Page 1

Pneumatic Control Valve

Type 3510-1 and Type 3510-7

Type 3510-7 with 120 cm2 actuator

and integrated positioner

Fig. 1 ⋅ Pneumatic control valves

Type 3510-1 with 60 cm

Mounting and

Operating Instructions

EB 8091 EN

Edition July 2002

2

actuator

Type 3510-1 with 120 cm

2

actuator

Page 2

Contents

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . . . . 4

2 Assembling and adjusting valve and actuator . . . . . . . . . . . . . . . . 6

2.1 Signal pressure connection . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Assembly and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Operation – Reversing the operating direction . . . . . . . . . . . . . . . . 8

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Replacing the stuffing box packing . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Replacing seat and plug . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Customer inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Note!

Non-electrical control valves which do not have a valve body lined with an insulating

material coating do not have their own potential ignition source according to the risk assess-

ment in the rare incident of an operating fault, corresponding to EN 13463-1: 2001 paragraph 5.2, and therefore do not fall within the scope of the European Directive 94/9/EC.

2

EB 8091 EN

Page 3

Safety instructions

The device may only be assembled, started up or operated by trained and ex-

perienced personnel familiar with the product.

According to these mounting and operating instructions, trained personnel is

referred to as individuals who are able to judge the work they are assigned to

and recognize possible dangers due to their specialized training, their knowledge and experience, as well as their knowledge of the applicable standards.

Any hazards which could be caused in the control valve by the process me-

dium, the operating pressure, the signal pressure or the moving parts are to

be prevented by means of the appropriate measures.

In addition, it is necessary to make sure that the control valve is only used in

areas where the operating pressure and temperatures do not exceed the operating values which are based on the valve sizing data submitted in the order.

Proper shipping and appropriate storage are assumed.

EB 8091 EN

3

Page 4

Design and principle of operation

1 Design and principle of operation

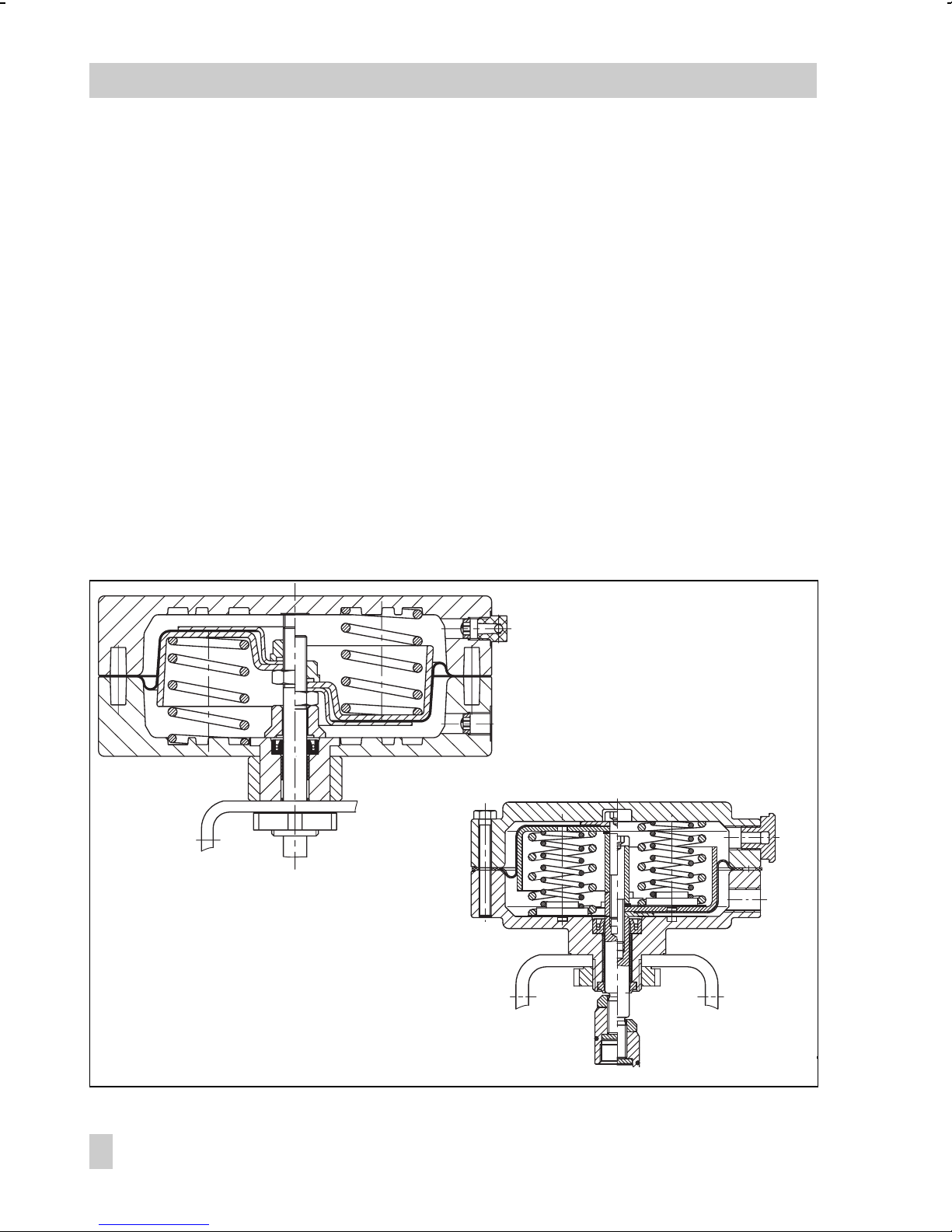

The pneumatic control valve consists of a

Type 3510 Micro-flow Valve (globe or

angle body style) and either a Type 3271-5

Pneumatic Actuator (Type 3510-1 Control

Valve) or a Type 3277-5 Pneumatic Actuator (Type 3510-7 Control Valve).

The modular design enables the actuators to

be exchanged, and the standard valve version to be enhanced to a version incorporating either a bellows seal or an insulating

section.

The process medium flows through the valve

in the direction indicated by the arrow. The

position of the valve plug (3) determines the

cross-sectional area of flow between the

valve seat (2) and the plug.

A change in the signal pressure acting on

the diaphragm of the actuator causes the

valve plug to move correspondingly. The

plug stem (6) is connected to the actuator

stem (8.1) via the stem connector (7) and

sealed with an adjustable stuffing box with

packing that contains PTFE sealing rings.

Fail-safe action:

Depending on the arrangement of the

springs (8.3) in the actuator, the control

valve has two different fail-safe actions:

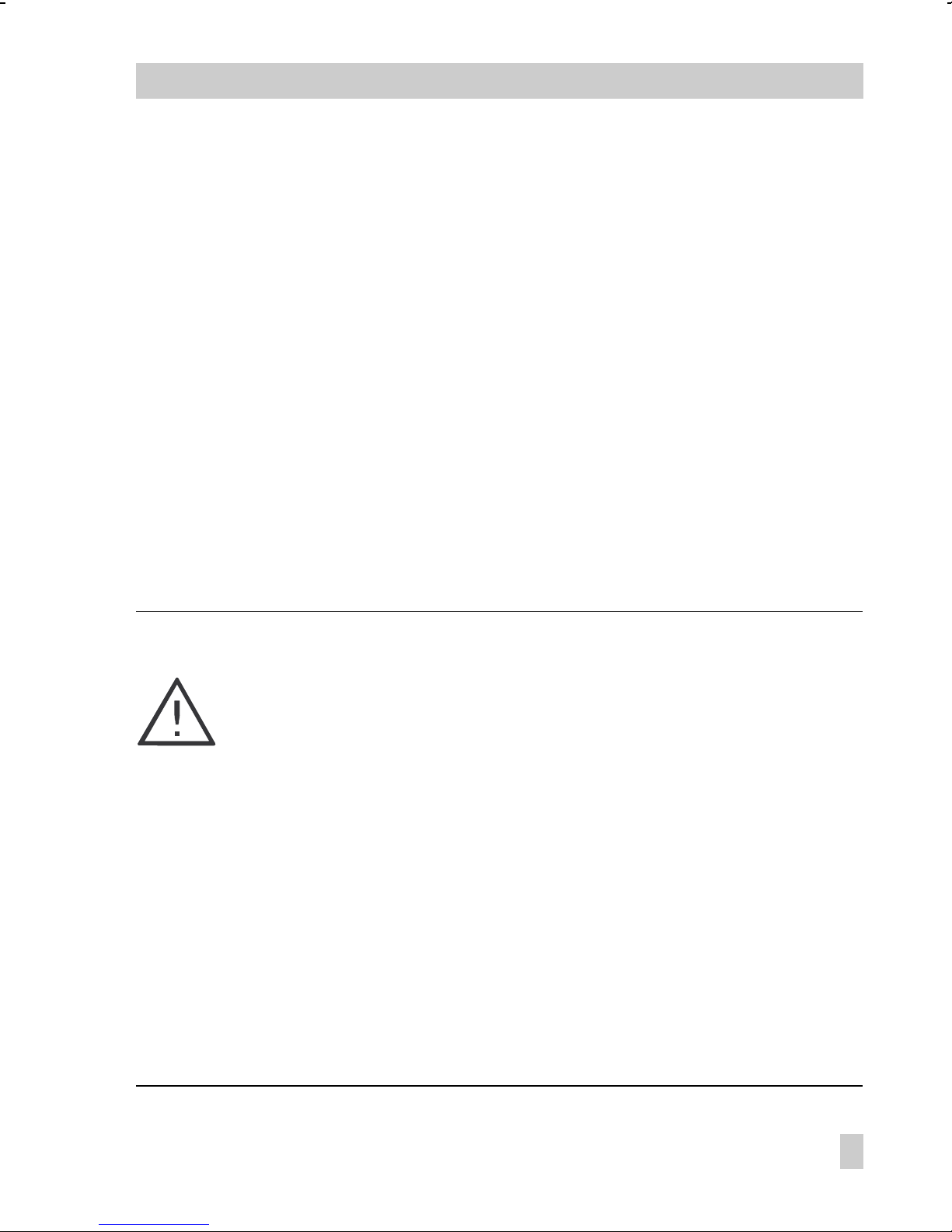

Actuator stem

retracts

Type 3271-5 Actuator with 120 cm

Fig. 2 ⋅ Type 3271-5 Actuators

4

EB 8091 EN

2

Actuator stem

extends

Type 3271-55 with 60 cm

Actuator stem

retracts

2

Actuator stem

extends

Page 5

Design and principle of operation

Actuator stem extends:

When the signal pressure is reduced or in

case of a supply air failure, the springs

move the actuator stem downwards and

close the valve. The valve is opened against

the spring force, when the signal pressure

increases.

1Body

1.1 Screw

2Seat trim

2.1 Seat

2.2 Plug

2.3 Sealing ring

2.4 Anti-rotation device with

trim identification number

3Nuts

4Packing rings

4.1 Packing washer

5 Valve bonnet

5.1 Threaded bushing

5.2 Slotted round nut

6Yoke

6.1 Travel indicator scale

7 Stem connector

7.1 Stem connector nut

7.2 Stem connector sleeve

7.3 Lock nut

8Actuator

8.1 Actuator stem

8.2 Slotted round nut

8.3 Spring

8.4 Diaphragm

14 Connecting or switchover plate

14.1 Signal pressure route

"Actuator stem extends"

14.2 Signal pressure route

"Actuator stem retracts"

8.4

8.3

8

8.1

8.2

7.3

7.1

7

7.2

5.1

5.2

5

Actuator stem retracts:

When the signal pressure is reduced or in

case of a supply air failure, the springs

move the actuator stem upwards and open

the valve. The valve is closed against the

spring force, when the signal pressure increases.

14

14.1

14.2

6

6.1

3

4.1

4

1.1

2.4

2.3

2.2

2.1

1

2

Fig. 3 ⋅ Sectional drawing of micro-flow control valve with Type 3277-7 Actuator

EB 8091 EN

5

Page 6

Assembling and adjusting valve and actuator

2 Assembling and adjusting valve

and actuator

If control valve and actuator have not been

pre-assembled by the manufacturer, observe the different signal pressure connections of the actuators on assembly.

2.1 Signal pressure connection

Type 3510-1 Control Valve

with Type 3271-5 Actuator

The signal pressure connection for fail-

safe action "Actuator stem extends" is located at the bottom of the diaphragm

case. For "Actuator stem retracts", the

connection is to be found at the top of

the diaphragm case.

Type 3510-7 Control Valve

with Type 3277-5 Actuator

Actuator with positioner:

The signal pressure is transferred to the diaphragm case via bores at the left and right

side of the yoke and via a switchover plate

(accessories). The fail-safe action "Actuator

stem extends" or "Actuator stem retracts"

determines how the switchover plate needs

to be aligned to the mark.

Turn the switchover plate, so that the ap-

propriate symbol for the fail-safe action

is aligned to the mark.

Whether the actuator is attached to the

left or right depends on the operating direction (>>) or (<>) of the positioner.

Actuator without positioner:

Instead of a switchover plate, a connecting

plate (accessories) is required if the actua-

tor is used without positioner

Here, the signal pressure is transferred to

the diaphragm case directly via the signal

pressure connection of the connecting plate.

Turn the connecting plate, so that the ap-

propriate symbol for the fail-safe action

"Actuator stem extends" or "Actuator

stem retracts" is aligned to the mark.

Make absolutely sure that the gasket of

the connecting plate is inserted correctly.

The connecting plate provides bores for

NPT and G threads. Seal the unused connection with a rubber gasket and a

square plug.

Accessories:

Switchover plate and connecting plate need

to be ordered as accessories.

Note that actuators with device modification

index 01, e.g. 3277-531xxx20.01 (old =

.00) must be equipped with new plates.

Old and new plates are not interchangeable.

Switchover plate new Order no. 1400-6822

old Order no. 1400-6819

Connecting platenew Order no. 1400-6823

old G thread Order no. 1400-6820

old NPT thread Order no. 1400-6821

6

EB 8091 EN

Page 7

Assembling and adjusting valve and actuator

Note!

When used in connection with the microflow valve, the pneumatic actuators with failsafe action "Actuator stem retracts" are

limited to the max. permissible supply pressures [bar] listed in the table.

For actuators with fail-safe action "Actuator

stem extends", the max. supply pressure is

limited to 4 bar.

Valves with positioners are to be adjusted

to these max. perm. supply pressures.

Signal pressure

range

0.2 to 1 0.4 to 0.8 2.5

0.4 to 2.0 0.8 to 1.6 3.3

1.4 to 2.3 1.7 to 2.1 3.8

2.1 to 3.3 2.4 to 3.0 4.7

Adjusted to Max. perm.

pressure

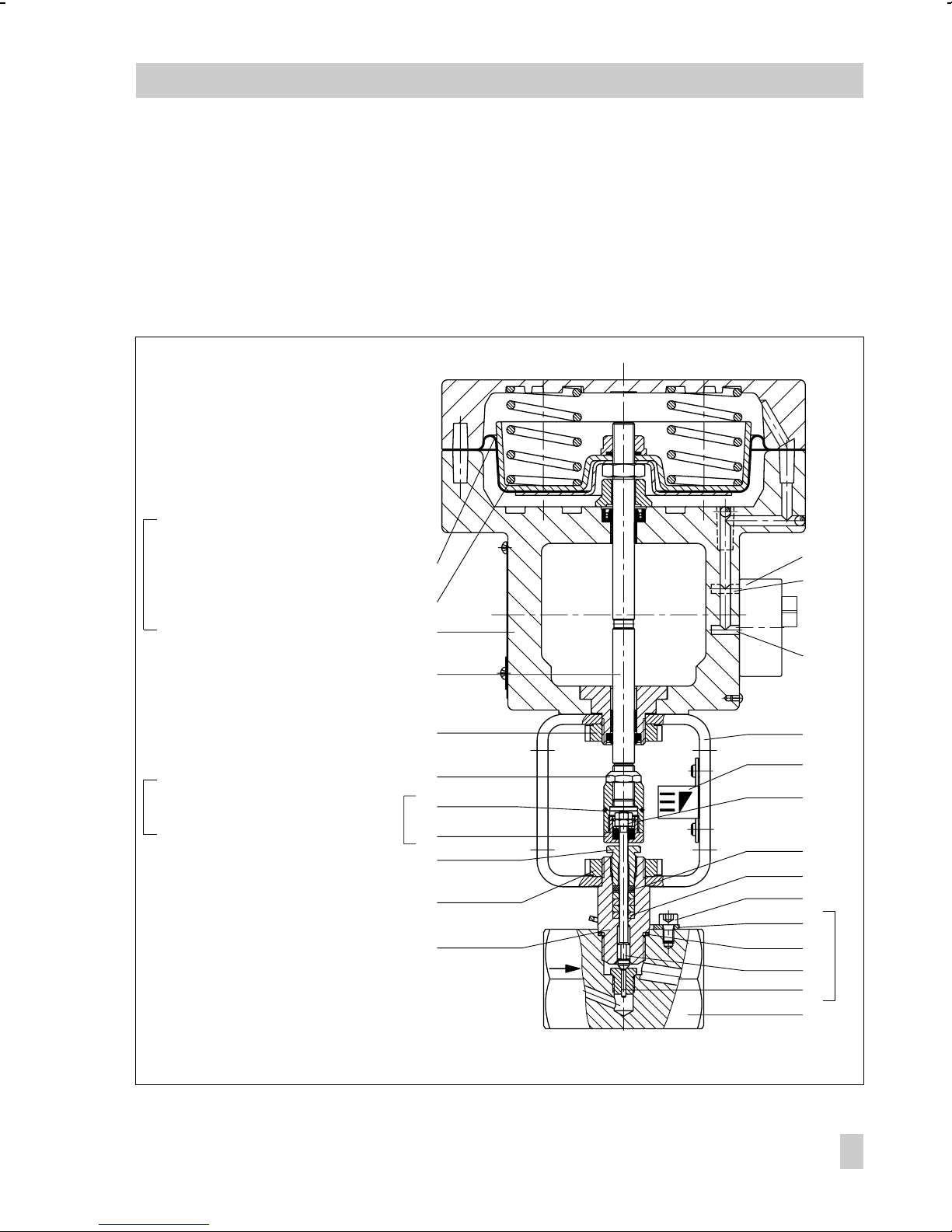

2.2 Assembly and adjustment

For actuators with a switchover plate for attachment of a positioner, a suitable adapter

needs to be connected to the bores at the

side. Alternatively, the connecting plate

(Fig. 4, right) can be used.

1. On the actuator stem, loosely screw

both stem connector nut (7.1) and lock

nut (7.3) all the way up (Fig. 3).

2. Slide slotted round nut (8.2 ) over both

coupling nut and lock nut.

3. Place the actuator on the yoke (7) and

fasten with slotted round nut (8.2). For

fail-safe action "Actuator stem extends", apply approx. 50 % of the signal pressure range (see nameplate) to

the signal pressure connection of the actuator using a pressure regulator, caus-

Switchover plate

Signal

pressure

Actuator stem extends

Left Attachment Right

Fig. 4 ⋅ Signal pressure connections

Signal pressure

Signal

pressure

Symbol

Mark

Actuator stem retracts

Left Attachment Right

Connecting plate

Actuator stem

extends retracts

EB 8091 EN

7

Page 8

Installation

ing the actuator stem to retract far

enough to screw together stem connector nut (7.1) and stem connector sleeve

(7.2).

4. Screw together stem connector sleeve

(7.2) and stem connector nut (7.1) as

tightly as possible.

5. Apply lower range value of the signal

pressure range to the signal pressure

connection.

For a signal pressure range (bench

range) of, for example, 0.4 to 0.8 bar

and an actuator with fail-safe action

"Actuator stem extends", the lower signal pressure range value is 0.4 bar; for

"Actuator stem retracts" it is 0.8 bar.

6. Rotate stem connector (7) on actuator

stem until plug stem moves from the

closed position at the corresponding initial value. To do so, change signal

pressure each time using the pressure

regulator, and return to the initial lower

range value.

7. Fasten lock nut (7.3) to secure the stem

connector.

3Installation

3.1 Mounting position

Any desired mounting position is possible.

Note! Make sure the valve is installed free

of stress. If necessary, support the pipes

near the connections.

Flush pipes thoroughly before installing the

valve.

For valve versions with bellows seal or insulating section, which are installed in pipes

to be insulated, do not insulate the bellows

intermediate piece or insulating section (9).

Test connection

The version with metal bellows seal can be

equipped with a test connection (16) with

G 1/8 thread at the bellows seal. This connection is used to check the tightness of the

bellows.

It is recommended to install a suitable leakage indicator, in particular when explosive

and hazardous media are used.

8. Align travel indicator scale (6.1) to the

black ring on the stem connector.

8

EB 8091 EN

4 Operation - Reversing the operating direction

If it becomes necessary to reverse the failsafe action of the actuator from "Actuator

stem extends" to "Actuator stem retracts" or

vice versa, refer to the mounting and operating instructions of the actuator for details.

EB 8310 EN for Type 3271-5,

EB 8311 EN for Type 3277-5.

Page 9

5 Troubleshooting

If the valve leaks, the packing may be defective or, in the bellows version, the metal bellows may be defective.

Tight shut-off of the valve can also be impaired by impurities or other foreign particles between seat and plug, or by damaged seat joints.

Remove the affected components, clean

them thoroughly and, if necessary, replace

them.

Troubleshooting

Caution!

Make sure to relieve the pressure

from the pressurized part of the

plant and, depending on the medium, drain it completely before performing maintenance. For high temperatures, allow the plant to cool

down to ambient temperature.

Disconnect and lshut off the supply

air as well as the control signals to

prevent against danger posed by

moving parts at the valve.

As valves are not free of dead cavities, remember that there might still

be residual media in the valve. This

particularly applies for valve version

with bellows seal or insulating section.

Note!

The seat and special tools required for installation as well as the appropriate tightening torques are to be found in the SAM-

SON Special tools brochure WA 029.

A complete tool kit for the Type 3510

Micro-flow Valve can be ordered separately

(order no. 1280-3050).

It is recommended to remove the

valve from the pipeline for maintenance.

EB 8091 EN

9

Page 10

Troubleshooting

5.1 Replacing the stuffing box

packing

If leakage occurs at the stuffing box, the

stuffing box packing must be replaced as

described below.

1. For actuators with "Actuator stem extends", apply approx. 50 % of the signal pressure range (see nameplate) to

the actuator, causing the actuator stem

to retract.

Place socket wrench (width across flats

(SW) 17) on stem connector nut (7.1)

and unscrew stem connector sleeve

(7.2) with a second SW 17 wrench.

2. Unscrew the bottom slotted round nut

(5.2). Remove actuator (8) including

yoke (6) from the valve, turning the

slotted round nut (5.2), so that a groove

points towards the travel indicator scale

(6.1).

3. Take out the nuts (3). Remove stem connector sleeve (7.2) from the plug stem.

4. Remove the screw (1.1) and the anti-rotation device (2.4). Unscrew the valve

bonnet (5) from the valve body.

5. Unscrew threaded bushing (5.1). Pull

the plug stem, together with the plug

(2.2), out of the valve bonnet (5).

For versions with bellows intermediate

piece or insulating section, separate

valve bonnet and bellows intermediate

piece/insulating section (9). The plug

stem extension (10.1, Fig. 6) remains

fixed in the extension bonnet.

6. Remove packing washers (4.1) and

packing rings (4) from the packing

chamber using a suitable tool. Make

sure not to damage the sealing edges.

Clean packing chamber thoroughly.

Assembly:

7. Insert new sealing rings. Start with a

white ring, followed by two black rings

and another white one. Make sure that

the butt joints of successive rings are

not positioned on top of each other.

8. Insert packing washer(s) (4.1). Tighten

threaded bushing (5.1) manually.

9. Slide plug stem with plug (2.2) into the

valve bonnet as far as it will go. Tighten

threaded bushing (5.1), observing a

minimum gap of 1.3 mm between valve

bonnet and threaded bushing. If this is

not the case, add required number of

packing washers (4.1) (min. 1, max. 3

washers).

10. Insert new sealing ring (2.3) into the

body. Screw together valve bonnet and

body.

11. Place anti-rotation device (2.4) on the

valve bonnet and tighten it, so that the

fastening screw (1.1) is seated in the oblong hole.

12. Push stem connector sleeve (7.2) onto

the plug stem with the thread facing upwards. Screw on nuts (3).

Lock nuts against each other, so that approx. 1 mm of the thread is still visible.

13. Place actuator including yoke onto

valve bonnet. Tighten with slotted round

nut (5.2).

For actuators with "Actuator stem extends", apply approx. 50 % of the signal pressure range (see nameplate) to

the actuator using a pressure regulator,

causing the actuator stem to retract far

10

EB 8091 EN

Page 11

Troubleshooting

enough to screw together stem connector nut (7.1) and stem connector sleeve

(7.2).

14. Screw together stem connector sleeve

(7.2) and stem connector nut (7.1) as

tightly as possible. Tighten lock nut

(7.3).

8.1

7.3

7.1

7

7.2

15. Check adjustment according to instructions given in section 2.2, items 5 to 8.

6

6.1

3

5.1

1Body

1.1 Screw

2Seat trim

2.1 Seat

2.2 Plug

2.3 Sealing ring

2.4 Anti-rotation device

3Nuts

4Packing rings

4.1 Packing washer

5 Valve bonnet

5.1 Threaded bushing

5.2 Slotted round nut

6Yoke

6.1 Travel indicator scale

7 Stem connector

7.1 Stem connector nut

7.2 Stem connector sleeve

7.3 Lock nut

8.1 Actuator stem

Fig. 5 ⋅ Replacing the stuffing box packing

5.2

5

4.1

4

1.1

2.4

2.3

2

2.2

2.1

1

EB 8091 EN

11

Page 12

Troubleshooting

5.2 Replacing seat and plug

Standard version:

For assembly/disassembly, proceed as

described in section 5.1. Additionally,

unscrew the seat (2.1) using a socket

wrench.

Important!

If, on replacing the seat trim (parts 2.1 to

2.4), you wish to install a trim with a different K

must also be replaced with the one included

in the new trim. On the anti-rotation device

as well as on the seat and plug themselves,

there is an identification number indicating

which trim parts belong together as well as

the material, K

Never combine seats and plugs belonging

to different trims!

The seat thread imposes restrictions on replacing trims. Only the K

ated seat threads can be exchanged (see

table below).

value, the old anti-rotation device

V

value and characteristic.

VS

values of associ-

V

Versions with bellows seal or insulating

section:

Unscrew valve bonnet (5).

In the insulating section version, remove

insulating section (9) from the valve

body, so that the plug stem including

plug (2.2) can be unscrewed from the

plug stem extension (10.1).

In the metal bellows version, unscrew bel-

lows seal (10) together with plug stem extension (10.1) and plug (2.2) from the

bellows intermediate piece (9) using a

bellows nut wrench.

Unscrew plug stem including plug from

the plug stem extension and remove bellows intermediate piece from valve body.

Before reassembling, replace sealing rings

(9.1 and 9.2). In addition, secure bellows intermediate piece (9) or insulating section (9)

as well as the valve bonnet using additional

anti-rotation devices (11 and 12).

The upper anti-rotation devices (2.4 and

12) are secured by the disk (15).

Table seat thread

Seat thread M10 x 1 M16 x 1

value 0.0001 to 0.4 0.63 to 1.6

K

VS

PN max. 400 100

12

EB 8091 EN

Page 13

2.4

15

12

9.1

13

1.1 Screw

2.2 Plug

2.4 Anti-rotation device with

trim identification number

5 Valve bonnet

9 Bellows intermediate piece/insulating section

9.1 Sealing ring

9.2 Sealing ring

10 Bellows seal

10.1 Plug stem extension

(in version with insulating section without

metal bellows)

11 Anti-rotation device

12 Anti-rotation device

13 Screw

15 Disk

16 Test connection (optional)

16

9.2

10

10.1

9

1.1

11

2.2

Fig. 6 ⋅ Metal bellows version

EB 8091 EN

13

Page 14

Customer inquiries

6 Customer inquiries

Please include the following details in your

inquiry:

Order number

Type, product and identification number

Valve style: globe or angle valve

Nominal size and pressure of the valve,

additionally K

tion number of the attached trim

Pressure, density, viscosity and tempera-

ture of the flow medium

Flow rate in m3/h

Direction of flow through the valve

Bench range (signal pressure range, e.g.

0.2 to 1 bar) of the attached actuator

Has a strainer been installed?

Installation drawing

value and the identifica-

VS

For dimensions and weights of the valve

versions, refer to Data Sheet T 8091 EN.

14

EB 8091 EN

Page 15

EB 8091 EN

15

Page 16

SAMSON AG ⋅ MESS- UND REGELTECHNIK

Weismüllerstraße 3 ⋅ 60314 Frankfurt am Main ⋅ Germany

Phone: +49 69 4009-0 ⋅ Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 8091 EN

S/Z 2002-07

Loading...

Loading...