Samsung CLP-775ND Service Manual

ColorLaserPrinter

CLP-775NDseries

MANUAL

SERVICE

ColorLaserPrinterContents

1.Precautions

2.Productspecandfeature

3.DisassemblyandReassembly

4.AlignmentandTroubleshooting

5.SystemDiagram

6.ReferenceInformation

RefertotheservicemanualintheGSPN(seetherearcover)formoreinformation.

Contents

Contents

1.Precautions......................................................................................................................................1−1

1.1.Safetywarning........................................................................................................................1−1

1.2.Cautionforsafety....................................................................................................................1−2

1.2.1.Toxicmaterial.............................................................................................................1−2

1.2.2.Electricshockandresafetyprecautions.........................................................................1−2

1.2.3.Handlingprecautions...................................................................................................1−3

1.2.4.AssemblyandDisassemblyprecautions...........................................................................1−3

1.2.5.Disregardingthiswarningmaycausebodilyinjury............................................................1−4

1.3.ESDprecautions......................................................................................................................1−5

2.Productspecandfeature.....................................................................................................................2−1

2.1.ProductSpecications..............................................................................................................2−1

2.1.1.ProductOverview........................................................................................................2−1

2.1.2.Specications.............................................................................................................2−2

2.1.2.1.GeneralPrintEngine......................................................................................2−2

2.1.2.2.ControllerandSoftware..................................................................................2−2

2.1.2.3.PaperHandling.............................................................................................2−3

2.1.2.4.Reliability&Service.....................................................................................2−4

2.1.2.5.Consumables................................................................................................2−4

2.1.2.6.Maintenancepart...........................................................................................2−5

2.1.2.7.Environment................................................................................................2−6

2.1.2.8.Packing&Accessory.....................................................................................2−6

2.1.2.9.Options.......................................................................................................2−6

2.1.3.ModelComparisonTable..............................................................................................2−7

2.2.SystemOverview.....................................................................................................................2−8

2.2.1.FrontView.................................................................................................................2−8

2.2.2.RearView..................................................................................................................2−9

2.2.3.PaperPath..................................................................................................................2−10

2.2.4.SystemLayout............................................................................................................2−11

2.2.4.1.FeedingSection............................................................................................2−12

2.2.4.2.FuserUnit....................................................................................................2−13

2.2.4.3.DriveUnit...................................................................................................2−14

2.2.4.4.LSU(LaserScannerUnit)...............................................................................2−15

2.2.4.5.PTB(PaperTransferBelt)Unit........................................................................2−16

2.2.4.6.TonerCartridge.............................................................................................2−17

2.2.5.HardwareConguration................................................................................................2−18

2.2.5.1.MainPBA...................................................................................................2−19

2.2.5.2.SMPSboard.................................................................................................2−21

2.2.5.3.HVPSBoard................................................................................................2−23

iCopyright©1995-2016SAMSUNG.Allrightsreserved.

Contents

2.2.5.4.HVPSsubboard...........................................................................................2−25

2.2.5.5.FuserDriveBoard.........................................................................................2−26

2.2.5.6.OPEBoard...................................................................................................2−27

2.2.5.7.Sensor.........................................................................................................2−28

2.2.6.SoftwareDescriptions..................................................................................................2−30

2.2.6.1.Overview.....................................................................................................2−30

2.2.6.2.Architecture.................................................................................................2−30

2.2.6.3.DataandControlFlow...................................................................................2−31

3.DisassemblyandReassembly..............................................................................................................3−1

3.1.Precautionswhenreplacingparts................................................................................................3−1

3.1.1.Precautionswhenassemblinganddisassembling...............................................................3−1

3.1.2.PreautionswhenhandlingPBA......................................................................................3−1

3.1.3.ReleasingPlasticLatches..............................................................................................3−2

3.2.Screwsusedintheprinter..........................................................................................................3−3

3.3.Replacingamaintenanceparts....................................................................................................3−6

3.3.1.FuserUnit..................................................................................................................3−6

3.3.2.Pick-Uproller.............................................................................................................3−7

3.3.3.RetardRoller..............................................................................................................3−8

3.3.4.DustCleaningKit........................................................................................................3−9

3.4.DisassemblyProcedure.............................................................................................................3−10

3.4.1.Cover........................................................................................................................3−10

3.4.2.FrontCover................................................................................................................3−13

3.4.3.OPEUnit...................................................................................................................3−14

3.4.4.MainPBA..................................................................................................................3−14

3.4.5.HVPSboard...............................................................................................................3−15

3.4.6.SMPSBoard...............................................................................................................3−15

3.4.7.HVPSSubBoard(ACBoard)........................................................................................3−16

3.4.8.FuserControlBoard.....................................................................................................3−17

3.4.9.LSU..........................................................................................................................3−18

3.4.10.ClutchPick-UpandClutch-Feed....................................................................................3−19

4.AlignmentandTroubleshooting...........................................................................................................4−1

4.1.AlignmentandAdjustments.......................................................................................................4−1

4.1.1.ControlPanel..............................................................................................................4−1

4.1.2.UnderstandingTheStatusLED......................................................................................4−2

4.1.3.JAMRemoval.............................................................................................................4−3

4.1.3.1.ClearingPaperJams......................................................................................4−3

4.1.4.Usefulmenuitemforservice.........................................................................................4−7

4.1.5.PeriodicDefectiveImage..............................................................................................4−8

4.1.6.Usefulmanagementtools..............................................................................................4−9

4.1.6.1.UsingSamsungEasyPrinterManager(Windowsonly)........................................4−9

Copyright©1995-2016SAMSUNG.Allrightsreserved.ii

Contents

4.1.6.2.UsingSamsungPrinterStatus(Windowsonly)...................................................4−10

4.1.6.3.UsingSmartPanel(MacintoshandLinuxonly)..................................................4−12

4.1.7.UpdatingFirmware......................................................................................................4−14

4.1.7.1.UpdatethermwarebyusingtheUSBport........................................................4−14

4.1.7.2.Updatethermwarebyusingthenetwork..........................................................4−15

4.1.8.TechMode.................................................................................................................4−17

4.1.8.1.ToentertheTechMode..................................................................................4−17

4.1.8.2.TechModeMenuMap...................................................................................4−18

4.1.8.3.TechModeMenudescription...........................................................................4−19

4.2.Troubleshooting......................................................................................................................4−24

4.2.1.ProcedureofCheckingtheSymptoms.............................................................................4−24

4.2.1.1.BasicCheckList...........................................................................................4−25

4.2.2.Errorcodeandtroubleshooting......................................................................................4−26

4.2.3.Imagequalityproblems................................................................................................4−60

4.2.4.Othererrors................................................................................................................4−64

5.SystemDiagram................................................................................................................................5−1

5.1.BlockDiagram........................................................................................................................5−1

5.2.ConnectionDiagram.................................................................................................................5−2

6.ReferenceInformation........................................................................................................................6−1

6.1.ToolforTroubleshooting...........................................................................................................6−1

6.2.AcronymsandAbbreviations.....................................................................................................6−2

6.2.1.Acronyms..................................................................................................................6−2

6.2.2.ServiceParts...............................................................................................................6−4

6.3.TheSamplePatternfortheTest..................................................................................................6−7

6.3.1.A4ISO19798StandardPattern......................................................................................6−7

6.4.Selectingalocation..................................................................................................................6−8

iiiCopyright©1995-2016SAMSUNG.Allrightsreserved.

1.Precautions

Inordertopreventaccidentsanddamagestotheequipmentpleasereadtheprecautionslistedbelowcarefullybefore

servicingtheproductandfollowthemclosely.

1.1.Safetywarning

1)Onlytobeservicedbyafactorytrainedservicetechnician.

Highvoltagesandlasersinsidethisproductaredangerous.Thisproductshouldonlybeservicedbyafactorytrained

servicetechnician.

2)UseonlySamsungreplacementparts.

Therearenouserserviceablepartsinsidetheproduct.Donotmakeanyunauthorizedchangesoradditionstothe

productasthesecouldcausetheproducttomalfunctionsandcreateanelectricshocksorrehazards.

3)LaserSafetyStatement

TheprinteriscertiedintheU.S.toconformtotherequirementsofDHHS21CFR,chapter1SubchapterJfor

ClassI(1)laserproducts,andelsewhereiscertiedasaClassIlaserproductconformingtotherequirementsof

IEC/EN60825-1:2014.ClassIlaserproductsarenotconsideredtobehazardous.Thelasersystemandprinterare

designedsothereisneveranyhumanaccesstolaserradiationaboveaClassIlevelduringnormaloperation,user

maintenanceorprescribedservicecondition.

1.Precautions

•Wavelength:800nm

•Beamdivergence

-Parallel:11degrees

-Perpendicular:35degrees

•Maximumpowerofenergyoutput:12mW

WARNING

NeveroperateorservicetheproductwiththeprotectivecoverremovedfromLaser/Scannerassembly.Thereected

beam,althoughinvisible,candamageyoureyes.

Whenusingthisproduct,thesebasicsafetyprecautionsshouldalwaysbefollowedtoreduceriskofre,electric

shock,andpersonalinjury.

4)Lithiumbatterynotreplaceablebyuser

Copyright©1995-2016SAMSUNG.Allrightsreserved.1-1

1.Precautions

1.2.Cautionforsafety

1.2.1.Toxicmaterial

Thisproductcontainstoxicmaterialsthatcouldcauseillnessifingested.

1)Pleasekeepimagingunitandtonercartridgeawayfromchildren.Thetonerpowdercontainedintheimagingunitand

tonercartridgemaybeharmful,andifswallowed,youshouldcontactadoctor.

1.2.2.Electricshockandresafetyprecautions

Failuretofollowthefollowinginstructionscouldcauseelectricshockorpotentiallycauseare.

1)Useonlythecorrectvoltage,failuretodosocoulddamagetheproductandpotentiallycauseareorelectricshock.

2)Useonlythepowercablesuppliedwiththeproduct.Useofanincorrectlyspeciedcablecouldcausethecableto

overheatandpotentiallycauseare.

3)Donotoverloadthepowersocket,thiscouldleadtooverheatingofthecablesinsidethewallandcouldleadtoare.

4)Donotallowwaterorotherliquidstospillintotheproduct,thiscancauseelectricshock.Donotallowpaperclips,pins

orotherforeignobjectstofallintotheproduct,thesecouldcauseashortcircuitleadingtoanelectricshockorrehazard.

5)Nevertouchtheplugsoneitherendofthepowercablewithwethands,thiscancauseelectricshock.Whenservicing

theproduct,removethepowerplugfromthewallsocket.

6)Usecautionwheninsertingorremovingthepowerconnector.Whenremovingthepowerconnector,gripitrmlyand

pull.Thepowerconnectormustbeinsertedcompletely ,otherwiseapoorcontactcouldcauseoverheatingpossibly

leadingtoare.

7)Takecareofthepowercable.Donotallowittobecometwisted,bentsharplyaroundcornersorwisedamaged.Donot

placeobjectsontopofthepowercable.Ifthepowercableisdamageditcouldoverheatandcauseare.Exposed

cablescouldcauseanelectricshock.Replacethedamagedpowercableimmediately,donotreuseorrepairthedamaged

cable.Somechemicalscanattackthecoatingonthepowercable,weakeningthecoverorexposingcablescausing

reandshockrisks.

8)Ensurethatthepowersocketsandplugsarenotcrackedorbrokeninanyway.Anysuchdefectsshouldberepaired

immediately.T akecarenottocutordamagethepowercableorplugswhenmovingthemachine.

9)Usecautionduringthunderorlightningstorms.Samsungrecommendsthatthismachinebedisconnectedfromthe

powersourcewhensuchweatherconditionsareexpected.Donottouchthemachineorthepowercordifitisstill

connectedtothewallsocketintheseweatherconditions.

10)A voiddampordustyareas,installtheproductinacleanwellventilatedlocation.Donotpositionthemachineneara

humidierorinfrontofanairconditioner.Moistureanddustbuiltupinsidethemachinecanleadtooverheatingand

causeareorcausepartstorust.

11)Donotpositiontheproductindirectsunlight.Thiswillcausethetemperatureinsidetheproducttorisepossiblyleading

totheproductfailingtoworkproperlyandinextremeconditionscouldleadtoare.

12)Donotinsertanymetalobjectsintothemachinethroughtheventilatorfanorotherpartofthecasing,itcouldmake

contactwithahighvoltageconductorinsidethemachineandcauseanelectricshock.

1-2Copyright©1995-2016SAMSUNG.Allrightsreserved.

1.Precautions

1.2.3.Handlingprecautions

Thefollowinginstructionsareforyourownpersonalsafetytoavoidinjuryandsoasnottodamagetheproduct.

1)Ensuretheproductisinstalledonalevelsurface,capableofsupportingitsweight.Failuretodosocouldcause

theproducttotiporfall.

2)Theproductcontainsmanyrollers,gearsandfans.T akegreatcaretoensurethatyoudonotcatchyourngers,hairor

clothinginanyoftheserotatingdevices.

3)Donotplaceanysmallmetalobjects,containersofwater,chemicalsorotherliquidsclosetotheproductwhichifspilled

couldgetintothemachineandcausedamageorashockorrehazard.

4)Donotinstallthemachineinareaswithhighdustormoisturelevels,besideonopenwindoworclosetoahumidieror

heater.Damagecouldbecausedtotheproductinsuchareas.

5)Donotplacecandles,burningcigarettes,etcontheproduct,Thesecouldcauseare.

6)Ensurethatthemachineisinstalledandusedinproperareatomeetthetemperatureandhumidityspecications.

•IfthemachineisstoredatbelowzeroCelsiusforalongtime,donotusethemachineinstantlyaftermovement.It

canmalfunction.Takecareofthemachinestorage.IfthemachineisstoredatbelowzeroCelsiusforalongtime,

keepthemachineatroomtemperatureandinstallit.

1.2.4.AssemblyandDisassemblyprecautions

ReplacepartscarefullyandalwaysuseSamsungparts.Takecaretonotetheexactlocationofpartsandalsocablerouting

beforedismantlinganypartofthemachine.Ensureallpartsandcablesarereplacedcorrectly.Pleasecarryoutthefollowing

proceduresbeforedismantlingtheproductorreplacinganyparts.

1)Checkthecontentsofthemachinememoryandmakeanoteofanyusersettings.Thesewillbeerasedifthemain

boardornetworkcardisreplaced.

2)Ensurethatpowerisdisconnectedbeforeservicingorreplacinganyelectricalparts.

3)Disconnectinterfacecablesandpowercables.

4)Onlyuseapprovedspareparts.Ensurethatpartnumber,productname,anyvoltage,currentortemperaturerating

arecorrect.

5)Whenremovingorre-ttinganypartsdonotuseexcessiveforce,especiallywhenttingscrewsintoplastic.

6)Takecarenottodropanysmallpartsintothemachine.

7)HandlingoftheOPCDrum

•TheOPCDrumcanbeirreparablydamagedifitexposedtolight.TakecarenottoexposetheOPCDrumeither

todirectsunlightortouorescentorincandescentroomlighting.Exposureforaslittleas5minutescandamage

thesurfaceofthephotoconductivepropertiesandwillresultinprintqualitydegradation.Takeextracarewhen

servicingtheproduct.RemovetheOPCDrumandstoreitinablackbagorotherlightproofcontainer.T ake

carewhenworkingwiththeCovers(especiallythetopcover)openaslightisadmittedtotheOPCareaandcan

damagetheOPCDrum.

•TakecarenottoscratchthegreensurfaceofOPCDrumUnit.IfthegreensurfaceoftheDrumCartridgeis

scratchedortouchedtheprintqualitywillbecompromised.

Copyright©1995-2016SAMSUNG.Allrightsreserved.1-3

1.Precautions

1.2.5.Disregardingthiswarningmaycausebodilyinjury

1)Becarefulwiththehightemperaturepart.

Thefuserunitworksatahightemperature.Usecautionwhenworkingontheprinter.W aitforthefusertocool

downbeforedisassembly.

2)Donotputngerorhairintotherotatingparts.

Whenoperatingaprinter,donotputhandorhairintotherotatingparts(Paperfeedingentrance,motor,fan,etc.).

Ifdo,youcangetharm.

3)Whenyoumovetheprinter.

Thisprinterweighs6kgincludingtonercartridgeandcassette.Usesafeliftingandhandlingtechniques.Usethelifting

handleslocatedoneachsideofthemachine.Backinjurycouldbecausedifyoudonotliftcarefully .

4)Ensuretheprinterisinstalledsafely .

Theprinterweighs6kg,ensuretheprinterisinstalledonalevelsurface,capableofsupportingitsweight.Failuretodo

socouldcausetheprintertotiporfallpossiblycausingpersonalinjuryordamagingtheprinter .

5)Donotinstalltheprinteronaslopingorunstablesurface.Afterinstallation,doublecheckthattheprinterisstable.

1-4Copyright©1995-2016SAMSUNG.Allrightsreserved.

1.Precautions

1.3.ESDprecautions

Certainsemiconductordevicescanbeeasilydamagedbystaticelectricity.Suchcomponentsarecommonlycalled

“ElectrostaticallySensitive(ES)Devices”orESDs.ExamplesoftypicalESDsare:integratedcircuits,someeldeffect

transistors,andsemiconductor“chip”components.Thetechniquesoutlinedbelowshouldbefollowedtohelpreducethe

incidenceofcomponentdamagecausedbystaticelectricity.

CAUTION

Besurenopowerisappliedtothechassisorcircuit,andobserveallothersafetyprecautions.

1)Immediatelybeforehandlingasemiconductorcomponentorsemiconductor-equippedassembly,drainoffany

electrostaticchargeonyourbodybytouchingaknownearthground.Alternatively,employacommerciallyavailable

wriststrapdevice,whichshouldberemovedforyourpersonalsafetyreasonspriortoapplyingpowertotheunit

undertest.

2)AfterremovinganelectricalassemblyequippedwithESDs,placetheassemblyonaconductivesurface,suchas

aluminumorcopperfoil,orconductivefoam,topreventelectrostaticchargebuildupinthevicinityoftheassembly .

3)UseonlyagroundedtipsolderingirontosolderordesolderESDs.

4)Useonlyan“anti-static”solderremovaldevice.Somesolderremovaldevicesnotclassiedas“anti-static”can

generateelectricalchargessufcienttodamageESDs.

5)DonotuseFreon-propelledchemicals.Whensprayed,thesecangenerateelectricalchargessufcienttodamageESDs.

6)DonotremoveareplacementESDfromitsprotectivepackaginguntilimmediatelybeforeinstallingit.Most

replacementESDsarepackagedwithallleadsshortedtogetherbyconductivefoam,aluminumfoil,oracomparable

conductivematerial.

7)ImmediatelybeforeremovingtheprotectiveshortingmaterialfromtheleadsofareplacementESD,touchtheprotective

materialtothechassisorcircuitassemblyintowhichthedevicewillbeinstalled.

8)MaintaincontinuouselectricalcontactbetweentheESDandtheassemblyintowhichitwillbeinstalled,until

completelypluggedorsolderedintothecircuit.

9)MinimizebodilymotionswhenhandlingunpackagedreplacementESDs.Normalmotions,suchasthebrushingtogether

ofclothingfabricandliftingone’sfootfromacarpetedoor,cangeneratestaticelectricitysufcienttodamageanESD.

Copyright©1995-2016SAMSUNG.Allrightsreserved.1-5

2.Productspecandfeature

2.Productspecandfeature

2.1.ProductSpecications

2.1.1.ProductOverview

1)Speed

•33(Color)/33(Black)ppminA4(35/35ppminLetter)

2)Processor

•600MHz

3)PrinterLanguage

•PS3,PCL5c,PCL6,PDF1.4

4)Memory

•384MB(Standard)/896MB(Max)

5)Interface

•HighSpeedUSB2.0

•10/100/1000BaseTXnetworkconnector

•802.11b/g/nwirelessLAN(Optional)

•IEEE1284Parallel(Optional)

•HDD250GB(Optional)

6)Tonercartridge

•Initial:3.5K(K)/3.5K(CMY)

•Sales:7K(K)/7K(CMY)

7)PaperHandling

•Maximum1,600SheetsPaperCapacity(500shcassette,500sh

SCFx2EA,100MP)

2-1Copyright©1995-2016SAMSUNG.Allrightsreserved.

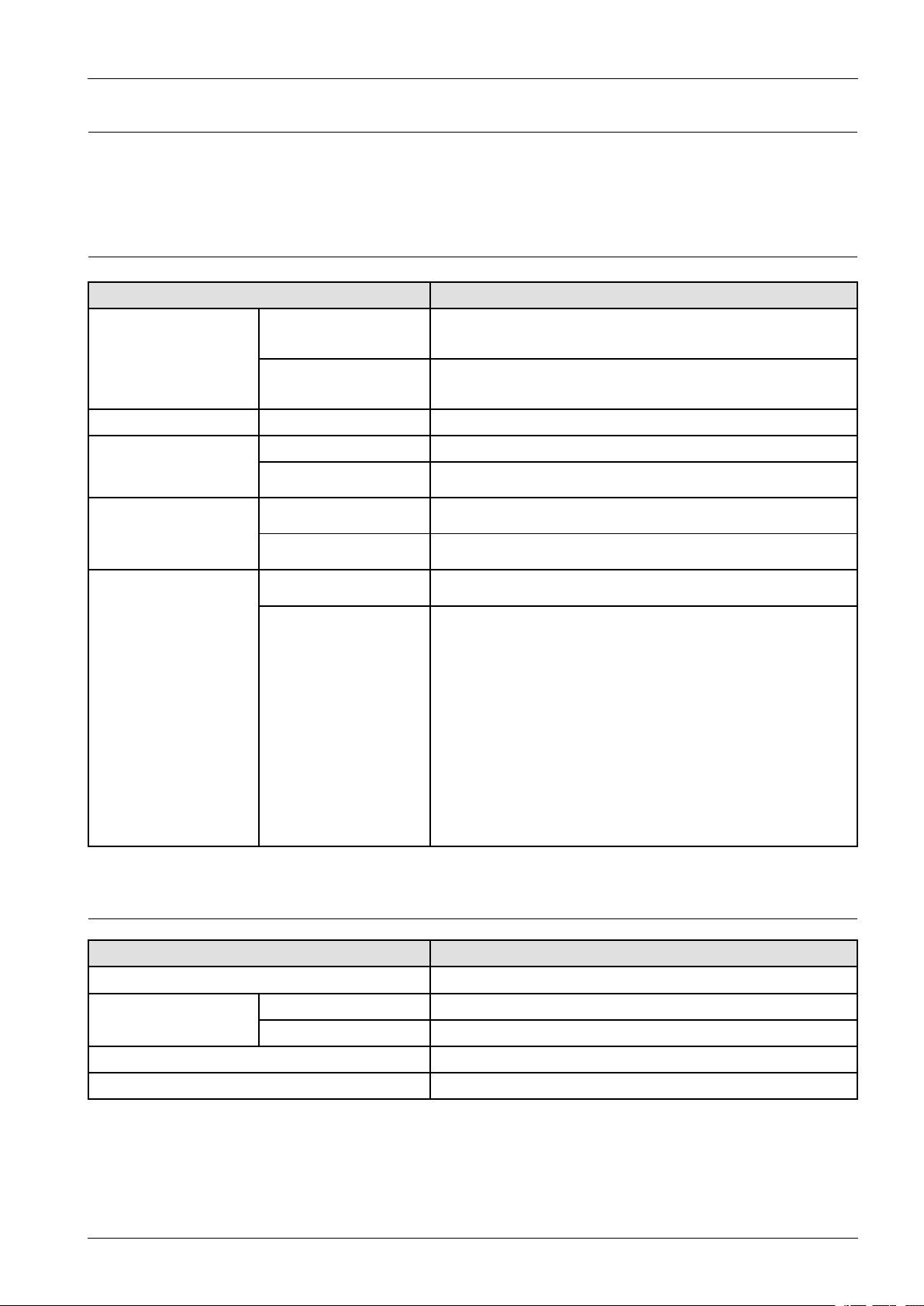

2.1.2.Specications

•ProductSpecicationsaresubjecttochangewithoutnotice.Seebelowforproductspecications.

2.1.2.1.GeneralPrintEngine

ItemsSpecication

2.Productspecandfeature

Simplex

EngineSpeed

Duplex

Warm-uptimeFromSleep≤25sec

FromReady≤10sec

FPOT(B&W)

FromSleep≤28sec

FromReady≤11sec

FPOT(Color)

FromSleep≤30sec

Optical600x600dpi

Resolution

Support

•B&W:Upto33ppminA4(35ppminLetter)

•Color:Upto33ppminA4(35ppminLetter)

•B&W:Upto14ppminA4(14ppminLetter)

•Color:Upto14ppminA4(14ppminLetter)

•PCL

•Best:9,600x600effectiveoutput

•Normal:2,400x600dpi

•Draft:600x600dpi

•PostScript3

•Best:9,600x600effectiveoutput

•Normal:1,200x600dpi

•Draft:600x600dpi

2.1.2.2.ControllerandSoftware

ItemsSpecication

Processor600MHz

Memory

PrinterLanguagesPS3,PCL5,PLC6

Fonts93scalable,1bitmapPCL,136PS

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-2

Std.384MB

Max896MB

2.Productspecandfeature

ItemsSpecication

Driver

Application

Interface

UserInterface

DefaultDriverPCL6

SupportingOS

WHQLWindows2000/XP(32/64bits)/Vista(32/64bits)/2003

ManagementToolEasyPrintManagement

NetworkManagementSetIP ,SyncThruWebAdminService4.0

IEEE1284ParallelOptional

USBHi-SpeedUSB2.0

WiredNetworkEthernet10/100/1000BaseTX

WirelessNetworkOptional

LCD4–LineLCD

LED1StatusLED

Windows2000/XP(32/64bits)/Vista(32/64bits)/2003

Server(32/64bits)/2008Server(32/64bits)/Win7/2008R2

•VariousLinuxOS

•RedHat8~9,

•FedoraCore1~4

•Mandrake9.2~10.1

•SuSE8.2~9.2

•MacOS10.3~10.6

Server(32/64bits)/2008Server(32/64bits)/Win7/2008R2

2.1.2.3.PaperHandling

ItemsSpecication

StandardCapacity500-sheetTray@80g/m²,100–sheetMPTray

Max.Capacity

Printing

StandardCassette

Tray

MPTray

Max.Size216x356mm(8.5"x14")

Min.Size76x127mm(3.0"x5")

Capacity500sheets@80g/m²

Mediasizes76x127mm(3”x5”)~216x356mm(8.5”x14”)

MediatypesPlainpaper

Mediaweight16~43lb(60~163g/m²)

SensingPaperEmpty

Capacity100-sheet@80g/m²

MediasizesA4148.5x210~Legal216x356(8.5”x14”)

Mediatypes

1600sheets@80g/m²(500–sheetbasicTray,500–sheetSCFTrayx2,100–sheet

MP)

PrinterDefault,PlainPaper,Thick,Thin,Cotton,ArchivePaper,Bond,Card

Stock,Labels,Preprinted,ColorPaper,Envelope,Recycled

Mediaweight16~58lb(60to220g/m²)

SensingPaperEmpty

2-3Copyright©1995-2016SAMSUNG.Allrightsreserved.

2.Productspecandfeature

ItemsSpecication

Capacity500sheets@80g/m²

MediasizesA5148.5x210mm~Legal216x356mm(8.5"x14")

OptionalCassette

Tray

MediatypesPlainpaper

Mediaweight16~43lb(60~163g/m²)

SensingPaperEmpty

OutputStackingFace-Down

Duplex

2.1.2.4.Reliability&Service

PrintingV olume(SETAMPV)1800Pages,1080/720pages(Colorandmonoprints)

2.1.2.5.Consumables

250sheets@80g/m²(BaseLinePaper:SamsungPremium/Xerox4200)NN

Condition

SupportingStandard

MediasizesA4,Letter,Legal,Ocio,Folio

MediatypesPalinpaperonly

Mediaweight16~32lb(60~120g/m²)

ItemsSpecication

MaxMonthlyDuty120,000pages

MPBF65,000pages

MTTR<30min.

TonerCartridge

PaperTransferBelt(PTB)

ItemsSpecication

CLT-C609S(Cyan)

Model

Yield

ModelCLT-T508

Yield50Kpages

CLT-M609S(Magenta)

CLT-Y609S(Y ellow)

CLT-K609S(Black)

•Initial(CMYK):AverageCartridgeYield3.5Kstandardpages.

•Sales(CMYK):AveragecartridgeY ield7Kstandardpages

DeclaredcartridgeyieldinaccordancewithISO/IEC19798.

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-4

2.Productspecandfeature

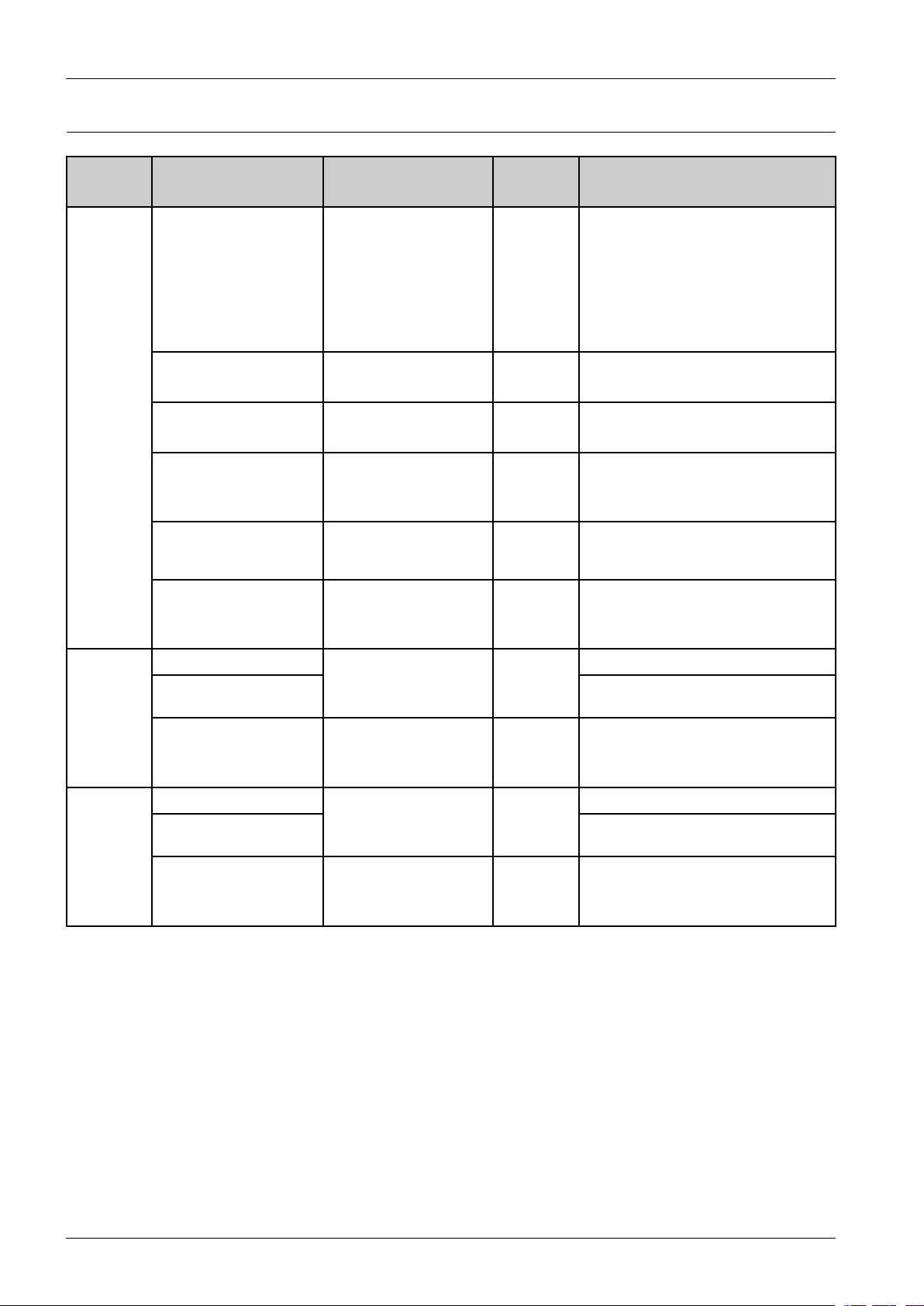

2.1.2.6.Maintenancepart

Items

FuserUnit

Pickup-Roller(Tray1)

Main

Set

RetardRoller(Tray1)

Pickup-Roller(MPT)

FrictionPad(MPT)

DustcleaningKit

PartCode

(PartName)

JC96-05454B

(Fuser,110V)

JC96-05455B

(Fuser,220V)

JC73-00340A

(RUBBER-PICKUP)

JC90-01063A

(CASSETTE-RETARD)

JC66-03043A

(ROLLER-RUBBER

P/UPMP)

JC73-00132A

(RPR-FRICTIONP AD

MP)

JC93-00399A

(FRAME-REGICLEANING)

Life

[LowStatus]

F:PrepareFuserunit

100K

Pages

100K

Pages

100K

Pages

100K

Pages

100K

Pages

100K

Pages

A:Preparenewfuserunit

[EmptyStatus]

F:ReplaceFuserunit

A:Replacewithnewfuserunit

N/A

F:ReplaceRetardroller

A:ReplacewithnewTray1Retardroller

N/A

N/A

F:ReplaceDustCleaning

A:ReplacewithnewDustCleaningkit

UIWarningMessage

F:First,A:After"OK"Button

Pickup-Roller(Tray2)N/A

ForwardRoller(Tray2)

SCF1

RetardRoller(Tray2)

Pickup-Roller(Tray3)N/A

ForwardRoller(Tray3)

SCF2

RetardRoller(Tray3)

JC97-02259A

(MEAUNIT -ROLLER

PU)

JC97-02259A

(MEAUNIT -ROLLER

PU)

JC97-02259A

(MEAUNIT -ROLLER

PU)

JC97-02259A

(MEAUNIT -ROLLER

PU)

200K

Pages

100K

Pages

200K

Pages

100K

Pages

N/A

F:ReplaceRetardroller

A:ReplacewithnewTray2Retardroller

N/A

F:ReplaceRetardroller

A:ReplacewithnewTray3Retardroller

2-5Copyright©1995-2016SAMSUNG.Allrightsreserved.

2.Productspecandfeature

2.1.2.7.Environment

ItemsSpecication

OperatingEnvironment

AcousticNoiseLevel

(SoundPower/Pressure)

InputV oltage110-127V AC,50/60Hzor220-240VAC,50/60Hz

PowerConsumption

Dimension(WxDxH)SET446x481x464mm(17.6x18.9x18.3inches)withoutoptionaltray

WeightSETwithconsumables30.4kg(67lbs)

Temperature15℃~32.5℃

Humidity10%~80%

PrintingLessthan54dBA

StandbyLessthan35dBA

SleepBackGroundLevel

ReadyLessthan60Wh

A VG.Lessthan750Wh

Max/PeakLessthan1000Wh

SleepLessthan8Wh

2.1.2.8.Packing&Accessory

ItemAccessory

DriverInstallCD-ROM

PowerCable

USBCable(CIS/China/Korea/India)

In-Box

QuickInstallGuide

WarrantyRegistrationCard

User’sManual(HTML)

InitialTonerCartridge(CMYK)

2.1.2.9.Options

ItemsModelNameRemark

MemoryML-MEM170512MB

SecondCassetteFeederCLP-S775500–sheetCassette

WirelessNetworkML-NWA65L

HardDiskML-HDK425250GB

IEEE1284BParallelML-PAR100

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-6

2.Productspecandfeature

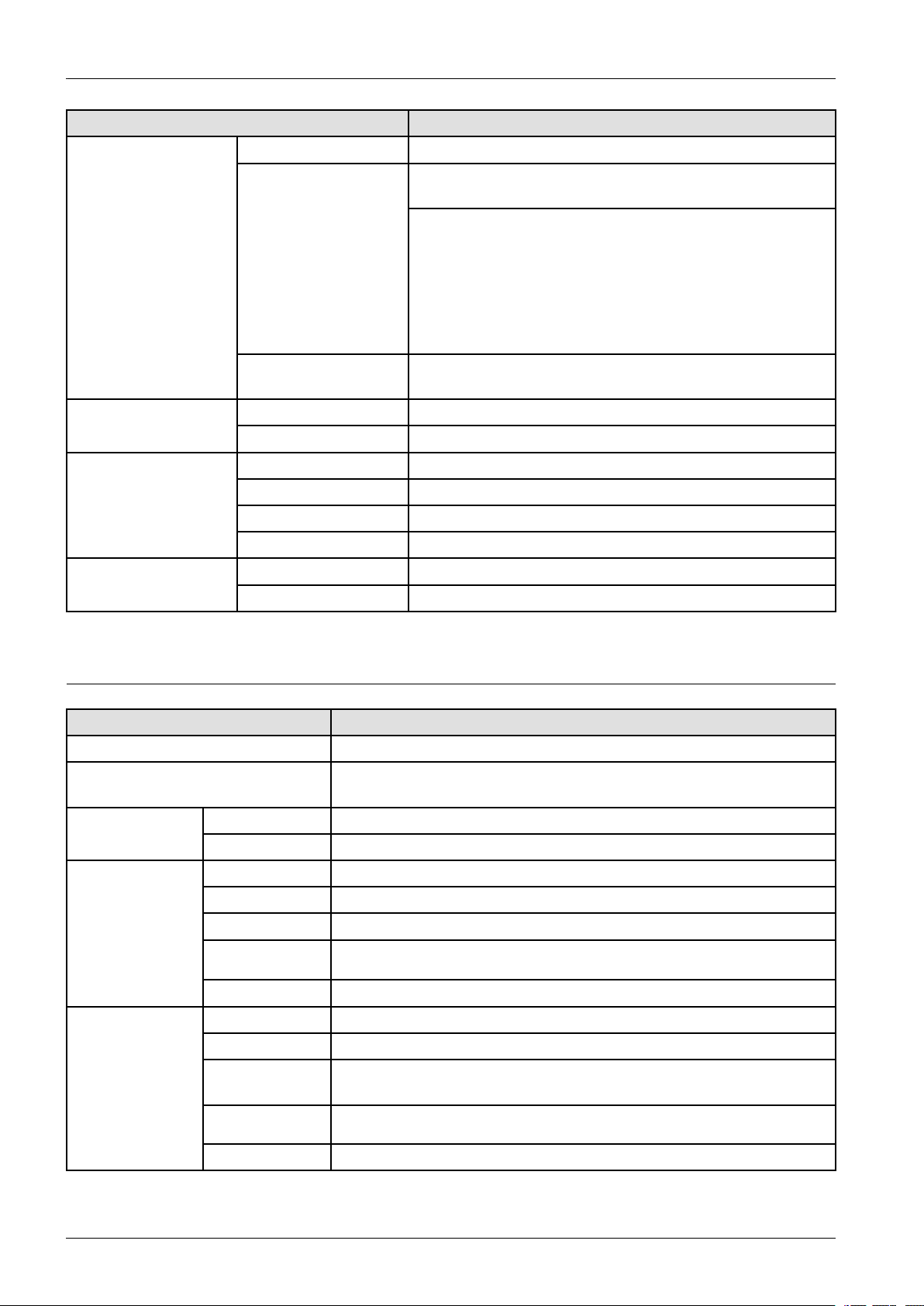

2.1.3.ModelComparisonTable

SamsungCLP-775NDSamsungCLP-770NDHPP1505n

Image

Mono/ColorSpeed(A4)33ppm/33ppm32ppm/32ppm30ppm/30ppm

Processor600MHzDualCore800MHz516MHz

Memory(Std/Max)384MB/896MB256MB/768MB256~512MB/1024MB

PrintLanguagePCL5/6,PS3,PDF1.4PCL5/6,PS3,PDF1.4PCL5/6,PS3,PDF1.4

PaperInput

DuplexStdStdStd

Interface

Size(mm)446x481x464mm446x481x464mm513x490x358mm

TonerCartridge

(Mono/Color)

500Cassette,100MP

500x2SCF

HighSpeedUSB2.0

GigabitEthernet

USBHost

7K/7K7K/7K10.5K/7K

500Cassette,100MP

500x2SCF

HighSpeedUSB2.0

GigabitEthernet

USBHost

250Cassette,100MP

HighSpeedUSB2.0

GigabitEthernet

USBHost

500SCF

2-7Copyright©1995-2016SAMSUNG.Allrightsreserved.

2.2.SystemOverview

Thischapterdescribesthefunctionsandoperatingprincipalsoftheprinter.

2.2.1.FrontView

2.Productspecandfeature

Thisillustrationmaydifferfromyourmachinedependingonitsmodel.

1OutputTray8FrontCoverHandle

2OutputSupport9FrontCover

3PaperLevelIndicator10ControlPanel

4OptionalTray*11Multi-PurposeTrayPaperWidthGuide

5Tray112TonerCartridge

6Multi-PurposeTray13PaperTransferBelt(PTB)

7Multi-PurposeTrayHandle

*:Thisisanoptionfeature.

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-8

2.Productspecandfeature

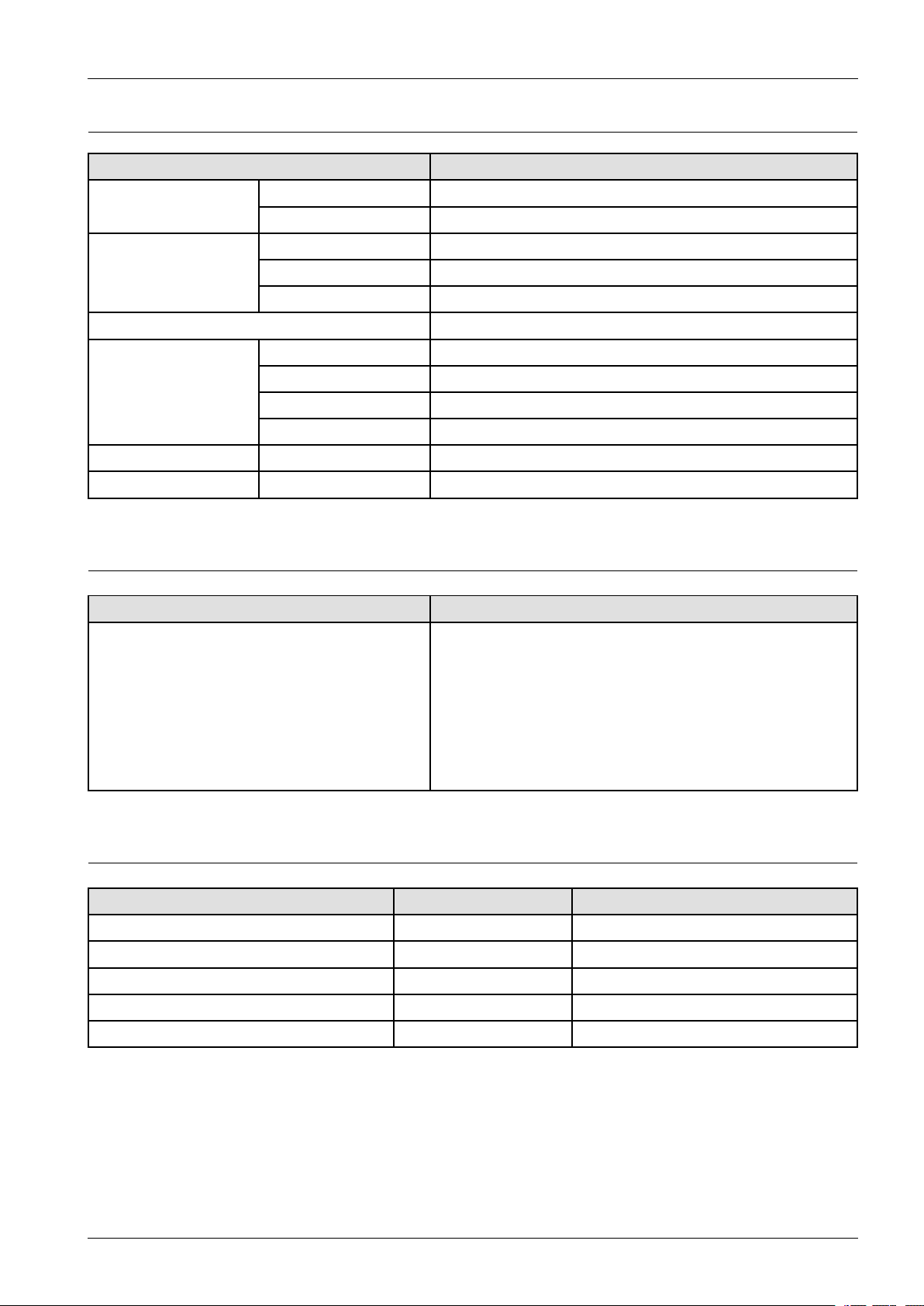

2.2.2.RearView

Thisillustrationmaydifferfromyourmachinedependingonitsmodel.

1ControlBoardcover6NetworkPort

2Powerreceptacle7USBPort

3Power-Switch8Externaldeviceinterface(EDI)*

4Handle9IEEE802.11b/g/nWirelessLAN**

5IEEE1284ParallelConnector

*:ExternaldeviceinterfaceforSamsungandthirdpartysolutions.

**:Thisisanoptionalfeature.

2-9Copyright©1995-2016SAMSUNG.Allrightsreserved.

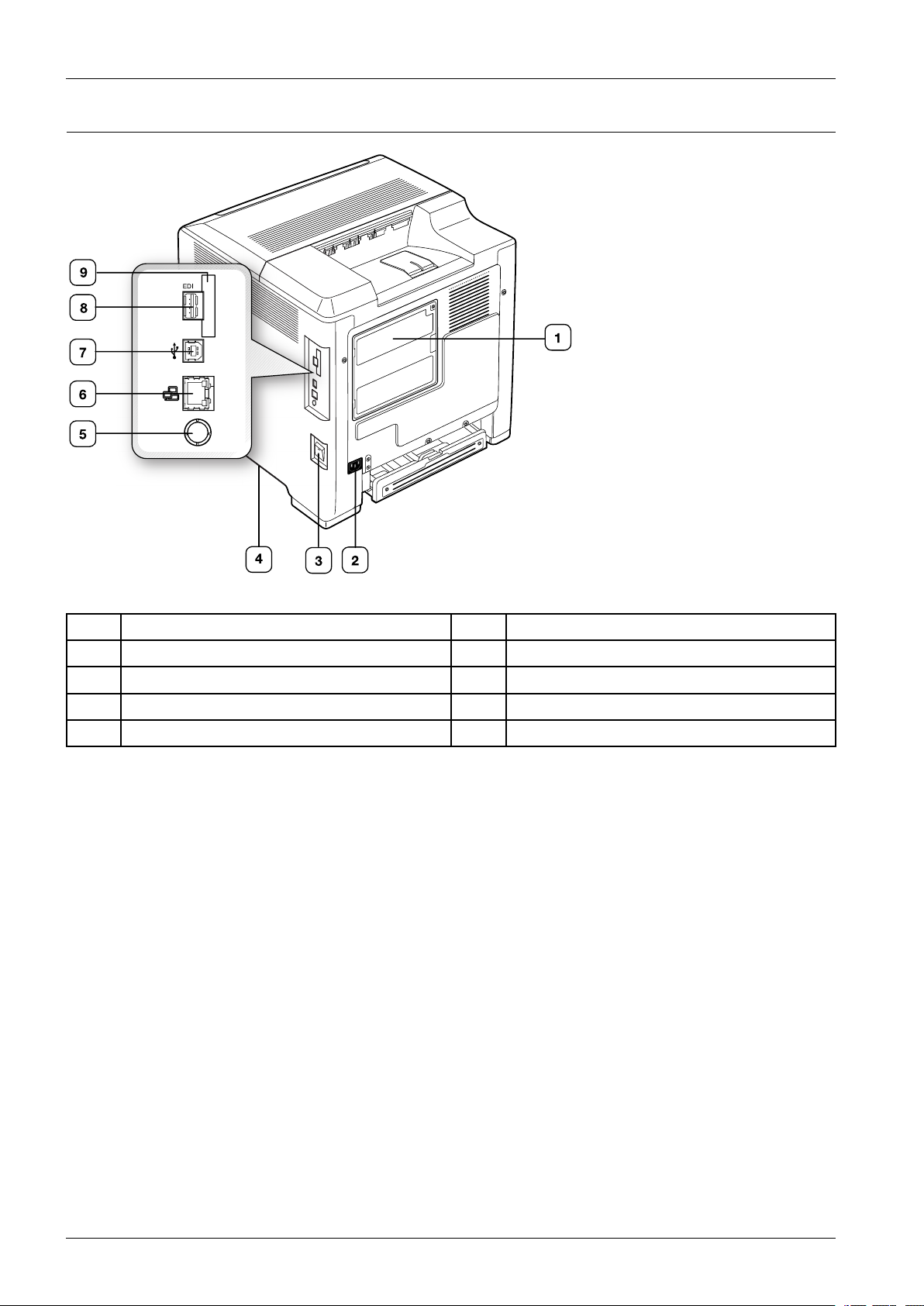

2.2.3.PaperPath

Cassette Feed

SCF1 Feed

SCF2 Feed

Simplex

Pass

Duplex Pass

Exit Pass

MP Feed

Cassette Feed

SCF1 Feed

SCF2 Feed

Simplex

Pass

Duplex Pass

Exit Pass

MP Feed

Cassette Feed

SCF1 Feed

SCF2 Feed

Cassette Feed

SCF1 Feed

SCF2 Feed

Simplex

Pass

Duplex Pass

Exit Pass

MP Feed

Simplex

Pass

Simplex

Path

Duplex Pass

Exit Pass

MP Feed

Duplex PassDuplex Path

Exit Pass

MP Feed

Exit Path

MP Feed

Thefollowingdiagramdisplaysthepaththepaperfollowsduringtheprintingprocess.

2.Productspecandfeature

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-10

2.Productspecandfeature

16

14

15

17

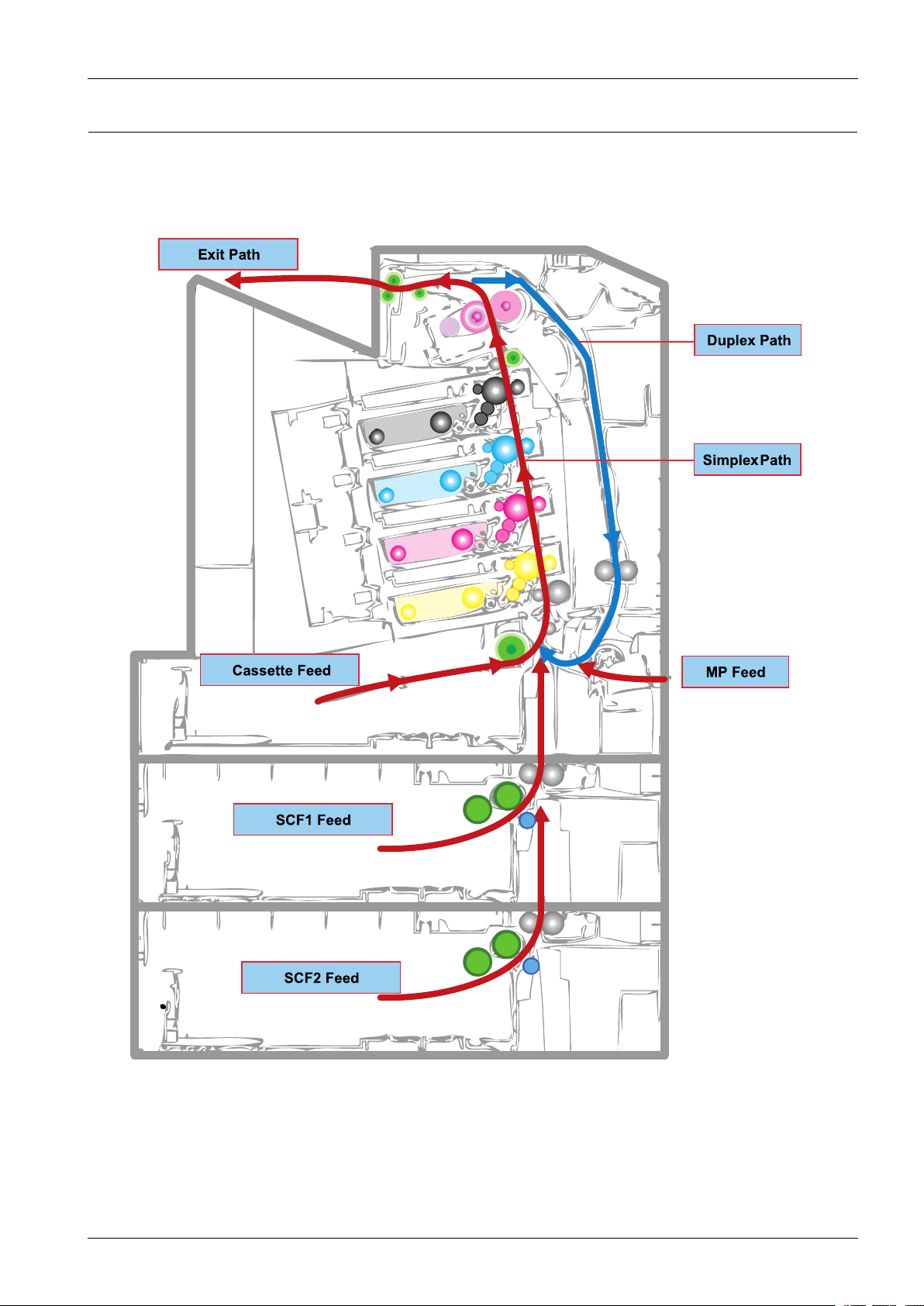

2.2.4.SystemLayout

Thismodelconsistsofthemechanicalpartsandhardwareparts.MechanicalpartsconsistsofFrame,Feeding,Developing,

Driving,Transferring,Fusing.Hardwarepartsconsistsofthemaincontrolboard,SMPSboard,HVPSboard,Fuser

controlboard,operationpanel,PCInterface.

NoNameNoName

1LSU10OPEUnit

2TonerCartridge(K)11FuserUnit

3TonerCartridge(C)12PaperTransferUnit(PTB)

4TonerCartridge(M)13Mainboard/SMPSboard/FuserDrive

5TonerCartridge(Y)14Pick-UpRoller

6Tray1(BasicTray)15RetardRoller

7SCFUnit(Optional)16RetardRoller

8Pick-UpRoller17Pick-UpRoller

9ExitRoller

2-11Copyright©1995-2016SAMSUNG.Allrightsreserved.

Board(FDB)

2.Productspecandfeature

2.2.4.1.FeedingSection

Itisconsistsofabasiccassette,anMPtrayforsupplyingdifferenttypesofmedia(envelope,label,specialpaper)and

partsrelatedtopapertransferring.

1)Tray1(BasicT ray)

Thismodelhasacassettetypetray.

Ittakesacenterloadingmethodandapplies‘semiretardseparatingmethod.’

Ithasapaperexistencesensingfunction,paperarrangingfunction.

Inthefrontside,thereisapaperlevelindicator.

2)Pick-uproller

ItistostarttheinitializationofpaperfeedoutoftheCassetteTray,andsubsequenttransporttotheRegistrationRollers.

ThePick-uprollerisdrivenbyasolenoid.

3)RegistrationRoller

ItisusedatheprimaryRegistrationRoller,whichisusedtotimethepaperwiththevisiblytonerimageontheTransfer

Belt;itisusedasanantiskewdeviceaswell.

4)MPTray

Themulti-purposetraycanholdspecialsizesandtypesofprintmaterial,suchaspostcards,notecards,andenvelopes.It

isusefulforsinglepageprintingonletterheadorcoloredpaper.

5)SCF(SecondCassetteFeeder ,2nd/3rdtray)

SCFistheoptionunitofCLP-775ND.Thisadditionallystoresandautomaticallyfeedsprintingpaper .Itsfunctionisthe

sameastheCassette(1sttray).ThisSCFcanbeinstalleduntilMax.2ea.

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-12

2.Productspecandfeature

2.2.4.2.FuserUnit

ThisunitconsistsofHeatRoller,aThermostat,andThermistors,etc.Itfusesthetonerthatwastransferredbythetransfer

rollerontothepaper,byapplyingpressureandhightemperaturetocompletefusingprocess.

•FusingType:[DualLampHeating,800W/500W]

•HeatRoller:PipeT ype(LampInside)

1)Thermostat

Whenaheatlampisoverheated,aThermostatcutsoffthemainpowertopreventover-heating.

•ThermostatT ype:Non-Contacttype

2)Thermistor

Itisatemperaturedetectingsensor .

3)FuserBelt

Thefuserbelttransferstheheatfromthelamptoapplyaheatonthepaper .Thesurfaceofthefuserbeltiscoatedwith

Teon,sotonerdoesnotsticktothesurface.

4)Pressureroller

Apressurerollermountedunderaheatrollerismadeofasiliconresin,andthesurfacealsoiscoatedwithTeon.Whena

paperpassesbetweenaheatrollerandapressureroller,toneradherestothesurfaceofapaperandispermanentlyfused.

2-13Copyright©1995-2016SAMSUNG.Allrightsreserved.

2.Productspecandfeature

1

2

3

4

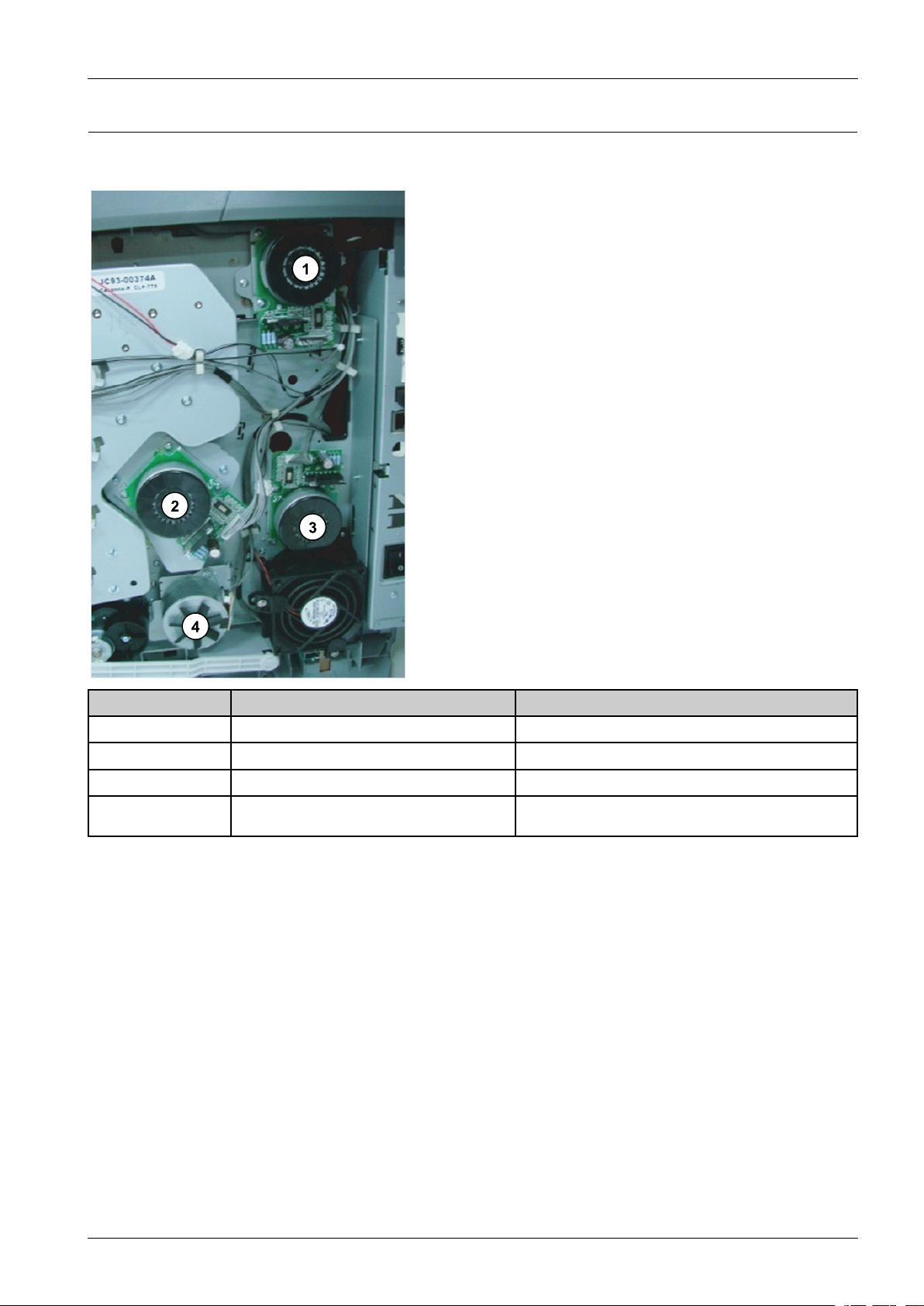

2.2.4.3.DriveUnit

Thisproducthavemanymotors.ThesemotorsdrivethePTBunit,fuserunit,feederunit,exitunit,etc.

NoMotorFunction

1BLDCMotorForFuserUnit

2BLDCMotorForOPCDriveUnit

3BLDCMotorForDEVEDriveUnit

4StepMotorForFeedDriveUnit

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-14

2.Productspecandfeature

OP C Drum

Photo Diode

LD Driver circit

Prote ctor panel

LD(La s er Diode)

Polygon Mirror

Polygon Motor

Motor Driver

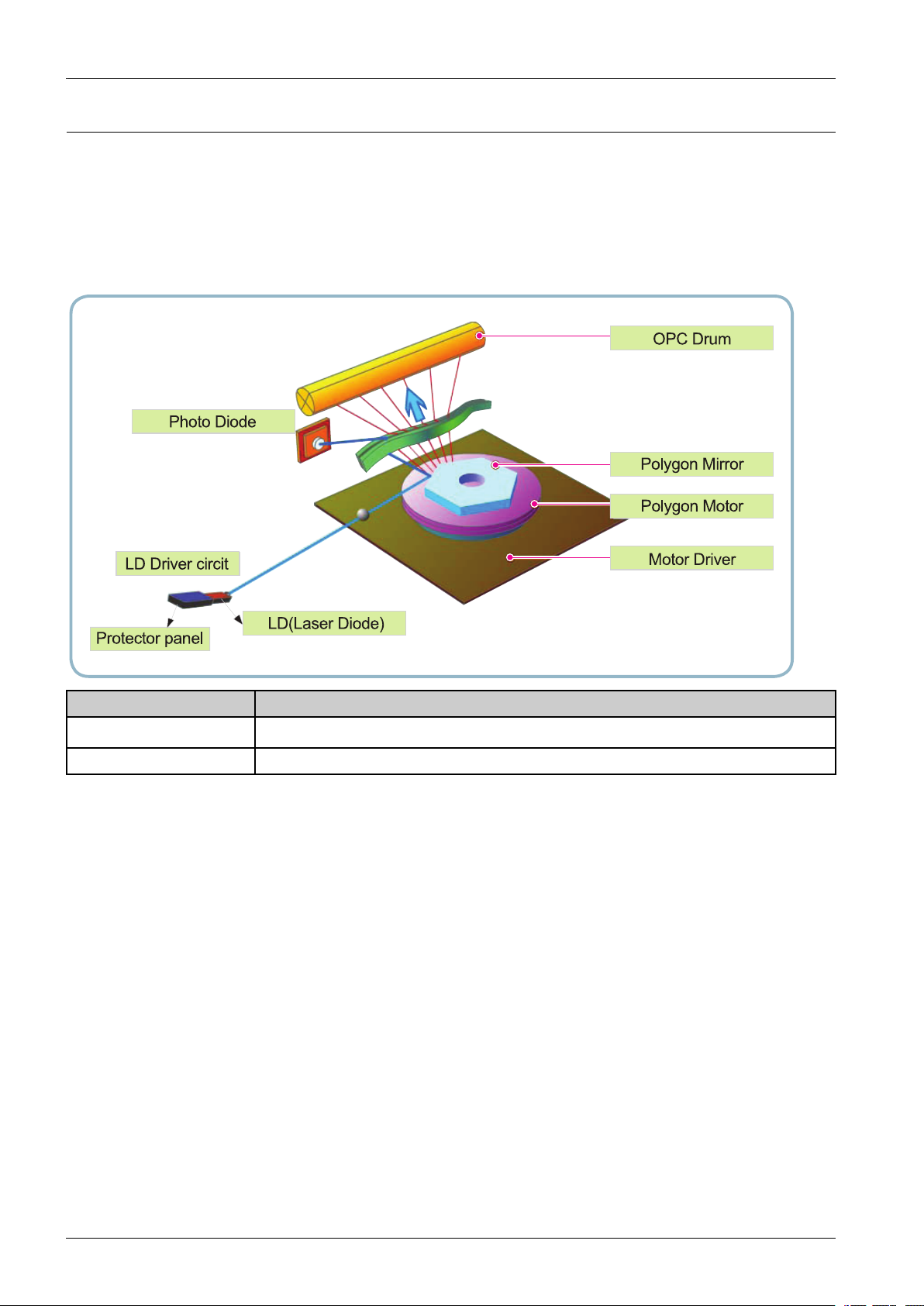

2.2.4.4.LSU(LaserScannerUnit)

ItisthecorepartoftheLBPwhichswitchesfromthevideodatareceivedtothecontrollertotheelectrostaticlatentimage

ontheOPCdrumbycontrollinglaserbeam,exposingOPCdrum,andturningprincipleofpolygonmirror.TheOPCdrumis

turnedwiththepaperfeedingspeed.The/HSYNCsignaliscreatedwhenthelaserbeamfromLSUreachestheendofthe

polygonmirror,andthesignalissenttothecontroller.Thecontrollerdetectsthe/HSYNCsignaltoadjusttheverticallineof

theimageonpaper.Inotherwords,afterthe/HSYNCsignalisdetected,theimagedataissenttotheLSUtoadjusttheleft

marginonpaper.Theonesideofthepolygonmirrorisonelineforscanning.

TroubleFailureAnalysis

PolygonMotorErrorTheRotationofPolygonMotorcannotreachstable.

HsyncErrorThoughtherotationofPolygonMotorreachstable,thesignalofHsyncisnotoccurred.

2-15Copyright©1995-2016SAMSUNG.Allrightsreserved.

2.Productspecandfeature

2.2.4.5.PTB(PaperTransferBelt)Unit

Thisunitconsistsofatransferbelt,transferroller,duplexunit.wastetonertank,etc.Thetransferbeltcarriestheprinting

paperthroughOPCdrumsofeachcolors.AsthepaperandtransferbeltpassbetweenthetransferrollerandtheOPC

drum,thenegativelychargedtonerimagesformedonOPCdrumaretransferredtotheprintingmediumpaperbypositive

biasappliedtothetransferroller .Thetonerimagestransferredtothepaperismelteddownandxedonthepaperby

thefusingsystem.

•BeltCleaning:CollectthetonerbyusingRubberBlade

•Managementofwastedtoner:TheW asteT onerT ankisequipped.

•LifeSpan:50,000images(DeclaredyieldvalueinaccordancewithISO/IEC24712)

•TransferV oltageControl:ADCControlonConductiveSpongeRoller

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-16

2.Productspecandfeature

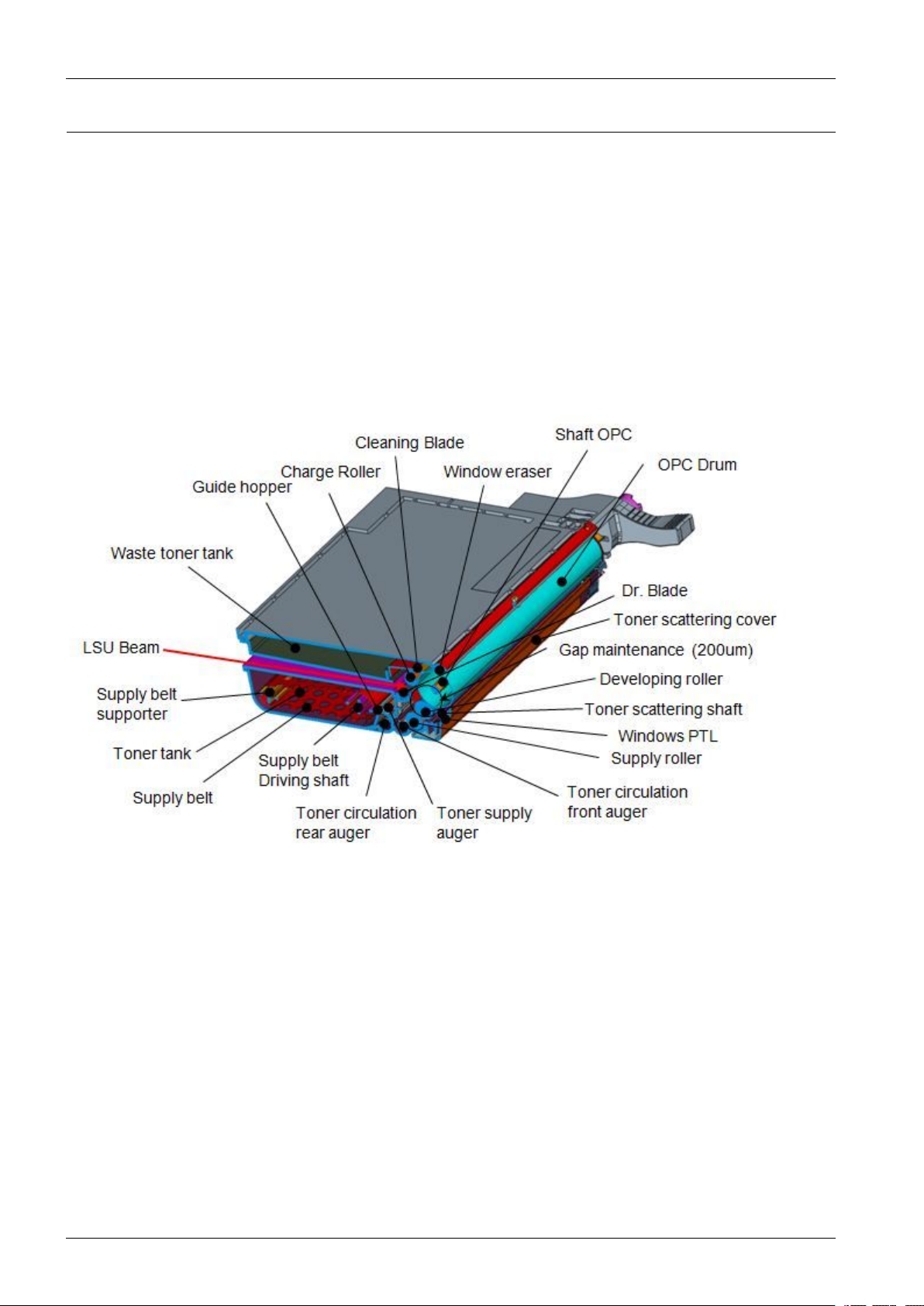

2.2.4.6.TonerCartridge

Byusingtheelectronicphotoprocess,itcreatesavisualimage.EachtonercartridgeconsistsoftheOPCunitandthe

developingunit.TheOPCunithasOPCdrumandchargingroller,andthetonercartridgeunithastoner,supplyroller,

developingroller,andblade(Doctorblade)

•Developingmethod:Non-magneticone-componentnon-contactingmethod

•Toner:Nonmagneticone-componentpulverizedtoner

•Theexpectedlifeoftonercartridge:7,000(YMCK)pages(N/N,Simplex,ISO/IEC24712standardpages)

•OPCCleaning:CollectthetonerbyusingCleaningBlade

•MethodofTonersupply:Toneriscarriedtothedevelopingrollerbysupplybelt.

2-17Copyright©1995-2016SAMSUNG.Allrightsreserved.

2.2.5.HardwareConguration

LP E C 3

ASIC

En gin e

Co n trol

DDR 2

32b it

SO DIMM

MODULE

M

U

X

SMPS TYPE5 ( STAG E3)

PO WER

CO RD

FUS ER Lam p Co nt rol

Moto r

-O PC BLDC

-DEVE BLDC

-FU SER BLDC

-FE ED STEP MOTO R

S ole no id/C lut c h

-CS T Pic kup S ole noid

-DEVE K Clutc h

- REG I Clu tch

-Fu se r Fa n

-Re ar Fa n

P TB UNIT

ACR s en s or L/R

LSU

-2 Po lyg on Moto r

-2 Bea m 4 LD

-LSU Tem p

FUS ER UNIT

Th ermis tor1

Th ermis tor2

800 W lam p

Th ermo sta t

500 W lam p

S CF UNIT

(OP TION)

HVPS

5V

5VS

S ATA

US B

HUB

EE PRO M

M2451 2

WLAN

ED I

Fla s h Me m ory

32 M

Co ver

Switc h

24VS1

24V1

Se n s or

-FC F Emp ty

-CS T Dete ct

-Fe ed Se ns or

-Exit Se ns o r

-Re gi Se ns or

-P- size S en so r

Ca s se tt e

-MP Pic kup So lenoid

-MP Emp ty Sen s o r

24V1/24 V2 /24V3

5V_SMPS

DE VICE

US B

RE S E T IC

DC Co nv er ter

Re gu lat o r

SC L0_C 4

SD A0_C 4

ADDR

DATA

GIGA BIT

RTL82 11D

1W MICOM

n POWE R_O FF

5V

n KEY_PO WER _SW

n SLEE P_2 4V_OFF

SC F_R XD

SC F_T XD

PANE L_RX

D

PANE L_TX

D

FU SER CONT ROL

FU SER BIAS

SC L_B ELT

SD A_B ELT

AN_C TD1_P

AN_C TD2_P

ADC_ CTDL ED

Se n s or -Ana log

-TEMP_ IN

-Hum id ity/TEMP_OUT

OUT BIN SENS O R

AC

OP

Pa n e l

MAIN P BA

Ch o ru s

4

OP TION

DEVE CRUM IF PB A

DEVE Y C RUM

DEVE M CR UM

DEVE C CRUM

DEVE K CRUM

CL K_LP EC

3

n RES ET

n F_R ESE T

PWM Con ’

SATA I/ F

US B Hos t

DE VICE

US B

3.3 V

1.1 V 1 .8V

Sy s tem

C4 Lp ec 3

VDDQ VTT

1.8 .V 0.9 V

MCLK

SS CG

UCLK

SATA_CLK

SS CG

RTC CLK

12Mh z

15Mh z

32. 768K hz

12Mh z

VCLK

SC L_DE V

SD A_DE V

P a ra llel pwr

CR UM

CTD s en so r

SUB_AC

-HVPS F an

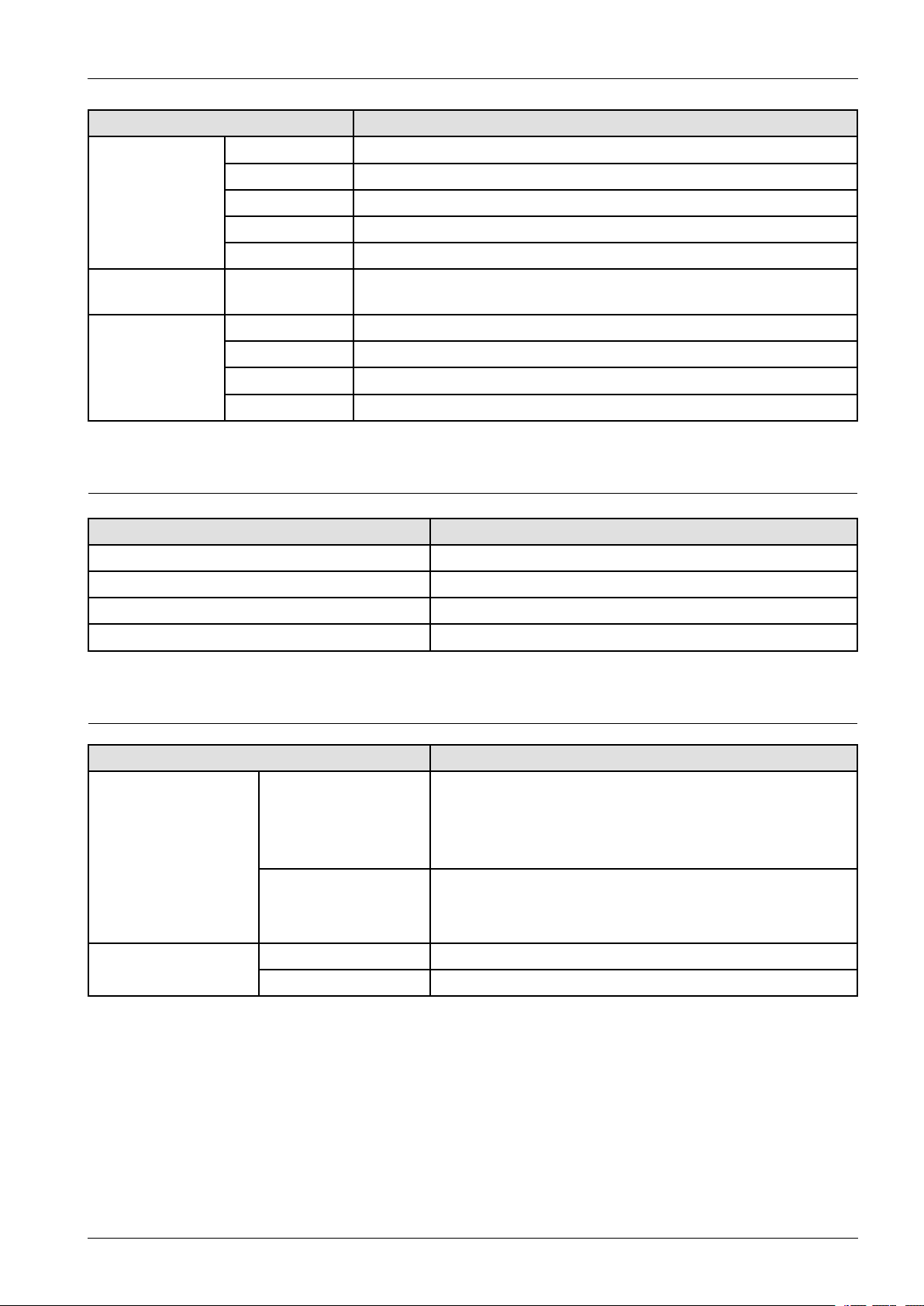

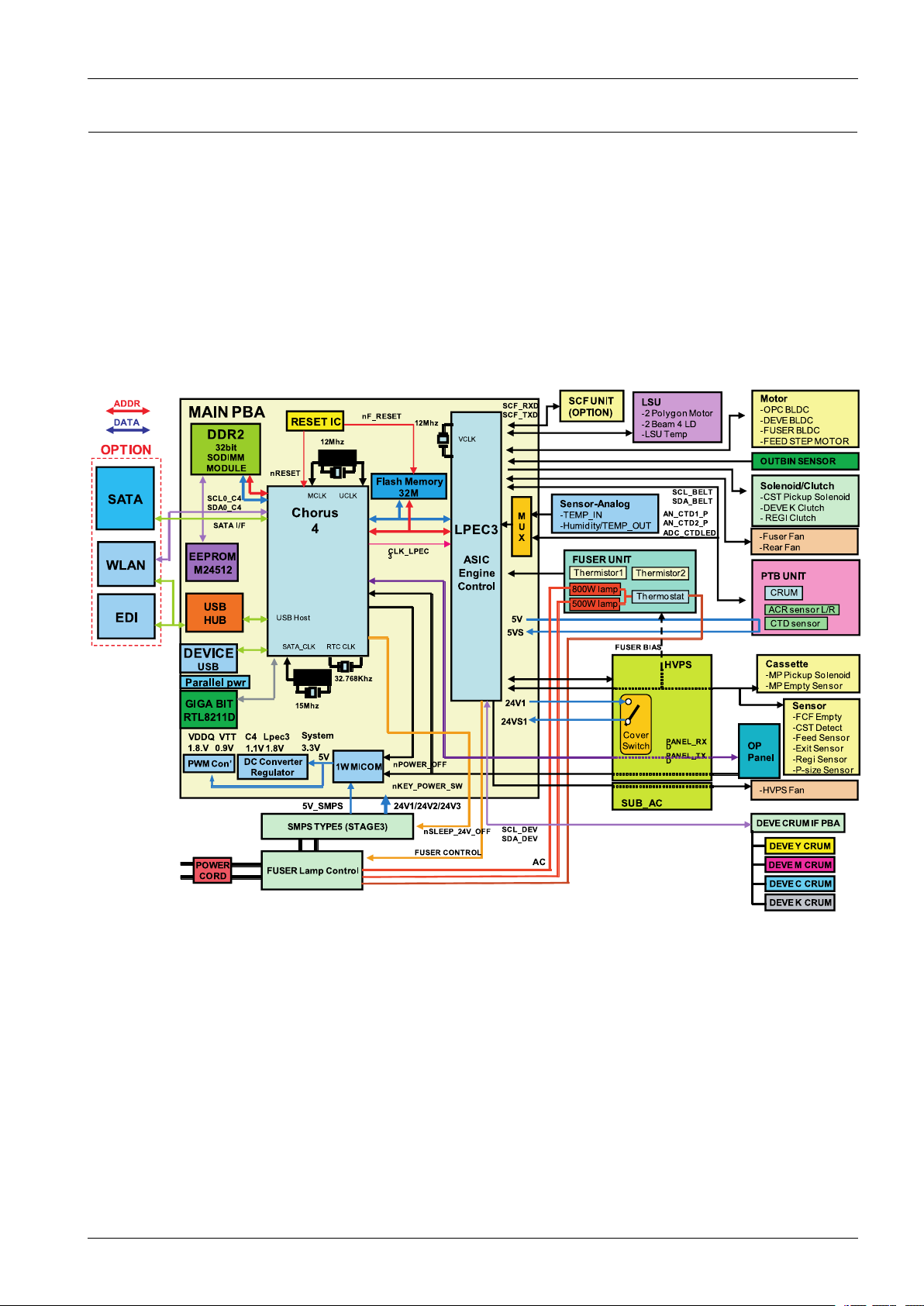

TheCLP-775NDElectricalCircuitSystemconsistsofthefollowing:

•Mainboard

•SMPSboard

•HVPSboardandHVPSsubboard

•FuserDriveboard

•OPEboard

CLP-775NDBlockDiagram

2.Productspecandfeature

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-18

2.Productspecandfeature

1

2

3

4

5

6

7

8

9

1

0

111

2

1

3

1

4

1

5

1

6

1

7

1

8

2

0

1

9

3

3

3

1

3

2

3

0

2

9

2

8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

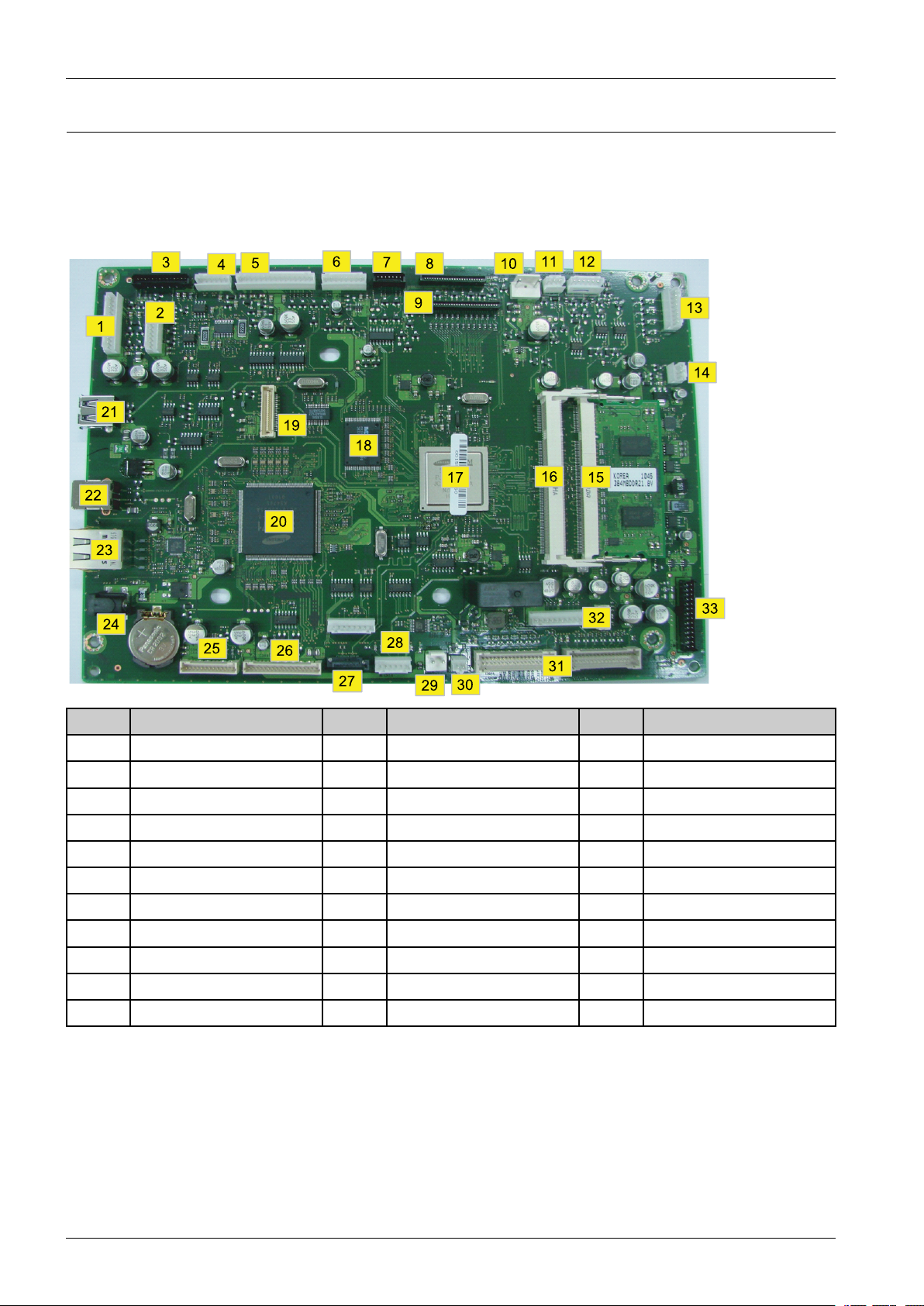

2.2.5.1.MainPBA

TheCLP-775NDsystemcontrollerconsistsofamaincontrollerandanenginecontrollerinone-board.Themaincontroller

usesaARMScorechipasmainprocessors,whicharededicatedforprintingseveralinternaloperatingblocksthrough

systemprogramsstoredinFlashMemory.TheenginecontrollerhasanenginecontrolSoC,whichincludesmotordrivers,

PWMdrivers,LSUdrivers,sensors,high-voltagedrivers,andotherdrivingunitsformechanicalparts.

NOConnectorNOConnectorNOConnector

1DEVEBLDC12pin12FUSERTHERMISTOR6pin23NETWORKJACK

2OPCBLDC10pin13PTL8pin24DCJACK

3PTB14pin14FANRear3pin25MHV12pin

4FEEDMotor6pin15BASEDIMM26SCFI/F18pin

5FUSERBLDC15pin16OPTIONDIMM27HDDSA TA7pin

6HUMIDITYsensor8pin17Chorus4asic28FUERHEATCTL6pin

7DEVECRUM7pin1832MBFlashmemory29HDDPWR2pin

8HVPSInterface23pin19WLAN30LSUTemp2pin

9HVPSInterface30pin20LPEC3ASIC31LSU32pin/34pin

10Coveropen2pin21HOSTJACK32LSUPWR10pin

11OUTBINSensor3pin22USBJACK33SMPS28pin

2-19Copyright©1995-2016SAMSUNG.Allrightsreserved.

CPU

1)ARMv5TEcompliantcore800MHz(I-Cache:32KB,D-Cache:32KB)

Memory

1)ROM

•NorFlashused(32MB)

•InterfaceWithChorus4ROMController

2)SDRAM

•Size:CLP-775ND(DDR2):Default384MB(Option512MB)

3)EEPROM

•Size:512KB

•InterfaceWithSPGPV4I2CController

4)SDRAM

•Size:256Byte

2.Productspecandfeature

I/OInterface

1)USB

•DEVICE:HighSpeedUSB2.0(Highspeed480Mbps)

•Host:J-SCRIBEEnablerKit(Fullspeed12Mbps)

2)N/WEmbedded

•Chorus4WithMIIInterface

•ActiveLED(Y ellow)/LinkLED(Green)

3)PWM

•HighV oltageControlWithDuty

•MainMotorClock

4)I2CInterface

•NVRAM(systeminformation+networkinformation)

•CRUM

Copyright©1995-2016SAMSUNG.Allrightsreserved.2-20

2.Productspecandfeature

1

2

24V Fuse

5V Fuse

Varistor

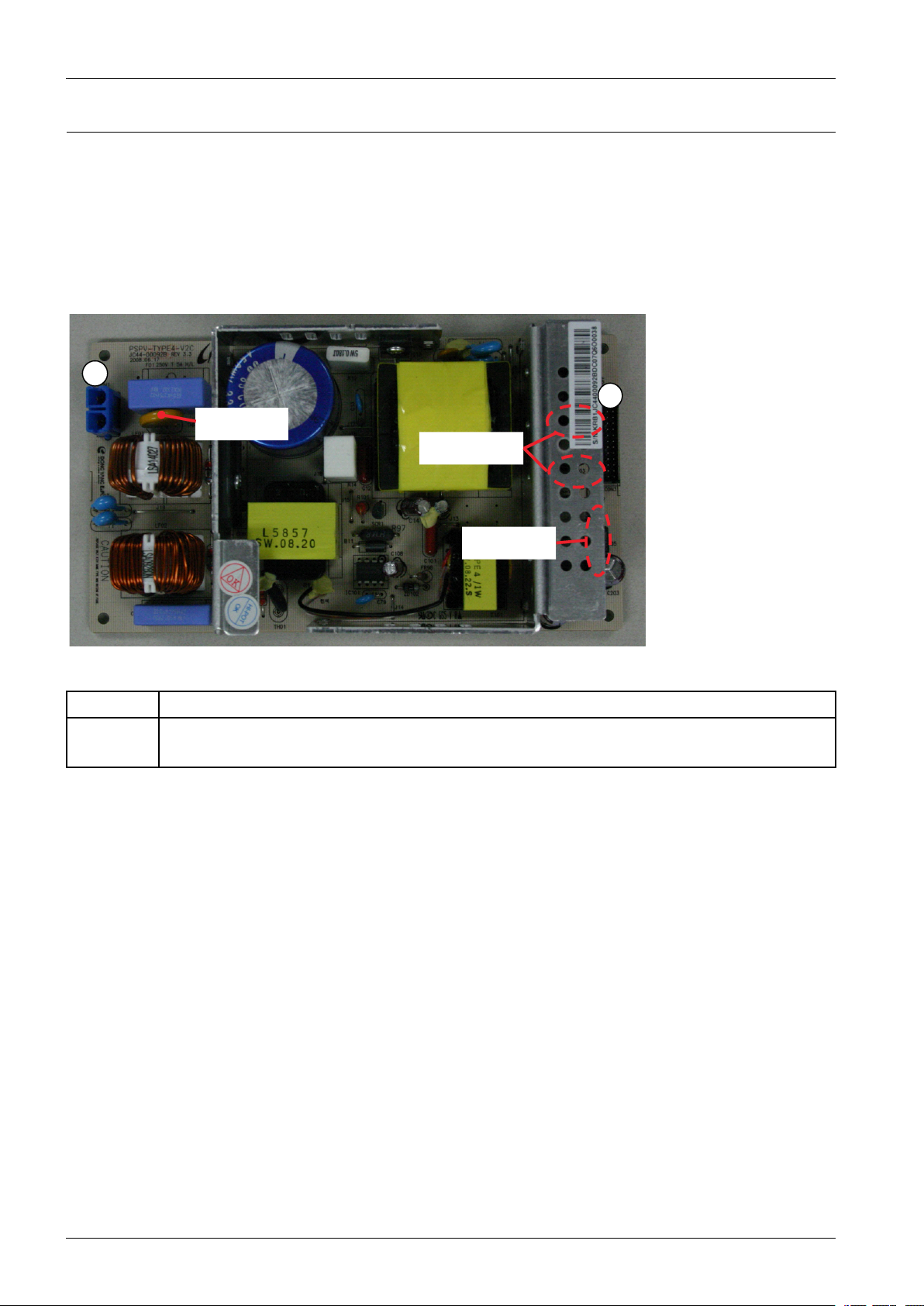

2.2.5.2.SMPSboard

SMPS(SwitchingModePowerSupply)BoardsupplieselectricpowertoaMainBoardandotherboardsthroughaMain

Controllerby+5V ,+24Vfrom110V/220Vpowerinput.Ithassafetyprotectionmodesforovercurrentandload.

•Specication

-AC110V(90V~135V)/AC220V(180V~270V)

-OutputPower:192W/Max.270W

-DC5V:24W~30W/DC24V :168W~240W

■Connection

1INPUT_AC(FuserDriveBoard)

2OUTPUT_5V,24V(MainPBA)

INPUT_24V_Control(MainPBA)

2-21Copyright©1995-2016SAMSUNG.Allrightsreserved.

Loading...

Loading...