Page 1

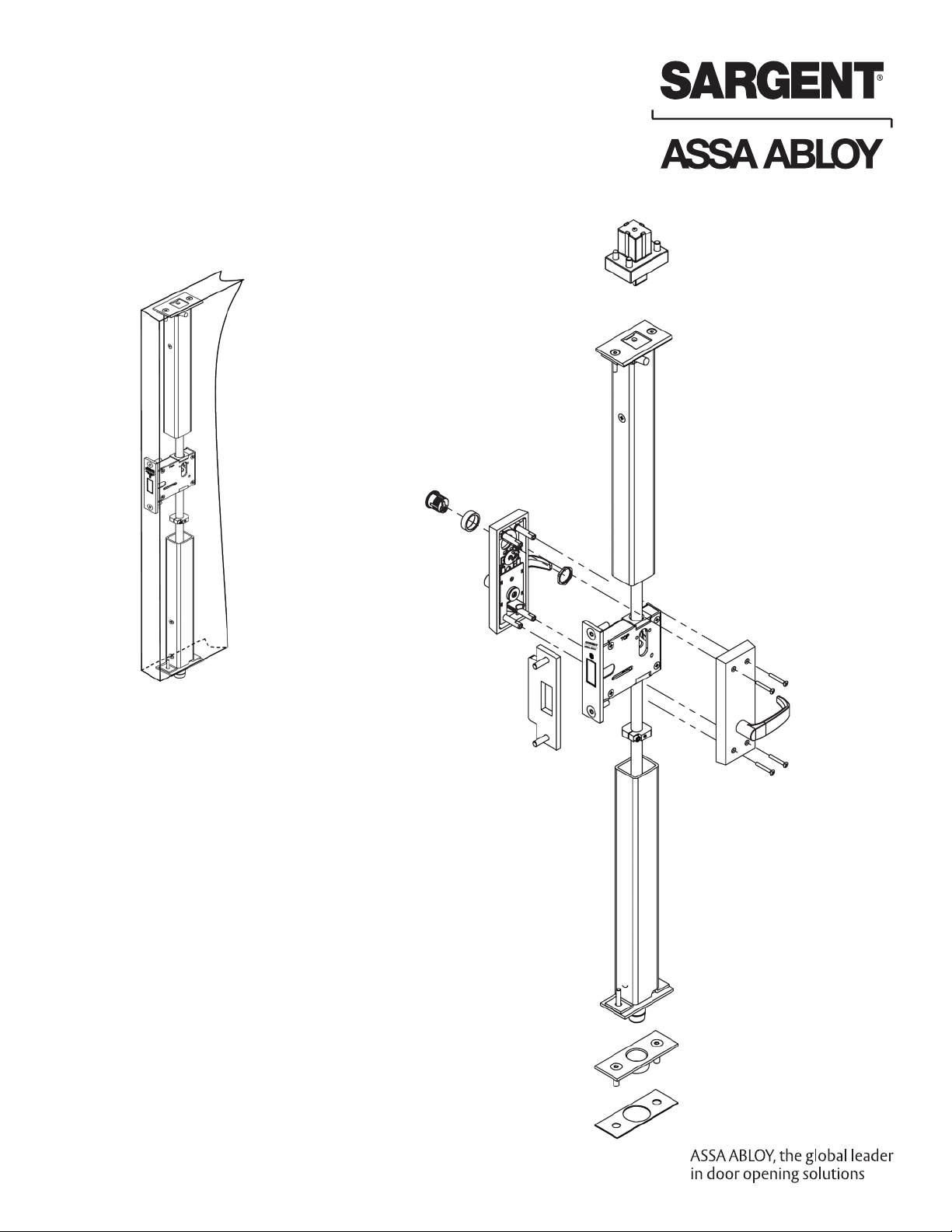

FM6100 Series Multi-Point Lock

Installation Instructions for

Window Shutter Applications

Recommended Installation:

Install FM6100 so that the

deadbolt is equidistant

from the top and bottom

of the shutter.

A8058:A

4/16/10

Copyright © 2010, Sargent Manufacturing Company,an ASSA ABLOY Group company.All rights reserved.

Reproduction in whole or in part without theexpress written permission of Sargent Manufacturing Company is prohibited.

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com

Page 2

FM6100 Series Multi-Point Lock

Table of Contents

1

Installation of Deadbolt Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2

Installation of Bottom Bolt Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 & 4

3

Installation of Top Pusher Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4

Aligning assemblies in preparation for drilling and pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 & 6

5

Applying the Drill Jig for proper drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6

Pinning the Rods to engage the Deadbolt Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7

Installation of Inside and Outside Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8

Installation of Cylinder in Outside Trim (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Assemble the Top Latch to the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9

10

Installation of Deadbolt Strike . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

11

Install the Bottom Strike . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

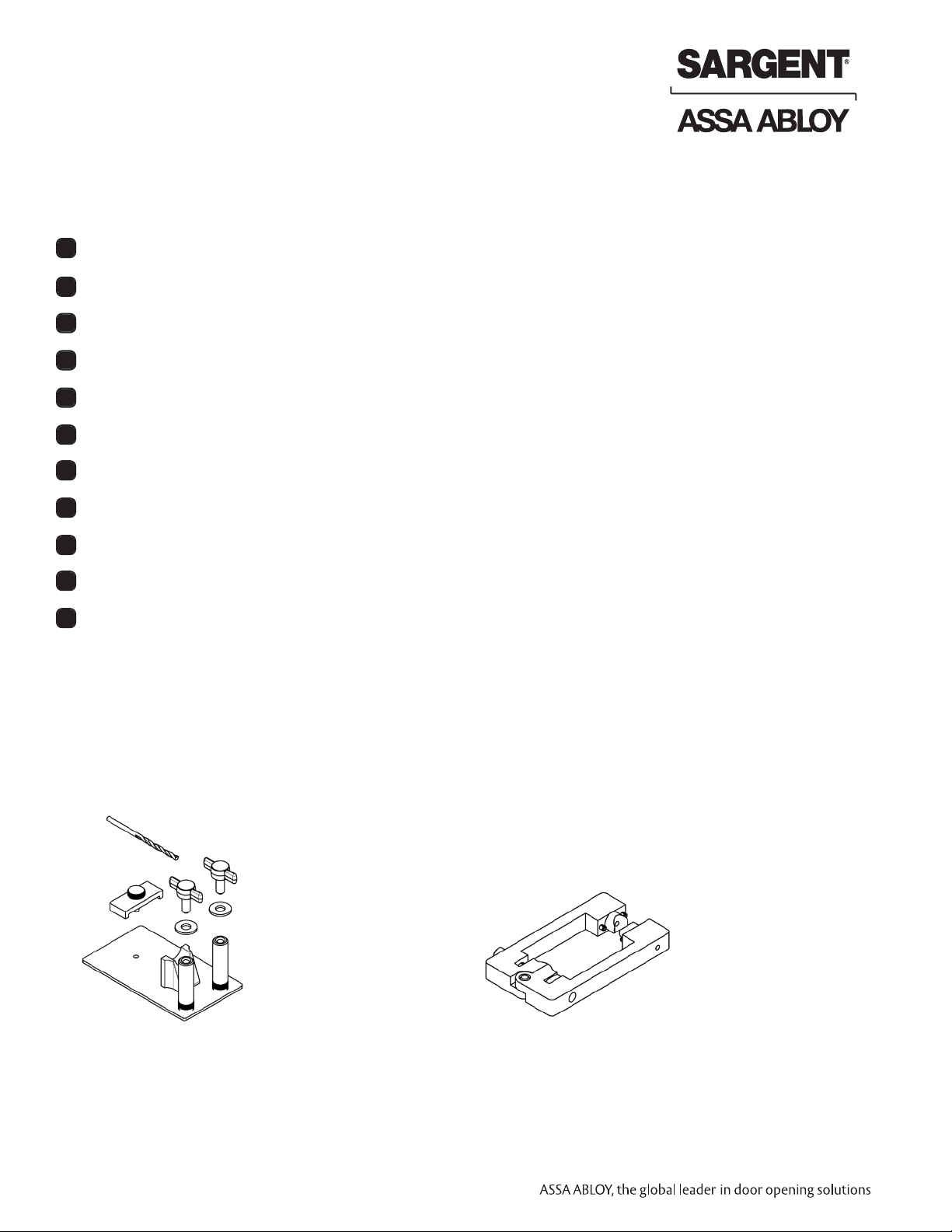

Important

This device is intended to be part of an integrated window shutter, frame and hardware assembly UL-approved

for both FEMA 361 and ICC 500 guidelines for inswing window shutters. This instruction sheet will take you

through the following steps for full installation.

Installation Jig Components Drill Guide for Deadbolt Case

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

www.sargentlock.com • A8058:A

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

Page 3

FM6100 Series Multi-Point Lock

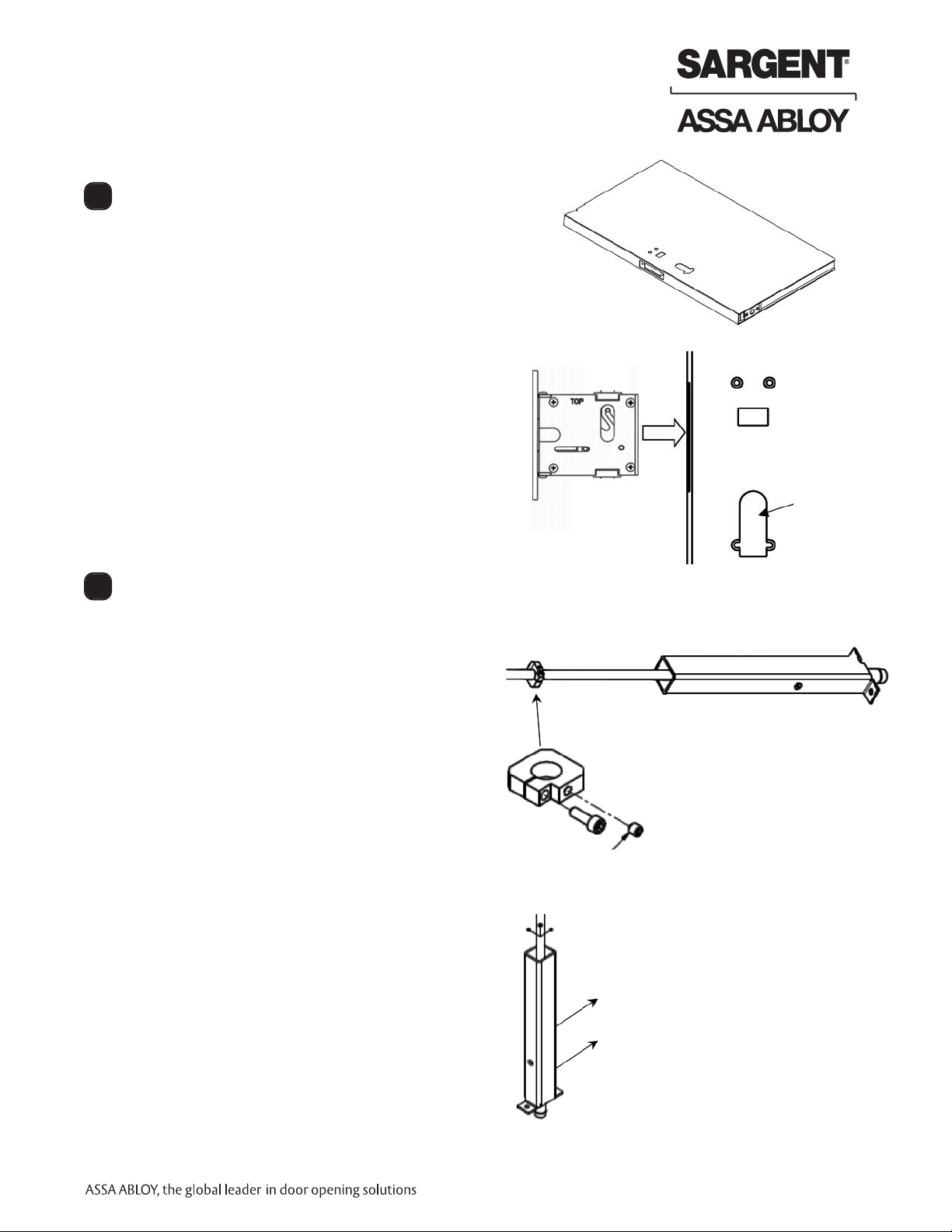

1

Installation of the Deadbolt Assembly

• Place the window shutter on a horizontal surface with the

pin lever notch located at the top of the shutter facing up.

• The recommended deadbolt assembly location should be

equidistant from the top and bottom of the shutter.

• Assemble the deadbolt case into the lock pocket

provided in the door. Note the orientation of the lock, the

top of the deadbolt case indicates that this should be

toward the top of the shutter.

• Assemble the lock to the edge of the shutter using

"

(2) 1/4 – 20 by 1

Flat Head Cap Screws.

Lower

Through

Bolt Cutout

2

Installation of the Bottom Bolt Assembly

• Loosen the set screw so that the lifting platform will slide

along the lower rod tubing but not slide on its own when

the rod is held vertically. Be sure that the set screw is

oriented so that it will be accessible through the Lower

Through Bolt Cutout on the top side of the shutter.

• When you insert the assembly into the shutter and

through the nylon guides of the deadbolt case this lifting

pad will be in a position to allow you to make the final

necessary adjustment.

Note the orientation of the bottom bolt assembly the

double screw head side (not shown in this image) should

be facing the hinge side of the shutter.

Continue on next page………….

Set Screw

A8058:A • www.sargentlock.com

3

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

Page 4

FM6100 Series Multi-Point Lock

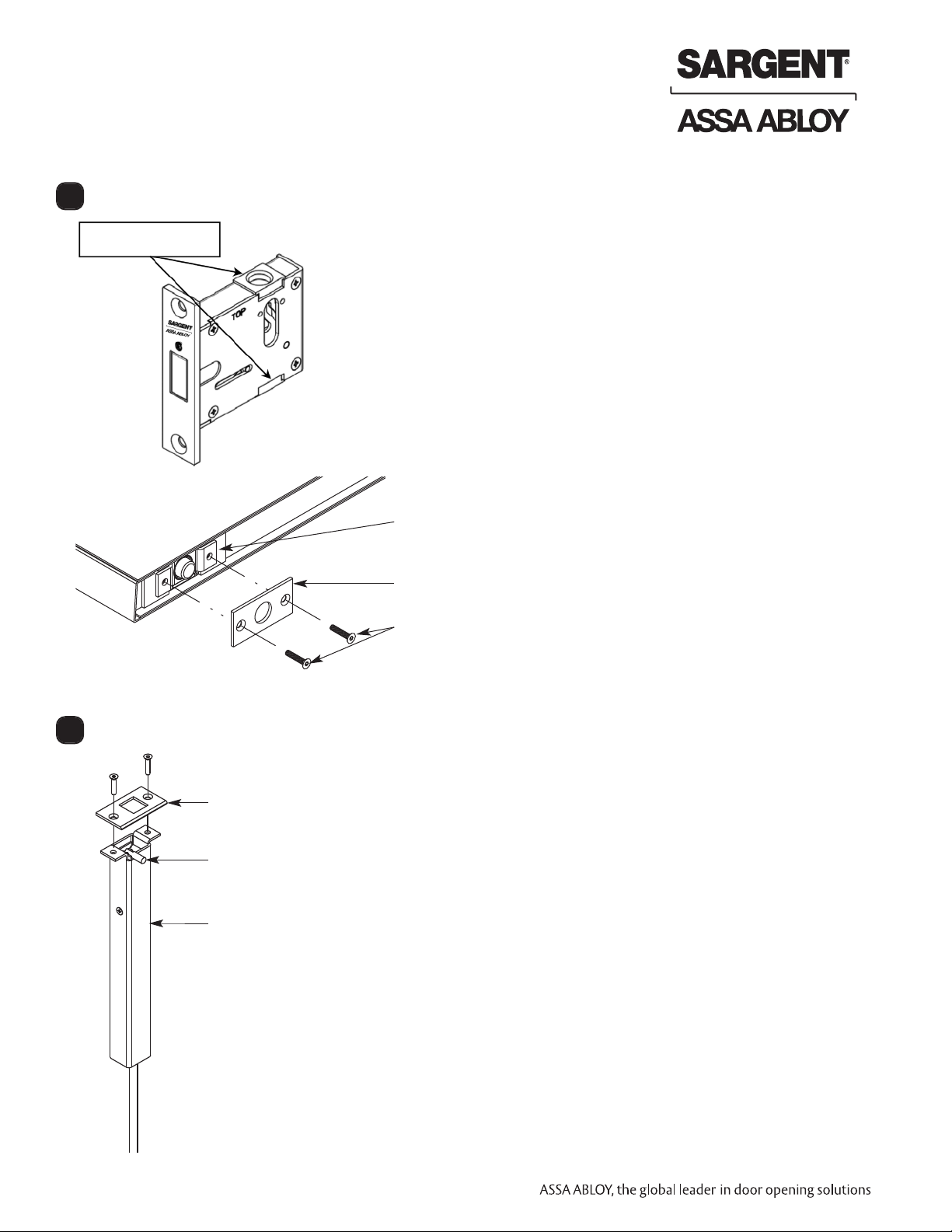

2

Installation of the Bottom Bolt Assembly continued

Nylon Guides

• With the Deadbolt Retracted, slide the Bottom Bolt Sub

Assembly into the prep. hole in the bottom of the shutter. As

you guide the assembly up into the shutter you will need to

guide it into the bottom nylon guide of the Deadbolt Assembly

and then up through the top nylon guide.

3

Installation of the Top Pusher Assembly

Strike Plate note

beveled edge position

Plunger Pin

Top Pusher Assembly

• Seat the bottom bolt bracket against the shutters lower

reinforcement plate.

• Align Bottom Bolt Plate to shutter prep.

• Fasten the Bottom Bolt Assembly and Bottom Bolt Plate to

the bottom of the shutter using (2) #12-24 by 1" Flat Head

Cap Screws.

• Slide this assembly into the prep. at the top of the shutter,

making sure the plunger pin is oriented with the clearance

slot on the stop side of the shutter.

• Visually align the rod of the Top Pusher Assembly so that it

enters the tube of the Bottom Bolt Assembly that extends

out of the Deadbolt Assembly.

• Align the Top Strike plate to shutter prep. Noting the position

of the beveled edge. It should be on the same side as the

plunger pin.

• Fasten the Top Strike plate and Top Pusher Assembly to the

top of the shutter using (2) #12-24 by 1" Flat Head Cap

Screws.

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

4

www.sargentlock.com • A8058:A

Page 5

FM6100 Series Multi-Point Lock

4

Alignment of components in preparation for drilling and pinning

• Thread the Top Bolt Clamp into the threaded hole so that

it extends the top latch to the proper position for pinning.

The Top Bolt Clamp will assure that the top latch is in the

correct position for final installation.

Top Bolt Clamp

• Prepare the lifting platform installation jig by removing the two

wing fasteners and their washers

3

Lifting platform jig

• Introduce the lifting platform jig up through the under side of

the shutter as shown.

• Using the two wing fasteners and their washers, secure the

lifting platform jig to the shutter.

The lifting platform jig will now be in position to allow sliding the

lifting platform (shown in step 2) so that it rests against the shelf

of the jig.

Continued on next page………….

A8058:A • www.sargentlock.com

5

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

Page 6

FM6100 Series Multi-Point Lock

4

Alignment of components in preparation for drilling and pinning continued

Before continuing to the next step be certain the top pusher

and bottom bolt are in the correct position.

• Bottom Bolt should be flush to the bottom of

the shutter.

• The lifting platform (item 1) should be moved down the bottom

rod and placed against the shelf of the lifting platform jig.

• Next secure the platforms position by tightening the cone

point set screw (item 2). This will assure the point on the set

screw embeds itself firmly into the bottom rod.

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

6

www.sargentlock.com • A8058:A

Page 7

FM6100 Series Multi-Point Lock

5

Applying the drill jig for proper drilling

• Manually project the deadbolt by applying force to the

deadbolt lever toward the bottom of the shutter.

Drill Guide

clamping screw

Deadbolt

Lever

Drill Guide

Positioning

Holes

Drill Guide

Positioning

Pins

• The deadbolt lever is now in a position to allow the Drill Guide

to be positioned above the deadbolt and fixed into position

using the two drill guide positioning holes provided in both

sides of the deadbolt case.

• The Drill Guide is an alligator type jig. Loosen the Drill Guides

clamping screw, allowing the jaws to rotate 90 degrees to

allow the guide to be positioned above the deadbolt and

closed around the shutter so that the pins on both sides of

the Drill Guide engage the two Drill Guide Positioning Holes.

Drill Guide

Hole

• Once the Drill Guide is engaged in the positioning holes,

tighten the Drill Guides clamping screw so that it will firmly

secure the jig around the shutter.

• Using the Drill Guide Hole, drill a 1/8" hole (drill provided

with Jig Components) through both sets of rods.

A8058:A • www.sargentlock.com

7

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

Page 8

FM6100 Series Multi-Point Lock

6

Pinning the Rods to engage the Deadbolt Lever

• Loosen the Drill Guides clamping screw allowing the Drill

Guide to be removed from the shutter.

• Manually retract the Deadbolt by applying force to the

deadbolt lever toward the top of the shutter.

• This will put the pinning hole in the proper position for

fastening the Drive Pin.

• Insert the Drive Pin from the underside of the shutter and

through the holes in the rods and fasten the Drive Pin in

place with the spring washer.

The Lifting Platform Jig and the Top Clamp can now be

removed from the shutter.

Hole shown in proper

pinning position.

7

Installation of Inside and Outside Trim

• Install the outside trim by inserting it from underneath

the shutter (outside face).

• As it enters the shutter cavity the lifting pad in the

escutcheon will rest on the underside of the lifting pad

secured to the rods in step 4.

• Press the outside escutcheon against the shutter

surface.

• Install the inside trim by placing it over the shutter

prep. and positioning the lifting pad of the inside trim

on the underside of the lifting pad.

• Visually align the mounting holes of the inside

escutcheon to the mounting posts from the outside

escutcheon.

• Insert 4 mounting screws #12 – 24 by 1 ½" and

tighten screws.

Insid

e

c

urfa

S

r

e

o

Do

f

o

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

8

www.sargentlock.com • A8058:A

Page 9

FM6100 Series Multi-Point Lock

8

Installation of Cylinder in Outside Trim (Optional)

Insert the Cylinder into the Cylinder Collar

•

• Place the Cylinder Retaining Nut against the backplate of the outside trim assembly.

• Feed the cylinder and cylinder collar into the cylinder hole of the escutcheon and screw the

cylinder retaining nut to the cylinder until it is fully seated with the cam straight up as shown.

• Secure the cylinder to the escutcheon by tightening the cylinder retaining nut.

Cylinder

Cylinder

Collar

Backplate

Outside Trim

Assembly

9

Assemble the Top Latch to the Frame

• Insert the top latch into the top of the frame using

(4) ¼" – 20 by 1" Flat Head Screws. The angled

surface should face the shutter.

Cylinder Retaining Nut

(4) Flat Head Screws

A8058:A • www.sargentlock.com

9

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

Page 10

FM6100 Series Multi-Point Lock

10

Installation of Deadbolt Strike

Assemble the Deadbolt Strike to the frame using

•

(2) ¼" – 20 by 1" Flat Head Cap Screws.

Deadbolt Strike

11

Install the Bottom Strike

• Place the Bottom Strike into the Strike Shim and

fasten to the frame using (2) ¼" – 20 Screws.

Install the Shutter into the frame assembly and shim for proper shutter

gap and for the shutter being square and plumb

END OF INSTALLATION INSTRUCTIONS

Bottom Strike

Strike Shim

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

4/16/10 Copyright © 2010,Sargent Manufacturing Company, anA SSAABLOY Group company.All rights reserved.

10

www.sargentlock.com • A8058:A

Page 11

Page 12

Founded in the early 1800s, SARGENT®is a market leader in locksets, cylinders, doorclosers, exit devices,

electro-mechanical products and access control systems for newconstruction, renovation, and replacement applications.

The company’s customer base includes commercialconstruction, institutional, and industrial markets.

Copyright © 2010, Sargent Manufacturing Company, an ASSA ABLOY Groupcompany. All rights reserved.

Reproduction in whole or in part without theexpress written permission of Sargent Manufacturing Company is prohibited.

ASSA ABLOYis the global leader in dooropening solutions, dedicated to

satisfying end-user needs forsecurit y, safety and convenience.

A8058:A-4/16/10

Loading...

Loading...