Page 1

Specifications

Power Rating . . . . . . . . . . . . . . . . . . . . . . . . 120VAC

351W, 4.2A (Max)

Antenna Input Impedance . . . . . . . . . . . . . . . . . 75Ω

UHF/VHF/CATV

Digital

Receiving Channel . . . . . . . . . . . . . . . . 2 - 13 (VHF),

14 - 69 (UHF),

01, 14-94, 95-125 (CATV)

1-99 (Digital)

Remote Ready . . . . . . . . . . 32 Key Remote Control

Sound Output . . . . . . . . . . . . . . . . . . . . . . 5.0 W/CH

Intermediate Frequency

Picture IF Carrier. . . . . . . . . . . . . . . . . . 45.75MHz

Sound IF Carrier . . . . . . . . . . . . . . . . . . 41.25MHz

Color Sub Carrier . . . . . . . . . . . . . . . . . 42.17MHz

Cabinet Dimensions

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1206mm

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . 720mm

Depth including base . . . . . . . . . . . . . . . . 248mm

REFERENCE No. SM780114

DP42746, J3TZ, PRODUCT CODE 111009300

Contents

Safety Instructions . . . . . . . . . . . . . . . . . . 2

Service Adjustments . . . . . . . . . . . . . 3 – 5

Power Failure Circuit . . . . . . . . . . . . . . . . 6

Mechanical Disassemblies. . . . . . . . 7 – 12

Chassis Electrical Parts List . . . . . . 13 – 20

Cabinet Parts List . . . . . . . . . . . . . . . . . . 21

Component and Test Point

Locations . . . . . . . . . . . . . . . . . . . 22 – 24

Block Diagrams . . . . . . . . . . . . . . . . 25 – 28

Trouble Shooting Flow Charts . . . . 29 – 31

Control Port Functions. . . . . . . . . . . 32 – 33

Schematic Notes . . . . . . . . . . . . . . . . . . . 34

Pin Layouts. . . . . . . . . . . . . . . . . . . . . . . . 35

Capacitor and Resistor Codes . . . . . . . . 36

Board Connections . . . . . . . . . . . . . 37 – 40

Schematic Diagrams . . . . . . . . . . . . 41 – 44

AS

FILE NO.

SERVICE MANUAL Remote Control Plasma

Color Television

DP42746 (U.S.A.)

(CANADA)

ORIGINAL VERSION

Chassis No. 42746-00

NOTE: Match the Chassis No. on

the unit’s back cover with

the Chassis No. in the

Service Manual.

If the Original Version

Service Manual Chassis

No. does not match the

unit’s, additional Service

Literature is required. You

must refer to “Notices” to the

Original Service Manual

prior to servicing the unit.

Servicing should be performed by only trained and qualified service personnel.

with a double “Z” is a registered trademark

of Sanyo Manufacturing Corporation.

© Sanyo Manufacturing Corporation 2006

AS

Page 2

— 2 —

SAFETY PRECAUTIONS

WARNING: The chassis of this receiver has a floating

ground with the potential of one half the AC line voltage in

respect to earth ground. Service should not be attempted by

anyone not familiar with the precautions necessary when

working on this type of equipment.

The following precautions must be observed:

1. An isolation transformer must be connected in the power

line between the receiver and the AC line before any service is performed on the receiver.

2. Comply with all caution and safety-related notes provided

inside the cabinet, on the chassis, and on the back.

3. When replacing a chassis in the cabinet, always be certain

that all the protective devices are installed properly, such

as control knobs, adjustment covers, shields and barriers.

4. Before replacing the back cover of the set, thoroughly

inspect the inside of the cabinet to see that no stray parts

or tools have been left inside.

Before returning any television to the customer, the

service technician must perform the following safety

checks to be sure that the unit is completely safe to

operate without danger of electrical shock.

ANTENNA COLD CHECK

Remove AC plug from the 120 VAC outlet and place a

jumper across the two blades. Connect one lead of an ohmmeter to the jumpered AC plug, and touch the other lead to

each exposed antenna terminal (UHF and VHF antenna terminals). The resistance must measure between 1M ohm and

5.2M ohm. Any resistance value below or above this range

indicates an abnormality which requires corrective action.

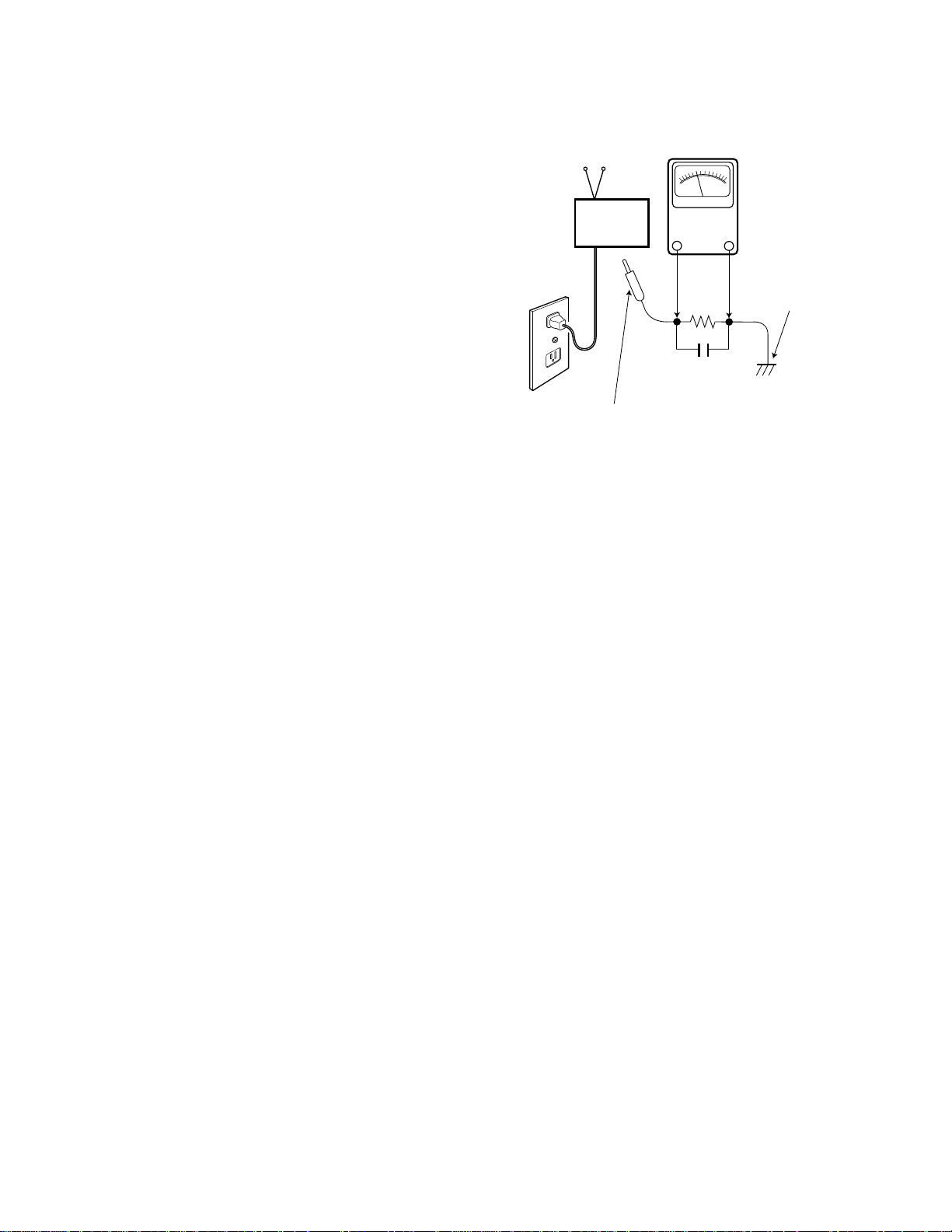

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120 VAC outlet. (Do not

use an isolation transformer for this check.) Use an AC voltmeter, that has 5000 ohms per volt or more sensitivity.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 µF

150 VAC capacitor, between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of the

cabinet (antennas, handle bracket, metal cabinet, screw

heads, metal overlays, control shafts, etc.). Measure the AC

voltage across the 1500 ohm resistor. The AC voltage

should not exceed 750 mV. A reading exceeding 750 mV

indicates that a dangerous potential exists. The fault must

be located and corrected. Repeat the above test with the

receiver power plug reversed.

NEVER RETURN A RECEIVER TO THE CUSTOMER

WITHOUT TAKING THE NECESSARY CORRECTIVE ACTION.

PRODUCT SAFETY NOTICE

When replacing components in a receiver, always keep in

mind the necessary product safety precautions. Pay special

attention to the replacement of components marked with a

star () in the parts list and in the schematic diagrams. To

ensure safe product operation, it is necessary to replace

those components with the exact same PARTS.

SERVICING ELECTROSTATICALLY SENSATIVE DEVICES

Semiconductors (solid-state devices) that can be damaged

by static electricity are referred to as Electrostatically

Sensitive (ES) devices. Examples of typical ES devices are:

Integrated Circuits (IC), Field-Effect Transistors (FET), and

“chip” components. The following techniques should be

observed strictly, to reduce the occurrence of semiconductor damage due to electrostatic discharge.

1. Immediately prior to handling any semiconductor component or an assembly containing a semiconductor

device or devices, discharge the electrostatic buildup on

your body by touching a known earth ground. You may

also obtain and wear a commercially available discharging wrist strap device.

CAUTION: Be sure to remove the wrist strap before

applying power to any unit being serviced.

2. After removing an ES equipped assembly, place it on a

conductive surface, such as, aluminum foil, to prevent

buildup or exposure to static electricity.

3. Use only grounded-tip soldering irons to solder or unsolder ES devices.

4. Use only anti-static solder removal devices. Some suction-type devices can generate static electricity adequate

to damage ES devices.

5. A replacement ES device will come packaged in protective

material (conductive foam, aluminum foil, or some comparable conductive material). Do Not remove an ES device

from its protective packaging unless you are prepared to

install it immediately.

6. Precisely prior to removing an ES device from its protective

packaging, touch the protective packaging to the chassis or

assembly in which the device will be installed.

CAUTION: Be sure that no power is applied to the chassis or

circuit assembly.

7. Incidental body movements, such as, lifting a foot from a

carpeted floor or the rubbing of fabric together can generate static electricity sufficient to damage ES devices.

Therefore, minimize all body movements while handling

exposed (unpackaged) ES devices.

SAFETY INSTRUCTIONS

AC OUTLET

READING SHOULD NOT EXCEED 750 mV.

(5000 ohms per volt or more sensitivity)

TELEVISION

RECEIVER

To be touched to all of exposed metal parts.

Voltmeter Hook-up for Leakage Current Check.

AC VOLTMETER

1500 ohm

10 watt

0.15 µF 150V AC

Good earth ground

such as a water pipe,

conduit, etc.

Page 3

— 3 —

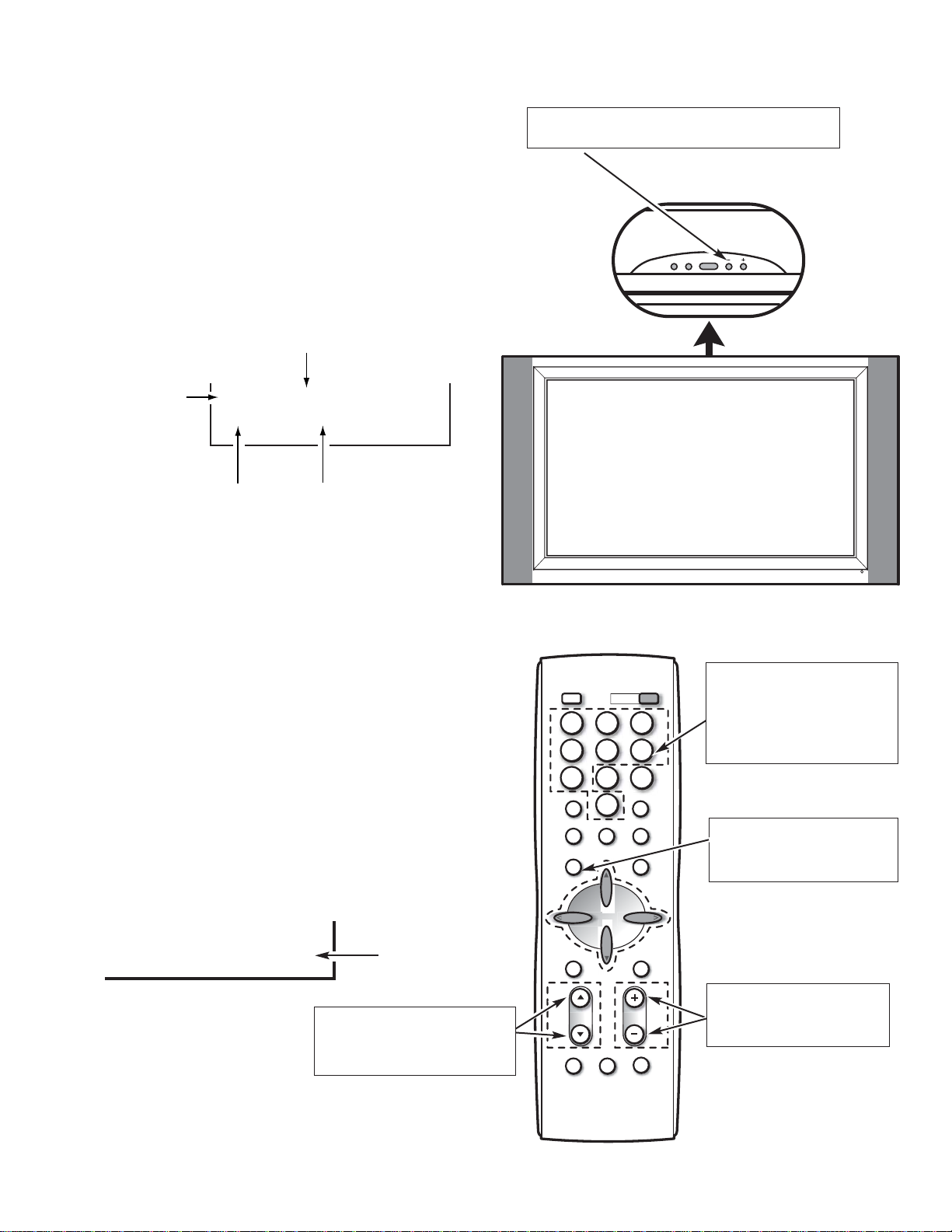

SERVICE ADJUSTMENTS

Volume – : Enter Service Menu

GENERAL

This set has an On-screen Service Menu system included in

the CPU that allows remote operation for most of the service adjustments.

ON-SCREEN SERVICE MENU SYSTEM

1. Enter the Service Menu:

•Turn off the receiver and disconnect the AC power

supply.

•While pressing the Volume (–) button on the televi-

sion, reconnect the AC power supply. The Service

Menu will now appear. The remote can now be used

to make adjustments. See Figure 1 below.

2. Service Adjustments:

•Press the Channel or key to select the desired

service menu item you want to adjust. See page 4

for the On-screen Service Menu.

•Use the Volume + or – key or number keys to adjust

the data.

The + or – keys will increase or decrease the data

sequentially. The number keys (0 ~ 7) toggle only

their respective bits between 1 and 0 and are used to

change the Sub-Address. For example to change bit

5 press the number 5 key. See below.

Note: Using the + or – is not recommended due to possi-

ble rapid changes.

3. Exit from the Service Menu:

•Press the MENU key to turn off the Service Menu

display.

(b7) (b6) (b5) (b4) (b3) (b2) (b1) (b0)

0 1 0 1 0 1 1 0

BINARY DATA

(8 bit)

080 ATT

07 00000111

Figure 1. Service Menu Display

ITEM NO.

TITLE

BINARY DATA

(8 bit)

HEX DATA

Menu:

Exit Service Menu

Volume + / –:

Adjust Service Menu

Numeric:

0, 1, 2, 3, 4, 5, 6, 7:

Change Binary Data

Channel :

Select Item

POWER

CH

VOL

INPUT

POWER

1

2 3

4 5 6

7 809

INFO

RECALL

TUNER MUTE

MENU

SLEEP

ENTER

CAPTION EXIT

CH

VOL

RESET AUDIO PIX SHAPE

Page 4

— 4 —

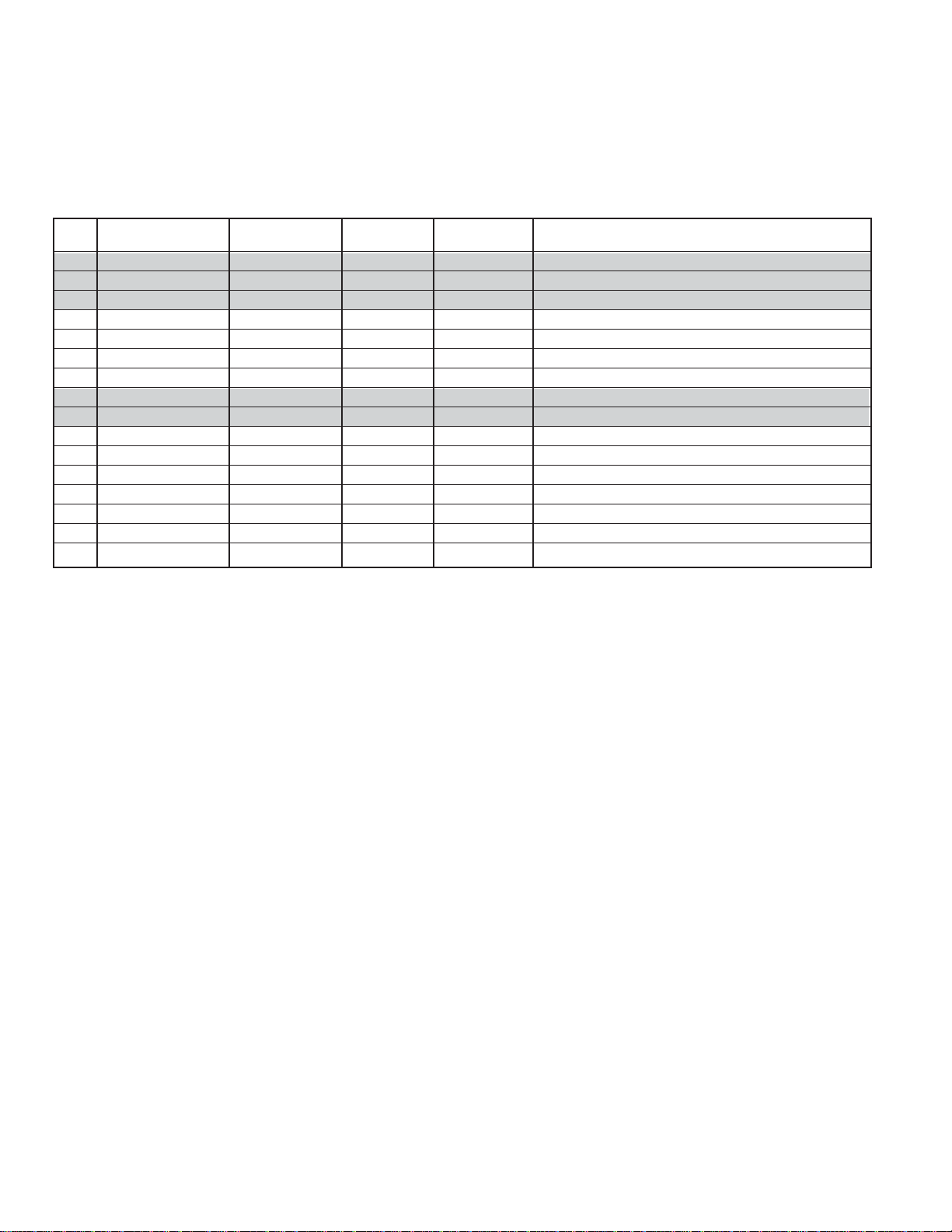

ON-SCREEN SERVICE MENU

• All data except in gray box area is fixed. Do not change for correct operation.

• Data in gray box is initial. Can be set according to adjustment information.

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as below. The shaded menu should

be checked and be set up or readjusted according to the procedures described in the following pages. Initial Setup Data

marked with an * should be changed from Initial Reference Data. See page 3 for On-Screen Service Menu access and

adjustments.

PROGRAM CODES

The microprossesor used in this model is a multi-purpose type and is used in several different models. To ensure

proper operation and the correct features for your particular model, the program codes must be correct.

Note 1. Option Data 1 (NO. 087 OPT) should be hexadecimal 0A (00001010 binary). See 087 above. If this program

code is wrong the TV will not operate properly.

Note 2. Option Data 2 (NO. 088 OP2) should be hexadecimal 00 (00000000 binary). See 088 above. If this program

code is wrong the TV will not operate properly.

No. TITLE

INITIAL REFERENCE INITIAL SETUP INITIAL SETUP

FUNCTION

DATA HEX DATA HEX DATA BINARY

080 ATT 07 07 00000111 Attenuation -MTS Input Level (3~0)

081 SPC 20 20 00100000 Spectral - High Separation (5~3)

082 WDB 20 20 00100000 Wide Band - Low Separation (5~0)

083 SCO 00 00 00000000 Sub Color (NOT AVAILABLE)

084 STI 00 00 00000000 Sub Tint (NOT AVAILABLE)

085 SB 00 00 00000000 Sub Bright (NOT AVAILABLE)

086 SSH 00 00 00000000 Sub Sharpness (NOT AVAILABLE)

087 OP1 0A 0A 00001010 b7:PDP HD=0 b3:W/HDMI=1, PDP: b1,b0=10

088 OP2 00 00 00000000 b7:HD=0

08A PER 00 00 00000000 Temperature Failure History (No Failure = 0, Failure = 1)

PUT 0000 0000 00000000 Total Operation Time

1C0 ↓↓↓00000000 Not Used

1FF ↓↓↓↓Not Used

200 1R01 00 00 00000000 ROM Correction Data

↓↓ ↓ ↓ ↓↓

298 2R48↓ 00 00 00000000 ROM Correcetion Data

Page 5

— 5 —

SERVICE ADJUSTMENTS (Continued)

MULTI-SOUND SECTION ADJUSTMENTS

Note: Multi-Sound Section must be adjusted after

A101 (U/V Tuner), IC3401 (MTS Decoder), Digital

Module or IC802 (EEPROM) is replaced.

INPUT LEVEL ADJUSTMENT

1. Connect a signal to the analog antenna terminal with

audio of 1 KH

Z 100% modulation.

2. Turn off the receiver and disconnect the AC power cord

(AC 120V line).

3. Connect voltmeter (RMS) to TP317 and ground on the

Main PC board.

4. While pressing the VOLUME – key, reconnect the AC

power cord. The Service Menu will now appear.

5. Select NO. 080 (ATT: MTS Input Level) with the or

key.

6. Adjust the + or – key for a voltmeter reading of 400 ±

20 mVrms at TP317.

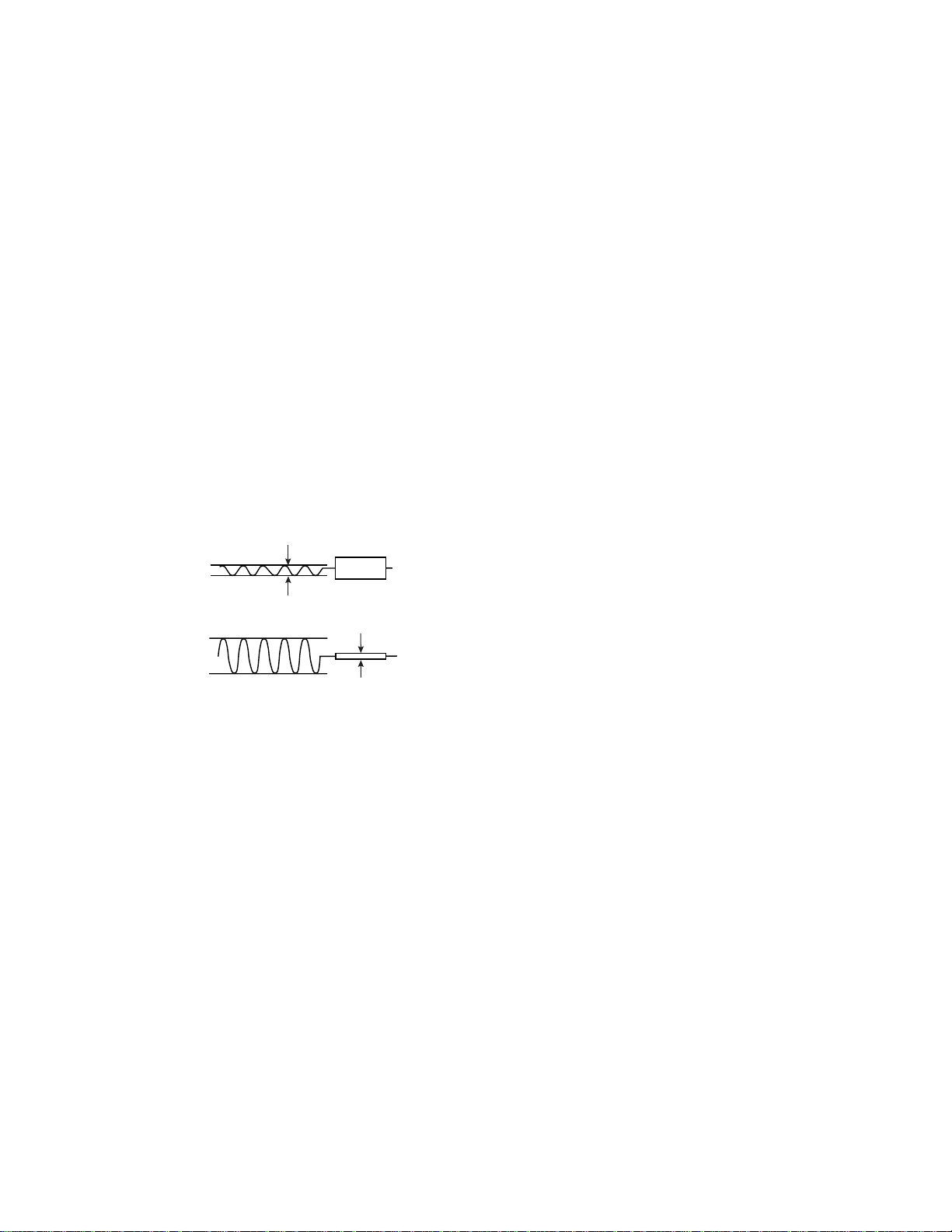

Figure 2. Separation Adjustments

SEPARATION ADJUSTMENT

7. Turn off the receiver and disconnect the AC power cord

(AC 120V line).

8. Connect oscilloscope CH1 to TP317 and CH2 to TP318

and ground.

9. Connect an MTS TV/Stereo generator to antenna terminal.

10. While pressing the VOLUME – key, reconnect the AC

power cord. The Service Menu will now appear.

11.Select pilot, 300Hz audio frequency and Left modulating

signal.

12. Select NO. 082 (WDB: Wide Band) with the or key.

13. Adjust the + or – key for minimum low frequencies at

TP317. See Figure 2.

14. Select 4 KHz audio frequency and Right modulating signal.

15. Select NO. 081 (SPC: Spectral) with the or key.

16. Adjust the + or – key for minimum high frequencies at

TP318. See Figure 2.

Repeat adjustments (steps 11–16) until no further decreases

in amplitude can be obtained. Press the MENU key to turn

off the Service Menu display.

Minimize L leakage

TP317 (R)

300Hz

Minimize R leakage

TP318 (L)

4KHz

Page 6

— 6 —

POWER FAILURE CIRCUIT

CPU (IC801) is programmed so the set will go to the standby mode when there is circuit failure as described below.

(Refer to”Power Supply Lines.”)

1. Power Failure : Detected voltage failure. (Connected to

IC801 pin 32.)

(Normal: High; Failure: Low)

2. Temperature Failure : Detected temperature failure for

Power Unit of PDP module. (Connected to IC801 pin 41.)

(Normal: Low; Failure: High)

LED Flashing

When IC801 detects the Power Failure 3 times the LED will

flash to indicate a power failure has occurred.

Note: The LED does not flash for Temperature Failures.

Note: If power failure is detected 3 times in 15 minutes, the

set will enter the standby mode and cannot be

switched On. To reset the operating programs of the

CPU it is necessary to disconnect the AC cord for a

short time.

History of Power Failure

When finishing the repair or stopping the Power Failure,

the history of past failures can be checked.

To see the history

1. Enter the service mode. See “Service Adjustments”

page 3.

2. Select Item No. 08A PER Temperature Error.

If Temperature Failure has accured the data in Item No.

08A will be 01h (1).

Attention:

After servicing, reset the data of Item No. 08A to 00h (0)

with the Volume + or – key.

Q801

Power On

Thermal Detector

D1607

11 10 3 4 9 5 6 11

D1606

D3.3V

K8B K8A

IC801 (CPU)

41

Power Fail

32

14

D1605 D1604 D1603 D1601

D5V

TV33V

12V AMP

Q803

A5V

D1602

4

IC1601

A9V

39

K8MA

DIGITAL

BOARD

POWER BOARD

Page 7

— 7 —

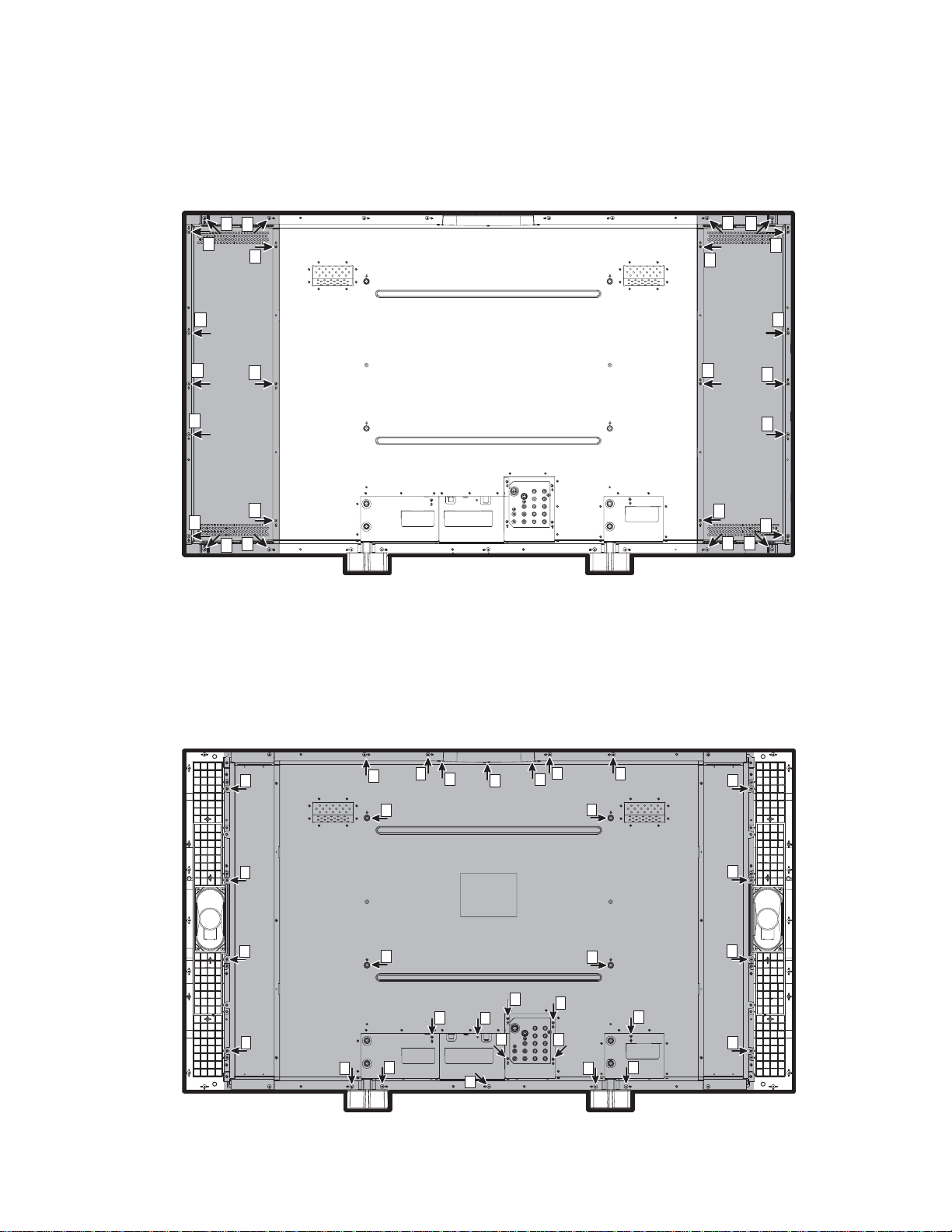

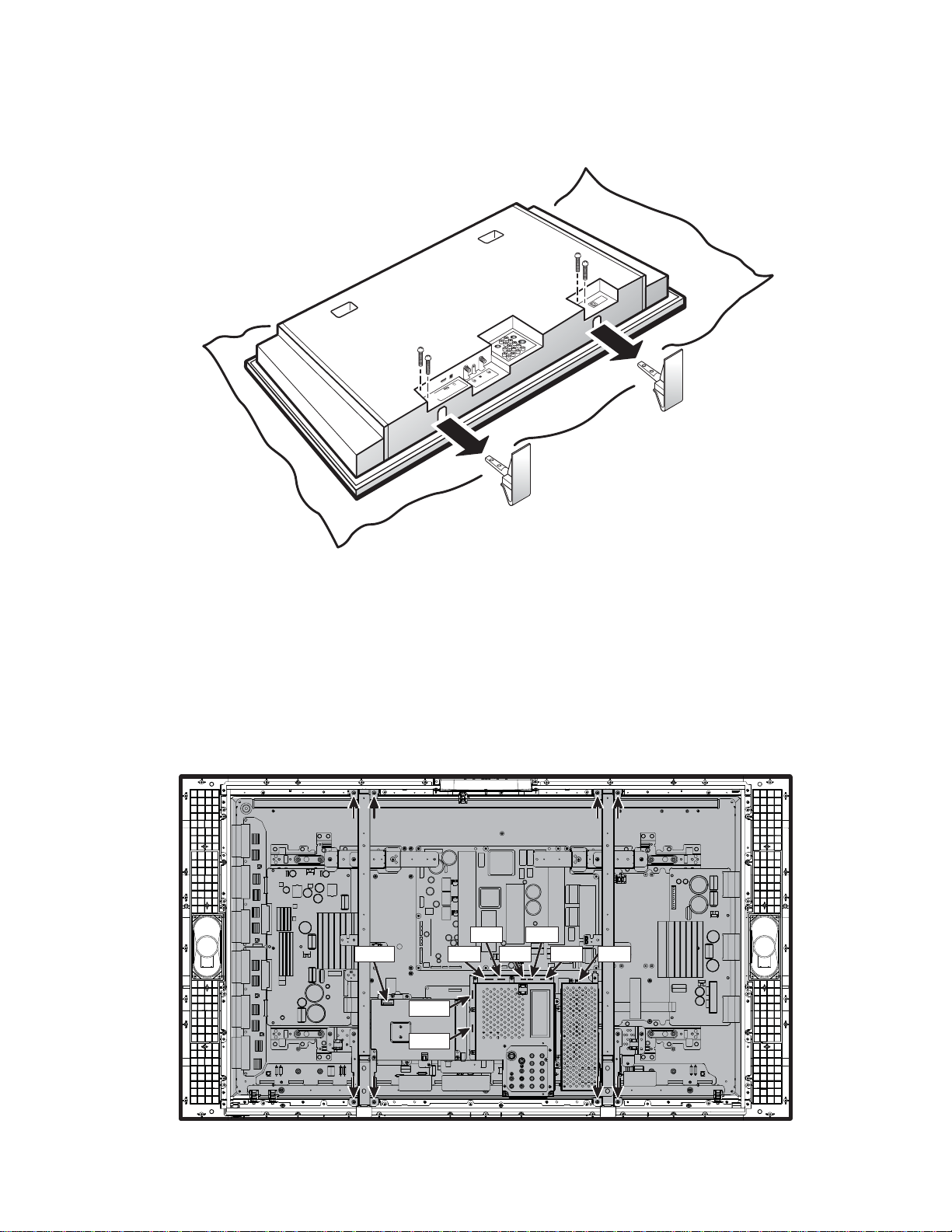

MECHANICAL DISASSEMBLY

BACK CABINET REMOVAL – SIDES

Remove 24 screws to take the side cabinets off.

(A:3X8, 6pcs; B:4X12, 18pcs)

BACK CABINET REMOVAL– CENTER

Remove 31 screws to take the back cabinet off.

(C:3X8, 10pcs; D:4X12, 17pcs; E:6X18, 4pcs)

B

B

B

B

A

B

B

A

B

B

A

A

B

B

A

B

B

A

B

B

B

B

BB

D

D

D

D

D

D

D

C

C

E

E

C

C

C

D

D

D

C

C

C

C

D

E

E

C

D

D

D

D

D

D

Page 8

— 8 —

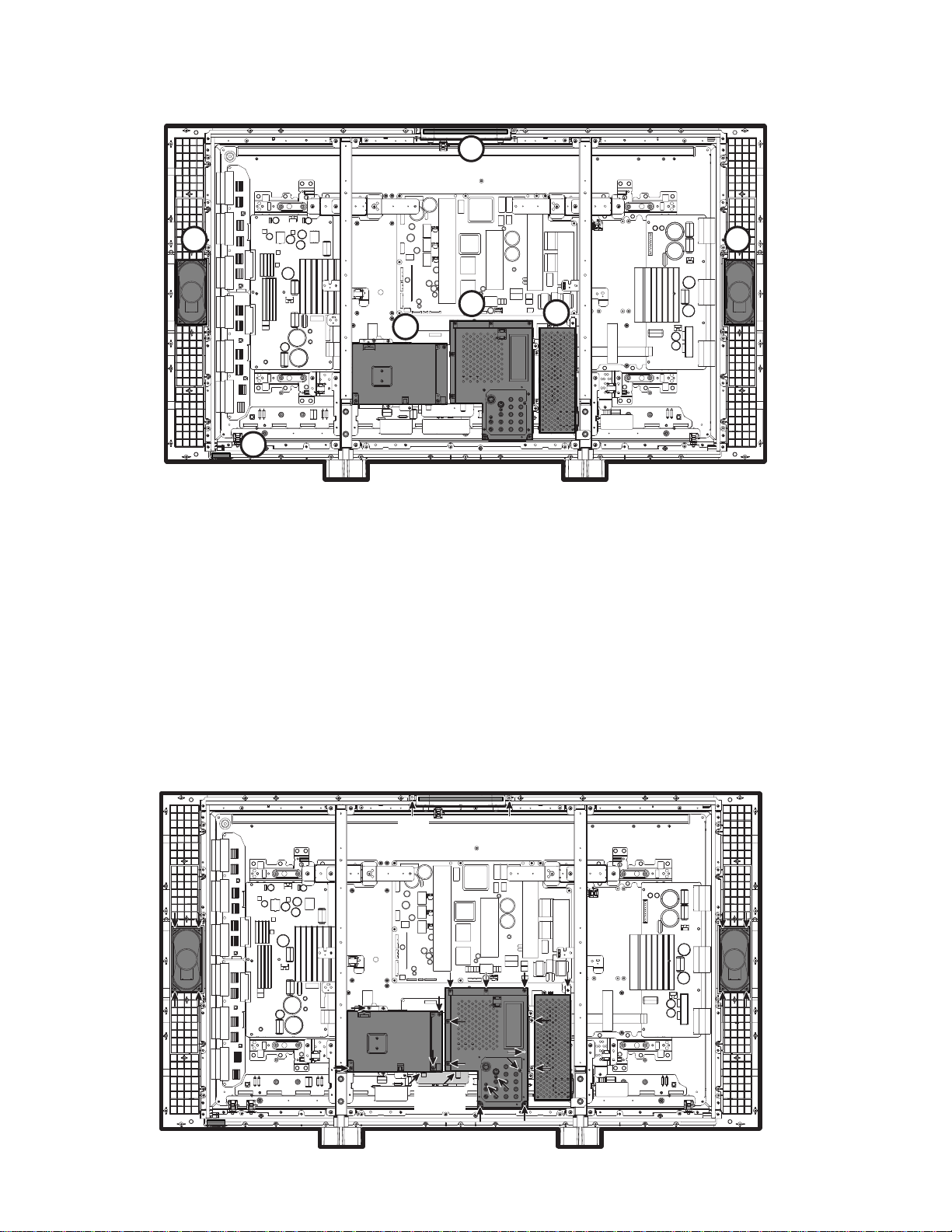

BOARD LOCATIONS

1: MAIN BOARD REMOVAL

Remove 2 tuner nuts (Digital and Analog) and take off the

terminal base. Disconnect plugs K8MB, K8MA, K8A, K8B,

K8F, K8E, and KSP. Remove 11 screws (3X8: 2 types) to

take the main board with the shield case (assembly parts)

off.

2: D-TU BOARD REMOVAL

Remove the terminal base. Disconnect plug K8LV. Remove

5 screws (3X8) to take the D-TU (digital) board with the

shield case (assembly parts) off.

3: FILTER BOARD REMOVAL

Disconnect plug KAC. Remove 3 screws (3X8) to take the

filter board with the shield case (assembly parts) off.

4: KEY SW BOARD REMOVAL

Disconnect plug K8E. Remove a screw (4X12) to take the

key switch board with the panel, button, and holder

(assembly parts) off.

5: CONTROL BOARD REMOVAL

The control board can be taken off, after the filter glass is

removed. (Refer to ‘FILTER GLASS REMOVAL’.)

6: SPEAKER REMOVAL

Disconnect plug KSP. Remove 4 screws (4X10) to take off

each speaker.

MECHANICAL DISASSEMBLY (CONT.)

SCREW LOCATIONS

4

6 6

2

5

1

3

Hook

Terminal

Base

Page 9

— 9 —

A

C

I

N 1

2

0

V

UH

F/

V

HF/

CA

T

V

D

I

G

I

TA

L

A

NT

E

N

N

A

I

N

S

E

RV

I

CE

D

I

G

I

TA

L

A

U

D

I

O

OU

T

P

U

T

H

D

MI

I

N

P

U

T

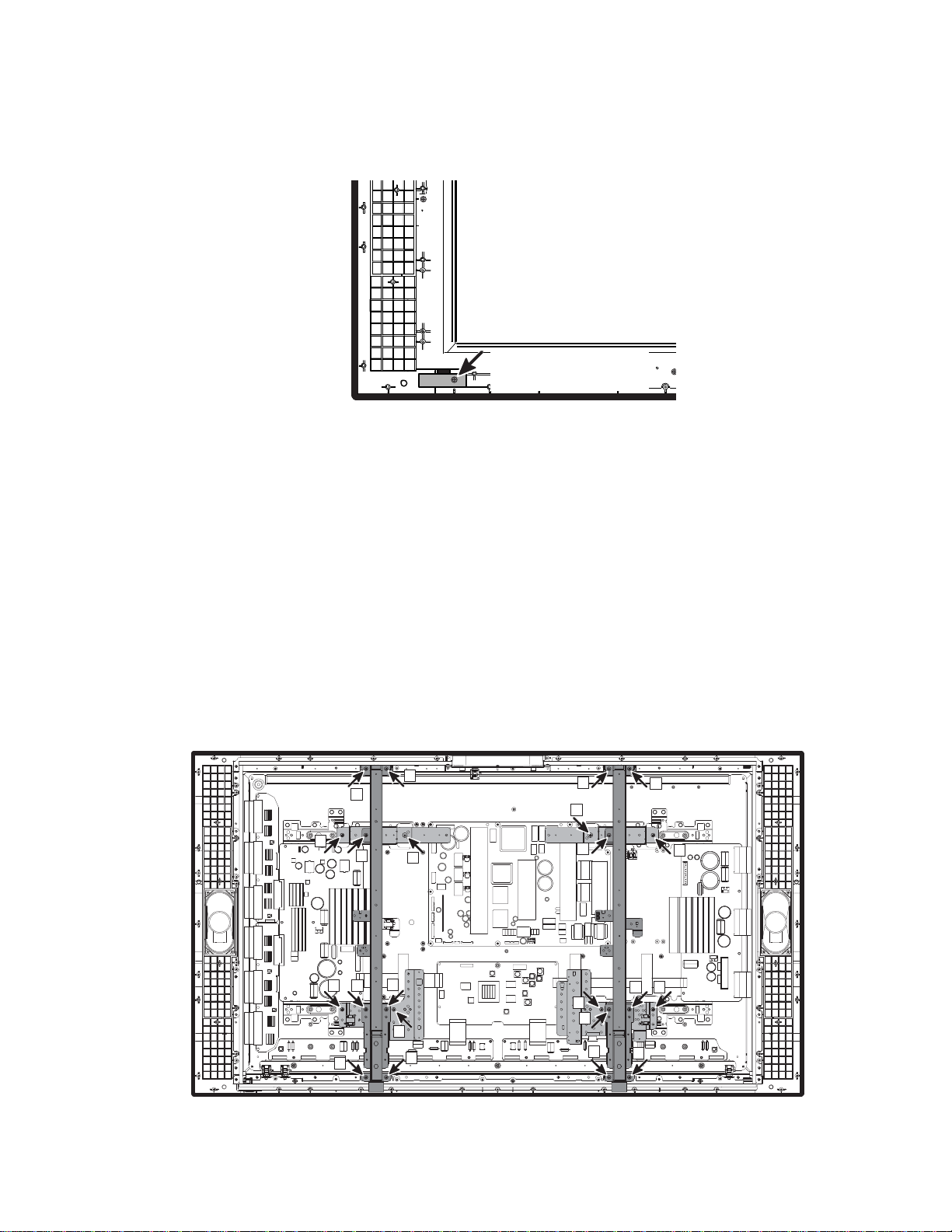

STAND REMOVAL

Position TV face down on a padded or cushioned surface to protect the screen and finish.

Remove 2 screws (6X18) from each foot and remove.

FILTER GLASS REMOVAL

1. Remove the key switch board.

2. Disconnect the following socket connections.

Control Board ~ Main Board: K8E

Speakers ~ Main Board: KSP

3. Remove 8 screws (4X8) to take the panel module, power unit,

and panel holders (Mounting Brackets) with boards off.

PLUG LOCATIONS

V

0

2

1

N

I

AC

ATV

C

/

F

H

V

F/

H

U

E

VIC

R

SE

L

A

N

I

A

IGIT

N

D

TEN

N

L

A

A

T

I

IG

IO

D

D

T

U

U

A

P

T

U

O

I

M

D

H

UT

P

IN

K8LV

K8B

K8A

K8MB

K8P

K8E

KSP

KAC

K8MA

Page 10

— 10 —

FRONT CABINET REMOVAL

1. Remove 18 screws (F:4X12) to take the filter glass with upper and

lower plates (assembly parts) off.

2. Remove the speakers.

3. Remove a screw (4X10) to take the control board and holder off.

4. Remove 20 screws (G:3X8) to take the filter glass and upper plates off.

MECHANICAL DISASSEMBLY (CONT.)

FILTER GLASS REMOVAL (Cont.)

F

F

F

F

F

F F F F

F

F

F

F

F

F

F

F

F

G

G

G

G

G G G G

G

G

G G

G

GGGG

G

G

G

Page 11

— 11 —

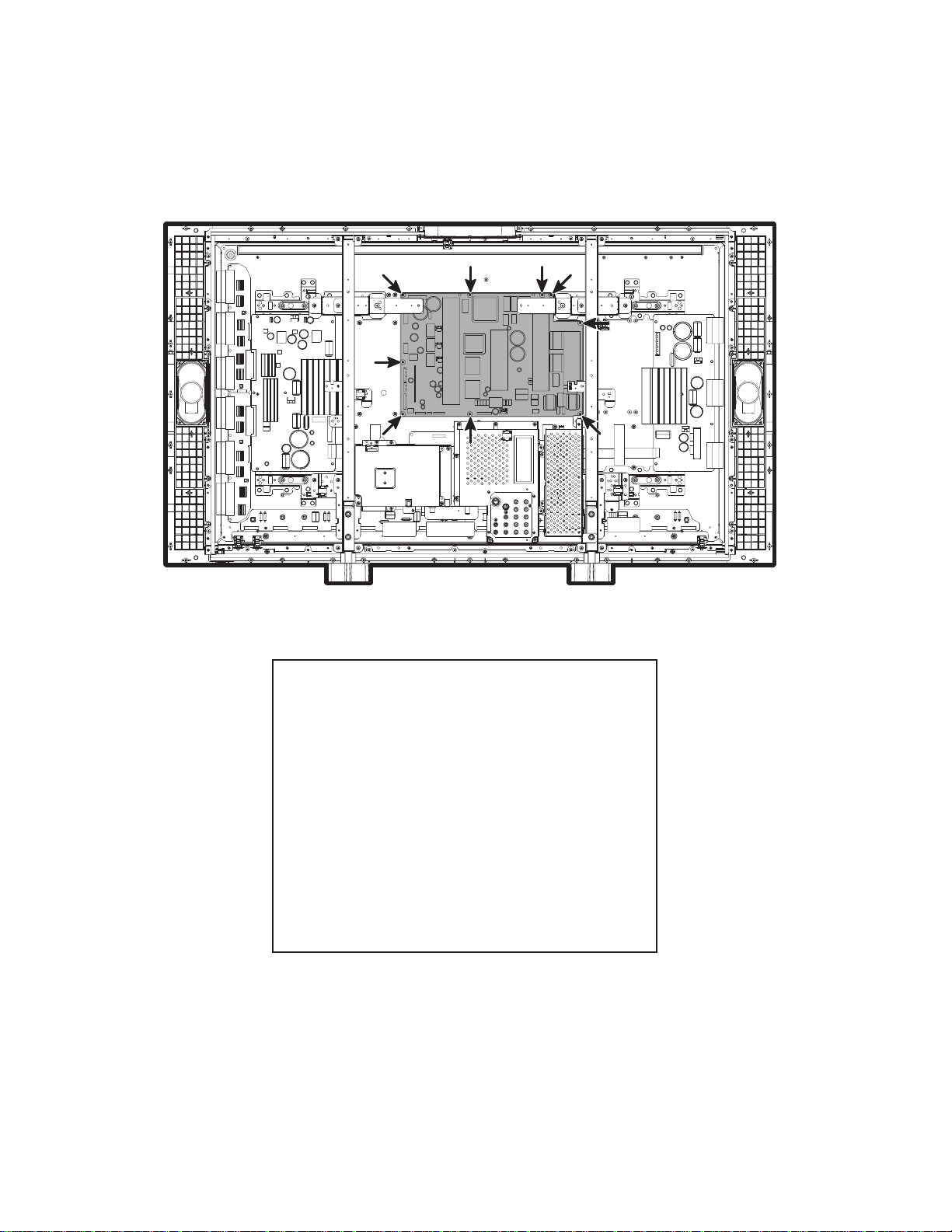

PANEL MODULE REMOVAL

1. Remove the key switch board.

2. Disconnect the following socket connections.

Main Board ~ Power Unit: CN8004, CN8007

D-TU Board ~ Power Unit: CN8010

Filter Board ~ Power Unit: CN8001

Control Board ~ Main Board: K8E

Speakers ~ Main Board: KSP

PDP Module ~ D TU Board K8LV

3. Remove the main board, D-TU board, and filter board.

4. Remove the 16 screws from the panel holders (Mounting

Brackets) to take the panel module off.

(H:4X8, 14pcs; I:5X10, 2pcs)

Control Board (Upper)

Holder (Lower)

H

H

H

H

H

H

H

I

H

H

H

H

I

H

H

H

H

H

H

HH

H

Page 12

— 12 —

POWER UNIT REMOVAL

Remove 9 screws to take the power unit off.

ATTENTION

This PDP TV uses several different kinds of

screws. Using the correct screw is required to

prevent damage.

The gasket is provided to prevent interference

to other radio and television receivers. The

gasket must be returned to its previous position

after servicing.

Lead wires must be redressed to previous posi-

tions after servicing.

MECHANICAL DISASSEMBLY (CONT.)

Page 13

— 13 —

CHASSIS ELECTRICAL PARTS LIST

CAUTION: To Protect against electrical shock and for continued product safety, refer to SAFETY PRECAUTIONS,

and PRODUCT SAFETY NOTICE on Page 2.

PRODUCT SAFETY NOTICE

PRODUCT SAFETY SHOULD BE CONSIDERED WHEN A REPLACEMENT IS MADE IN ANY AREA OF A RECEIVER.

COMPONENTS INDICATED BY A STAR () IN THIS PARTS LIST AND THE SCHEMATIC DIAGRAM DESIGNATE

COMPONENTS IN WHICH SAFETY CAN BE OF SPECIAL SIGNIFICANCE. IT IS PARTICULARLY RECOMMENDED

THAT ONLY PARTS DESIGNATED ON THE FOLLOWING PARTS LIST BE USED FOR COMPONENT REPLACEMENT

DESIGNATED BY A STAR. NO DEVIATIONS FROM RESISTANCE, WATTAGE, AND VOLTAGE RATINGS MAY BE MADE

FOR REPLACEMENT ITEMS DESIGNATED BY A STAR.

Note: Schematic part location numbers may not always match with the part descriptions.

The part descriptions are correct and should be used.

RESISTORS

CAPACITORS

NOTES:

Read description of the Capacitor as follows:

(Example)

CERAMIC 100P K 50V

Rated Voltage

Tolerance Symbols:

Less than 10pF

A : Not specified B : ±0.1pF C : ±0.25pF

D : ±0.5pF E : +0 -1pF F : ±1PF

G : ±2pF H : +0.1 -0pF L : +0 -0.1pF

R : ±0.25 -0pF S : +0-0.25pF

More than 10pF

A :Not specified B : ±0.1% C : ±0.25%

D : ±0.5% F : ±1% G : ±2%

H :±3% J :±5% K :±10%

L :±15% M :±20% N :±30%

P :+100-0% Q :+30-10% T :+50-10%

U :+75-10% V :+20-10% W :+100-10%

X :+40-20% Y :+150-10% Z : +80-20%

Rated value: P=pico farad, U=micro farad

Material:

CERAMIC........... Ceramic

MT-PAPER......... Metallized Paper

POLYESTER...... Polyester

MT-POLYEST.....Metallized Polyester

POLYPRO.......... Polypropylene

MT-POLYPRO.... Metallized Polypropylene

COMPO FILM..... Composite Film

MT-COMPO........ Metallized Composite

STYRENE........... Styrene

TA-SOLID........... Tantalum Solid

AL-SOLID........... Aluminium Solid

ELECT................ Electrolytic

NP-ELECT.......... Non-polarised Electrolytic

OS-SOLID.......... Aluminium Solid with Organic

Semiconductive Electrolytic

NOTES:

Read description of the Resistor as follows:

(Example)

CARBON 4.7K J A 1/4W

Rated Wattage

Performance Symbols:

A...General B...Non-flammable

Z...Low noise

Other... Temperature coefficient

Tolerance Symbols:

A...0.05% B...0.1% C...25%

D...0.5% F...1% G...2%

J...5% K...10% M...20%

P...+5 -15%

Rated Value, ohms:

K...1,000 M...1,000,000

Material:

CARBON .............

MT-FILM ..............

OXIDE-MT ...........

SOLID ..................

MT-GLAZE ...........

WIRE WOUND .....

CERAMIC RES ....

FUSIBLE RES .....

Carbon

Metal Film

Oxide Metal Film

Composition

Metal Glaze

Wire Wound

Ceramic

Fusible

Page 14

— 14 —

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

MAIN PC BOARD

CAPACITORS

C002 CE1C470M4ZANN ELECT 47U M 16V

C004 CK1H472KLZBNG CERAMIC 4700P K 50V

C005 CE1E4R7M4ZANN ELECT 4.7U M 25V

C007 CK1H472KLZBNG CERAMIC 4700P K 50V

C008 CE1E4R7M4ZANN ELECT 4.7U M 25V

C009 CE1E4R7M4ZANN ELECT 4.7U M 25V

C012 CE1C102M4ZANN ELECT 1000U M 16V

C013 CE1C102M4ZANN ELECT 1000U M 16V

C015 CEXLB1C101WAN ELECT 100U M 16V

C016 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C017 CH1H103JAGANN MT-COMPO 0.01U J 50V

C018 CH1H103JAGANN MT-COMPO 0.01U J 50V

C019 CH1H103JAGANN MT-COMPO 0.01U J 50V

C020 CH1H103JAGANN MT-COMPO 0.01U J 50V

C101 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C102 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C105 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C106 CEXLB1H470WAN ELECT 47U M 50V

C107 CEXLB0J102WAN ELECT 1000U M 6.3V

C805 CC1H220JLZCNG CERAMIC 22P J 50V

C806 CC1H220JLZCNG CERAMIC 22P J 50V

C807 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C810 RGF5602JTCANL MT-GLAZE 56K JA 1/10W

C811 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C813 CEXLB1A470WAN ELECT 47U M 10V

C814 CK1H222KLZBNG CERAMIC 2200P K 50V

C815 CC1H220JLZCNG CERAMIC 22P J 50V

C816 CC1H220JLZCNG CERAMIC 22P J 50V

C820 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C824 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C825 CC1H330JLZCNG CERAMIC 33P J 50V

C826 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C827 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C829 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C834 CEXLB1C220WAN ELECT 22U M 16V

C835 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C836 CC1H120JLZCNG CERAMIC 12P J 50V

C837 CC1H120JLZCNG CERAMIC 12P J 50V

C838 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C839 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C840 CK1H333KLZBNG CERAMIC 0.033U K 50V

C841 CEXLB1H2R2WAN ELECT 2.2U M 50V

C843 CC1H221JLZCNG CERAMIC 220P J 50V

C1001 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1002 CEXLB1C100WAN ELECT 10U M 16V

C1003 CEXLB1C100WAN ELECT 10U M 16V

C1004 CEXLB1H2R2WAN ELECT 2.2U M 50V

C1005 CEXLB1H2R2WAN ELECT 2.2U M 50V

C1021 CEXLB1C101WAN ELECT 100U M 16V

C1022 CEXLB1C100WAN ELECT 10U M 16V

C1023 CEXLB1C100WAN ELECT 10U M 16V

C1024 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1025 CEXLB1C100WAN ELECT 10U M 16V

C1026 CEXLB1H2R2WAN ELECT 2.2U M 50V

C1027 CEXLB1H2R2WAN ELECT 2.2U M 50V

C1061 CEXLB1C101WAN ELECT 100U M 16V

C1062 CEXLB1C100WAN ELECT 10U M 16V

C1063 CEXLB1C100WAN ELECT 10U M 16V

C1064 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1065 CEXLB1C100WAN ELECT 10U M 16V

C1066 CEXLB1H2R2WAN ELECT 2.2U M 50V

C1067 CEXLB1H2R2WAN ELECT 2.2U M 50V

C1101 CEXLB1E4R7WAN ELECT 4.7U M 25V

C1102 CEXLB1E4R7WAN ELECT 4.7U M 25V

C1201 CEXLB1C101WAN ELECT 100U M 16V

C1202 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1203 CEXLB1C100WAN ELECT 10U M 16V

C1251 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1601 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1602 CEXLB0J221WAN ELECT 220U M 6.3V

C1603 CEXLB1C221WAN ELECT 220U M 16V

C1604 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1605 CEXLB1C221WAN ELECT 220U M 16V

C1606 CEXLB1H470WAN ELECT 47U M 50V

C1607 CEXLB1C221WAN ELECT 220U M 16V

C1608 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1612 CEXLB0J221WAN ELECT 220U M 6.3V

C1613 CEXLB0J221WAN ELECT 220U M 6.3V

C1614 CEXLB0J221WAN ELECT 220U M 6.3V

C1616 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1617 CEXLB0J221WAN ELECT 220U M 6.3V

C1618 CEXLB0J221WAN ELECT 220U M 6.3V

C1619 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1620 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1621 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1623 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C1624 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1625 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1801 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1851 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1852 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1853 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1854 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C1855 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

C3401 CPXLB1H4R7ZAN NP-ELECT 4.7U M 50V

C3402 CEXLB1HR10WAN ELECT 0.1U M 50V

C3403 CPXLB1H4R7ZAN NP-ELECT 4.7U M 50V

C3404 CK1H562KLZBNG CERAMIC 5600P K 50V

C3405 CK1H123KLZBNG CERAMIC 0.012U K 50V

C3406 CEXLB1H1R0WAN ELECT 1U M 50V

C3407 CEXLB1HR47WAN ELECT 0.47U M 50V

C3408 CEXLB1C470WAN ELECT 47U M 16V

C3409 CEXLB1E4R7WAN ELECT 4.7U M 25V

C3410 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

C3411 CPXLB1H4R7ZAN NP-ELECT 4.7U M 50V

C3412 CEXLB1E4R7WAN ELECT 4.7U M 25V

C3413 CEXLB1C471WAN ELECT 470U M 16V

C3414 CPXLB1H4R7ZAN NP-ELECT 4.7U M 50V

C3415 CK1H272KLZBNG CERAMIC 2700P K 50V

C3416 CK1H473KLZBNG CERAMIC 0.047U K 50V

C3417 CT1A3R3KDRANG TA-SOLID 3.3U K 10V

C3418 CPXLB1H4R7ZAN NP-ELECT 4.7U M 50V

C3419 CT1A100KDRANG TA-SOLID 10U K 10V

Page 15

— 15 —

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

C3420 CEXLB1H1R0WAN ELECT 1U M 50V

C3421 CEXLB1H1R0WAN ELECT 1U M 50V

C3422 CEXLB1H1R0WAN ELECT 1U M 50V

C3423 CEXLB1H1R0WAN ELECT 1U M 50V

C3424 CEXLB1H1R0WAN ELECT 1U M 50V

C3425 CK1H223KLZBNG CERAMIC 0.022U K 50V

C3426 CK1H472KLZBNG CERAMIC 4700P K 50V

C3427 CPXLB1H4R7ZAN NP-ELECT 4.7U M 50V

C3428 CEXLB1HR10WAN ELECT 0.1U M 50V

C3429 CK1H472KLZBNG CERAMIC 4700P K 50V

C3430 CEXLB1C471WAN ELECT 470U M 16V

DIODES

D001 DDRB551V-30-G DIODE RB551V-30 TE-17

D801 DD1SS355----G DIODE 1SS355 TE-17

D802 DZUDZS6.2B--G ZENER DIODE UDZS6.2B TE-17

D803 DD1SS355----G DIODE 1SS355 TE-17

D1601 DD1SS355----G DIODE 1SS355 TE-17

D1602 DD1SS355----G DIODE 1SS355 TE-17

D1603 DD1SS355----G DIODE 1SS355 TE-17

D1604 DD1SS355----G DIODE 1SS355 TE-17

D1605 DD1SS355----G DIODE 1SS355 TE-17

D1606 DD1SS355----G DIODE 1SS355 TE-17

D1607 DZUDZS3.0B--G ZD UDZS3.0B-TE-17

D1801 DZUDZS10B---G ZENER DIODE UDZS10B TE-17

D3401 DDRB551V-30-G DIODE RB551V-30 TE-17

INTEGRATED CIRCUITS

IC001 QLA42072N-E-N IC LA42072N-E

IC801 QXXAAJQ0730-- IC LC87F4164AU-PDP001

QXXAVC779---M IC LC874164A-57XX-E

IC802 Q24LC08BT/SNP IC 24LC08BT/SN

IC803 QMN1381-Q---N IC MN1381-Q

IC805 QTC7SH08FU--P IC TC7SH08FU

IC806 QTC7SET08F--P IC TC7SET08F-TE85L

IC1201 QCD4052BNSR-P IC CD4052BNSR

QTC4052BF---P IC TC4052BF-EL

IC1251 QCD4052BNSR-P IC CD4052BNSR

QTC4052BF---P IC TC4052BF-EL

IC1601 QBA90BC0WFP-P IC BA90BC0WFP-E2

IC1604 QXXAVC550---G IC PQ018EZ02ZPH

IC3401 QCXA2234Q---P IC CXA2234Q-T6

COILS

L001 1AV4L26B2770G INDUCTOR, 220 OHM

L002 1AV4L26B2770G INDUCTOR, 220 OHM

L004 1AV4L26B2770G INDUCTOR, 220 OHM

L005 1AV4L26B2770G INDUCTOR, 220 OHM

L101 1AV4L2FB3R3MG INDUCTOR, 3.3U M

L102 1AV4L2FB3R3MG INDUCTOR, 3.3U M

L103 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

L106 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

L107 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

L801 1AV4L2FB3R3MG INDUCTOR, 3.3U M

L802 1AV4L26B2770G INDUCTOR, 220 OHM

L805 1AV4L26B0130G INDUCTOR, 600 OHM

L806 1AV4L26B0130G INDUCTOR, 600 OHM

L1021 1AV4L2FB3R3MG INDUCTOR, 3.3U M

L1201 1AV4L2FB3R3MG INDUCTOR, 3.3U M

L1601 1AV4L26B2770G INDUCTOR, 220 OHM

L1602 1AV4L26B2770G INDUCTOR, 220 OHM

L1605 1AV4L26B0130G INDUCTOR, 600 OHM

L1609 1AV4L26B2770G INDUCTOR, 220 OHM

L1610 1AV4L26B2770G INDUCTOR, 220 OHM

L1611 1AV4L26B2770G INDUCTOR, 220 OHM

L1612 1AV4L26B2770G INDUCTOR, 220 OHM

L1615 1AV4L26B2770G INDUCTOR, 220 OHM

L1616 1AV4L26B2770G INDUCTOR, 220 OHM

L1617 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1618 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1619 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1620 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1801 1AV4L26B0130G INDUCTOR, 600 OHM

L1803 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1804 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1805 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1806 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1807 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1808 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1809 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1810 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1815 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1885 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1891 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1893 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1894 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1895 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L1896 RGFR000ZTAANL MT-GLAZE 0.000 ZA 1/10W

L3401 1AV4L2FB3R3MG INDUCTOR, 3.3U M

TRANSISTORS

Q101 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q102 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q801 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

Page 16

— 16 —

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q803 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q804 T2SA1037AK-RP TR 2SA1037AK T146 R

T2SA1037AK-SP TR 2SA1037AK T146 S

T2SA1037K-R-P TR 2SA1037K-T-96-R

T2SA1037K-S-P TR 2SA1037K-T-96-S

T2SA1179-M6-P TR 2SA1179-M6

T2SA1179-M7-P TR 2SA1179-M7-TB

T2SA1179N-M6P TR 2SA1179N-M6-TB

T2SA1179N-M7P TR 2SA1179N-M7-TB

T2SA1235A1E-P TR 2SA1235A1E

T2SA1235A1F-P TR 2SA1235A1F

Q805 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q901 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q902 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q1021 T2SA1037AK-RP TR 2SA1037AK T146 R

T2SA1037AK-SP TR 2SA1037AK T146 S

T2SA1037K-R-P TR 2SA1037K-T-96-R

T2SA1037K-S-P TR 2SA1037K-T-96-S

T2SA1179-M6-P TR 2SA1179-M6

T2SA1179-M7-P TR 2SA1179-M7-TB

T2SA1179N-M6P TR 2SA1179N-M6-TB

T2SA1179N-M7P TR 2SA1179N-M7-TB

T2SA1235A1E-P TR 2SA1235A1E

T2SA1235A1F-P TR 2SA1235A1F

Q1022 T2SA1037AK-RP TR 2SA1037AK T146 R

T2SA1037AK-SP TR 2SA1037AK T146 S

T2SA1037K-R-P TR 2SA1037K-T-96-R

T2SA1037K-S-P TR 2SA1037K-T-96-S

T2SA1179-M6-P TR 2SA1179-M6

T2SA1179-M7-P TR 2SA1179-M7-TB

T2SA1179N-M6P TR 2SA1179N-M6-TB

T2SA1179N-M7P TR 2SA1179N-M7-TB

T2SA1235A1E-P TR 2SA1235A1E

T2SA1235A1F-P TR 2SA1235A1F

Q1023 T2SA1037AK-RP TR 2SA1037AK T146 R

T2SA1037AK-SP TR 2SA1037AK T146 S

T2SA1037K-R-P TR 2SA1037K-T-96-R

T2SA1037K-S-P TR 2SA1037K-T-96-S

T2SA1179-M6-P TR 2SA1179-M6

T2SA1179-M7-P TR 2SA1179-M7-TB

T2SA1179N-M6P TR 2SA1179N-M6-TB

T2SA1179N-M7P TR 2SA1179N-M7-TB

T2SA1235A1E-P TR 2SA1235A1E

T2SA1235A1F-P TR 2SA1235A1F

Q1061 T2SA1037AK-RP TR 2SA1037AK T146 R

T2SA1037AK-SP TR 2SA1037AK T146 S

T2SA1037K-R-P TR 2SA1037K-T-96-R

T2SA1037K-S-P TR 2SA1037K-T-96-S

T2SA1179-M6-P TR 2SA1179-M6

T2SA1179-M7-P TR 2SA1179-M7-TB

T2SA1179N-M6P TR 2SA1179N-M6-TB

T2SA1179N-M7P TR 2SA1179N-M7-TB

T2SA1235A1E-P TR 2SA1235A1E

T2SA1235A1F-P TR 2SA1235A1F

Q1062 T2SA1037AK-RP TR 2SA1037AK T146 R

T2SA1037AK-SP TR 2SA1037AK T146 S

T2SA1037K-R-P TR 2SA1037K-T-96-R

T2SA1037K-S-P TR 2SA1037K-T-96-S

T2SA1179-M6-P TR 2SA1179-M6

T2SA1179-M7-P TR 2SA1179-M7-TB

T2SA1179N-M6P TR 2SA1179N-M6-TB

T2SA1179N-M7P TR 2SA1179N-M7-TB

T2SA1235A1E-P TR 2SA1235A1E

T2SA1235A1F-P TR 2SA1235A1F

Q1063 T2SA1037AK-RP TR 2SA1037AK T146 R

T2SA1037AK-SP TR 2SA1037AK T146 S

T2SA1037K-R-P TR 2SA1037K-T-96-R

T2SA1037K-S-P TR 2SA1037K-T-96-S

T2SA1179-M6-P TR 2SA1179-M6

T2SA1179-M7-P TR 2SA1179-M7-TB

T2SA1179N-M6P TR 2SA1179N-M6-TB

T2SA1179N-M7P TR 2SA1179N-M7-TB

T2SA1235A1E-P TR 2SA1235A1E

T2SA1235A1F-P TR 2SA1235A1F

Q1101 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Page 17

— 17 —

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

Q1102 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q1201 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q1202 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q1203 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q1251 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q1252 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q1801 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q3404 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

Q3405 T2SC2412K-R-P TR 2SC2412K-T-96-R

T2SC2412K-S-P TR 2SC2412K-T-96-S

T2SC2812-L6-P TR 2SC2812-L6-TB

T2SC2812-L7-P TR 2SC2812-L7-TB

T2SC2812N-L6P TR 2SC2812N-L6-TB

T2SC2812N-L7P TR 2SC2812N-L7-TB

T2SC3928A1R-P TR 2SC3928A1R

T2SC3928A1S-P TR 2SC3928A1S

RESISTORS

R001 RG11R00JTEANL MT-GLAZE 1 JA 1W

R002 RG11R00JTEANL MT-GLAZE 1 JA 1W

R003 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R004 RGF6801JTCANL MT-GLAZE 6.8K JA 1/10W

R005 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R006 RGF6801JTCANL MT-GLAZE 6.8K JA 1/10W

R007 RG11R00JTEANL MT-GLAZE 1 JA 1W

R012 RGA2R20JTDANL MT-GLAZE 2.2 JA 1/2W

R013 RGA2R20JTDANL MT-GLAZE 2.2 JA 1/2W

R014 RGA2R20JTDANL MT-GLAZE 2.2 JA 1/2W

R015 RGA2R20JTDANL MT-GLAZE 2.2 JA 1/2W

R016 RGF5601JTCANL MT-GLAZE 5.6K JA 1/10W

R101 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R102 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R103 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R104 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R105 RGF56R0JTCANL MT-GLAZE 56 JA 1/10W

R109 RGF4700JTCANL MT-GLAZE 470 JA 1/10W

R110 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R111 RGF33R0JTCANL MT-GLAZE 33 JA 1/10W

R112 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R801 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R803 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R806 RGF2202JTCANL MT-GLAZE 22K JA 1/10W

R807 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R809 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R812 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R815 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R816 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R818 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R822 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R823 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R824 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R825 RGF2201JTCANL MT-GLAZE 2.2K JA 1/10W

R828 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R829 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R830 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R831 RGF4702JTCANL MT-GLAZE 47K JA 1/10W

R832 RGF4702JTCANL MT-GLAZE 47K JA 1/10W

Page 18

— 18 —

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

R833 RGF2701JTCANL MT-GLAZE 2.7K JA 1/10W

R834 RGF2701JTCANL MT-GLAZE 2.7K JA 1/10W

R838 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R839 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R840 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R841 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R842 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R843 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R844 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R846 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R847 RGF5601JTCANL MT-GLAZE 5.6K JA 1/10W

R848 RGF5601JTCANL MT-GLAZE 5.6K JA 1/10W

R849 RGF1003JTCANL MT-GLAZE 100K JA 1/10W

R850 RGF1003JTCANL MT-GLAZE 100K JA 1/10W

R851 RGF1003JTCANL MT-GLAZE 100K JA 1/10W

R853 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R854 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R855 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R856 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R858 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R859 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R860 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R861 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R863 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R864 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R865 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R866 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R867 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R868 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R870 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R873 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R874 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R875 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R876 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R883 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R884 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R885 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R887 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R888 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R889 RGF1004JTCANL MT-GLAZE 1M JA 1/10W

R893 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R894 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R895 RGF4703JTCANL MT-GLAZE 470K JA 1/10W

R896 RGF3901JTCANL MT-GLAZE 3.9K JA 1/10W

R897 CK1H103ZLZFNG CERAMIC 0.01U Z 50V

R899 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R900 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R901 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R902 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R903 RGF3302JTCANL MT-GLAZE 33K JA 1/10W

R904 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R905 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R906 RGF56R0JTCANL MT-GLAZE 56 JA 1/10W

R907 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R908 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R909 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1001 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1002 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1003 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1004 RGF4703JTCANL MT-GLAZE 470K JA 1/10W

R1005 RGF4703JTCANL MT-GLAZE 470K JA 1/10W

R1006 RGF2200JTCANL MT-GLAZE 220 JA 1/10W

R1007 RGF2200JTCANL MT-GLAZE 220 JA 1/10W

R1008 RGF2200JTCANL MT-GLAZE 220 JA 1/10W

R1009 RGF2200JTCANL MT-GLAZE 220 JA 1/10W

R1010 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1011 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1021 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1022 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1023 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1024 RGF4703JTCANL MT-GLAZE 470K JA 1/10W

R1025 RGF4703JTCANL MT-GLAZE 470K JA 1/10W

R1027 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1028 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1029 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1030 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1031 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1032 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1033 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1034 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1035 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1036 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1037 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1038 RGF5600JTCANL MT-GLAZE 560 JA 1/10W

R1039 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1040 RGF5600JTCANL MT-GLAZE 560 JA 1/10W

R1041 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1042 RGF5600JTCANL MT-GLAZE 560 JA 1/10W

R1043 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1061 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1062 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1063 RGF75R0JTCANL MT-GLAZE 75 JA 1/10W

R1064 RGF4703JTCANL MT-GLAZE 470K JA 1/10W

R1065 RGF4703JTCANL MT-GLAZE 470K JA 1/10W

R1067 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1068 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1069 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1070 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1071 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1072 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1073 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1074 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1075 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1076 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1077 RGF1202JTCANL MT-GLAZE 12K JA 1/10W

R1078 RGF5600JTCANL MT-GLAZE 560 JA 1/10W

R1079 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1080 RGF5600JTCANL MT-GLAZE 560 JA 1/10W

R1081 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1082 RGF5600JTCANL MT-GLAZE 560 JA 1/10W

R1083 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1101 RGF8200JTCANL MT-GLAZE 820 JA 1/10W

R1102 RGF8200JTCANL MT-GLAZE 820 JA 1/10W

R1103 RGF1003JTCANL MT-GLAZE 100K JA 1/10W

R1104 RGF1003JTCANL MT-GLAZE 100K JA 1/10W

R1105 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

Page 19

— 19 —

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

R1106 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R1201 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1202 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1203 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1204 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R1205 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1206 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1207 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R1208 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1209 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1210 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R1253 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R1254 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1255 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1256 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1257 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1260 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R1261 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1262 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1263 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1264 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1265 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1266 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1267 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1268 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1269 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1270 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1271 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1272 RGF2203JTCANL MT-GLAZE 220K JA 1/10W

R1605 RGF3302JTCANL MT-GLAZE 33K JA 1/10W

R1606 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1609 RG11R20JTEANL MT-GLAZE 1.2 JA 1W

R1610 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1626 RG12R20JTEANL MT-GLAZE 2.2 JA 1W

R1802 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1803 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1804 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1805 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1806 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1807 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1809 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1812 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1813 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1814 RGF8200JTCANL MT-GLAZE 820 JA 1/10W

R1815 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1816 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1817 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1819 RGE1000JTBANL MT-GLAZE 100 JA 1/8W

R3401 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R3402 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R3403 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R3404 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R3405 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R3406 RGF1004JTCANL MT-GLAZE 1M JA 1/10W

R3407 RGF1003JTCANL MT-GLAZE 100K JA 1/10W

R3416 RGF1501JTCANL MT-GLAZE 1.5K JA 1/10W

R3417 RGF1801JTCANL MT-GLAZE 1.8K JA 1/10W

R3418 RGF4701JTCANL MT-GLAZE 4.7K JA 1/10W

R3419 RGF6802FTCANL MT-GLAZE 68K FA 1/10W

R3420 RGF3301JTCANL MT-GLAZE 3.3K JA 1/10W

R3421 RGF3001JTCANL MT-GLAZE 3K JA 1/10W

R3422 RGF3901JTCANL MT-GLAZE 3.9K JA 1/10W

R3425 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R3426 RGF47R0JTCANL MT-GLAZE 47 JA 1/10W

R3427 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R3428 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R3431 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R3432 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R3439 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R3440 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

SURGE-ABSORBER

SC1001 1AV4Z30B0220G SURGE-ABSORBER

SC1002 1AV4Z30B0220G SURGE-ABSORBER

SC1003 1AV4Z30B0220G SURGE-ABSORBER

SC1004 1AV4Z30B0220G SURGE-ABSORBER

SC1005 1AV4Z30B0220G SURGE-ABSORBER

SC1006 1AV4Z30B0220G SURGE-ABSORBER

SC1021 1AV4Z30B0220G SURGE-ABSORBER

SC1022 1AV4Z30B0220G SURGE-ABSORBER

SC1023 1AV4Z30B0220G SURGE-ABSORBER

SC1024 1AV4Z30B0220G SURGE-ABSORBER

SC1025 1AV4Z30B0220G SURGE-ABSORBER

SC1061 1AV4Z30B0220G SURGE-ABSORBER

SC1062 1AV4Z30B0220G SURGE-ABSORBER

SC1063 1AV4Z30B0220G SURGE-ABSORBER

SC1064 1AV4Z30B0220G SURGE-ABSORBER

SC1065 1AV4Z30B0220G SURGE-ABSORBER

SC1101 1AV4Z30B0220G SURGE-ABSORBER

SC1102 1AV4Z30B0220G SURGE-ABSORBER

SC1801 1AV4Z30B0220G SURGE-ABSORBER

SC1802 1AV4Z30B0220G SURGE-ABSORBER

SC1803 1AV4Z30B0220G SURGE-ABSORBER

SC1804 1AV4Z30B0220G SURGE-ABSORBER

SC1805 1AV4Z30B0220G SURGE-ABSORBER

SC1806 1AV4Z30B0220G SURGE-ABSORBER

SC1807 1AV4Z30B0220G SURGE-ABSORBER

CRYSTAL / OSCILLATORS

X801 1AV4V10B0560N OSC, CRYSTAL 32.768KHZ

1AV4V10B0570N OSC, CRYSTAL 32.768KHZ

MISCELLANEOUS

A101 1AV4F1FAM0170 TUNER, TU/IF

A801 1AA0B10N2020A ASSY, PWB, MAIN J3TZ

K1001 1AV4J31B07700 TERMINAL, BOARD

K1021 1AV4J12B3960N JACK, RCA-5(6-1)

K1061 1AV4J12B3960N JACK, RCA-5(6-1)

K1101 1AV4J12B3970N JACK, RCA-2

1LB4J12B08100 JACK, RCA-2

Page 20

— 20 —

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

FILTER PC BOARD

CAPACITORS

C602 CGXAV27224CAN MT-POLYEST 0.22U M 275V

C606 CKXAV2E102AAC CERAMIC 1000P M 250V

C607 CKXAV2E102AAC CERAMIC 1000P M 250V

COILS

LF601 1AV4F35B1390N LINE FILTER

LF602 1AV4F35B1390N LINE FILTER

MISCELLANEOUS

SC601 1AV4Z30B0170N SURGE-ABSORBER

VA601 DVXAAEV0043-- VARISTOR ENC471D-14AS

VA602 DVXAAEV0047-- VARISTOR ENC271D-10AS

A600 1AA0B10N20300 ASSY, PWB, FILTER-J3TZ

F601 F32S10RA2LTTL FUSE 250V 10A

F601A 1AV4J20B0040N HOLDER, FUSE

F601B 1AV4J20B0040N HOLDER, FUSE

K601 1AV4U20B61300 UNIT, NOISE FILTER

CONTROL PC BOARD

CAPACITORS

C1902 CK1H102KLZBNG CERAMIC 1000P K 50V

C1903 CK0J106KGMBNG CERAMIC 10U K 6.3V

C1904 CK0J106KGMBNG CERAMIC 10U K 6.3V

DIODES

D1903 DLSLP-381C51N LED SLP-381C-51

D1903A 1AV2SA9SD01K- SPACER

RESISTORS

R1900 RGFR000ZTCANL MT-GLAZE 0.000 ZA 1/10W

R1916 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1917 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

SURGE-ABSORBERS

SC1901 1AV4Z30B0220G SURGE-ABSORBER

SC1902 1AV4Z30B0220G SURGE-ABSORBER

MISCELLANEOUS

A1901 1AA0B10N2020B ASSY, PWB, CONTROL J3TZ

A1902 1AV4U20B24401 UNIT, REMOCON RECEIVER

KEY SWITCH PC BOARD

CAPACITORS

C1951 CK1E104ZLZFNG CERAMIC 0.1U Z 25V

DIODES

D1957 DZUDZS10B---G ZENER DIODE UDZS10B TE-17

D1958 DZUDZS10B---G ZENER DIODE UDZS10B TE-17

COILS

L1955 1AV4L26B0130G INDUCTOR, 600 OHM

RESISTORS

R1953 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1954 RGF1000JTCANL MT-GLAZE 100 JA 1/10W

R1956 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R1957 RGF1001JTCANL MT-GLAZE 1K JA 1/10W

R1958 RGF1002JTCANL MT-GLAZE 10K JA 1/10W

R1959 RGF1801JTCANL MT-GLAZE 1.8K JA 1/10W

R1961 RGF2201JTCANL MT-GLAZE 2.2K JA 1/10W

R1962 RGF3901JTCANL MT-GLAZE 3.9K JA 1/10W

R1963 RGF5601JTCANL MT-GLAZE 5.6K JA 1/10W

SWITCHES

SW1951 1AV4S10B3530G SWITCH, PUSH 1P-1TX1

SW1952 1AV4S10B3530G SWITCH, PUSH 1P-1TX1

SW1953 1AV4S10B3530G SWITCH, PUSH 1P-1TX1

SW1954 1AV4S10B3530G SWITCH, PUSH 1P-1TX1

SW1955 1AV4S10B3530G SWITCH, PUSH 1P-1TX1

MISCELLANEOUS

A1951 1AA0B10N2020C ASSY, PWB, KEY_SW J3TZ

DIGITAL PC BOARD

A5500 1AA0B10N20400 ASSY, PWB, DIGITAL-J3TZ

Nonservicable part. No discreet parts provided for this pc board.

MISCELLANEOUS

EL901 1AV4T44B01700 PDP MODULE / POWER SUPPLY

U901 1AV4U20C02100 UNIT, PDP-LOGIC

SP901 1LB4A10B05700 SPEAKER 8

SP902 1LB4A10B05700 SPEAKER 8

Page 21

— 21 —

CABINET PARTS LIST

1 1AA2CAM0493-F CABINET FRONT

2 1AV4Z12B38600 EL902 OPTICAL FILTER

3 1AA2CBF0019-- CABINET BACK SIDE (2)

4 1AA0CBF0005-A ASSY, CABINET BACK CENTER

5 1AA2PAM0146A- PANEL

6 1AA2BUM0431-- UNITED BUTTON

7 1AA2DES0784-H DEC SHEET, AC

8 1AA2DES0874-- DEC SHEET, AV

9 1AA2DES0784-G DEC SHEET, TUNER

10 1AA2DES0789-G DEC SHEET DTV

11 1AA2SDA0008-F STAND (2)

12 1AA2DEM0371-- DEC RC LED

13 1AA2DES0861 DEC SHEET, DTV

14 1AV2BAAS015A- BADGE, SANYO

15 1AA2DES0712-F DEC SHEET, VIZON

1AA6P1P5111-- OWNERS MANUAL (ENG/SPA)

1JC6P1P0218-- OWNERS MANUAL (FRENCH)

1JC6P1P0230-- QUICK ’N EASY SETUP SHEET

1AV0U10B43101 ASSY, REMOCON

1AA2RCM0295-A RC-BATTERY LID

1AV4W11B17100 CORD, POWER-3.0MK

CABINET PARTS LIST

KEY NO. PARTS NO. DESCRIPTION

ACCESSORY PARTS LIST

KEY NO. PARTS NO. DESCRIPTION

3

4

5

15

6

7

8

1

2

9

10

11

P

OW

E

R

3

14

13

12

Page 22

— 22 —

COMPONENT AND TESTPOINT LOCATIONS

MAIN BOARD PARTS SIDE

B

K8A

C1603

C1605

IC1601 IC1604

C3413

L3401

D3401

C3430

X251

8

R257

R258

1

7

IC251

R252

R253

C253

C255

C254

R1041

R1043

PWB,MAIN-J3TZ

R1079

1AA4B10N1650A

TP-CVBS

L101

L102

R111

C106

C1618

C256

C3421

L1894

40

2

L1899

L1885

L103

L107

L1813

10

L1887

C1606

12

C1851

C1852C1853

C1607

K8MB

C1854

D1602

C1855

1

D1603

D1604

D1601

L1895

C257

L106

C258

C259

39

K8MA

1

L1814

14

L251

R261

R260

C260

L1891

C251

L1893

JP1851

R1039

R1081

R1083

L105

C107

C1617

C1602

C1616

R1610

C3412

R3420

R3421

C3416

C3420

C3423 C3424

R110

Q101

1

C1619

R108

C108

C1614

C3418

C3415

D1607

12

R3402

1

C1201

C1203

R1807

TPD3.3V

C3428

L1201

R1804

C1613

C833

R1806

C3402

16

R1270

R1809

1

D1605

R3401

1

R1271

C1251

L1801

C1801

C3401

R1272

L807

C3404

R3406

1

R1264

C1002

C

R871

R880

R884

C1612

R885

C829

L806

L801

IC805

C843

D1606

IC803

E

Q807

C837

R883

R878

C832

C3405

R3407

C3406

C831

C3403

Q806

Q3401Q3402

R3408 R3409

R3439

R3411

Q1203

R1209

R1208

R1210

R1207

R1211

C1202

9

IC1201

8

R1257

16

9

8

R1265

R1266

C1003

K_IIC

11

K8B

R904 R905

36

R3416

C3414

R897

25

C3422

R825

Q801

R3417

Q3404

R3430

R107

24

37

Q901

R903

R3418

C3411

IC3401

Q3405

R3434

R906

C3407

C3409

R1625

R3429

C3427

R3425

R3433

A101

Q902

C3408

13

48

R3426

L108

R1805

L104

L1886

R876

C836

X801

R877

R887

R888

C839

C840

R3410

R3440

R3413

R3412

R1254

IC1251

C1004

R875

C838

R2808

R2809

R2810

C2812

C2814

R2812

R2813

K8F

R1817

1

4

R1816

R901

C827

R867

R868

L805

IC806

D803

R889

C824

C823

C822

C821

C819

C818

C817

C841

R847

C1005

C830

R890

R899

R806

C834

IC801

48

49

R886

64

1

R807

R823

R818

R820

C813

L802

R834

D802

Q804

D801

Q803

R831

R003

R840

R005

R839

R895

R838

R837

R851

R908

R909

C2813

L2801

R850

R849

C816

C815

R2803

R2805

R2806

R2807

C1023

C1022

R836

R835

R848

C2811

K1001

DE

K8E

1

R1812

R870

R872

R862

R863

R894

33

16

R812

R824

8

1

C003

C004

R004

C006

C007

R006

D001

KFAN1

KFAN2

TH1801

5

C820

R846

R1815

R864

R865

32

17

R816

R815

5

IC802

4

R801

R814

R811

C2808

R844

R843

R842

C1810

Q805

K_DL

R861

R866

D898

R826

Q802

C861

C862

K_DEBUG

C002

C005

C008

C009

IC001

HD

IC2801

C1025

TPHS

TPVS

C1021

15

C1026

C015

1

K1021

C1027

L004

C012

L005

C2810

C2809

C2807

L1021

R2802

C2805

C2804

C2803

C2802

C2801

C1062

L2802

16

30

VD

R830

R852

R854

R855

R856

R891

C013

X2801

C1063

R892

C2806

R012

C851

D899

C1065

K1061

KSP

C017

C1061

R015

C1066

1

L1889

6

R013

R014

C018

C019

C020

5

IC001A

4

L1888

3

C1067

K1101

C1101

C1102

L1897

C

2

1

L1898

DE

Page 23

— 23 —

MAIN BOARD FOIL SIDE

L1612

C3418

C3422

C105

C102

R1609

C3412

C3424

C1621

11

L1601

R3424

B

C1602

C3420

C3423

R104

R109

C3413

R3423

R106

C3421

L1606

C1601

C1618

R3422

L1602

C1617

JP251

R101

C1603

R259

K8A

Q252

C1620

C1604

C106

L1607

10

L1618

L1605

L1617

C1624

C1605

C1607

R1605

R1606

C3430

X251

R256

R251

Q251

C252

C260

R254

R255

C107

R112

C1606

L1808

C1623

C1608

L1896

L1805

C251

L1815

L1892

Q102

L1810

L1811

L1812

1

C810

R1256

C1004

SC1802

R873

C804

R1205

C

1

L1619

L1620

L1609

L1610

L1616

C1612

C1625

C1613

R874

R882

IC803

C3408

C833

C803

C3403

C3406

C3402

C3401

C3407

C3409

R3405

R3404

C3428

PWB,MAIN-J3TZ

1AA4B10N1650A

R1202

R1206

R1268

SC1804

R1103

R1104

Q1202

R1267

R1269

SC1801

K1101

R1261

C1003

SC1805

SC1102

R1262

SC1101

R1102

SC1807

SC1806

C1002

Q1252

R1263

L1803

R1201

Q1201

R1204

R1203

R1260

R1253

K_IIC

D1801

C1101

C1102

R1258

R1252

C1201

C1203

R1259

R1251

R102

R103

L1611

R1819

C3427

R3403

C103

K8B

L1615

R3419

C3429

C104

L1614

C3411

C3410

C3426

R3431

L1613

R853

R803

C1614

R896

R1626

C3414

C3417

+

C3425

+

C3419

R3427

R3432

R3428

R105

C101

R1810

C842

K_DL

C1810

K_DEBUG

C005

C009

R007

DE

L1802

Q1801

R1813

R1814

R857

R859

R860

R858

C2808

R902

C826

C825

R869

R822

R1811

R907

R819

R817

R841

R813

R809

R829

C015

R002

R808

R810

R802

C811

R828

C813

R001

L001

R900

R016

L1809

R800

C828

R893

C834

E

C835

X801

C805

C806

C807

C809

R821

C812

C808

R805

C841

R833

C814

R832

L002

KSP

1

L1806

6

C020

C017

C018

C019

5

IC001A

KFAN2

C853

C851

R898

C016

KFAN1

C852

R827

C002

1

C008

IC001

C011

C012

13

4

R2816

R2817

X2801

C2806

C1065

R1082

R1074

Q1063

R1075

C1063

R1080

Q1062

R1073

R1072

R1078

Q1061

C1062

R1076

R1077

L1807

C1061

C1064

3

C1067

C1066

K1061

R1084

R1066

R1067

R1061

R1068

R1085

R1062

R1069

R1070

R1071

R1063

R1064

R1065

R1086

SC1063

SC1064

SC1065

2

L1804

1

SC1061

SC1062

R1027

R1028

R1021

R1029

R1030

R1031

R1022

R1023

R1024

R1025

C1024

C1027

K1021

SC1024

C1021

R1045

R1044

R1046

SC1023

SC1025

R2801

R1036

R1026

SC1022

R2819

R1037

C1026

SC1021

Q2801

R2818

Q1023

R1042

R1007

D1002

Q2802

R2814

C1025

R1010

R1002

SC1002

R1004

R2815

C2815

R2811

Q1022

C1023

SC1005

R2804

K1001

SC1003

R1009

R1005

R1011

Q1021

C1022

R1003

SC1006

R1008

C2811

C2813

R1034

SC1004

R1035

C1005

C1001

R1107

R1040

R1803

R1001

D1003

R1255

R1033

R1802

R1006

SC1001

R1101

Q1101

R1106

Q1251

R1032

SC1803

R1038

R1105

Q1102

DE

C

Page 24

— 24 —

COMPONENT AND TESTPOINT LOCATIONS (Cont.)

CONTROL BOARD PARTS SIDE

CONTROL BOARD FOIL SIDE

KEY BOARD FOIL SIDE

KEY BOARD PARTS SIDE

FILTER BOARD PARTS SIDE

FILTER BOARD FOIL SIDE

JP1910

C1904

C1903

A1902

SCA191

1

5

K19E

R1916

C1902

SC1902

R1917

SC1955

SW1951

SC1954

SW1952

JP1951

R1963

B10N1650C

COOL

SCB063

HOT

T10AH

250V

F601A

K601H2

K601H1

F601

SCB064

F601B

K601

K601H4K601H3

K601

B10N1650B

D1903

R1900

SC1901

SW1955

PWB,CONTROL J3TZ

C613

VA601

R601

C614

R1953

C601

LF601H2

VA602

SC601

A1902

SC1953

SW1954

SC1952

SC1956

C1951

D1958

L1955

SW1953

B10N1650C

R1954

1PIN

R1959

R1958

R1957

R1956

C606

C602

R1961

R1962

R1951

R1952

SCB062

LF601H1

LF601H4

LF601H3

LF601

C607

SCB065

PWB,FILTER-J3TZ

D1956

LF602

D1957

1

LF602H4

LF602H2

SCB191

4

B10N1650B

C1952

LF602H3

LF602H1

1PIN

B10N1660A

K19F

COOL

HOT

D1903

C608

C609

C603

A30C5

KACH2

KACH1

SCB061

KAC

KAC

SCB066

K601

K601H1

K601H4

XX

C614

F601B

R601

X

F601A

VA601

C613

PWB,FILTER-J3TZ

B10N1660A

C601

SCB065

X

SC601

X

VA602

LF601H4

LF601H3

C607

C602

LF601

LF601H1

LF601H2

SCB062

C606

X

COOL

HOT

LF602H1

LF602H3

X

C609

LF602H2

C603

LF602

LF602H4

C608

X

K601H3

SCB064SCB066

K601H2

SCB063

A30C5

KAC

KACH1

KACH2

COOL

HOT

SCB061

Page 25

— 25 —

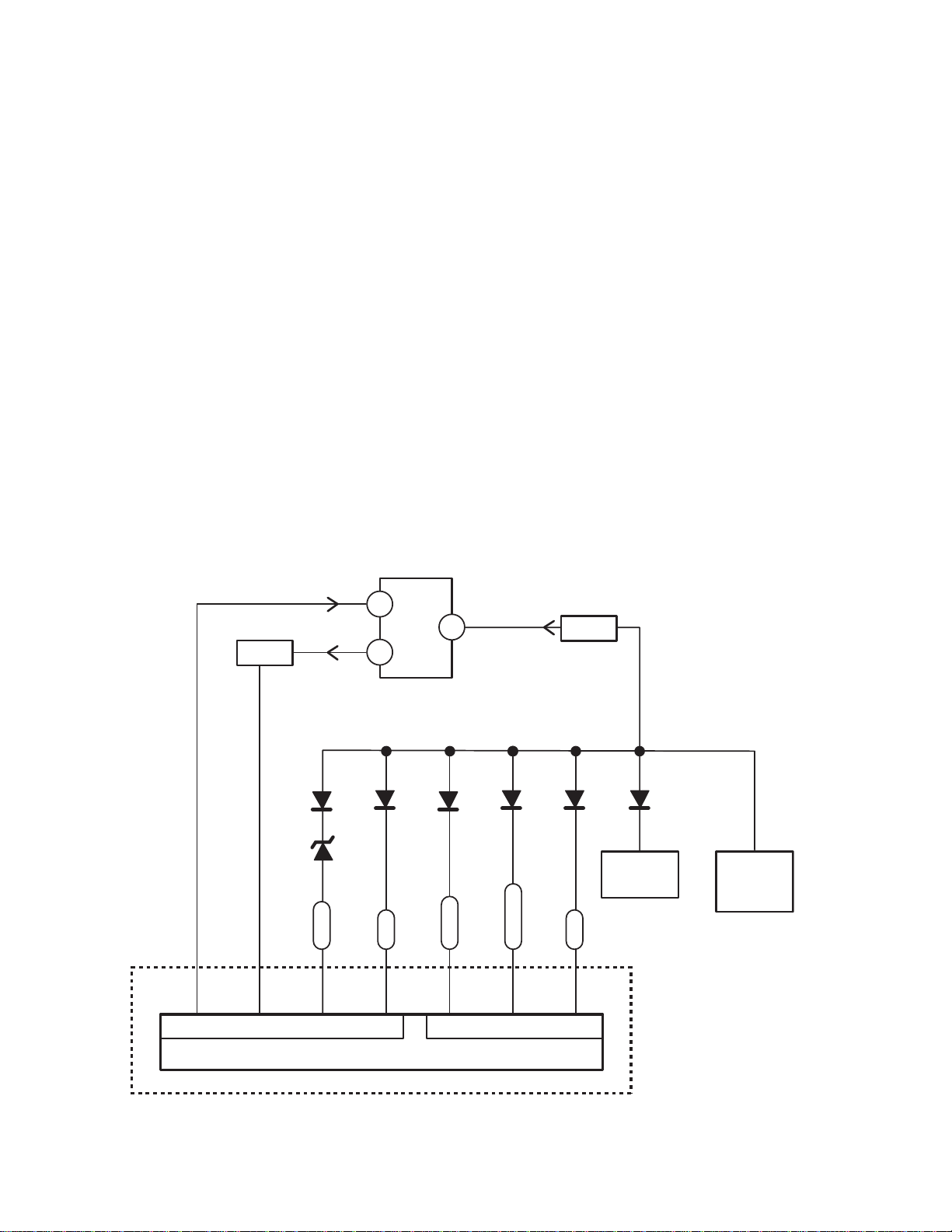

BLOCK DIAGRAM POWER LINES

A1902

RC Pre-AMP

3

5V_ST

Key SW Board

3

3

Normal -> "H"

Failure -> "L"

Power Failure

32

14

On -> "H"

K19F

K8F

P-Fail

Q803/804

CPU

IC801

2

Q901/902

Power_On

5V_ST

Control Board

5

5

2

IC803

RESET

8

IC802

EEPROM

44,62

41

Normal -> "L"

K19E

K8E

IC8063IC805

3

P-Fail

D1606D1607

D1605

P-Fail

Digital Board

10

D5V

D1.8V

3

IC1604

1

4

D3.3V

P-Fail

7,8

D1.8V

D1603

IC001

7

IC1251

IC1201

19

Audio AMP

IC3401

K6MA

12

A9V

16

Audio SW

P-Fail

16

Video SW

D3401

A9V

4

Audio Control

IC1601

2

2

TU33V

D1602

A101

12

P-Fail

D1601

Tuner

(Analog)

14

P-Fail

D1604

AC

Filter Board

K601

KAC

Main Board

CN8001

Line_Off

Q801

8

Power Unit

D5V

5V_ST

Thermal Detection

11710

1

K8B

CN8007

D3.3V

3,4

12V_AMP

5,6

A12V

3

A5V

1

K8A

CN8004

TU33V

9

Page 26

— 26 —

BLOCK DIAGRAM SIGNAL LINES

UART

IIC Bus

Output

HDMI Optical

Tuner

(ATSC)

CPU

IC801

33

Q1201

SW_Y/CV

3

PDP PANEL

R/G/B

(LVDS)

Digital Module

35

23

AV2 _Y

AV2 _Cb

21

25

AV2 _Cr

UART

AV3 _Y

29

AV3 _Cb

27

AV3 _Cr

31

39

DM_L

37

DM_R

SPEAKER

R-OUT

33

34

DM_R

DM_L

(Right)

SPEAKER

L-OUT

8(+)9(–)

IC001

Audio AMP

4

2

L

R

3

4

Audio

IC3401

36

SEL_R

3

(Left)

12(+)11(–)

Control

37

SEL_L

13

AUDIO

OUT

Q3404

Q3405

AUDIO OUT_L

AUDIO OUT_R

39

38

13

IIC Bus

AV1

IC1201

Video SW

1

AV1 _CV

2

5

AV1 _Y

S Video

Composite Video

Q101

TV_CV

Audio

IC1251

R: 2

Audio SW

L: 15

R: 4

L: 11

Q1021

Q1022

AV1 _C

Q1023

Q1061

Q1062

Q1063

L: 14

R: 5

Q102

AV2

Audio

Component Video

AV3

Audio

Component Video

17

Tuner

TV (A101)

AV1_L/R

6

IIC Bus

IF

AV2_L/R

AV3_L/R

TV_L/R(COMP)

Page 27

— 27 —

IC BLOCK DIAGRAMS

Audio Processor (IC3401)

AUX2-L

37

FEXT2

AUX1-R

33

AUX1-L

MAININ

34

8

TVSW

FEXT1

MATRIX

TRE-L

BASS-R

BASS-L

SURRTC

AUX2-R

36

TVOUT-R

TVOUT-L

38

39

EXT1/EXT2/M1

M2

40

SURROUND

SURR

2

45

47

BASS

BASS

BASS

VCA

VE

TRE-R

41

TREB

TREB

TREBLE

RMSDET

TOUT-R

44

VOLIN-R

48

RMSDET

SPECTRAL

VOL-L

VOL-R

VOL-R

VOL-L

3

4

48

1

31

32

30

29

28

27

26

LSOUT-R

LSOUT-L

VOLIN-L

TOUT-L

VCATC

VCAWQT

VCAIN

VEOUT

VETC

VEWQT

VE

MAINOUT

9

SUBOUT

21

PLINT

12

PCINT2

11

PCINT1

10

1/4 1/2

LFLT VCO

HPF

NRSW/FOMO/SAPC

WIDEBAND

LPF VCAFLT

DeEm

"STEREO"

LPFVCA LPF

(+6dB)

STIND

ATT/ATTSW

LOGIC

LPF

SAPVCOBPF

DeEm

"NOISE"

DET

NOISE

"SAP"

SAPIND

LPF LPF

AMP

(+6dB)

I2C BUS I/F

IREF

SW

"PONRES"

22

25

24

5

6

7

15

14

STIN

SAPIN

SAPOUT

SDA

SCL

DGND

IREF

VGR

10

COMPIN

19

Vcc

17

GND

23

NOISETC

18

SAPTC

Page 28

— 28 —

IC BLOCK DIAGRAMS (Cont.)

Audio AMP (IC001)

IC1201, IC1251 Video and Audio Select

Standby Vcc

5 7

Standby SW

CH 1

Input

PRE-GND

(For input)

CH 2

Input

2

RNf1

3

RNf2

4

CH 1

AMP

(in)

CH 2

AMP

(in)

Protect popped noise

Rf1

REF

AMP

(Thermal protection curcuit)

Rf2

Ripple Filter Block

6 1

CH 1

AMP

(out)

TSD Protector

CH 2

AMP

(out)

FilterP. P.

12

10

8

CH 1

Output

POWER

GND

(For output)

CH 2

Output

VDD

16

A

10

B

9

INH

Control & Input

6

8

VSS

CONVERTER

LOGIC LEVEL

X-COMMOM

13

I/O c O/I

I/O c O/I

I/O c O/I

I/O c O/I

I/O c O/I

I/O c O/I

I/O c O/I

I/O c O/I

7

V

EE

0X

12

1X

14

2X

15

3X

11

0Y

1

1Y

5

2Y

2

3Y

4

Y-COMMOM

3

Page 29

— 29 —

TROUBLESHOOTING FLOW CHARTS

NO POWER

Is

fuse (F601)

Yes

open?

No

Is

the voltage

No

to "5V_ST" line

supplied?

Yes

No:

Is

(except '5V_ST' line)

the voltage to all lines

supplied?

Yes

(or the voltage to some lines is not supplied.)

After a few seconds, the set will be switched off.

Check 'Power Failure' Circuit.

Check:

Varistor (VA611),Power Unit

Check: Power Unit

All 0V

Check: around

CPU (IC801), IC (IC802,IC1803),

Crystal (X801), Transistor (Q801),

Power Unit

Power Failure Line

CPU (IC801) 32pin

Q803-Q804

Diode

D1605

Detected Voltage

D5V

D1606/D1607 D3.3V

D1603 12V_AMP

D1602 A9V

D1601 A5V

D1604 TU33V

Page 30

— 30 —

NO AUDIO

All Modes ?

Ye s

No

Is there

signal at speaker

terminal ?

No

Is there

signal at IC001 2pin (L)

or 4pin (R) ?

No

Ye s

Audio Out only

RF(TV) only

Digital Module only

Check:

Speaker (SP901, SP902)

Ye s

Check:

Line: IC001 6pin - IC801 (CPU) 38pin (Mute)