Page 1

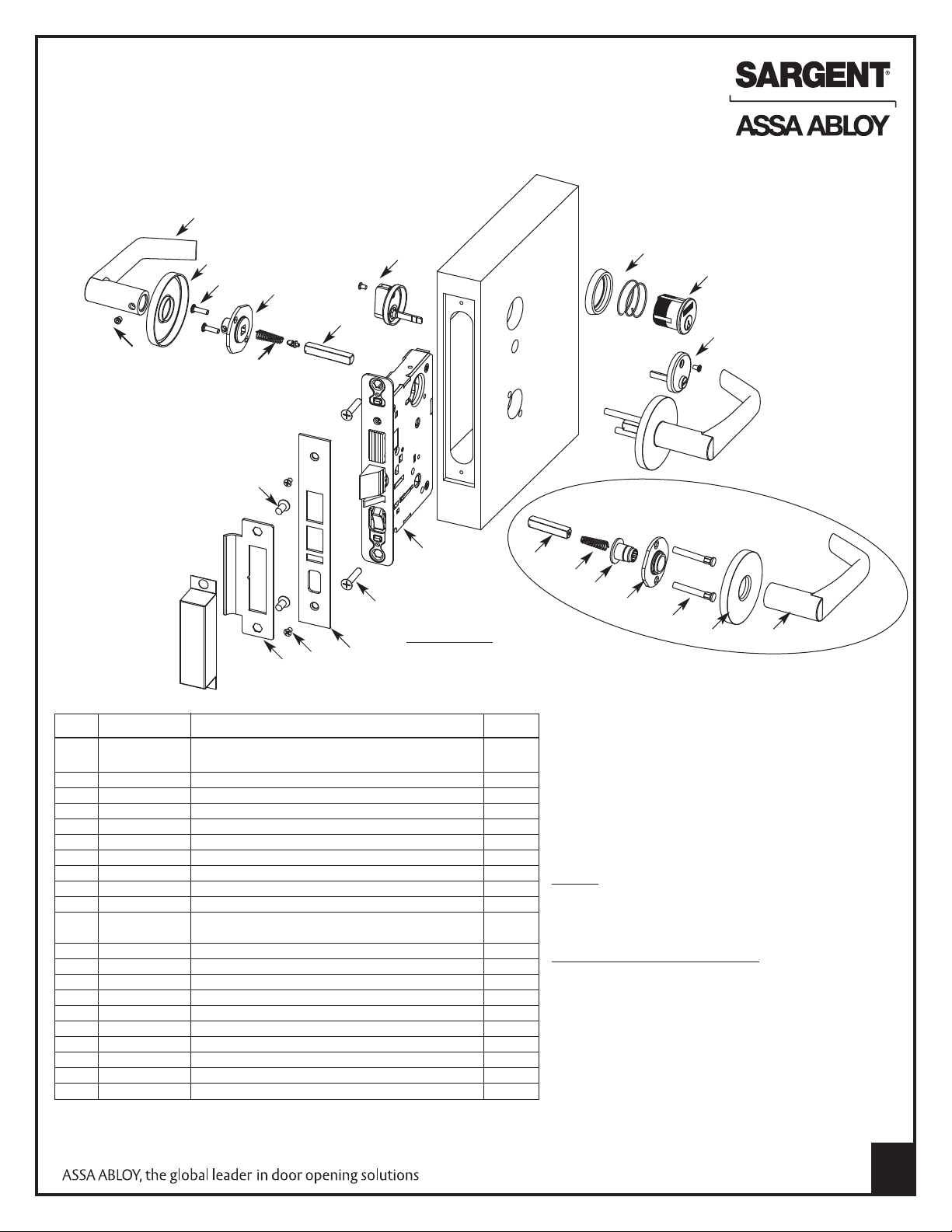

Instructions for Installing

SARGENT 7900 Lever or Knob Mortise Lock

U.S. Patent Number: 5,678,870

All trim components shown will vary by function number

Trim one-side functions - refer to separate instruction sheet

1

4

5

6

18

9

1

20

7

2

3

16

12

13

* IMPORTANT: Knob trim has

14

15

17

Part # Description Req.

1 ———– Inside lever/knob

(designs vary- some handed) 1

2 82-1038 Lever set screw 10-32 (T20 Torx head) 1

3 82-0347 Lever spring 2

4 ———– Rose (designs vary) Escutcheons optional 2

5 01-1495 Machine screw #8-32 x 5/8" 2

*6 82-4577 Inside adapter & plate assembly 1

7 82-0368 Spindle 2

8 81-0723 Through-bolt posts 2

*9 82-0691 Bushing 1

*10 82-4576 Outside mounting plate assy. 1

11 ———– Outside lever/knob

(designs vary- some handed) 1

12 ———– Lockbody (functions vary) 1

13 01-1019 Metal/machine screw #12-24 x1/2" 2

14 ———– Outside front plate (functions vary) 1

15 01-1028 Metal/machine screw #8 - 32 x 1/4" 2

16 01-1019 Machine screw # 12 - 24 x 1/2" 2

17 82-0110 Curve lip strike (1-1/4" lip) 1

18 130W Thumb Turn 1

19 97 Rosette Cylinder Collar/Rosette 1

20 ———– Cylinder-per function only (key systems vary) 21 184W

Emergency release 65 & 66 Functions

different mounting plates and

bushings than the lever trim.

21

7

3

9

10

8

4

11

Outside Lever

& Rose Assembly

(“O” Rose with “BL” Lever)

Tools Required:

• Phillips screwdriver (# 2 and # 3 size)

• Flat blade screwdriver

• T20 Torx wrench

Strikes - Standard strike part# 82-0110- 1-1/4"

lip x Lip Length x Finish (wrought box strike optional)

Screw Pack for all lockbodies - Lockbody,

front & strike screws (part #77-4236).

1

Copyright © 2006-2010, Sargent Manufacturing Company,

an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express

written permission of Sargent Manufacturing Company

is prohibited.

A7859:C 7-16-10

1

Page 2

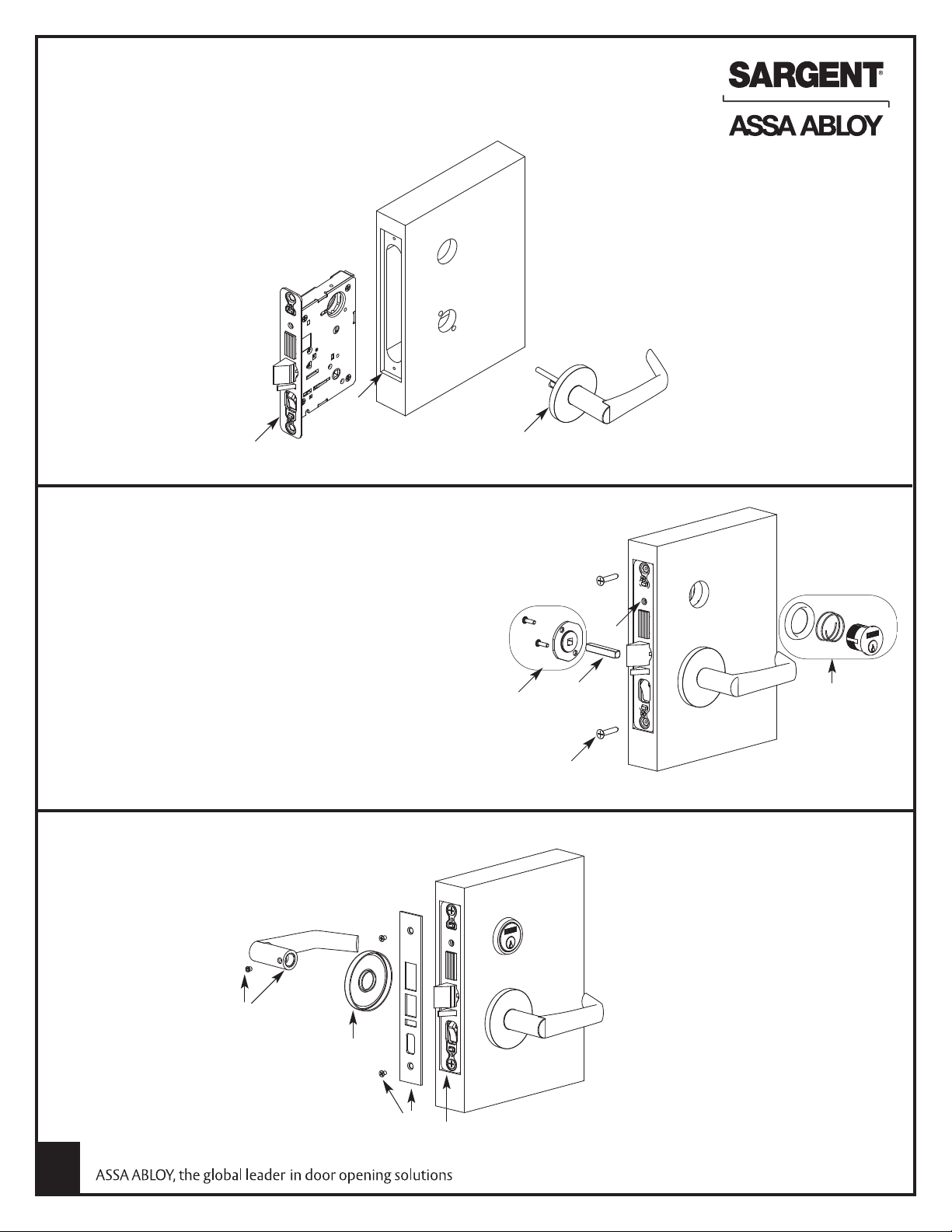

Installation Instructions for 7900 Mortise Locks

See particular trim section for your lock - rose trim shown

nside of

I

door

(1) Important: Check template 4589 or 4588 to

prep door for function holes, size & location.

Verify strike location according to

template. Clean out door pocket and

door edge of any debris.

Note: Always keep door held

open while installing lock

2) Make sure the hand of the lockbody match

(

the hand of the door (see page 4 on how to

rehand lockbody). Slide lockbody into the

door's mortise pocket.

(3) Slide outside trim assembly through the door

and lockbody.

1

2

Right Hand Door Shown

(4) For cylinder functions; slide cylinder through the spring and

collar/rosette; then thread the cylinder into the lockbody until

cylinder face is flush with collar/rosette.

Note: SARGENT logo must be horizontal & on the top portion

of the cylinder. Standard cylinder for 1-3/4" door is a #41

(1-1/8) length.

(5) Tighten cylinder clamp screw with a #2 Phillips screwdriver

(6) Secure lockbody in mortise pocket with two #12 x 1-1/4"

for wood doors or two machine screws #12-24 x 1/2" for

metal doors.

(7) Slide spindle into lockbody hub

(8) Slide inside adapter & plate assembly over spindle & secure

with two # 8 -32 x 5/8" screws

(9) Screw rose onto inside adapter &

plate assembly until tight against

door (For escutcheons, see

instruction page 3)

Outside of

door

3

8

Inside of

door

7

6

Note: If installing lever/knob

on just one side, see separate

instruction sheet

5

4

Outside of

door

(11) As required; install

thumbturn/emergency release

according to instructions on bag

(12) Attach outside front with two

#8-32 x 1/4" flat head screws

(13) Check lock for proper operation by

function number prior to closing door

10

(10) Position inside lever and secure

set screw with T20 Torx wrench

2

Note: LFIC and SFIC cylinders require a

control key (key stamped with “C”) to

remove and install the cylinder cores.

9

12

13

Copyright © 2006-2010, Sargent Manufacturing Company,

an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express

written permission of Sargent Manufacturing Company

is prohibited.

Not provided standard; must be requested

separately.

A7859:C 7-16-10

Page 3

Instructions for CE, LE, TE, KW1 and LW1 Escutcheon

M

I

Inside of

door

Plate varies

per escutcheon

Through-bolt the inside escutcheon to the

outside escutcheon with two #8-32 x 1-7/8"

screws (item I)

Note: Screw heads should be visible on inside

of door only

Note: Cylinder collar(s) are required

for functions with two cylinders and

cylinders longer than # 41 (1-1/8").

Outside of

door

Instructions for WT Escutcheon

Inside of

The inside & outside escutcheons are surface applied

using eight #6 x 3/4" wood screws or eight #6-32 x 3/4"

metal/machine screws (item M)

door

Note: Cylinder collar(s) are required

for functions with two cylinders and

cylinders longer than # 41 (1-1/8") or

doors 1-3/8" thick

Outside of

door

Copyright © 2006-2010, Sargent Manufacturing Company,

an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express

written permission of Sargent Manufacturing Company

is prohibited.

A7859:C 7-16-10

3

Page 4

9

3

Dummy trim

9

4

Dummy trim

9

5

Single trim

dummy lock

65/F22

Privacy bedroom

o

r bath lock

66/F19

Privacy bedroom

o

r bath lock

7

0/71

Electrical

7

0: Fail safe

71: Fail secure

7

2/73

Electrical

7

2: Fail safe

73: Fail secure

4

5/F12

Dormitory or

e

xit lock

5

0/51F15

Hotel guest

lock/Store room

deadbolt lock

55/F04

O

ffice or

entry lock

3

7/F05

Classroom lock

3

8/F32

C

lassroom

security intruder

l

atchbolt lock

2

4/F21

Room door

lock

25/F13

D

ormitory or

exit lock

26/F14

Store door lock

0

4/F07

Storeroom

closet lock

1

5/F01

Passage or closet

latch

1

6/F09

Apartment or exit

or public toilet

l

ock

43/F20

Apartment

c

orridor door lock

SARGENT 7900 Mortise Lock Function List

INSIDE

INSIDE

OUTSIDE

OUTSIDE

LEFT HAND

LEFT HAND

REVERSE

BEVEL

RIGHT HAND

RIGHT HAND

REVERSE

BEVEL

DOOR HANDS DETERMINED FROM OUTSIDE (KEYED/LOCKED)

DOOR HANDING

Note: Shaded Levers are rigid at all times

How To Change Hand of Lock

7900 lockbody

(right hand shown)

To Change Hand of Locking Piece

1. Position lockbody with red surface of locking

piece visible

2. Insert blade type screwdriver into lockingvpiece slot

to rotate locking piece

3. Push locking piece toward back of lockbody and

rotate 180°, until RED surface shows on opposite side

4. RED indicates locked (outside) side

To Reverse the Bevel of Latchbolt & Deadlatch

1. Remove outside front

2. Rotate latchbolt 180º

3. Replace outside front, which prevents the latch

from rotating

4. Flip deadlatch by hand to match bevel of latchbolt

Lockbody

Outside front

Inside front

Locking guide slot/

red locking piece

4

Copyright © 2006-2010, Sargent Manufacturing Company,

an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express

written permission of Sargent Manufacturing Company

is prohibited.

A7859:C 7-16-10

Loading...

Loading...