Page 1

Operator Manual

For printer models:

www.satoamerica.com

PN: 9001239(A)

CT4i Series

Page 2

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support: (704) 644.1660

Technical Support Fax: (704) 644.1661

E-Mail: satosales@satoamerica.com

techsupport@satoamerica.com

www.satoamerica.com

Copyright 2011 SATO America, Inc. All rights reserved

Caution

(1) Reproduction in any manner of all or part of this document is prohibited.

(2) The contents of this document may be changed without prior notice.

(3) Great care has been taken in the preparation of this document. However, if, for any reason, problems,

mistakes, or omissions are found, please contact your SATO reseller or technical support center.

FCC statement

The printer complies with the requirements in Part 15 of FCC Rules for a Class B Computing Device.

Operating the printer in a residential area may cause unacceptable interference to radio and TV reception.

If the interference is unacceptable, you can reposition the equipment, which may improve reception.

Page 3

Table of Contents

Table of Contents

INTRODUCTION ...................................................................................1 - 1

About This Manual.................................................................................................... 1 - 2

General Description.................................................................................................. 1 - 3

TECHNICAL DATA................................................................................2 - 1

Interface Selection .................................................................................................... 2 - 6

RS232C High-Speed Serial Interface (25-Pin)................................................................... 2 - 6

IEEE1284 Parallel Interface ............................................................................................... 2 - 8

Universal Serial Bus (USB) ................................................................................................ 2 - 9

Local Area Network (LAN) Ethernet................................................................................... 2 - 9

802.11G Wireless............................................................................................................. 2 - 10

All Interfaces .................................................................................................................... 2 - 13

ACK/NAK Protocol ........................................................................................................... 2 - 13

Status5 Return ................................................................................................................. 2 - 13

INSTALLATION ....................................................................................3 - 1

Overview .................................................................................................................... 3 - 2

Unpacking & Parts Identification............................................................................. 3 - 5

Printer Installation .................................................................................................... 3 - 6

Site Location ...................................................................................................................... 3 - 6

Media Selection.................................................................................................................. 3 - 6

Media Loading: Rolled Paper............................................................................................. 3 - 6

Ribbon Loading .................................................................................................................. 3 - 7

Loading Fanfold Paper ............................................................................................. 3 - 8

Label Sensing............................................................................................................ 3 - 9

Operational Mode Selection................................................................................... 3 - 10

Continuous Mode ............................................................................................................. 3 - 10

Tear-off Mode................................................................................................................... 3 - 10

Cutter Mode ..................................................................................................................... 3 - 10

Dispense Mode ................................................................................................................ 3 - 10

Linerless Mode................................................................................................................. 3 - 10

PRINTER CONFIGURATION .................................................................4 - 1

Configuration Modes ................................................................................................ 4 - 2

4.1 Operating Panel ........................................................................................................... 4 - 2

4.2 The Rear Panel ............................................................................................................ 4 - 3

4.3 The Configuration Panel............................................................................................... 4 - 4

DIP Switch Settings............................................................................................................ 4 - 4

4.4 Operational Modes....................................................................................................... 4 - 7

4.9 Offsets........................................................................................................................ 4 - 14

4.10 Potentiometer Adjustments ...................................................................................... 4 - 15

4.12 Printing Test Labels.................................................................................................. 4 - 18

4.13 Printing Factory/Service Test Prints......................................................................... 4 - 19

TROUBLESHOOTING ...........................................................................5 - 1

CT4i Series Operator Manual Page 1

Page 4

Table of Contents

Troubleshooting Guide ............................................................................................ 5 - 2

Interface Troubleshooting........................................................................................ 5 - 6

Test Print Troubleshooting ...................................................................................... 5 - 8

Hex Dump .......................................................................................................................... 5 - 8

Test Label Printing ............................................................................................................. 5 - 8

MAINTENANCE ....................................................................................6 - 1

Cleaning Procedures ................................................................................................ 6 - 2

Adjustment Procedures...................................................................................................... 6 - 3

Adjusting the Print Quality.................................................................................................. 6 - 3

Cleaning the Print Head, Platen and Rollers...................................................................... 6 - 4

Releasing/Replacing the Print Head .................................................................................. 6 - 6

Cleaning the Sensor........................................................................................................... 6 - 7

SATO group of Companies ...................................................................................... 7 - 1

SATO Group of Companies ............................................................................................... 7 - 2

Page 2 CT4i Series Operator Manual

Page 5

Unit 1: Introduction

INTRODUCTION

• About This Manual

• General Description

• Control Features

CT4i Series Operator Manual 1-1

Page 6

Unit 1: Introduction

ABOUT THIS MANUAL

This manual is laid out consistent with the product discussed and provides all of the information required for printer

installation, configuration, operation, and light maintenance. Refer to this product’s Programming Reference

document for instructions on printer programming through a host system.

This manual also incorporates the use of special information boxes. Examples of these boxes and the type of

information provided in each, are below.

WARNING: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY RESULT IN

PERSONAL INJURY.

CAUTION: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY RESULT IN

EQUIPMENT DAMAGE.

ATTENTION: Provides information that is deemed of special importance but will not

result in personal injury or product damage if unheeded.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

LCD DISPLAY: Provides the specific display that should be visible on the LCD at that

point.

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid movement within. The

contents identify the different Units, Chapters, and some Sections. Each references the page number of their

commencement.

The pages of this manual have embedded headers and footers to assist the user in identifying his or her exact

position within the manual. The header provides the unit number followed by its name. The footer identifies the

product on the left, the page number in the center, and the manual’s part number to the right side of the page.

Page enumeration is two-part with each separated by a hyphen. The first character set references the Unit and the

second identifies the page number within that unit. Page numbers begin with the numeral one (1) at the beginning

of a new unit and ascend sequentially.

CT4i Series Operator Manual 1-2

Page 7

Unit 1: Introduction

Ribbon Take-up

spindle

Spring loaded holder

for ribbon mechanism

Support stand for lifting

ribbon mechanism

upward

Label Holder

Cover release

Top cover

Power switch

LED/DIP switches

and potentiometers

ONLINE button

FEED button

Power/Error LEDs

Platen Roller

Label Sensor

Label Holder

Label Holder release

knob

Print Head

Fanfold loading window

Front cover and

compartment for

optional cutter

Ribbon Supply

spindle

GENERAL DESCRIPTION

The compact CT4xxi Series printers are designed for use in medium-volume labeling applications demanding a

low footprint, crisp print quality of up to 600dpi; hardware versatility, ease of use, and great reliability. Its

antibacterial chassis also positions it ideally for clinical environments. The printer’s main parts are described below.

Figure 1-1, Primary Parts (Direct Thermal model)

Figure 1-2, Primary Parts (Thermal Transfer model)

CT4i Series Operator Manual 1-3

Page 8

Unit 1: Introduction

This page is left blank intentionally.

CT4i Series Operator Manual 1-4

Page 9

Unit 2: Technical Data

TECHNICAL DATA

• Physical Characteristics

• Environmental Specs

• Power Supply

• Processing

• Printer Language

• Interface Modules

•Print

• Sensing

•Media

• Ribbon

• Regulatory Approvals

• Character Font Capabilities

• Barcode Capabilities

CT4i Series Operator Manual 2-1

Page 10

Unit 2: Technical Data

PHYSICAL CHARACTERISTICS

Width 7.8 in. (198 mm)

Height

Depth

Weight

5.5 lbs (2.5 Kg) excluding AC adaptor

8.8 in. (225 mm)

7.1 in. (180 mm)

ENVIRONMENTAL (EXCLUDING MEDIA)

Operating Temperature/Humidity 5° to 35°C @ 30 to 80%RH

Storage Temperature/Humidity -5° to 60°C @ 30 ~ 90%RH, non-condensing (NA for media)

POWER SUPPLY

100-240 Volts AC +/- 10%, 50/60 Hertz

Input Voltage (AC)

Input Voltage (DC)

Power Consumption 90 Watts (when print ratio is 30%)

Rated Input voltage: 25 V DC

Rated current: 1.5 A

Rated voltage: 24.0 VDC - 25.25 VDC

Rated current: 2 A (Current peak: 13 A)

PROCESSING

CPU 32 Bit RISC

Flash ROM 4 Megabytes

SDRAM 16 MB

PRINTER LANGUAGE

Standard SATO Barcode Printer Language (SBPL) 4.3

INTERFACES

Factory-installed only Bluetooth

Standard configurations

Optional Interface Board

(user installable)

2) USB 2.0 with LAN (10BASE-T/100BASE-TX Automatic Switching)

Either 1) USB 2.0 with RS-232C or

IEEE1284, 802.11g Wireless Wi-Fi

CT4i Series Operator Manual 2-2

Page 11

PRINT

Unit 2: Technical Data

Method

Maximum Speed (selectable)

Resolution

Maximum Print Width 4 in. (104 mm)

Maximum Print Length 15.75 in. (400 mm)

TT models: Thermal Transfer and Direct Thermal (switchable)

DT models: Direct Thermal only

2, 3, 4, 5, 6 Inches Per Second (CT408i)

2, 3, 4 Inches Per Second (CT412i)

2, 3 Inches Per Second (CT424i)

CT408i: 203 Dots Per Inch (8 dpmm)

CT412i: 305 Dots Per Inch (12 dpmm)

CT424i: 609 Dots Per Inch (24 dpmm)

SENSING

Gap Sensitivity Adjustable

Reflective Eye-Mark Sensitivity Adjustable

Head Open Fixed

Media Out Fixed (always enabled)

Ribbon Out Fixed (always enabled)

MEDIA

Media Width: 1.0 in. - 4.5 in. (25-115 mm)

Width

Note: For Dispensing Mode, specifications may vary depending on the requirements

Length

Type

Configuration

Thickness 0.003 in.- 0.01 in. (0.08 - 0.19 mm)

Wind Direction Face Out

Direct Thermal / Thermal Transfer depending on print model (DT or TT)

With backing paper: 1.0 - 4.0 in. (28 - 118 mm)

0.5 -16.0 in. (15 - 397 mm)

1.0 - 15.7 in. (18 - 400 mm with Backing Paper)

Roll stock / Fan-fold

Roll stock: Max. outer diameter: 4.3 in. (110 mm)

Wound face-out, Inner diameter of roll: 1.5 in. (40 mm)

Fanfold: Max. stack height: 3.9 in. (100 mm) (external supply)

RIBBON

Width 4.3 in. (111 mm)

Length 328.0 feet (100 M)

Wound Face Out

Core Diameter 0.5 in. (12.7 mm)

Roll Diameter 1.5 in. (39 mm)

CT4i Series Operator Manual 2-3

Page 12

Unit 2: Technical Data

REGULATORY

USA/Canada UL60950-1(2001), CSA C22.2 No.60950-1-03

China CCC (GB4943-2001)

EU CE, Nemko (EN60950-1)

Singapore SS337:2001

Korea MIC, EK (only AC-Adapter applicable)

FCC Part 15, Subpart B, Class B (USA/Canada)

GB9254-1998, GB17625.1-2003 (China)

Radiation Noise

WLAN/RFID/Bluetooth

Antibacterial Finish JISZ2801 (control panel and enclosure)

Environmental (RoHS)

R&TTE (EN300 328 V1.4: 2003-04, EN301 489 V1.4.1: 2002-08);

CE (EN55022, EN55024, EN61000-3-2/-3) (EU)

CISPR22, CISPR24 (reference standard, Singapore)

KN22, KN24 (Korea)

FCC15B / FCC15C (USA/Canada)

SRRC (China)

Wireless LAN/Bluetooth (2.45GHz)

HF Band: RFID (13.56MHz) (EU)

R&TTE (EN300-330)

IDATS (Singapore)

MIC (Korea)

Chromium: below 0.1%

Lead: below 0.1%

Mercury: below 0.1%

Cadmium: below 0.01%

Polybrominated Bipheny (PBB): below 0.1%

Polybrominated Diphenyl Ether (PBDE): below 0.1%

CHARACTER FONT CAPABILITIES

MATRIX FONTS

XU 5 dots W x 9 dots H (Helvetica)

XS 17 dots W x 17 dots H (Univers Condensed Bold)

XM 24 dots W x 24 dots H (Univers Condensed Bold)

CT408i: 15 dots W x 22 dots H

OA Font (OCR-A)

OB Font (OCR-B)

AUTO SMOOTHING FONTS

XB 48 dots W x 48 dots H (Univers Condensed Bold)

XL 48 dots W x 48 dots H (Sans Serif)

DOWNLOADABLE FONTS

Up to 1600 characters of 64 bit x 64 bit sized font can be downloaded to Flash Memory

Expansion up to 12 x in either the X or Y coordinates.

CT412i: 22 dots W x 33 dots H

CT424i: 44 dots W x 66 dots H

CT408i: 20 dots W x 24 dots H

CT412i: 30 dots W x 36 dots H

CT424i: 60 dots W × 72 dots H

Character Pitch Control

Line Space Control

Journal Print Facility

0, 90, 180, and 270-degree rotation

CT4i Series Operator Manual 2-4

Page 13

BARCODE CAPABILITIES

Unit 2: Technical Data

Linear Bar Codes

Two Dimensional

Ratios 1:2, 1:3, 2:5, User definable bar widths

Bar Height 4 to 999 dots, User programmable

Rotation 0, 90, 180, and 270 Degrees

UPC-A/E, EAN, CODABAR, CODE39, CODE93, CODE128, UCC/EAN128, Interleaved

2of5, Industrial 2of5, Matrix 2of5, MSI, BOOKLAND, POSTNET, EAN/UCC symbol

QR code (Ver8.1), PDF417 (Ver2.4), MAXI code (Ver3.0), Data Matrix (Ver1.3) *Only

ECC200 is supported

CT4i Series Operator Manual 2-5

Page 14

Unit 2: Technical Data

INTERFACE SELECTION

This unit presents the printer interface types and their specifications. These specifications include detailed

information to assist in the selection of the most appropriate method for the printer to interface with the host. The

five acceptable interface methods are:

• RS232C High-Speed Serial

• IEEE1284 Parallel

• Universal Serial Bus (USB)

• Bluetooth

• Local Area network (LAN) Ethernet

• 802.11g Wireless

Following the selection of the desired interface, proceed to the next unit for instructions on how to configure the

printer for that interface type.

WARNING: NEVER CONNECT OR DISCONNECT INTERFACE CABLES (OR USE

A SWITCH BOX) WITH POWER APPLIED TO EITHER THE HOST OR THE

PRINTER. THIS MAY CAUSE DAMAGE TO THE INTERFACE CIRCUITRY IN THE

PRINTER/HOST AND IS NOT COVERED BY WARRANTY.

RS232C HIGH-SPEED SERIAL INTERFACE (25-PIN)

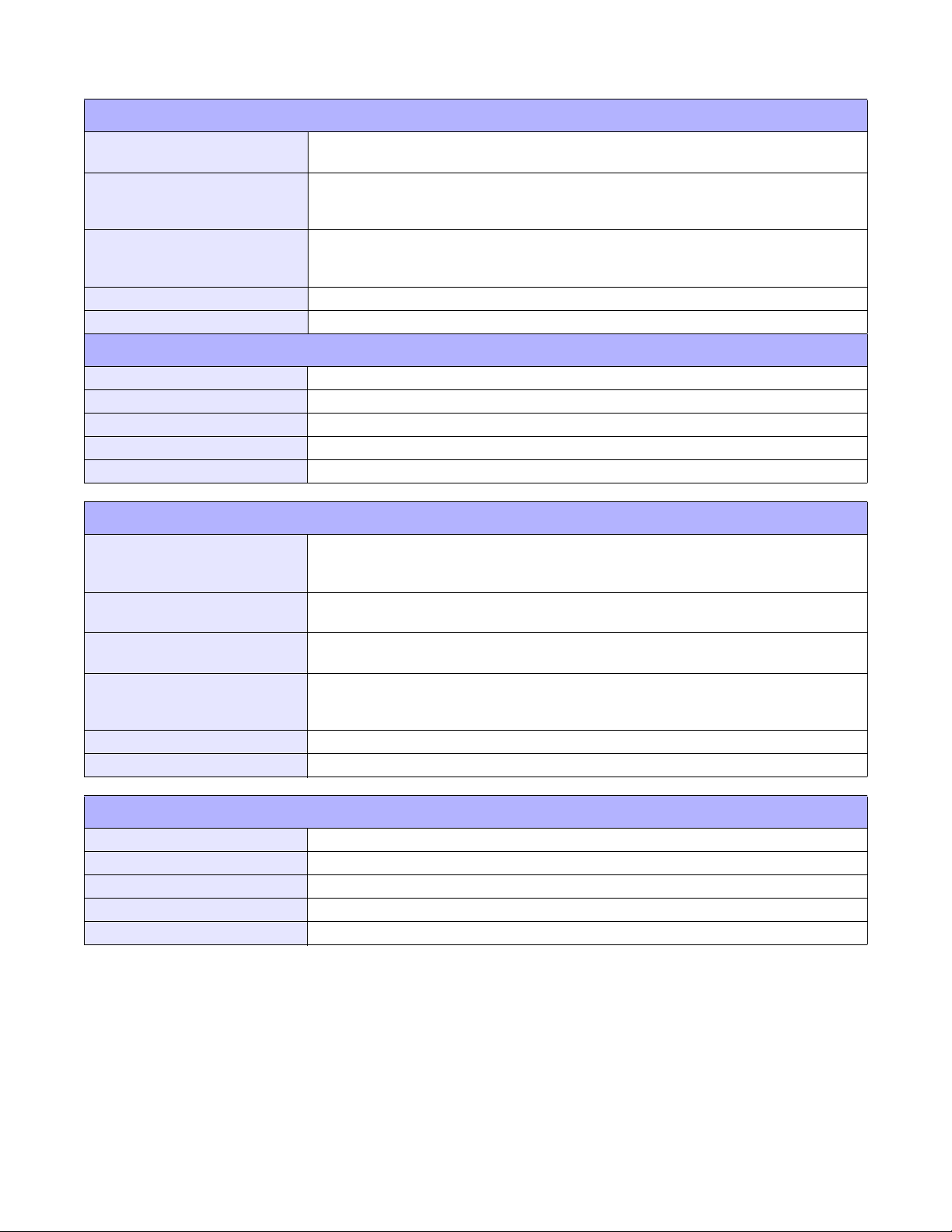

INTERFACE SPECIFICATIONS

Asynchronous ASCII Half-duplex communication

Bi-Directional Communication

Data Transmission Rate 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 bps

Transmission Form Start, b1, b2, b3, b4, b5, b6, b7, b8, Stop (b8 will be omitted if using 7 bit oriented)

Data Length 7 or 8 bit (selectable)

Stop Bit 1 or 2 bit (selectable)

Parity Bit ODD, EVEN, NONE (selectable)

Codes Used ASC II Character Codes: 7 bits, Graphics: 8 bits

Control Codes STX (02H), ETX (03H), ACK (06H), NAK (15H)

Connector (Printer Side) DB-25 Male (equivalent)

Cable Connector DB-25 Female (equivalent)

Cable Length 5 meters or less.

Signal Levels High = +5V to +12V, Low = -5V to -12V

Protocol Ready/Busy, X-On/X-Off, Protocol for Driver, Status2, Status3, Status4, Status5

Figure 3-5, Serial Connector Pin Assignments

CT4i Series Operator Manual 2-6

Page 15

Unit 2: Technical Data

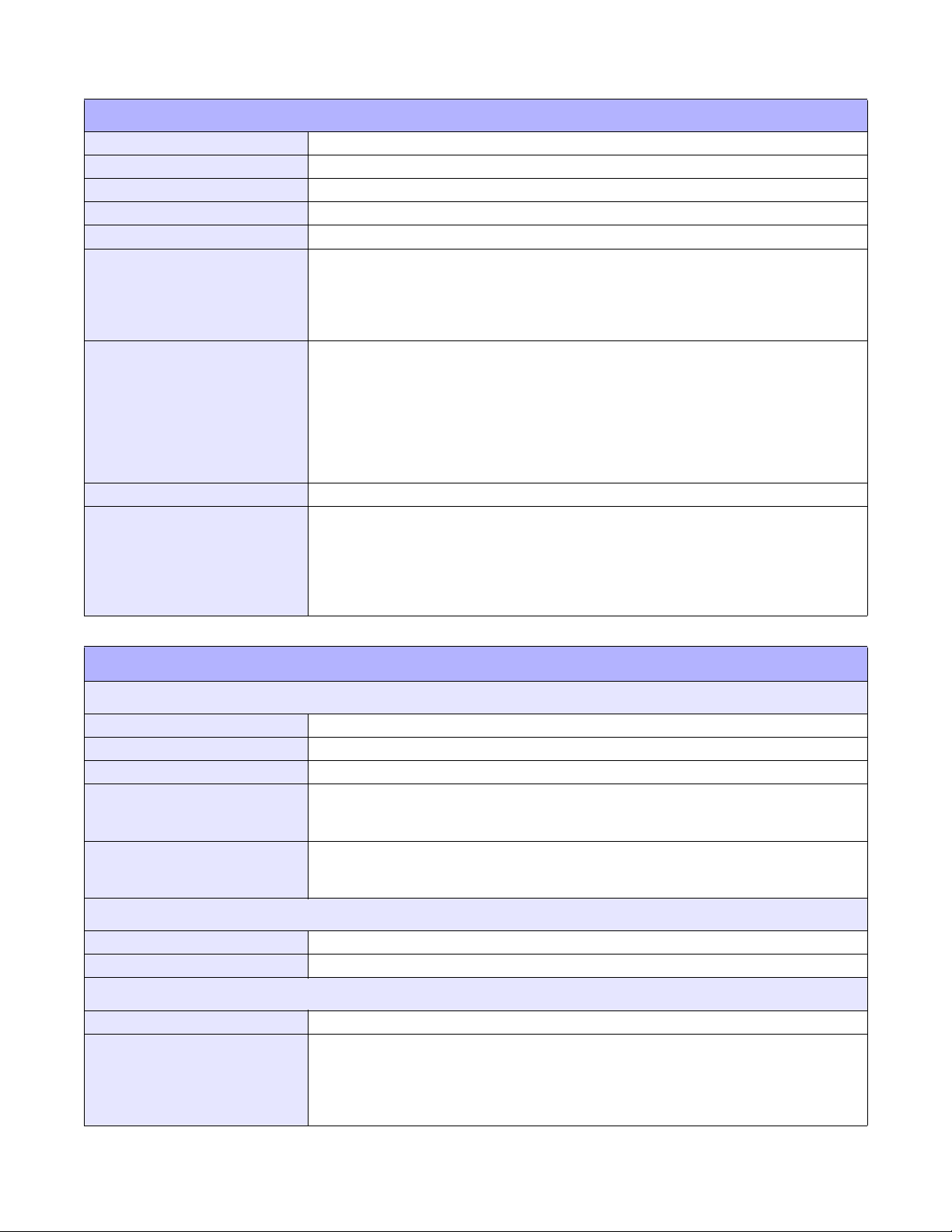

I/O SIGNALS

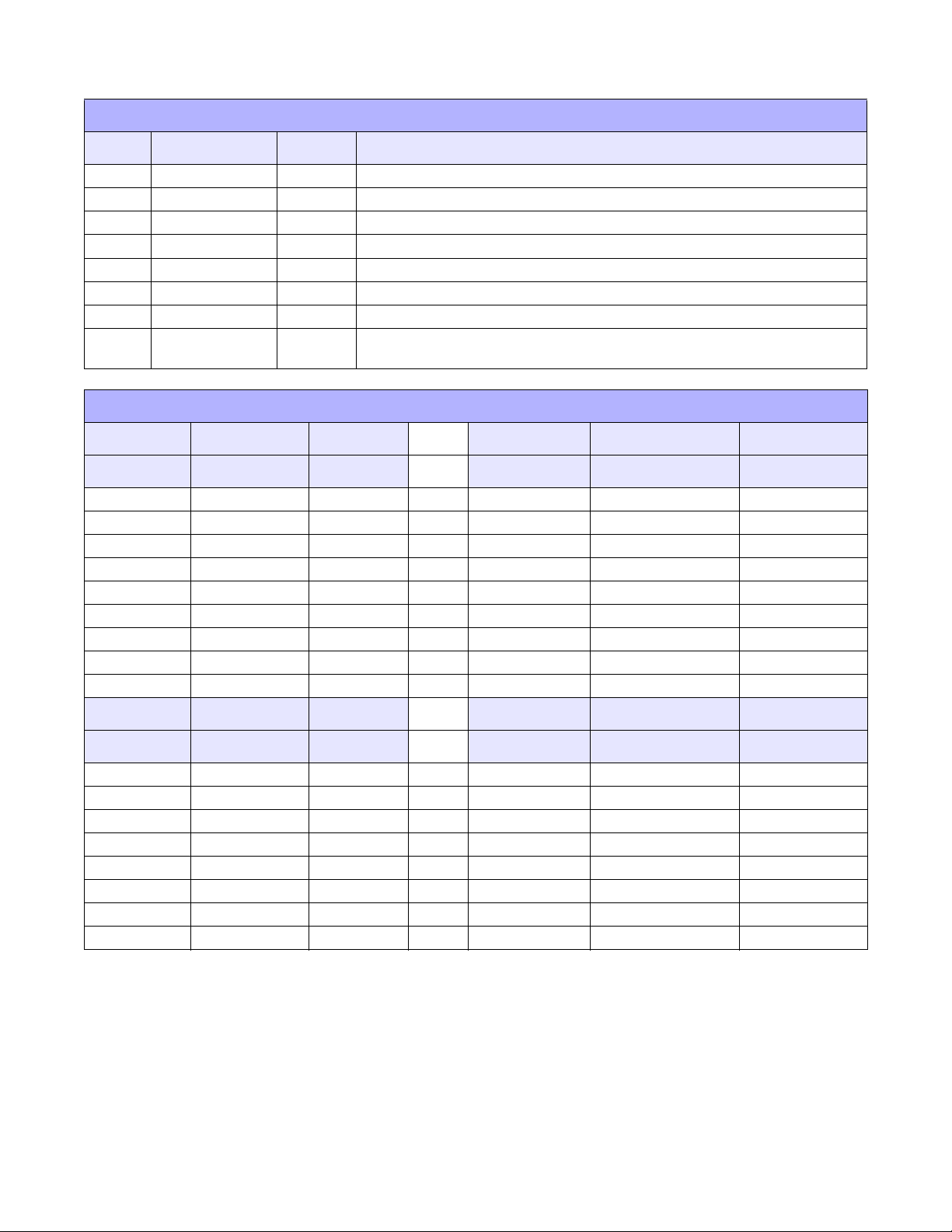

PIN# SIGNAL I/O DESCRIPTION

1 FG - Framework Ground

2 SD Output Data transferred from Printer to Host

3 RD Input Data transferred from Host to Printer

4 RS Output Goes to the Low state when an error occurs in the printer

5 CS Input Maintained at the High state

6 DR Input Maintained at the High state

7 SG - Signal Ground

20 ER Output Goes to the High state when printer is ready to receive data

Goes Low when printer is OFFLINE or errors have occurred in the printer

LINE CONNECTION

1. DB25P 2. DB9P

PRINTER HOST PRINTER HOST

FG 1 1 FG FG 1

SD 2 3 RD SD 2 2 RD

RD 3 2 SD RD 3 3 SD

RS 4 5 CS RS 4 8 CS

CS 5 4 RS CS 5 7 RS

DR 6 20 ER DR 6 4 ER

SG 7 7 SG SG 7 5 SG

ER 20 6 DR ER 20 6 DR

3. DB25P 4. DB9P

PRINTER HOST PRINTER HOST

FG 1 1 FG FG 1

SD 2 3 RD SD 2 2 RD

RD 3 2 SD RD 3 3 SD

RS 5 20 ER RS 4 6 DR

CS 4 6 DR CS 5 4 ER

DR 6 4 RS DR 6 7 RS

SG 7 7 SG SG 7 5 SG

ER 20 5 CS ER 20 8 CS

Note: When executing Windows hardware control, 3. and 4. above work as the connection.

CT4i Series Operator Manual 2-7

Page 16

Unit 2: Technical Data

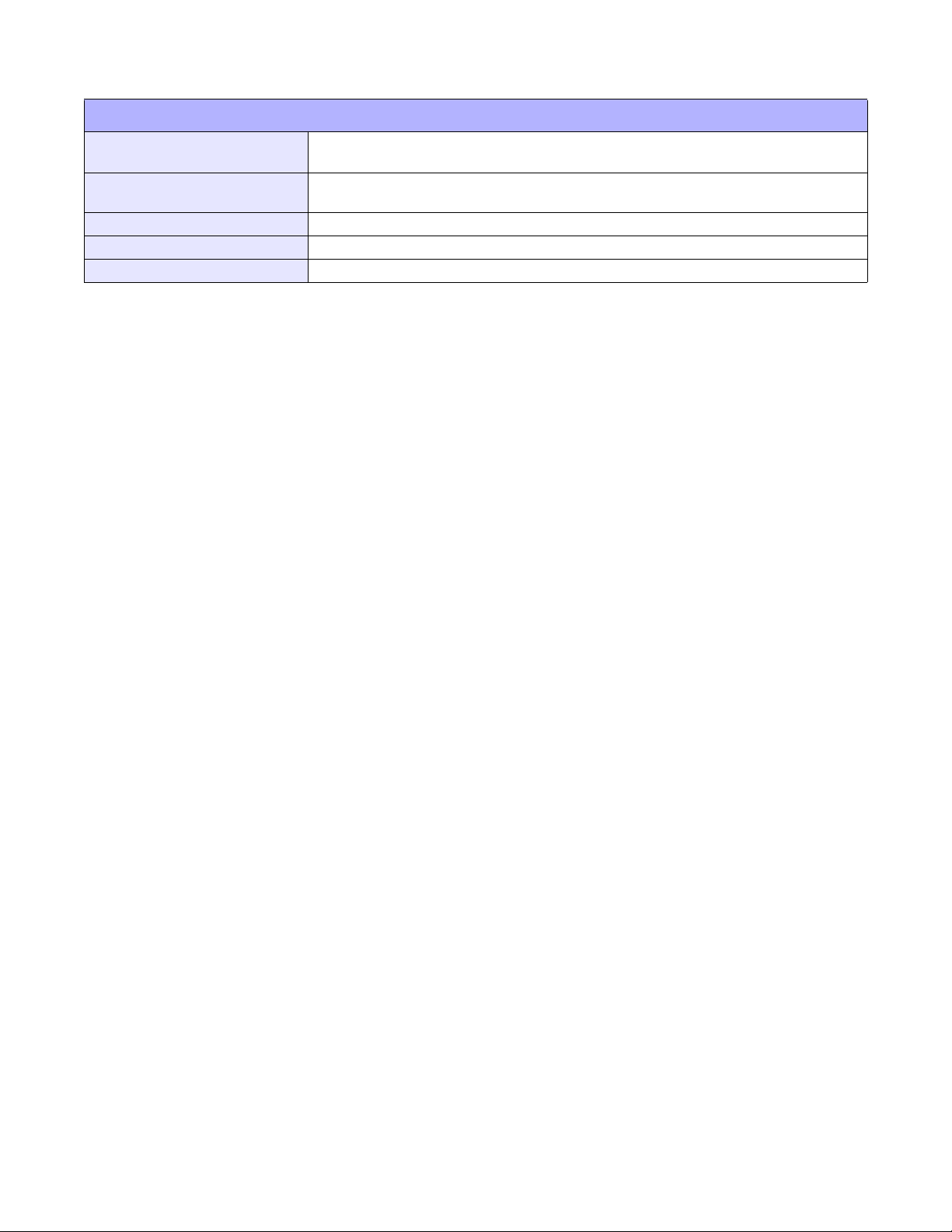

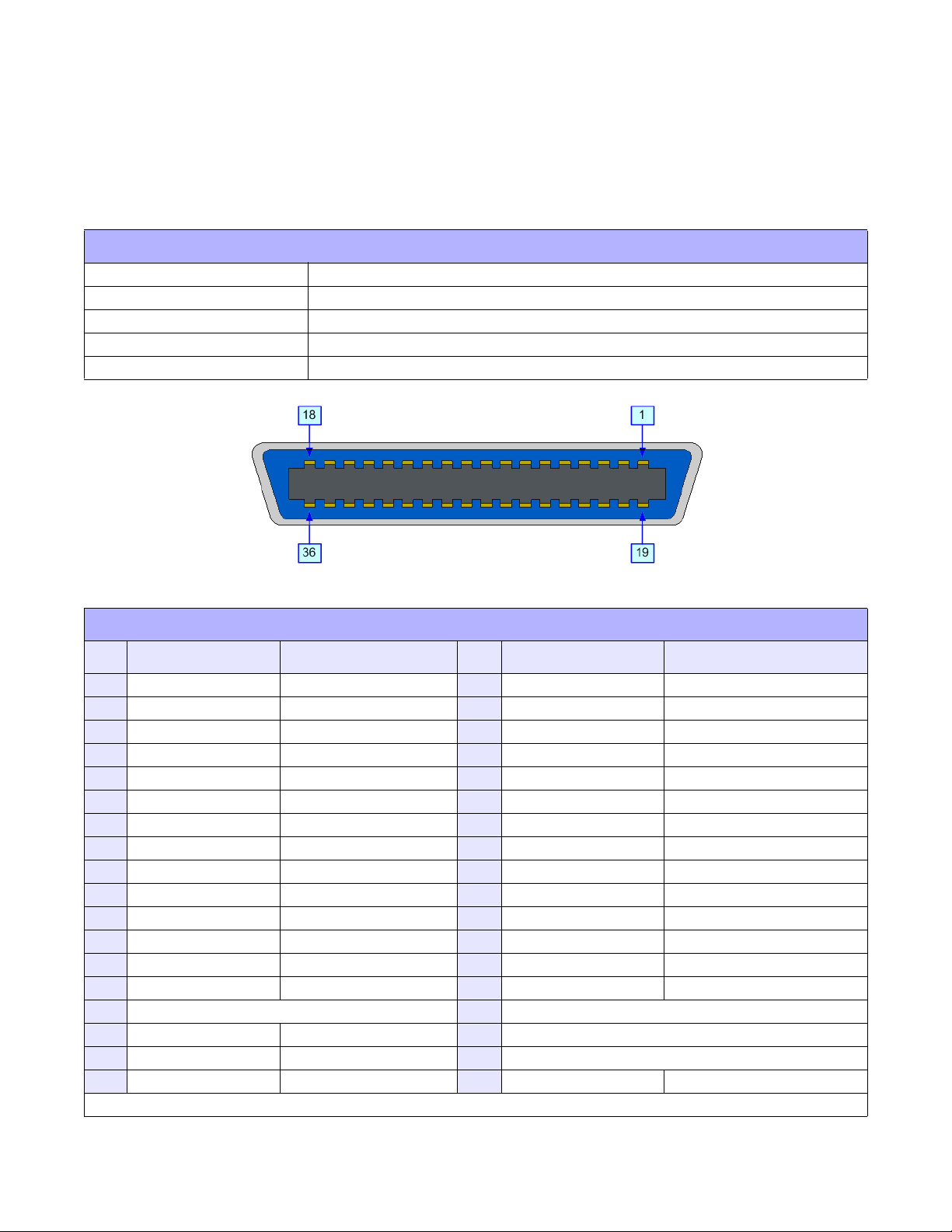

IEEE1284 PARALLEL INTERFACE

The parallel interface is a plug-in module that can be installed by the user and conforms to IEEE1284

specifications. It automatically detects the IEEE1284 signals and operates in the high speed mode. If the

IEEE1284 signals are not detected, it will operate in the slower standard Centronics mode. For this reason, an

interface cable and host interface conforming to the IEEE1284 specification must be present to fully utilize the

speed capabilities. This interface also operates bi-directionally and can report the status of the printer back to the

host.

SPECIFICATIONS

Printer Connector AMP 57-40360 DDK (or equivalent)

Cable Connector AMP 57-30360 DDK (or equivalent)

Cable 4.9 ft. (1.5 meter) or less

Signal Level High = +2.4V to +5.0V, Low = 0V to -0.4V

Data Stream <ESC>A . . Job#1 . . <ESC>Z<ESC>A . . Job#n . . <ESC>Z

Figure 3-6, Parallel Connector Pin Assignments

PIN ASSIGNMENTS

PIN SIGNAL DIRECTION PIN SIGNAL DIRECTION

1 Strobe To Printer 19 Strobe Return Reference

2 Data 1 To Printer 20 Data 1 Return Reference

3 Data 2 To Printer 21 Data 2 Return Reference

4 Data 3 To Printer 22 Data 3 Return Reference

5 Data 4 To Printer 23 Data 4 Return Reference

6 Data 5 To Printer 24 Data 5 Return Reference

7 Data 6 To Printer 25 Data 6 Return Reference

8 Data 7 To Printer 26 Data 7 Return Reference

9 Data 8 To Printer 27 Data 8 Return Reference

10 ACK To Host 28 ACK Return Reference

11 Busy To Host 29 Busy Return Reference

12 Ptr Error To Host 30 PE Return Reference

13 Select To Host 31 INIT From Host

14 AutoFD1 To Host 32 Fault To Host

15 Not Used 33 Not Used

16 Logic Gnd 34 Not Used

17 FG Frame Gnd 35 Not Used

18 +5V (z=24k ohm) To Host 36 SelectIn1 From Host

1 Signals required for IEEE 1284 mode.

CT4i Series Operator Manual 2-8

Page 17

Unit 2: Technical Data

UNIVERSAL SERIAL BUS (USB)

The Universal Serial Bus (USB) interface is a Plug-In Interface Module that can be installed by the user. It requires

a driver (shipped with each printer that has the interface installed) that must be loaded onto the PC and configured

to support USB peripherals using Windows 2000 or above. Details for loading the USB driver are contained in the

USB Interface Manual that is shipped with each printer with a USB Optional interface installed. Up to 127 devices

may be connected to a USB port using powered hubs.

ATTENTION: This Interface Type Is Not Compatible With Windows 98 Or Windows

Me.

SPECIFICATIONS

Printer Connector USB Type B Plug

Cable 10 feet (3 m) maximum

Host Windows 2000 or above with USB Port

Power Supply BUS Power through cable

Power Consumption +5 V at 80 ma

LOCAL AREA NETWORK (LAN) ETHERNET

A Local Area Network (LAN) interface is an optional Plug-In Interface Module that can be installed by the user. It

requires a driver shipped with each printer that has the interface installed. The driver that must be loaded onto the

host computer and configured to run one of the supported network protocols using a 10Base-T or 100Base-TX

LAN connection. Details for loading the LAN driver are contained in the LAN Interface Manual that is shipped with

each printer with a LAN Optional interface installed.

SOFTWARE SPECIFICATIONS

Corresponding Protocol TCP/IP

Network Layer ARP, RARP, IP, ICMP

Session Layer TCP, UDP

Application Layer LPD, FTP, TELNET, BOOTP, DHCP

NOTE: Print data can be sent by LPR and FTP of TCP/IP and dedicated socket protocol. Printer status is obtainable by

dedicated socket protocol.

NOTE: In the TCP/IP protocol environment, LPD and FTP are provided for printing; TELNET for variable setup; ARP, RARP,

and BOOTP/DHCP for address setup.

LPD protocol complies with RFC1179 and handles the list of logical printer name as queue name such as lp, sjis, euc. In

addition, a banner page can be printed by a proper setup.

When sending the job by LPR, the transmission order of data file/control file within the job will not affect print operation. In

addition, if the banner page is specified, it will be added to each data file. Job deletion by LPR is not available.

FTP protocol complies with RFC959 and handles the list of logical printer name as a transfer directory. File transfer to this

directory executes print operation. It is possible to specify ASCII(A), Binary(I) and TENEX(L8) as transfer mode - although the

mode difference is dependent on the client. A banner page may be printed with a proper setup.

TELNET Complies with RFC854. This operation consists of interactive menu form and enables change and reference of

internal setup, and to display status. To change the setup, enter “root” user and password at the time of login. Default of root

password is set as null (linefeed only).

CT4i Series Operator Manual 2-9

Page 18

Unit 2: Technical Data

SPECIFICATIONS

Connector RJ-45 Receptacle

Cable 10/100BaseT Category 5

Cable Length 328 ft. (100 meters) or less

Power Supply Powered from printer

Protocol Status3 return

Protocol for Driver (cyclic response mode)

Protocol for Driver (ENQ response mode)

Status5 return

IP Address 0.0.0.0 to 255.255.255.255

Subnet Mask 0.0.0.0 to 255.255.255.255

Gateway Address 0.0.0.0 to 255.255.255.255

802.11G WIRELESS

The wireless print server provides easy printer interface with 802.11g Wi-Fi compliant networks free of wired

connections. Each printer is shipped with an integrated driver and interface installed. The driver must be loaded

onto the host computer and configured to run one of the supported protocols.

SPECIFICATIONS

Variable Data Rates 54, 11, 5.5, 2 and 1 Mbps

Frequency Band 2.4 GHz ISM Band

Wired Equivalent Privacy 128 bit, 64 bit (compatible with 40bit), none (WPA)

Sensitivity (typ, AAWGN, 8E-2 PER): -91dBm at 1Mbps, -88dBm at 2 Mdps, -87dBm at 5.5Mbps, -

84dBm at 11Mbps.

Range 100m indoors, 300m outdoors (environmentally dependent)

Protocols TCP/IP, IPX/SPX, Direct Mode IPX/IP, DLC/LLC, NetBEUI, NetBIOS/IP

Protocol Status3 return

Protocol for Driver (cyclic response mode)

Protocol for Driver (ENQ response mode)

Status5 return

IP Address 0.0.0.0 to 255.255.255.255

Subnet Mask 0.0.0.0 to 255.255.255.255

Gateway Address 0.0.0.0 to 255.255.255.255

Communication Mode 802.11 Ad hoc, Ad hoc, Infrastructure

SSID Optional alphanumeric character string (up to 32 characters)

Channels 01 to 11

LED INDICATOR STATUS

Network Port Off ---

Link LED (green)

Status LED (orange)

Front Panel

Network Port Off ---

Front Panel Blinking Receiving packet

Blinking Waiting for link

On Linked

CT4i Series Operator Manual 2-10

Page 19

Unit 2: Technical Data

LED INDICATOR STATUS

Wireless LED (green) Front Panel

Blinking Ad-hoc mode

On Infrastructure mode

WIRELESS LAN SIGNAL STRENGTH

Off 0 to 50% (weak)

Network Port Link LED

Blinking 50 to 75% (medium)

On 75 to 100% (strong)

SOFTWARE SPECIFICATIONS

Corresponding Protocol TCP/IP

Network Layer ARP, RARP, IP, ICMP

Session Layer TCP, UDP

Application Layer LPD, FTP, TELNET, BOOTP, DHCP

NOTE: Print data can be sent by LPR and FTP of TCP/IP and dedicated socket protocol. Printer status is obtainable by

dedicated socket protocol.

NOTE: In the TCP/IP protocol environment, LPD and FTP are provided for printing; TELNET for variable setup; ARP, RARP,

and BOOTP/DHCP for address setup.

LPD protocol complies with RFC1179 and handles the list of logical printer name as queue name such as lp, sjis, euc. In

addition, a banner page can be printed by a proper setup.

When sending the job by LPR, the transmission order of data file/control file within the job will not affect print operation. In

addition, if the banner page is specified, it will be added to each data file. Job deletion by LPR is not available.

FTP protocol complies with RFC959 and handles the list of logical printer name as a transfer directory. File transfer to this

directory executes print operation. It is possible to specify ASCII(A), Binary(I) and TENEX(L8) as transfer mode - although the

mode difference is dependent on the client. A banner page may be printed with a proper setup.

TELNET Complies with RFC854. This operation consists of interactive menu form and enables change and reference of

internal setup, and to display status. To change the setup, enter “root” user and password at the time of login. Default of root

password is set as null (linefeed only).

CT4i Series Operator Manual 2-11

Page 20

Unit 2: Technical Data

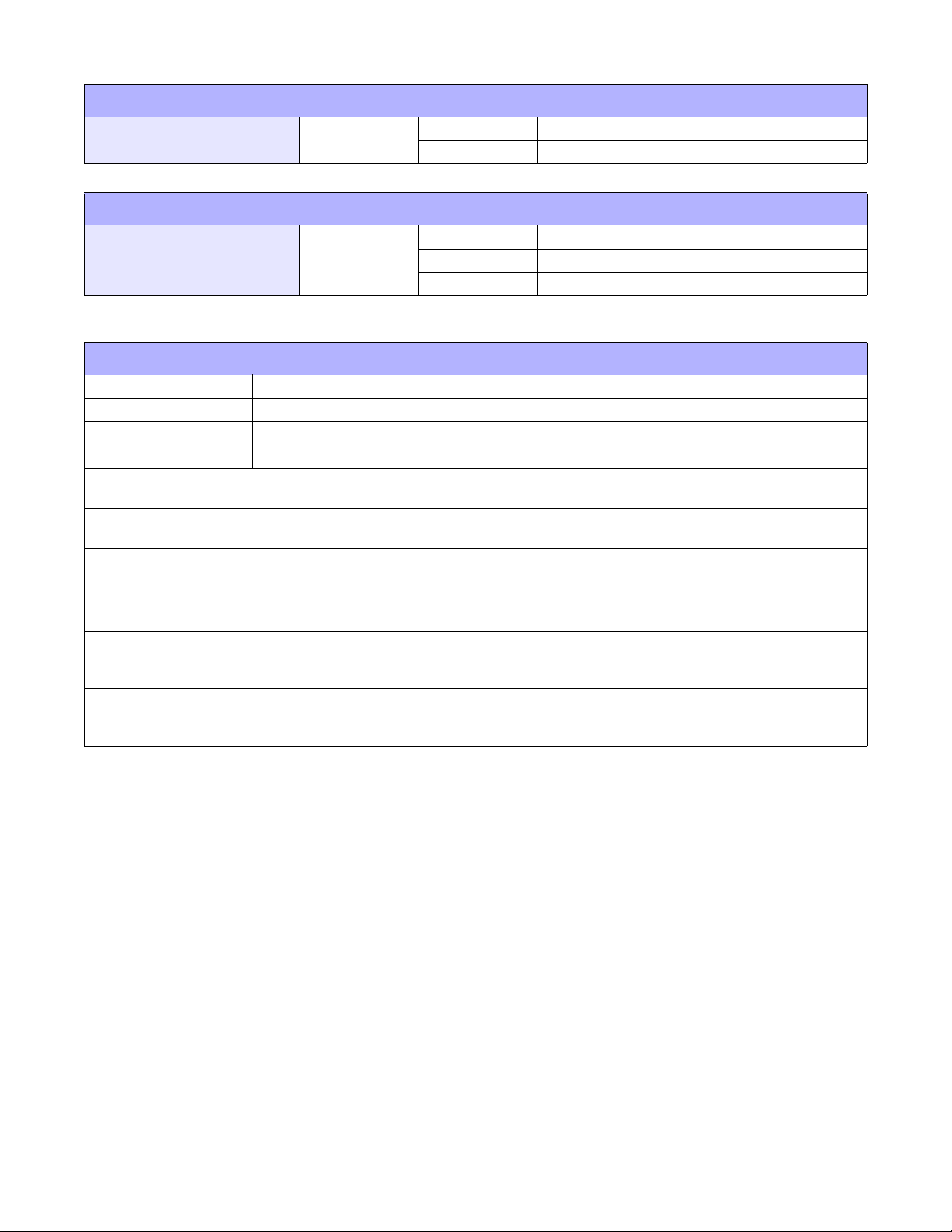

Figure 3-7, Socket Connection Diagram

CT4i Series Operator Manual 2-12

Page 21

Unit 2: Technical Data

ALL INTERFACES

Receive Buffer

The data stream is received from the host to the printer one job at a time. This allows the software program to

maintain control of the job print queue so that it can move a high priority job in front of ones of lesser importance.

A multiple job buffer allows the printer to continuously receive print jobs while compiling and printing other jobs at

the same time. It acts much like a Print buffer to maximize the performance of the host and the printer.

The printer receives and prints one job at a time. If a print job exceeds the buffer size, transmission will be rejected

by the printer. Error conditions that occur during the Print Data transmission will cause the printer to return a NAK.

ACK/NAK Protocol

Bi-Directional ACK/NAK protocol is used for error control. In a normal transmission sequence when the

transmission is received, the printer will return an ACK (06H) signifying that it was received without a transmission

error. After the transmission command structure has been analyzed, a status byte is returned to the host. This

status byte informs the host of the validity of the command structure.

If the command structure is error free, the printer proceeds with the print operation. When the print operation is

completed, a Printer Status message is returned to the host. If an error was detected during the initial transmission

sequence, a NAK (15H) will be returned signalling to the host that the received transmission contained errors and

must be resent. If the returned Status byte indicates a command structure error, the error must then be corrected

before the print data is resent to the printer.

A valid transmission to the printer must be bounded by an STX/ETX pair, with the STX (02H) signifying the start of

the Print Data and ending with an ETX (03H) signifying the end.

Status5 Return

This communication protocol is designed for the purpose of monitoring and controlling print data status in the host

and featuring various functions.

INTERFACE SIGNALS

SIGNAL SIGNAL DEFINITION

FGN (Frame Ground)

SxD (Send Data) - Data from the printer to the host.

RxD (Receive Data) - Data from the host to the printer.

SGN (Signal Ground)

Note: Depending on the host used, the CS and RS (maintaining at high) may need to be looped on the host side. Refer to host computer

documentation for details.

CABLE REQUIREMENTS

DB9 HOST DIRECTION DB9 PRINTER

2 Send Data To Printer 2 Receive Data

3 Receive Data To Host 3 Send Data

5 Frame Ground Bi-Directional 5 Frame Ground

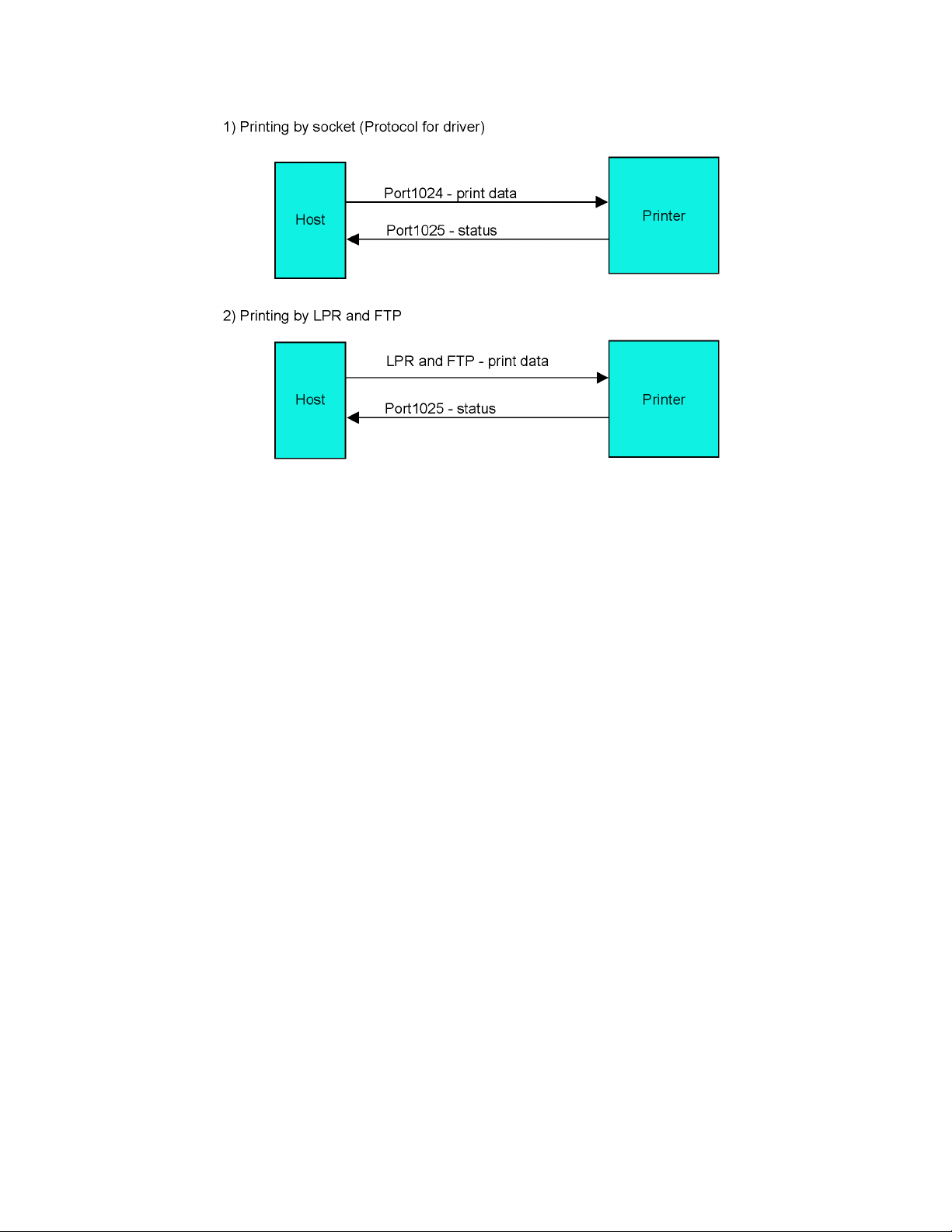

RECEIVE BUFFER CONTROL

Causes For Receive Buffer Near Full Occurs when the remaining free space of the buffer drops to 0.95MB of 2.95MB

capacity or when the remaining free space is available for storing 50 of 500 items in

the history buffer.

Release Of Receive Buffer Near Full Can be released when the remaining free space rises to 1.95MB or when the

remaining free space is available for storing 200 items in the history buffer.

CT4i Series Operator Manual 2-13

Page 22

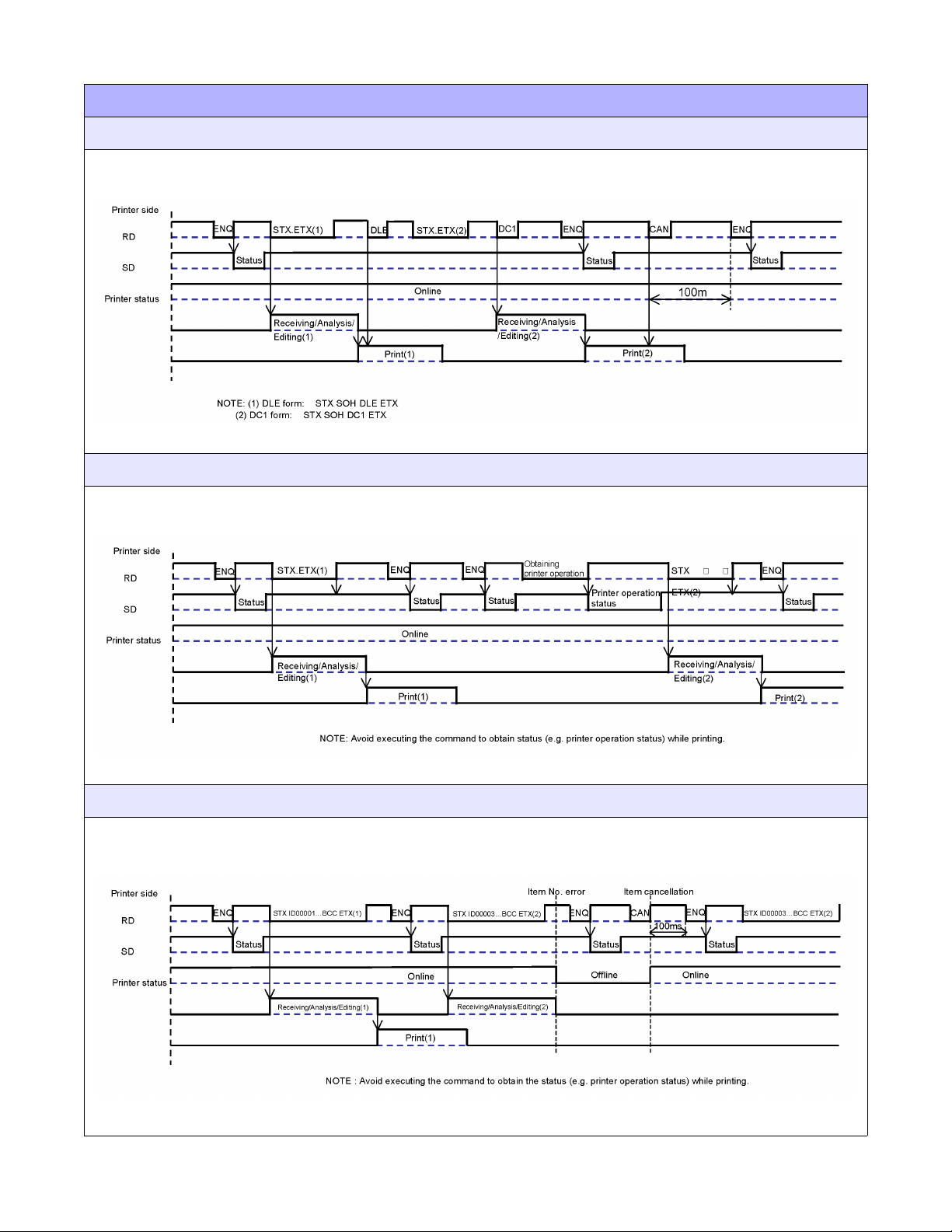

NORMAL PROCESS

(Figure 3-8a)

CANCEL PROCESS

Unit 2: Technical Data

STATUS5 TIMING CHARTS

(Figure 3-8b)

ERROR PROCESS

(Figure 3-8c)

CT4i Series Operator Manual 2-14

Page 23

PRINT PROCESS

(Figure 3-8d)

COMMAND PROCESS

Unit 2: Technical Data

STATUS5 TIMING CHARTS

(Figure 3-8e)

BCC ERROR PROCESS

(Figure 3-8f)

CT4i Series Operator Manual 2-15

Page 24

Unit 2: Technical Data

This page is intentionally left blank.

CT4i Series Operator Manual 2-16

Page 25

Unit 3: Installation

INSTALLATION

• Unpacking & Parts Identification

• Printer Installation

• Operational Mode Selection

• Interface Selection

• Accessories Installation

CT4i Series Operator Manual 3-1

Page 26

Unit 3: Installation

OVERVIEW

This section assists you in unpacking the printer from the shipping container. You will also be guided

through a familiarization tour of the main parts and controls. The following information is provided herein:

• Safety Precautions

• Unpacking and Parts Identification

• Loading Media

• Adjusting the Sensor

CT4i Series Operator Manual 3-2

Page 27

Unit 3: Installation

SAFETY PRECAUTIONS

Please read the following information carefully before installing and using the printer

THE CAUTION SYMBOL

Whenever the triangular Caution logo appears in this manual, pay special attention to the warning(s) cited

below it. Failure to abide by the warnings may result in injury or damage to property.

PRINTER PLACEMENT TIPS

• Place the printer on a solid, stable, horizontal surface that is not subject to strong vibrations from adjacent mechanical devices.

• Avoid shaky or slanting tables, or platforms that are

liable to collapse under a heavy weight. If the printer

is dropped or damaged, immediately turn off the

power, pull out the power plug and contact a service

center. In this case, continued use of the printer may

cause a fire or electric shocks.

• Avoid installing the printer in direct sunlight, or in

dusty, very hot or slippery areas. Also avoid placement in damp, unventilated or humid areas. If condensation forms, immediately turn off the power, and

do not use the printer until the condensation disappears. Otherwise the moisture may cause electric

shocks.

• Avoid placing the printer near large high-current

equipment, as such equipment can cause spikes or

under-voltages in the power supply.

• Do not leave containers of water or chemicals

around the printer. If any liquid is spilled onto

the printer, immediately turn off the power, pull

out the power cable from the AC outlet, and

contact a sales outlet, dealer, or service center.

In this case, continued use of the printer may

cause fires or electric shocks.

• Do not move the printer with any paper loaded.

The stack of paper may fall off, causing trips

and accidents.

• When laying the printer down, be careful not to

catch your foot or fingers under it.

• When moving the printer, be sure to pull out the

power cable from the AC outlet, and check that

any other external interface cables have been

disconnected. Otherwise, the connected cables

may be damaged, or may cause trips and falls,

in addition to or a fire or electric shocks.

ELECTRICAL PRECAUTIONS

• When using head cleaning liquid, note that it is flammable. Never heat it or throw it into a fire. Keep it out

of children’s reach to avoid accidental consumption.

Should this occur, consult a doctor immediately.

• When opening/closing the cover, beware of getting

your fingers caught. Also, hold the opening/closing

cover well so that it will not slip and fall onto the

hand.

• After printing, the print head remains hot. When

replacing paper or cleaning the printer immediately

after printing, be careful not to burn yourself.

• Touching even the edge of the printer head may

cause injuries. When replacing paper or cleaning the

printer, be careful not to hurt yourself.

• If the printer will not be used for extended periods of

time, disconnect the power cable for safety.

• When releasing and locking down the printer head,

be careful not to catch any other foreign matter in it

except label paper.

• Do not disassemble or perform modifications to

the printer, as this renders the product unsafe.

For maintenance, troubleshooting and repairs,

consult a sales outlet, dealer, or service center

for help, instead of attempting to perform this

yourself. Renewable annual service contracts

are available.

• When maintaining or cleaning the printer,

always disconnect the power cable for safety.

• Do not insert your hand or other objects into the

cutter.

• When loading roll paper, be careful not to catch

your fingers between the paper and the feeder.

• Be careful not to hurt yourself when detaching

the back cover of the fanfold through the hole

and attaching it.

• The simplified cutter (if applicable to the printer)

is structured as a blade. Be careful to avoid

injury when operating the printer.

CT4i Series Operator Manual 3-3

Page 28

Unit 3: Installation

GENERAL PRECAUTIONS

• When using head cleaning liquid, note that it is flammable. Never heat it or throw it into a fire. Keep it out

of children’s reach to avoid accidental consumption.

Should this occur, consult a doctor immediately.

• When opening/closing the cover, beware of getting

your fingers caught. Also, hold the opening/closing

cover well so that it will not slip and fall onto the

hand.

• After printing, the print head remains hot. When

replacing paper or cleaning the printer immediately

after printing, be careful not to burn yourself.

• Do not disassemble or perform modifications to

the printer, as this renders the product unsafe.

For maintenance, troubleshooting and repairs,

consult a sales outlet, dealer, or service center

for help, instead of attempting to perform this

yourself. Renewable annual service contracts

are available.

• When maintaining or cleaning the printer,

always disconnect the power cable for safety.

• Do not insert your hand or other objects into the

cutter.

• Touching even the edge of the printer head may

cause injuries. When replacing paper or cleaning the

printer, be careful not to hurt yourself.

• If the printer will not be used for extended periods of

time, disconnect the power cable for safety.

• When releasing and locking down the printer head,

be careful not to catch any other foreign matter in it

except label paper.

• When loading roll paper, be careful not to catch

your fingers between the paper and the feeder.

• Be careful not to hurt yourself when detaching

the back cover of the fanfold through the hole

and attaching it.

• The simplified cutter (if applicable to the printer)

is structured as a blade. Be careful not to cut

yourself.

This is a piece of Class B information technology equipment based on the standards of the Voluntary Control

Council for Interference by Information Technology Equipment (VCCI). Although this equipment is for use in home

environment, if it is used close to a radio or television set, it may cause poor reception. Handle it properly in

accordance with the content from the instruction manual.

CT4i Series Operator Manual 3-4

Page 29

Unit 3: Installation

1

4

2

5

3

CT4xxi Printer

User documentation and software

package (where applicable)

UNPACKING & PARTS IDENTIFICATION

When unpacking the printer, take note of the following:

The box should stay right-side up.

Lift the printer out of the box carefully.

If the printer has been stored in the

cold, allow it to reach room

temperature before turning it on.

Remove the plastic covering from the

printer.

Set the printer on a solid, flat surface.

Inspect the shipping container and

printer for any sign of damage that

Remove the accessory items from their

may have occurred during shipping.

protective containers.

Note:

The following parts shown here are representative only. Due to regional requirements and our policy of continual

improvement, your printer may not be packed with the exact parts as shown here, but the unpacking steps are

similar.

Figure 3-1, Unpacking & Parts Identification

CT4i Series Operator Manual 3-5

Page 30

Unit 3: Installation

Load the label roll. Its core should

rotate freely over the black rollers.

Get the media ready. Press the label guide release

knob and pull the guides apart.

Push the left label guide’s tab

outward before loading labels.

Pull the paper under the label

sensor, out to front of the printer.

Close the cover. Direct thermal

printing is now possible.

1 2 3

black roller

4 5

6

PRINTER INSTALLATION

This chapter provides guidance on how to station, connect, and load the printer once unpacked. Following printer

setup, proceed to the next chapter for information on interface selection.

SITE LOCATION

• Station the printer on a solid flat surface.

• Station it away from hazardous materials or dusty environments.

• Station it within operational distance of the host computer, within interface cable specifications

MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration before printer

purchase. Ideally, the media width will be equal to, or just narrower than, the print head. Using media that does not

cover the print head will allow the platen roller to tread on it and wear it out. The media edge will also wear a groove

in the platen roller affecting print quality.

MEDIA LOADING: ROLLED PAPER

There are two general label types that may be loaded and used; rolled and fan-folded. Each of those types may

again be defined by whether their print application is direct thermal or thermal transfer. Those factors determine

how the media is loaded and if ribbon stock is loaded at all.

Thermal transfer media requires the use of ribbon stock for print application. In such a scenario, it is the ribbon

stock (carbon paper) that contains the ink that will be transferred to the media. Direct thermal media has a coating

on the surface that is made visible through the application of heat from the print head. Rolled media of standard

diameter is loaded within the printer and suspended by the media holder.

Figure 3-3a, Rolled Label Loading

CT4i Series Operator Manual 3-6

Page 31

Unit 3: Installation

Get the media ready. The label

roll is optional in this procedure.

Raise the ribbon loader

assembly as shown here.

Load the ribbon roll (shiny side up)

into the supply spindle from

underneath (see blue arrow).

Ribbon

Supply

Spindle

Load the ribbon core into the takeup spindle.

Ribbon

Take-up

Spindle

Turn the the take-up spindle to

reduce any slack in the ribbon.

Ribbon loading is now complete.

The loading path is as depicted.

1 2

3

RIBBON LOADING

This chapter provides guidance on how to station, connect, and load the printer once unpacked. Following printer

setup, proceed to the next chapter for information on interface selection.

1. For best printing results and minimal operational

problems, use only genuine SATO-approved

combinations of ribbon and labels.

2. Beware of injury when lifting or closing the printer covers.

3. Remove the label and ribbon media before transporting

the printer.

4. For ribbon widths of 76 mm/59 mm/45 mm, insert the

supplied Core Adapter into the core of the ribbon roll

before loading it into the printer.

5. The ribbon loading assembly can be stowed away inside the top cover and held in place by the black

plastic latching mechanism (see “general description” on page 1-3)

6. Do extended test prints of specific combinations of ribbon and label media before purchasing them for

volume usage.

7. If an optional cutter is installed, be sure to keep your hands away from the cutter blade when

attempting to load or adjust media.

Figure 3-3b, Ribbon Loading

NOTES

CT4i Series Operator Manual 3-7

Page 32

Unit 3: Installation

Pull up

the

loading

slot

Pull

open

the Top

Cover

Overview of the fanfold-paper loading path

Figure 3-4, Fanfold paper loading

LOADING FANFOLD PAPER

Fan-folded media is fed inward from the rear, via the rear housing cover (highlighted in yellow below), but is

stacked as opposed to suspended. Ribbon can be wound in or wound out.

1. Place the fanfold media behind the printer with the printing surface up.

2. Carefully pull up the Fanfold-label Loading Slot from the

back of the Top Cover.

3. Open the Top Cover by pressing on the cover release latch

located on the right-hand side of the printer. This releases

the cover and allows it to swing upward on the rearmounted hinges.

4. With the Top Cover in the upright position, press the Paper

Guide Release while adjusting the Paper Guides until they

allow the media to fit between them. A millimeter scale is

molded into the case to provide a guide when making the

adjustment. The Paper Guides are center-justified and

interact with each other so that each moves an equal distance apart from each other.

5. Route the label material through the Sensor Assembly and

6. Close the Top Cover.

7. After loading the label media, it is

over the Platen. See figure 3-4 for the label route.

recommended that you run a Test Print to

make sure the labels are correctly loaded

and printed.

CT4i Series Operator Manual 3-8

Page 33

Unit 3: Installation

Inside edge of Label

Inside

edge of

Backing

Paper

Direction

of label

motion

Inter-label gap:

Min: 0.12” (3 mm)

Max: 0.20” (5 mm)

Printer Label Sensor Positioning

LABEL SENSING

The SATO CT4xxi uses label Gap (see-thru) sensing. The Sensor Assembly is located on the left edge

of the media and is automatically positioned by the Paper Guides.

CT4i Series Operator Manual 3-9

Page 34

Unit 3: Installation

OPERATIONAL MODE SELECTION

There are two modes of printer operation; Dispense and Continuous. The difference between the two is the way

that the label and paper backing is ejected. Before printer configuration, one must determine which mode will be

used. This chapter identifies the functional differences between the two.

ATTENTION: Refer to the Printer Configuration unit of this manual to program the

printer’s internal memory to suit individual needs using the integrated menu options.

Refer to the Programming Reference document to remotely program the printer’s

features and functions through a host system.

CONTINUOUS MODE

With this mode of operation, the media remains in position for printing at all times. To do so, means that the

previous printed label is only available for removal when one to four additional labels have been printed (quantity is

depended on label size). This mode of operation is specifically suited for printing bulk quantities to be applied later.

TEAR-OFF MODE

With this method of operation, after printing, the printer feeds the first (outermost) label so that it is fully extended

out of the printer’s front for removal. Printing of the next label will not begin until the prior printed label has been

removed. This mode of operation is specifically suited for immediate application at the time of print.

Upon removal of the prior printed label, the printer retracts the media so that the next label in line may be printed,

then prints. This cycle, repeats for each consecutive label.

CUTTER MODE

With the cutter assembly installed and enabled, this mode of operation will cut individual printed labels or in

multiples. The media will be advanced to the cutter blade, the label cut will occur, and the unprinted media will

retract for positioning of the next print.

DISPENSE MODE

When the dispenser assembly is installed and enabled, this mode of operation will peel the paper backing from the

printed label as it is advanced to the printer’s front. Once the printed label has been removed from the printer for

application, the unprinted media will retract and position itself so the next label may be printed.

This operational mode is specifically applicable to print operations where the label is to be immediately adhered.

LINERLESS MODE

When the linerless option is installed and enabled, this mode of operation allows for the feeding and printing of

linerless media. In this mode, the printer’s functionality is the same as with the continuous or tear-off modes depending on configuration settings.

CT4i Series Operator Manual 3-10

Page 35

LABEL PRINT DIRECTION

REFLECTIVE SENSORTRANSMISSION SENSOR

Base Print Position

CONTINUOUS MODE

REFLECTIVE SENSORTRANSMISSION SENSOR

Base Print & Tear-

Off Position

TEAR-OFF MODE

REFLECTIVE SENSORTRANSMISSION SENSOR

Base Print & Cut

Position

CUTTER MODE

Base Print Position

Base Print Position

REFLECTIVE SENSOR

TRANSMISSION SENSOR

Base Print &

Dispense Position

DISPENSE MODE

Base Dispense Position

Base Print Position

REFLECTIVE SENSOR

Base Cut Position

LINERLESS MODE

Base Print Position

Unit 3: Installation

CT4i Series Operator Manual 3-11

Figure 3-4, Label Reference Position

Page 36

Unit 3: Installation

This page is intentionally left blank.

CT4i Series Operator Manual 3-12

Page 37

Unit 4: Printer Configuration

PRINTER CONFIGURATION

• Configuration Modes

• Configuration Modes

• Menu Definition Tables

CT4i Series Operator Manual 4-1

Page 38

Unit 4: Printer Configuration

CONFIGURATION MODES

Before using the printer, read this manual thoroughly first. Otherwise, you may disturb default settings

upon which the instructional procedures in this manual are based.

buttons and/or potentiometers located on the printer’s front panel. All of the printer’s buttons, switches, and

potentiometers are used either singularly, or in conjunction, to perform configuration activities.

4.1 OPERATING PANEL

The Operator Panel consists of three LED indicators and three switches.

POWER

The green LED lights up when the printer is ON.

ERROR

The red LED lights up when there is a system fault

such as an unlatched print head.

The printer may be configured via the

ON LINE

The green LED lights up when the printer is ON LINE

and ready to receive data. The ON LINE button

takes the printer ON LINE or OFF LINE.

ON LINE Button

If the ONLINE LED is lit, pressing it will take the printer

OFF LINE. Pressing the button again then takes the printer

back ON LINE. When ON LINE, the printer is ready to

receive data from the host. When OFF LINE, the printer

will not print or accept data from the host. While the

printer is printing, press this button to suspend the

printing. To resume printing, press this button again.

FEED BUTTON

Press this button to eject one label in OFF LINE mode.

Hold this button down while power is applied, to print a printer status

label.

POWER SWITCH

A two position switch for turning the printer ON (I) or OFF (0).

CT4i Series Operator Manual 4-2

Page 39

Unit 4: Printer Configuration

Fanfold-label Loading Slot

Remove this panel to route fanfold paper into the printer

4.2 THE REAR PANEL

All of the printer cable connectors are located on the Rear Panel, as follows.

CT4i Series Operator Manual 4-3

Page 40

Unit 4: Printer Configuration

DIP switch for

Configuration

Error

Status

LED

VR1

potentiometer

Paper handling

Reserved

Head Check

VR1 adjust

DATA Dump

Reserved

DSW1 DSW2 DSW3 Mode

Off Off Off Continuous

Off Off On Linerless

On Off Off Tear Off

Off On Off Cutter

On Off On Program

Download

Mode

Off On On Load Font

Configuration Switch

ON

OFF

12345678

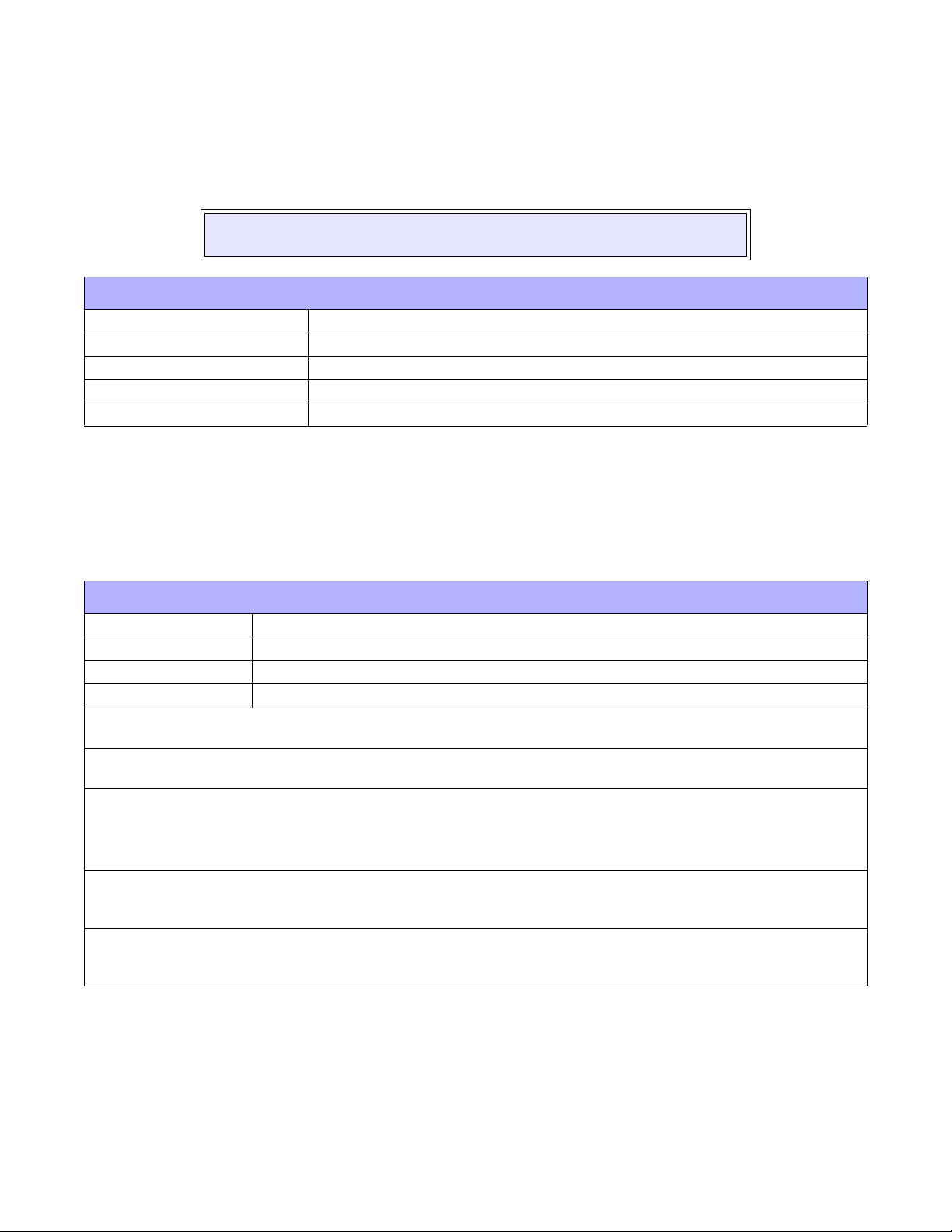

4.3 THE CONFIGURATION PANEL

The Configuration Panel is accessible when you lift up the top cover.

The panel consists of an eight-position DIP switch, three adjustment potentiometers and a sevensegment LED Error Status display. Receptacles for connecting the optional Cutter (factory installed) are

also located on this panel.

DIP SWITCH SETTINGS

This is an eight-position switch used for setting the operating conditions of the printer. Switches 1 to 3

act as control for both paper handling and the loading of programs or fonts into the printer.

Switches 1–3: Paper Handling settings

These three switches select the method used for

controlling paper handling:

Continuous mode - (default mode) Does not use the

sensor for paper indexing. The paper movement will

stop after all the label data has been printed.

Tear Off mode - Paper is fed out to the cut/tear off

position after printing is complete. Before the next label

is printed, the paper is pulled back in to the first print

line position.

Cutter mode - Enables the Cutter option if installed.

CT4i Series Operator Manual 4-4

Page 41

Unit 4: Printer Configuration

DSW1 DSW2 DSW3 Mode

Off On On Load Font

Configuration Switch

ON

OFF

12345678

DSW4 Mode

Off DT

On TT

Configuration Switch

ON

OFF

12345678

DSW5 Mode

Off Disabled

On Enabled

Configuration Switch

ON

OFF

12345678

4.3 DIP SWITCH SETTINGS (CONT’D)

Switches 1–3: Font/Graphic loading settings

Enables the loading of fonts and/or graphics into printer

memory for faster retrieval.

Switch 4: DT/TT Mode

Switches the printer between Direct Thermal (DT) or

Thermal Transfer (TT).

Switch 5: Head Check

Enables or Disables the printer function that checks the

print head for open circuits automatically. On detecting a

head error along any part of the print head, the ERROR

LED will be lit continuously. The printer will not allow any

further operation unless the following buttons are press, or

certain actions are taken.

1) Press the ONLINE and FEED buttons for five seconds.

The ONLINE LED lights for a brief moment, and then the

printer is taken OFFLINE. Restart the printer to continue

printing as per normal.

2) The printer can be set to another type of head checking, whereby the printer analyzes the print data

for the location of barcodes, and only checks the print head areas involved in printing those barcodes.

To switch to this mode, at the detection of head error, press the FEED button for five seconds. The new

head check mode takes effect. This limited-type of head check for barcode printing integrity only applies

to barcodes printed via the ESC+B, ESC+D, ESC_BD commands. The head check is not effective in

cases where barcodes are created as graphics.

CT4i Series Operator Manual 4-5

Page 42

Unit 4: Printer Configuration

DSW6 Mode

Off Pitch Offset

On Print Darkness

Configuration Switch

ON

OFF

12345678

DSW7 Mode

Off DISABLED

On ENABLED

Configuration Switch

ON

OFF

12345678

DSW8 Mode

Off Use extended

interface

On Use internal

interface

Configuration Switch

ON

OFF

Switch 6: VR1 Potentiometer Adjustment mode

Selects the function adjusted by VR1. If DSW6 is Off, VR1

adjusts the pitch offset value over a range of +/- 3.75 mm.

When DSW6 is On, VR1 adjusts the print darkness range.

Switch 7: DATA Dump

When ON, the printer will print out the hex value for each

character received. When OFF, the printer will accept and

process the data stream in a normal fashion.

Switch 8: Interface Board selection

This switch lets you choose whether to use the factory

installed interface board connectors, or the user-installable

Extended Interface board.

If not extended interface board is detected, switching

DSW8 to Off will not affect the use of the built-in interface.

CT4i Series Operator Manual 4-6

Page 43

Unit 4: Printer Configuration

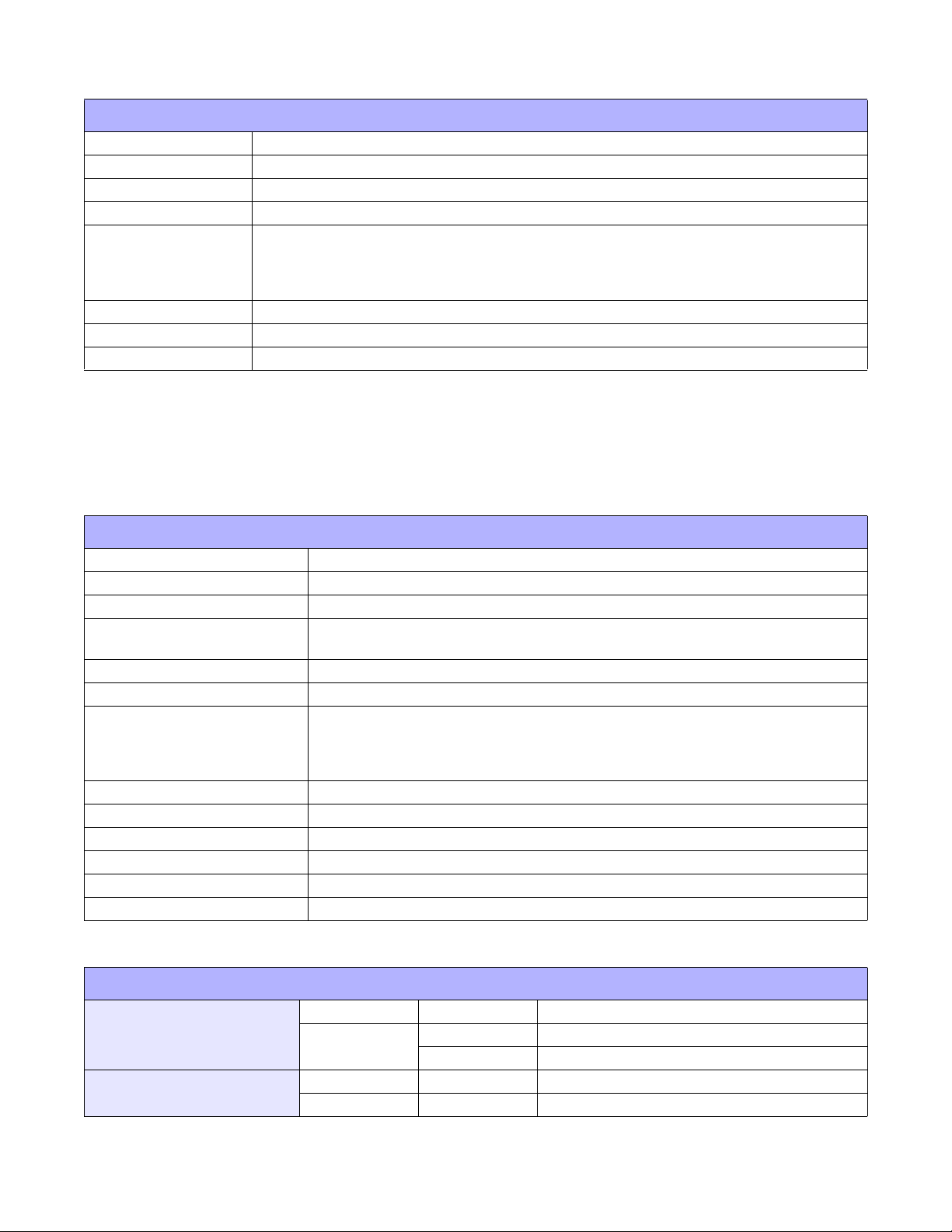

4.4 OPERATIONAL MODES

The CT4xxi operates in 10 different modes, where each mode can by invoked via combinations of

pressing the front panel buttons in a certain sequence together with DIP switch settings and print head

status. The table below lists all the modes and how they can be invoked.

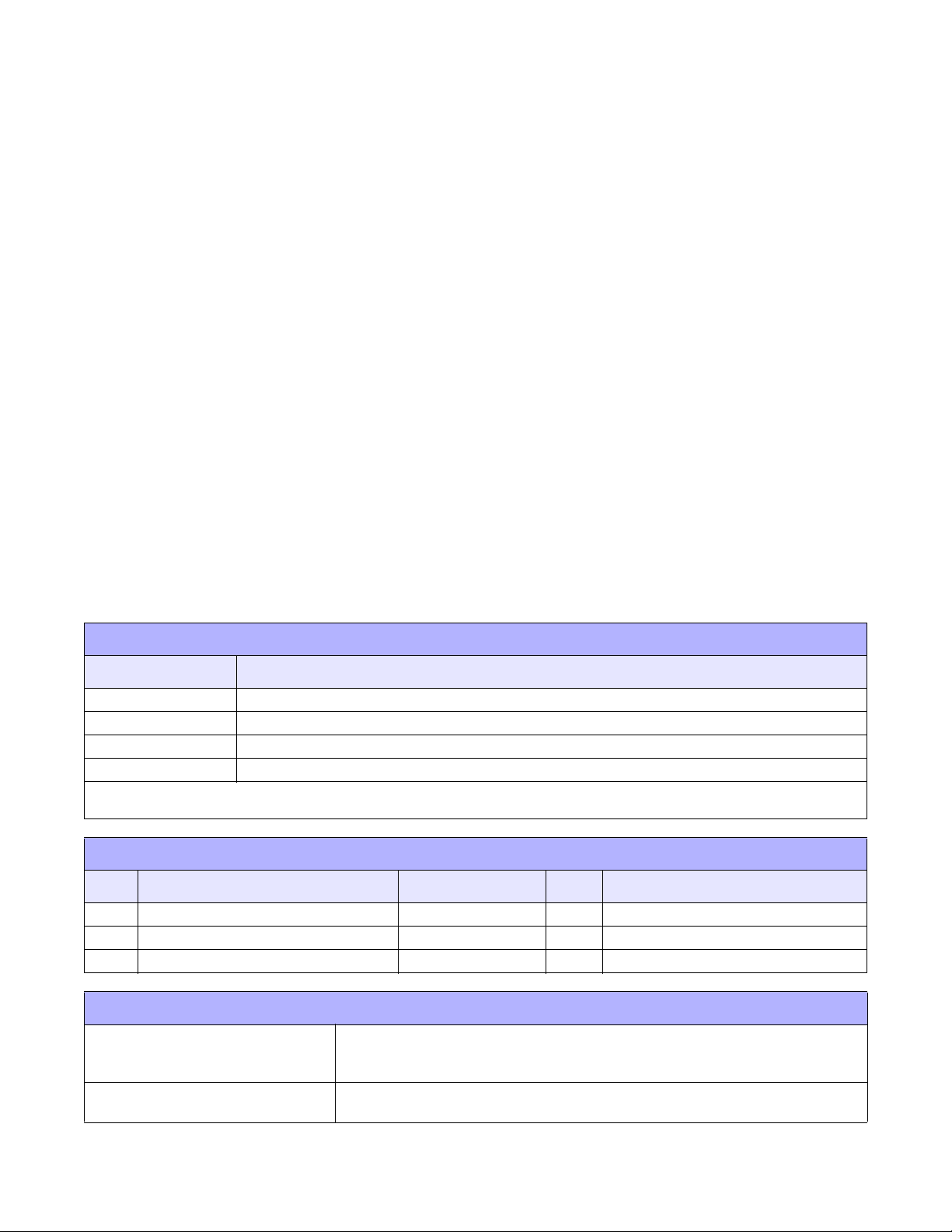

Table 1: Power ON sequence for various Operational Modes

Mode #

1 Normal Operational Mode

2 Press User Test Print Mode

3 Press Press Default Setting Mode

4 Press Press Head Open Factory Clear Mode

5 DSW7=ON HEX Dump Mode

6DSW1=On

7DSW1=Off

8 Press Press Head Open DSW7=On Head Check Mode

9 Press Press DSW1~8=On Boot Download Mode

10 DSW1=On

ONLINE

BUTTON

FEED

BUTTON

PRINT HEAD

STATUS

DSW

SETTING

DSW2=Off

DSW3=On

DSW2=On

DSW3=On

DSW2=On

DSW3=On

Operational Mode

Program Download Mode

Font Download Mode

Partial Cut Compatibility Mode

CT4i Series Operator Manual 4-7

Page 44

Unit 4: Printer Configuration

6

Y

Y

l

4.4 OPERATIONAL MODES (CONT’D)

Following are the standard operational functions and procedures available for selected modes. Modes

not covered here are covered in the Service Manual.

4.4.1 Normal Mode

The printer normally starts up in this mode. It automatically goes ONLINE and is ready for printing jobs.

The following operations are possible:

• Pressing the ONLINE button repeated takes the printer to ONLINE or OFFLINE mode alternately.

• During a print job, pressing the ONLINE button will pause the job. Press the ONLINE button again to resume the job.

• Pressing the FEED button in OFFLINE mode will advance a blank label if the label sensor is enabled.

• Pressing the FEED button in OFFLINE mode if the label sensor is disabled, results in the paper size not being verified and

the paper is fed in as long as the FEED button is held down. The feed procedure is stopped as soon as the FEED button is

released. Also, for concurrent cutter/liner-less operation, the paper cutting is executed as soon as the feed is halted (the

feed button is released). A back-feed may be performed after the cut has been executed.

• Taking the printer OFFLINE and pressing the ONLINE and FEED buttons will disable response to any JOB-CANCEL

command from the host computer. Then press the FEED button to return to OFFLINE mode. The LED shows

• Taking the printer OFFLINE and pressing the ONLINE and FEED buttons will disable response to any JOB-CANCEL

command from the host computer. To enable the JOB-CANCEL command, press the ONLINE button followed by the FEED

button. The printer will return to OFFLINE mode. The LED shows

Table 2: LED and Buzzer status during Normal Mode operation

Function

Normal printing operation ON OFF 1 beep

Online ON OFF -

Offline OFF OFF -

Job-cancel command switch-over to

select Disable

Sets Job-cancel command to Disable OFF OFF -

Sets Job-cancel command to Enable OFF OFF -

Switch-over from Job-cancel command

(Sets to Enable or Disable) to offline state

Switch-over from enabled Job-cancel

command to preferred interface selection

USB interface preferred OFF OFF -

ONLINE

LED

OFF OFF 1 beep

OFF OFF 1 beep

OFF OFF 1 beep

ERROR

LED

BUZZER

Other interfaces preferred OFF OFF -

Switch-over to offline after having

selected preferred interface

• After a print job is cancelled, the printer will switch to a preferred interface, granting priority to the USB interface, but

otherwise switching to the next available interface. The automatically selected interface will be indicated on the LED. Press

the ONLINE button to choose another available interface instead. Or press the FEED button to confirm the automatically

selected interface. The LED shows for USB interface selection, or for other interfaces

CT4i Series Operator Manual 4-8

OFF OFF 1 beep

Page 45

Unit 4: Printer Configuration

4.4.2 User Test Print Mode (FEED + POWER ON)

This mode produces test labels for diagnostic purposes. Upon entering this mode on startup, release the

FEED button. A beep is then produced, and the ERROR LED will light up.

When labels have been loaded properly, press the ONLINE or FEED button to start printing. Pressing

the FEED button produces small test label data, while the ONLINE button produces a big test print.

The ERROR LED goes off during the test printing. Pressing the FEED button at any time during the test

print operation will pause or resume the print job.

Note: To end the test print, make sure to press the FEED button to pause the printing, then turn the

printer OFF.

The following data will be produced on the test print:

Table 3: Data found on Test Prints

No. Data Printed

1 Base reference point offset (Vertical, horizontal)

2 Pitch offset

3 Cut position offset

4 Dispensing position offset

5 Tear off position offset

6 Label size (Pitch, width)

7 Print speed

8 Print darkness

9 Sensor type

10 Kanji character code

11 Paper end detection method

12 Zero slash

13 Proportional pitch

14 Buzzer

15 Initial feed

16 Interface settings

Type, buffer control, protocol, communication settings

17 Dip switch input/output function

18 Protocol code setting value

19 Euro-code (CT Series)

For a picture of the print sample, refer to “test label printing” on page 5-8.

CT4i Series Operator Manual 4-9

Page 46

Unit 4: Printer Configuration

4.4.3 Default Settings Mode (ONLINE + FEED + POWER ON)

Turning the printer ON in this mode simply resets major settings to their default values. (See table). After

the default values have been restored, the printer emits three beeps. The ERROR LED also lights up

during the reset operation, but goes off after the settings have been activated.

Parameter Default Setting

Reference position Vertical: 0dot, Horizontal: 0dot

Pitch offset 0 dot

Cut position offset 0 dot

Dispensing position offset 0 dot

Tear off position offset 0 dot

Label size (Pitch, width) Pitch=3200 dot x width 832dot [8dots/mm]

Pitch=4800 dot x width 1248dot [12dots/mm]

Pitch=9600 dot x width 2496dot [23.6 dots/mm]

Print speed 100 mm/s [8dots/mm] [12dots/mm]

50 mm/s [23.6dots/mm]

Print darkness 3A [Direct thermal]

3B [Thermal transfer]

Sensor type Gap

Kanji character code JIS

Paper end detection means Roll type

Zero slash Enable

Proportional pitch Enable [CT Series]

Buzzer Enable

Initial feed Disable

Auto-feed Disable

Gap size 24dots [8dots/mm]

36dots [12dots/mm]

72dots [23.6dots/mm]

Optional operation modes Operation No. 1

VR (Potentiometer) Option stop position offset =0, print darkness=0

Interface settings IEEE1284: Multi buffer, ACK width =500ns

RS-232C: Baud rate=19200bps, Data-bit=8bit, Parity=off, Stop bit=1bit, Control=READY/BUSY control (multi- buffer)

LAN/Wireless LAN: Driver exclusive protocol (Status 4) cycle response mode (2port connection using Port 1024 and Port 1025, or 1 port connection using Port

9100.)

USB: (no default settings)

Bluetooth: Bluetooth mode = Status 4, PIN code = 0000000000000000, Authenti-

cation mode = Authentication Level 1, ISI=0800, ISW=0012, PSI=0800, PSW=0012,

Device name = SATO ONLINE PRINTER, CRC Check = Disable

CT4i Series Operator Manual 4-10

Page 47

Unit 4: Printer Configuration

4.4.4 HEX Dump Mode (POWER ON with DSW7=ON)

When turned ON in this mode, the printer will print a dump of its buffer contents received for the host.

The printer awaits data feeds and when data arrives, it prints out the HEX data continuously.

To terminate the HEX Dump, set DSW7 to OFF and restart the printer.

4.4.5 Factory Clear Mode (Print head left open + ONLINE + FEED + POWER ON)

When turned ON in this mode, the printer clears various counters and settings, then generates printouts

for the user’s reference.

Three DIP Switches (DSW5, DSW6, DSW8) can be set in various configurations to determine which

settings are reset.

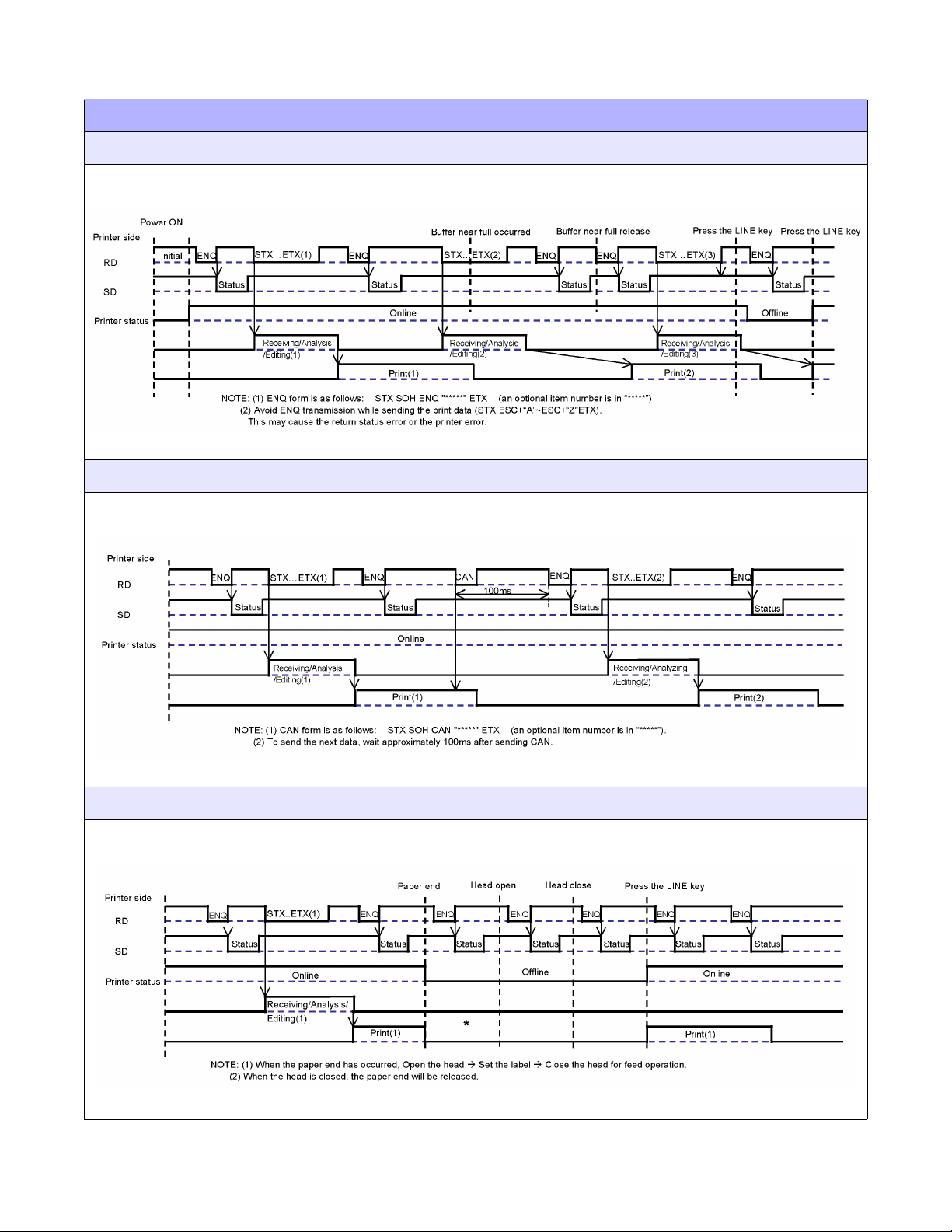

DSW5 DSW6 DSW8 Settings Affected

OFF OFF - No reset

OFF ON - Cutter counter reset

ON OFF - Head counter reset

ON ON -

ON ON OFF All-clear (Cutter, head, factory counter, printer settings)

*applicable to CT408iDT / CT412iDT / CT424iDT only

ON ON ON All-clear (Cutter, head, factory counter, printer settings)

*applicable to CT408iTT / CT412iTT / CT424iTT only]

The following operations are possible:

• Once the printer has been started in this mode, latch the print head to clear all affected counters.

• Next, select the test print size by pressing ONLINE (big size) or FEED (small size).

• The printer issues a label feed, and then starts printing once the factory settings have been applied. The ONLINE LED turns

OFF while the printer is waiting to print. The ERROR LED turns ON once, during the start of the factory clear mode, but is

otherwise OFF.

• Pressing the FEED button each time will pause or resume the printing.

• To terminate the test printing, pause the printing and turn the printer OFF.

• The setting of DSW7 can affect the print head check result.

CT4i Series Operator Manual 4-11

Page 48

Unit 4: Printer Configuration

4.4.6 Program Download Mode (DSW1=ON, DSW2=OFF, DSW3=ON + POWER ON)

In this mode, the printer is set to receive an application program from the host computer to download into

its memory. Remember to set the printer to the correct active interface to be used for the data transfer.

The status of various indicators in this mode is summarized below:

Function ONLINE ERROR BUZZER

During download mode ON OFF 1 beep 1

Wait to receive data ON OFF - 1

During data transfer

(start of data transfer)

Data editing ON OFF - 3

Flash ROM clear ON OFF - 4

Writing to Flash ROM ON OFF - 5

Download completed ON OFF 3 long beeps 1

Download error Blinking Blinking 1 long beep F

ON OFF 1 beep 2

LED

Display

• To exit this mode, make sure the printer is waiting to receive data (ONLINE LED=ON, ERROR

LED=OFF, LED Displays “1”, No Buzzer beep) and not performing any data transfer.

• Restart the printer after completion of the download, and perform a factory test print.

4.4.7 Font Download Mode (DSW1=OFF, DSW2=ON, DSW3=ON + POWER ON)

In this mode, the printer is set to download fronts from the host computer. Remember to set the printer to

the correct active interface to be used for the data transfer. The status of various indicators in this mode

is summarized below:

Function ONLINE ERROR BUZZER

During download mode ON OFF 1 beep 1

Wait to receive data ON OFF - 1

During data transfer

(start of data transfer)

Writing font data ON OFF - 3

Writing font information ON OFF - 4

Download completed ON OFF 1 beep 5

Download error ON ON 3 beeps F

ON OFF 1 beep 2

LED

Display

• To exit this mode, make sure the printer is waiting to receive data (ONLINE LED=ON, ERROR

LED=OFF, LED Displays “1”, No Buzzer beep) and not performing any data transfer.

CT4i Series Operator Manual 4-12

Page 49

Unit 4: Printer Configuration

4.4.8 Errors during Font and Program Download Modes

• Possible causes of errors could be that the data transfer is not correct between the printer and host,

due to interface setting incompatibilities or faults in the cable.

The flash ROM may be in a state that does not permit data being written to it. The following error

diagnostics are useful to help you troubleshoot the actual cause(s):

Cause ONLINE ERROR BUZZER

Flash ROM Error OFF ON 1 long beep O

Error during data download OFF OFF 1 long beep F

Error during font download ON ON 3 short beeps F

LED

Display

CAUTION

• Make sure that you do NOT turn the printer OFF when data is transferring to the flash ROM in

Program or Boot Download mode, as it may corrupt the firmware and prevent the printer from starting

up correctly.

• Ensure that the printer is running on a stable power supply during such flash ROM writing operations.

CT4i Series Operator Manual 4-13

Page 50

Unit 4: Printer Configuration

4.9 OFFSETS

There are two offset settings stored in the printer; one for the Cut mode and one for the Tear-Off mode.

These two offsets can be set independently and will remain in the printer until a new command is

received changing the setting or until power is turned off.

The default settings can be determined by printing a User Test Label.

The following should be used as starting points for establishing the three Offset values:

Mode Length of Offset (mm) Length of Offset (in) Print head resolution

CUTTER 17.9 0.70 143/215

TEAR-OFF 29.2 1.15 234/350

CT4i Series Operator Manual 4-14

Page 51

Unit 4: Printer Configuration

ABCDEFG

ABCDEFG

ABCDEFG

Leading Edge of

Label as detected

by the sensor

Moved with

Positive (+) Offset

to print on trailing

edge of label

Must be moved with Minus (-)

Offset to print on leading edge of

label

Original First Line

Print Position

label movement direction

4.10 POTENTIOMETER ADJUSTMENTS

PITCH OFFSET

This can be done using the VR1 potentiometer on the Configuration Panel. This potentiometer is set at

the factory so that it has a range of +/- 0.15” (3.75 mm). The midpoint setting should have no effect on

the label pitch. Turning the potentiometer all the way clockwise should move the print position 0.15”

(3.75 mm) upward toward the leading edge of the label. Turning the it all the way counterclockwise

should move the print position down 0.15” (3.75 mm) away from the leading edge of the label.

1. Place DSW6 on the Configuration Switch in the OFF position.

2. Turn the power OFF.

3. While pressing the FEED button on the Operator

Panel, turn the power ON.

4. When you hear one beep from the printer, release

the FEED button.

5. Press the LINE button to begin printing large Test

Labels (press the FEED button if you are using

labels smaller than 4.1" (104 mm) in width).

6. Adjust potentiometer VR1 until the first print posi-

tion is at the desired location on the label.

7. Press the FEED button to stop printing.

Note:

Adjusting the Label Pitch with VR1 will affect the

stop position of the label and the cut/tear-off positions.

CT4i Series Operator Manual 4-15

Page 52

Unit 4: Printer Configuration

4.10 POTENTIOMETER ADJUSTMENTS (CONT’D)

Print Darkness

A fine adjustment for PRINT DARKNESS can be made using potentiometer VR1 on the Front Operator

Panel. It provides a continuous range of adjustment, allowing you to make precise changes. Turning

VR1 clockwise will make the print darker, and counterclockwise will make it lighter.

1. Place DSW6 on the Configuration Switch in the ON position.

2. Turn the Power Switch OFF.

3. While pressing the FEED button on the Operator Panel, turn the Power Switch ON.

4. When you hear one beep from the printer, release the FEED button.

5. Press the LINE button to begin printing large Test Labels (press the FEED button if you are using

labels smaller than 4.1" (104 mm) in width).

6. Adjust potentiometer VR1 until the desired print darkness is obtained.

7. Press the FEED button to stop the printing.

Adjustment of the Print Darkness using VR1 will affect the darkness range adjustable using the PCL

command @PJL SET SPEED= [2 - 4]. That is, if the print darkness is adjusted with VR1 for lighter print,

the darkness will be lighter in all the Print Darkness ranges selected by the @PJL SET SPEED

command.

CT4i Series Operator Manual 4-16

Page 53

Unit 4: Printer Configuration

Note:

Depending on the version of your printer’s onboard software, the appearance of your test

printout may be different from that shown here.

4.11 DATA DUMP DIAGNOSTIC LABEL

The contents of the printer buffer can be examined using the DATA Dump mode. This printout labels

each line of the received data in the left hand column, the data in the middle column followed by the

same data in ASCII format in the right-hand column.

1. Turn the printer OFF.

2. Place DSW7 on the configuration Switch in the ON position.

3. Turn the printer ON.

4. Transmit data to the printer.

5. The data received is printed on the label.

6. Place DSW7 in the OFF position.

7. Turn the printer OFF and then back ON to place it back in the normal print mode.

CT4i Series Operator Manual 4-17

Page 54

Unit 4: Printer Configuration

Note:

Depending on the version of your printer’s onboard software, the appearance of your test

printout may be different from that shown here.

4.12 PRINTING TEST LABELS

1. The User Test Label prints the current default settings of the printer.

2. Press the FEED button while turning the power ON.

3. When the printer beeps, release the FEED button.

4. To print a large (4" wide) test label, press the ON LINE button. To print a small (2" wide) test label,

press the FEED button.

5. The printer will continuously print the USER TEST LABEL until the FEED button is pressed. If the

FEED button is pressed another time, printing will resume.

6. To remove the printer from the Test Label mode, power the printer OFF.

CT4i Series Operator Manual 4-18

Page 55

Unit 4: Printer Configuration

Note:

Depending on the version of your printer’s onboard software, the appearance of your test

printout may be different from that shown here.

4.13 PRINTING FACTORY/SERVICE TEST PRINTS

The Factory/Service Test Label prints the internal operating parameters of the printer.

1. Release the print head. (see “Releasing/Replacing the Print Head“” on page 3).

2. Press the LINE and FEED buttons while turning the printer ON.

3. When the printer beeps, release the LINE and FEED buttons. The printer will then beep 3 times indi-

cating it is in the Factory/Service Print Test mode.

4. Re-latch the Print Head.

5. Press the LINE button to print a large (4" wide") Factory/Service Test Label. Press the FEED button

to print a small (2" wide) Factory/Service Test Label.