Page 1

Operator Manual

For printer model:

Page 2

Copyrights

Any unauthorized reproduction of the contents of this document, in part or whole, is strictly prohibited.

Limitation of Liability

SATO Corporation and its subsidiaries in Japan, the U.S. and other countries make no representations or

warranties of any kind regarding this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. SATO Corporation shall not be held responsible for errors

contained herein or any omissions from this material or for any damages, whether direct, indirect, incidental or

consequential, in connection with the furnishing, distribution, performance or use of this material.

Specifications and contents in this document are subject to change without notice.

Be sure to perform a virus check for the USB memory before connecting it to the printer. SATO Corporation

shall not be held responsible for any printer malfunctions caused by a virus spread via USB memory.

Trademarks

SATO is a registered trademark of SATO Holdings Corporation and its subsidiaries in Japan, the U.S. and

other countries.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

®

is a registered trademark of Wi-Fi Alliance.

Wi-Fi

Wi-Fi Direct™, Wi-Fi Protected Setup™, WPA™ and WPA2™ are trademarks of Wi-Fi Alliance.

Cisco, the Cisco logo, and Cisco Systems are trademarks or registered trademarks of Cisco Systems, Inc.

and/or its affiliates in the United States and certain other countries.

Bluetooth is a trademark of Bluetooth SIG, Inc., U.S.A.

®

ENERGY STAR

and ENERGY STAR mark are registered U.S. marks.

ICODE, I-CODE, and SLI are registered trademarks of NXP B.V.

®

MIFARE

is a registered trademark of NXP B.V.

Tag-it™ is a trademark of Texas Instruments.

my-d™ is a registered trademark of Infineon Technologies AG.

FeliCa is a registered trademark of Sony Corporation.

FeliCa is a contactless IC card technology developed by Sony Corporation.

Android is a trademark of Google Inc.

All other trademarks are the property of their respective owners.

Version: GBS-CL4NX_CL6NX-r08-01-08-16OM

© 2016 SATO Corporation. All rights reserved.

Page 3

Table of Contents

Table of Contents ................................................................................... 1

Before You Start ..................................................................................... 7

Features of the Product............................................................................................ 7

Safety Precautions.................................................................................................... 8

Precautions for Installation and Handling ............................................................ 11

Regulatory Approval............................................................................................... 12

1 Parts Identification............................................................................. 15

1.1 Parts Identification of the Printer .................................................................... 15

1.1.1 Front View ............................................................................................................... 15

1.1.2 Rear View ................................................................................................................ 16

1.1.3 Internal View............................................................................................................ 17

1.2 Parts on the Operator Panel............................................................................. 18

1.2.1 Operator Panel ........................................................................................................ 18

1.2.2 LED Indicator........................................................................................................... 19

2 Installing the Printer .......................................................................... 21

2.1 Installation Precautions.................................................................................... 21

2.2 Installation Space.............................................................................................. 22

2.2.1 Front View (CL4NX) ................................................................................................ 22

2.2.2 Front View (CL6NX) ................................................................................................ 22

2.2.3 Side View (CL4NX/CL6NX) ..................................................................................... 23

2.2.4 Bottom View (CL4NX) ............................................................................................. 24

2.2.5 Bottom View (CL6NX) ............................................................................................. 24

2.3 Checking the Bundled Accessories ................................................................ 25

2.4 Connecting the Interface Cable ....................................................................... 26

2.4.1 Available Interfaces ................................................................................................. 26

2.4.2 Interface Settings..................................................................................................... 27

2.4.3 NFC Interface Connection ....................................................................................... 27

2.5 Connecting the Power Cord............................................................................. 28

2.6 Power On/Off the Printer .................................................................................. 29

2.6.1 Power On the Printer ............................................................................................... 29

2.6.2 Power Off the Printer ............................................................................................... 30

CL4NX/CL6NX Operator Manual

1

Page 4

Table of Contents

2.7 Starting Up the Printer (Startup Guide)........................................................... 31

2.7.1 Startup Screen......................................................................................................... 31

2.7.2 Language Selection................................................................................................. 31

2.7.3 Region Setting with Optional RTC........................................................................... 32

2.7.4 City Setting with Optional RTC ................................................................................ 32

2.7.5 Date Setting with Optional RTC............................................................................... 32

2.7.6 Time Setting with Optional RTC .............................................................................. 33

2.7.7 Print Method Setting ................................................................................................ 33

2.7.8 Ribbon Setting ......................................................................................................... 34

2.7.9 Setting the Media Sensor Type ............................................................................... 34

2.7.10 Media Setting......................................................................................................... 35

2.7.11 Confirmation Screen.............................................................................................. 36

2.7.12 Startup Guide Cancelation .................................................................................... 36

3 Loading the Ribbon and Media........................................................... 37

3.1 Checking the Ink Side of the Ribbon............................................................... 37

3.2 Loading the Ribbon .......................................................................................... 38

3.3 Removing the Ribbon ....................................................................................... 41

3.4 Usable Media ..................................................................................................... 42

3.4.1 Adjusting the Position of the Media Sensor............................................................. 42

3.5 Loading Media ................................................................................................... 43

3.5.1 Loading Media Roll.................................................................................................. 43

3.5.2 Loading Fan-fold Media........................................................................................... 45

3.5.3 Loading Media with the Optional Cutter .................................................................. 46

3.5.4 Loading Media with an Optional Dispenser and Liner Discharge Outlet ................. 46

3.5.5 Loading Media with an Optional Dispenser and Liner Rewinder............................. 47

3.5.6 Removing the Liner from the Rewinder ................................................................... 49

4 Operation and Configuration .............................................................. 51

4.1 Display and Operation ...................................................................................... 51

4.1.1 Online Mode/Offline Mode....................................................................................... 51

4.1.2 Status Icon............................................................................................................... 52

4.1.3 Error Icon................................................................................................................. 55

4.1.4 Guidance Video ....................................................................................................... 58

4.1.5 Adjusting the Print Settings During Printing............................................................. 61

4.1.6 Canceling the Print Job ........................................................................................... 62

4.2 Settings Mode.................................................................................................... 63

4.2.1 Changing to Settings Mode ..................................................................................... 63

4.2.2 Log In to/Log Out of the Settings Mode................................................................... 64

4.2.3 Item Selection.......................................................................................................... 65

4.2.4 Setting Value Input or Selection .............................................................................. 66

4.3 Settings Menu Tree Structure .......................................................................... 69

CL4NX/CL6NX Operator Manual

2

Page 5

Table of Contents

4.4 Details of the Settings Menu Screen ............................................................... 83

4.4.1 Shortcut Menu ......................................................................................................... 83

4.4.2 Printing Menu .......................................................................................................... 84

4.4.3 Interface Menu....................................................................................................... 105

4.4.4 Applications Menu ................................................................................................. 177

4.4.5 System Menu......................................................................................................... 205

4.4.6 Tools Menu............................................................................................................ 216

4.4.7 Information Menu................................................................................................... 238

4.5 Web Configuration .......................................................................................... 248

4.5.1 Dashboard ............................................................................................................. 248

4.5.2 Settings.................................................................................................................. 249

4.5.3 Tools...................................................................................................................... 251

4.5.4 Certificates............................................................................................................. 253

5 Cleaning and Performing Printer Adjustments ................................ 255

5.1 Maintenance .................................................................................................... 255

5.2 Maintenance of the Print Head and Platen Roller ........................................ 256

5.2.1 Maintenance using the Cleaning Kit ...................................................................... 256

5.2.2 Additional Procedure for the Optional Linerless Cutter Kit (CL4NX only).............. 259

5.2.3 Maintenance using the Cleaning Sheet................................................................. 260

5.3 Adjusting the Base Reference Point ............................................................. 262

5.3.1 About the Base Reference Point ........................................................................... 262

5.3.2 Adjusting the Print Position.................................................................................... 263

5.3.3 Adjusting the Media Stop Position......................................................................... 265

5.3.4 Notes on the Stop/Cut Position of Different Media ................................................ 266

5.4 Adjusting the Print Quality............................................................................. 268

5.4.1 Adjusting the Print Darkness ................................................................................. 268

5.4.2 Adjusting the Print Speed ...................................................................................... 269

5.5 Adjusting the Buzzer Volume ........................................................................ 271

5.6 Adjusting the Head Pressure Balance .......................................................... 272

5.6.1 Head Pressure Setting .......................................................................................... 272

5.6.2 Pressure Balance Setting ...................................................................................... 273

6 Troubleshooting................................................................................ 275

6.1 When an Error Message Occurs.................................................................... 275

6.1.1 More Information about Command Error............................................................... 283

6.2 When the LED Lights Red/Blue ..................................................................... 285

6.3 Troubleshooting Table ................................................................................... 286

6.3.1 No Power/Nothing on the Screen .......................................................................... 286

6.3.2 Cannot Feed the Media ......................................................................................... 286

6.3.3 Can Feed the Media but Cannot Print ................................................................... 287

6.3.4 Bad Print Quality.................................................................................................... 288

6.3.5 Incorrect Print Position .......................................................................................... 289

6.3.6 Cannot Read Barcodes When Using the Barcode Check Function ...................... 290

CL4NX/CL6NX Operator Manual

3

Page 6

Table of Contents

6.4 Interface Troubleshooting.............................................................................. 291

6.4.1 USB Interface ........................................................................................................ 291

6.4.2 LAN Ethernet Interface .......................................................................................... 291

6.4.3 Bluetooth Interface ................................................................................................ 291

6.4.4 NFC Interface ........................................................................................................ 292

6.4.5 RS-232C Interface................................................................................................. 292

6.4.6 IEEE1284 Interface ............................................................................................... 292

6.4.7 External Signal Interface (EXT) ............................................................................. 293

6.4.8 Wireless LAN Interface.......................................................................................... 293

7 Appendix ........................................................................................... 295

7.1 List of Initial Values ........................................................................................ 295

7.1.1 Printing Menu ........................................................................................................ 295

7.1.2 Interface Menu....................................................................................................... 298

7.1.3 Applications Menu ................................................................................................. 308

7.1.4 System Menu......................................................................................................... 311

7.1.5 Tools Menu............................................................................................................ 313

7.1.6 Information Menu................................................................................................... 315

7.2 Media Sensor Positions and Media Stop Positions..................................... 316

7.3 Replacing the Print Head................................................................................ 318

7.4 Replacing the Platen Roller............................................................................ 320

7.4.1 Guideline to Replace the Linerless Platen Roller (CL4NX only)............................ 321

7.5 Optional RFID Configuration (CL4NX only) .................................................. 322

7.5.1 Printing RFID Tag Errors ....................................................................................... 325

7.5.2 RFID Error and Reset Timing ................................................................................ 329

7.5.3 External (EXT) Signal Interfaces when RFID Mode is Enabled ............................ 332

7.5.4 RFID Printing Tips ................................................................................................. 332

7.6 Optional Barcode Check Function Configuration........................................ 333

7.6.1 Basic Specifications of the Barcode Check Function ............................................ 333

7.6.2 Setting Up the Barcode Checker ........................................................................... 339

7.6.3 Changing How the RS-232C Interface is Used

(When Using the KEYENCE Barcode Checkers)........................................................... 340

7.6.4 Doing a Test Read with the Barcode Checker ...................................................... 342

7.6.5 Enabling the Barcode Check ................................................................................. 345

7.6.6 Restrictions for the Barcode Check Function ........................................................ 349

7.7 Printer Specifications ..................................................................................... 351

7.7.1 Hardware ............................................................................................................... 351

7.7.2 Ribbon and Media ................................................................................................. 354

7.7.3 Interface................................................................................................................. 356

7.7.4 Built-in Functions ................................................................................................... 357

7.7.5 Printer Languages ................................................................................................. 357

7.7.6 Fonts/Symbols/Barcodes....................................................................................... 358

7.7.7 Options .................................................................................................................. 361

7.7.8 Accessories ........................................................................................................... 361

7.7.9 Standards .............................................................................................................. 362

CL4NX/CL6NX Operator Manual

4

Page 7

Table of Contents

7.8 Interface Specifications.................................................................................. 363

7.8.1 USB Interface ........................................................................................................ 364

7.8.2 LAN Ethernet Interface .......................................................................................... 365

7.8.3 Bluetooth Interface ................................................................................................ 366

7.8.4 NFC Interface ........................................................................................................ 366

7.8.5 RS-232C Interface................................................................................................. 367

7.8.6 IEEE1284 Interface ............................................................................................... 369

7.8.7 External Signal Interface (EXT) ............................................................................. 371

7.8.8 Wireless LAN Interface.......................................................................................... 380

CL4NX/CL6NX Operator Manual

5

Page 8

Table of Contents

This page is intentionally left blank.

CL4NX/CL6NX Operator Manual

6

Page 9

Before You Start

Thank you for purchasing this SATO CL4NX/CL6NX printer (hereafter referred to as “the printer”).

This manual supplies basic information on how to operate the printer. Read the manual carefully to

understand each function before operation.

Features of the Product

This SATO CL4NX/CL6NX printer is a high-performance labeling system with a robust casing made of

metal and equipped with versatile functions. The main features of the printer are as follows:

• Simple and stylish design

• High-quality printing

• Designed for better usability

• Equipped with high legibility TFT color 3.5 inch LCD and LED

• Onboard Guidance Videos

• Print head and platen roller can be replaced without using extra tools

• Supports a 600 m ribbon

• Supports thirty-one languages for display and forty-seven languages for printing scalable fonts

• Supports various communication interfaces

• Supports protocols such as IPv6, SNMP and NTP

• Certified by Wi-Fi alliance

• Compatible with Cisco CCX V4.0

SATO CL4NX/CL6NX printer has tested compatible with Cisco CCX, version 4.0.

The Cisco Compatible logo signifies that SATO product has undergone

interoperability testing by SATO together with Cisco and a third-party test house

based on testing criteria set by Cisco.

SATO is solely responsible for the support and warranty of its product. Cisco

makes no warranties, express or implied, with respect to SATO product or its inter

operation with the listed Cisco product(s) and disclaims any implied warranties of

merchantability, fitness for a particular use, or against infringement.

®

• Conforms to international ENERGY STAR

program

The products described herein comply with the requirements of the ENERGY

STAR. As an ENERGY STAR Partner, SATO Corporation has determined that this

product meets the ENERGY STAR guidelines for energy efficiency.

CL4NX/CL6NX Operator Manual

7

Page 10

Before You Start

Safety Precautions

This section describes how to safely operate the printer. Be sure to read and understand all instructions

carefully before you install and use the printer.

Pictographic Symbols

This operator manual and printer labels use a variety of pictographic symbols. These symbols show the safe

and correct operation of the printer and how to prevent injury to others and property damage. The symbol

explanations are as follows.

The Warning symbol indicates that

you can cause death or serious

injury if you do not follow the

Warning

Example Pictographs

Place the printer on a stable area.

Do not place containers filled with liquid on the

printer.

instruction or procedure.

The pictograph means “Caution is required”. The pictograph includes a

specified warning symbol (for example, the left symbol shows electric shock).

The pictograph means “Must not be done”. The pictograph includes a specified

prohibited symbol (for example, the left symbol means “Disassembly prohibited”).

The pictograph means “Must be done”. The pictograph includes a specified

mandate action symbol (for example, the left symbol means “Disconnect the

power plug from the outlet”).

• Place the printer on a stable area. Do not

place the printer on an unstable table,

slanted surface or an area subject to

strong vibration. If the printer falls off or

topples, it could cause injury to

someone.

• Do not place flower vases, cups, or other

containers filled with liquids, on the

printer. If any liquid spills into the printer,

immediately power off the printer and

disconnect the power plug from the

outlet. Then contact your SATO reseller

or technical support center. If you

operate the printer in this condition, it

could cause a fire or electric shock.

The Caution symbol indicates that

you can cause injury or property

damage if you do not follow the

Caution

instruction or procedure.

Warning

Do not place objects into the printer.

• Do not place metal or flammable objects

inside the printer’s opening. If a foreign

object gets into the printer, immediately

power off the printer and disconnect the

power plug from the outlet. Then contact

your SATO reseller or technical support

center. If you operate the printer in this

condition, it could cause a fire or electric

shock.

Do not use other than the specified voltage.

• Do not use other than the specified

voltage (AC 100 V - 240 V). Doing so

could cause a fire or electric shock.

CL4NX/CL6NX Operator Manual

8

Page 11

Warning

Before You Start

Always ground connections.

• Always connect the printer’s ground wire

to a ground. Not grounding the ground

wire could cause an electric shock.

Handling the power cord

• Do not break or change the power cord.

Do not place heavy objects on the power

cord, heat it, or pull it. Doing so could

cause damage to the power cord and

cause a fire or electric shock.

• If the power cord becomes damaged

(core is exposed, wires broken, etc.),

contact your SATO reseller or technical

support center. Using the power cord in

this condition could cause a fire or

electric shock.

• Do not change, overly bend, twist, or pull

the power cord. Using the power cord in

such a way could cause a fire or electric

shock.

When the printer has been dropped or broken

• If the printer is dropped or broken,

immediately power off the printer and

disconnect the power plug from the

outlet. Contact your SATO reseller or

technical support center. Using the

printer in this condition could cause a fire

or electric shock.

Do not use the printer when something is

unusual about it.

• Continuing to use the printer in the event

something is unusual about it, such as

smoke or unusual smells coming from it,

could cause a fire or electric shock.

Immediately power off the printer and

disconnect the power plug from the

outlet. Then contact your SATO reseller

or technical support center for repairs.

Under no circumstances should you

attempt repairs on your own; it is too

dangerous.

Do not disassemble the printer.

• Do not disassemble or modify the printer.

Doing so could cause a fire or electric

shock. Contact your SATO reseller or

technical support center to perform

internal inspections, adjustments, and

repairs.

Regarding the cutter

• Do not touch the cutter with your hands,

nor place objects into the cutter. Doing

so could cause an injury.

Using the head cleaning fluid

• Use of flame or heat around the head

cleaning fluid is prohibited. Do not heat it

or subject it to flames.

• Keep the fluid out of reach of children. If

a child accidentally drinks the fluid,

immediately consult with a physician.

Laser beam

• Do not look into the laser radiation

window of the barcode checker, and do

not direct the laser beam at someone. If

the laser beam hits eyes, it may cause

visual disturbance.

Print head

• The print head will become hot after

printing. Be careful not to touch it when

replacing media or cleaning immediately

after printing, to avoid being burned.

• Touching the edge of the print head

immediately after printing could cause an

injury. Use caution when replacing the

media or cleaning the print head.

• Never replace the print head if you have

not received the correct training.

Do not use in hazardous locations.

• The printer is not explosion proof

certified.

• Do not use in a potentially explosive

environment or atmosphere.

CL4NX/CL6NX Operator Manual

9

Page 12

Before You Start

Caution

Do not use in areas of high humidity.

• Do not use the printer in areas of high

humidity or where condensation forms. If

condensation forms, immediately power

off the printer and do not use the printer

until it dries. Using the printer while

condensation is on it could cause an

electric shock.

Carrying the printer

• When moving the printer, always

disconnect the power cord from the

outlet and check to make sure that all

external wires are disconnected before

moving it. Moving the printer with the

wires still connected could cause

damage to the cords or connecting

wires, resulting in a fire or electric shock.

• Do not carry the printer while it contains

media. The media could fall out and

cause an injury.

• When setting the printer on the floor or a

stand, be sure not to get your fingers or

hands pinched under the printer feet.

• Do not carry the printer with the barcode

checker stand installed. The barcode

checker stand could fall out and cause

injury.

Handling the barcode checker stand kit

• Be careful avoid injury from pointed part

of the barcode checker stand kit.

Top cover

• Be careful not to get your fingers pinched

when opening or closing the top cover.

Also, be careful that the top cover does

not slip off and drop.

Loading media

• When loading a media roll, be careful not

to get your fingers pinched between the

media roll and the supply unit.

When not using the printer for a long time

• When not using the printer for a long

time, disconnect the power cord from the

outlet to maintain safety.

During maintenance and cleaning

• When maintaining and cleaning the

printer, disconnect the power cord from

the outlet to maintain safety.

Power supply

• If your hands are wet, do not operate the

power button, connect the power cord or

disconnect the power cord. Doing so

could cause an electric shock.

Power cord

• Keep the power cord away from hot

devices. Placing the power cord near hot

devices could cause the cord’s covering

to melt and cause a fire or electric shock.

• When disconnecting the power cord from

the outlet, be sure to hold the plug.

Pulling the cord could expose or break

the wires and cause a fire or electric

shock.

• The power cord set that comes with the

printer is designed especially for this

printer. Do not use it with any other

electrical devices.

CL4NX/CL6NX Operator Manual

10

Page 13

Before You Start

Place the printer on a surface that is flat and level.

If the surface is not flat and level, this may cause bad

print quality. This may also cause a malfunction and

decrease the life span of the printer.

Do not place the printer on a location that

produces vibration.

Giving serious vibration or shock to the printer may

cause a malfunction and shorten the life span of the

printer.

Keep the printer out of high temperature and

humidity.

Avoid locations subject to extreme or fast changes in

temperature or humidity.

Do not place the printer in a location subject to

water or oil.

Do not place the printer in a location where it will be

exposed to water or oil. Water or oil entering inside

the printer may cause a fire, electric shock or

malfunction.

Avoid dust.

Dust build up may result in bad print quality.

Keep out of direct sunlight.

This printer has a built-in optical sensor. Exposure to

direct sunlight will make the sensor less responsive

and may cause the media to be sensed incorrectly.

Close the top cover when printing.

This printer requires an AC power supply.

Be sure to connect the printer to an AC power

supply.

Connect the power cord to a grounded power

outlet.

Make sure that the printer is connected to a

grounded power outlet.

Supply a stable source of electricity to the printer.

When using the printer, do not share its power outlet

with other electrical devices that could cause power

fluctuations and performance issues with your

printer.

Precautions for Installation and Handling

Printer operation can be affected by the printer environment.

Refer to the following instructions for installation and handling of the CL4NX/CL6NX printer.

Select a Safe Location

Power Supply

CL4NX/CL6NX Operator Manual

11

Page 14

Before You Start

Regulatory Approval

FCC Warning

You are cautioned that changes or modifications not expressly approved by the party responsible for

compliance could void your authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Shielded cable must be used in order to comply with the emission limits.

FCC Statement for Optional Wireless LAN

This device complies with RF radiation exposure limits set forth for an uncontrolled environment.

The antenna used for this transmitter must be installed to provide a separation distance of at least 20 cm

from all people and must not be collocated or operating in conjunction with any other antenna or

transmitter.

Bluetooth/Wireless Communication

Compliance Statement

This product has been certified for compliance with the relevant radio interference regulations of your

country or region. To make sure continued compliance, do not:

• Disassemble or modify this product.

• Remove the certificate label (serial number seal) affixed to this product.

Use of this product near microwave and/or other wireless LAN equipment, or where static electricity or

radio interference is present, may shorten the communication distance, or even disable communication.

CL4NX/CL6NX Operator Manual

12

Page 15

Before You Start

Industry Canada (IC) Statement for Bluetooth

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions:

• This device may not cause interference.

• This device must accept any interference, including interference that may cause undesired operation

of the device.

This equipment complies with IC radiation exposure limits set forth for an uncontrolled environment and

meets RSS-102 of the IC radio frequency (RF) Exposure rules. This equipment should be installed and

operated keeping the radiator at least 20 cm or more away from person’s body (excluding extremities:

hands, wrists, feet and ankles).

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts

de licence. L’exploitation est autorisée aux deux conditions suivantes :

• L’appareil ne doit pas produire de brouillage.

• L’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

Cet équipement est conforme aux limites d’exposition aux rayonnements énoncées pour un

environnement non contrôlé et respecte les règles d’exposition aux fréquences radioélectriques (RF)

CNR-102 de l’IC. Cet équipement doit être installé et utilisé en gardant une distance de 20 cm ou plus

entre le dispositif rayonnant et le corps (à l’exception des extrémités : mains, poignets, pieds et

chevilles).

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union

and other European countries with separate collection systems)

A product marked with this symbol on itself or on its packaging shall not be treated as

household waste. Instead, it shall be handed over to an appropriate collection point for

the recycling of electrical and electronic equipment in accordance with local regulations.

Inappropriate waste handling of this product may cause detrimental consequences for

the environment and damage to human health. The recycling of materials will help to

conserve natural resources and contribute to your community. For more detailed

information on recycling of this product, contact your local municipal organization, your

household waste disposal service or the dealer where you purchased the product.

EN55022 Warning

This is a class A product.

In a domestic environment, this product may cause radio interference, in which case the user may be

required to take adequate measures.

EN55022 Warnung

Warnung! Dies ist eine Einrichtung der Klasse A.

Diese Einrichtung kann im Wohnbereich Funkstörungen verursachen. In diesem Fall kann vom Betreiber

verlangt werden, angemessene Maßnahmen durchzuführen.

Das Gerät ist nicht für die Benutzung im unmittelbaren Gesichtsfeld am Bildschirmarbeitsplatz

vorgesehen. Um störende Reflexionen am Bildschirmarbeitsplatz zu vermeiden, darf dieses Produkt

nicht im unmittelbaren Gesichtsfeld platziert werden.

CL4NX/CL6NX Operator Manual

13

Page 16

Before You Start

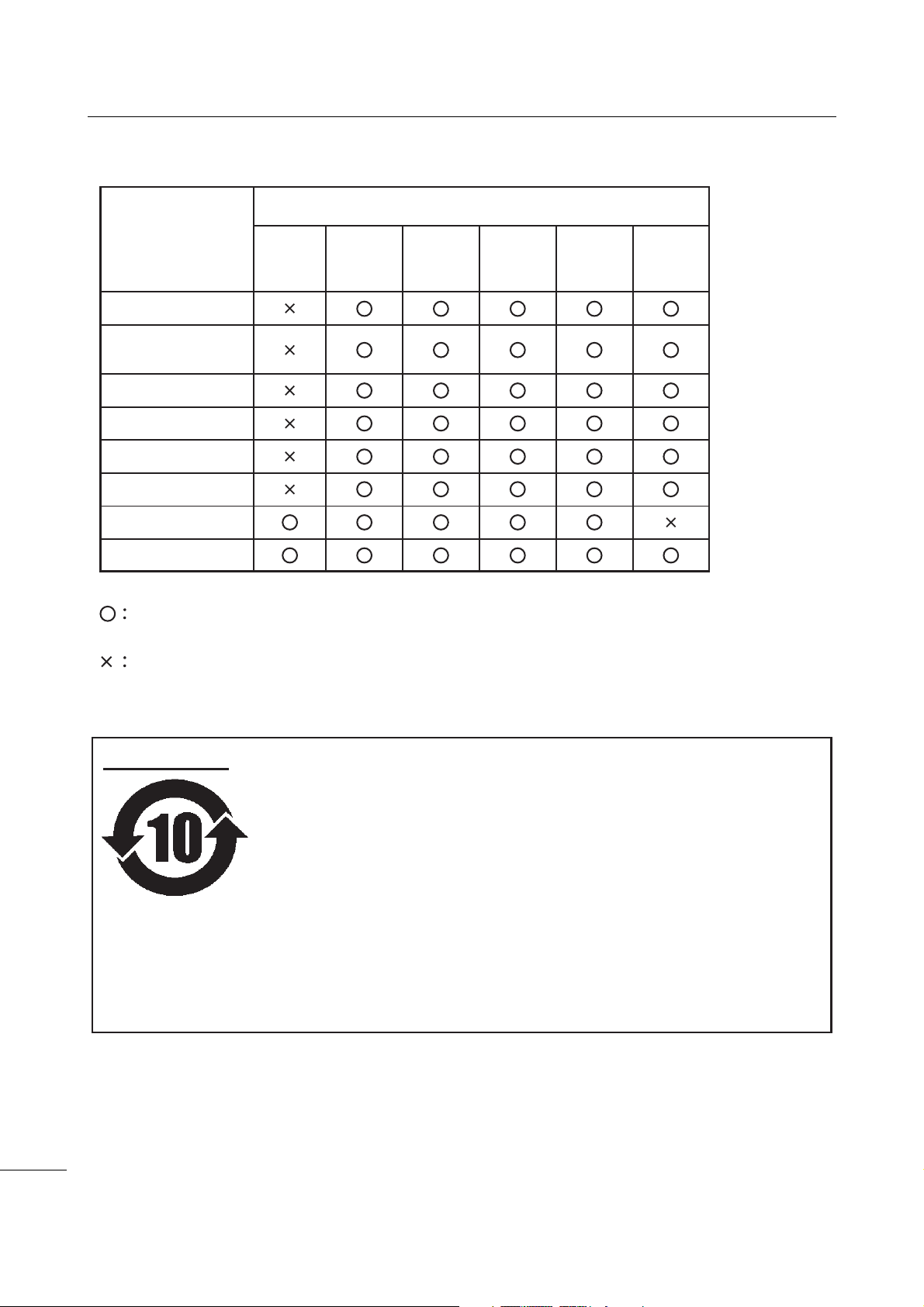

㺞⽰䈛ᴿ∈ᴿᇩ⢟䍞㠩ቇ൞䈛䜞ԬⲺḆжൽ䍞ᶆѣⲺ䠅䎻࠰

GB/T 26572ć⭫ᆆؗᚥӝѣᴿ∈ᴿᇩ⢟䍞Ⲻ䲆䠅㾷≸ĈⲺḽ㿺ᇐȾ

(Pb)

(Hg)

ᵰಞ〦ᶗ⸷ᢉদᵰ

䜞Ԭ〦

ᴿ∈ᴿᇩ⢟䍞ᡌݹ㍖

䫻⊔

দ⭫䐥ᶵ

(Cd)

䭿

(Cr6+)

ޣԭ䬢

(PBB)

ཐ⓪㚊㤥

(PBDE)

ཐ⓪ӂ

㤥䟐

⭫ⓆȽӚ⍷䖢ᦘಞ

⭫⊖

✣ᮅཪ

Ƚ

⏨Წᱴ⽰ኅ

⭫ࣞᵰ

Ƚ

࠽㓮ᵰ

ṇ㜸ABS

Ƚ

PCㅿ

䠇ኔ䫷

Ƚ

䶔䫷䠇ኔ

⭫㔼ㅿ

㻻ᶆᯏ㓮ⴈㅿ

㺞⽰䈛ᴿ∈ᴿᇩ⢟䍞൞䈛䜞Ԭᡶᴿൽ䍞ᶆѣⲺ䠅ൽ൞

GB/T 26572 ć⭫ᆆؗᚥӝѣᴿ∈ᴿᇩ⢟䍞Ⲻ䲆䠅㾷≸ĈⲺḽ㿺ᇐԛсȾ

ᵢ㺞ṲדᦤSJ/T 11364Ⲻ㿺ᇐ㕌Ⱦ

ᵢḽᘍѣⲺᒪᮦθᱥṯᦤ2006ᒪ2ᴾ28ᰛޢᐹⲺć⭫ᆆؗᚥӝ⊗ḉ䱨↘㇗⨼

ࣔ⌋ĈૂSJ/T11364ćӝ⊗ḉ䱨↘ḽ䇼㾷≸Ĉθ䘸⭞ӄ൞ѣӰ≇ާૂളδ

䲚⒴Ƚ俏⑥ૂ◩䰞ཌε⭕ӝᡌ䘑Ⲻ⭫ᆆؗᚥӝⲺć⧥ֵؓ⭞ᵕ䲆ĈȾ൞

䚫ᆾֵ⭞䈪᱄Ҝѣ䇦䖳Ⲻᴿީᵢӝᆿޞૂֵ⭞рⲺ⌞ᝅӁ亯Ƚъ⋗ᴿެԌ⌋

ᗁૂ㿺ᇐⲺރ䍙Ӂ⭧Ⲻ߫сθ൞Ԅ⭕ӝᰛᔶခⲺр䘦ᒪ䲆θӝⲺᴿ∈Ƚ

ᴿᇩ⢟䍞ᡌݹ㍖уՐ⭕ཌ⋺ᡌシθֵ⭞䈛ӝуՐሯ⧥ູ䙖ᡆћ䠃⊗ḉᡌ

ሯֵ⭞㘻Ӱ䓡Ƚ䍘ӝ䙖ᡆћ䠃ᦕᇩȾ

ć⧥ֵؓ⭞ᵕ䲆Ĉуᱥᆿޞֵ⭞ᵕ䲆Ⱦቚެуӄะӄ⭫≊ᙝ㜳ᆿޞȽ⭫ᆿޞㅿഖ㍖㙂㻡䲆

ᇐⲺֵ⭞ᵕ䲆Ⱦӝ൞㔅䘸ᖉֵҾԛᓕᔹᰬᑂᵑד➝ᴿީ⭫ᆆؗᚥӝⲺഔ᭬ૂ߃⭞

Ⲻ⌋ᗁф㿺ᇐ䘑㺂༺⨼Ⱦ

⌞1):

ᵢḽᘍѣⲺᒪᮦѰć⧥ֵؓ⭞ᵕ䲆ĈθуᱥӝⲺ䍞䠅ؓ䇷ᵕ䲆Ⱦሯӄж㻻⭫⊖Ƚ

ݻ⭫ಞㅿ䱺ኔⲺӝθӝૂ䱺ኔⲺ⧥ֵؓ⭞ᵕ䲆㜳уȾ

⌞2):

⧥ֵؓ⭞ᵕ䲆

CL4NX/CL6NX Operator Manual

14

Page 17

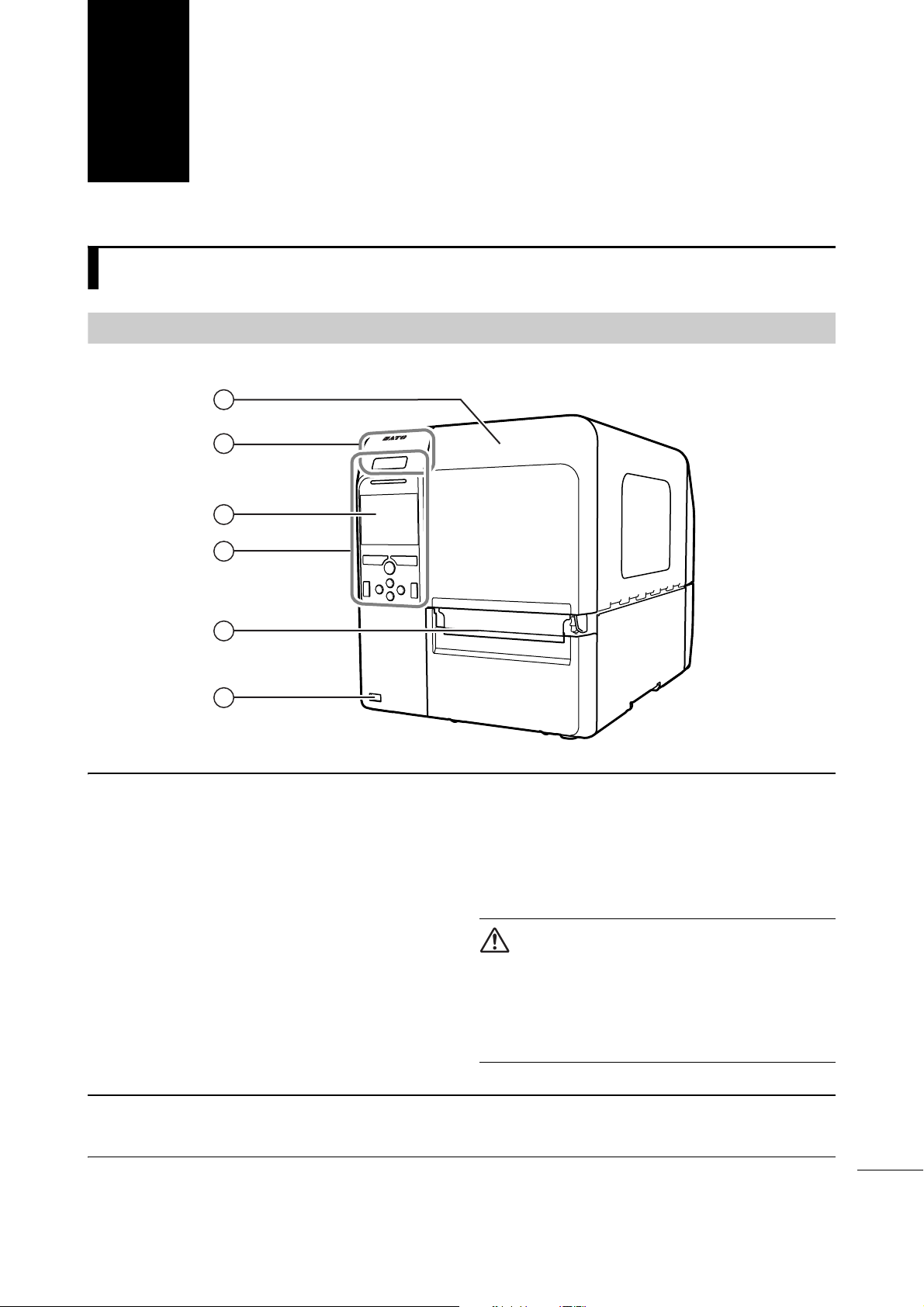

1

1

5

6

3

4

2

q

Top cover

w

NFC antenna location

*This feature is supported on printers from

serial number 6B~ and above.

e

Color LCD

r

Operator panel

t

Media discharge outlet

y

USB connector (Type A)

Enable the storage of printer setting

information with USB memory and for

connecting other devices like a barcode

checker, barcode scanner or a keyboard.

CAUTION

Be sure to perform a virus check for the USB

memory before connecting it to the printer. SATO

Corporation shall not be held responsible for any

printer malfunctions caused by a virus spread via

USB memory.

Parts Identification

1.1

1.1.1

Parts Identification of the Printer

Front View

Note

The pictures in this manual show the CL4NX unless otherwise stated.

CL4NX/CL6NX Operator Manual

15

Page 18

1 Parts Identification

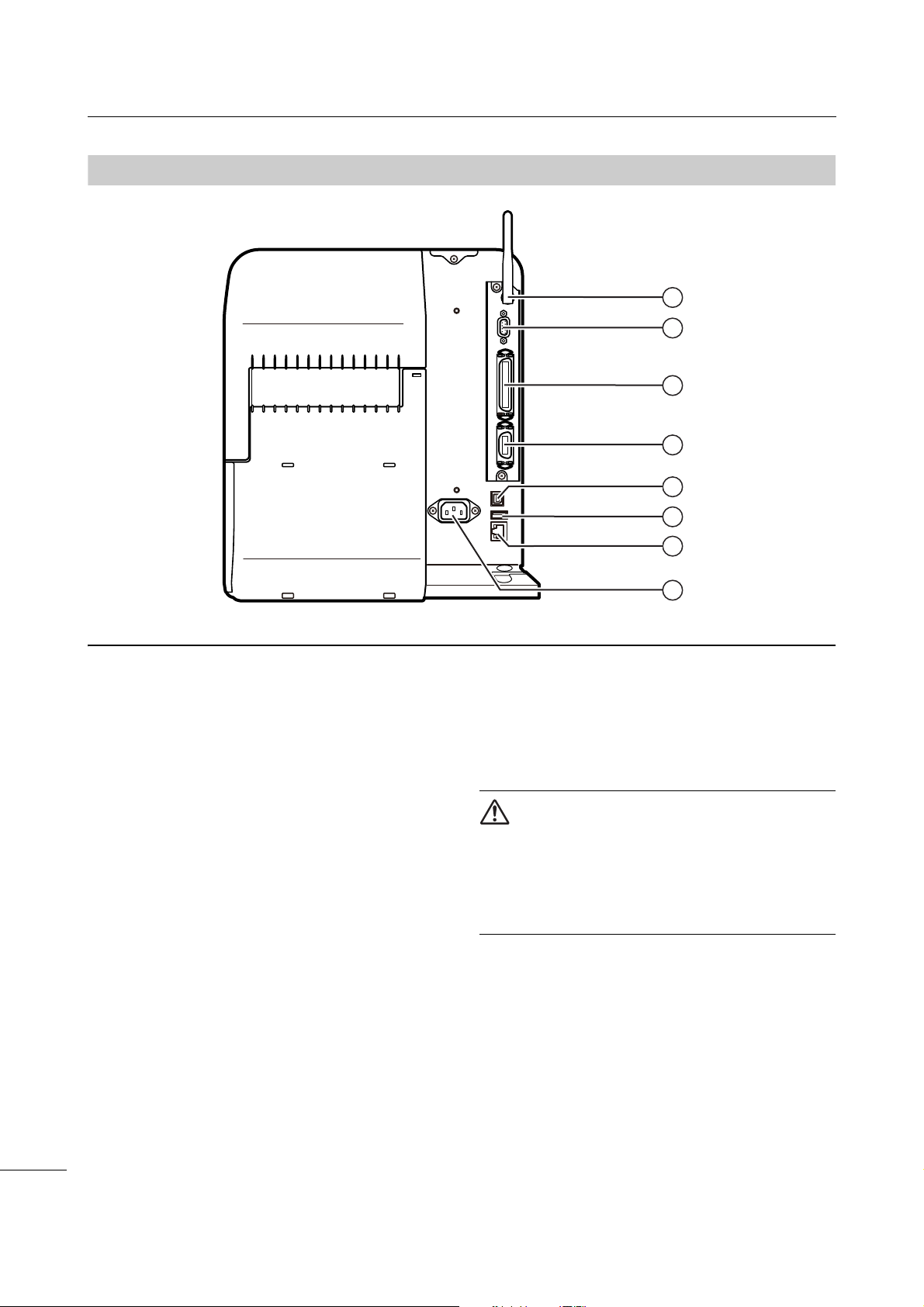

14

9

10

7

8

11

12

13

u

Wireless LAN antenna (optional)

Connector for installation of optional wireless

LAN antenna.

i

RS-232C connector

To connect the printer to the computer using

the RS-232C serial interface.

You can also connect a barcode checker.

Usage of the RS-232C interface can be

selected in the Interface > RS-232C >

Interface menu.

o

IEEE1284 connector

To connect the printer to the computer using

the IEEE1284 interface.

a

EXT connector (External signal

interface)

Interface connector for external signals.

Connect an optional device to this terminal.

s

USB connector (Type B)

To connect the printer to the computer using

the USB interface.

d

USB connector (Type A)

Enable the storage of printer setting

information with USB memory and for

connecting other devices like a barcode

checker, barcode scanner or a keyboard.

CAUTION

Be sure to perform a virus check for the USB

memory before connecting it to the printer. SATO

Corporation shall not be held responsible for any

printer malfunctions caused by a virus spread via

USB memory.

f

LAN connector

To connect printer to the network using the

LAN interface.

g

AC input terminal

Supplies power to the printer through the

inserted power cord.

Before connecting, make sure that the AC

voltage of your region is in the range of AC 100

to 240 V, 50 to 60 Hz.

1.1.2

Rear View

CL4NX/CL6NX Operator Manual

16

Page 19

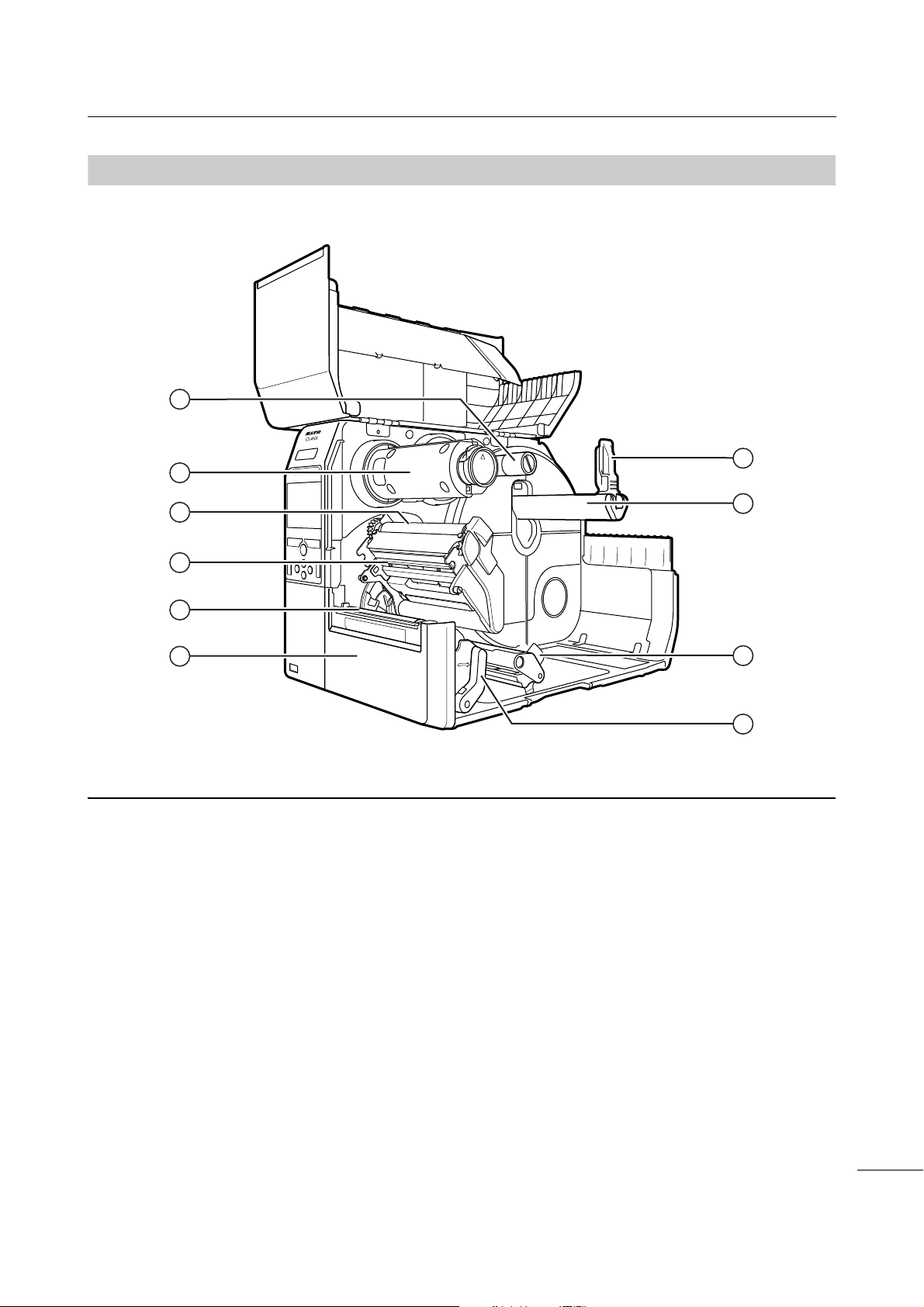

1 Parts Identification

15

18

20

16

19

24

23

21

22

17

h

Ribbon supply spindle

j

Ribbon rewind spindle

k

Ribbon roller

l

Print head (Consumables)

Creates an image directly on the media or by

using a ribbon. Highest print quality is achieved

when regular maintenance is performed.

;

Platen roller (Consumables)

2)

Front cover

2!

Media holder guide

Used to hold the media roll.

2@

Media roll holder

Hang the media roll to the bar.

2#

Media guide

2$

Head lock lever

Used to release the print head assembly.

1.1.3

Internal View

CL4NX/CL6NX Operator Manual

17

Page 20

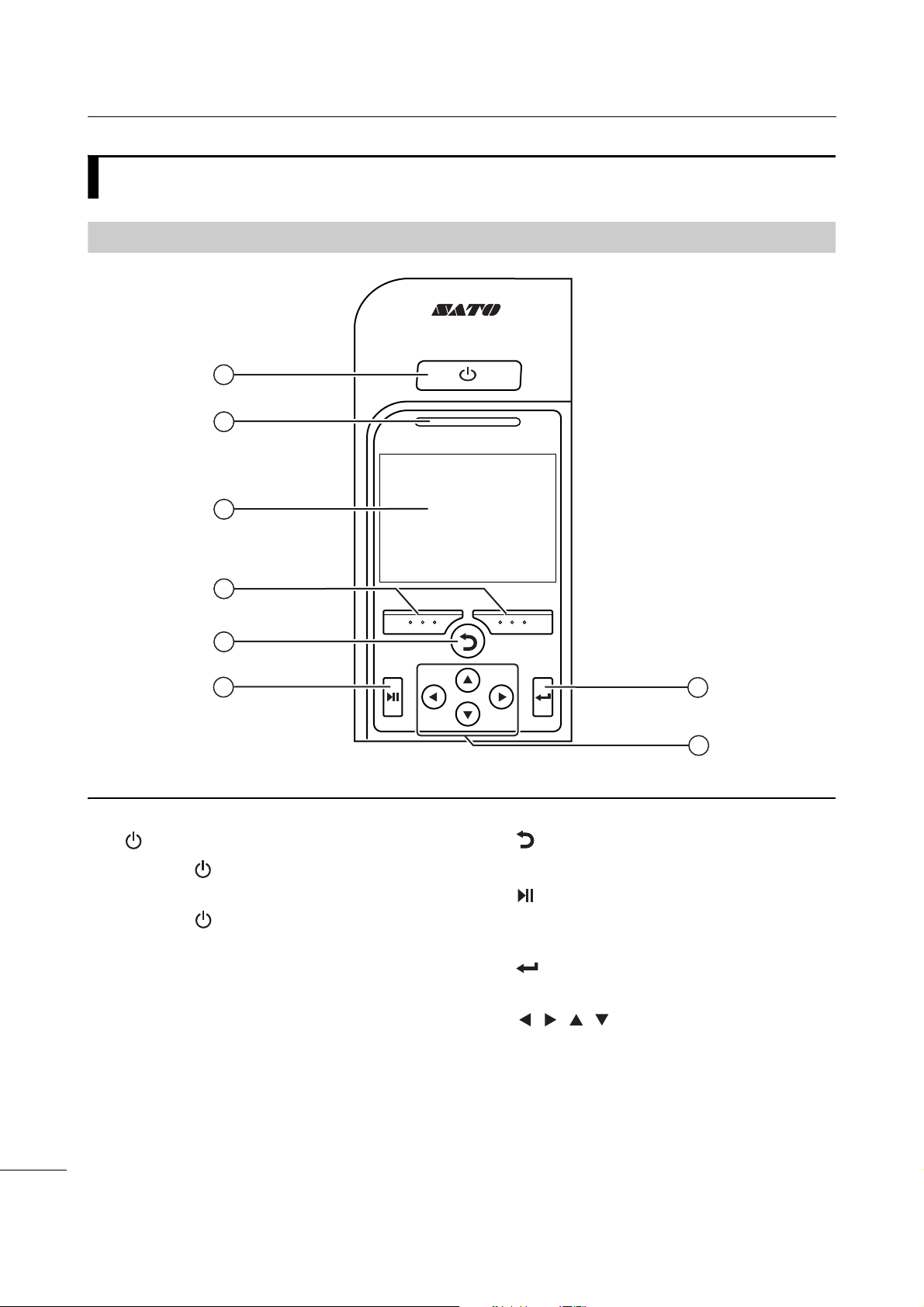

1 Parts Identification

1

5

2

3

6

7

8

4

q

Power button

Press the power button until the LED lights

up in blue to power on the printer.

Press the power button for more than two

seconds to power off the printer.

w

LED indicator

e

Color LCD

r

Soft buttons

The functions change depending on the

screen. The functions of the buttons are

indicated on the bottom of the screen.

(For example, when in offline mode, left soft

button: ONLINE; right soft button: FEED)

t

Back button

Returns to the previous screen.

y

Line button

Toggle between online/offline mode or

playback/pause the video.

u

Enter button

Confirm the selected item or setting value.

i

/ / / Arrow buttons

Navigate the selection in the screen menu.

1.2

1.2.1

Parts on the Operator Panel

Operator Panel

18

CL4NX/CL6NX Operator Manual

Page 21

1 Parts Identification

1.2.2

Flashes at intervals of two

seconds.

LED Indicator

LED Indicator Color Description

Blue Online mode

(Light off) Power off or offline mode

Red Printer error (For example, when the ribbon runs out)

Blue Sleep mode (energy saving mode)

Note

• If the printer enters sleep mode during a printer error status (LED lights red), the LED indicator will flash blue

at intervals of two seconds.

• By default, the printer goes into sleep mode after 60 minutes of inactivity. Refer to Section 4.4.5 System

Menu to change the period before the printer enters sleep mode.

CL4NX/CL6NX Operator Manual

19

Page 22

1 Parts Identification

This page is intentionally left blank.

CL4NX/CL6NX Operator Manual

20

Page 23

2

Installing the Printer

2.1

Install this printer in a location as follows:

• A location that is horizontal and stable.

• A location that has sufficient space for operating the printer.

Do not install this printer in a location as follows. Doing so could cause the printer to malfunction.

• A location that is subject to vibration.

• A location with high temperature and humidity.

• A dusty location.

• A location exposed to direct sunlight.

• A location with a lot of electrical noise.

• A location with a large fluctuation in power.

• A location with an explosive atmosphere (flammable gas or vapor).

Installation Precautions

CL4NX/CL6NX Operator Manual

21

Page 24

2 Installing the Printer

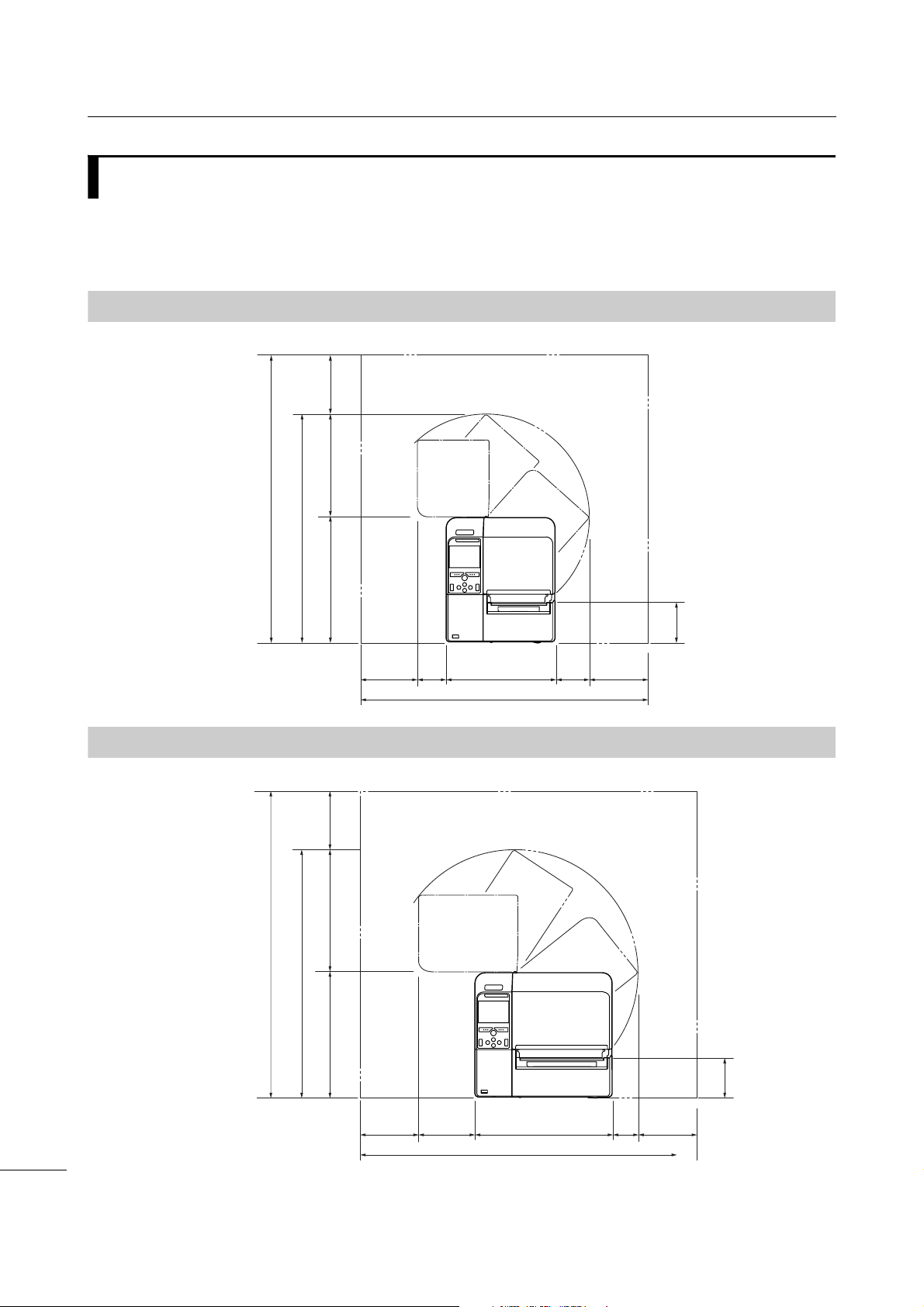

737 mm (29”)

271 mm

(10.7”)

83

mm

(3.3”)

83

mm

(3.3”)

150 mm

(5.9”)

150 mm

(5.9”)

729 mm (28.7”)

321 mm (12.6”)

150 mm

(5.9”)

258 mm (10.2”)

579 mm (22.8”)

Standard model

111 mm

(4.4”)

853 mm (33.6”)

337.5 mm

(13.3”)

150 mm

(5.9”)

778 mm (30.6”)

321 mm (12.6”)

150 mm

(5.9”)

307 mm (12.1”)

628 mm (24.7”)

Standard model

150 mm

(5.9”)

150 mm

(5.9”)

65.5

mm

(2.6”)

111 mm

(4.4”)

2.2

Installation Space

Make sure that there is sufficient space around the printer so that the top cover can be fully opened

when operating or cleaning the printer, or replacing consumables.

2.2.1

Front View (CL4NX)

2.2.2

Front View (CL6NX)

CL4NX/CL6NX Operator Manual

22

Page 25

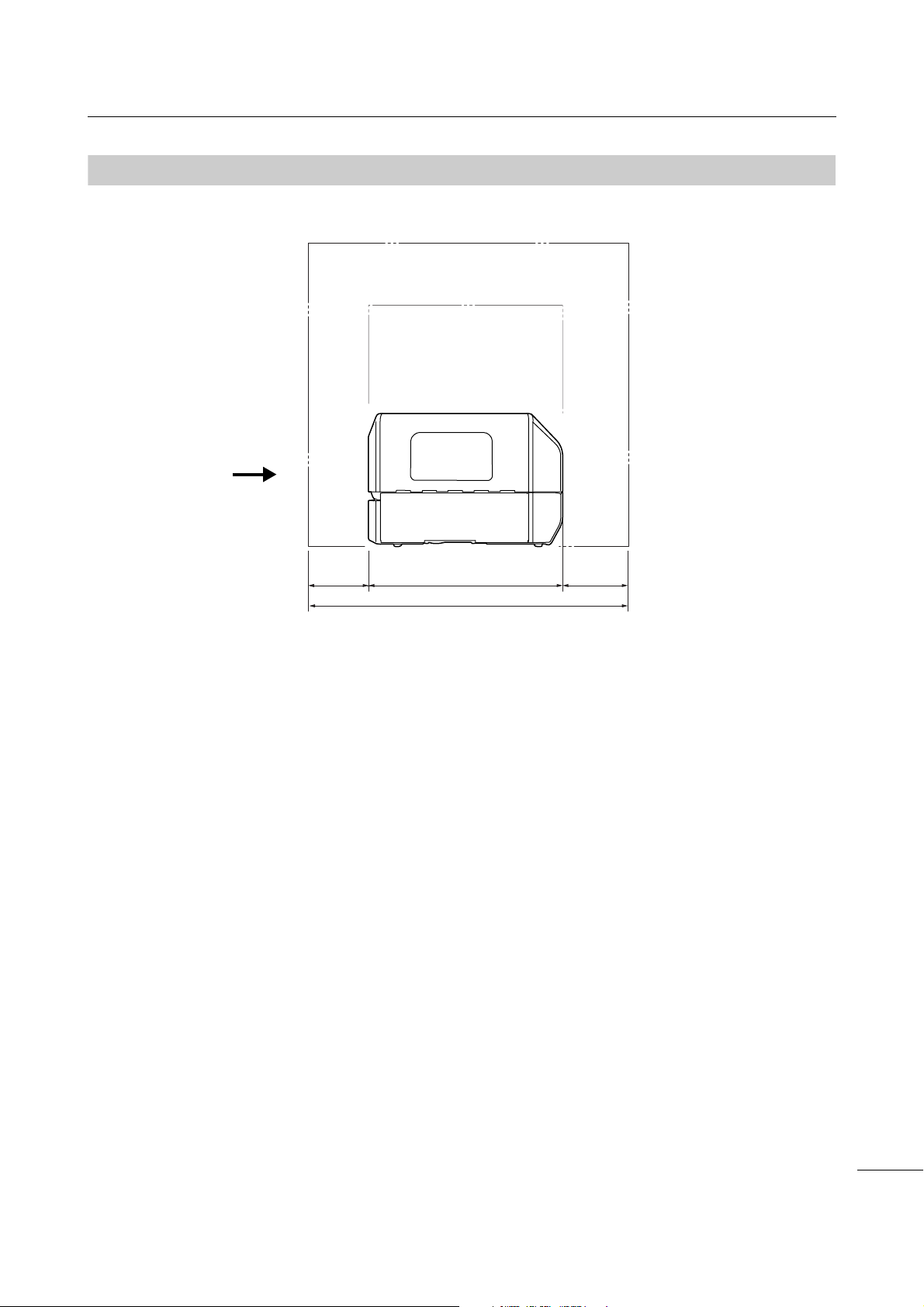

2 Installing the Printer

757 mm (29.8”)

457 mm

(18.0”)

150 mm

(5.9”)

150 mm

(5.9”)

Printer front view

2.2.3

Side View (CL4NX/CL6NX)

Make sure that there is sufficient space on the rear side of the printer so that no stress is applied to the

power cord or cables connected to the printer.

CL4NX/CL6NX Operator Manual

23

Page 26

2 Installing the Printer

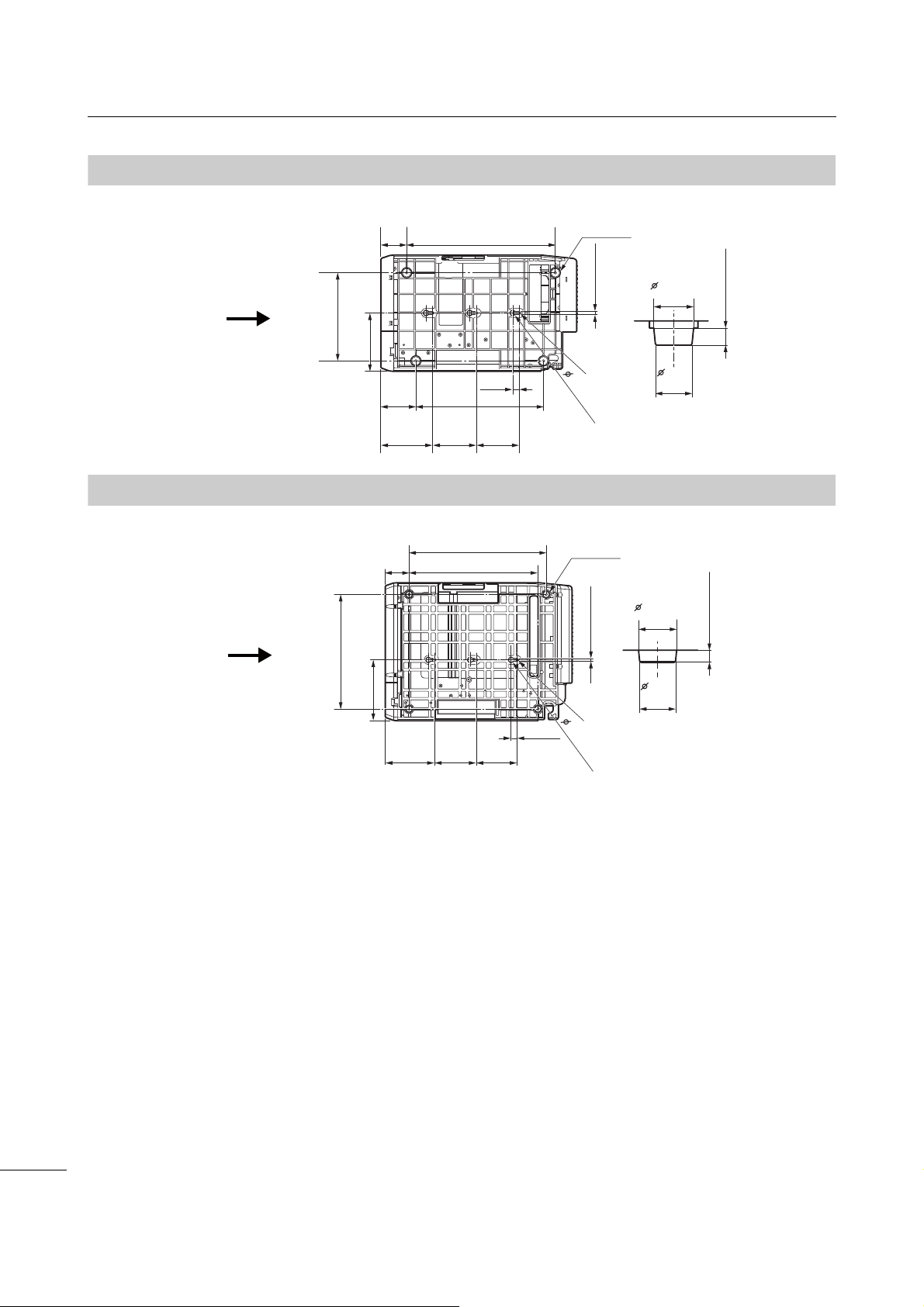

135.9 mm

(5.4”)

6 mm (0.2”)

120.4 mm

(4.7”)

102 mm

(4.0”)

100 mm

(3.9”)

15 mm (0.6”)

R3

13 mm (0.5”)

60 mm

(2.4”)

346.4 mm (13.6”)

205.6 mm

(8.1”)

297.5 mm

(11.7”)

81.5 mm

(3.2”)

8.5 mm (0.3”)

19.7 mm

(0.8”)

18 mm

(0.7”)

Rubber foot

Printer front view

6.2 mm (0.2”)

19.2 mm

(0.8”)

18 mm

(0.7”)

148.5 mm

(5.8”)

6 mm (0.2”)

120.4 mm

(4.7”)

102 mm

(4.0”)

100 mm

(3.9”)

15 mm (0.6”)

R3

13 mm

58.4 mm

(2.3”)

315 mm (12.4”)

280 mm (11.0”)

Rubber foot

2.2.4

2.2.5

Bottom View (CL4NX)

Bottom View (CL6NX)

335 mm (13.1”)

Printer front view

(0.5”)

24

CL4NX/CL6NX Operator Manual

Page 27

2 Installing the Printer

User documents

(Quick guide, Warranty, etc.)

AC power cord*

* The shape of power plug varies depending on the region in which it was purchased.

2.3

After unpacking the printer, make sure that you have all the bundled accessories: if there are any

missing items, contact the SATO reseller where you purchased the printer.

Checking the Bundled Accessories

Note

Keep the packaging box and cushioning material after installing the printer. You can pack the printer with this

packaging box for shipment when requesting for repairs.

CL4NX/CL6NX Operator Manual

25

Page 28

2 Installing the Printer

2.4

The connection of the interface cable is explained as follows:

2.4.1

This printer supports the following interfaces.

A printer connected with multiple interface cables can continue to operate when receiving data.

However, you cannot receive data from more than one interface at a time. Normally, do not use multiple

interfaces at a time.

The printer prints the received data in the reception order. The next received data is stored in the receive

buffer while the first data is printed.

• NFC (front side)

*This feature is supported on printers from serial

number 6B~ and above.

•USB

•LAN

• Bluetooth

• RS-232C

• IEEE1284

• External signal (EXT)

• Wireless LAN

Connecting the Interface Cable

Available Interfaces

Note

• The wireless LAN interface is optional.

• The NFC interface supports the handover function that simplifies the Bluetooth/Wi-Fi connection setup with

Android devices. For details, refer to Section 2.4.3 NFC Interface Connection.

In addition, the NFC interface can be used for changing printer settings with an Android device while the

printer is powered off and the power cord is not connected.

CAUTION

Do not connect or disconnect the interface cables (or use a switch box) with power supplied to either the

printer or computer. This may cause damage to the interface circuitry in the printer or computer and is not

covered by warranty.

CL4NX/CL6NX Operator Manual

26

Page 29

2 Installing the Printer

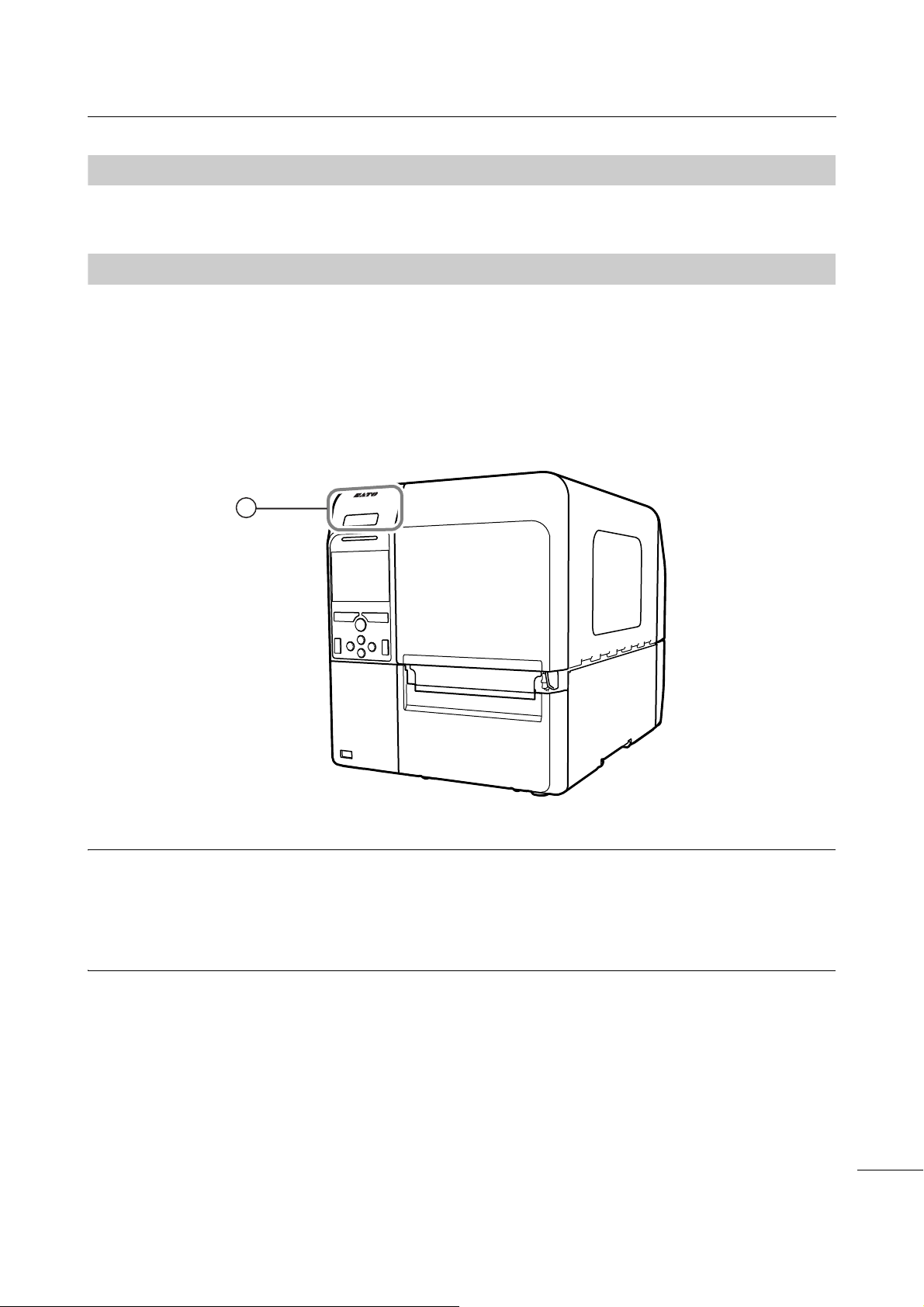

1

2.4.2

You can set the various interface settings of the printer through Interface in the Settings menu. For

details, refer to Interface in chapter 4 Operation and Configuration.

2.4.3

The NFC interface of the printer supports a handover function that simplifies the Bluetooth/Wi-Fi

connection setup with Android devices.

The handover function only performs the connection setup, such as the pairing and authentication with

NFC, and passes the actual interface to the more advanced Bluetooth and Wi-Fi when communicating

between NFC supported devices. In general, the pairing and authentication require some procedures to

enter authentication information, but the connection can be completed simply by holding the Android

devices over the printer while using NFC.

Touch the NFC antenna

Interface Settings

NFC Interface Connection

q of the printer with the NFC mark on the Android device.

Note

• This feature is supported on printers from serial number 6B~ and above.

• If it does not communicate well, shift the Android device to the front, back, left and right, and then hold it up

again.

• For the operation of the NFC for the Android device, refer to the user manual for the Android device.

CL4NX/CL6NX Operator Manual

27

Page 30

2 Installing the Printer

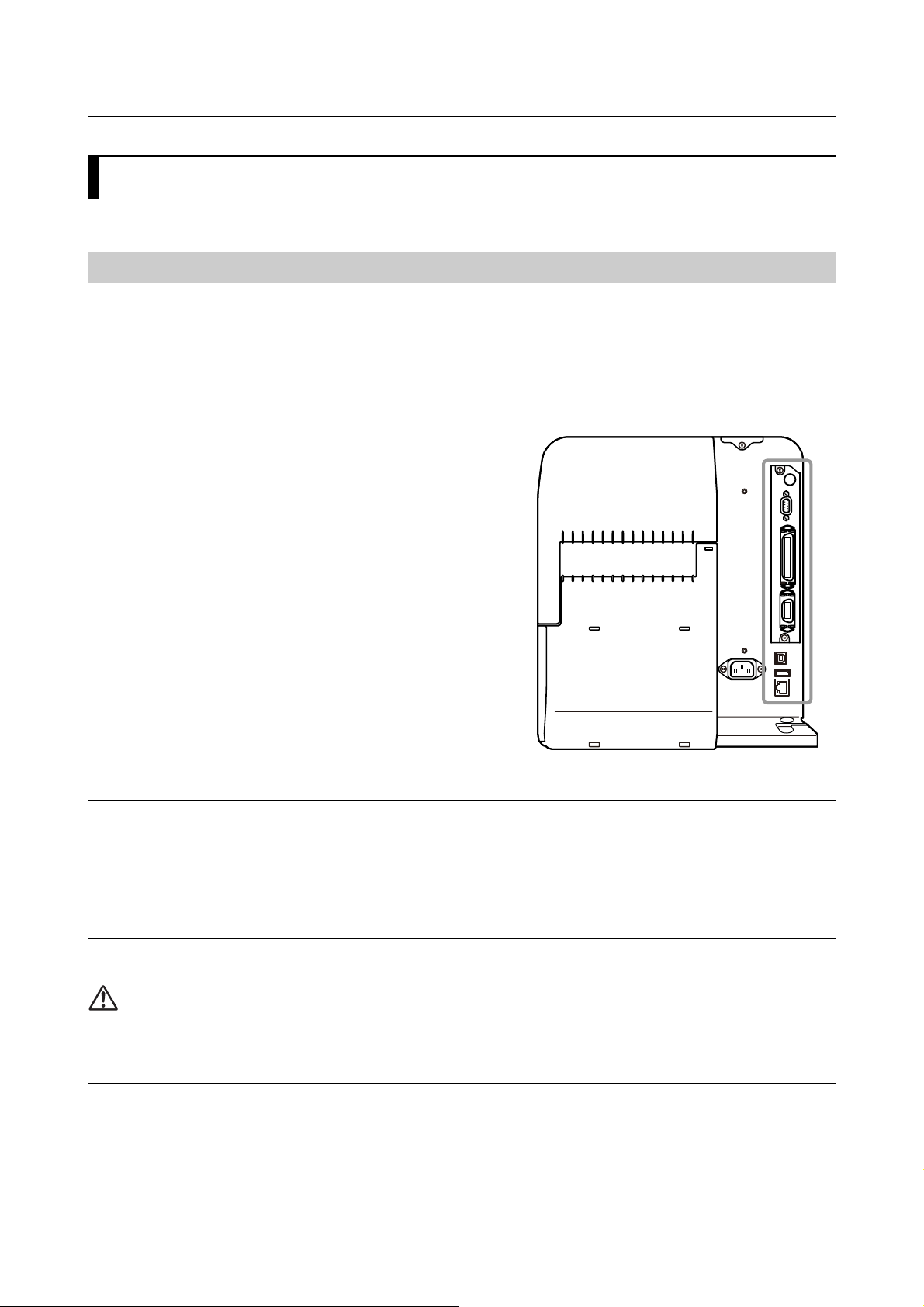

1

*

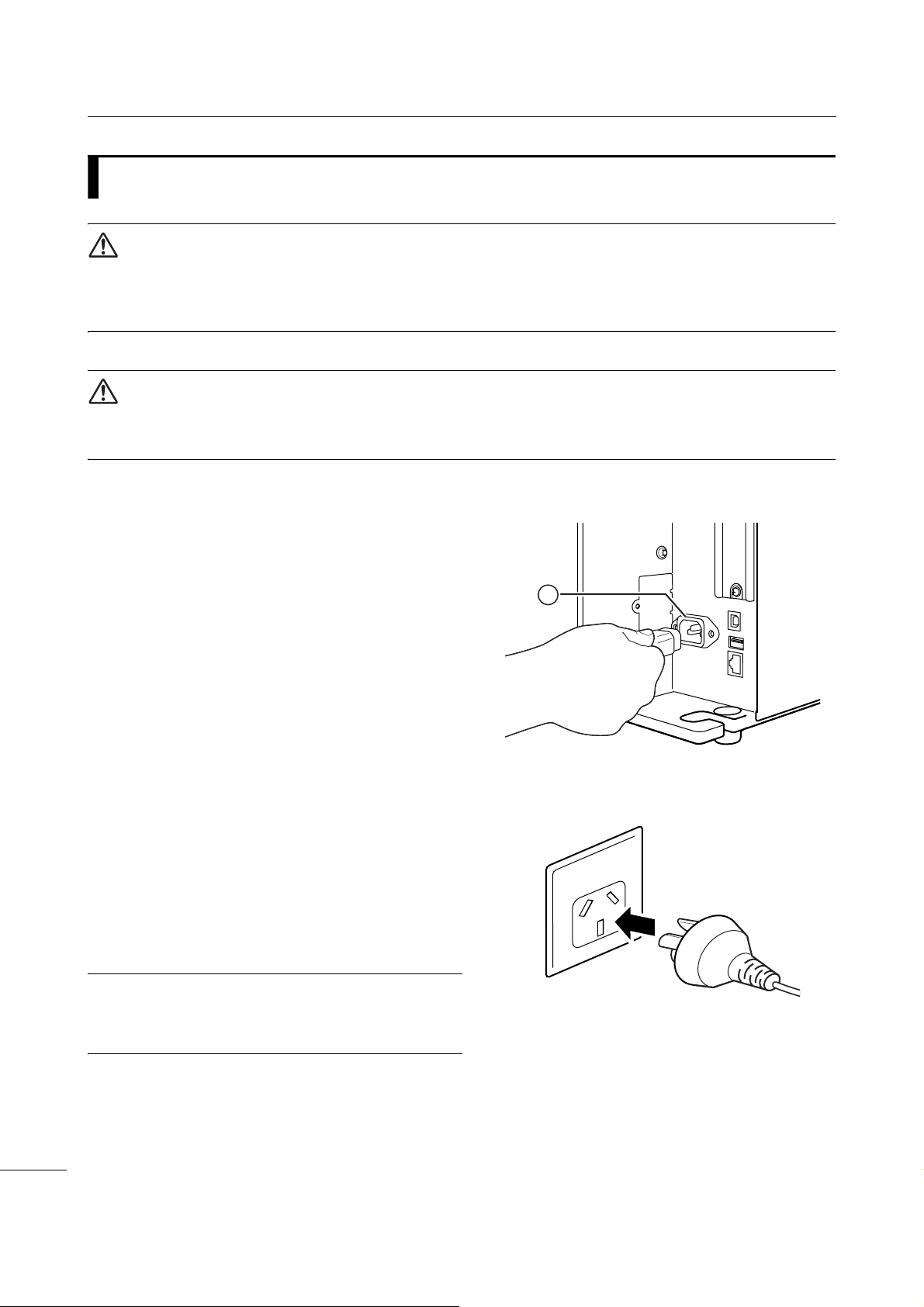

2.5

WARNING

• Do not touch the power button, connect or disconnect the power cord while your hands are wet. Doing so

could cause an electric shock.

• Always connect the ground wire to a ground terminal. Electric shock could occur if you do not.

CAUTION

• The attached power cord is designed exclusively for this printer.

• Do not use the attached power cord with other devices.

Connecting the Power Cord

1 Connect the power cord to the AC input

terminal q at the rear of the printer.

Take note of the orientation of the connector.

Secure the printer with one hand, and insert the

connector tightly.

2 Insert the power plug into an AC outlet.

Make sure that the AC voltage of your region is in

the range of AC 100 - 240 V, 50 - 60 Hz. If your

local voltage is not in the stated range, contact

your SATO reseller or technical support center.

*The shape of the power plug varies depending

on the region in which it was purchased.

Note

This product is also designed for IT power distribution

system with phase-to-phase voltage 230 V.

CL4NX/CL6NX Operator Manual

28

Page 31

2 Installing the Printer

2.6

WARNING

Do not touch the power button, connect or disconnect the power cord while your hands are wet. Doing so

could cause an electric shock.

CAUTION

An incorrect power on/off operation may damage the printer settings. In such a case, the printer settings are

reset to their default values. It is always recommended to use the power button to allow proper shutdown of

the printer and ensure changes made to menu settings are saved appropriately.

Note

You can power on/off the printer from the main power source by enabling Start on AC under the System

menu.

2.6.1

Power On/Off the Printer

Power On the Printer

1 Press the power button on the

operator panel until the LED lights up in

blue to power on the printer.

2 Online shows on the screen.

CL4NX/CL6NX Operator Manual

29

Page 32

2 Installing the Printer

2.6.2

• Do not power off the printer during operation, such as when printing or updating. Doing so could cause a

malfunction of the printer.

• Do not disconnect the power cord until the powering off process is completed on the printer.

Power Off the Printer

CAUTION

1 Make sure that the printer is in offline

mode before you power off.

If Online shows on the screen, press the

button to change to offline mode.

2 Press the power button for more

than two seconds to power off the

printer.

CL4NX/CL6NX Operator Manual

30

Page 33

2 Installing the Printer

2.7

When you power on the printer for the first time after purchase, the display shows the startup guide. The

startup guide is a function to help you through the initial printer configuration, such as setting date and

time, and loading the ribbon and media.

You can cancel the startup guide and perform the configuration later from the menu.

*If you have installed the optional RTC (Real Time Clock) kit, the time zone, date and time setting

screens show.

2.7.1

The startup screen shows when you first power on

the printer.

Starting Up the Printer (Startup Guide)

Startup Screen

2.7.2

Select the display language.

Select the language name using the /

buttons, then press the right soft button or

button to confirm.

Language Selection

CL4NX/CL6NX Operator Manual

31

Page 34

2 Installing the Printer

2.7.3

Set the region (time zone).

Select the region using the / buttons, then

press the right soft button or button to confirm.

2.7.4

Set the city (time zone).

Select the city using the / buttons, then press

the right soft button or button to confirm.

Region Setting with Optional RTC

City Setting with Optional RTC

2.7.5

Set the date.

Select the current value using the / buttons,

and move the cursor using the / buttons.

When you have completed the date setting, press

the right soft button or button to confirm.

Date Setting with Optional RTC

CL4NX/CL6NX Operator Manual

32

Page 35

2 Installing the Printer

2.7.6

Set the time.

Select the current value using the / buttons,

and move the cursor using the / buttons.

When you have completed the time setting, press

the right soft button or button to confirm.

Time Setting with Optional RTC

Note

The time is set in 24-hour format.

2.7.7

Set whether to use the ribbon or direct thermal

media to print.

The options are as follows:

• Use Ribbon: Print with a ribbon.

• Direct Thermal: Print using direct thermal

media.

Select the print method using the / buttons,

then press the right soft button or button to

confirm.

Print Method Setting

CL4NX/CL6NX Operator Manual

33

Page 36

2 Installing the Printer

2.7.8

Load the ribbon.

*Shows if you have selected Use Ribbon in the print

method setting.

You can check the setting method of the ribbon

through the video. Press the button to watch the

video.

Press the button to stop the video and return to

the previous screen.

After you complete the ribbon setting, press the right

soft button to go to the next screen.

Ribbon Setting

2.7.9

Set the type of sensor for sensing the media.

The available options will vary depending on the

default print mode of your printer.

The options are as follows:

• None: Disable the media sensor.

• Gap: Use the transmissive type sensor.

• I-Mark: Use the reflective type sensor.

Select the media sensor type using the /

buttons, then press the right soft button or

button to confirm.

Setting the Media Sensor Type

CL4NX/CL6NX Operator Manual

34

Page 37

2 Installing the Printer

2.7.10

Load the media.

You can check the setting method of the media

through the video.

Press the button to select video mode.

Media Setting

Note (for CL4NX only)

When you are using the linerless model, the video is

shown immediately after the button is pressed.

The selection screen of the video for playback

shows. (Not available for linerless model of

CL4NX.)

Select the video to playback using the /

buttons, then press the right soft button or

button to playback the video.

The options are as follows:

The options vary depending on the printer model.

Standard Model and Cutter Model

• Roll: Shows the video on how to load the media

roll.

• Fanfold: Shows the video on how to load the

fan-fold media.

Dispenser Model

• Dispenser: Shows the video on how to eject the

liner out of the printer.

• Rewinder: Shows the video on how to rewind

the liner in the printer.

Press the button to stop the video and return to

the previous screen.

After you complete the media setting, press the

right soft button to go to the next screen.

CL4NX/CL6NX Operator Manual

35

Page 38

2 Installing the Printer

2.7.11

This screen shows when the startup guide

completes.

If you want the startup guide to show the next time

you start up, press the left soft button. If not, press

the right soft button.

When you press one of the soft buttons, the printer

automatically feeds the media (to the print head

position) and enters online mode.

Confirmation Screen

Note

You can enable or disable the startup guide in Startup Guide under the Tools menu.

2.7.12

You can cancel the startup guide at any time.

When you press the left soft button on the setting

screen, the screen to the right shows.

Select whether or not to show the startup guide

during the next startup using the / buttons,

and press the right soft button to confirm.

To cancel and return to the startup guide setting,

press the left soft button.

Startup Guide Cancelation

Note

• You can enable or disable the startup guide in Startup Guide under the Tools menu.

• Even if you cancel the startup guide during play, the printer will save the settings you have changed.

CL4NX/CL6NX Operator Manual

36

Page 39

+

The ink is coated

on the inner side.

(Face-in ribbon)

The ink is coated

on the outer side.

(Face-out ribbon)

Loading the Ribbon and

3

This printer supports two types of print methods, thermal transfer and direct thermal. Thermal transfer

printing transfers the ink of the ribbon to the media. Direct thermal printing creates the image on direct

thermal media. Ribbon is not necessary if you are using direct thermal media.

3.1

There are two wind directions for the ribbon. Face-out means the ink is on the outer side and Face-in

means the ink is on the inner side. This printer supports both wind directions. You can examine the ink

side of the ribbon using the following procedure:

Media

Checking the Ink Side of the Ribbon

1 Place the outer side of the ribbon onto

the media (touching).

2 Scratch the inner side of the ribbon with

your fingernail or a pointed object.

3 If there is a mark on the media, the ink is

coated on the outer side of the ribbon.

CL4NX/CL6NX Operator Manual

37

Page 40

3 Loading the Ribbon and Media

Face-in ribbon

Face-out ribbon

1

3.2

Use genuine SATO media and ribbons for the printer, for optimum print quality.

CAUTION

• The print head and its surroundings are hot after printing. Be careful not to touch it, to avoid being burned.

• Touching the edge of the print head with your bare hand could cause injury.

The routing path of the ribbon is shown in the right

picture.

Loading the Ribbon

Note

You can also refer to the sticker located on the inner side of the top cover.

1 Open the top cover q.

CAUTION

Open the top cover fully to prevent accidental drop of

the cover.

CL4NX/CL6NX Operator Manual

38

Page 41

2 Push the ribbon rewind spindle w all the

2

3

5

4

way in.

If there is any ribbon on the ribbon rewind spindle,

remove it from the spindle before installing new

ribbon.

3 Push the head lock lever e towards the

rear.

3 Loading the Ribbon and Media

4 Load the ribbon r onto the ribbon supply

spindle t.

While taking note of the wind direction, insert the

ribbon all the way in.

CL4NX/CL6NX Operator Manual

39

Page 42

3 Loading the Ribbon and Media

6

5

7

2

7

2

5 From the ribbon supply spindle t, pass

the ribbon below the print head y.

6 Wind the ribbon counterclockwise to the

ribbon rewind spindle w and grip sheet

u.

Turn the ribbon rewind spindle counterclockwise for

several rounds, to wind the ribbon.

7 If the media is already loaded, press the

print head down until the head lock lever

is locked.

If the media is not loaded, continue with Section 3.5

Loading Media.

8 Close the top cover.

CL4NX/CL6NX Operator Manual

40

Page 43

3 Loading the Ribbon and Media

1

3.3

Removing the Ribbon

1 Press the tab q on the tip of the ribbon

rewind spindle to pull it out.

2 Pull to remove the used ribbon from the

ribbon rewind spindle.

3 Push the ribbon rewind spindle all the

way in.

CL4NX/CL6NX Operator Manual

41

Page 44

3 Loading the Ribbon and Media

14 mm

(0.55”)

1.5 mm (0.06”)

I- m a r k journal paper/

linerless label (CL4NX only)

Gap labelI-mark label

3 mm (0.12”)

3 mm

(0.12”)

3 mm

(0.12”)

1.5 mm (0.06”)

14 mm

(0.55”)

3 mm

(0.12”)

Media feed

direction

Media feed

direction

Media feed

direction

3.4

Usable Media

This printer can print on two types of media; media roll and fan-fold media. The printer uses media

sensors to detect I-marks or Gaps on the media in order to precisely print the content.

3.4.1

Adjusting the Position of the Media Sensor

When you use nonstandard media (for example, media with printing on the underside, or media with a

special shape), the media sensor cannot sense the I-mark or Gap of the media correctly. In such a case,

adjust the position of the media sensor to sense the I-mark or Gap correctly.

Adjust the media sensor guide to the position where it

can sense the I-mark or Gap of the media.

The I-mark sensor is below the mark, and the Gap

sensor is below the mark.

42

CL4NX/CL6NX Operator Manual

Page 45

3 Loading the Ribbon and Media

Face-in media

Face-out media

3.5

Use genuine SATO media and ribbons for the printer, for optimum print quality.

CAUTION

• The print head and its surroundings are hot after printing. Be careful not to touch it, to avoid being burned.

• Touching the edge of the print head with your bare hand could cause injury.

3.5.1

The routing path of the media is shown in the right

picture.

When loading the media, make sure that the print side

is facing up.

Loading Media

Loading Media Roll

1 Open the top cover.

CAUTION

Open the top cover fully to prevent accidental drop of

the cover.

2 Push the head lock lever towards the

rear to unlock the print head.

CL4NX/CL6NX Operator Manual

43

Page 46

3 Loading the Ribbon and Media

2

1

3

4

1

5

6

3 Pull the media holder guide q and media

guide w away from the printer.

Turn the knob e counterclockwise to release the

media guide.

4 Load the media in the media holder r.

Make sure that the media roll is all the way

in to inside of the printer.

5 Push the media holder guide q lightly

against the media roll.

6 Pass the media below the media damper

t and media sensor guide y while

pushing the media to inside of the printer.

Make sure that the end of the media extends out the

front of the printer.

CL4NX/CL6NX Operator Manual

44

Page 47

7 Press the print head down until the head

2

3

Load the media from the

rear of the printer.

Load the media from the

bottom of the printer.

lock lever is locked.

8 Press the media guide w lightly against the

end of the media, then turn the knob e to

lock the media guide.

9 Close the top cover.

10

After loading the media and ribbon, perform

a test print to make sure that the media is

loaded correctly.

Refer to the Test Print menu in Section 4.4.6 Tools

Menu for details on how to perform a test print.

3 Loading the Ribbon and Media

CAUTION

When closing the top cover, be careful not to pinch your fingers.

3.5.2

Place the fan-fold media on a flat location, then load the media from the media slot on the rear or the

bottom of the printer.

The routing path of the media is shown in

the right picture.

When loading the media, make sure that

the print side faces up.

After passing the media through the slot,

refer to steps 5 through 10 of

3.5.1 Loading Media Roll

media.

Loading Fan-fold Media

Section

to load the

Note

If a media jam frequently occurs with the media being loaded from the bottom of the printer, change the load

location to the rear of the printer.

CL4NX/CL6NX Operator Manual

45

Page 48

3 Loading the Ribbon and Media

1

1

2

1

2

3.5.3

Refer to the procedure in Section 3.5.1 Loading Media Roll or Section 3.5.2 Loading Fan-fold Media to

load the media.

For models with a cutter installed, pull the tab

the cutter unit in the direction shown, then open up

the cutter-open lever before passing the media

through it.

After loading media, close the cutter-open lever and

then push the tab

Loading Media with the Optional Cutter

q of

q in the reverse direction to lock it.

CAUTION

Be careful not to touch the cutter blade.

3.5.4

Loading Media with an Optional Dispenser and Liner Discharge Outlet

This section describes the procedure to dispense the

label and eject the liner out of the printer.

1 Refer to steps 1 through 6 of Section

3.5.1 Loading Media Roll to load the

media.

2 Press the tab q at the front of the printer to

open the dispenser unit w.

CL4NX/CL6NX Operator Manual

46

Page 49

3 Remove about 30 cm (11.8”) of labels e

4

5

3

4

Label

Liner

from the liner r, then pass the liner r

through the gap of the dispenser unit to the

outside of the printer.

4 Adjust the dispenser roller t to the center

of the label.

5 Close the dispenser unit.

6 Close the print head and top cover.

3 Loading the Ribbon and Media

3.5.5

This section describes the procedure to dispense the label and rewind the liner in the printer.

Note

The maximum diameter of the liner that can be rewound in the printer is 120 mm (4.72”).

The routing path of the media is shown in the right

picture.

Loading Media with an Optional Dispenser and Liner Rewinder

CL4NX/CL6NX Operator Manual

47

Page 50

3 Loading the Ribbon and Media

1

2

4

5

3

4

7

4

6

1 Refer to steps 1 through 7 of Section

3.5.1 Loading Media Roll to load the

media.

2 Press the tab q at the front of the printer to

open the dispenser unit w.

3 Remove about 80 cm (31.5”) of labels e

from the liner r, then pass the liner r

through the gap of the dispenser unit to

the inside of the printer.

4 Adjust the dispenser roller t to the center

of the label.

5 Pass the liner r below the liner rewinder

y, then attach it with the clip u.

6 Rotate the liner rewinder y

counterclockwise by hand, to wind the liner.

7 Close the dispenser unit.

8 Close the print head and top cover.

CL4NX/CL6NX Operator Manual

48

Page 51

3 Loading the Ribbon and Media

2

1

3.5.6

Removing the Liner from the Rewinder

1 Pull the clip q away from the printer then

pull to remove the liner w.

2 Place the clip back to its original position.

Note

The rewinder can take up maximum a diameter of 120

mm (4.72”) of liner.

CL4NX/CL6NX Operator Manual

49

Page 52

3 Loading the Ribbon and Media

This page is intentionally left blank.

CL4NX/CL6NX Operator Manual

50

Page 53

Change to

offline mode.

Change to

online mode.

Show the adjustments mode

when the print job is paused.

Show the settings mode

when there are no print jobs.

Cancel the print job.

Feed the media.

Operation and

4

The display of the printer varies depending on the following modes:

• Online mode: refer to Section 4.1.1 Online Mode/Offline Mode.

• Offline mode: refer to Section 4.1.1 Online Mode/Offline Mode.

• Error display: refer to Section 4.1.3 Error Icon.

• Settings mode: refer to Section 4.2 Settings Mode.

4.1

4.1.1

In online mode, you can execute the print job.

Configuration

Display and Operation

Online Mode/Offline Mode

In offline mode, the print job will stop.

You can adjust the print settings, cancel the print job or feed the media.

After you complete or cancel the print job, you can show the settings mode.

CL4NX/CL6NX Operator Manual

51

Page 54

4 Operation and Configuration

Status Bar

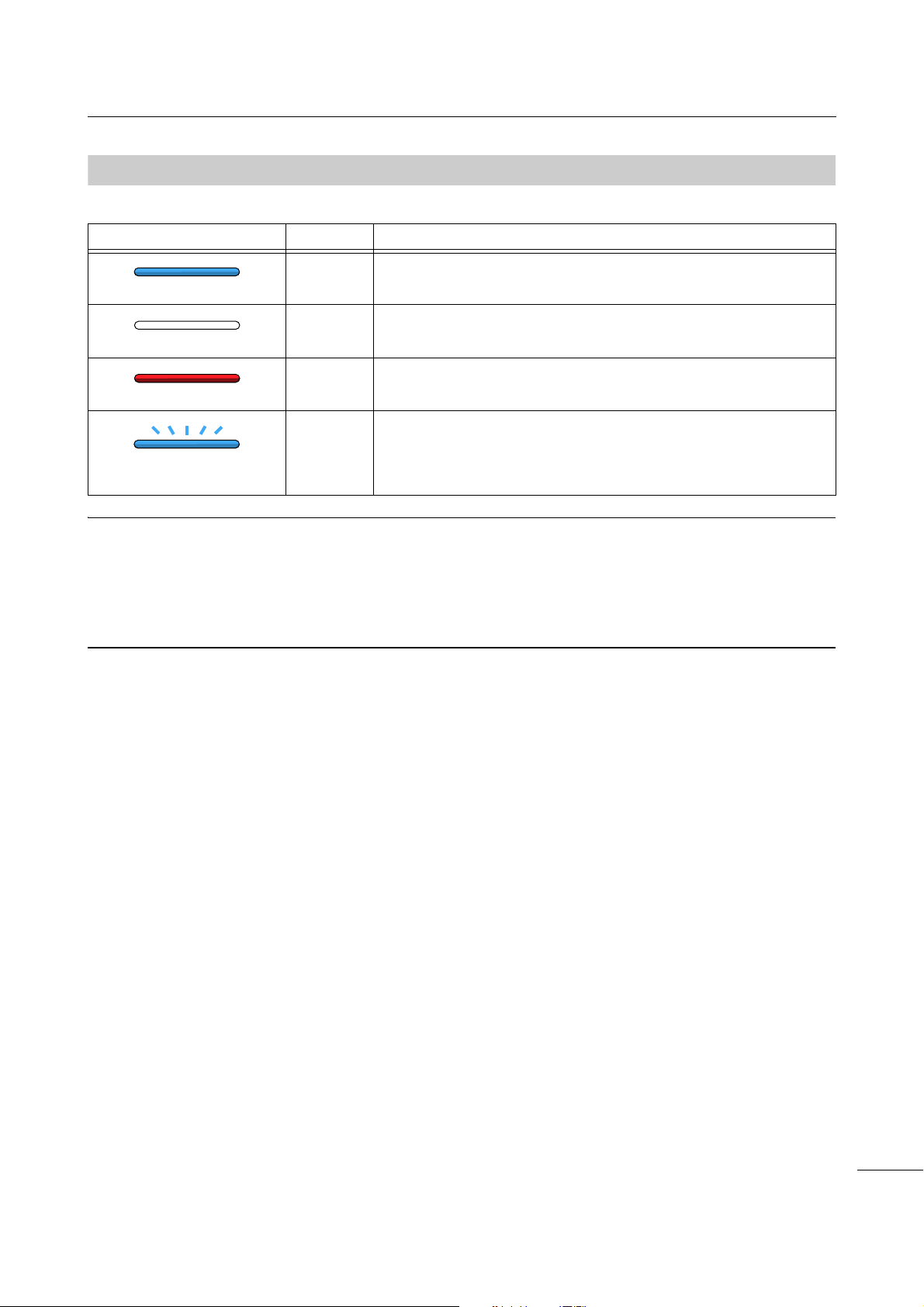

4.1.2

The icons on the status bar of the display show the printer status.

• Communication Interface Status

Status Icon

Icon Description

Bluetooth is enabled but not connected.

Bluetooth is enabled and connected.

Network link is enabled but not connected.

Network link is enabled and connected.

NFC is enabled but not connected.

NFC is enabled and connected.

Not connected to the NTP time server.

Wi-Fi is not connected.

Wi-Fi is connected.

Signal Level: 1

Wi-Fi is connected.

Signal Level: 2

CL4NX/CL6NX Operator Manual

52

Page 55

Icon Description

Wi-Fi is connected.

Signal Level: 3

Wi-Fi is connected.

Signal Level: 4

Wi-Fi Direct is not connected.

Wi-Fi Direct is connected.

Signal Level: 1

Wi-Fi Direct is connected.

Signal Level: 2

Wi-Fi Direct is connected.

Signal Level: 3

4 Operation and Configuration

Wi-Fi Direct is connected or the printer is set to act as an access point.

Signal Level: 4

Printer is connected to USB host.

Waiting for external input/output signal.

RFID mode is enabled (CL4NX only).

Standard code is disabled (Non-standard code).

• USB Memory Status

Icon Description

USB memory is connected.

• Barcode Checker Status

Icon Description

Barcode checker is connected.

CL4NX/CL6NX Operator Manual

53

Page 56

4 Operation and Configuration

?

• Barcode Scanner Status

Icon Description

Barcode scanner is connected in AEP mode.

• Print Job Status

Icon Description

Waiting for media removal. Remove the media.

Ribbon is near the end. Prepare a new ribbon.

Label is near the end. Prepare new media.

Command error detected. Check the print data.