Page 1

EZ Manual CL4xxe

Electric Checks and Adjustments

Ribbon Clutch Adjustment

Print Head Position Alignment

Print Head Balance Adjustment

home | next

Barcode SATO International Pte Ltd

Page 2

This explains how to check levels of DC power supply,

I-mark sensor and gap sensor. Ensure that printer power

is off. Re move the LH cover and then perform the

following steps.

Additional equipment required

TP T est Module

Digital Multimeter

STEPS

EZ Manual: CL4xxe

Electric Checks

and Adjustments

2

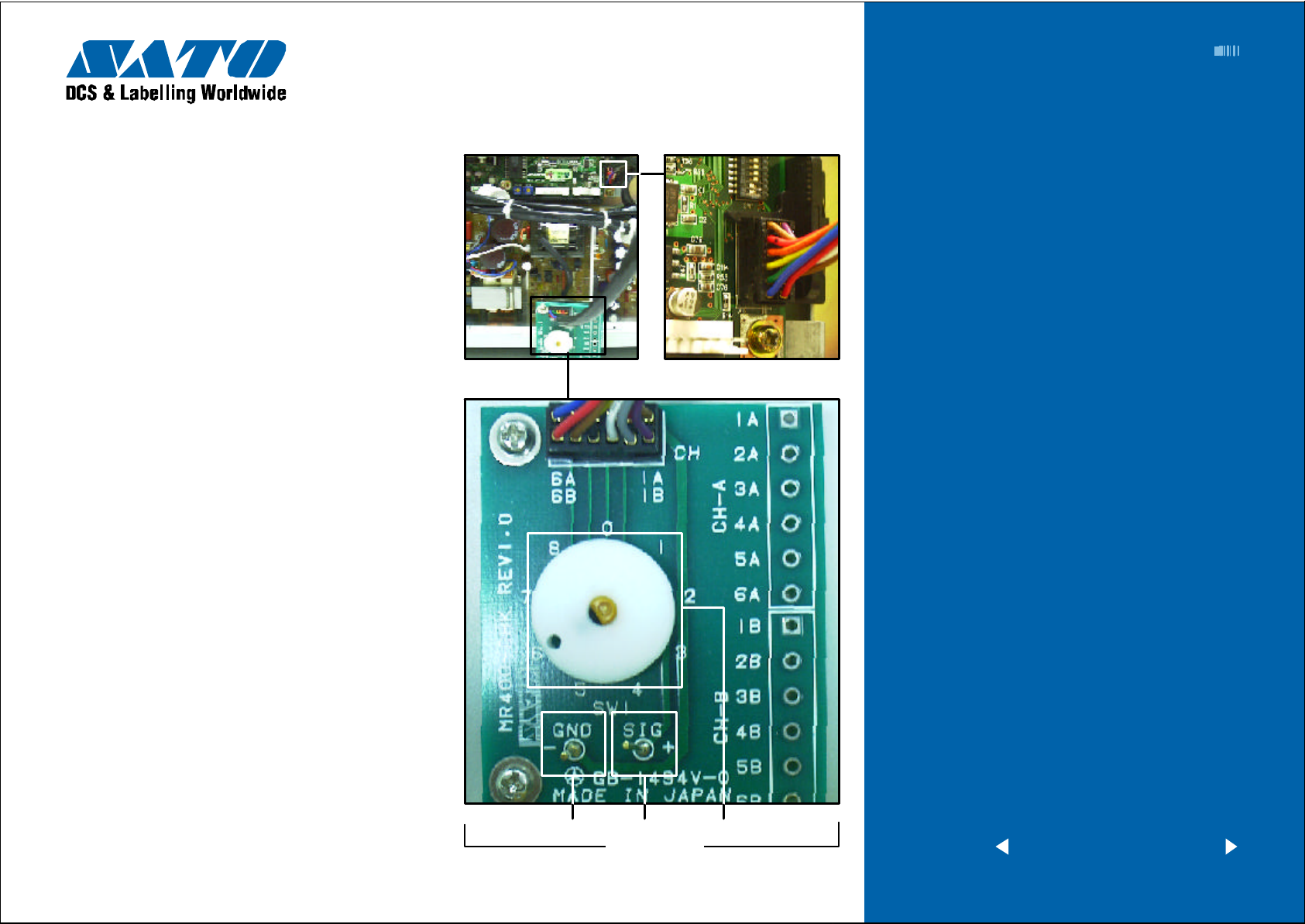

1 Attach the connector from the TP T est Module to the

test port on the MAIN PCB. Note correct positioning

of connector. Nibs on the connector are placed down

on the PCB in the forward position.

2 Attach the ground probe of the Digital Multimeter to

the TP T est Module ground pin (GND PIN).

3 Attach positive probe of the Multimeter to the + SIG

PIN on the TP Test Module terminal.

4 Turn printer power on and rotate the dial to a position

0-5 on the TP T est Module by referring to the diagram

on the next page. Record the values from the Multimeter.

5 Confirm the recorded voltages are within the voltage

range. If not, replace parts or adjust sensor level. Refer

to Check and Adjustment chart.

6 Aft er p erforming test, put the LH cover b ack to

the printer.

Cable to PCB

Cable to TP T est Module

Ground PIN

SIG PIN Dial

TP Test Module

< previous | home | next >

Barcode SATO International Pte Ltd

Page 3

EZ Manual: CL4xxe 3

Electric Checks and Adjustments

Chart 1

TP TEST POINT CHART

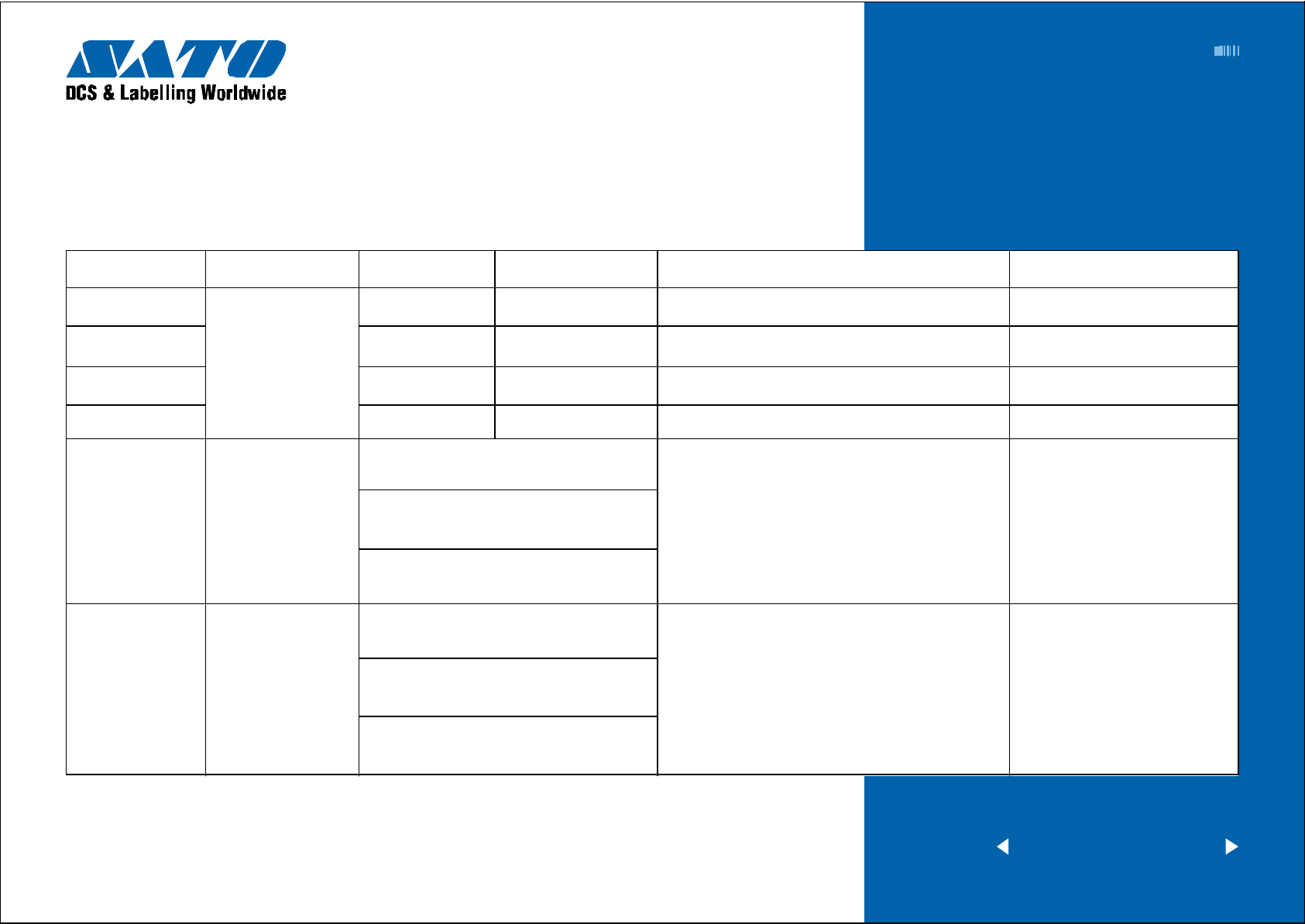

Dial test point Comment Voltage Voltage Range Check pin on TP Test Module and Main PCB Adjustment to VR

0 +5.0 VDC +4.8V to +5.2V CH3A(+5.0V) - CH1A(GND) N/A

1

DC power Supply

2 +3.3 VDC +3.1V to +3.5V CH5A(+3.3V) - CH1A(GND) N/A

3 +24.0 VDC +23.5V to +24.5V CH6A(+24.0V) - CH1A(GND) N/A

4 I-Mark Sensor Level CH1B(+8.4V) - CH1A(GND) VR5

5 Gap sensor Level CH2B - CH1A(GND) VR4

+2.0 VDC +1.9V to +2.1V CH4A(+2.0V) - CH1A(GND) N/A

Low level (Set the blank area

on the sensor) = A

High level (Set the I-mark

on the sensor) = B

High level - Low level =

A - B = m ore than +0.9V

Low level (Set the label backing liner or the

centre hole [in case of the centre hole tag]

on the sensor) = C

High level (Set the label or

tag on the sensor) = D

High level - Low level =

C - D = more than +0.9V

< previous | home | next >

Barcode SATO International Pte Ltd

Page 4

EZ Manual: CL4xxe 4

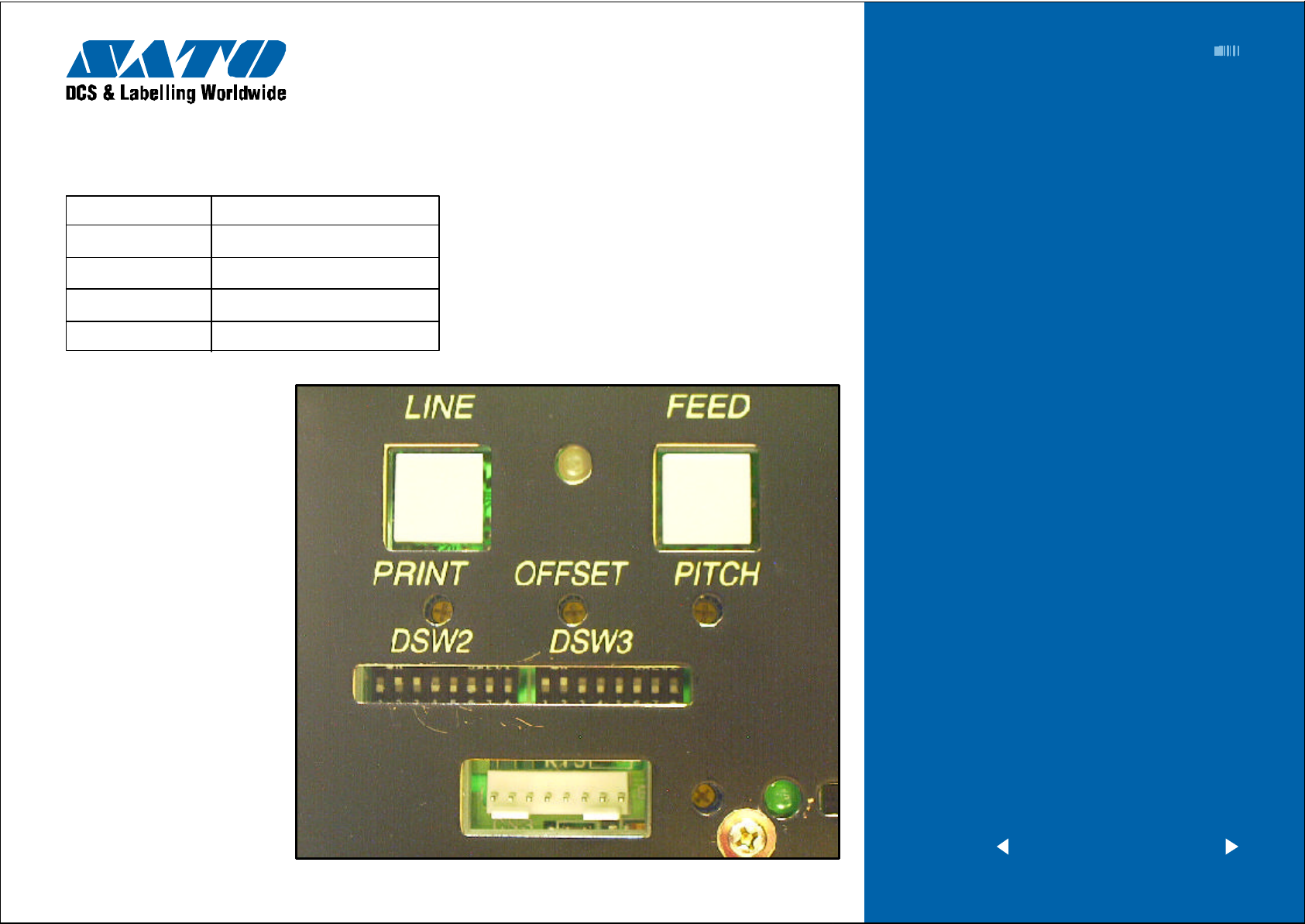

Potentiometers are located on MAIN PCB.

Adjustment VR Function

VR1(OFS) Pitch Offset Adjustment

VR2(DEM) Not used

VR3(CE) Not used

VR4(GAP) Gap Sensor Level Adjustment

VR5(IM) I-M ark Sensor Level Adjustment

Electric Checks and Adjustments

Chart 2

VR5 I-mark

VR4 Gap

VR1 Offset

VR2 DEM VR3 CE

MAIN PCB

< previous | home | next >

Barcode SATO International Pte Ltd

Page 5

EZ Manual: CL4xxe 5

Potentiometers are located on FRONT P ANEL

Adjustment VR Function

PRINT (VR1) Print Darkness Adjustm ent

OFFSET (VR2) Label Stop Position Adjustment

PITCH (VR3) Print Position Adjustment

Label T ake Sensor Dispenser Level Adjustm ent

Electric Checks and Adjustments

Chart 3

< previous | home | next >

Barcode SATO International Pte Ltd

Page 6

EZ Manual: CL4xxe 6

Excessive ribbon unwind and rewind tension will result in

variable motion and could be the cause of print quality

problems.

Ensure the ribbon rewind and unwind tensions are within

specifications or adjustment of either clutch is necessary.

Required equipment

1 Empty Ribbon Core and String

2 12mm Wrench

3 2kg T ension Gauge

4 “+” Screwdriver (JIS No.2 equivalent)

3

2

4

STEPS

1 Sw itch t he printer OFF a nd disconnect the

power cable.

2 Open the top and front access door. Remove the

ribbon and label stock if installed.

3 Attach string to an empty ribbon core and place on

the Ribbon Spindle. W ind the string tightly around the

ribbon core in single layer and in clockwise direction.

Attach the end of the string to the tension gauge.

4 Gradually lift the tension gauge and pull the string,

unwinding it from the core. Once the spindle starts to

move, the gauge should indicate 950 to 1050 grams

of tension for ribbon rewind, and 450 to 550 grams of

tension for ribbon unwind. Refer to pictures on the

next page.

Ribbon Clutch

Adjustment

1

5 T o adjust the clutch, loosen the locking screw and

move the adjust nut CW for more tension and CCW

for less tension. Tighten the locking screw and repeat

steps 3 and 4 until the correct tension is achieved.

< previous | home | next >

Barcode SATO International Pte Ltd

Page 7

EZ Manual: CL4xxe 7

Ribbon Clutch

Adjustment continued

Ribbon Rewind Clutch

T ension Guage T ension Guage

Empty Ribbon Core

450g-550g Unwind

Empty Ribbo n Core

Locking Screw is inside Adjust Nut

Adjust Nut

950g-1050g Rewind

Ribbon Unwind Clutch

< previous | home | next >

Barcode SATO International Pte Ltd

Page 8

Minor Adjustment

EZ Manual: CL4xxe 8

Print Head Position

Required equipment

10mm Open End Wrench

“+” Screwdriver (JIS No.2 equivalent)

T o adjust the print head alignment and ensure consistent

quality ac ross label, perform the following steps:

STEPS

1 Loosen the screws on the head plate. Print user test

patte rn. Realign the print head by prying the adjust

plate forward or backward with flat blade screwdriver.

Refer to illustrations and note adjustment marks.

2 Tighten the screws.

Alignment

Adjustment Marks

Screws

Print head “open” lever

< previous | home | next >

Barcode SATO International Pte Ltd

Page 9

Major Adjustment

EZ Manual: CL4xxe 9

Print Head Position

Required equipment

“+” Screwdriver (JIS No.2 equivalent)

T o further optimize print quality, especially when using

thick label stock, additional adjustments are possible.

Perform the following steps using head pattern as a guide.

STEPS

1 Load the ribbon and label stock into the printer.

2 Loosen and adjust screw along slot to move indexing

pointer for maximum print quality.

Alignment continued

Loosen the screw .

Then indexing pointer shifts head BACK WARD/FORWARD

Loosen the screw 1/4 T urn

< previous | home | next >

Barcode SATO International Pte Ltd

Page 10

Minor Adjustment

EZ Manual: CL4xxe 10

Print Head Balance

Required equipment

10mm Wrench

“+” Screwdriver (JIS No.2 equivalent)

T o optimize print quality, perform the following steps to

adjust the Print Head Balance using Factory Test Print.

STEPS

1 Load the ribbon and label stock into the printer.

2 Loosen the screws by 1/4 turn. Please refer to picture.

3 Adjust color by rotating CW or CCW.

4 Tighten screw to secure eccentric nut in place.

5 Loosen and adjust screw along slot to move indexing

pointer maximum print quality.

Adjustment

Loosen the screw 1/4 T urn

Indexing Marks

Use the 10m m wrench to adjust eccentric nut

CW or CCW and tighten screw .

< previous | home | next >

Barcode SATO International Pte Ltd

Loading...

Loading...