PROFIBUS Positioner

Type 3785

PA device profile version 2.0

Mounting and

Operating Instructions

EB 8382-1 EN

Firmware version R 1.4x/K 1.6x

Edition July 2004

Fig. 1 · Type 3785 PROFIBUS Positioner

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . 8

1.1 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Attaching the positioner. . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Direct attachment to Type 3277 Actuator . . . . . . . . . . . . . . . . 10

2.2 Attachment according to IEC 60534-6 . . . . . . . . . . . . . . . . . 14

2.2.1 Mounting sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Presetting the valve travel . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Attachment to rotary actuators . . . . . . . . . . . . . . . . . . . . . 18

2.3.1 Mounting the cam follower roll lever . . . . . . . . . . . . . . . . . . 18

2.3.2 Mounting the intermediate piece . . . . . . . . . . . . . . . . . . . . 18

2.3.3 Aligning and mounting the cam disk . . . . . . . . . . . . . . . . . . 20

2.3.4 Reversing amplifiers for double-acting actuators . . . . . . . . . . . . 22

2.4 Fail-safe position of the actuator . . . . . . . . . . . . . . . . . . . . 22

3 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Pneumatic connections. . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.1 Pressure gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.2 Supply air pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Forced venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.2 Limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.3 Establishing communication (bus address) . . . . . . . . . . . . . . . 28

3.2.4 Local interface (SSP) . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1 LED controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 Write protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Activate/deactivate forced venting . . . . . . . . . . . . . . . . . . . 31

4.4 Default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.1 Adjusting mechanical zero. . . . . . . . . . . . . . . . . . . . . . . 32

4.4.2 Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5 Adjusting the inductive limit switches . . . . . . . . . . . . . . . . . . 34

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Servicing explosion-protected devices . . . . . . . . . . . . . . . . . 35

2 EB 8382-1 EN

Contents

7 How to implement a Class 1 PROFIBUS Master . . . . . . . . . . . . 36

7.1 Device database files (GSD) . . . . . . . . . . . . . . . . . . . . . . 36

7.2 Data exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Parameter description . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.4 Coding of measured value status . . . . . . . . . . . . . . . . . . . . 42

7.5 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8 List of parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9 Messages and diagnostics. . . . . . . . . . . . . . . . . . . . . . . 61

9.1 Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2 Extended diagnostic messages . . . . . . . . . . . . . . . . . . . . . 63

9.3 CHECKBACK messages . . . . . . . . . . . . . . . . . . . . . . . . 64

9.4 Messages during initialization . . . . . . . . . . . . . . . . . . . . . 66

Dimensional drawing . . . . . . . . . . . . . . . . . . . . . . . . . 69

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

EB 8382-1 EN 3

Contents

4

The device is to be assembled, started up or operated only by trained and experienced personnel familiar with the product.

According to these mounting and operating instructions, trained personnel is

referred to as individuals who are able to judge the work they are assigned to

and recognize possible dangers due to their specialized training, their knowledge and experience as well as their knowledge of the applicable standards.

4

Explosion-protected versions of this device are to be operated only by personnel who have undergone special training or instructions, or who are authorized to work on explosion-protected devices in hazardous areas.

4

Any hazards that could be caused in the positioner by the process medium,

the operating pressure, the signal pressure or by moving parts are to be prevented by means of the appropriate measures.

If inadmissible motions or forces are produced in the pneumatic actuator as a

result of the supply air pressure level, the pressure must be restricted using a

suitable supply pressure reducing station.

4

Proper shipping and storage are assumed.

4

Note! Devices with a CE marking fulfil the requirements of the Directives

94/9/EC and 89/336/EEC. The declaration of conformity is available at

http://www.samson.de and on request.

!

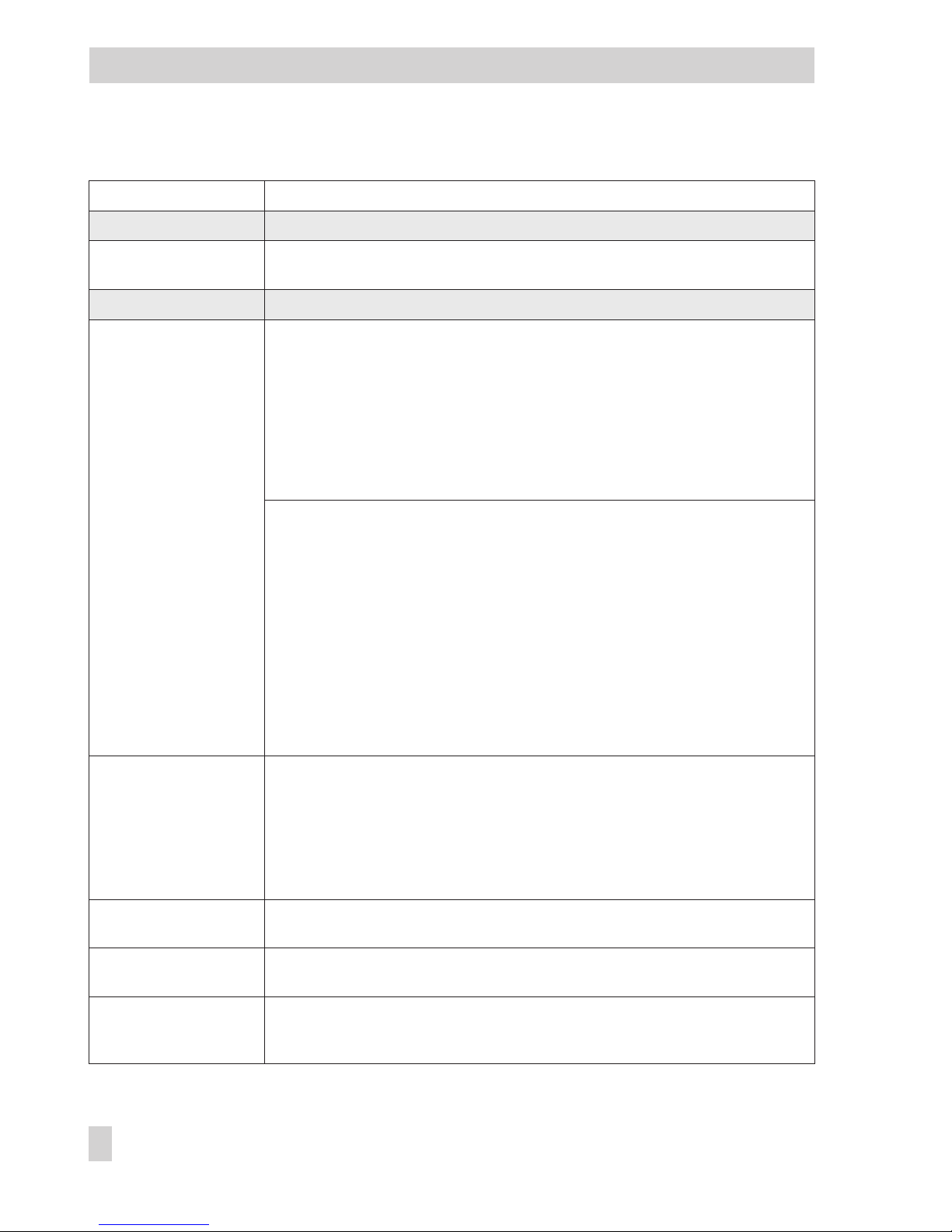

Modifications of the firmware compared to the previous version

Old New

Control R 1.23 R 1.31

Firmware adaptation for a new hardware version

Hardware version device index .01

Control R 1.31 R 1.4

Actuator type When the actuator type is switched from "linear actuator" to "rotary actua-

tor", the following applies:

Initialization method . . . Based on maximum range

Transmission code . . . . 590

Nominal angle . . . . . 90°

End position for w < . . . 1 %

End position for w > . . . 99 %

Rot. angle range starts at 0°

Rot. angle range ends at 90°

When the actuator type is switched from "rotary actuator" to "linear actuator", the following applies:

Attachment . . . . . . . Integral . . . . . . . . . NAMUR

Initialization method . . . Based on nominal range . Based on nom. range

Mounting position: arrow Towards actuator . . . . Away from actuator

Transmission code . . . . D1 . . . . . . . . . . . –

Pin position . . . . . . . – . . . . . . . . . . . . A

Rated travel . . . . . . . 15 mm . . . . . . . . . 15 mm

End position for w < . . . 1 % . . . . . . . . . . . 1 %

End position for w > . . . 125 % . . . . . . . . . 125 %

Lower travel range value. 0 mm . . . . . . . . . . 0 mm

Upper travel range value 15 mm . . . . . . . . . 15 mm

Lever length . . . . . . . – . . . . . . . . . . . . 42 mm

Initialization method When the initialization method is switched from "maximum range" to "nomi-

nal range", the following applies:

End position for w < 1% End position for w > 125 %

When the initialization method is switched from "nominal range" to "maximum range", the following applies:

End position for w < 1% End position for w > 99 %

Desired transit time

open/closed

The adjustment range of the desired transit time is now limited to 75 s.

Initialization During initialization, the minimum control pulses are determined for 20 % to

80 % of the manipulated variable range and saved in the EEPROM.

Proportional-action

coefficients

KP_Y1 and KP_Y2

The coefficients are adapted to the selected actuator type and the measured

transit times.

4 EB 8382-1 EN

Firmware modifications

Control R 1.41 R 1.42

Correction when zero calibration was triggered by communication.

Communication K 1.34 K 1.41

Firmware adaptation for new hardware version

Hardware version device index .01

Communication 1.41 K 1.51

Bit 7 of the CHECKBACK parameter indicates the current status of control

loop monitoring. In contrast to bit 13, bit 7 is automatically reset when control

loop monitoring detects no further errors. The function of bit 13 remains unchanged. Messages issued by bit 7 are only supported with firmware version

R 1.41 and higher.

The "warm start" message indicated by bit 11 of the DIAGNOSIS parameter

is automatically reset after 10 s.

In Local Override mode, bit 2 of the CHECKBACK parameter is activated.

Communication 1.51 K 1.60

A bad set point status no longer causes the positioner to move the valve to

fail-safe position in any case. Rather, the positioner's behavior is determined

by the FSAVE_TYPE parameter.

Using the serial interface, the positioner can be configured and operated with

SAMSON's TROVIS-VIEW Configuration and Operator Interface software.

EB 8382-1 EN 5

Firmware modifications

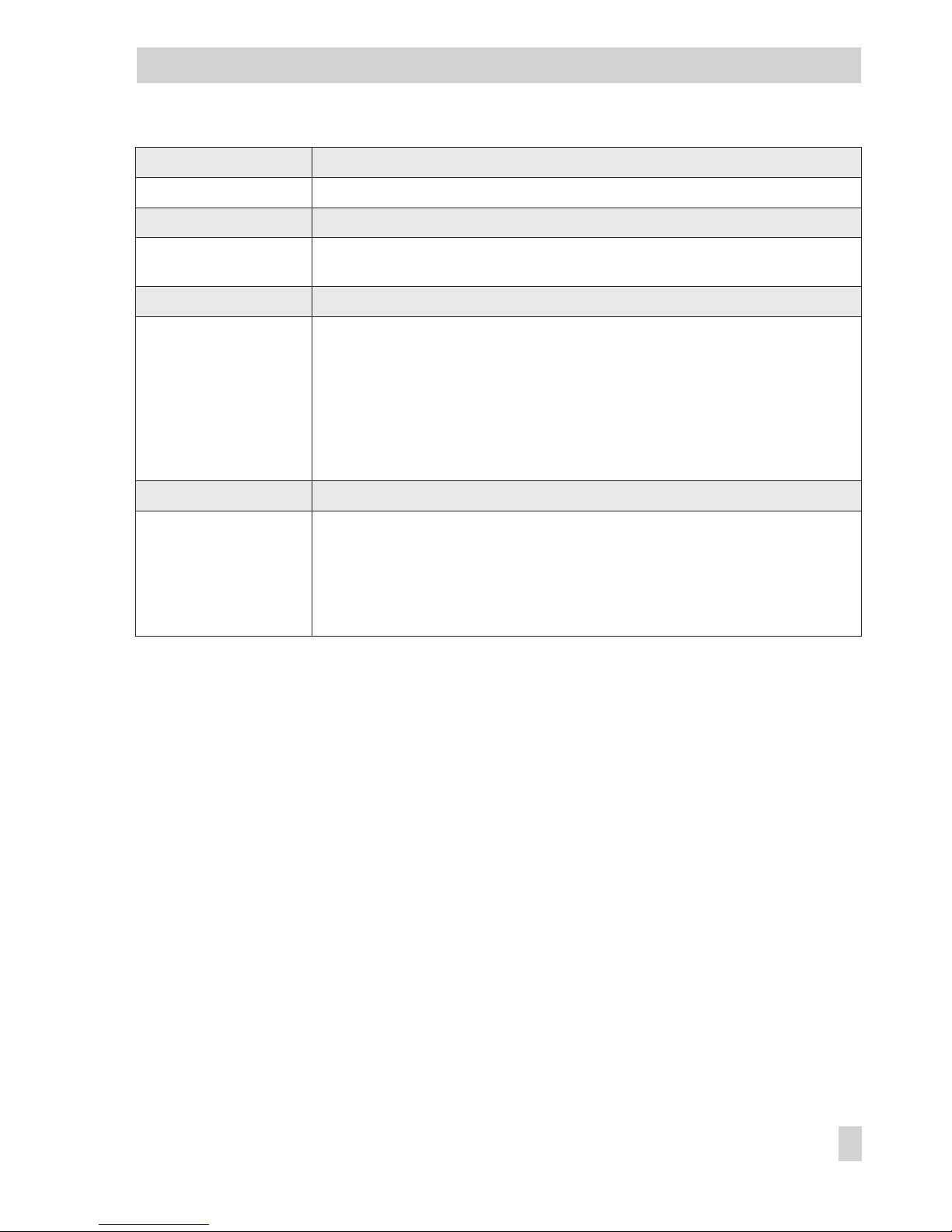

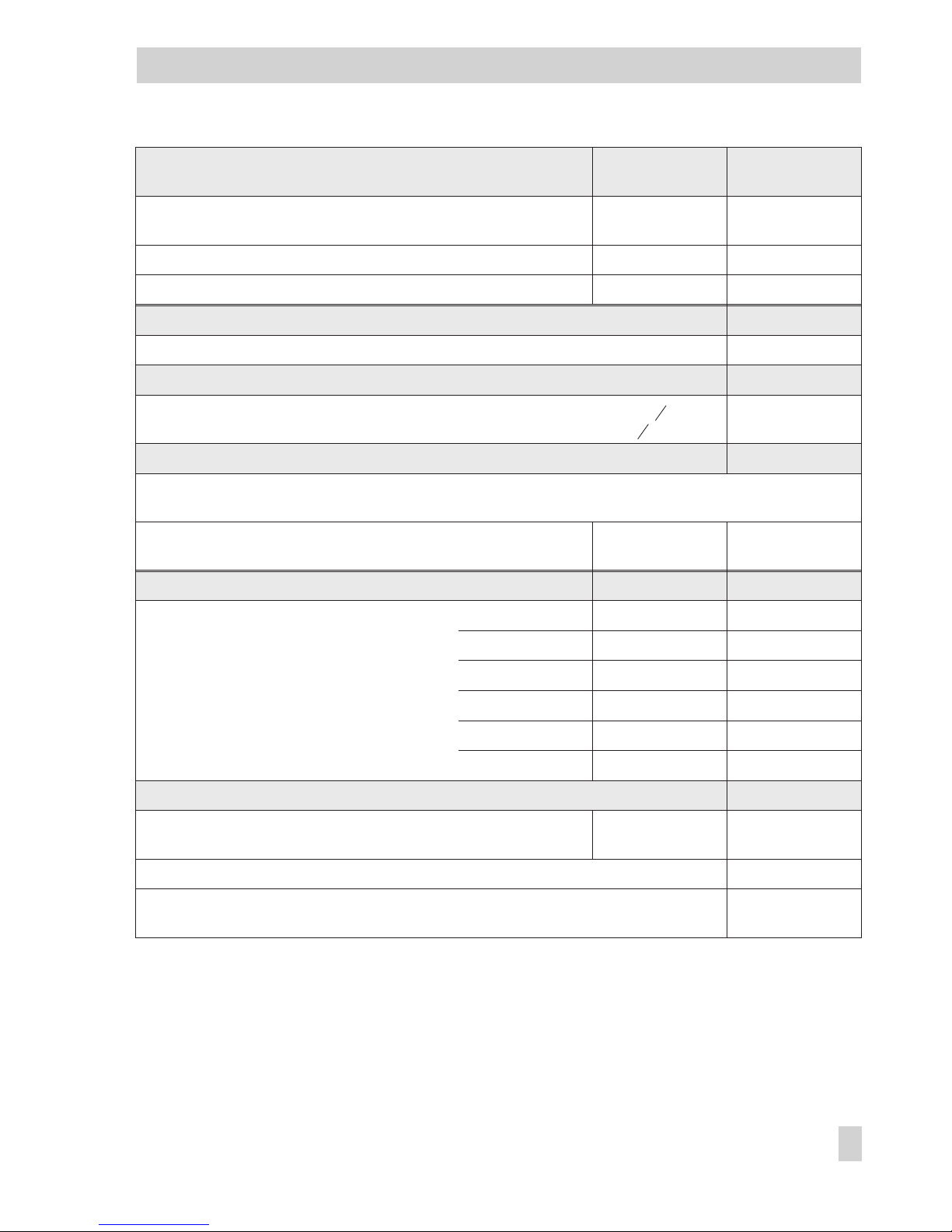

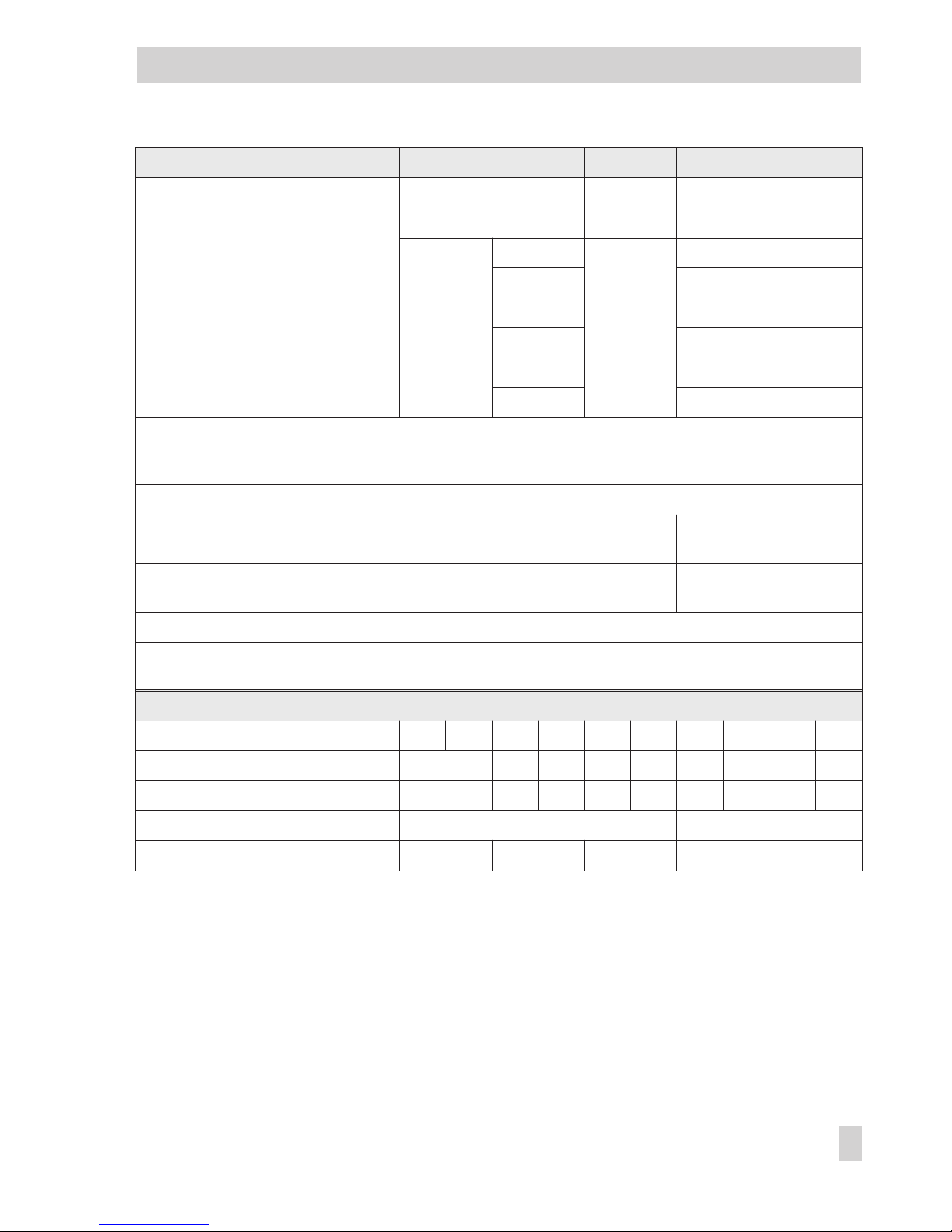

Positioner

Travel

Direct attachment Type 3277

Acc. to IEC 60534-6 (NAMUR)

Adjustable

5 mm to 30 mm

5 mm to 255 mm or 30° to 120° for rotary actuators

Bus connection Fieldbus interface according to IEC 61158-2

Field unit according to FISCO (Fieldbus Intrinsically Safe Concept)

Permissible operating voltage 9 to 32 V DC; the specifications in the EC type examination certifi-

cate additionally apply to explosion-protected devices.

Voltage supplied over bus cable

Static destruction limit 35 V

Max. operating current 10 mA

Current in case of fault 0 mA

Auxiliary energy Supply pressure of 1.4 to 6 bar (20 to 90 psi)

Air quality according to ISO 8573-1:2001, i.e. max. particle size

and density: Class 4; oil content: Class 3;

pressure dew point: Class 3 or at least 10 K above lowest ambient

temperature to be expected

Signal pressure (output) 0 bar up to supply air pressure

Adjustable characteristic Linear, equal percentage, reverse equal percentage, user-defined

Deviation from characteristic≤1 %

Dead band Adjustable from 0.1 to 10.0 %, default 0.5 % (based on rated

travel/angle)

Resolution < 0.05 % (internal measurement)

Desired transit time Up to 75 s, separately adjustable for exhaust and supply air

Direction of action Reversible, adjusted using software

Air consumption Independent of supply air < 90 l

n

/h

Air supply

Actuator pressurized for Δp = 6 bar: 9.3 mn³/h, for Δp = 1.4 bar: 3.5 mn³/h

Actuator vented for Δp = 6 bar: 15.5 m

n

³/h, for Δp = 1.4 bar: 5.8 mn³/h

Permissible ambient temperature

–40 °C to 80 °C, the specifications in the EC type examination

certificate additionally apply to explosion-protected devices

Influences Temperature:≤0.15 %/10 K, auxiliary energy: none

Vibration: none up to 250 Hz and 4 g

Explosion protection II 2 G EEx ia IIC T6 acc. to ATEX, see EC type examination certificate

Degree of protection IP 65 using the included filter check valve

Electromagnetic compatibility Requirements acc. to EN 61000-6-2, EN 61000-6-3 and NE 21 met

Binary input Internal power supply 5 V DC,

R

i

= 100 kΩfor alarm function, e.g. connection of pressure switch

6 EB 8382-1 EN

Technical data

Forced venting

Input

K

V

coefficient

To be activated using switch inside the positioner

6 to 24 V DC, static destruction limit 45 V

R

i

approx. 6 kΩat 24 V DC (depending on voltage)

Switching point for "1" signal at≥3 V, switching point for "0" signal

only at 0 V

0.17

Communication Data transmission acc. to PROFIBUS-PA, Profile Class B, version 2.0

acc. to DIN EN 50170 and DIN 19245, Part 4 (version 3.0 also

available)

Local interface SAMSON SSP interface for configuration and start-up

Bus address Adjustable using software or microswitch, default upon delivery: 126

Accessories

Inductive limit switches Two Type SJ2SN proximity switches

For connection to switching amplifier according to EN 60947-5-6

Materials

Housing Die-cast aluminum, chromated and plastic-coated

External parts Stainless steel 1.4571 and 1.4301

Weight Approx. 1.3 kg

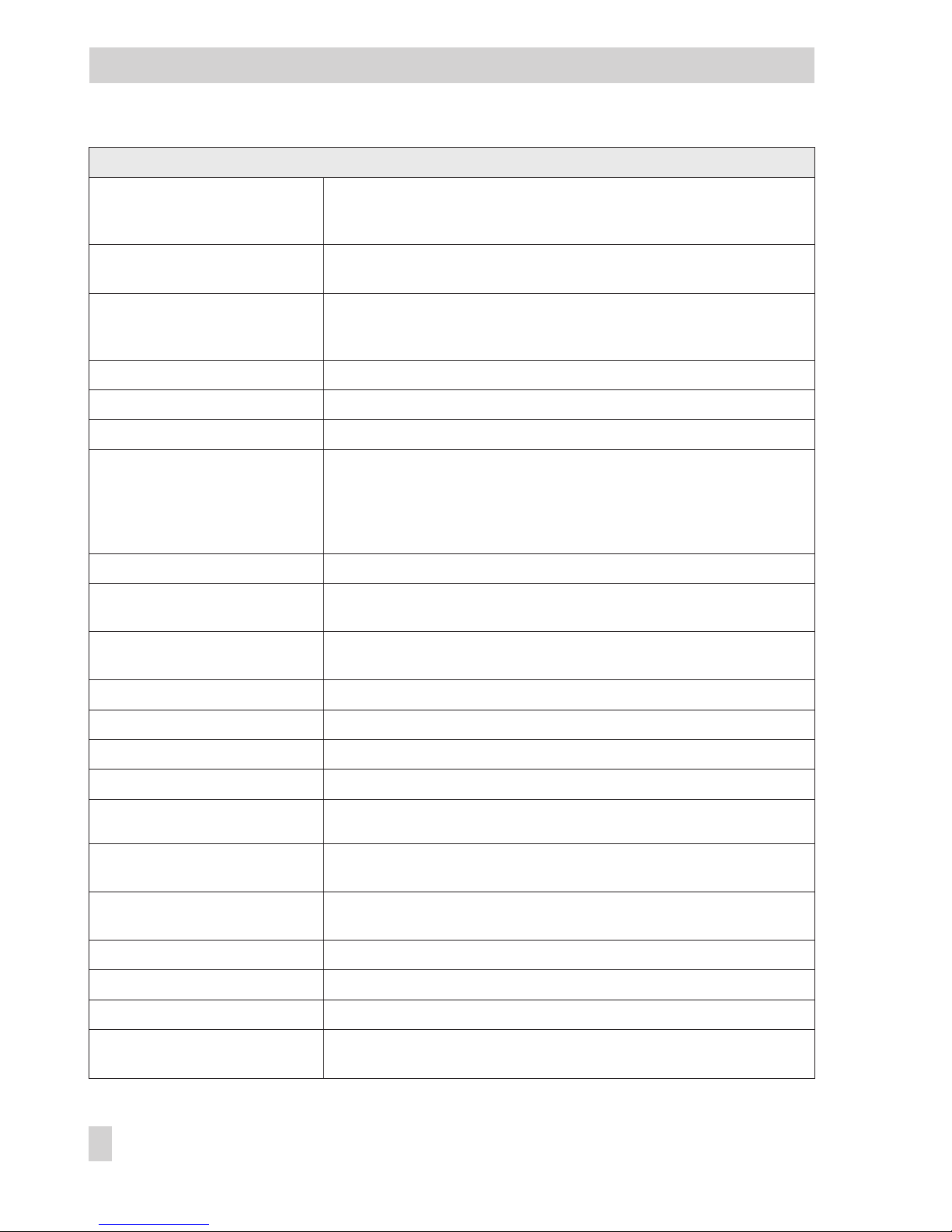

Positioner versions

Type 3785– XXXXX

3

X

Explosion

protection

Without

Ex II 2 G Ex ia IIC T6 acc. to ATEX

With Ex ia CSA/FM

Ex II 3 G Ex nA II T6 acc. to ATEX

0

1

3

8

Accessories Limit switches Without

2 inductive

0

22

Forced venting Without

With

0

12

PA device profile Version 2.0

Version 3.0

0

1

Pneumatic

connections

NPT ¼-18

ISO 228/1-G ¼

1

2

Electrical

connections

Cable gland M 20 x 1.5 with shielding,

nickel-plated brass

Quantity: 1

Quantity: 2

1

2

EB 8382-1 EN 7

Technical data

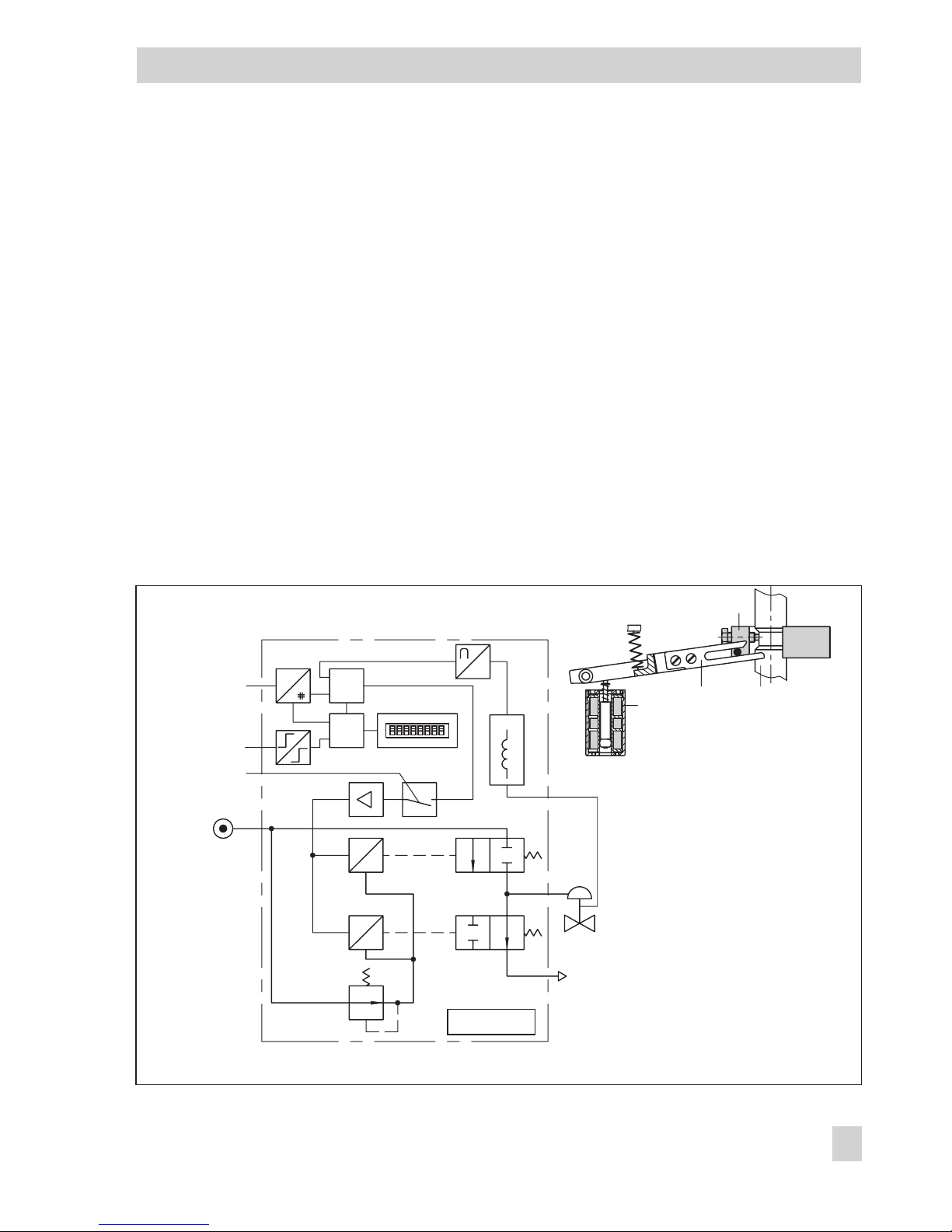

1 Design and principle of opera-

tion

The digital PROFIBUS-PA positioner is designed for attachment to pneumatic control

valves. It is used to assign the valve stem position (controlled variable) to the control signal (reference variable). It compares the digital output signal to the travel of the control

valve and generates a corresponding pressure signal as the output variable. As a result, the positioner requires auxiliary supply

air with a pressure of 1.4 to 6 bar. The necessary electrical power is supplied by the bus

of the PROFIBUS-PA segment based on

IEC 61158-2 standard transmission technology.

The positioner consists of an inductive,

contactless travel pick-off system and an

electrically controlled valve block comprising

two on/off valves and an electronic unit. This

unit contains two microcontrollers for processing the control algorithm and managing

PROFIBUS communication.

If a deviation between the actual valve travel

(actual value) and the reference variable (set

point) occurs, the microcontroller produces

binary pulse-pause modulated signals to

control the two on/off valves, each of which

is assigned a downstream amplifier. One of

these valves controls the exhaust air, the

other the supply air.

The supply air valve (3) controls the connection between the supply air (7, supply air

pressure 1.4 to 6 bar) and the actuator

(pressurizing). The exhaust air valve (4) controls the air exhausted from the actuator to

the atmosphere (venting). The on/off valves

can either have the switching states ("permanently open", "permanently closed" or gen-

erate single pulses of changing widths). The

two valves cause the plug stem to move to a

position corresponding to the reference variable. If there is no system deviation, both the

supply air valve and the exhaust air valve

are closed.

By default, the positioner is equipped with a

binary input for floating contacts, which additionally signals the switching state of a

further field device via PROFIBUS.

Activating the write protection switch, which

is located next to the bus address in the

hinged lid, prevents the positioner settings

from being overwritten by PROFIBUS communication.

Positioner with forced venting function:

The positioner is controlled by a 6 to 24 V

signal, causing the signal pressure to be applied to the actuator. If this voltage signal decreases, the signal pressure is shut off and

the actuator is vented. The springs in the actuator move the valve to its fail-safe position.

The forced venting function is included in all

positioners and can be activated/deactivated

as required over a switch. Refer to section 4.3 for details.

1.1 Optional accessories

As a supplement to the standard positioner

version, the positioner can be equipped with

limit switches. Two proximity switches can be

used to indicate the valve's end positions in

safety-related circuits.

1.2 Communication

The positioner is completely controlled by

digital signal transmission according to the

PROFIBUS-PA Profile Class B based on

8 EB 8382-1 EN

Design and principle of operation

DIN EN 50170 and DIN 19245, Part 4.

Data is transmitted as bit-synchronous current modulation at a transmission rate of

31.25 kbit/s over twisted-pair cables according to IEC 61158-2. Positioners are generally set up using a PC. One or more

positioners are connected to the PC's

PROFIBUS segment via segment coupler.

After mechanically resetting the positioner to

zero, it can be automatically started up using

an initialization routine. During initialization,

zero is automatically adjusted and the preset

span is checked.

The positioner is delivered with a standard

configuration for a control valve with a rated

travel of 15 mm designed for integral

positioner attachment.

Customized configuration to adapt the

positioner to other actuators can only be carried out using communication.

Configuration

The positioner is configured and operated on

the PC over the SSP interface (13) using

TROVIS-VIEW. Alternatively, it can be configured and operated via a segment coupler,

e.g. using the COMMUWIN II user interface

(by Endress + Hauser) or the SIMATIC PDM

user interface (by SIEMENS).

During configuration, parameters such as

control characteristic, direction of action,

travel limitation, travel range, transit time

and alarms, can be entered.

EB 8382-1 EN 9

Design and principle of operation

11

10

1

12

e

p

3

4

2

5

9

7

6

1

G

μC

61158-2

IEC

e

p

G

μC

PROFIBUS-PA

8

Serial Interface

13

Fig. 2 · Functional diagram

Binary input

Forced venting

Supply

air

Exhaust

air

1 Inductive travel pick-off

2 Microcontroller

3 On/off valve for supply air

4 On/off valve for exhaust air

5 Microcontroller

6 Switch for bus address and

write protection

7 Binary input

8 Forced venting

9 IEC 61158-2 interface module

10 Actuator stem

11 Lever

12 Clamp

13 SSP interface

2 Attaching the positioner

The positioner can be attached either directly

to a SAMSON Type 3277 Actuator or according to NAMUR (IEC 60534-6) to control

valves with cast yokes or rod-type yokes.

In combination with an intermediate piece,

the positioner can also be attached as a rotary positioner to rotary actuators.

Since the standard positioner unit is delivered without accessories, refer to the corresponding tables for required mounting parts

and their order numbers.

Note!

For fast control valves with small travels

(transit time < 0.6 s), replace the filter in the

signal pressure output with a screw-in restriction, if necessary, to improve the control

properties. See also sections 2.1, 2.2 and

2.3.

Important!

The positioner does not have its own vent

plug so that the air is exhausted to the atmosphere through vent plugs located on the accessories (see also Figs. 3, 5 and 6).

A filter check valve for the exhaust air is included with each positioner (underneath the

transparent cover on the back of the

positioner).

Replace the standard vent plug included in

the accessories with this filter check valve.

This is necessary to achieve degree of protection IP 65 by preventing dirt and moisture

from entering the device.

2.1 Direct attachment to

Type 3277 Actuator

For selection of the required mounting parts,

refer to Tables 1, 2 and 3 on page 13.

When looking at the signal pressure connection or the switchover plate (120 cm² actuator) from the top, the positioner must be attached to the left side of the actuator.

The arrow on the black housing cover

(Fig. 11) points towards the diaphragm

chamber.

Exception: control valves in which the plug

closes the seat area when the actuator stem

retracts. In this case, the positioner has to be

attached to the right side of the actuator, i.e.

with the arrow pointing away from the diaphragm chamber.

1. Screw clamp (1.2) to the actuator stem,

ensuring that the fastening screw is located in the groove of the actuator stem.

2. Screw associated lever D1 or D2 (for

700 cm² actuator) to the transmission lever of the positioner.

3. Fasten distance plate (15) with the seal

pointing towards the actuator yoke.

4. Place positioner on the plate so that the

pick-off lever D1 or D2 slides centrically

over the pin of the clamp (1.2). Screw

positioner to the distance plate (15).

5. Mount cover (16).

10 EB 8382-1 EN

Attaching the positioner

EB 8382-1 EN 11

Attaching the positioner

SUPPLY

1817 19

1.2

D2

D1

17

16

15

1.2

16

17

15

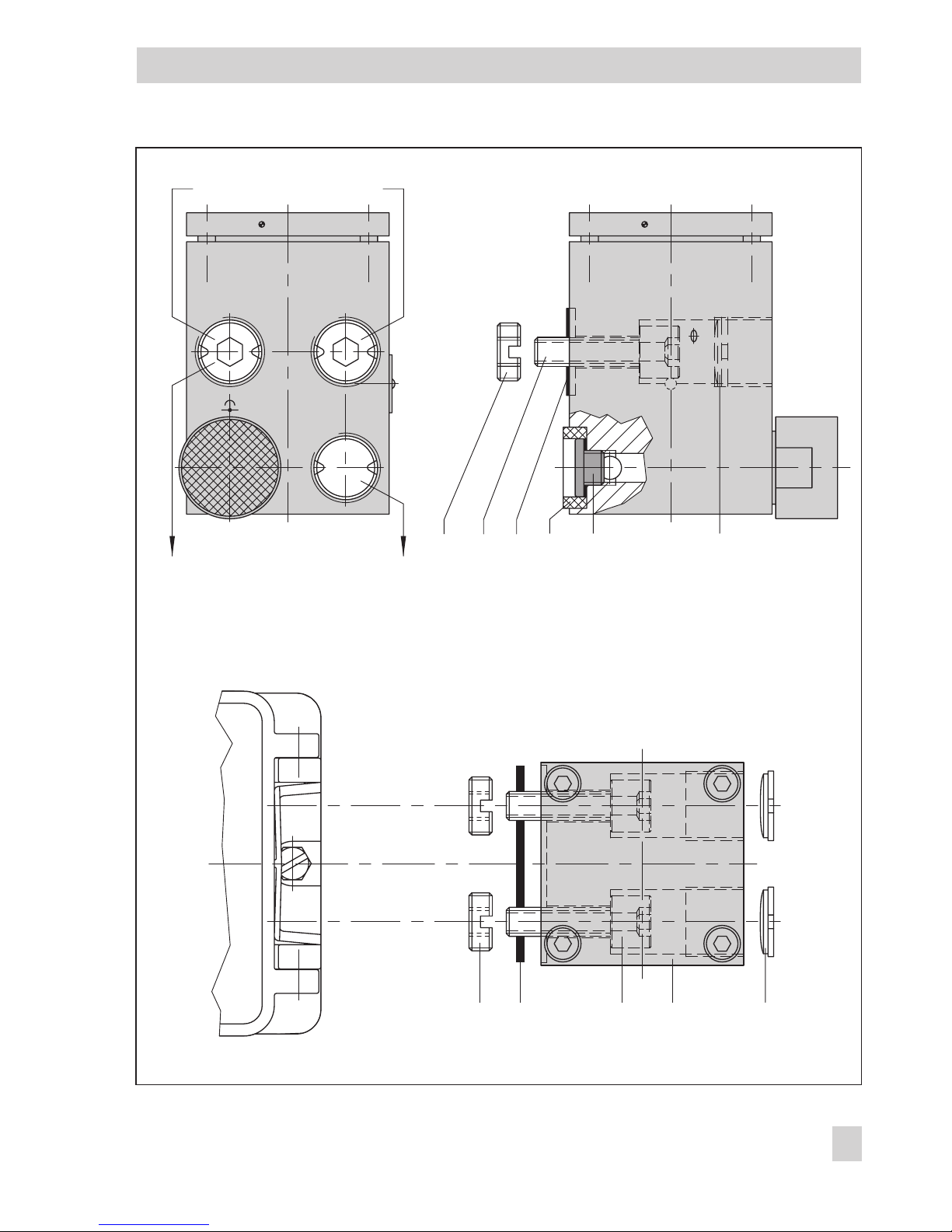

Fig. 3 · Attachment and signal pressure connection for Types 3277 (top) and 3277-5 with 120 cm² (bottom)

1.2 Clamp

D1 Lever

D2 Lever

15 Distance plate

16 Cover

17 Seal

18 Cover plate

19 Switch plate

Actuator stem

extends

Actuator stem

retracts

Switchover plate Signal pressure input

Marking

Signal pressure input with

brass restriction, if required

Signal pressure bore Switchover plate

Vent

Connection block

Side view of connection block

with seal (new) with switch plate (old)

Actuator stem extends Actuator stem retracts

Internal signal pressure

connection

Signal pressure

connection over piping

Symbol "Actuator

stem extends"

Marking

Symbol "Actuator

stem retracts"

240, 350 and 700 cm² actuators

6. Check whether the tongue of the

seal (17) is properly aligned at the side

of the connection block with the actuator

symbol "Actuator stem extends" or "Actuator stem retracts" to match the actuator

version used. If it does not match, remove

the three fastening screws and the cover

plate (18), turn the seal (17) by 180° and

reinsert it.

When the old connection block is used,

turn the switch plate (19) to align the arrow with the actuator symbol.

7. Place connection block with the associated sealing rings against the positioner

and the actuator yoke and screw it tight

using the fastening screw.

For actuators with fail-safe position "Actuator stem retracts", additionally mount

the prefabricated signal pressure line.

120 cm² actuator

For Type 3277-5 Actuators with 120 cm²,

the signal pressure is transmitted to the diaphragm chamber over the switchover plate

(see Fig. 3, bottom).

For a rated travel of 7.5 mm, a brass restriction (see Accessories table on page 13) must

be pressed into the seal located in the signal

pressure input on the actuator yoke.

With 15 mm rated travel, this is only required if the supply pressure exceeds 4 bar

6. Remove screw at the back of the

positioner and close the signal pressure

output (output 38) at the side with the associated plug included in the accessories

kit.

7. Mount positioner so that the bore in the

distance plate (15) is aligned with the

seal located in the bore of the actuator

yoke.

8. Align switchover plate with the corresponding symbol for attachment on the

left. Screw the plate to the actuator yoke.

Important!

If, in addition to the positioner, a solenoid

valve or a similar device is attached to the

120 cm² actuator, the rear M3 screw must

not be removed. In this case, the signal pressure has to be fed from the signal pressure

output to the actuator over the required connecting plate (see Table 2). The switchover

plate is no longer required.

Note!

For faster control valves with a transit time

< 0.6 s, replace the filter in the signal pressure output (output 38) with a screw-in

restriction (see Accessories table), if necessary.

Filling the spring chamber with air

If the Type 3277 Actuator's spring chamber

must be pressurized with the air exhausted

from the positioner, the spring chamber (version "Actuator stem extends") can be connected to the connection block using a tube

(Table 3). To do so, remove the plug on the

connection block.

With the Type 3277-5, version "Actuator

stem retracts", the spring chamber is constantly pressurized with the air exhausted

from the positioner through an internal bore.

12 EB 8382-1 EN

Attaching the positioner

Table 1

Required lever with associated clamp and distance plate

Actuator size

cm²

Mounting kit

Order no.

D1 (33 mm in length with clamp, 17 mm in height) 120 (G ¼)

120 (¼ NPT)

1400-6790

1400-6791

D1 (33 mm in length with clamp, 17 mm in height) 240 and 350 1400-6370

D2 (44 mm in length with clamp, 13 mm in height) 700 1400-6371

Table 2 Order no.

Switchover plate for 120 cm² actuator Actuator 3277-5xxxxxx.00 (old) 1400-6819

Switchover plate new Actuators with index .01 or higher (new) 1400-6822

Connecting plate for additional attachment

of, e.g. a solenoid valve

3277-5xxxxxxxx.00 G

1

8

(old)

1

8

NPT

1400-6820

1400-6821

Connecting plate new Actuators with index .01 or higher (new) 1400-6823

Note! Only new switchover plates and connecting plates can be used with the new actuators (modifica-

tion index .01). Old and new plates are not interchangeable.

Connection block required for actuator sizes 250, 350 and

700 cm² (including seals and fastening screw)

G ¼

¼ NPT

1400-8811

1400-8812

Table 3 Actuator size cm² Material Order no.

Required tubes including fittings 240 Steel 1400-6444

240 Stainless steel 1400-6445

For version

"Actuator stem retracts"

or

when pressurizing the upper diaphragm

chamber

350 Steel 1400-6446

350 Stainless steel 1400-6447

700 Steel 1400-6448

700 Stainless steel 1400-6449

Accessories Order no.

Pressure gauge mounting kit for supply air and signal pressure St. steel/brass

St. steel/St. steel

1400-6957

1400-6958

Signal pressure restrictions (screw-in and brass restriction) 1400-6964

Filter check valve, replaces vent plug and increases degree of protection to IP 65

(one included with every positioner delivered)

1790-7408

EB 8382-1 EN 13

Attaching the positioner

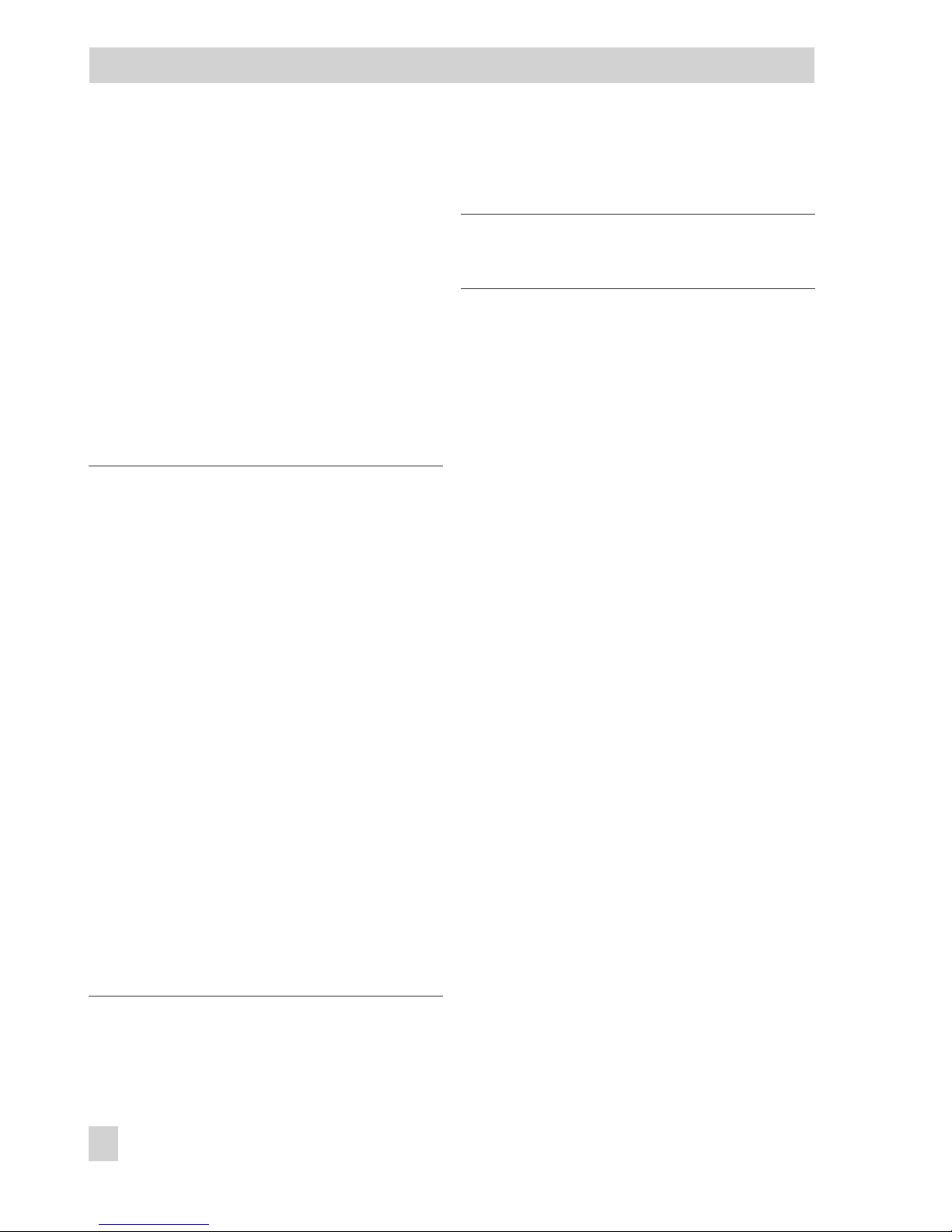

2.2 Attachment according to

IEC 60534-6

For selection of the required mounting

parts, refer to Tables 4 and 5 on page 17.

For positioner attachment according to

NAMUR as shown in Fig. 4, an adapter

housing is required. The valve travel is transmitted over the lever (18) and shaft (25) to

the bracket (28) of the adapter housing and

then to the pin (27) located on the positioner

lever.

To attach the positioner, the mounting parts

listed in Table 4 are required. Which lever is

to be used depends on the rated valve travel.

The positioner must be attached to the

adapter housing so that the arrow on the

black housing cover points away from the diaphragm actuator towards the valve.

Exception: control valves in which the plug

closes the seat area when the actuator stem

retracts. In this case, the arrow must point towards the diaphragm actuator.

If the adapter housing cannot be mounted

between the actuator and the valve (e.g.

non-SAMSON actuators), make sure the arrow on the housing cover points towards the

control valve.

Note!

For faster control valves with a transit time

< 0.6 s, replace the filter in the signal pressure output (output 38) with a screw-in restriction (see Accessories table), if necessary.

2.2.1Mounting sequence

Important!

Before mounting the parts, apply a signal

pressure to the actuator so that the valve is

set to 50 % of its travel. It is only in this position that the lever (18) and bracket (28) can

be aligned exactly.

Control valve with cast yoke

1. Use countersunk screws to attach the

plate (20) to the coupling that connects

the plug and actuator stem. For 2100

and 2800 cm² actuators, use additional

mounting bracket (32).

2. Remove rubber plug from the adapter

housing and fasten the housing to the

NAMUR rib using the hexagon head

screw.

Control valve with rod-type yoke

1. Screw plate (20) to the follower clamp of

the plug stem.

2. Screw studs (29) into the adapter housing.

3. Place housing with the plate (30) on either the right or left side of the valve rod

and screw the housing tight using

nuts (31). Align the height of the housing

so that the lever (18) to be mounted subsequently is horizontal.

4. Move clamp (21) to surround the

pin (19). Screw pin in the center row of

bores in the plate (20) and lock it so that

it will be located above the correct lever

marking (1 to 2) for the assigned travel

(see Table 5).

Intermediate values must be interpolated.

14 EB 8382-1 EN

Attaching the positioner

EB 8382-1 EN 15

Attaching the positioner

2

1,5

1

2826

AB

24 25 22

32

31

20 19

19 21 2023 18

27b

27a

29

30

Fig. 4 · Attachment according to IEC 60534-6 (NAMUR)

Mounting position

Attachment to

NAMUR rib

Attachment to rods

18 Lever N1, N2

19 Pin

20 Plate

21 Clamp

22 Clamping plate

23 Screw

24 Pointer

25 Shaft

26 Lever of positioner

27a Transmission pin

27b Lock nut

28 Bracket

29 Studs

30 Plate

31 Nuts

32 Mounting bracket

5. Measure distance between the center of

the shaft (25) and the center of the

pin (19). This value must later be entered

when configuring the positioner.

2.2.2Presetting the valve travel

1. Adjust shaft (25) in the adapter housing

so that the black pointer (24) is aligned

with the cast marking on the adapter

housing.

2. Screw clamping plate (22) tight in this

position using a screw (23).

3. Screw in pin (27) at the positioner lever (26) on the side of the insert nuts and

secure it with a hex nut on the opposite

side. Observe mounting position A or B

according to Table 5 and Fig. 5.

4. Place positioner on the adapter housing

such that the transmission pin (27a) lies

properly within the arms of the

bracket (28). To do so, insert a 2.5 mm

Allen wrench or screwdriver from the

front into the bore located below the oblong hole on the cover plate and push the

positioner lever to the required position.

5. Screw positioner to the adapter housing.

6. Relieve actuator of the signal pressure.

16 EB 8382-1 EN

Attaching the positioner

Table 4 Attachment IEC 60534-6

Control valve Travel [mm] With lever Order no.

NAMUR mounting kit

Parts, see Fig. 4

Valve with cast yoke

7.5 to 60

N1 (125 mm)

1400-6787

30 to 120

N2 (212 mm)

1400-6789

Valve with

rod-type

yoke,

rod diame

-

ter [mm]

20 to 25 N1 1400-6436

20 to 25 N2 1400-6437

25 to 30 N1 1400-6438

25 to 30 N2 1400-6439

30 to 35 N1 1400-6440

30 to 35 N2 1400-6441

Attachment to linear Fisher and Masoneilan actuators

(one each of both mounting kits is needed per actuator)

1400-6771

and

1400-6787

Accessories Order no.

Pressure gauge mounting block G ¼

¼ NPT

1400-7106

1400-7107

Pressure gauge mounting kit (output and supply)

Order with every pressure gauge kit: 2 restrictions (1790-6121)

St. st./Brass

St. st./St. st.

1402-0938

1402-0939

Signal pressure restrictions (screw-in and brass restrictions) 1400-6964

Filter check valve, replaces vent plug and increases degree of protection to IP 65

(one included with every positioner delivered)

1790-7408

Table 5 Attachment acc. to IEC 60534-6

Travel in mm*

7.5 15 15 30 30 60 30 60 60 120

Pin on marking* 1 1 2 1 2 1 2 1 2

Corresp. distance pin to lever fulcrum 42 42 84 42 84 84 168 84 168

With lever N1 (125 mm long) N2 (212 mm long)

Transmission pin (27) on position A A B A B

* Deviating travel values (intermediate values) are to be interpolated accordingly

EB 8382-1 EN 1

7

Attaching the positioner

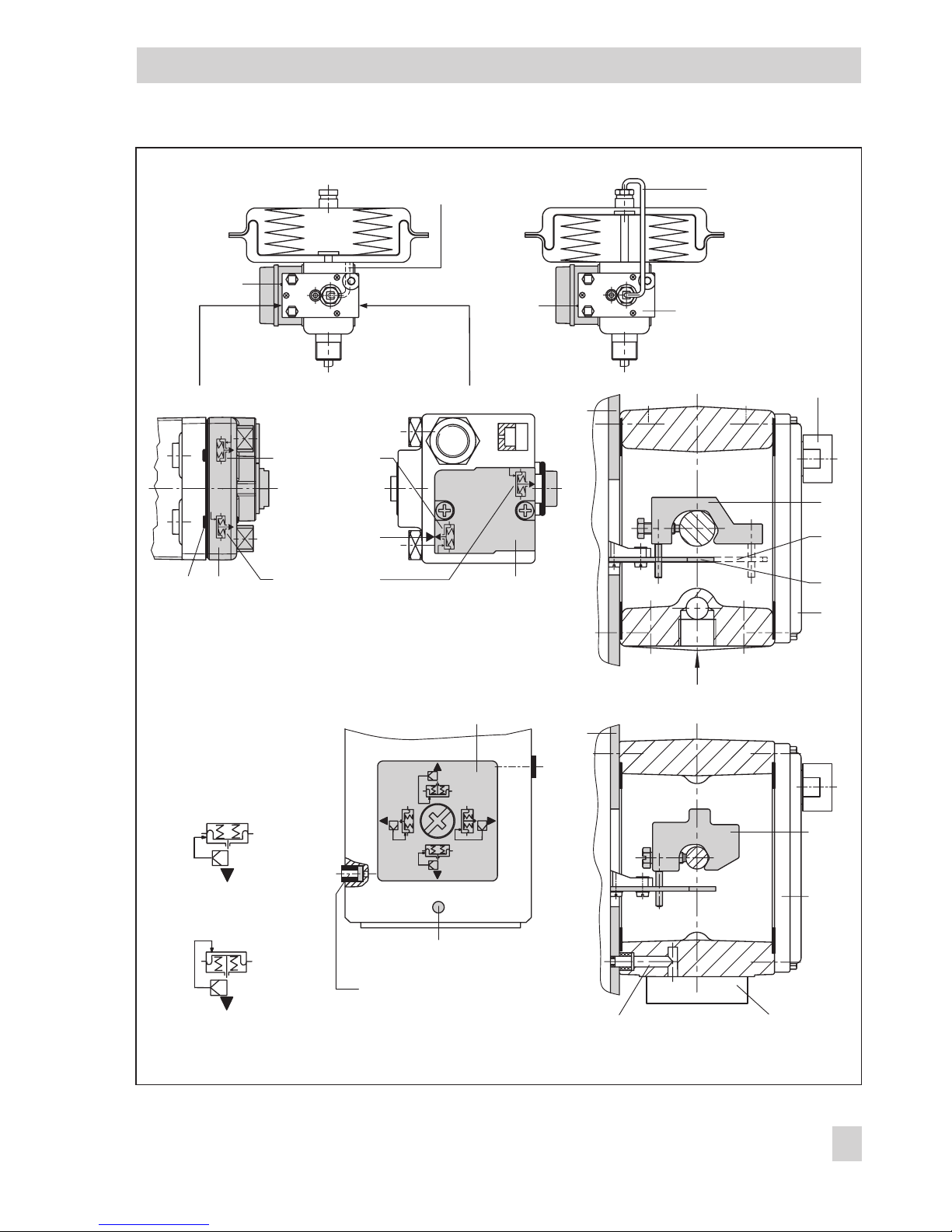

2.3 Attachment to rotary actuators

For selection of the required mounting

parts, refer to Table 6 on page 21.

The positioner can also be attached to rotary

actuators in accordance with VDI/VDE 3845

using the mounting parts and accessories

listed in Table 6. In this arrangement, the actuator's rotary motion is converted via the

cam disk on the actuator shaft and the follower roll of the positioner lever to a linear

motion required by the positioner's inductive

travel pick-off system.

Each cam disk is suitable for two curves: for

angles of rotation from 0° to 90° (for all angles smaller than 90°) and for 0° to 120°

(for all angles of 90° and larger).

For double-acting, springless rotary actuators, it is necessary to connect a reversing

amplifier to the connection side of the

positioner (see section 2.3.4).

If the positioner is attached to a SAMSON

Type 3278 Rotary Actuator, the positioner's

exhaust air is routed to the inside of the actuator and the chamber behind the diaphragm. No additional tubing is required.

If the positioner is attached to non-SAMSON

actuators (NAMUR), the air is applied to the

chamber behind the diaphragm through a

tube assembly and a tee, connected between

the actuator and the exhaust connection of

the intermediate piece.

Note!

For faster control valves with a transit time

< 0.6 s, replace the filter in the signal pressure output (output 38) with a screw-in restriction (see Accessories table), if necessary.

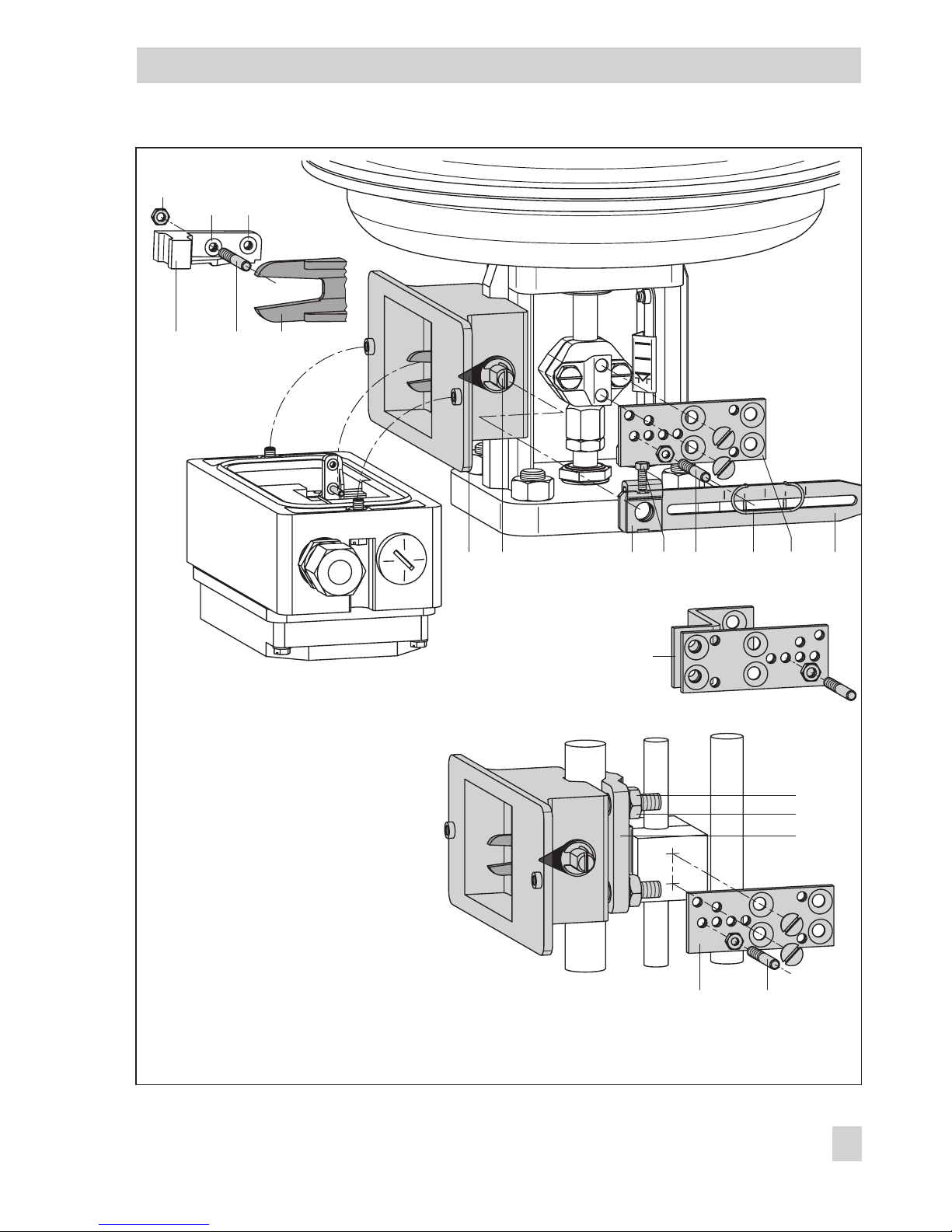

2.3.1Mounting the cam follower

roll lever

1. Place lever with the attached roll (35) on

the transmission lever (37) and secure it

with the enclosed screws (38) and washers.

2.3.2Mounting the intermediate

piece

SAMSON Type 3278 Actuator

1. Screw adapter (36) to the free end of the

rotary actuator shaft using two screws.

2. Place the positioner's intermediate

piece (34) on the actuator housing and

secure it using two screws. Align intermediate piece so that the air connections of

the positioner face towards the diaphragm case side.

Non-SAMSON actuators

1. Position complete intermediate piece (34,

42, 44 and 45) on the bracket (fixing

level 1, VDI/VDE 3845) delivered with

the actuator and fasten it with screws.

2. Align cam disk (40) and scale according

to section 2.3.3 and fasten them with

screws.

With springless actuators, the reversing amplifier (45) must be screwed to the side of the

positioner housing. Refer to section 2.3.4 for

details.

18 EB 8382-1 EN

Attaching the positioner

EB 8382-1 EN 19

Attaching the positioner

33

3835

39

39

40

34

36

40

34

44

45

42

43

37

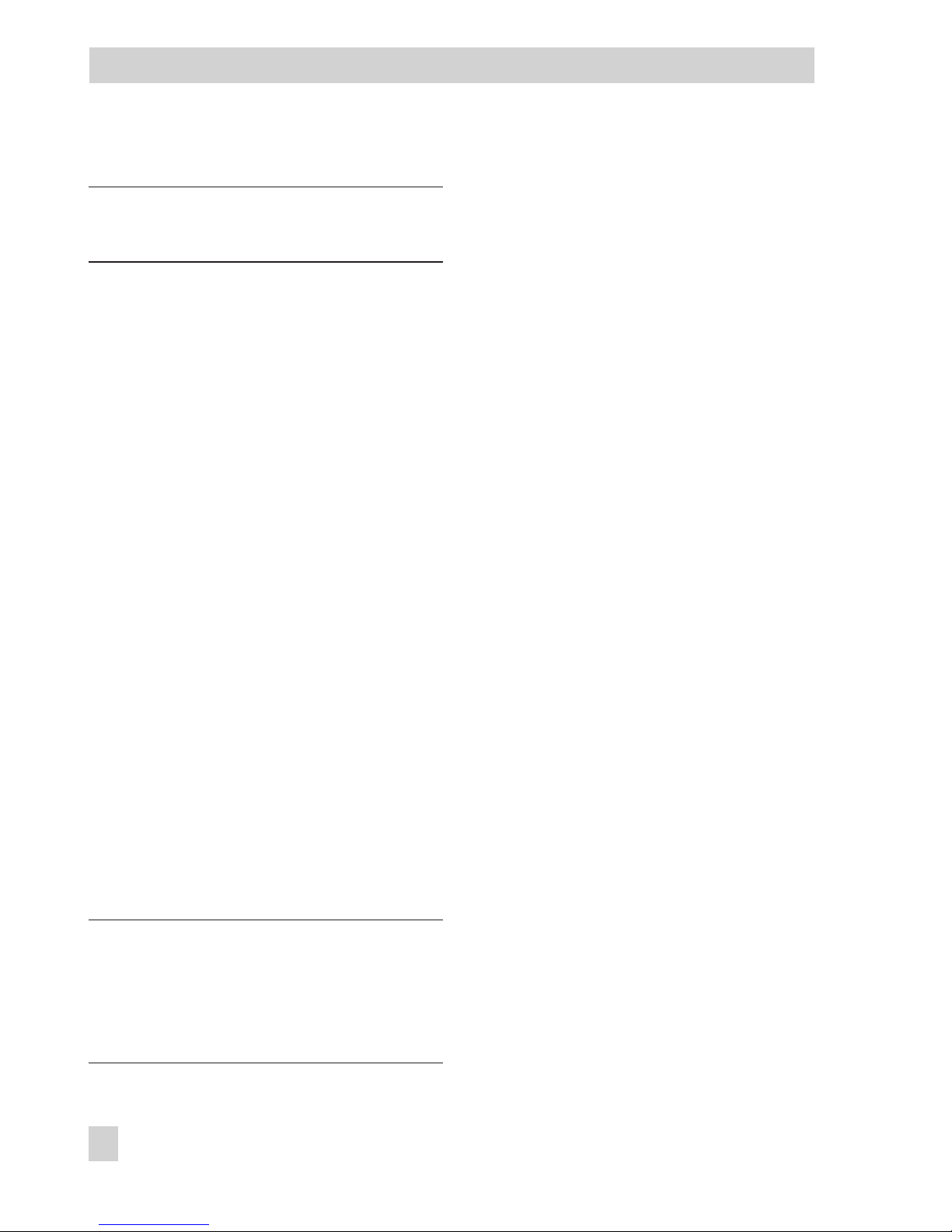

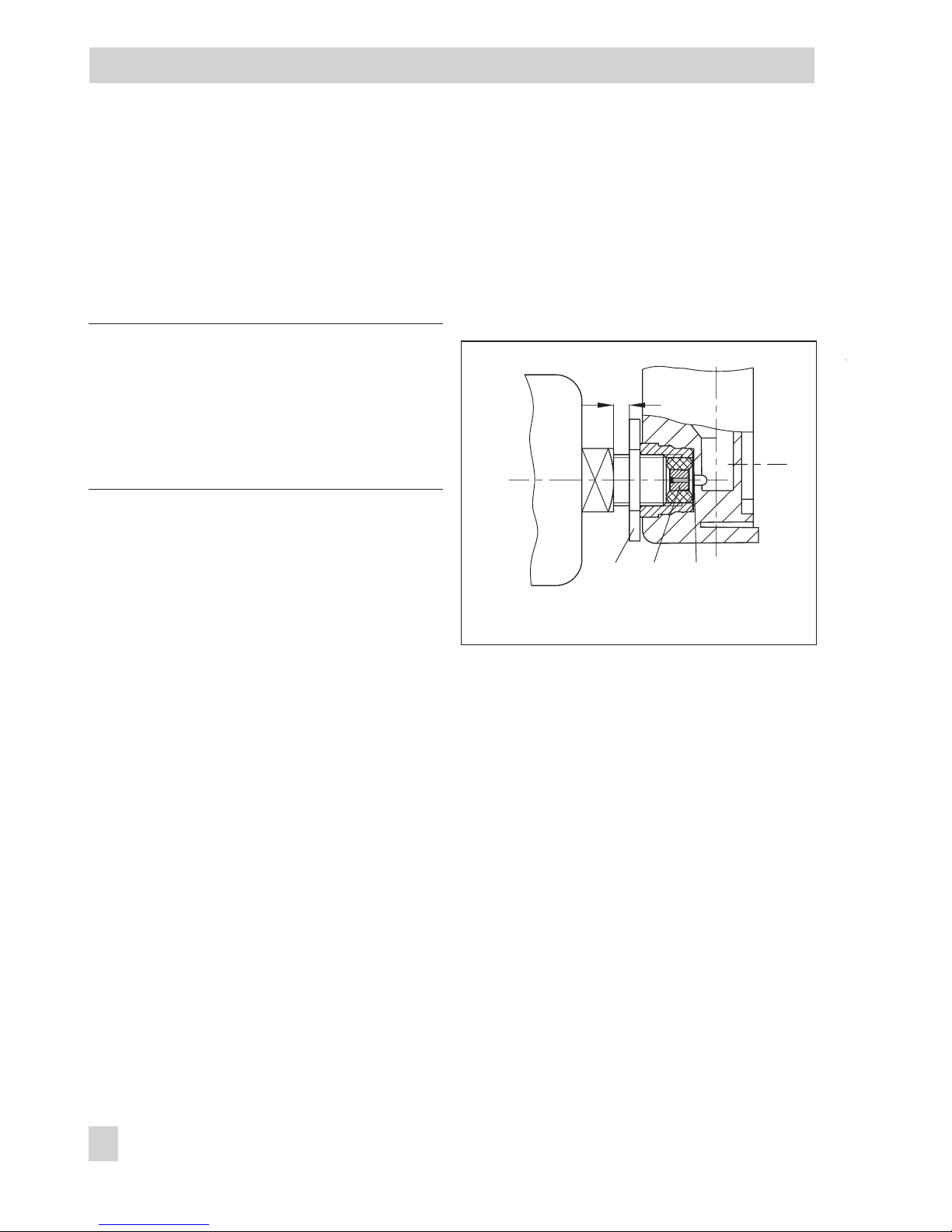

Fig. 5 · Attachment to rotary actuators

Attachment to

SAMSON Type 3278 Actuator

Attachment acc. to

VDI/VDE 3845

Vent plug or

filter check valve

33 Positioner

34 Intermediate piece

35 Lever with cam follower roll

36 Adapter

37 Transmission lever

38 Screws

39 Scale

40 Cam disk

41 Actuator shaft

42 Plate

43 Bracket

44 Coupling

45 Seal

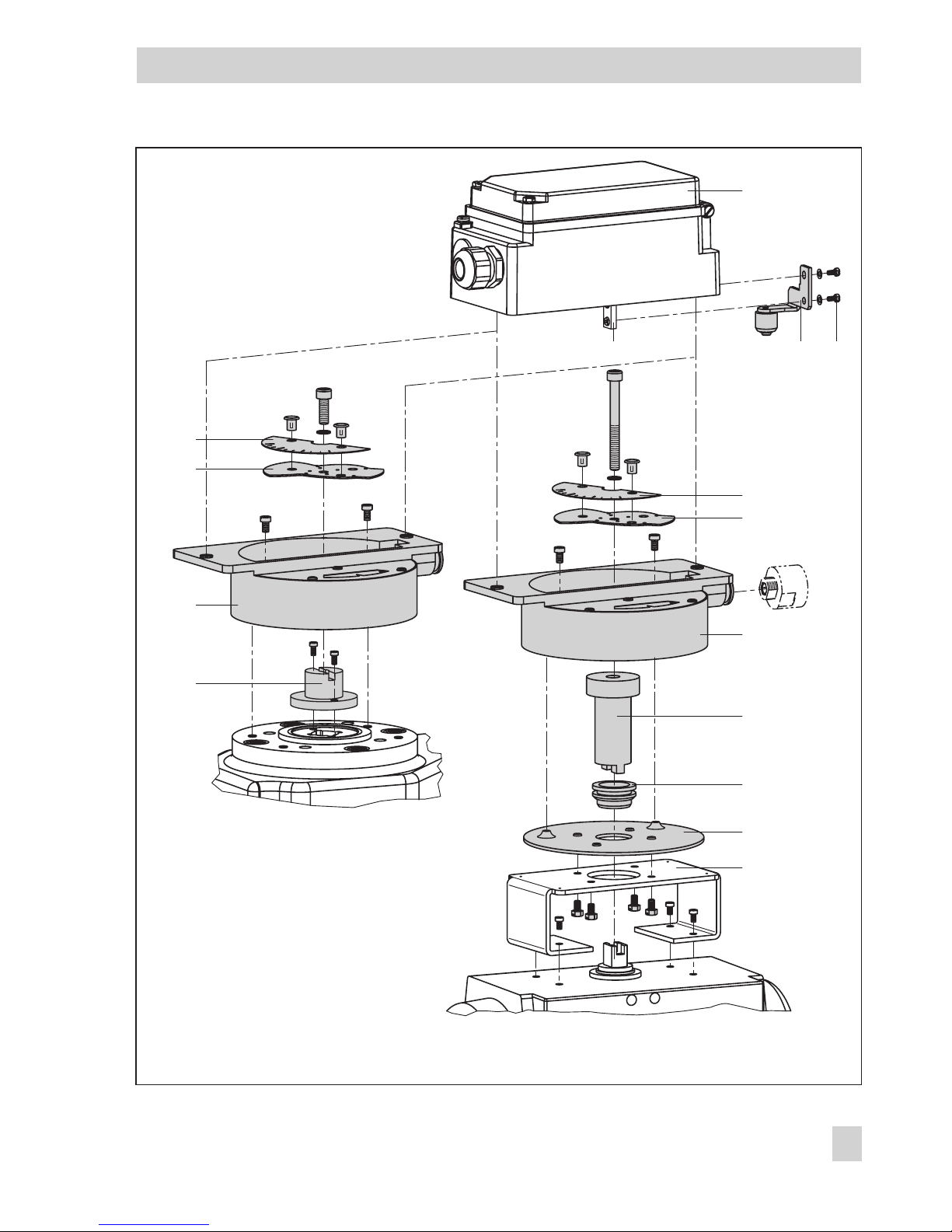

2.3.3Aligning and mounting the

cam disk

In rotary actuators with spring-return mechanism, the built-in actuator springs determine

the fail-safe position and the direction of rotation of the control valve (clockwise,

counterclockwise).

With double-acting, springless rotary actuators, the direction of rotation depends on

both the actuator and the valve model used.

Close the valve before making any adjust-

ments.

The positioner's direction of action, i.e.

whether the valve opens or closes when the

reference variable increases, has to be software-adjusted using communication (increasing/increasing or increasing/decreasing).

1. Position cam disk with scale on the

adapter (36) or the coupling (34) and

fasten the screw loosely at first.

The cam disk carries two cam sections. The

starting point of each section is marked by a

small bore.

Important!

With the valve closed, the starting point

(bore hole) of the respective curve is to be

aligned so that the center of rotation of the

cam disk, the 0° position on the scale, and

the arrow mark on the plate are aligned.

The starting point for the closing position

must not be below 0° position!

In actuators with fail-safe position "Control

valve open" (OPEN), pressurize the actuator

with the max. signal pressure before aligning

the cam disk.

In springless actuators, connect the supply

air.

2. On aligning the cam disk, the double-sided scale disk must be clipped on

so that the value on the scale corresponds to the control valve's direction of

rotation. Tightly secure the cam disk with

the fastening screws now.

Securing the aligned cam disk

If you want to additionally secure the cam

disk to prevent it from being turned, proceed

as follows:

Four bore holes are located centrically

around the center bore on the cam disk. Select a suitable hole to secure the cam disk.

Through this hole, drill a hole in the

adapter (36) or coupling (44) and insert a

2 mm dowel pin.

3. Attach positioner to the intermediate

piece (34) so that the lever (35) contacts

the cam disk with its cam follower roll. To

do so, insert a 2.5 mm Allen wrench or

screwdriver from the front into the bore

located below the oblong hole on the

cover plate and push the positioner lever

to the required position.

4. Screw positioner to the intermediate

piece.

20 EB 8382-1 EN

Attaching the positioner

Table 6 Rotary actuators (complete mounting parts, but without cam disk)

Attachment acc. to

VDI/VDE 3845,

level 1

SAMSON Type 3278 Actuator Attachment to Masoneilan actuators

160 cm²

actuator

320 cm²

actuator

Camflex I

DN 25 to 100

Camflex I

DN 125 to 250

Camflex II

Order no.

1400-8815 1400-7103 1400-7104 1400-7118 1400-7119 1400-7120

Piping kit, 8 x 1 stainless steel

G: 1400-6670 G: 1400-6672

NPT: 1400-6669 NPT: 1400-6671

Accessories Order no.

Reversing amplifier for springless double-acting actuators G: 1079-1118 NPT: 1079-1119

Cam disk (0050-0089) with accessories, angle of rotation 0° to 90° and 0° to 120° 1400-6959

Cam disk (0050-0089) esp. for VETEC, adjustable by software from 0° to 75° 1400-6960

Cam disk (0050-0090) esp. for Camflex, adjustable by software from 0° to 50° 1400-6961

Pressure gauge mounting block G ¼: 1400-7106 ¼ NPT: 1400-7107

Pressure gauge set Stainl. steel/Br:

1400-6957

St. steel/st. steel:

1400-6958

Signal pressure restrictions (screw-in and brass restrictions) 1400-6964

Filter check valve, replaces vent plug and increases degree of

protection to IP 65 (one included with every positioner delivered)

1790-7408

EB 8382-1 EN 21

Attaching the positioner

Fig. 6 · Aligning the cam disk

Cam follower roll

Starting point

Bore holes to secure

the cam disk

Insert clip and press

tongues outward.

View onto actuator shaft from positioner

Control valve opens counterclockwise Control valve opens clockwise

2.3.4Reversing amplifiers for double-acting actuators

For the use with double-acting actuators, the

positioner must be fitted with a reversing amplifier. The reversing amplifier is listed as an

accessory in Table 6 on page 21.

The signal pressure of the positioner is supplied at output A1 of the reversing amplifier.

An opposing pressure, which equals the required supply pressure when added to the

pressure at A

1

, is applied at output A2. The

rule A

1

+ A2= Z applies.

Mounting

1. Screw special nuts (1.3) from the acces-

sories of the reversing amplifier into the

threaded connections of the positioner.

2. Remove sealing plug (1.5) from the re-

versing amplifier. The rubber seal (1.4)

must remain installed.

3. Insert gasket (1.2) into recess of the re-

versing amplifier and push both hollow

special screws (1.1) into the connection

bores A1 and Z.

4. Place reversing amplifier onto the

positioner and screw tight using both

special screws (1.1).

5. Replace vent plug in the reversing ampli-

fier with the included filter check valve.

Signal pressure connections

A

1

: Connect output A1to the signal pressure

connection at the actuator that opens the

valve when the pressure increases.

A

2

: Connect output A2to the signal pressure

connection at the actuator that closes the

valve when the pressure increases.

4

Set up the actuator as "Double-acting

without spring-return mechanism" in the

user interface under Start-up -> Actuator

type.

2.4 Fail-safe position of the actuator

Important!

If the fail-safe position of the actuator is

changed subsequently by modifying the actuator springs from "Actuator stem extends" to

"Actuator stem retracts", readjust mechanical

zero and re-initialize the positioner.

22 EB 8382-1 EN

Attaching the positioner

EB 8382-1 EN 23

Attaching the positioner

1.3 1.2 1.1 1

Output 38 Supply 9

A

1

1.5 1.6

Z

A

2

1.4

A

1

A

2

Output 38 Supply 9

1.3 1.21.1

1.6

Z

A

1

Fig. 7 · Mounting a reversing amplifier

From the positioner

Control signals

to the actuator

1 Reversing amplifier

1.1 Special screws

1.2 Gasket

1.3 Special nuts

1.4 Rubber seal

1.5 Plug

1.6 Filter

3 Connections

3.1 Pneumatic connections

The air connections are either ¼ NPT or G ¼

tapped holes. Common fittings for metal and

copper tubes or plastic hoses can be used.

Important!

The supply air must be dry and free of oil

and dust. The maintenance instructions for

upstream pressure reducing stations must be

observed. Carefully purge all air tubes and

hoses before connecting them.

If the positioner is attached directly to the

Type 3277 Actuator, the connection of the

signal pressure to the actuator is fixed. For

NAMUR attachment, the signal pressure can

be applied to either the upper or lower diaphragm chamber of the actuator, depending

on the actuator's fail-safe action (either "Actuator stem retracts" or "stem extends").

Exhaust air: The exhaust air connection of

the positioner is located on the mounting kit.

For direct attachment, a vent plug is located

on the plastic cover of the actuator. For

NAMUR attachment, the vent plug can be

found at the adapter housing. For attachment

to rotary actuators, it is either located either

on the intermediate piece or the reversing

amplifier.

To guarantee degree of protection IP 65, the

vent plug must be replaced with the filter

check valve included with the positioner.

Refer to section 2 on page 10 (Important!)

for details.

3.1.1Pressure gauges

To monitor positioner operation, it is recommended to connect pressure gauges for the

supply air and signal pressure. The required

gauges are listed as accessories in Tables 3,

4 or 6.

24 EB 8382-1 EN

Connections

2...3mm

Fig. 8 · Mounting pressure gauges

Nut Restriction with filter

Order no. 1790-6121

3.1.2Supply air pressure

The required supply air pressure depends on

the bench range and the operating direction

(fail-safe action) of the actuator. The bench

range is indicated on the nameplate as a

spring range or signal pressure range.

Actuator stem extends:

Required supply air pressure = upper bench

range value + 0.2 bar, at least 1.4 bar

Actuator stem retracts:

The required supply air pressure for

tight-closing valves is estimated on the basis

of the maximum signal pressure p

st max

:

p

st max

= F +

d² p p

4A

⋅⋅⋅Δ

[bar]

d = Seat diameter [cm]

Δp = Differential pressure across the valve [bar]

A = Actuator area [cm²]

F = Upper bench range value of actuator [bar]

If there are no specifications, calculate as

follows:

Required supply air pressure = upper bench

range value + 1 bar

3.2 Electrical connections

For electrical installation, you are required to observe the relevant

electrotechnical regulations and the

accident prevention regulations that

apply in the country of use. In Germany, these are the VDE regulations

and the accident prevention regulations of the employers’ liability insurance.

The following regulations apply for

installation in hazardous areas:

EN 60079-14:2003; VDE 0165

Part 1:1998 ”Electrical apparatus for

explosive gas atmospheres”, and

EN 50281-1-2: VDE 0165

Part 2:1999 ”Electrical apparatus for

use in the presence of combustible

dust”.

For intrinsically safe electrical equipment approved in accordance with

Directive 79/196/EEC, the data

specified in the certificate of conformity apply for the connection of intrinsically safe circuits. For intrinsically safe electrical equipment approved in accordance with Directive

94/9/EC, the data specified in the

EC type examination certificate apply

for the connection of intrinsically safe

circuits.

Caution! The terminal assignment

specified in the certificate must be

observed! Switching the assignment

of the electrical terminals may cause

the explosion protection to become

ineffective! Do not loosen enameled

screws in or on the housing.

EB 8382-1 EN 25

Connections

!

Note on the selection of cables and wires

To run several intrinsically safe circuits in one

multi-core cable, observe section 12 of

EN 60079-14; VDE 0165:1998.

Note especially that, for commonly used insulating materials such as polyethylene, the

radial thickness of the conductor insulation

must be at least 0.2 mm. The diameter of a

single wire of a flexible conductor must not

be smaller than 0.1 mm.

The conductor ends must be protected

against unlaying, e.g. by using wire-end ferrules. When two separate cables are used

for connection, an additional cable gland

can be installed.

Cable entries left unused must be sealed with

plugs.

Positioners used in ambient temperatures

down to –40 °C must be fitted with metal cable entries.

For terminal assignment, refer to Fig. 9 or to

the designations on the cover plate inside the

lid.

Cable entries

Cable entry with M20x1.5 cable gland, 7 to

12 mm clamping range.

There is a second M20x1.5 cable gland in

the housing that can be used for additional

connection, if required.

The screw terminals are designed for wire

cross-sections of 0.2 to 2.5 mm² (tightening

torque at least 0.5 Nm).

Bus line

The shielded PROFIBUS connecting cable

must be routed over the EMC-proof brass cable gland (standard) of the positioner to the

terminals. The shield, which is placed over

the clamping insert, is connected over a

large area to the gland and housing.

1. To connect the bus line, remove coupling

nut and clamping insert from the

positioner. Also remove the dust cap.

2. Slide coupling nut and clamping insert

over the connecting cable.

3. Strip insulation off the end of the bus line

to the required connecting length. Cut off

the wire shield up to a length of approx.

13 mm. If necessary, cut off any filling

cable cores as well.

4. Disentangle the braided shield and pull it

over the clamping insert.

5. Press clamping insert into connecting

screw gland. Tighten coupling nut until

the connecting cable is clamped tightly.

6. Route two-wire bus line to the screw ter-

minals marked "IEC 1158-2"; when doing so, no polarity has to be observed.

In exceptional cases, if the plant does not

permit such a connection, feed the cable

shield through the cable gland and connect it

to be capacitive over terminal "S". However,

make sure that no conducting connection occurs from the shield to the cable gland or

housing.

26 EB 8382-1 EN

Connections

Refer to PROFIBUS-PA User and Installation

Guideline (PROFIBUS User Organization

document 2.091) for further information.

At the binary input, a passive floating contact can be used. The positioner signals the

circuit's state using the bus protocol.

Important!

The connection of limit switches, binary input

and forced venting function requires an additional cable gland that must replace the

cap fitted on the housing.

Accessories: M20 x 1.5 cable gland,

nickel-plated brass, order no. 8808-0143

3.2.1Forced venting

For positioners with forced venting function,

a voltage of 6 to 24 V DC must be applied to

the associated terminals.

The forced venting function can be activated

or deactivated over an internal switch. See

section 4.3 for details.

Note!

If there is no voltage connected or when the

voltage signal is interrupted, the positioner

vents the actuator and does not respond to

the reference variable.

EB 8382-1 EN 27

Connections

Fig. 9 · Electrical connections (terminal assignment according to DIN 45140)

GW2 GW1

PE

S

NC

-52

+51

-42

+41 -86

+85

-82 +81

IEC 1158-2

PROFIBUS-PA

6...24 VDC

Brass cable gland Shielding Clamping insert Coupling nut

Switching amplifier

acc. to EN 60947-5-6

Bus line

Limit switches Binary input Forced venting

3.2.2Limit switches

Switching amplifiers have to be connected in

the output circuit to operate limit switches. To

ensure operational safety of the positioner,

these switching amplifiers must comply with

the limits of the control circuit according to

NAMUR. Observe the relevant regulations if

the positioner is installed in hazardous areas.

3.2.3Establishing communication

(bus address)

Communication between positioner, programmable logic controller or automation

system, i.e. between PC or workstation and

the positioner(s), is established using a segment coupler (see Fig. 10) in accordance

with the PROFIBUS guidelines.

If the positioner is used in hazardous areas,

exlosion-protected PROFIBUS-PA segment

couplers must be used.

A maximum of 32 positioners can be operated in parallel on a segment coupler in one

PROFIBUS-PA segment. In hazardous areas,

fewer positioners can be connected.

Each positioner in a segment must be assigned a unique bus address between 0

and 125. Seven microswitches located on the

inside of the positioner's hinged lid serve to

enter the bus address either directly by

switch numbers 1, 2, 4 etc. or by adding up

several switch positions. The positioner is delivered with the default address set to 126.

Make absolutely sure that the switches are

adjusted all the way to either 1 or 0, not set

to an intermediate position.

Note!

Start the positioner up again for a new bus

address to be adopted.

3.2.4Local interface (SSP)

The local interface is located on the inside of

the positioner's hinged lid. It is connected to

a PC over the serial interface adapter (order

no. 1400-7700). The positioner can be

started up using the interface and

SAMSON's TROVIS-VIEW software.

It is no longer necessary to connect the device to a PROFIBUS DP/PA segment. Only

the power supply needs to be connected over

the bus terminals of the positioner (any DC

voltage supply unit between 9 and 32 V).

The TROVIS-VIEW software and the device

module 3785 in version 2.02 are required.

The positioner can also be accessed over the

SSP interface when it is connected to a bus

segment.

Cyclic and acyclic data exchange are not affected. The value written last is always valid

for the device parameters.

28 EB 8382-1 EN

Connections

EB 8382-1 EN 29

Connections

PROFIBUS-DP(E) RS 485

3785

3785

3785

3785

PROFIBUS-PA IEC 61158-2

PROFIBUS-DP RS 485

3785-1

3785-1

3785-1

3785-1

PROFIBUS-PA IEC 61158-2

PROFIBUS-DP(E) RS 485

PROFIBUS-DP RS 485

Fig. 10 · PROFIBUS connection

Controller/PLC/control system

(Class 1 Master)

Display and control component

(Class 2 Master)

Segment coupler

Termination

Termination

Fig. 10.1 · Connection of Type 3785 Positioners

Fig. 10.2 · Connection of Type 3785-1 Positioners in hazardous areas

Controller/PLC/control system

(

Class 1 Master)

Display and control component

(

Class 2 Master)

Termination

Ex-proof segment coupler

Termination

Non-hazardous

area

Hazardous area

4 Operation

Warning!

Before putting the positioner into operation, carefully move the control

valve to its end position by covering

the hole (manually) on the cover plate

(Fig. 11). Check whether the lever

mechanism functions properly.

If the maximum angle of rotation is

exceeded by selecting the wrong lever mechanism or sizing the lever

mechanism incorrectly, the positioner

may be destroyed.

4.1 LED controls

Two LEDs located inside the cover serve to

monitor the positioner, indicating the

positioner's status during start-up, operation

and in the event of defects.

The colors indicate the following:

Red Start-up or error, no control

operation possible

Green No error recognized, control

operation or fail-safe position

(e.g. if not initialized)

Red + Green Error recognized, control

operation possible

For details, refer to the table below.

30 EB 8382-1 EN

Operation

!

Description LED

Positioner start-up Red ON

No errors

Positioner connected to bus, cold start performed, initialization required

When initializing or adjusting zero

Positioner initialized, no valid set point

Positioner initialized, valid set point, control operation

Green, generally

Green blinks slowly

Green blinks quickly

Green blinks 3 times quickly + long pause

Green ON

Errors during control operation

Zero point error

Control loop error

Red and green

Red and green blink slowly

Red and green blink quickly

Errors causing the first initialization to be canceled

(positioner does not start standard operation)

Zero point error

Error in mechanics/pneumatics section

Control loop error

Red, generally

Red blinks slowly

Red ON

Red blinks quickly

Errors causing the positioner to stop control operation

Positioner recognized an internal error Red blinks 3 times quickly + long pause

4.2 Write protection

A microswitch marked "write protection" is

located to the right of the seven bus address

selector switches inside the hinged cover.

When it is activated (position ON), the

positioner settings are write-protected so that

they cannot be overwritten by the PROFIBUS

communication protocol. If you want to

change the settings via communication, set

the switch to position OFF.

4.3 Activate/deactivate forced

venting

For model index .03 and higher:

1. Remove four screws from the cover inside

the hinged lid and remove the cover.

2. Remove screw in the middle of the

printed circuit board and turn the PCB to

one side.

3. Set switch to desired position:

1 ENABLED > function activated

2 DISABLED > function deactivated

4.4 Default settings

All parameters are set to their default values.

Refer to section 8 for descriptions of the parameters.

Caution!

Manual operation and activated end

position function can cause the actuator to be pressurized with the maximum supply pressure. If this causes

inadmissible forces, restrict the supply

pressure using a suitable pressure reducing station.

EB 8382-1 EN 31

Operation

GW1

GW2

3785

PE

IEC 1158-2

S

NC -52

+51

-42

+41

-86

+85

-82

+81

LED 1

LED 2

1

2

4

8

16

32

64

Write protection

Caution!

Valve

actuates

Init/Zero

Bus address

10

0N0FF

0

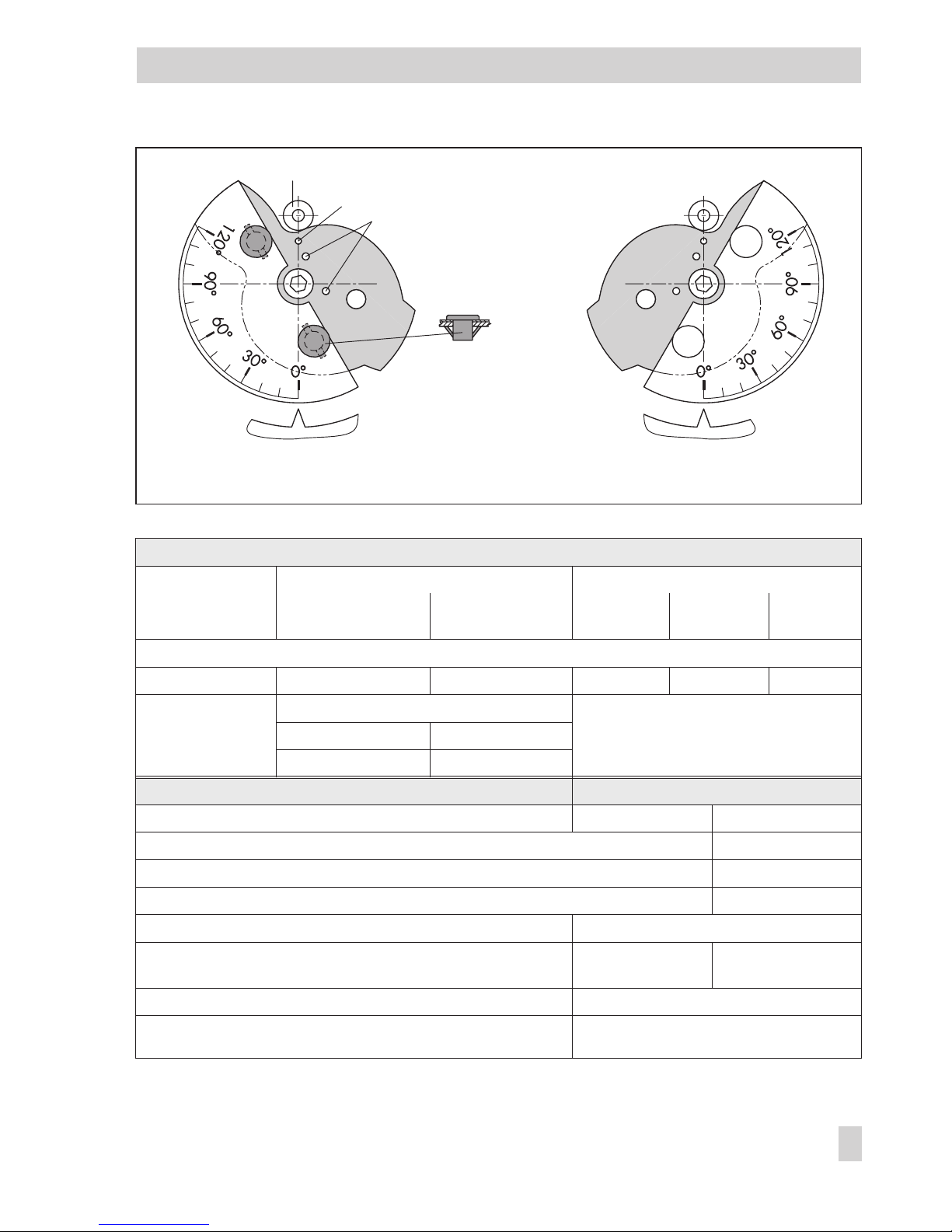

Fig. 11 · Inside view of the cover plate

Arrow for

mounting position Pointer Manual operation Bus address Write protection switch

Zero point lever Metal tags Adjustment screws LEDs Key for initialization

for limit switches or zero adjustment

!

4.4.1Adjusting mechanical zero

Important!

Zero must be adjusted with the valve closed

(for three-way valves with the actuator stem

extended).

4

Firmly push the zero point lever, which is

located on the cover plate of the

positioner, once in the direction indicated

by the arrow as far as it will go. The yellow pointer will then be on the white

marking.

For control valves with starting position

OPEN, e.g. an actuator with fail-safe action

"Actuator stem retracts", feed supply air to

the positioner first.

As soon as the manual operation function is

activated, the signal pressure builds up and

the valve moves to closed position. Subsequently, the zero point lever can be operated.

4.4.2Initialization

After the electric reference variable and the

supply air have been connected to the

positioner, the initialization process can be

started. During initialization, the positioner is

optimally adapted to the friction conditions

and signal pressure demands of the control

valve.

Warning!

The initialization process takes several minutes. During that time, the

valve changes its position. Therefore,

never initialize the positioner during

a running process; only perform initialization during the start-up cycle

when the shut-off valves in the plant

are closed or when the control valve

with the positioner has been removed

from the plant and is used on a test

bench.

4

Enter data for valve and actuator in the

Start-up section of the operating software.

4

Set "Type of initialization" to "Rated

range". Select "Maximum range" for

three-way valves only.

4

Start initialization.

A successful initialization is indicated in the

operating software and over the LEDs (see

section 4.1).

4

Carry out the configuration suitable for

the valve type.

The following settings are recommended:

4

Fail-safe position "Actuator stem extends":

Direction of action: increasing/increasing

(>>), a globe valve opens with increasing

reference variable

End position at a reference variable below 1 % (tight closing)

End position at a reference variable

above 125 % (function deactivated).

4

Fail-safe position "Actuator stem retracts":

Direction of action: increasing/decreasing (<>), a globe valve closes with increasing reference variable

End position at a reference variable

below –2.5 % (function deactivated)

End position at a reference variable

above 99 % (tight closing).

32 EB 8382-1 EN

Operation

!

4

Set delay time to at least 30 s.

4

Enter tag identification.

4

If necessary, configure the positioner

further, e.g. special characteristics for rotary valves.

If no communication can be established on

the valve, the positioner can also be initialized directly on the device itself.

4

Connect positioners that are not mounted

on a valve to a power supply and initialize the positioner as described in section

4.4.2.

If communication cannot be established,

the default settings must be used.

4

Mount positioner and adjust mechanical

zero as described in section 4.4.1.

4

Start initialization by pressing the

Init/Zero key on the positioner's hinged

lid using a suitable tool.

Initialization is completed when the

positioner moves to the position predetermined by the reference variable.

Note!

Once the positioner has been initialized successfully for the first time, pressing the

Init/Zero key only starts a zero calibration.

After a successful initialization, the positioner

can be re-initialized when communication is

established.

A completed initialization routine can be

canceled using communication with the "Reset to default values" command. After that,

the Init/Zero key can be pressed again to

start a complete initialization.

Electric zero calibration

If mechanical zero has shifted during the

valve's operation, an electric zero calibration

can be carried out. To do so, press the

Init/Zero key located on the inside of the

lid (Fig. 11).

Caution!

The control valve moves to its end position.

4

Firmly push the zero point lever, which is

located on the cover plate of the

positioner, once in the direction indicated

by the arrow as far as it will go. The yellow pointer will then be on the white

marking.

4

Press key again to start electric calibration.

After the key has been pressed for the second time, it is locked for approximately one

minute.

Electric calibration is completed when the

positioner moves to the position predetermined by the reference variable.

EB 8382-1 EN 33

Operation

!

4.5 Adjusting the inductive limit

switches

The positioner version with inductive limit

switches has two adjustable metal tags that

are mounted on the shaft of the positioner lever and operate the associated proximity

switches.

Connect appropriate switching amplifiers to

the output circuit to operate the inductive

limit switches (see section 3.2.2).

If the tag is inside the inductive field of the

proximity switch, the switch assumes a high

resistance. If the tag is outside the field, the

switch assumes a low resistance.

Normally, the limit switches are adjusted

such that they will provide a signal in both

end positions of the valve. These switches,

however, can also be adjusted to signal intermediate valve positions.

The desired switching function, i.e. whether

the output relay is to be pulled in or dropped

out when the tag has entered the field, has to

be determined at the switching amplifier, if

required.

Adjusting the switching point

The limit switches are marked GW1 and

GW2 on the inside of the housing cover. Yellow tags and the associated adjustment

screws (Fig. 11) are located below these

markings.

Each switching position can optionally be

signaled when the tag has entered or left the

field.

4

Move the valve to the switching position

and adjust the tag of the desired limit

switch GW1 or GW2 by turning the related adjustment screw until the switching

point is reached. This is indicated by the

LED at the transistor relay.

When doing so, one edge of the yellow tag

is aligned with the white, horizontal line on

the housing cover. This indicates the side

from which the tag enters the inductive field

of the proximity switch.

To ensure safe switching under all ambient

conditions, the switching point is to be adjusted to a value approx. 5 % before the mechanical stop (OPEN - CLOSED).

34 EB 8382-1 EN

Operation

5 Maintenance

The positioner is maintenance free.

Pneumatic connection 9/Supply contains a

filter with a mesh size of 100 µm. Remove

and clean the filter, if required.

Observe the maintenance instructions for upstream pressure reducing stations for supply

air, if applicable.

6 Servicing explosion-protected

devices

If a part of the positioner on which the explosion protection is based needs to be serviced,

the positioner must not be put back into operation until an expert has inspected it according to explosion protection requirements,

has issued a certificate stating this or given

the device a mark of conformity.

Inspection by an expert is not required if the

manufacturer performs a routine test on the

device prior to putting it back into operation.

The passing of the routine test must be documented by attaching a mark of conformity to

the device.

EB 8382-1 EN 35

Maintenance

7 How to implement a Class 1 PROFIBUS Master

7.1 Device database files (GSD)

The device data are provided as a text file (SAMS3785.GSD). It is available from

SAMSON AG under order no. 1400-7417 on a 3½" 1.44 MB floppy disk or on the Internet

at http://www.samson.de or http: //www.profibus.com.

The device database file permit the standardized implementation of the SAMSON

Type 3785 PROFIBUS Positioner as a PROFIBUS slave unit in the programming and configuration environment of a Class 1 master (example: SIEMENS Simatic Step 7, HWConfig).

Using the device database file, the Class 1 master is informed about the basic possibilities of

cyclic data exchange with the slave unit – in this case, the Type 3785 Positioner.

7.2 Data exchange

According to the PROFIBUS PA device profile for electropneumatic actuators, a total of seven

cyclic parameter combinations is available for the exchange of data. One of the combinations is to be selected in the programming and configuration environment of the Class 1

master.

The terms "Output" and "Input" refer to the control system/Class 1 master.

Variant 1: Module = SP; 0xA4

Output value (Output)

Byte 0 1234

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

SP, value

(floating point, IEEE)

Status

Variant 2: Module = RCAS_OUT, RCAS_IN; 0xB4

Input value (Input)

Byte 0 1234

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

RCAS_OUT, value

(floating point, IEEE)

Status

36 EB 8382-1 EN

How to implement a Class 1 PROFIBUS Master

Output value (Output)

Byte 0 1234

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

RCAS_IN, value

(floating point, IEEE)

Status

Variant 3: Module = READBACK + POS_D, SP; 0x96, 0xA4

Input value (Input)

Byte 0 123456

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5 Octet 1 Octet 2

READBACK, value

(floating point, IEEE)

Status POS_D

value

POS_D

status

Output value (Output)

Byte 0 1234

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

SP, value

(floating point, IEEE)

Status

Variant 4: Module = CHECKBACK, SP; 0x92, 0xA4

Input value (Input)

Byte 0 1 2

Octet 1 Octet 2 Octet 3

CHECK_

BACK[0]

CHECK_

BACK[1]

CHECK_

BACK[2]

EB 8382-1 EN 37

How to implement a Class 1 PROFIBUS Master

Output value (Output)

Byte 0 1234

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

SP, value

(floating point, IEEE)

Status

Variant 5: Module = READBACK + POS_D + CHECKBACK, SP; 0x99, 0xA4

Input value (Input)

Byte 0 123456789

Octet 1

Sign, ex-

ponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5 Octet 1 Octet 2 Octet 1 Octet 2 Octet 3

READBACK, value

(floating point, IEEE)

Status POS_D

value

POS_D

status

CHECK_

BACK[0]

CHECK_

BACK[1]

CHECK_

BACK[2]

Output value (Output)

Byte 0 1234

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

SP, value

(floating point, IEEE)

Status

Variant 6: Module = RCAS_OUT + CHECKBACK, RCAS_IN; 0x97, 0xA4

Input value (Input)

Byte 0 1234567

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5 Octet 1 Octet 2 Octet 1

RCAS_OUT, value

(floating point, IEEE)

Status CHECK_

BACK[0]

CHECK_

BACK[1]

CHECK_

BACK[2]

38 EB 8382-1 EN

How to implement a Class 1 PROFIBUS Master

Output value (Output)

Byte 0 1234

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

RCAS_IN, value

(floating point, IEEE)

Status

Variant 7:

Module = READBACK + RCAS_OUT + POS_D + CHECKBACK, SP + RCAS_IN; 0x9E, 0xA9

Input value (Input)

Byte 0 123456789

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5 Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

READBACK, value

(floating point, IEEE)

Status RCAS_OUT, value

(floating point, IEEE)

Status

Byte 10 11 12 13 14

Octet 1 Octet 2 Octet 1 Octet 2 Octet 3

POS_D

value

POS_D

status

CHECK_

BACK[0]

CHECK_

BACK[1]

CHECK_

BACK[2]

Output value (Output)

Byte 0 123456789

Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5 Octet 1

Sign,

exponent

Octet 2

Exponent,

fraction

Octet 3

Fraction

Octet 4

Fraction

Octet 5

SP, value

(floating point, IEEE)

Status RCAS_IN, value

(floating point, IEEE)

Status

EB 8382-1 EN 39

How to implement a Class 1 PROFIBUS Master

7.3 Parameter description

SP – Set point with status: Reference variable w in "Auto" operating mode

The reference variable w of the positioner is preset by SP in automatic mode (AUTO).

SP consists of a floating point value (4 bytes) and the associated status (1 byte). Value and

status must be transferred together (data consistency = 5 bytes). If the status of the reference

variable is "bad" (value < 64 dec.), the positioner remains in the fail-safe position determined by the actuator.

RCAS_IN/RCAS_OUT: Reference variable w in RCAS operating mode

The reference variable w of the positioner is preset in REMOTE CASCADE (RCAS) operating

mode by RCAS_IN/RCAS_OUT. RCAS_IN/RCAS_OUT both consist of one floating point

value (4 bytes) and the associated status (1 byte).

Value and status must be transferred together (data consistency = 5 bytes). If the status of the

reference variable is "bad" (value < 64 dec.), the positioner remains in the fail-safe position

determined by the actuator.

Note! RCAS operating mode is implemented in version K1.60 and higher.

READBACK – Current position with status: Controlled variable x

Position feedback is provided by the READBACK parameter and consists of a floating point

value (4 bytes) and the associated status (1 byte).

POS_D – Discrete valve position feedback with status: End position indication

The final valve position is indicated by the POS_D parameter and consists of one message

value (1 byte) and the associated status (1 byte). The message value is encoded as follows:

0 = not initialized, 1 = closed (x < 0.5 %), 2 = open (x > 99.5 %), 3 = intermediate position

CHECK_BACK – Device status: Detailed device information, bit-wise encoded

Bit no. Name Description Byte

0 CB_FAIL_SAFE Fail-safe position (mode = Out of Service)

0

1 CB_REQ_LOC_OP Request for local operation

2 CB_LOCAL_OP Device in local mode

3 CB_OVERRIDE Emergency operation / forced venting active

4, 5, 6 Not used

7 CB_TRAV_TIME Status of travel monitoring (reset automatically) 0

8, 9 Not used

1

10 CB_UPDATE_EVT Indicates change to static device data

40 EB 8382-1 EN

How to implement a Class 1 PROFIBUS Master

11 CB_SIMULATE

Simulation mode, i.e. value are not derived from the

process

1

12 CB_DISTURBANCE Error, refer to DIAGNOSIS parameter for cause

13 CB_CONTR_ERR

Error in internal positioner control loop (to be confirmed by Class 2 master), indicated by LED, reset automatically when control loop monitoring no longer

detects any errors

14 CB_CONTR_INACT Positioner inactive (mode = Out of Service)

15 CB_SELFTEST Positioner in self-test mode (mode = Out of Service)

16 CB_TOT_VALVE_TRAV Limit for total valve travel exceeded

2

17 to 23 Not used

Diagnostic messages of the positioner (slave diagnostic information)

In addition to the standard diagnostic messages, the positioner can provide further messages

as "Ext_Diag_Data". These are bit-wise encoded as well and correspond to the

PROFIBUS PA profile DIAGNOSIS parameter.

Bit no. Name Description

0 DIA_HW_ELETR Hardware error, electronics

1 DIA_HW_MECH Hardware error, mechanics

4 DIA_MEM_CHKSUM Checksum error, memory

5 DIA_MEASUREMENT Measurement error

6 DIA_NOT_INIT Positioner not initialized (no auto-initialization performed)

7 DIA_INIT_ERR Auto-initialization error

8 DIA_ZERO_ERR Zero point error (end position)

10 DIA_CONF_INVAL Invalid configuration

11

DIA_WARMSTART Restart (warm start) completed, refer to Profile A for definition of

warm start

12

DIA_COLDSTART New start (cold start) completed, refer to Profile A for definition of

cold start

13 DIA_MAINTENANCE Maintenance required