Page 1

EB 8395 EN

Translation of original instructions

Type3724 Positioner (cover removed)

Type3724 Electropneumatic Positioner

Firmware version 1.01

Edition October 2018

Page 2

Note on these mounting and operating instructions

These mounting and operating instructions assist you in mounting and operating the device

safely. The instructions are binding for handling SAMSON devices.

Î For the safe and proper use of these instructions, read them carefully and keep them for

later reference.

Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service

Department (aftersalesservice@samson.de).

The mounting and operating instructions for the devices are included in

the scope of delivery. The latest documentation is available on our website

at www.samson.de > Service & Support > Downloads > Documentation.

Denition of signal words

!

DANGER

Hazardous situations which, if not avoided,

will result in death or serious injury

!

WARNING

Hazardous situations which, if not avoided,

could result in death or serious injury

2 EB 8395 EN

!

NOTICE

Property damage message or malfunction

Note

Additional information

Tip

Recommended action

Page 3

Contents

1 Safety instructions and measures ...................................................................5

1.1 Notes on possible personal injury ...................................................................7

1.2 Notes on possible property damage ................................................................7

2 Markings on the device .................................................................................9

2.1 Nameplate ....................................................................................................9

2.2 Article code ...................................................................................................9

3 Design and principle of operation ................................................................10

3.1 Technical data .............................................................................................12

3.2 Dimensions in mm ........................................................................................14

4 Measures for preparation ............................................................................15

4.1 Unpacking ..................................................................................................15

4.2 Transporting ................................................................................................15

4.3 Storage .......................................................................................................15

5 Mounting and start-up .................................................................................16

5.1 Pneumatic connections..................................................................................16

5.1.1 Supply pressure ...........................................................................................16

5.2 Electrical connections ...................................................................................18

5.2.1 Accessories .................................................................................................18

5.2.2 Selecting cables and wires ............................................................................19

5.2.3 Cable entry .................................................................................................19

6 Operation ...................................................................................................20

6.1 Operating controls .......................................................................................20

7 Operating the positioner ..............................................................................22

7.1 Adapting the display ....................................................................................23

7.2 Enabling conguration to change parameters.................................................23

7.3 Adjusting the volume restriction Q .................................................................24

7.4 Entering the opening direction/direction of action ..........................................25

7.5 Entering the direction of action ......................................................................25

7.6 Limiting the signal pressure ...........................................................................25

7.7 Adjusting the limit contacts ...........................................................................26

7.8 Setting other parameters ...............................................................................26

7.9 Initialization ................................................................................................27

7.10 Zero calibration ...........................................................................................28

7.11 Manual mode ..............................................................................................29

7.12 Reset ...........................................................................................................30

EB 8395 EN 3

Page 4

Contents

8 Servicing.....................................................................................................31

8.1 Preparation for return shipment .....................................................................31

8.2 Firmware update..........................................................................................31

9 Malfunction .................................................................................................32

9.1 Error codes ..................................................................................................33

9.2 Emergency action ........................................................................................34

10 Decommissioning and removal ....................................................................35

10.1 Decommissioning .........................................................................................35

10.2 Removing the positioner ...............................................................................35

10.3 Disposal ......................................................................................................35

11 Appendix ....................................................................................................36

11.1 After-sales service ........................................................................................36

11.2 Code list ......................................................................................................37

4 EB 8395 EN

Page 5

Safety instructions and measures

1 Safety instructions and measures

Intended use

The Type3724 Positioner is delivered as a ready-mounted unit on Type3379 Pneumatic

Piston Actuators. It is used to assign the valve position to the control signal. The device is

designed to operate under exactly dened conditions (e.g. operating pressure, temperature).

Therefore, operators must ensure that the positioner is only used in applications where the

operating conditions correspond to the technical data. In case operators intend to use the

positioner in other applications or conditions than specied, contact SAMSON.

SAMSON does not assume any liability for damage resulting from the failure to use the device for its intended purpose or for damage caused by external forces or any other external

factors.

Î Refer to the technical data for limits and elds of application as well as possible uses.

Reasonably foreseeable misuse

The Type3724 Positioner is not suitable for the following applications:

− Use outside the limits dened during sizing and by the technical data

Furthermore, the following activities do not comply with the intended use:

− Use of non-original spare parts

− Performing maintenance activities not specied by SAMSON

Qualications of operating personnel

The positioner must be mounted, started up and serviced by fully trained and qualied

personnel only; the accepted industry codes and practices are to be observed. According to

these mounting and operating instructions, trained personnel refers to individuals who are

able to judge the work they are assigned to and recognize possible hazards due to their

specialized training, their knowledge and experience as well as their knowledge of the

applicable standards.

Personal protective equipment

No personal protective equipment is required for the direct handling of the positioner. Work

on the control valve may be necessary when mounting or removing the device.

Î Observe the requirements for personal protective equipment specied in the valve docu-

mentation.

Î Check with the plant operator for details on further protective equipment.

EB 8395 EN 5

Page 6

Safety instructions and measures

Revisions and other modications

Revisions, conversions or other modications of the product are not authorized by SAMSON.

They are performed at the user's own risk and may lead to safety hazards, for example. Fur-

thermore, the product may no longer meet the requirements for its intended use.

Safety features

Upon failure of the air supply or electric signal, the positioner vents the actuator, causing the

valve to move to the fail-safe position determined by the actuator.

Warning against residual hazards

The positioner has direct inuence on the control valve. To avoid personal injury or property

damage, plant operators and operating personnel must prevent hazards that could be

caused in the control valve by the process medium, the operating pressure, the signal pres-

sure or by moving parts by taking appropriate precautions. They must observe all hazard

statements, warning and caution notes in these mounting and operating instructions, especially for installation, start-up and service work.

If inadmissible motions or forces are produced in the pneumatic actuator as a result of the

supply pressure level, it must be restricted using a suitable supply pressure reducing station.

Responsibilities of the operator

The operator is responsible for proper operation and compliance with the safety regulations.

Operators are obliged to provide these mounting and operating instructions to the operating

personnel and to instruct them in proper operation. Furthermore, the operator must ensure

that operating personnel or third persons are not exposed to any danger.

Responsibilities of operating personnel

Operating personnel must read and understand these mounting and operating instructions as

well as the specied hazard statements, warning and caution notes. Furthermore, the operating personnel must be familiar with the applicable health, safety and accident prevention

regulations and comply with them.

Referenced standards and regulations

The device with a CE marking fullls the requirements of the Directive 2014/30/EU and the

Directive 2014/35/EU. The Declaration of Conformity is available on request.

Referenced documentation

The following documents apply in addition to these mounting and operating instructions:

− The mounting and operating instructions of the components on which the positioner is

mounted (valve, actuator, valve accessories etc.).

6 EB 8395 EN

Page 7

Safety instructions and measures

1.1 Notes on possible personal injury

!

WARNING

Risk of personal injury due to moving parts on the valve.

During initialization of the positioner and during operation, the actuator stem moves

through its entire travel range. Injury to hands or ngers is possible if they are inserted

into the valve.

Î During initialization, do not touch any moving valve parts.

1.2 Notes on possible property damage

!

NOTICE

Risk of malfunction due to incorrect sequence during start-up.

The positioner can only work properly if the mounting and start-up are performed in the

prescribed sequence.

Î Perform mounting and start-up as described in section16 in page5.

Unauthorized manual adjustments to the positioner will damage it!

Î Do not move the pick-up rod manually.

Dirty supply air will cause the positioner to malfunction!

Î Only use supply air that is dry and free of oil and dust.

Î Blow through all air pipes and hoses thoroughly before connecting them.

An incorrect electric signal will damage the positioner.

A current source must be used to provide the electrical power for the positioner.

Î Only use a current source and never a voltage source.

EB 8395 EN 7

Page 8

Safety instructions and measures

Incorrect assignment of the terminals will damage the positioner and will lead to malfunction.

For the positioner to function properly, the prescribed terminal assignment must be observed.

Î Connect the electrical wiring to the positioner according to the prescribed terminal

assignment.

A reference variable above or below the static destruction limit will damage the positioner.

Î Keep the reference variable within the static destruction limit of ±32V.

Malfunction due to initialization not yet completed.

The initialization causes the positioner to be adapted to the mounting situation. After initialization is completed, the positioner is ready to use.

Î Initialize the positioner on the rst start-up.

Î Re-initialize positioner after changing any parameters.

The process is disturbed by the movement of the actuator stem.

Î Do not perform the initialization while the process is running. First isolate the plant by

closing the shut-off valves.

Risk of positioner damage due to incorrect grounding of the electric welding equipment.

Î Do not ground electric welding equipment near to the positioner.

8 EB 8395 EN

Page 9

Markings on the device

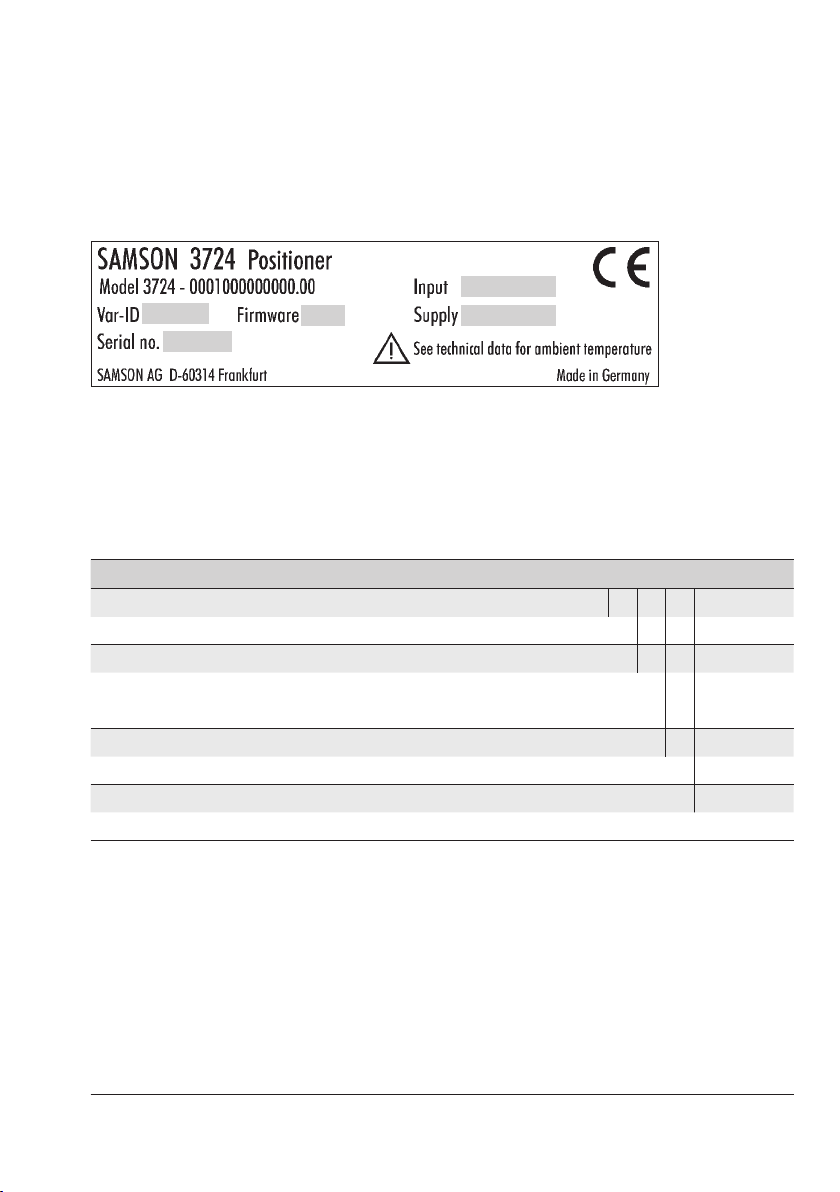

2 Markings on the device

2.1 Nameplate

4

1

3

1 Conguration ID

2 Firmware version

3 Serial number

4 Reference variable

5 Supply

2

5

2.2 Article code

Positioner Type3724- 0 0 0 0 0 0 x 0 0 0 0 0

Housing material

Housing: 1.4409 · Cover: 1.4404 0

Surface nish

Micro-bead blasted 1

Polished (R

Permissible ambient temperature

–20 to +80°C 0

Degree of protection

IP 65

1)

≤0.6µm) 2

a

1)

(only applies in combination with Type3379 Pneumatic Actuator) 0

Pending

EB 8395 EN 9

Page 10

Design and principle of operation

3 Design and principle of oper-

ation

The Type3724 Positioner is delivered as a

ready-mounted unit on Type3379 Pneumatic

Piston Actuators.

The positioner is used to assign the valve po-

sition (controlled variable x) to the control

signal (reference variable w). The positioner

compares the electric control signal of a control system to the travel of the control valve

(1) and issues a signal pressure (output variabley) for the pneumatic actuator.

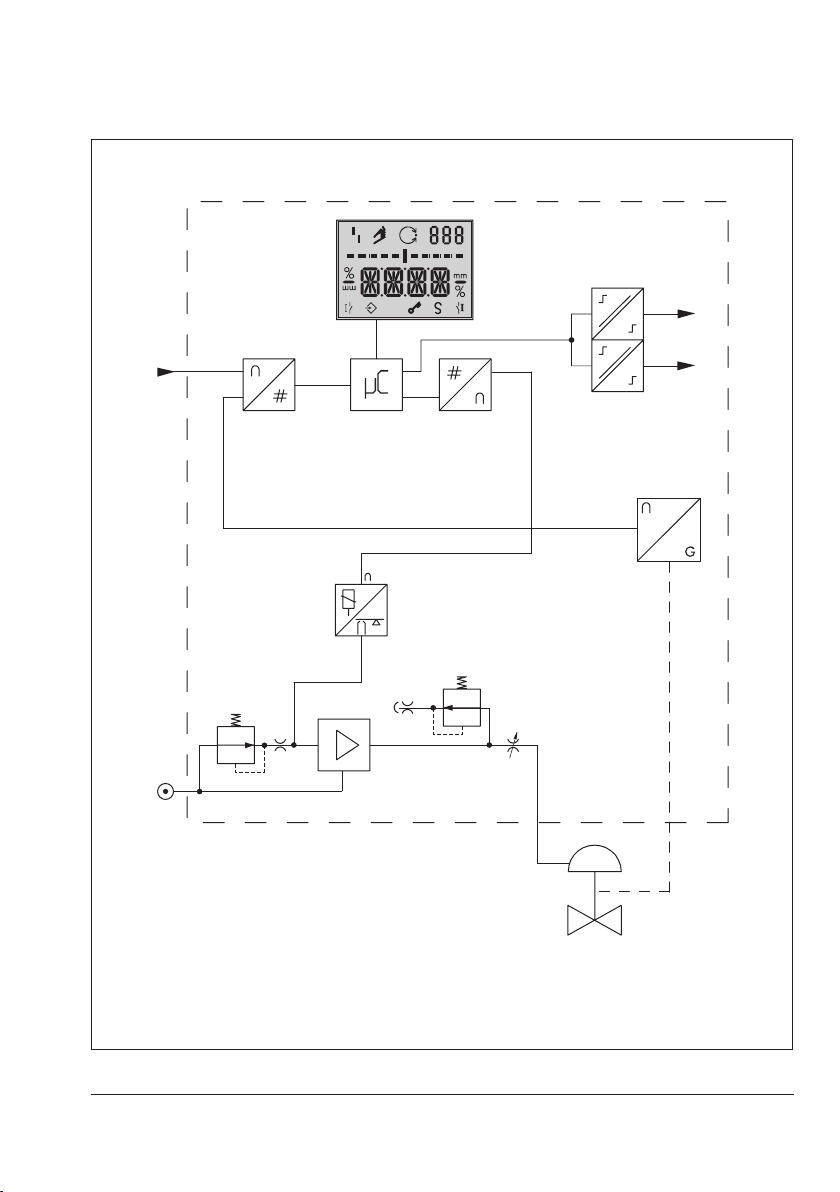

The positioner mainly consists of the follow-

ing components (see Fig.1):

− Magnetoresistive sensor (2)

− Analog i/p converter (6) with a down-

stream air capacity booster (7)

− Electronics unit with microcontroller (4)

− Software limit contacts (12)

The travel is measured by an internal pick-up

rod, which is connected to a magnet, as well

as a non-contact magnetoresistive sensor

and the downstream electronics.

The motion of the pick-up rod causes the di-

rection of the magnetic eld to change. This

change is sensed by the sensor (2). The elec-

tronics unit determines the current valve position from this information.

The position of the valve is transmitted to the

microcontroller (4) over its A/D converter

(3). The microcontroller contains a modied

PID controller which compares the actual

valve position with the 4 to 20mA control

signal. The resulting output value is passed

on to the D/A converter. In case of a system

deviation, the activation of the i/p module

(6) is changed so that the actuator (1) is

pressurized or vented accordingly over the

downstream air capacity booster (7). The

supply air is supplied to the booster (7) and

the pressure regulator (8).

!

NOTICE

Unauthorized manual adjustments to the positioner will damage it!

Do not move the pick-up rod manually.

The output signal pressure supplied by the

booster can be limited to 2.3bar by software.

The volume restriction Q (10) is used to optimize the positioner by adapting it to the ac-

tuator.

Tight-closing function

The pneumatic actuator is completely lled

with air or vented as soon as the reference

variable falls below 1% or exceeds 99%

(see set point cutoff in P10 and P11 parameter codes).

10 EB 8395 EN

Page 11

Design and principle of operation

w

11

12

A1

A2

3

8

1 Control valve

2 Sensor

3 A/D converter

4 Microcontroller

5 D/A converter

6 i/p converter

4

6

7

7 Air capacity booster

8 Pressure regulator

9 Flow regulator

10 Volume restriction

11 Display

12 Limit contacts

5

2

9

10

Q

y

1

x

Fig.1: Circuit diagram

EB 8395 EN 11

Page 12

Design and principle of operation

3.1 Technical data

Table1: General technical data

Positioner

Attachment Type3379 piston Ø: 63mm · Effective area: 31cm²

Type3379 piston Ø: 90mm · Effective area: 63cm²

Travel 4 to 16mm, adjustable in steps of 0.5mm

Reference variable w

(reverse polarity protection)

Static destruction limit ±32V

Minimum current

Load impedance Max. 6.3V

Supply air

Air quality acc. to

ISO8573-1

Signal pressure (output) 0 bar up to the supply pressure minus 0.4bar

Characteristic Three selectable characteristics:

Transit time Only for actuators with initialization time > 0.4s

Direction of action w/x reversible

Perm. ambient temperature –20 to +80°C

Electromagnetic

compatibility

Degree of protection IP 65

Compliance

Materials

Housing 1.4409

Cover 1.4404

Dome (visual indicator) Polycarbonate

Weight (without actuator) Approx. 1.2kg

1)

For faster actuators, a volume restriction must be used. Otherwise, the initialization cannot be

performed successfully.

2)

Pending

4 to 20mA signal range · Two-wire device

Split-range operation 4 to 11.9mA and 12.1 to 20mA

3.8mA

Supply air: 1.4 to 7bar (20 to 105psi)

Max. particle size and density: Class 4 · Oil content: Class 3 · Pressure

dew point: Class 3 or at least 10K below the lowest ambient

temperature to be expected

Can be limited to approx. 2.3bar by software

Linear · Equal percentage · Reverse equal percentage

1)

Complying with EN 61000-6-2, EN 61000-6-3 and NAMUR

Recommendation NE21

2)

(only applies in combination with Type3379 Pneumatic

Actuator)

12 EB 8395 EN

Page 13

Design and principle of operation

Table2: Limit contacts

Binary contacts Two software limit contacts (min., max.)

Version Reverse polarity protection, galvanic isolation

Adjustment range 0 to 100% (see section7.7 on page 26)

Step size 0.5%

Static destruction limit ± 32V

Signal

state

For connection to

No response Non-conducting (highly resistive), I < 100µA

Response

− Binary input of a PLC acc. to IEC 61131-2,

= 400mW

P

max

Conducting (R = 330Ω)

EB 8395 EN 13

Page 14

Design and principle of operation

135

3.2 Dimensions in mm

130

285

Ød

Ø108

Fig.2: Dimensional drawings of Type3724 Positioner with Type3379 Pneumatic Piston Actuator

Actuator Piston Ø Ød

Type3379

63mm 69mm

90mm 94mm

14 EB 8395 EN

Page 15

Measures for preparation

4 Measures for preparation

After receiving the shipment, proceed as follows:

1. Check the scope of delivery. Compare

the shipment received with the delivery

note.

2. Check the shipment for transportation

damage. Report any transportation damage.

4.1 Unpacking

!

NOTICE

Risk of positioner damage due to foreign

particles entering it.

Do not remove the packaging and protective

lm/protective caps until immediately before

mounting and start-up.

1. Remove the packaging from the positioner.

2. Dispose of the packaging in accordance

with the valid regulations.

4.2 Transporting

4.3 Storage

!

NOTICE

Risk of positioner damage due to improper

storage.

− Observe storage instructions.

− Avoid long storage times.

− Contact SAMSON in case of different stor-

age conditions or long storage periods.

Storage instructions

− Protect the positioner against external in-

uences (e.g. impact, shocks, vibration).

− Do not damage the corrosion protection

(coating).

− Protect the positioner against moisture

and dirt. In damp spaces, prevent condensation. If necessary, use a drying

agent or heating.

− Observe storage temperature depending

on the permissible ambient temperature

(see technical data in section3.1).

− Store positioner with closed cover.

− Seal pneumatic and electrical connec-

tions.

− Protect the positioner against external in-

uences (e.g. impact).

− Protect the positioner against moisture

and dirt.

− Observe transport temperature depend-

ing on the permissible ambient tempera-

ture (see technical data in section3.1).

EB 8395 EN 15

Page 16

Mounting and start-up

5 Mounting and start-up

!

NOTICE

Risk of malfunction due to incorrect sequence

of mounting, installation and start-up.

Observe the prescribed sequence.

Note

The unit consisting of the Type3724 Positioner, Type3379 Actuator and valve is

ready assembled on delivery.

In special cases, the valve and actuator are

delivered separately and must be assembled

on site. In this case, read the associated

valve documentation.

Î Sequence to be kept on installing and

starting up the positioner:

1. Remove the protective caps from the

pneumatic connections.

2. Perform pneumatic installation.

Î Section5.1 onwards

3. Perform electrical installation.

Î Section5.2 onwards

4. Perform settings.

Î Section7 onward

5.1 Pneumatic connections

The Type3724 Positioner is delivered ready

mounted on the Type3379 Pneumatic Piston

Actuator. The pneumatic connections of the

positioner are connected internally to the

connections of the actuator.

The pneumatic connections of the actuator

are used (see Mounting and Operating Instructions of the Type3379 Pneumatic Piston

Actuator uEB8315) for start-up (see section7 on page22).

!

NOTICE

Dirty supply air will cause the positioner to

malfunction!

Only use supply air that is dry and free of oil

and dust.

Blow through all air pipes and hoses thor-

oughly before connecting them.

5.1.1 Supply pressure

The required supply air pressure depends on

the bench range and the actuator's operat-

ing direction (fail-safe action). The bench

range is written on the nameplate either as

the bench range or signal pressure range.

The operating direction is marked FA or FE

or by a symbol.

16 EB 8395 EN

Page 17

FA: actuator stem extends (air to open/

ATO)

Fail-close (for globe and angle valves):

Required supply pressure = Upper bench

range value + 0.4bar, minimum 1.4bar.

FE: actuator stem retracts (Air to close/ATC)

Fail-open (for globe and angle valves):

For tight-closing valves, the maximum signal

pressure pst

is roughly estimated as fol-

max

lows:

Mounting and start-up

pst

max

= F +

d² · π · ∆p

4 · A

[bar]

d = Seat diameter [cm]

∆p = Differential pressure across the

valve [bar]

A = Actuator area [cm²]

F = Upper bench range value [bar]

If there are no specications, calculate as

follows:

Recommended supply pressure =

Upper bench range value + 1bar

Note

The signal pressure at the output (38) of the

positioner can be restricted to approx.

2.3bar by setting P9 parameter code to

ON.

EB 8395 EN 17

Page 18

Mounting and start-up

5.2 Electrical connections

!

NOTICE

An incorrect electric signal will damage the

positioner.

Only use a current source and never a voltage source.

Î Connect the wiring as shown in Fig.3.

Î Select cables and wires as described in

section5.2.2.

Î Insert cables as described in sec-

tion5.2.3.

!

NOTICE

Incorrect assignment of the terminals will

damage the positioner and will lead to malfunction.

Connect the electrical wiring to the positioner according to the prescribed terminal assignment.

5.2.1 Accessories

Description Order no.

Cable gland:

Black plastic, M16x1.5

Plastic part

8808-1010

+11 –12

+11/–12: mA control signal

+41/–42: Limit contact 1 (min.)

+51/–52: Limit contact 2 (max.)

Fig.3: Electrical connections Fig.4: Cage clamp terminals

+41 –42

+51 –52

18 EB 8395 EN

Page 19

Mounting and start-up

5.2.2 Selecting cables and

wires

The minimum radial thickness of the conductor insulation must be suitable for the conductor diameter and type of insulation. It

must be at least 0.2mm.

The diameter of an individual wire in a

ne-stranded conductor must not be smaller

than 0.1mm.

Protect the conductor ends against splicing,

e.g. by using wire-end ferrules.

5.2.3 Cable entry

The M16x1.5 cable gland is designed for a

clamping range of 6 to 12mm.

The cage clamp terminals hold wire

cross-sections of 0.2 to 1.5mm².

Î Unscrew the cover and remove it.

Î To unlock the cage clamp terminals:

place a slotted screwdriver on the plastic

part (Fig.4) and lightly push it into the

terminal block.

Î Insert or remove the wire without force.

Î Guide wires for the reference variable to

the terminals +11 and –12 located on

the housing.

!

NOTICE

A reference variable above or below the

static destruction limit will damage the positioner.

Keep the reference variable within the static

destruction limit of ±32V.

Mounting the cover

Î Mount the cover, briey turn it counter-

clockwise to center it. Turn it clockwise to

rmly close it.

EB 8395 EN 19

Page 20

Operation

6 Operation

The positioner is operated by three pushbut-

tons for menu navigation on the display (see

Fig.5):

Up

:

Conrm

:

Down

:

Î To adapt the air capacity, adjust the vol-

ume restriction (see section 7.3).

6.1 Operating controls

Press or button to select a parameter

code (P0 to P20). Then press

conrm the selected code.

button to

Manual mode Closed-loop control

To save changes to parameters in a non-volatile memory, proceed as follows:

Î After changing parameters, press or

button to change to Code P0 or

Î wait three minutes until the display re-

turns automatically to P0.

Note

− The

icon on the display indicates that

the changed parameter settings have not

yet been saved in the non-volatile memory.

− The selected parameter code remains ac-

tive until you change the setting or exit the

parameter code.

− After changing settings in P2, P4 and P8

parameter codes, the positioner must be

re-initialized.

Fault

Bar graph/

system deviation

Limit contact 1 (min.)

Settings not yet

saved in a nonvolatile memory

Fig.5: Display with all readings

Operation

locked

Fail-safe position

active

Parameter/error code

Unit/sign

Limit contact 2 (max.)

20 EB 8395 EN

Page 21

Cover

Positioner

Operation

Pick-up rod

Pushbuttons

Terminals

Vent plug

Actuator

Fig.6: Type3724 Positioner mounted on Type3379 Pneumatic Piston Actuator

EB 8395 EN 21

Page 22

Operating the positioner

Volume restriction Q

The volume restriction serves to adapt the air

output capacity to the size of the actuator.

Two xed settings are possible (refer to section 7.3).

Reading

Display Meaning

ESC Stop

Err Faults

LOW w too low

MAN Manual mode

MAX Maximum range

RST Reset

INIT Initialization

ON/OFF Activated/deactivated

ZERO Zero calibration

Icons which are assigned to certain codes

and functions are indicated on the display.

The bar elements indicate the system devia-

tion that depends on the sign (+/–) and the

value.

One bar element appears per 1% set point

deviation.

If the positioner has not yet been initialized,

the position of the pick-up rod is indicated in

the operating range of ±10mm.

If the fault indication icon

press

or until ERR is displayed to view

is displayed,

the relevant E0 to E15 error code(s) (see

code list in section 33 on page9.1).

7 Operating the positioner

!

NOTICE

The process is disturbed by the movement of

the actuator stem.

Do not perform the initialization while the

process is running. First isolate the plant by

closing the shut-off valves.

Î Perform pneumatic connections on the

actuator as described in u EB8315.

Î Connect the supply air to signal pressure

connection.

Î Check whether a vent plug or silencer is

screwed into the exhaust port.

Î Connect the 4 to 20mA signal.

à Terminals +11/–12

Î Connect software limit contacts, if appli-

cable.

à Terminals +41/–42:

(limit contact 1, min.)

à Terminals +51/–52:

(limit contact 2, max.)

Note

− LOW on the display indicates that the

reference variable is lower than 3.8mA.

− The positioner is ready for operation with

its default settings for most applications.

22 EB 8395 EN

Page 23

Operating the positioner

Reading after connecting the electrical signal

Code P0 is displayed. The fault indication

icon and S (fail-safe position) appear on the

display when the positioner has not yet been

initialized. The reading indicates the position

of the pick-up rod in the operating range of

±10mm.

Reading when the posi-

tioner has not yet been

initialized

Code P0 and the valve position in % appear

on the display after connecting the electrical

signal to an initialized positioner.

Initialization successfully

completed, positioner runs

in closed-loop operation

Note

The positioner has a function to monitor the

working range. If the pick-up rod moves too

close to the mechanical stops (risk of me-

chanical damage), the positioner vents the

actuator and the valve moves to its fail-safe

position (S displayed together with E8 error

code).

7.1 Adapting the display

The display reading direction can be rotated

by 180°. If the displayed data appear upside down, proceed as follows:

Press

or until Code P1 appears.

Code P1: Reading direction

Press to conrm the selected code.

P1 blinks.

Press or until the display is set in the

desired direction.

Press to conrm display direction.

7.2 Enabling conguration to

change parameters

Before changing parameter settings in an

initialized positioner, conguration must be

enabled rst by selecting Code P19.

LOCK and the key icon in-

dicate that the conguration is locked.

Press or until Code P19 appears.

Press

P19 blinks.

Press until OPEN is displayed.

Touch

to conrm the selected code.

to unlock operation.

EB 8395 EN 23

Page 24

Operating the positioner

If no settings are entered within three minutes, the enabled conguration function becomes invalid.

7.3 Adjusting the volume restriction Q

The volume restriction Q serves to adapt the

air output capacity to the size of the actua-

tor:

− Actuators with a transit time < 0.4s re-

quire a restricted air ow rate.

Setting to MIN

− Actuators with a transit time ≥ 0.4s do

not require the air ow rate to be restricted.

Setting to MAX

Intermediate settings are not permitted.

!

NOTICE

Malfunction due to changing the volume restriction setting!

Re-initialize positioner after changing the

volume restriction setting.

Position of the volume restriction Q

MIN position:

Arrow points toward the positioner

MAX position:

Arrow points away from the

positioner

Fig.7: Setting of the volume restriction

24 EB 8395 EN

Page 25

Operating the positioner

7.4 Entering the opening direction/direction of action

− AIR TO OPEN (ATO) applies to a valve

opening as the signal pressure increases.

− AIR TO CLOSE (ATC) applies to a valve

closing as the signal pressure increases.

The signal pressure is the pneumatic pressure

at the internal output of the positioner applied to the actuator.

Enable conguration (section 7.2).

Default ATO

Press or until Code P2 appears.

Press

Press

sition appears.

Press to conrm setting.

The changed opening direction/direction of

action rst becomes effective after the positioner has been re-initialized.

to conrm selected code. P2 blinks.

or until the required fail-safe po-

Note

7.5 Entering the direction of action

The direction of action (P7) is set to increasing/increasing by default.

For checking purposes: After successfully

completing initialization, the positioner display should read 0% when the valve is

closed and 100% when the valve is open.

If necessary, the direction of action can be

changed either before or after initialization.

The following correlation applies:

Valve CLOSED OPEN

Reading 0% 100%

>> 4mA 20mA

<> 20mA 4mA

>>: increasing/increasing

<>: increasing/decreasing

7.6 Limiting the signal pressure

If the maximum actuator force may cause

damage to the valve, the signal pressure

must be limited. Set Code P9 to ON. This

limits the signal pressure to approx. 2.3bar.

Make sure the conguration is enable (section 7.2) before changing this setting.

EB 8395 EN 25

Page 26

Operating the positioner

7.7 Adjusting the limit contacts

The electronic limit contact can be triggered

by the position of pick-up rod exceeding or

falling below an adjustable switching point.

Limit contact 1, min. (Code P12):

The limit contact is activated when the pickup rod moves below the adjusted switching

value. The limit contact is deactivated when

the pick-up rod moves above the adjusted

switching value by 1% again.

indicates it is active

Î

Limit contact 2 (max., Code P13):Limit contact 2, max. (Code P13):

The limit contact is activated when the pickup rod moves above the adjusted switching

value. The limit contact is deactivated when

the pick-up rod moves below the adjusted

switching value by 1% again.

indicates it is active

Î

Press

contact 1 or P13 for limit contact 2.

Press , P12 or P13 blinks.

Press

ing value in steps of 0.5% and press

conrm the value.

The switching values for P12 and P13 must

be adjusted at least 5% from one another. It

is not possible to enter switching values that

are less than 5% from one another.

or to select Code P12 for limit

or

to adjust the required switch-

Note

to

7.8 Setting other parameters

The following table lists all the parameter

codes and their default settings. If you want

to change the default setting of a parameter,

proceed as described previously.

More details concerning the parameter

codes can be found in section 11.2.

Parameter codes [Default setting]

Codes marked with * indicate that the positioner needs to be re-initialized afterwards

P0 Status reading

P1 Reading direction

P2* ATO/ATC [ATO]

P4* Nominal range [MAX]

P5 Characteristic [0]

P6 Reference variable [4 to 20mA]

P7 w/x direction of action [>>]

P8* Gain Kp [50]

P9 Pressure limitation 2.3bar [OFF]

P10 Set point cutoff decrease (end

position w <) [ON]

P11 Set point cutoff increase (end

position w >) [OFF]

P12 Limit A1, min. [2%]

P13 Limit A2, max. [98%]

P14 Display of reference variable w

P15 INIT Start initialization

P16 ZERO Start zero calibration

P17 MAN Manual mode

P18 RST Reset

P19 Enable conguration

P20 Firmware version

26 EB 8395 EN

Page 27

7.9 Initialization

%

During initialization the positioner adapts itself optimally to the friction conditions and

the signal pressure required by the control

valve.

!

NOTICE

The process is disturbed by the movement of

the actuator stem.

Do not perform the initialization while the

process is running. First isolate the plant by

closing the shut-off valves.

The type and extent of self-adaptation depends on the preset parameters.

MAX is the default setting for the nominal

range (Code P4).

During the initialization process, the posi-

tioner determines the travel range of the

valve (from the CLOSED position to the opposite end position).

Alternatively, a different travel can be select-

ed in Code P4 (see code list in section11.2).

Note

The travel set in Code P4 is only limited

during initialization. However, it might be

exceeded in closed-loop control when the

control signal is higher than 20mA.

Start initialization by activating Code P15 as

follows:

Operating the positioner

Press or to select Code P15.

Press

and hold for six seconds. 6-5-4-3-

2-1- is counted down on the display.

Initialization starts. INIT blinks on the display!

Note

The time required for the initialization procedure depends on the actuator transit time

and can take a few minutes.

Initialization successfully

completed, positioner runs

in closed-loop operation

After a successful initialization, the positioner changes to closed-loop operation indicated by the

closed-loop operation icon and

control position in % predetermined by the

reference variable on the display. Congura-

tion is locked.

A malfunction leads to the process being in-

terrupted and the positioner moving to the

fail-safe position. The fault indication icon is

displayed (see section9).

EB 8395 EN 27

Page 28

Operating the positioner

Canceling initialization

The initialization can be canceled by pressing .

− ESC blinks on the display.

− Press

This code must be conrmed by touching

Otherwise, the code remains active.

Initial state 1:

Positioner has not been initialized

The positioner goes to the fail-safe position

after the initialization process has been canceled.

Initial state 2:

Positioner is initialized

On canceling a new initialization process,

the positioner returns to closed-loop opera-

tion. The settings of the previous initialization

are used.

A new initialization can be started directly

afterwards.

to conrm.

Note

7.10 Zero calibration

In case of inconsistencies in the closed posi-

tion of the valve (e.g. with soft-seated plugs),

it might be necessary to recalibrate zero. Enable conguration as described in section7.2.

Start the zero calibration by activating Code

P16 as follows:

.

Press or until Code P16 appears.

Press

2-1- is counted down on the display.

Zero calibration starts, the display blinks!

The positioner moves the control valve to the

CLOSED position and recalibrates the internal electric zero point.

When the zero calibration has been success-

fully completed, the positioner returns to

closed-loop operation (display with status indication).

and hold for six seconds. 6-5-4-3-

28 EB 8395 EN

Page 29

Operating the positioner

Canceling zero calibration

The zero calibration can be canceled by

pressing .

− ESC blinks on the display.

− Press

This code must be conrmed by touching

Otherwise, the code remains active.

The positioner returns to closed-loop opera-

tion without performing a zero calibration.

A new zero calibration can be started direct-

ly afterwards.

to conrm.

Note

7.11 Manual mode

The valve position can be moved as follows

using the Manual mode function:

Enable conguration as described in section

7.2.

Press

Press

2-1- is counted down on the display.

.

P17 blinks.

The manual set point is indicated on the dis-

play of an initialized positioner.

If the positioner has not yet been initialized,

the position of the pick-up rod is indicated in

the operating range of ±10mm.

Press

point.

Initialized positioner

The manual mode starts using the last set

point used in closed-loop operation, ensuring a bumpless changeover.

The bar elements on the display indicate the

system deviation between the manual set

point and set point used for closed-loop con-

trol while manually moving the valve in Code

P17.

The manual set point is adjusted in steps of

0.1 %. You can move the valve controlled

within its range.

or until Code P17 appears.

and hold for six seconds. 6-5-4-3-

or to change the manual set

EB 8395 EN 29

Page 30

Operating the positioner

Positioner that has not been initialized

Press

valve manually.

The valve is only moved in one direction un-

controlled. The bar elements on the display

indicate the change in direction.

Press

The Manual mode function can only be exited as described or by interrupting the electrical supply (cold start). The positioner does

not automatically exit this function and re-

turn to the display showing the status indication.

or for a long time to move the

to deactivate manual mode.

Note

7.12 Reset

A reset causes an initialization to be undone

and all parameters settings are reset to the

default settings (see code list in section11.2).

Enable conguration (section 7.2).

Press

Press and hold for six seconds. 6-5-4-3-

2-1- is counted down on the display.

RST blinks while is pressed. As soon as

the key is released, the reset process is completed and the display returns to status indication (P0).

The

a reset since the positioner needs to be

re-initialized. The error code E2 is also acti-

vated (see section9.1).

or until Code P18 appears.

Note

fault indication icon is displayed after

30 EB 8395 EN

Page 31

Servicing

8 Servicing

Note

The positioner was checked by SAMSON

before it left the factory.

− The product warranty becomes void if

service or repair work not described in

these instructions is performed without

prior agreement by SAMSON's After-sales

Service department.

− Only use original spare parts by

SAMSON, which comply with the original

specications.

The Type3724 Positioner requires no maintenance.

Î Observe the maintenance instructions of

any upstream supply air pressure reducing stations.

8.1 Preparation for return shipment

Defective positioners can be returned to

SAMSON for repair.

Proceed as follows to return devices to

SAMSON:

1. Put the control valve out of operation.

See associated valve documentation.

2. Fill in the Declaration on Contamination.

The declaration form can be downloaded from our website at uSERVICE &

SUPPORT > After-sales Service.

3. Remove the positioner (see section10).

4. Send the positioner to your nearest

SAMSON subsidiary. SAMSON

subsidiaries are listed on our website at

uwww.samson.de > Contact.

8.2 Firmware update

Contact your local SAMSON engineering

and sales ofce or subsidiary (www.samson.

de > About SAMSON > Sales ofces) to request a rmware update.

Required specications

Please submit the following details on requesting a rmware update:

− Type

− Serial number

− Conguration ID

− Current rmware version

− Required rmware version

EB 8395 EN 31

Page 32

Malfunction

9 Malfunction

In case of a fault, the fault indication icon

is displayed.

If the fault indication icon appears after a

parameter code setting has been changed,

this indicates that this setting does not match

the values determined during initialization.

See Code E1 (see code list in section9.1).

Press buttons past Code P0 or P20. The re-

spective error code E0 to E15 together with

ERR appear on the display.

Refer to the code list for the cause of the errors and the recommended action.

Example:

If, for instance, a travel has been entered in

Code P4 (nominal range) which is larger

than the maximum valve travel possible, the

initialization process would be interrupted

(E2 error code) because the rated travel

would not have been reached (E6 error

code). The valve moves to the fail-safe position (S indicated on the display).

Reset error codes

The E0 and E8 error codes can be reset as

follows:

Press or to select the error code.

Press to conrm the error code. ESC is

displayed. E8 blinks.

Press or until RST appears.

Press to reset the error.

mm

Display of the fault indication

The reset procedure can be canceled by

pressing when ESC appears.

The nominal range (Code P4) must be

changed and the positioner re-initialized to

remedy this problem.

32 EB 8395 EN

Page 33

9.1 Error codes

In case of a fault, the fault indication icon is displayed.

The errors listed in the following table are assigned to error classes:

Error class 1: No operation possible

Error class 2: Manual operation only possible

Error class 3: Manual operation and closed-loop control possible

Code Description

E0 Zero error

(operational error)

Recommended action Check valve and positioner attachment.

E1 Displayed and INIT val-

ues are not identical

(operational error)

Recommended action Reset parameters or perform initialization.

E2 Positioner has not been

initialized

Recommended action Set parameters and initialize the positioner over Code P15.

E3 K

E4 Transit time too short

setting

P

(initialization error)

Recommended action Check the volume restriction setting as described in section

(initialization error)

Recommended action Check the volume restriction setting as described in section

Only with tight-closing function P10 (set point cutoff

decrease set to ON).

The zero point has shifted by more than 5% compared to

initialization. The error may arise when the valve seat trim

is worn.

If OK, perform a zero calibration over Code P16 (see

section 7.10).

Error code can be reset (see section 9).

Adjusted and displayed valves are not identical to the INIT

values as the parameters were changed after initialization.

Malfunction or parameter change requiring the positioner

to be re-initialized.

Positioner hunts.

Volume restriction set incorrectly, too much gain.

7.3. Limit gain K

The transit times of the actuator determined during initialization are so short (below 0.4 second) that optimal positioner

tuning is not possible.

7.3. Re-initialize the positioner.

in Code P8. Re-initialize the positioner.

P

Malfunction

Class

3

3

2

2

2

EB 8395 EN 33

Page 34

Malfunction

E5 Standstill detection is

not possible

(initialization error)

Recommended action Check supply air and positioner mounting.

E6 Travel is not achieved

during initialization

(initialization error)

Recommended action Check supply air, positioner mounting and setting.

E7 Actuator does not move

(initialization error)

Recommended action Check supply air, positioner mounting and mA input signal.

E8 x > range Pick-up rod in range of the end stops

Recommended action Check positioner mounting and re-initialize the positioner.

E9

to

Device error (internal) Return positioner to SAMSON AG for repair. 1/3

E15

Supply pressure varies. Mounting incorrect.

Re-initialize the positioner.

Supply pressure is too low, actuator leaks, incorrect travel

adjusted or pressure limit function activated.

Re-initialize the positioner.

No supply air, mounting blocked.

Re-initialize the positioner.

Error code can be reset (see section 9).

2

2

2

1

9.2 Emergency action

Upon failure of the air supply or electric signal, the positioner vents the actuator, causing the

valve to move to the fail-safe position determined by the actuator.

The plant operator is responsible for emergency action to be taken in the plant.

Tip

Emergency action in the event of valve failure is described in the associated valve documentation.

34 EB 8395 EN

Page 35

Decommissioning and removal

10 Decommissioning and

removal

!

NOTICE

The process is disturbed by interrupting

closed-loop control.

Do not mount or service the positioner while

the process is running and only after isolat-

ing the plant by closing the shut-off valves.

10.1 Decommissioning

To decommission the positioner before removing it, proceed as follows:

1. Disconnect and lock the air supply and

signal pressure.

2. Open the positioner cover and discon-

nect the wires for the control signal.

10.2 Removing the positioner

1. Disconnect the wires for the control sig-

nal from the positioner.

2. Disconnect the lines for air supply and

signal pressure.

3. Disassemble as described in the associat-

ed actuator or valve documentation.

10.3 Disposal

Î Observe local, national and internation-

al refuse regulations.

Î Do not dispose of components, lubricants

and hazardous substances together with

your other household waste.

EB 8395 EN 35

Page 36

Appendix

11 Appendix

11.1 After-sales service

Contact SAMSON's After-sales Service department for support concerning service or

repair work or when malfunctions or defects

arise.

E-mail address

You can reach the After-sales Service Department at aftersalesservice@samson.

Addresses of SAMSONAG and its subsidiaries

The addresses of SAMSON AG, its subsidiaries, representatives and service facilities

worldwide can be found on our website

(www.samson.de) or in all SAMSON product catalogs.

Required specications

Please submit the following details:

− Type designation

− Conguration ID

− Serial number

− Firmware version

36 EB 8395 EN

Page 37

11.2 Code list

Appendix

Code Display, values

[default setting]

Note:

Codes marked by an asterisk (*) indicate that the positioner needs to be re-initialized

afterwards

P0 Status reading with

basic information

P1 Reading direction The reading direction of the display is turned by 180°.

P2* ATO/ATC

[ATO]

P4* Nominal range

[MAX]

P5 Characteristic

0 to 2

[0]

P6 Reference variable

[4 to 20mA]

SRLO/SRHI

P7 w/x

[>>]/<>

P8* Gain K

P9 Pressure limitation

P10 Set point cutoff

P

30/[50]

ON/[OFF]

decrease (end

position w <)

[ON]/OFF

The reading indicates the valve position in % when the positioner is

initialized.

to display the actual valve position when the positioner is

Press

initialized.

Parameter to adapt the positioner to how the control valve functions:

ATO – Air to open (valve CLOSED in fail-safe position)

ATC: Air to close (valve OPEN in fail-safe position)

The travel is adjustable from 4 to 16mm in steps of 0.5mm.

MAX: Maximum possible travel

Three different characteristics can be selected to dene the relationship between the input variable and the position of the actuator

stem:

0 à Linear

1 à Equal percentage

2 à Reverse equal percentage

For split-range operation:

SRLO: low range 4 to 11.9 mA

SRHI: high range 12.1 to 20mA

Direction of action of the reference variable w to the travel/rotational angle x (increasing/increasing or increasing/decreasing)

On initializing the positioner, the gain is set to the selected value.

If the positioner hunts, the Kp value can be reduced.

The signal pressure can take on the same pressure as the supply air

at the maximum [OFF] or, in the case that the maximum actuator

force can damage the valve, the pressure is limited to approx.

2.3bar.

Lower tight-closing function:

If w reaches up to 1% towards the nal value that causes the valve

to close, the actuator is immediately completely vented (with ATO air to open) or lled with air (with ATC - air to close).

Description

EB 8395 EN 37

Page 38

Appendix

Code Display, values

Description

[default setting]

P11 Set point cutoff

increase (end position

w >)

ON/[OFF]

P12 Limit A1, min.

[2%]

Upper tight-closing function:

If w reaches up to 99% towards the nal value that causes the valve

to open, the actuator is immediately completely lled with air (with

ATO - air to open) or vented (with ATC - air to close).

The lower switching point can be adjusted in steps of 0.5%.

Note:

Keep a distance of 5 % to the switching value adjusted in

P13.

P13 Limit A2, max.

[98%]

The upper switching point can be adjusted in steps of 0.5%.

Note:

Keep a distance of 5 % to the switching value adjusted in

P12.

P14 Info w Initialized Indicates the internally adjusted set point in the positioner (adjusted

set point in 0 to 100% according to the settings in P6 and P7).

to display external set point (applied set point in 0 to

Press

100% according to the 4-20mA signal).

Not initialized Displays external set point in 0 to 100% according to the 4-20mA

signal.

P15 Start initialization

Press button to cancel the initialization process. As a result, the

valve moves to the fail-safe position.

After a power supply failure during initialization, the positioner

starts with the values of the last initialization (if available).

P16 Start zero calibration

The zero calibration process can be interrupted by pressing

. The

control valve returns to closed-loop operation.

Note: A zero calibration cannot be started when E1 error code ex-

ists.

After a power supply failure during zero calibration, the positioner

starts with the settings from the last zero calibration.

P17 Manual mode

1)

Press or to enter the set point.

P18 Reset Parameters are reset to their default setting.

The positioner can only return to closed-loop operation after it has

been re-initialized.

P19 Enable

conguration

[LOCK]/OPEN

P20 Firmware version

Enable conguration to change parameter settings.

This function is automatically canceled when none of the keys are

touched within three minutes.

Installed rmware version is displayed. Press

to display the last

four digits of the serial number.

1)

Also not available when the positioner has not been initialized

38 EB 8395 EN

Page 39

EB 8395 EN 39

Page 40

EB 8395 EN

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

samson@samson.de · www.samson.de

2018-10-10 · English

Loading...

Loading...