Page 1

2014-01-21

Product Information PI 21.3

Disk-type tool turret

without tool drive

Series

with tool drive

Series

0.5.460.4xx

0.5.456.4xx (axial)

0.5.450.4xx (radial)

Page 2

Page 3

PI 21.3

3

Page 4

Page 5

Contens

Contens

Turret system Description........................................................................................................................................................6

Disk-type tool turret series 0.5.460.4xx

without tool drive ......................................................................................................................................................................8

Description .............................................................................................................................................................................8

Technical data ......................................................................................................................................................................10

Commodities ........................................................................................................................................................................13

Admissible loads ..................................................................................................................................................................14

Dimension ............................................................................................................................................................................16

Precision...............................................................................................................................................................................20

Disk-type tool turret series 0.5.456.4xx

with axial tool drive ................................................................................................................................................................21

Description ...........................................................................................................................................................................21

Tool configuration.................................................................................................................................................................22

Performance data at the tool coupling..................................................................................................................................23

Alternative configuration.......................................................................................................................................................25

Disk-type tool turret series 0.5.450.4xx

with radial tool drive ...............................................................................................................................................................26

Description ...........................................................................................................................................................................26

Performance data at the tool coupling..................................................................................................................................27

Dimension ............................................................................................................................................................................28

Options ....................................................................................................................................................................................29

Housing version....................................................................................................................................................................29

Arrangement of the drive......................................................................................................................................................30

Electrical connections...........................................................................................................................................................30

Working position...................................................................................................................................................................31

Type key...................................................................................................................................................................................32

Ordering details.......................................................................................................................................................................33

Please request: Project Planning Guide PA 21.3

NOTE:

The information contained in this Product Information is in conformity with the knowledge at the point of printing. Subject to

modifications which occur within the framework of continuous further development.

PI_21_3_en_2013-12-11.fm

PI 21.3

5

Page 6

Turret system description

Turret system description

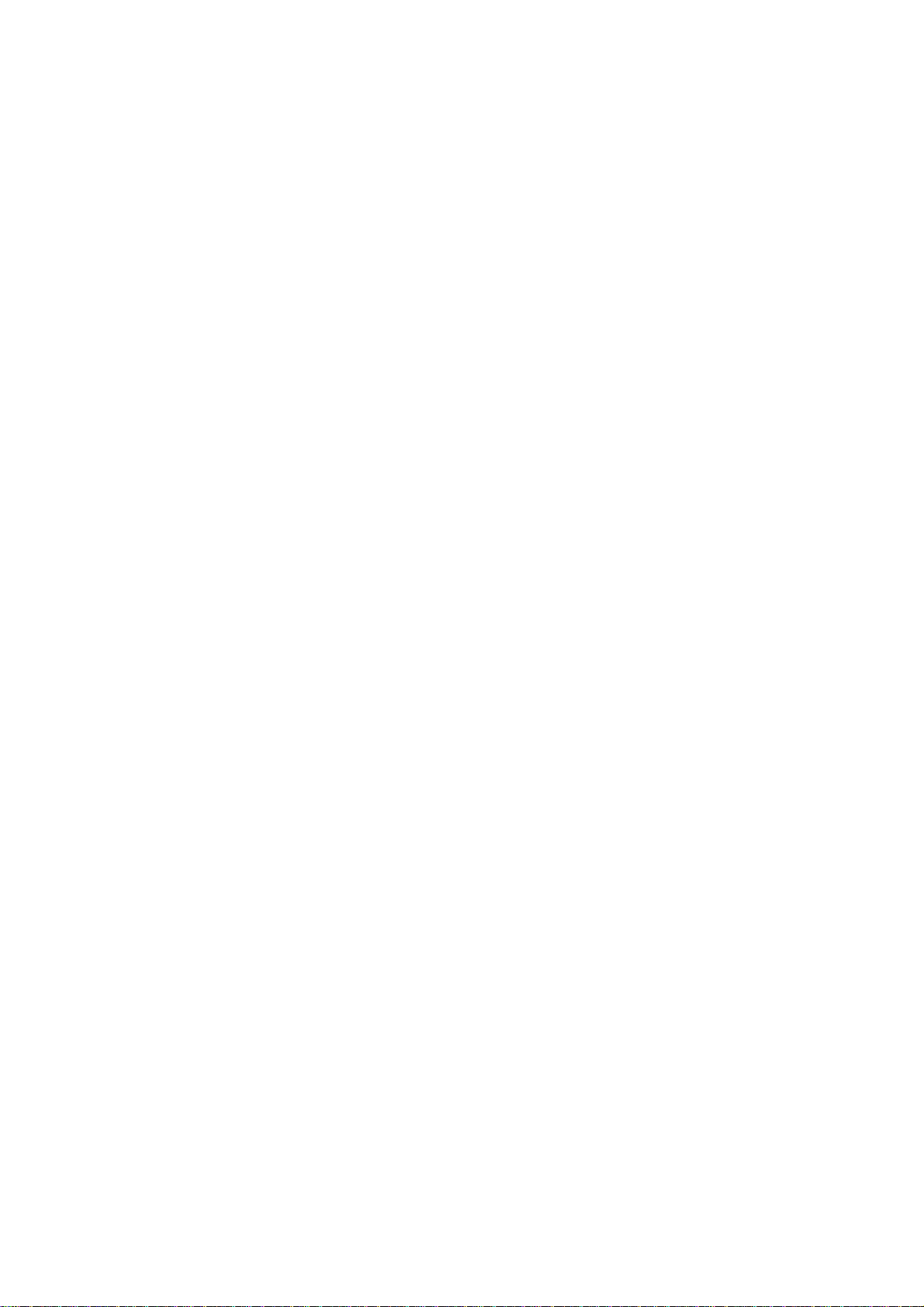

These turrets are suitable for use on high-capacity turning machines for forward as well as equipollent reverse machining. They

are equipped with all of the features and functions of modern high-performance and high-capacity tool turrets. Their robust design and short switching times mean they are also very well suited for heavy-duty use in series manufacture

Turret series

• 0.5.460.4xx without tool drive

• 0.5.456.4xx with axial tool drive

• 0.5.450.4xx with radial tool drive

Features:

• Single Motor Technology

– The turret and the tool drive share one motor; this means lower investment costs and higher level of reliability

• For equal high-performance forward and reverse machining

• Drive with standard servo or spindle motors for fast bidirectional positioning

• High degree of stability due to high locking forces

• Locking device uses special triple generating Hirth-type gear (pat.)

• Not affected by collisions due to safety clutch and annular slot for the disk tool

• Directly controllable with machine controller

• Connection with centralised lubricating system to ensure extremely high service and usage life*)

• Can be installed in any position

• Stable housing with large fastening surface ensuring high stiffness

• High thermal stability

*)

High dependance due to seal tool disk by means of sealing with air purge

6 PI 21.3

Page 7

Options:

• Air purge connection for turrets with radial tool drive

• Housing available as block or L-shaped, right and left design

• Central rotary feed-through for fluid-actuated tools and a high-pressure coolant device

• Attachment of transfer elements for switching sensors in tool disk

• Attachment of sensors to monitor cutting force

• Turrets with Y-axis slide units

• Software package for operating the system with a Siemens control Type 840-D

• Fluid rotary feedthrough

Turret system description

– The turret are available with a central rotary feedthrough

version „uncontrolled“ Feedthrough in all indexing positions

e.g. air purge, tool gripper

version „controlled“ Feedthrough in single position

e.g. coolant, tool changing

– Feed through for max. three pipelines in turret center.

pressure P

max= 100 bar (Standard)

PI 21.3

7

Page 8

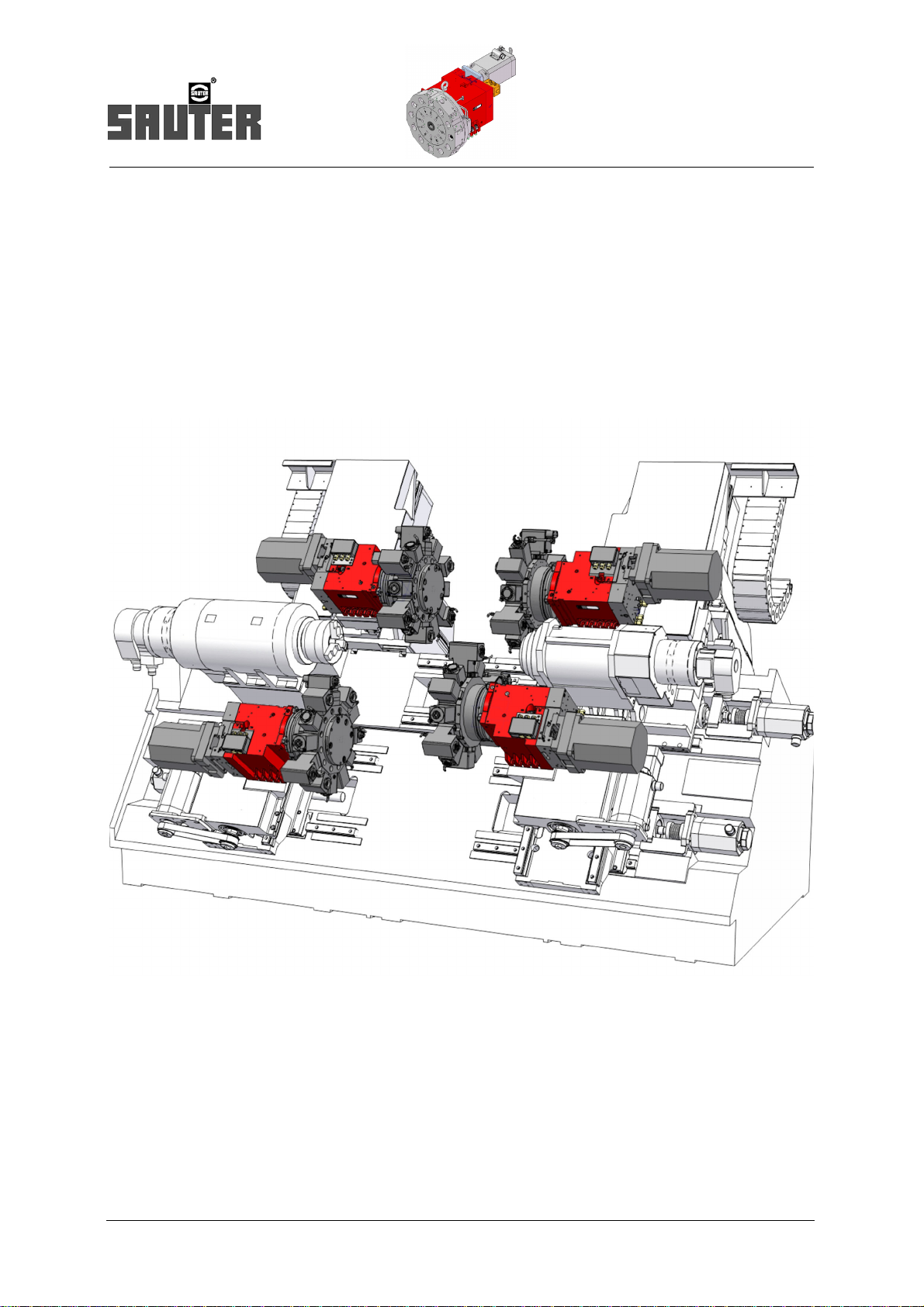

12

3

4

5

678

Hydraulics

Description

Series 0.5.460.4xx

Disk-type tool turret series 0.5.460.4xx

without tool drive

Description

8 PI 21.3

Page 9

1 Tool disk

2 Spur gear

Description

Series 0.5.460.4xx

3 Safety clutch for turret drive

4 Electrical locking control

5 Drive motor

6 Reference switches

7 Hirth-type gearing

8 Coolant valve

PI 21.3

9

Page 10

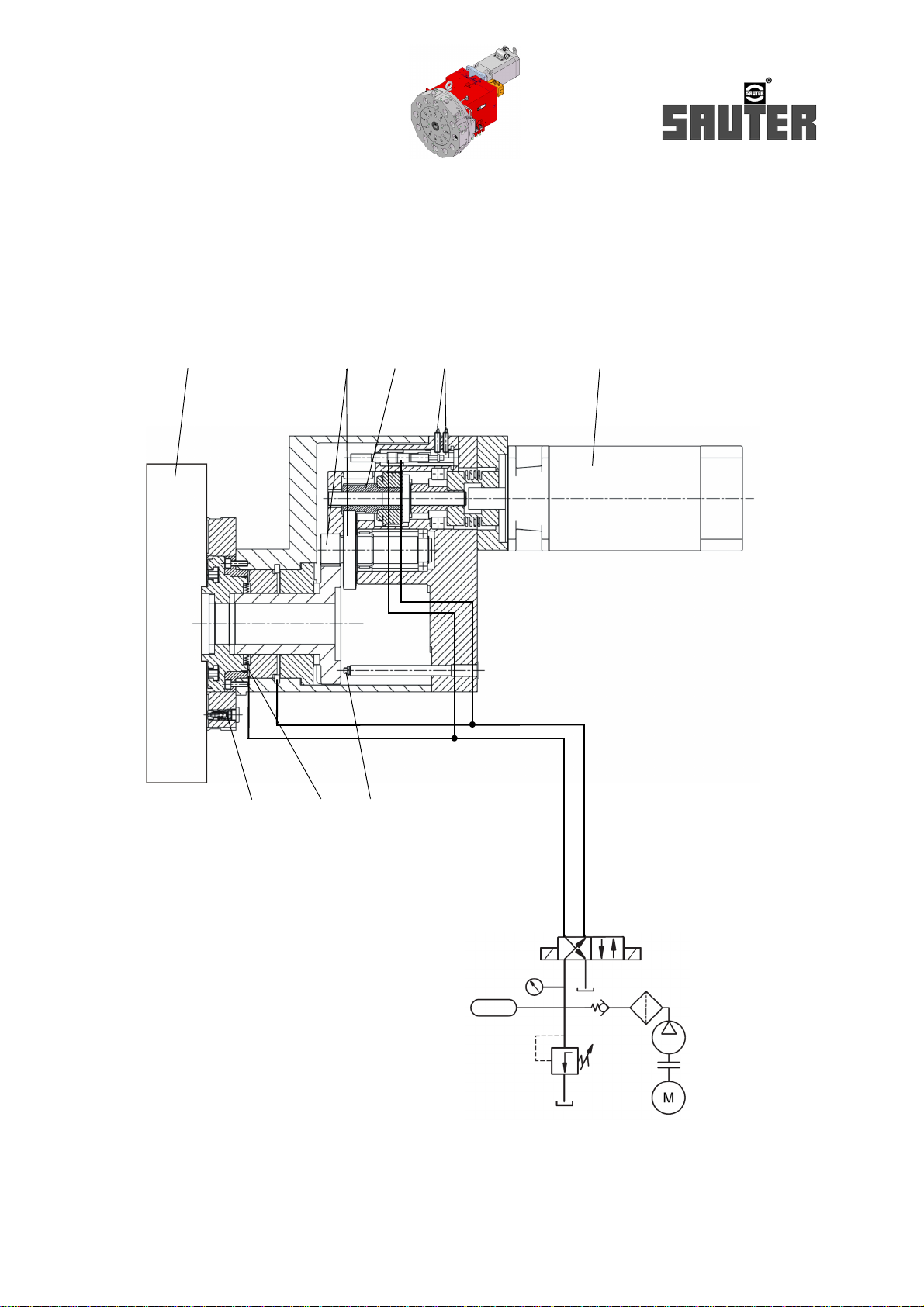

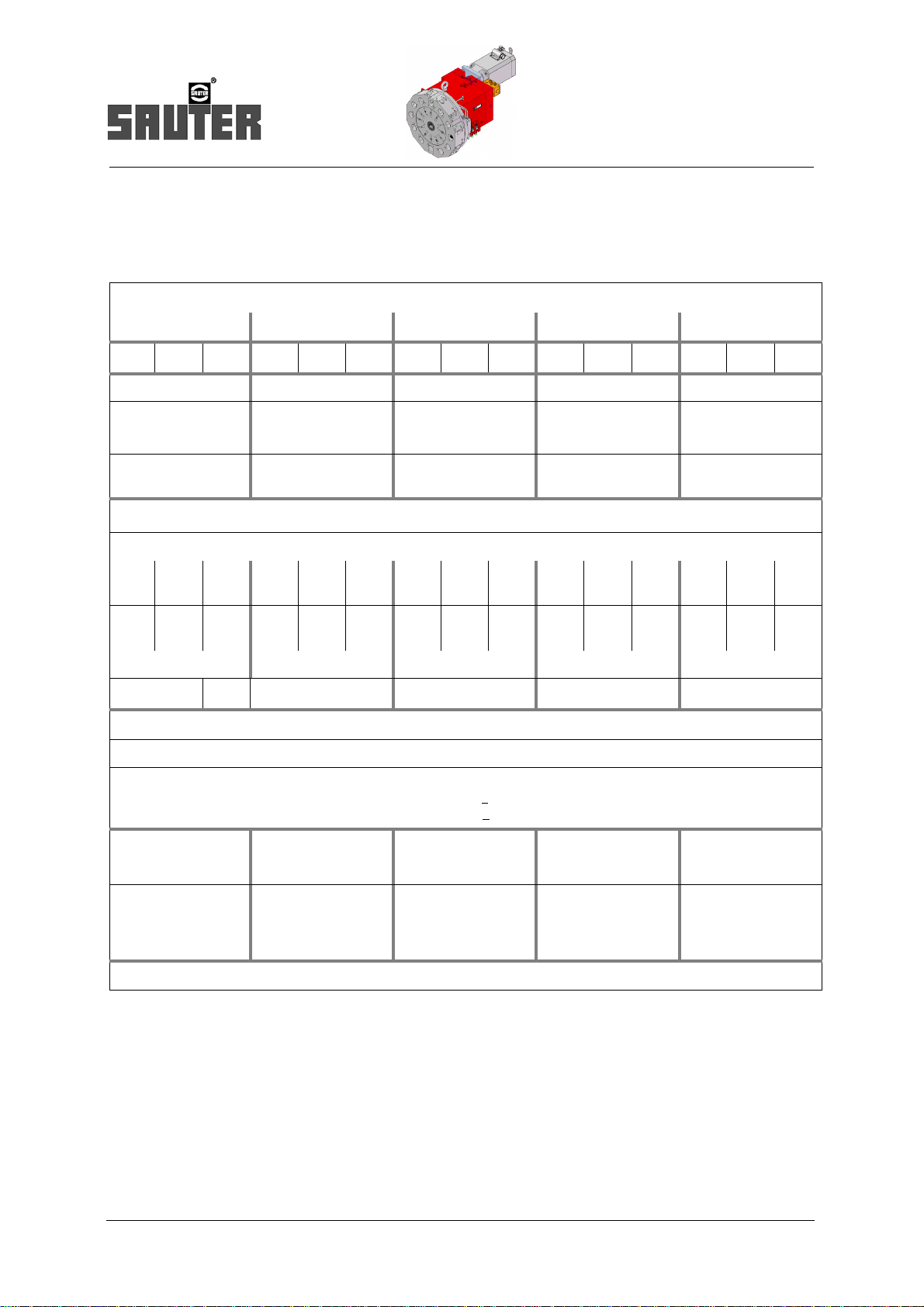

Technical data

Series 0.5.460.4xx

Technical data series 0.5.460.4xx

Series 0.5.460.4xx

Number of switching positions

Admissible tangential load (turret locked) kNm

Adm. mass moment of inertia of tools

(tool disk and holder)

Standard load stage

High load stage

kgm

kgm

2

2

Adm. out-of-balance due to tooling Standard load stage

High load stage

Indexing times

1)

Nm

Nm

Rotate tool disk

• incl. acceleration and braking per partial step Standard load stage

High load stage

• without acceleration and braking per additional partial step Standard load stage

High load stage

Turret unlock or lock (hydraulic) s

1)

Adm. indexing frequency

(median switching angle m=90°)

min

Operating pressure

Hydraulic ± 10% bar

Coolant

• with medium pressure valve

• with central high-pressure coolant device

bar

bar

Fluid absorption volume

Turret unlock/lock

cm

Mass

s

s

s

s

-1

1

1

3

• Turret (incl. standard housing,without tool disk, without motor) m

• Tool disk and tooling m

zul

Adm. ambient temperature

1) Conditions:

• Direct drive with Siemens servo motors and driving torques in accordance with the table on page 12

• Fluid supply sufficiently large

• Turret up to operating temperature

• without controller-related non-productive time

• Attention! Increased indexing times with

– higher mass moment of inertia of tool disk and toolholders

– higher mass moment of inertia of other motors

– lower driving torque

2) Ensure compliance with the required filter fineness for the tools used. For example spindle heads with internal coolant supply.

kg

kg

°C

10 PI 21.3

Page 11

Technical data

Series 0.5.460.4xx

Size

12 16 20 25 32

s 1)

0,18

0,24

0,08

0,15

min

8

12 16

8

12 16

12

1)

16

8

8

12

1)

16

0,8 1,8 3,6 7,2 12,5

0,8

1,6

12

16

0,12

0,16-0,17

0,05

0,10-0,08

0,20

0,27

0,08

0,15

1,8

4,0

25

32

0,14

0,19-0,19

0,05

0,10-0,08

0,22

0,29

0,09

0,19

3,2

6,3

40

63

0,16

0,21-0,20

0,06

0,10-0,09

0,28

0,37

0,12

0,24

8

16

80

125

0,20

0,26-0,20

0,08

0,16-0,12

0,10 0,10 0,12 0,14 0,5

-1

25 20 16 12,5 8

50

5 - 25 Filtering < 100μm

100 Filtering < 25μm

2)

2)

8

0,40

0,50

0,19

0,38

1)

12

16

25

50

160

200

0,32

0,4-0,32

0,12

0,24-0,19

1

PI 21.3

15

55

40

30 45 65 114

100

80

125

160

200

250

480

500

+ 10 ... + 40

11

Page 12

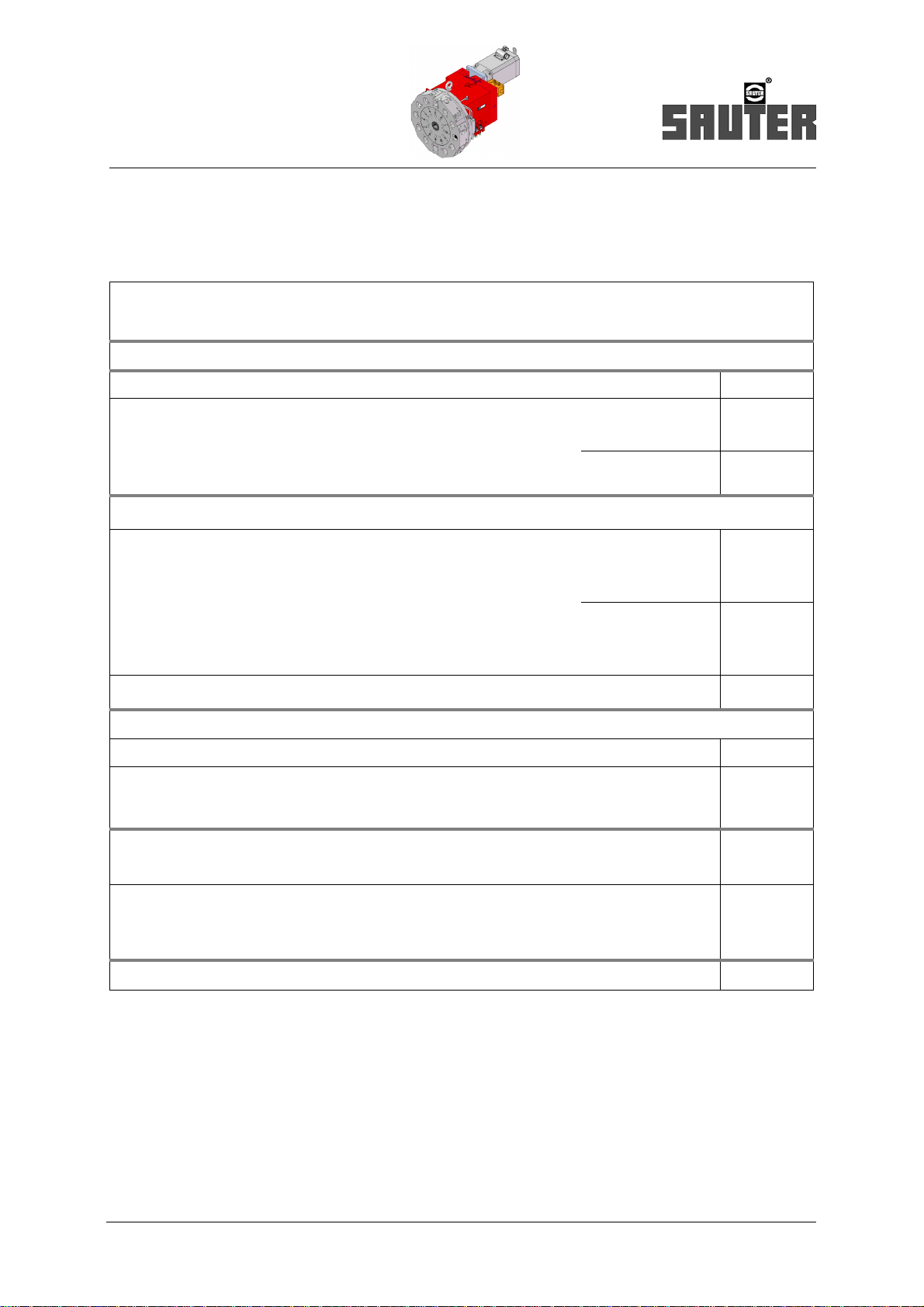

Technical data

Series 0.5.460.4xx

Technical data series 0.5.460.4xx

Series 0.5.460.4xx Size

12 16 20 25 32

Number of indexing positions 8 12 16 8 12 16 8 12 16 8 12 16 8 12 16

Rated speed

turret drive

Driving torque

Gear ratio i = n1 /

Recommended drive motors preferred series

Standard

load stage

High load

stage

1)

n

-1

1600 1200 - 1600 1200 - 1300 1000 - 1000 750 - 650 500 -

min

-1

min

rev

800 600 800 800 600 800 650 500 650 500 375 500 325 250 325

18 25 18 30 40 30 48 63 48 75 100 75 120 160 120

Nm

16 12 16 16 12 16 16 12 16 16 12 16 16 12 16

2)

Siemens

Servomotor

Fanuc

Servomotor

Fanuc

Spindle motor

1) Torque limitation on the motor converter!

2) The motors are not included in the SAUTER scope of supply

Other motors upon request.

1FT6.. ..064.. ..084.. ..086.. ..105.. ..108..

..

..

8/4000 is 12/4000 is 22/4000 is

..1,5 ..2 ..3 ..6 ..8

12 PI 21.3

Page 13

Commodities

Commodities

Commodities/Media

12 16 20 25 32

Hydraulic (locking)

pressure bar 50 ±10%

flow rate max. l/min 15 - 20

Coolant (Standard)

Druck bar 5 - 25 (Filtering <

Central high pressure-coolant device (Options)

pressure bar bis 100 (Filtering <

air purge (Tool disk and driven tools)

pressure bar 0,4 - 0,8

flow rate l/min ca. 6 - 10

Central lubrication (gear)

a) Oil consumption

grease consumption

(alternative)

cm

cm

3

/h

3

/24h

ca. 0,09 - 0,18

ca. 0,06 - 0,12

Size

100 μm)

25 μm)

PI 21.3

13

Page 14

Advance force ±F

z

(drilling forward and backward)

±F

z

= +Fx = 40% F

y

Size 25

Size 32

Size 20

Size 16

Size 12

Size 25

Size 32

Size 20

Size 16

Size 12

Admissible loads

Admissible loads

Note: The diagrams only apply to static loads. In the event of shock loads (discontinuous cutting) it is necessary to use significantly lower values.

Combination force ±Fy (+Fx,+Fz )

Type Turn- forward- and reverse machining

14 PI 21.3

Page 15

Shunt load +Fx

Size 25

Size 20

Size 16

Size 12

Size 32

leading edge is the basis

for dimension a

Admissible loads

PI 21.3

15

Page 16

Dimensions

Series 0.5.460.4xx

Dimensions Turret series 0.5.460.4xx ( L-shape )

16 PI 21.3

Page 17

Dimensions

Series 0.5.460.4xx

Series

0.5.460.4xx

A1 / A2

12 16 20 25 32

1)

- / 90 100 / 115 125 / 140 150 / 180 200 / -

Size

B 170 200 250 300 400

C1 / C

D1 / D

2

2

- /198 264 / 246 350 / 325 406 / 373 520 / -

- / 68 102 / 82 125 / 100 158 /125 198 / -

E2030354048

F 8 x M 8 8 x M 8 11 x M 10 11 x M 12 15 x M 12

G M 8 M 10 M 12 M 16 M20

H3240415262

Ø K 70 90 105 120 150

L

344

Siemens

359

Fanuc

373

Siemens

393

Fanuc

442

Siemens

462

Fanuc

510

Siemens

510

Fanuc

656

Siemens

M 300 345 397 445 591

N

/ N

1

2

- / 178 240 / 220 295 / 270 370 / 337 476 / -

O 68 80 100 125 160

P 120 150 185 230 300

Ø Q 175 210 255 318 396

510

Fanuc

Ø S 90 120 145 182 220

T 76 105 120 150 200

V 94 127 144 176 234

W2834404252

1) Option

PI 21.3

dimensions in mm

17

Page 18

Dimensions

Series 0.5.460.4xx

Dimensions Turret series 0.5.460.4xx ( Block-shape)

18 PI 21.3

Page 19

Dimensions

Seires 0.5.460.4xx

Series

0.5.460.4xx

A1 / A2

12 16 20 25 32

1)

- / 90 100 / 115 125 / 140 150 / 180 200 / -

Size

B 170 200 250 300 400

/ C

C

1

D1 / D

2

2

- /198 264 / 246 350 / 325 406 / 373 520 / -

- / 68 102 / 82 125 / 100 158 /125 198 / -

E2030354048

F 8 x M 8 8 x M 8 11 x M 10 11 x M 12 15 x M 12

G M 8 M 10 M 12 M 16 M20

H3240415262

Ø K 70 90 105 120 150

L

344

Siemens

359

Fanuc

373

Siemens

393

Fanuc

442

Siemens

462

Fanuc

510

Siemens

510

Fanuc

656

Siemens

M 300 345 397 445 591

N

1

/ N

2

- / 178 240 / 220 295 / 270 370 / 337 476 / -

O 68 80 100 125 160

P 120 150 185 230 300

Ø Q 175 210 255 318 396

510

Fanuc

Ø S 90 120 145 182 220

V5062657896

W2834404452

1) Option

dimensions in mm

PI 21.3

19

Page 20

Precision

Precision

Repeating accuracy

Indexing precision

(Multiple move to a switching position from the same direction)

(Multiple move to a switching position from different direction)

20 PI 21.3

Page 21

Spur gear

Driving motor

Gear case

Basic turret

working position

Coupling wheel

fluid-activated

tool coupling

Description

Series 0.5.456.4xx

Disk-type tool turret Series 0.5.456.4xx

with axial tool drive

Description

• series and a decentralized tool drive for individually switchable, axially placed tools for forwards machining.

• Hydraulic operation mode

One-motor technology:

• Turret and powered tools (spindle unit) are powered by single motor after the gear switching. Engaging and disengaging

the active tool is effected through fluid activation, after positioning of the drive spindle - no tooth on tooth situation! This

allows for quick engaging without searching. The tool coupling is designed for spindle heads with coupling toothing in

accordance with DIN 5480 and with spindle locking system.

• SAUTER-Spindle units-Type 0.5.941.xxx

• Product Information PI 29.3.

PI 21.3

21

Page 22

8 Pos.-1 reference circle

12 Pos.-1 reference circle 16 Pos.-1 reference circle

12 Pos.-2 reference circles

16 Pos.-2 reference circles

Position with tool drive

Position without tool drive

Description

Series 0.5.456.4xx

Tool arrangement

Tool arrangement:

22 PI 21.3

Page 23

Performance data at tool coupling 0.5.456.4xx

Performance data

Series 0.5.456.4xx

Size

12 16 20 25 32

2)

P

zul

M

zu

n

zu

kW

Nm

-1

min

2

4)

6

20

6000

..064-AK..

Nm

min

-1

14

6000

8/4000 is

Nm

min

-1

12

4000

1,5

Nm

min

-1

11

6000

8

32

5000

..084-AK..

28

5000

12/4000 is

18

4000

2

25

5000

10

63

4000

1,0

..086-AH..

40

4000

22/4000 is

33

4000

3

40

4000

12,5

100

4000

..105-AF..

68

4000

40/4000 is

60

4000

6

56

4000

15

160

3200

.. 108-A ..

100

3200

auf

Anfrage

70

3200

Gear performance data

Adm. driv rating

Adm. torque

Adm. rpm

Gear ratio i = n1 / n

1)

2)

1)3)

Recommended drive motors

Siemens-Servomotor, Typ 1FT6..

Max. torque

Adm. rpm

Fanuc-Servomotor, Typ

Adm. torque

Adm. rpm

Fanuc-Spindelmotor Typ

Adm. torque

Adm. rpm

1) The values are reference values for short-term operation. Higher rpms generate more heat and noise, especially when the belt drive is used!

2) Torque limitation at motor converter required! Admissible torque partially smaller than with turret drive!The listed torque values apply to smooth machining

(such as thread-cutting). In the case of machining with severe shock loads (e.g. face milling and similar operations), it is necessary to reduce the motor

drive torque by 50% or more.

3) With absolute value encoder.

4) Other motors upon request.

5) At tool coupling 40% WT – 5 min(Angaben der Motorenhersteller)

5)

5)

5)

5)

5)

5)

PI 21.3

23

Page 24

M

zul

P

zul

00

n

zul

n

zul

P

c

P

zul

n

c

n

zul

]

]

]

]

P

c

P

adm

=

n

c

n

adm

75 %

und

=

75 %

Pc = P

adm

P

c

P

adm

=

10 kW 75 %

= 7,5 kW

.

n

c

= n

adm

n

c

n

adm

=

4000 min

-1

= 3000 min

-1

.

.

75 %

und

.

]

]

]

]

Performance data

Performance data at the tool coupling

Admissible duty cycle of the tool drive during short-time operation (reference values)

Admissible duty cycle [DC] (5 min)

Admissible relative drive rating

and

Admissible relativ rpm

P

= required cutting rate [kW]

c

n

= required cutting rpm [min-1]

c

P

= Adm. drive rating [kW]

adm

n

= Adm. rpm [min-1] (see chart S. 23)

adm

100% 80% 60% 40% 25%

25% 40% 50% 75% 100%

Example calculation:

Wich speed nc and wich power Pc with 40% DC (5 min) are supported on a tool drive, size 20?

According to the table on page S. 23:

P

= 10 kW, n

Adml

Acc. to chart page 22, 40% DC:

= 4000 min-1

adml

In this example the tool drive can be operated with

P

= 7,5 kW and

c

n

= 3000 min-1

c

for 2 minutes and then it must rest for 3 minutes.

24 PI 21.3

Page 25

Ø d

1

D

K

+/- y

+/- x

Alternative configurations

Series 0.5.456.4xx

Alternative configurations type series 0.5.456.4xx

Size

Turret

version

12 Right 3°°

Working position

x / y D K

Position

+98,54 / -17

+100 / 0

+142,5 / 0

Coupling

profile

DIN 5480

14 x 0,8 25

2)

Toolholder

DIN 69880

location

Ø d

1

Dimensions

280

280

346

32

Mass

kg

(ca.)

90

90

120

1)

Max. possible tool

arrangement

(see page 22)

12 - 2

12 - 2

12 - 1

+117,4 / -25

+125 / -25

16 Right 3°°

+135 / 0

+150 / 0

+170 / 0

+155 / 0

20 Right 3°°

25 Right 3°°

32

on request

1) Overall weight of the turret incl. tool disk, without motor

2) further particulars see tool turret 0.5.461.4xx

Variants printed in bold are readily available!

Additonal variants – e.g variation „left-hand“ upon request

+170 / 0

+185 / 0

+210 / 0

+198 / -70

+200 / -20

+210 / 0

+235 / -70

+240 / 0

16 x 0,8 30

20 x 0,8 40

24 x 1,25 50

360

375

342

372

440

422

452

630

590

512

582

40

41

52

155

165

170

180

230

245

260

300

310

310

350

12 - 2

12 - 2

12 - 2

12 - 1

12 - 2

12 - 2

12 - 1

12 - 2

12 - 2

12 - 2

12 - 1

Dimensions in mm

PI 21.3

25

Page 26

Description

tool turret housing

in L- (or Block-) Form

drive motor

Gear head with

to ol co uplin g

12°°

option

Working position

9°°

3°°

Series 0.5.450.4xx

Disk-type tool turret Series 0.5.450.4xx

with radial tool drive

Description

• Basic turret series 0.5.460.4xx

• series and a centralized tool drive for individually switchable, radially placed tools for forwards and backwards machining

• Hydraulic operation mode

One-motor technology:

Turret and powered tools (spindle heads) are powered by single motor after the gear switching.

Engaging and disengaging the active tool is effected through fluid activation, after positioning of the drive spindle

– no tooth on tooth situation!

– this allows quick engaging without searching.

The tool coupling is designed for spindle heads with coupling toothing in accordance with DIN 5480 and with spindle locking

system.

see

• Sauter spindle units 0.5.941.xxx serie

• Product Information PI 29.3

26 PI 21.3

Page 27

Performance data for the tool coupling 0.5.450.4xx

Performance data

Series 0.5.450.4xx

Series 0.5.450.4xx

Gear performance data

Adm. drive rating

Adm. torque

Adm. rpm

Gear ratio i = n

1)

2)

1)3)

Recommended drive motors

Siemens-Servomotor, Typ 1FT6..

Adm. torque

Adm. rpm

Fanuc-Servomotor, Typ

Adm. torque

Adm. rpm

Fanuc-Spindle motor

Adm. torque

Adm. rpm

5)

5)

5)

5)

5)

5)

2

P

M

n

n

4)

zul

zu

Size

12 16 20 25 32

kW

Nm

zu

/

1

2

min

-1

6

20

6000

..064-AK..

Nm

min

-1

14

6000

8/6000 is

Nm

min

-1

12

6000

1,5

Nm

min

-1

11

6000

8

32

5000

..084-AK..

28

5000

12/6000 is

18

5000

2

25

5000

10

63

4000

1,0

..086-AH..

40

4000

22/4000 is

33

4000

3

40

4000

12,5

100

4000

..105-AF..

68

4000

40/4000 is

60

4000

6

56

4000

15

160

3200

.. 108-A ..

100

3000

on

request

70

3200

1) The values are reference values for short-term operation. Higher rpms generate more heat and noise, especially when the belt drive is used!

2) Torque limitation at motor converter required! Admissible torque partially smaller than with turret drive!The listed torque values apply to smooth

machining (such as thread-cutting). In the case of machining with severe shock loads (e.g. face milling and similar operations), it is necessary

to reduce the motor drive torque by 50% or more!

3) With absolute value encoder.

4) Other motors upon request.

5) At tool coupling 40% DC – 5 min

(details the engine producer)

PI 21.3

27

Page 28

Dimensions

Series 0.5.450.4xx

Dimensions Series 0.5.450.4xx

Series 0.5.450.4xx

6)

Size

12 16 20 25 32

Coupling profile DIN 5480 14 x 0,8 16 x 0,8 20 x 0,8 24 x 1,25 30x1,25

Dimensions K

P

A

Weight approx.

1)

kg 85 150 220 360 650

Toolholder system Cylinder shaft DIN 69880

32

76

48

2)

40

105

55

41

120

80

52

150

100

200

120

62

Width across flats

SW

Toolholder system Sandvik Capto

d

1

-Standard

1

3)4)

SW

2

3)4)

SW

5)

3)

25 30 40 50 60

220 270 320 380 470

240 - 360 410 -

300 340 380 - -

NG C3 C4 C5 C5 -

Width across flats

1) Overall weight of the turret incl. tool disk SW1 and without motor.

2) See SAUTER spindle units, type 0.5.941.xxx (Product information PI 29.3) and

SAUTER toolholder (Product information PI 07.2).

3) Valid for 8 and 12 tool positions / 16 tool positions on request.

4) High load load stage required.

5) See SAUTER spindle units, type 0.5.935.xxx (Product information PI 45)

Other toolholder systems – e.g. HSK – on request.

6) Further particulars see tool turret 0.5.460.4xx

SW-Standard

3)4

280 340 380 420 -

INDICATION: Instruction the operating duration (DC) see page 24.

Dimensions in mm

28 PI 21.3

Page 29

Options

Housining shape

Options

Version Left Version Right

L-shape housing

For forwards and backwards machining

with turret type 0.5.460/450

Block-shape housing

For forwards machining

with turret type 0.5.460/450

L-shape housing

For forward and backwards machining

with turret type 0.5.460/450

Block-shape housing

For forwards machining

With turret type 0.5.460/450

Block-shape housing

For forwards machining

with turret type 0.5.456

PI 21.3

Block-Form

For forwards machining

with turret type 0.5.456

Further housing shapes upon request

29

Page 30

U - 9°°

(Opt io n wi th

belt dri ve)

U - 9°°

direct (Standard)

U - 12°°

U - 3°°

U - 3°°

Redirection:

C ab le co nn ection

Co nnect ion „ top“

Co nnectio n „r ear“

Cable connection

Electrical connections:

• Terminal box (standard)

• Terminal box with round plug connectors (optional)

• Arrang ement "t op“ o r "r ear"

Options

Arrangement of the drive motor for series 0.5.460 / 456 / 450

Electrical connection for series 0.5.460 / 456 / 450

30 PI 21.3

Page 31

Working position

The working position is defined as that turret position, in which the tool is supplied with coolant and

– with turret series 0.5.456.4xx and 0.5.450.4xx - driven.

Tool location axial (Series 0.5.460.4xx, 0.5.456.4xx)

Options

Tool location radial (Series 0.5.460.4xx, 0.5.450.4xx)

PI 21.3

31

Page 32

Series

Operating medium

Size

0.5.450.4xx

0.5 . 456 . 4 20

disk-type tool turret with radial tool drive

disk-type tool turret with axial tool drive

0.5.456.4xx

disk-type tool turret without tool drive

0.5.460.4xx

4 - Hydraulics

12

16

20

25

32

Type key

Type key

1)

on request

32 PI 21.3

Page 33

Ordering details

Company:

Street:

Postal Code:

Name:

Phone:

++49 (0) 7123-926-190

++49 (0) 123-926-0

info@sauter-feinmechanik.com

Sauter Feinmechanik GmbH

Postfach 1551

D-72545 Metzingen

Germany

Fax:

E-Mail:

City

Ordering details

Ordering details Possible variants Your selection

Basic turret

Size

Number of indexing positions

Version

Housing shape

Axis height

Intended drive motor

Arrangement of the drive motor

Electrical connections

Installation on a machine

Tool drive axial

Working position

Coupling profile

Tool drive radial

Working position

Coupling profile

Disk-type tool

Toolholder systemWerkzeughalter-Toolholder

nominal size

Working position

Clamping direction (with DIN 69880)

Support pin position

Sequence of numbers

Options

Rotary feedthrough s. page 7

Special requirements:

PI 21.3

12 / 16 / 20 / 25

8 / 12 / 16

right / left

L / Block

1 / A2

A

s. page 12

direct / U-3°°/ U-9°°/ U-12°°

s. page 30

e.g. 60° at horizontal behind the

rotating axis

X / Y

s. page 25

3°° / 9°° / 12°°

s. page 25

DIN 69880 / Capto

x/y / SW

right-hand / left-hand

in front of / rear / both

right-hand / left-hand

33

Page 34

Loading...

Loading...