Page 1

CX208

Desktop Label Printer

USER

GUIDE

Page 2

BAR CODE SATO ELECTRONICS (S) PTE LTD

438A Alexandra Road

#02-01/04 Alexandra Technopark

Singapore 119967

Tel: (65) 271 5300 Fax: (65) 273 6011

Service Hotline: (65) 273 6455

http://www.satosingapore.com

© Copyright 2001

BAR CODE SATO ELECTRONICS (S) PTE LTD

Warning: This equipment has been tested and found to comply with the limits for a Class B computing device pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed in accordance with

the instructions may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try and correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and the receiver.

•

Connect the equipment into an outlet or a circuit different from that

•

to which the receiver is connected.

Consult an experienced radio/TV technician for help.

•

Caution: The FCC warns the users that changes or modifications of the unit

not expressly approved by the party responsible for compliance could void

the user’s authority to operate the equipment.

All rights reserved. No part of this document may be reproduced or issued

to third parties in any form whatsoever without the express permission of

BAR CODE SATO ELECTRONICS (S) PTE LTD. The material in this

document is provided for general information and is subject to change without

notice. BAR CODE SATO ELECTRONICS (S) PTE LTD

responsibility for any errors that might appear.

PN9001091

Rev. A

assumes no

Page 3

BAR CODE SATO ELECTRONICS (S) PTE LTD

438A Alexandra Road

#02-01/04 Alexandra Technopark

Singapore 119967

Page 4

CX208 User Guide

Table of Contents

WhatYouGet ...............................1

Controls, Indicators, and Connections ..................2

Printer Power Connection.....................2

Printer Interface Connection....................4

Setup ...................................4

Loading Labels or Tags......................4

Loading Ribbon ..........................6

Sensor Calibration.........................8

Selecting the Label Sensor Type..................8

Using the Printer ..............................9

Printing a Self-test Label.....................9

Feeding Blank Labels.......................9

Label Reprint ...........................9

Sending Data to the Printer....................9

Printer Ready/Standby/Reset Control... .............9

Printing Labels..........................10

Controlling the Printer Using Direct Commands........10

Routine Maintenance ...........................11

What To Do If... ..............................12

READY light is not lit ......................12

READY light glows red .....................12

Self-test label willnot print ...................13

Labels will not feed........................13

Host stops responding ......................13

Labels feed continuously.....................14

Poor print quality.........................14

Technical Support.............................14

Printer Specifications...........................15

Communication Ports ..........................16

Standard Printer Cables.....................16

Serial Port Parameters......................16

CX Software................................17

Label Wizard CX.........................17

Windows Drivers.........................18

Media and Supplies ............................18

Page i

Page 5

CX208 User Guide

What You Get

The SATO CX208 Printers come complete and ready to install and

print labels. Your CX208 shipping carton contains the following items:

CX208 Printer

•

Parallel Printer Cable

•

40 Watt Power Supply (80 Watt Supply optional)

•

Stack of label

•

Thermal Transfer Ribbon (not supplied with the CX208DT)

•

User’s Guide

•

CD-ROM Containing:

•

Label Wizard CX Label Design and Production Software

Label Wizard CX Manual Files

CX208 User’s Guide

CX208 Programming Reference Guide

Windows Printer Driver for CX208

Label Wizard SE Evaluation Software

SATO Product Catalog

Adobe Acrobat Reader

®

for viewing and printing the manuals.

Page 1

Page 6

CX208 User Guide

N

C

w

s

(a

c

h

i

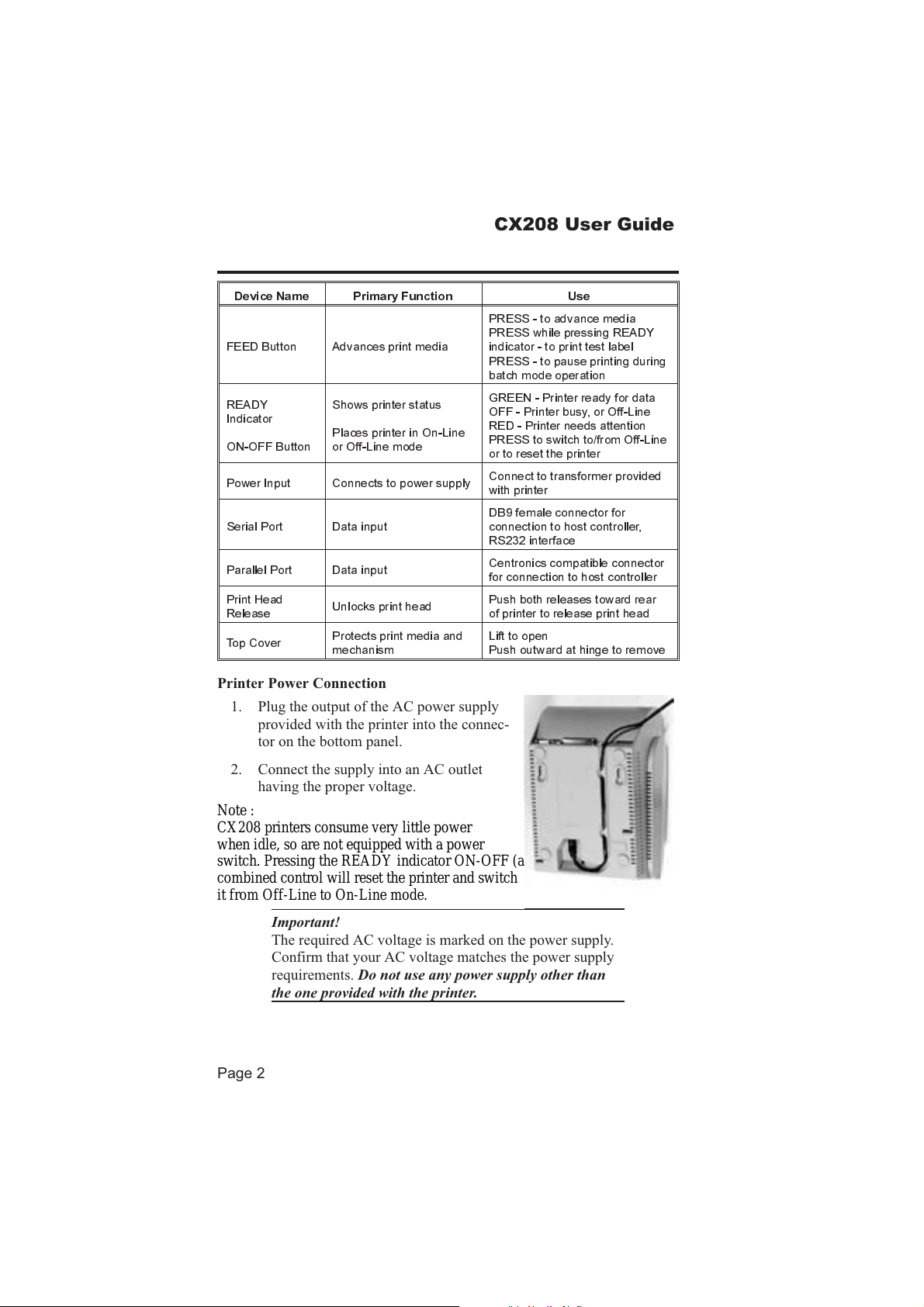

Controls, Indicators, and Connections

Device Name Primary Function Use

PRESS - to advance media

FEED Button Advances print media

READY

Indicator

ON-OFF Button

Power Input Connects to power supply

Serial Port Data input

Parallel Port Data input

Print Head

Release

Top Cover

Shows printer status

Places printer in On-Line

or Off-Line mode

Unlocks print head

Protects print media and

mechanism

PRESS while pressing READY

indicator - to print test label

PRESS - to pause printing during

batch mode operation

GREEN - Printer ready for data

OFF - Printer busy, or Off-Line

RED - Printer needs attention

PRESS to switch to/from Off-Line

or to reset the printer

Connect to transformer provided

with printer

DB9 female connector for

connection to host controller,

RS232 interface

Centronics compatible connector

for connection to host controller

Push both releases toward rear

of printer to release print head

Lift to open

Push outward at hinge to remove

Printer Power Connection

1. Plug the output of the AC power supply

provided with the printer into the connector on the bottom panel.

2. Connect the supply into an AC outlet

having the proper voltage.

ote :

Note:

X208 printers consume very little power

CX208/212 printers consume very little power

hen idle, so are not equipped with a power

when idle, so are not equipped with a power

switch. Pressing the READY indicator/ON-OFF (a

witch. Pressing the READY indicator ON-OFF

combined control) will reset the printer and switch

ombined control will reset the printer and switc

it from Off-Line to On-Line mode.

t from Off-Line to On-Line mode.

Important!

The required AC voltage is marked on the power supply.

Confirm that your AC voltage matches the power supply

requirements. Do not use any power supply other than

the one provided with the printer.

Page 2

Page 7

CX208 User Guide

Printer Interface Connection

1. Connect the supplied interface cable to the parallel printer port on the

computer.

2. Connect the other end to the parallel input port on the printer.

Ready LED Indicator/

ON-OFF Button

FEED Button

Top Cover

Print Head

Release

Paper

Guide

External Media

Feed Knockout

Parallel

Port

Serial

Port

Ribbon

Cover

Print Head

Release

Wall Mount Slots

Power Cable

Routing Channel

Power Input

Page 3

Page 8

Media Loading

Paper Guide Lock

P

d

S

t

Source

D

n

M

R

C

P

P

R

L

it

S

L

CX208 User Guide

rint Hea

ensor Ligh

rive Plate

edia

oll

Page 4

entre Justified

aper Guides

rint Head

elease

abel Ex

lot

abels

Page 9

CX208 User Guide

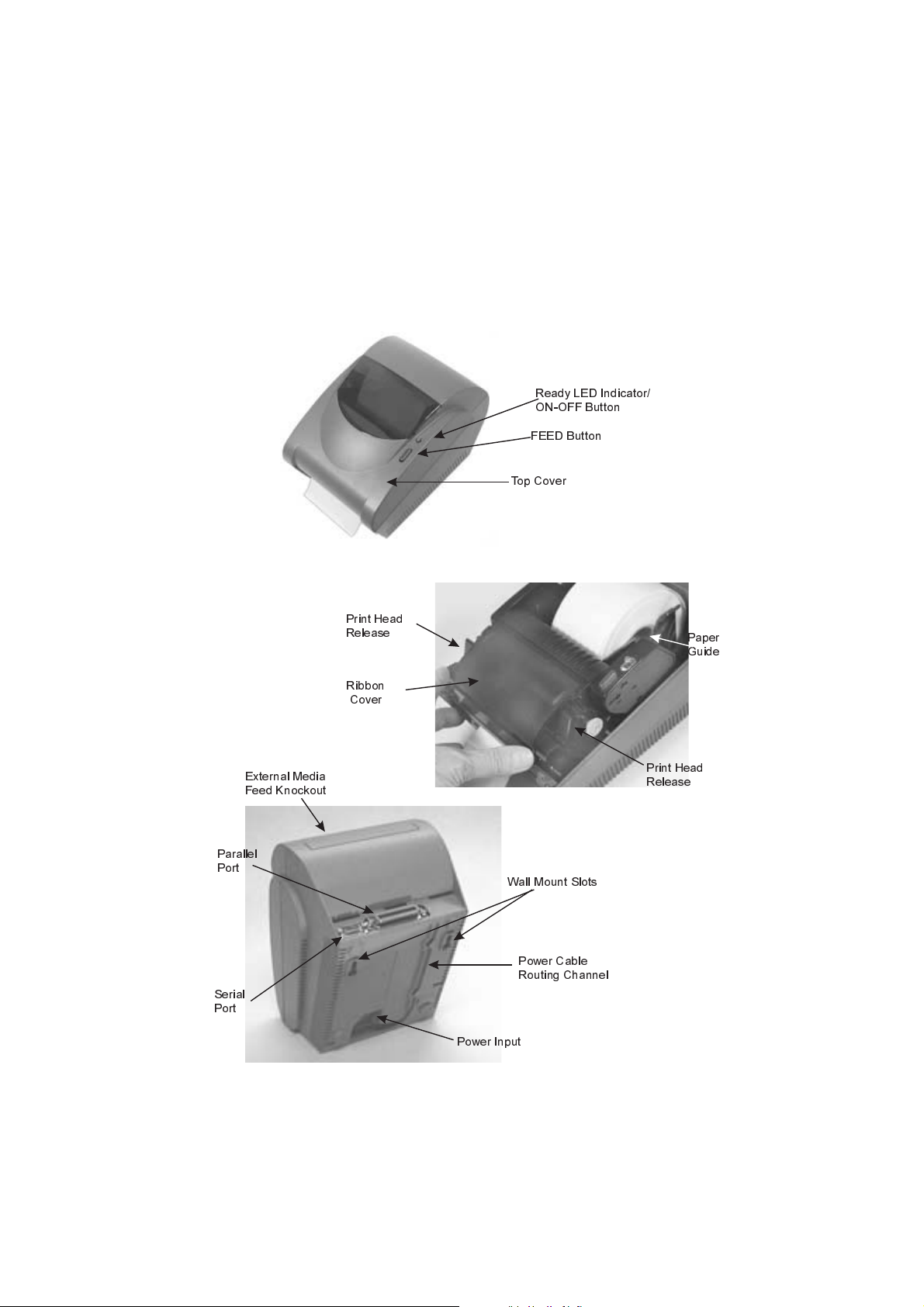

Setup

Loading Labels or Tags

1. Lift the top cover.

2. Press the two print head releases back to unlock the print head.

3. Unwrap the new media, and unwind a few labels from the roll. La-

bels should be wound face-in for the best results.

4. Slide the centre justified Paper Guides apart until the label roll will

drop down between them.

5. Place media roll in the paper tray such that the media unwinds from

the bottom of the roll toward the front of the printer. The label imaging surface must face up as it passes under the print head.

6. Lock the Paper Guides in place by pressing down on the green lock-

ing tab.

7. Lift the print head and slip the free end of the media under the print

head and out the front paper exit

8. Lower the print head and press it down firmly until it locks closed on

both sides.

9. Close the top cover.

10. Wait until the Ready Indicator glows green and press the FEED but-

ton to feed a label or to resume printing.

Loading Ribbon

The CX208TT thermal transfer printer transfers ink from a ribbon to

the label to produce an image.

1. Lift the top cover.

2. Press the two print head releases back to unlock the print head and

open the Ribbon Cover to expose the ribbon take-up spindles.

3. Unwrap the new ribbon and unwind about 4" from the roll. The end of

the ribbon is attached to a take-up core.

4. Observe the notches on both ends of the supply core and the take-up

core. These notches must fit on the corresponding nibs on both the supply and take-up spindles.

5. Roll several turns of ribbon on the take-up core, winding to the underside as shown. The dull (coated) side of the ribbon must be on the outside of the take-up roll.

Page 5

Page 10

R

ibbon Loading

Take-up Core

Left Take-up

Core Spindle

Left Supply

Spindle

CX208 User

Ribbon Supply Roll

Spring Loaded

Take-up Spindle

Spring Loaded

Supply Spindle

Guide

Spindle Notches

Page 6

Ribbon Cover

Ribbon Path

Take-up Core

Supply Roll

Supply Roll Mounted

on Spindles

Spring Loaded

Take-up Spindle

Page 11

CX208 User Guide

6. Place the take-up core (ribbon unrolling from the top side) into the left

take-up spindle. The take-up spindles are the top set of spindles.

7. Pull out the spring loaded knob on the right take-up spindle and place

the right end of the take-up core into the right spindle, lining up the

notches with the spindle nibs.

8. Pull the ribbon down and over the print head and insert the supply core

onto the left supply spindle, making sure the notches in the core fit over

the nibs.

9. Pull out the spring loaded knob on the right supply spindle and place

the right end of the supply core into the right spindle, lining up the

notches with the spindle nibs.

Note:

Make sure the (coated) dull side of the ribbon is to the outside where it will

be in contact with the label media.

10. Turnthesupplyspindletopulltheribbonovertheprintheadwithout

any slack. Check to make sure there are no ribbon wrinkles.

11. Close the Ribbon Cover and lower the print head. Press the print head

down firmly until it locks closed on both sides.

12. Closethetopcover.

13. Wait until the Ready Indicator glows green and press the FEED button

to feed a label or to resume printing.

Sensor Calibration

The CX208 uses a single sensor element for both direct thermal (without a ribbon) and thermal transfer (with a ribbon) printing. The method of

printing can be selected by using configuration settings in the software program or by sending the command directly to the printer (Please refer to the

Print

Head

Gap Sensor

Light Source

Programming Guide).

The mode of operation

can be determined by

running a Self Test Label.

The CX208DT direct thermal

Label Gap

and Eye

Mark Sensor

printer cannot be used for

thermal transfer printing

since there is no provision for controlling a ribbon and it is always in the

DirectTThermal mode. It

will ignore any com-

Page 7

Page 12

CX208 User Guide

mands that try to set it to the ThermalTTransfer mode.

A CX208TT unit is calibrated at the factory for use with SATO Stan-

dard ribbon and media. Other ribbon/media combinations may or may not

index properly with these settings. If you are experiencing difficulty with label indexing and are not using SATO labelsand/orribbon, it may be necessary to recalibrate the unit for your particular ribbon/media. This can be

done by selecting the Calibration buttons provided in the Label Wizard CX CX

software or the CX208 Windows Printer Driver.Ifyouarenotusingeither of these, you will have to send the calibration command directly to the

Senso

printer.SeetheProgramming Guideforinstructionsonusingthe

Calibration command.

Important!

The ribbon must be installed in the printer when calibrating in the thermal transfer mode.

Selecting the Label Sensor Type

CX208 printers can use Eye-Mark, gap, or notch label sensing. The

sensing method used by the printer must match to the media being used. If

you are using label printing software, it should provide a means to set up

these parameters. See your software documentation for details. If you are

writing your own software or controlling the printer using direct commands,

you must use printer commands to set up the print mode and sensing

method. Refer to the programming information provided in the Program.pdf

file for further information.

r

Note:

The Program.pdf file is in Adobe Acrobat format. To view it, you must install

Adobe Acrobat Reader which is included on the CD-ROM in the AcroRead

directory.

Selecting the Label Sensor Type

CX200 printers can use Eye-Mark, gap, or notch label sensing. The sensing

method used by the printer must match to the media being used. If you are

using label printing software, it should provide a means to set up these parameters. See your software documentation for details. If you are writing

your own software or controlling the printer using direct commands, you

must use printer commands to set up the print mode and sensing method.

Refer to the programming information provided in the Program.pdf file for

further information.

Note:

The Program.pdf file is in Adobe Acrobat format. To view it, you must install

Adobe Acrobat Reader which is included on the CD-ROM in the AcroRead

directory.

Page 8

Page 13

CX208 User Guide

Using the Printer

Printing a Self-test Label

Printing a self-test label checks the printer’s overall operability. To run a

self-test, confirm that the printer is loaded and connected to AC power and

no print jobs are in process. Then:

1. Press and hold in the READY Indicator.

2. Press and release the FEED button.

3. The printer should begin printing a self-test label. Release the

READY indicator after printing starts.

4. After the self-test label finishes printing, press the READY indicator

twice to reset the printer and restore normal operation.

Important!

The printer will be in hex dump mode after printing the

self-test label. It cannot print normal labels in hex dump

mode. The printer will return to normal operation after

you reset it as described in step 4 above.

Feeding Blank Labels

To feed a label, press and release the FEED button with the printerOffLine. Press and hold in the FEED button to feed multiple labels.

Label Reprint

If the last label printed has not been cleared from the print buffer by pressing the READY indicator to take the printer Off-Line,thenpressingthe

FEED button will cause the last printed label to be reprinted. (the label

Re-print feature may be disabled via software. See the Programming Manual

for details.

Sending Data to the Printer

To print labels using data sent from a host computer or terminal:

1. Connect the host and printer serial or parallel ports together using a

correctly wired interface cable (see page 16 for wiring information).

2. If you are using the serial port, confirm that the host and printer are

using the same communications parameters.

3. Confirm that the READY indicator is glowing green.

4. Send your data to the printer.

Printer Ready/Standby/Reset Control

The CX208 does not have a power switch, but you can effectively turn

it "off" by pressing the READY indicator. This resets the printer's micro-

processor and places the printer inOff-Line.Resettingthemicroprocessor

will:

Page 9

Page 14

CX208 User Guide

stop any printing.

•

delete the label format in process from memory.

•

reset the printer communication ports.

•

return all printer parameters to their default (first power-on) state.

•

Pressing the READY indicator a second time will return the printer to OnLine mode (its default condition). Resetting the printer in this manner

does not harm it in any way, nor does it affect the contents of nonvolatile

RAM or remove any stored objects. The effect is the same as if you had

unplugged and reconnected the printer power supply.

Printing Labels

To print labels, the host computer sends commands to the printer via the serial or parallel communications port. If you are using the Label Wizard CX

label printing software supplied on the CD-ROM, the computer and software control the entire printing process. You only need to set up the printer,

start your label printing program, and follow its instructions. If you are using another vendor’s software package, contact the software supplier or

manufacturer if you encounter difficulties. A complete Reference Manual

for the Label Wizard CX label design and printing software is included on

the CD-ROM. If you want to print labels from another Windows applica-

tion, the CX208 Windows Printer Driver must be installed. It is found

on the CD-ROM and must be loaded using the standard Windows printer installation instructions.

Controlling the Printer Using Direct Commands

You can also produce labels by sending commands directly to the printer.

Simple ASCII commands control the printer. You can write command files

using any text editor program that can output ASCII text (including the control codes). Since printer programming is potentially complex, programming information is not provided here. A printer command reference and

basic programming procedures are provided on the CD-ROM packed with

the printer. The file CXManual.pdf on the disk is in Adobe Acrobat format,

readable using the Adobe Acrobat Reader provided in the AcroRead directory on the CD-ROM or can be downloaded free of charge from

http://www.adobe.com. This program will allow you to search the contents

of the manual and/or print a hard copy. If you need programming information and are not using Windows (or cannot read the CXManual.pdf file for

any other reason), contact our Service Hotline at (65) 273 6455 for assistance.

Page 10

Page 15

CX208 User Guide

Routine Maintenance

SATO Singapore printers need very little maintenance other than occasional

cleaning. Clean the printer body as required, using soft cloth moistened with

a mild detergent cleaner. Clean the print head if it appears dirty or if print

quality is poor. Print head cleaning is easy and fast:

1. Unlatch and raise the print head if it is not already raised and latch it

in the open position.

2. Using a SATO Direct Thermal Print Head Cleaning Sheet or a soft

cotton sheet moistened with 99% pure isopropyl or denatured alcohol, clean all dirt and label residue from the print head, paying particular attention to the “burn line” (this is the thin black line near the

front edge of the print head). DO NOT USE SATO THERMAL

PRINT HEAD AND PLATEN CLEANER, it contains solvent that

can attack the plastic frame.

Caution!

Do not clean the print head or drive roller using abrasive

or metallic objects, ammonia-based cleaners or other

harsh chemicals. These practises can cause serious dam-

age and will void the warranty.

3. Wipe the drive roller with the cleaning cloth. To reach all portions of

the drive roller, press the FEED button. The roller will rotate 1/4 turn

each time you press the FEED button when the print head is

unlatched.

Caution!

Keep all objects clear of the drive roller when you press

the FEED button.

4. Confirm that the label sensor is unobstructed. Clean away any obstruction with a soft brush if necessary.

5. Resume the media loading procedure, or if there is already media in

the printer, lower and lock the print head.

6. Resume normal operation.

Page 11

Page 16

CX208 User Guide

What To Do If...

SATO printers are very reliable, so printing problems are unlikely. If you do

think you have a printer problem, proceed as follows:

1. Confirm that the printer has the right media installed, and that it is

loaded correctly. See page 4 for media loading instructions.

2. Confirm that the printer is connected to its power supply and the supply is plugged into an AC outlet having the proper voltage.

3. Open the print head and inspect the media path. Remove any obstructions, and clean the print head and drive roller according to the instructions on page 11.

4. Press down firmly on both print head latches to confirm that they are

closed.

5. Confirm that the printer READY indicator glows green.

6. Print a self-test label as described on page 9.

7. Press FEED to confirm that the printer will feed a label.

8. Review the common problems described in the following section.

9. If these steps do not correct the problem, contact your dealer or our

Technical Support Department.

Note:

The information here assumes you are using label printing software. If you

are programming the printer, please review the information in the CXMan-

ual.pdf file located on the CD-ROM.

Common Problems And Their Solutions

READY light is not lit

Double-check the AC source and the power supply connections. Disconnect

the cable between the printer and host, then reset the printer. If the READY

light glows green with the host disconnected, suspect a host computer or

cabling problem.

READY light glows red

1. Press the FEED switch to assure that the printer is not paused in

batch mode printing.

2. Confirm that the print media is not exhausted.

3. Confirm that the print head is securely latched down on both sides.

Page 12

Page 17

CX208 User Guide

4. If you have been printing many labels, the printer may have over-

heated. Normal operation will resume after the printer has cooled sufficiently.

Self-test label will not print

1. If printing in the direct thermal mode, confirm that you have loaded

direct thermal media.

2. Disconnect the cable between the printer and the host computer.

Reset the printer and try to print a self-test label again.

Labels will not feed

1. Confirm that the print media is loaded correctly.

2. Reset the printer and confirm that the printer LED indicator

glows green. Press the FEED button.

3. If the printer still does not feed, disconnect the communications cable

and repeat step 2. If the printer feeds with the cable disconnected,

suspect a problem with the host computer or cable.

Host stops responding or displays “printer not ready” message

1. Review your software setup, following the instructions provided with

the software.

2. Confirm that the host-to-printer communication cable is connected

and undamaged. If using the serial port, confirm that you are using a

null modem cable or adapter.

3. If using the serial port, confirm that the host and printer are both us-

ing the same serial port parameters. The self-test label shows the current printer serial port parameters.

4. If using a communications switch between the host and printer, re-

move the switch and connect the printer directly to the host.

5. Reset the printer and reset the host computer and software, and

try printing again.

Page 13

Page 18

CX208 User Guide

Labels feed continuously

1. Check that the print media is loaded correctly.

2. Confirm that the sensor type (Eye-Mark or gap) in your software

setup matches your print media.

Poor print quality

1. Confirm that the print media is properly loaded, and there is no sideto-side motion of the paper as it feeds through the printer.

2. Check your software’s print darkness and print speed settings. These

settings may need adjustment for optimum results.

3. Try different print media. Old or inferior quality media will degrade

print quality.

4. If you are printing in the direct thermal mode, make sure you are using direct thermal labels.

Technical Support

Please contact your local dealer for technical support. Your dealer is

knowledgeble about SATO printers, printing software, and your unique

system. If you still need technical assistance on your CX208 after contacting

your dealer, 90 days of free telephone support is provided to all users who

have returned the filled in registration card. The 90 day period starts with

the receipt of your first telephone support call. If you are having difficulty

with application software vendor for support. BAR CODE SATO

ELECTRONICS (S) PTE LTD cannot provide support for third party

software problems.

The Service Hotline can be reached at (65) 273 6455, Monday through

Friday, or FAX them at (65) 273 6011. If you must return any products

to the factory, first obtain a returned material authorisation number (RAM)

from our Technical Support Department. When calling, please have your

printer model number and serial number handy.

Support for the CX208 is provided via E-mail at technical@satosingapore.com.

Page 14

Page 19

CX208 User Guide

SPECIFICATIONS

CX208 TT CX208 DT

Print Method Thermal Transfer / Direct Thermal Direct Thermal

Max Ribbon Length 459 ft -- N.A --

Max Ribbon Roll Diameter 42.4mm (1.67”) -- N.A --

Carbon Ribbon Inner : 12.7mm (0.5”)

Core Diameter Outer : 19mm (0.75”)

Weight 2.68Kg (5.9Ib.) 2.64Kg (5.8lb.)

-- N.A --

Common Specifications

Print Head Density 8 dots/mm (203dpi)

Print Speed 38mm/sec (1.5") or 50mm/sec (2”) or 76mm/sec (3”), Selectable

Media Continuous Paper, Paper Labels, Vinyl Labels, Tag

Media Width 51 - 118mm (2” to 4.65”)

Max Roll Diameter 127mm (5.0”)

Label Roll Core Diameter 38.1mm (1.5”)

Max Print Width 104mm (4.1”)

Max Print Length 513mm (20")

Min Label Length 6.35mm (0.25”)

Min Inter-Label Gap 3.2mm (0.125”)

Max Inter-Label Gap 25.4mm (1")

Media Sensing Centre-justified, See-through sensor for die-cut gap or notched media

Centre-justified reflective sensor for Eye-mark Continuous Material

Interface Ports 9-pin RS232 Serial 36-pin Centronics

Baud Rates 600 - 38400 bps

Flow Control Xon/Xoff and RTS/CTS protocols

Memory 512Kb total RAM 512Kb flash memory

Bar Codes Supported UPC, EAN, EAN128, Code39, Plessey, MSI/MSI1, Code 16K

Code 128, Codeabar, MaxiCode, PDF417, Code93, I 2 of 5

o

Bar Code Rotations 0

Bar Code Ratios 1:2 1:3 2:5

Fonts Compatible with all SATO CL Printers Code Page 858,

Text Rotation 0

Graphic Formats SATO Hex/Binary .PCX Raster .BMP Formats

Graphic Rotation 0

Electrical 110V 115V or 230V AC, 50/60Hz

Size 178mmW x 254mmD x 168mmH (6.9" x 10" x 6.6")

Environment Operating : 5 to 40

Approvals CE T V FCC Class B cUL CSA

Accessories Dispenser RS 232C Interface Cable Enhanced Power Supply, Cutter

Additional Memory 2Mb or 4Mb additional flash memory

90o180o270

others available. U S M WB WL XU XS XM XB

XL OCR-A/B Outline Font (50 - 999 dots)

o

90o 180o 270

o

90o 180o 270

Storage : -20 to 50

o

o

o

o

C (15 - 85% RH, non condensing)

o

C (25 - 85% RH, non condensing)

Bar Code SATO Electronics (S) Pte Ltd

438A Alexandra Road

#02-01/04 Alexandra Technopark

SINGAPORE 119967

Tel : (65) 271 5300; Fax : (65) 273 6011

Email : sales@satosingapore.com

Website : www.satosingapore.com

Page 15

Page 20

CX208 User Guide

Communication Ports

CX208 printers are equipped with a standard (not EPP or ECP) Centronics parallel and an RS232C communication port, wired as shown below.

Serial Input Connector (DB9S)

Pin # Description

2 RXD (data to printer)

3 TXD (data from printer)

5Ground

7 RTS (printer busy)

8CTS

1, 9 +5VDC, 200 mA max.

Parallel Input Connector (Centronics 36 pin)

Pin # Description

1 Strobe

2-9 Data bits 0-7

10 Acknowledge

11 Busy

12 Out of Paper

13 +5DC

17 Chassis Ground

31 Reset

32 +5VDC

16, 33

19-30

Signal Ground

Standard Printer Cables

The following standard cables are available for CX208 printers:

Centronics Parallel Cable, 6 ft.: Order PN 14S000132

RS232 Cable, DB9M to DB9F, 6 ft.: Order PN 14S000133

RS232 Cable, DB9M to DB25F, 6 ft.: Order PN 14S000134

Serial Port Parameters

CX208 printers are configured as Data Terminal Equipment (DTE)

equipment, and use Request-To-Send/Clear-To-Send (RTS/CTS) handshaking or X-On/X-Off flow control (control characters are DC2 and DC4). The

serial port supports the following parameters:

Speed: 600, 1200, 2400, 4800, 9600, 19200 or 38400 Baud

Parity: Odd, Even, or None

Data Bits: 7 or 8 bits

Stop Bit(s): 1 or 2 bits

Default parameters: 9600 baud, no parity, 8 data bits, 1 stop bit

Page 16

Page 21

CX208 UserGuide

N

C

c

c

.

O

ote:

Note:

X208 printers require a "null modem" cable (pins 2-3 and 7-8 cross

CX208/212 printers require a null modem cable (pins 2-3 and 7-8 cross

onnected) when connected to another DTE device such as a personal

connected) when connected to another DTE device such as a personal com-

omputer. The SATO serial cables are wired in a null modem configuration

puter. The SATO serial cables are wired in a null modem configuration.

ther cables may require an external null modem adapter.

Other cables may require an external null modem adapter.

CX208 Software

Two basic software packages are supplied on the Ready-To-Go CD-ROM

included with each CX208 printer. Each package allows you to easily

change the configuration of the printer and print labels.

Label Wizard CX

Label Wizard CX is a full-featured label design and production software

package. It supports only the CX Series printers and cannot be used with

other SATO Singapore printers. Windows 3.1 or Windows 95/98/ME must be

installed and operating on your computer to use the software. You can upgrade to the complete Label Wizard PRO package that supports all SATO

Singapore printers, including the CX208. Please contact your dealer for

upgrade information. The CD-ROM will Autorun under Windows

95/98/ME. To manually load the software, place the CD-ROM in your CD

drive and then select RUN from the Start Menu. Enter X:\CXWizard\Disk1\Install (where X is the drive letter associated with your CD

drive). Follow the instructions on the screen. After the software has been installed, you must must then install the SATO Generic printer (not the CX208

Windows Driver) using the Add New Printer selection in the Printer Folder.

When asked for the disk with the driver, enter C:\CXWizard\Drivers\Win3X95 as the location of the driver.

Label Wizard CX stores the printer configuration with each label format.

When you enter the program for the first time, a Label Definition dialog

box is opened. You enter the basic information about your label (width,

length, etc.) in this box. Selecting the Printer button in the lower right corner will take you to the Advanced Printer Setup

dialog box.

Page 17

Page 22

CX208 User Guide

Selecting Immediate will bring up thg Immediate Commands dialog box al-lowing you to set the RS232 serial parameters. The printer configuration

and calibration information is stored in non-volatile RAM. The settings will

remain active until new information is sent. The current settings can be verified by printing a test label (page 9). Complete operation and instructions

are contained in the CXWizard.PDF fileinthe Manuals directory on the

CD-ROM.

Windows Drivers

The CX208 Windows Driver lets you print labels using virtually any

Windows application program. The driver is loaded like any other Windows

printer. The driver is located in the Windrive directory on the CD-ROM. After the driver is installed, you can send data to the CX208 just like any

other printer on your system: simply specify proper CX model in the Print

dialog box of yourWindows application. Printer configuration is managed

using the Advanced dialog box. To print bar codes, you must first define a

bar code font using the Barcodes dialog box.

Media and Supplies

The CX208 comes from the factory set up to operate with the SATO

media supplies that are shipped with the printer. These supplies have been

carefully selected to give optimum results with your printer. Contact SATO

sales at (65) 271 5300 for ordering information.

Other media supplies may or may not give acceptable results. It is also

probable that you will have to calibrate the sensors and heat settings before

acceptable results is obtained. Calibration is accomplished by using the

Windows Driver or by selection of the Printer button in the Label Wizard

CX Label Setup dialog box. Instructions for calibrating the printer for use

with different media supplies is contained in the CX208 Printer Programming Guide found on the CX Series Ready-To-Go CD-ROM.

Page 18

Loading...

Loading...