Page 1

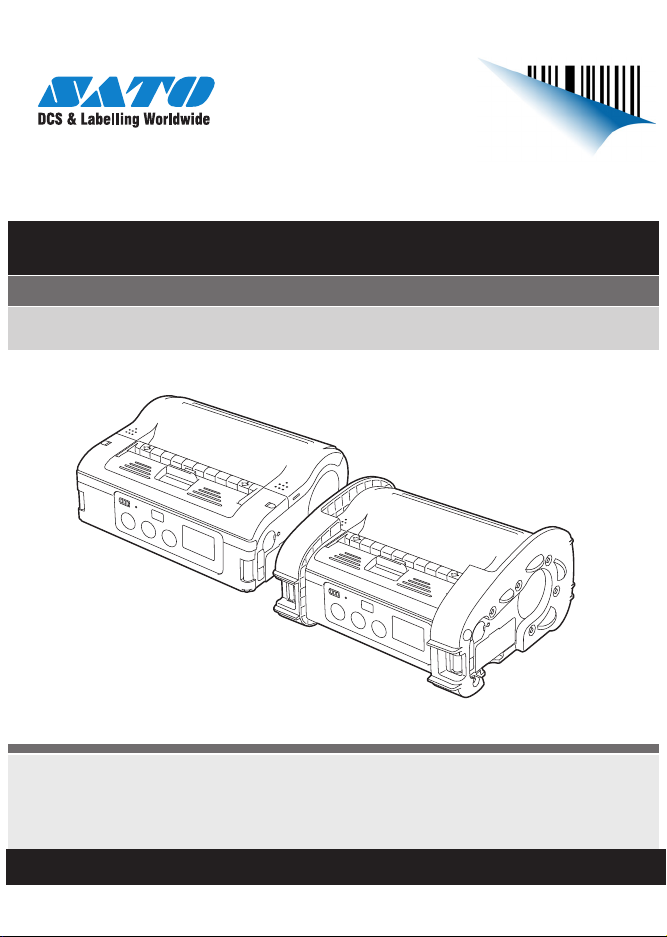

Quick Guide

For printer model:

MB400i / MB410i

www.satoworldwide.com

PN: 9001191(D)

www.satoamerica.com

Page 2

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support: (704) 644.1660

Technical Support Fax: (704) 644.1661

E-Mail: satosales@satoamerica.com

techsupport@satoamerica.com

www.satoamerica.com

Copyright 2009 SATO America, Inc. All rights reserved

Page 3

Table of Contents

Preface ..................................................................................................... 1

For the Bluetooth or wireless LAN options ...............................................1

1. Safety Precautions ..................................................... 3

Markings and Symbols ............................................................................. 3

2. Unpacking ................................................................. 12

3. Names of Parts ......................................................... 13

Names and Functions of Operating Parts ..............................................15

4. Preparing for First-time Operation ......................... 17

Charging the Battery Pack ..................................................................... 17

Installing and Removing the Battery Pack .............................................. 20

Using the AC Adapter ............................................................................. 21

Loading Labels ....................................................................................... 23

5. Turning the Power On .............................................. 31

Power ON ............................................................................................... 31

Power OFF ............................................................................................. 31

6. Test Printing .............................................................. 32

7. Operation with an RS-232C Cable ........................... 33

8. Operation with a USB Cable .................................... 34

9. Operation via Infrared Communication .................. 36

i

Page 4

10. Operation with Bluetooth or Wireless LAN .......... 38

11. Removing printed labels ........................................ 39

When the next label is not printed .......................................................... 40

12. Troubleshooting ..................................................... 41

When printing fails (automatic printing) .................................................. 44

13. Daily Care ................................................................ 46

Caring for the thermal head .................................................................... 46

Caring for the platen/dispenser roller/paper sensor ............................... 47

14. Reference ................................................................ 48

Included Items ........................................................................................ 48

Options ................................................................................................... 48

Operation Modes .................................................................................... 53

DIP Switch .............................................................................................. 61

Basic Specifications of MB400i/MB410i ................................................. 63

15. SATO Contacts ....................................................... 67

ii

Page 5

Preface

Thank you for purchasing the Barcode Printer, MB400i/410i.This manual

is created so that a first-time user of MB400i/MB410i can learn its basic

operations in a short time. Please read this manual carefully to make full

use of the functions of MB400i/MB410i.

Use this section to ensure you properly care for and use the MB400i/

MB410i printer. Read this section carefully before using your printer.

Cautions

1. Reproduction of all or part of this manual is prohibited.

2. The content of this manual is subject to change without notice.

3. This manual was created with utmost care regarding its content. However, if you find any unclear points, errors, or omissions, please contact

the dealer from whom you purchased this printer.

For the Bluetooth or wireless LAN options

Cautions regarding radio waves

This product is certified to meet technical standards based on the Radio

Law. Therefore, no wireless license is required to use this printer.

The following actions can be punishable by law:

• Disassembly or modification of this printer

• Removing the certification label (serial label) on this printer

Use in the following locations may drastically shorten the communication

distance, or prevent communication:

• Near a microwave oven

• Locations where static electricity or radio wave interference is abundant

• Near wireless LAN equipment

1

Page 6

“Bluetooth” is a registered trademark of Bluetooth SIG, Inc. USA.

Our company is using this trademark based on a licensing contract with

this association.

Before using the wireless LAN interface, be sure to set all security-related

settings for the wireless LAN equipment according to this manual.

2

Page 7

1. Safety Precautions

In this section, safety precautions about printer operation are explained to

ensure proper care and usage. Make sure to read these carefully before

using your printer.

Markings and Symbols

The following symbols or markings are used in this manual and on

the printer so that you can properly use the printer, and to prevent any

damage to property, harm or injury to yourself and others. Be sure to read

their explanations carefully to familiarize yourself with their meanings.

Warning

Caution

Symbol examples

The triangle indicates something you should take absolute care with. The cautions are indicated concretely

within the symbol. The symbol on the left indicates a

risk of electric shock.

This symbol indicates information

that, if ignored or applied incorrectly,

creates the danger of death or serious personal injury.

This symbol indicates information

that, if ignored or applied incorrectly,

creates the possibility of personal

injury or property damage.

3

Page 8

A circle with a diagonal line indicates something you

should not do. The symbol on the left indicates that you

should not try to take the unit apart.

A black circle with a picture inside indicates something

you need to do. The symbol on the left indicates that

you should unplug the unit from the wall outlet.

Specific Warnings

Liquid

Foreign Matter

Do not place any container with water or

chemicals, such as flower vase or cup, as

well as small metallic objects, near the

printer. If any of these should drop into the

printer, immediately turn off the power and

contact your nearest dealer or service center.

Continued use creates a danger of fire or

electric shock.

Do not drop or insert metallic or flammable

objects into the openings on the printer (such

as outlets for cables). If any of these should

fall into the printer, immediately turn off the

power and contact your nearest dealer or service center. Continued use creates a danger

of fire or electric shock.

4

Page 9

Dropping and Damage

Abnormal Conditions

Disassembly

Should the printer ever be dropped or otherwise become damaged, immediately turn off

the power and contact your nearest dealer or

service center. Continued use creates a danger of fire or electric shock.

Continued use of the printer while it is emitting smoke or strange odors creates the

danger of fire or electric shock. Immediately

turn off the power and contact your

nearest dealer or service center. Do not try to

service the printer by yourself.

Never try to take the unit apart or modify it in

any way. Doing so creates the danger of fire

or electric shock. Contact your nearest dealer

or service center for checking, adjustment, or

repair.

5

Page 10

Battery Pack

• Never try to take apart the battery pack or

modify it in any way such as with a solder

iron.

• Never expose the battery to direct flame,

throw it into fire, or take any actions that may

lead to shorting.

• When charging the battery pack, make sure

to use the printer or the specified battery

charger.

Warning

Warning

AC Adaptor / Battery Charger (Option)

Use only the specified voltage. Using a different voltage may create the danger of fire or

electric shock.

Use only the specified AC adapter. Using a

different one may create the danger of fire or

electric shock.

6

Page 11

Warning

Specific Cautions

Location

Never use the battery charger with any other

battery pack except for the specified one.

Doing so can rupture the battery, cause leakage, fire or electric shock.

• Never cut, damage or modify the power

cord. Also, never place heavy objects on the

power cord or heat or pull the power cord.

Doing so may damage the cord and

create the danger or fire or electric shock.

• Should the power cord ever become seriously damaged (internal wiring exposed or

shorted), contact your nearest dealer or service center for repair. Continued use of such

a cord creates the danger of fire or electric

shock.

• Never modify, excessively bend, twist, or

pull the power cord. Doing so creates the

danger of fire or electric shock.

Do not locate the printer in the area subjected

to high humidity or dew. If dew forms inside

the printer, immediately turn off the printer

and do not use it until it has been dried up.

Continued use creates the danger of electric

shock or the printer damage.

7

Page 12

Power

• Do not use wet hands to operate the power

switch, replace the battery pack or unplug the

AC adapter or battery charger. Doing so creates the danger of electric shock.

• The AC adapter set provided for this printer

is specific to this printer. Do not use it for

other electric equipment.

Thermal Head and Stepping Motor

• The thermal head gets very hot after printing. Take care when replacing the label or

cleaning the printer just after printing to avoid

burns.

• Touching the end of the thermal head with

bare hands may cause injury. Take care when

replacing the label or cleaning the printer to

avoid injury.

• Do not try to replace the thermal head by

yourself. Doing so creates the danger of

injury, burns, or electric shock.

8

Page 13

Tear-off Bar

This part contains a blade. Take care to avoid

being injured by the blade and other sharp

parts in the printer.

Replacing the Battery Pack

• Use only the specified battery pack.

• When replacing the battery pack, make sure

to install the pack in the correct orientation.

Incorrectly replacing the battery creates the

danger of injury or damage to surrounding

areas, or explosion.

• Replacing a small-size rechargeable battery

(Lithium ion battery)

Apply insulation treatment for the old battery

pack by sealing the contact with tape or the

like and ask our sales representative or service center for the measures to be taken to

recycle the reusable materials.

Do not place the battery pack together with

other batteries such as dry batteries.

9

Page 14

Leaving the printer unused for a long time

If you have no plan to use the printer for a

long time, remove the battery pack from the

printer and unplug the AC adapter from the

wall outlet.

Maintenance and Cleaning

For safe maintenance or cleaning of the

printer, make sure to remove the battery pack

and the AC adapter from the printer.

Precautions in Use

Do not place the printer in a hot or cold place.

The operation temperature range is 5° F to 122° F (-15°C to 50°C) (for

wireless LAN: 32° F to 122° F (0 to 50°C) where humidity does not cause

condensation. Do not place the printer in an area with high humidity or at a

temperature outside the specified range.

Do not drop or apply undue shock to the printer.

The printer is generally resistant to vibration possibly caused during normal transportation. However, do not apply extreme vibration or shock by

dropping the printer.

10

Page 15

Do not disassemble or modify the printer.

The printer has high-precision components inside requiring fine adjustment. Do not disassemble the printer.

Connect the correct cables to the external input terminals.

Cables of the correct specifications are required for connection to the

external equipment through the external input terminals. Contact your

nearest dealer or service center if necessary.

Use the recommended accessories.

Using optional equipment other than the specified equipment may cause a

malfunction.

Always use the equipment specified in this guide.

Use the correct media.

Use the specified media. Otherwise, faulty printing or printer damage may

occur.

11

Page 16

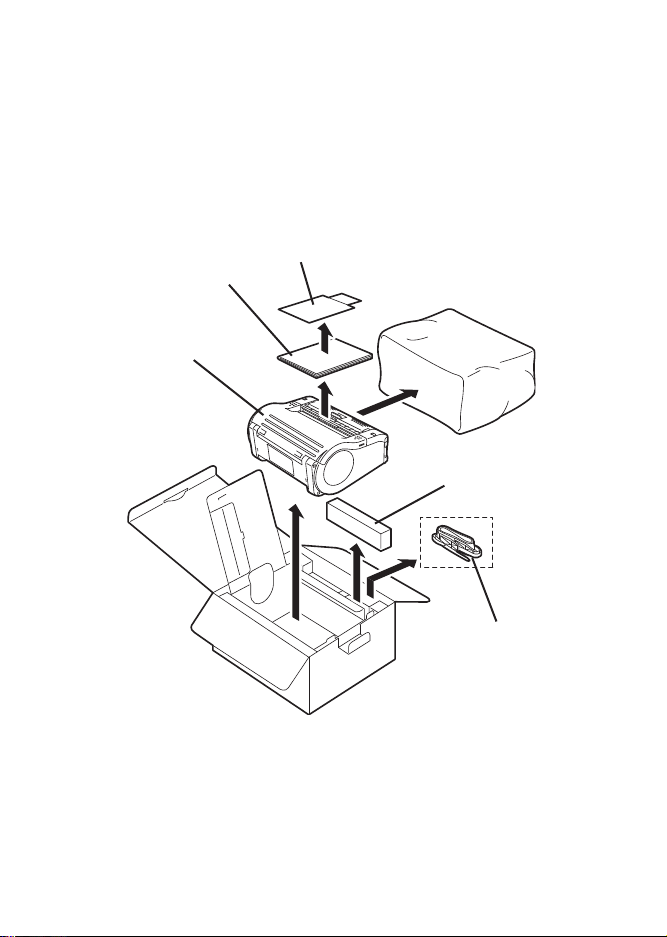

2. Unpacking

Warranty

Quick Guide

Printer unit

Battery pack

Shoulder belt

Make sure you have all the printer components shown here. If any component is missing, contact the dealer where you purchased the product from.

The appearance of any cushioning material supplied (such as protector

pads on the printer holder) may be changed across different production

batches.

12

Page 17

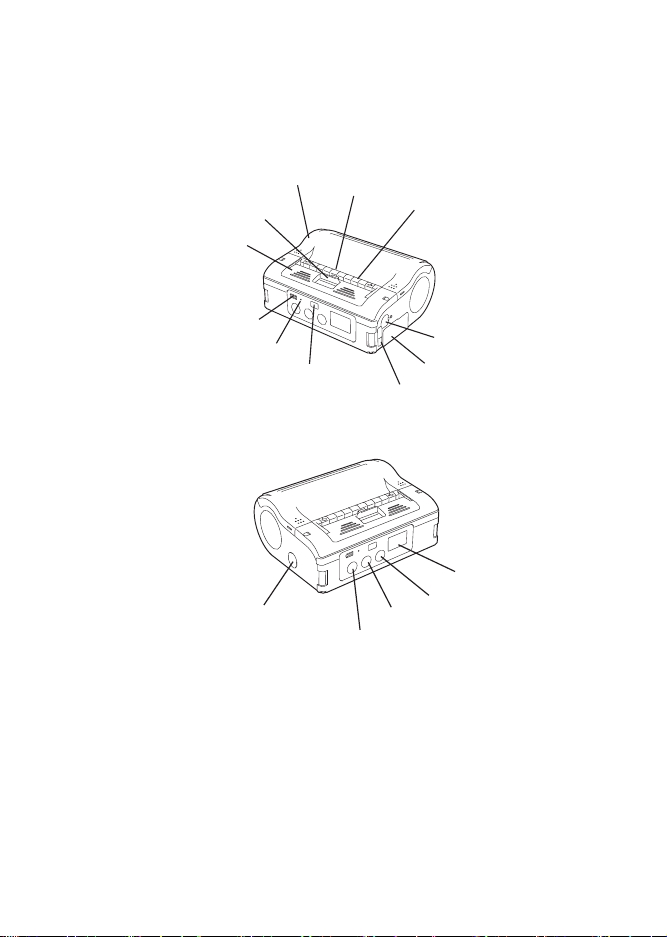

3. Names of Parts

Infrared communication sensor

STATUS (LED)

Battery life indicator

(LED) *

2

Main cover

Cover release lever

Dispenser unit

RS-232C cover

Battery cover

Label dispenser

USB/DIP switch cover

Tear-o bar

POWER button

LCD *

1

PRINT button

FEED button

DC input terminal cover

*2 On a wireless LAN interface operating panel (manufacturer option), a CHARGE

LED is provided.

*1 Only provided on wireless LAN interface operating panel (manufacturer option).

For other options, see Options in chapter 14, Reference.

Note: The MB200i and MB400i series of portable thermal printers is available in two

distinctive exterior designs. The MB400i features the use of an industrial “boot”

which helps to protect the unit in rugged and demanding industrial environments. The

MB200i product may be ordered with this boot as an option, but it is traditionally

offered without it. For expediency, this document displays the printer without a rubber boot.

13

Page 18

234

4

D

1

ON

Label guide

Label width scale

Platen

Label guide stopper

DIP switch

USB connector

RS-232C connector

Label guide

110

100

908070

60

14

Page 19

Names and Functions of Operating Parts

RS-232C cover:

This covers the RS-232C connector.

RS-232C connector:

Connects with a PC etc.

USB/DIP switch cover:

Covers the USB connector and DIP

switch.

USB connector:

Connects with a PC etc.

Main cover:

Open this cover to set the labels.

Cover release lever:

Use this to release the main cover.

Tear-off bar

Cuts the printed label. Set the position of this bar for dispense mode and continuous mode.

Infrared communication sensor:

Contains an infrared receiver/transmitter element.

DIP switch:

Sets the operation mode. (See DIP Switch in chapter 14, Reference)

Dispenser unit:

Move this when using Dispense mode printing for the labels.

15

Page 20

POWER button:

Turns the power on and off.

Battery cover:

A specialized battery pack is placed inside.

Battery life indicator (LED):

Displays the available battery power.

Label guide:

Set this to match the size of the label width used.

Label guide stopper:

Press this toward the back to unlock the label guide and adjust the label guide.

Label dispenser:

Printed labels are ejected here.

Label width scale:

Use this scale to match the label width used.

DC input terminal:

Connect the AC adapter.

DC input terminal cover:

Cover for the DC input terminal.

FEED button:

Feeds the labels.

PRINT button:

Takes the printer ONLINE and OFFLINE.

STATUS (LED):

Displays the printer status. (See chapter 12, Troubleshooting, and Operation

Modes section of chapter 14, Reference.)

16

Page 21

4. Preparing for First-time Operation

Charging the Battery Pack

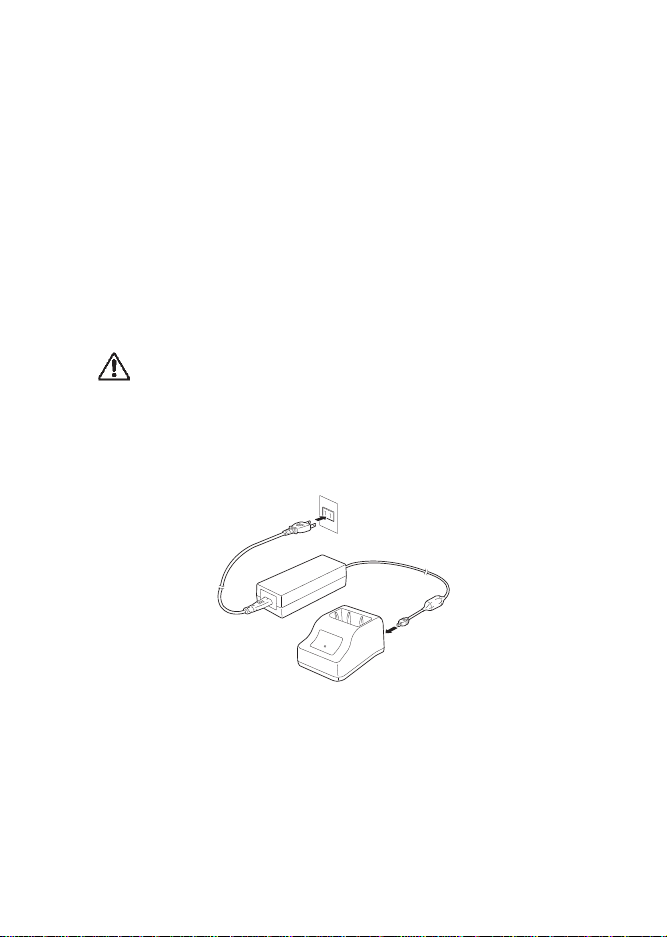

Charging by installing the battery pack in the battery charger

(optional)

Install the battery pack in the battery charger (optional) and charge it.

The optional battery charger set provided for this printer is

specific to this printer. Do not use it for other electric

equipment.

1. Connect the power cord to the charger unit, then plug it into the

outlet.

When charging is complete, the CHARGE lamp lights green (fully

charged).

17

Page 22

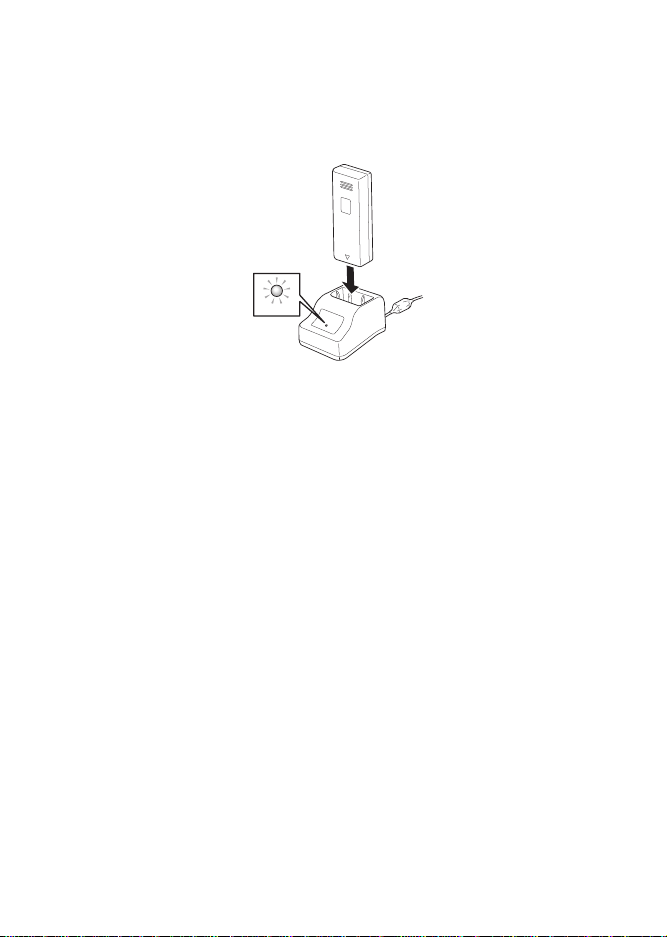

2. Insert the battery pack into the slot, with the terminal pointing down-

CHARGE

ward.

When charging begins, the CHARGE lamp (red) lights. When

charging is complete, the CHARGE lamp lights green (fully charged).

3. Remove the battery pack when charging is complete.

Charging time

It takes about 1.5 hours for the CHARGE lamp to turn off when charging a

completely depleted battery.

Notes

• When the CHARGE lamp is not lit, check that the battery pack is

installed securely. The battery may not be charged when not

securely installed.

• When a charged battery pack is installed, the CHARGE lamp first

lights red, then lights green.

18

Page 23

Charging by installing the specialized AC adapter (optional) on the

printer

This charges the battery pack while it is installed in the printer.

The AC adapter set provided for this printer is specific to

this printer. Do not use it for other electric equipment.

1. Remove the DC input terminal cover, and insert the DC output

terminal.

2. Plug the AC adapter into the outlet.

When charging begins, the battery life indicator lights red. When charging

is complete, the battery life indicator disappears (fully charged).

On a wireless LAN interface operating panel (manufacturer option), the

CHARGE LED lights red when charging begins. When charging is complete, the CHARGE LED turns off (fully charged).

Charging time

It takes about 5 hours for the battery remaining power display to turn off

when charging a completely depleted battery.

19

Page 24

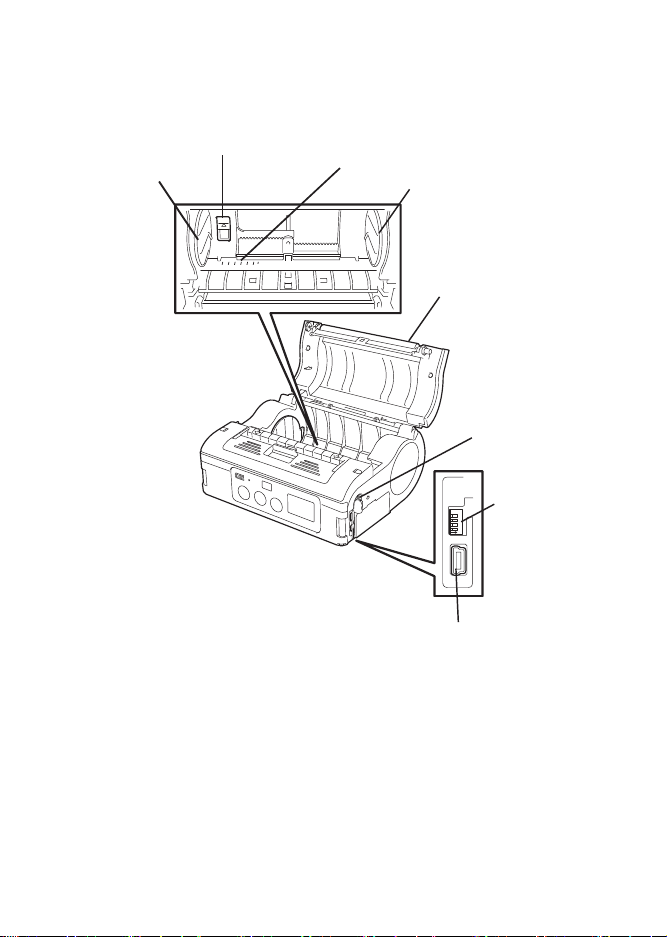

Installing and Removing the Battery Pack

Terminal

Handle

1. Open the battery cover.

2. While pressing the gray hook, insert the battery pack, then

close the battery cover.

Insert the battery pack with the terminal Handle side toward the printer.

3. To remove the battery, press the gray hook to unlock it, then hold

the handle and pull out the battery.

20

Page 25

Notes:

Battery pack

Hook

• Be sure to turn the power off before removing or replacing the battery

pack. When the power is off, the STATUS LED turns off (see Power

OFF in the section, Turning the Power On). Do not remove the battery pack until this light turns off.

• Make sure to check that the STATUS LED has turned off before

removing the battery pack.

• Removing the battery pack by the operation described on the previous page may prevent updating the information in the printer memory.

Using the AC Adapter

Note:

Use AC ADAPTER: Model No.TG-5001+19v (LEAD YEAR ENTERPRISE

Co., LTD.

The AC adapter set provided for this printer is specific to

this printer. Do not use it for other electric equipment.

21

Page 26

Install the specialized AC adapter (optional) on the printer for use. The

DC output terminal

AC adapter

DC input terminal

label installation method differs by printing mode.

1. Remove the DC input terminal cover, and insert the DC output terminal

into the input terminal.

2. Connect the AC adapter to the outlet.

• Be sure to turn the printer power off before detaching the DC output

terminal for the AC adapter, or disconnecting the power supply.

• Note that disconnecting the power supply in ways other than

described above may prevent the printer from correctly storing any

settings in memory.

• No battery pack is necessary when the AC adapter is used.

• When the battery pack and AC adapter are used simultaneously,

charging begins if the battery is not fully charged. The display

becomes normal when fully charged (See the header, Charging by

installing the specialized AC adapter, optional, on the printer, in this

chapter, Preparing for First-time Operation).

22

Page 27

Loading Labels

Label paper

Journal paper

/ Linerless label

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

The label installation method differs by printing mode.

Continuous Printing Mode

See the printers in the figure under the header, Operation Modes, in chapter 14, Reference.

The figure below shows how labels come out of the printer in continuous

mode.

23

Page 28

1. Slide the cover release lever in the arrow direction to open the

Label guide stopper

cover. First, slide the dispenser unit to the continuous printing mode position. (See Switching from Dispense mode printing to Continuous printing

mode, in this section, Preparing for First-time Operation.)

2. While pressing the label guide stopper, slide the label guide to the label

size to be used.

24

Page 29

3. Load the paper in the printer. Make sure the roll is oriented correctly.

4. Confirm that the label roll can be rotated easily by hand.

If rotation is labored, this can cause a feed error. Remove the label roll and

adjust the label guide. Note that the label guides do not require adjustment

when you are using labels with the same width.

5. Check that the label tip is protruding. Then close the main

cover by pressing the middle of the cover. Close the main cover slowly,

while pulling the cover release lever.

This completes loading the labels for continuous printing mode.

25

Page 30

Dispense mode printing

Linerless label

with perforation

Label paper

Linerless label

n

L

per

1234567

ABCDEFG

abcdefg

abel pa

with perforatio

See the printers in the figure under the header Operation Modes, in chapter 14, Reference.

The figure below shows how labels come out of the printer in dispense

mode.

26

Page 31

1. Slide the cover release lever in the arrow direction to open the cover.

Label guide stopper

First, slide the dispenser unit to the continuous printing mode position.

(See Switching from Dispense mode printing to Continuous printing mode,

in this section, Preparing for first-time operation.)

Never slide the dispenser unit while the main cover is open.

2. While pressing the label guide stopper, slide the label guide to the label

size to be used.

27

Page 32

3. Peel the label at the tip of the label paper.

This step is unneccessary when you are using linerless labels.

4. Load the paper in the printer. Make sure the roll is oriented correctly.

28

Page 33

5. Confirm that the label roll can be rotated easily by hand. If rotation is

10mm

labored, this can cause a feed error. Remove the label roll and adjust the

label guide. Note that the label guides do not require adjustment when

using labels with the same width.

6. Check that the label tip is protruding (10 mm or more). Then close the

main cover by pressing the middle of the cover. Close the main cover

slowly, while pulling the cover release lever.

29

Page 34

7. For linerless labels with perforation, pull the label upward to tear along

the perforated line. Ensure that the tear-off edge is just at the beginning of

the red platen roller. Otherwise, re-load the label.

8. Slide the dispenser unit until it stops. If the linerless label clogs at the

dispenser, clear the label and re-load the label.

This completes loading of the labels for dispense mode printing.

Switching from Dispense mode printing to Continuous printing

mode

Grip the Tear-off bar, lift it upward slightly, and then slide it toward you.

Never pull it with the bar still engaged. This may damage the dispenser

unit.

When using dispense mode printing, be sure to follow the procedure

above to switch the dispenser unit from dispense mode printing to continuous printing mode, before changing the paper.

30

Page 35

5. Turning the Power On

POW

E

R

PRIN

T

FE

E

D

POW

ER

PRIN

T

FE

E

D

When the preparation steps are complete, turn the power on or off.

Power ON

1. Hold down the POWER button until the STATUS LED lights green. Then

release the POWER button.

Power OFF

2. Hold down the POWER button again, until the STATUS LED turns off.

Then release the POWER button.

31

Page 36

6. Test Printing

POW

ER

P

R

INT

FE

E

D

1

2

1234567

ABCDE FG

abcdefg

1234567

ABCDE FG

abcdefg

1. When pressing the FEED button and holding down the POWER button

simultaneously, the printer enters the test mode. Press the FEED button

again to start test printing.

2. Verify the following using the output of the test print.

• There are no chipped characters.

• Printing condition is good.

In test printing, the estimated remaining battery power is displayed as .

( when completely charged.) When the remaining battery power is

, charge the battery.

If a problem occurs, contact the dealer where you purchased the printer

from, or our sales personnel or service center.

32

Page 37

7. Operation with an RS-232C Cable

2341

ON

RS-232C cable

RS-232C cover

To print with an optional RS-232C cable connected to a PC or a handheld

terminal, perform the following operations.

1. Remove the USB/DIP switch cover, and set the DIP switch (DSW) to

DSW-1, 2, 3, 4 = (OFF, OFF, OFF, OFF).

2. Remove the RS-232C connector cover.

3. Insert the RS-232C cable into the connector.

Match the arrow on the RS-232C cable connector with the arrow beside

the printer connector, and insert it firmly.

4. Connect the other end of the RS-232C cable to the connector on the PC

or the handheld terminal.

For the connector on the PC or the handheld terminal, see the manuals

provided with that equipment.

33

Page 38

8. Operation with a USB Cable

2341

ON

To print with an optional USB cable (mini B type) connected to a PC or a

handheld terminal, perform the following operations.

1. Remove the USB/DIP switch cover, and set the DIP switch (DSW) to

DSW-1, 2, 3, 4 = (ON, ON, OFF, OFF).

34

Page 39

2. Insert the USB cable in the connector.

USB cover

USB cable

Match the arrow on the USB cable connector with the arrow beside the

printer connector, and insert it firmly.

3. Connect the other end of the USB cable to the connector on the PC or

the handheld terminal.

For the connector on the PC or the handheld terminal, see the manuals

provided with that equipment.

35

Page 40

9. Operation via Infrared Communica-

2341

ON

tion

To print using a Bluetooth interface or a wireless LAN interface, perform

the following operations.

1. Remove the USB/DIP switch cover, and set the DIP switch (DSW) to

DSW-1, 2, 3, 4 = (ON, OFF, OFF, OFF).

2. Place the printer within 8 inches (20 cm) of the PC or handheld terminal

for infrared communication.

36

Page 41

3. Adjust the printer position so that the PC or handheld terminal is within

30°

30°

a 30° area vertically and horizontally (cone shape) from the center of the

infrared communication sensor.

The maximum usage distance for infrared communication

is 6 to 8 inches (15 to 20 cm).

However, this differs with the usage environment and the

communicating equipment. Communication may not be

possible in direct sunlight or under powerful illumination. In such cases, either shield the infrared communication sensor from harsh light, or place the infrared

communication sensor in contact with the communicating equipment.

37

Page 42

10. Operation with Bluetooth or Wire-

2341

ON

less LAN

To print using a Bluetooth interface or a wireless LAN interface, perform

the following operations.

1. Remove the USB/DIP switch cover, and set the DIP switch (DSW) to

DSW-1, 2, 3, 4 = (OFF, ON, OFF, OFF).

Note that the effective distance varies with the usage envi-

ronment, computer, or handheld terminal in use.

38

Page 43

11. Removing printed labels

1234567

ABCDE FG

abcdefg

1234567

ABCDE FG

abcdefg

1. Data is sent from a PC.

2. When printing is complete, hold the right or left corner of the label, pull it

in the direction of the arrow, and tear the label.

The number of labels that can be printed with one battery

pack differs between continuous printing mode and dispense mode printing.

When the linerless labels are severed somewhere other

than the perforated line, and the next label is not

printed, perform the operations on the page following

this one.

39

Page 44

When the next label is not printed

12345 67

ABCDE

F

G

abcdefg

1

ABC

ab

cd

FEED button

PRINT button

1234567

ABCDE FG

abcdefg

1234567

ABCDE FG

abcdefg

1. With the printer online, press the PRINT button to take the printer offline

(STATUS LED turns off).

2. Press the FEED button to feed the labels.

3. When the paper stops, pull it in the direction of the arrow to cut the

label.

4. Press the PRINT button to put the printer online (STATUS LED lights

green).

40

Page 45

12. Troubleshooting

The status of this printer is indicated by the STATUS LED display and a

buzzer sound. When the STATUS LED display or buzzer indicates the status as described in the table that follows, the printer is in an abnormal

condition. Clear the error using the clearing method.

The printer will automatically turn off in about 30 seconds after a low battery display appears. Confirm that the power is off, then remove the battery pack and charge it.

41

Page 46

STATUS LED/buzzer Mode Content -->

LED: ON (red) All modes Low battery A

LED: Blinking (red) every 2

seconds

Buzzer: One long beep

LED: ON (red) After turning

LED: Two colors blinking alternately (green --> red) every 2

seconds.

Buzzer: One long beep

LED: Blinking (red) every 0.5

seconds. Buzzer: Three short

beeps.

LED: Blinking (green) every 1

second.

Buzzer: One long beep.

LED: Blinking (green) every 0.5

seconds.

Buzzer: One long beep.

LED: Blinking (red) every 4

seconds

Buzzer: One long beep

LED: Blinking (green) every 2

seconds

LED: Patterned lighting (red +

OFF + green --> OFF) every 1

second

LED: Two colors blinking alternately (green-->orange) every

0.5 seconds

Online Module error (Blue-

power on

Online Head error D

Online Cover open E

Online Communication error H

Online (printing or receiving data)

Online (priniting or receiving data)

All modes Sleep mode K

All modes Head overheating

Online (automatic dispenser printing

or dispenser

operation 2)

tooth or wireless LAN)

1 Program abnormality error

2 FLASH ROM error

Out of paper F

Sensor error G

Buffer almost full I

Buffer overvlow J

protection function

Manual dispensing

mode

B

C

L

M

42

Page 47

--> Cause Clearing Method

A 1 The battery is not fully charged. 1 Charge the battery.

B 1 Interface module is in abnormal

condition, (Bluetooth or wireless

LAN)

C 1 A FLASH ROM reading/writing

error has occured.

D 1 The head has a broken wire. 1 Replace the head.##

E 1 The cover is not locked.

2 Cover opening/closing sensor is in

abnormal condition.

F 1 Out of labels. 1 Set a new roll of labels.

G 1 The sensor level is incorrect.

2 The sensor type is incorrect.

3 The paper is misrouted.

H 1 The communication conditions are

incorrect.

2 Cable connection is in abnormal

condition.

I 1 The receiving buffer is running out

of capacity.

J 1 Data has exceeded the receiving

buffer capacity.

2 The communication conditions are

incorrect.

K 1 This is not an error.

The printer is operating in low power

consumption mode.

L 1 This is not an error.

The head overheating protection

function operates when the head

temperature exceeds 70°C.

M 1 This is not an error.

2 Press the PRINT button to print

one label.

## Contact your nearest service center or dealer.

1 Replace the board. ##

1 Replace the FLASH ROM.##

2 Re-download the program.##

1 Lock the cover.

2 Adjust the sensor.##

1 Adjust the sensor level.##

2 Match the sensor type.

3 Remove & correctly place label roll.

1 Correct the communication conditions.

2 Check the cable connections.

1 Pause host data transmission, wait

for the buffer to empty, then retransmit data.

1 Transmit data corresponding with

the communication conditions.

2 Correct the communication conditions.

1 Clear by pressing a button, receiving

data, or opening/closing the main

cover.

1 This is cleared when the head temperature falls to 55°C.

1 Automatically cleared when the designated number of labels are printed.

43

Page 48

When printing fails (automatic printing)

In direct sunlight or under illumination, the internal sensors may mis-operate (assuming a label is present in the dispenser unit), and prevent printing. In such malfunction, either shield the dispenser unit from harsh light,

or operate using one of the following methods.

1. Operation using manual printing

Switch to manual printing by specifying the dispenser operation mode.

(See Charging the dispense mode printing setting in Operation Modes

section of chapter 14, Reference.)

2. Operate using operation 2 for the dispenser operation

Using the printer setup tool, switch the dispenser operation to operation 2.

When operation 2 is set for the dispenser operation, if harsh light is preventing printing, print using the following procedure.

Press the PRINT button to switch to manual printing, and print one label.

When printing multiple labels, operate with manual printing until the designated number of labels are printed.

While operating in manual printing mode, the STATUS LED alternates

between lighting green and orange (every 0.5 seconds).

Print condition Causes Countermeasure

Smudged 1 The head is dirty

2 The rollers are dirty

1 Clean the head (See Caring for the

thermal head section in chapter 13 Daily

Care).

2 Clean the platen (See Caring for the

platen/dispenser roller/paper sensor in

chapter 13, Daily Care).

44

Page 49

Print condition Causes Countermeasure

Vertical stripes 1 The head is dirty

Characters

printing diagonally

Blank (not

printed)

## Contact your nearest service center or dealer.

2 The head is defective

1 The label guide position is

incorrect

2 The rollers are dirty

1 The RS-232C/USB cable

connection is poor

2 Infrared communication

error

3 Bluetooth/wireless LAN

communication error.

4 The DIP switch settings

are incorrect

5 The head is defective

1 Clean the head (See Caring for the

thermal head section in chapter 13 Daily

Care)

2 Replace the head ##

1 Reset the label (See the Loading

Labels section of chapter 4 Preparing for

First-time Operation).

2 Clean the platen (See Caring for the

platen/dispenser roller/paper sensor in

chapter 13, Daily Care).

1 Check the RS232C\USB cable connections (See section, Operation with an

RS-232C Cable, chapter 7, or section,

Operation with a USB Cable, chapter 8.)

2 The distance between the PC and the

printer should be within 6-8 inches (1520 cm.). In addition, check that the PC

is within a 30 degree area vertically and

horizontally (cone shaped) from the center of the printer infrared communication

sensor (See chapter, Operation via Infrared Communication).

3 Check all settings.

4 Check the DIP switch settings (See the

DIP Switch section of chapter 14, Reference).

5 Replace the head. ##

45

Page 50

13. Daily Care

Thermal head

Be sure to turn the power off and remove the battery pack before performing the following operations.

Caring for the thermal head

1. Slide the cover release lever to open the cover.

When in dispense mode printing, first slide the dispenser unit to the continuous printing mode position. (See section, Switching from Dispense

mode printing to Continuous printing mode, in chapter 4, Preparing for

First-Time Operation.)

2. Wipe off any smudges with a cloth dipped in alcohol.

Do not use thinner, benzene, or kerosene.

46

Page 51

Caring for the platen/dispenser roller/paper

Platen

Paper sensor

Dispenser roller

sensor

1. Slide the cover release lever to open the main cover.

When in dispense mode printing, first slide the dispenser unit to the continuous printing mode position. (See section, Switching from Dispense

mode printing to Continuous printing mode, in chapter 4, Preparing for

First-Time Operation.)

2. Wipe off any smudges with a cloth dipped in alcohol. Do not use thinner, benzene, or kerosene.

47

Page 52

14. Reference

Included Items

Shoulder belt

This belt allows you to carry the printer on your shoulder.

1. Thread the shoulder belt through the belt holes on the printer, from the outside to the inside.

2. Thread the end of the shoulder belt through the buckle, and adjust the length. If the belt is not routed correctly, the belt may detach and the printer may drop.

Options

User options

Battery pack (one pack provided with this printer)

Having extra batteries available will minimize work interruptions caused by

depleted batteries.

48

Page 53

Battery charger (single)

This charges a single battery pack.

AC adapter for printer

Use this to supply power from a household power outlet (AC100V or

240V).

Connect the DC output terminal of the AC adapter to the printer.

• Be sure to use the specified adapter.

• Hold the printer when connecting or disconnecting.

• Be careful not to damage the cord.

• Unplug for storage when not in use.

• The AC adapter set provided for this printer is specific to this

printer. Do not use it for other electric equipment.

49

Page 54

Case with rain-resistant cover

You can buy a Waist case or a case that hangs from the shoulder. The

shoulder case is a version of the Waist case that has a rain-resistant

cover. You can use these cases only with the model without the rubber

boot.

Fastening method

1. Open the cover and place the printer in it with the operating parts facing up.

2. Place the lower side in the case so that the printer is completely in the case.

3. Close the cover.

50

Page 55

4. Affix the rain-resistant cover to the Waist case with the buttons and set

Rain-resistant cover

Waist case

Shoulder strap

in place.

5. Attach the shoulder strap to the case.

Waist case - Does not fit over rubber boot

This protective case is for carrying the printer by attaching it to your belt.

Fastening method

1. Open the cover and place the printer in it with the operating parts facing up.

51

Page 56

2. Place the lower side in the case so that the printer is completely in the case.

3. Close the Waist case cover.

4. Run a belt through the Waist case loops.

RS-232C cable

This connects with a PC or handheld terminal.

USB cable

This connects with a PC or handheld terminal.

Manufacturer options

Wireless LAN interface operating panel (with LCD)

This is an operating panel with an LCD to display the wireless communiction status.

52

Page 57

Operation Modes

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

Continuous printing

Dispenser printing

(label paper)

Dispenser printing

(non-separated labels)

Test printing

Continuous printing

Dispenser printing

Online printing

Continuous printing

Dispenser printing

Prints the printer status

(Receives data from a PC or

handheld terminal and prints it)

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

Continuous printing

Dispenser printing

(label paper)

Linerless labels

Test printing

Continuous printing

Dispenser printing

Online printing

Continuous printing

Dispenser printing

Prints the printer status

(Receives data from a PC or

handheld terminal and prints it)

1234567

ABCDE F

G

abcdefg

1

A

B

C

ab

c

d

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

1234567

ABCDEFG

abcdefg

Continuous printing

(label paper/linerless label/

Journal paper)

Dispenser printing

(label paper)

Dispenser printing

(Linerless label with

perforation)

Test printing

Continuous printing

Dispenser printing

Online printing

Continuous printing

Dispenser printing

Prints the printer status

(Receives data from a PC or

handheld terminal and prints it)

1234567

ABCDE F G

abcdefg

1

A

B

C

a

b

c

d

There are two printer operation modes: continuous printing mode, and dispense mode printing. Test printing and online printing are available in both

modes.

Use the printer setting tool to set dispense mode printing (linerless labels

with perforation).

53

Page 58

Normal operation mode

The LED display for the normal operation mode is as follows.

Operation status STATUS (LED)

Starting normal printing mode

Online ON (green)

Offline OFF

ON (orange)

When the buzzer sound mode is enabled, the buzzer sounds upon

startup.

The battery life indicator remains on even when the printer is OFFLINE.

Power saving mode

1. Sleep mode:

With the printer is online, the STATUS (LED) blinks (green) every two seconds. When offline, the STATUS (LED) is off. The battery life indicator

(LED) remains on even when the printer is OFFLINE.

The printer enters sleep mode (standby status) when it has not been operated for five seconds.

Normal status is resumed by pressing the PRINT button or the FEED button, by receiving data, or by opening and closing the main cover.

54

Page 59

Test printing mode (FEED button + POWER ON)

When the buzzer sound mode is enabled, the buzzer sounds upon

startup. Release the FEED button to stop the buzzer.

55

Page 60

Dispense mode printing

(1) Automatic dispenser printing setting

DSW-1,2,3,4=(OFF,OFF,OFF,ON) + cover open+ PRINT button + POWER

(2) Manual dispenser printing setting

DSW-1,2,3,4=(OFF,OFF,OFF,ON) + cover open + FEED button + POWER

Processing dispenser operation mode setting

(STATUS LED flashes green)

Setting completes

(STATUS LED lights green)

Dispense mode printing setting

Type Operation Default

Automatic

printing setting

Manual printing

setting

Prints one label after receiving data, then waits for

label to be peeled. After the label is peeled, the next

label is printed automatically.

Prints one label after receiving data, then enters

offline status. When the PRINT button is pressed, the

next label is printed. After the specified number of

labels are printed, printing is ended, and no labels are

printed when the PRINT button is pressed.

Changing the dispense mode printing setting

The dispenser operation mode setting is changed by the DIP switch

(DSW) settings when the power is turned on, and by button settings. The

settings are enabled upon turning the power off.

Notes: When the buzzer sound mode is enabled, the buzzer sounds upon

startup.

Release the PRINT/FEED button to stop the buzzer.

To end the dispenser operation mode setting, confirm that the STATUS

LED is on in green, then turn the power off. After changing the dispenser

operation mode setting, be sure to restore the DSW to their original settings.

Manual printing

setting

56

Page 61

Head check setting mode

Setting head check function

(STATUS LED flashes green)

Setting completes

(STATUS LED lights green)

DSW settings (A/B) + cover open + PRINT/FEED button + POWER

In the head check setting mode, a check can be performed in two checking areas: the printing area and the barcode printing area.

The presence of the head check function and the head check range settings are set by the DIP switch (DSW) settings when the power is turned

on, by button pressing status, and by the cover status.

DIP switch settings

(A) OFF ON OFF ON

(B) ON OFF OFF ON

DSW

settings

(A) PRINT button + cover open Head check range set as

(B) PRINT button + cover open Head check range set as bar-

Note:

When the buzzer sound mode is enabled, the buzzer sounds upon startup.

Release the PRINT/FEED button to stop the buzzer. To check the settings for head

check setting mode, see the test print output (See chapter 6, Test Printing).

To end head check setting, confirm that the STATUS LED is on in green, then turn

power off. After changing the head check setting mode, be sure to restore the DSW

to their original settings.

DSW-1 DSW-2 DSW-3 DSW-4

Button and cover

status

FEED button + cover open Head check function set as

FEED button + cover open Head check function set as

Function Default

printing area

disabled

code printing area only

Head

check

range

set as

printing

area

disabled

57

Page 62

Online command setting mode

Processing setting

(STATUS LED flashes green )

Settings complete

(STATUS LED lights green )

(1) MB400 compatibility command setting

DSW-1,2,3,4=(ON,ON,ON,O N) + cover open + PRINT button + POWER

(2) SBPL command setting

DSW-1,2,3,4=(ON,ON,ON, ON) + cover open + FEED button + POWER

Online command setting details

Type Operation Default

MB400 compatibility

command setting

SBPL command setting

Sets the online command as standard

legacy command (of theMB200/400

series).

Sets the online command as an SBPL

command.

Change online command setting

The online command setting is changed by the DIP switch (DSW) settings

when the power is turned on, and by button settings. The settings are

enabled upon turning the power off.

Note:

When the buzzer sound mode is enabled, the buzzer sounds upon

startup.

Release the PRINT/FEED button to stop the buzzer. To check the settings

for head check setting mode, see the test print output (See Section 6, Test

Printing).

To end head check setting, confirm that the STATUS LED is on in green,

then turn power off. After changing the head check setting mode, be sure

to restore the DSW to their original settings.

SBPL command setting

58

Page 63

Buzzer sound mode setting

Processing setting

(STATUS LED flashes gr een)

Setting completes

(STATUS LED lights green)

(1) D isable buzzer sound

DSW-1,2,3,4=(OFF,OFF,ON,ON) + cover open + PRINT button + POWER

(2) E nable buzzer sound

DSW-1,2,3,4=(OFF,OFF,ON,ON) + cover open + FEED button + POWER

A buzzer can be sounded upon starting up the printer and upon errors.

The buzzer is enabled by default. This can be enabled or disabled by the

initial operation and by online command.

Change buzzer sound setting

Note:

When the buzzer sound mode is enabled, the buzzer sounds upon

startup.

Release the PRINT/FEED button to stop the buzzer. To check the settings

for the buzzer sound setting mode, see the test print output (See P. 23).

To end buzzer sound setting, confirm that the STATUS LED is on in green,

then turn the power off. After changing the buzzer sound setting mode, be

sure to restore the DSW to their original settings.

59

Page 64

Standard/non-standard code setting mode

Processing setting

(STATUS LED flas hes green)

Setting completes

(STATUS LED lights green)

(1) Non-standard code setting

DSW-1,2,3,4=(ON,ON,OFF,ON) + cover open + PRINT button + POWER

(2) Standard code setting

DSW-1,2,3,4=(ON,ON,OFF,ON) + cover open + FEED button + POWER

Standard/non-standard code settings for control codes can be changed using the

control code setting command.

Standard/non-standard specifications

Type Operation Default

Standard

code

setting

Non-standard code

setting

The following control codes are set as standard codes. Standard

Control code Binary

STX 02H

ETX 03H

ESC 1BH

ENQ 1BH

CAN 18H

NULL 00H

The following control codes are set as non-standard codes.

Control code Binary

STX 7BH({)

ETX 7DH())

ESC 5EH(^)

ENQ 40H(@)

CAN 21H(!)

NULL 7EH(~)

Non-standard codes can be changed using the user download setting command.

Change standard/non-standard code setting

The standard code/non-standard code setting is changed by the DIP switch (DSW)

settings when the power is turned on, and by button settings. The settings are

enabled upon turning the power off.

Notes: When the buzzer sound mode is enabled, the buzzer sounds upon startup.

Release the PRINT/FEED button to stop the buzzer. To check the setting for the

standard code/non-standard code setting mode, see chapter 6, Test Printing. To end

standard code/non-standard code setting, confirm that the STATUS LED is on in

green, then turn power off. After changing the standard code/non-standard code setting mode, be sure to restore the DSW to their original settings.After changing the

dispenser operation mode setting, restore the DSW to their original settings.

60

code

setting

Page 65

DIP Switch

2341

ON

Setting DIP switch

1. Turn the power OFF.

2. Open the DIP switch cover.

3. Use a pointed object, such as the tip of a ballpoint pen, to change the switch position.

61

Page 66

DIP Swith setting items

DIP Switch Cover Key Startup Mode

1234 PrintFeedInterface Content

OFFOFF OFFOFFclose OFF OFF RS-2C Normal printing mode

OFFOFF ON ON close OFF OFF RS-2C HEX dump mode

OFFOFF OFFON open ON OFF - Set Automatic peeling printing

OFFON OFFOFF close OFF OFF Bluetooth

OFF ON OFFON open ON OFF - Head check (printing area)

OFFONONONclose OFFOFFBluetooth

ON OFFOFFOFF close OFF OFF Infrared

ON OFFON ON close OFF OFF Infrared

ON OFFOFFON open ON OFF - Head check (Barcode printing

ON ON OFFOFFclose OFF OFF USB interface Normal operation

ON ON ON ON close OFF OFF USB interface HEX dump mode

ON ON OFFON open ON OFF - Non-standard Control codes

close OFF ON - User test printing mode

open ON OFF - Buzzer sound disabled

open OFF ON - Buzzer sound enabled

open OFF ON - Set Manual peeling printing

interface

Wireless LAN

close OFF ON - User test printing mode

open OFF ON - Head check disabled

open ON OFF - CRC check enabled

open OFF ON - CRC check enabled

close OFF ON - Test printing mode

open OFF ON - Head check disabled

close OFF ON - Test printing mode

open ON OFF - Set compatibility with MB400

open OFF ON - Set compatibility with SBPL

open OFF ON - Standard Control codes

interface

interface

Wireless LAN

interface

interface

interface

Normal printing mode

setting

HEX dump mode

Normal startup mode

HEX dump mode

area) setting

Online Commands

Online Commands

62

Page 67

Basic Specifications of MB400i/MB410i

Item MB400i MB410i

Printing method Thermal printing

Head density 8 dots/mm (203 dpi) 12 dots/mm (305 dpi)

Maximum effective

printing area

Printing speed Maximum 4”/sec (103 mm/sec) [printing speed is 3”/sec

Dimensions

• MB400i/410i without

rubber boot

Dimensions

• MB400i/410i with rubber boot

Weight

• MB400i/410i without

rubber boot

Weight

• MB400i/410i with rubber boot

Power source [battery] Pack type [lithium ion] 1700 mAh can continuously print

4.09” (104 mm) [width] × 11.69” (297 mm) [pitch]

(75 mm/sec) during dispenser printing]. The speed differs, depending on printing duty and usage

environment.

Printing speed can be changed using the printing speed

setting command.

Printer: 6.7” (170 mm) [width] × 3” (76 mm) [depth] ×

5.3” (134 mm) [height]

Printer: 8” (202 mm) [width] × 3.9” (99 mm) [depth] ×

6.5” (165 mm) [height]

1.65 lbs (750 g) or less [Standard model, including battery pack]

2 lbs (910 g) [Standard model, including battery pack]

four rolls of thermal labels [equivalent to 164 ft (50 m)]

when fully charged [however, at a printing rate of 16% or

less].

63

Page 68

Item MB400i MB410i

Paper

Paper thickness

Paper shape

Label size [backing

liner and I-mark pitch]

Label printing Continuous printing (Paper sensor enabled)

Self-diagnosis function Head check/battery check/paper end/cover open/test

Always use genuine SATO labels.

2.5 Mil to 7.5 Mil (0.064 mm to 0.190 mm)

Roll media: Face-out winding

Maximum outer diameter: 2.63” (67 mm)

Standard Width: 2” to 4.3” (50 to 111 mm)

[2.1” to 4.4” (53 to 114 mm)]

Pitch: 1” to 11.6” (25 to 297 mm)

[1.1” to 11.8” (28 to 300 mm)]

Dispenser Width: 2” to 4.3” (50 to 111 mm)

[2.1” to 4.4” (53 to 114 mm)]

Pitch: 1” to 7.1”(25 to 182 mm )

[1.1” to 7.2” (28 to 185 mm)]

Linerless Width: 2” to 4.2” (53 to 107 mm)

Pitch: 1” to 7.1” (28 to 182 mm)

Dispenser printing (Paper sensor enabled)

Journal printing (Paper sensor disabled)

Linerless printing (Paper sensor enabled)

Label printing can be changed using the printer command <PG>.

printing

64

Page 69

Item MB400i MB410i

Low power

consumption function

Item MB400i MB410i

Interface

• RS-232C

• USB

• Optical coupling

• Bluetooth option

• Wireless LAN option

Paper sensor Reflective sensor (I-mark), transmission type (gap), Dis-

Character magnification

Character rotation 0°, 90°, 180°, 270°

Bitmap Font SATO standard fonts: XU, XS, XM, XB, XL, OCR-A,

True Type Fo nt CG Times, CG Triumvi rate

Enters sleep mode after five seconds of non-activity

(button press, data reception or cover operation). Automatically powers off after five minutes of continued nonactivity. Note: The default setting for the Bluetooth or the

wireless LAN models is to disable automatic power-off.

The automatic power-off time can be changed using the

<PG> printer operation command. For command

details, see the programming guide.

Mini DIN (specified)

mini B type

3-Wire Cooked Mode, Infrared communication (compliant with IrDA Standard Ver 1.2)

Bluetooth Specification

Wireless LAN interface (IEEE 802.11b/g)

TCP/IP (FTP, LPR, SOCKET)

penser sensor

Bitmap Font: 1 to 6 times

Agfa True Type Font: 6 to 99 point

OCR-B, POP character

Kanji:16 × 16, 22 × 22, 24 × 24 square Gothic (JIS level1 and level-2 set), Mark-down fonts

65

Page 70

Item MB400i MB410i

Barcode EAN8/13, UPC-E/UPC-A, NW-7, CODE39, CODE93,

2-D code PDF417, QR code (includes micro QR), Data matrix

Switch POWER button, PRINT button, FEED button

Indicators STATUS LED: 1 (lights in three colors: green, red, and

Buzzer Printer status information buzzer

Safety regulation CSA (CSA22.2 No.60950-1-03), CCC (GB4943-(2001)),

EMC regulation FCC15B Class B, GB9254-1998, GB17625.1(2003),

Wireless regulation

(Wireless LAN/ Bluetooth)

Protective circuit Overcharging prevention, over-discharging prevention,

Water resistance Meets IPX3 JIS C0920-2003

Environment conditions (including battery

pack)

Options Battery pack, AC adapter, battery charger (single), rain-

CODE128, INTERLEAVED 2 of 5, POSTNET, RSS-14

Note: However, barcodes are to be used at:

Parallel barcode: thin bar width 2 dots or more

Serial barcode: thin bar width 3 dots or more

code (ECC200), MAXI code, composite symbols

orange)

Battery remaining power display LED : 3 (lights in two

colors: green and red)

SS337:2001, MIC, EK(AC adapter only)

EN55022, EN55024

FCC15C, GB4943, GB9254, GB17625.1, R&TTE

(EN300 328 V1.4:2003-

04), (EN301 489 V1.4.1:2002-08), IDATSSSS

print head overheating protection function, low battery

detection

When using rain-resistant case (option)

* Excludes when communication cable is connected.

Operating ambient temperature :

5 to 122°F (-15 to 50°C)

[for wireless LAN: 32 to 122°F

(0 to 50°C)

Humidity : 20 to 80% Non-condensing

Storage ambient temperature :

13 to 140°F (-25 to 60°C)

Humidity : 20 to 80% Non-condensing

Excludes paper environment

resistant case, belt case, RS-232C cable, USB cable

66

Page 71

15. SATO Contacts

67

Page 72

SATO GROUP OF COMPANIES

• Extensive contact information of worldwide SATO operations

can be found on the Internet at www.satoworldwide.com

Asia Pacific & Oceania Region

SATO ASIA PACIFIC PTE. LTD.

438A Alexandra Road #05-01/04,

Alexandra Technopark, Singapore 119967

Tel: +65-6271-5300

Fax: +65-6273-6011

Email: technical@satoasiapacific.com

www.satoasiapacific.com

SATO AUTO-ID MALAYSIA SDN. BHD.

No.25, Jalan Pemberita U1/49,

Temasya Industrial Park, Section U1,

40150 Shah Alam, Selangor Darul Ehsan,

Malaysia

Tel: +60-3-7620-8901

Fax: +60-3-5569-4977

Email: service@satosms.com.my

www.satoasiapacific.com

SATO AUTO-ID (THAILAND) CO., LTD.

292/1 Moo 1 Theparak Road,

Tumbol Theparak, Amphur Muang,

Samutprakarn 10270, Thailand

Tel: +66-2-736-4460

Fax: +66-2-736-4461

Email: technical@satothailand.com

www.satothailand.co.th

SATO SHANGHAI CO., LTD.

307 Haining Road, ACE Bldg,

10th Floor, Hongkou Area, Shanghai,

China 200080

Tel: +86-21-6306-8899

Fax: +86-21-6309-1318

Email: tech@satochina.com

www.satochina.com

SATO ASIA PACIFIC PTE. LTD.

Korea Representative Office

6F, Korea Housing Center,

Yeouido-dong 45-11, Yeongdeungpo-gu,

Seoul, Korea 150-736

Tel: +82-2-761-5072

Fax: +82-2-761-5073

Email: technical@satoasiapacific.com

www.satoasiapacific.com

SATO ASIA PACIFIC PTE. LTD.

India Representative Office

Regus Level 2, Connaugh Place,

Bund Garden Road, Pune. 411001, India

Tel: +91-20-4014-7747

Fax: +91-20-4014-7576

Email: technical@satoasiapacific.com

www.satoasiapacific.com

SATO AUSTRALIA PTY LTD.

1/1 Nursery Avenue, Clayton Business

Park, Clayton, VIC 3168 Australia

Tel: +61-3-8814-5330

Fax: +61-3-8814-5335

Email: enquiries@satoaustralia.com

www.satoaustralia.com

SATO NEW ZEALAND LTD.

30 Apollo Drive, Mairangi Bay

Auckland, New Zealand

Tel: +64 9-477-2222

Fax: +64-9-477-2228

Email:

global.warranty@satonewzealand.com

www.satonewzealand.com

European Region

SATO LABELLING SOLUTIONS

EUROPE GmbH (BELGIUM)

Leuvensesteenweg 369,

1932 Sint-Stevens-Woluwe, Belgium

Tel: +32-2-788-80-00

Fax: +32-2-788-80-80

Email: info@nl.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (GERMANY)

Ersheimer Straße 71,

69434 Hirschhorn, Germany

Tel: +49-6272-9201-160

Fax: +49-6272-9201-347

Email: service@de.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (NORWAY)

Hovfaret 4 0275 Oslo, Norway

Tel.: +47-225-106-70

Fax: +47-225-106-71

Email: kundeservice@satonorge.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (NETHERLANDS)

Techniekweg 1b, 3481 MK Harmelen,

Netherlands

Tel.: +31-348-444437

Fax: +31-348-446403

Email: info@nl.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (ITALY)

Viale Europa 39/1,

20090 Cusago, Milano, Italy

Tel.: +39-2-903-944-64

Fax: +39-2-903-940-35

Email: info@it.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (SWITZERLAND)

Allmendstraße 19,

8320 Fehraltorf, Switzerland

Tel: +41-44-954-84-00

Fax: +41-44-954-84-09

Email: info@ch.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (AUSTRIA)

Niederlassing Austria

Jochen-Rindt-Straße 13

1230 Wien, Austria

Tel: +43-2762-52690

Fax: +43-2762-52018

Email: info@at.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (DENMARK)

Naverland 29A DK-2600

Glostrup, Denmark

Tel.: +45-43204700

Fax: +45-43204709

Email: info@dk.satoeurope.com

www.satoeurope.com

SATO POLSKA SP. Z O.O.

ul. Wrocawska 123, Radwanice,

55-015 w. Katarzyna, Poland

Tel: +48-71-381-03-60

Fax: +48-71-381-03-68

Email: info@sato.pl

www.sato.pl

SATO IBERIA S.A.

Dels Corrals Nous, 35-39

Pol. Can Roqueta, 08202 - Sabadell

Barcelona, Spain

Tel: +34-902-333-341

Fax: +34-902-333-349

Email: info@es.satoeurope.com

www.satoeurope.com

SATO FRANCE S.A.S.

Parc d'Activités, Rue Jacques Messager,

59 175 Templemars, France

Tel: +33-3-20-62-96-40

Fax: +33-3-20-62-96-55

www.satoeurope.com

SATO UK LTD.

Valley Road, Harwich,

Essex CO12 4RR, United Kingdom

Tel: +44-1255-240000

Fax: +44-1255-240111

Email: enquiries@satouk.com

www.satouk.com

American Region

SATO AMERICA, INC.

10350-A Nations Ford Road, Charlotte,

NC 28273, U.S.A.

Tel: +1-704-644-1650

Fax: +1-704-644-1662

www.satoamerica.com

SATO LABELING SOLUTIONS

AMERICA, INC.

1140 Windham Parkway, Romeoville,

Illinois 60446, U.S.A.

Tel: +1-800-645-3290

Fax: +1-630-771-4210

www.satolabeling.com

68

Loading...

Loading...