Page 1

7000

ELR Series

Multi-Point Lock

Installation Instructions

To view helpful video installation tips, scan the Microsoft®

Tags with your mobile phone. Download the free mobile

app at http://gettag.mobi.

A8147A

1/13

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Page 2

Table of Contents

1

Warning ...................................................................................2

2

General Description .................................................................3

3

Hardware Specifications .........................................................3

4

Electronics Specifications .......................................................3

5

Parts Breakdown For 7000 Exit Device ...................................6

6

Installation Instructions ..........................................................6

7

Wiring Diagrams ......................................................................9

8

Mechanical Operational Check .............................................10

Electrical Operational Check .................................................11

9

1

Warning

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation.

This equipment generates, uses and can radiate radio frequency energy and if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

the interference will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced TV technician for help

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme avec la norme NMB-003 du Canada.

The term “IC:” before the radio certification number only signifies that Industry Canada technical specifications were

met. This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment

Regulations. Operation is subject to the following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne causant des

règlements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer

l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui

peut causer l’opération peu désirée.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Observe precautions for handling electrostatic sensitive devices.

!

Any retrofit or other field modification to a fire rated opening can potentially impact the fire rating of the

opening, and SARGENT Manufacturing makes no representations or warranties concerning what such impact may

be in any specific situation. When retrofitting any portion of an existing fire rated opening, or specifying and installing

Copyright © 2012, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

a new fire-rated opening, please consult with a code specialist or local code official (Authority Having Jurisdiction) to

ensure compliance with all applicable codes and ratings.

2

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 3

ELR 7000 Series Multi Point Lock

2

General Description

The SARGENT stand alone ELR 7000 series multi point lock is designed to automatically retract the

rods, concealed within the door.

1. Functions

The 7000 ELR can be configured to work in either of two modes:

POWER MODE (see Section II: POWER MODE)

The device is not energized when locked. When electrified, the device and remain in the retracted posi-

tion until power is removed. Power is typically applied through a relay triggered by an access control

device.

TIMER MODE (see Section III: TIMER MODE)

The device is always energized and retraction is triggered by a momentary or maintain switch.

In TIMER MODE:

When the timer circuit is closed using a momentary switch, the device retracts, remains retracted for a set

duration, and releases. The duration of the retraction is set through an onboard timer setting.

When the timer circuit is closed using a maintain switch, the device retracts. The device releases when

the contact is opened.

2. Important

Caution: Disconnect all input power before servicing.

Installer must be a trained and experienced service person.

Wiring must comply with applicable local electrical codes, ordinances and regulations.

3. Installation Notes

Earth Ground: Required for electrostatic discharge (ESD) protection, unless already grounded through

the metal door and frame.

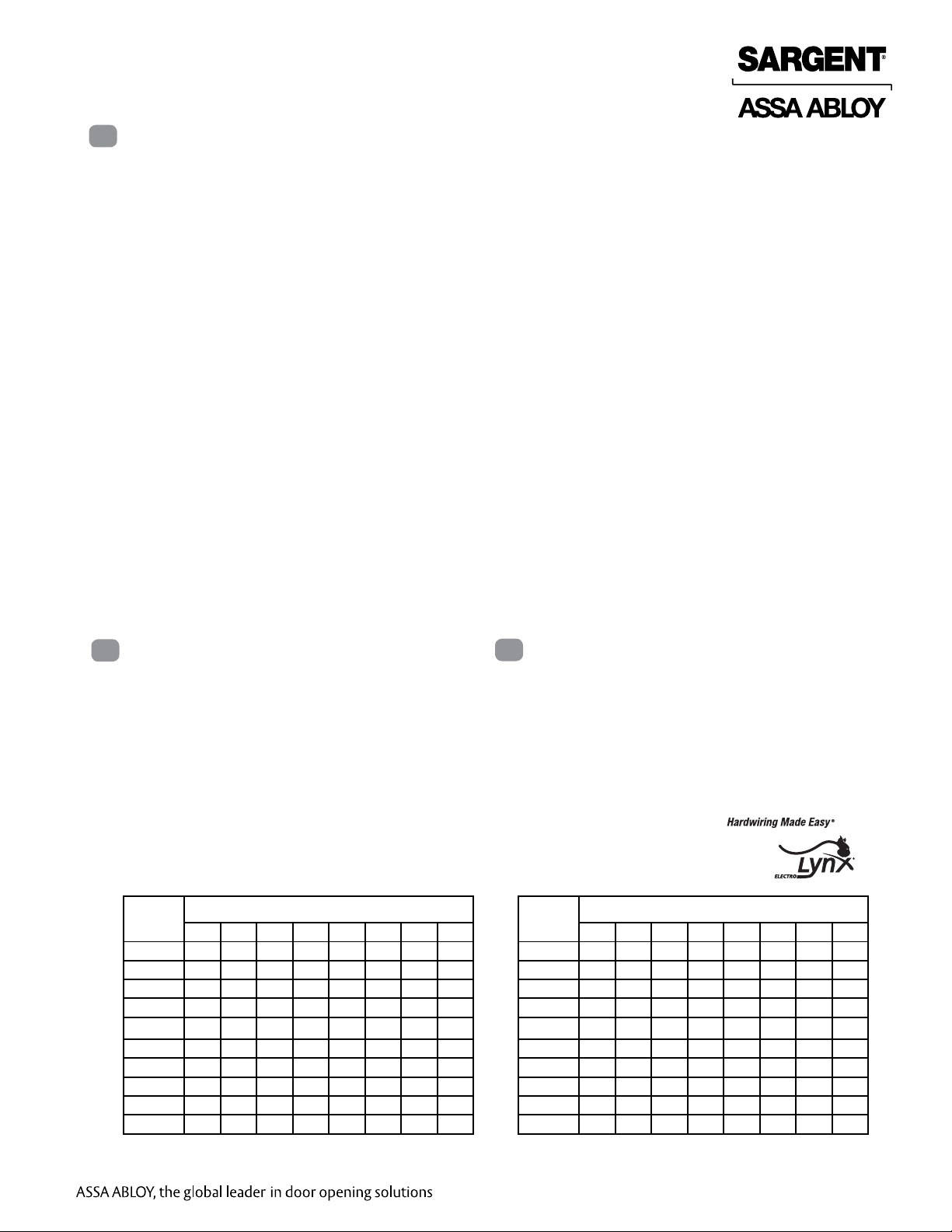

3

Hardware Specifications

• Certified ANSI/BHMA A156.3 Grade 1

• Fire rated devices available

• UL and CUL listed for use on Fire Doors

• Multi point lock furnished for 1-3/4” doors

• Wire from EAC Panel to door must be shielded

with a drain terminated at EAC Panel controller

7000 Series Multi Point Lock

• Cylinder override available for 7000 CVR with

106 Series Auxiliary Control

Total

One-Way

Length of

Wire Run (ft)

1/4A 1/2A 3/4A 1A 1-1/4A 1-1/2A 2A 3A

100 20 18 16 14 14 12 12 10

150 18 16 14 12 12 12 10 —

200 16 14 12 12 10 10 — —

250 16 14 12 10 10 10 — —

300 16 12 12 10 10 — — —

400 14 12 10 — — — — —

500 14 10 10 — — — — —

750 12 10 — — — — — —

1,000 10 — — — — — — —

1,500 10 — — — — — — —

Load Current @ 12VDC

4

Wire Gauge Charts

Total

One-Way

Length of

Wire Run (ft)

Electronic Specifications

12VDC System

• 12VDC ELR Draw = 850mA

24VDC System

• 24VDC ELR Draw = 700mA

Load Current @ 24VDC

1/4A 1/2A 3/4A 1A 1-1/4A 1-1/2A 2A 3A

100 24 20 18 18 16 16 14 12

150 22 18 16 16 14 14 12 10

200 20 18 16 14 14 12 12 10

250 18 16 14 14 12 12 12 10

300 18 16 14 12 12 12 10 —

400 18 14 12 12 10 10 — —

500 16 14 12 10 10 — — —

750 14 12 10 10 — — — —

1,000 14 10 10 — — — — —

1,500 12 10 — — — — — —

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

3

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

1/31/13

Page 4

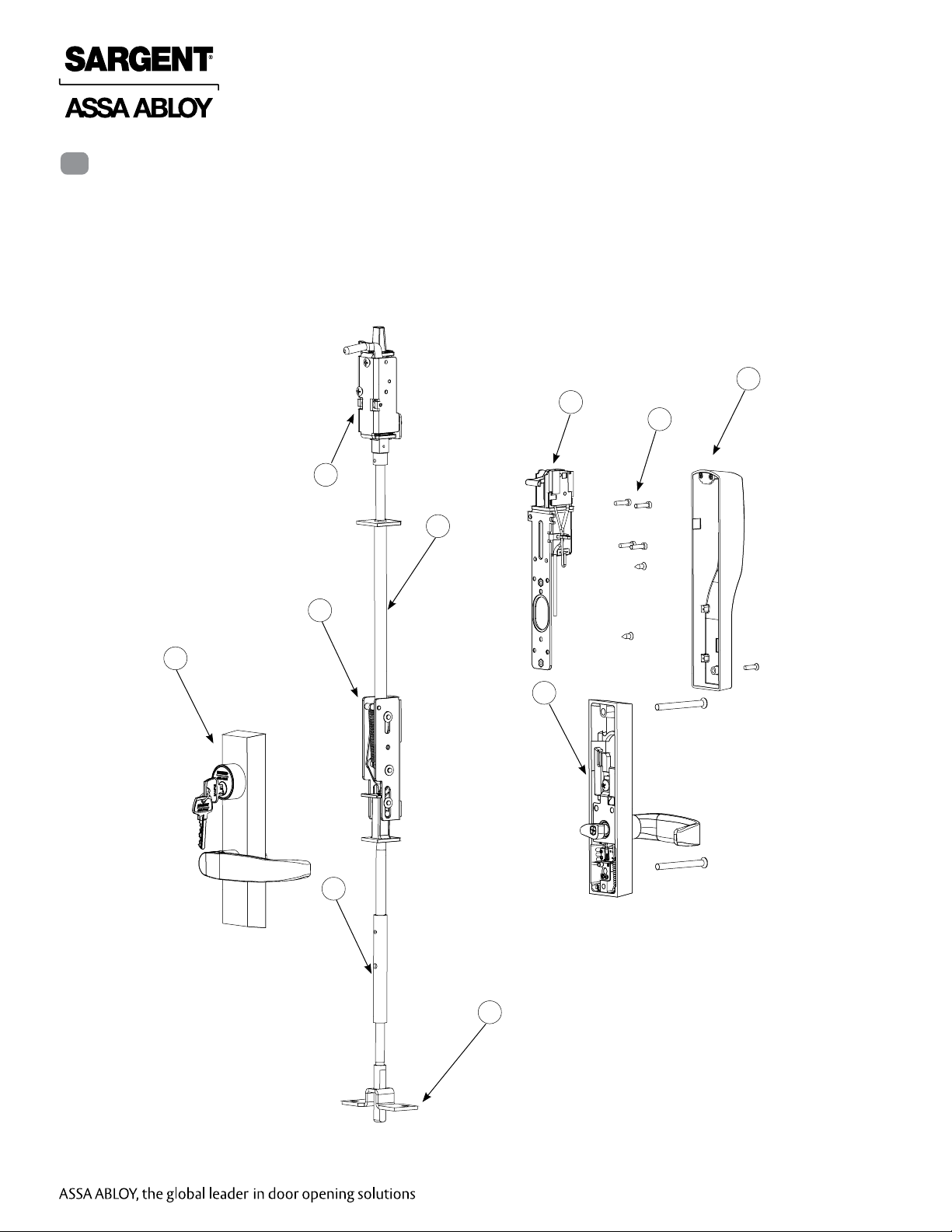

5

Parts Breakdown for ELR 7000 Series

Tools Required

• Phillips screw driver (standard size)

• Slotted screw driver (standard size)

• Drill

• #8-32 tap & tap drill

(for metal door applications)

6

ELR 7000 Series Multi Point Lock

10

11

12

5

3

2

1

7

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

4

4

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 5

ELR 7000 Series Multi Point Lock

Parts Breakdown Continued...

ITEM PART # Description Req.

1 MP-7XX-2 WD/MD/AD Inside Trim Assembly 1

2 7XX-2 Outside Trim Assembly 1

3A 94-2411 MD/AD Inner Chassis Assembly

94-2412 MD/AD Inner Chassis Assembly, Fire (12-)

94-2414 MD/AD Monitoring Inner Chassis, Fire (53-/12-53-)

3B MD69IT WD Inner Chassis Assembly 1

WD69IT WD Monitoring Inner Case (53-)

4 68-0888 Bottom Case 1

5A 68-7062 MD/AD Top Rod and Bolt Assembly 1

5B 68-5829 WD Top Rod and Bolt Assembly 1

6 68-5374 Top Case Assembly 1

7 96-2085 Bottom Rod and Bolt Assembly 1

8 97-0825 Standard Plate (Rectangular) (Not shown) 2

97-0826 Sculpted Plate (Optional) (Not shown)

9 68-1264 WD Top Case Bracket (Not shown) 1

10 97-4056 Cover Assembly 1

10B 650 Top Strike Pack (Not shown) 1

606 Bottom Strike Pack, Fire (12-)(HC)(WS) (Not shown)

652 Top and Bottom Strike Pack, STD (Not shown)

11 52-4697 ELR Assembly 1

11A 94-2415 MD/AD Screw Pack (Not shown) 1

11B 94-2431 WD Screw Pack (Not shown) 1

12 52-5236 Screw Pack (Not shown) 1

12A 52-4723 MD/AD Mounting Hardware 1

12B 52-4724 WD Mounting Hardware 1

How to Specify ET Trim

Specify: 7 for ET Series Trim, Function, Suffix, Lever, Finish and handing (e.g., 713-2 ETL

x 26D x RH).

Note: Suffix requirements are based on type of device to be used:

• -2 suffix is required for all 7000, WD, MD and AD.

• MP- prefix is for inside 7000 trim.

5

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

Page 6

ELR 7000 Series Multi Point Lock

6

Installation Instructions

1 Door Preparation

A. Verify Hand and Bevel of Door

• Check hand of door. The Multi-Point lock may be handed.

• Door should be fitted and hung.

• Verify box label for size of the Multi-Point lock, function and

hand.

B. Door Preparation

Prepare door according to appropriate template. If necessary,

refer to www.intelligentopenings.com.

• Metal door (MD/AD): A7860

- Template: 4582

• Wood door (WD): A7971

- Template: 4624

Left Hand

Reverse

LHR

Inside

Outside

Fig. 1A

Right Hand

Reverse

RHR

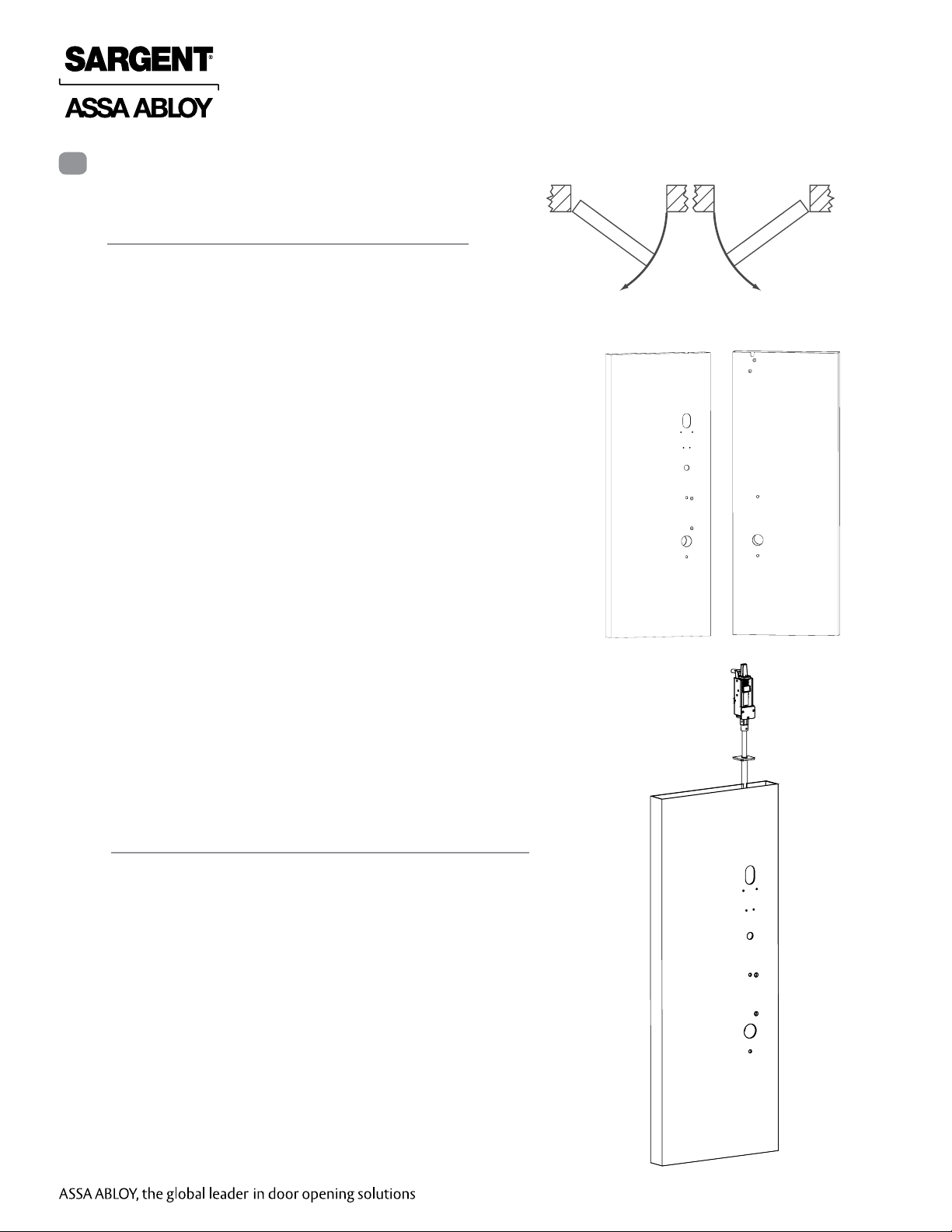

2 Rod and Inner Case Installation

1. Refer to instruction sheet A7860 for rod and inner

case installation on metal doors.

2. Refer to instruction sheet A7971 for rod and inner

case installation on wood doors.

Fig. 1B Metal Shown

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

6

Fig. 2

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 7

ELR 7000 Series Multi Point Lock

3 Install Outside Trim and Inside Trim

A. Outside Trim

1. Mount inside trim lever to outside trim lever using

(2) # 1/4” -20 x 3” Phillips oval head machine screws.

Outside trim

4 Inside Mounting Plate & ELR Assembly

1. Install the upper left mounting screw, #8 - 32 x 5/8 Fillister head

for metal door & #8 x 5/8 self tapping Fillister for wood doors.

See Figure 4A.

Note: Leave the screw loose enough to slide the ELR assembly

on.

2. Snake the wire through the ELR assembly.

3. Slide the mounting clip of the ELR Assembly underneath the

installed screw and secure in place.

4. Tighten the upper left mounting screw.

Note: Be careful not to pinch or disconnect the wire located

in that area.

5. Install the remaining (3) 8-32 x 5/8 Fillister mounting screws on

metal doors.

6. Install the remaining #8 x 5/8 self tapping Fillister mounting screws

(wood doors).

7. Install (2) 1/2” self-tapping screws on either diagonal, Figure 4B,

one above molex connector and one below.

8. Connect the 8-pin molex connectors.

Inside trim

#8-32 x 5/8”

(2) 1/4”

self-tapping

screws

#8-32 x 5/8”

Fig. 3

#8-32 x 5/8”

Scan to see a

video of this

installation step.

Fig. 4

Fig. 4A Fig. 4B

7

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Fig. 4C

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

Page 8

5 Installation of Inside Escutcheon

1. Position escutcheon against door by hooking the top

edge on the top of the ELR assembly.

Verify that no wires are being pinched.

2. Mount inside escutcheon assembly to plate

using (1) #8-32 x 5/8" Phillips flat head

undercut machine screw, Figure 5B.

ELR 7000 Series Multi Point Lock

Fig. 5

Fig. 5B Machine

screw detail

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

8

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 9

ELR 7000 Series Multi Point Lock

7

Wiring Diagrams

Product 8 PIN CONNECTOR

ACCESS CONTROL DEVICES: ELR 7000 ElectroLynx wire

SARGENT -

ELR 7000

1-Black 2-Red 3-White 4-Green 5-Orange

Color / Function assignments

NEG POS Timer A EGND Timer B

PIN 4 (Green – EARTH GROUND)

PIN 2 (Red – 12 or 24 POS)

PIN 1 (Black – 12 or 24 NEG)

PIN 5 (Orange – Timer B)

1 Timer Mode: Typical Wiring

For use when wiring in TIMER MODE (using the

onboard timer).

If more than 20 seconds timed delay is

necessary, an external timer delay relay is

required (not provided).

Note: 24V supply is constant in TIMER MODE.

PIN 3 (White – Timer A)

Maintain or Relay Switch (Card

Reader, Access Control, etc.)

Momentary or

0V (Black)

+24V (Red)

EGND

24VDC

Power Supply

( C )

( NO )

Green (EGND)

Red (+24V)

Black (0V)

Fig. 6 TIMER MODE Typical Wiring

9

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

White

Orange

QC12 Electric Hinge

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

Page 10

2 Power Mode: Typical Wiring

For use when wiring in POWER MODE.

Notes:

• Onboard timer will not function in

POWER MODE. Add external time delay if

necessary.

• The switch is wired between the power

supply and the load. Do not cycle the

power supply.

( - )

( NO )

( NC )

( + )

Maintain

or Relay Switch, i.e., Card

Reader, Access Control, etc.

ELR 7000 Series Multi Point Lock

24VDC

Power Supply

0V (Black)

+24V (Red)

EGND

Green (EGND)

Red (+24V)

Black (0V)

QC12 Electric Hinge

Fig. 2 Power Mode Typical Wiring

8

Mechanical Operational Check

For devices without cylinders, go to step 3.

1. For devices with cylinders, insert key into cylinder and rotate.

2. Rotate the lever to retract latch and rods.

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

10

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 11

ELR 7000 Series Multi Point Lock

9

Electrical Operational Check

SECTION I: POWER MODE

In this configuration, the device is not energized when locked. When energized with a 12 or 24 volt input,

the latch(es) will retract and remain in the retracted position until power is removed. Power is typically applied through a relay triggered by an access control device.

For installations using the onboard timer circuit, refer to SECTION II: TIMER MODE.

1. POWER MODE Installation Instructions

How it works: The ELR module retracts when power is applied and

releases when power is removed.

1. Mount ELR 7000 Multi-point device using instruction sheet(s)

provided.

Note: Ensure proper mechanical function before attempting

electrical retraction:

• Verify the levers can be full rotated and the latch is fully

retracted.

• Adjust device mechanically, as required, before applying

power.

Fig. 1 Power Mode Settings

UP

1 2 3 4

DIP switch

setting location

Fig. 2 Settings Location

2. Connect the ElectroLynx harness in the door

(Fig. 2 POWER MODE Installation):

Plug the 8-pin ElectroLynx connector from the rail into the ElectroLynx harness or splice into

non-ElectroLynx harness.

3. Ensure all four DIP switches are in the UP position. This enables power mode.

4. Connect the ElectroLynx harness to the hinge and secure the electric hinge to door.

Notes: Make sure no wires are pinched or damaged in the process. Refer to detailed wiring

instructions under POWER MODE wiring.

5. Apply 12V or 24V according to ELR input requirements (below):

Confirm that the LED is blinking, that the system fully unlocks, and that

all bolts clear the strikes. Troubleshoot the device if issues are observed

using the steps outlined at the end of the POWER MODE section.

6. Store excess wiring under cover and assemble

with provided screws. Avoid pinching wires.

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

11

1/31/13

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 12

ELR- Input Requirements

Voltage: 24VDC

• Filtered and regulated power supply

• Motor operating current: 700mA

• Motor hold current: 150mA

Voltage: 12VDC

• Filtered and regulated power supply

• Motor operating current: 850mA

• Motor hold current: 250mA

Note: Earth Ground is required for Electrostatic

Discharge (ESD) protection unless the metal door

and frame are already earth grounded; otherwise,

earth ground wiring is required at pin 4

(Fig. 2 POWER MODE Installation).

ELR 7000 Series Multi Point Lock

McKinney QC8 Electric

Hinge (with 8-pin connector)

An ElectroLynx harness

is required to connect the

ElectroLynx hinge.

Note: Specified and

ordered separately

Stand Alone ELR

Fig. 2 POWER MODE Installation

2. LED Signalling Chart

SIGNAL CAUSE TROUBLESHOOTING

Dark / Unlit Controller microprocessor

is not active

Steady Flashing (GREEN) Normal operation Check that POWER MODE switch is set

Solid Light (GREEN) Input voltage is dropping out of

operating range

1 Flashes Followed by Pause (YELLOW) Retractor sensor problem Call 800-810-WIRE for assistance

2 Flashes Followed by Pause (YELLOW) Retractor sensor problem Call 800-810-WIRE for assistance

3 Flashes Followed by Pause (YELLOW) Retractor sensor problem Call 800-810-WIRE for assistance

Confirm connections and incoming

power

Check wire run and power supply output

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

12

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 13

ELR 7000 Series Multi Point Lock

3. POWER MODE Troubleshooting

Prior to electrical troubleshooting, confirm that the mechanical system properly functions; i.e., that the levers fully retract

all latches and the door opens freely. Refer to applicable Sargent 7000 Series Multi-point Device product instruction sheet to

correct mechanical installation issues.

IMPORTANT: *ALWAYS disconnect power before making any mechanical adjustments to the system.

The push rail does not move when 24V/12V input is applied:

o Check inputs to confirm proper voltage and wiring orientation.

o Remove cover and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

Note: When configured in POWER MODE, power is released to lock the device (LED will not blink when power is released).

o Confirm all four DIP switches are in the UP position.

The ELR module does not fully retract or push rail retracts completely and holds but does not open door

o *Verify mechanical installation and correct as necessary:

- Is excessive force required to depress the push bar?

- Are latches fully clearing the strikes when mechanically cycled?

The ELR module retracts and unlocks electrically but does not relock:

o Physically disconnect power from rail and confirm that input is off.

o *Check for mechanical interference (e.g., warped door, lack of shims, misalignment of rail, etc.).

The ELR module behaves abnormally (multiple cycles, clicking, delayed retraction, etc.):

o Remove cover and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

Note: When configured in POWER MODE, power is released to lock the device (LED will not blink when power is released).

For applications using automatic operator(s): Door(s) fail to unlock before doors begin to open:

o Adjust timing of operator to allow 750ms for the ELR module to fully retract.

For additional installation assistance, please contact 1-800-810-WIRE (9473). When calling, please provide the following information to

improve our service (provide what you can):

o Your name and contact number.

o Sargent 7000 Multi-point Device product type.

o Location and identification of the affected opening (e.g., site, building, and door number).

o SARGENT order number (located on product box), if available.

o Power supply manufacturer and rated output (i.e., voltage and current).

o Method of operation (e.g., POWER MODE).

o The number of devices connected to the power supply.

o Symptoms of problem (i.e., observed behavior).

13

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

Page 14

ELR 7000 Series Multi Point Lock

SECTION II: TIMER MODE

In this configuration, the device is always energized with a 24 or 12 volt input, and a timer circuit is opened or closed

to control rod retraction. A momentary or maintain switch is typically used to perform this operation.

For installations where the power input is cycled to retract the device, refer to SECTION I: POWER MODE.

When TIMER MODE is used in conjunction with an external device, such as a door operator, a keypad/reader with

two relays are required. Otherwise, an external relay board is required.

1. TIMER MODE Installation Instructions

How it works: ELR module retracts when timer input circuit is closed.

1. Mount ELR 7000 Multi-point device using installation instruction sheet(s) provided.

Note: Ensure proper mechanical function before attempting electrical retraction:

• Verify the levers can be fully rotated and the latch is fully retracted.

• Adjust device mechanically, as required, before applying power.

2. Ensure DIP Switch switch (position 1) disables POWER MODE. Set to DOWN to disable.

3. Connect the ElectroLynx harness in the door (Fig. 2 ElectroLynx TIMER MODE Wiring):

Plug the 8-pin ElectroLynx connectors from the device into the ElectroLynx harness or splice

into a non-ElectroLynx harness (Fig. 1 TIMER MODE Installation).

ELR Input Requirements

Voltage: 24VDC

• Filtered and regulated power supply

• Motor operating current: 700mA

• Motor hold current: 150mA

Voltage: 12VDC

• Filtered and regulated power supply

• Motor operating current: 850mA

• Motor hold current: 250mA

Note: Earth Ground is required for Electrostatic Discharge (ESD) protection unless the metal door and

frame are already earth grounded; otherwise, earth

ground wiring is required at pin 4 (Fig. 2 ElectroLynx

TIMER MODE Wiring).

McKinney QC8 Electric Hinge

(with 8-pin connectors)

Stand Alone ELR

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

14

Fig. 1 TIMER MODE Installation

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 15

ELR 7000 Series Multi Point Lock

2. TIMER MODE Installation Instructions (continued)

4. Connect the ElectroLynx harness to the hinge:

a. Plug the door harness’s 8-pin connector into the hinge’s ElectroLynx connector.

b. Secure the electric hinge to door.

Notes: Make sure no wires are pinched or damaged in the process.

Refer to detailed wiring instructions under TIMER MODE wiring.

5. Apply 24V/12V according to ELR- input requirements:

Confirm that the LED is blinking and close the timer input circuit to retract the device. When the system retracts

electrically, confirm that it fully unlocks and that all bolts clear the strikes. Troubleshoot the device if issues are

observed using the steps outlined at the end of the TIMER MODE section.

6. Store excess wiring under cover and assemble with provided screws. Avoid pinching wires.

3. TIMER MODE Wiring

ElectroLynx Opening Installation

This is the simplest installation method, requiring the installer to plug the

ElectroLynx connectors from the device to the harness to the hinge and

then to the pigtail, which is connected to the access control system.

Requirements

• ELR 7000 series device

• ElectroLynx connector harness (not supplied with ELR- device)

• McKinney QC ElectroLynx hinge (type of hinge depends on the application)

• ElectroLynx door

1 - Black (ELR 0VDC)

2 - Red (ELR +24VDC)

3 - White (TIMER A)

4 - Green (EG)

5 - Orange (TIMER B)*

7-pin M

ElectroLynx harness

with 8-and 4-pin connectors

(purchased separately)

Fig. 2 ElectroLynx TIMER MODE Wiring

8-pin M8-pin M

4-pin M

8-pin F

15

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

Page 16

ELR 7000 Series Multi Point Lock

4.

TIMER MODE Adjustment (Onboard Timer)

How it works: The 24/12 volt input is always energized and the system retracts when the timer input circuit

is closed.

• When the timer circuit is closed utilizing a momentary switch, the device retracts, remains retracted for a set

duration, and releases. The duration of the retraction is set using an onboard timer setting (0 - 20 second timer

adjustment). The countdown begins when the rail is first retracted.

• When the timer circuit is closed using a maintain switch, the device retracts.

The device releases when the circuit is re-opened.

Notes:

• Note: 24V/12V supply is constant in TIMER MODE. The duration of retraction is determined by whichever is

longer: the maintain switch closure or the onboard timer delay.

• If more than 20 seconds delay is necessary (exceeding the maximum setting), an external timer delay relay

is required (not provided).

Note: Refer to Figure. 3 for DIP Switch timer delay settings.

Fig. 3 Timer Delay Settings

(Default = 0 Seconds)

0 Seconds

Scan to see a

video of this

installation step.

2 Seconds

3 Seconds

4 Seconds

5 Seconds

10 Seconds

15 Seconds

20 Seconds

1 2 3 4

DELAY

5. LED Signalling Chart

SIGNAL CAUSE TROUBLESHOOTING

Dark / Unlit Controller microprocessor is not active Confirm connections and incoming power

Steady Flashing (GREEN) Normal operation Cycle device by closing the timer circuit

Solid Light (GREEN) Input voltage is dropping out of operating range Check wire run and power supply output

1 Flashes Followed by Pause (YELLOW) Retractor sensor problem Call 800-810-WIRE for assistance

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

2 Flashes Followed by Pause (YELLOW) Retractor sensor problem Call 800-810-WIRE for assistance

3 Flashes Followed by Pause (YELLOW) Retractor sensor problem Call 800-810-WIRE for assistance

Down

DIP switch

setting location

Fig. 3 Settings Location

1/31/13

16

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Page 17

ELR 7000 Series Multi Point Lock

6. TIMER MODE Troubleshooting

Prior to electrical troubleshooting, confirm that the mechanical system properly functions; i.e., that the lever fully retracts

the rods and the door opens freely. Refer to applicable SARGENT 7000 series Multi-point device product instruction sheet to

correct mechanical* installation issues.

IMPORTANT: *ALWAYS disconnect power before making any mechanical adjustments to the system.

The ELR module does not move when 24V input is applied:

o Check inputs to confirm proper voltage and wiring orientation

When configured for TIMER MODE, 24V/12V must be constantly applied and the timer circuit must be closed to cycle the device.

o Remove end cap from rail and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

The onboard timer duration adjustment is not working:

o Remove power when making adjustments to timer delay settings (DIP Switches).

o When a momentary signal is applied to the timer circuit, the circuit must be reopened for the timer to function.

The ELR module does not fully retract or ELR module retracts completely and holds but does not open door:

o *Verify mechanical installation and correct as necessary:

- Is excessive force required to depress the push bar?

- Are latches fully clearing the strikes when mechanically cycled?

The ELR module retracts electrically but does not release. System does not relock.

o Confirm that the TIMER MODE contact is opened (the ELR module will remain depressed until the contact is opened and the

delay has expired).

o Physically disconnect power from ELR (while electrically retracted) to verify if the issue is mechanical.

o *Check for mechanical interference (e.g., warped door, lack of shims, misalignment of rod, etc.).

Rail behaves abnormally (multiple cycles, clicking, delayed retraction, etc.):

o If a momentary contact is applied to the timer circuit, adjust the onboard timer to a longer duration.

o Remove cover from rail and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

For applications using automatic operator(s): Door(s) fail to unlock before doors begin to open:

o Adjust timing of operator to allow 750ms for the rail to fully retract.

o If a momentary contact is applied to the timer circuit, adjust the onboard timer to a longer duration to prevent the device from

locking prior to operator actuation.

For additional installation assistance, please contact 1-800-810-WIRE (9473). When calling, please provide the following information to

improve our service (provide what you can):

o Your name and contact number.

o SARGENT 7000 series Multi-point device product type.

o Location and identification of the affected opening (e.g., site, building, and door number).

o SARGENT order number (located on product box), if available.

o Power supply manufacturer and rated output (i.e., voltage and current).

o Method of operation (e.g., TIMER MODE).

o The number of devices connected to the power supply.

o Symptoms of problem (i.e., observed behavior).

17

A8147A • 800-810-WIRE (9473) • www.sargentlock.com

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1/31/13

Page 18

SARGENT Manufacturing

100 Sargent Drive

New Haven, CT 06511 USA

800-727-5477 • www.sargentlock.com

Founded in the early 1800s, SARGENT® is a market leader in locksets, cylinders, door closers, exit devices,

electro-mechanical products and access control systems for new construction, renovation, and replacement applications.

The company’s customer base includes commercial construction, institutional, and industrial markets.

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

ASSA ABLOY is the global leader in door opening solutions, dedicated to

satisfying end-user needs for security, safety and convenience.

A8147A - 1/13

Loading...

Loading...