Page 1

®

CL408e/CL412e Printers

Service Manual

PN 9001078

Rev. B

Page 2

SATO America, Inc.

10350-A Nations Ford Rd.

Charlotte, NC 28273

Main Phone: (704) 644-1650

Technical Support Hotline: (704) 644-1660

Fax: (704) 644-1661

http:\\www.satoamerica.com

ã Copyright 2001

SATO America, Inc.

The information supplied in this manual was current at time of

publication. If you come across procedures that need clarification or

find errors or have suggestions contact us at qc@satoamerica.com

PN 9001078

Rev. B

Warning: This equipment complies with the requirements in Part 15 of FCC

rules for a Class B computing device. Operation of this equipment in a

residential area may cause unacceptable interference to radio and TV

reception requiring the operator to take whatever steps are necessary to

correct the interference.

All rights reserved. No part of this document may be reproduced or issued to

third parties in any form whatever without the express permission of SATO

America, Inc. The materials in this document are provided for general

information and are subject to change without notice. SATO America, Inc.

assumes no responsibility for any errors that may appear.

SA TO CL408e/CL412e Service Manual

Page 3

Table of Contents

Section 1. Overview and Specifications Page

1 Overview ........................................................................................................... 1-1

2 Physical Characteristics.................................................................................. 1-2

3 Printer Features................................................................................................ 1-3

4 Sensors ............................................................................................................. 1-6

5 Operation Panel................................................................................................ 1-7

6 Installation Considerations ............................................................................. 1-9

7 Optional Accessories ...................................................................................... 1-9

8 Environment & Approvals ............................................................................. 1-10

9 General Printer Specifications...................................................................... 1-10

10 Character Fonts.............................................................................................. 1-13

11 Bar Codes ....................................................................................................... 1-14

Section 2. Configuration

1 Dip Switch Settings .......................................................................................... 2-1

2 Default Settings ................................................................................................ 2-7

3 LCD Panel Configuration................................................................................. 2-8

Normal Mode ................................................................................................ 2-9

Advanced Mode.......................................................................................... 2-13

Card Mode ................................................................................................... 2-17

Service Mode .............................................................................................. 2-25

Counters Mode ........................................................................................... 2-32

Test Print Mode ........................................................................................... 2-33

Default Setting Mode ................................................................................. 2-34

Maintenance Mode — Factory Mode........................................................ 2-35

Clear Non-Standard Protocol.................................................................... 2-37

Download User Defined Protocol Codes ................................................. 2-37

Hex Dump Mode......................................................................................... 2-38

Firmware Download Mode ........................................................................ 2-39

4 Sample Test Labels ........................................................................................ 2-40

Section 3. Interface Specifications

1 Overview...........................................................................................................3-1

2 Interface Types.................................................................................................3-1

3 Receive Buffer..................................................................................................3-3

4 IEEE 1284 Parallel Interface............................................................................3-4

5 RS232C Serial Interface...................................................................................3-6

6 Universal Serial Bus (USB) Interface .............................................................3-9

7 Ethernet Interface ............................................................................................3-10

8 Bi-Directional Communications .....................................................................3-10

9 Accessory (EXT) Connector ...........................................................................3-11

Section 4. Electrical Checks and Adjustments

1 Overview ........................................................................................................... 4-1

2 Steps Prior to Some Procedures .................................................................... 4-2

3 DC Power Voltage Checks............................................................................... 4-3

4 Potentiometer Assignments & Adjustments................................................. 4-6

5a Print Position Adjustment............................................................................... 4-8

5b Print Position Adjustment............................................................................... 4-9

6 Label Gap Adjustment................................................................................... 4-10

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

i

Page 4

Table of Contents

Section 4. Electrical Checks and Adjustments

7 Eye-Mark Adjustment .....................................................................................4-11

8 Offset Label Stop Position Adjustment ....................................................... 4-12

9a Ribbon Sensor Operation Verification ......................................................... 4-13

9b Ribbon Sensor Voltage Checking ................................................................ 4-14

10 Print Darkness Adjustment........................................................................... 4-16

Section 5. Mechanical Adjustments

1 Overview ........................................................................................................... 5-1

2 Ribbon Clutch Adjustments............................................................................ 5-2

3 Ribbon Guide Plate Adjustment ..................................................................... 5-5

4 Tear Plate Adjustment ..................................................................................... 5-6

5 Print Head Position Alignment ....................................................................... 5-7

6 Print Head Balance Adjustment...................................................................... 5-8

7 Print Head Alignment Adjustment.................................................................. 5-9

8 Timing Belt Tension Adjustment .................................................................. 5-10

Section 6. Replacement Procedures

1 Overview .......................................................................................................... 6-1

2 Replacing the Main Circuit Board.................................................................. 6-2

3 Replacing the Fuses........................................................................................ 6-7

4 Replacing the Power Supply........................................................................... 6-9

5 Replacing the Stepper Motor .........................................................................6-11

6 Replacing the Timing Belts ........................................................................... 6-12

7 Replacing the Print Head............................................................................... 6-14

8 Replacing the Platen...................................................................................... 6-17

9 Replacing the Ribbon Drive Clutch Washers .............................................. 6-19

10 Replacing the Ribbon Motion Sensor .......................................................... 6-23

11 Replacing the Label Sensor .......................................................................... 6-24

12 Replacing the Label Sensor Module ............................................................ 6-26

13 Replacing the Head Open Switch ................................................................. 6-27

14 Replacing the Display Panel PCB................................................................. 6-28

Section 7. Factory Resets

1 Overview ........................................................................................................... 7-1

2 Factory/Service Test Print............................................................................... 7-2

3 Clear Head Counters........................................................................................ 7-3

4 Clear Dispenser Counter ................................................................................. 7-4

5 Clear Cutter Counter........................................................................................ 7-5

6 Clear EEPROM.................................................................................................. 7-6

7 Sample Test Prints........................................................................................... 7-7

Section 8. Troubleshooting

1 Overview .......................................................................................................... 8-1

2 Initial Checklist ................................................................................................ 8-2

3 The IEEE 1284 Parallel Interface .................................................................... 8-2

4 The RS232C Serial Interface........................................................................... 8-4

5 The Universal Serial BUS (USB) .................................................................... 8-4

6 The LAN Ethernet Interface ............................................................................ 8-5

7 Error Signals .................................................................................................. 8-10

8 Troubleshooting Tables.................................................................................8-11

9 Head Pattern Examples ................................................................................ 8-15

10 Hex Dump Diagnostic Labels....................................................................... 8-17

ii

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 5

Table of Contents

Section 9. Optional Accessories

1 Overview .......................................................................................................... 9-1

2 Label Cutter Kit Installation............................................................................ 9-2

3 Label Dispenser Kit Installation..................................................................... 9-6

4 PCMCIA Memory Expansion Installation .................................................... 9-16

5 Flash Memory Expansion Installation ......................................................... 9-23

6 Real Time Clock Installation ......................................................................... 9-26

Section 10. Parts List

1 Overview ........................................................................................................ 10-1

2 Frame Assembly............................................................................................ 10-2

3 Print Head Assembly .................................................................................... 10-5

4 Ribbon Assembly .......................................................................................... 10-9

5 Base Cover Assembly................................................................................. 10-13

6 Main PCB Assembly.................................................................................... 10-20

7 Interface Options......................................................................................... 10-21

8 PCMCIA Memory Option............................................................................. 10-22

9 Cutter Assembly Option ............................................................................. 10-23

10 Dispenser Assembly Option .......................................................................10-25

Index .............................................................................................................................. Index -1

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

iii

Page 6

®

iv

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 7

Section

Overview and Specifications

1.1 Overview

The SATO CL408e/CL412e Printers Service Manual provides information for

installing and maintaining CL408e/CL412e Thermal Transfer printers. Step-bystep maintenance instructions are included in this manual with typical problems

and solutions. It is recommended that you become familiar with each section in

this manual before installing and maintaining the printer.

The major differences in the CL408e and the CL412e printers is the resolution of

the head. The CL408e with its 203 dpi head provides an economical labeling

solution for most applications. It can print labels up to 4.1 inches wide. The

CL412e provides a higher print resolution, 305 dpi to give laser-quality printing. It

is useful when higher resolution is needed for detailed graphic images.

The CL Series "e" printers use a subset of the standard SATO Command

Language. The CL408e/CL412e share the same command set, the only

differences are the allowable values representing the print positions on the label.

These values are specified in "dots" and will vary depending upon the resolution

of the printer and the amount of memory available for imaging the label. The

allowable range for each printer is specified in a table for those command codes.

The sections in this manual cover the following:

· Section 1. Overview and Specifications

· Section 2. Configuration

· Section 3. Interface Specifications

· Section 4. Electrical Checks and Adjustments

· Section 5. Mechanical Adjustments

· Section 6. Replacement Procedures

· Section 7. Factory Resets

· Section 8. T roubleshooting

· Section 9. Optional Accessories

· Section 10. Parts list

· Index

PN 9001078

Rev. B

SATO CL408e/CL412e Service Manual

Page 1-1

Page 8

Section 1. Overview and Specifications

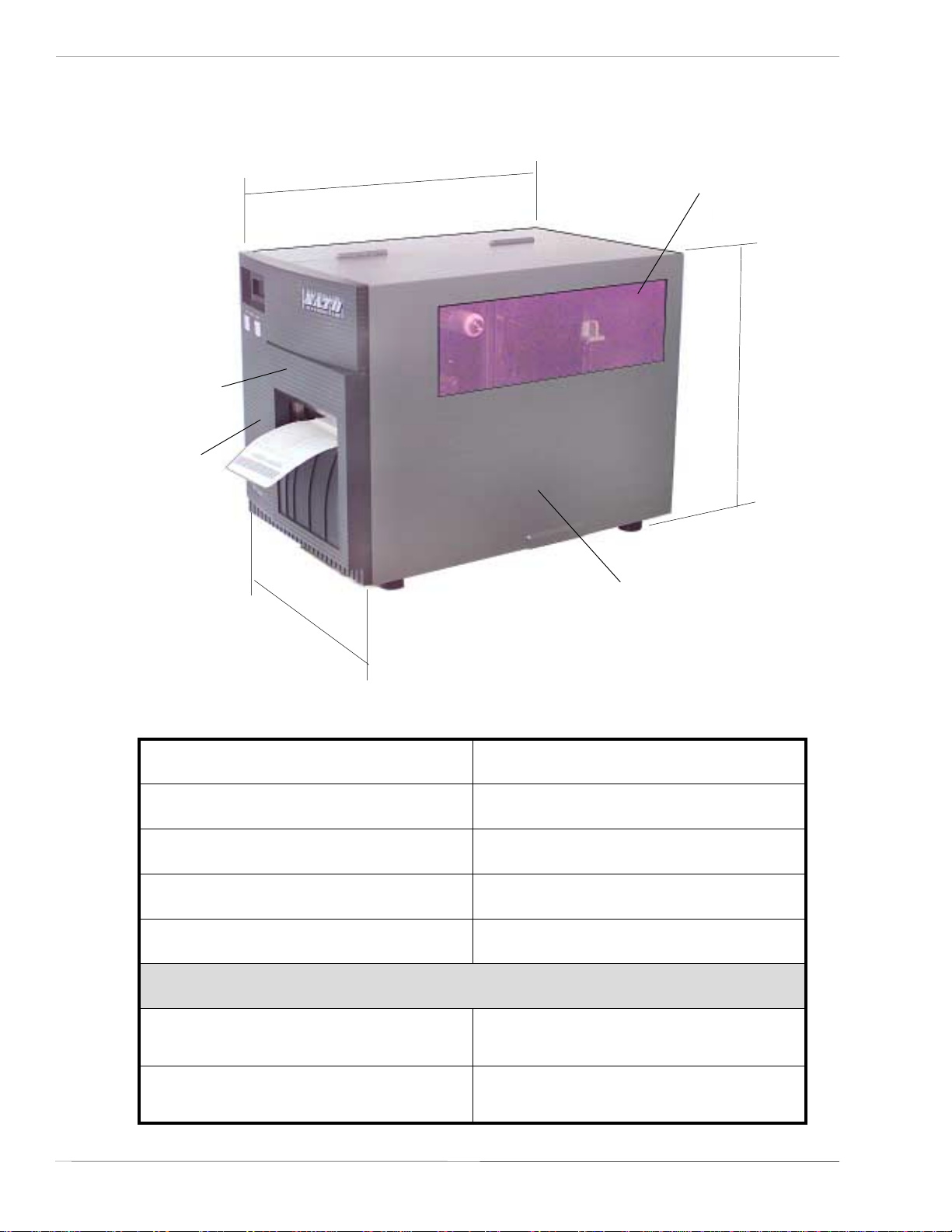

1.2 Physical Characteristics

FRONT ACCESS

DOOR

LABEL OUT

SLOT

Width

Depth

PAPER CHECK

WINDOW

Height

TOP ACCESS

DOOR

Page 1-2

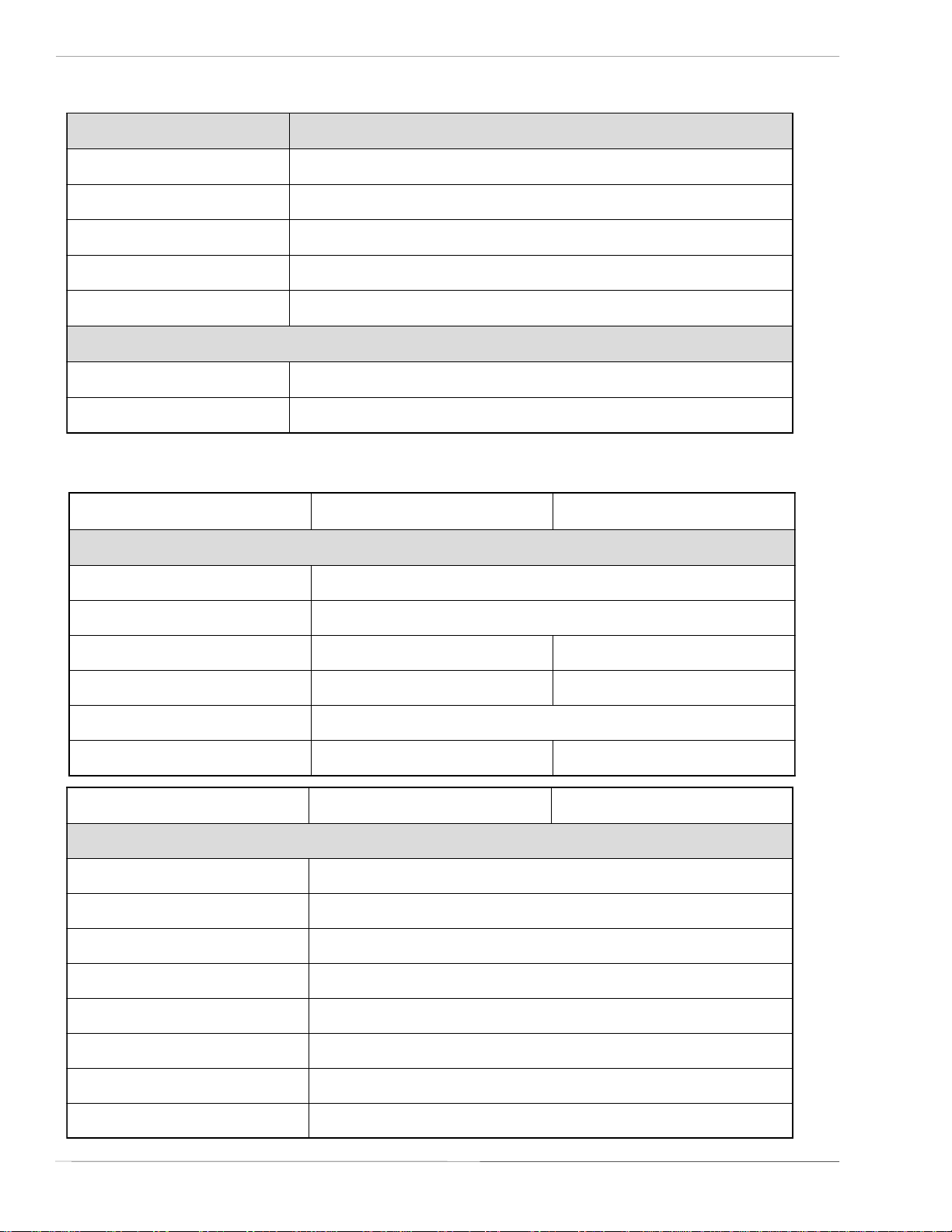

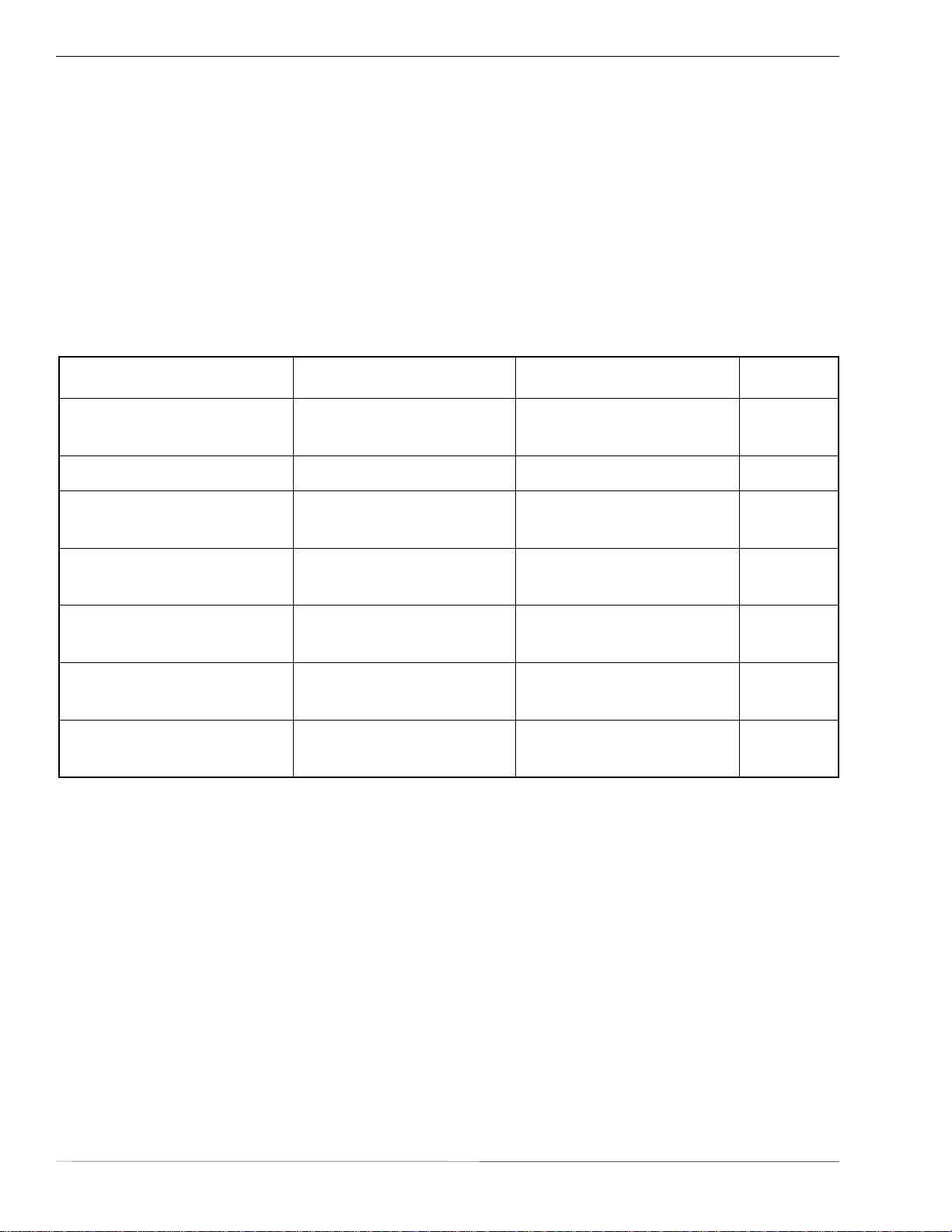

snoisnemiDe214LCe804LC

ediW)mm172(.ni7.01

peeD)mm034(.ni9.61

hgiH)mm123(.ni6.21

thgieW)gk31(.sbl7.82

stnemeriuqeRrewoP

egatloV

noitpmusnoCrewoP

SA TO CL408e/CL412e Service Manual

)%01-/+(V022-511

)%1-/+(zH06/05

eldiW05

gnitarepOW031

PN 9001078

Rev. B

Page 9

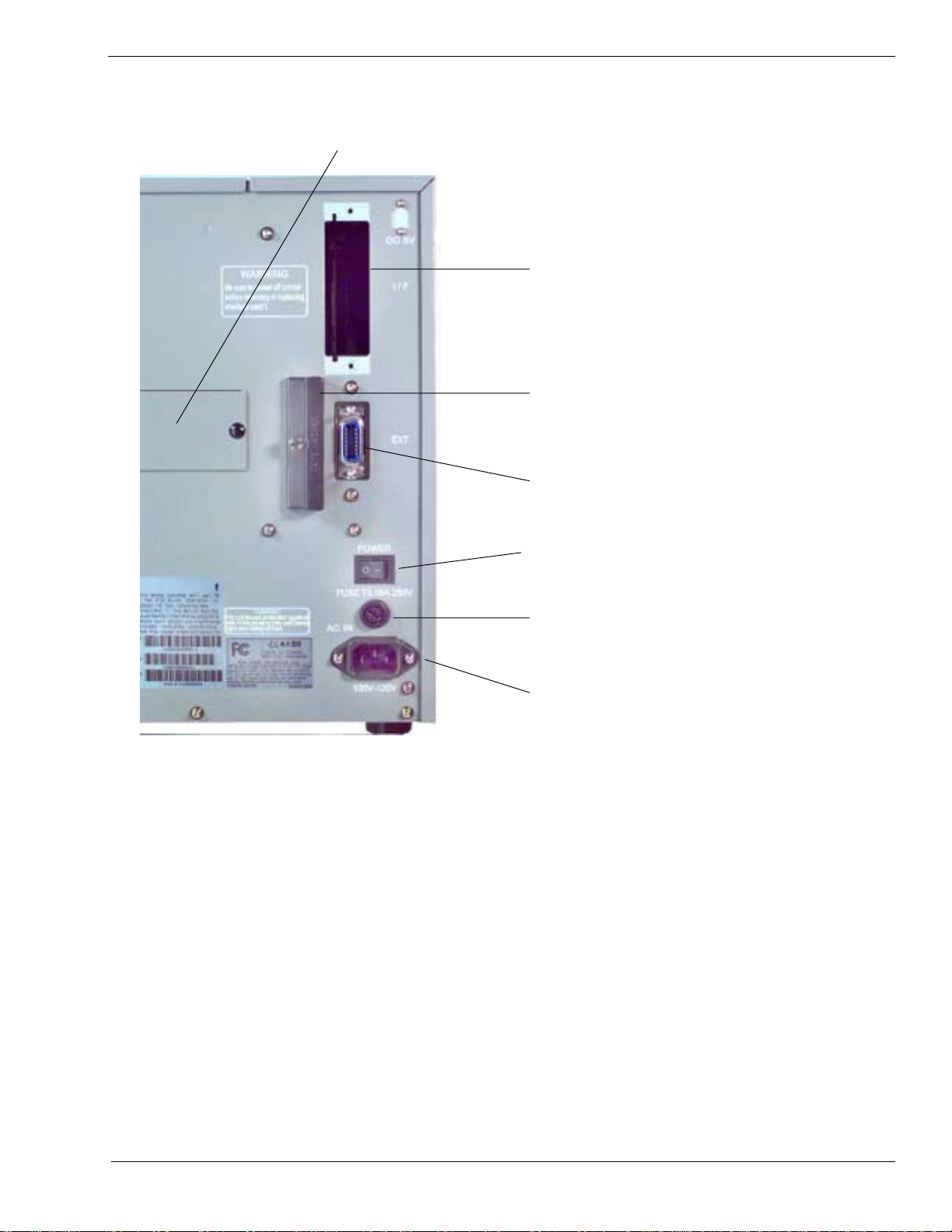

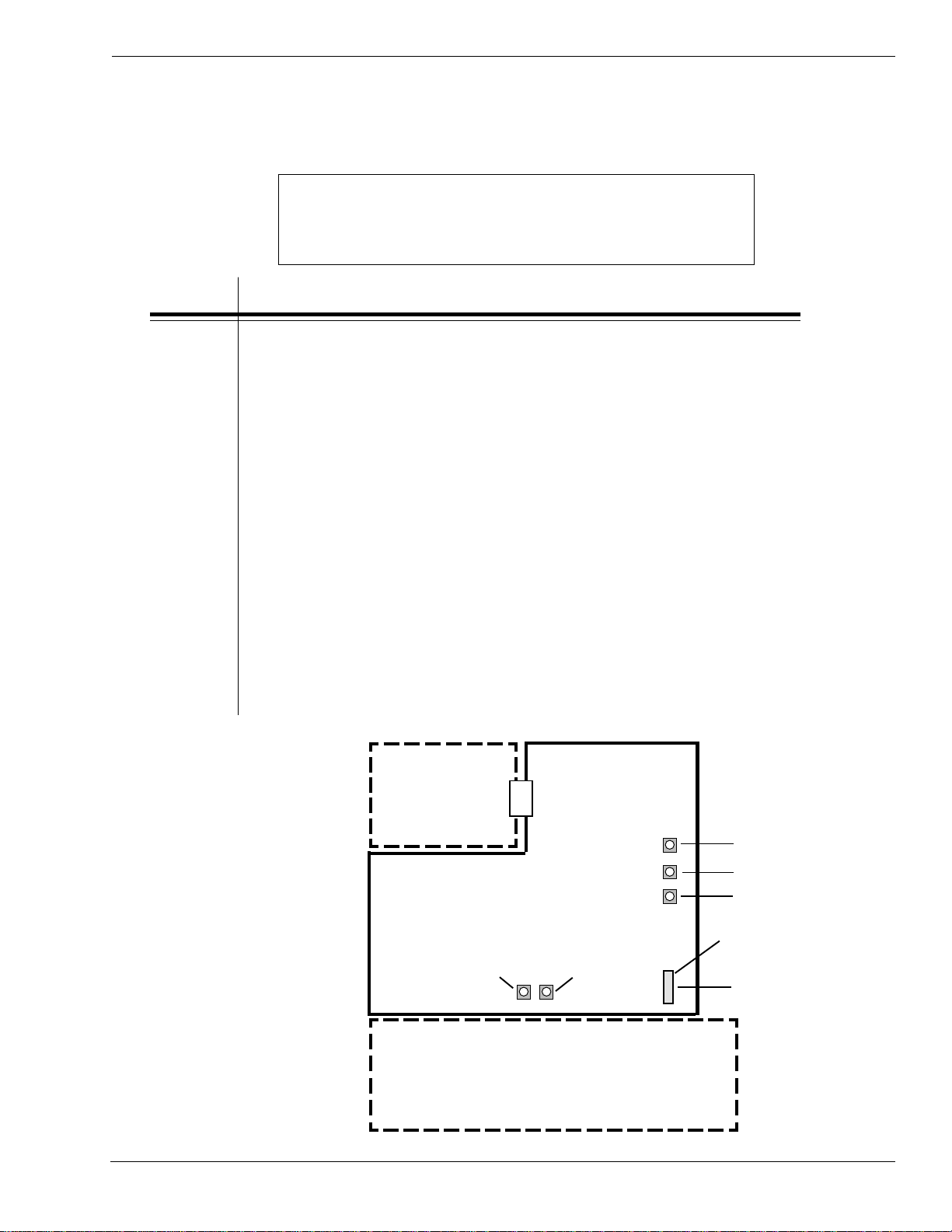

1.3 Printer Features

Section 1. Overview and Specifications

COVER PLATE-REMOVE FOR ACCESS

TO DISPENSER AND FAN-FOLD SLOTS

INTERFACE SLOT

PCMCIA MEMORY

EXPANSION SLOT

EXT CONNECTOR

POWER SWITCH

AC FUSE

AC POWER INPUT

CONNECTOR

Rear Panel

INTERFACE SLOT Slot to plug in an interface adapter. An adapter must be

connected before the printer is operational. The adapter types

available are:

RS232C Serial I/F Module, DB-25.

IEEE1284 Parallel I/F Module, AMP 57-40360

Universal Serial Bus I/F Module

Ethernet 10/100 BaseT I/F Module

RS-422/485 I/F Module, DB-9

MEMORY CARD SLOT One slot for optional PCMCIA Memory Cards.

PN 9001078

Rev. B

EXT CONNECTOR External signal connector for Accessories, AMP 57-60140

POWER SWITCH Turns power On/Off

AC FUSE Input power protection. Type 3A/250V.

AC POWER INPUT Input 115V 50/60 Hz connector. Use the cable provided.

SA TO CL408e/CL412e Service Manual

Page 1-3

Page 10

Section 1. Overview and Specifications

Printer Features

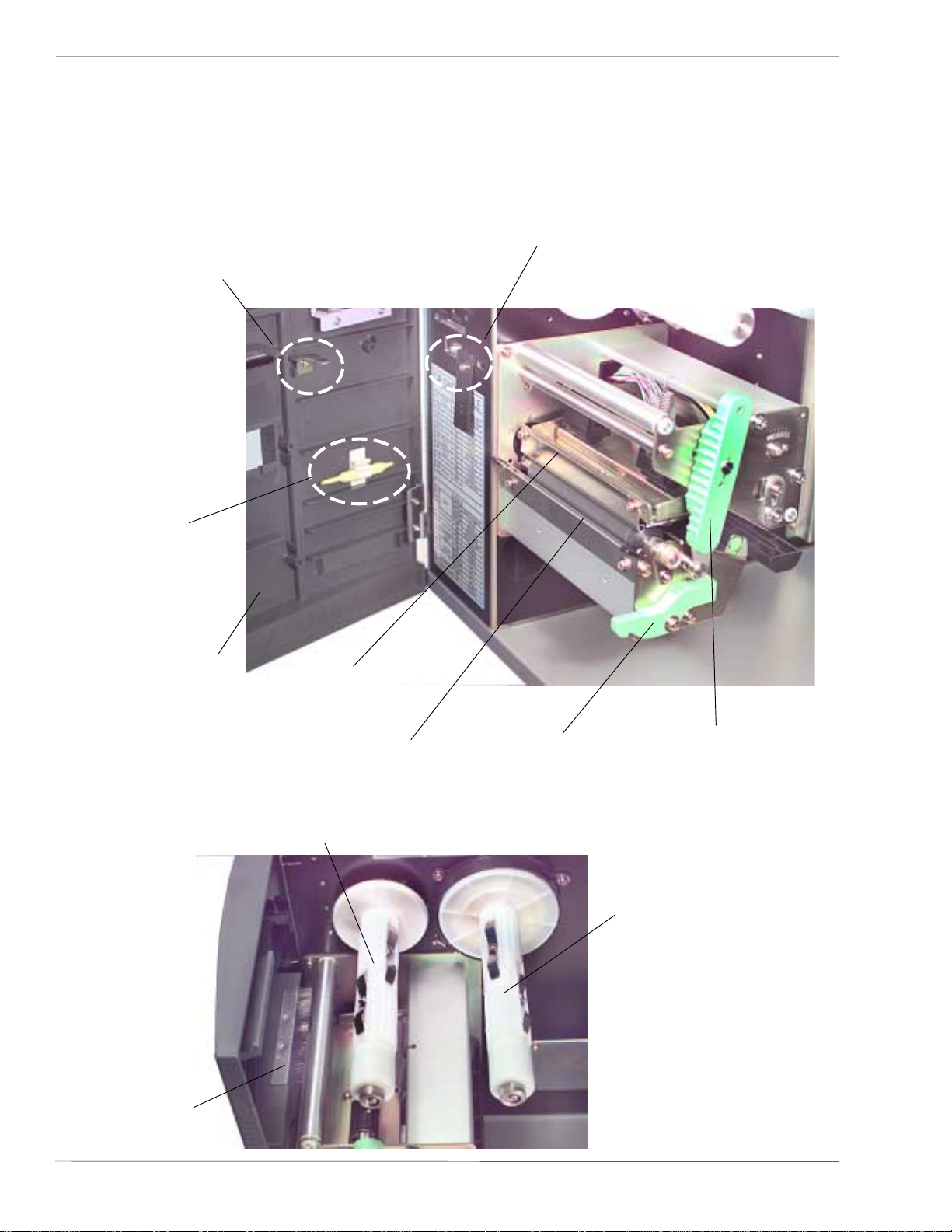

FRONT ACCESS DOOR

INTERLOCK :

This switch prevents printer

operation when the Front Access

Door is open. The Top Access

Door must be open before the

Front Access Door can be opened

or closed.

COVER OPEN SENSOR:

When this sensor is activated, the

printer will not operate and

Cover Open message will be

displayed on the display panel.

TOOL FOR

DARKNESS

ADJUSTMENT

FRONT ACCESS

DOOR OPENED

PRINT HEAD

ASSEMBLY UNIT

TEAR OFF

PLATE

RIBBON REWIND

SPINDLE

FRONT ACCESS

DOOR OPEN

LEVER

HEAD OPEN LEVER:

When the print head is

opened, this switch is

activated and the printer

will stop printing.

RIBBON SUPPLY

SPINDLE

BRUSH

(A TTACHED TO

DOOR)

Page 1-4

SA TO CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 11

Printer Features

Section 1. Overview and Specifications

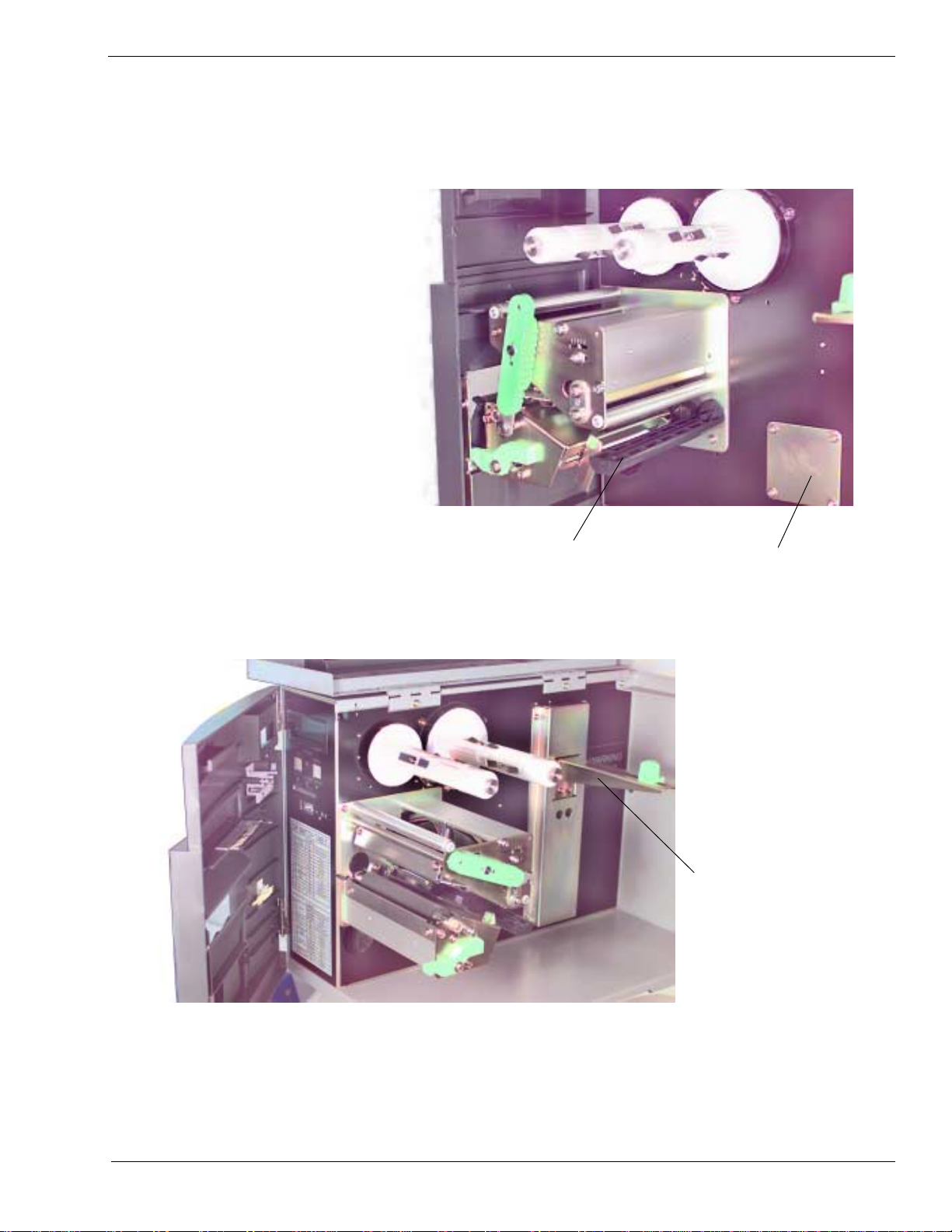

LABEL GUIDE

ACCESS PLATE

FOR OPTIONAL

LABEL

DISPENSER

MEDIA HOLDER

PN 9001078

Rev. B

SA TO CL408e/CL412e Service Manual

Page 1-5

Page 12

Section 1. Overview and Specifications

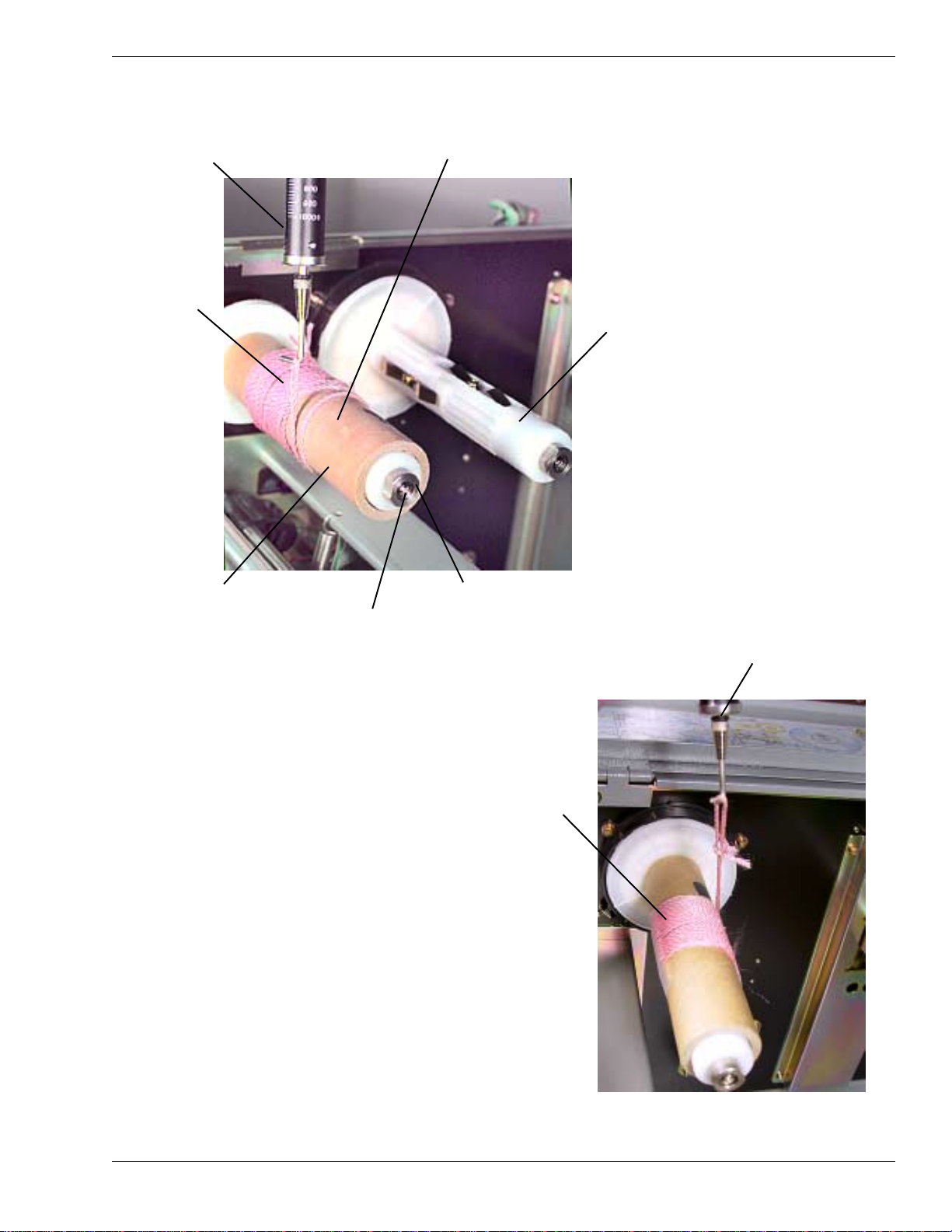

1.4 Sensors

RIBBON MOTION SENSOR:

This sensor is a motion detector that

signals the printer when the ribbon

supply is turning. This sensor is used

for both the ribbon end and ribbon

near end sensing.

LABEL SENSOR:

Both the "Eye-Mark" (reflective) and Gap

(transmissive) sensors can be adjusted over

a limited range. They are both located in

the label sensor unit. The assembly can be

adjusted by loosening the green sensor

knob located underneath the label transport

assembly and sliding the label sensor unit

to the desired position. The gap sensor can

be adjusted from a minimum of 0.67 in.

(17mm) to a maximum of 2.5 in. (64mm)

and the "Eye-Mark" from a minimum of

0.25 in. (6mm) to a maximum of 2.1 in.

(53mm) from the fixed position, "inside

label guide".

Page 1-6

SA TO CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 13

1.5 Operation Panel

Section 1. Overview and Specifications

LCD DISPLAY

PANEL

TWO-COLOR

STATUS LED

LINE KEY

PRINT/OFFSET/PITCH

POTENTIOMETERS

*DSW2 & 3

OPTION

CONNECTIOR

FEED KEY

LABEL TAKEN LED

LABEL T AKEN THRESHOLD

POTENTIOMETER

PN 9001078

Rev. B

*NOTE: Optional RS232 Communication Card contains DSW1 switches which are

configured when supplied with the printer.

The CL408e/CL412e Operator Panel consists of one two-color (red and green) LED

indicator, two momentary contact switches, two DIP switches (a third is located on the

RS232 interface card), four adjustment potentiometers and one LCD display. All of

these are accessible from the front of the printer, however some are not accessible

unless the front cover is open. They are used to set the printer operating parameters

and to indicate the status of the printer to the operator.

SA TO CL408e/CL412e Service Manual

Page 1-7

Page 14

Section 1. Overview and Specifications

Operation Panel

LCD DISPLAY PANEL 2 Line x 16 Character LCD display. Used for setting operational

parameters of the printer.

STATUS LED Two-color (Red, Green) LED that indicates the following status

conditions.

Green-Illuminated when printer is ready to receive data.

It is turned on and off by toggling the LINE key.

Red-Illuminated when there is a system fault such as an

open print head.

LINE KEY Momentary switch. Pressing this key toggles the printer between

the on-line and off-line mode. When the printer is on-line, it is

ready to receive data from the host. This key acts as a pause

during a print job by taking the printer off-line. It can also be

used as a PAUSE function key to stop label during the printing

process.

FEED KEY Momentary switch. Pressing this key feeds one blank label

through the printer when it is off-line. When the printer is online, there is a user selectable option in the Service Mode (see

page 2-28) to either print a copy of the previously printed label

or feed a blank label. The default is to feed a blank label.

POTENTIOMETERS

PRINT Located behind the Front Access Door. Potentiometer is used to

adjust print darkness (fine tuning).

OFFSET Located behind the Front Access Door. Potentiometer is used to

adjust amount of back/forward feed for dispenser/cutter/tear-off

bar position (+/- 3.75mm).

PITCH Located behind the Front Access Door. Potentiometer is used to

adjust home position of the label (+/- 3.75mm). Affects stop

position of label feed, print position and dispense position.

LABEL T AKEN Located behind the Front Access Door. Potentiometer is used to

THRESHOLD

adjust the sensing level of the Label Taken Sensor. Active only

when the Label Dispense option is installed.

DSW2 & DSW3 Located behind the Front Access Door. DIP switch array to set

operational parameters of the printer. DSW1 is used to set the

RS232 parameters and is located on the RS232 interface board if

installed in your printer.

OPTIONAL Located behind the Front Access Door. This connector is used for

CONNECTOR

the cutter and dispenser optional accessories.

LABEL TAKEN LED Located behind the Front Access Door. This LED is illiminated

when a label is not present in the Label Taken Sensor. If it is not

illuminated, a label has been detected in the sensor and printing

will be inhibited until it is removed. This LED is active only

when the Label Dispense option is installed.

Page 1-8

SA TO CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 15

Section 1. Overview and Specifications

1.6 Installation Considerations

Printer operation can be affected by the printer environment. The location of the

printer should be free from dust, humidity and sudden vibrations. To obtain optimum

results from the printer, avoid locations influenced by:

Direct or bright sunlight, since bright light will make the label sensor less responsive

and may cause the label to be sensed incorrectly.

Warm temperatures which can cause electrical problems within the printer. (See

Section 1-8 Environment.

1.7 Optional Accessories

YROSSECCA214LC/804LC

noisnapxEyromeM

.stnofepyTeurTdedaolnwod

*

4rohsalFBM61otpu(sdraCyromeMAICMCProftolsenO

rofdesuebnaC.MORhsalFlanretniBM4ro/dna)MARSBM

dnaegarotstamrof,noisnapxereffubtnirp,egarotselifcihparg

radnelaC

rettuClebaL

redniweRlebaL

ecafretnIlellaraPeludoMecafretnIlellaraP4821EEEI

ecafretnIlaireSeludoMecafretnI232SRlaireSdeepShgiH

resnepsiDlebaL

F/IlaireSlasrevinUeludoMecafretnIBSU

ecafretnItenrehtEeludoMecafretnITesaB001/01

ecafretnIxaniwT/xaoC

otdesuebnactahtpihcemiT/etaDdetnuomyllanretninA

.gnitnirpfoemitehttaslebalpmatsemit/etad

*

tatucebotslebalgniwollatnemhcattadetnuomyllanretninA

.gnimmargorphguorhtdellortnoC.slanretnideificeps

*

rofgnikcabmorfdeleepotslebalgniwollatnemhcattalanretnI

.pu-ekatgnikcablanretnI.noitacilppa)dnamedno(etaidemmi

erayehtretfalloraotnoslebalsdniwertahtnoitpolanretxE

.detnirp

2-7823MBInasetalumeF/IxaoC.eludoMecafretnIxairT/xaoC

F/IxaniwT.rotcennocCNBAepyTdradnatsahtiwretnirp

-otuahtiwsretnirp4124ro6225,5225,4225MBIsetalume

seitilibapacurht-elbac/etanimret

PN 9001078

Rev. B

Check with your software vendor to make sure these functions are supported.

*

SA TO CL408e/CL412e Service Manual

Page 1-9

Page 16

Section 1. Overview and Specifications

1.8 Environment & Approvals

latnemnorivnE e214LC/e804LC

erutarepmeTgnitarepO14

erutarepmeTegarotS0-

ytidimuHgnitarepOgnisnednoc-non,HR%58-51

ytidimuHegarotSgnisnednoc-non,HR%09xaM

egrahcsiDcitatsortcelEVK8

slavorppAyrotalugeR

ytefaSASC,LU

IME/IFRAssalCCCF

1.9 General Printer Specifications

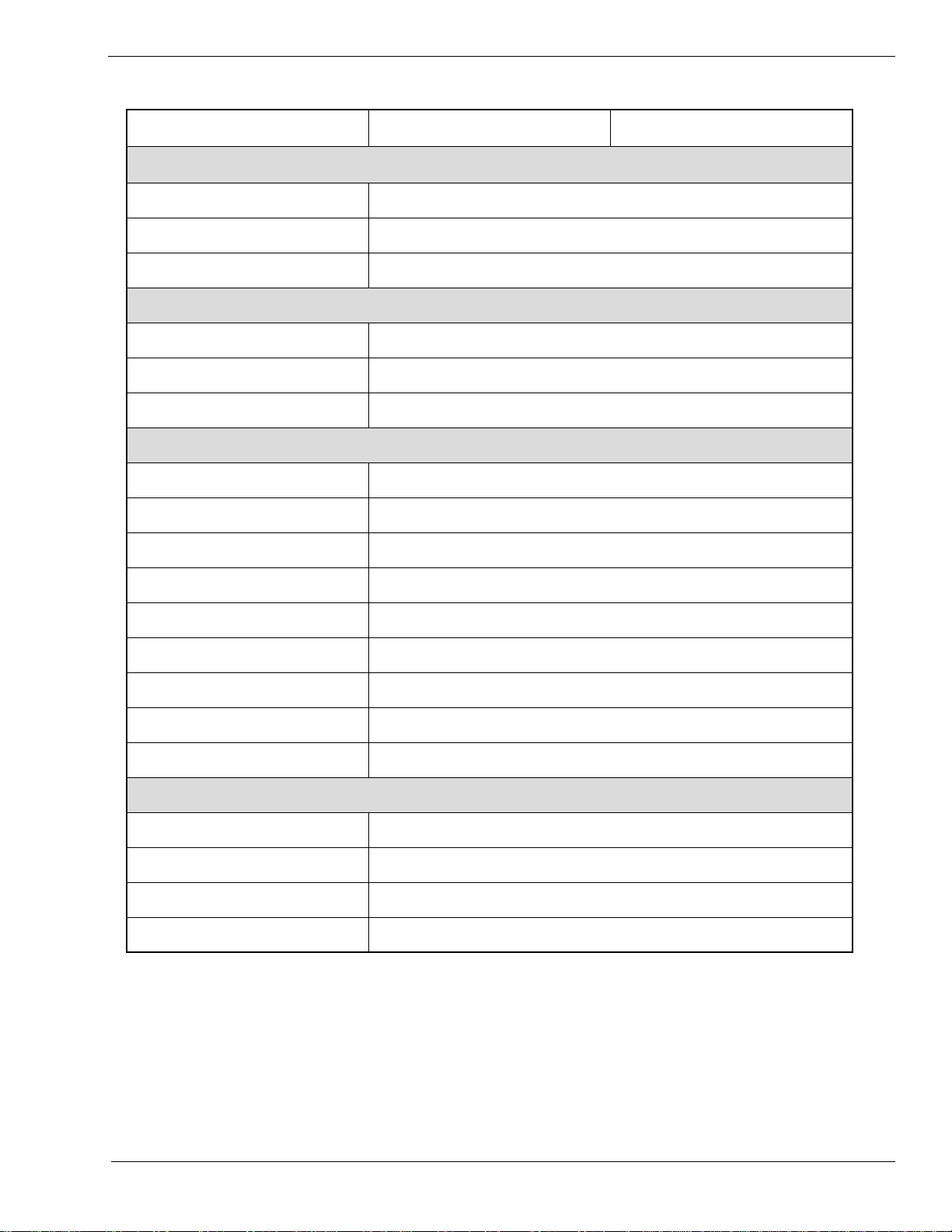

noitacificepSe804LCe214LC

tnirP

dohteMrefsnarTlamrehTrotceriD

0

0

0

401ot

0

401ot

0

5(F

0

02-(F

0

04ot

)C

0

04ot

)C

)elbatceleSresU(deepSs/mm051ot05-spi6ot2

)eziStoD(eludoMtnirPmm521.-.ni9400.mm380.-.ni3300.

noituloseRmmpd8-ipd302mmpd21-ipd503

htdiWtnirPmumixaMmm401-.ni1.4

htgneLtnirPmumixaMmm9421-.ni2.94mm338-.ni8.23

noitacificepSe804LCe214LC

aideM

htdiWmuminiM)mm22(.ni78.

htgneLmuminiM)mm6(.ni42.

htdiWmumixaM)mm131(.ni1.5

epyT suounitnoCrokcotSgaT,dloF-naF,slebaLtuCeiD

repilaC)mm52.(.ni010.

)xam(DOlloRdniWni-ecaF,)mm812(.ni6.8

Page 1-10

)nim(DIeroC)mm83(.ni5.1

)dednemmoceR(DIeroC)mm67(.ni3

SA TO CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 17

General Printer Specifications

noitacificepSe804LCe214LC

gnisneS

urht-eeSevissimsnarTelbavoM

kraM-eyEevitcelfeRelbavoM

mroFsuounitnoCdesutonrosneS

nobbiR

htdiWmumixaM)mm111(.ni4.4

htgneL)m054(.tf5741

ssenkcihTdniWniecaF,norcim5.4

slangiSdnaslortnoC

Section 1. Overview and Specifications

DELeniL-nOneerG=sutatS

DELrewoPenoN

DELtuOaideMdeR=sutatS

DELtuOnobbiRdeR=sutatS

DELrorrEdeR=sutatS

lenaPDCLretcarahC61xeniL2

hctiwSeniL-ffO/nOlenaPtnorF

hctiwSdeeFlebaLlenaPtnorF

hctiwSffO/nOrewoPlenaPraeR

stnemtsujdAretemoitnetoP

ssenkraDtnirPlenaPtnorF

hctiPlenaPtnorF

tesffOlenaPtnorF

)1(

)1(

)1(

)1(

PN 9001078

Rev. B

yalpsiDenoN

(1) Single two color (Red, Green) LED

SA TO CL408e/CL412e Service Manual

Page 1-11

Page 18

Section 1. Overview and Specifications

General Printer Specifications

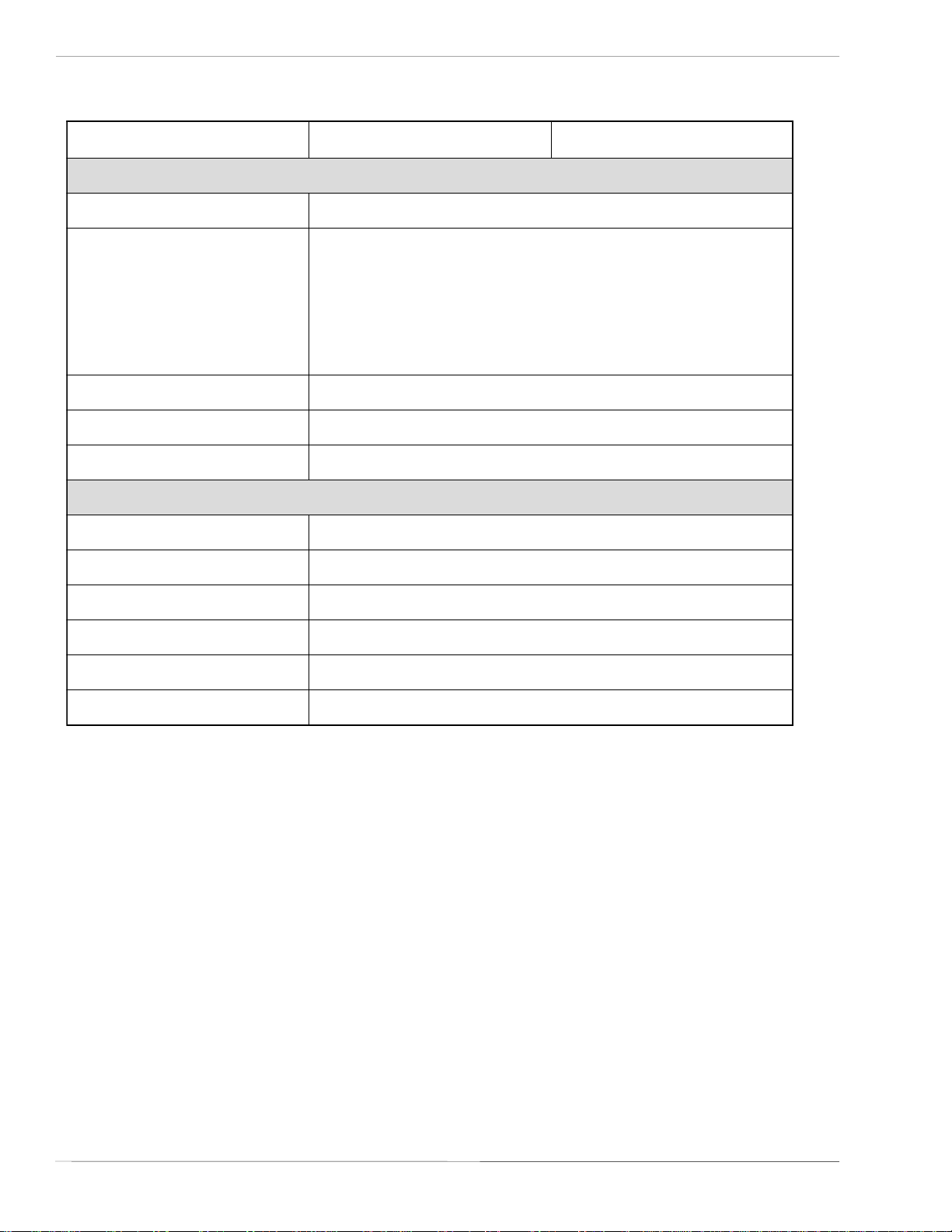

noitacificepSe804LCe214LC

seludoMecafretnI

lellaraPlellaraP4821EEEI

laireS

locotorPlaireS

suBlaireSlasrevinU1.1noisreVBSU

tenrehtETesaB001/01

noissimsnarTataDtamroFIICSA

gnissecorP

)spb006,75ot0069(C232SR

)spb006,75ot0069(584/224SR

)ysuB/ydaeR(lortnoCwolFerawdraH

)ffO-X/nO-X(lortnoCwolFerawtfoS

4ro3,2sutatSlanoitcerid-iB

UPCCSIRtiB23

MORhsalFBM2

MARDSBM61

reffuBevieceRBM59.2

MORhsalFlanoitpOBM4

yromeMAICMCPlanoitpOMARSBM4rohsalFBM61otpU

Page 1-12

SA TO CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 19

1.10 Character Fonts

noitacificepSe804LCe214LC

stnoFxirtaM

tnoFU)Hstod9xWstod5(

tnoFS)Hstod51xWstod8(

tnoFM)Hstod02XWstod31(

tnoFUXacitevleH)Hstod9xWstod5(

tnoFSX dloBdesnednoCsrevinU)Hstod71xWstod71(

tnoFMX dloBdesnednoCsrevinU)Hstod42xWstod42(

tnoFAOA-RCO)Hstod22xWstod51(A-RCO)Hstod33xWstod22(

tnoFBOB-RCO)Hstod42xWstod02(B-RCO)Hstod63xWstod03(

stnoFgnihtoomSotuA

Section 1. Overview and Specifications

BW)Hstod03xWstod81(tnoFBW

LW)Hstod25xWstod82(tnoFLW

BX dloBdesnednoCsrevinU)Hstod84xWstod84(tnoFBX

LX fireSsnaS)Hstod84xWstod84(tnoFLX

tnoFrotceV

®

stnoFretsaRAFGA

tnoFAtp27ot8,semiTGC

tnoFBtp27ot8,etarivmuirTGC

stnoFelbadaolnwoD

lortnoCretcarahC

gnicapSdexiFrolanoitroporP

stod999x999otstod05x05eziStnoF

snoitairaVtnoF01,acitevleH

margorPytilitUhtiwstnoFepyTeurTdeppaMtiB

PN 9001078

Rev. B

0

0

SA TO CL408e/CL412e Service Manual

0

09,

0

081,

setanidroocYroXehtrehtieniX21otpunoisnapxE

lortnochctiPretcarahC

lortnocecapSeniL

ytilicaftnirPlanruoJ

0

072dna

noitatoR

Page 1-13

Page 20

Section 1. Overview and Specifications

1.1 1 Bar Codes

noitacificepSe804LCe214LC

seigolobmyS

)latnemelppuSNAE/CPU(dnalkooB

31-NAE,8-NAE

RABADOC

93edoC

39edoC

821edoC

5fo2devaelretnI

5fo2lairtsudnI

5fo2xirtaM

ISM

TENTSOP

821-NAE/CCU

E-CPUdnaA-CPU

soitaR shtdiwrabelbanifedresU5:2,3:1,2:1

thgieHraBelbammargorpresU,stod006ot4

0

0

noitatoR0

09,

0

081,

0

072dna

serutaeFrehtO

gnirebmuNlaitneuqeS sedocrabdnasciremunhtobfognirebmunlaitneuqeS

sretcarahCmotsuCsretcarahclaicepsrofegarotsMAR

scihparG

stamrof

XCP.roPMB.,yraniB/xeHOTAS,scihpargelbasserddatodlluF

yalrrevOmroF stamrofxelpmocfognitidedeeps-hgihrofyalrevomroF

Page 1-14

SA TO CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 21

Section

Configuration

2

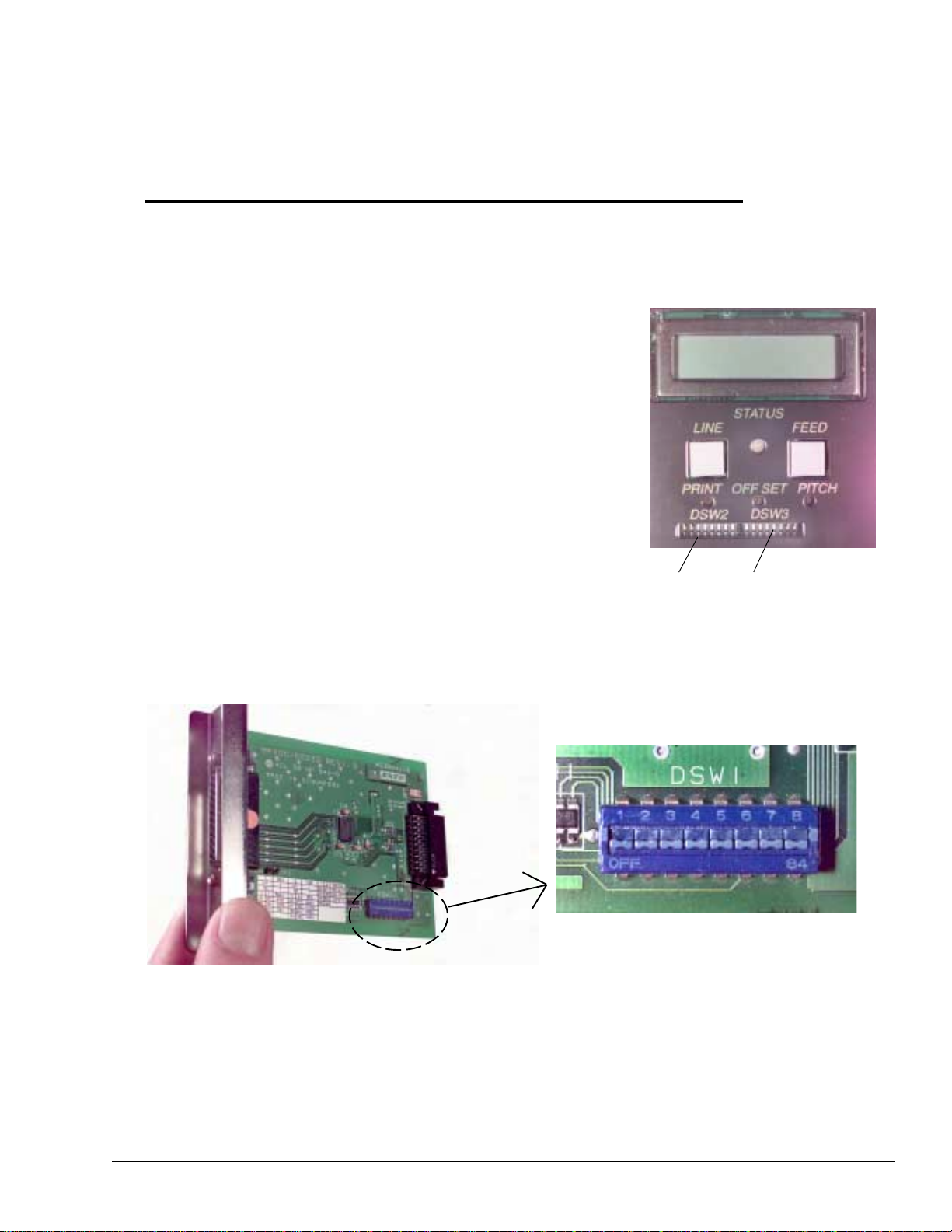

2.1 Dip Switch Settings

Two DIP switches (DSW2 & DSW3) are located inside the Front Access Door.

These switches can be used to set:

• Thermal transfer or direct thermal mode

• Head Check Mode

• Hex Dump Mode

• Label sensor enable/disable

• Single Job or Multi-Job Receive Buffer

• Operation Mode

DIP SWITCHES

In addition, a third DIP switch (DSW1) is located on the optional RS232 Serial

Adapter card and is used to set the RS232C transmit/receive parameters.

DSW1

Each switch is an eight section toggle switch. The On position is always to the

top. To set the switches, first power the unit Off, then position the DIP switches.

Finally after placing the switches in the desired positions, power the printer back

on. The switch settings are read by the printer electronics during the power-up

sequence. They will not become effect until the power is cycled.

PN 9001078

Rev. B

SA TO CL408e/CL412e Service Manual

Page 2-1

Page 22

Section 2. Configuration

Dip Switch Settings

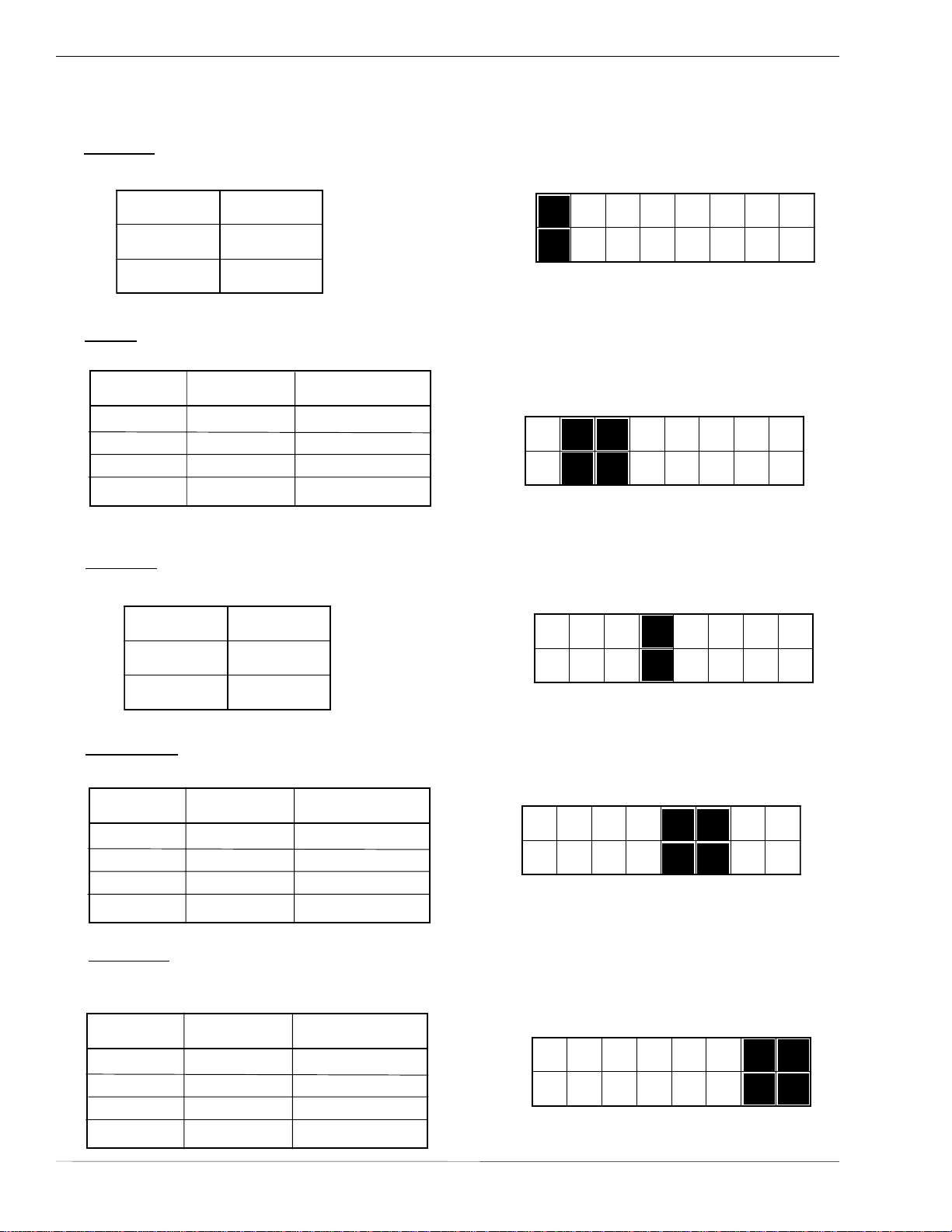

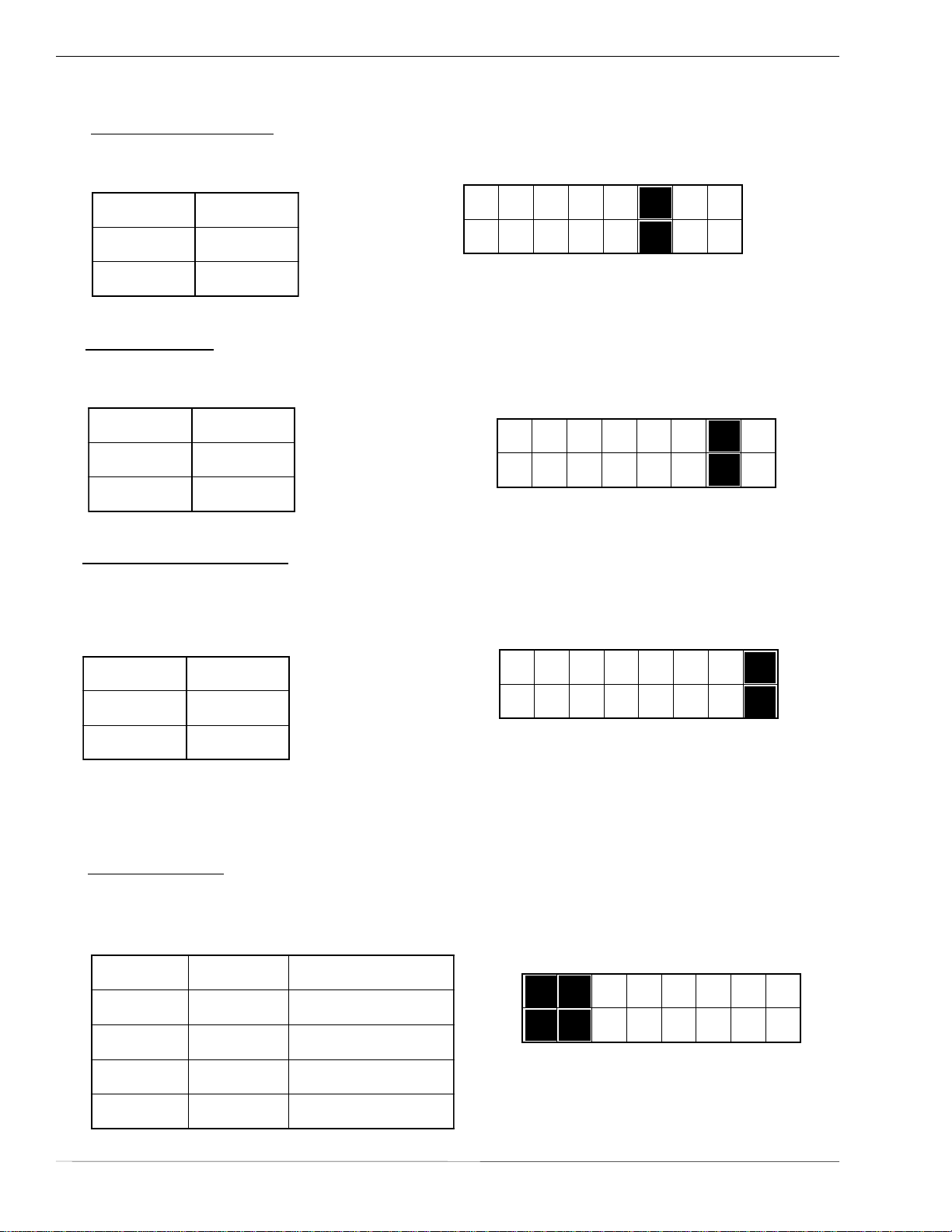

RS232 Transmit/Receive Setting (located on RS232 I/F Module)

Data Bit Selection (DSW1-1): This switch sets the printer to receive either 7 or 8

data bits for each byte transmitted.

DSW1-1 SETTING

ON

DSW1

Off 8 data bits

OFF

On 7 data bits

1 2 3 4

5 6 7 8

Parity Selection (DSW1-2, DSW1-3): These switches select the type of parity used

for error detection.

DSW1-2 DSW1-3 SETTING

DSW1

Off Off None

ON

Off On Even

On Off Odd

OFF

On On Not Used

1 2 3 4

5 6 7 8

Stop Bit Selection (DSW1-4): Selects the number of stop bits to end each byte

transmission.

DSW1

DSW1-4 SETTING

Off 1 Stop Bit

ON

OFF

On 2 Stop Bits

1 2 3 4

5 6 7 8

Baud Rate Selection (DSW1-5, DSW1-6): Selects the data rate (bps) for the RS232

port.

DSW1

DSW1-5 DSW1-6 SETTING

ON

Off Off 9600

Off On 19200

On Off 38400

On On 57600

OFF

1 2 3 4

5 6 7 8

Protocol Selection (DSW1-7, DSW1-8): Selects the flow control and status

reporting protocols.

(* Will select protocol Bi-Com 2 for M-8400 if DSW2-8 is ON)

DSW1-7 DSW1-8 SETTING

Off Off Rdy/Bsy

Off On Xon/Xoff

ON

OFF

DSW1

On Off Bi-Com 3

On On Bi-Com 4*

1 2 3 4

5 6 7 8

Page 2-2

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 23

Section 2. Configuration

Dip Switch Settings

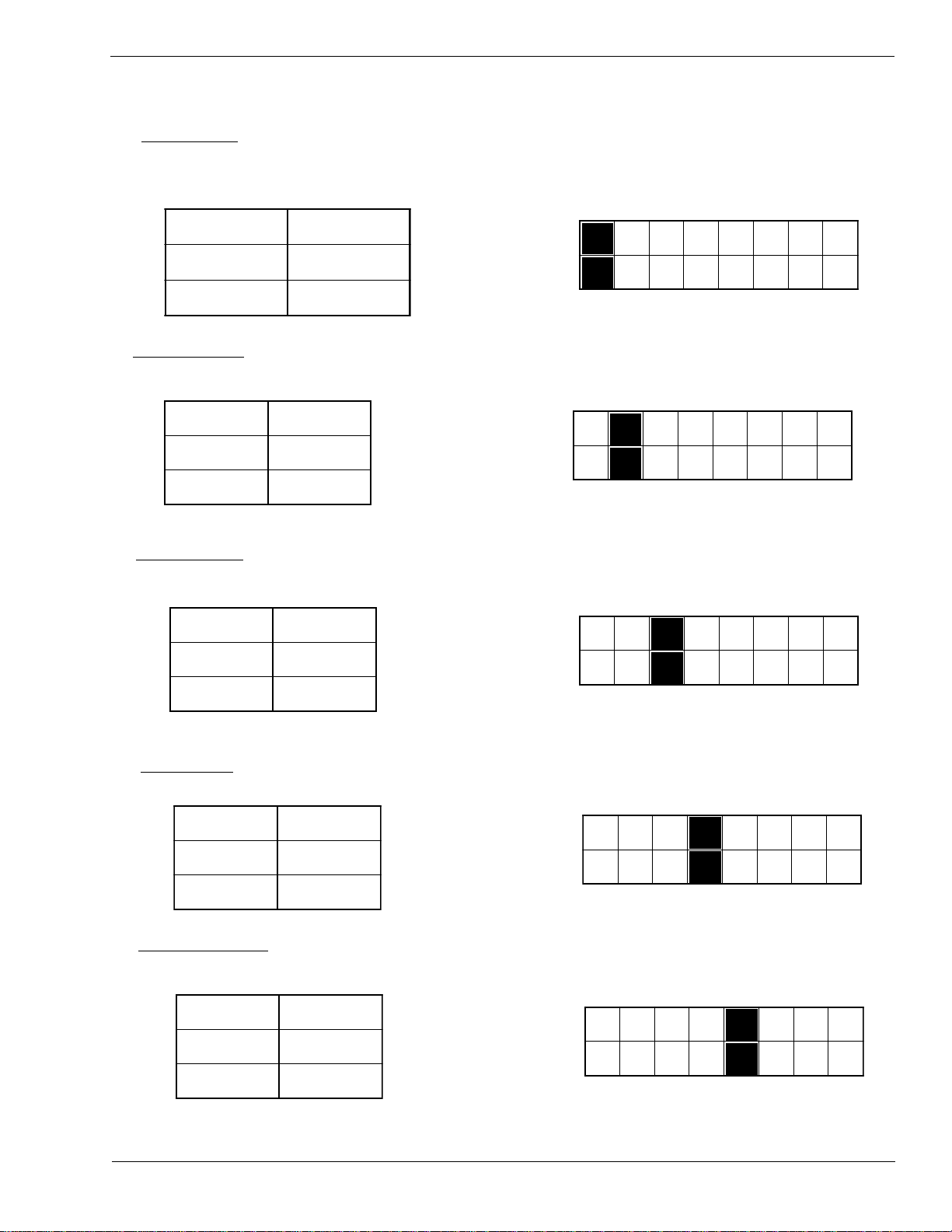

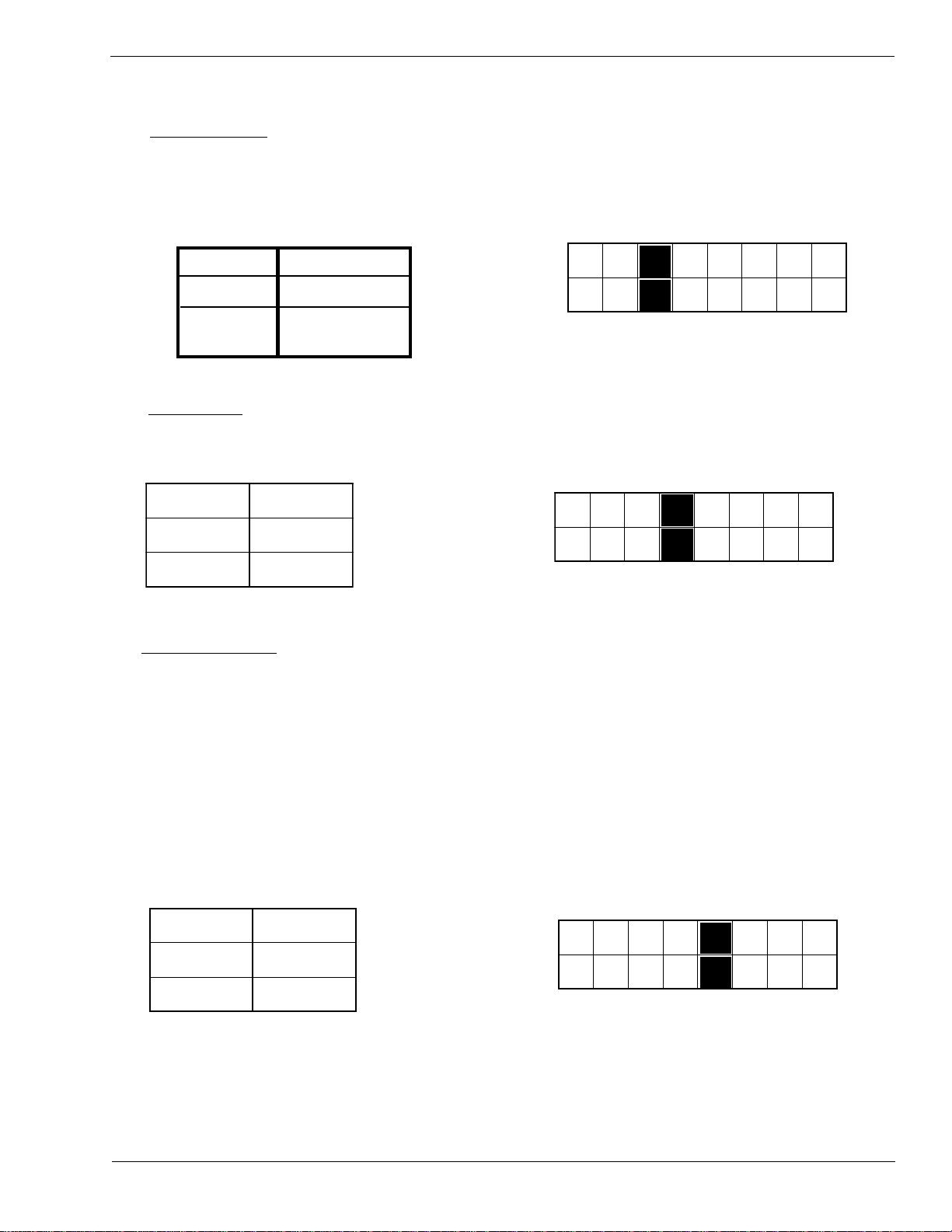

Printer Set up

Print Mode Selection (DSW2-1): Selects between direct thermal printing on

thermally sensitive paper and thermal transfer printing using a ribbon

DSW2

DSW2-1 SETTING

Off Transfer

On Direct Therm

ON

OFF

1 2 3 4

5 6 7 8

Sensor Type Selection (DSW2-2): Selects between the use of a label gap or a

reflective Eye-Mark.

DSW2

DSW2-2 SETTING

Off Gap

ON

OFF

On Eye-Mark

1 2 3 4

5 6 7 8

Head Check Selection (DSW2-3): When selected, the printer will check for head

elements that are electrically malfunctioning.

DSW2

DSW2-3 SETTING

Off Disable

ON

OFF

On Enable

1 2 3 4

5 6 7 8

Hex Dump Selection (DSW2-4):Selects Hex Dump mode.

DSW2

DSW2-4 SETTING

Off Disable

ON

OFF

On Enable

1 2 3 4

5 6 7 8

Receive Buffer Selection (DSW2-5): Selects the operating mode of the receive

buffer. See Section 3: Interface Specifications for more information.

DSW2

DSW2-5 SETTING

Off 1 Item

ON

OFF

On Multi-Job

1 2 3 4

5 6 7 8

For more information about the cause of troubleshooting printer errors, see

Section 8, Troubleshooting.

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-3

Page 24

Section 2. Configuration

Dip Switch Settings

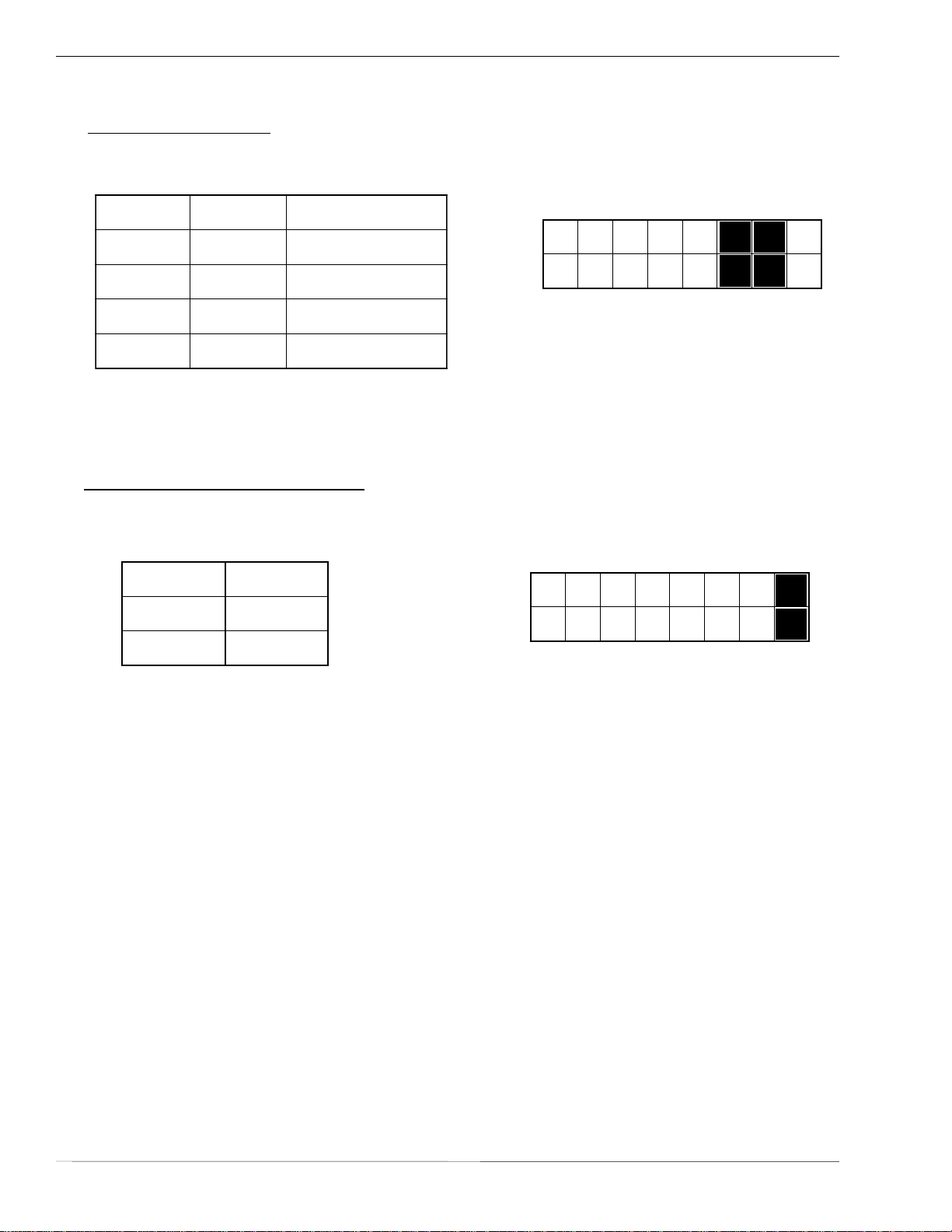

Firmware Download (DSW2-6): Places the printer in the Firmware Download mode

for downloading new firmware into flash ROM.

DSW2

DSW2-6 SETTING

Off Disabled

On Enabled

ON

OFF

1 2 3 4

5 6 7 8

Protocol Code Selection (DSW2-7): Selects the command code set used.

DSW2

DSW2-7 SETTING

Off Standard

ON

OFF

On Non-Std.

1 2 3 4

5 6 7 8

M8400 Emulation Mode (DSW2-8): For emulating earlier series software

commands. Should be used only if problems are encountered when using existing

software. This switch will also affect the setttings selected by DSW1-7 and DSW1-8.

DSW2

DSW2-8 SETTING

ON

Off Disabled

On Enabled

OFF

1 2 3 4

5 6 7 8

Mode Selection (DSW3-1 and DSW3-2): Selects the operating mode of the printer.

Batch/Continuous disables the label taken (dispense option) sensor.

DSW3

DSW3-1 DSW3-2 SETTING

ON

Off Off Batch/Continuous

OFF

Off On Tear Off

1 2 3 4

5 6 7 8

On Off Cutter

On On Dispenser

Page 2-4

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 25

Section 2. Configuration

Dip Switch Settings

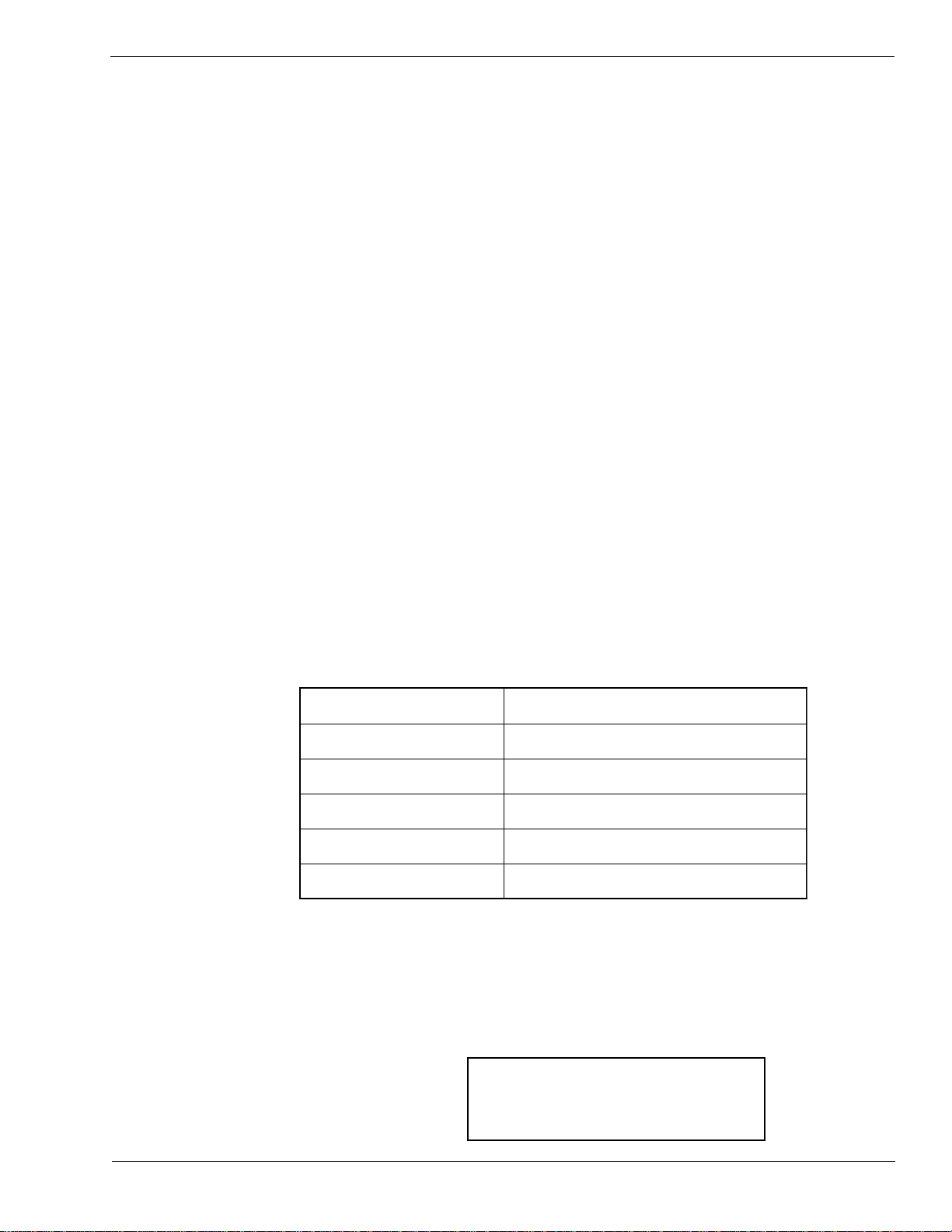

Label Sensor Selection (DSW3-3): Enables or disables the Label Pitch sensor. If the

sensor is enabled, it will detect the edge of the label and position it automatically. If

it is disabled, the positioning must be under software control using Line Feed

commands.

DSW3

DSW3-3 SETTING

Off Sensor Used

On Sensor Not

Used

ON

OFF

1 2 3 4

5 6 7 8

Back-Feed Selection (DSW3-4): When Back-Feed is enabled, the printer will

position the label for dispensing/cutting and retract it before printing the next label.

The amount of backfeed is adjustable.

DSW3

DSW3-4 SETTING

Off Enabled

ON

OFF

On Disabled

1 2 3 4

5 6 7 8

External Signal Interface

The EXT connector on the printer rear panel is intended for use with the external

printer accessories such as label rewinders or applicators. The 14-pin Centronics

type connector provides a choice of four different output signals along with various

error conditions.

PN 9001078

Rev. B

EXT Print Start Signal Selection (DSW3-5): Allows an external device to initiate

a label print for synchronization with the applicator. See Section 3: Interface

Specifications for a description of the signal level and requirements. When DSW35 is On, the unit is in the Continuous print mode, Backfeed is disabled an External

Signals are ignored.

DSW3

DSW3-5 SETTING

Off Disabled

ON

OFF

On Enabled

1 2 3 4

SA T O CL408e/CL412e Service Manual

5 6 7 8

Page 2-5

Page 26

Section 2. Configuration

Dip Switch Settings

External Signal Type Selection (DSW3-6, DSW3-7): Both the polarity and signal

type (level or pulse) of the external print synchronizing signal can be selected. See

Section 3 for a definition of signal types.

DSW3-6 DSW3-7 SETTING

DSW3

ON

Off Off Type 4

OFF

Off On Type 3

On O ff Type 2

1 2 3 4

5 6 7 8

On On Type 1

Repeat Print via External Signal (DSW3-8): Allows an applicator or other device

to reprint the last label of the print job. See Section 3: Interface Specifications for a

description of the signal requirements.

DSW3

DSW3-8 SETTING

Off Disabled

ON

OFF

On Enabled

1 2 3 4

5 6 7 8

Page 2-6

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 27

Section 2. Configuration

2.2 Default Settings

Dip Switch Selections

All switches are placed in the Off position (default) except Receive Buffer for shipping.

This will result in the following operating configuration:

Communications:

Protocol:

Sensor: Gap Sensor

Receive Buffer: Multi-Job

Mode: Batch Continuous

Label Sensor: Sensor Used

Backfeed: Enabled

External Signals: Disabled

(1) Applicable only if an RS232 Interface Card is installed in the printer.

Software Default Settings - The printer stores any software settings upon receipt from

the host and uses them until they are again changed by receipt of a command

containing a new setting. These settings are stored in non-volatile memory and are

not affected by powering the printer off. The printer may be reset to use the default

software settings by depressing the LINE and FEED keys simultaneously while

powering the printer on. You will be asked to confirm that you want the printer

default settings by selecting either YES or NO by using the LINE key to step the

underline cursor to the desired setting. If you select YES and press the FEED key, the

following default configuration will be stored:

(1)

(1)

8 data bits, no parity, 1 Stop bit, 9600 Baud

Ready/Busy

(1)

e214LC/e804LC

ssenkraDtnirP3

deepStnirP.cesrep.ni4

ecnerefeRtnirP0000=latnoziroH,0000=lacitreV

oreZhsalS

eniL-nOotuAdelbanE

Once the default operation is completed, a DEFAULT SETTING COMPLETED

message will be displayed on the LCD panel and a single "beep" will be heard. The

printer should be powered off while this message is being displayed. This saves the

default settings in the EEPROM where they will be automatically loaded the next time

the printer is powered on.

DEFAULT SETTING

COMPLETED

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-7

Page 28

Section 2. Configuration

2.3 LCD Panel Configuration

The LCD Panel on the CL408e/CL412e is used in conjunction with the LINE and FEED

switches by the operator to manually enter printer configuration settings. Many of the

settings can also be controlled via software commands and in the case of conflict between

software and control panel settings, the printer will always use the last valid setting. If you

load a label job that includes software settings and then enter a new setting via the LCD

Panel, the manually set values will be used by the printer. If you set the values manually

and then download a job with software settings, the software settings will be used.

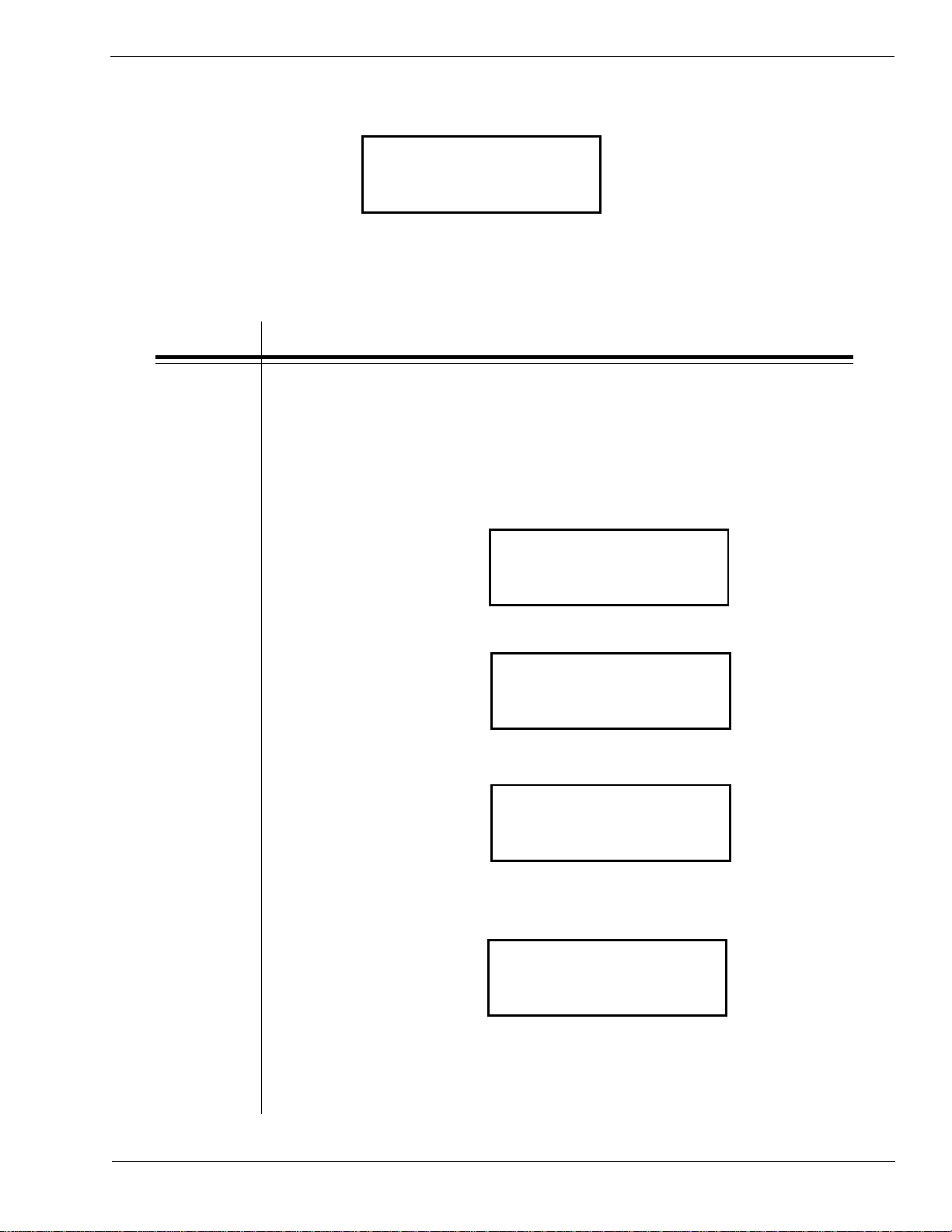

There are 7 configuration and operation modes you can access from the LCD panel. To

enter the desired mode, the KEY SEQUENCE combination listed in the table below must be

performed. The initial LCD display message is shown for each mode.

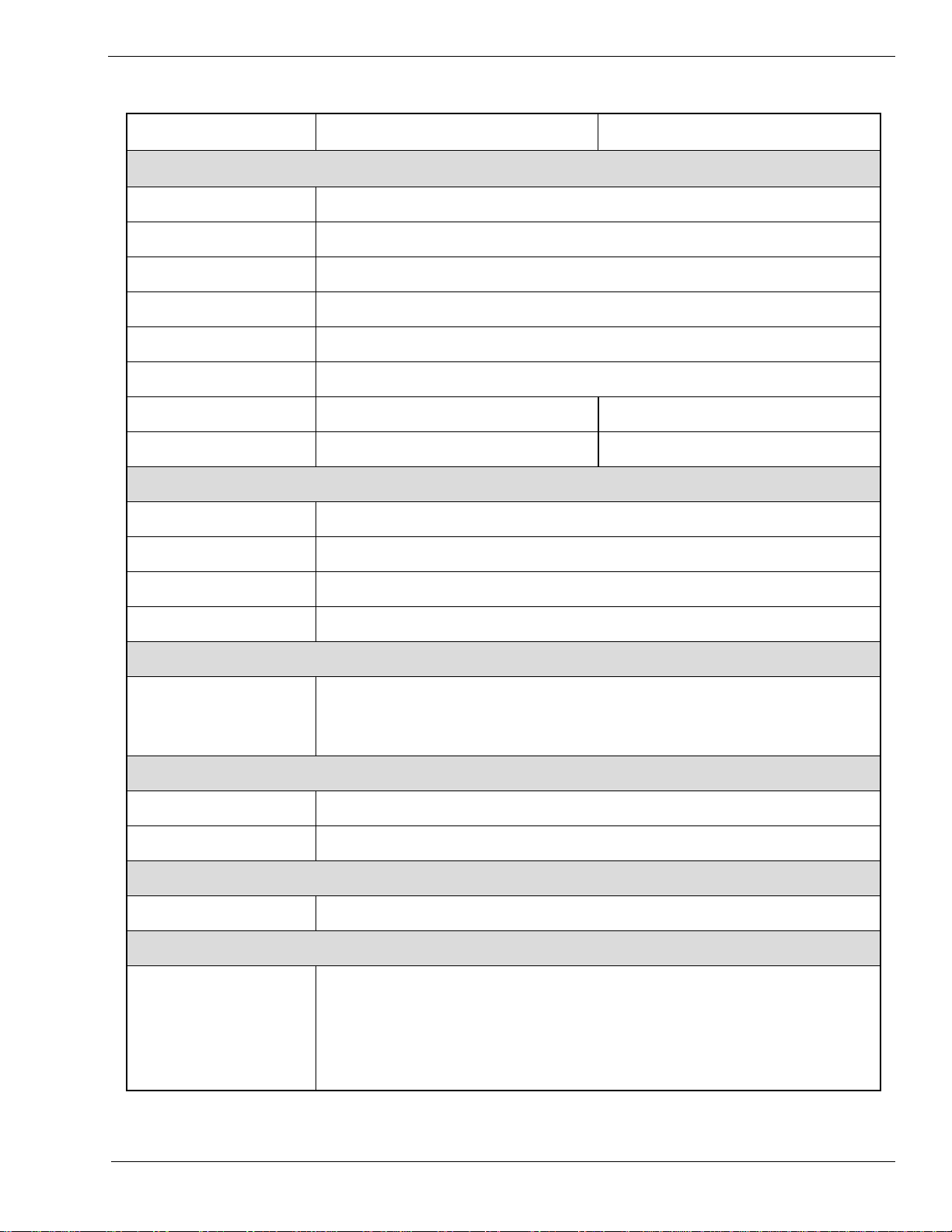

EDOMECNEUQESYEKYALPSIDLAITINIEGAP

edoMlamroNrewoP

ENILNO

000000:YTQ

edoMdecnavdAREWOP+ENILEDOMDECNAVDA31-2

edoMtnirPtseTREWOP+DEEF

edoMgnitteStluafeD

)locotorPdtS(

edoMecnanetniaM

edoMpmuDxeHREWOP+NO4-2WSD

erawmriF

edoMdaolnwoD

REWOP+DEEF+ENIL

+ENIL+NO4-2WSD

REWOP+DEEF

ENILNO

REWOP+NO6-2WSD

YDAER

EDOMTNIRPTSET

NOITARUGIFNOC

GNITTESTLUAFED

ONSEY

FFO>-NO4-2WSPID

000000:YTQ

DAOLNWODHSALF

9-2

33-2

43-2

EDOMECNANETNIAM

53-2

83-2

93-2

Page 2-8

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 29

Section 2. Configuration

LCD Panel — Normal Mode

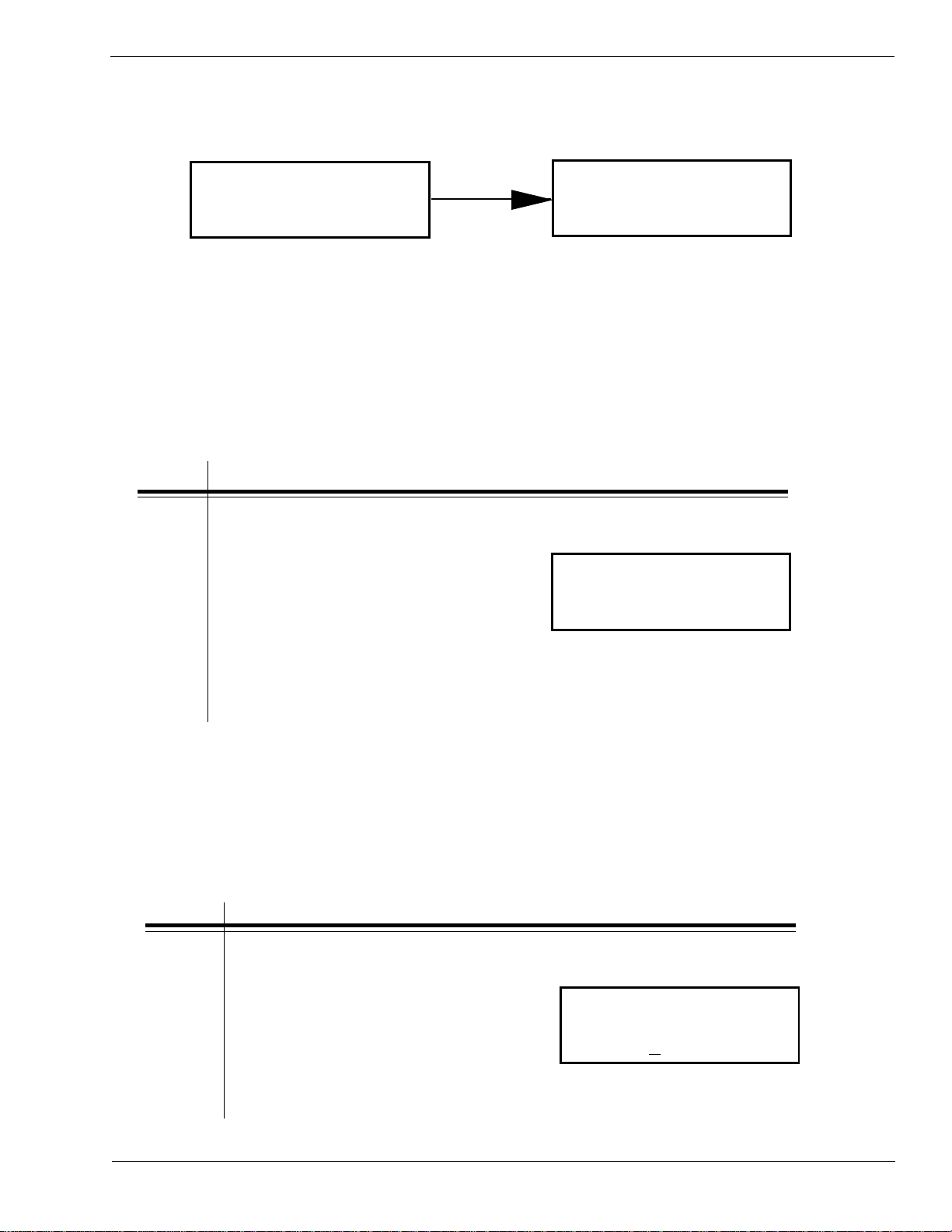

When the printer is first powered on it displays the current ROM version of the printer

then immediately displays the ONLINE mode.

initializing

rom v0.00.00.00

The LCD Panel will display the ONLINE status on the top line of the display. The bottom

line will contain the label quantity (QTY) status. The message will be changed to

OFFLINE whenever the printer is switched offline by depressing the LINE key. As soon as

a print job is received, the QTY message will indicate the number of labels to be printed.

As soon as the label job begins to print, the display will indicate the number of labels

remaining in the print job that remain to be printed. The user can access the User

Settings using the following procedures.

ONLINE

QTY: 000000

User Settings

STEP PROCEDURE

1. The printer is first taken offline by pressing the LINE key once.

The display will change to OFFLINE.

OFFLINE

000000

2. Press the LINEand FEED keys simultaneously for more than one

second. The printer now displays the first USER mode

adjustment (Print Darkness).

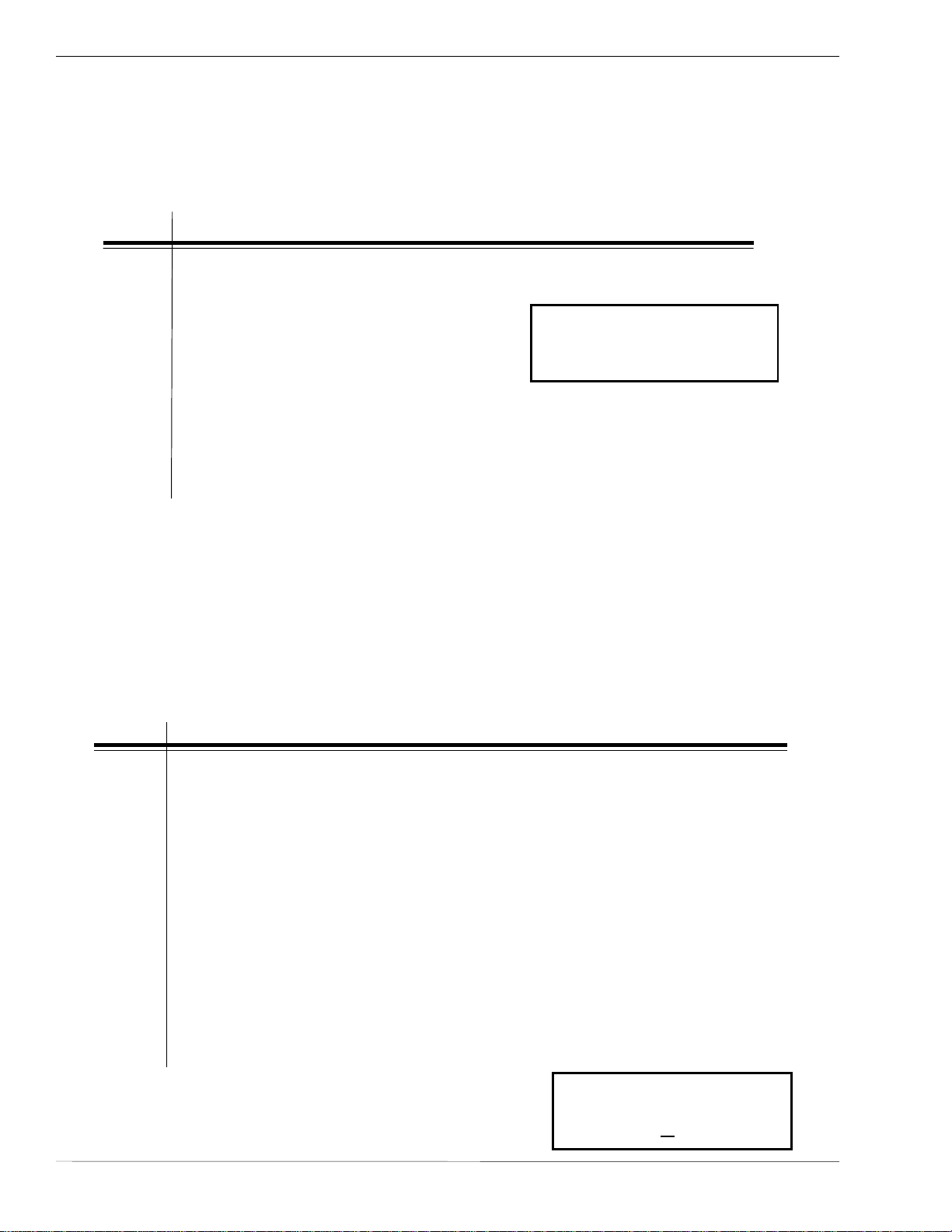

Print Darkness Setting

There are five Darkness (or heat range) settings on the printer. The higher

numbers represent darker settings. The current setting is indicated by a line under

one of the range settings.

To change the setting perform the following steps:

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired

setting.

2. Once the correct setting is underlined, press the FEED key to

accept the setting and advance to the next adjustment.

1 = Light

2 = Slightly Light

3 = Medium

4 = Slightly Dark

5 = Dark

PRINT DARKNESS

12 345

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-9

Page 30

Section 2. Configuration

LCD Panel — Normal Mode

Print Speed Adjustment

There are five Speed settings on the printer. The setting is listed on the bottom line

of the display. The current setting is indicated by an underline under one of the

speed settings. To change the setting:

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired

speed setting.

2 = 2 in/s (50mm/s)

PRINT speed

3 = 3 in/s (75mm/s)

4 = 4 in/s (100mm/s)

5 = 5 in/s (125mm/s)

6 = 6 in/s (150mm/s)

2. Once the correct setting is underlined, press the FEED key to

accept the setting and advance to the next adjustment.

Pitch Offset Adjustment

The label pitch is the distance from the leading edge (the edge that comes out of the

printer first) of a label and the leading edge of the next label. The leading edge position of

the label can be adjusted relative to the print head +/- 49mm in increments of 1mm.

Once the position is set, it can be fine adjusted +/- 3.75mm using the PITCH

potentiometer on the adjustment panel.

STEP PROCEDURE

1. The underline cursor will initially be positioned underneath the Pitch

Direction setting. Use the LINE key to step the underline to either the

positive (+) or negative (-) selection. A position selection moves the

leading edge of the label forward (away from the print head) while a

negative selection moves the leading edge of the label back into the

mechansim.

2345 6

2. Once the correct setting is underlined, press the FEED key to

3. Use the LINE Key to step the first digit of the counter to the desired setting.

Page 2-10

accept the setting and advance to the Offset adjustment.

The display will increment one step each time the LINE key is pressed. The

reading will advance to a setting of 4 after which it will automatically wrap

and start at 0 again.

pitch offset

+00mm

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 31

LCD Panel — Normal Mode

Pitch Offset Adjustment

STEP PROCEDURE

4. Press the FEED key to accept the setting and advance the cursor to the

second digit. Again use the LINE key to step to the desired setting.

Once it is correct, press the FEED key to advance to the next

adjustment.

Print a test label after completing the adjustments to ensure it is

correct.

Leading Edge of Label

A B C D E F G

Section 2. Configuration

Moved with negative (-)

offset to print on leading

edge of the label

Line Feed Direction

A B C D E F G

A B C D E F G

Original (0 offset) first

line position

Moved with positive (+)

offset to print on trailing

edge of the label

Sensor Position

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-11

Page 32

Section 2. Configuration

LCD Panel— Normal Mode

Cancel Print Job

If the printer has a print job(s) loaded in memory, selecting YESwill cause the

job(s) to be cleared. The default selection is NO. Make sure that you want to

cancel the print job before selecting YES as the job cannot be recovered and will

have to be retransmitted to the printer.

To cancel the print, perform the following steps:

cancel print job

yes no

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to either

No or Yes.

2. Once the correct setting is underlined, press the FEED key to accept

the setting.

3. After the print job(s) have been cleared from memory, the printer will

display a COMPLETED message for 3 seconds and then return to the

initial ONLINE Normal Mode.

cancel print job

COMPLETED

If you wish to change any of the settings, you must enter the User

mode again by taking the printer OFFLINE and simultaneously

pressing FEED and LINEkeys.

Page 2-12

SATO CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 33

Section 2. Configuration

LCD Panel— Advanced Mode

Advanced mode is provided to make adjustments that require only occasional adjustments.

Since they affect the basic operation of the printer, the procedure for entering this mode is

designed to prevent someone from accidentally changing the settings.

To Enter Advanced Mode:

STEP PROCEDURE

1. Press the LINE key while simultaneously turning the power on.

When the printer emits one long beep, release the LINE key to

display the first screen.

initializing

advanced mode

rom v00.00.00.00

2. Press the FEED key to display the Zero Slash display.

Zero Slash

ZERO SLASH

YES NO

This setting determines if a zero is printed with a slash or without a slash. This setting can

also be controlled via software commands. When YES is selected, the printer internal fonts

will have a slash through the center of the zero character.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to either Ye s or No.

2. Once the correct setting is underlined, press the FEED key to accept

the setting and advance to the Auto Online display.

PN 9001078

Rev. B

AutoOnline

auto online

YES NO

This setting determines the mode in which the printer powers up. If YES is selected the

printer powers up in the ONLINE mode and is ready to print. If NO is selected, the

printer powers up in the OFFLINE mode and must be manually placed in the ONLINE

mode by pressing the LINE key before it is ready to print.

STEP PROCEDURE

1. Use the LINE key to step the underline to either the YES or NO

selection.

2. Once the correct setting is underlined, press the FEED key to accept

the setting and advance the display to the Offset display.

SA T O CL408e/CL412e Service Manual

Page 2-13

Page 34

Section 2. Configuration

LCD Panel — Advanced Mode

Print Offset

Print offset

v:+0000 H:+000

Since the printer moves the label in discrete steps equal to the size of the print dot, the

units of measure for Vertical and Horizontal Offset distance is dots.

Vertical Offset is the distance down from the leading edge in dots (the edge of the

label that comes out of the printer first) to the first vertical print position. A positive

setting moves the first print position down the length of the label while making it

negative moves it up the length of the label. The maximum value that can be set is 823

dots.

Horizontal Offset is the distance that the label image is shifted either to the right or

left on the label. For a positive setting the image is shifted to the left (towards the inside

edge of the label). For a negative setting the image the image is shifted to the right

(towards the outside edge of the label). This setting changes the base reference point for

all subsequent label jobs. The effect is identical to the <ESC>A3 Base Reference point

command. The maximum value that can be set is 1424 dots.

STEP PROCEDURE

1. Use the LINE key to step the first digit of the counter to the desired setting.

The display will increment one step each time the LINE key is pressed.

2. Press the FEED key to accept the setting and advance the cursor to the

second digit. Again use the LINE key to step to the desired setting. Once it

is correct, press the FEED key to advance to the next adjustment.

3. Once the setting is correct, press the FEED key to accept the setting and

advance to the next display.

Print a test label after completing the adjustments to ensure it is correct.

Note: This setting can be overridden by the Base Reference Point Command in

your software.

Set Calendar

set calendar

YES NO

This message will only be displayed if the Calendar Option is installed in the printer.

The Calendar is an optional feature in CL408e/CL412e printers allowing the date and time

to be set manually using the LCD Display or via the <ESC>WT Calendar Set command.

The last setting, set either manually via software command, received by the printer will be

the value used. The format of the display is YY/MM/DD hh:mm (Year/Month/Day/

hours:minutes). The date format is fixed and cannot be changed.

To enable the Calendar feature (if installed), press the LINE key until the underline cursor

is beneath the YES. If the Calendar feature is to be disabled, press the LINE key until the

cursor is underneath the NO. When the desired setting is selected, Press the FEED key.

Page 2-14

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 35

LCD Panel — Advanced Mode

Set Calendar

(Continued)

Section 2. Configuration

Calendar

calendar

00/00/00 00:00

00/00/00 00:00

STEP PROCEDURE

1. Year - The first display shown will have the two digit year selection

underlined. You can scroll through the dates by pressing the LINE

key. The year number will increase by one each time the LINE key is

pressed until it reaches its maximum leagal value (i.e., "99" for the

year digits) at which point it will wrap around to the "00" setting.

2. Month - After you have set the correct year, pressing the FEED key

will advance the underline cursor to the two digit Month position.

You can scroll through the numbers corresponding to the month by

pressing the LINE key. The month number will increase by one each

time the LINE key is pressed until it reaches a value of "12" at which

point it will wrap around to the "01" setting.

3. Day - After you have set the correct month, pressing the FEED key

will advance the underline cursor to the two digit Day position. You

can scroll through the numbers corresponding to the month date by

pressing the LINE key. The date number will increase by one each

time the LINE key is pressed until it reaches a value of "31" at which

point it will wrap around to the "01" setting.

4. Hour - After you have set the correct date, pressing the FEED key

will advance the underline cursor to the two digit Hour position. You

can scroll through the numbers corresponding to the hour (using a 24

hour clock) by pressing the LINE key. The hour number will increase

by one each time the LINE key is pressed until it reaches a value of

"24" at which point it will wrap around to the "01" setting.

5. Minute - After you have set the correct hour, pressing the FEED key

will advance the underline cursor to the two digit Minute position.

You can scroll through the numbers corresponding to the hour by

pressing the LINE key. The minute number will increase by one each

time the line key is pressed until it reaches a value of "60" at which

point it will wrap around to the "01" setting.

6. After you have set the minutes, pressing the FEED key will accept the

setting and advance to the Ignore CR/LF selection.

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-15

Page 36

Section 2. Configuration

LCD Panel — Advanced Mode

Ignore CR/LF

ignore cr/lf

YES NO

This setting tells the printer to strip out all carriage return/line feed pairs (CRLF) from the

data stream, including graphics and 2D bar codes. It is used primarily to maintain

compatibility with earlier models of SATO printers.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to either YES or NO.

2. Once the desired setting is underlined, press the FEED key to accept

the setting and advance to the Character Pitch display.

Character Pitch

character pitch

prop fixed

This setting allows you to set the default character pitch to either fixed character spacing

or proportional character spacing.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

2. Once the desired setting is underlined, press the FEED key to accept

the setting and advance to Cover Open Sensor display.

Note: This command can be overriden by the <ESC>PR or <ESC>PS

Character Pitch Commands.

Cover Open Sensor

cover open sensor

Yes No

This setting allows the user to enable or disable the Cover Open Sensor. Selecting YES will

enable the sensor and selecting NO will disable it.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

Page 2-16

2. Once the desired setting is underlined, press the FEED key to accept

the setting and return to the Advanced Mode Display.

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 37

LCD Printer — Card Mode

Section 2. Configuration

Exit Advanced Mode

To exit the Advanced mode, power off the printer then back on.

The Card Mode allows the operator to manage the Expanded Memory (PCMCIA Card or

Internal Expanded Flash ROM). The Card Mode is entered from the Advanced Mode

display by pressing the LINE key once.

Advanced Mode

The Card Mode display indicates that the printer is in the Card Mode. To advance to the

Mem Select (CC1), press the FEED key.

Advanced Mode

card Mode

Mem Select (CC1)

mem select (CC1)

Card Memory

This selection determines which type of optional expanded memory will be addressed as

"CC1" in the command streams. The CARD selection specifies the optional PCMCIA card as

CC1 and the optional Expanded Flash ROM as CC2.

STEP PROCEDURE

1. Use the LINE key to step the cursor to the desired setting (Card or

Memory).

2. Once the desired setting is underlined, press the FEED key to accept

the setting and advance the display.

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-17

Page 38

Section 2. Configuration

LCD Panel — Card Mode

Card ->MemoryCopy

TrueTypeFont Y/N

card ->MemoryCopy

TrueTypeFont y/n

This selection allows you to copy TrueType fonts from the PCMCIA Memory card installed

in the Memory Card slot (on the rear of the printer) to the optional Flash ROM.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Card Copy mode.

If No is selected, the display will advance to Card to Memory Copy

SATO Font mode. Press the FEED key to accept the selection and

advance the display.

2. Confirm your selection by stepping the underline cursor to the Yes

selection. If you select No, the display will return to the previous

selection.

copy start

yes no

3. Press the FEED key to accept the selection. If Yes was selected, the

copy process will start.

truetypefontcopy

copying

4. Once the copy process is completed, press the FEED key to advance

the display.

truetypefontcopy

completed

5. If an error is encountered in the copy process, one of the following

messages will be displayed on the second line.

CARD COPY/FORMAT

XXXXXXX ERROR

Page 2-18

R/W Error Indicates a Read/Write error occurred

No Card Error Indicates no card was recognized

Mem Full Error Indicates that there is insufficient

memory available

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 39

Section 2. Configuration

LCD Panel — Card Mode

Card ->MemoryCopy

SatoFont Y/N

card ->MemoryCopy

SATOFont y/n

This selection allows you to copy SATO fonts from the PCMCIA Memory card installed in

the Memory Card slot (on the rear of the printer) to the optional Flash ROM.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Card Copy mode.

If No is selected, the display will advance to Card->MemoryCopy All

mode. Press the FEED key to accept the selection and advance the

display.

2. Confirm your selection by stepping the underline cursor to the Yes

selection. If you select No, the display will return to the previous

selection.

copy start

yes no

3. Press the FEED key to accept the selection. If Yes was selected, the

copy process will start.

Sato font copy

copying

4. Once the copy process is completed, press the FEED key to advance

the display.

sato font copy

completed

5. If an error is encountered in the copy process, one of the following

messages will be displayed on the second line.

PN 9001078

Rev. B

CARD COPY/FORMAT

XXXXXXX ERROR

R/W Error Indicates a Read/Write error occurred

No Card Error Indicates no card was recognized

Mem Full Error Indicates that there is insufficient

memory available.

SA T O CL408e/CL412e Service Manual

Page 2-19

Page 40

Section 2. Configuration

LCD Panel — Card Mode

Card ->MemoryCopy

All Y/N

card ->MemoryCopy

all y/n

This selection allows you to copy the entire contents from PCMCIA Memory card installed

in the Memory Card slot on the rear of the printer to the optional internal Expanded

Memory.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Card Copy mode.

If No is selected, the display will advance to Card->MemoryCopy All

mode.

2. Confirm your selection by stepping the underline cursor to the Yes

selection. If you select No, the display will return to the previous

selection.

copy start

yes no

3. Press the FEED key to accept the selection. If Yes was selected, the

copy process will start.

card -> memory

copying

4. Once the copy process is completed, press the FEED key to advance

the display.

card ->memory

completed

5. If an error is encountered in the copy process, one of the following

messages will be displayed on the second line.

CARD COPY/FORMAT

XXXXXXX ERROR

R/W Error Indicates a Read/Write error occurred

No Card Error Indicates no card was recognized

Mem Full Error Indicates that there is insufficient

memory available

Page 2-20

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 41

LCD Panel — Card Mode

Section 2. Configuration

Memory->Card Copy

Memory ->cardCopy

All <XMB> Y/N

all <xmb> y/n

This selection allows you to copy the entire contents of the optional Expanded Memory to

the PCMCIA Memory card installed in the Memory Card slot on the rear of the printer.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Card Copy mode.

If No is selected, the display will advance to Card->MemoryCopy All

mode.

2. Confirm your selection by stepping the underline cursor to the Yes

selection. If you select No, the display will return to the previous

selection.

copy start

yes no

3. Press the FEED key to accept the selection. If Yes was selected, the

copy process will start.

memory-> card copy

copying

4. Once the copy process is completed, press the FEED key to advance

the display.

memory-> card copy

completed

5. If an error is encountered in the copy process, one of the following

messages will be displayed on the second line.

CARD COPY/FORMAT

XXXXXXX ERROR

R/W Error Indicates a Read/Write error occurred

No Card Error Indicates no card was recognized

Mem Full Error Indicates that there is insufficient

memory available

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-21

Page 42

Section 2. Configuration

LCD Panel — Card Mode

Card->Memory Copy

card ->memoryCopy

Program Y/N

program y/n

This selection allows you to copy printer firmware from the PCMCIA Memory card to the

printer.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Card Copy mode.

If No is selected, the display will advance to the mode display.

2. Confirm your selection by stepping the underline cursor to the Yes

selection. If you select No, the display will return to the previous

selection.

copy start

yes no

3. Press the FEED key to accept the selection. If Yes was selected, the

copy process will start.

card-> memory copy

copying

4. Once the copy process is completed, press the FEED key to advance

the display.

card-> memory copy

completed

5. If an error is encountered in the copy process, one of the following

messages will be displayed on the second line.

CARD COPY/FORMAT

XXXXXXX ERROR

R/W Error Indicates a Read/Write error occurred

No Card Error Indicates no card was recognized

Mem Full Error Indicates that there is insufficient

memory available

Page 2-22

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 43

LCD Panel — Card Mode

Section 2. Configuration

Memory->Card Copy

Memory->cardCopy

Program Y/N

program y/n

This selection allows the user to copy the current firmware installed in the printer to a

PCMCIA Memory Card.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Card Copy mode.

If No is selected, the display will advance to the mode display.

2. Confirm your selection by stepping the underline cursor to the Yes

selection. If you select No, the display will return to the previous

selection.

copy start

yes no

3. Press the FEED key to accept the selection. If Yes was selected, the

copy process will start.

memory-> card copy

copying

4. Once the copy process is completed, press the FEED key to advance

the display.

memory-> card copy

completed

5. If an error is encountered in the copy process, one of the following

messages will be displayed on the second line.

CARD COPY/FORMAT

XXXXXXX ERROR

R/W Error Indicates a Read/Write error occurred

No Card Error Indicates no card was recognized

Mem Full Error Indicates that there is insufficient

memory available

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-23

Page 44

Section 2. Configuration

LCD Panel — Card Mode

Card Format

Card format

Yes N o

yes no

Before a PCMCIA card can be used, it must be formatted.

Note: Formatting a card destroys all data currently stored on the Card.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Card Format mode.

If No is selected, the display will advance to the mode display.

Memory Format

memory format

Yes No

yes no

Before the internal Expanded Memory can be used, it must be formatted.

Note: Formatting the memory will destroy any stored data.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will enter the Memory Format mode.

If No is selected, the display will advance to the mode display.

To exit the Card Mode, power off the printer, then back on.

card mode

Page 2-24

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 45

Section 2. Configuration

LCD Panel — Service Mode

The Service Mode allows the operator to set up the basic operation parameters of the

printer and is entered from the Advanced Mode.

To Enter Advanced Mode:

STEP PROCEDURE

1. Press the LINE key while simultaneously turning the power on.

When the printer emits one long beep, release the LINE key to display

the first screen.

ADVANCED MODE

2. Press the LINE key twice to enter the Service Mode.

service mode

The Service Mode display indicates that the printer is in the Card

Mode. To advance to the first selection, press the FEED key.

Gap [X.XV]

gap [x.xv]

Input [X.XV}

input [x.xv]

The CL408/CL412e printers determine the location of the leading edge of the label by

measuring the difference between light levels when it sees either a label gap or a black

"EYE" mark. This adjustment allows you to manually set the threshold voltage level

between the maximum and minimum light levels. DIP switch DSW2-2 selects the sensor

type. If DSW2-2 is in the OFF position, the setting will be for a See-Thru (or Gap) sensor

and the LCD will display "GAP" on the top line along with the current setting. If DSW2-2 is

in the ON position, the LCD will display "EYE" on the top line with its current setting. If

the value entered for the bottom line setting is "0.0V", then the printer will automatically

calculate the setting when the first label is fed after the printer is powered on or the head

is closed. There are some instances where the automatically calculated value must be

adjusted to ensure reliable label feeding, such as when the backing opacity or the

reflectance of the "EYE" mark varies significantly within a roll of labels or between label

rolls. In these instances the value should be set using the following procedures.

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-25

Page 46

Section 2. Configuration

LCD Panel — Service Mode

Gap [X.XV]

Input [X.XV}

GAP - When setting the "GAP" threshold, the voltage shown on the top line of the display

must be measured with nothing but the backing in the sensor and then again with a label

still attached to the backing. The formula to be used for setting the threshold is:

(High Voltage Level + Low Voltage Level) x 0.5 = Start Value

STEP PROCEDURE

1. Insert a label still attached to the backing into the sensor and close

the Label Hold-Down. Record the voltage shown on the top line of

the LCD panel. This line should have the message "GAP" on the top

line (DIP switch DSW2-2 = OFF). Make sure the label is all the way

under the sensor.

2. Strip the label from the backing and insert the backing strip under the

sensor and close the Label Lid. Record the voltage shown on the top

line of the LCD panel. The voltage ranges measured should be within

the following range.

gap [x.xv]

input [x.xv]

Backing without label = 0.5V or less

Backing with label = 1.0V above the low value

If the measured values are outside this range, you may have trouble

finding a value that will work properly under all conditions. If this is

the case, a higher quality label may be needed to get adequate

performance.

3. Calculate the starting point voltage using the formula.

4. Use the LINE key to step the counter to the desired setting. The

display will increment one step for each time the LINE key is pressed.

If the LINE key is held down for more than two seconds, it will

automatically go into the fast scroll mode. The reading will advance

to a setting of 3.3 (the maximum voltage) after which it will

automatically wrap and start at "0.0" again. If a value of "0.0" is set,

the printer will automatically set the level each time the printer is

powered on with labels loaded or the head is closed.

5. Once the setting is correct, pressing the FEED key will accept the

setting and advance to the Online Feed display.

Page 2-26

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 47

LCD Panel — Service Mode

Section 2. Configuration

Eye [X.XV]

Input [X.XV}

EYE - When setting the "EYE" threshold, the voltage must be measured with nothing but

the label under the sensor and then again with the printed "eye" mark under the sensor.

The formula to be used for this is:

(High Voltage Level + Low Voltage Level) x 0.5 = Start Value

STEP PROCEDURE

1. Insert a label into the sensor and close the Label Hold-Down. Make

sure the printed "eye" mark in not under the sensor. Record the

voltage shown on the top line of the LCD panel. This line should have

the message "EYE" on the top line (DIP switch DSW2-2 = ON).

2. Now pull the label forward until the "eye" mark is positioned under

the sensor (the voltage reading shown on the top line of LCD panel).

The voltage ranges measured should be within the following ranges:

eye [x.xv]

input [x.xv]

Label Only = 0.3 - 0.5V

Eye-mark = Equal to or greater than 1.2V

above the low value.

If the measured values are outside this range, you may have trouble

finding a value that will work properly under all conditions. If this is

the case, a higher quality label may be needed to get adequate

performance.

3. Calculate the starting point voltage using the formula.

4. Use the LINE key to step the counter to the desired setting. The

display will increment one step for each time the LINE key is pressed.

If the LINE key is held down for more than two seconds, it will

automatically go into the fast scroll mode. The reading will advance

to a setting of 3.3 (the maximum voltage) after which it will

automatically wrap and start at "0.0" again. If a value of "0.0" is set,

the printer will automatically set the level each time the printer is

powered on with labels loaded or the head is closed.

5. Once the setting is correct, pressing the FEED key will accept the

setting and advance to the Auto Online Feed display.

PN 9001078

Rev. B

SA T O CL408e/CL412e Service Manual

Page 2-27

Page 48

Section 2. Configuration

LCD Panel — Service Mode

Auto Online Feed

Auto online feed

Yes N o

yes no

This selection specifies whether or not the printer will automatically feed a blank label

when it is placed in the Online mode.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will feed a blank label anytime it enters

the Online mode.

If No is selected, the display will advance to the mode display.

Feed on Error

feed on error

Yes No

yes no

This selection specifies whether or not the printer will feed a blank label automatically

when an error condition is cleared.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will feed a blank label anytime an error

condition is cleared.

If No is selected, the display will advance to the mode display.

Reprint W/Feed

reprint w/feed

Yes No

yes no

This selection specifies whether or not the printer will print the last printed label stored in

memory when the FEED key is pressed in the Normal Online mode.

STEP PROCEDURE

1. Use the LINE key to step the underlined cursor to the desired setting.

IF Yes is selected, the printer will reprint the last label when the FEED

key is pressed when the printer is Online. If the printer is Offline,

pressing the FEED key will feed a blank label.

Page 2-28

If No is selected, the display will advance to the mode display.

SA T O CL408e/CL412e Service Manual

PN 9001078

Rev. B

Page 49

LCD Panel — Service Mode

Section 2. Configuration

Forward/Backfeed

forward/backfeed

Distance Default

distance default

This display will only appear when Backfeed is enabled (DSW3-4 = OFF). The maximum

backfeed distance is 255mm.

STEP PROCEDURE

1. Press the FEED key to use the default distance. This setting will be

appropriate for use with standard labels with a 1/8" gap between labels

and most tag stock applications.

2. Press the LINE key to set your own backfeed distance up to 255mm.

Each time you press the LINE key, the distance is advanced 1mm.

CAUTION: A backfeed distance over 40mm may cause ribbon wrinkle

and require ribbon tension adjustments.

forward/backfeed

distance XXXmm