Page 1

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

SECTION I: OVERVIEW

1. Description

The Sargent 56- prefix ELR works with 80 Series exit devices to provide remote-controlled latch retraction. It is

compatible with the following prefixes:

• 53 - Latchbolt Monitor Switch: The latch monitor provides tamper resistant latch monitoring.

The monitor switch is activated when there is physical movement of the latch.

• 55 - Signal Switch (Request to Exit): This signal switch monitors the touch

bar position. Touch bar monitoring can be used to detect egress,

sound an alarm, send a signal to a remote location,

or de-energize an electromagnetic lock.

• TL- (SARGuide): Illuminated touchpad for

80 Series exit devices.

Note: The 56- is also compatible

with 16-, HK-, and 12-

mechanical configurations.

Fig. 1 56- ELR

Sargent Manufacturing Company (New Haven, CT).

2011. Electronic push retraction exit device. U. S.

Patent 7,484,777, filed June 30, 2006, and issued

Feb. 3, 2009. Additional patent(s) pending.

2. Functions

The 56- ELR can be configured to work in either of two modes:

POWER MODE (see Section II: POWER MODE)

The device is not energized when locked. When electrified, the push rail and latch(es) will retract and remain in

the retracted position until power is removed. Power is typically applied through a relay triggered by an access

control device.

TIMER MODE (see Section III: TIMER MODE)

The device is always energized and retraction is triggered by a momentary or maintain switch. In TIMER MODE:

• When the timer circuit is closed using a momentary switch, the device retracts, remains retracted for a set

duration, and releases. The duration of the retraction is set through an onboard timer setting.

• When the timer circuit is closed using a maintain switch, the device retracts. The device releases when the

contact is opened.

3. Important

• Caution: Disconnect all input power before servicing.

• Installer must be a trained and experienced service person.

• Wiring must comply with applicable local electrical codes, ordinances and regulations.

• Cylinder (16-) or “hex-key” (HK-) mechanical dogging CANNOT be used on FIRE RATED DOORS.

4. Installation Notes

• The 56- ELR rail works only with Sargent 80 Series exit devices.

• Always perform mechanical installation using the appropriate installation instructions, prior to electrical wiring.

• If used in conjunction with M56 or R56 kits, follow instructions A7926 prior to using these instructions.

• Earth Ground: Required for electrostatic discharge (ESD) protection, unless already grounded through the

metal door and frame.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7925D 1

Copyright © 2011 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/09/11

Page 2

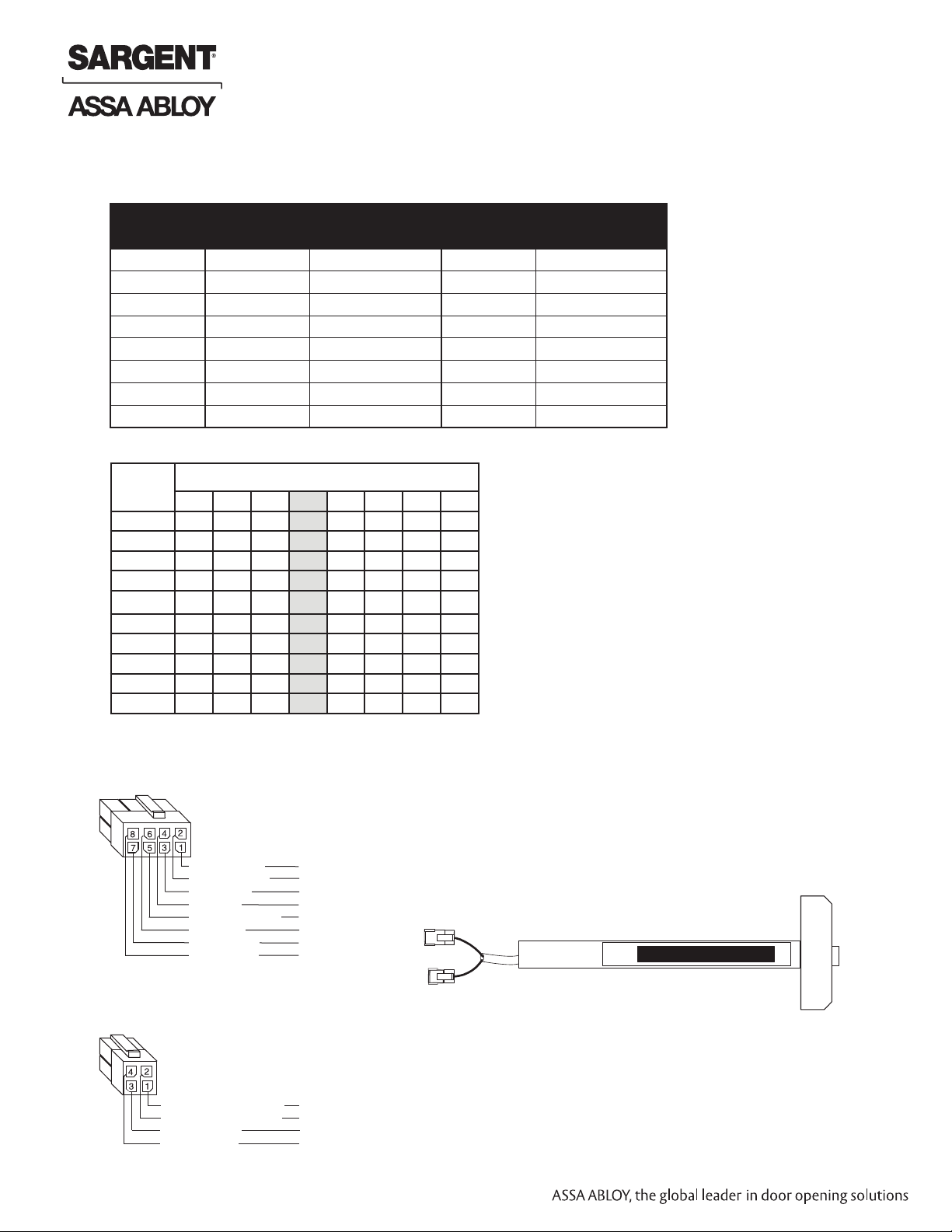

5. Hinge Requirements

Application Wires Recommended Hinge Wires Recommended Hinge

56- 3 wires QC8 5 wires QC12

53- 56- 5 wires QC8 7 wires QC12

55- 56- 6 wires QC8 8 wires QC12

53- 55- 56- 8 wires QC8 10 wires QC12

TL-56- 5 wires QC12 7 wires QC12

TL-53- 56- 7 wires QC12 9 wires QC12

TL-55- 56- 8 wires QC12 10 wires QC12

TL-53- 55- 56- 10 wires QC12 12 wires QC12

6. Wire Gauge Chart

Total

One-Way

Length of

Wire Run (ft)

1/4A 1/2A 3/4A *1A 1-1/4A 1-1/2A 2A 3A

100 24 20 18 18 16 16 14 12

150 22 18 16 16 14 14 12 10

200 20 18 16 14 14 12 12 10

250 18 16 14 14 12 12 12 10

300 18 16 14 12 12 12 10 —

400 18 14 12 12 10 10 — —

500 16 14 12 10 10 — — —

750 14 12 10 10 — — — —

1,000 14 10 10 — — — — —

1,500 12 10 — — — — — —

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

Without Timer With Timer

Load Current @ 24VDC

*When calculating voltage drop, use 1A as the

recommended current draw for the 56- ELR.

7. Wire Locations and Positions

56- Electric Latch Retraction devices are supplied with one 4-pin and one 8-pin Molex® connector.

Molex connectors allow simple installation using the ASSA ABLOY ElectroLynx® system.

1 - Black (56- 0VDC)

2 - Red (56- +24VDC)

3 - White (53- C)

4 - Green (EG)

5 - Orange (53- NC/NO)*

6 - Blue (55- C)

7 - Brown (55- NO)

8 - Yellow (55- NC)

*NO/NC (Normally Open/Normally Closed)

is selectable on controller (refer to 53- DIP

switch instructions section III, part 5).

Factory preset is NO.

1 - Violet (TL- Prefix is an option)

Copyright © 2011 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

2 - Grey (TL+ Prefix is an option)

3 - Pink (56- Timer A)

4 - Tan (56- Timer B)

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

06/09/11

2 A7925D

8-pin Molex

4-pin Molex

Fig. 2 Wire Color and Position

Page 3

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

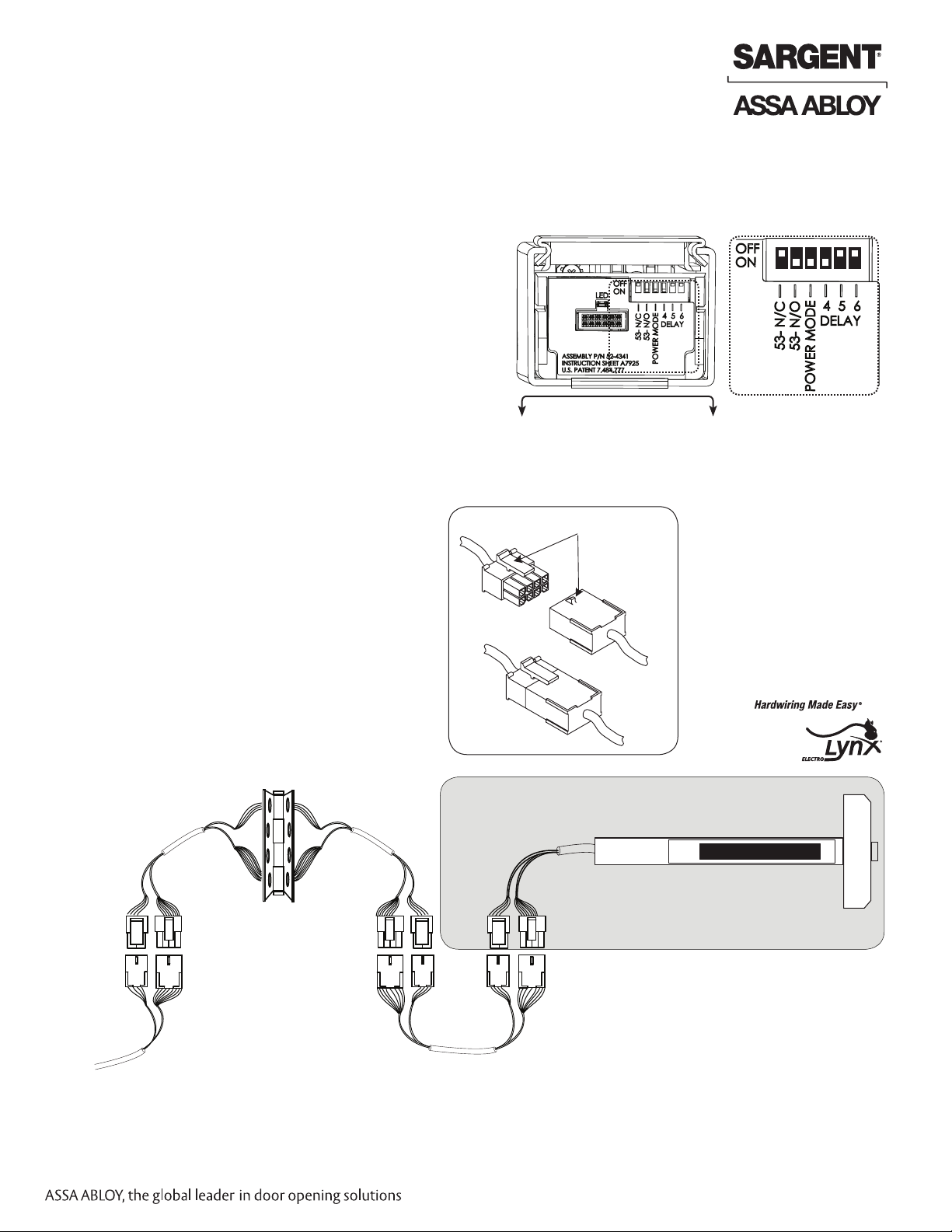

8. DIP (Dual Inline Package) Switch Settings

DIP Switch assignments are as follows, starting from left:

1: Closed (Switch set to ON) when selecting 53- NC

(Normally Closed) contact.

2: Closed (Switch set to ON) when selecting 53- NO

(Normally Open) contact.

NOTE: Only 1 or 2 should be closed at one time,

not both.

3: Closed when bypassing external trigger, i. e., Power Mode.

4, 5, 6: Select software options, allows up to 8 Time/Delay

settings (refer to TIMER MODE, Section III, part 5).

Default Setting: 53- NO (Normally Open) and POWER MODE set to ON.

9. ElectroLynx Wiring System

IMPORTANT: ElectroLynx connectors plug and

lock together in only one way.

Do NOT force connectors together.

Fig. 4 ElectroLynx Connections

Receptacle

Locking Mechanism

Door

Surface

Fig. 3 DIP Switch Settings

(Factory Default Shown)

Plug

4-pin F

McKinney QC12 Hinge

(available direct from McKinney)

Provided With Product

8-pin F

8-pin M4-pin M

Fig. 5 Typical ElectroLynx Wiring

Note: *The three inch connector is not included with the product, door, or hinge and

must be ordered separately (P/N available in POWER MODE Wiring section).

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

8-pin F

8-pin M

4-pin F

4-pin M

*3” Harness

8-pin F

8-pin M

Typical ElectroLynx Wiring Harness Connections

TL-53-55-56- wired in TIMER MODE requires all 12 wires.

A7925D 3

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/09/11

Page 4

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

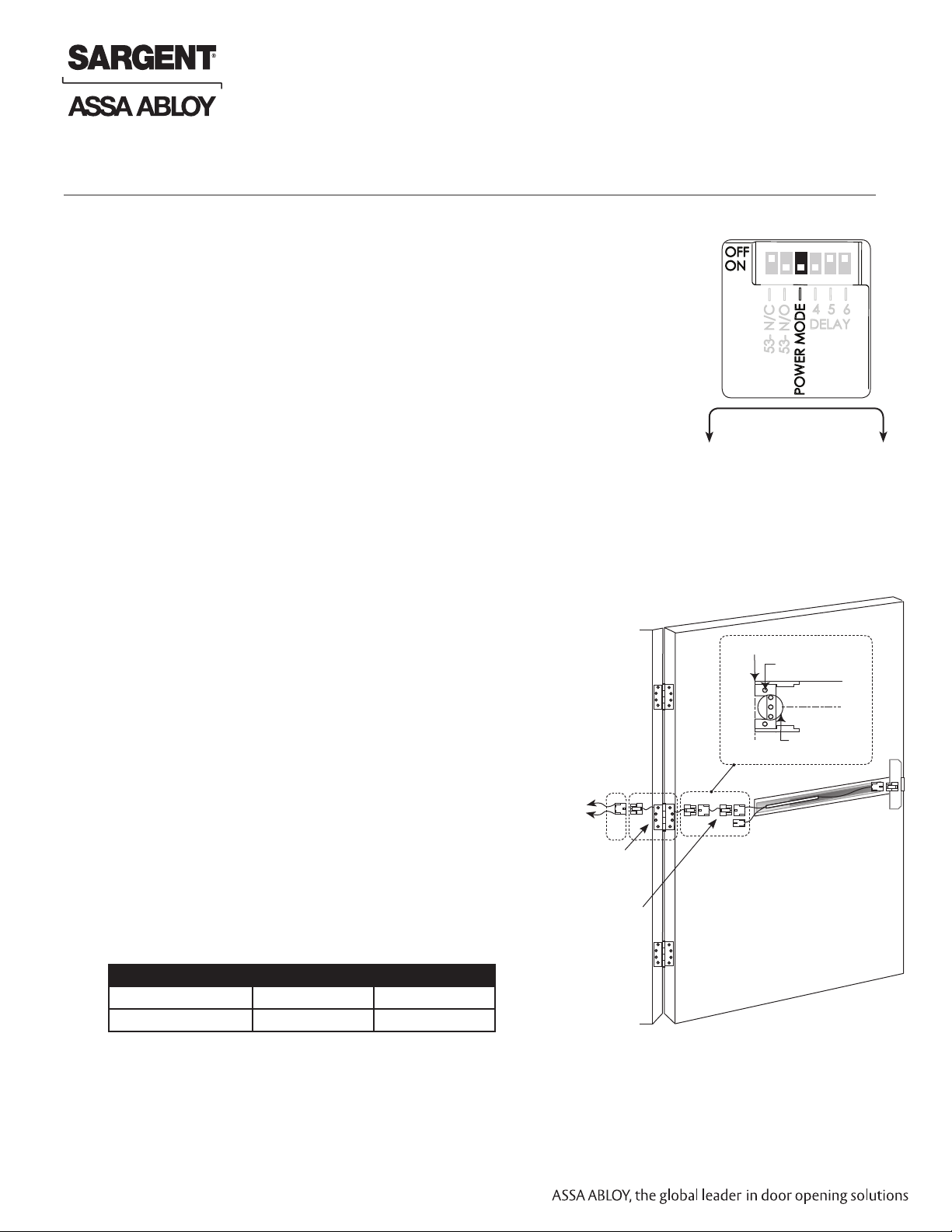

SECTION II: POWER MODE

In this configuration, the device is not energized when locked. When energized with a 24 volt input, the push rail and latch(es)

will retract and remain in the retracted position until power is removed. Power is typically applied through a relay triggered by

an access control device.

For installations using the onboard timer circuit, refer to SECTION III: TIMER MODE.

1. POWER MODE Installation Instructions

How it works: Rail retracts when power is applied and releases when power is removed.

1. Mount 80- Series exit device using mechanical installation instruction sheet(s) provided.

Note: Ensure proper mechanical function before attempting electrical retraction:

• Verify the push rail can be fully depressed and the latch is fully retracted.

• On vertical rod exit devices, verify the latchbolts do not enter hold-back

position until the push rail is fully depressed.

• Adjust device mechanically, as required, before applying power.

2. Connect the ElectroLynx harness in the door (Fig. 8

a. Plug the 8-pin ElectroLynx connector from the rail into the 3" ElectroLynx harness or splice into non-ElectroLynx harness

(Fig. 10 Non-ElectroLynx POWER MODE Wiring).

b. Feed the 3" harness through the 1” hole in the door and secure the rail to the door using the mounting bracket

and two supplied screws (Fig. 7 POWER MODE Installation Diagram).

Note: Do not install the end cap until electrical operation is verified in order to confirm LED signalling.

Do not discard the end cap and hardware.

3. Ensure DIP switch (position 3) enables POWER MODE (Fig. 6).

4. Connect the ElectroLynx harness to the hinge and secure the electric

hinge to door.

Notes: Make sure no wires are pinched or damaged in the process.

Refer to detailed wiring instructions under POWER MODE wiring.

4. Apply 24V according to 56- input requirements (below):

Confirm that the LED is blinking, that the system fully unlocks, and that

all bolts clear the strikes. Troubleshoot the device if issues are observed

using the steps outlined at the end of the POWER MODE section.

5. Store excess wiring under end cap and assemble

with provided screws. Avoid pinching wires.

ElectroLynx POWER MODE Wiring):

and TL- (SARGuide) Connection Instructions

Door Surface

Fig. 6 DIP Switch Setting

for POWER MODE Installation

Mounting Bracket

Screw Location

1” Diameter

Hole in Door

Exit Device

56- Input Requirements

Voltage: 24VDC

• Filtered and regulated power supply

• Motor operating current: 600mA

• Motor hold current: 250mA

55- REX 53- LATCH BOLT

Contact Rating (Resistive) 300mA @ 30VDC 2A @ 30VDC

Contact Resistance 150m Ω 30m Ω

Note: Earth Ground is required for Electrostatic Discharge (ESD)

protection unless the metal door and frame are already earth

grounded; otherwise, earth ground wiring is required at pin 4

(Fig. 8 ElectroLynx POWER MODE Wiring).

Copyright © 2011 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

06/09/11

Hinge (with 8-pin connector)

rail to the ElectroLynx hinge.

4 A7925D

McKinney QC8 Electric

A 3" ElectroLynx harness

is required to connect the

Note: Specified and

ordered separately

55-56- or 12-55-56-

80 Series Rail with

8-pin Connector

Fig. 7 POWER MODE Installation

Page 5

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

2. POWER MODE Wiring

ElectroLynx Opening Installation

This is the simplest installation method, requiring the installer to plug the ElectroLynx connectors from the exit device to the

harness to the hinge and then to the pigtail, which is connected to the access control system.

Requirements

• 56- Exit device

• 3” ElectroLynx connector harness (not supplied with 56- device)

• McKinney QC ElectroLynx hinge (type of hinge depends on the application)

• ElectroLynx door

3” ElectroLynx Harness

With 8-pin Connector

8-pin M

(purchased separately)

8-pin M

8-pin F

*NO/NC (Normally Open/Normally Closed)

is selectable on controller (refer to 53 DIP Switch Instructions in Section III).

Factory preset is NO.

1 - Black (56- 0VDC)

2 - Red (56- +24VDC)

3 - White (53- C)

4 - Green (EG)

5 - Orange (53- NC/NO)*

6 - Blue (55- C)

7 - Brown (55- NO)

8 - Yellow (55- NC)

4-pin F

Not Used

Fig. 8 ElectroLynx POWER MODE Wiring

Non-ElectroLynx Opening Installation

Standard door with standard electric hinge: Molex connectors with flying leads can be purchased separately (Fig. 9).

MOLEX BOTH ENDS MOLEX TO PINS

3 INCH QC-C003 QC-C003P

6 INCH QC-C006 QC-C006P

12 INCH QC-C012 QC-C012P

To identify part numbers and order harness(es), visit the McKinney

website, www.mckinneyhinge.com, and search the catalog for ElectroLynx.

Fig. 9 Molex with 12-pin Connector Pinned

If Molex pinned connectors are not available, remove the ElectroLynx connector from the 56- Exit Device and wire nut the

56- wires to the wires from the electric hinge (color coordinating wire colors is recommended).

1 - Black (56- 0VDC)

2 - Red (56- +24VDC)

3 - White (53- C)

4 - Green (EG)

5 - Orange (53- NC/NO)*

6 - Blue (55- C)

7 - Brown (55- NO)

8 - Yellow (55- NC)

Non-ElectroLynx

Electric Hinge

Loose wires with no termination

connected with wire nuts

4-pin F

Not Used

Fig. 10 Non-ElectroLynx POWER MODE Wiring

56- Wires with ElectroLynx Connector Removed

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7925D 5

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/09/11

Page 6

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

3. POWER MODE Typical Wiring

For use when wiring in POWER MODE.

Notes:

• Onboard timer will not function in POWER MODE.

Add external time delay if necessary.

• The switch is wired between the power supply

and the load. Do not cycle the power supply.

( - )

Maintain

or Relay Switch, i.e.,

Card Reader, Access

Control, etc.

Fig. 11 56- 80 Series Exit Device Typical POWER MODE Wiring

4. Configuration Instructions DIP Switch Settings (53-)

For 56- applications using the optional 53- latchbolt monitor switch (53-56-), pin 5 of the 8-pin ElectroLynx connector will be

either a NO contact or NC contact depending on the position of the DIP switches on the motor controller faceplate.

( + )

( NO )

( NC )

Green (EGND)

Red (+24V)

Black (0V)

24VDC

Power Supply

0V (Black)

+24V (Red)

EGND

QC8 Electric Hinge

Door Surface

Copyright © 2011 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

06/09/11

6 A7925D

Fig. 12 DIP Switch Setting

for 53- Latch Bolt Monitoring

NO (Default) Shown

Fig. 13 NC Alternative

DIP Switch Setting

Page 7

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

5. LED Signalling Chart

SIGNAL CAUSE TROUBLESHOOTING

Dark / Unlit Controller microprocessor is not active Confirm connections and incoming power

Steady Flashing Normal operation Check that POWER MODE switch is set

Solid Light Input voltage is dropping out of operating range Check wire run and power supply output

2 Flashes Followed by Pause Retractor sensor problem Call 800-810-WIRE for assistance

3 Flashes Followed by Pause Motor mechanism problem Call 800-810-WIRE for assistance

6. POWER MODE Troubleshooting

Prior to electrical troubleshooting, confirm that the mechanical system properly functions; i.e., that the push bar fully retracts

all latches and the door opens freely. Refer to applicable Sargent 80 Series Exit Device product instruction sheet to correct

mechanical installation issues.

IMPORTANT: *ALWAYS disconnect power before making any mechanical adjustments to the system.

The push rail does not move when 24V input is applied:

o Check inputs to confirm proper voltage and wiring orientation (Fig. 6 ElectroLynx POWER MODE Installation).

o Remove end cap from rail and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

Note: When configured in POWER MODE, power is released to lock the device (LED will not blink when power is released).

o Confirm DIP switch position 3 is set to ON.

The push rail does not fully retract or push rail retracts completely and holds but does not open door

o *Verify mechanical installation and correct as necessary:

- Is excessive force required to depress the push bar?

- Are latches fully clearing the strikes when mechanically cycled?

The push rail retracts and unlocks electrically but does not relock:

o Physically disconnect power from rail and confirm that input is off.

o *Check for mechanical interference (e.g., warped door, lack of shims, misalignment of rail, etc.).

o *Was a motor kit (M56) installed? Verify the rail assembly.

Rail behaves abnormally (multiple cycles, clicking, delayed retraction, etc.):

o Remove end cap from rail and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

Note: When configured in POWER MODE, power is released to lock the device (LED will not blink when power is released).

For applications using automatic operator(s): Door(s) fail to unlock before doors begin to open:

o Adjust timing of operator to allow 750ms for the rail to fully retract.

53- switch wiring: The design requires normally open functionality and the circuit is normally closed (or vice versa),

There is only a two-wire input for the 53- circuit. Normally open or normally closed configuration is set by toggling the DIP switches on the controller

bracket to the required position (refer to chart in section 4).

For additional installation assistance, please contact 1-800-810-WIRE (9473). When calling, please provide the following information to improve our

service (provide what you can):

o Your name and contact number.

o Sargent 80 Series Exit Device product type (e.g. 55- 56- 8810).

o Location and identification of the affected opening (e.g., site, building, and door number).

o Sargent order number (located on product box), if available.

o Power supply manufacturer and rated output (i.e., voltage and current).

o Method of operation (e.g.,

o The number of devices connected to the power supply.

o Symptoms of problem (i.e., observed behavior).

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

POWER MODE).

A7925D 7

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/09/11

Page 8

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

SECTION III: TIMER MODE

In this configuration, the device is always energized with a 24 volt input, and a timer circuit is opened or closed to control rail retraction.

A momentary or maintain switch is typically used to perform this operation.

For installations where the power input is cycled to retract the device, refer to SECTION II: POWER MODE.

1. TIMER MODE Installation Instructions

How it works: Rail retracts when timer input circuit is closed.

1. Mount 80- Series exit device using mechanical installation instruction sheet(s) provided.

Note: Ensure proper mechanical function before attempting electrical retraction:

• Verify the push rail can be fully depressed and the latch is fully retracted.

• On vertical rod exit devices, verify that the latchbolts do not enter

hold-back position until the push rail is fully depressed.

• Adjust device mechanically, as required, before applying power.

2. Ensure DIP Switch switch (position 3) disables POWER MODE (Fig. 16). Set to OFF to disable.

3. Connect the ElectroLynx harness in the door (Fig. 17

a. Plug the 8-pin and 4-pin ElectroLynx connectors from the rail into the 3” ElectroLynx harness or splice into a

non-ElectroLynx harness (Fig. 17 TIMER MODE Installation).

b. Feed the 3” harness through the 1” hole in the door and secure the rail to the door using the mounting bracket

and two supplied screws (Fig. 17 TIMER MODE Installation).

Note: Do not install the end cap until electrical operation is verified in order to confirm LED signaling.

Do not discard the end cap and hardware.

ElectroLynx TIMER MODE Installation):

Door Surface

Fig. 14 DIP Switch Setting

for TIMER MODE Installation

56- Input Requirements

Voltage: 24VDC

• Filtered and regulated power supply

• Motor operating current: 600mA

• Motor hold current: 250mA

55- REX 53- LATCH BOLT

Contact Rating (Resistive) 300mA @ 30VDC 2A @ 30VDC

Contact Resistance 150m Ω 30m Ω

Note: Earth Ground is required for Electrostatic Discharge (ESD)

protection unless the metal door and frame are already

earth grounded; otherwise, earth ground wiring is required

at pin 4 (Fig. 18 ElectroLynx TIMER MODE Wiring).

McKinney QC12 Electric Hinge

(with 8- and 4-pin connectors)

ElectroLynx Door Harness

(with 8- and 4-pin connector)

Mounting Bracket

Screw Location

1” Diameter

Hole in Door

Exit Device

55-56- or 12-55-56-

80 Series Rail with

8 and 4-pin Connectors

Copyright © 2011 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

06/09/11

8 A7925D

Fig. 15 TIMER MODE Installation

Page 9

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

1. TIMER MODE Installation Instructions (continued)

4. Connect the ElectroLynx harness to the hinge:

a. Plug the door harness’s 8-pin and 4-pin connectors into the hinge’s ElectroLynx connector.

b. Secure the electric hinge to door.

Notes: Make sure no wires are pinched or damaged in the process.

Refer to detailed wiring instructions under TIMER MODE wiring.

5. Apply 24V according to 56- input requirements:

Confirm that the LED is blinking and close the timer input circuit to retract the device. When the system retracts electrically,

confirm that it fully unlocks and that all bolts clear the strikes. Troubleshoot the device if issues are observed using the

steps outlined at the end of the TIMER MODE section.

6. Store excess wiring under end cap and assemble with provided screws. Avoid pinching wires.

2. TIMER MODE Wiring

ElectroLynx Opening Installation

This is the simplest installation method, requiring the installer to plug the ElectroLynx

connectors from the exit device to the harness to the hinge and then to the pigtail,

which is connected to the access control system.

Requirements

• 56- Exit device

• 3” ElectroLynx connector harness (not supplied with 56- device)

• McKinney QC ElectroLynx hinge (type of hinge depends on the application)

• ElectroLynx door

*NO/NC (Normally Open/Normally Closed)

is selectable on controller (refer to 53- DIP

switch instructions in this section, number 5).

Factory preset is NO.

1 - Black (56- 0VDC)

2 - Red (56- +24VDC)

3 - White (53- C)

4 - Green (EG)

5 - Orange (53- NC/NO)*

6 - Blue (55- C)

7 - Brown (55- NO)

8 - Yellow (55- NC)

3” ElectroLynx harness

with 8-and 4-pin connectors

4-pin M

(purchased separately)

Fig. 16 ElectroLynx TIMER MODE Wiring

8-pin M8-pin M

4-pin M

8-pin F

4-pin F

1 - Violet (TL- Prefix is an option)

2 - Grey (TL+ Prefix is an option)

3 - Pink (56- Timer A)

4 - Tan (56- Timer B)

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7925D 9

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/09/11

Page 10

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

2. TIMER MODE Wiring (continued)

Non-ElectroLynx Opening Installation

Standard door with standard electric hinge: Remove the ElectroLynx connector from the 56- Exit Device and wire nut

the 56- wires to the wires from the electric hinge (color coordinating wire colors is recommended).

MOLEX BOTH ENDS MOLEX TO PIN OUT

3 INCH QC-C003 QC-C003P

6 INCH QC-C006 QC-C006P

12 INCH QC-C012 QC-C012P

To identify part numbers and order harness(es), visit the McKinney website,

www.mckinneyhinge.com, and search the catalog for ElectroLynx.

Non- ElectroLynx

Electric Hinge

1 - Black (56- 0VDC)

2 - Red (56- +24VDC)

3 - White (53- C)

4 - Green (EG)

5 - Orange (53- NC/NO)*

6 - Blue (55- C)

7 - Brown (55- NO)

8 - Yellow (55- NC)

*NO/NC (Normally Open/Normally Closed)

is selectable on controller (refer to 53- DIP

switch instructions in this section (III), part 5).

Factory preset is NO.

Fig. 17 Non-ElectroLynx TIMER MODE Connection

56- Wires with ElectroLynx Connector Removed

3. TIMER MODE Typical Wiring

For use when wiring in TIMER MODE (using the

onboard timer).

If more than 20 seconds timed delay is necessary,

an external timer delay relay is required (not provided).

Note: 24V supply is constant in TIMER MODE.

Refer to settings in Section III, part 5 (Configuration

Instructions DIP Switch Settings).

Loose wires with no termination

connected with wire nuts

Momentary or

Maintain or Relay Switch

(Card Reader, Access

Control, etc.)

( C )

( NO )

1 - Violet (TL- Prefix is an option)

2 - Grey (TL+ Prefix is an option)

3 - Pink (56- Timer A)

4 - Tan (56- Timer B)

24VDC

Power Supply

0V (Black)

+24V (Red)

EGND

Pink

Tan

Green (EGND)

Red (+24V)

Black (0V)

Exit Device

QC12 Electric Hinge

56-

80 Series

Copyright © 2011 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Fig. 18 TIMER MODE Typical Wiring

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

06/09/11

10 A7925D

Page 11

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

4. TIMER MODE Adjustment (Onboard Timer)

How it works: The 24 volt input is always energized and the system retracts when the timer input circuit is closed.

• When the timer circuit is closed utilizing a momentary switch, the device retracts, remains retracted for a set duration,

and releases. The duration of the retraction is set using an onboard timer setting (0 - 20 second timer adjustment).

The countdown begins when the rail is first retracted.

• When the timer circuit is closed using a maintain switch, the device retracts.

The device releases when the circuit is re-opened.

Notes:

• Note: 24V supply is constant in TIMER MODE. The duration of retraction is determined by whichever is longer:

the maintain switch closure or the onboard timer delay.

• If more than 20 seconds delay is necessary (exceeding the maximum setting), an external timer delay relay

is required (not provided).

NOTE: Refer to settings in Section III, part 5 (Fig. 19-21) for DIP Switch timer delay settings.

5. Configuration Instructions DIP Switch Settings (for 53- and timer duration)

For 56- applications using the optional 53- latchbolt monitor switch (53-56-), pin 5 of the 8-pin ElectroLynx connector

will be either an NO contact or NC contact depending on the position of the DIP switches on the motor controller faceplate.

6. LED Signalling Chart

SIGNAL CAUSE TROUBLESHOOTING

Dark / Unlit Controller microprocessor is not active Confirm connections and incoming power

Steady Flashing Normal operation Cycle device by closing the timer circuit

Solid Light Input voltage is dropping out of operating range Check wire run and power supply output

2 Flashes Followed by Pause Sensor or motor issue Call 800-810-WIRE for assistance

3 Flashes Followed by Pause Mechanical issue Call 800-810-WIRE for assistance

Door Surface

Fig. 19 DIP Switch Setting

for 53- Latch Bolt Monitoring

Fig. 20 Alternate DIP

Switch Setting (53- NC)

Fig. 21 Timer Delay Settings

(Default = 5 Seconds)

0 Seconds

2 Seconds

3 Seconds

4 Seconds

5 Seconds

10 Seconds

15 Seconds

20 Seconds

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7925D 11

06/09/11

Page 12

56- Electric Latch Retraction Exit Devices

Installation and Wiring Instructions

With Optional 53- Latchbolt; 55- Request to Exit;

and TL- (SARGuide) Connection Instructions

7. TIMER MODE Troubleshooting

Prior to electrical troubleshooting, confirm that the mechanical system properly functions; i.e., that the push bar fully retracts

all latches and the door opens freely. Refer to applicable Sargent 80 Series Exit Device product instruction sheet to correct

mechanical* installation issues.

IMPORTANT: *ALWAYS disconnect power before making any mechanical adjustments to the system.

The push rail does not move when 24V input is applied:

o Check inputs to confirm proper voltage and wiring orientation.

When configured for

o Remove end cap from rail and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

The onboard timer duration adjustment is not working:

o Remove power when making adjustments to timer delay settings (DIP Switches).

o When a momentary signal is applied to the timer circuit, the circuit must be reopened for the timer to function.

The push rail does not fully retract or push rail retracts completely and holds but does not open door:

o *Verify mechanical installation and correct as necessary:

- Is excessive force required to depress the push bar?

- Are latches fully clearing the strikes when mechanically cycled?

The push rail retracts electrically but does not release. System does not relock.

o Confirm that the

o Physically disconnect power from rail (while electrically retracted) to verify if the issue is mechanical.

o *Check for mechanical interference (e.g., warped door, lack of shims, misalignment of rail, etc.).

o *Was a motor kit (M56) installed? Verify the rail assembly.

Rail behaves abnormally (multiple cycles, clicking, delayed retraction, etc.):

o If a momentary contact is applied to the timer circuit, adjust the onboard timer to a longer duration.

o Remove end cap from rail and confirm that LED is blinking steadily when power is applied. If not, refer to LED signaling.

For applications using automatic operator(s): Door(s) fail to unlock before doors begin to open:

o Adjust timing of operator to allow 750ms for the rail to fully retract.

o If a momentary contact is applied to the timer circuit, adjust the onboard timer to a longer duration to prevent the device from locking prior

to operator actuation.

53- switch wiring: The design requires normally open functionality and the circuit is normally closed (or vice versa),

There is only a two-wire input for the 53- circuit. Normally open or normally closed configuration is set by toggling the DIP switches on the

controller bracket to the required position (refer to chart in Section III, part 5).

For additional installation assistance, please contact 1-800-810-WIRE (9473). When calling, please provide the following information to improve our

service (provide what you can):

o Your name and contact number.

o Sargent 80 Series Exit Device product type (e.g., 55- 56- 8810).

o Location and identification of the affected opening (e.g., site, building, and door number).

o SARGENT order number (located on product box), if available.

o Power supply manufacturer and rated output (i.e., voltage and current).

o Method of operation (e.g.,

o The number of devices connected to the power supply.

o Symptoms of problem (i.e., observed behavior).

TIMER MODE, 24V must be constantly applied and the timer circuit must be closed to cycle the device.

TIMER MODE contact is opened (the rail will remain depressed until the contact is opened and the delay has expired).

TIMER MODE).

Copyright © 2011 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

06/09/11

12 A7925D

Loading...

Loading...