Page 1

Series 373x Positioners

EXPERT+Valve Diagnostics

Operating Instructions

EB 8388 EN

Firmware version 1.4x

Edition November 2006

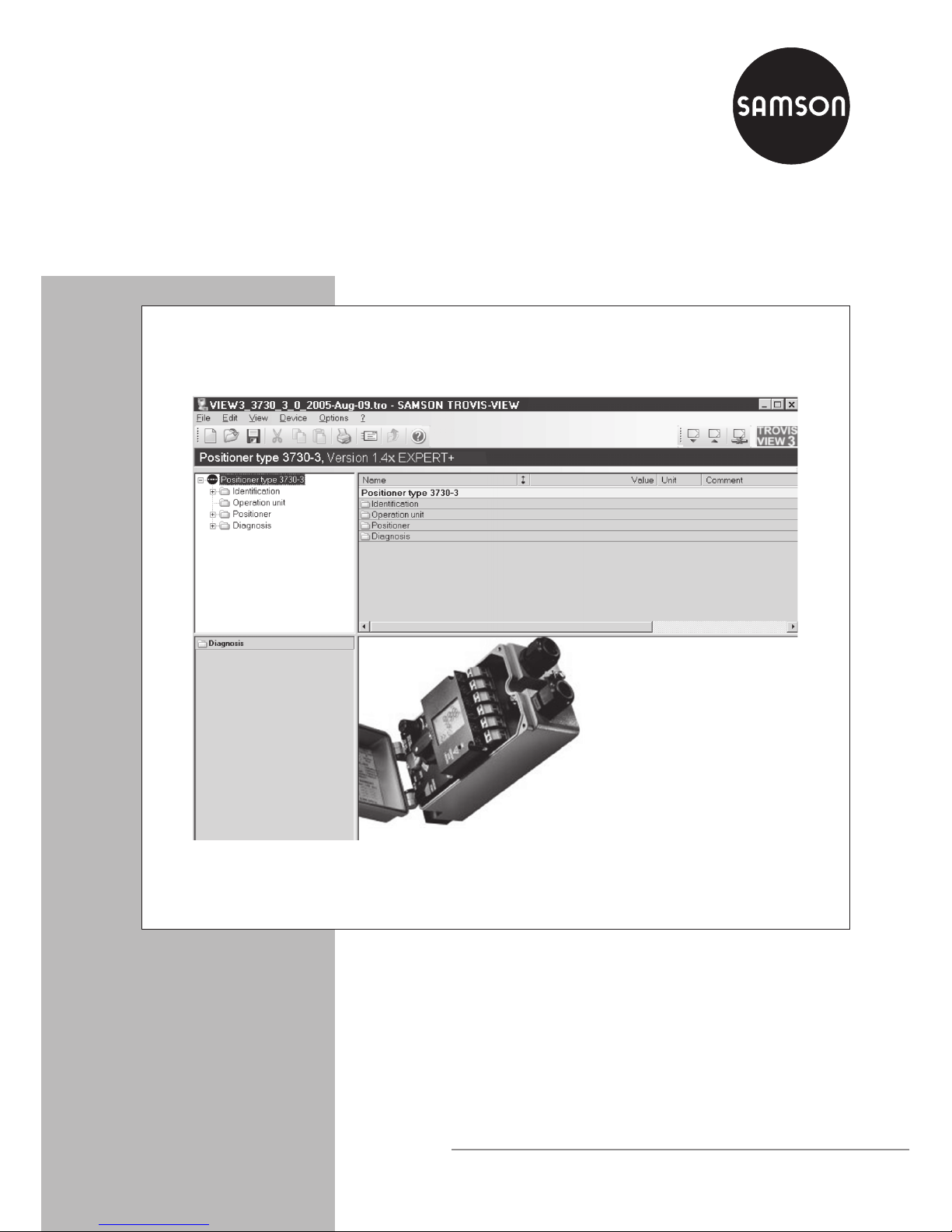

Fig. 1 · Valve diagnostics with SAMSON TROVIS-VIEW Operator Interface, e.g. for Type 3730-3 Positioner

Page 2

Contents Page

1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Diagnostic tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Activating EXPERT

+

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Actuator and valve specification data . . . . . . . . . . . . . . . . . . 5

1.5 Start the reference test . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 SUb initialization mode, double-acting actuator and booster . . . . . . . 6

1.7 Activation, analysis and presentation of diagnostic data . . . . . . . . . 7

1.7.1 Printing the diagnostic/ESD log . . . . . . . . . . . . . . . . . . . . . 8

2 Statistical information AUTO . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Data logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Travel histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Setpoint deviation histogram. . . . . . . . . . . . . . . . . . . . . . 12

2.4 Cycle counter histogram . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Drive signal diagram . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.1 Steady-state drive signal. . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.2 Hysteresis test (d5) . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6 End position trend. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Tests MAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Drive signal diagram steady-state (d1) . . . . . . . . . . . . . . . . . 22

3.2 Drive signal diagram hysteresis (d2) . . . . . . . . . . . . . . . . . . 23

3.3 Static characteristic (d3) . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 Step response (d4) . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Status and diagnostic alarms . . . . . . . . . . . . . . . . . . . . . 28

4.1 Standard EXPERT diagnostic alarms . . . . . . . . . . . . . . . . . . 28

4.2 Extended EXPERT

+

diagnostic alarms . . . . . . . . . . . . . . . . . . 28

4.3 Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 Classification of the status alarms . . . . . . . . . . . . . . . . . . . 29

4.5 Condensed state . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.6 Status modification . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Resetting diagnostic parameters. . . . . . . . . . . . . . . . . . . . 31

6 Diagnostic parameters saved in non-volatile memory . . . . . . . . . 34

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 EXPERT

+

without TROVIS-VIEW . . . . . . . . . . . . . . . . . . . . 38

2 EB 8388 EN

Contents

Page 3

1 Description

1.1 General

These instructions EB 8388 EN supplement

the standard mounting and operating in

-

structions of the positioners:

Type Standard EB

3730-2 EB 8384-2 EN

3730-3 EB 8384-3 EN

3730-4 EB 8384-4 EN

3730-5 EB 8384-5 EN

3731-3 EB 8387-3 EN

EXPERT+is an optional diagnostic firmware

integrated in the positioner which allows the

predictive, status-oriented maintenance of

pneumatic control valves. Refer to section

1.3 on how to activate this option.

EXPERT

+

upgrades the standard EXPERT diagnostics firmware incorporated in the

positioner. The upgraded version provides

extended functions to pinpoint valve parameters that have worsened, allowing the user

to plan predictive maintenance and service

work before malfunctions can affect the pro

-

cess, causing unscheduled plant shutdowns.

EXPERT

+

records the valve faults in auto

matic mode while the process is running

and issues alarms on the required mainte

nance work. In addition, numerous tests can

be performed in manual mode to pinpoint

emerging faults.

Owing to the numerous diagnostic tests,

EXPERT

+

is able to generate classified status

alarms on the state of the control valve.

The EXPERT

+

diagnostics are completely in

tegrated in the positioner. Data required for

diagnostics are compiled automatically and

the test data are analyzed in automatic or

manual mode in the positioner itself. The re

-

sulting data are used to issue classified sta

tus alarms.

The diagnostics data, results and status

alarms are available over the DD (Device

Description). All the necessary reference

graphs are automatically plotted after the

positioner has been initialized and are

available when required.

After performing the basic settings at the

positioner using the rotary pushbutton, the

TROVIS-VIEW3 or DTM software allow the

parameters to be viewed and set

conveniently.

Type Integration

3730-2 TROVIS-VIEW3

373x-3 TROVIS-VIEW3, DD, DTM

3730-4 TROVIS-VIEW3, DD, DTM

3730-5 TROVIS-VIEW3, DD

The following sections contain a description

on how to operate the diagnostics over the

TROVIS-VIEW3 software.

Note!

All the parameter settings that are changed

over the operator interface must also be

downloaded onto the positioner to allow

them to become effective.

EB 8388 EN 3

Description

Page 4

Note!

The optional integrated solenoid valve is

implemented by a forced venting function in

Types 3731-x Positioners.

1.2 Diagnostic tests

There are two main groups of diagnostic

tests available.

Statistical information AUTO

These tests are performed while the process

is running (automatic mode) without disrupt

ing the process.

Activated tests are automatically performed

when they are triggered by their start condition (e.g. data logger and drive signal diagram hysteresis).

Other tests are already performed in the

background without being activated (e.g.

histograms, cycle counter, drive signal

steady-state and end position trending).

Tests MAN

These tests should not be performed while

the process is running (i.e. in manual mode

instead) as the positioner cannot follow the

reference variable at the same time.

The valve is moved to a certain position de

fined by the test settings and the valve may

move through its full range.

1.3 Activating EXPERT

+

The extended EXPERT

+

diagnostics can be

activated later at the positioner when

EXPERT

+

is not already activated on delivery

of the positioner.

The required activation code can be ordered

(order number 1400-9318). On ordering

this option, specify the serial number of the

positioner (see nameplate or in the soft

-

ware).

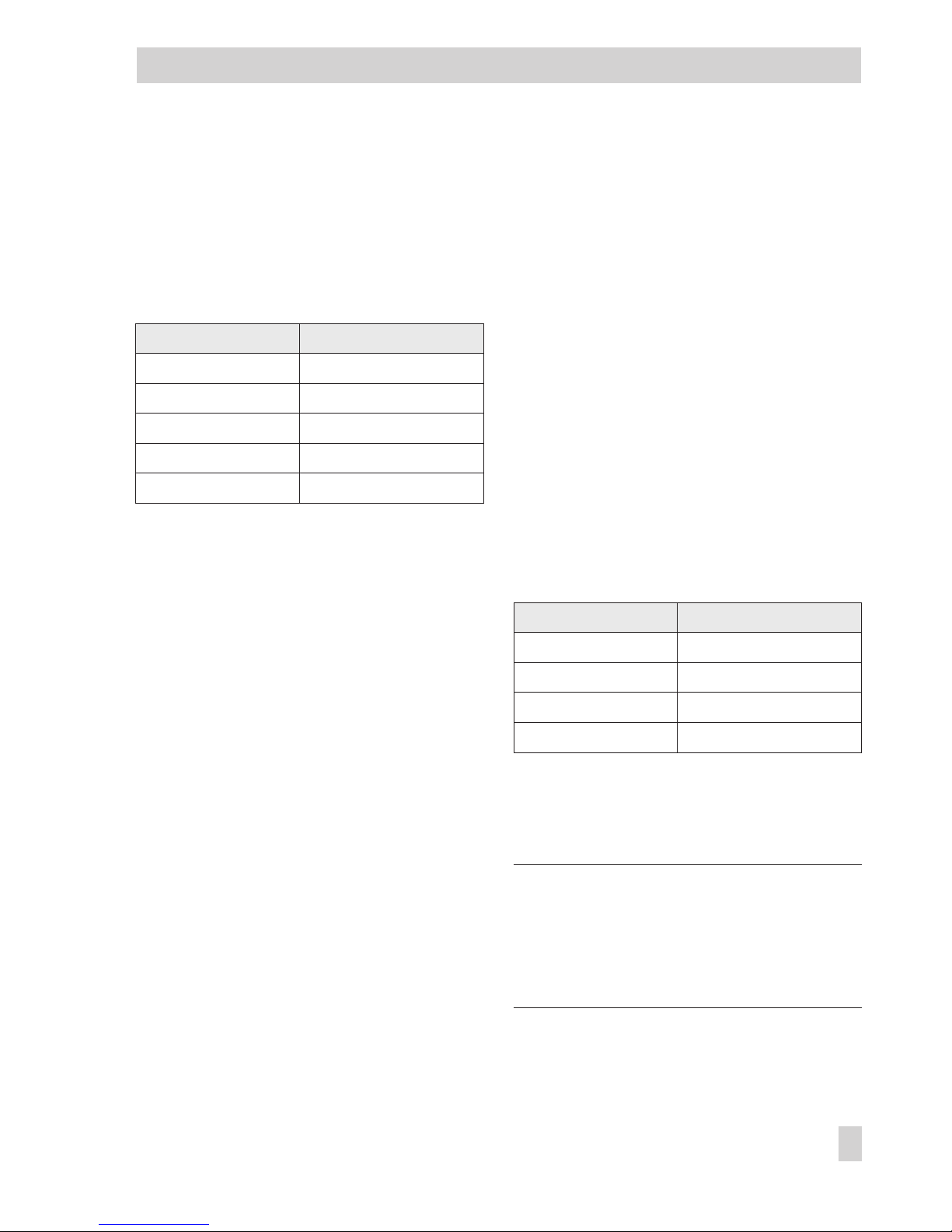

To activate EXPERT

+

, proceed as follows:

Enable configuration at the positioner:

Turn

→

Code

3

, press ,

turn

→

ON

, press .

After enabling configuration:

Turn

→

Code

48

, press

Code

48

blinks.

Turn to select

d

, press ,

turn to select

d8, press .

d8

blinks

Turn and set the activation code XXXX.

Press to confirm the entered code.

4 EB 8388 EN

Description

Page 5

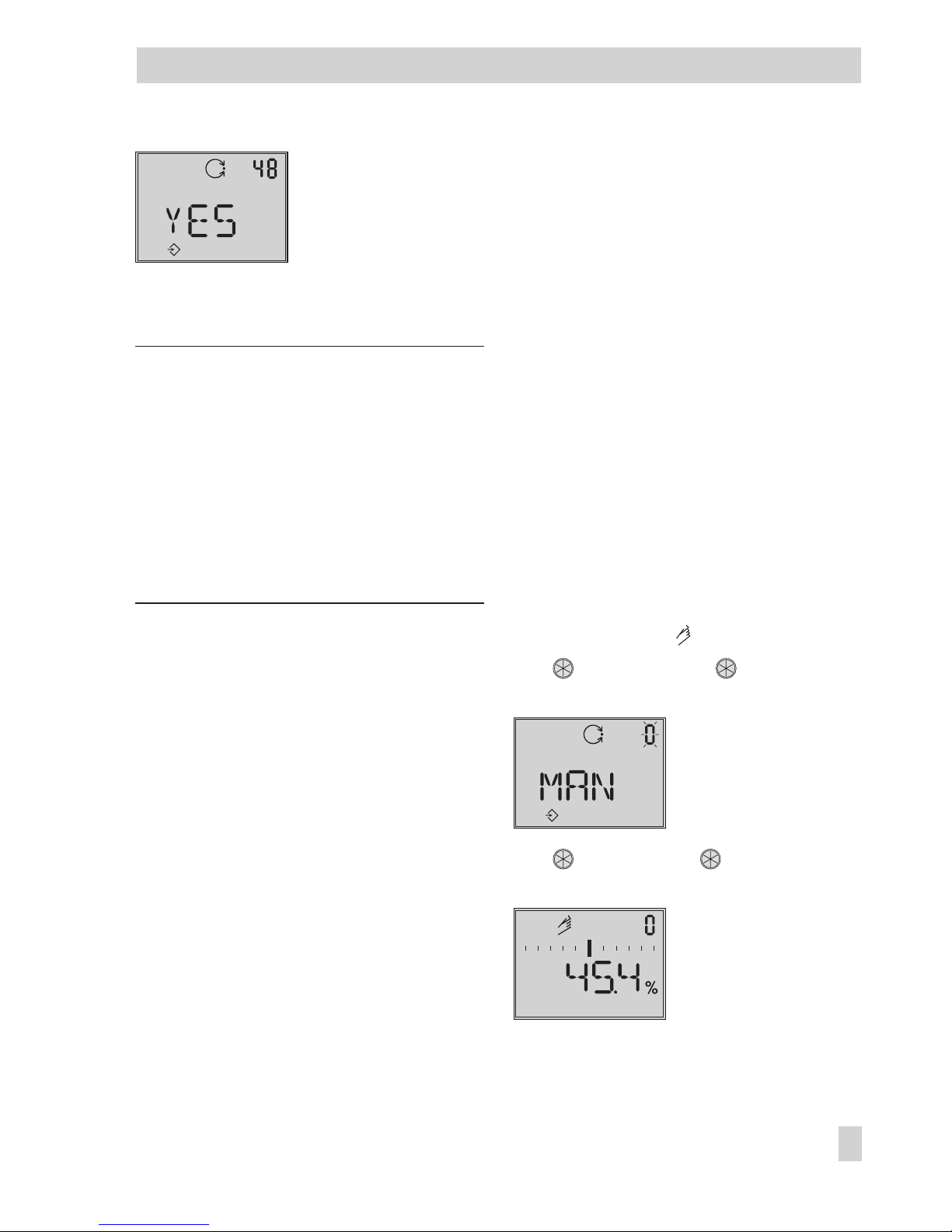

After the activation has been successfully

completed,

YES

appears on the display.

Note!

On entering the wrong activation code, the

display returns to Code 0. The activation of

EXPERT

+

has been unsuccessful.

After an incorrect activation code has been

entered three times, Err appears on the

display after selecting Code 48 and d8. An

activation code can only be entered again

after the positioner has been reset to its

default settings (Code 36).

1.4 Actuator and valve

specification data

To correctly analyze the diagnostic data,

several actuator and valve specifications

need to be entered for the EXPERT

+

diagnos

tics.

Enter the required data in the

Identification

folder (>

Positioner > Actuator

) as well as

(>

Positioner > Valve

).

Download the data to the positioner.

The

Model

and

Booster

parameters in the

Actuator

folder and

Stuffing box

parameter

in the

Valve

folder need to be entered.

The default settings of these parameters are:

4

Model

> Single-acting

4

Booster

> Not present

4

Stuffing box

> Self-adjustable

These parameters do not need to be

changed if the control valve also has these

default settings.

1.5 Start the reference test

After EXPERT+has been activated properly,

the reference graphs for future diagnostic

purposes need to be plotted to allow the di

-

agnostics to function in their full scope.

The reference graphs are plotted automati

cally after the positioner has been initialized

when the EXPERT

+

has been activated (e.g.

already on delivery).

On activating EXPERT

+

at later time, the reference graphs are plotted after the

positioner is re-initialized.

If reference graph plotting is to be started separately in an initialized positioner or if graphs

are to be replotted, proceed as follows:

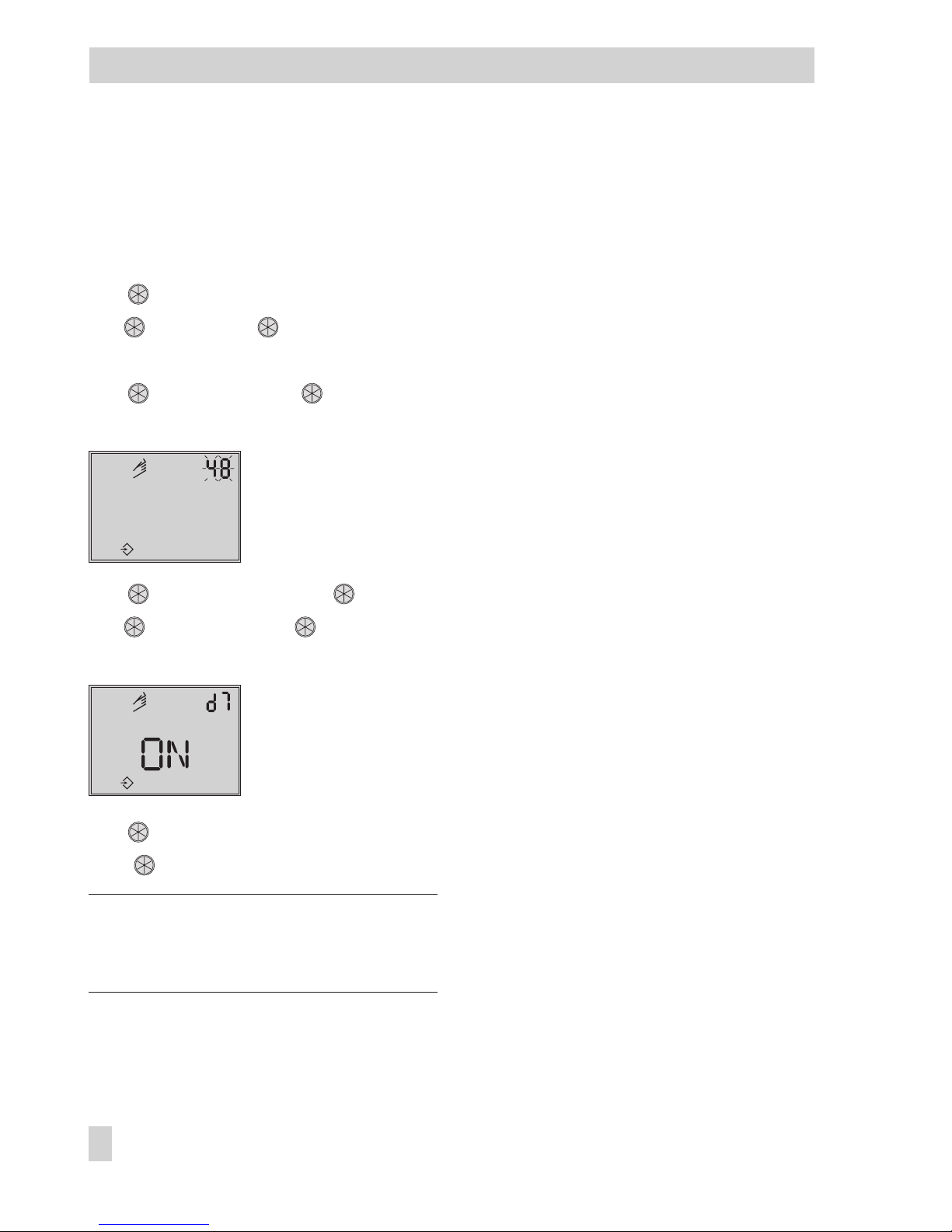

Set the positioner to manual mode:

Turn

→

Code

0

, press ,

Code

0

blinks.

Turn

→

MAN

, press , the positioner

moves to manual mode.

Manual operating mode

You can activate the reference test either by

selecting the

Diagnosis

folder (>

Start refer

-

EB 8388 EN 5

Description

Page 6

ence test

) and right-click the parameter to

select

Execute

, or, alternatively, start the ref

-

erence test at the positioner itself by select

-

ing Code

48

as follows:

Enable configuration at the positioner:

Turn

→

Code

3

,

turn

→

ON

, press .

After enabling configuration:

Turn

→

Code

48

, press

Code

48

blinks.

Turn until

d

appears, press ,

turn to select

d7, press .

d7

blinks.

Turn

→

ON

,

press to start the reference test.

Caution!

The control valve moves through its travel

range during the reference test.

The tests

d1

(drive signal diagram

steady-state) and

d2

(drive signal diagram

hysteresis) are performed during the diag

-

nostic reference test.

During the reference test,

tESt

and

d1

or

d2

appear in alternating sequence on the

positioner display.

The measured data are used as reference

data and any existing reference graphs are

overwritten.

If the reference graphs could not be plotted

correctly or are incomplete, Code 81 is is

sued and saved in a non-volatile memory.

The positioner can function properly after it

has been initialized successfully without the

reference data.

1.6 SUb initialization mode,

double-acting actuator and

booster

The following points need to be observed

when the positioner is initialized in

SUb

mode or when a double-acting actuator

and/or booster is used:

Positioner initialization in SUb mode:

4

Analysis in automatic or manual mode is

deactivated.

4

All tests for both statistical information

AUTO and tests MAN of drive signal di

agrams steady-state and hysteresis are

inactive.

4

The reference test is inactive.

4

The automatic test to start all tests MAN

is inactive.

Double-acting actuator with reversing

amplifier:

4

All tests for both statistical information

AUTO and tests MAN of drive signal

diagrams steady-state and hysteresis are

inactive.

4

The reference test is inactive.

6 EB 8388 EN

Description

Page 7

Booster:

4

The analysis of the tests for both statisti

cal information AUTO and tests MAN of

drive signal diagrams is inactive.

1.7 Activation, analysis and

presentation of diagnostic

data

All diagnostic tests which do not compile

data automatically in the background (data

logger, drive signal diagram hysteresis)

must be activated to start them.

To start these tests, select the corresponding

test order (>

Start data loggerorStart test

)

and right-click the parameter to select

Exe-

cute

to activate the test.

Note!

The tests in statistical information AUTO in

automatic mode can only be activated when

the positioner is in automatic operating

mode.

To activate the tests MAN in manual mode,

the positioner must first be set to manual

mode over Code 0.

Canceling diagnostic tests

There are two ways to cancel an active test:

4

On the TROVIS-VIEW operator interface,

select the corresponding folder (>

Stop

test

) to cancel the test. The positioner

then moves to the previously set operat

-

ing mode and to the travel value previ

ously set (manual mode) or returns to the

reference variable (automatic mode).

4

Press once to cancel the tests MAN

d1

(drive signal diagram steady-state)

d2

(drive signal diagram hysteresis)

d3

(static characteristic)

d4

(step response),

and the test in statistical information

AUTO

d5

(drive signal diagram hysteresis)

as well as the reference test over

Code

48

.

On canceling a test (d1 to d4), the

positioner moves to the fail-safe position.

The positioner only goes into automatic

mode on canceling test

d5

.

The reference graphs must be plotted before

the tests for drive signal diagrams

steady-state and hysteresis in manual mode

can be analyzed.

Note!

The analysis of raw data in automatic mode

is started after the positioner has been in

controlled operation for over one hour (after

initialization).

This does not apply to the end position trend

test and the dynamic stress factor in the

cycle counter histogram as their analysis

starts directly after controlled operation

begins.

Alarms generated from the tests MAN are

marked

TEST

.

If the electrical auxiliary power is too low,

the test being performed is ended and the

positioner moves to the fail-safe position.

Upon failure of the auxiliary power, tests in

tests MAN and statistical information AUTO

must be restarted due reasons of safety.

EB 8388 EN 7

Description

Page 8

However, the test in statistical information

AUTO drive signal diagram hysteresis re

mains activated.

In the event that the solenoid valve

(Type 3730-x) is triggered or the forced

venting function (Type 3731-x) is activated,

active tests are stopped and the positioner

moves to the fail-safe position.

However, the test in statistical information

AUTO drive signal diagram hysteresis re

mains activated.

In the event that the solenoid valve

(Type 3730-x) is triggered or the forced

venting function (Type 3731-x) is activated,

active tests are stopped and the positioner

moves to the fail-safe position.

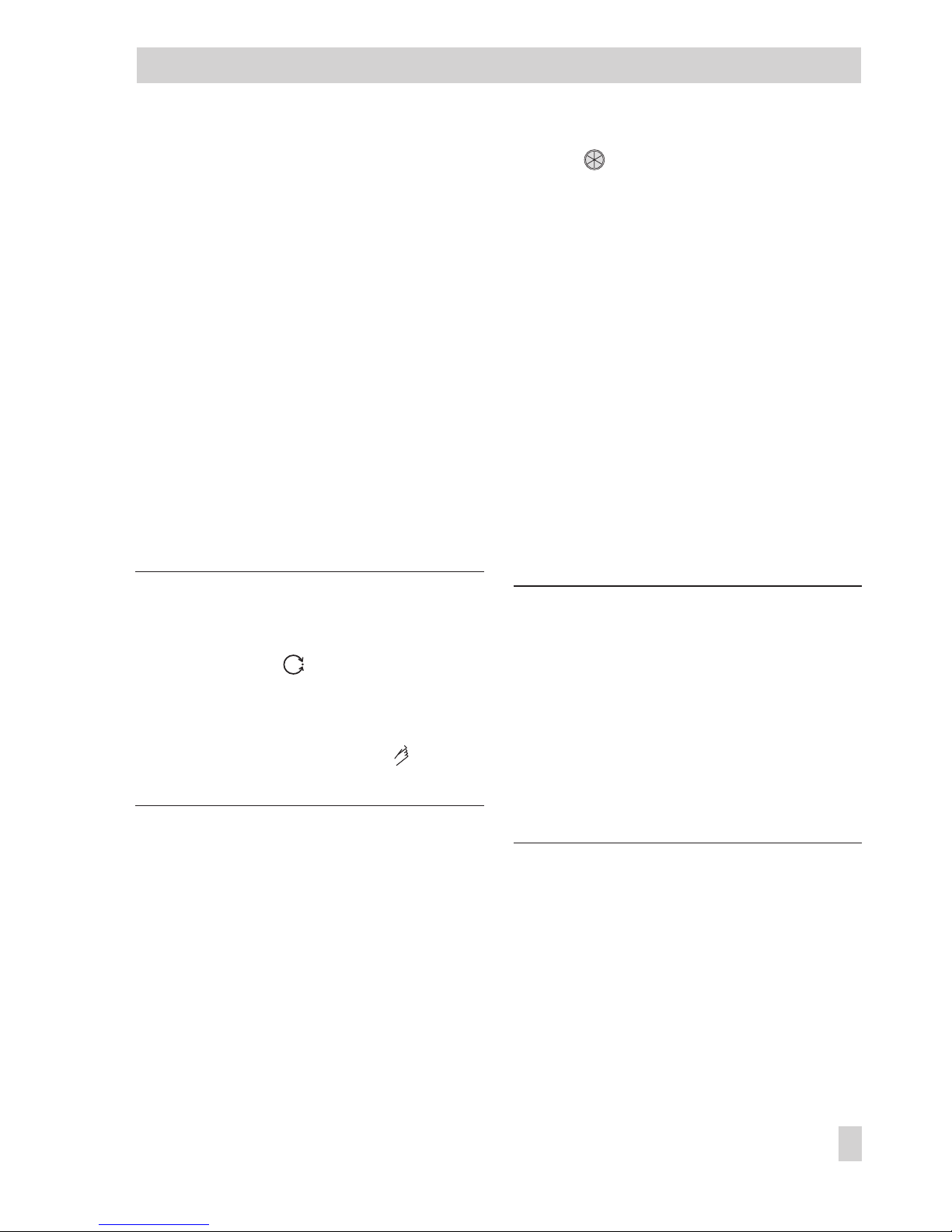

1.7.1 Printing the diagnostic/ESD

log

The Print command allows you to print out a

diagnostic log of individual tests or the entire diagnosis.

The diagnostic log includes a title page and

a list of all the data points including all their

values and properties.

The title page contains all key information

for clear identification of the printed log (de

-

vice type, file name, time and date of cre

ation, time and date of the last change and

TROVIS-VIEW version).

Select Print in the File menu to add further

information.

1. In the File menu, select Print Options to

choose the scope of the diagnostic log.

After installing/updating the

TROVIS-VIEW software, customer data

(Customer data in the Edit menu) and

summary (table of contents) are listed in

the diagnostic log by default.

Check the check boxes for the Comments

and Graphics options to add these op

-

tions to the diagnostic log.

2. Right-click the [Diagnosis] folder or the

required subfolder and select Print from

the context-sensitive menu to print the diagnostic log.

The printout contains the contents of the

folder and its subfolders.

8 EB 8388 EN

Description

Page 9

2 Statistical information AUTO

The signals x, w and y need to be analyzed

on a more precise basis to obtain advanced

diagnostic information also over the valve,

actuator and pneumatic air supply. The

positioner compiles raw data for this pur

pose.

The signals are plotted, stored and analyzed

while the process is running. In addition, an

additional underlayed hysteresis test detects

any changes in friction.

The diagnostic tests do not have any affect

on the positioner’s control performance.

2.1 Data logger

The data logger allows the reference variable w, controlled variable x in relation to

the working range, drive signal y and

setpoint deviation e to be plotted over time.

The measured data are saved in an FIFO

memory with a capacity to save 100 data

points in the positioner.

In addition to the permanent plotting of

data, the plotting can be automatically trig

gered when a start condition is fulfilled. The

travel condition (setpoint) or the optional in

tegrated solenoid valve (optional integrated

forced venting) can be used to trigger the

data logger.

The data logger is completely integrated into

the positioner.

The software is only necessary for activation

and to set the parameters.

In addition, the measured data can be

viewed as a graph or in a list by selecting

Upload from Device

in the

Device

menu or

by clicking on the device toolbar.

Note! Upon disconnection of the auxiliary

power or upon changing the operating

mode, the test is inactive and must be reactivated.

Data logging

Select

Data logger

folder (>

Selection

) and

select

PermanentorTrigger

and set the

Scan

rate

parameter. Right-click the

Start data

EB 8388 EN 9

Statistical information AUTO

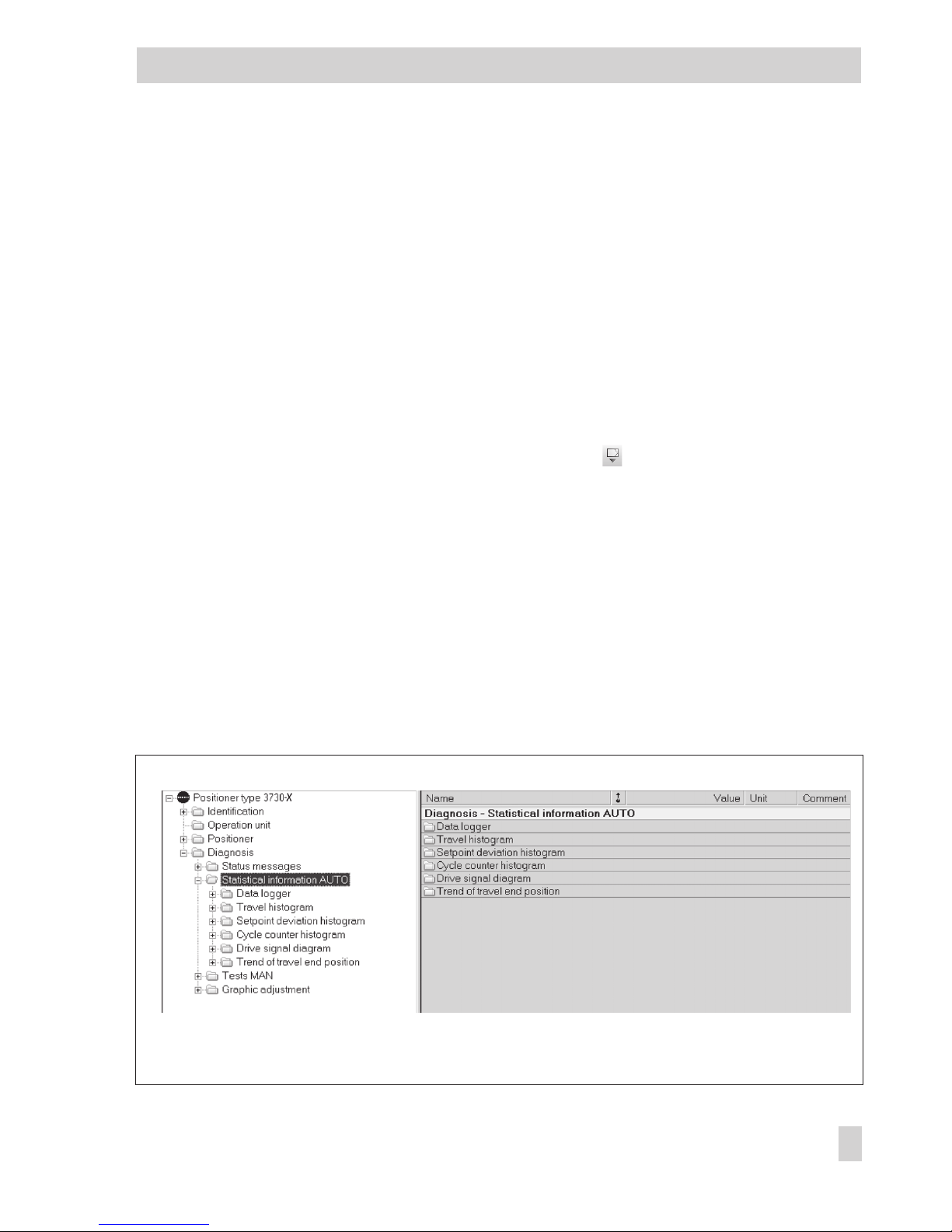

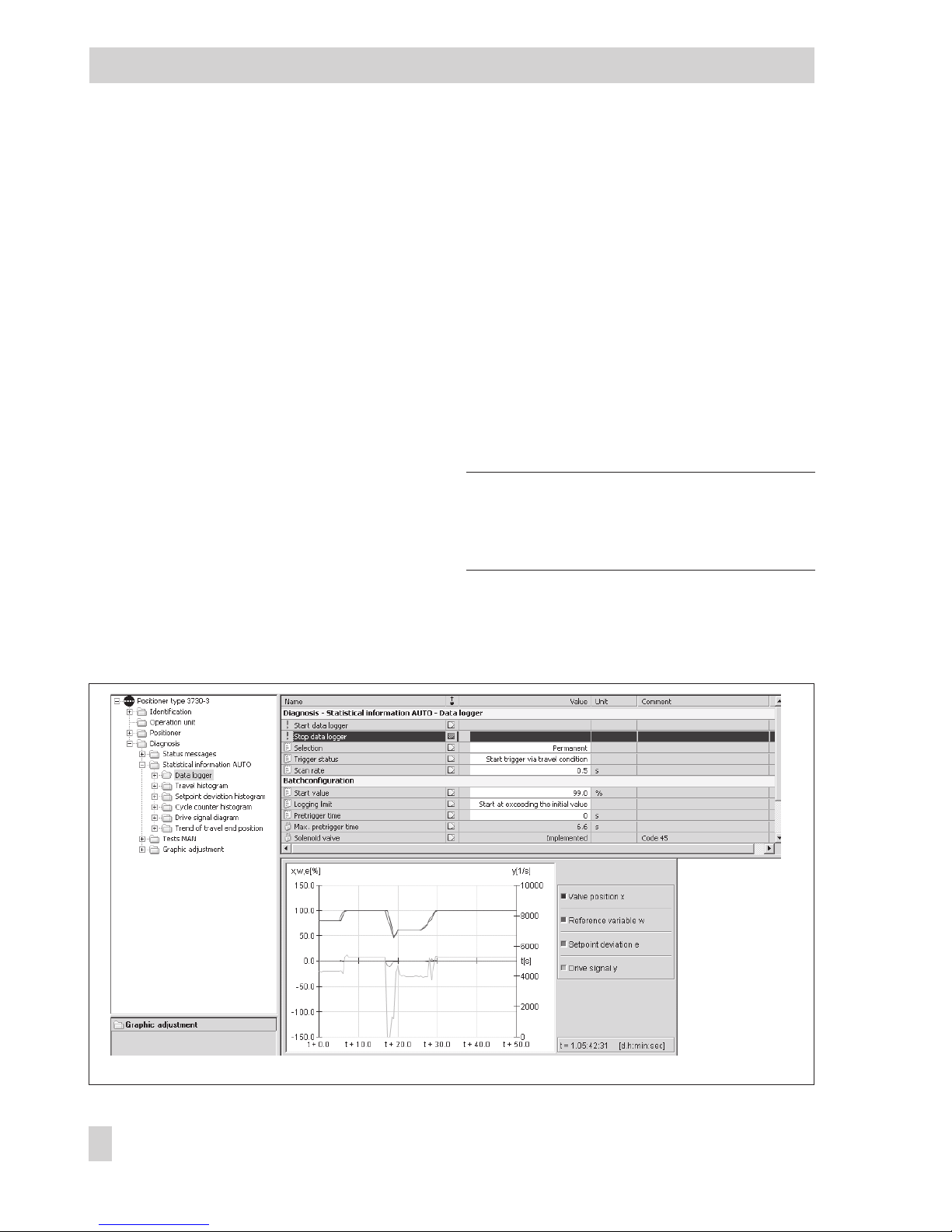

Fig. 2 · Statistical information AUTO

Page 10

logger

parameter and select

Execute

to start

data logging.

Permanent data logging

The variables w, x, y, and e are logged ac

cording to the adjusted scan rate and saved

in the FIFO memory which always stores the

last 100 measured data points of each vari

-

able.

Triggered data logging

On selecting

Trigger

in the

Selection

param

eter, the data logger records the measured

data permanently in the background. A trig

gering event leads to the last 100 measured

data points being stored together with the

pretrigger time and leads to the data logging of the triggering condition.

The following parameters can be changed

for this function:

4

Trigger status:

Triggered by the travel condition

(setpoint) and/or solenoid valve condi

-

tion (forced venting)

4

Start value:

Limit indicating from which travel condi

tion (setpoint) the data logger should be

triggered

4

Logging limit:

Indicating whether data logging should

start when the travel condition (setpoint)

exceeds or falls below the start value.

Travel condition (setpoint)

Note!

The valve position is used as the travel

condition in positioners in ESD version.

Select

Trigger status

parameter and select

Start trigger via travel condition (setpoint)

.

Activate data logging by selecting

Start data

10 EB 8388 EN

Statistical information AUTO

Fig. 3 · Data logger

Page 11

logger

parameter and select

Execute

.

The triggering event starts data logging

when the start value exceeds or falls below

an entered value.

Enter the required value at which data log

ging should be triggered in relation to the

setpoint in the

Start value

parameter.

Select whether data logging should start

when the entered value exceeds or falls be

-

low the start value in the

Logging limit

pa

rameter.

After being triggered, the variables w, x, y

and e are logged at the adjusted scan rate

and saved in the FIFO memory.

Additionally, there is a pretrigger time avail

able to allow the variables to be stored that

were logged before the triggered event.

Enter the required pretrigger time by

right-clicking the parameter and selecting

Modify

. However, the pretrigger time entered may not be higher than the maximum

pretrigger time determined by the

positioner. This maximum pretrigger time is

shown in the

Max. pretrigger time

parameter. The data logging finishes automatically

as soon as the maximum memory capacity

of 100 measured data points for each vari

able including the pretrigger time is

reached.

Solenoid valve condition (forced venting)

Select

Trigger status

parameter and select

Start via solenoid valve condition (forced

venting)

. Activate data logging by selecting

Start data logger

parameter and select

Exe

-

cute

to start data logging as soon as the in

tegrated solenoid valve is triggered or the

forced venting function is activated.

Similar to the travel condition (setpoint), the

variables w, x, e and y are logged at the

adjusted scan rate and saved in the FIFO

memory on triggering.

Additionally, there is a pretrigger time avail

able to allow the variables to be stored that

were logged before the triggered event.

Enter the required pretrigger time by

right-clicking the parameter and selecting

Modify

. However, the pretrigger time en

tered may not be higher than the maximum

pretrigger time determined by the

positioner. The data logging finishes auto

matically as soon as the maximum memory

capacity of 100 measured data points for

each variable including the pretrigger time

is reached.

Travel (setpoint) or solenoid valve condition

(forced venting)

Select

Trigger status

parameter and select

Start via travel (setpoint)/solenoid valve

condition (forced venting)

. Activate data

logging by selecting

Start data logger

pa-

rameter and select

Execute

. The triggering

event starts data logging when the valve

travel (setpoint)/solenoid valve conditions

(forced venting) are met.

The measured data are plotted over time in

graphs. In addition, the compiled measured

data are stored in the

Measured values

folder (see Fig. 3).

2.2 Travel histogram

The valve travel histogram is a statistical

analysis of the plotted valve travel.

The histogram provides information, for ex

ample, about where the valve mainly works

during its service life and whether it shows a

recent trend concerning changes in its work

ing range.

The valve travel is recorded and assigned to

valve travel classes. The distribution showing

EB 8388 EN 11

Statistical information AUTO

Page 12

how often the valve travel remains within a

class is shown in per cent. The result is pre

-

sented as a bar graph.

The

Travel histogram

folder contains

long-term data, i.e. measured data are up

-

dated cyclically (scan rate 1 s) over the en

tire positioner service life and stored every

24 hours in the positioner’s non-volatile

memory for long-term monitoring.

The

Number of measurement values

param

eter shows the total amount of classified

measured data points previously recorded.

The

Average value x long

parameter con

tains the class in which the travel remained

on average the most.

In order to be able to recognize any

short-term changes in valve travel properly,

the last 100 measured data points are

stored at a scan rate (default: 1 s) in a

non-volatile memory. The scan rate can be

changed in the

Scan rate short time

param-

eter. On changing the scan rate, old data in

the short-term histogram are deleted.

The

Average values x short

parameter con

tains the average class assignment for the

last 100 measured data points stored in the

non-volatile memory.

Data can be reset in the

Status messages

folder.

2.3 Setpoint deviation histogram

The setpoint deviation histogram contains a

statistical analysis of any setpoint deviations

recorded. This provides a summary of how

often and to which level a setpoint deviation

has occurred during the positioner service

life and whether it shows a recent trend concerning the setpoint deviation.

The setpoint deviation is recorded and assigned to predetermined level classes. The

percentages showing how often the setpoint

deviation remains within a class is presented

12 EB 8388 EN

Statistical information AUTO

Fig. 4 · Travel histogram

Page 13

as a bar graph. Ideally, the setpoint devia

-

tion should be as small as possible.

Similar to the valve travel histogram, the

Setpoint deviation histogram

folder contains

long-term data, i.e. measured data are up

-

dated cyclically (scan rate 1 s) over the en

-

tire positioner service life and stored every

24 hours in the positioner’s non-volatile

memory for long-term monitoring.

Additional information determined from this

long-term histogram are shown in Fig. 5.

The minimum and maximum setpoint devia

tions are also indicated.

In order to obtain a summary of recent

setpoint deviations, the last 100 setpoint deviations are logged at an adjustable scan

rate (default: 1 s) and saved in an FIFO

memory.

The scan rate can be changed in the

Scan

rate short time

parameter. On changing the

scan rate, old data in the short-term histogram are deleted.

The

Average values e short

parameter indi

-

cates the class in which the last 100 mea

-

sured setpoint deviations were stored on av

erage in the FIFO memory.

Data can be reset in the

Status messages

folder.

2.4 Cycle counter histogram

The histogram shows the span of cycles the

valve has moved through and the frequency

of the cycles.

A valve cycle starts at the point where the

valve stroke changes direction until the point

where it changes direction again. The valve

stroke between these two changes in direction is the cycle span.

The cycle counter histogram provides a statistical analysis of the cycles. As a result, the

cycle counter also provides information on

the dynamic stress of a bellows seal or

packing.

EB 8388 EN 13

Statistical information AUTO

Fig. 5 · Setpoint deviation histogram

Page 14

The

Dynamic stress factor

parameter is spec

ified as a percentage reflecting the stress of

the packing. An alarm is issued if the dy

namic stress factor exceeds 90 %.

The

Dynamic stress factor

is determined from

the cycle span and how often the cycle spans

occurred (frequency) depending on which

packing has been selected (see section 1.4)

self-adjusting, adjustable or bellows seal.

To ensure this factor is correctly determined,

make sure the correct packing is selected in

the

Stuffing box

parameter in the

Identifica

-

tion

folder (>

Positioner>Valve

).

The cycle counter records the number of cy

cles and the cycle spans which are assigned

to cycle classes.

The calculated percentages on how often a

cycle occurs within a class are shown as a

bar graph.

The

Cycle counter histogram

folder contains

long-term data, i.e. measured data points

are updated cyclically over the entire

positioner service life and stored every 24

hours in the positioner’s non-volatile mem

ory for long-term monitoring.

The

Average value z long

parameter con

tains the cycle class in which the average

cycle spans were found.

The

Counter of all measured values

parame

ter contains the total of classified measured

data points previously recorded.

In order to obtain a summary of recent cy

cles, the last 100 cycles measured are

stored in an FIFO memory.

The

Short

folder contains this additional cy

cle counter histogram.

The

Average value z short

parameter contains the average cycle class for the last 100

measured data points stored in the FIFO

memory.

Data can be reset in the

Status messages

folder.

14 EB 8388 EN

Statistical information AUTO

Fig. 6 · Cycle counter histogram

Page 15

2.5 Drive signal diagram

2.5.1 Steady-state drive signal

The signature diagram plotting drive signal

versus valve position is based upon the drive

signal y being the internal control signal of

the i/p converter.

This signal runs linear in relation to the valve

position, similar to the signal pressure in the

pneumatic actuator.

This graph is plotted after initialization and

is stored as a reference in the positioner.

A pressure drop across the valve while the

process is running causes the signal pres

sure in the actuator to change by the same

amount as the valve travel because the flow

forces have an affect on the equilibrium of

forces at the valve stem.

A similar effect arises when the actuator

springs loose their compression due to one

or more springs failing. As a result, a

change in the correlation between the internal drive signal y and the valve travel also

pinpoints to one of these events having oc

curred.

A reduced spring force or a control valve

with the fail-safe position ”Fail-to-close”

leads to the drive signal y shifting down

wards with an ever smaller gradient.

In contrast, the pressure drop across the

valve while the process is running does

cause the drive signal y to drop, but the

gradient rises irrelevant of the valve travel.

If significant leakage in the pneumatics

arises due to screw fittings that are not tight

-

ened properly or due to a tear in the dia

phragm, the drive signal even starts to rise

steadily at a certain valve opening com

pared to the reference graph.

The drive signal y starts to rise almost unsteadily at the restricted valve position if the

positioner supply pressure is insufficient.

The steady-state drive signal diagram contains recent data to allow recent changes to

be recognized. Furthermore, long-term data

are also analyzed to be able to detect problems due to supply pressure changes or air

EB 8388 EN 15

Statistical information AUTO

Fig. 7 · Steady-state drive signal diagram

Page 16

leaks in the pneumatics before they have an

impact on the process.

The measured data allows the following

problems to be detected and the associated

alarms to be issued:

4

Air leakage in the pneumatics

4

Spring force reduced

4

Changes in supply pressure

The valve position and its associated drive

signal y are measured after the pressure

conditions have settled (steady-state). Each

pair of measured data points recorded is

assigned to a valve position class. The

average drive signal y is calculated for each

class. The stored data can be read.

The reference data required are plotted and

stored after initialization.

Long-term monitoring

The long-term monitoring involves the average drive signal y for each valve position

class being determined from all measured

data points per valve position class.

The

Long-term

folder contains a table of the

valve position classes with the associated

average drive signal y.

Short-term monitoring

The short-term monitoring involves the aver

age drive signal y determined from the last

measured data points per valve position

class. This allows short-term changes in ac

tuator pressure to be pinpointed at various

valve positions.

The

Differential drive signal

and

Valve posi

-

tion

s folders contain a table of the last ten

measured data points.

Graphs

The

Steady-state

folder contains a common

graph for long-term, short-term and refer

-

ence data. The graph plotted using the ref

erence data covers the full range of the

valve.

The data for long-term and short-term moni

toring are recorded online while the process

is running, and therefore, the graphs do not

necessarily cover the full range of the valve.

Reference values are used in cases where no

data could be compiled for valve positions x

as the valve did not move to those positions

or a steady-state could not be reached.

The diagram allows changes in drive signal

y at the corresponding valve positions to be

easily recognized. Changes in pressure are

also evident as the drive signal y is proportional to the actuator pressure.

Data can be reset in the

Status messages

folder.

Test requirements:

A successfully plotted reference graph is

necessary to record and analyze the data.

Refer to section 1.6 in case a double-acting

actuator with reversing amplifier or a

booster is used or SUb initialization mode is

set.

Note!

The valve can be moved through its travel

range in manual mode, during plant shut

-

down or when the process allows it by se

-

lecting

Drive signal diagram steadyinTest

MAN

to check the results or statements de

-

termined in automatic mode in the

Status

message

folder (> Extended).

16 EB 8388 EN

Statistical information AUTO

Page 17

2.5.2 Hysteresis test (d5)

The hysteresis test allows changes in friction

to be analyzed and an alarm is issued when

a significant change in friction is detected.

If the diagnostic test d5 is activated and the

condition for the

Minimum time between

tests

parameter is met and the pressure con

ditions have settled, the test is performed

with a change in travel < 1% to find∆y.

tESt

and

d5

appear on the positioner dis

play in alternating sequence and for

manual mode appears while the test is run

-

ning.

The test is immediately canceled and the

positioner returns to automatic mode if the

valve travel leaves the tolerance band or a

change in the reference variable occurs

which is greater than the tolerance band set.

If the test was interrupted due to a change in

the reference variable, the test is started

again after waiting 30 seconds using the

new operating point.

If the test is canceled again at this point due

to a change in the reference variable∆w,

the test is started again after waiting 60 sec

onds with the operating point.

This can happen ten times, during which the

time between tests is increased by 30 sec

-

onds each time (30 s x Number of tests re

peated).

After the test is canceled for the tenth time

(due to∆w), the time entered in

Minimum

time between tests

parameter is kept again.

The hysteresis test is deactivated by default.

We recommend activating the test after entering

Minimum time between tests

by select-

ing

Start now

.

The

Minimum time between tests

and the

control parameters are stored in the

non-volatile memory of the positioner.

EB 8388 EN 17

Statistical information AUTO

Fig. 8 · Hysteresis test diagram

Page 18

Long-term monitoring

The measured results∆y are classified ac

cording to the valve position x in the valve

position classes. The average value∆y per

valve position class is determined from all

the measured data.

The

Long-term

folder contains a table of the

results.

Short-term monitoring

To provide a short-term trend, the last ten

valve positions x and the associated∆y val

-

ues are saved in the

Short-term

folder

(>

Valve position

and

Difference signal

drive

).

Graphs

The

Hysteresis

folder contains a graph with

two curves plotted. The

Measurement

curve

shows the measured data recorded for

long-term monitoring and the

Reference

curve shows the reference data recorded after initialization.

The graph plotted using the reference data

covers the full range of the valve.

The data for long-term monitoring are re

corded online while the process is running,

and therefore, the graphs do not necessarily

cover the full range of the valve.

Reference values are used in cases where no

data could be compiled for valve classes.

If the test has not yet been activated, the

graph for the reference data is represented

by a straight line.

The diagram allows changes in∆y with the

corresponding valve positions to be

recognized.

Changes in friction are highlighted as∆y is

proportional to the actuator pressure which,

in turn, is a measurement for friction. A

change in friction leads to an alarm being

issued.

Test requirements:

The test is possible in relation to the travel

range between 2 and 98 %.

4

A successfully plotted reference graph is

necessary in order to analyze the fric

-

tion.

4

The test can only be started when the tol

-

erance band (Code 19) or

Positioner

folder (>

Error control>Tolerance band

)

is greater than 1 %.

4

The characteristic type (Code20) must

be set to

Linear

in order to record the

data.

4

Refer to section 1.6 in case a double-acting actuator with reversing amplifier or a

booster is used or the SUb initialization

mode is set.

Note!

The valve can be moved through its travel

range in manual mode, during plant

shutdown or when the process allows it by

selecting

Drive signal diagram hysteresis

in

Test MAN

to check the results or statements

determined in automatic mode in the Status

message folder (> Extended).

18 EB 8388 EN

Statistical information AUTO

Page 19

The following parameters are changed dur

-

ing hysteresis test/d5 correspondingly:

4

Lower x-range value (Code 8): 0 %

4

Upper x-range value (Code 9): 100 %

4

Lower/upper x-limit (Code 10/11): OFF

4

Setpoint cutoff w decrease/increase

(Code 14/15): OFF

4

Pressure limit (Code 16): Active pressure

limit is raised one stage higher

4

W-ramp OPEN/CLOSED (Code 21/22):

Variable

Data can be reset in the

Status messages

folder.

2.6 End position trend

The end position trend is used to detect a

creeping zero point shift due to seat and

plug wear or dirt between the seat and

plug. A fluctuating zero point also causes an

alarm to be issued.

To accomplish this function, the valve posi-

tion x and the drive signal y are automati

-

cally logged and time-stamped by the oper

ating hours counter in automatic mode

when the valve moves to the lower end posi

tion. The measured data are stored in an

FIFO memory that always stores 30 mea

sured data points.

The measured data are first stored in a ring

buffer if the valve position x differs by

±0.25 % from the measured value previ

ously recorded.

To allow the test to run automatically in the

background, activate the tight-closing func

-

tion (over Code 14 or in the

Positioner

folder (>

Reference variable>Setpoint cut

-

off decrease

) and make sure the positioner

is in AUTO operating mode.

When the valve moves to the zero point for

the first time in controlled operation, this

measured value serves as a reference. The

reference value is stored in a non-volatile

memory independent from the ring buffer.

EB 8388 EN 19

Statistical information AUTO

Fig. 9 · End position trend with zero point shift at measuring point 1

Page 20

An alarm is generated after a change in

zero point or when a zero point shift outside

of the zero point limit is detected.

Enter the zero point limit in the

Positioner

folder (>

Error control>Zero point limit

) or

over Code 48 in the positioner, selecting d5

(default setting 5 %).

Note!

The valve end position is also logged when

the valve moves to the fail-safe position over

the forced venting option and with an

actuator with AIR TO OPEN.

Graph versions

Select

Trend of valve end position

folder to

view a graph of the recorded end positions.

The reference value is represented by a

straight line in the graph.

The graph highlights a trend and a change

in the end position.

The

Lower end position

folder contains a

table of the measured data (valve position x,

drive signal y) with time stamp.

Data and the reference value can be reset in

the

Status messages(> Reset

) folder.

20 EB 8388 EN

Statistical information AUTO

Page 21

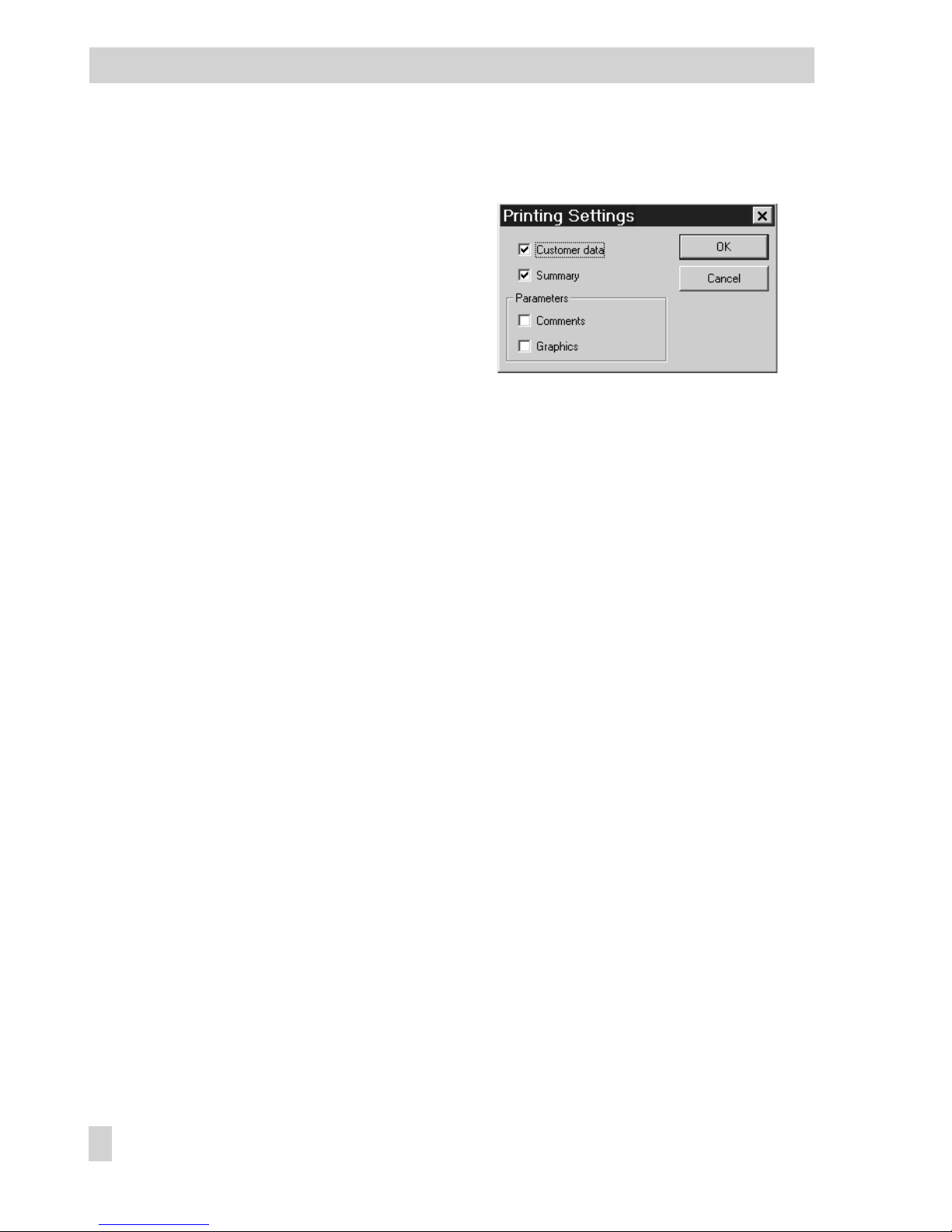

3 Tests MAN

These tests are performed when the process

in not running (i.e. manual operation). The

positioner does not follow its reference vari

-

able.

In all the following tests, the control valve

moves through the full range of the valve af

-

ter the test is started. Therefore, before start

ing the test, it is absolutely important to

make sure whether the process and plant

conditions allow it.

In contrast to the tests in statistical informa

tion AUTO, the corresponding test MAN

covers the full range of the valve and also

serves to detect errors within the travel

range.

The tests MAN provide a trend showing the

current control valve state, any possible existing malfunctions and help to pinpoint

faults and to schedule predictive maintenance work. For reasons of safety, the tests

MAN can only be started when the

positioner is in manual operating mode.

Select the operating mode over Code 0 on

the positioner or in

Positioner

folder (>

Op

-

erating mode

).

Select the

Start all tests parameter

to start all

tests automatically in sequence.

During the test, the following parameters are

changed for all tests MAN (d1 to d4):

4

Lower x-range value (Code 8): 0 %

4

Upper x-range value (Code 9): 100 %

4

Lower/upper x-limit (Code 10/11): OFF

(not in a step response test)

4

Setpoint cutoff w decrease/increase

(Code 14/15): OFF

4

Pressure limit (Code 16): Active pressure

limit is raised one stage higher

4

Characteristic (Code 20): Linear

4

W-ramp OPEN/CLOSED (Code 21/22):

Variable

Note!

The tests MAN can only be activated in

manual operating mode.

EB 8388 EN 21

Tests MAN

Fig. 10 · Tests MAN

Page 22

3.1 Drive signal diagram

steady-state (d1)

As described in detail in section 2.5 on the

drive signal diagram, the drive signal y plot

-

ted versus valve position x allows the follow

-

ing changes at the control valve to be recog

-

nized (and an alarm issued):

4

Air leakage in the pneumatics

4

Spring force reduced

4

Changes in the supply pressure

This test (

tESt d1

) causes the valve to move

through the travel range to allow the results

and alarms issued in automatic mode to be

accurately checked.

After starting the test, the valve is moved to

various fixed valve positions x distributed

over the full range of the valve.

The drive signal y is measured for each

valve position x and stored in the positioner

memory. The necessary data set for the ref

erence graph is automatically plotted and

stored directly after initialization. The start

time for the reference graph is stored with a

reference time stamp in the positioner’s

non-volatile memory.

Any further measurement is stored as a re

peated measurement. Previously recorded

repeated measurements stored in the

positioner are overwritten. However, note

that you can upload previous repeated mea

surements to a PC before starting a new test.

While the test is active,

d1

and

tESt

appear

on the positioner display in alternating sequence and indicates manual operating

mode.

22 EB 8388 EN

Tests MAN

Fig. 11 · Drive signal diagram steady-state

Page 23

Viewing the recorded parameters:

The

Drive signal diagram steady-state

folder

contains the reference and repeated mea

surements plotted in a graph.

The individual measured points are saved in

the corresponding subfolders:

> Reference valve position

> Reference drive signal

> Repetition value of valve position

> Repetition value of drive signal.

Test requirements:

4

A successfully plotted reference graph

and repetition lines are necessary in or

der to analyze the data.

If a reference graph still has not been

plotted on starting the test, this test is

adopted as the reference.

4

Refer to section 1.6 in case a double-acting actuator with reversing amplifier or a

booster is used or SUb initialization

mode is set.

3.2 Drive signal diagram

hysteresis (d2)

Similar to the corresponding test in auto

-

matic mode, this test (

tESt d2

) is used to an

alyze the change in friction forces.

However, unlike the test in automatic mode,

this test causes the valve to move to defined

valve positions over the full range of the

valve, and determines∆y for each valve po

sition.

The valve is made to move to fixed nodes of

the valve position x and the valve position is

ramped up (< 1 %) correspondingly.

The drive signal y and the change in valve

opening are analyzed during this test phase

concerning changes in∆y for changes in direction, to precisely check the results or

alarms issued in automatic mode.

To enable a test, the tolerance band (Code

19 or in

Positioner

folder (>

Error control

)

must be greater than 1 % (default: 5 %).

If the valve cannot move to a certain valve

position node or the setpoint leaves the tolerance band during the test, an alarm is

generated in

Test information

and the test is

canceled.

The necessary data set for the reference

graph is automatically plotted and stored di

rectly after initialization. The start time for

the reference graph is stored with a refer

ence time stamp in the non-volatile memory

of the positioner.

Any further measurement is stored as a re

peated measurement. Previously recorded

repeated measurements stored in the

positioner are overwritten. However, you

can upload previous repeated measure

-

ments to a PC before you start a new test.

EB 8388 EN 23

Tests MAN

Page 24

While the test is active,

d2

and

tESt

appear

on the positioner display in alternating se

quence. indicates manual operating

mode.

Viewing the recorded parameters:

The

Drive signal diagram hysteresis

folder

contains a graph with reference

measurements and the last measurement

performed plotting the change in drive sig

-

nal∆y versus the valve position x. The

Refer

-

ence valve position

subfolder contains a list

of the valve positions that the valve moved

to.

The recorded∆y are saved in the corre

sponding subfolders:

> Reference hysteresis

> Repetition value of hysteresis.

Test requirements:

4

A successfully plotted reference graph

and repeated measurements are neces

sary in order to analyze the data.

If a reference graph still has not been

plotted on starting the test, this test is

adopted as the reference.

4

Refer to section 1.6 in case a double-act

ing actuator with reversing amplifier or a

booster is used or the SUb initialization

mode is set.

24 EB 8388 EN

Tests MAN

Fig 12 · Drive signal diagram hysteresis

Page 25

3.3 Static characteristic (d3)

The static performance of the control valve is

affected by the friction hysteresis and the

elastic processes in the valve stem packing.

The static characteristic is plotted to check

the static performance. The analysis of

minimum, maximum and average dead

band parameters allows the control loop to

be evaluated.

To accomplish this, the reference variable w

is commanded in small steps and the re

sponse of the controlled variable x is plotted

after waiting a predetermined period of

time.

This test

(tESt d3)

allows the full range of the

valve to be recorded in manual mode.

It is also possible to define a test range by

selecting the

Start

and

End

parameters. The

ascendent and descendent are plotted within

the test range.

100 measured points are plotted at the

maximum, i.e. max. 50 measured points are

available for the ascendent and the descen

dent.

The step height and the number of measur

ing points are determined automatically by

the adjusted test range. The dead zone is

analyzed by a step height smaller than

0.2 %.

The setpoint difference that causes a mini

mal change in the valve position x is termed

dead band. It is recorded and analyzed in

the positioner for each step.

EB 8388 EN 25

Tests MAN

Fig. 13 · Static characteristic

Page 26

Fig. 13 lists the settings and information pa

-

rameters.

While the test is active,

d3

and

tESt

appear

on the positioner display in alternating se

quence. indicates manual operating

mode.

Viewing the recorded parameters:

The

Static characteristic

folder contains a

graph of the measured points, plotting the

valve position x versus the reference vari

able.

The

Measured values

subfolder (>

Valve po

-

sition x

) and (>

Reference variable w

) con

tain a table of the individual corresponding

measured points.

Data can be reset in the

Status messages

folder.

Test requirements:

4

The starting point must be smaller than

the final point.

The dead band is analyzed if the step

height is smaller than 0.2 %.

3.4 Step response (d4)

The dynamic valve performance can be ex

amined by recording the step responses.

Usually, two steps in reference variable are

performed and the course of the valve posi

tion x and the drive signal y are plotted until

a steady state is reached. This test is stored

and analyzed in the positioner.

The reference variable w, the setpoint devia

-

tion e and time t are also stored and ana

lyzed.

The default setting is two steps with the first

step usually starting at a defined start value

and ending at a defined end value.

After a certain delay, the second step is performed, starting at the end value of the first

step and ending at the defined start value of

the first step.

The data are automatically analyzed in the

positioner after the test is completed. Parameters such as overshoot, dead time, T63,

T98, rise time and settling time are determined separately for each step.

Refer to Fig. 14 for the setting and information parameters.

The following analysis parameters are deter

-

mined separately for each step:

> Overshoot (relative to the step height) in %

> Dead time

> T63

> T98

> Rise time

> Settling time.

While the test is active,

d4

and

tESt

appear

on the positioner display in alternating se

quence. indicates manual operating

mode.

26 EB 8388 EN

Tests MAN

Page 27

Viewing the recorded parameters:

The parameters required to analyze the step

response test such as reference variable w,

valve position x, setpoint deviation e and

drive signal y are plotted in graphs over

time in the

Step response

folder.

The

Measured values

subfolder contains all

measured and analyzed parameters such as

valve position, setpoint, drive signal,

setpoint deviation and the points in time at

which they were recorded.

Data can be reset in the

Status messages

folder.

EB 8388 EN 27

Tests MAN

Fig. 14 · Step response test

Page 28

4 Status and diagnostic alarms

4.1 Standard EXPERT diagnostic

alarms

The standard EXPERT diagnostics provides

information about positioner states such as

operating hours counter, process monitor

ing, number of zero calibrations and

initializations, total valve travel, tempera

ture, initialization diagnostics, zero/control

loop errors, etc.

In addition, the standard EXPERT diagnostics

generates diagnostic and status alarms

which allow faults to be pinpointed quickly

when a fault occurs.

The diagnostic and status alarms issued by

EXPERT appear on the positioner display

and can also be viewed in TROVIS-VIEW

software in the

Diagnosis

folder (>

Status

messages

).

Alarms are classified in the following main

groups:

4

Status

4

Operation

4

Hardware

4

Initialization

4

Data memory

4

Temperature

Further information on the positioner status

(e.g. limit switches, tight-closing function)

and the parameters (e.g. characteristics) are

displayed in the

Positioner

folder).

The following folders contain particularly in

-

formative data for valve diagnostics:

4

Positioner

folder (process data)

Information on the current process vari

ables, condensed status, operating

mode, limit switch, temperature.

The Trend Viewer function (activate Trend

Viewer in the

View

menu) allows process

variables to be shown in one or more

graphs.

To proceed, drag and drop the required

process variable into the graph.

4

Positioner

folder (>

Error control

)

Information on total travel with a freely

defined limit

4

Positioner

folder (>

Start-up>Initializa-

tion

)

List of initialization errors which can also

be found in the

Diagnosis

folder (>

Sta-

tus messages

).

4.2 Extended EXPERT+diagnostic

alarms

Further status alarms are generated from the

extensive information gained in the diagnos

-

tic tests of EXPERT

+

which provide the user

with information covering the whole control

valve (see table below).

These status alarms can be viewed in the

Di

-

agnosis

folder (>

Extended

).

An active diagnostic alarm issued by

EXPERT

+

appears on the positioner display

over Code

79.

28 EB 8388 EN

Status and diagnostic alarms

Page 29

4.3 Logging

The last thirty alarms (EXPERT/ EXPERT+) are

stored in the positioner with a time-stamp

(logged by the operating hours counter).

However, it is important to note that the

same alarm is only logged once when it first

occurs.

The alarms stored can be viewed in the

Log

-

ger

folder.

Entries can be reset in the

Reset

folder.

4.4 Classification of the status

alarms

Any event or alarm is assigned a status.

The following states listed in the table below

are possible:

4.5 Condensed state

To provide a better overview, the state of the

positioner is summarized in a condensed

status which is made up from a summary of

all classified positioner alarms.

Note!

If an event is classified as “No message”,

this event does not have any affect on the

condensed status of the positioner.

The condensed status is displayed in the en

gineering tool as well as on the positioner

display as in the table below.

Furthermore, the condensed state is issued

at the fault alarm output. Refer to the mounting and operating instructions of the

positioner for further details.

EB 8388 EN 29

Status and diagnostic alarms

Individual status alarm

Engineering tool

TROVIS-VIEW/DTM

Inactive status_ok.ico

Active · “No message”

classification

status_on.ico

Active · “Maintenance

required/Maintenance

demanded“ classification

status_main.ico

Active · “Function

check“ classification

status_funct.ico

Active · “Maintenance

alarm“ classification

status_critic.ico

Status alarm

Engineering tool

TROVIS-VIEW/DTM

Device

display

“Maintenance

alarm”

status_critic.ico

“Maintenance

required/

Maintenance

demanded

status_main.ico

“Function

check“

status_funct.ico Text

“No

message”

status_ok.ico

Page 30

4.6 Status modification

The classification of the status alarms can be

changed as required. The following assign

-

ment of the states are:

4

Maintenance alarm

4

Maintenance required/Maintenance

demanded

4

No message possible

Select

Positioner

folder (>

Error control

>

Status classification

) to modify the classifica

-

tion of standard alarms issued by EXPERT.

Select

Positioner

folder (>

Error control

>

Status classification > Extended)

to modify

the classification of alarms issued by

EXPERT+.

Note!

All additional alarms generated by EXPERT

+

have the status “No message” by default.

On resetting the positioner parameters to

their default settings (Code 36), the status

classification is also reset to the default set

-

ting.

If modifications that have already been

made should be kept, we recommend

uploading them on a PC before performing

a reset and then downloading them onto the

positioner again afterwards.

Note!

In the Type 3730-5 Positioner (Foundation

Fieldbus), block error alarms as well as the

condensed states can be assigned to events .

Refer to EB 8384-5 EN for further

instructions.

30 EB 8388 EN

Status and diagnostic alarms

Page 31

5 Resetting diagnostic

parameters

When an alarm is issued, the source of the

error should be first located and the error

remedied.

In the case of an EXPERT alarm, we recom

mend reading the corresponding remedy

notes listed in the error code list (refer to the

Operating Instructions of the positioner).

Remedy notes on EXPERT

+

alarms are listed

in the table in section 7.

EXPERT

Alarms generated by EXPERT which are

indicated on the positioner display by an error code can be confirmed by pressing the

rotary pushbutton after selecting the corre

sponding error code.

Resetting error codes as well as resetting op

tions such as logging or the total valve travel

can be performed using an engineering

tool, for example, TROVIS-VIEW3 software.

EXPERT

+

Extended alarms generated by EXPERT+are

based upon the statistical information AUTO

and tests MAN. An active EXPERT

+

alarm is

indicated by Code 79 at the positioner.

Select

Diagnosis

folder (>

Status messages

>

Reset

) to reset data from statistical infor

-

mation AUTO and tests MAN (see Fig. 15).

EB 8388 EN 31

Resetting diagnostic parameters

Fig. 15 · Resetting diagnostic parameters

Page 32

Note that the corresponding short-term his

togram/short-term monitoring is also reset

on resetting long-term histogram/long-term

monitoring.

On performing the tests MAN, the measur

ing data of the last measurement as well as

the reference measurements (for d1 and d2)

are stored in the positioner.

On restarting a test MAN, the existing data

are updated by the repeated measurement

data.

In addition, the repeated measurements of

the tests MAN such as drive signal diagram

steady-state and drive signal diagram hys

teresis can be reset by selecting the

Status

messages

folder (>

Reset

).

Note!

Resetting the measured data does not cause

the reference graphs to be reset:

4

Drive signal diagram steady-state

4

Drive signal diagram hysteresis

4

Reference value for the end position

trend

However, the existing data set is replaced

by the new reference data when the refer

ence graphs for steady-state and hysteresis

graphs (see section 1.5) are replotted.

The data sets from already existing mea

surements of steady-state and hysteresis

graphs recorded in both statistical informa

tion AUTO and tests MAN are reset when

both reference graphs are updated.

Initialization

After an initialization has been successfully

completed, new reference measurements are

automatically plotted and the existing refer

-

ence data are overwritten. The new refer

-

ence data and the optimized control param

-

eters cause the following statistical informa

-

tion AUTO and MAN tests to be reset:

4

Drive signal diagram steady-state

(AUTO and MAN tests)

4

Drive signal diagram hysteresis

(AUTO and MAN tests)

4

Setpoint deviation histogram (long-term

and short-term)

4

End position trend

Resetting over Code 36 (EXPERT/EXPERT

+

)

Activate Code 36 or select

Operation unit

folder (> Start with default settings) to reset

the positioner parameters to their default

settings (see code list in the mounting and

operating instructions of the positioner).

The following diagnostic functions of

EXPERT/EXPERT

+

diagnostics are reset:

4

Settings and activated statistical information AUTO and tests MAN in EXPERT

+

4

Status classification settings

(EXPERT/EXPERT

+

)

4

Operating hours counter: (>

Device

switched on since initialization

) and

(>

Device since initialization in control

loop

) (EXPERT)

4

Total valve travel (EXPERT)

4

All short-term histograms (EXPERT+)

Drive signal diagram steady-state and

diagram hysteresis

Statistical information AUTO and tests

MAN (EXPERT

+

)

4

Static characteristic and step response

(EXPERT

+

)

4

End position trend (EXPERT+)

32 EB 8388 EN

Resetting diagnostic parameters

Page 33

If the same status classification is to be used

in future, you can upload the settings onto a

PC over, for example, the TROVIS-VIEW

software.

Mounting the positioner onto another con

-

trol valve

As the EXPERT

+

extended diagnostics pro

vides statements about the entire control

valve, the data from statistical information

AUTO and tests MAN need to be reset

when the positioner is attached to a different

control valve.

After mounting the positioner on the new

control valve, perform a reset over Code 36

and re-initialize the positioner. This leads to

the most of the diagnostic functions being

reset.

We recommend additionally to manually reset the long-term travel histogram and the

long-term cycle counter histogram as well as

the logging by selecting the

Diagnosis

folder

(>

Reset

).

EB 8388 EN 33

Resetting diagnostic parameters

Page 34

6 Diagnostic parameters saved in non-volatile memory

The following parameters are saved in a non-volatile memory to prevent their loss:

Which data are saved if a

parameter change is detected

Cyclic saving (24 h)

Statistical information AUTO

Data logger

Data logging, scan rate, start

value, logging limit, trigger

status

Travel histogram

Scan rate

of short-term monitoring

Data for long-term histogram

Setpoint deviation histogram

Cycle counter histogram

Drive signal histogram

(steady-state)

Data for short-term and

long-term histograms

Drive signal histogram (hysteresis)

(d5)

Minimum time between tests,

start test

Data for long-term monitoring

End position trend Measured values when end

position changes

Tests MAN

Drive signal diagram (steady-state)

(d1)

Reference test,

reference time stamp

Drive signal diagram (hysteresis)

(d2)

Static characteristic (d3)

Step response (d5)

Scan rate, step start, step end,

delay time after step, number of

step responses, analysis

parameters

General

Details on actuator and valve data

Yes

Logging Save when a new alarm is issued

Classification of status alarms

Yes

34 EB 8388 EN

Diagnostic parameters saved in non-volatile memory

Page 35

7 Troubleshooting

Fault category Alarm Remedy Resetting alarm

Supply pressure Possibly changed (test)

Check supply pressure.

Refer to the section on

supply pressure in the EB

of the positioner.

Reset

y-x signature measured

data

Possibly at full capacity (test)

Possibly insufficient

Reset over Code 57.

Reset y-x long-term and

short-term monitoring

Trend

concerning full

range of valve

Working range shift

CLOSED position

Check the valve working

range.

Reset

x long-term and short-term

histograms

Working range shift

max. OPEN

Air leakage in

the pneumatics

Possibly exists (test)

Check pneumatic

actuator and

connections for leakage.

Reset

y-x signature measured

data

Possibly too much (test)

Possibly too much

Reset

y-x long-term and

short-term monitoring

Reset over Code 57.

Possibly exists

Restriction of full

range of valve

Downwards Check pneumatic

accessories and

connections for leakage.

Check supply pressure

and increase it, if

necessary.

Refer to the section on

supply pressure in the EB

of the positioner.

Check plug stem for

problems caused by an

external source.

Reset over Code 57.

Reset

e short-term histogram

Reset

e long-term histogram

Upwards

No change possible

(terminals)

EB 8388 EN 35

Troubleshooting

Page 36

End position

trend

Zero point shift downwards

monotonic

Average value above the

reference line

Check plug and seat

Reset

lower end position trend

Zero point shift upwards

monotonic

Average value above the

reference line

Zero point fluctuates

Average value above the

reference line

Zero point shift downwards

monotonic

Average value below the

reference line

Zero point shift upwards

monotonic

Average value below the

reference line

Zero point fluctuates

Average value below the

reference line

Mechanical

connection

linking

positioner/

control valve

Possible restriction of the full

range of valve

Check attachment

Reset

e short-term histogram

Full range of

valve

Mainly near to CLOSED

position

Reconsider whether the

working range is

suitable

Reset

x long-term histogram

Mainly near to max. OPEN

Mainly CLOSED position

Mainly max. OPEN

36 EB 8388 EN

Troubleshooting

Page 37

Friction Much higher over the full

range of valve

Check packing

Reset

hysteresis long-term and

short-term monitoring

Much lower over the full

range of valve

Much higher over part of the

range

Much lower over part of the

range

Much higher/lower over the

full range of valve (test)

Reset

hysteresis measured data

Much higher/lower over part

of the range (test)

Actuator springs Spring rigidness possible

reduced (spring failure)(test)

Check springs in the

actuator

Reset

y-x signature measured

data

Compression possible

reduced (test)

Seat leakage

Possibly different Check plug and seat

Reset

y-x signature measured

data

Reset

e short-term histogram

Leakage to the

atmosphere

Maybe to be expected soon Check packing

Reset hysteresis long-term

and short-term monitoring

Reset

hysteresis measured data

Reset

z long-term histogram

Dynamic stress

factor*

Percentage as information on

packing load

Leakage to the atmosphere

alarm active when greater

than 90 %

Check packing

Reset

z long-term histogram

* This value is included in the Cycle counter histogram in statistical information AUTO

EB 8388 EN 37

Troubleshooting

Page 38

8 EXPERT+without TROVIS-VIEW

The EXPERT+valve diagnostics are displayed in different ways depending on the type of

communication and the connected engineering tool.

The TROVIS-VIEW software with communication over the SSP interface provides full access

to EXPERT

+

diagnostic functions:

4

Numerical display of parameters

4

Display of parameters in the form of graphs

4

Parameterization, where applicable

The representation may differ in other engineering tools. The table below illustrates the differ

-

ences.

Communication HART – DD HART-DTM HART-EDD FF – DD Profibus-EDD

Engineering tool e.g. PACTWare e.g. Siemens PDM

Various Siemens PDM

Start reference test

(section 1.5)

•• • ••

Statistical information AUTO (refer to section 2 for description)

Data logger

No numerical

display

No graphical

display

•

No numerical

display

No graphical

display

No numerical

display

No graphical

display

•

Travel histogram ·

long-term

1)

No graphical

display

••

No graphical

display

•

Travel histogram ·

short-term

No graphical

display

No parame

-

terization

••–•

Setpoint deviation

histogram · long-term

1)

No graphical

display

••–•

Setpoint deviation

histogram · short-term

No graphical

display

No parame

-

terization

••–•

Cycle counter

histogram · long-term

1)

No graphical

display

••

No graphical

display

•

Cycle counter

histogram · short-term

1)

No graphical

display

••–•

Steady-state drive

signal · long-term

1)

No graphical

display

••–•

38 EB 8388 EN

EXPERT+without TROVIS-VIEW

Page 39

Communication HART – DD HART-DTM HART-EDD FF – DD Profibus-EDD

Engineering tool e.g. PACTWare e.g. Siemens PDM

Various Siemens PDM

Steady-state drive

signal · short-term

1)

No graphical

display

–•–•

Hysteresis test ·

long-term

No graphical

display

••

No numerical

display

No graphical

display

•

End position trend

1)

No graphical

display

••–•

Tests MAN (refer to section 3 for description)

Drive signal

diagram steady-state

(d1)

No graphical

display

••

No numerical

display

No graphical

display

•

Drive signal

diagram hysteresis

(d2)

No graphical

display

••

No numerical

display

No graphical

display

•

Static

characteristic (d3)

Restricted

numerical

display

2)

No graphical

display

••

Restricted

numerical

display

2)

No graphical

display

•

Step response (d4)

Restricted

numerical

display