Page 1

Quick Guide

For printer model:

CG4 Series

www.satoamerica.com

PN: 9001222A

Read this Quick Guide before using this product.

Keep this document available for future reference.

CG408DT

CG412DT

Direct Thermal Type

CG408TT

CG412TT

Thermal Transfer Type

Page 2

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support: (704) 644.1660

Technical Support Fax: (704) 644.1661

E-Mail: satosales@satoamerica.com

techsupport@satoamerica.com

www.satoamerica.com

© Copyright 2010 SATO America, Inc.

All rights reserved.

Reproduction in any manner of all or part of this document is prohibited.

The content of this document may be changed without prior notice.

Great care has been taken in the preparation of this document. If any problems, mistakes, or omissions are found,

please contact your SATO reseller or technical support center.

FCC Statement

The printer complies with the requirements in Part 15 of FCC Rules for a Class B Computing Device. Operating

the printer in a residential area may cause unacceptable interference to radio and TV reception. If the interference

is unacceptable, you can reposition the equipment, which may improve reception.

Page 3

Safety Precautions

Safety Precautions

Please read the following information carefully before installing and using the printer.

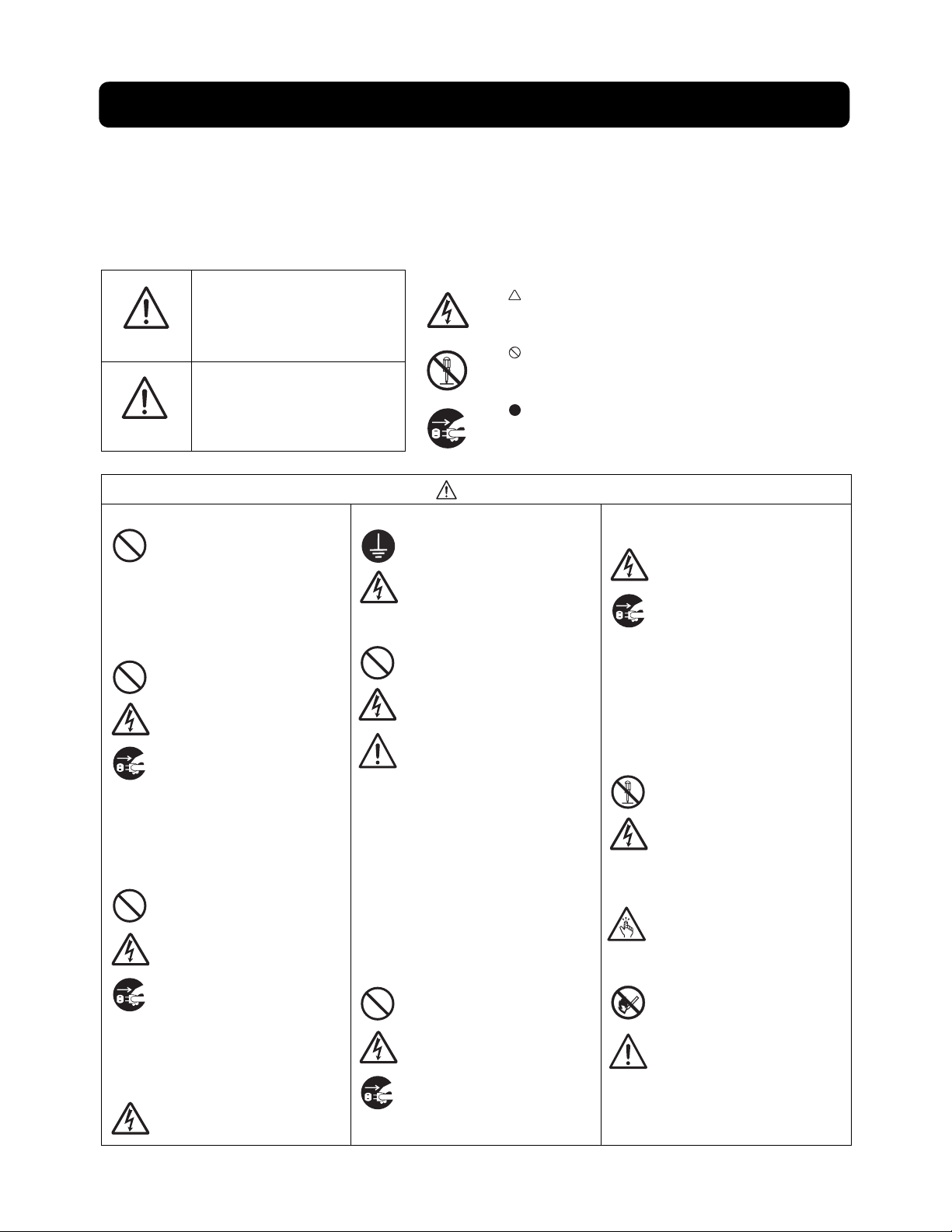

Pictographic Symbols

This instruction manual and the printer labels use a variety of pictographic symbols to facilitate safe and

correct use of the printer and to prevent injury to others and property damage. The symbols and meanings for

them are given below. Be sure to understand these symbols well before reading the main text.

Ignoring the instructions marked

by this symbol and erroneously

operating the printer could result

in death or serious injury.

Warning

Ignoring the instructions marked

by this symbol and erroneously

operating the printer could result

Caution

Do not set on an unstable area

• Do not set on an unstable area,

Do not place containers full of water

or other liquid on the printer

• Do not place flower vases,

Do not put objects inside the printer

• Do not insert or drop in metal or

Use only the specified voltage

•

in injury or property damage.

such as a wobbly table or

slanted area or an area subject

to strong vibration. If the printer

falls off or topples over, it could

injure someone.

cups, or other containers holding liquids, such as water or

chemicals, or small metal

objects near the printer. If they

are spilled and get inside the

printer, immediately turn off the

power switch, unplug the power

cord from the outlet, and contact

your SATO reseller or technical

support center. Using the

printer in this condition could

cause a fire or electric shock.

burnable objects inside the

printer’s openings (cable outlets, etc.). If foreign objects do

get inside the printer, immediately turn off the power switch,

unplug the power cord from the

outlet, and contact your SATO

reseller or technical support

center. Using the printer in this

condition could cause a fire or

electric shock.

Do not use other than the specified

voltage. Doing so could result in fire

or electric shock.

Example Pictographs

The pictograph means “Caution is required.” A specific

warning symbol is contained inside this pictograph (The symbol at left is for electric shock).

The pictograph means “Should not be done.” What is specifically prohibited is contained in or near the pictograph (The

symbol at left means “Disassembly prohibited”).

The pictograph means “Must be done.” What is specifically

to be done is contained in the pictograph (The symbol at left

means “Unplug the power cord from the outlet”).

Warning

Always ground the connections

• Always connect the printer’s

ground wire to a ground. Not

grounding the ground wire could

result in electric shock.

Handling of the power cord

• Do not damage, break, or modify the power cord. Also, do not

place heavy objects on the

power cord, heat it, or pull it

because doing so could damage the power cord and cause a

fire or electric shock.

• If the power cord becomes

damaged (core is exposed,

wires broken, etc.), contact your

SATO reseller or technical support center. Using the power

cord in this condition could

cause a fire or electric shock.

• Do not modify, excessively

bend, twist, or pull the power

cord. Using the power cord in

such a condition could cause a

fire or electric shock.

When the printer has been dropped or

broken

• If the printer is dropped or broken, immediately turn off the

power switch, unplug the power

cord from the outlet, and contact

your SATO reseller or technical

support center. Using the

printer in this condition could

cause a fire or electric shock.

Do not use the printer when something is abnormal about it

• Continuing to use the printer in

the event something is abnormal about it, such as smoke or

unusual smells coming from it,

could result in fire or electric

shock. Immediately turn off the

power switch, unplug the power

cord from the outlet, and contact

your SATO reseller or technical

support center for repairs. It is

dangerous for the customer to

try to repair it, so absolutely do

not attempt repairs on your own.

Do not disassemble the printer

• Do not disassemble or modify

the printer. Doing so could result

in fire or electric shock. Ask your

SATO reseller or technical support center to conduct internal

inspections, adjustments, and

repairs.

Regarding the cutter

• Do not touch the cutter with

your hands or do not put something into the cutter. Doing so

could result in an injury.

Using the head cleaning fluid

•

Use of flame or heat around the

head cleaning fluid is prohibited.

Absolutely do not heat it or subject

it to flames.

• Keep the fluid out of reach of children to prevent them from accidentally drinking it. If the fluid is drunk,

immediately consult with a physician.

CG4 Series Quick Guide Page i

Page 4

Safety Precautions

Do not place in areas with high

humidity

• Do not place the printer in areas

with high humidity or where condensation forms. If condensation forms, immediately turn off

the power switch and do not use

the printer until it dries. Using

the printer while condensation is

on it could result in electric

shock.

Carrying the Printer

• When moving the printer,

always unplug the power cord

from the outlet and check to

make sure all external wires are

disconnected before moving it.

Moving the printer with the wires

still connected could damage

the cords or connecting wires

and result in a fire or electrical

shock.

• Do not carry the printer with

paper loaded in it. The paper

could fall out and cause an

injury.

• When setting the printer on the

floor or a stand, make sure not

to get your fingers or hands

pinched under the printer feet.

Power supply

• Do not operate the power

switch or plug in/unplug the

power cord with wet hands.

Doing so could result in electric

shock.

Caution

Power cord

• Keep the power cord away from

hot devices. Getting the power

cord close to hot devices could

cause the cord’s covering to

melt and cause a fire or electrical shock.

• When unplugging the power

cord from the outlet, be sure to

hold it by the plug. Pulling it by

the cord could expose or break

the core wires and cause a fire

or electric shock.

• The power cord set that comes

with the printer is especially

made for this printer. Do not use

it with any other electrical

devices.

Top cover

• Be careful not to get your fingers pinched when opening or

closing the top cover. Also be

careful the top cover does not

slip off and drop.

Print head

• The print head is hot after printing. Be careful not to get burned

when replacing paper or cleaning immediately after printing.

• Touching the edge of the print

head immediately after printing

could result in injury. Use caution when replacing the label or

cleaning the print head.

• You should not replace the print

head without having received

the proper training.

Loading paper

• When loading roll paper, be

careful not to get your fingers

pinched between the paper roll

and the supply unit.

When not using the printer for a long

time

• When not using the printer for a

long time, unplug the power

cord from the outlet to maintain

safety.

During maintenance and cleaning

• When maintaining and cleaning

the printer, unplug the power

cord from the outlet to maintain

safety

Page ii CG4 Series Quick Guide

Page 5

Precautions for Installation and Handling

Printer operation can be affected by the printer environment.

Refer to the following instructions for installation and handling of CG4 Series printer.

Select a Safe Location

Safety Precautions

Place the printer on a surface that is flat and level.

If the surface is not flat and level, this may result in poor

print quality. This may also cause malfunction and

shorten the life span of the printer.

Do not place the printer on a location that

produces vibration.

Giving serious vibration or shock to the printer may

cause malfunction and shorten the life span of the

printer.

Keep the printer out of high temperature and humidity.

Avoid locations subject to extreme or rapid changes

in temperature or humidity.

Do not place the printer in a location subject to

water or oil.

Do not place the printer in a location where it will be

splashed with water or oil. Water or oil entering

inside the printer may cause a fire, electric shock, or

malfunction.

Avoid dust.

Dust build up may result in poor print quality.

Keep out of direct sunlight.

This printer has a built-in optical sensor. Exposure to

direct sunlight will make the sensor less responsive

and may cause the label to be sensed incorrectly.

Close the top cover when printing.

Power Supply

This printer requires an AC power supply.

Be sure to connect the printer to an AC power supply

via the supplied AC adapter.

Connect the power cord to a grounded power

outlet.

Make sure that the printer is plugged into a grounded

power outlet.

CG4 Series Quick Guide Page iii

Provide a stable source of electricity to the

printer.

When using the printer, do not share its power outlet

with other electrical devices which could cause

power fluctuations and performance issues with your

printer.

Page 6

Safety Precautions

Page iv CG4 Series Quick Guide

Page 7

Table of Contents

Table of Contents

Checking Accessories................................................................................................ 1-1

About the Box ....................................................................................................................... 1-1

Names of Parts............................................................................................................ 1-2

Turning On the Power ................................................................................................ 2-1

Power Setting........................................................................................................................2-1

Basic Specifications................................................................................................... 3-1

SATO Group of Companies ....................................................................................... 4-1

SATO Group of Companies .................................................................................................. 4-2

CG4 Series Quick Guide Page 1

Page 8

Table of Contents

Page 2 CG4 Series Quick Guide

Page 9

Section 1: Names of Parts

CHECKING ACCESSORIES

Make sure that you have received all of the following items in the package. If there are any accessories

missing, contact your SATO reseller.

User documents

(Quick Guide, warranty) AC power cord AC adapter

ABOUT THE BOX

Please retain both the box in which the printer was packed, and the cushioning material (cushions that hold

the printer in place). If you need to send in the printer for repair, repack it in this box.

CG4 Series Quick Guide Page 1-1

Page 10

Section 1: Names of Parts

1

2

3

4

7

5

6

8

1

2

3

4

5

6

7

7

8

8

NAMES OF PARTS

Front view

Operator panel

1

It consists of two contact buttons and two

LED indicators (green and red).

Top cover

2

Open this cover to load the media and ribbon.

Cover open/close latch

3

Pull these latches on both sides of the printer

forward to open the Top cover of the printer.

Media ejection slot

4

Opening for media output.

POWER button

5

Press this button to turn the power on or off.

FEED/LINE button

6

Press this button to select the printer status

(online/ offline) or to feed the media.

ERROR LED indicator

The LED lights or blinks red when an error is

detected in the printer.

During printer configuration setting, the

ERROR indicator responses in conjunction

with the ON LINE (POWER) indicator to show

the modes of the printer.

ON LINE (POWER) LED indicator

The LED lights green when the printer is online

and blinks green when the printer is offline.

During printer configuration setting, the ON

LINE (POWER) indicator responds in

conjunction with the ERROR indicator to show

the modes of the printer.

Page 1-2 CG4 Series Quick Guide

Page 11

Back view

9

10

Type1:

USB and RS232C on-board

Type2:

USB and LAN on-board

11

12

13

15

14

11

12

13

15

16

9

USB and RS232C interface on-board

10

USB and LAN interface on-board

USB and IEEE interface on-board

11

10

10

11

11

12

13

14

9

9

10

10

11

11

12

12

13

14

Section 1: Names of Parts

Media inlet

An opening for Fan-folded media or media

from unwinder to feed in to the printer.

DC input power terminal

Supplies power to the printer by inserting the

power cable via the AC adapter.

USB interface terminal

To connect printer to the host computer using

the USB interface.

RS-232C interface terminal

To connect printer to the host computer using

RS-232C interface.

Or, to connect the optional Keypad, Scanner or

Smart keyboard to the printer.

LAN interface terminal

13

To connect printer to the host computer using

LAN interface.

IEEE interface terminal

14

To connect printer to the host computer using

IEEE interface.

CG4 Series Quick Guide Page 1-3

Page 12

Section 1: Names of Parts

CG408DT/ CG412DTCG408TT/ CG412TT

15

20

16

17

18

19

21

22

15

18

20

19

21

22

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

Internal view when Top cover is opened

Print head

This component is used to print on the media.

Perform maintenance at regular intervals.

Ribbon unit

Used to load the ribbon and wind up the used

ribbon.

Pull out lever

This is used to pull out the ribbon unit from the

top cover for ribbon loading.

Roll media holder

To hold the roll media.

Media guide slide lever

Set to meet the size of the media used.

Media guide and I-Mark/ Gap sensor

A guide for the media to feed properly.

Detects the I-Mark on the media or gap of the

label.

Platen roller

This roller feeds the media. Perform

maintenance at regular intervals.

Optional device compartment

Used to install optional cutter or dispenser unit.

Page 1-4 CG4 Series Quick Guide

Page 13

Section 1: Names of Parts

When Top cover is opened (Cutter Type, Optional)

Paper holder

Cutter unit

Platen roller

Paper sensor

Paper holder slide lever

When Top cover is opened (Dispenser Type, Optional)

Paper holder

Backing paper discharge outlet

Dispenser paper sensor

Platen roller

Paper sensor

Paper holder slide lever

Dispenser unit

(When the dispenser unit is open)

CG4 Series Quick Guide Page 1-5

Page 14

Section 1: Names of Parts

When Top cover is opened (Linerless Type, Optional)

Paper holder

Linerless paper sensor

Platen roller

Paper sensor

Paper holder slide lever

Page 1-6 CG4 Series Quick Guide

Page 15

Section 2: Turning On the Power

AC power cord

AC adapter

AC power cord

AC adapter

TURNING ON THE POWER

POWER SETTING

Connect the DC power cord of the AC adapter to the printer and turn on the power.

1. Connect the AC power cord to the AC adapter.

CG4 Series Quick Guide Page 2-1

Page 16

Section 2: Turning On the Power

DC input power terminal

(Power connector)

DC input power terminal

(Power connector)

Make sure the at side

of the DC power cord is

facing up.

Plug

DC power cord

Make sure the at side

of the DC power cord is

facing up.

Plug

DC power cord

2. Connect the printer to the AC adapter. Connect the AC adapter to the AC power outlet. When connecting

the DC power cord to the printer’s power connector, make sure the DC power cord connector is oriented

properly. When connecting the DC power cord to the printer connector, use one hand to hold the printer

while using the other hand to plug in the cord

3. Press the POWER button on the operation panel of the printer. The ON LINE (POWER) lamp is on. Check

that the ON LINE (POWER) lamp is on.

Page 2-2 CG4 Series Quick Guide

Page 17

Section 2: Turning On the Power

4. Press the POWER button to turn off the printer. When the power is off, the ON LINE (POWER) lamp turns

off.

CAUTION

• The power cord set supplied with this printer is only for use with this printer. Do not use it for other electrical

products.

• Do not operate the POWER button or plug in/unplug the power cord with wet hands. Doing so could result

in electric shock.

CG4 Series Quick Guide Page 2-3

Page 18

Section 2: Turning On the Power

Page 2-4 CG4 Series Quick Guide

Page 19

Section 3: Basic Specifications

BASIC SPECIFICATIONS

Model name CG408 DT CG412 TT CG408 TT CG412 TT

Printing method Direct Thermal Thermal Transfer (Direct Thermal/

Thermal Transfer)

Head density

(resolution)

Printing effective

area

Unprintable area Label:

Printing speed 1.97, 2.95, or 3.94 inches/second (50, 75 or 100 mm/second) (Setting: 2, 3, 4)

Paper type /

Paper shape

Paper thickness 60 to 190μm (0.06 to 0.19 mm)

203 dpi (8 dots/

mm)

4.09” wide x 11.81” pitch

(104 mm wide x 300 mm pitch)

Length direction Upper: 0.06” (1.5 mm) Lower: 0.06” (1.5 mm)

(Not including backing paper)

Width direction Left: 0.06” (1.5 mm) Right 0.06” (1.5 mm)

(Not including backing paper)

Linerless label

Length direction Upper: 0.16” (4.0 mm) Lower: 0.06” (1.5 mm)

Width direction Left: 0.06” (1.5 mm) Right: 0.06” (1.5 mm)

* Printing speed varies, depending on paper type and usage environment.

Roll paper (Face-out or face-in winding)

We recommend using paper manufactured by SATO.

305 dpi (12 dots/

mm)

203 dpi (8 dots/

mm)

305 dpi (12 dots/

mm)

CG4 Series Quick Guide Page 3-1

Page 20

Section 3: Basic Specifications

Model name CG408 DT CG412 TT CG408 TT CG412 TT

Label size Label

Continuous type

Width: 0.87 to 4.21 in. (Backing paper 0.98 to 4.33 in.); 22 to 107 mm (Backing

paper 25 to 110 mm)

Pitch: 0.28 to 11.81 in. (Backing paper 0.39 to 11.93 in.); 7 to 300 mm (Backing

paper 10 to 303 mm)

Cutter type

Width: 0.87 to 4.21 in (Backing paper 0.98 to 4.33 in.); 22 to 107 mm (Backing

paper 25 to 110 mm)

Pitch: 0.87 to 11.81 in. (Backing paper 0.98 to 11.93 in.); 22 to 300 mm (Backing

paper 25 to 303 mm)

Dispenser type

Width: 0.87 to 4.21 in. (Backing paper 0.98 to 4.33 in.); 22 to 107 mm (Backing

paper 25 to 110 mm)

Pitch: 0.87 to 3.94 in. (Backing paper 0.98 to 4.06 in.); 22 to 100 mm (Backing

paper 25 to 103 mm)

Tear-off type

Width: 0.87 to 4.21 in. (Backing paper 0.98 to 4.33 in.); 22 to 107 mm (Backing

paper 25 to 110 mm)

Pitch: 0.87 to 11.81in. (Backing paper 0.98 to 11.93 in.); 22 to 300 mm (Backing

paper 25 to 303 mm)

Outer diameter of

paper or Roll size

Linerless type (label without backing paper)

Width: 0.87 to 4.33 in.;22 to 110 mm

Pitch: 0.87 to 3.94 in.; 22 to 100 mm

Non-adhesive label

Continuous type

Width: 0.98 to 4.33 in.; 25 to 110 mm

Pitch: 0.39 to 11.81 in.; 10 to 303 mm

Cutter type

Width: 0.98 to 4.33 in.; 25 to 110 mm

Pitch: 0.98 to 11.81 in.; 25 to 303 mm

Tear-off type

Width: 0.98 to 4.33 in.; 25 to 110 mm

Pitch: 0.98 to 11.81 in.; 25 to 303 mm

Maximum ø5.04” (ø128 mm)

Inner diameter of roll core: ø1.5” (ø40 mm)

Page 3-2 CG4 Series Quick Guide

Page 21

Section 3: Basic Specifications

Model name CG408 DT CG412 TT CG408 TT CG412 TT

Ribbon size

Ribbon type

Ribbon winding

direction

Label issuing

mode

Dimensions 7.05 (W) x 9.37 (D) x 6.81 (H) in.

Weight 3.75 pounds; 1.7 kg 4.19 pounds; 1.9 kg

Power specifications

- Length: 328.08 feet; 100 m

Width: 3.94 in. +/_0.02 in.; 110 +/-0.5

mm

Outer diameter: Maximum ø1.5 in.;

ø38 mm

(Inner diameter of ribbon core: ø0.50

in; ø12.7 mm)

Winding direction: Face out

Ribbon winding method: Ribbon core

winding method

* We recommend use of carbon ribbon

manufactured or specified by SATO.

Standard: Continuous mode, Tear off mode, Sensor-off mode

Option: Dispenser mode, Cutter mode, Linerless mode

179 (W) x 2238 (D) x 173 (H) mm

*Excluding the protrusion portion.

AC adapter

Input power voltage: AC 100V to 240V +/-10% (full range)

Frequency: 50/60Hz

Output power voltage: DC 19V

Power consumption

Input power voltage conditions: AC 100V

At peak: 50 W (at 30% printing ratio)

During standby: 2.5W

Environmental

conditions (temperature and

humidity)

Interface Select one of the following (The factory will provide the unit with the selected

Options Cutter unit, Dispenser unit (with dispenser paper sensor), RTC kit,

LED 1. Error: (Red)

Operation button [POWER], [FEED/LINE]

Paper length

detection sensor

Operating environment: 39.2 to 100.4°F; 4 to 38°C; 30 to 80% RH (However, no

condensation)

Storage environment: 14.0 to 140°F; -10 to 60°C; 15 to 85% RH (However, no

condensation)

(Not including ribbon, labels, and other supplies)

interface.)

1. USB (B type) and RS-232C (D-SUB 9-pin)

2. USB (B type) and LAN (10 BASE-T/100 BASE-TX auto switching)

3. USB (B type) and IEEE1284

Non-cutter unit for linerless label, Simplified input Keypad, TSC Smart Keyboard,

1D barcode scanner

2. ON LINE (POWER): (Green)

I-mark sensor (Reflective type)

Label gap sensor (Transmissive type)

CG4 Series Quick Guide Page 3-3

Page 22

Section 3: Basic Specifications

Model name CG408 DT CG412 TT CG408 TT CG412 TT

Barcode UPC-A/UPC-E, JAN/EAN, CODE39, CODE93, CODE128, GS1-128

(UCC/EAN-128), CODABAR (NW-7), ITF, Industrial 2 of 5, Matrix 2 of 5,

BOOKLAND, MSI, POSTNET, GS1 DataBar (RSS)

* GS1 DataBar is the new version of RSS-14.

2D barcode PDF417 (Ver. 2.4), MAXI code (Ver. 3.0), QR code, GS1 DataMatrix (ECC200)

Composite symbol

Standard installed fonts

Bitmap font U font 5 x 9 dots (alphanumeric characters and symbols)

EAN-13 Composite (CC-A/CC-B)

EAN-8 Composite (CC-A/CC-B)

UPC-A Composite (CC-A/CC-B)

UPC-E Composite (CC-A/CC-B)

GS1-128 Composite (CC-A/CC-B/CC-C)

GS1 DataBar Composite (CC-A/CC-B)

GS1 DataBar Truncated Composite (CC-A/CC-B)

GS1 DataBar Stacked Composite (CC-A/CC-B)

GS1 DataBar Stacked Omni-Directional Composite (CC-A/CC-B)

GS1 DataBar Limited Composite (CC-A/CC-B)

GS1 DataBar Expanded Composite (CC-A/CC-B)

GS1 DataBar Expanded Stacked Composite (CC-A/CC-B)

* GS1 DataBar is the new version of RSS-14.

S font 8 x 15 dots (alphanumeric characters and symbols)

M font 13 x 20 dots (alphanumeric characters and symbols)

WB font 18 x 30 dots (alphanumeric characters and symbols)

WL font 28 x 52 dots (alphanumeric characters and symbols)

XU font 5 x 9 dots (alphanumeric characters and symbols)

XS font 17 x 17 dots (alphanumeric characters and symbols)

XM font 24 x 24 dots (alphanumeric characters and symbols)

XB font 48 x 48 dots (alphanumeric characters and symbols)

XL font 48 x 48 dots (alphanumeric characters and symbols)

OCR-A

15 x 22 dots (alphanumeric and symbols)

OCR-B

20 x 24 dots (alphanumeric and symbols)

Simplified Chinese (2.6 MB)

Gothic type GB2312 24 x 24 dots

Korean (1.6 MB)

Gothic type KSX1001 16 x 16 dots

Mincho type KSX1001 24 x 24 dots

Rasterized font CG Times (alphanumeric and symbols)

CG Triumvirate (alphanumeric and symbols)

Outline font Alphanumeric and symbols

Printing direction

(Characters and

barcode)

Barcode ratio 1:2, 1:3, 2:5, Free specification

Page 3-4 CG4 Series Quick Guide

Characters: 0°, 90°, 180°, 270°

Barcode: Parallel 1 (0°), Parallel 2 (180°), Serial 1 (90°), Serial 2 (270°)

OCR-A

22 x 33 dots (alphanumeric and symbols)

OCR-B

30 x 36 dots (alphanumeric and symbols)

Page 23

Section 3: Basic Specifications

Model name CG408 DT CG412 TT CG408 TT CG412 TT

Magnification

ratio

(Characters and

barcode)

Standard functions

Self-diagnostic

function

Noise (EMC)

standard

Safety standards UL60950-1(2001), CSA22.2 No. 60950-1-03

Characters: Vertical 1 to 12 times, horizontal 1 to 12 times

Barcode: 1 to 12 times

1. Status return function

2. Graphic function

3. Sequential number function

4. Form overlay function

5. Custom character registration function

6. Black/white inversion function

7. Ruled line function

8. Format registration function

9. Zero slash switching function

1. Paper end detection

2. Cover open detection

3. Test print

4. Ribbon end detection (for thermal transfer type only)

5. Cutter error (when the cutter unit is installed)

FCC15B Class B

Notice regarding the registered trademarks and trademarks of other companies:

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

CG4 Series Quick Guide Page 3-5

Page 24

Section 3: Basic Specifications

Page 3-6 CG4 Series Quick Guide

Page 25

SATO GROUP OF COMPANIES

Section 4: SATO Group of Companies

CG4 Series Quick Guide Page 4-1

Page 26

Section 4: SATO Group of Companies

Asia Pacific & Oceania Region

SATO ASIA PACIFIC PTE. LTD.

438A Alexandra Road #05-01/04,

Alexandra Technopark, Singapore 119967

Tel: +65-6271-5300

Fax: +65-6273-6011

Email: technical@satoasiapacific.com

www.satoasiapacific.com

SATO AUTO-ID MALAYSIA SDN. BHD.

No.25, Jalan Pemberita U1/49,

Temasya Industrial Park, Section U1,

40150 Shah Alam, Selangor Darul Ehsan,

Malaysia

Tel: +60-3-7620-8901

Fax: +60-3-5569-4977

Email: service@satosms.com.my

www.satoasiapacific.com

SATO AUTO-ID (THAILAND) CO., LTD.

292/1 Moo 1 Theparak Road,

Tumbol Theparak, Amphur Muang,

Samutprakarn 10270, Thailand

Tel: +66-2-736-4460

Fax: +66-2-736-4461

Email: technical@satothailand.com

www.satothailand.co.th

SATO SHANGHAI CO., LTD.

307 Haining Road, ACE Bldg,

10th Floor, Hongkou Area, Shanghai,

China 200080

Tel: +86-21-6306-8899

Fax: +86-21-6309-1318

Email: tech@satochina.com

www.satochina.com

SATO ASIA PACIFIC PTE. LTD.

Korea Representative Office

6F, Korea Housing Center,

Yeouido-dong 45-11, Yeongdeungpo-gu,

Seoul, Korea 150-736

Tel: +82-2-761-5072

Fax: +82-2-761-5073

Email: technical@satoasiapacific.com

www.satoasiapacific.com

SATO ASIA PACIFIC PTE. LTD.

India Representative Office

Regus Level 2, Connaugh Place,

Bund Garden Road, Pune. 411001, India

Tel: +91-20-4014-7747

Fax: +91-20-4014-7576

Email: technical@satoasiapacific.com

www.satoasiapacific.com

SATO AUSTRALIA PTY LTD.

1/1 Nursery Avenue, Clayton Business

Park, Clayton, VIC 3168 Australia

Tel: +61-3-8814-5330

Fax: +61-3-8814-5335

Email: enquiries@satoaustralia.com

www.satoaustralia.com

SATO NEW ZEALAND LTD.

30 Apollo Drive, Mairangi Bay

Auckland, New Zealand

Tel: +64 9-477-2222

Fax: +64-9-477-2228

Email:

global.warranty@satonewzealand.com

www.satonewzealand.com

European Region

SATO LABELLING SOLUTIONS

EUROPE GmbH (BELGIUM)

Leuvensesteenweg 369,

1932 Sint-Stevens-Woluwe, Belgium

Tel: +32-2-788-80-00

Fax: +32-2-788-80-80

Email: info@nl.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (GERMANY)

Ersheimer Straße 71,

69434 Hirschhorn, Germany

Tel: +49-6272-9201-160

Fax: +49-6272-9201-347

Email: service@de.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (NORWAY)

Hovfaret 4 0275 Oslo, Norway

Tel.: +47-225-106-70

Fax: +47-225-106-71

Email: kundeservice@satonorge.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (NETHERLANDS)

Techniekweg 1b, 3481 MK Harmelen,

Netherlands

Tel.: +31-348-444437

Fax: +31-348-446403

Email: info@nl.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (ITALY)

Viale Europa 39/1,

20090 Cusago, Milano, Italy

Tel.: +39-2-903-944-64

Fax: +39-2-903-940-35

Email: info@it.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (SWITZERLAND)

Allmendstraße 19,

8320 Fehraltorf, Switzerland

Tel: +41-44-954-84-00

Fax: +41-44-954-84-09

Email: info@ch.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (AUSTRIA)

Niederlassing Austria

Jochen-Rindt-Straße 13

1230 Wien, Austria

Tel: +43-2762-52690

Fax: +43-2762-52018

Email: info@at.satoeurope.com

www.satoeurope.com

SATO LABELLING SOLUTIONS

EUROPE GmbH (DENMARK)

Naverland 29A DK-2600

Glostrup, Denmark

Tel.: +45-43204700

Fax: +45-43204709

Email: info@dk.satoeurope.com

www.satoeurope.com

SATO POLSKA SP. Z O.O.

ul. Wrocławska 123, Radwanice,

55-015 Św. Katarzyna, Poland

Tel: +48-71-381-03-60

Fax: +48-71-381-03-68

Email: info@sato.pl

www.sato.pl

SATO IBERIA S.A.

Dels Corrals Nous, 35-39

Pol. Can Roqueta, 08202 - Sabadell

Barcelona, Spain

Tel: +34-902-333-341

Fax: +34-902-333-349

Email: info@es.satoeurope.com

www.satoeurope.com

SATO FRANCE S.A.S.

Parc d'Activités, Rue Jacques Messager,

59 175 Templemars, France

Tel: +33-3-20-62-96-40

Fax: +33-3-20-62-96-55

www.satoeurope.com

SATO UK LTD.

Valley Road, Harwich,

Essex CO12 4RR, United Kingdom

Tel: +44-1255-240000

Fax: +44-1255-240111

Email: enquiries@satouk.com

www.satouk.com

American Region

SATO AMERICA, INC.

10350-A Nations Ford Road, Charlotte,

NC 28273, U.S.A.

Tel: +1-704-644-1650

Fax: +1-704-644-1662

www.satoamerica.com

SATO LABELING SOLUTIONS

AMERICA, INC.

1140 Windham Parkway, Romeoville,

Illinois 60446, U.S.A.

Tel: +1-800-645-3290

Fax: +1-630-771-4210

www.satolabeling.com

• Extensive contact information of worldwide SATO operations

can be found on the Internet at www.satoworldwide.com

SATO GROUP OF COMPANIES

Page 4-2 CG4 Series Quick Guide

Loading...

Loading...