Page 1

Global LCD Panel Exchange Center

www.panelook.com

Approval

T O

DATE

SAMSUNG TFT-LCD

SAMSUNG TFT-LCD

MODEL NO.:LTN150PG-L02

MODEL NO.:LTN150PG-L02

: Dell /Compal

: Set. 19. 2003

Any Modification of Spec is not allowed without SEC’ permission

APPROVED BY :

PREPARED BY : Technical Customer Service Team

SAMSUNG ELECTRONICS CO., LTD.SAMSUNG ELECTRONICS CO., LTD.

Doc.No. Rev.No Page / 32LTN150PG-L02 104-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

CONTENTS

www.panelook.com

Approval

Revision History

General Description

1. Absolute Maximum Ratings

1.1 Absolute Ratings of environment

1.2 Electrical Absolute Ratings

2. Optical Characteristics

3. Electrical Characteristics

3.1 TFT LCD Module

3.2 Backlight Unit

4. Block Diagram

4.1 TFT LCD Module

4.2 Backlight Unit

5. Input Terminal Pin Assignment

5.1 Input Signal & Power

5.2 LVDS Interface

5.3 Backlight Unit

5.4 Timing Diagrams of LVDS For Transmitting

5.5 Input Signals, Basic Display Colors and Gray Scale of Each Color.

5.6 Pixel format

-------------------( 3 )

-------------------( 4 )

-------------------( 5 )

-------------------( 7 )

-------------------( 10 )

-------------------( 14 )

-------------------( 16 )

6. Interface Timing

6.1 Timing Parameters(DE Mode)

6.2 Timing Diagrams of interface Signal (DE Mode)

6.3 Power ON/OFF Sequence

7. Outline Dimension

8. Packing

9.Markings and Others

10. GENERAL PRECAUTIONS

Appendix 1.EDID

Appendix 2.Inverter spec.

Doc.No. Rev.No Page / 32LTN150PG-L02 204-A00-S-030919

-------------------( 22 )

-------------------( 24 )

-------------------( 25 )

-------------------( 26 )

-------------------( 28 )

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

Date

Apr. 16, 2003 P00 All

Set. 01, 2003 A00 All

Rev.No. Summary

Page

16

24

Appendix To update EDID

REVISION HISTORY

REVISION HISTORY

LTN150PG-L02 model rev.P00 specification was First issued.

To correct typos

To correct the input connector (JAE, FI-XB30SRL-HF11)

To change the length of lamp wire tape (52mm60mm)

Approval

Doc.No. Rev.No Page / 32LTN150PG-L02 304-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

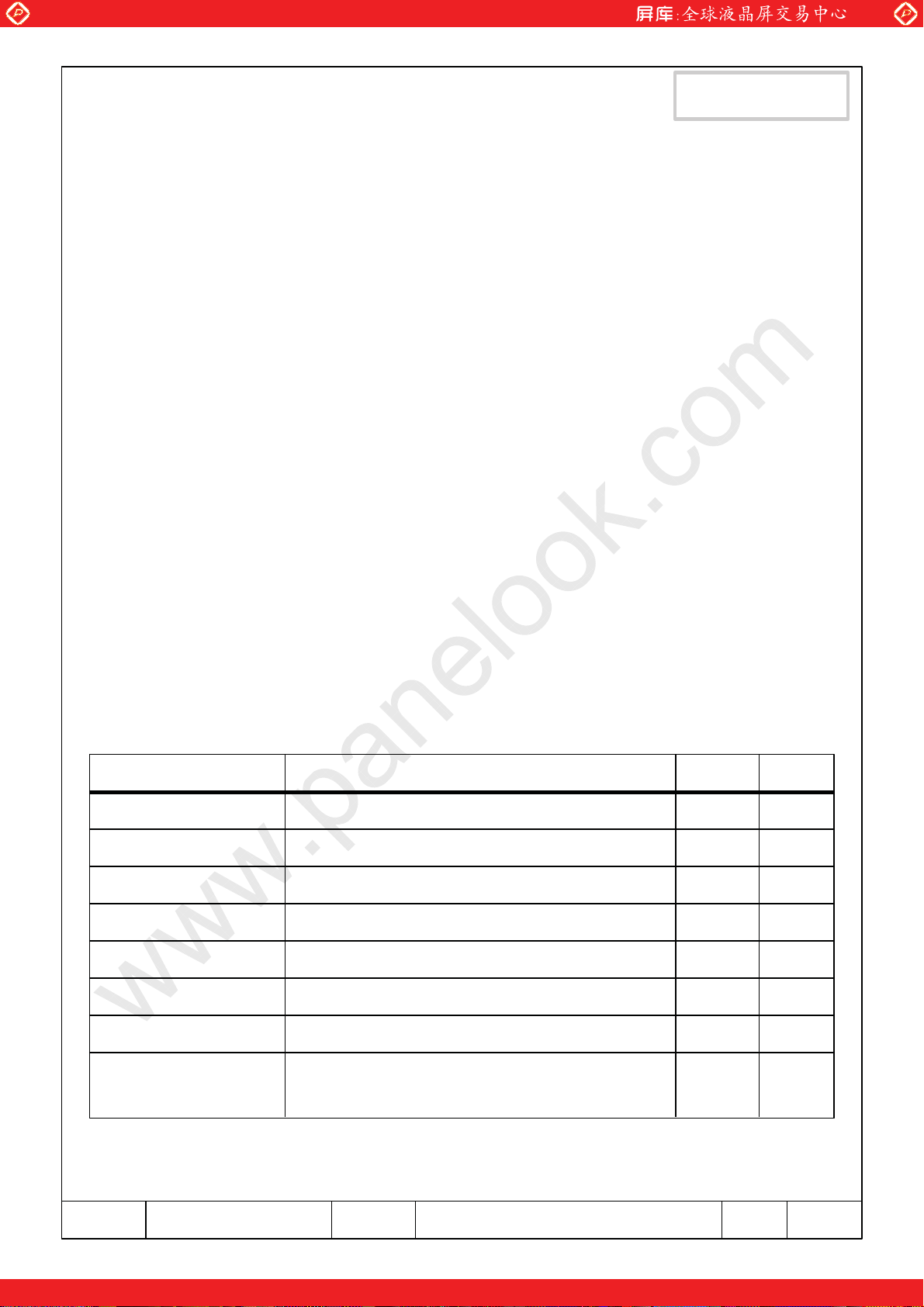

GENERAL DESCRIPTION

DESCRIPTION

LTN150PG-L01 is a color active matrix TFT (Thin Film Transistor) liquid crystal display

(LCD) that uses amorphous silicon TFT as a switching devices. This model is composed of

a TFT LCD panel, a driver circuit and a backlight system. The resolution of a 15.0" contains

1400 x 1050 pixels and can display up to 262,144 colors. 6 O'clock direction is the Optimum

viewing angle.

FEATURES

• Thin and light weight

• High contrast ratio

• SXGA-Plus (1400x1050 pixels) resolution

• Low power consumption

• DE (Data enable) only mode.

• LVDS Interface with 2 pixel / clock (2 channel)

www.panelook.com

Approval

APPLICATIONS

• Notebook PC and desktop monitors

• Display terminals for AV application products

• Monitors for Industrial machine

• If the usage of this product is not for PC application, but for others, please contact SEC

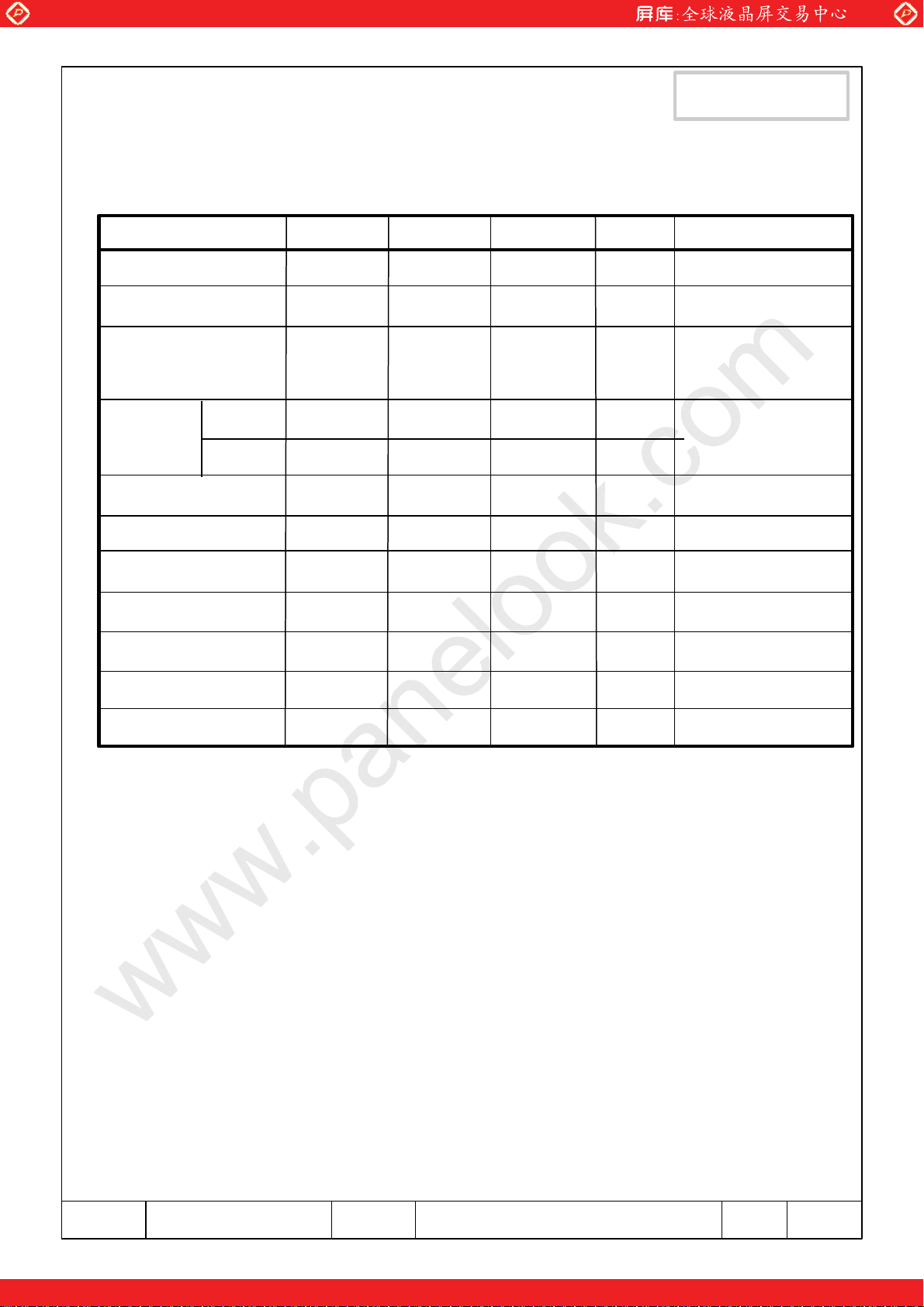

GENERAL INFORMATION

ITEM SPECIFICATION

Display area 304.1(H)X228.1(V) (15.0” diagonal)

Driver element a-si TFT active matrix

Display colors 262,144

Number of pixel 1400 x 1050 (SXGA-Plus)

Pixel arrangement RGB vertical stripe

UNIT

mm

pixel

NOTE

Pixel pitch 0.2175(H) x 0.2175(V)

Normally whiteDisplay Mode

Surface treatment

Doc.No. Rev.No Page / 32LTN150PG-L02 404-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

HAZE 25, HARD-COATING 3H

mm

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

Mechanical Information

ITEM TYP. MAX. NOTE

Horizontal (H)

Module

Size

Note (1) Depth of signal interface connector part.

Vertical (V)

Depth (D) -

Weight

MIN.

316.8

241.6

1. ABSOLUTE MAXIMUM RATINGS

1.1 ENVIRONMENTAL ABSOLUTE RATINGS

ITEM UNIT

Storage temperate

SYMBOL MIN. MAX.

T

STG

317.3

242.1 242.6

- 6.0

550g

-25 60

317.8

565g

O

Approval

Without Inverter

NOTE

C

(1)

Operating temperate

(Temperature of glass surface)

Shock ( non-operating )

Vibration (non-operating)

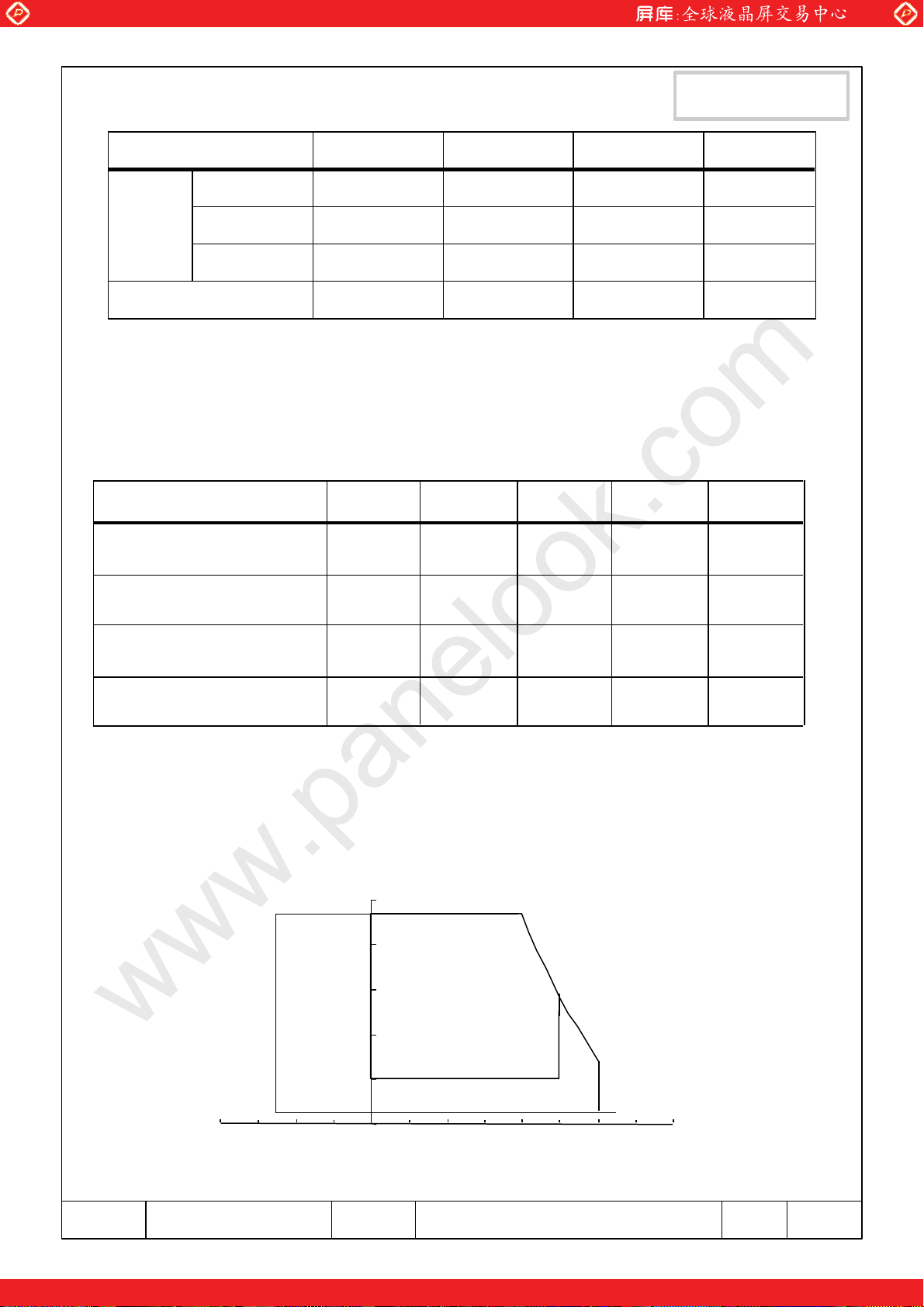

Note (1) Temperature and relative humidity range are shown in the figure below.

95 % RH Max. ( 40

Maximum wet - bulb temperature at 39

(2) 2ms, half sine wave, one time for ᇹX,ᇹY,ᇹZ.

(3) 10 300 10 Hz, Sweep rate 10 min, 30 min for X,Y,Z.

(4) At testing Vibration and Shock, the fixture in holding the Module to be tested have to be

hard and rigid enough so that the Module would not be twisted or bent by the fixture.

O

C ᆚTa)

100

95

80

60

40

T

OPR

Snop

Vnop

0

-

-

O

C or less. (Ta > 40 OC) No condensation.

Relative Humidity ( %RH)

Operating Range

50

220 G

1. 5

O

C

G

(1)

(2), (4)

(3), (4)

20

Storage Range

5

0

-40-20 0 2040 6080

Temperature (

O

C)

Doc.No. Rev.No Page / 32LTN150PG-L02 504-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

1.2 ELECTRICAL ABSOLUTE RATINGS

(1) TFT LCD MODULE

ITEM SYMBOL MIN. MAX. UNIT NOTE

Power Supply Voltage

Logic Input Voltage V

NOTE (1) Within Ta ( 25 ᇹ2

Vcc

O

C )

Vss-0.3 4.0

IN

Vss-0.3

(2) BACK-LIGHT UNIT

ITEM SYMBOL

Lamp current I

Lamp frequency

L

L

F

MIN. UNIT. NOTE

3.0

50

MAX.

7.0

80 KHz

mA

Approval

( Vss = GND = 0 V)

V

VVcc + 0.3

rms

( 1 )

( 1 )

Ta = 25 ᇹ2 OC

(1)

(1)

NOTE (1) Permanent damage to the device may occur if maximum values are exceeded.

Functional operation should be restricted to the conditions described under Normal Operating

Conditions.

Doc.No. Rev.No Page / 32LTN150PG-L02 604-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

2. OPTICAL CHARACTERISTICS

The following items are measured under stable conditions. The optical characteristics

should be measured in a dark room or equivalent state with the methods shown in Note

(5).

Measuring equipment : TOPCON BM-5A

www.panelook.com

Approval

ITEM SYMBOL CONDITION MIN. TYP. MAX. UNIT

Contrast Ratio

(5 Points)

Response

Time at 25

ఁ

Luminance

of White

Color

Chromaticity

( CIE )

Rising T

Falling

Red

Green

Blue

CR

T

YL

R

R

GX

GY

BX

BY

* Ta = 25 ± 2°C, V

DD=3.3V, fv= 60Hz, fDCLK=54MHz, IL = 6.3 mA

NOTE

300

R

F

-

-

-

10

15 20

200180

φ = 0,

X

Y

θ = 0

Normal

0.560

0.320

0.580

0.340

-

15

-

0.600

0.360

msec

cd/m

2

(1), (3)

(1), (4)

@6.3mm

Viewing

Angle

0.290

0.530

0.135

0.135

0.310

0.550

0.155

0.155

0.330

0. 570

0.175

0.175

(1), (5)

PR650

Viewing

Angle

13 Points

White Variation

White

Hor.

Ver.

WX

WY

θ

θ R

φ H

φ L

L

(at center point)

CR ᆚ10

0.293

0.309

60

60

45

45

0.313

0.333

0.329 0.349

-

-

-

-

-

-

-

-

2.0-

Degrees

(6)

Doc.No. Rev.No Page / 32LTN150PG-L02 704-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Note 1) Definition of Viewing Angle :

θ L

θL =90

o

x

6 O’ clock

direction

φL= 90

o

Note 2) Definition of Contrast Ratio (CR) :

CR1 + CR2 + CR3 + CR4 + CR5

CR =

φ L

5

Normal Line

o

θ = 0

φ = 0

,

φ H

Approval

o

θ R

12 O’ clock

y

direction

φH= 90

o

x’y’

o

=90

θ

R

POINTS : , , , , at FIGURE OF NOTE 6)

45 9

7

10

Note 3) Definition of Response time :

Display data

Optical

Response

White(TFT OFF)

100%

90%

Black(TFT ON)

TR

White(TFT OFF)

TF

10%

0%

Note 4) Definition of Average Luminance of White : measure the luminance of white at 5 points.

Average Luminance of White ( Y L,AVE )

Y

L4 + YL5 + YL7 + YL9 + YL10

Y L,AVE =

Time

5

POINTS : , 5 , , , at FIGURE OF NOTE 6)

45 9

7

10

Doc.No. Rev.No Page / 32LTN150PG-L02 804-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

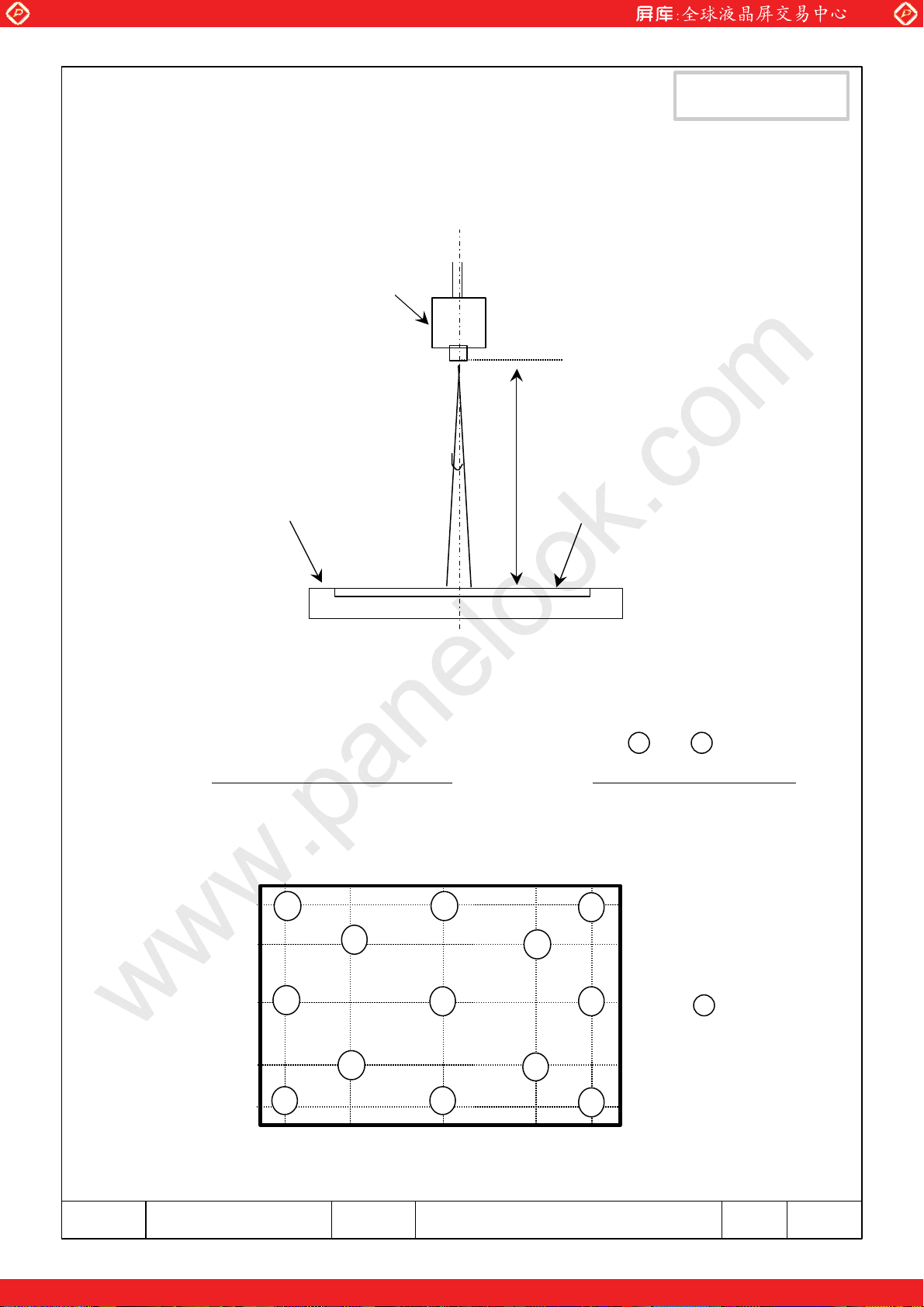

Note 5) After stabilizing and leaving the panel alone at a given temperature for 30 minutes, the measurement

should be executed. Measurement should be executed in a stable, windless,and dark room.

30 minutes after lighting the back-light. This should be measured in the center of screen.

Lamp current : 6.0 mA

Environment condition : Ta = 25 ± 2 °C

Photo detector

( TOPCON BM-5A)

www.panelook.com

Approval

Field = 2

TFT-LCD module

Optical characteristics measurement setup

Note 6) Definition of 13 points white variation (

δ L

Maximum luminance of 13 points

=

Minimum luminance of 13 points

45 979

13 12

256 512 768

o

Center of the screen

50 cm

LCD panel

δ

W ), CR variation( CVER ) [ ~ ]

δ C

R

=

11

113

Maximum CR of 13 points

Minimum C

45

R of 13 points

VIEW AREA

10

8

5

3

7

2

9

4

192

384

6

576

1

723

(lines)

: test point

Doc.No. Rev.No Page / 32LTN150PG-L02 904-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

www.panelook.com

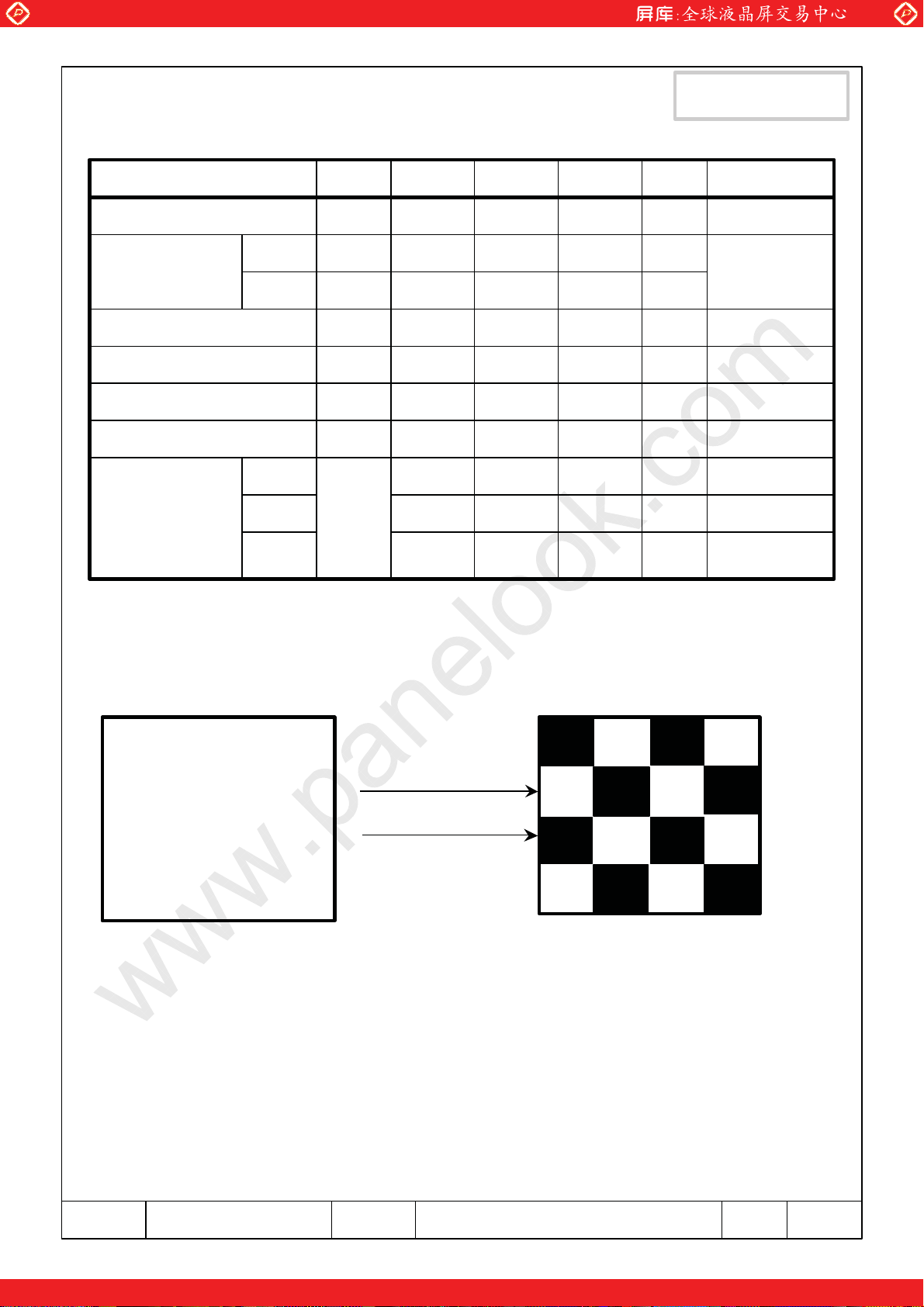

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE

ITEM SYMBOL MIN TYP MAX UNIT NOTE

Voltage of Power Supply VDD 3.0 3.3 3.6 V

Differential Input

High

Voltage for LVDS

Receiver Threshold

Low

Vsync Frequency fv - 60 - Hz

Hsync Frequency f

Main Frequency f

Rush Current I

White

Current of

Power Supply

Mosaic (2),(3)*b

Max

Pattern

IH - - +100 mV

V

IL -100 - - mV

V

H - 63.98 - KHz

DCLK 42.7 54 85 MHz

RUSH - - 1.5 A (4)

- 430 - mA (2),(3)*a

DD - 450 - mA

I

-

550 600

mA

Approval

Ta=25 ± 2 º C

V

CM=+1.2V

(2),(3)*c

Note (1) Display data pins and timing signal pins should be connected.(GND=0V)

(2) f

V=60Hz, fDCLK =54MHZ, Vdd = 3.3V , DC Current.

(3) Power dissipation pattern

*a) White Pattern *b) Mosaic Pattern

VIEW AREA

Display Brightest Gray Level

Display Darkest Gray Level

Doc.No. Rev.No Page / 32LTN150PG-L02 1004-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

*c) Maximum Power pattern : 1dot vertical stripe

4) Rush current measurement condition

www.panelook.com

Approval

RGBRGBRGBRG

GBRGB RGB RG

R

R

GBRGB RGB RG

RGBRGBRGBRG

CONTROL SIGNAL

(HIGH to LOW)

3.3V

R1

47K

R2

1K

12V

V

R3

C3

1uF

DD rising time is 470us

47K

GND

C2

10000pF

0.1VDD

M1

2SK1059

M2

2SK1399

0.9VDD

FUSE

470us

VDD ( LCD INPUT)

C1

1uF

3.3V

Doc.No. Rev.No Page / 32LTN150PG-L02 1104-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

www.panelook.com

mArms

rms

V

kHz

V

rms

V

rms

Approval

Ta=25 ± 2

NOTEUNITMAXTYPMINSYMB

IL=6.0mA655

25°C

0 °C

(5)

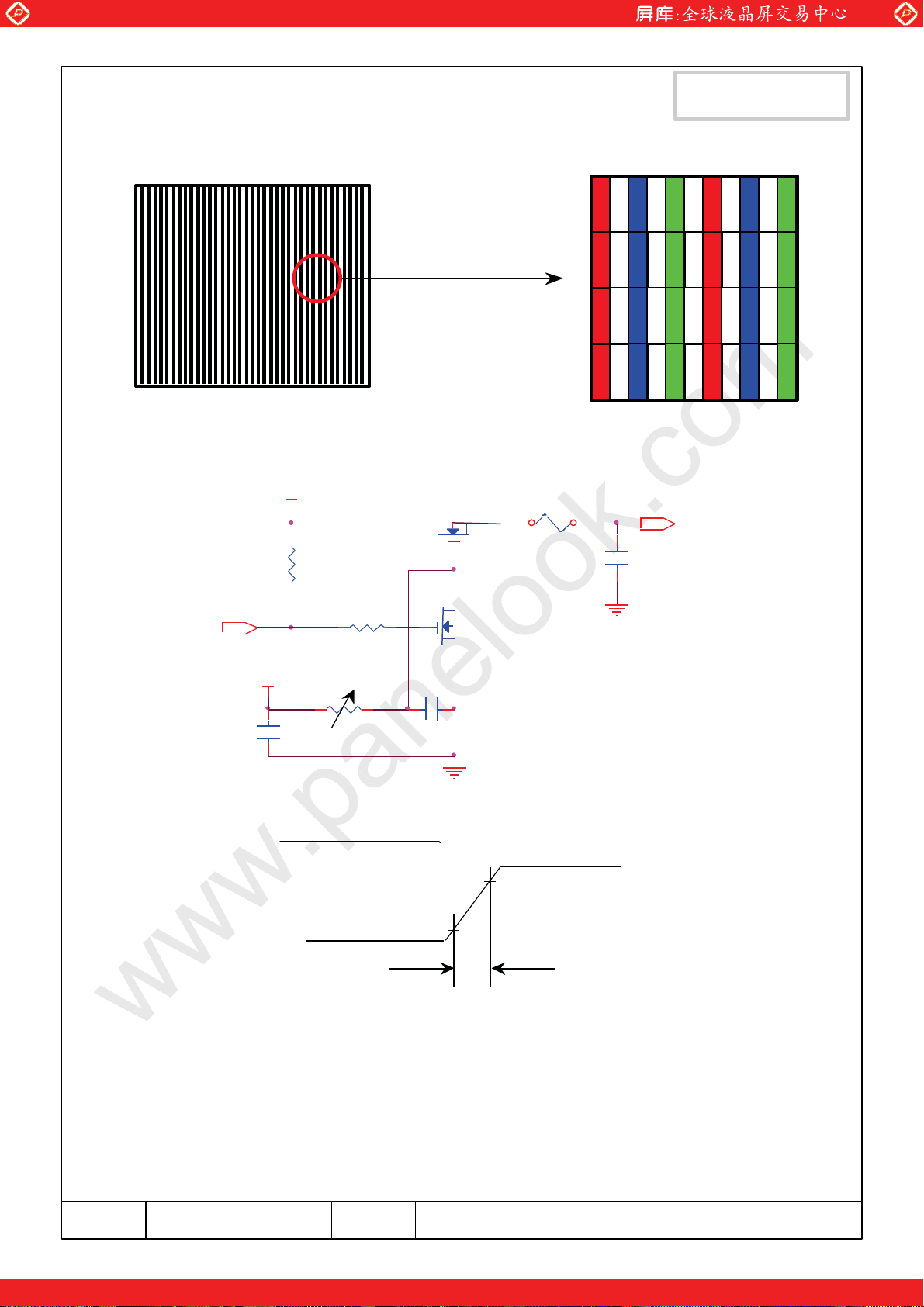

3.2 BACK-LIGHT UNIT

The backlight system is an edge - lighting type with a single CCFT ( Cold Cathode Fluorescent Tube ).

The characteristics of a single lamp are shown in the following tables.

INVERTER : Ambit / Sumida

ITEM

Lamp Current I

Lamp Voltage

Frequency

Power Consumption PL - (3)

Operating Life Time Hr 15,000 Hour- - (4)

Startup Voltage

Lamp Startup Time

Note) The waveform of the inverter output voltage must be area symmetric and the design of the inverter

must have specifications for the modularized lamp.

The performance of the backlight, for example life time or brightness, is much influenced by the

characteristics of the DC-AC inverter for the lamp. So all the parameters of an inverter should be carefully

designed so as not to produce too much leakage current from high-voltage output of the inverter.

When you design or order the inverter, please make sure that a poor lighting caused by the mismatch of

the backlight and the inverter(miss lighting, flicker, etc.) never occur. When you confirm it, the module

should be operated in the same condition as it is installed in your instrument.

L 2.0 6.0 7.0 (1)

VL

fL

VS

VS - - sec1

45 (2)

-W

-

60 80

4.0

1150

1380

o

C

Note (1) Lamp current is measured with a high frequency current meter as shown below.

HOT : BLUE

LCD

MODULE

(2) Lamp frequency may produce interference with horizontal synchronous frequency and this

may cause line flow on the display. Therefore lamp frequency should be detached from the

horizontal synchronous frequency and its harmonics as far as possible in order to avoid interference.

(3) refer to I

(4) Life time (Hr) of a lamp can be defined as the time in which it continues to operate under the

condition Ta = 25 ±2

1. When the brightness becomes 50% or lower than the original.

(5) The voltage above this value should be applied to the lamp for more than 1 second to startup

Otherwise the lamp may not be turned on.

L X VL to calculate.

o

C and IL = 6.0 mArms until one of the following event occurs.

1

2

No 2 Pin is V

COLD : WHITE

A

LOW.

INVERTER

Ambit / Sumida

Doc.No. Rev.No Page / 32LTN150PG-L02 1204-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

3.3 INVERTER

Inverter : AMBIT/SUMIDA Ta = 25 ± 2°CTa = 25 ± 2°C

www.panelook.com

Approval

ITEM MIN

Input Voltage(Vin)

Open Circuit Voltage

PWM duty cycle

Optical

Efficiency

Electrical

Operating Frequency

PWM Frequency

Input Voltage Ripple - Vpp

Input Power Consumption

In-rush current

7.5 14.4

10 ±2

@SMB_DAT

FFH

20

-

-

-

TYP MAX

21.0

18001400

-

80

5545

210 Hz220200 Vin=14.4V

5.0

--

100

@SMB_DAT

00H

-

65

0.5

5.7

1.5

UNIT

mArms

Vrms

%

Nit/W--

%

kHz SMB_DAT=00H

W

A

After 30min turn on

at the center of LCD

Vin=14.4V @6.0mA(3)

Peak to peak value

NOTE

IL =6.0 mArms

Vin=14.4V

(1)

Iout=6.0mArms

Shutdown time

Start-up time

1.0-

--

1.4

0.1 (2)

Note

(1) Vin=14.4V, IL=6.0mA

(2) Inverter start-up time

(3) Efficiency should be calculated as below formulation.

Optical efficiency = output Brightness(nits) / Input power(watt)

Electrical efficiency = output power / input power

sec

sec

Doc.No. Rev.No Page / 32LTN150PG-L02 1304-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

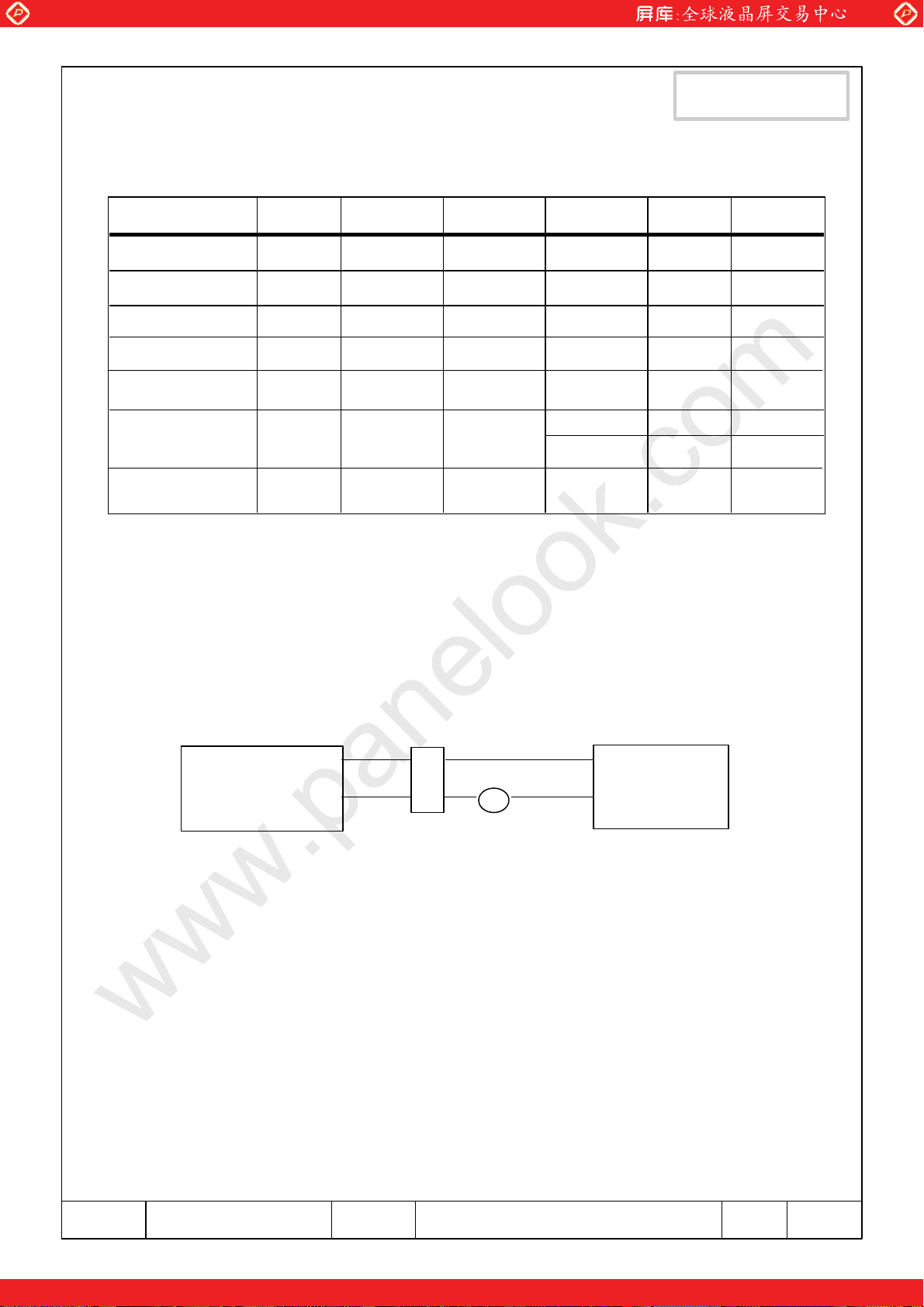

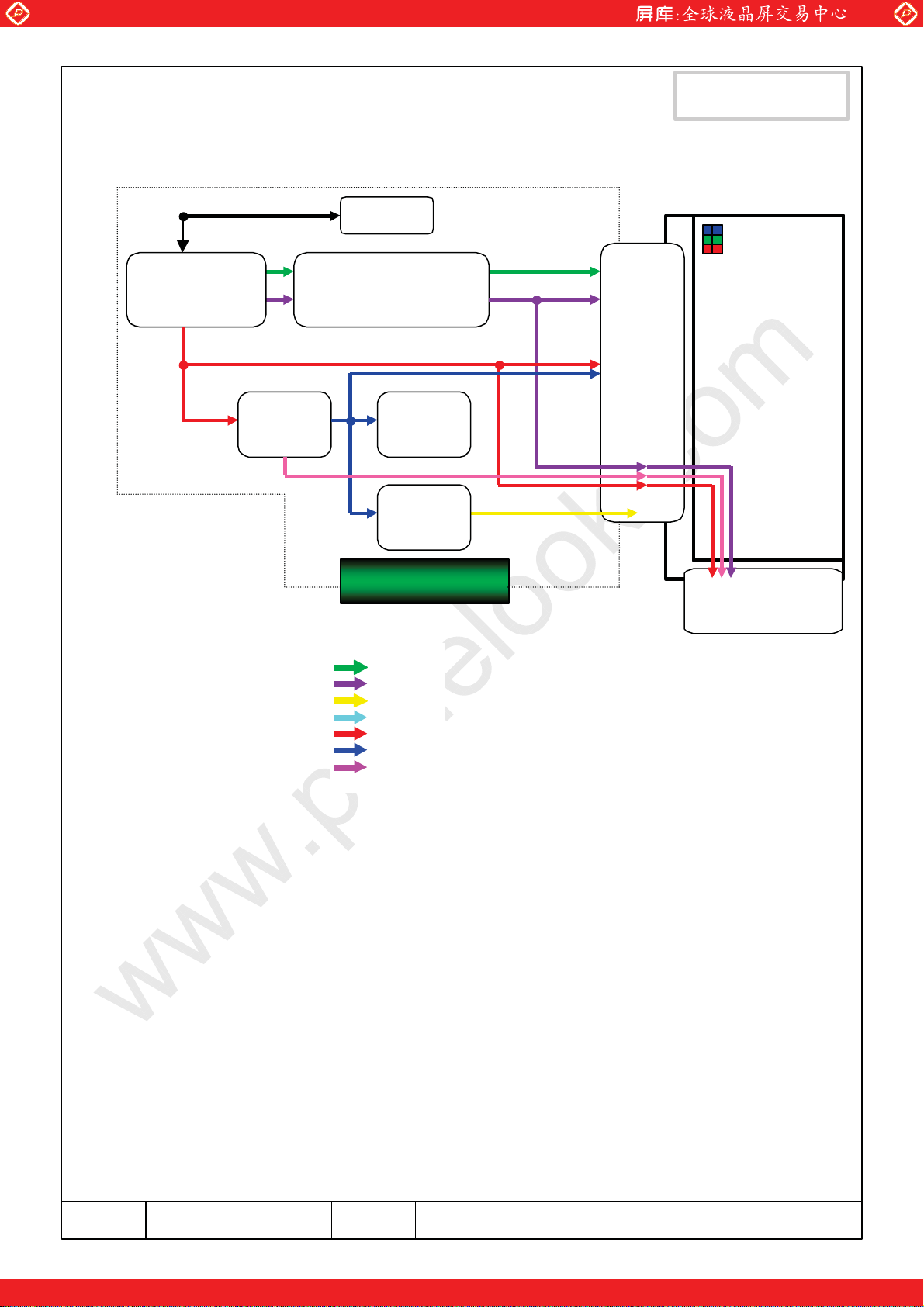

4. BLOCK DIAGRAM

4.1 TFT LCD Module

www.panelook.com

Approval

I2 C bus

Input-

Connector

FI-XB30S-HF10

or Compatible

LVDS

DC-DC

Converter

EDID

EEPROM

LVDS Input/RSDS Output

Timing Controller

Gamma

Generator

VCOM

Generator

SOURCE PCB

RSDS

Source

Driver

IC

15.0” SXGA+

TFT-LCD Panel

Gate Driver IC

Video Signal

Control Signal

VCOM

Gamma

DVDD

AVDD

Von/Voff

Doc.No. Rev.No Page / 32LTN150PG-L02 1404-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

4.2 BACKLIGHT UNIT

Reflector

Note) The output of the inverter may change according to the material of the reflector.

www.panelook.com

LAMP

Approval

1

HOT BLUE

2

COLD WHITE

4.3 Inverter UNIT

- Input Connector : HONDA, LVC-D20SFYG

Data & CLK

DVdd

Input

Connector

AVdd

SMBUS

Controller

Driving

Controller

OVL & OCL

Detection

Transformer

Open lamp

Detection

Lamp

Connector

Doc.No. Rev.No Page / 32LTN150PG-L02 1504-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

www.panelook.com

5. INPUT TERMINAL PIN ASSIGNMENT

5.1. Input Signal & Power LVDS, Connector : (JAE, FI-XB30SRL-HF11)

Approval

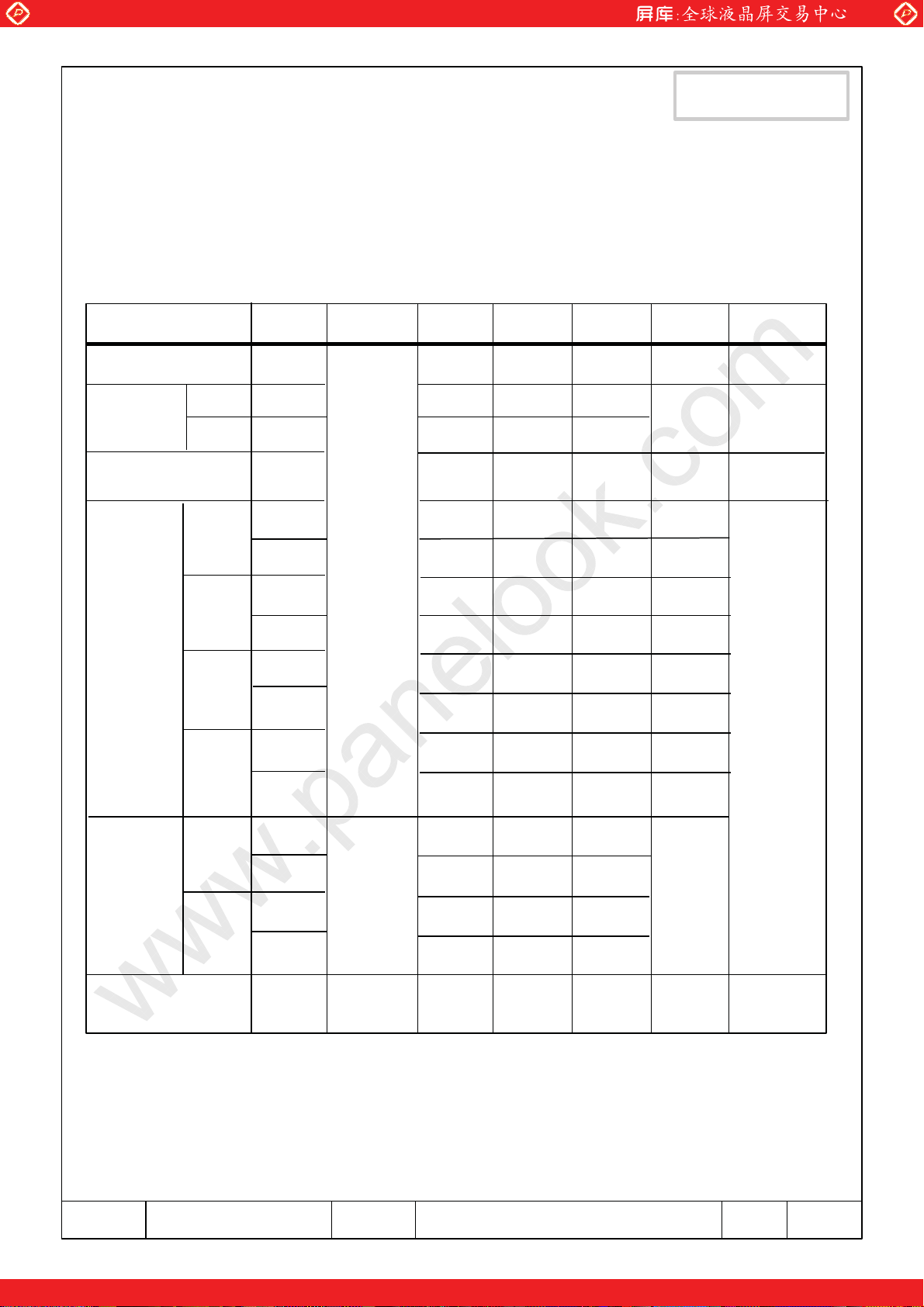

PIN NO SYMBOL POLARITY REMARK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Vss

VDD

VDD POWER SUPPLY +3.3V

VEEDID

BIST

CLKEDID N/A (DDC Clock)

DATAEDID N/A (DDC data)

O_RxIN0-

O_RxIN0+

Vss Ground

O_RxIN1-

O_RxIN1+

Vss Ground

O_RxIN2-

Ground

POWER SUPPLY +3.3V

N/A (DDC 3.3V Power)

Panel BIST control

LVDS Differential Data INPUT (Odd R0-R5,G0)

LVDS Differential Data INPUT (Odd R0-R5,G0)

LVDS Differential Data INPUT (Odd G1-G5,B0-B1)

LVDS Differential Data INPUT (Odd G1-G5,B0-B1)

LVDS Differential Data INPUT (Odd B1-B5,Sync,DE)

FUNCTION

Negative

Positive

Negative

Positive

Negative

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

O_RxIN2+

Vss Ground

O_RxCLK-

O_RxCLK+

Vss Ground

E_RxIN0-

E_RxIN0+

Vss

E_RxIN1-

E_RxIN1+

Vss Ground

E_RxIN2- LVDS Differential Data INPUT (Even B1-B5,Sync,DE)

E_RxIN2+

Vss Ground

E_RxCLK -

LVDS Differential Data INPUT (Odd B1-B5,Sync,DE)

LVDS Differential Data INPUT (Odd Clock)

LVDS Differential Data INPUT (Odd Clock)

LVDS Differential Data INPUT (Even R0-R5,G0)

LVDS Differential Data INPUT (Even R0-R5,G0)

Ground

LVDS Differential Data INPUT (Even G1-G5,B0-B1)

LVDS Differential Data INPUT (Even G1-G5,B0-B1)

LVDS Differential Data INPUT (Even B1-B5,Sync,DE)

LVDS Differential Data INPUT (Even Clock)

Positive

Negative

Positive

Negative

Positive

Negative

Positive

Negative

Positive

Negative

30

E_RxCLK +

LVDS Differential Data INPUT (Even Clock)

Positive

Doc.No. Rev.No Page / 32LTN150PG-L02 1604-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

5.2 LVDS Interface : Transmitter DS90CF363 or Compatible

LVDS for Odd pixel

Pin No. Name RGB Signal Pin No. Name RGB Signal

44 TxIN0 RO0 12 TxIN11 GO5

45 TxIN1 RO1 13 TxIN12 BO0

47 TxIN2 RO2 15 TxIN13 BO1

48 TxIN3 RO3 16 TxIN14 BO2

1 TxIN4 RO4 18 TxIN15 BO3

3 TxIN5 RO5 19 TxIN16 BO4

www.panelook.com

Approval

4 TxIN6 GO0 20 TxIN17 BO5

6 TxIN7 GO1 22 TxIN18 Hsync

7 TxIN8 GO2 23 TxIN19 Vsync

9 TxIN9 GO3 25 TxIN20 DE

10 TxIN10 GO4 26 TxCLK IN Clock

LVDS for Even pixel

Pin No. Name RGB Signal Pin No. Name RGB Signal

44 TxIN0 RE0 12 TxIN11 GE5

45 TxIN1 RE1 13 TxIN12 BE0

47 TxIN2 RE2 15 TxIN13 BE1

48 TxIN3 RE3 16 TxIN14 BE2

1 TxIN4 RE4 18 TxIN15 BE3

3 TxIN5 RE5 19 TxIN16 BE4

4 TxIN6 GE0 20 TxIN17 BE5

6 TxIN7 GE1 22 TxIN18 Hsync

7 TxIN8 GE2 23 TxIN19 Vsync

9 TxIN9 GE3 25 TxIN20 DE

10 TxIN10 GE4 26 TxCLK IN Clock

Doc.No. Rev.No Page / 32LTN150PG-L02 1704-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

Flat Link Interface

www.panelook.com

Approval

Graphics controller

36-bit

ODD RED0

ODD RED1

ODD RED2

ODD RED3

ODD RED4

ODD RED5

ODD GREEN0

ODD GREEN1

ODD GREEN2

ODD GREEN3

ODD GREEN4

ODD GREEN5

ODD BLUE0

ODD BLUE1

ODD BLUE2

ODD BLUE3

ODD BLUE4

ODD BLUE5

Hsync

Vsync

Enable

CLOCK

EVEN RED0

EVEN RED1

EVEN RED2

EVEN RED3

EVEN RED4

EVEN RED5

EVEN GREEN0

EVEN GREEN1

EVEN GREEN2

EVEN GREEN3

EVEN GREEN4

EVEN GREEN5

EVEN BLUE0

EVEN BLUE1

EVEN BLUE2

EVEN BLUE3

EVEN BLUE4

EVEN BLUE5

Hsync

Vsync

Enable

CLOCK

DS90CF363

or compatible

44

45

47

48

1

3

4

6

7

9

10

12

13

15

16

18

19

20

22

23

25

26

TxOUT0-

TxOUT0+

TxOUT1-

TxOUT1+

TxOUT2-

TxOUT2+

TxCLKOUT-

TxCLKOUT+

DS90CF363

or compatible

44

45

47

48

1

3

4

6

7

9

10

12

13

15

16

18

19

20

22

23

25

26

TxOUT0-

TxOUT0+

TxOUT1-

TxOUT1+

TxOUT2-

TxOUT2+

TxCLKOUT-

TxCLKOUT+

41

40

39

38

35

34

33

32

41

40

39

38

35

34

33

32

11

12

14

15

17

18

20

21

23

24

26

27

29

30

LVDS+I/F IC

8

100 Ω

9

100 Ω

100 Ω

100 Ω

100 Ω

100 Ω

100 Ω

100 Ω

O_RxIN0-

O_RxIN0+

O_RxIN1-

O_RxIN1+

RxIN2-

RxIN2+

RxCLK -

RxCLK+

E_RxIN0-

E_RxIN0+

E_RxIN1-

E_RxIN1+

E_RxIN2-

E_RxIN2+

E_RxCLK -

E_RxCLK +

Note : The LCD Module uses a 100ohm resistor between positive and negative lines of each

receiver input.

Doc.No. Rev.No Page / 32LTN150PG-L02 1804-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

5.3 BACK LIGHT UNIT

www.panelook.com

Approval

Connector : JST BHSR - 02VS -1

Pin NO.

1

2

Symbol

HOT

COLD

Color

Blue

White

5.4 Timing Diagrams of LVDS For Transmission

TxCLK OUT

RxCLK IN

T/7

Function

High Voltage

Ground

T

Rx IN2

Rx IN1

RxOUT26 RxOUT25 RxOUT22RxOUT24 RxOUT21 RxOUT20 RxOUT19

DE

T/7

RxOUT18 RxOUT15 RxOUT13RxOUT14 RxOUT12 RxOUT9 RxOUT8

T/7

RxOUT7 RxOUT6 RxOUT3RxOUT4 RxOUT2 RxOUT1 RxOUT0

G0 R4R5 R2 R1 R0

Vsync B2Hsync B5 B3B4

G4B1 G 5B0 G3 G2 G1

R3

Doc.No. Rev.No Page / 32LTN150PG-L02 1904-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

5.5 Input Signals, Basic Display Colors and Gray Scale of Each Color

DATA SIGNAL

RED GREEN BLUE

COLOR

GRAY

SCALE

OF

RED

DISPLAYCOLOR

R0 G0 B0 B5G5R5R2 G2 B2 B4G4R4R1 G1 B1 B3G3R3

BLACK

BLUE

GREEN

MAGENTA 1 1 1 1 1 1 0 0 0 0 0 0 1 1 1 1 1 1 -

YELLOW 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 -

WHITE 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 -

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R0

DARK

LIGHT

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -

0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 -

0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0 -

0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 -CYAN

1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 -RED

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1

0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R2

: : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : :

1 0 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 R61

0 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 R62

Approval

GRAY

SCALE

LEVEL

R3~R60

GRAY

SCALE

OF

GREEN

GRAY

SCALE

OF

BLUE

RED

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G0

DARK

LIGHT

GREEN

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 B0

DARK

LIGHT

GREEN

1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 R63

0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 G1

0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 G2

: : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : :

0 0 0 0 0 0 1 0 1 1 1 1 0 0 0 0 0 0 G61

0 0 0 0 0 0 0 1 1 1 1 1 0 0 0 0 0 0 G62

0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0 G63

0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 B1

0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 B2

: : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : :

0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 B61

0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 B62

0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 B63

G3~G60

B3~B60

Note 1) Definition of gray :

Rn: Red gray, Gn: Green gray, Bn: Blue gray (n=gray level)

Note 2)Input signal: 0 =Low level voltage, 1=High level voltage

Doc.No. Rev.No Page / 32LTN150PG-L02 2004-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

5.6 Pixel Format in the display

Pixel 1 Pixel 1400

www.panelook.com

Approval

Line 1

Line 1050

RGB RGB

RGB RGB

LTN150PG-L02 Panel

RGB RGB RGB RGB

Doc.No. Rev.No Page / 32LTN150PG-L02 2104-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

6. INTERFACE TIMING

6.1 Timing Parameters

www.panelook.com

Approval

Signal Item Symbol MIN TYP MAX

Frame Frequency

Vertical Active

Display Term

One Line

Scanning Time

Horizontal Active

Display Term

Cycle

Display Period

Cycle

Display Period

6.2 Timing diagrams of interface signal

VD

T

T

TV

TVD

TH

THD

V

Unit

-- 1066 lines

-- 1050 lines

-- 844 clocks

- 700 clocks

-

Note

(1 )

DE

TH

DCLK

C

T

HD

T

DE

DATA

SIGNALS

Note : All input condition(level&timing) for SN75LVDS88 are the same with those of LPD11826 or compatible.

Valid display data ( 1024 pixel)

Doc.No. Rev.No Page / 32LTN150PG-L02 2204-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

<

<

≤

≤

www.panelook.com

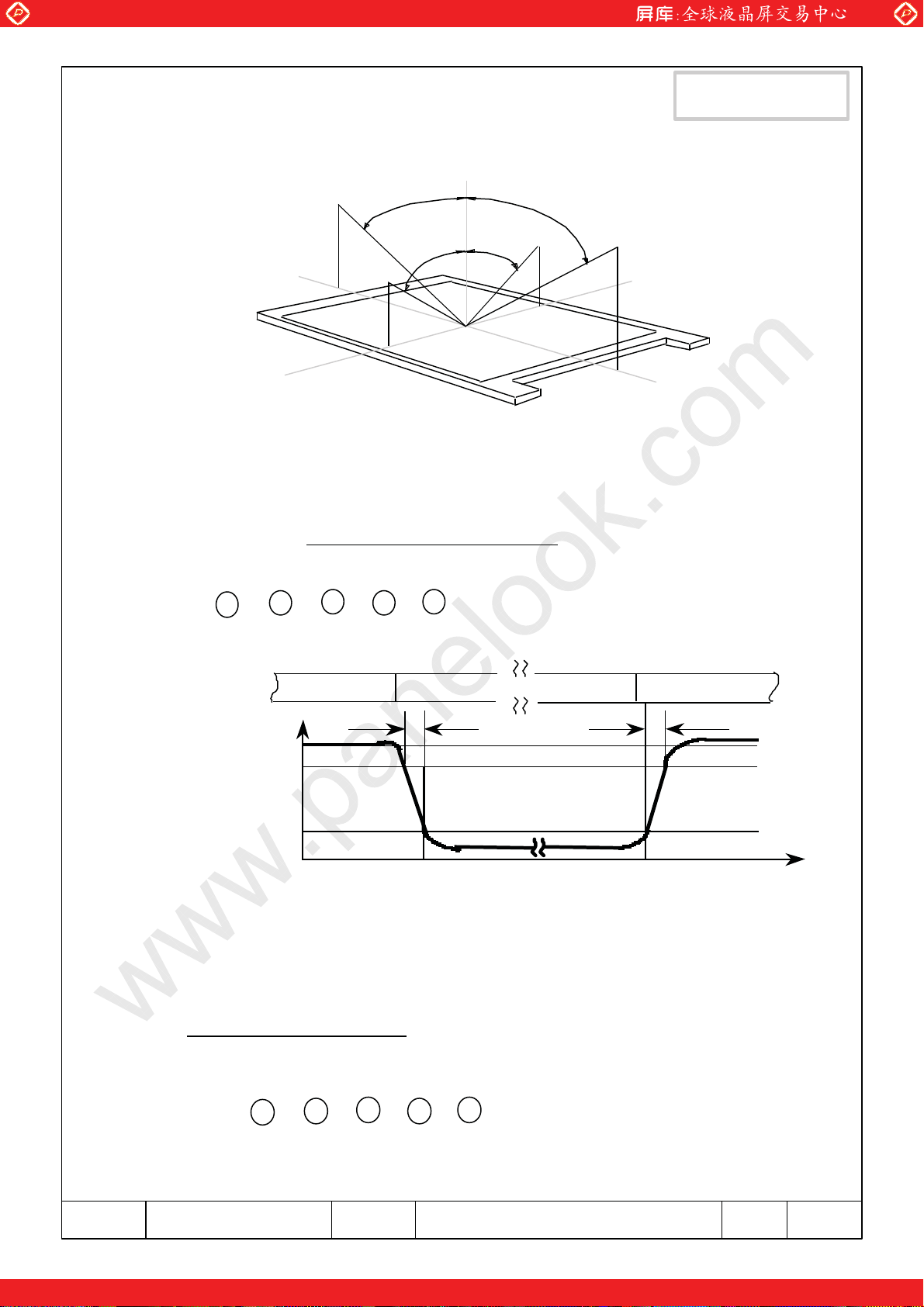

6.3 Power ON/OFF Sequence

Approval

: To prevent a latch-up or DC operation of the LCD module, the power on/off sequence

shall be as shown below.

Power Supply

V

DD

0V

0 <T1 ≤10 msec

0

T2 ≤50 msec

0

T3 ≤50 msec

400ms

T4

0 V

Signals

0.9 VDD 0.9 VDD

0.1 VDD

T1

T3

T2

VALID

Power On

Power Off

0.1 VDD

T4

Back-light

200 msec

T5

50% 50%

200 msec<T6

T5 T6

Power ON/OFF Sequence

T1 : Vdd rising time from 10% to 90%

T2 : The time from Vdd to valid data at power ON.

T3 : The time from valid data off to Vdd off at power Off.

T4 : Vdd off time for Windows restart

T5 : The time from valid data to B/L enable at power ON.

T6 : The time from valid data off to B/L disable at power Off.

NOTE.

(1) The supply voltage of the external system for the module input should be the same

as the definition of V

(2) Apply the lamp voltage within the LCD operation range. When the backlight turns on

before the LCD operation or the LCD turns off before the backlight turns off, the

display may momentarily become white.

(3) In case of V

DD = off level, please keep the level of input signals on the low or keep

a high impedance.

DD.

(4) T4 should be measured after the module has been fully discharged between power

off and on period.

(5) Interface signal shall not be kept at high impedance when the power is on.

Doc.No. Rev.No Page / 32LTN150PG-L02 2304-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

www.panelook.com

8. PACKING

1. CARTON(Internal Package)

(1) Packing Form

Corrugated Cardboard box and Corrupad form as shock absorber

(2) Packing Method

CUSHION CAP

Approval

PANEL

CUSHION PAD

Note 1)Total Weight : Approximately 9.0 kg

2) Acceptance number of piling : 10 sets

PACKING CASE

3) Carton size : 317(W)×286(D)×355(H)

4) MAX accumulation quantity : 5 cartons

Doc.No. Rev.No Page / 32LTN150PG-L02 2504-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

Approval

No

1

2

3

4

Static electric protective sack 10

Packing case(Inner box)

included shock absorber

Part name Quantity

1 set

Pictorial marking 2 pics

Carton 1 set

9. MARKINGS & OTHERS

A nameplate bearing followed by is affixed to a shipped product at the

specified location on each product.

(1)Parts number : LTN150PG-L02

(2)Revision : One letter

(3)Control code : One letter

(4)Lot number : 4 H 3 A XXX XX X

Cell Position No.(In the one Glass)

Glass No.(In the one Lot)

Lot No.(Glass)

Month

Year(Note 1)

Product Code

Line

NOTE 1). This code indicating year is omitted in the products o f KIHENG site.

(5) Nameplate Indication

LTN150PG-L02

0315

4H3A000000 000

DP / N KR –0Y0813- 39793 - 0B0 - 00YF

REV.A00

80 mm

40 mm

Parts name : LTN150PG - L02

Lot number : 4H3A000000

Inspected work week : 0315

DP/N : Dell Part Number (“

0Y0813” is for 150PG-L02)

REV.A00 : Product Revision Code

Doc.No. Rev.No Page / 32LTN150PG-L02 2604-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

This HIGH VOLTAGE CAUTION is carved in mold frame

www.panelook.com

Approval

HIGH VOLTAGE

CAUTION

RISK OF ELECTRIC SHOCK

DISCONNECT THE ELECTRIC

POWER BEFORE SERVICE

(6) Packing box attach

THIS COVER CONTAINS

FLUORESCENT LAMP.

PLEASE FOLLOW LOCAL

ORDINANCES OR

REGULATIONS FOR ITS DISPOSAL

70mm

0Y0813

10mm

High voltage

caution

(7) Packing box Marking : Samsung TFT-LCD Brand Name

Doc.No. Rev.No Page / 32LTN150PG-L02 2704-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

10. GENERAL PRECAUTIONS

1. Handling

(a) When the module is assembled, It should be attached to the system firmly

using every mounting holes. Be careful not to twist and bend the modules.

(b) Refrain from strong mechanical shock and / or any force to the module. In addition to

damage, this may cause improper operation or damage to the module and CCFT backlight.

(c) Note that polarizers are very fragile and could be easily damaged. Do not press or scratch

the surface harder than a HB pencil lead.

(d) Wipe off water droplets or oil immediately. If you leave the droplets for a long time,

Staining and discoloration may occur.

(e) If the surface of the polarizer is dirty, clean it using some absorbent cotton or soft cloth.

(f) The desirable cleaners are water, IPA(Isoprophyl Alcohol) or Hexane.

Do not use Keptone type materials(ex. Acetone), Ethyl alcohol, Toluene, Ethyl acid or Methyl

chloride. It might permanent damage to the polarizer due to chemical reaction.

Approval

(g) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or

mouth . In case of contact with hands, legs or clothes, it must be washed away thoroughly

with soap.

(h) Protect the module from static , it may cause damage to the C-MOS Gate Array IC.

(i) Use fingerstalls with soft gloves in order to keep display clean during the incoming

inspection and assembly process.

(j) Do not disassemble the module.

(k) Do not pull or fold the lamp wire.

(l) Do not adjust the variable resistor which is located on the back side.

(m) Protection film for polarizer on the module shall be slowly peeled off just before use so

that the electrostatic charge can be minimized.

(n) Pins of I/F connector shall not be touched directly with bare hands.

Doc.No. Rev.No Page / 32LTN150PG-L02 2804-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

2. STORAGE

Approval

(a) Do not leave the module in high temperature, and high humidity for a long time.

It is highly recommended to store the module with temperature from 0 to 35°C and

relative humidity of less than 70%.

(b) Do not store the TFT-LCD module in direct sunlight.

(c) The module shall be stored in a dark place. It is prohibited to apply sunlight or fluorescent

light during the store.

3. OPERATION

(a) Do not connect,disconnect the module in the “ Power On” condition.

(b) Power supply should always be turned on/off by following item 6.3

“ Power on/off sequence “ .

(c) Module has high frequency circuits. Sufficient suppression to the electromagnetic

interference shall be done by system manufacturers. Grounding and shielding methods

may be important to minimize the interference.

(d) The cable between the backlight connector and its inverter power supply shall be a

minimized length and be connected directly . The longer cable between the backlight

and the inverter may cause lower luminance of lamp(CCFT) and may require higher

startup voltage(Vs).

4. OTHERS

(a) Ultra-violet ray filter is necessary for outdoor operation.

(b) Avoid condensation of water. It may result in improper operation or disconnection

of electrode.

(c) Do not exceed the absolute maximum rating value. ( the supply voltage variation, input

voltage variation, variation in part contents and environmental temperature, so on)

Otherwise the module may be damaged.

(d) If the module displays the same pattern continuously for a long period of time,it can be

the situation when the image “ sticks” to the screen.

(e) This module has its circuitry PCB’ s on the rear side and should be handled carefully in

order not to be stressed.

Doc.No. Rev.No Page / 32LTN150PG-L02 2904-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

www.panelook.com

Appendix 1. EDID

Address Value ASCII

DEC NotesFUNCTION BI N

(HEX) HEX Data

00 00 00000000 0

01 FF 11111111 255

02 FF 11111111 255

03 FF 11111111 255

04 FF 11111111 255

05 FF 11111111 255

06 FF 11111111 255

07 00 00000000 0

08 4C 01001100 76 S

09 A3 10100011 163 C

0A

0B

0C 00 00000000 0

0D 00 00000000 0

0E 00 00000000 0

0F 00 00000000 0

10 Week of manufacture 00 00000000 0

11 Year of manufacture 0D 00001101 13 2003

12 EDID Structure Ver. 0 1 00000001 1 1

13 EDID revision # 03 00000011 3 3

14 Video input definition 80 10000000 128

15 Max H image size 1E 00011110 30 30

16 Max V image size 17 00010111 23 23

17 Display Gamma 78 01111000 120 2.2

18 Feature support 0A 00001010 10

19 Red/green low bits 87 10000111 135

1A Blue/white low bits F5 11110101 245

1B Red x/ high bits 94 10010100

1C Red y 57 01010111

1D Green x 4F 01001111

1E

1F Blue x 27 00100111

20 Blue y 27 00100111

21 White x 50 01010000

22 White y 54 01010100

23 Established timing 1 00 00000000 0

24 Established timing 2 00 00000000 0

25 Established timing 3 00 00000000 0

Header

ID Manufacturer Name

ID Product Code

32-bit serial no.

Green y 8C 10001100

50 01010000 80

47 01000111 71

148

140

87

79

39

39

80

84

or

0.580

0.340

0.310

0.550

0.155

0.155

0.313

0.329

Approval

EDID Header

3 character ID

E

"SEC"

P

G

"P"

"G"

2003

EDID Ver. 1.0

EDID Rev. 3

30.45cm

22.8375cm

Gamma 2.2

10000111

11110101

Red x 0.580=

1001010010

Red y 0.340=

0101011100

Green x 0.310=

0100111101

Green y 0.550=

1000110011

Blue x 0.155=

0010011111

Blue y 0.155=

0010011111

White x 0.315=

0101000001

White y 0.329=

0101010001

Doc.No. Rev.No Page / 32LTN150PG-L02 3004-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

www.panelook.com

Address Value ASCII

DEC NotesFUNCTION BI N

(HEX) HEX Data

Approval

or

26 01 00000001 1

27 01 00000001 1

28 01 00000001 1

29 01 00000001 1

2A 01 00000001 1

2B 01 00000001 1

2C 01 00000001 1

2D 01 00000001 1

2E 01 00000001 1

2F 01 00000001 1

30 01 00000001 1

31 01 00000001 1

32 01 00000001 1

33 01 00000001 1

34 01 00000001 1

35 01 00000001 1

36 30 00110000 48 108

37 2A 00101010 42

38 78 01111000 120 1400

39 20 00100000 32 288

3A 51 01010001 81

3B 1A 00011010 26 1050

3C 10 00010000 16 16

3D 40 01000000 64

3E 30 00110000 48 48

3F 70 01110000 112 112

40

Standard timing #1

Standard timing #2

Standard timing #3

Standard timing #4 not used

Standard timing #5

Standard timing #6

Standard timing #7

Standard timing #8

Detailed timing/monitor

descriptor #1

14 00010100 20

1

4

not used

not used

not used

not used

not used

not used

not used

Main clock= 108 MHz

Hor active=700*2 pixels

Hor blanking=288 pixels

4bit : 4bit

Vertcal active=1050 lines

Vertical blanking=16 lines

4bit : 4bit

Hor sync. Offset=24 pixels

H sync. Width=56 pixels

V sync. Offset=1 lines

V sync. Width=4 lines

41 00

42 30 00110000 48 304

43 E4 11100100 228 228

44 10 00010000 16

45 00 00000000 0

46 00 00000000 0

47 19 00011001 25

48 00 00000000 0

49 00 00000000 0

4A 00 00000000 0

4B

4C 00 00000000 0

4D 00 00000000 0

4E 00 00000000 0

4F 00 00000000 0

Detailed timing/monitor

0F

00000000 0

00001111

15

2bit : 2bit :2bit :2bit

H image size= 304.5 mm(approx)

V image size = 228.375 mm(approx)

No Horizontal Border

No Vertical Border

Manufacturer Specified (Timing)

Value =HSPWmin / 2

Value =HSPWmax / 2

Value =Thbpmin /2

Doc.No. Rev.No Page / 32LTN150PG-L02 3104-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 32

Global LCD Panel Exchange Center

www.panelook.com

Address Value ASCII

DEC NotesFUNCTION BI N

(HEX) HEX Data

Approval

or

50 00 00000000 0

51 00 00000000 0

52 00 00000000 0

53 00 00000000 0

54 00 00000000 0

55 0F 00001111

56 F2 11110010

57 02 00000010

58 4B 01001011

59 00 00000000

5A 00 00000000 0

5B 00 00000000 0

5C 00 00000000 0

5D FE 11111110 254

5E 00 00000000 0

5F 59 01011001

60 30 00110000

61 38 00111000

62 31 00110001

63 33 00110011

64 03 00000011

65 31 00110001

66 35 00110101

67 30 00110000

68 50 01010000

69 47 01000111

6A 0A 00001010

6B 20 00100000 32 [ ]

6C 00 00000000 0

6D 00 00000000 0

6E 00 00000000 0

6F FE 11111110 254

70 00 00000000 0

71

72

73

74

75

76

77

78

79

7A

7B

7C

7D 20 00100000 32

7E Extension Flag 00 00000000 0

7F Checksum AF 10101111 175

descriptor #2

Detailed timing/monitor

descriptor #3

Detailed timing/monitor

descriptor #4

15

242

2

75

0

89 [Y]

48 [0]

56 [8]

49 [1]

51 [3]

3 3

49 [1]

53 [5]

48 [0]

80 [P]

71 [G]

10 [^]

CE 11001110 206

C6 11000110 198

BA 10111010 186

AB 10101011 171

95 10010101 149

77 01110111 119

4D 01001101 77

12 00010010 18

01 00000001 1

0A 00001010 10

20 00100000 32

20 00100000 32

Value =Thbpmax /2

Value =VSPWmin /2

Value =VSPWmax /2

Value =Tvbpmin / 2

Value =Tvbpmax / 2

Thpmin=value*2 + HA pixelclks

Thpmax= value*2 + HA pixelclks

Tvpmin=value*2 + VA lines

Tvpmax= value*2 + VA lines

Module revision

ASCII Data String Tag

Monitor Name Tag (ASCII)

Doc.No. Rev.No Page / 32LTN150PG-L02 3204-A00-S-030919

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 33

Global LCD Panel Exchange Center

Inverter Design Specification P2

www.panelook.com

Approval Inverter Specification for P2

SEC : LTN150XC-L01 / LTN150PG-L02

2003. 03. 25

REV. 0. 0

- Inverter Input Voltage Range : 7.5 ~ 21V

REV. 0.1

- Lamp Current

Max : 6.0(± 0.3)mA → 6.3(± 0.3)mA

Min : 1.8(± 0.3)mA →2.0(± 0.3)mA

2003. 04. 24

SAMSUNG ELECTRONICS Co. Ltd. AMLCD Division prepared by Y. S. Kwon

03-09-09 1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 34

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

1. General

This specification should be used as a guideline for designing the inverter used in P2 Program.

Brightness control method of inverter should be PWM(Burst) mode control.

1.1 Model

Type Samsung Part Number Supplier Part Number Remark

TFT_LCD

LTN150XC-L01

LTN150PG-L02

2. Specification

2.1 General electrical specification Referenced Panels: Samsung TFT-LCD

Item Minimum Typical Maximum Remarks

Input voltage(Vin) 7.5 V 14.4V 21.0 V

Open Circuit Voltage 1.4 k Vrms - 1.8kVrms

Lamp voltage - 6 5 5Vrms -

Lamp Current

2.0 ± 0.3

mArms

-

@ SMB_DAT

FFH

6.3± 0.3

mArms

@SMB_DAT

00H

Vin = 7.5 ~ 21.0V

Dimming Duty Cycle 10(± 2%) 100%

Efficiency

Optical 20nits/W - -

Electrical - 80% -

Operating Frequency 45 kHz 55kHz 65kHz

After 30min turn on at the center

of the LCD.

Vin = 14.4V, Iout=6.0mArms

PWM Frequency 210 ± 10Hz

Input Power

Vin = 14.4V, Iout = 6.0mArms

- - 5.7W

Consumption

SMB_DAT=00H

In-rush current - - 1.5A

Shutdown time 0.6sec 1.0sec 1.4sec

Start-up time 0.1sec

SAMSUNG ELECTRONICS Co. Ltd. AMLCD prepared by Y. S. Kwon

03-09-09 2

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 35

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

2.2 Connectors

2.2.1 Backlight connector (CN1)

2.2.1.1 Backlight connector CN1 must be same as table 1.

Connector Maker Connector Part No. Remark

JST SM02B-BHSS-1-TB

2.2.1.2 Pin assignment

2.2.1.2.1 SM02B-BHSS-1-TB

Pin No Symbol Description Remark

1 HV Power supply for CCFL

2 RTN Return

2.2.2 Input connector(CN2)

It must be a HONDA, LVC-D20SFYG 20pin connector, and the pin assignment is ;

Input connector

Voltage Comments

HONDA LVC-D20SFYG

Pin Function

1 INV_SRC 7.5V to 21V

2 INV_SRC 7.5V to 21V

3 INV_SRC 7.5V to 21V

4 NC - No Connection

5 GND Ground

6 5VSUS 5V

7 5VALW 5V

8 GND Ground

This power rail should be used as a power rail to drive

the backlight DC-AC converter

This power rail should be used as a power rail to drive

the backlight DC-AC converter

This power rail should be used as a power rail to drive

the backlight DC-AC converter

This should be used as power source for the control

circuitry on the inverter

This should be used as power source that stores the

brightness/contrast values & the circuit that interfaces

with SMB_CLK & SMB_DAT

9 SMB_DAT

10 SMB_CLK

11 GND Ground

12 FPBACK

13 GND Ground

SMBus interface for sending brightness & contrast

information to the inverter/panel

SMBus interface for sending brightness & contrast

information to the inverter/panel

Control signal input into the inverter to turn the backlight

ON & OFF (1 - ON, 0 – OFF)

SAMSUNG ELECTRONICS Co. Ltd. AMLCD Division prepared by Y. S. Kwon

03-09-09 3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 36

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

14 LAMP_STAT Lamp Status, on(High)/off(Low), from control chip

15 ~ 20 NC No Connection

SAMSUNG ELECTRONICS Co. Ltd. AMLCD prepared by Y. S. Kwon

03-09-09 4

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 37

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

2.2.3 SMBUS Address Definition

Table 9.8 SMBus address definition for brightness & contrast

Device Identifier Device Address Read/Write Bit

0 1 0 1 A2 A1 A0 R/W=0

Inverter SMBUS Address A2 A1 A0

Address = 58H 1 0 0

Recommend using Dallas Semiconductor DS1803 (Dual

digital potentiometer) or equivalent function IC.

Use Wiper 0 for contrast control & Wiper 1 for brightness

(Backlight) control in case DS1803.

2.2.4. Circuit Block Diagram

Input

Panel ID bit

Setting

DVdd

Data & Clock

SMBUS

Controller

AVdd

Driving

Controller

Transformer

CCFL

Connector

OVL & OCL

Detection

Open lamp

Detection

SAMSUNG ELECTRONICS Co. Ltd. AMLCD Division prepared by Y. S. Kwon

03-09-09 5

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 38

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

3.0 Safety Requirement

Inverter must comply with UL1950 3

rd

edition, CSA22.2 No. 950-95, EN60950-1992 + A1 & A2 and other

applicable regulations.

The inverter has several safety critical components due to high voltage. See list and associated comments:

PWB : The PWB must be UL Recognized and have a 94V-1 or V-0 rating.

Transformer : Bobbin and other plastic parts must be UL Recognized and have appropriate temperature

ratings for the application. Plastic must have 94V-1 or V-0 Flame Rating.

High Voltage Capacitors : Must have adequate ratings for the application.

Fuse : Must be UL Listed with appropriate ratings for application.

Output Connector(s) : Must be UL Recognized. Must provide adequate spacing from pin to pin for high voltage.

Note) It is preferable that the inverter be a UL Recognized assembly. If assembly is not UL Approved, then a

CFM (Confirmation List of Material) must be provided with each shipment of inverters providing

manufacturer identification and material/part identification for each critical part.

4.0 Emissions Requirements

Inverter design must be such that is does not prevent host product from complying with CFR47-Part 15 Class B

Limits, CISPR-22 Class B Limits, and EN55022 Class B Limits. Consideration should be given to high frequency

signals, ringing on signals, filtering of ground and voltage lines, and use of good high frequency grounding

techniques.

5.0 Immunity Requirements

Inverter Design must be such that it does not prevent host product from complying with EN50082-1 Generic

Immunity Requirements for European Union. This includes ESD, EFT, FRI, Surge, Harmonics, and Flicker.

6.0 Reliability

Minimum MTBF: 10,000 Hrs min @ 25C +/- 1C, 60% RH.

7.0 Mechanical Spec.

7.1 Drawing - Refer to separate drawing.

Inverter Layout Drawing

Please see attached drawing

SAMSUNG ELECTRONICS Co. Ltd. AMLCD prepared by Y. S. Kwon

03-09-09 6

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 39

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

Appendix A. Inverter Design Features

(Inverter design – checklist)

Following table outlines the desired features and design checklist of the inverter.

Item Feature Description

1 Soft-start Lamp should soft start.

Short/Open

2

detection

Over current

3

protection

Over voltage

4

Protection

Start-up time

5

Control

6 If dual conversion stage is used both stages shall synchronize

7 There is no indication that the inverter design must be tuned to the bulb.

8 Verify that Strike time and Strike voltage meet the Panel specification

9

10

11

12

13

14 Check stress factors on critical components (i.e. voltage and power ratings).

15

16

17

18

19

20

Lamp out (mechanical broken) detection should be provided.

Over current protection : Must be checked at all temperature/voltage extremes

Over voltage protection : Must be checked at all temperature/voltage extremes

And have a stable cut off point.

Good start-up transient response

The inverter board is designed with test nodes and an ICT fixture is in place to

Verify that all components are within the design tolerances.

Four corner testing (Voltage vs. Temperature) has been performed on several

Inverters using a lamp with components (i.e. BJT & Zener Diodes from different build lots

Four corner testing (min. & max.Voltage vs. Temperature) has been performed on several

Inverters not using a lamp with components (i.e. BJT & Zener Diodes) from different build

lots.

Efficiency should be measured – in side the panel and outside of the panel. Results should be

analyzed and circuit modified, if the difference between efficiencies is too great.

Test inverter over the operating temperature inside the panel. (Notebook operating temperature

ambient of 0 to 40 °C

Panel should be observed in all display modes to ensure that pattern interference is not present.

Look for this in the area of the panel that is closest to the bulb. This is sometimes termed as beat

frequencies problem.

Abnormal what if analysis must be performed. For e.g. what happens if a component opens,

shorts? The goal here is to make sure that failures do not result in safety issues.

Obtain drawings of key components, Transformer, inductor, ballast cap, valves, resonant cap etc.

Verify that none of the aforementioned is over stressed.

Check thermals, to ensure that hotspots are not present, such that the customer can feel heat

through the plastics, or display discoloration results.

Ensure that the inverter can not be heard (humming or clicking noises) and that control loop is

stable

EMI recommendation:

1.The GND on the inverter board should be connected to the display metal which should be

connected to the notebook system GND. This should be achieved through a secure mechanism

such as a screw, copper washer etc. and NOT using conducting foam or copper tape.

2.The ground of the inverter should also be positively connected to the GND on the source PCBs

on the panel.

The GND point should be physically close to the input connector of the inverter.

SAMSUNG ELECTRONICS Co. Ltd. AMLCD Division prepared by Y. S. Kwon

03-09-09 7

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 40

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

SAMSUNG ELECTRONICS Co. Ltd. AMLCD prepared by Y. S. Kwon

03-09-09 8

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 41

Global LCD Panel Exchange Center

Inverter Design Specification P2

www.panelook.com

Appendix B. CCFL Specification

Our Backlight system is an edge-lighting type with single CCFT(Cold Cathode Fluorescent Tube)Lamp . The

characteristics of single lamp are shown in following table.

1. LTN150XC-L01/LTN150PG-L02

Items Symbol Min. Typ. Max. Unit Remark

Lamp current IL 2.0 6 .0 7.0 mArms Note1, 2

Lamp Voltage VL - 655 - Vrms +/-5% @ IL=6.0mA

Lamp power Pcfl - 3.93 - Watt @ I L=6. 0mA

Lamp frequency Fcfl 4 5 60 80 kHz Note 3

Kick-off Voltage Vs

Life time Hlife Hour Note4, @ IL=6.0mA

CCFL turn on time Ton - - 0.5 msec

- - 1150 Ta=25°C

- - 1380

Vrms

Ta=0°C

Note1. If CCFT lamp was flowed below minimum current, lamp become unstable for ignition.

And if the CCFT lamp was flowed over maximum current, lamp life time should be shorter than normal

condition.

Note2. At the condition of luminance YL= TBD cd/m2 on TFT-LCD Panel output.

Note3. Lamp frequency may produce interference with Horizontal synchronous frequency and this may cause beat on

the display. Therefore lamp driving frequency shall be detached as much as possible from the horizontal

synchronous frequency and its harmonics to avoid interference.

Note4. Lamp life time is defined as the time when either A or B occur in the continuous operation under the condition of

Ta=25°C and at maximum current.

A) Brightness becomes 50% of the original value.

B) Kick-off voltage at Ta=0°C exceeds maximum value.

SAMSUNG ELECTRONICS Co. Ltd. AMLCD Division prepared by Y. S. Kwon

03-09-09 9

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 42

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

Appendix C. P2 Inverter Test Plan.

1. Functional Test Items

Check Items Split Condition

Output current

(Min, Max) &

Output deviation

Output Voltage

Input Power

Kick-off Voltage &

Operating freq.

Shutdown time

Turn-on time

Electrical Efficiency

Optical Performance

(Nits/W)

Stress Factor

Display pattern check

Acoustic noise

Temperature rise

Measurement

Input voltage

Vin=7. 5V, 14.4V, 21V

Temperature

°C, Ta=25°C, Ta=50°C

Ta=0

Output current

SMBUS_DAT=FFH and 00H

Temperature

°C, Ta=25°C, Ta=50°C

Ta=0

Output current

SMBUS_DAT=FFH and 00H

Temperature

Ta=0

°C, Ta=25°C, Ta=50°C

Temperature

°C , Ta=25°C Ta=50°C

Ta=0

Temperature

Ta=0

°C , Ta=25°C, Ta=50°C

Temperature

°C , Ta=25°C, Ta=50°C

Ta=0

Output current

6mA(00H)

Temperature

°C, Ta=25°C, Ta=50°C

Ta=0

Output current

SMBUS_DAT= 00H

Temperature

Ta=0

°C, Ta=25°C, Ta=50°C

Critical components

SEC standard test pattern

Humming & clicking noise

Power on 2 hours under 25±5°C

60±5°C, measure key component’ s

body temperature.

Quantity

5

5

5

5

5

5

5

5

5

5

5

5

All functional test will perform by inverter supplier and LCD manufacturer(SEC).

And both company should be correct test results.

Sample

Test

Condition

SMB_DAT=00H

SMB_DAT=FFH

Input voltage

Vin=7. 5V, 14.4V, 21V

Input voltage

Vin=7. 5V, 14.4V, 21V

Vin=14.4V, SMB_DAT=00H

No load condition

Vin=14.4V, SMB_DAT=00H

Open voltage detection

& shutdown time check

Vin=14.4V,

SMB_DAT=00H

Vin=14.4V,

SMB_DAT=00H

Vin=14.4V,

SMB_DAT=00H

Voltage and power rating

Vin=14.4V,

SMB_DAT=00H

Remark

SEC test

only

SEC test

only

SAMSUNG ELECTRONICS Co. Ltd. AMLCD prepared by Y. S. Kwon

03-09-09 10

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 43

Global LCD Panel Exchange Center

Inverter Design Specification P2

www.panelook.com

2. Reliability Test Items

No Items Test Condition

Power on at max. input with load.

1

High temp. operation

2 Low temp. operation

3 High temp. storage

4 Low temp. storage

5 Thermal Cycle

6 Power On/Off test

7 Signal On/Off test

8 Hot Start test

9 Cold Start test

10 PCB bending test PCB bending rate : 1mm max. 20

MTBF demo stress

11

Test

Vibration test

12

(Storage)

Operation at Ta=50°C, 500Hours

SMB_DAT=00H, 95%RH

Power on at min. input with load.

Operation at Ta=0°C,500hours

SMB_DAT=00H

Power off

High temperature 85°C, 500hours

Power off

Low temperature –20°C, 500hours

Power off storage

Ta=-20°C(30min) ⇔ Ta=60°C(30min)

100cycles

Max. input & min. input.

Power on full load(SMB_DAT= 00H)

10sec On/10sec Off, 30,000cycle

Signal HI(SMB_DAT=00H), 10sec

Signal Low(SMB_DAT=FFH), 10sec

Max. Vinput, Power on full load.

30,000cycle

After storage at Ta=50°C for 2hour,

Then power on at min. Vinput, max. Ioutput.

10times.

After storage at Ta=0°C for 2hour,

Then power on at min. Vinput, min. Ioutput.

10times

Power on at Ta=60°C

Max. input voltage, Full load operation

2G, 10~500Hz, 30min.

500Hz~10Hz, 30min .

Sample

size

20 Function test

20 Function test

10 Function test

10 Function test

20 Function test

10

each

10 Function test

10 Function test

10 Function test

100 MTBF

10 Function test

Check Point

Function test

Cosmetic

inspection

3. TEST Schedule

ITEM D+1W D+2W D+3W D+4W D+5W D+6W D+7W D+8W remark

Functional test

Reliability test

Long life test

SAMSUNG ELECTRONICS Co. Ltd. AMLCD Division prepared by Y. S. Kwon

03-09-09 11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Test by SEC/Maker

Test by Maker, 500hours

Test by Maker, 1,000hours

www.panelook.com

Page 44

Global LCD Panel Exchange Center

www.panelook.com

Inverter Design Specification P2

SAMSUNG ELECTRONICS Co. Ltd. AMLCD prepared by Y. S. Kwon

03-09-09 12

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...