Page 1

™

Degree

Technical Manual

Key System

Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

Page 2

Table of Contents

Degree™ Key System Technical Manual

Table of Contents

The Degree™ Advantage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DG1 Key Cuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

DG2 & DG3 Key Cuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Pinning Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Construction Master Keying (21-Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Visual Key Control Tamper Proof Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Degree Pin Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cylinder Parts: DG1-34 Rim/ DG1-40 Series Mortise. . . . . . . . . . . . . . . . . . . . . . . . .8

Cylinder Parts: DG2-34 Rim/ DG2-40 Series Mortise. . . . . . . . . . . . . . . . . . . . . . . . .9

Cylinder Parts: DG3-34 Rim/ DG3-40 Series Mortise. . . . . . . . . . . . . . . . . . . . . . . .10

Cylinder Parts: DG1-LFIC Cores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cylinder Parts: DG2-LFIC Cores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cylinder Parts: DG3-LFIC Cores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cylinder Parts: DG1 Bored, Auxiliary, & Integralock . . . . . . . . . . . . . . . . . . . . . . . . 14

Cylinder Parts: DG2 Bored, Auxiliary, & Integralock . . . . . . . . . . . . . . . . . . . . . . . . 15

Cylinder Parts: DG3 Bored, Auxiliary, & Integralock . . . . . . . . . . . . . . . . . . . . . . . . 16

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

On The Cover

DG1-41 Mortise cylinder, Degree Key

and Degree DG1-6300 series core

1-800-727-5477 • www.sargentlock.com

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 3

e Degree™ Advantage

Degree™ Key System Technical Manual

The Degree Key System

The patented Degree system from SARGENT

provides the right level of security for each

opening in your facility. Three levels of ANSI/

BHMA Grade 1 protection, from patented

keyway to UL437 certified, secures every opening.

A common key for all three levels of security

enhances key control and simplifies administrative

procedures. Key blanks are controlled through

authorized distribution and geographical

protection is available. Available for mortise, rim,

component and Large Format Interchangeable

Core (LFIC) cylinders, SARGENT offers the

right Degree of protection for every door in

your facility.

Benefits

• Patent protection from unauthorized key

duplication through 2027

• New keyway family protects system integrity

from legacy systems

• Keys are significantly stronger than

competitive systems

• User-friendly design with minimal components

provides easy field service

• Availability in all existing SARGENT cylinder

types provides cost-effective upgrade for

SARGENT facilities

• Bump resistance for added protection

Degree Level 1 (DG1) features a utility patented

keyway and provides protection against bumping

for mortise, rim and component fixed cylinders.

These cylinders easily retrofit into existing

hardware and are appropriate for most

applications. The keys for DG1 can only open

DG1 cylinders.

Degree Level 2 (DG2) builds on the utility

patented keyway of DG1 and adds patented side

bar locking with unique angled bottom pins that

provide end users with geographical exclusivity.

Cylinders provide protection against bumping

and picking. Because of its superior key control

and patent protection until 2027, DG2 products

are recommended for use in conjunction with

DG3 for new installations or when retrofitting

systems, including large format interchangeable

core systems.

Degree Level 3 (DG3) combines the utility

patented keyway and side bar locking with

unique angled bottom pins that provide end

users with geographical exclusivity, and adds

certification to UL437. They are classified as high

security because of their superior resistance to

physical attack and protection against unauthorized

key duplication. Because of its superior key control,

patent protection until 2027, and physical

strength, we recommend DG3 products for new

high-security installations or when retrofitting

systems, including large format interchangeable

core systems. SARGENT also offers anti-vandal

and high security locksets that complement

DG3 cylinders for those openings most vulnerable

to attack.

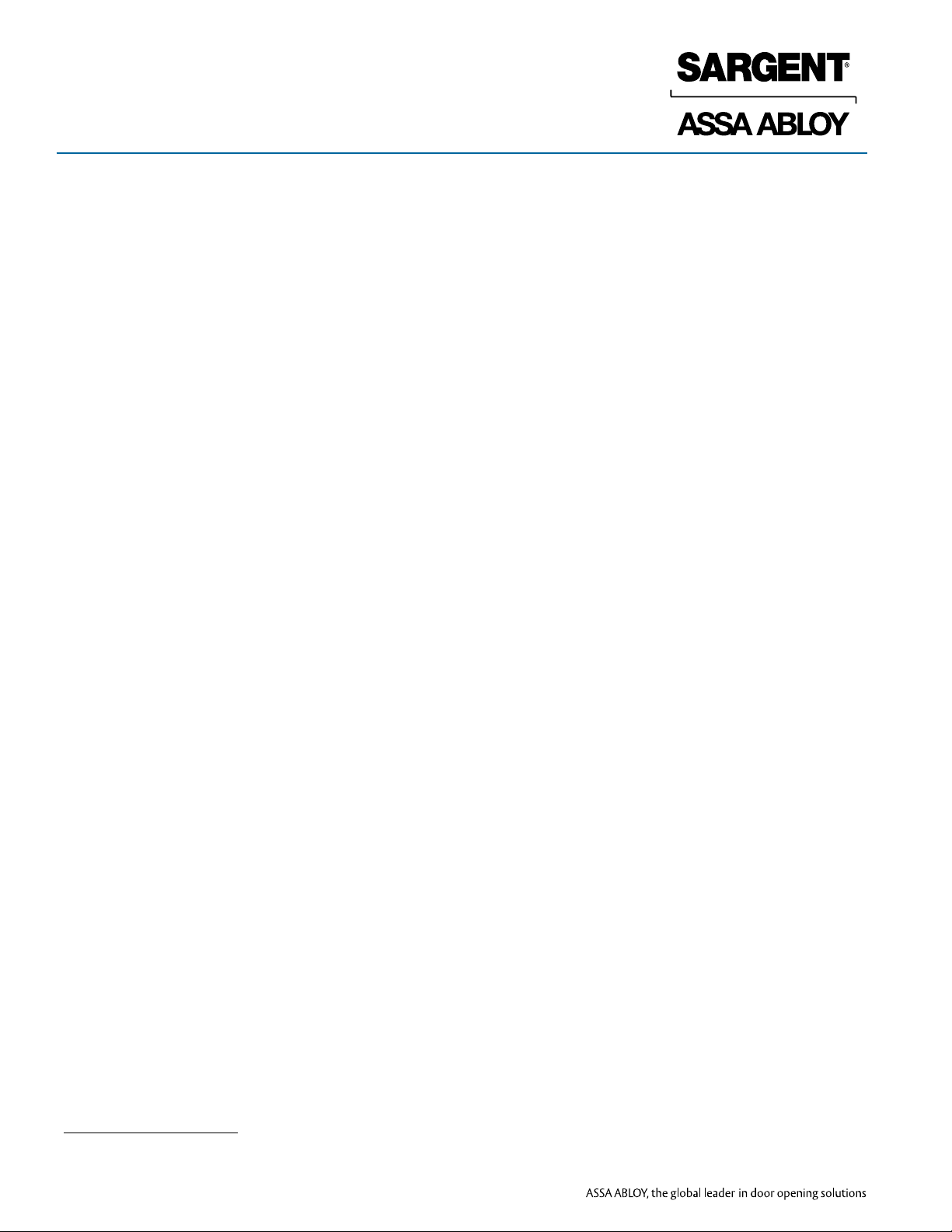

SARGENT Cylinder & Key Control Products

High

Security

Security

Patented Keyway

Open Conventional

High Security: UL437 Drill & Pick Resistant Systems offer protection

against physical attacks. Includes Degree DG3, UL-Signature

and UL-Keso.

Extra

Security: Protection against picking. Includes Degree DG2,

Control

Signature and Keso.

Patented Keyway: Keys are protected against unauthorized

duplication. Includes Degree DG1 and XC.

Open Conventional: Legacy systems whose patents

have run out and are not protected.

Intermediate

Control

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

1-800-727-5477 • www.sargentlock.com

1

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 4

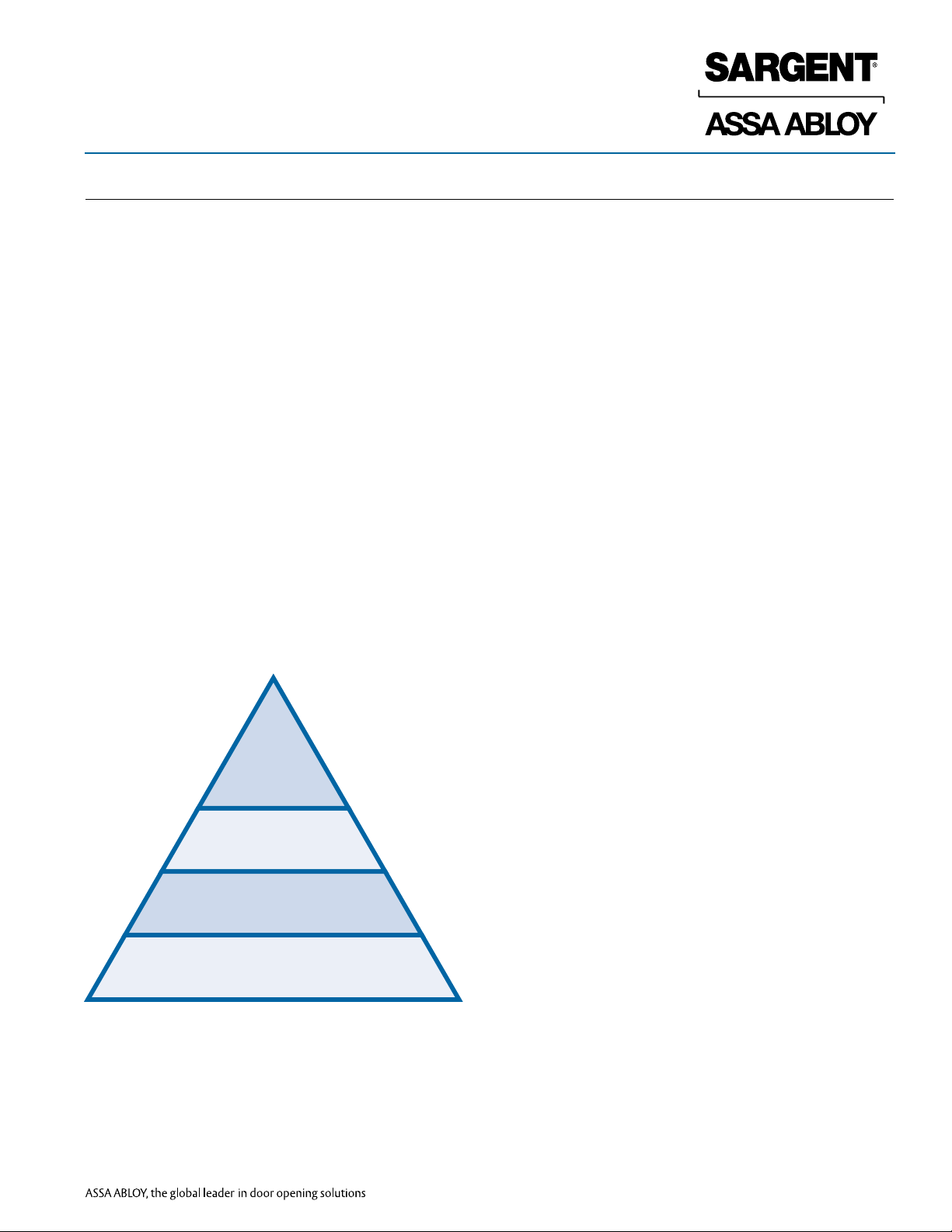

DG1 Key Cuts

Degree™ Key System Technical Manual

DG1 cuts from Bow to Tip

.170±.001

.2440±.0025

TYP.

1234 56

(.307)

90°

TYP.

.054±.001

REFERENCE LINE BOTTOM OF KEY

.271±.0015

.241±.0015

(1)

(2)

.211±.0015

.181±.0015

.151±.0015

(3)

(4)

.121±.002

(5)

(6)

Bottom Pins (BP)

for DG1- cylinders

Size # Part No. Length

1 DG-0021 .231

2 DG-0022 .261

3 DG-0023 .291

4 DG-0024 .321

5 DG-0025 .351

6 DG-0026 .381

Driver Pins (DP)

for DG1- standard cylinders

Size # Part No. Length

1 DG-0051 .030

2 DG-0052 .060

3 DG-0053 .090

4 DG-0054 .120

5 DG-0055 .150

6 DG-0246 .180

7 DG-0247 .210

8 DG-0248 .240

9 DG-0249 .270

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

Master Wafers (MW)

for all DG- series

Size # Part No. Length

1 DG-0051 .030

2 DG-0052 .060

3 DG-0053 .090

4 DG-0054 .120

5 DG-0055 .150

Driver Pins (DP)

for DG2- & DG3- cylinders and

all DG- Large Format

Interchangeable Cores

Size # Part No. Length

1 DG-0051 .030

2 DG-0052 .060

3 DG-0053 .090

4 DG-0054 .120

5 DG-0045 .150

6 DG-0044 .180

7 DG-0043 .210

8 DG-0042 .240

9 DG-0041 .270

Control Drivers (CD) for all DG- Large

Format Interchangeable Cores (3 & 4

Chambers)

Size # Part No. Length

1 DG-0051 .030

2 DG-0052 .060

3 DG-0053 .090

4 DG-0054 .120

5 DG-0055 .150

6 n/a

7 DG-0247 .210

8 DG-0248 .240

9 DG-0249 .270

10 DG-0250 .300

11 DG-0251 .330

Driver Pins (DP) for Bump

Resistance (DG1 Only)

Size # Part No. Length

1 DG-0036 .120

2 DG-0035 .150

3 DG-0034 .180

5 DG-0033 .210

6 DG-0032 .240

7 DG-0031 .270

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

2

1-800-727-5477 • www.sargentlock.com

Page 5

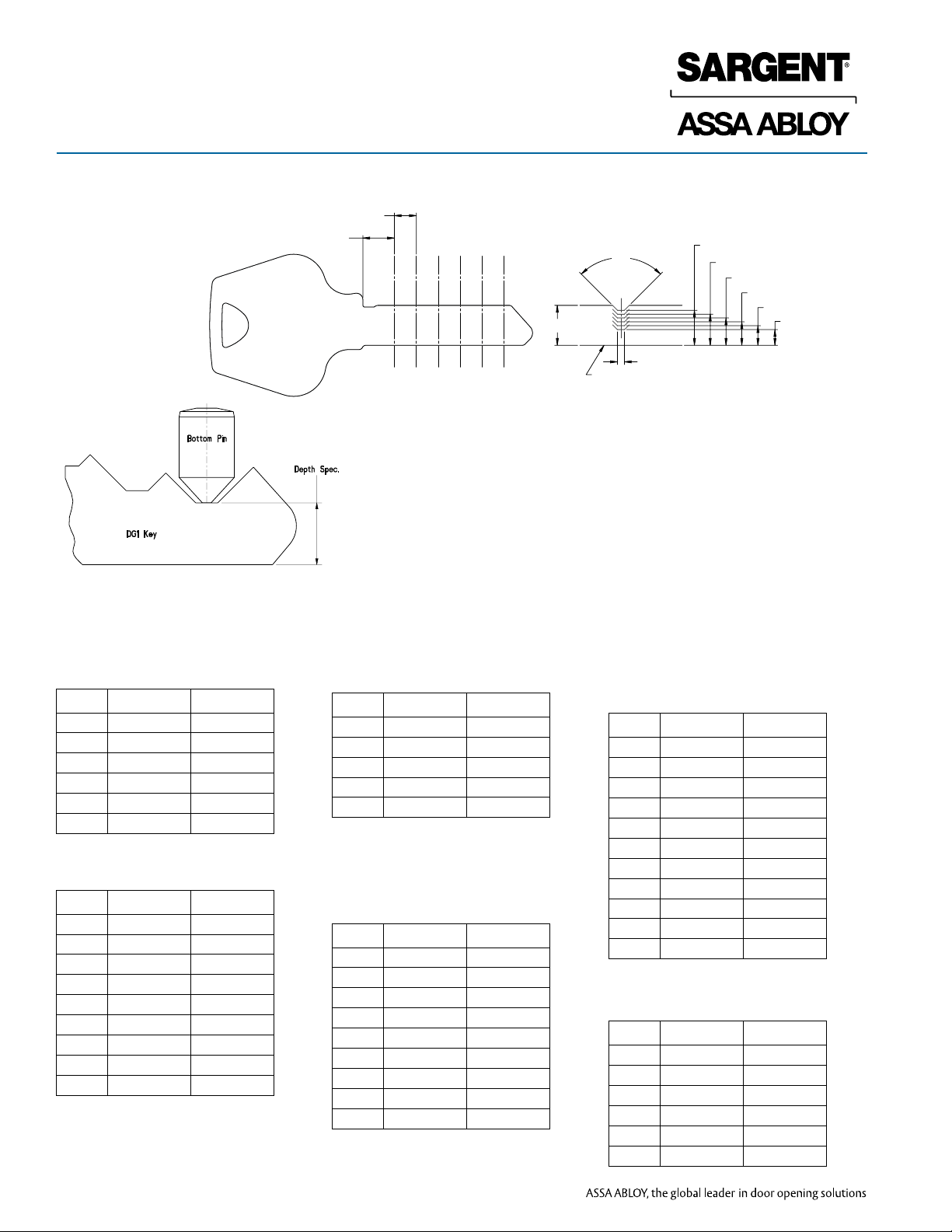

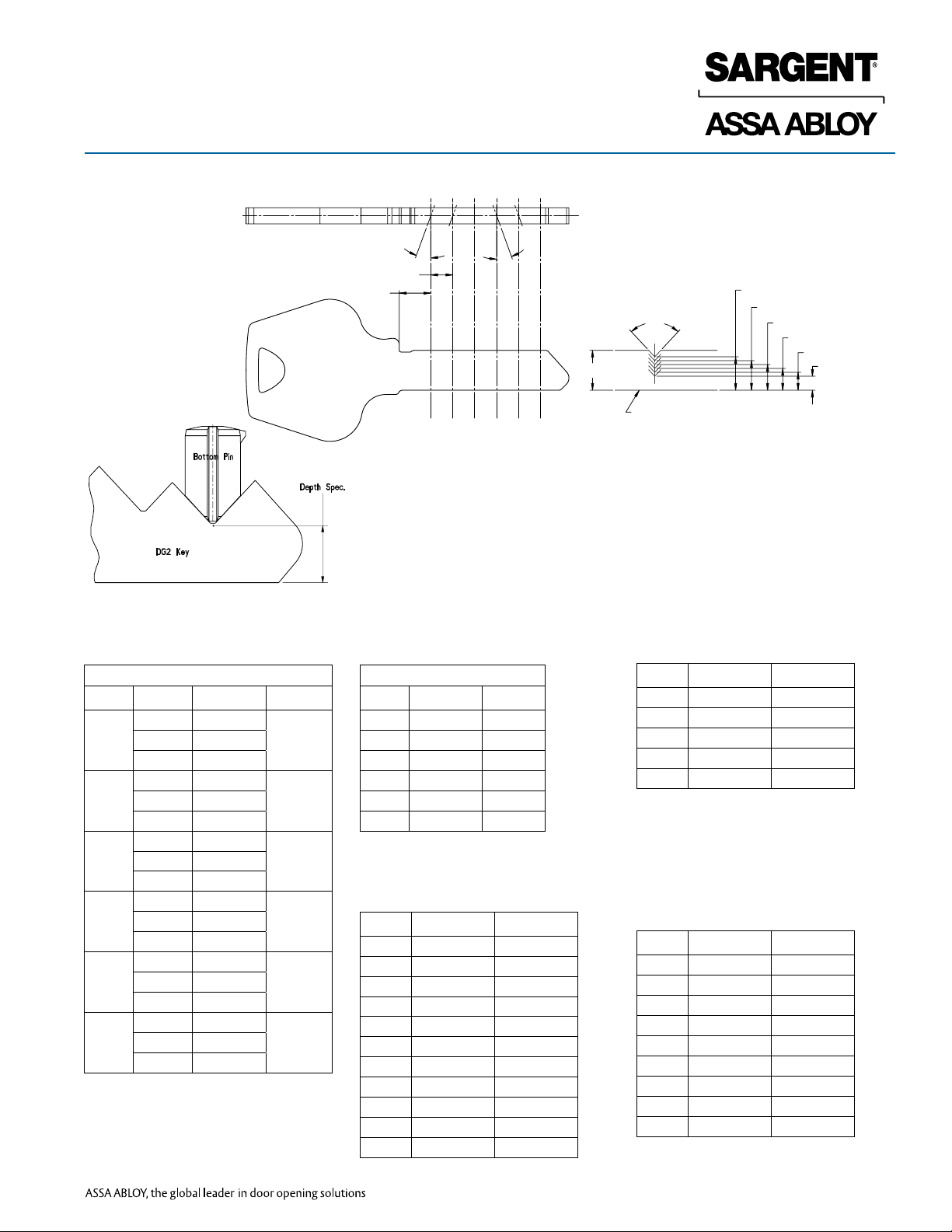

DG2 & DG3 Key Cuts

Degree™ Key System Technical Manual

DG2 DG3 cuts

Dimensions shown are to theoretical intersection

Bottom Pins (BP)

for DG2- & DG3- cylinders

.170 ±.001

.2440±.0025

R

C

R

20°

TYP.

1234 56

LL

20°

C

.259±.001 (1)

.229±.001 (2)

.199±.001 (3)

.169±.001 (4)

.139±.001 (5)

.109±.001 (6)

(.307)

86°

TYP.

REFERENCE LINE BOTTOM OF KEY

Master Wafers (MW)

for all DG- series

First 5 positions (Angled Pins)

Size # Angle Part No. Length

L DG-0111

1

R DG-0131

L DG-0112

2

R DG-0132

L DG-0113

3

R DG-0133

L DG-0114

4

R DG-0134

L DG-0115

5

R DG-0135

L DG-0116

6

R DG-0136

.231C DG-0121

.261C DG-0122

.291C DG-0123

.321C DG-0124

.351C DG-0125

.381C DG-0126

6th (last) position

Size # Part No. Length

1 DG-0021 .231

2 DG-0022 .261

3 DG-0023 .291

4 DG-0024 .321

5 DG-0025 .351

6 DG-0026 .381

Control Drivers (CD) for all DGLarge Format Interchangeable

Cores (3 & 4 Chambers)

Size # Part No. Length

1 DG-0051 .030

2 DG-0052 .060

3 DG-0053 .090

4 DG-0054 .120

5 DG-0055 .150

6 n/a

7 DG-0247 .210

8 DG-0248 .240

9 DG-0249 .270

10 DG-0250 .300

11 DG-0251 .330

Size # Part No. Length

1 DG-0051 .030

2 DG-0052 .060

3 DG-0053 .090

4 DG-0054 .120

5 DG-0055 .150

Driver Pins (DP)

for DG2- & DG3- cylinders and

all DG- Large Format

Interchangeable Cores

Size # Part No. Length

1 DG-0051 .030

2 DG-0052 .060

3 DG-0053 .090

4 DG-0054 .120

5 DG-0045 .150

6 DG-0044 .180

7 DG-0043 .210

8 DG-0042 .240

9 DG-0041 .270

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

1-800-727-5477 • www.sargentlock.com

3

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 6

Pinning Formula

Degree™ Key System Technical Manual

Fixed Core Cylinders - All 6 Chambers

Large Format Interchangeable Cores

(Chambers 1-2-5-6)

Non-LFIC

Driver Pin (DP)

10 MINUS

Plug Total

Master Wafer

(MW) Pin =

Deepest Minus

Shallowest

Operating Cut

Bottom Pin =

Shallowest

Operating Cut

Example

Master Key 1 2 3 4 6 4

Change Key 3 4 5 2 2 2

Driver Pin (DP) 7 6 5 6 4 6

Master Wafer (MW) 2 2 2 2 4 2

Bottom Pin (BP) 1 2 3 2 2 2

Plug Total (MW + BP)

Large Format Interchangeable Core -

(Chambers 3 and 4 Only)

LFIC

Driver Pin (DP)

13 MINUS Plug

Total and

Control Driver

Control

Driver (CD) =

Control Cut PLUS 6

MINUS Plug Total

Master Wafer

(MW) Pin =

Deepest MINUS

Shallowest

Operating Cut

Bottom Pin =

Shallowest

Operating Cut

Control Chambers

Example

Control Key 1 5 5 4 3 2

Master Key 1 5 2 6 3 2

Change Key 3 1 4 3 1 5

Driver Pin (DP) 7 5 2 3 7 5

Control Driver (CD) x x 7 4 x x

Master Wafer (MW) 2 4 2 3 2 3

Bottom Pin (BP) 1 1 2 3 1 2

Plug Total (MW +BP)

Instructions

Bottom Pin = shallowest operating cut

Master Wafer (if required) = Deepest minus

shallowest operating cut

(Plug Total = Bottom Pin + Master Wafer)

Driver Pin = 10 MINUS Plug Total

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

4

1-800-727-5477 • www.sargentlock.com

Instructions

Bottom Pin = shallowest operating cut

Master Wafer (if required) = Deepest minus

shallowest operating cut

(Plug Total = Bottom Pin + Master Wafer)

Control Driver (CD) = Control cut PLUS 6 MINUS

Plug Total

Driver Pin = 13 MINUS Plug Total and CD# = DP

Page 7

Construction Master Keying

(21- Option)

Degree™ Key System Technical Manual

Construction Master Keying (Lost/Wafer Design) for DG1-, DG2- & DG3-

SARGENT Degree cylinders when master keyed are offered with the

convenience of construction keying when specified with the 21- option.

This is not recommended with DG3 key systems or any system where strict

key control and management is enforced.

Construction keying simplifies the process when the building gets turned

over. With this feature, the 21- cylinder is master keyed with a special

construction feature in one of the chambers. The plug is prepped in two

places along both sides of the same chamber containing the construction

feature. This allows the construction master key to be used during the

construction phases.

It is highly recommended that all construction keys are collected and

accounted for once the project is complete to protect the integrity of the

key system. This is not recommended with DG3 key systems or any system

where strict key control & management is enforced.

Wafer

New systems supplied with six construction master keys unless

otherwise specified. Orders to existing key systems that require

additional construction keys are to be specified and ordered separately.

Orders with 21- will have all change keys shipped separately from

hardware. Six construction master keys provided per system unless

otherwise specified.

The 21- is not available with hotel function cylinders or large format

interchangeable cores (6300 series). If construction keying is required

for LFIC, specify 64-DG- construction keyed cores.

As change key rotates,

construction wafer falls into

“donut” hole in the side of plug.

Only construction wafer will

fall due to hole through its center.

Cutaway cylinder showing construction

master key being used, putting the wafer

below the shear line while key is turned.

Note the two empty “donut” holes

on either side of the chamber.

Change key rotated to

position for extraction.

Change key inserted in cylinder

putting the wafer at the shear line.

Construction key inserted after

wafer is trapped. Driver now

extends into plug chamber.

Construction key if used will not rotate.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

1-800-727-5477 • www.sargentlock.com

5

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 8

Visual Key Control

Tamper Proof Packaging

Degree™ Key System Technical Manual

Visual Key Control (Stamping)

To allow for easier key and cylinder identification, SARGENT offers permanent stamping of keys and/or optional cylinder concealed stamping with

industry standard alpha-numeric key set symbols.

All DG keys are stamped with key set symbol and “DO NOT DUPLICATE” as standard.

All DG master and control keys are stamped with the key set symbol and the key system register # cylinders as standard, (Item B) unless alternate

stamping is requested on the order.

Master level keys do not include bitting numbers. Master level keys include system register numbers stamped on the first line and the standard visual key

control designations on the second line (Item B).

Change keys have one line for up to 7 characters for key set stamping available for permanent Visual Key Control

• Key and cylinder identified by industry standard alpha-numeric keyset symbols

• Cylinder-slide stamping available on mortise, rim, LFIC and all bored cylinders except for 8-Line and 7600 (Items C, D, & E)

• Core side engraving available for 8-Line and 7600 (Item F)

Keyway

AB1

PAT. NO. 7,552,608

DO NOT DUPLICATE

Item A

Change (Day)

Key Stamping

Key Set

Example

system

number

Symbol to

identify

factory-cut

key

PAT. NO. 7,552,608

DO NOT DUPLICATE

Item B

Master Level

Key Stamping

Example

of keyset

Item C

Item D

Item E

Item F

Tamper Proof Packaging

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

For the highest level of security for the end user, tamper proof packaging is used on all Degree master keys and key blanks. This heat sealed shrink wrap

identified with “SARGENT Sealed For Your Security” provides assurance of the integrity of the factory generated key system.

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

6

1-800-727-5477 • www.sargentlock.com

Page 9

Degree Pin Kits

Degree™ Key System Technical Manual

437 DG1 Standard Pinning Kit

The 437 DG1 Kit is used to pin DG1 fixed and LFIC cylinders. The heavy duty steel kit prevents pins from mixing.

The kit includes:

- 100 each of bottom pins sizes 1-6

- 100 each of control drivers sizes 1-11

- 100 each of driver pins sizes 1-9

- 100 each of bump resistant pins sizes 4-9

- 25 sidebar springs part number DG-0059

- 100 KIK spring cover part number 13-1341

- 25 KIL/MRT/RIM/LFIC spring cover DG-0040

- 10 each Sidebar (LFIC only) part number DG-2818

- 100 each compression spring part number DG-0017

- 100 each compression spring (LFIC only) part number DG-0097

- Tweezer

- Degree key gauge

See pages 2 and 3 for individual pin part #s.

The kit has additional empty compartments for future upgrades to DG2 and DG3 cylinders.

The 437 DGM “Master Kit” has all pins needed for pinning DG1, DG2 and DG3 cylinders.

437 DGM Master Pinning Kit

The 437 DGM “Master Kit” includes all pins needed to re-pin DG1, DG2 and DG3 cylinders.

Kit includes all the same components as in the 437 DG1 kit, with the additional parts to service DG2

and DG3 cylinders.

- 10 each Side bar part number DG 0056

- 25 each slider spring part number DG 0060

- 100 each of Left, Center and Right “Chisel Bottom Pins” sizes 1 thru 6

See pages 2 and 3 for individual part numbers.

Cylinder Spray Lubricant

Degree cylinders are mechanical devices and require preventive maintenance. At a minimum, Degree

cylinders should be lubricated twice a year; more if installed in extreme installations.

Degree cylinders should not be exposed to chemical washes or painted.

3.0 oz aerosol part number 18-0070.

Cylinder Spray Cleaner/Deicer: 3.0 oz aerosol part number 18-0435.

1-800-727-5477 • www.sargentlock.com

7

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 10

Cylinder Parts:

DG1-34 Rim/ DG1-40 Series Mortise

Degree™ Key System Technical Manual

DG1-34 Rim/ DG1-40 Series Mortise Cylinder Parts

Item Description Part Number Where Used / Cylinder Length Comment

DG-2894 DG1-34 –

DG-2911 DG1-41 & 78-DG1-41 1-1/8" (29mm)

1 Plug

2 Cylinder Shell

3 Conical Bottom Pin See Page 2 and 3 DG1-40 Series Mortise & DG1-34 Rim

4 Master Wafer See Page 2 and 3 DG1-40 Series Mortise & DG1-34 Rim

5 Bump-Resistant Driver Pin See Page 2 and 3 DG1-40 Series Mortise & DG1-34 Rim

6 Compression Spring DG-0017 DG1-40 Series Mortise & DG1-34 Rim

7 Cam See Degree Catalog DG1-40 Series Mortise

8 Screw DG-0016 DG1-40 Series Mortise # 2-56 x 5/16" (8mm) PH. FL.

10 Retainer DG-0090 DG1-34 Rim

11 Tailpiece Retainer DG-0195 DG1-34 Rim

12 Tailpiece DG-0196 DG1-34 Rim

13 Spring Cover DG-0040 DG1-40 Series Mortise & DG1-34 Rim

14 Standard Connecting Screws 13-0074 DG1-34 Rim # 12-24 x 2-1/8" (54mm)

15 Rim Cylinder Back Plate 13-0086 DG1-34 Rim

DG-2912 DG1-42 & 78-DG1-42 1-1/4" (32mm)

DG-2913 DG1-43 & 78-DG1-43 1-3/8" (35mm

DG-2914 DG1-44 1-1/2" (38mm)

DG-2915 DG1-46 1-3/4" (44mm)

DG-0621 DG1-41 & DG1-34 1-1/8" (29mm)

DG-0622 DG1-42 1-1/4" (32mm)

DG-0623 DG1-43 1-3/8" (35mm)

DG-0624 DG1-44 1-1/2" (38mm)

DG-0625 DG1-46 1-3/4" (44mm)

DG-0221 78-DG1-41 1-1/8" (29mm)

DG-0222 78-DG1-42 1-1/4" (32mm)

DG-0223 78-DG1-43 1-3/8" (35mm)

Plug finishes: 04, 15

Shell finishes: 03, 04, 09,

10, 10B, 10BL, 14, 15,

20D, 26, 26D

No finish.

For use with mortise locks

with LE3 or LE4 trim only.

13

6

5

3

2

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

8

1-800-727-5477 • www.sargentlock.com

4

15

8

7

12

11

1

10

14

Page 11

Cylinder Parts:

DG2-34 Rim/ DG2-40 Series Mortise

Degree™ Key System Technical Manual

DG2-34 Rim / DG2-40 Series Mortise Cylinder Parts

Item Description Part Number Where Used / Cylinder Length Comment

DG-0191 DG2-34 –

DG-0411 DG2-41 & 78-DG2-41 1-1/8" (29mm)

1 Plug

2 Cylinder Shell

3 Chisel Tipped Bottom Pin See Page 2 and 3 DG2-40 Series Mortise & DG2-34 Rim In pin chambers 1 through 5

4 Conical Bottom Pin See Page 2 and 3 DG2-40 Series Mortise & DG2-34 Rim In pin chamber 6 only

5 Master Wafer See Page 2 and 3 DG2-40 Series Mortise & DG2-34 Rim

6 Driver Pin See Page 2 and 3 DG2-40 Series Mortise & DG2-34 Rim

7 Compression Spring DG-0017 DG2-40 Series Mortise & DG2-34 Rim

8 Slider C6M6 DG-0087 DG2-40 Series Mortise & DG2-34 Rim For keys with a #6 slider cut

9 Slider Spring DG-0060 DG2-40 Series Mortise & DG2-34 Rim

10 Sidebar Spring DG-0059 DG2-40 Series Mortise & DG2-34 Rim

11 Sidebar DG -2818 DG2-40 Series Mortise & DG2-34 Rim

12 Cam See Degree Catalog DG2-40 Series Mortise

13 Screw DG-0016 DG2-40 Series Mortise # 2-56 x 5/16" (8mm) PH. FL.

15 Retainer DG-0090 DG2-34 Rim

16 Tailpiece Retainer DG-0195 DG2-34 Rim

17 Tailpiece DG-0196 DG2-34 Rim

18 Spring Cover DG-0040 DG2-40 Series Mortise & DG2-34 Rim

19 Standard Connecting Screws 13-0074 DG2-34 Rim # 12-24 x 2-1/8" (54mm)

20 Rim Cylinder Back Plate 13-0086 DG2-34 Rim

DG-0412 DG2-42 & 78-DG2-42 1-1/4' (32mm)

DG-0413 DG2-43 & 78-DG2-43 1-3/8" (35mm

DG-0414 DG2-44 1-1/2" (38mm)

DG-0415 DG2-46 1-3/4" (44mm)

DG-0631 DG2-41 & DG2-34 1-1/8" (29mm)

DG-0632 DG2-42 1-1/4" (32mm)

DG-0633 DG2-43 1-3/8" (35mm)

DG-0634 DG2-44 1-1/2" (38mm)

DG-0635 DG2-46 1-3/4" (44mm)

DG-0231 78-DG2-41 1-1/8" (29mm)

DG-0232 78-DG2-42 1-1/4" (32mm)

DG-0233 78-DG2-43 1-3/8" (35mm)

Plug finishes: 04, 15

Shell finishes: 03, 04, 09,

10, 10B, 10BL, 14, 15,

20D, 26, 26D

No finish.

For use with mortise locks

with LE3 or LE4 trim only.

18

7

6

3

2

11

10

8

9

5

4

16

1

13

12

17

15

20

1-800-727-5477 • www.sargentlock.com

19

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

9

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 12

Cylinder Parts:

DG3-34 Rim/ DG3-40 Series Mortise

Degree™ Key System Technical Manual

DG3-34 Rim / DG3-40 Series Mortise Cylinder Parts

Item Description Part Number Where Used / Cylinder Length Comment

DG-2895 DG3-34 –

DG-2881 DG3-41 & 78-DG3-41 1-1/8" (29mm)

DG-2882 DG3-42 & 78-DG3-42 1-1" (32mm)

DG-2883 DG3-43 & 78-DG3-43 1-3/8" (35mm

DG-2884 DG3-44 1-1/2" (38mm)

DG-2885 DG3-46 1-3/4" (44mm)

DG-0641 DG3-41 & DG3-34 1-1/8" (29mm)

DG-0642 DG3-42 1-1/4" (32mm)

DG-0643 DG3-43 1-3/8" (35mm)

DG-0644 DG3-44 1-1/2" (38mm)

DG-0645 DG3-46 1-3/4" (44mm)

DG-0241 78-DG3-41 1-1/8" (29mm)

DG-0242 78-DG3-42 1-1/4" (32mm)

DG-0243 78-DG3-43 1-3/8" (35mm)

Plug finishes: 04, 15

Shell finishes: 03, 04, 09,

10, 10B, 10BL, 14, 15,

20D, 26, 26D

No finish.

For use with mortise locks

with LE3 or LE4 trim only.

10

11

12

13

14

16

17

18

19

20

21

1

2

3

Chisel Tipped Bottom Pin See Page 2 and 3 DG3-40 Series Mortise & DG3-34 Rim In pin chambers 1 through 5

4

5

6

7

8

9

Standard Connecting Screws 13-0074 DG3-34 Rim # 12-24 x 2-1/8" (54mm)

Plug

Cylinder Shell

Conical Bottom Pin See Page 2 and 3 DG3-40 Series Mortise & DG3-34 Rim In pin chamber 6 only

Master Wafer See Page 2 and 3 DG3-40 Series Mortise & DG3-34 Rim

Driver Pin See Page 2 and 3 DG3-40 Series Mortise & DG3-34 Rim

Compression Spring DG-0017 DG3-40 Series Mortise & DG3-34 Rim

Slider C6M6 DG-0087 DG3-40 Series Mortise & DG3-34 Rim For keys with a #6 slider cut

Slider Spring DG-0060 DG3-40 Series Mortise & DG3-34 Rim

Sidebar Spring DG-0059 DG3-40 Series Mortise & DG3-34 Rim

Sidebar DG -2818 DG3-40 Series Mortise & DG3-34 Rim

Security Plate DG-0057 DG3-40 Series Mortise & DG3-34 Rim Required for UL437

Cam See Degree Catalog DG3-40 Series Mortise

Screw DG-0016 DG3-40 Series Mortise # 2-56 x 5/16" (8mm) PH. FL.

Retainer DG-0090 DG3-34 Rim

Tailpiece Retainer DG-0195 DG3-34 Rim

Tailpiece DG-0196 DG3-34 Rim

Spring Cover DG-0040 DG3-40 Series Mortise & DG3-34 Rim

Cylinder Back Plate 13-0086 DG3-34 Rim

19

7

6

3

2

12

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

8

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

10

1-800-727-5477 • www.sargentlock.com

9

11

10

5

4

17

1

14

13

18

16

21

20

Page 13

Cylinder Parts:

DG1-LFIC Cores

Degree™ Key System Technical Manual

DG1 LFIC Cores

Item Description Part Number Comment

1

2

3

4

5

6

7

8

9

10

11

12

Plug DG-0200 Plug finishes: 04, 15

Cylinder Shell DG-0290 Shell finishes: 04, 15

Control Sleeve DG-0215

Conical Bottom Pin See Page 2 and 3

Master Wafer See Page 2 and 3

Control Pin See Page 2 and 3

Driver Pin See Page 2 and 3

Compression Spring DG-0097

Plug Retainer DG-0090

Sidebar Spring DG-0059

Sidebar DG-0056

Spring Cover DG-0040

12

8

7

5

6

9

4

2

1

3

10

11

1-800-727-5477 • www.sargentlock.com

11

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 14

Cylinder Parts:

DG2-LFIC Cores

Degree™ Key System Technical Manual

DG2 LFIC Cores

Item Description Part Number Comment

1 Plug DG-0201 Plug finishes: 04, 15

2 Cylinder Shell DG-0291 Shell finishes: 04, 15

3 Control Sleeve DG-0216

4 Chisel Tipped Bottom Pin See Page 2 and 3 In pin chambers 1 through 5

5 Conical Bottom Pin See Page 2 and 3 In pin chamber 6 only

6 Master Wafer See Page 2 and 3

7 Control Pin See Page 2 and 3

8 Driver Pin See Page 2 and 3

9 Compression Spring DG-0097

10 Slider C6M6 DG-0087 For keys with a #6 slider cut

11 Slider Spring DG-0060

12 Sidebar Spring DG-0059

13 Sidebar DG-2818

14 Plug Retainer DG-0090

15 Spring Cover DG-0040

15

9

7

4

2

1

12

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

11

10

13

8

6

5

14

3

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

12

1-800-727-5477 • www.sargentlock.com

Page 15

Cylinder Parts:

DG3-LFIC Cores

Degree™ Key System Technical Manual

DG3 LFIC Cores

Item Description Part Number Comment

1 Plug DG-2901 Plug finishes: 04, 15

2 Cylinder Shell DG-0292 Shell finishes: 04, 15

3 Control Sleeve DG-0216

4 Chisel Tipped Bottom Pin See Page 2 and 3 In pin chambers 1 through 5

5 Conical Bottom Pin See Page 2 and 3 In pin chamber 6 only

6 Master Wafer See Page 2 and 3

7 Control Pin See Page 2 and 3

8 Driver Pin See Page 2 and 3

9 Compression Spring DG-0097

10 Slider C6M6 DG-0087 For keys with a #6 slider cut

11 Slider Spring DG-0060

12 Sidebar Spring DG-0059

13 Sidebar DG-2818

14 Plug Retainer DG-0090

15 Spring Cover DG-0040

15

9

7

4

2

1

12

13

11

10

8

6

5

14

3

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

1-800-727-5477 • www.sargentlock.com

13

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 16

Cylinder Parts:

DG1 Bored, Auxiliary & Integralock

Degree™ Key System Technical Manual

13

6

5

3

2

1

4

9

8

7

12

11

10

DG1 Bored, Auxiliary, & Integralock Cylinder Parts

Item Description Part Number Where Used / Cylinder Length Comment

Plug with tailpiece retainer

1

2

3

4

5

6

7

8

9

10

11

12

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

13

(item 7)

Plug with roll pin DG-3071 7, 8, 9 Line Cylinders (Knob Locks)

Plug DG-3029 460, 470, 480, 7500DB Series Deadbolt Cylinders

Plug DG-3043 7600 Integralock Cylinder

Cylinder Shell

Conical Bottom Pin See Page 2 and 3 All Cylinders

Master Wafer See Page 2 and 3 All Cylinders

Driver Pin See Page 2 and 3 All Cylinders

Compression Spring DG-0017 All Cylinders

Tailpiece Retainer 13-0680 6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

Tailpiece

Plug Retainer DG-0090

Plug Retainer (Deadbolt) DG-0150 460, 470, 480, 7500DB Series Deadbolt Cylinders

Retainer Screw DG-0151 460, 470, 480, 7500DB Series Deadbolt Cylinders # 2-56 x 1/4" (6mm) PH. PAN

Tailpiece

Spring Cover

DG-3061

DG-0171 6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

DG-0261 7, 8, 9 Line Cylinders (Knob Locks)

DG-0161 460, 470, 480, 7500DB Series Deadbolt Cylinders

DG-0271 7600 Integralock Cylinder

13-0895 7, 8L, 10, 6500, 7500 Line Cylinders (Lever Locks)

13-1385 11 Line Cylinders

13-0907 6 Line (S & N knobs) Cylinders

13-0908 6 Line (B knob) Cylinders

DG-2875 Single-Cylinder Deadbolts

DG-2876 Double-Cylinder Deadbolts

13-1341

DG-0039

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders

(Lever Locks)

Plug finishes: 04, 15

No finish

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

7, 8, 9 Line Cylinders (Knob Locks)

7600 Integralock Cylinder

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

460, 470, 480, 7500DB Series Deadbolt Cylinders

7, 8, 9 Line Cylinders (Knob Locks)

7600 Integralock Cylinder

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

14

1-800-727-5477 • www.sargentlock.com

Page 17

Cylinder Parts:

DG2 Bored, Auxiliary & Integralock

Degree™ Key System Technical Manual

18

7

5

3

2

9

815

1

6

4

14

13

12

10

11

17

16

DG2 Bored, Auxiliary, & Integralock Cylinder Parts

Item Description Part Number Where Used / Cylinder Length Comment

Plug with tailpiece retainer

1

Plug with roll pin DG-3072 7, 8, 9 Line Cylinders (Knob Locks)

2

Chisel Tipped Bottom Pin See Page 2 and 3 All Cylinders In pin chambers 1 through 5

3

4

Conical Bottom Pin See Page 2 and 3 All Cylinders In pin chamber 6 only

5

6

7

Compression Spring DG-0017 All Cylinders

8

9

10

11

12

Tailpiece Retainer 13-0680 6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

13

14

15

Plug Retainer (Deadbolt) DG-0150 460, 470, 480, 7500DB Series Deadbolt Cylinders

16

17

18

(item 12)

Plug DG-0166 460, 470, 480, 7500DB Series Deadbolt Cylinders

Plug DG-0276 7600 Integralock Cylinder

Cylinder Shell

Master Wafer See Page 2 and 3 All Cylinders

Driver Pin See Page 2 and 3 All Cylinders

Slider C6M6 DG-0087 All Cylinders For keys with a #6 slider cut

Slider Spring DG-0060 All Cylinders

Sidebar Spring DG-0059 All Cylinders

Sidebar DG -2818 All Cylinders

Tailpiece

Plug Retainer DG-0090

Retainer Screw DG-0151 460, 470, 480, 7500DB Series Deadbolt Cylinders # 2-56 x 1/4" (6mm) PH. PAN

Tailpiece

Spring Cover

DG-3062

DG-0172 6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

DG-0262 7, 8, 9 Line Cylinders (Knob Locks)

DG-0162 460, 470, 480, 7500DB Series Deadbolt Cylinders

DG-0272 7600 Integralock Cylinder

13-0895 7, 8L, 10, 6500, 7500 Line Cylinders (Lever Locks)

13-1385 11 Line Cylinders

13-0907 6 Line (S & N knobs) Cylinders

13-0908 6 Line (B knob) Cylinders

DG-2875 Single-Cylinder Deadbolts

DG-2876 Double-Cylinder Deadbolts

13-1341

DG-0039

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders

(Lever Locks)

Plug finishes: 04, 15

No finish

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

7, 8, 9 Line Cylinders (Knob Locks)

7600 Integralock Cylinder

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

460, 470, 480, 7500DB Series Deadbolt Cylinders

7, 8, 9 Line Cylinders (Knob Locks)

7600 Integralock Cylinder

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

1-800-727-5477 • www.sargentlock.com

15

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Page 18

Cylinder Parts:

DG3 Bored, Auxiliary & Integralock

Degree™ Key System Technical Manual

18

7

5

3

2

9

815

1

6

4

14

13

12

10

11

17

16

DG3 Bored, Auxiliary, & Integralock Cylinder Parts

Item Description Part Number Where Used / Cylinder Length Comment

Plug with tailpiece retainer

(item 12)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

Plug with roll pin DG-3073 7, 8, 9 Line Cylinders (Knob Locks)

Plug DG-3030 460, 470, 480, 7500DB Series Deadbolt Cylinders

Plug DG-3044 7600 Integralock Cylinder

Cylinder Shell

Chisel Tipped Bottom Pin See Page 2 and 3 All Cylinders In pin chambers 1 through 5

Conical Bottom Pin See Page 2 and 3 All Cylinders In pin chamber 6 only

Master Wafer See Page 2 and 3 All Cylinders

Driver Pin See Page 2 and 3 All Cylinders

Compression Spring DG-0017 All Cylinders

Slider C6M6 DG-0087 All Cylinders For keys with a #6 slider cut

Slider Spring DG-0060 All Cylinders

Sidebar Spring DG-0059 All Cylinders

Sidebar DG -2818 All Cylinders

Tailpiece Retainer 13-0680 6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

Tailpiece

Plug Retainer DG-0090

Plug Retainer (Deadbolt) DG-0150 460, 470, 480, 7500DB Series Deadbolt Cylinders

Retainer Screw DG-0151 460, 470, 480, 7500DB Series Deadbolt Cylinders # 2-56 x 1/4" (6mm) PH. PAN

Tailpiece

Spring Cover

DG-3063

DG-0172 6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

DG-0262 7, 8, 9 Line Cylinders (Knob Locks)

DG-0162 460, 470, 480, 7500DB Series Deadbolt Cylinders

DG-0272 7600 Integralock Cylinder

13-0895 7, 8L, 10, 6500, 7500 Line Cylinders (Lever Locks)

13-1385 11 Line Cylinders

13-0907 6 Line (S & N knobs) Cylinders

13-0908 6 Line (B knob) Cylinders

DG-2875 Single-Cylinder Deadbolts

DG-2876 Double-Cylinder Deadbolts

13-1341

DG-0039

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders

(Lever Locks)

Plug finishes: 04, 15

No finish

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

7, 8, 9 Line Cylinders (Knob Locks)

7600 Integralock Cylinder

6, 7, 8L, 10, 11, 6500, 7500 Line Cylinders (Lever Locks)

460, 470, 480, 7500DB Series Deadbolt Cylinders

7, 8, 9 Line Cylinders (Knob Locks)

7600 Integralock Cylinder

90726:E 4/30/14 Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

16

1-800-727-5477 • www.sargentlock.com

Page 19

Page 20

SARGENT Manufacturing Company

100 Sargent Drive

New Haven, CT 06511 USA

800-727-5477

www.sargentlock.com

Founded in the early 1800s, SARGENT® is a market leader in locksets, cylinders, door closers, exit devices, electro-mechanical products and access control systems for

new construction, renovation, and replacement applications. The company’s customer base includes commercial construction, institutional, and industrial markets.

Copyright © 2013-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without the express

written permission of Sargent Manufacturing Company is prohibited.

90726:E 4/30/14

Loading...

Loading...