Page 1

INSTALLATION INSTRUCTIONS

7800 MORTISE LOCK WITH PT PADDLE TRIM

FOR INSTALLATION ASSISTANCE, CALL SARGENT AT 1-800-727-5477 • www.sargentlock.com

TOOLS REQUIRED

• Phillips screwdriver #2

• Drill

• 7/46" Drill Bit (Wood Door)

• #8-32 Tap (Metal Door)

• 0.136" (#18) Tap Drill

• Screw Pack with screws for lockbody,

fronts & strike screws (part # 77-4236)

• T15 torx bit

• 1/8" Allen key

Copyright © 2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

A8130C

1

Page 2

1

INSTALLATION OF LOCK

• Slide lock into the door

• Secure lock in door with (2) wood screws

#12 x 1-1/4" or machine screws #12-24 x 1/2"

• Do not tighten screws fully at this point

2

INSTALLATION OF CYLINDER

* For non-cylinder functions proceed to STEP 3

• Thread the cylinder into the lockbody

• Verify the cylinder is flush with the collar and the

name is horizontal

• Secure cylinder with cylinder clamping screw

located above the deadbolt opening

• Verify the cylinder functions correctly

3

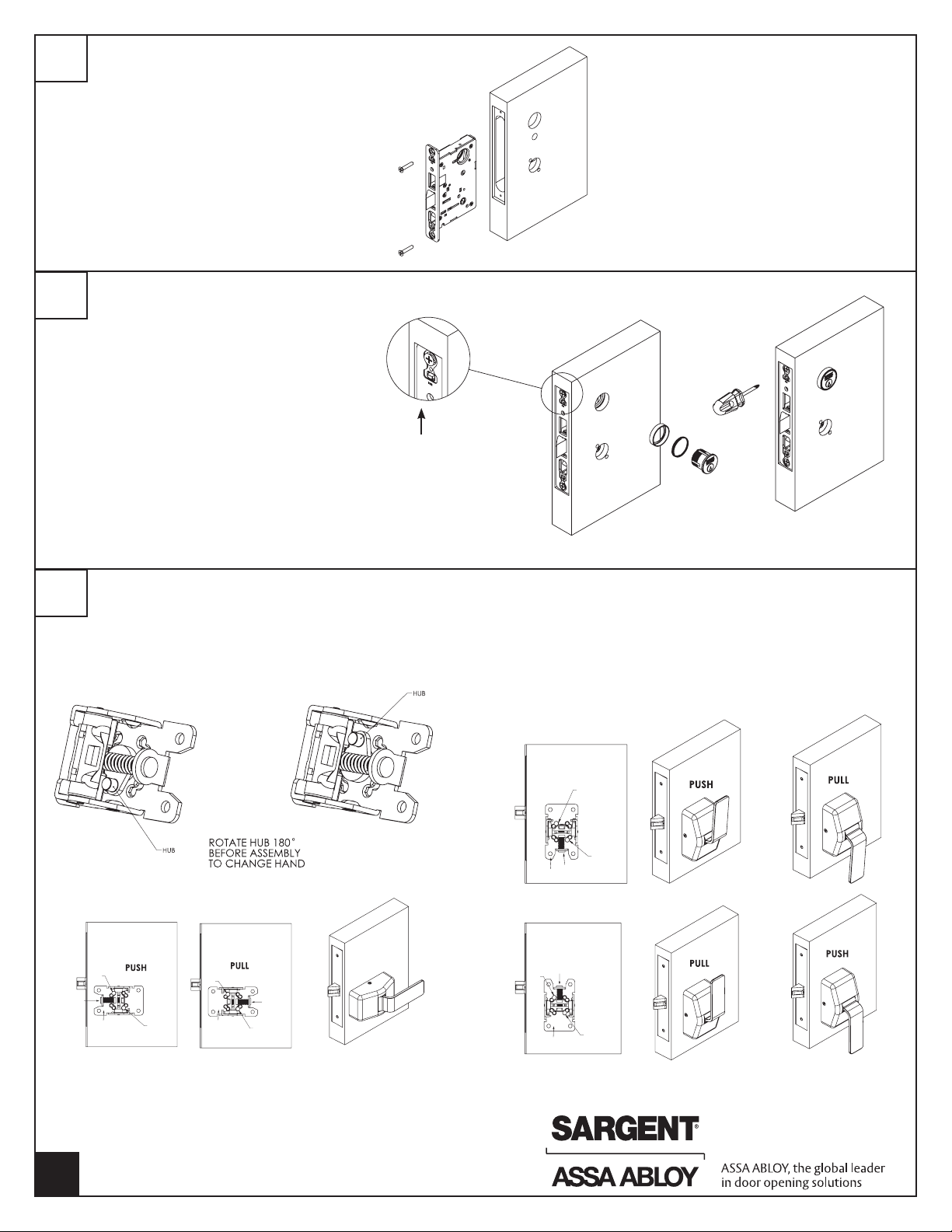

DETERMINE ORIENTATION AND HANDING OF TRIM

• The trim can be mounted vertically or horizontally

*NOTE: Chassis is packed with paddle attached

Remove paddle before installing

Note that the lock front

screws are not fully

tightened, screws will

be tightened once trim

is installed

Install Cylinder

Vertical Mounting

Tighten Cylinder

Clamping Screw

Outside of door

Horizontal Mounting

THRU

SPRING

BOLT

CHASSIS

THRU

BOLT

THRU

BOLT

CHASSIS

THRU

BOLT

SPRING

To change from PUSH to PULL orientation, chassis will need

to be turned 180° and paddle installed in the correct direction

*NOTE: Before installing chassis to door, make sure

spring orientation is correct

Copyright © 2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

2

A8130C

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

CHASSIS

THRU

BOLT

SPRING

CHASSIS

SPRING

THRU

BOLT

THRU

BOLT

THRU

BOLT

Page 3

4

INSTALLATION OF CHASSIS

• Check handing of chassis before installing mounting screws

• Insert the (2) mounting posts through the outside chassis,

then secure with (2) #8-32 x 5/8" machine screws through

the inside chassis

Do not tighten fully at this point

• Lockbody screws on edge of door are to be securely fastened

at this point

• Level chassis

• Tighten thru bolt screws

• Attach the outside front plate to lock front with (2) #8-32 x 1/4"

flat head screws

• Tighten all screws firmly, be sure not to over tighten

Machine

Screws

Thru

Bolt

5

INSTALLATION OF PADDLES AND COVERS

• Insert paddle in slot

• Install set screw

• Slide cover over paddle and align with mounting holes

• Install cover screws

Set screw

1/8" Allen key

CHASSIS

UP POSITION

PADDLE

(2) Torx cover screws

T15 torx bit

DOWN POSITION

PADDLE

Copyright © 2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Cover

A8130C

3

Page 4

7800PT MULTI FUNCTION LOCK INSTRUCTIONS

36

05

37

38

04 06 13 17 31

CHECK HUB

HUB

INSIDE

INSIDE

OUTSIDE

OUTSIDE

LEFT HAND

LEFT HAND

REVERSE

BEVEL

RIGHT HAND

RIGHT HAND

REVERSE

BEVEL

DOOR HANDS DETERMINED FROM OUTSIDE

DOOR HANDING

How to Change Function of Lock:

Green catch screw must be located as designated on lock case to create desired function.

3 locations: One for 05, 37 & 38 functions (15 function in unlocked position)

One for 04, 06, 13, 17 & 31 functions

And one for 36 function

Note: When moving green catch screw to 04, 06, 13, 17 & 31 functions, hub

position must be at 45° as shown on lockcase.

Note: 17 function requires both levers to be rigid. Rotate red locking piece 90°,

so red surface of slide faces back of lockbody.

7800PT lockbody is required when using PT paddle trim, 8200 lever lockbody

will not function properly with the PT trim.

Items needed to create each of the following functions:

Function

04 X X X

05 X X X X***

06 X X X

13 X X

17 X X X X

31 X X X

36 X X X

37 X X X

38 X X X X

Outside

Lever

Inside

Lever

Trim One

Side Kit

Outside

Cylinder

Inside

Cylinder

Thumb

Turn

#41 Cylinder is standard for both single & double cylinder

functions for 1-3/4" thick door

NOTE: Trim-one-side functions always require an

inside trim assembly which can be used on the inside

or outside of the door

U.S. Patent (Pending) No. 5,678,870

How To Change Hand of Lock

Note: Red surface of locking piece must face secure

(keyed/locked) side of door.

To rotate locking piece:

1. Position lockbody with red surface of locking piece visible.

2. Insert blade type screwdriver into locking piece slot to rotate

locking piece.

3. Push locking piece toward back of lock body and rotate 180°

until RED surface shows on opposite side.

IMPORTANT: 04, 06, 13, 17 and 31 Functions require:

(a) Green catch screw

to be removed

(b) Rotate hub 45°

to vertical position

(c) Rotate locking piece

for required hand

(d) Red surface faces

locked side of door

(e) Rotate hub to the

original 45° position

as shown on lockcase

(f) Green catch screw is

then reinstalled

4

A8130C

Copyright © 2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Locking

piece

slot

Red color

indicates locked

side of door or

hold back side

(91 and 92

Functions)

Note: Beveled surface of latch must face strike. The deadlatch

is self adjusting. To change hand of latch:

1. Insert screwdriver blade into

the spade shaped slot

2. Rotate screwdriver 90º to push latch out until back of latch

clears lock front. Then rotate latch 180º. Latch will then re-enter

lockbody. (Note: Latch can not be unscrewed)

Loading...

Loading...