Sargent Fireguard 2900 Series,Fireguard 12-2960,Fireguard 9-2960,Fireguard 2960 Installation Instructions Manual

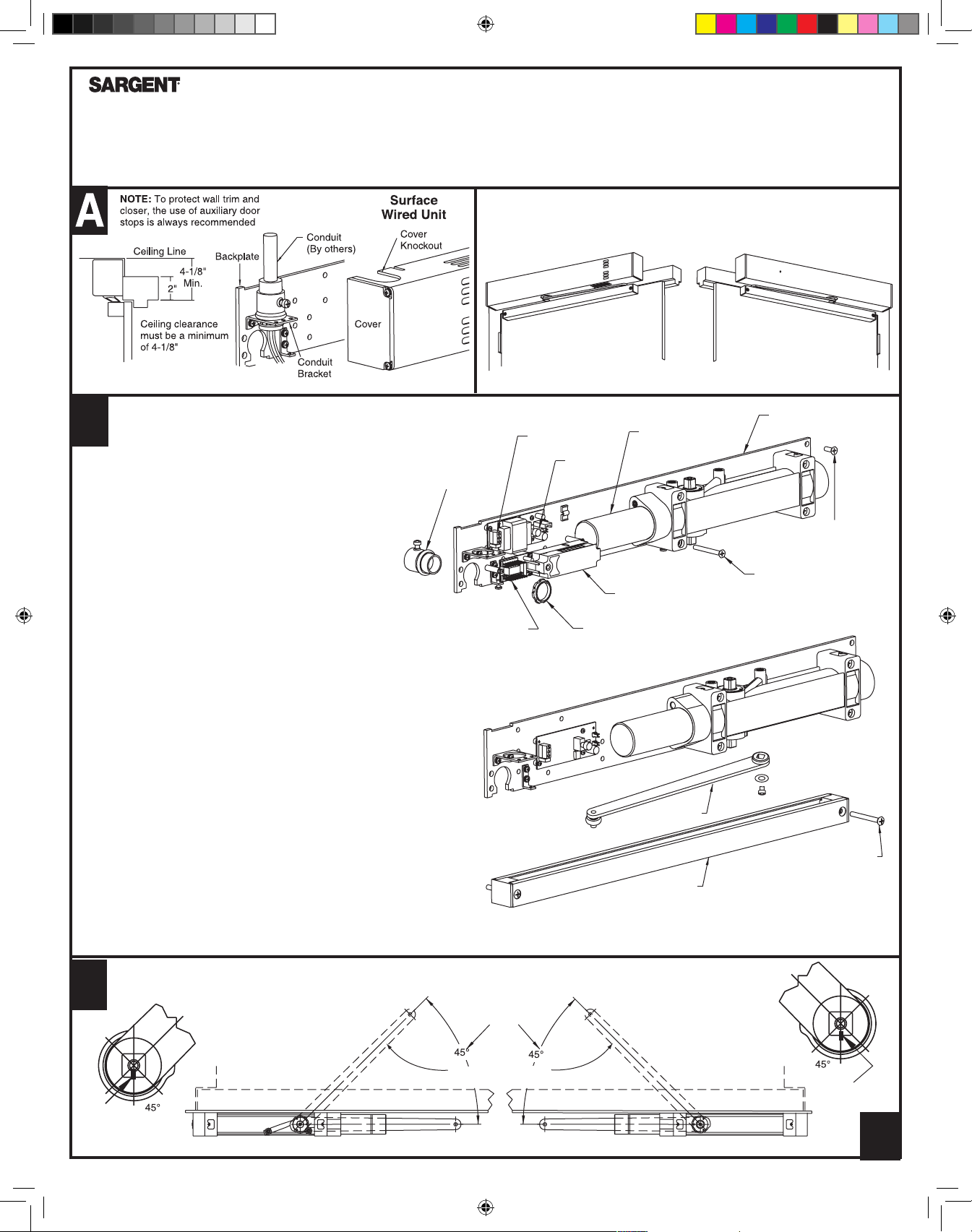

2900 FIREGUARD® Electromechanical Closer-Holder Device Models

B

NOTE:

12-2960, 9-2960 and 2960 Multipoint Hold Open with Rigid Arms

Pull (Hinge) Side Installation Instructions

CAUTION: FAILURE TO INSTALL OR ADJUST PROPERLY MAY RESULT IN INJURY OR DAMAGE

For assistance, contact SARGENT at 800-810-WIRE (9473) or www.sargentlock.com

FOR MODELS 12-2960 / 9-2960 / 2960

1. Use dimensions shown on page 5 provided to locate

attaching screws on frame and door. Prepare holes

For concealed wire applications only

Locate and drill 1-1/8" diameter hole in the frame face for

3/4" conduit. (This is normally done at the time the frame

is being installed.) Connect conduit to backplate before

fastening backplate to frame

2. Attach backplate/closer assembly to frame. Position backplate

end with terminal strips away from hinge edge of frame

3. Make electrical connections:

A) 12-2960: Select and follow the wiring diagram from wiring

instructions sheet A7408 and 'Checkout Procedure' from Page 3.

B) 9-2960: Make solenoid wire connections with power input wires

from 12-2960 using two wire nuts provided in screw pack. Select

proper wiring diagram and 'Checkout Procedure' from Page 3.

4. Make input power connections to the power supply board as directed.

NOTE: If electrical connections are to be made at a later date,

place cover on chassis now to prevent its loss, see Step F.

3/4" Conduit

(By others)

MODEL

12-2960

RH - Right Hand Door

LHR - Left hand Reverse

Terminal

Strips

On/Off

Switch

Terminal

Strips

Devices are handed

and must be the same

hand as door.

Closer/Holder

Smoke

Detector

Conduit Nut

(By others)

12-2960

MODELS

2960/9-2960

LH - Left Hand Door

RHR - Right Hand Reverse

Backplate

Backplate

Screw (6)

Closer

Screw (4)

5. Installation of arm on closer: With appropriate size wrench, rotate

closer top spindle approximately 45ϒ (see step C below) (NOTE:

Closing both valves for door speed and latching speed makes this

procedure much easier). Position closer arm on bottom spindle

approximately parallel to the door and arm length away from hinge.

Secure arm with screw and washer

6. Installation of track on door: Remove end cap from track. Position

track with open side up. Insert roller end of closer arm in sliding

groove of track. With arm engaged in slide groove, slide track, into

position so that prepared holes on door align with track holes

Replace end cap and secure track to door

Companion unit (without electronics) not shown

Position of Arms and Index Settings

C

View Looking Up When

Assembling Arm to Spindle

Index

Mark on

Spindle

Right Hand Door

2960

9-2960

Approximate

Preload

Position of Main Arm

When Assembled to Spindle

Rigid Arm

Track

View Looking Up When

Assembling Arm to Spindle

Left Hand Door

Track Screw

(2 Reqd)

Index

Mark on

Spindle

A7395C

1

A7395C.indd 1 10/29/18 12:44 PM

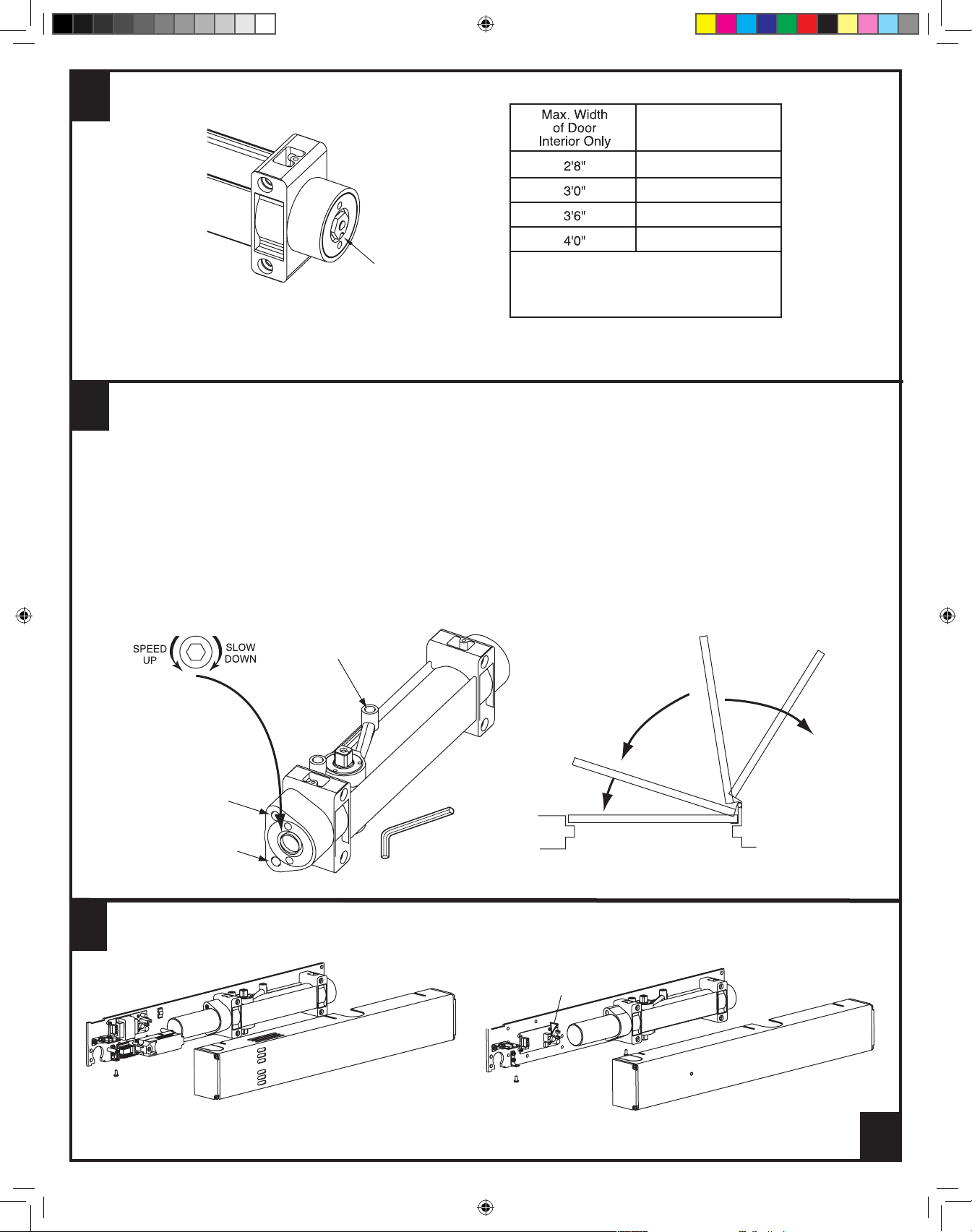

Adjust Spring Power According to Chart

D

Clockwise Turns

of Adjusting Nut

8

8

12

16

5/8 " Adjustment Nut

Tu rn the spring adjusting nut clockwise the required number of turns to match door width as indicated in chart. Where strong drafts exist, increase spring power

as needed. 351 Series door closers leave the factory with the spring adjustment set at eight (8) turns

Maximum adjustment is

approximately 20 turns.

Do not forcibly extend

adjustment beyond limits.

Adjustment Instructions

E

Minimum recommended door closing time is 6 seconds for doors opened to 90 degrees.

Use 1/8" hex (Allen) wrench to adjust valves as needed.

Closing and latching speeds:

Turn valves clockwise to slow down or counterclockwise to speed up door movement.

F

Backcheck:

To regulate the intensity of backcheck action, turn valve clockwise to increase or counterclockwise to decrease checking.

Caution: Set valve for slight cushioning effect. Closer can be damaged if the checking action is too abrupt. Never use the backcheck

as a door stop. Always use a door stop to stop the door.

Backcheck

valve

CLOSING SPEED

RANGE

Closing

speed

valve

Latching

speed

valve

To Install Cover

Adjust closers as directed

in steps D and E

LATCHING SPEED

1/8” HEX SOCKET

WRENCH

1. Assemble (3) short cover screws

(#8-32 x 5/16") into bottom of

closer body and cover mounting

bracket, approx. one turn

RANGE

2. Slide cover onto backplate and

closer assembly. Secure with

three cover screws

BACKCHECK

RANGE

12-2960

CAUTION: Avoid

interference with

electronics and wires

during installation of cover

A7395C.indd 2 10/29/18 12:44 PM

9-2960 Without Electronics not shown

On/Off

Switch

2960

A7395C

2

Loading...

Loading...