / 0

+185 / 0

9°°

12°°

9°°

12°°

9°°

9°°

9°°

DIN 5482-

DIN 5482-

9°°

+200 / 0

+200 / -20

+235 / -70

9°°

12°°

9°°

DIN 5482-

Turret series

15x12

17x14

20x17

DIN 5480-

W11x0.8

DIN 5480-

W14x0.8

DIN 5480-

W16x0.8

DIN 5480-

W20x0.8

DIN 5480W24x1.25

Tool holder

Receptacle

Ø

DIN 69880

d

1

20

20

20

25 12-2

30

30

30

30

30

40

40

40

50

50

50

50

Possible

tool

arrangement

see page 13

12-2

12-2

16-1

12-2

12-2

12-2

12-1

12-1

12-2

12-2

12-1

12-2

12-2

12-2

12-1

32 +265 / -80 12°°

40 +387.8 / -125 9°° 60 12- 1

DIN 5482-

25x22

–

60 12- 1

Bold print indicates quickest delivery!

Additional variations – e.g. variation “left” upon request.

15PI 36.3 e

Page 16

Radial tool drive

Description

Disk-type tool turret 0.5.675.1xx

with radial tool drive

These turrets consists of the following:

• Basic turret series 0.5.680.1xx and

• tool drive central

for individually switchable radial tools

for forward and backward machining.

The tool drive is intended for the spindle positioning. This requires spindle heads with spindle locking system

– Sauter spindle heads series 0.5.941.xx .

Tool drive motor

Geared head

Tool disk

Tool coupling

Belt drive

Central drive shaft

The tool drive motor drives the drive shaft, which is located centrally within the turret in a hollow shaft. The relevant tool

is switched into the working position by means of a bevel gear and a fluid-switched coupling in the gearbox head at the

front.

Coupling and decoupling of the spindle head located in the working position is executed after each positioning of the

drive spindle – not tooth-on-tooth situation, shortest switching time!

The tool disk is an integrated part of the turret with these turret systems.

16 PI 36.3 e

Page 17

Radial tool drive

Motor arrangement

Motor arrangement

The tool drive motor can be installed directly on the turret or with a belt drive, depending on the application specifications.

• Direct motor installation

• Motor installation with belt drive

Z – 9°° (left)

Z – 3°° (right)

U – 9°° (left)

U – 3°° (right)

17PI 36.3 e

Page 18

Radial tool drive

Performance data/Drive motors

Performance data for the tool coupling

The gearbox is designed for the performance data given below for the tool coupling.

The actually available performance data depend on the utilised drive motor (see below).

Series Size

Disk-type tool turret 0.5.675.1xx 12 16 20 25

Gearbox performance data

Adm. drive rating

Adm. torque

Adm. rpm

1.) 3.)

Gear ratio i = n

2.)

1.)

P

M

n

Adm.

Adm.

Adm.

1/n2

kW

Nm

min

6

-1

20

6000

8

32

5000

10

63

4000

12.5

100

4000

1.0 1.0 1.0 1.0

Recommended drive motors

Siemens servomotor,

Max. torque

Max. torque

5.)

5.)

Indramat servomotor,

Max. torque

Max. torque

5.)

5.)

Type 1 FT 6..

Type MKD..

4.)

Nm

min

Nm

min

..064-.AK.

-1

14

6000

..071B

-1

14

6000

.0.084-.AK.

28

5000

.0.090B

22

5000

..086-.AH.

40

4000

.0.112B

48

4000

..105-.AF..

68

4000

..112C

68

4000

Fanuc spindle motor,

Max. torque

Max. torque

1.) The values are reference values for short-term operation. Higher rpms generate more heat and noise, especially when the belt drive is

used!

2.) Torque limitation at motor converter required!

The listed torque values apply to smooth machining (such as thread-cutting). In the case of machining with severe shock loads (e.g. face

milling and similar operations), it is necessary to reduce the motor drive torque by 50% or more.

3.) Higher rpms upon request.

4.) With absolute value encoder.

5.) At tool coupling 40% WT – 10 min

5.)

5.)

Type Alpha..

Nm

min

-1

1.5

15

6000

2

25

5000

3

40

4000

6

56

4000

Adm. relative working time – Reference values for gears –

Favourable

conditions

Adm. rpm

Unfavourable

conditions

Adm. drive rating

Working time WT – 10 min

18 PI 36.3 e

Example for size 20:

Tool coupling = 3000 min

n

adm.

⇒ n

Tool coupling

= 4000 min

= 75% n

-1

-1

adm.

⇒ Working time 40% – 10 min

(max. 4 min ON – min. 6 min OFF)

Page 19

Radial tool drive

Selectable

working positions

12 o’clock

Dimensions

9 o’clock

3 o’clock

Series Size

Disk-type tool turret 0.5.675.1xx 12 16 20 25

Coupling profile DIN 5480 14 x 0.8 16 x 0.8 20 x 0.8 24 x 1.25

Distance A

dimension A

(standard)

1

(upon request)

2

–

80

K 324041 52

Tool holder receptacle system

Cylinder shaft DIN 69880

d

1

SW

standard 220 270 320 380

1

SW

2

SW

3

Tool system

Coromant Capto

2.)

1.)

25 30 40 50

240 360 410

300 340 380

NG C3 C4 C5

SW 280 340 380

1.) Use SAUTER spindle heads Type 0.5.941.xxx (product information PI 29.3)

2.) Use SAUTER spindle heads Type 0.5.934.xxx (product information PI 45)

Additional tool systems – e.g. HSK available upon request.

55

96

80

159

100

198

Dimensions in mm

19PI 36.3 e

Page 20

Type key

Type key

Turret series 0.5.680.xxx and 0.5.675.xxx

Example:

0.5.675.1xx

Size

12

16

0.5.680.120

.

25

32

40

12

16

0.5.675.120

25

Function/

configuration

Turret series 0.5.673.xxx and 0.5.676.xxx

Example:

0.5.676.2xx

Size

Function/

configuration

0.5.675.1 Hydraulically operated disk-type turret

0.5.680.1 Hydraulically operated disk-type turret

12

16

0.5.673.220

25

32

40

0.5.673.2 Hydraulically operated disk-type turret with single

with single radial tool drive

Tool coupling with spindle positioning

without tool drive

12

16

0.5.676.220

25

axial tool drive

Tool coupling with small number of revolutions per

minute

Electromagnetically activated tool coupling

0.5.676.2 Hydraulically operated disk-type turret

20 PI 36.3 e

with single axial tool drive

Tool coupling with spindle positioning

Hydraulically activated tool coupling

Page 21

Ordering details

Fax ++49 (0) 7123-926-190

@

SAUTER Disk-Type Tool Turret 0.5.680.1xx / 0.5.673.2xx / 0.5.676.2xx / 0.5.675.1xx

Ordering details Alternate configurations Your selection

Basic turret

++49 (0) 7123-926-0

info@sauter-gmbh.com

SAUTER Feinmechanik GmbH

Postfach 1551

D-72545 Metzingen

Germany

Size

Number of switching positions

Load stage

Housing shape/form

Installation position

Fluid rotary feed-through

Company:

Street:

ZIP/City:

Name:

Phone:

Fax:

12 / 16 / 20 / 25 / 32 / 40

8 / 12 / 16

Standard / high load

Standard /

Block/flange design

...........................

...........................

Axial tool drive

Working position X / Y

Motor position

Intended drive motor

Gear ratio

Coupling profile

Radial tool drive

Working position

Tool disk SW

Neck length A

Tool receptacle system

Drive motor arrangement

Intended drive motor

Electronic control unit

Special requirements/requests:

see page 14/15

3°° / 9°° / 12°°

see page 11/12

1.0 / ~1.5

see page 14/15

3°° / 9°° / 12°°

SW

/ SW2 / SW

1

A1 / A

DIN 69880 /Sandvik Capto

direct – U/Z – right / left

see page 18

EK 501

3

2

21PI 36.3 e

Loading...

Loading...