Page 1

Positioner with HART® communication

Type 3780

Mounting and

Operating Instructions

EB 8380-1 EN

Firmware R 2.22/K 2.23

Edition June 2004

Fig. 1 ⋅Type 378 0

Page 2

Contents Page

1. Design and principle of operation

. . . . . . . . . . . . . . . . . . . . . . 10

1.1 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Attachment to the control valve

. . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Direct attachment to Type 3277 Actuator . . . . . . . . . . . . . . . . . . . 14

2.2 Attachment according to IEC 60534-6 . . . . . . . . . . . . . . . . . . . . 18

2.2.1 Mounting sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.2 Presetting the valve travel . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Attachment to rotary valves . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.1 Mounting the cam follower roll lever . . . . . . . . . . . . . . . . . . . . . 22

2.3.2 Mounting the intermediate piece . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.3 Aligning and mounting the cam disk . . . . . . . . . . . . . . . . . . . . . 24

2.3.4 Reversing amplifiers for double-acting actuators . . . . . . . . . . . . . . . . 26

2.4 Fail-safe action of the actuator . . . . . . . . . . . . . . . . . . . . . . . . 26

3. Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.1 Pneumatic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.1.1 Pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.1.2 Supply air pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2.1 Switching amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2.2 Establishing communication . . . . . . . . . . . . . . . . . . . . . . . . . 32

4. Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1 Write protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2 Activate/deactivate forced venting function . . . . . . . . . . . . . . . . . . 34

4.3 Default setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3.1 Adjusting mechanical zero point . . . . . . . . . . . . . . . . . . . . . . . 35

4.3.2 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4 Adjusting inductive limit switches . . . . . . . . . . . . . . . . . . . . . . . 37

5. Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6. Servicing explosion-protected versions

. . . . . . . . . . . . . . . . . . . . 38

7. Summary of parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8. List of parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9. Error messages and diagnostics

. . . . . . . . . . . . . . . . . . . . . . . 53

9.1 Information/alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Contents

2

EB 8380-1 EN

Page 3

9.3 Error messages during initialization without abortion . . . . . . . . . . . . 59

9.4 Error messages during initialization with abortion . . . . . . . . . . . . . . 60

Dimensional diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Type examination certificates

. . . . . . . . . . . . . . . . . . . . . . . 63

Safety instructions

Assembly, commissioning and operation of the device may only

be performed by trained and experienced personnel familiar

with this product. According to these mounting and operating instructions, trained personnel is referred to persons who are able

to judge the work they are assigned to and recognize possible

dangers due to their specialized training, their knowledge and

experience as well as their knowledge of the relevant standards.

Explosion-protected versions of this device may only be operated by personnel who have undergone special training or instructions or who are authorized to work on explosion-protected

devices in hazardous areas. See section 6 for more details.

For devices in type of protection EEx nA, the following applies:

live circuits may only be connected, interrupted, and switched

for installation, maintenance or repair purposes.

Devices that have already been used outside of hazardous areas

and are intended for use in hazardous areas in future shall comply with the safety demands placed on serviced devices. Prior to

operation, they shall be tested according to paragraph 26 "Repairing explosion-protected devices" of EN 50014:2000 to

meet the safety requirements specified in this standard.

Any hazards which could be caused by the process medium, the

signal pressure and moving parts of the control valve are to be

prevented by means of appropriate measures.

If inadmissible motions or forces are produced in the actuator as

a result of the level of the supply air pressure, this must be restricted by means of a suitable pressure reducing station.

Proper shipping and appropriate storage are assumed.

Note:

Devices with the CE mark meet the requirements specified in the

Directive 94/9/EC and the Directive 89/336/EEC.

The Declaration of Conformity is available on request.

EB 8380-1 EN

3

Page 4

Modifications of positioner firmware

Modifications of positioner firmware in comparison to previous version

Former New

For more details on the listed parameters, please also refer to the

list of parameters in section 8.

Positioner R 1.41 R 2.01

Parameters:

Operating direction Direction of action

The reference variable (w) is not assigned to the output signal

pressure (y) anymore, but to the travel/angle of rotation (x).

>> increasing/increasing, valve opens with increasing reference

variable.

<> increasing/decreasing, valve closes with increasing reference

variable.

Minimum transit time

filling/venting

Minimum transit time open/closed

The measured time is not referenced to filling/venting the

actuator, but to the opening and closing the valve.

Required transit time

filling/venting

Required transit time open/closed

The actuating time is not referenced to filling/venting the actuator,

but to the opening and closing the valve.

Cycle time factor

K_IS

Omitted

Initialization

For version

R2.02

or higher, an alarm message is generated for

deviations larger than 10 % when the type of initialization is

maximum range. It is for the user to decide if he wants to tolerate

the deviation.

Tolerated overshoot

If overshoot and dead band are exceeded by the negative

deviation value, the pulse is adapted.

Text field

Free space for storing information text in the field device.

4

EB 8380-1 EN

Page 5

Modifications of positioner firmware

Former New

Positioner 2.02 R 2.11

Parameters:

Minimum pulse

filling/venting

The minimum pulses for filling and venting are determined for

the travel ranges 0 to 20 %, 20 to 80 % and 80 to 100 %. The

minimum pulses are no longer determined during initialization.

Proportional-action

coefficient

KP_Y1 and KP_Y2

These factors are adapted to the actuator type selected and to

the transit times measured.

Gain factor

KD

Initialization

"Air leakage of pneumatic system" is displayed as alarm

message, but does not cause abortion of initialization anymore.

Upon initialization in the "nominal range", the positioner

assumes only 100 % travel (no overtravel).

"Wrong selection of rated travel/angle of rotation or

transmission" is displayed as alarm message, but does not cause

abortion of initialization anymore.

Positioner 2.11 R 2.21

Type of actuator

Change over type of actuator from "linear actuator" to "rotary

actuator"

Initialization type .................Based on maximum range

Transmission code................S90

Nominal angle.....................90°

End position when w <..........1 %

End position when w >..........99 %

Rot ation al an gle r ange star t ..0°

Rot ation al an gle r ange end ... 90°

Change over type of actuator from "rotary actuator" to "linear

actuator"

Attachment

.........................

Integral

...............................

Acc. to NAMUR

Initialization type .................Based on nominal range.......Based on nominal range

Mounting position................Arrow towards actuator........Arrow away from actuator

Transmission code................D1......................................

Pin position.......................... ........................................A

Rated travel .........................15 mm ................................15 mm

End position when w <..........1 %.....................................1 %

End position when w >..........125 %.................................125 %

Travel range start..................0 mm..................................0 mm

Travel range end ..................15 mm................................15 mm

Length of lever...................... ........................................42 mm

EB 8380-1 EN

5

Page 6

Modifications of positioner firmware

End position when w

</>

Changing the type of initialization from "maximum range" to

"nominal range" causes:

End position at < 1 % End position at > 125 %

Changing the type of initialization from "nominal range" to

"maximum range" causes:

End position at < 1 % End position at > 99 %

Extended

valve diagnostics

Supports TROVIS-EXPERT in version 1.0 or higher

Required transit time

open/closed

The adjustment range for the required transit times has been

limited to 75 s. Safe functioning can only be guaranteed up to

this limit value.

Initialization

During initialization, the minimum control pulses for the range

20 % to 80 % of the range of the manipulated variable are

determined and saved in the EEPROM.

Proportional-action

coefficient

KP_Y1 and KP_Y2

These factors are adapted to the type of actuator chosen and the

transit times measured.

Positioner 2.21

R 2.22

Correction in "manual" operating mode and direction of action

Correction in zero calibration started via communication

Communication K 1.00 K 2.01

Characteristic type

Free space for entering information on the description of the

user-defined characteristic saved in the device. Can be stored in

the field device.

For version K 2.02 or higher, when selecting [equal percentage]

or [equal percentage reverse], the description text in parameter

characteristic type of the device is automatically set to the

selection made.

Communication K 2.02 K 2.11

Supports all functions of R 2.11

Type of initialization

For K 2.11 or higher, the default value is "maximum range"

End position when w >

For K 2.11 or higher, the default value is 99 %

6

EB 8380-1 EN

Page 7

Positioner versions

Former New

Communication

K 2.13 K 2.21

Supports all functions of R 2.21 as well as TROVIS-EXPERT in

version 1.0 or higher

Communication

K 2.21

K 2.22

Supports all functions of R 2.21 as well as TROVIS-VIEWin

version 2.0 or higher

New for model index

3780-

x...x. 01 or higher:

Write protection switch

If this option is activated using the switch, the positioner settings cannot be written over by

HART

®

communication. See section 4.1 for more details on the write protection switch.

Model index

3780-

x...x. 03 or higher are suitable for the extended valve diagnosis using

the TROVIS-EXPERT software.

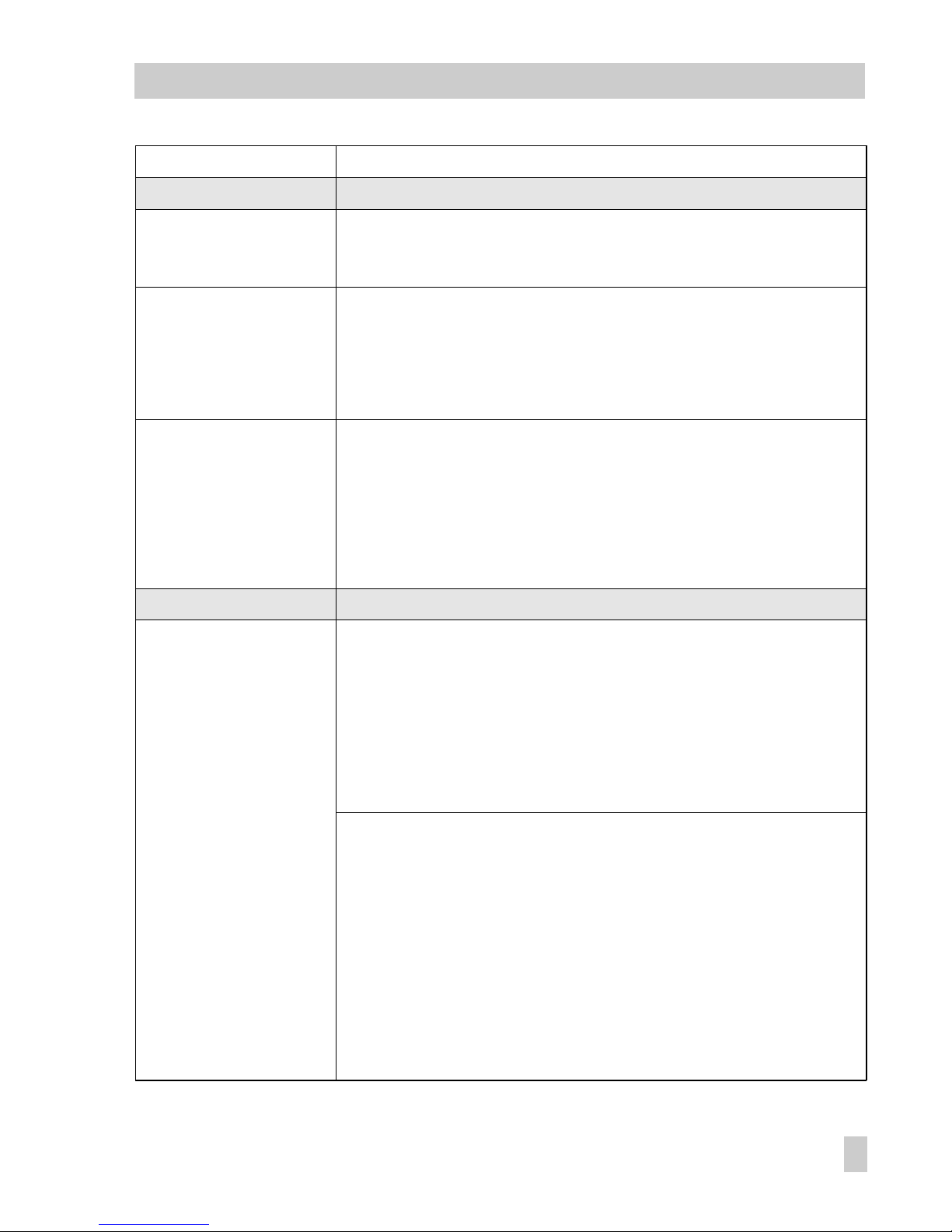

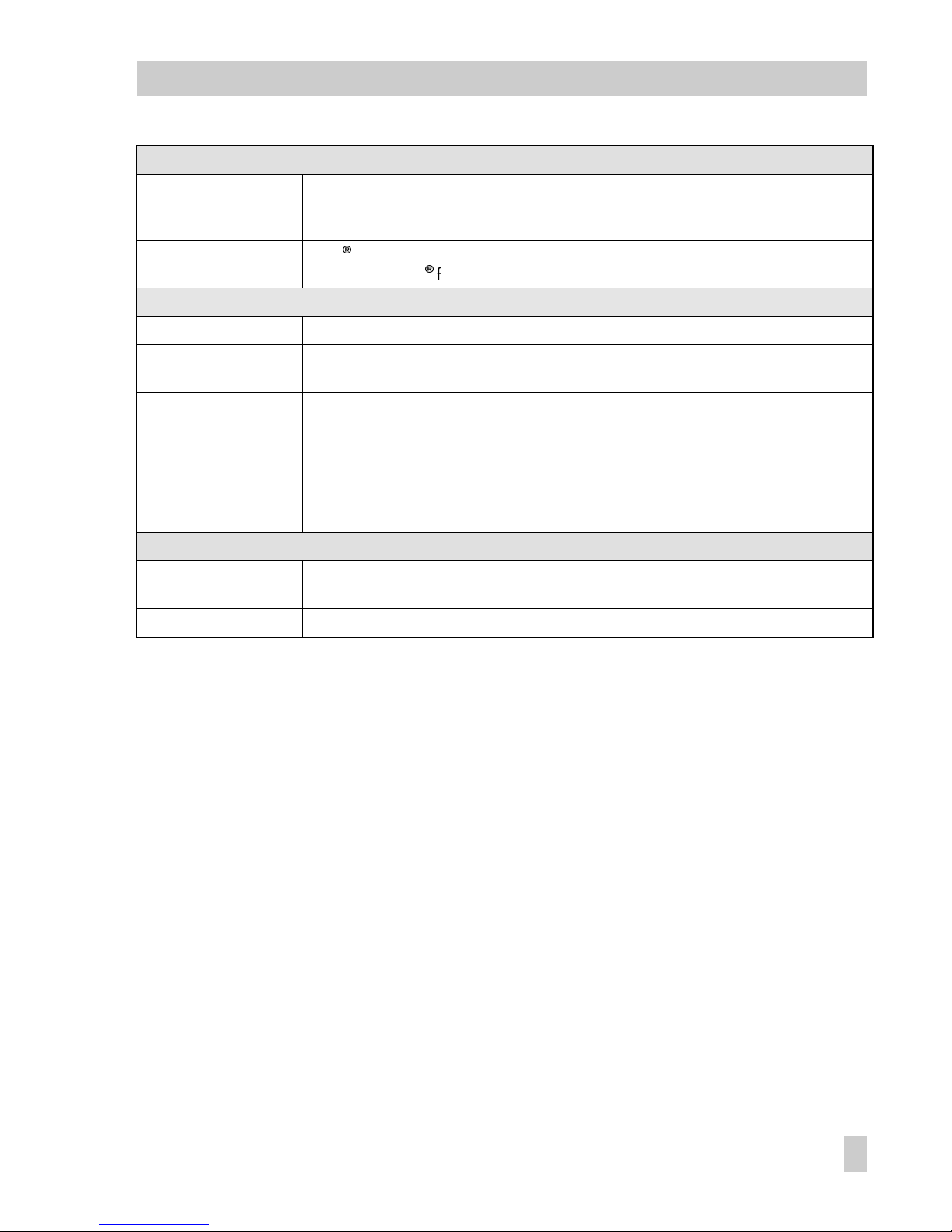

Positioner versions

Model

3780 -

XXXXX

Explosion

protection

Without

Ex II 2 G EEx iA IIC T6 as per ATEX

CSA/FM

Ex II 3 G EEx nA II T6 as per ATEX

0

1

3

8

Additional

accessories

Limit switches Without

2 inductive

2 software

0

2

3

Forced venting Without

With

0

1

Position transmitter Without

4...20 mA

0

1

Pneumatic

connections

NPT 1/4-18

ISO 228/1-G 1/4

1

2

EB 8380-1 EN

7

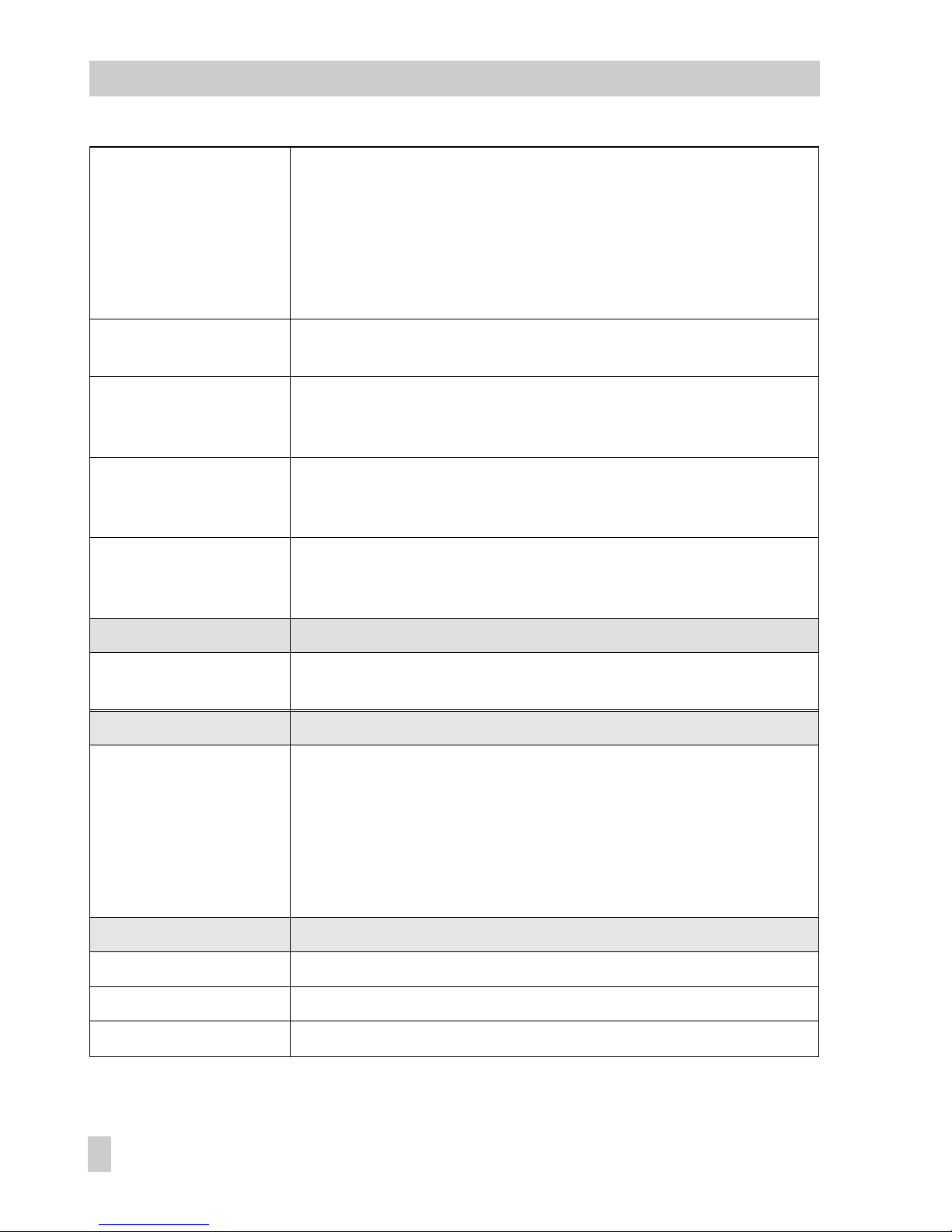

Page 8

Positioner

Rated travel, adjustable Direct attachm. 5 to 30mm

Attachment acc. to IEC 60534-6 (NAMUR), 5 to 255 mm or 30 to 120° C

Reference variable Two-wire connection, signal range 4 to 20 mA, span 4 to 16 mA

Min. cu rrent = 3 .6 mA , load ≤10.8 V (corresponding to 540 Ω at 20 mA),

static destruction limit 500 mA

Supply Supply air from 1.4 to 6 bar (20 to 90 psi)

Sign al pres su re (out pu t) 0 ba r t o p ressu re of supp ly ai r

Characteristic, adjustable Linear, equal percentage, reverse equal percentage, user-programmable

Deviation from characteristic ≤1 %

Dea d ban d Adj ustable f rom 0. 1 to 10 %, d efault 0.5 %

Resolution

≤

0.05 %

Transit time to travel Up to 75 s, separately adjustable for exhaust and supply air

Moving direction Reversible, adjustment via software

Air consumption Independent of supply air <90l

/h

Air delivery Actuator filled: for Δp = 6 bar 9.3 m

/h, for Δp = 1.4 bar 3.5 m

/h

Actuator vented: for Δp = 6 bar 15.5 m

/h, for Δp = 1.4 bar 5.8 m

/h

Perm. ambient temperature− 20 to 80 °C, with metal cable gland − 40 to 80 °C

Devices with position transmitter only − 20 to 80 °C

For explosion-protected devices, see type examination certificate in appendix

Effects Temperature: ≤0.15 %/10 K, supply: none, vibrations: none up to 250 Hz and 4 g

Explosion protection EEx ia IIC T6, see type examination certificate

Degree of protection IP 65 by using the filter check valve included

Electromagnetic

compatibility

Requirements stipulated in EN 61000-6-2, EN 61000-6-3 as well as NAMUR

Recommendation 21 have been met

Electrical connections 1 cable gland M20x1.5, black plastic;

other threaded hole M20x1.5 available

Fault alarm output For connection to switching amplifier acc. to EN 60947-4-6, static destruction limit 16 V

Forced venting

(model index .03 or

higher)

Activated/deactivated by a switch inside case

Input: 6...24 V DC, R

appr ox . 6 kΩ, at 24 V D C ( de pendin g o n volta ge ), swit ch ing poi nt

for "1" signal at ≥ 3 V, si gnal "0 " o nl y at 0 V, K

val ue 0.17; st at ic dest ru ction l im it 45 V

Technical data

8

EB 8380-1 EN

Page 9

Communication

Hardware requirements SAMSONs TROVIS-VIEW Operator Interface (see Data Sheet T 6661 EN) or handheld

communicator, e.g. Type 275 by Rosemount

Integration of other operator interfaces, e.g. DTM, are available

Data transmission HART

®

Fiel d C om munica ti on Prot oc ol

Impedance in HART

®

frequency range: receive: 350 to 450 Ω; send: approx. 115

Ω

Accessory equipment

Inductive limit switches Two Type SJ 2 SN Prox. Switches for connection to switching amplifier acc. to EN 60947-5-6

Software limit switches Two configurable limit values for connection to switching amplifier acc. to EN 60947-5-6

Switching hysteresis 1%, static destruction limit 16 V

Analog position

transmitter

Two-wire transmitter, output 4 to 20 mA

Sup pl y: termin al vo ltage 12 to 35 V D C, stat ic de struct io n limit 40 V

Direction of action reversible, characteristic linear, operating range: 10 % to + 114 %

DC current signal ripple content: 0.6 % at 28 Hz/IEC 381 T1

Resolution ≤0.05 %

HF influence <2 % with f= 50 to 80 Mhz

Infl ue nce au x. su pply: n on e; temp er ature i nf luence : s ame as p os itione r

Materials

(num be rs acc or di ng to DIN )

Case Di e- cast al um inum, c hr om ed and pl astic- co at ed

External parts: stainless steel 1.4571 and 1.4301

Weight Approx. 1.3 kg

Versions

EB 8380-1 EN

9

Page 10

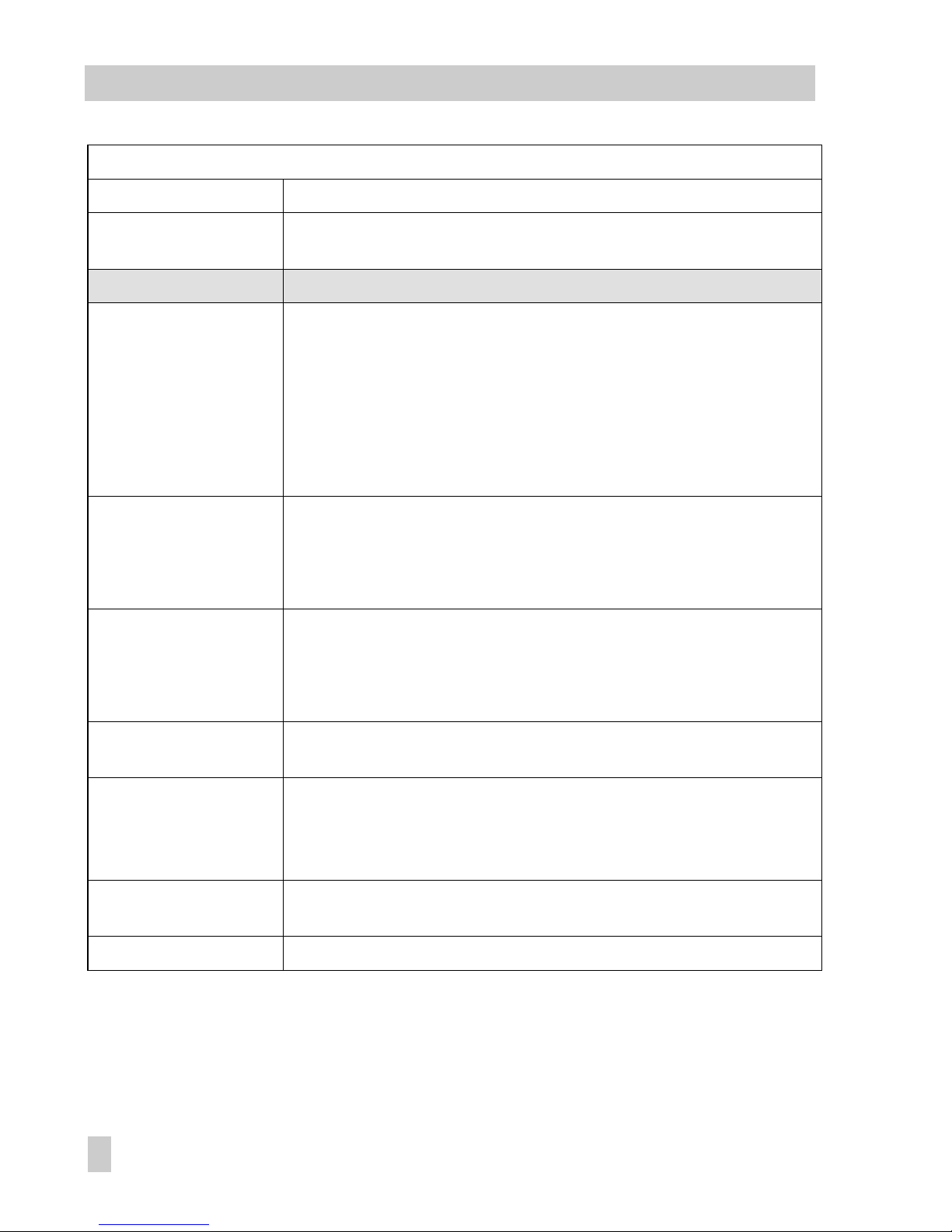

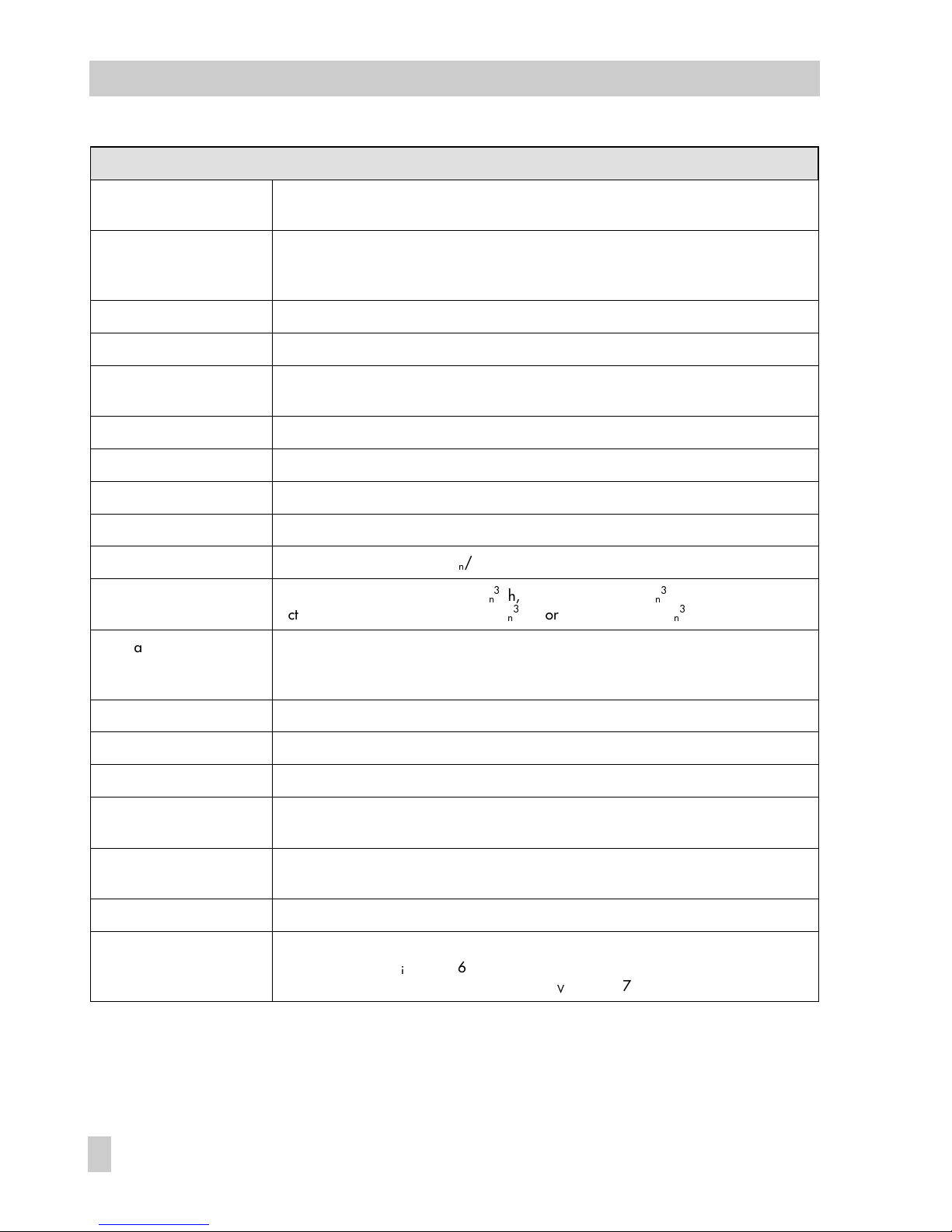

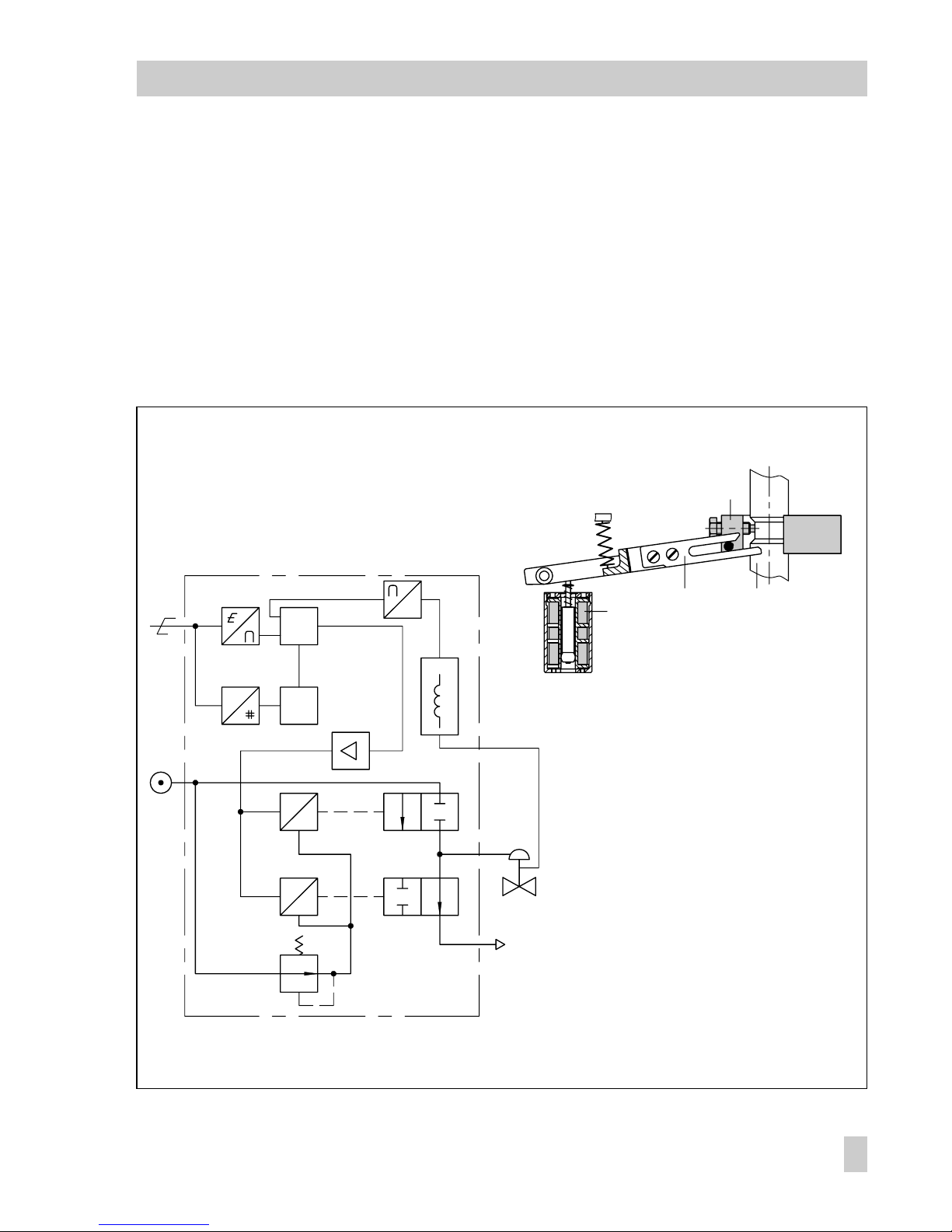

1. Design and principle of operation

The positioner essentially consists of an inductive, non-contact travel measuring system and an electrically controlled valve

block comprising two 2/2-way on-off

valves and an electronic unit. This unit contains two microcontrollers for processing the

control algorithm and managing the communication.

Whenever a deviation between the actual

valve travel (actual value) and the reference

variable (set point) occurs, the microcontroller produces binary pulse-pause modulated

signals to control the two 2/2-way on-off

valves, each of which is assigned an amplifier. One of these valves controls the exhaust air, and the other one controls the supply air.

The supply air valve (3) switches the supply

air (7, supply air pressure 1.4 to 6 bar) to

the actuator (filling). The exhaust air valve

(4) controls the air exhausted from the actuator to the atmosphere (venting). These onoff valves can either have the switching

states - permanently open, permanently

closed - or generate single pulses of changing widths. With the two valves being controlled, the plug stem moves to a position

corresponding to the reference variable. If

there is no system deviation, both the supply

air and the exhaust air valve are closed.

As a standard feature, the positioner is

equipped with a fault alarm output (binary

output according to EN 60947-5-6) used to

signalize a fault to the control room.

Activating the write protection switch located in the hinged cover prevents the positioner settings from being overwritten by the

HART

®

protocol.

Forced venting function

The positioner is controlled via a 6 to

24 V signal, causing the signal pressure

to be applied to the actuator. If this voltage signal decreases, the signal pressure is

shut off and the actuator is vented. The

springs contained in the actuator move the

valve to its fail-safe position.

The forced venting function is installed in all

positioners from model index .03 or higher.

The function can be activated or deactivated by a switch. See section 4.2 (page

34) for more details.

1.1 Options

As a supplement to the standard positioner

version, there are several additional options

to extend the positioner functions.

Limit switches

To signalize the valves end positions in failsafe circuits, either two software limit switches or two proximity switches can be used.

Position transmitter

The position transmitter is an intrinsically

safe 2-wire transmitter controlled by the

microcontroller of the positioner. It serves to

assign the valve position with the 4 to 20

mA output signal. The position transmitter

signalizes both end positions, "valve closed"

or "valve fully open", as well as all intermediate positions. Since the valve positions

are signalized to the positioner independently of the input signal (minimum

current must be observed), the position

transmitter is a suitable option for checking

the current valve position.

10

EB 8380-1 EN

Design and principle of operation

Page 11

1.2 Communication

For communication, the positioner is

equipped with an interface for the HART

®

protocol (Highway Addressable Remote

Transducer). Data transmission is accomplished by superimposing an FSK signal

(FSK = Frequency Shift Keying) over the

existing 4 to 20 mA signal lines for the reference variable.

You can configure and operate the positioner either via HART

®

-compatible, handheld communicator or via PC, using an FSK

modem and an RS-232 interface.

After mechanically resetting the positioner

to zero, it can be automatically started up

via initialization procedure. During this initialization procedure, zero is automatically

adjusted, and the preset span is checked.

Fig. 2 ⋅Functional diagram

11 10

1

12

e

p

3

4

2

5

1

G

μC

FSK

e

p

G

μC

6

7

8

1 Inductive displacement sensor

2 Microcontroller

3 2/2 way valve for supply air

4 2/2 way valve for exhaust air

5 Microcontroller

6 Pressure regulator

7 Supply air 1.4 to 6 bar

8 Reference variable 4 to 20 mA

with superimposed FSK signal

10 Actuator stem

11 Lever

12 Clamp

EB 8380-1 EN

11

Design and principle of operation

Page 12

The positioner is supplied with a standard

configuration applying to a valve with

15 mm rated travel, which is designed for

integrated positioner attachment.

An individual configuration needed to

adapt the positioner to deviating actuators

can only be carried out by means of a communicator or a PC with a connected FSK

modem, using the HART

®

protocol.

You can enter the following parameters:

control characteristic, direction of action,

limitation of travel, travel range, transit time

to travel and fault messages.

Operating software

TROVIS-VIEW

for devices with firmware K 2.11 or

higher, Data Sheet T 6661 EN

IBIS

(DOS-based, no longer runs on

Windows 2000/ME/XP/NT),

see EB 8380-2 EN for more details

DMT 1.2 and PACTware

Integration

e.g. Fisher AMS, Siemens PDM, etc.

Handheld communicator

DD-based handheld communicators,

e.g. Fisher-Rosemount HART

®

Communica-

tor.

12

EB 8380-1 EN

Design and principle of operation

Page 13

2. Attachment to the control valve

The positioner can be attached either directly to a SAMSON Type 3277 Actuator,

or according to Namur (IEC 60534-6), to

control valves with cast yokes or rod-type

yokes.

In combination with an intermediate piece,

the device can also be attached as rotary

positioner to rotary actuators.

Since the standard positioner unit is delivered without accessories, the required

mounting parts and their order numbers

have to be derived from the tables.

Note!

For quick-acting control valves with a small

travel volume (transit time < 0.6 s), it might

be necessary to replace the filter installed in

the output pressure bore with a screw-in

throttle to obtain good control properties.

For further information, refer to sections

2.1, 2.2 and 2.3.

Caution!

The positioner does not have a venting

plug. Instead the air is exhausted via venting plugs on the mounting parts (see also

Fig. 3, 5 and 7).

A filter check valve for the exhaust air is supplied with every positioner (located underneath a transparent cover at the back of the

positioner). Use this filter check valve in

place of the standard venting plug included

in the accessories. The IP 65 degree of protection to prevent dirt and moisture entering

the device is only achieved when this filter

check valve is used.

EB 8380-1 EN

13

Attachment to the control valve

Page 14

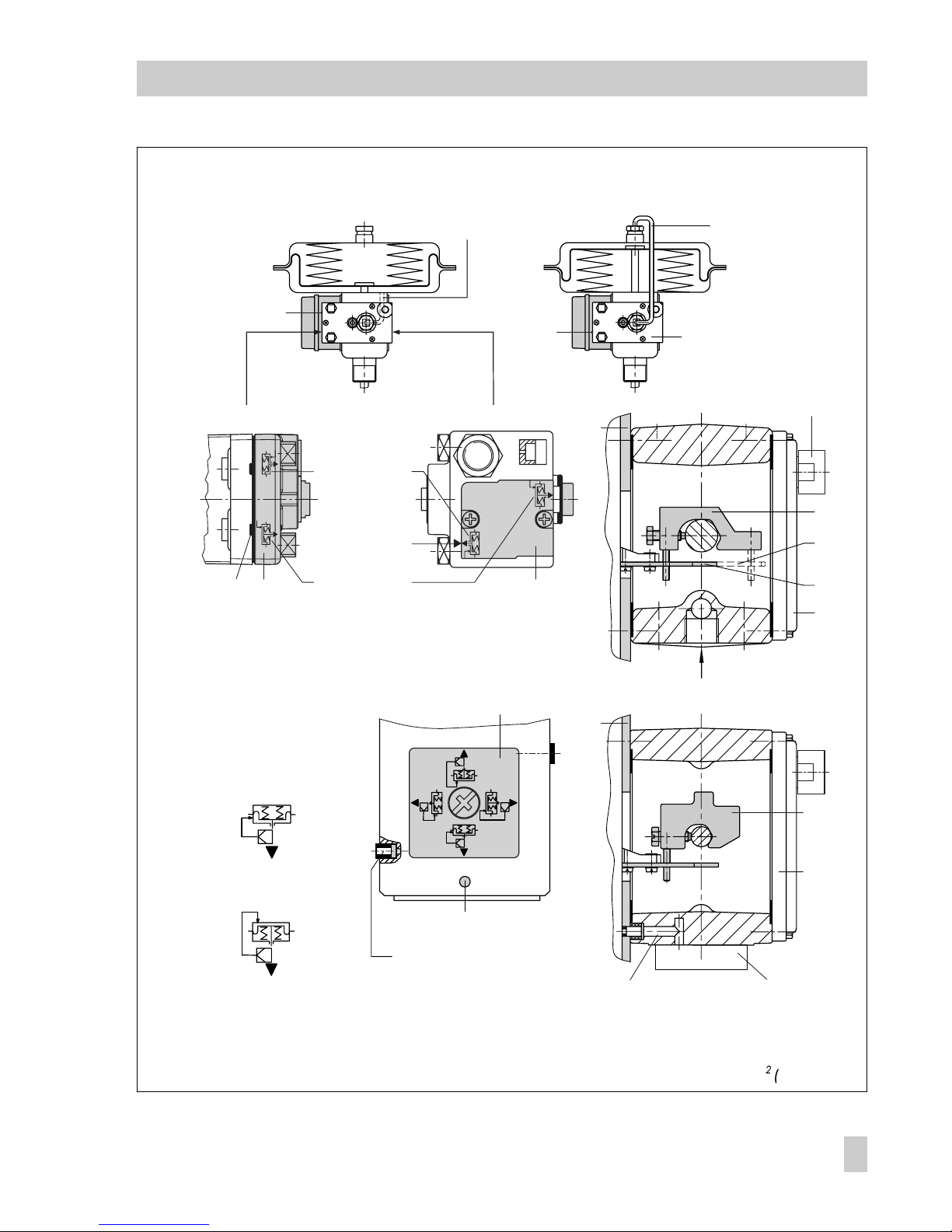

2.1 Direct attachment to Type 3277

Actuator

For the selection of the required mounting

parts, refer to Tables 1, 2 and 3 (page 17).

When looking at the signal pressure connection or the switchover plate (Fig. 3) from the

top, the positioner must be attached to the

left side of the actuator. The

arrow

on the

black case cover (Fig. 12) should then point

towards

the

diaphragm chamber.

Exception:

Control valves in which the plug

closes the seat area when the actuator stem

retracts. In this case, the positioner has to

be attached to the right side of the yoke, i.e.

with the arrow pointing away from the diaphragm chamber).

1. First screw the clamp (1.2) to the actua-

tor stem. Make sure the fastening screw

is located in the groove of the actuator

stem.

2. Screw the associated lever D1 or D2 to

the transmission lever of the positioner.

3. Fasten distance plate (15) with seal to-

wards the actuator yoke.

4. Place positioner on the plate (15) so

that the lever D1 or D2 will slide centrically over the pin of the clamp (1.2).

Then screw on to distance plate (15).

5. Attach cover (16).

Note!

For quick-acting control valves (transit time

< 0.6 s), it is necessary to replace the filter

installed in the output pressure bore (Output

38) with a screw-in throttle (accessories specified in Table 3).

Actuator with 240, 350 and 700 cm

2

6. Check whether the tongue of the

seal (17) is aligned on the side of the

connection block such that the actuator

symbols for "Actuator stem extends" or

"Actuator stem retracts" match the actuator design.

Otherwise, remove the three fixing

screws, remove the cover plate (18) and

reinsert the seal (17) turned by 180°.

When using an

old

connection block,

turn the switch plate (19) such that the

corresponding actuator symbol is

aligned with the arrow.

7. Place connection block with the associated sealing rings against the positioner

and the actuator yoke and screw it

tight, using the fastening screw.

For actuators with fail-safe action "actuator stem retracts", additionally install

the ready-made signal pressure pipe

between the connection block and the

actuator.

Actuator with 120 cm

2

With Type 3277-5 Actuator with 120 cm

2

the signal pressure is transmitted via the

switchover plate to the diaphragm chamber.

For a rated travel of 7.5 mm, a brass

throttle has to be pressed into the seal located in the signal pressure input on the actuator yoke. With 15 mm rated travel, this

is only required when the supply air pressure is higher than 4 bar.

6. Remove the vent plug on the back of the

positioner and close the side-located

signal pressure output (38) with the

plug from the accessory kit.

14

EB 8380-1 EN

Attachment to the control valve

Page 15

Actuator stem

retracts

Ventin g

"Actuator stem

retracts" symbol

With switch plate (formerly)

With seal

(new)

SUPPLY

1817 19

1.2

D2

D1

17

16

15

1.2

16

17

15

Actuator stem retracts

Internal signal pressure connection

Signal pressure

connection via piping

1.2 Clamp

D 1 Lever

D2 Lever

15 Distance plate

16 Cover

17 Seal

18 Cover plate

19 Switch plate

Signal pressure hole

Side view of connection block

Connection block

Mark

Mark

"Actuator stem

extends" symbol

Switchover plate

Switchover plate

Signal pressure input

Signal pressure

input, if necessary

with brass throttle

Actuator stem extends

Actuator stem

extends

Fig. 3 ⋅Attachment and signal pressure connection for Type 3277 (top) and Type 3277-5 with 120 cm (below)

EB 8380-1 EN

15

Attachment to the control valve

Page 16

7. Mount the positioner so that the hole in

the distance plate (15) matches the seal

located in the hole of the actuator yoke.

8. Align the switchover plate with the

corresponding symbol for left attachment according to the marking and

screw tight onto the actuator yoke.

Important!

If, with the 120 cm

2

actuator in addition to

the positioner, a solenoid valve or a similar

device is attached to the actuator, do not

remove the rear M3 screw. In this case, the

signal pressure has to be fed from the signal pressure output to the actuator via the

required connecting plate (see Table 2). The

switchover plate is not used.

Note!

For quick-acting control valves (transit time

< 0.6 s), it is necessary to replace the filter

installed in the output pressure bore (Output

38) with a screw-in throttle (accessories specified in Table 3).

Filling the spring chamber with air

If the spring chamber of the Type 3277 Actuator must be filled with the air exhausted

from the positioner, the spring chamber (version "Actuator stem extends") can be connected to the connection block by means of

a tube (see Table 3). To proceed, remove

the venting plug in the connection block.

In Type 3277-5 when "Actuator stem retracts" the exhausted air from the positioner

is constantly applied to the spring chamber

through an internal hole.

16

EB 8380-1 EN

Attachment to the control valve

Page 17

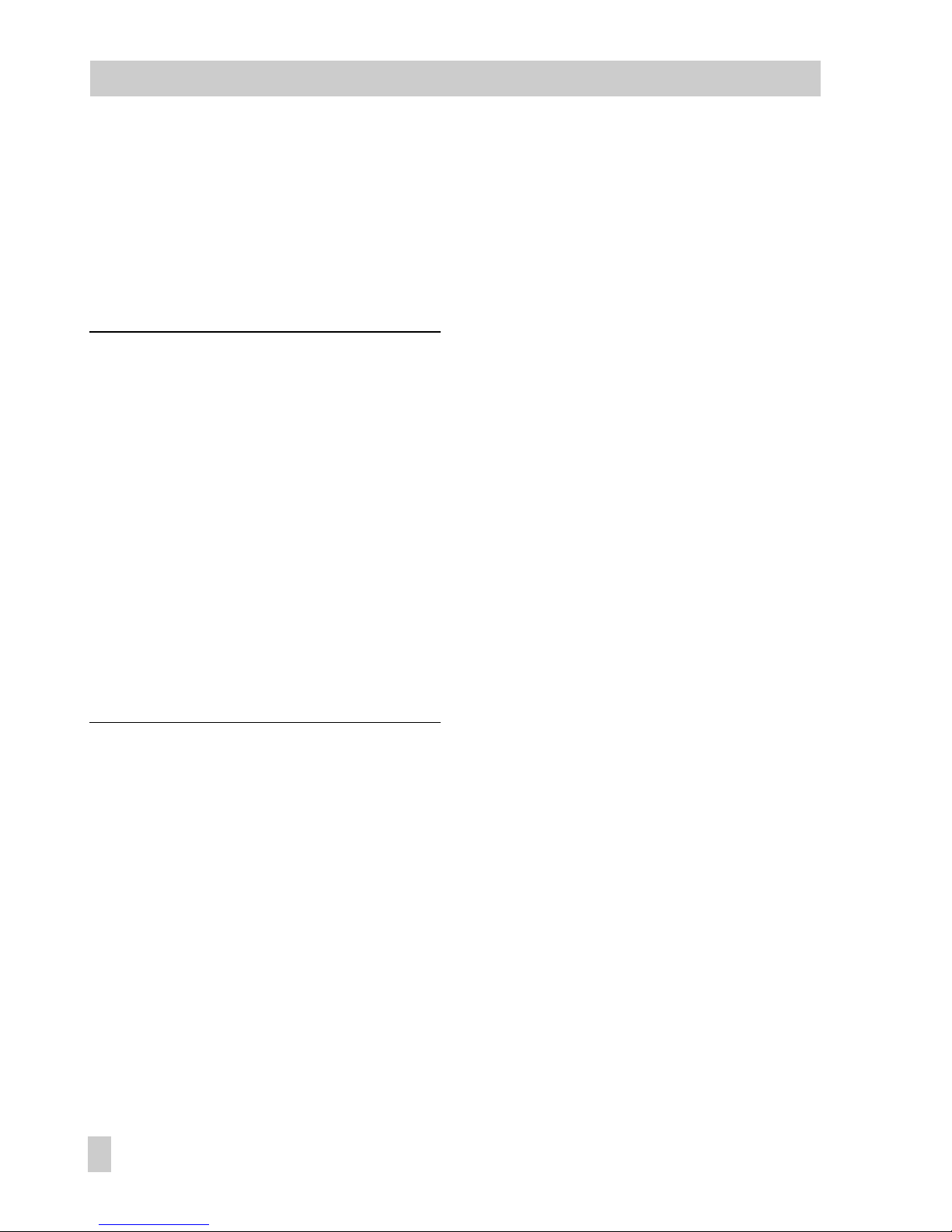

1)

Order with every pressure gauge kit: 2 restrictions (1790-6121)

1)

1402-0938 1402-0939

Page 18

2.2 Attachment according to

IEC 60534-6

For the selection of the required mounting

parts, refer to Tables 4 and 5 (page 21).

The positioner is attached according to

NAMUR using an adapter housing as

shown in Fig. 4. The valve travel is transmitted via the lever (18) and the shaft (25)

to the bracket (28) of the adapter housing

and then to the pin (27a) located at the positioner lever.

To attach the positioner, the mounting parts

listed in Table 4 are required. Which lever

is to be used depends on the rated valve

travel.

Once the positioner is attached, however,

the

arrow

on the black case cover has to

point downwards

away

from the

dia-

phragm actuator

. (

Exception

: Control

valves in which the plug closes the seat area

when the actuator stem retracts. In this case,

the arrow has to point

towards

the dia-

phragm actuator).

Note!

For quick-acting control valves (transit time

< 0.6 s), it is necessary to replace the filter

installed in the output pressure bore (Output

38) with a screw-in throttle (accessories specified in Table 4).

2.2.1 Mounting sequence

NOTE

Before you mount the parts, load the actuator with air pressure so that the valve is set

to 50 % of its travel. This will ensure the

exact alignment of the lever (18) and the

bracket (28).

Control valve with cast yoke

1. Use countersunk screws to screw the

plate (20) to the coupling which connects the plug and actuator stem. With

2100 and 2800 cm

2

actuators, use ad-

ditional mounting bracket (32).

2. Remove rubber plug from the adapter

housing and fasten the housing to the

NAMUR rib, using the hexagon head

screw.

Control valve with rod-type yoke

1. Screw plate (20) to the follower clamp

of the plug stem.

2. Screw studs (29) into the adapter housing.

3. Place the housing with the plate (30) on

either the right or left side of the valve

rod and screw the housing tight by

using nuts (31). While doing so, make

sure that lever (18) to be mounted subsequently is horizontal (when the valve

is at midtravel).

4. Screw the pin in a hole in the center

row of holes in the plate (20) and lock it

such that it will be located above the

correct lever marking (1 to 2) for the assigned travel, see Table 5. Intermediate

values must be calculated. Beforehand,

18

EB 8380-1 EN

Attachment to the control valve

Page 19

2

1,5

1

2826

AB

24 25 22

32

31

20 19

19 21 2023 18

27b

27a

29

30

Mounting position

Fig. 4 ⋅Attachment according to IEC 60534-6 (NAMUR)

18 Lever N1, N2

19 Pin

20 Plate

21 Clamp

22 Clamping plate

23 Screw

24 Pointer

25 Shaft

26 Lever of positioner

27a Coupling pin

27b Lock nut

28 Bracket

29 Studs

30 Plate

31 Nuts

32 Mounting bracket

Attachment to

NAMUR rib

Attachment to rod-type yoke

EB 8380-1 EN

19

Attachment to the control valve

Page 20

move the clamp (21) to surround the

pin.

5. Measure the distance between the center of the shaft (25) and the center of

the pin (19). You will be prompted for

this value subsequently during the configuration of the positioner.

2.2.2 Presetting the valve travel

1. Adjust the shaft (25) in the adapter

housing so that the black pointer (24) is

aligned with the casted marking on the

adapter housing.

2. Screw tight clamping plate (22) in this

position, using a screw (23).

3. Screw in the pin (27) at the positioner

lever (26) and secure it with a hex nut

on the opposite side. Note the mounting position A or B respectively according to Table 5 and Fig. 5.

4. Put the positioner to the adapter housing such that the pin (27) will lie

properly within the arms of the bracket

(28).

To do so, insert a 2.5 mm Allen key or

a screwdriver from the front into the

hole located below the oblong hole on

the cover plate, and push the positioner

lever in the required position.

5. Screw the positioner to the adapter

housing.

6. Relieve the actuator from the signal

pressure.

20

EB 8380-1 EN

Attachment to the control valve

Page 21

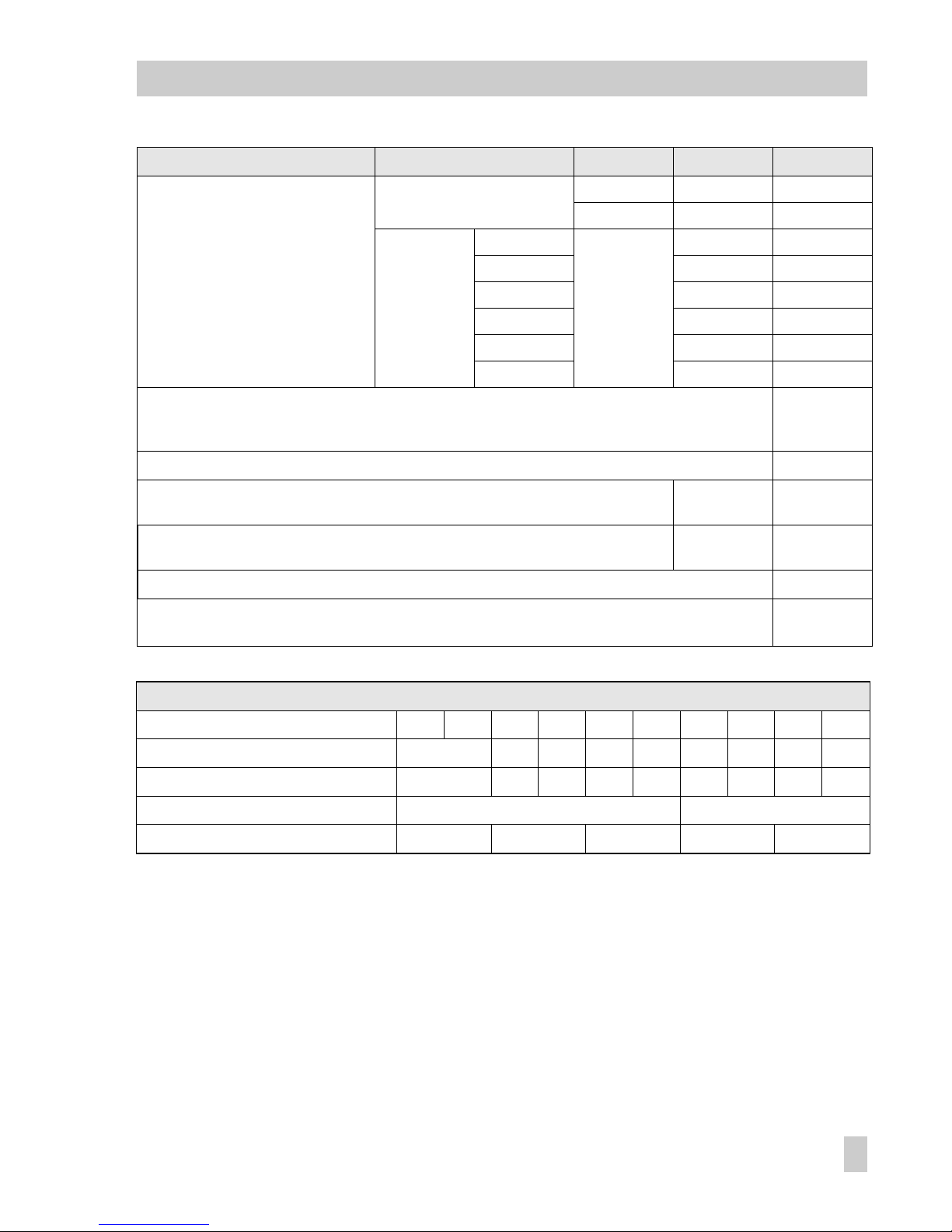

Ta bl e 4

Attachment acc. to IEC 60534-6 Control valve Travel in mm With lever Order no.

NAMUR mounting kit

Parts illustrated in Fig.4

Valve with cast yoke

7.5 to 60 N1 (125 mm) 1400-6787

30 to 120 N2 (212 mm) 1400-6789

Valve with

rod-type yoke

with

rod diameter

in mm

20 to 25 N1 1400-6436

20 to 25 N2 1400-6437

25 to 30 N1 1400-6438

25 to 30 N2 1400-6439

30 to 35 N1 1400-6440

30 to 35 N2 1400-6441

Attac hm ent to F is he r and M as on eilan l inear a ct uators (o ne each of bo th mo unting ki ts is needed per one

actuator)

1400-6771

and

1400-6787

Accessories

Order no.

Pre ss ure gau ge mo unting bl ock G 1/4

1/4 N PT

1400-7458

1400-7459

Pre ss ure gau ge set St. s t. /Brass

St. st./St. st.

1400-6957

1400-6958

Signal pressure throttles (screw-in type and brass throttle) 1400-6964

Filter check valve, replaces venting plug and increases the degree of protection to IP 65

(one in cluded wi th the d el ivere d p os itione r)

1790-7408

Table 5

Attachment according to IEC 60534-6

Travel in mm *) 7.51515303060306060120

Pin on marking *) 1 12121212

Corresp. distance pin/lever fulcrum 42 428442848416884168

With lever N1 (125 mm in length) N2 (212 mm in length)

Transmission pin (27) on position A A B A B

*) Deviating travel values (intermediate values) must be calculated accordingly.

EB 8380-1 EN

21

Attachment to the control valve

Page 22

2.3 Attachment to rotary actuators

For the selection of the required mounting

parts, refer to Table 6 (page 25).

The positioner can also be attached to rotary actuators in accordance with VDI/VDE

3845 by using the mounting parts and accessories listed in Table 6. In this arrangement, the actuators rotary motion is converted via the cam disk on the actuator shaft

and the feeler roll of the positioner lever to

a linear motion required by the positioners

inductive displacement sensor system.

Each cam disk is suitable for two characteristics, i.e. for the ranges of angle of rotation from 0 to 90° (recommended for

angles below 90°) and 0 to 120° (recommended for 90° and greater).

For double-acting, springless rotary actuators, it is necessary that a reversing amplifier be attached to the positioner on the side

of the connection. (See section 2.3.4.)

If the positioner is attached to a SAMSON

Type 3278 Rotary Actuator, the air exhausted from the positioner is admitted to

the inside of the actuator and the chamber

behind the diaphragm. No additional piping is required.

If the positioner is attached to actuators of

other manufacturers (NAMUR) the air is applied to the chamber behind the diaphragm

through a tube assembly and a tee, connected between actuator and intermediate

piece.

Note!

For quick-acting control valves (transit time

< 0.6 s), it is necessary to replace the filter

installed in the output pressure bore (Output

38) with a screw-in throttle (accessories spe-

cified in Table 6).

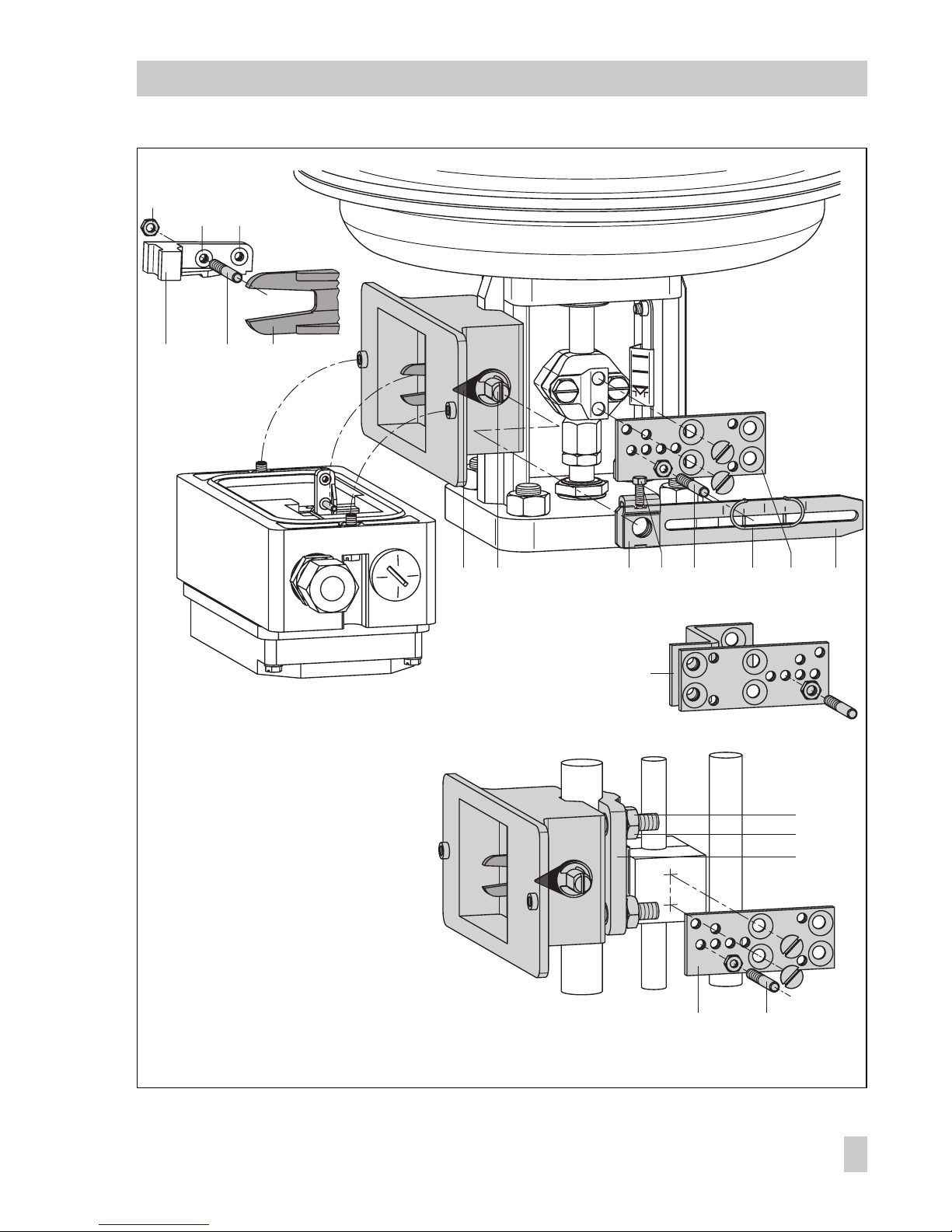

2.3.1 Mounting the cam follower

roll lever

1. Place lever with the attached roll (35)

on the side of the transmission lever

(37) and secure it with the enclosed

screws (38) and washers.

2.3.2 Mounting the intermediate

piece

SAMSON Type 3278 Actuator:

1. Screw adapter (36) to the free end of the

rotary actuator shaft with two screws.

2. Place the intermediate piece (34) on the

actuator case and fasten with two

screws. Align intermediate piece of the

positioner so that the air connections of

the positioner will face towards the diaphragm case side.

Actuators according to VDI/VDE 3845

1. Place the complete intermediate piece

(34, 44, 45 and 42) onto the mounting

bracket included in the delivery (fixing

level 1 VDI/VDE 3845) and screw tight.

2. Align the cam disk (40) and scale (39) as

described in section 2.3.3 and fasten tight.

With springless actuators, the reversing amplifier must be screwed to the side of the positioner case. See section 2.3.4 for more details.

22

EB 8380-1 EN

Attachment to the control valve

Page 23

Fig. 5 ⋅Attachment to rotary actuators

33

3835

39

39

40

34

36

40

34

44

45

42

43

37

Attachment to SAMSON Type 3278

Attachment acc. to

VDI/VDE 3845

Vent plug or filter

check valve

33 Positioner

34 Intermediate piece

35 Lever w. cam follower roll

36 Adapter

37 Transmission lever

38 Screws

39 Scale

40 Cam disk

41 Actuator shaft

42 Plate

43 Bracket

44 Coupling

45 Seal

EB 8380-1 EN

23

Attachment to the control valve

Page 24

2.3.3 Aligning and mounting of

the cam disk

In rotary actuators with spring-return mechanism, the built-in actuator springs determine the fail-safe position and the direction

of rotation of the control valve (either

counterclockwise or clockwise).

With double acting, springless rotary actuators, the direction of rotation depends on

both the actuator and the valve model used.

Any adjustments are only permitted when

the valve has been closed.

The direction of action of the positioner, i.e.

whether the valve shall either open or close

when the reference variable increases, has

to be software-adjusted via the communication (increasing/increasing or increasing/decreasing direction of action).

1. Position the cam disk with the scale on

the adapter (36) or the coupling (44)

and fasten the screw loosely at first.

The cam disk carries two cam sections. The

starting point of each section is marked by

a small bore.

Note!

With the valve closed, the starting point

(bore hole) of the respective characteristic is

to be aligned so that the center of rotation

of the cam disk, the 0° position on the

scale, and the arrow mark on the disk are

aligned.

The starting point when the valve is closed

should not under any circumstances be

below the 0° position!

With actuators with fail-safe position "Valve

OPEN", the maximum signal pressure must

be applied to the actuator before aligning

the cam disk.

With springless actuators, the supply air

must be connected.

2. In aligning the cam disk, clip on the

double-sided scaled disk in such a way

that the valve on the scale will correspond to the direction of rotation of the

control valve. Only then, secure the

cam disk with the fastening screws.

Securing the aligned cam disk

If the cam disk should be additionally secured to prevent it from being turned, proceed as follows:

Choose one of the four bore holes located

centrically around the center bore on the

cam disk which is suitable to secure the cam

disk.

Drill a hole in the adapter (36) or coupling

(44) through the selected hole so that a

2 mm dowel pin can be inserted in this hole.

3. Attach the positioner to the intermediate

piece (34) so that the lever (35) contacts

the cam disk with its cam follower roll.

To do so, insert a 2.5 mm hexagon

socket key or a screw driver from the

front into the bore hole which can be

seen below an oblong hole on the cover

plate and bring the positioner lever in

the required position.

4. Screw the positioner onto the intermediate piece.

24

EB 8380-1 EN

Attachment to the control valve

Page 25

Fig. 6 ⋅Aligning the cam disk

Ta b le 6

Rotary actuators (Complete mounting parts, but without cam disks)

SAMSON Type 3278 Actuator Attachmt. acc. to VDI/VDE 3845 Attachment to Masoneilan actuator

Actuator

160 cm

Actuator

320 cm2

Camflex I

DN 25 ...100

Camflex I

DN 125...250

Camflex II

Order no.

1400-7103 1400-7104 1400-8815 1400-7118 1400-7119 1400-7120

Pip in g kit 8 x 1 st ai nl. st ee l

G 1400-6670 1400-6672

NPT 1400-6669 1400-6671

Accessories

Order no.

Reversing amplifier for double-acting, springless actuators G: 1079-1118 NPT: 1079-1119

Cam disk (0050-0089) with accessories, angle of rotation 0 to 90° and 0 to 120° 1400-6959

Cam disk (0050-0089) especially for VETEC, adjustable to 0 to 75° via software 1400-6960

Cam disk (0050-0090) especially for Camflex, adjustable to 0 to 50° via software 1400-6961

Pressure gauge mounting block G 1/4: 1400-7458 1/4 NPT: 1400-7459

Pressure gauge set St. st./Br.: 1400-6957 St. st./St. st.: 1400-6958

Signal pressure throttles (screw-in type and brass throttle) 1400-6964

Filt er check v alve, r ep laces v enting pl ug and i nc rease s t he degre e o f p ro tectio n t o I P 6 5

(one included with the delivered positioner)

1790-7408

Cam follower roll

Starting point

Holes to secure

cam disk

Insert clip and then press

tongues outwards!

Control valve opens

counterclockwise

View onto actuator shaft from positioner

Control valve opens

clockwise

EB 8380-1 EN

25

Attachment to the control valve

Page 26

2.3.4 Reversing amplifier for

double-acting actuators

For the use with double-acting actuators,

the positioner must be fitted with a reversing

amplifier.

The reversing amplifier is listed as an accessory in the Table 6 on page 25.

The output signal pressure of the positioner

is supplied at the output A

1

of the reversing

amplifier. An opposing pressure, which

equals the required supply pressure when

added to the pressure at A

1,

is applied at

output A

2

. The rule A1 + A2 = Z applies.

Mounting

Note!

Prior to attaching the reversing amplifier,

remove the sealing plug (1.5). The rubber

seal (1.4) must remain installed.

1. Screw the special nuts (1.3) from the ac-

cessories of the reversing amplifier into

the threaded connections of the positioner.

2. Insert the gasket (1.2) into the recess of

the reversing amplifier and push both

the hollowed special screws (1.1) into

the connecting boreholes A1 and Z.

3. Place the reversing amplifier onto the

positioner and screw tight using both

the special screws (1.1).

4. Screw the enclosed filter (1.6) into the

connecting boreholes A1 and Z using a

screwdriver (8 mm wide).

Signal pressure connections

A

1

: Output A1 leading to the signal pressure connection at the actuator which opens

the valve when the pressure increases

A

2

: Output A2 leading to the signal pressure connection at the actuator which closes

the valve when the pressure increases

Enter the actuator as "Double-acting

without spring-return mechanism" in

the user interface under Start-up → Actuator type.

2.4 Fail-safe action of the actuator

Note!

If the fail-safe action of the actuator is

changed subsequently by modifying the actuator springs from "Actuator stem extends"

to "Actuator stem retracts", the mechanical

zero must be readjusted and the positioner

must be re-initialized.

26

EB 8380-1 EN

Reversing amplifier for double-acting actuators

Page 27

1.3 1.2 1.1 1

Output 38 Supply 9

A

1

1.5 1.6

Z

A

2

1.4

A

1

A

2

Output 38 Supply 9

1.3 1.21.1

1.6

Z

A

1

Fig. 7 ⋅Mounting a reversing amplifier

Control signals

to the actuator

1 Reversing amplifier

1.1 Special screws

1.2 Gasket

1.3 Special nuts

1.4 Rubber seal

1.5 Plug

1.6 Filter

From the positioner

EB 8380-1 EN

27

Reversing amplifier for double-acting actuators

Page 28

3. Connections

3.1 Pneumatic connections

The air connections are either 1/4 NPT or

G 1/4 tapped holes. The customary fittings

for metal and copper tubes or plastic hoses

can be used.

Note!

The supply air has to be dry and free from

oil and dust. The maintenance instructions

for upstream pressure reducing stations

must be observed. Carefully blow through

all air tubes and hoses before connecting

them.

If the positioner is attached directly to the

Type 3277 Actuator, the connection of the

positioners output pressure to the actuator

is fixed. For Namur attachment, the signal

pressure can be applied to either the upper

or lower diaphragm chamber of the actuator, depending on the actuators fail-safe position.

Exhaust air:

The exhaust air connection of

the positioner is located in the mounting kit.

If the positioner is attached directly, a vent

plug is located in the plastic cover of the actuator. For Namur attachment, it is in the

adapter housing and for attachment to rotary actuators, it will either be located in

the intermediate piece or in the reversing

amplifier.

3.1.1 Pressure gauge

To monitor the positioner operation, we recommend connecting a pressure gauge for

supply air and signal pressure. These parts

are listed as accessories in Table 3, 4 or 6.

Nut Throttle with filter

(1790-6121)

Fig. 8 ⋅Attaching the pressure gauge

2...3mm

28

EB 8380-1 EN

Connections

Page 29

3.1.2 Supply air pressure

The required supply air pressure depends

on the bench range and the actuators failsafe action. The bench range is registered

on the nameplate either as spring range or

signal pressure range.

Actuator stem extends:

required supply air pressure =

upper bench range value + 0.2 bar

at least 1.4 bar.

Actuator stem retracts:

for tight-closing valves, the signal pressure

p

st max

is roughly estimated as follows:

pst

max

= F +

d

2

⋅ π ⋅ Δp

4 ⋅ A

[bar]

d = Seat diameter [cm]

Δ

p = Differential pressure p

p [bar]

A = Actuator area [cm

]

F = Upper bench range value of the actuator [bar]

If there are no specifications, calculate as

follows:

required supply air pressure =

upper bench range value + 1 bar

3.2 Electrical connections

As far as the electrical installation of

the device is concerned, the relevant

national regulations governing the

installation of electrical equipment

and the national accident prevention

regulations of the country of destination must be adhered to.

In Germany, these are the VDE regulations and accident prevention regulations of the employers liability insurance.

For installation in hazardous areas,

the following standards apply: EN

60079-14: 1997; VDE 0165 Part

1/8.98 "Electrical apparatus for explosive gas areas" and EN 50281-12: VDE 0165 Part 2/11.99 "Electrical apparatus for use in the

presence of combustible dust".

For intrinsically safe electrical apparatus that are certified according

to the Directive 79/196/EEC, the

data specified in the certificate of

conformity apply for connection of

intrinsically safe circuits.

For intrinsically safe electrical apparatus that are certified according

to the Directive 94/9/EC, the data

specified in the EC type examination

certificate apply for connection of intrinsically safe circuits.

Note:

It is absolutely necessary to

keep to the terminal plan specified

in the certificate. Reversal of the electrical connections may cause the explosion protection to be ineffective!

EB 8380-1 EN

29

Connections

Page 30

Note on the selection of cables and wires:

To run several intrinsically safe circuits in a

multi-core cable, read paragraph 12 of

EN 60039-14; VDE 0165/8.98.

For generally used insulating materials, for

example polyethylene, the radial thickness

of the conductor insulation has to be at least

0.2 mm. The diameter of a single wire in a

flexible conductor shall not be smaller than

0.1 mm.

The conductor ends are to be protected

against unlaying, e.g. by using wire end ferrules. If the positioner is connected via two

separate cables, an additional cable gland

can be mounted.

Wire entries left unused must be sealed with

caps.

Cable entries

The cable entry with M20x1.5 cable gland,

7 to 12 mm clamping range.

There is a second M20x1.5 cable gland in

the housing that can be used for additional

connection, if required.

The screw terminals are designed for wire

cross-sections of 0.2 to 2.5 mm

2

. Tighten by

at least 0.5 Nm.

The wires for the reference variable are to

be connected to the terminals 11 and 12 located in the case as shown in Fig. 9. Make

sure to connect the appropriate poles. The

voltage applied must not exceed 15 V.

Caution!

If the poles are connected incorrectly, just 1.4 V is sufficient to reach the

static destruction limit of 500 mA.

The + and socket contacts allow a communication to be connected locally.

Supply voltage for

position transmitter

Control signal i

mA

Limit switches

Fault alarm

Forced

venting

Communication

6 to 24 V DC

Fig. 9 ⋅Electrical connections

i

G

GW2 GW1

PE –12+11 –52+51 –42+41 –82+810 –32+31–84+83

i

–

+

U

S

+–

Switching amplifier

acc. to EN 60947-5-6

30

EB 8380-1 EN

Connections

Page 31

In general, it is not necessary to connect the

positioner to a bonding conductor (0).

Should there be the need, however, this conductor can be connected either to the inside

or outside of the case. For plants in hazardous areas, see paragraph 5.3.3 of VDE

standard 0165.

Depending on the supplied version, the positioner is equipped with either inductive limit

switches, software limit switches and/or

forced venting function. All electric circuits

are electrically isolated.

In versions with position transmitter, the

built-in transmitter is operated in a two-wire

circuit. With regard to the resistance of the

supply lead, the voltage at the position

transmitter terminals must not be lower than

12 V and not higher than 35 V DC.

Terminal assignment is shown in Fig. 9 and

is indicated on the cover plate inside the

case cover.

Accessories:

Model index 3780-x...x. 0

1

Cable gland PG 13.5:

Black Order no. 1400-6781

Blue Order no. 1400-6782

Adapter PG 13.5 on 1/2" NPT:

Metallic Order no. 1400-7109

Blue finish Order no. 1400-7110

Model index 3780-x...x. 02 or higher

Cable gland M20 x 1.5:

Black plastic Order no. 1400-6985

Blue plastic Order no. 1400-6986

Adapter M20 x 1.5 on1/2" NPT:

Aluminum powder-coated

Order no. 0310-2149

3.2.1 Switching amplifiers

For operation of the limit switches and the

fault alarm output, switching amplifiers complying to EN 60947-5-6 have to be connected in the output circuit.

If the positioner is to be installed in hazardous areas, the relevant regulations are to be

observed.

EB 8380-1 EN

31

Connections

Page 32

3.2.2 Establishing communication

Communication between PC and positioner

via FSK modem or communicator, if necessary, using an isolating amplifier is based on

the HART

®

protocol.

Viator FSK modem

RS-232 EEx ia Order no. 8812-0129

RS-232 not Ex Order no. 8812-0130

PC MCIA Order no. 8812-0131

USB not Ex Order no. 8812-0132

If the supply voltage of the controller or control station becomes too low because it has

been reduced by the load in the circuit, an

isolating amplifier is to be connected between controller and positioner (interfacing

same as for positioner connected in hazard-

ous areas, see Fig. 10).

If the positioner is used in hazardous areas,

an explosion-protected isolating amplifier is to

be used. Connection of an FSK bus always requires interfacing of isolating amplifiers.

By means of the HART

®

protocol, all control

room and field devices connected in the

loop are accessible through their address

via point-to-point or standard bus (multidrop).

Point-to-point:

The bus address/polling address must always be set to zero (0).

Standard bus (multidrop):

In the standard bus (multidrop) mode, the

positioner follows the analog current signal

(reference variable) as for point-to-point

Communicator or

2nd FSK modem (explosion-protected design)

FSK modem

Non-haz. area Hazardous area

3780

3780–1

PC RS 232

PC RS 232

Controller/ control station

Controller/control station

Communicator or

2nd FSK modem

4 to 20 mA

FSK modem

Ex isolating amplifier

Connection in hazardous areas

Connection in non-hazardous areas

Fig. 10 ⋅Connection with FSK modem

32

EB 8380-1 EN

Connections

Page 33

communication. This operating mode is, for

example, suitable for split-range operation

(series connection) of positioners. The bus

address/polling address has to be within a

range of 1 to 15.

Connect the FSK modem to the interface of

the PC. If several interfaces are available,

the selected interface may have to be configured over the user interface.

Note:

Communication faults

may occur when the

process controller/control station output is

not HART

®

compatible. For adaptation, the

Z box, order no. 1170-2370, can be installed between output and communication

interface. At the Z box a voltage of approx.

330 mV is released (

=

^

16.5 Ω at 20 mA).

Alternatively, a 250-Ω resistor can be connected in series and a 22-μF capacitor can

be connected in parallel to the analog output. Note that in this case, the controller output load will increase.

22 μF

250 Ω

Controller/ control station

Fig. 11 ⋅Adapting the output signal

EB 8380-1 EN

33

Connections

Page 34

4. Operation

Caution!

Before taking the positioner into

operation, carefully move the control valve to its end position by

covering the hole (manual adjustment) on the cover plate (Fig. 12).

Check whether the lever mechanism

functions properly.

If the wrong lever is used or the lever

mechanism does not function

properly, the valve will exceed the

maximum permissible angle of rotation, which can destroy the positioner.

4.1 Write protection

A sliding switch is located inside the hinged

cover.

When it is activated (position 1), the positioner settings are write-protected so that

they cannot be overwritten by the HART

®

protocol. If you want to change the settings

via communication, set the switch to 0 position.

4.2 Activate/deactivate forced

venting function

Model index .03 or higher

1. Remove cover inside the positioners lid

by unscrewing the four screws.

2. Loosen the screw in the center of the

board and swivel out the board.

3. Set switch to desired position

1 ENABLED > Function activated

2 DISABLED > Function deactivated.

Arrow for

mounting position

Manual adjustment

Zero point lever

Pointer

Adjustment screws GW

(option)

Metal tags

Key for initialization or

zero calibration

Write protection switch

GW1

GW2

0

1

0

Initialisierung / Nullabgleich

Iintialization / Zero adjustm.

Initialistation / Tarage zéro

Inicialización / Puesta acero

Vorsicht !

Caution !

Attention !

Atención

!

Ventil wird verstellt

Valve actuates

Vanne en mouvement

La válvula actua

Schreibgeschützt

Write protected

Protégé en écriure

Fig. 12 ⋅Inside view of cover plate

34

EB 8380-1 EN

Operation

Page 35

4.3 Default setting

All parameters are set to default values. See

section 8 for a description of parameters.

Note!

Manual operation and activated

final position functions can cause

the actuator to be filled with the

maximum supply pressure.

Should this lead to impermissible

forces occurring, the supply pressure

must be restricted by a reducing station.

4.3.1 Adjusting mechanical zero

point

Note!

Zero must be adjusted with the valve completely closed (for three-way valves with the

actuator stem extended).

Firmly push the zero point lever, which

is located in the cover plate of the positioner, once in the direction indicated

by the arrow, as far as it will go. The

yellow pointer will then be on the white

marking line.

For control valves with the starting position

OPEN, e.g. an actuator employing fail-safe

action "actuator stem retracts", it is first

necessary to supply the positioner with auxiliary air.

If the manual operation function is activated

then, the signal pressure builds up and the

valve moves to the closed position. Subsequently, the zero point lever can be operated.

4.3.2 Initialization

After the electric reference variable and the

auxiliary supply pressure have been connected to the positioner, the initialization

process can be started. In this process, the

positioner adapts itself optimally to the

mechanical conditions (friction) and signal

pressure requirements of the control valve.

See list of parameters on page 48 for required changes of the proportional-action

coefficient KP_Y1 and KP_Y2.

Caution!

The initialization process takes several minutes. During that time the

valve leaves its position. Therefore,

never initialize the positioner during

a running process, but only during

the start-up cycle when the shut-off

valves in the plant are closed, or

when the control valve with the positioner has been removed from the

plant and is used on a test stand.

Enter data on valve and actuator under

"Start-up" in the operating software.

Set "Type of initialization" to "Rated

range", select "Maximum range" only

for three-way valves.

Start initialization.

When the initialization process is completed, perform configuration suitable

for the type of valve.

The following setting is recommended:

EB 8380-1 EN

35

Operation

Page 36

Fail-safe position "Actuator stem extends"

(FA):

Direction of action: increasing/increasing (>>), the globe valve opens with increasing reference variable

Final position at a reference variable

less than 1% (tight closing),

Final position at a reference variable

larger than 125 % (function deactivated).

Fail-safe position "Actuator stem retracts"

(FE):

Direction of action: increasing/decreasing (<>), the globe valve closes with increasing reference variable

Final position at a reference variable

less than −2.5% (function deactivated),

Final position at a reference variable

larger than 99 % (tight closing).

Set delay time to 30 s at the minimum.

Enter tag identification.

If necessary, other configuration, e.g.

special characteristics for rotary valves.

If there is

no communication

set up on the

valve, initialization directly at the valve is

also possible.

Connect positioners that are not

mounted on a valve to a power supply

and initialize the positioner as described in section 4.3.2.

If communication is not possible, the default setting must be used.

Mount positioner and set the mechanical zero point as described in section

4.3.1.

Start initialization by pressing the

Init/Zero

key on the positioner hinged

cover using a suitable tool.

The initialization is completed when the positioner takes on the position predetermined

by the reference variable.

Note!

After the positioner has been initialized successfully for the first time, pressing the

Init/Zero

key subsequently only starts a

zero calibration.

A new initialization routine can only be

started after this when communication is

connected.

A completed initialization can be cancelled

via the communication with the command

"Reset to default values". After this, the

Init/Zero key can be pressed to start a complete initialization.

Electric zero calibration

If, during the valves operation, the mechanical zero has shifted, an electric zero calibration can be carried out. To do this, press

the Init/Zero key located on the inside of

the cover (Fig. 12).

Caution!

The control valve moves to its final

position.

Firmly press the zero lever, located on

the cover plate of the positioner, in the

direction indicated by the arrow as far

as it will go once. The yellow pointer

will then be aligned with the white line.

Press the key again to start the electric

calibration.

After the key is pressed twice, it is locked

for approximately one minute!

36

EB 8380-1 EN

Operation

Page 37

The electric calibration has been completed

when the positioner takes on the position

predetermined by the reference variable.

4.4 Adjusting inductive limit switches

The positioner version with inductive limit

switches has two adjustable tags that are

mounted on the shaft of the positioner lever

and operate the associated proximity switches.

For operation of the inductive limit switches,

the corresponding switching amplifiers have

to be connected to the output (see section

3.2.1). If the tag is in the inductive field of

the switch, the switch assumes a high resistance. If the tag is out of the field, the switch

assumes a low resistance.

Normally, the limit switches are adjusted

such that they will provide a signal in both

end positions of the valve. These switches,

however, can also be adjusted to signalize

intermediate valve positions.

The desired switching function, i.e. whether

the output relay shall be picked up or released when the tag has entered the field,

has to be selected, if necessary, at the

switching amplifier.

Adjusting the switching point:

The limit switches are marked GW1 and

GW2 on the inside of the case cover. Yellow tags and the associated adjustment

screws (Fig. 12) are located below these

markings.

Each switching position can optionally be signalized when the tag has entered the field,

or when it has left the field.

Move the valve to the switching position and adjust the tag of the required

limit switch GW1 or GW2 by turning

the related adjustment screw until the

switching point is reached. This is indicated by the LED at the switching amplifier.

In so doing, one edge of the yellow tag will

be in alignment with the white, horizontal

line on the case cover. This indicates the

side from which the tag enters the inductive

field of the proximity switch.

To ensure safe switching under any ambient

conditions, the switching point should be adjusted to a value of approx. 5% before the

mechanical stop (OPEN - CLOSED).

EB 8380-1 EN

37

Operation

Page 38

5. Maintenance

The positioner is maintenance-free.

The pneumatic connection 9/Supply features a filter with 100 μm mesh size. If required, the filter can be unscrewed and

cleaned.

The maintenance instructions for any upstream air pressure reducing stations for

supply air must be observed.

6. Servicing explosion-protected

versions

In the event that a positioners part on

which the explosion protection is based

must be serviced, the positioner must not be

put back into operation again until an expert has inspected the device according to

explosion protection requirements, has issued a certificate stating this, or given the

device a mark of conformity.

Inspection by an expert does not have to be

carried out, if the manufacturer performs a

routine check test on the device prior to taking it into operation again, and the success

of the routine check test is documented by

attaching a mark of conformity to the device.

Explosion-protected components may only

be replaced by original checked components from the manufacturer.

38

EB 8380-1 EN

Maintenance

Page 39

7. Summary of parameters

The list of parameters describes - in alphabetical order - all parameters of the Type 3780 Positioner that can be transferred via HART

®

communication and displayed or modified on a

PC, a handheld communicator, or a similar device.

Device identification

MSR no./bus identification

Manufacturer

Type number controller

Product number controller

Serial number controller

Hardware version electronics/mechanics

Firmware version communication/control

HART

®

universal revision, field device revision

Number of required preambles

Bus address/polling address

Message/loop tag identification/numbers

Description/plant identification

Date

Type of protection

Identification of the options forced venting, contacts, position transmitter

Ident. number actuator

Ident. number valve

Text field, not allocated

Start-up

Actuator type

Attachment

Model

Mounting position

Rated travel/nominal angle

Transmission code/length/pin position

Initialization related to nominal range /maximum range

Fail-safe position

EB 8380-1 EN

39

Summary of parameters

Page 40

Minimum control pulses

Minimum transit time on/off

Initialization cycle

Device settings

Configuration

Reference variable range

Final position with reference variable below preset value

Final position with reference variable above preset value

Travel range/angle of rotation

Limitation of travel range / angle of rotation

Moving direction

Selection of characteristic

User-defined characteristic with 11 co-ordinates

Required transit time on/off

Limit values for software limit switches GW1/GW2

GW1/GW2 on when the respective limit value is exceeded/not attained

Operating direction position transmitter

Write protection

Parameters

Dead band Xtot

Proportional-action coefficient KP_Y1/KP_Y2

Derivative-action coefficient KD

Tolerated overshoot

Operation

Operating mode

Reference variable w_analog

Reference variable w_manual

Reference variable w

Controlled variable x

Error e

State fault message

40

EB 8380-1 EN

Summary of parameters

Page 41

State software limit switches GW1/GW2

Forced venting function

Diagnostics

Device status (control loop monitoring, zero point monitoring, etc.)

Total valve travel

Limit value total valve travel

Error monitoring tolerance band/lag time

Fault message in case of communication fault

Fault message with controller in special function

Fault message if limit value for total valve travel is exceeded

Test of fault indication output

Test of position transmitter

Test of software limit switches GW1/GW2

Zero adjustment

EB 8380-1 EN

41

Summary of parameters

Page 42

8. List of parameters

Actuator id number

Range:

Manufacturers identification (id) number of the actuator and the positioner.

0 to 999 999

Actuator type

----

States:

Default (coldstart value):

Linear actuator/rotary actuator

Linear actuator

Angle range

End

Uppe r l imit of th e e ff ec tive wo rk ing ran ge (o penin g a ngle). Fo r a non-li near ch ar acteri st ic,

the characteristic is adapted to the reduced angle.

If in it ializa ti on is ba se d o n "maxi mu m r ange" , t he angle r ange is al ways re lated t o t he

entered nominal angle.

The working range may not be selected 1/4 less than the nominal angle.

Maximum value = nominal angle.

Range:

Default (coldstart) value:

0.0 degrees to 120.0 degrees

90.0 degrees

Angle range

Start

Lowe r l imit of th e e ff ec tive wo rk ing ran ge (o penin g a ngle). Fo r a non-li near ch ar acteri st ic,

the characteristic is adapted to the reduced angle.

If in it ializa ti on is ba se d o n "maxi mu m r ange" , t he angle r ange is al ways re lated t o t he

entered nominal angle.

The working range may not be selected 1/4 less than the nominal angle.

Range:

Default (coldstart) value:

0.0 degrees to 120.0 degrees

0.0 degrees

Attachment

Defi nes the po si tioner at ta chment to th e contr ol va lve wi th a linea r a ct uator. For a r ot ar ymoti o n actuat or, only att achme nt accord ing to VDI / VDE 3845 (NAMUR ) is possible.

States:

Default (coldstart) value:

Integral - Type of attachment in combination with a SAMSON Type 3277 Linear Actuator.

NAMUR - Type of attachment according to IEC 60534-6 (NAMUR).

Integral

Bus address

Address used by the control station to identify a field device. Changeable by the user: 0 for

point-to-point, 1 to 15 for multidrop communication.

Range:

Default (coldstart) value:

0 to 15

0

Non-IBIS devices → poll ing add re ss

Bus identification

Text for instrument identification in connection with the field device installation. The text

may b e f reely as si gned. We re co mm end to cl ea rly ide nt ify the fi eld dev ic e. For f ie ld bus

installation, a bus identification has to be assigned.

Length: 8 characters

Non-IBIS devices → MSR no.

42

EB 8380-1 EN

List of parameters

Page 43

Characteristic

Creation of assignments between the reference variable and valve travel/angle range.

When th e equal percen ta ge char ac terist ic is sele ct ed, thi s c harac te ristic is co pied in th e

user-defined characteristic, overwriting the previously entered user-defined characteristic.

The control loop is interrupted (for approx. 3 seconds) while the characteristic is internally

transmitted.

States:

Default (coldstart) value:

User defined - characteristic in accordance with enterable coordinates x[n], y[n], preset to

butterfly valve equal percentage

Linear linear characteristic

Equal percent. equal percentage characteristic

Equal percent. reverse equal percentage reverse characteristic

Linear

Characteristic co-ordinates

x [0] /y [0 ] to

x [10] /y [10]

Characteristic co-ordinates for user-defined assignment between reference variable and

travel/angle range.

x[n] = reference size in % of the reference size range.

y[n] = t ravel/ an gle in % o f t ra vel/an gle ran ge .

The control loop is interrupted until the characteristic transmission is completed (max. 15 s).

Range:

Default (coldstart) :

0.0 % to 100 %

For characteristic points: butterfly valve equal percentage.

Date

A date entered according to the European date format [DD.MM.YYYY] can be stored in the

field device. The date can be entered as required.

Dead band Xtot

Maximum tolerated deviation between set point value and actual value specified as a

percentage of the travel range.

A small dead band means a high degree of control accuracy.

The smallest possible dead band is determined by the quality of the control valve; high

friction and a small actuator volume can otherwise lead to unstable operation.

Range:

Default (coldstart) value:

0.0 1 % to 0.00 % o f the nomin al tr avel/nominal angle

0.5 %

Description

Tex t s to red in t he field d ev ice. L en gt h: 16 ch ar acters .

For IBIS → plant identification

Direction of action

Dete rm ines th e a ssignm en t o f refe re nc e vari ab le to the tr avel/ an gle of ro ta ti on.

States: >>, Increasing reference variable opens the valve (for three-way valves: Actuator stem

retracts)

<>, Increasing reference variable closes the valve (for three-way valves: Actuator stem

extends)

Default (coldstart) value: >>

End position when w:

above limit value

If the reference value exceeds the entered limit, the valve moves in the pre-determined end

position, corresponding to 100 % of the reference variable. Hysteresis 1 %.

When the value is 125 %, the function is deactivated.

Range:

Default (coldstart) value:

0 % to 125.0 %

99 %

EB 8380-1 EN

43

List of parameters

Page 44

Caution:

Sin ce th e actua to r w ill au to ma ti cally be fi lled ( lo ad ed with ai r) or ven ted

(exhausted) when this function is executed, the control valve moves to its absolute end

position. Constraints specified in the function "travel range" or "travel limit" are

inapplicable here. This function must be deactivated if unacceptably high positioning forces

might result from the complete filling/venting action.

End position when w:

below limit value