RFID KIT USER GUIDE

For printer models:

GL 4xxe Series

Read this User Guide before and during the operation of the

above accessory. Keep this Guide handy for future reference.

9001173A

www.satoamerica.com

1 General

Important information

Limitation of liability

FCC WARNING

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

NOTICE

This quick guide provides important information on how to setup your

new SATO product.

Be sure to read this quick guide thoroughly before using this printer. It

is an integral part of the product and should be kept in the immediate

vicinity of the device and available to the operating staff.

All information in this manual have been compiled under due

consideration of federal standards and regulations.

The manufacturer will not be held liable for damage resulting from:

z Disregarding these instructions

z Unintended use of the printer

z Unauthorized technical modifications

z Use of unapproved spare parts

z Use of unapproved consumables

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation.

2

1.2 Explanation of symbols

This instruction manual uses various warning icons to help you

understand the safe operation of your printer. Explanations of the

icons are below.

WARNING!

Indicates neglectful or erroneous use may cause

irreparable damage to the product, serious injury to

the operator, or worse.

CAUTION!

Indicates a specific point where caution should be

used. The graphic within the triangle will indicate the

specific issue, i.e.; the sign on the left indicates a

caution for potential electrical shock.

CAUTION!

Indicates a potentially hazardous situation which,

if not avoided, may result in damage to your

product or host equipment.

NOTE!

Emphasizes useful tips or recommendations for

efficient and smooth operation of your printer.

3

A

(Reg

A

V

/

y

A

1.3 Contact and Document Information

.

Leuvensesteenweg 369, 1932 Sint-Stevens-Woluwe, Brussels, Belgium

Parc D'Activities - Rue Jacques Messager - 59175 Templemars, France

438A Alexandra Road #05-01/04, Alexandra Technopark, Singapore 119967

International Headquarters

SATO INTERNATIONAL PTE. LTD

438A Alexandra Road #05-01/04,

Alexandra

Phone: 65-6271-2122 Fax : 65-6271-2151

Technopark, Singapore 119967

Email: sales@sato-int.com

SATO AMERICA, INC.

10350 Nations Ford Road Suite A,

Phone: 1-704-644-1650 Fax: 1-704-644-1662

Phone: 32(0)-2-788-80-00 Fax: 32(0)-2-788-80-80

SATO LABELLING SOLUTIONS EUROPE GmbH

Phone: 49-6272-9201-324 Fax: 49-6272-9201-399

Phone: 33-3-20-62-96-40 Fax: 33-3-20-62-96-55

SATO INTERNATIONAL ASIA PACIFIC PTE. LTD.

Phone : 65-6271-5300 Fax : 65-6273-6011

Phone: (86) 021- 63068899 Fax: (86) 021- 63091318

PO Box 305-031, North Shore, Auckland, New Zealand

Phone: 64-9-477-2222 Fax: 64-9-477-2228

Charlotte, NC

Email: satosales@satoamerica.com

SATO INTERNATIONAL EUROPE N.V.

Email: info @b e. s ato -eu r op e. c om

69434 Hirschhorn, Germany

438A Alexandra Road #05-01/04,

Alexandra

SATO ASIA PACIFIC PTE. LTD.

Phone: 65-6271-5300

Email: sa les@satoasiapacific .com

SATO SHANGHAI CO., LTD.

307 Haining

SATO NEW ZEALAND LTD

30 Apollo Drive, Mairangi Bay

ional HQ)

Ersheimer Straße

SATO FRANCE SAS

(Regiona l H Q)

Technopark, Singapore 119967

Email: sales@sato-int.com

Road, ACE Bldg, 10th Floor,

Hongkou Area,

Shanghai, China 200080

SATO GROUP OF COMPANIES

28273

71,

Asia Pacific & Oceania

Fax: 65-6273-6011

mericas

Europe

mericas

SATO INTERNATIONAL AMERICA, INC.

Phone: 1-704-644-1650 Fax: 1-704-644-1662

SATO LABELING SOLUTIONS AMERICA, INC.

1140 Windham Parkw ay, Romeoville, Illinois 60446

Phone: 630-771-4200 Fax : 630-771-4210

Phone: 1-386-274-5566 Fax: 1-386-274-5599

(Regional HQ)

10350 Nations Ford Road Suite A,

Charlotte, NC 28273

Email: sa t o sales@s a t o america. com

Email: sales@satolabeling.com

Horticultural Division

930 Jimmy Ann Drive

Daytona B each, FL 32117

SATO UK LTD

United Kingdom

Email : enquiries@satouk.com

SATO POLSKA SP Z O.O.

K/Wroclawia, Poland

Email: info@sato-europe.com

SATO IBERIA S.A.

08202 - Sabadell, Barcelona, Spain

Industrial Park

Section U1, 40150 Shah Alam,

Darul Ehsan, Malaysia

Selangor

Email: sa les@sato sms.com.my

SATOAUSTRALIA PTY LTD.

VIC 3168, Melbour ne, Austr alia

For a full list of all SATO offices ,

refer to

www.satoworldwide.com

1Nurser

1

alleyRoad,Harwich, Essex England Co12 4RR,

Phone: 44-1255-240000

Ul. Wroclawska 123, 55-015 Radwanice

Phone: 48-71-381-03-60 Fax: 48-71-381-03-68

Dels Corrals Nous, 35-39, Pol. Can Roqueta,

Phone: 34-93-492-5750 Fax : 34-93-786-3451

SATO AUTO-ID MALAYSIA SDN. BHD.

No.25, Jalan Pemberita U1/49, Temasya

Phone: 60-3-7620-8901 F ax: 60-3-5569-4977

SATO AUTO-ID (THAILAND) CO., LTD.

292/1 Moo 1 Theparak Road, Tumbol Theparak,

Amphur Muang, Samutprakarn 10270

Phone: 662-736-4460 Fax: 662-736-4461

venue, Clayton Business Park (1508 Centre Road) Clayton

Phone: 61-3-8814-5330 Fax: 61-3-8814-5335

Fax : 44-1255-2401 11

Extensive contact information of worldwide SATO operations can be found on the Internet at

www.satoworldwide.com

Version: SI-GL4xxe-01rA-13-06-07-RFKUG © Copyright 1994 – 2007

All rights reserved. No part of this document may be reproduced or issued to third parties in any

form whatsoever without the express permission of SATO. The materials in this document are

provided for general information and are subject to change without notice. SATO assumes no

responsibilities for any errors that may appear.

4

Overview

This User Manual describes the operation and programming procedures for RFID smart

labels (with embedded RFID tags) on the SATO GL4xxe series printers fitted with the

RFID Kit.

By incorporating RFID commands into the SATO

(SBPL) programs as described herein, users can produce smart labels to take

advantage of the power of RFID technology.

®

Basic Programming Language

This manual is organized as follows:

1. Introduction to the RFID configuration options in the GL4xxe series printer

firmware

2. RFID Command Specifications

3. GL4xxe Coupler Design

4. Error Messages and Troubleshooting

5

L

d

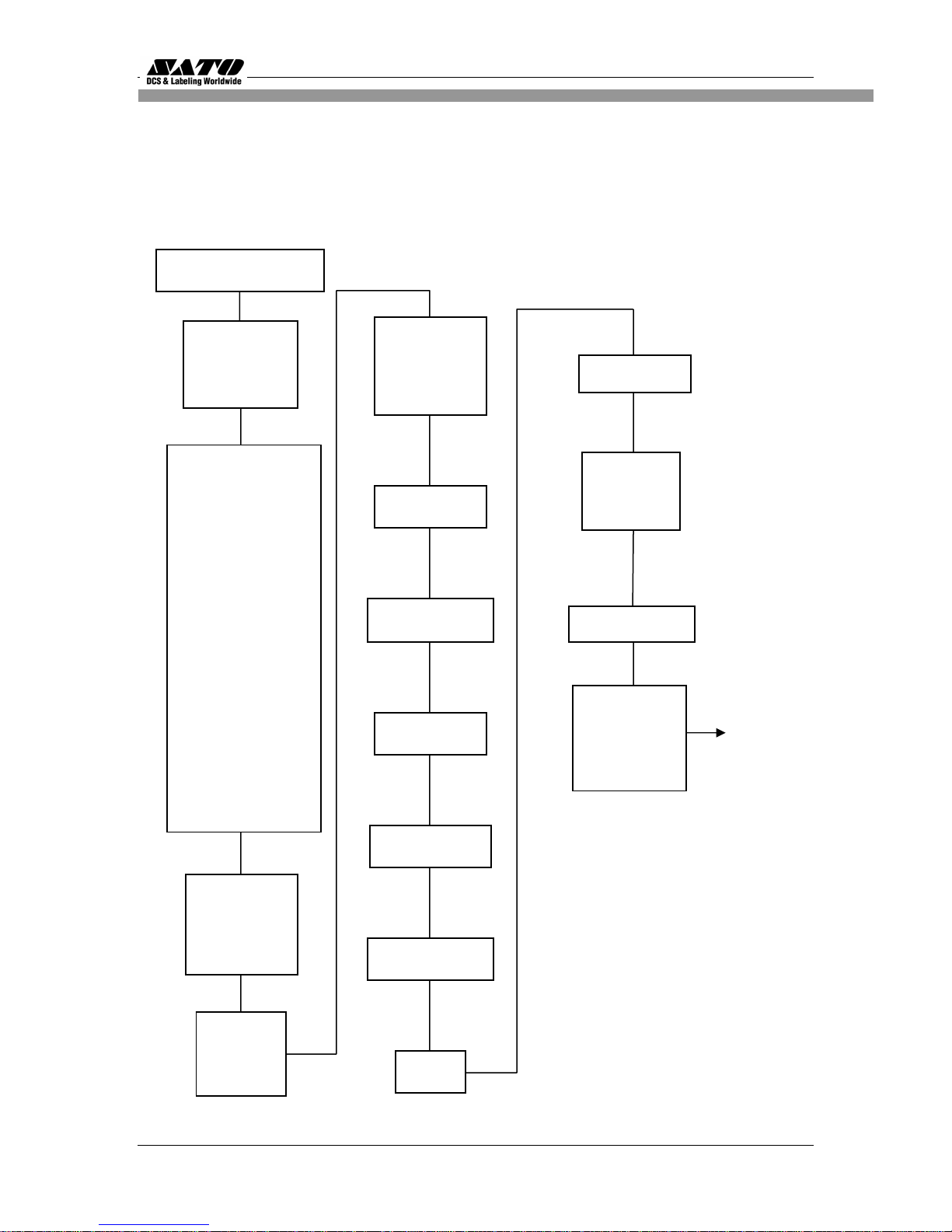

1. Introduction to the RFID configuration options

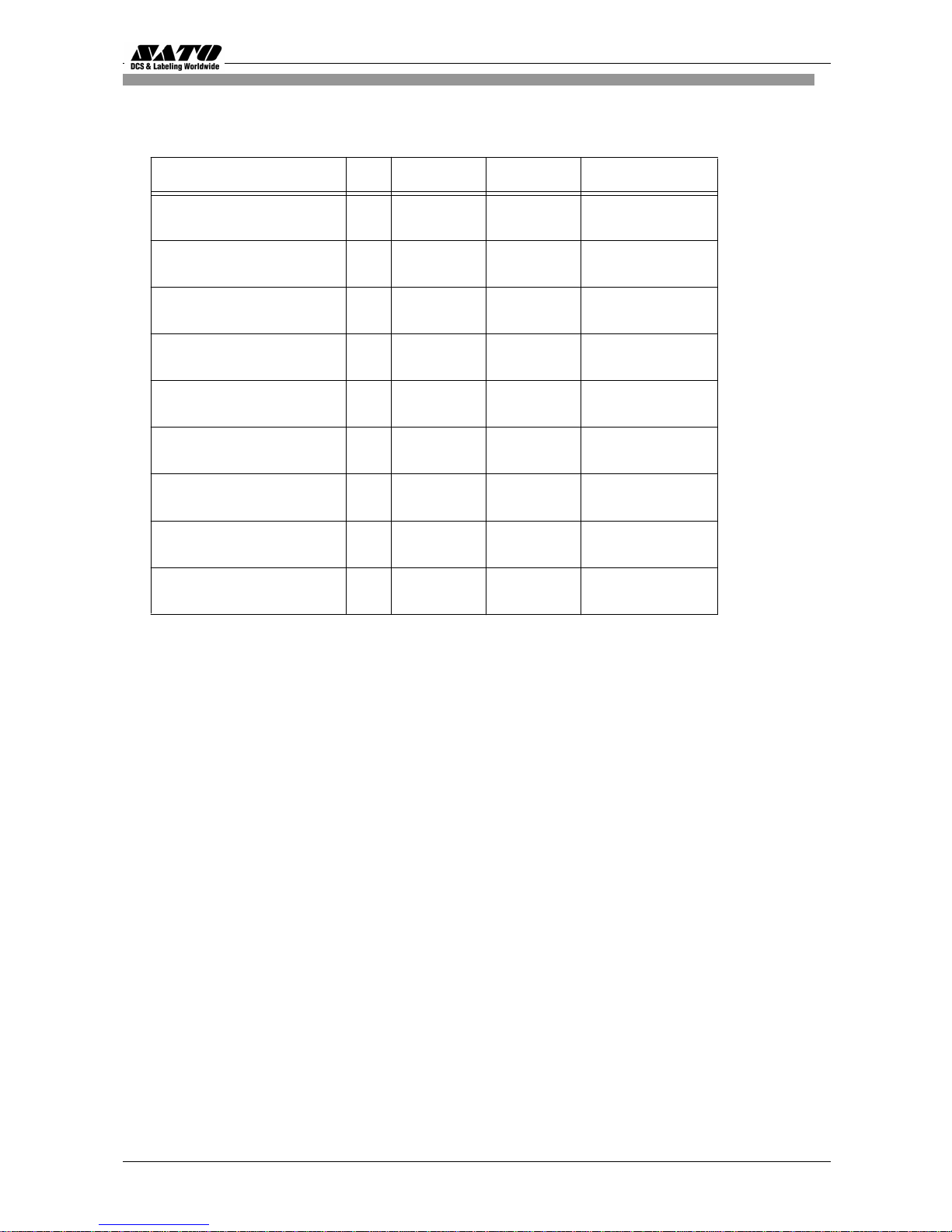

RFID CONTROL Menu (GL4xxe Series)

RFID CONTROL

RFID Reader

Enable*

Disable

Alien 9460 G2

Alien Squig G2

Avery AD220 G2

EPC G2 Phil1

EPC G2 Phil2

EPC G2 Phil3

EPC G2 Phil4

Flex Wing G2

Imp Banjo G2

KSW Excal G2

KSW Templar G2

Omron Wave G2

RAF Frog G2

RAF Short G2

Sym Trident G2

Sym Trident G2

TI Dallas G2

Error Handling

Overstrike*

None

Stop

Tag Type

Label Retry

10*

1 to 10

Max Retry

Error

Enable*

Disable

Tag Write Cnt

Failed Tag Cnt 1

Tag Void Cnt

Tag Read Cnt

1

1

1

Clear Tag Stat

Read tag

Read Tag &

Eject

Comm Retry

2*

1 to 9

Display

F/W Version

Overstrike

Style

Grid*

Error Type Msg

egen

* = Default

Italicized items appear only when Admin User is set to Enable

(in the Advanced menu).

1 This item is information only, it is not an option that can be

adjusted.

:

continued on

next page...

6

T

T

Not

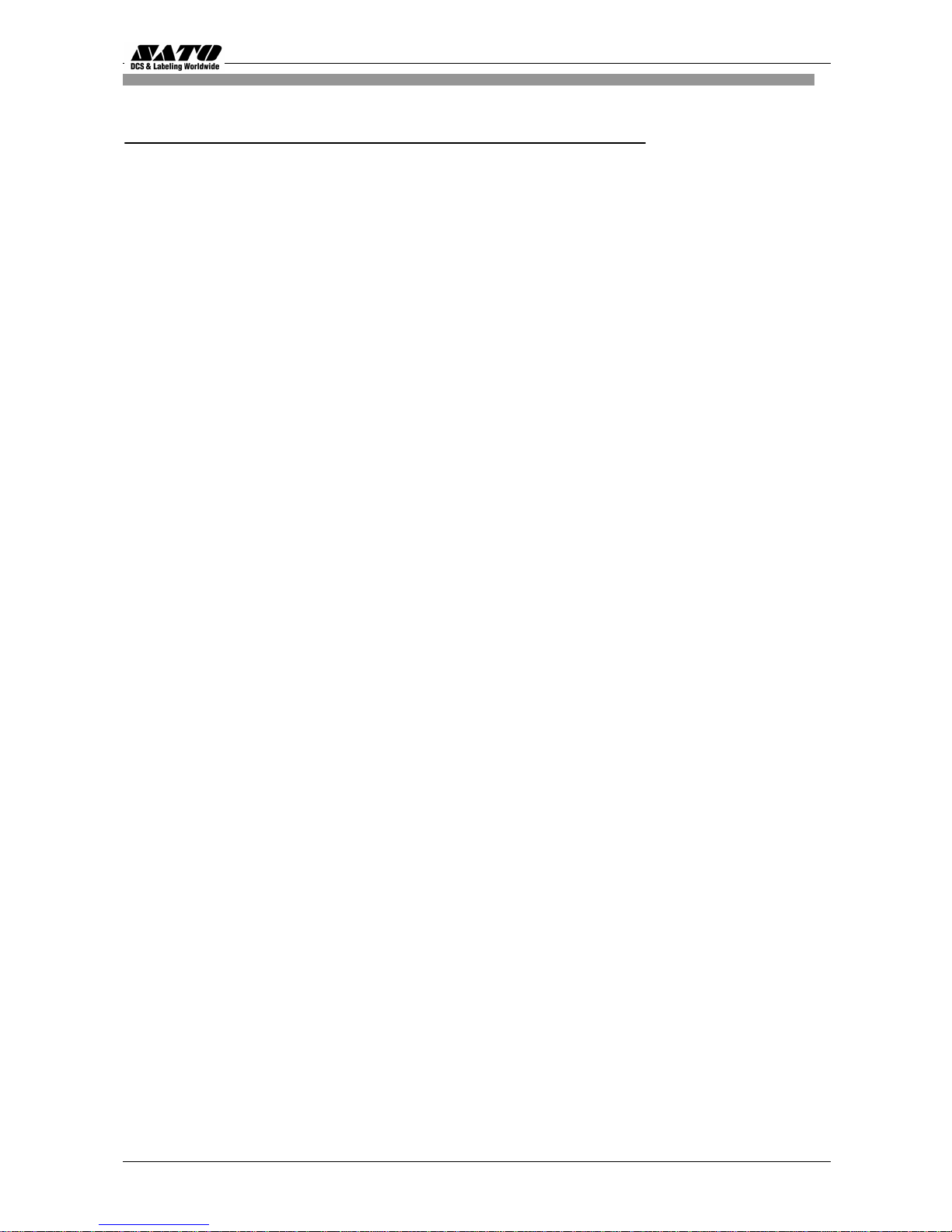

...continued from previous page

RFID CONTROL

Custom Tag

Duplicate*

Disable

Enable

Write Power

6*

1 to 20

Read Power

5*

1 to 20

EPC Byte Length

12*

8 to 32

EPC Address

0*

0 to 32

USR Byte Length

0*

0 to 32

USR Address

0*

0 to 32

ID B yte Length

8*

0 to 8

ID Address

2*

0 to 32

Block Write Len

8*

0 to 32

Custom Setting

Tag Class

Class 1*

GEN 2

Class 0

Class 0+

Class 1.19

Class Zuma

Read Tries

2*

1 to 10, infinite

Write Tries

9*

1 to 10

RFID Calibrate

To Run Press∞

Tag Position

0.0 mm*

-13 to 127 mm

Scan Start Pos

0.0 mm*

0.0 to 127 mm

Scan Length

76 mm*

0.0 to127 mm

Cal Min Power

1*

1 to 20

Cal Max Power

20*

1 to 20

es

:

* = Default.

Italicized

User is set to Enable (in the PRINTER

SETUP

items appear only when Admin

menu).

Non-RFID

Warning

Disable*

Enable

7

I

RFID

R

)

y

p

ntroduction to the

configuration options

FID Menu Items(GL4xxe

RFID Reader

This menu item enables or disables the RFID encoder. The default is

Enable

.

Tag Type

This menu item selects the tag type for use.

alphabetical

order. Other types may be added in the future.

See

Table 3 for supported tag types listed in

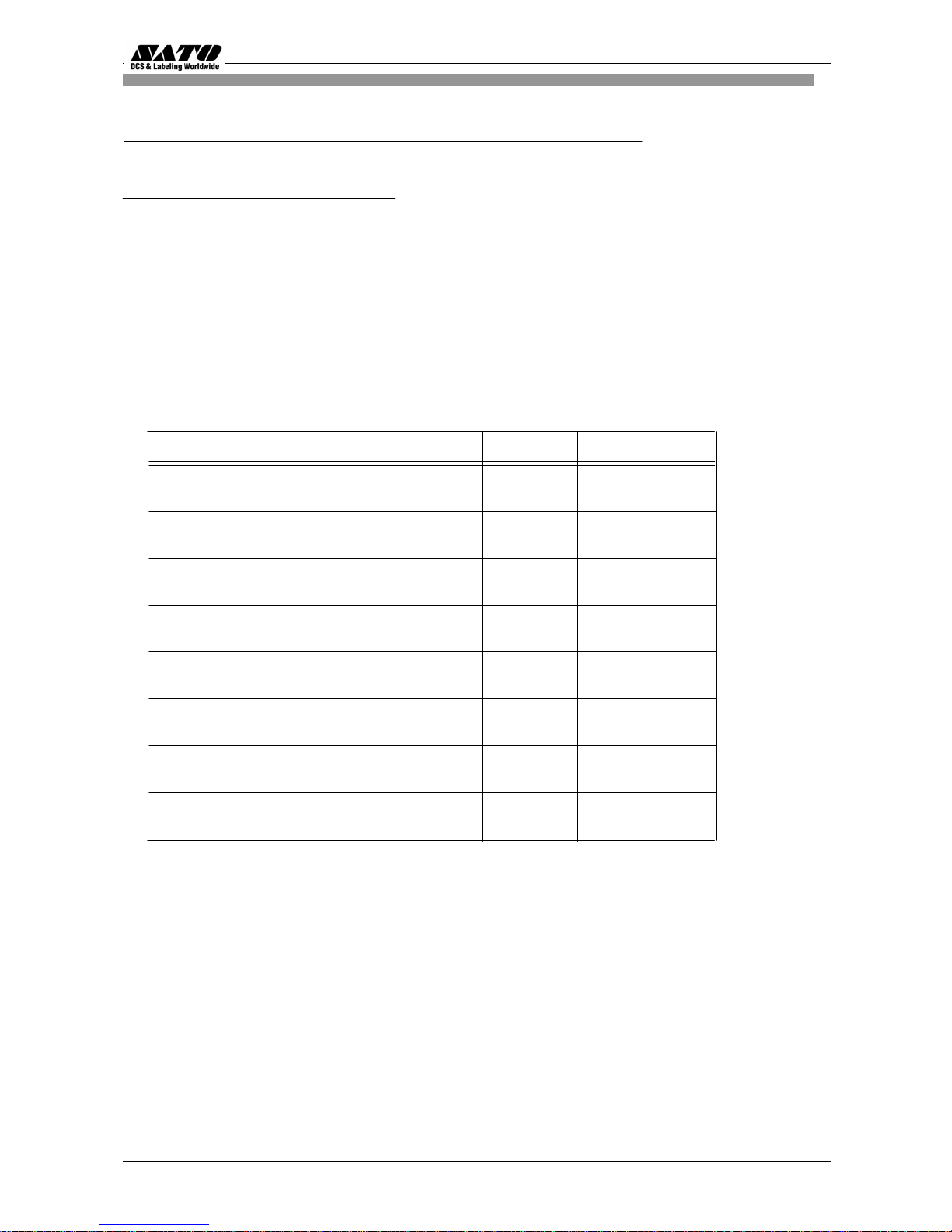

Table 3. Supported RFID Tag Types (GL4xxe)

Tag N ame

Bits

Protocol

Tag C l as s

Menu Selection

Alien Gen 2 Omni-Squiggle 96 Class 1,

Alien Gen 2 Squiggle

96 Class 1,

Gen 2

Gen 2

Gen 2 Alien 9460 G2

Gen 2

Alien Squig G2

Avery AD-220

(aka Runway)

Generic Philips

(coupler yellow)

Generic Philips

(coupler orange)

Generic Philips

(coupler red)

Generic Philips

(coupler blue)

96 Class 1,

Gen 2

96 Class 1,

Gen 2

96 Class 1,

96 Class 1,

96 Class 1,

Gen 2

Gen 2

Gen 2

Gen 2 Aver

Gen 2 EPC G2 Phil1

AD220 G2

Gen 2 EPC G2 Phil2

Gen 2 EPC G2 Phil3

Gen 2 EPC G2 Phil4

Impinj Gen 2 Banjo

96 Class 1,

Gen 2

Gen 2 Im

8

Banjo G2

)Tag

T

(

g

y

Name

Tab le 3. Supported RFID TagTypes (GL4xxe

Bits Protocol TagClass Menu Selection

KSW Gen 2 Excalibur

KSW Gen 2 Templar

Omron Gen 2 Wave

Rafsec Gen 2 Frog

3000790)

Rafsec Short Dipole

(OneTenna)

RF IDentics Gen 2

Flex Wing

Symbol Gen 2 Four T

96 Class 1,

Gen 2

96 Class 1,

Gen 2

96 Class 1,

Gen 2

96 Class 1,

Gen 2

96 Class 1,

Gen 2

96 Class 1,

96 Class 1,

Gen 2

Gen 2

Gen 2 KSW Excal G2

Gen 2 KSW

emplar G2

Gen 2 Omron Wave G2

Gen 2 RAF Fro

Gen 2 RAF Short G2

G2

Gen 2 Flex WingG2

Gen 2 S

m 4T G2

Symbol

TI Gen 2 Dallas

Gen 2 Trident

96 Class 1,

Gen 2

Gen 2 Sym Trident G2

96 Class 1,

Gen 2

Gen 2 TI Dallas G2

Label Retry

NOTE: Label Retry only applies when the Error Handling mode is set to Overstrike.

This menu item selects the number of label retries that the RFID encoder will attempt

before declaring a fault. This may indicate a problem with the RFID encoder, the

coupler assembly, the printer setup, or the label stock. The default is 10 retries.

9

I

RFID

ntroduction to the

Tag Write Cnt

Displays the number of tags attempted to be written since the last Clear Tag Stat operation was initiated.

(See “Clear Tag Stat”.)

Failed Tag Cnt

Displays on the LCD the number of failed tag write attempts since the last Clear Tag Stat operation has

been initiated. (See “Clear Tag Stat”)

Tag Void Cnt

Always displays 0 unless the RFID encoder is used with an attached Online Barcode Validator (OBV).

When used with a validator, Tag Void Cnt represents how many valid RFID tags were overstruck due to

bad barcode scanning.

Tag Read Cnt

This menu item displays the number of tags read since the last Clear Tag Stat. (See “Clear Tag Stat”)

Non-RFID Warning

When set to Enable, this option causes the printer to check to make sure that non-RFID jobs are not

being printed on RFID labels (to prevent RFID labels from being wasted).

If RFID labels are installed in the printer, and a job is printed with at least one form that contains no RFID

commands, a fault will be declared and the data for the forms that contain no RFID commands will be

absorbed.

The default is Disable.

configuration options

10

A

Introducti

RFID

Admin User Menu Items (GL4 xxe)

These menu items are visible only when the

(See the GL408/412e Operator’s Manual.)

IMPORTANT

Admin User menu items should only be used by authorized personnel.

Error Handling

This menu item selects the error handling mode for RFID failures. The default is Overstrike.

In Overstrike mode, each failed label prints with the Overstrike pattern and the form retries on a new

label until the Label Retry count is exhausted. Whether or not an error message will display (or the failed

label will reprint) depends upon the Max Retry Error setting.

In None mode, no specific action is taken when a tag fails to be programmed.

In Stop mode, when a tag fails to be programmed, the printer will halt and display the error message

“RFID Error: Check Media.” The label is discarded and reprinting of the label (if desired) must be

initiated from the host. When the error is cleared, the label with the failed tag moves forward until the

next label is in position to be printed.

Max Retry E r r or

Enables or disables Max Retry Error. If it is set to Disable, errors are not declared and the print content

for the current label is discarded. The default is Enable.

Clear Ta g S tat

This menu item clears the Tag Write Cnt, Failed Tag Cnt, Tag Void Cnt, and Tag Read Cnt menu items.

on to the

configuration options

dmin User option is set to Enable in the Advan ced menu.

11

Introducti

RFID

Read Tag

Reads the tag in range of the internal RFID coupler and reports the tag data to the debug port and

momentarily displays it on the control panel’s LCD. It is mainly intended for data verification purposes.

IMPORTANT

This menu item does not position the RFID tag over the coupler. Make sure to position the tag

over the coupler to receive an accurate reading.

Read Tag & Eject

IMPORTANT

This menu item does not position the RFID tag over the coupler. Make sure to position the tag

over the coupler to receive an accurate reading.

The menu item works exactly the same as Read Tag (above), except that after the printer reads the tag,

it feeds the label to the next top-of-form.

Comm Retry

Selects the number of automatic (internal) retries that the printer will attempt on the same tag before

declaring a tag error and performing the Error Handling mode selected (Overstrike, Stop, or None).

The default value is 2.

Display F/W-Ver

Displays the reader firmware version on the control panel’s LCD.

Overstrike Style

Selects the style of the overstrike pattern. The default is Grid.

For the Grid option, a grid pattern is printed during overstrikes. For the Error Type Msg option, an error

message is printed to indicate which error occurred.

on to the

configuration options

12

g

T

t

Introducti

RFID

on to the

configuration options

Error Messa

ag R/W Err x

Check media

Ta g Co mm Err x

Check cable

NOTE:

The x in the error messages represents a number code that identifies the area

in the printer software or RFID encoder where the failure occurred.

Tab le 4. Printed Overstrike Error Messages

e

The printer software attempted to write to or read from the

RFID tag, but the RFID encoder indicated that the tag could

not be written to, or read from.

The printer software temporarily lost communication with the

RFID encoder, or communication between the printer

software and the RFID encoder was not synchronized and

had

o be forced.

Explanation

Custom Setting

This menu item contains submenus that allow the RFID encoder to work with tag types that are not

listed in the Tag Type menu item.

NOTE: SATO cannot guarantee the performance of tag types not certified by SATO.

Custom Setting Submenus

Custom Tag

This menu item enables or disables the Custom Setting submenus. The default is Disable.

When Custom Tag is set to Disable, the settings in the Custom Setting submenus are ignored by

the RFID encoder.

When it is set to Enable, the RFID encoder uses the settings in the Custom Setting submenus,

which must be set to match the characteristics of the custom tag.

When it is set to Duplicate, the settings of the selected Tag Type menu item are copied into the

Custom Setting submenus, but are ignored by the RFID encoder.

13

Introduction to the RFID configuration options

Write Power

This menu item selects the write power level to be used in the RFID encoder. 1 is the lowest power level

setting, and 20 is the highest. The default is 6.

Read Power

This menu item selects the read power level to be used in the RFID encoder. 1 is the lowest power level

setting, and 20 is the highest. The default is 5.

EPC Byte Length

This menu item selects the number of bytes in the tag. The default is 12.

EPC Address

This menu item selects the starting location of the EPC block within the RFID tag memory. The default is

0.

USR Byte Length

This menu item selects the size of the USR block within the RFID

tag memory. The default is 0.

USR Address

This menu item selects the starting location of the USR block within the RFID tag memory. The default is

0.

TID Byte Length

This menu item selects the size of the TID block within the RFID tag memory. The default is 8.

TID Address

This menu item selects the starting location of the TID block within the RFID tag memory. The default is

2.

Block Write Len

This menu item selects the maximum number of bytes written to the

USR block within the RFID tag memory at one time. The default is 8.

14

Introduction to the RFID con fig urat io n options

Tag Class

Selects the class of the custom tag. Class 0+, Class 1.19, Gen 2, and Class Zuma tags are read/write.

Class 0 tags are read only. The default is Gen 2.

Read Tries

Selects how many times the RFID encoder will try each read command. The default is infinite, which

causes the encoder to try until the operation times out.

Write Tries

Selects how many times the RFID encoder will try each write command. The default is 9.

RFID Calibrate

Causes the printer to run calibration for the current RFID tags installed in the printer. After the

calibration is complete, the custom settings are changed to work with the tags installed. These settings

do not take effect until Custom Tag is set to Enable.

Tag Position

Determines how far the RFID tag position of the currently installed custom tags differs from the RFID

tag position of the standard SATO tag. SATO printers print at maximum speed with RFID labels that

have RFID tags in the standard position. The default is 0.0 mm.

15

r

Introduction to the RFID configuration options

Scan St art Pos

Determines where on the label the RFID calibration will begin. By default, the calibration procedure will

start at the beginning of the label (0.0 mm). To speed this up change this value to force the calibration to

begin after the beginning of the label.

Scan Length

Determines how much of the label will be scanned during the RFID calibration procedure. The default is

76mm.

Cal Min Powe

Determines the minimum power level that the calibration procedure will use when attempting to find

the ideal power level. To speed this up, increase the value to exclude the lower power levels. The

default is 1.

Cal Max Power

Determines the maximum power level that the calibration procedure will use when attempting to find

the ideal power level. To speed this up, decrease this value to exclude the higher power levels. The

default is 20.

16

Req

)

Introduction to the RFID configuration options

uesting AnRFID Report

This procedure prints a summarized RFID report. (This report also includes validator data if the printer

has a validator.

GL4xxe

1. Take the printer offline and press ENTER to enter Menu mode.

2. Press the Down Arrow and ENTER buttons at the same time until a message “THE ENTER KEY IS

3. Press the Right Arrow key until DIAGNOSTICS displays.

4. Press ENTER to enter the DIAGNOSTICS menu. Make sure Printer Tests is

5. Press the Left Arrow button until RFID Report displays.

6. Press ENTER to print the report.

7. Press the Down and ENTER buttons at the same time to lock the ENTER button, then press the

8. Press the LINE button again to take the printer online.

UNLOCKED” is displayed.

selected.

LINE button to take the printer offline.

17

Introduction to the RFID configuration options

Advanced RFID Calibration

Tag Profiler

Read and Write power settings can be optimized using the Tag Profiler. Before running the

Tag Profiler, it is important to ensure that the proper Gap Sensing procedure has been

followed. It is recommended that you calibrate the printer to ensure that gap sensing settings

are correct.

To use the Tag Profiler, first ensure that the tag type that you have selected from the Tag Type

menu or page 3 [GL4xxe] for a list of supported tag types) either matches the tag type you are

about to calibrate or is at least of the same Class and data length (i.e. 64 or 96 bits). Next, check

that Custom Tag is set to Duplicate. The correct defaults will then be set for Custom Tag Class

and Tag (EPC Byte) Length.

Before initiating the calibration cycle, the Tag Profiler can be optimized by setting appropriate

limits on the following four custom entries:

• Custom (Scan) Start Pos. Identifies the starting position of the calibration scan. The default

will start at the Top Of Form (TOF). To avoid inefficient scanning at points far away from the

target tag, set the (Scan) Start Pos within one inch of the center of the physical tag. E.g., if

the center of the tag is physically 76mm from the TOF, set (Scan) Start Pos to 51mm (25mm

(1 inch) before the center of the tag).

• Custom Scan Length. This refers to the distance that the Tag Profiler will scan to determine

the optimum tag position. For improved performance, set Custom Scan Length to 51mm or

less. This will prevent the printer from looking for a tag far beyond its actual location.

• Custom (Cal) Min Power. Sets the lower level that will be tested during calibration. To

speed up calibration, set Custom Min Power to two points lower than the Custom Read

Power that was set prior to initiating calibration.

18

r

• Custom (Cal) Max Power. Sets the upper level that will be tested during calibration. To

speed up calibration, set Custom (Cal) Max Power to two points higher than the Custom

Write Power that was set prior to initiating calibration.

After setting the four custom entries, initiate the calibration cycle: access the RFID Calibrate

menu and press Enter. The calibration will proceed using the first three good tags. A calibration

progress indicator will update on the display. At the end of the calibration cycle, the Tag Profiler

will update the Custom Write Power, Read Power, and Tag Position.

Custom Tag Configurator

When Custom Tag is set to Duplicate, you can manually edit all the custom entries. This allows

you to overwrite the values discovered by the calibration in case you want to experiment further.

It is generally best to accept the calibration values as is unless you are intimately familiar with the

printer and its RFID processes.

Before you leave the Custom Tag Configurator, record the result from Custom Tag Position. This

will be useful when deriving the optimum position for your tag with your converter. Tell the

converter to move the tag from the current position by the amount in Custom Tag Position. A

positive value means move toward TOF, a negative value means move away from TOF.

Auto Inlay Locate

After you have run the Tag Profiler (using Custom Run Cal or RFID Calibrate) and recorded the

Custom Tag Position (offset from optimum position), you may now set Custom Tag to Enable in

preparation to use the media with the Auto Inlay Locator.

When Cust om Tag is set to Enable, the Auto Inlay Locator uses the results of the Tag Profiler

calibration cycle to automatically advance the label to the correct encoding position, encode the tag

with the correct write/read power, back-feed the label to the TOF, and proceed normally to print the

full label without interruption.

19

2.RFID Command Specification

With the SATO GL4XXe, it is possible to return RFID information before writing data.

The printer supports Continuous, Tear-off, Dispenser and Cutter print mode options. Usually, writing

information to the RFID supply takes about 3 seconds to complete. Any abnormality that interrupts

the writing of information presented by RFID supply, takes about 5 seconds to show up as an error.

However, process time still varies, depending on the data size of the write information. If reading and

writing of RFID information fails due to defectiveness such as RFID supply, it takes about 10 seconds

to present as an error. Keystrokes do not register when information writing is under progress.

20

EPC Code Write

Command ESC IP0 Parameter

Hex code <1B>16 <49>16<50>16<30>16 e, d, k, a, u, m, f,p, s, t, c, n

Initial value Nil

When power switch is

Valid range

and term of

command

[Function]

This is a control function for Writing data to Gen2 RFID tag.

[Format]

<IP0> e: x , d:xxxxxxxxxxxxxxxxxxxxxxxx, k:xxxxxxxx, a:xxxxxxxx, p:xxxxxxxx, u:x….x, m:xxxxx,f:x, p:xx,

s:xx, c: xx, t:x, n:xxxxxxxxxxxx;

[Parameters]

e = [EPC Type]

a: EAN128 SSCC 96

c: EAN13 SGTIN 96

z: free mapping

d = [EPC Data] 24 digits if ‘e’ = z

17 digits if ‘e’ = a

13 digits if ‘e’ = c

Parameters when ‘e’ = Free mapping

k = [Kill code] (Max. Data Length is 8 bytes, Data should be Hex (0 to F))

a = [Present Access Code] (Max. Data Length is 8 bytes, Data should be Hex (0 to F))

p = [New Access Code] (Max. Data Length is 8 bytes Data should be Hex (0 to F))

u = [User Memory] (Max. Data Length depends on the tag manufacturer, Data should be Hex

m = [Locking of blocks] (5 digit Mask, 0: Unlock 1: Lock)

OFF

Valid range within item The set parameter becomes invalid.

Valid range between

items

The set command is not maintained.

The set parameter becomes invalid.

(0 to F))

Block

Mask byte (digit

from right)

ESC+IP0

When e = “a” (EAN128 SSCC 96) or “c”(EAN13 SGTIN 96)

f = filter value (a value between 0 and 7)

s = total number of digits for serial reference (Should be any value with 5 to 11, a combination

t = total number of digits for item reference (Should be any value with 1 to 7, a combination

EPC Area (d) 00001 (0)

Kill Code (k) 00010 (1)

Access code (a) 00100 (2)

TID Area 01000 (3)

User Memory (u) 10000 (4)

of s and c should be 17. Applicable only if

EAN128 SSCC 96 is selected)

of s and c should be 13. Applicable only if

EAN128 SSCC 96 is selected)

21

c = total number of digits for company prefix (Should be any value with 6 to 12 according to

the number of digits of ‘s’ or ‘t’ parameters)

n = serial Number (12digits) (Should be any value with 12 digits, only

applicable when EAN13 STGIN 96)

Coding Examples

【Example 1】

Description:

This example illustrates the method to write and lock EPC data of an unlocked tag and write

access code to the blank access code area.

Data:

<A>

<V>50<H>50<X22>,AAAA01234567890123456789

<IP0>e:z,d:AAAA01234567890123456789,a:1111AAAA,m:00001;

<Q1>

<Z>

【Example 2】

Description:

This example illustrates to write to a locked tag with out changing the access code.

Data:

<A>

<V>50<H>50<X22>,BBBB01234567890123456789

<IP0>e:z,d:BBBB01234567890123456789,p:1111AAAA,m:00001;

<Q1>

<Z>

【Example 3】

Description:

This example illustrates to write to a locked tag and to write a new access code.

Data:

<A>

<V>50<H>50<X22>,CCCC01234567890123456789

<IP0>e:z,d:CCCC01234567890123456789,p:1111AAAA,a:2222BBBB,m:00001;

<Q1>

<Z>

【Example 4】

Description:

This example illustrates to write data to the user memory blank of the tag.

Data:

<A>

<V>50<H>50<X22>,USER_MEMORY_56CHAR

<IP0>e:z,u:01234567890123456789012345678901234567890123456789012345;

<Q1>

<Z>

22

【Example 5】

Description:

This example illustrates to write EAN 128 data to the tag.

Data:

<A>

<V>50<H>50<X22>,3114F536CCCE4C3097000000

<IP0>e:a,d:34017587461099671,f:0,s:10,c:7;

<Q1>

<Z>

Note:

The EAN 128 data will be encrypted as per EPC Generation 1 Tag Data Standards Version 1.1

Rev.1.27 (SSCC 96).

【Example 6】

Description:

This example illustrates to write EAN 13 data to the tag.

Data:

<A>

<V>50<H>50<X22>,301803CB4F48B38000000001

<IP0>e:c,d:4003885006606,f:0,t:7,c:6,n:000000000001;

<Q1>

<Z>

Note:

The EAN 128 data is encrypted as per EPC Generation 1 Tag Data Standards Version 1.1

Rev.1.27 (SGTIN 96).

[Notes]

1. If EPC code cannot be coded into the tag, printer will execute an error action according to the settings

done from RFID mode.

2. Except “e”, which is imperative and in the fixed position (top), parameters can be omitted when not

needed.

3. Multiple print designations are only possible if IP0 command is used in combination with other print

data.

4. A word about access code, two parameters are used for access code (p: present access code and a:

New access code to be encoded into the tag)

- If ‘a’ parameter is used alone in an IP0 command, the data of ‘a’ parameter will be written in to

the access code area of the tag.

- If ‘p’ parameter is used alone in an IP0 command, the data of ‘p’ parameter will be used as a key

to write other memory blanks of the tag. The access code area remains unchanged.

- If both ‘a’ and ‘p’ parameters are used in an IP0 command, the data of ‘p’ parameter will be used

as a key to write other memory blanks of the tag and data of ‘a’ parameter will be written in to

the access code area of the tag.

23

5. The optional parameters could be omitted. Refer the table bellow to find optional parameters.

parameters

e: EPC Type

d: EPC Data [F***]17 Digits

k: Kill Code × ×

a: New Access Code × × [F*](8 digits)

p: Present access code × × [F*](8 digits)

m: Lock Mask × × [F*](5 digits)

u: User memory × × [F**](1024 digits)

Gen2

[F***]a

(EAN128 SSCC96)

[F***]c

(EAN13

SGTIN96)

[F***]13

Digits

[F***]z

(free mapping)

[F**]16、24

Digits

[F**](8 digits)

f: filter value

No of digits of serial

s:

t: Item reference ×

c: company prefix

n: Serial number × [F***]12digits ×

[F***]

[F**]

[F*]

x

reference

: Can not be omitted

: More than one is needed

: Could be omitted

: Can not be

specified

[F***]0~7 [F***]0~7

[F***]5~11 *1

[F***]6~12 *1

*1 Combination of company prefix

and serial reference should be 17

*2 Combination of company prefix

and item reference should be 13

× ×

[F***]1~7 *2

[F***]6~12

*2

×

×

×

24

EPC Code Read

Command ESC IP1 Parameter

Hex code <1B>16 <49>16<50>16<31>16 b

Initial value Nil

When power switch is

Valid range

and term of

command

[Function]

This is a control function for reading data from the EPC code-compatible RFID tag.

OFF

Valid range within item The set parameter becomes invalid.

Valid range between

items

The set command is not maintained.

The set parameter becomes invalid.

ESC+IP1

[Format]

<IP1> ,b:X;

Where ,

b = Block Number

Block Name Block No

EPC Area 1

TID Area 2

User 3

[Return Status Format]

[STX(02H)] + Data + [ETX(03H)]

Return status list

Item Contents (Binary) No. of bytes

STX(02H) Start code 1 byte

Data Data Depends on tags and blocks

ETX(03H) End code 1 byte

[Coding Example 1]

<A>

<IP1>,b:1;

<Z>

25

[Return Status Example 1]

When [8000 0000 4000 0001] is saved in an EPC-compatible tag.

02 Start code

38 30 30 30 30 30 30 30 34 30 30 30 30 30 30 31

03 End code

* In actuality, all data is continuous.

* Data is displayed in hexadecimal code.

[Return Status Example 2]

When there is no EPC-compatible tag .

02 Start code, error flag

45 50 43 5F 54 61 67 5F 45 72 72 Returning [EPC_Tag_Err] in ASCII char

03 End code

* In actuality, all data is continuous.

* Data is displayed in hexadecimal code.

[Notes]

1. This command cannot be used in combination with other commands.

2. This command is to be processed after the completion of print, not during the print.

3. It takes a few seconds after the command is sent until all return statuses are returned to the host

computer. If the port is closed before all return statuses are returned to the host, the tag data will not

be correctly returned and the data other than return status format is returned. You must then sort the

data before operating.

26

EPC Trade Mark Print

ESC+TM

code

Initial value Nil

Valid range

and term of

command

[Function]

This is a Graphic function specifying the print of EPC trade mark on a tag label.

[Format]

<TM>X

[Parameters]

X=[Logo ID No.]

1:

2:

[Coding Example1] [Coding Example2]

<A> <A>

<V>50<H>50<TM>1

<Z> <Z>

[Notes]

1. Rotation <%> and Enlargement <L> are also available.

2. Specify the command Enlargement <L> right before <TM> in case of its usage.

3. The original print area is,

4. When the parameter X is left blank, the logo 1 will be printed.

ESC TM Parameter Hexadecimal

<1B>16 <54>16<4D>16 X

When power switch is

OFF

Valid range within item The set parameter becomes invalid.

Valid range between

items

<V>50<H>50<TM>2

W143XH101 dots for logo1

W202XH101 dots for logo2 (without the designation of enlargement)

The set parameter is not maintained.

The set parameter becomes invalid.

27

Sequential nu mbering

ESC+F

code

Initial value Nil

Valid range

and term of

command

[Function]

This is a control function to specify data to be sequentially incremented or decremented.

In the data stream this command should be placed before EPC write command.

[Format]

<F> a a a a b c c c c (, dd, e e, f)

[Parameters]

aaaa Number of times to repeat the same data : 0001-9999

b Plus or minus symbol (+ for increments; - for decrements)

cccc Value of step for sequence (0001-9999)

,dd Number of digits for sequential numbering (01-99), if these digits are left out, the default is 8.

,ee Number of digits free from sequential numbering (00-99) starting with the rightmost position.

ESC F Parameter Hexadecimal

<1B>16 <46>16 a a a a b c c c c, d d, e e, f

When power switch is

OFF

Valid range within item The set parameter becomes invalid.

Valid range between

items

If these digits are left out, the default is 0.

The set parameter is not maintained.

The set parameter becomes invalid.

f Decimal or Hexadecimal : 0 = decimal

1= Hexadecimal

When this digit is left out, the default is 0.

[Coding Example 1] Write EPC and Lock Tag

Number of times to repeat the same data : 1, incrementing :+, step of sequence:1,Number of digits for

Sequential numbering: 5, Number of digits free from sequential numbering: 0

<A>

<V> 100<H>100<X21>, Sequential Test

<F>1+1,5,0

<Q> 2

<Z>

<IP0>e:z,d:1122334455ABCDEF01234567,a:1111AAAA,m:00001;

28

[Coding Example 2] Write EPC and User memory

Number of times to repeat the same data : 1, incrementing :+, step of sequence:100,Number of digits for

Sequential numbering: 3, Number of digits free from sequential numbering:2

<A>

<V>100<H>100<P>2<L>0202

<F>1+100,3,2,0

<Q>3

<Z>

[Notes]

1. Up to Max. eight different sequential fields can be specified per label.

2. This command can not be used with the following commands.

Reverse Image command <(>

Line Feed command <E>

3. Among the RFID commands, only IP0 should be used in combination with this command. Only free

mapping functionality of (EPC area and User Area) IP0 command is valid with this command.

4. If EPC area and user area is specified in the same IP0 command, the sequential functionality will be valid

for both fields.

<IP0>e:z,d:ABCDE1122334455ABCD056CC,u:ABC078CC;

29

3. GL RFID Coupler Design

The GL4xxe RFID has a coupler design that supports a greater variety of tag types. You

can move the coupler horizontally by using the coupler handle. See figures on

pages.

The coupler has four positions on a four inch printer.

Yellow:

1st Position (furthest inboard)

following

Orange:

Red:

Blue:

Once you select a

displayed on the LCD:

Set Antenna Pos

To x

If Done Press Enter

Where x is the word Yellow, Orange, Red and Blue

2nd Position

3rd Position

4th Position (furthest outboard on a 4 inch printer)

tag type from the front panel, the following message will be

30

4. Adjusting the Coupler position

Remove the

thumbscrew

that secures

the lower front

cover to the

printer. Slide

the cover to

the left

(toward the

electrical half

of the printer)

to remove it.

31

Adjusting the Coupler position

Use the coupler handle to adjust the coupler so that the coupler position indicator points to

the correct color on the colored position strip.

Aligning the tabs, install the lower front cover (See RFID Kit Installation Guide) Step 2.

Secure the lower front cover to the printer using the thumbscrew.

32

4. Error Messages

The RFID encoder can detect a number of errors. When one of these errors occurs, the RFID encoder

alerts the printer to perform the currently selected error action

Error Message

NON-RFID DATA On Rfid Tag A job was printed that had no RFID

RFID Comm Err

Check Cable

RFID FW ERR: Version

Mismatch

RFID LOCK CMD: Not

supported!

RFID MAX RETRY Check

System

RFID TAG ERR: Read-Only

Tag

RFID TAG FAILED Check Media

RFID UNLOCK CMD: Not

Supported!

RFID ACS FIELD: Not Supported The ACS field was accessed on a

RFID KIL FIELD: Not

Supported!

Explanation

commands on at least one form of

the job while RFID tags were

installed in the printer and the NonRFID Warning menu item is set to

Enable.

RFID error: communication cannot

be established with the RFID

encoder. Reader will be set to

Disable in the RFID (or RFID

CONTROL) menu and the

previous port settings restored

The RFID encoder firmware

version is not capable of operating

with the printer software.

A lock command was executed on

a tag which does not support

locking. All Class 1 tags and most

Gen 2 tags support locking. Other

tag classes such as Class 0+,

Class 1.19, and Class Zuma do

not support locking.

Error Handling = Overstrike in the

RFID (or RFID CONTROL) menu,

and the Label Retry count has

been exhausted.

A write was attempted on a

read-only tag.

Error Handling = Stop in the RFID

(or RFID CONTROL) menu, and

the RFID encoder could not read

the RFID tag.

An unlock command was executed

on a tag which does not support

locking.

tag which does not support the

ACS field

The KIL field was accessed on a

tag which does not support the

KIL field.

Solution

Press LINE to clear the message.

Set Non-RFID Warning to Disable,

print a job with RFID commands

on every form, or install non-RFID

labels in the printer

Press LINE to clear the message.

Press LINE to clear the

message.

Re-download the program file to

the printer.

Press LINE to clear the

message.

Remove the lock command from

the application.

Press LINE to clear the message.

Press LINE to clear the message.

Change media to writable tags or

remove the write command from

the application

Press LINE to clear the message.

Press LINE to clear the message.

Remove the unlock command

from the application.

Press LINE to clear the message.

Remove references to the ACS

field from the application

Press LINE to clear the message.

Remove references to the KIL field

from the application.

33

Troubleshooting

If you are having trouble with the RFID encoder, consult Table below for a list of symptoms and possible

solutions.

Symptom

No communication between

the printer and the reader

Solution

1. Make sure Reader = Enable in the RFID (or RFID

2. Use the RFID Test option in the RFID (or RFID CONTROL)

menu (Admin User enabled) to read and display the current RFID

tag content..

CONTROL) menu.

Tag failed

1. The label could be misaligned. Perform the Auto Calibrate

procedure to ensure the label is at top-of-form

2. Make sure the media are smart labels with RFID tags located

in the correct position.

3. The RFID tag could be defective. Try another tag.

4. Make sure the application does not send too few or too many

Inconsistent results

digits to the RFID tag.

Make sure the media is loaded correctly.

The RFID encoder works, but

it does not meet expectations

Make sure that both Error Handling and Label Retry are set to

desired values in the RFID (or RFID CONTROL) menu

34

35

Loading...

Loading...