Page 1

Series 430

Pneumatic Indicating Controllers

Type 3430

Type 3432 Controller Station

– with Type 3435 Transmitter Module for Pressure

– with Type 3436 Transmitter Module for Temperature

– with Type 3438 Transmitter Module for Temperature (Pt 100)

– for standardized signals

Version shown with lockable door and integrated

Type 3436 Transmitter Module for Temperature

Fig. 1 · Controller stations

Mounting and

Operating Instructions

EB 7030 EN

Edition October 2010

Type 3431 Controller Station

– for standardized signals

Page 2

Contents

Contents Page

1 Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Settings at the controller modules . . . . . . . . . . . . . . . . . . . . 4

2.1.1 Operating action . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.2 Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.3 Proportional-action coefficient Kp . . . . . . . . . . . . . . . . . . . . 6

2.1.4 Reset time Tn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.5 Rate time Tv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.6 Operating point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Setting the limit switches. . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Tuning the controller . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.1 Setting the operating point in P and PD controllers . . . . . . . . . . . . 9

3.2 Smooth automatic/manual mode changeover . . . . . . . . . . . . . 10

3.3 Smooth changeover between the internal and external reference variable 10

3.4 Readjusting the controller’s zero point . . . . . . . . . . . . . . . . . 10

4 Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 Transmitter modules . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Controller station . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Controller modules. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3.1 Type 3433 Controller Modules . . . . . . . . . . . . . . . . . . . . . 14

5.3.2 Type 3434 Controller Modules . . . . . . . . . . . . . . . . . . . . . 17

5.4 Additional modules . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.4.1 Type 6112 i/p Converter . . . . . . . . . . . . . . . . . . . . . . . 18

5.4.2 w

selector switch . . . . . . . . . . . . . . . . . . . . . . . . 18

int/wext

5.4.3 Supply pressure regulators . . . . . . . . . . . . . . . . . . . . . . . 18

5.4.4 Inductive limit switches . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1.1 Changing scales. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Installing the temperature sensor . . . . . . . . . . . . . . . . . . . . 22

7 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Pneumatic connections . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1.1 Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1.2 Adjusting the supply air for version with supply pressure regulator. . . . 25

7.2 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2 EB 7030 EN

Page 3

Contents

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.1 Checking the air supply . . . . . . . . . . . . . . . . . . . . . . . . 27

9 Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.1 Changing the controller function . . . . . . . . . . . . . . . . . . . . 28

9.2 Exchanging the transmitter module . . . . . . . . . . . . . . . . . . . 30

9.3 Checking the controller function . . . . . . . . . . . . . . . . . . . . 30

10 Use in hazardous areas . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 Servicing explosion-protected devices . . . . . . . . . . . . . . . . . 31

11 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

General safety instructions

The device may only be assembled, started up or operated by trained and

4

experienced personnel familiar with the product.

According to these mounting and operating instructions, trained personnel is

referred to as individuals who are able to judge the work they are assigned

to and recognize possible dangers due to their specialized training, their

knowledge and experience as well as their knowledge of the relevant

standards.

Explosion-protected versions may only be operated by personnel who have

4

undergone special training or instructions or who are authorized to work on

explosion-protected devices in hazardous areas.

Any hazards that could be caused by the signal pressure are to be

4

prevented by means of the appropriate measures.

Proper shipping and appropriate storage of the device are assumed.

4

EB 7030 EN 3

Page 4

Application

1 Application

The Series 430 Pneumatic Indicating Con

trollers are used for applications in process

automation and industrial plants.

The controllers directly measure the con

trolled variables (pressure, temperature,

electric or pneumatic standardized signal)

and display the value. They compare the

measured variable with the set point and is

sue a corresponding pneumatic control sig

nal from 0.2 to 1 bar (3 to 15 psi).

A supply pressure of 1.4 bar±0.1 bar

(20 psi±1.5 psi) is required or an operat

ing pressure of 2 to 12 bar (30 to 180 psi)

when a supply pressure regulator is installed.

-

2 Operation

-

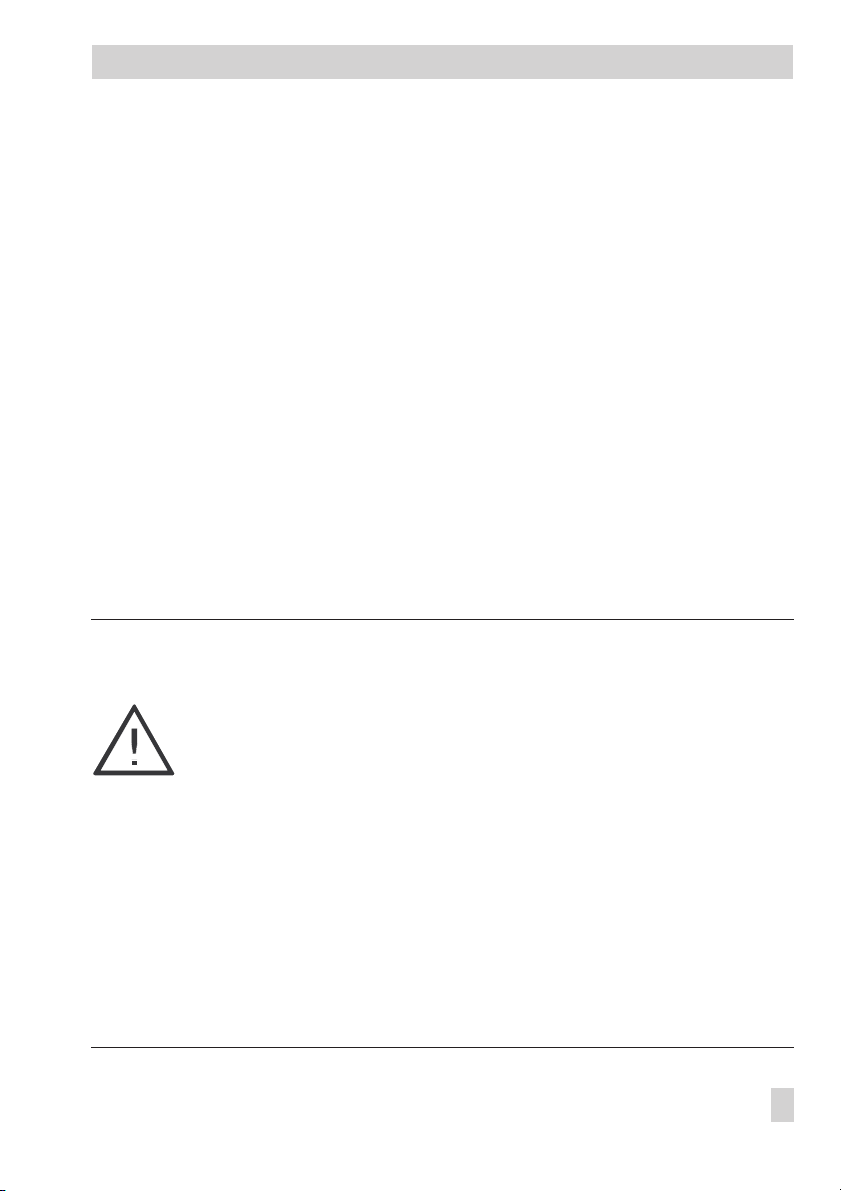

2.1 Settings at the controller

modules

The controller module in the station can be

accessed after the lock (Fig. 2) has been re

leased and the indicating unit (5) has been

opened out.

-

The settings for operating action (turnboard

-

A) and air supply (turnboard B) must be

performed prior to commissioning.

Unscrew the mounting screw (6) on the

4

-

controller module. Pull it off its self-seal

ing hose fittings and lift out of the controller station.

2.1.1 Operating action

The operating action for the control loop is

set at the turnboard A (Fig. 2), where the

position of its arrow symbol according to the

arrow symbol on the controller module determines the operation action of the controller.

34 Arrow tips facing opposite

directions:

Operating direction:

Increasing/decreasing =

As the controlled variable x increases,

the output signal pressure y

decreases.

44 Arrow tips facing the same direction:

Operating direction:

Increasing/increasing

As the controlled variable x increases,

the output signal pressure y

increases.

-

-

4 EB 7030 EN

Page 5

Operation

Setting or modifying the operating direction:

Unfasten the screw in turnboard A (Fig. 2)

and lift it off together with the turnboard. If

necessary, lever the board at the side.

Do not lose the rubber seal.

Turn the board by 90° so that the re

4

quired arrow is aligned with the arrow

on the base plate.

Insert board and tighten screw.

4

Reassemble the controller module in the

4

controller station.

1 Controller station (Type 3432)

1

1.1 Scale

1.3

1.3 Actual value pointer (red)

1.1

1.4 Set point adjuster

4

2 Transmitter module

1.4

3 Controller module

5

3.1 Comparator

3.2 Connecting plate

3.3 Hex screws

2

Air supply

B

Oper. action

A 3.2 3.4 8 9 3.1

3.4 Screws (inside)

2.1.2 Air supply

(only with Type 3433 Controller Module)

The position of the turnboard B (Fig. 2) with

its arrow symbol determines the air supply

to the feedback bellows. It can be accessed

-

after the comparator (3.1) has been re

moved.

4yA Normal air supply, approx. 1 m

4R Large air supply, approx. 3 m

or connecting base

-

³/h

n

per % of the system deviation

³/h

n

per % of the system deviation

(not with P or PD controller modules)

4 Lock

5 Indicating unit

6 Mounting screw

7 Restriction

8 Zero adjuster

9 Kp adjuster

10 Tn adjuster

11 Tv adjuster (only in

PD or PID controller)

12 Operating point adjuster

(only in P or PD controller)

63109

Type 3432 Contr. Module

Side view without comparator

Fig. 2 · Turnboards and adjusters

3.3

3

6

7

Type 3433-2 (PI) Controller Module

10

12

11

Type 3434-2 (PI) Controller Module

Oper. action

A

8

EB 7030 EN 5

Page 6

Operation

Unfasten screws (3.3) and pull off the

4

connecting plate (3.2) together with nuts

and bolts from the controller module.

Unscrew the hexagonal socket-head

4

screws (3.4) at the side and lift the com

parator (3.1) out of the controller mod

ule.

Setting or modifying the air supply:

Unfasten screw in turnboard B and lift it

4

off together with the turnboard. If neces

sary, lever the board at the side.

Do not lose the rubber seal.

Turn the board so that the arrow is

4

aligned with the mark yA or R on the

controller module. Insert board and

tighten screw.

Reassemble the controller module in the

4

controller station.

2.1.3 Proportional-action

coefficient Kp

2.1.5 Rate time Tv

For Type 3433 Controller versions with de

rivative-action component, the rate time Tv

needs to be set at the restriction (11). The

setting depends on the controlled system that

is being tuned (section 3.1).

2.1.6 Operating point

Controller modules without integral-action

component such as P or PD controllers have

an operating point. In Type 3433 Controller

Module, it can be adjusted between 0 and

100 % which corresponds to 0.2 to 1 bar by

an operating point adjuster (12). The setting

depends on the manipulated variable y (section 3.1.1).

In Type 3434 P Controller Module, the operating point is fixed at 0.6 bar.

-

The setting of the KP(adjuster 9) determines

the controller gain and is related to the controlled system that is being tuned (section

3.1).

2.1.4 Reset time Tn

Controller versions with integral-action com

ponent require the reset time to be set at the

restriction (10). The setting depends on the

controlled system that is being tuned

(section 3.1).

6 EB 7030 EN

-

Page 7

2.2 Setting the limit switches

Only applies to controller stations with the

limit switch option:

To set the limit switches, first release the lock

(4, Fig. 2) and open out the indicating unit

(5). The contacts can be accessed at the

back.

Adjust proximity switches by placing a

screwdriver in the clamps between 0 and

100 % of the reference scale and move until

a contact is made over the connected switch

ing amplifier.

Clamps with proximity switch

Operation

-

Fig. 3 · Limit switches

EB 7030 EN 7

Page 8

Commissioning

3 Commissioning

Prior to commissioning the control loop,

check all devices to make sure they are con

nected correctly, do not leak and function

properly.

Release lock (4) and open out the indicating

unit (5) to enable easy access to the operat

ing controls at the controller.

Check the turnboard to make sure the cor

rect operating action is set at the controller

(see section 2.1.1).

3.1 Tuning the controller

The controller needs to be tuned to the characteristics of the controlled system using the

and Tnand/or Tvadjusters at the control-

K

P

ler module to ensure that the controller can

keep any system deviations for all set points

caused by the disturbance variables to zero

or at least to minimize them.

In case of controller stations which have a

manual/ automatic switch (1.6), the plant

must be started up manually.

We recommend to determine the settings by

using a tuning test (following the Ziegler and

Nichols method) which produces sufficient

results in most cases:

1. Apply supply air (1.4 ±0.1 bar).

2. Set the proportional-action coefficient K

to a low value at the comparator.

3. Set T

restrictor to its maximum value

n

and T

to its lowest value (applies only to

v

PI and PID controllers).

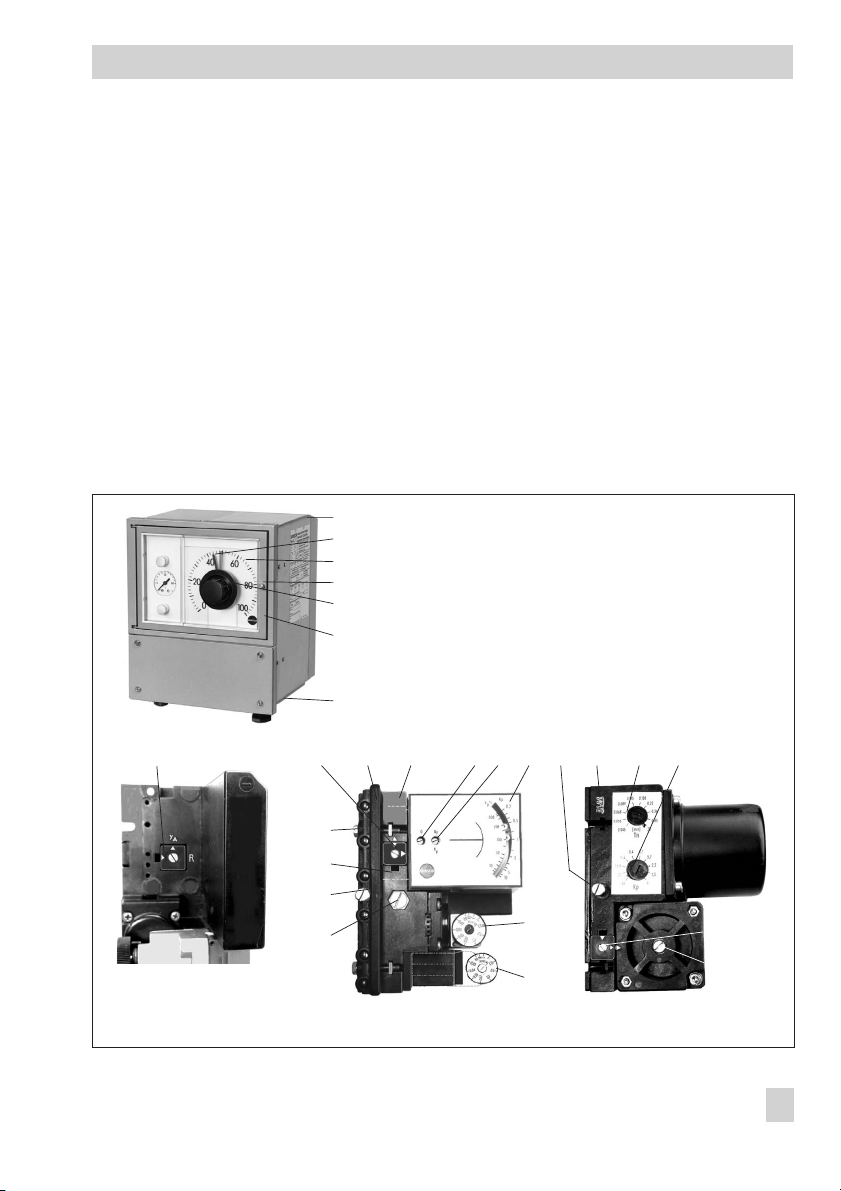

1.8

1.6

-

1.5

1.7

-

1.3 Actual value pointer (red)

1.4 Set point adjuster with green pointer

1.5 Signal pressure display

1.6 Manual/automatic switch

1.7 Adjuster for signal pressure (manual)

1.8 Differential pressure indicator

4 Lock

5 Indicating unit

Fig. 4 · Front view

Setting in manual mode:

4. Set manual/automatic switch to Manual.

5. Operate manual adjuster (1.7) for the

control signal so that the controlled variable (actual value pointer 1.3) slowly

settles on the adjusted set point (set point

pointer 1.4).

Should the differential pressure indicator

(1.8) move to zero, set the manual/auto

matic switch (1.6) to Automatic.

P

Proceed as described in points 6 and 7.

Setting in automatic mode:

4. Set the set point to the required value at

the rotary knob (1.4) on the indicating

unit.

5. Set the T

restriction briefly to its lowest

n

value (completely open) to move the red

1.3

1.4

4

5

-

8 EB 7030 EN

Page 9

Commissioning

–

actual value pointer to the green set

point pointer. Close the T

restriction

n

again.

6. Starting from a low value, increase the

proportional-action coefficient K

P

until

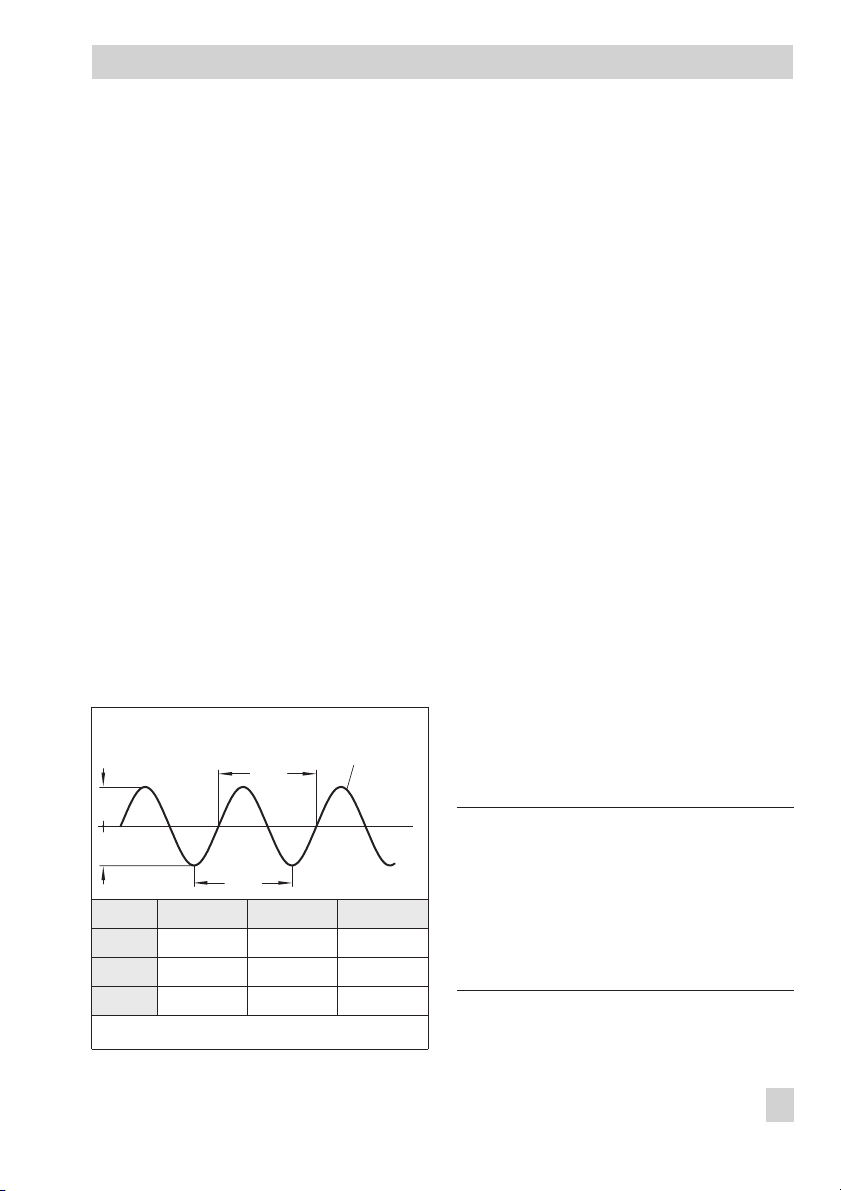

the actual value pointer displays an har

monic oscillation pattern (uniform oscil

lation amplitudes as shown in Fig. 5) of

the controlled variable.

If oscillations do not arise with a large

K

setting, turn the rotary knob to

P

change the set point slightly and then re

turn it to its former setting. It may be

necessary to increase the gain (K

)

P

slightly until an harmonic oscillation pattern arises.

7. Write down the adjusted value of the K

scale you have just adjusted as the critical proportional-action coefficient K

Pkrit

Use a stopwatch to time the oscillation

time for one entire oscillation as T

krit

(PI

and PID controller only).

Controlled variable

(actual value)

Tkrit

+

Tkrit

Cntr. K

P 0.50 · K

PI 0.45 · K

PID 0.59 · K

Fig. 5 · Harmonic oscillation, settings

P

P,krit

P,krit

P,krit

T

n

0.85 · T

0.50 · T

T

v

krit

0.12 · T

krit

Multiply both values with the values in

the table (Fig. 5) and set as the favor

able settings for K

, Tn, and Tvat the

P

controller.

Should oscillations still occur despite these

settings, slightly reduce K

Repeat these steps, if necessary, until the

control loop shows a satisfactory perfor

and increase Tn.

P

mance. Leave enough time in between set

ting to allow the controller to stabilize.

3.1.1 Setting the operating point in

-

P and PD controllers

(Type 3433 Controller Module only)

After setting the proportion-action coefficient

as described previously, set the operating

K

P

P

point for P and PD controllers instead of the

.

reset time T

Read off the controlled variable yA of the

4

.

n

controller at the display (1.5) when the

plant is in a steady-state condition and

set this value directly at the operating

point adjuster (12, Fig. 2). (Setting 0.2 to

1 bar = 0 to 100 %).

Recorrect slightly until the system devia

4

tion is zero. In case the signal pressure

display deviates, average the value.

Note!

On changing set point or reference variable,

the operating point must be set again as de

scribed above.

If the reference variable is changed more of

ten, set the operating point to 0.6 bar =

50 % (average value).

krit

-

-

-

-

-

-

EB 7030 EN 9

Page 10

Commissioning

Note!

restriction must be completely opened

The T

n

with a P/PI controller is switched over to P

action to allow the operating point adjuster

to work without delay.

Version with w-dependent operating point

This version does not need to be adjusted

since the operating point automatically fol

lows the set point w.

-

3.2 Smooth automatic/manual

mode changeover

(only for controller station with manual/automatic changeover, Fig. 4)

The smooth switchover ensures that no pressure surges can reach the valve when the

manual/automatic switch is activated as follows:

Changeover from automatic to manual

Use the manual adjuster (1.7) to adjust

signal pressure manual yH until the differen

tial pressure indicator (1.8) is zero. Switch

over to manual at the switch.

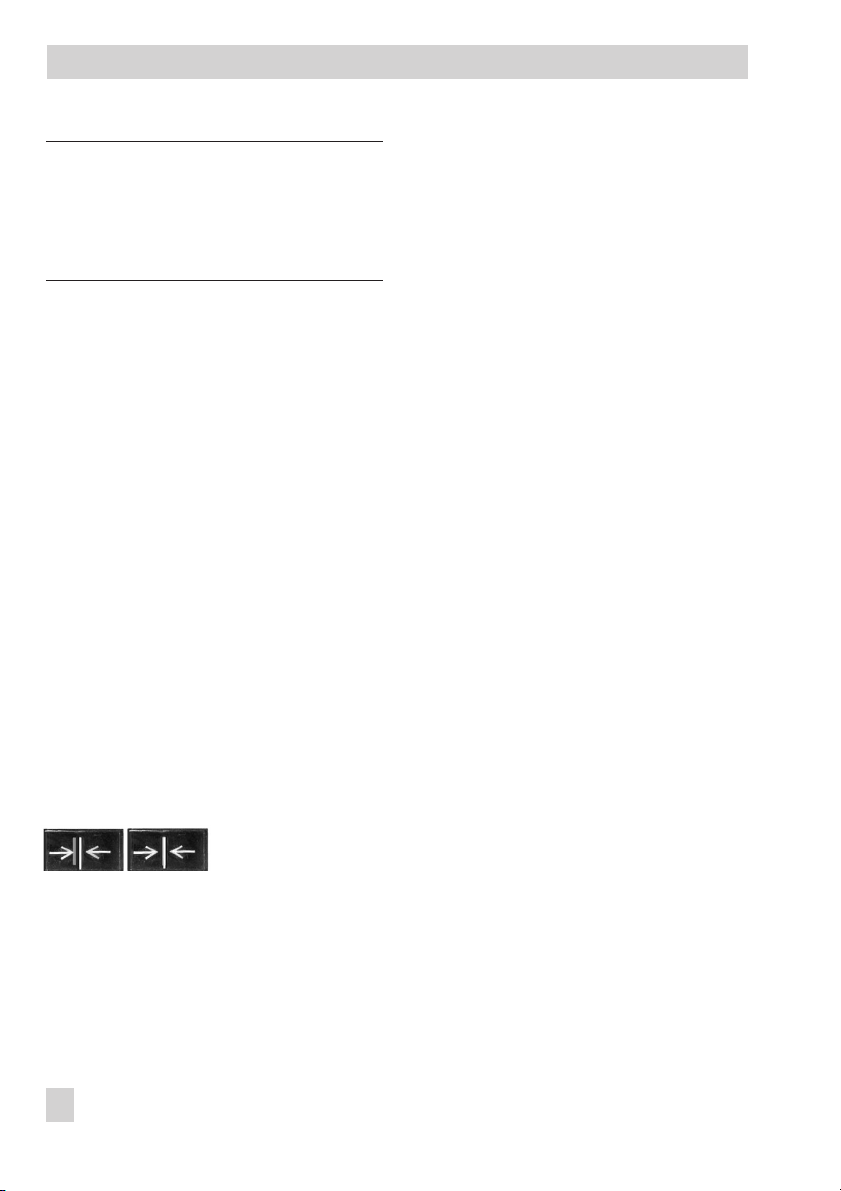

Differential pressure indicator

With Without deviation

adjuster (1.4).

The switch (1.6) can only be set to automatic

after the differential pressure indicator (1.8)

is at zero.

Set the set point again to the required value.

3.3 Smooth changeover between

the internal and external re

ference variable

When combining the fixed set point control

and follower control, the Type 3432 Con

troller Station is equipped with a w

switch, a pressure adjuster and a differential

pressure indicator (Fig. 10).

The differential pressure indicator must first

be brought to zero by activating the pressure adjuster in order to switch between the

reference variables.

3.4 Readjusting the controller’s

zero point

Should deviations arise between the actual

value and set point during operation, the

zero point adjustment can be readjusted by

turning the zero screw at the back of the dis

play unit (5) until the actual value and set

point on the front display are the same

again.

Deviations between the actual value and set

point can also be corrected at the zero point

adjuster (8, Fig. 2) of the controller module.

-

-

int/wext

-

Changeover from manual to automatic

If the plant is to be controlled manually to

the required value, the automatic signal

pressure yA must be matched to the manual

signal pressure yH by adjusting the set point

10 EB 7030 EN

Page 11

Construction

4 Construction

The controllers designed according to the

modular principle form an entire automation

unit consisting of a controller station, a con

troller module tuned to the local conditions,

and, where applicable, a transmitter as well

as other additional modules.

Controllers with Type 3432 Controller Sta

tion are mainly designed for installation of a

Type 3435 Transmitter Module for Pressure

or a Type 3436 Transmitter Module for

Temperature with direct process fluid con

nection.

The Type 3431 Controller Station receives

the controlled variable as a standardized

signal from 0.2 to 1 bar or 3 to 15 psi. The

controlled variable can also be supplied as

a current signal from 4 or 0 to 20 mA or

1 to 5 mA over an integrated i/p converter.

The controller station can be equipped with

the Type 3433 or Type 3434 Controller

Module.

For special control applications, the Type

3433 Controller Module can be combined

with Type 3437 Additional Modules for

pressure limitation, control mode switchover

or smooth manual/automatic transfer.

The controller station can also be upgraded,

if required, with a manual/automatic trans

fer, consisting of a selector switch, adjuster

for manual mode, and differential pressure

indicator.

The controller station must be equipped with

an additional module for w

int/wext

over when used for applications as a com

bined fixed set point controller and follower

controller. An additional pneumatic or elec

tric output for the external reference variable

(e.g. 0.2 to 1 bar or 4 (0) to 20 mA)

w

ext

change

-

-

-

-

is likewise required when used as a follower

controller. Additionally, inductive limit

switches, that are adjustable at a scale, can

be mounted on the indicating units 1 or 2.

-

Note! Refer to the corresponding Data

Sheets for details about the controller sta

tions and their controller modules.

T 7030 EN · Pneumatic Indicating

Controllers - Information Sheet with product

overview.

T 7032 EN · Pneumatic Indicating

Controllers for Pressure

T 7034 EN · Pneumatic Indicating

Controllers for Temperature with Capillary

Sensor

T 7036 EN · Pneumatic Indicating

Controllers for Temperature with Pt 100

Resistance Thermometer

T 7038 EN · Pneumatic Indicating

Controllers for Standardized Signals

T 7040 EN · Type 3433 Pneumatic

Controller Modules and Type

3437Additional Modules

T 7041 EN · Type 3434 Pneumatic

Controller Modules

T 7045 EN · Type 6112 i/p Converter

-

Module

5 Principle of operation

5.1 Transmitter modules

Type 3435 for Pressure

The process fluid pressure p is transmitted to

-

the transmitter module (2) where it causes a

deflection at the Bourdon tube measuring

-

EB 7030 EN 11

Page 12

Principle of operation

system (2.1). The deflection is converted by

the pneumatic servo system (2.2) into a

pneumatic signal (controlled variable x)

which is proportional to the pressure p. The

signal is transferred to the bellows measur

ing system of the actual value display (1.3)

as well as to the controller module (3).

Type 3436 for Temperature with capillary

sensor

The temperature of the medium produces a

pressure in the gas-filled sensor (2.3) of the

transmitter module which is proportional to

the temperature. This pressure is offset by a

force on the beam (2.4) and converted into

the output pressure p

at the feedback bel-

A

lows (2.6).

The supply air flows over the restriction (2.9)

and nozzle (2.8) and hits the flapper (2.7).

As the temperature rises, the flapper moves

closer to the nozzle. This results in an increase in output air pressure p

supplied to

A

the bellows (2.6) until a new state of equilibrium is reached, i.e. until the output signal is

proportional to the temperature measured.

This signal is transmitted as the actual value

signal (controlled variable x) to the bellows

measuring system of the actual value display

(1.3) and the controller module (3).

Type 3438 for Temperature with Pt 100 re

sistance thermometer

The Type 3438 Transmitter Module consists

of an electric transmitter and a downstream

i/p converter to connect a Pt 100 sensor.

The resistance value of the Pt 100 sensor is

converted into a 4 to 20 mA current signal

in the electric transmitter. Its output signal (4

to 20 mA) is converted into a pneumatic sig

nal between 0.2 and 1 bar by the i/p con

verter. The output pressure, which is propor

tional to the temperature, is supplied to the

bellows measuring system of the controlled

variable display and the controller module

as a pneumatic controlled variable signal

(controlled variable x).

-

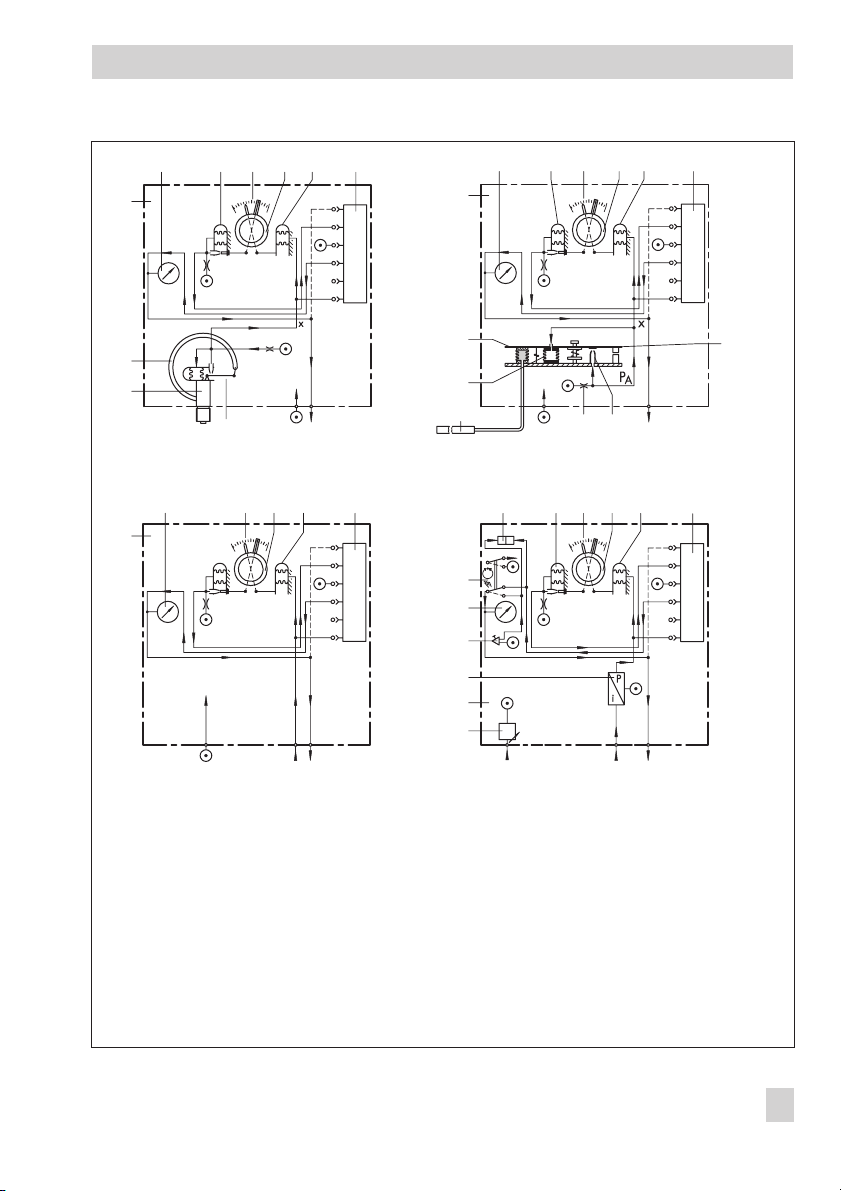

5.2 Controller station

The actual value signal x causes a deflection

at the bellows measuring system of the ac

tual value display (1.3) which is transmitted

to the pointer over a gear mechanism.

The set point (reference variable w) can be

adjusted at the scale (1.2) on the front. The

position of the set point adjuster (1.4) is

transmitted to the set point transmitter over a

gear mechanism. This pneumatic servo system (1.41) converts the adjusted set point

into a pneumatic set point signal (w) which

is transmitted to the controller module.

The controller module compares the actual

value signal (x) with the set point signal (w)

and controls using the control signal yA depending on the system deviation and the adjusted control parameters. The control signal

is connected to the signal pressure display

(1.5) and the output port y.

The controller station with manual/auto

matic switchover (Figs. 2 and 4) additionally

features a manual/automatic switch (1.6),

-

an adjuster for manual mode (1.7), and a

differential pressure indicator (1.8).

Signal pressure display (1.5) and output

port y are connected to the automatic output

signal y

matic” and to the manual output signal y

set at the adjuster (1.7) with a switch posi

tion at “Manual”.

-

A smooth switchover from manual to auto

-

matic mode is possible when the differential

-

pressure indicator (1.8) shows that y

y

H

with a switch position at “Auto

A

are identical.

-

-

-

H

-

-

and

A

12 EB 7030 EN

Page 13

Principle of operation

1.5 31.2

1

y

w

1.4 1.31.41 1.5 31.2 1.4 1.31.41

R

w

PI

z

P

A

y

PPI

/

PID

S

x

2.1

2

y

Z

2.2

Type 3432 with Type 3435 Transmitter for Pressure

1.5

1

y

w

1.2 1.4 1.3

3

R

w

PI

z

P

A

y

PPI

/

S

PID

x

Zx

Type 3431 and 3432 for pneumatic standardized signals

1 Controller station

1.2 Scale

1.3 Actual value display with pointer,

gear mechanism and bellows

measuring system

1.4 Set point adjuster with pointer,

gear mechanism and set point (1.41),

set point display only for follower

controllers

1.5 Signal pressure display

1.8 Differential pressure indicator

for smooth manual/automatic

switchover

1.9 Supply pressure regulator

2 Transmitter module

2.1 Bourdon tube meas. system

2.2 Pneumatic servo system

2.3 Temperature sensor

2.4 Beam

2.6 Feedback bellows

Fig. 6 · Principle of operation of controllers

1

2.4

2.6

2.3

wxwx

w

R

w

PI

z

P

y

A

PPI

/

PID

S

x

2.7

Z

y

2.9 2.8

Type 3432 with Type 3436 Transmitter for Temperature

y

A

w

1.21.41 1.4 1.3 3

w

xwx

R

w

PI

z

P

A

y

PPI

S

PID

x

x

/

1.6

1.5

1.7

1.8

y

H

S

y

H

4

Z

1

1.9

P

B

y

x

Type 3432 with manual/automatic switch (1.6),

supply pressure regulator (1.9) and i/p converter

2.7 Flapper

2.8 Nozzle

2.9 Restriction

3 Controller module

4 Type 6112 i/p Converter

Z = Supply pressure 1.4 bar

= Output pressure

P

A

= Compressed air network

P

B

EB 7030 EN 13

Page 14

Principle of operation

5.3 Controller modules

The controller modules are designed as

plug-in units. They are inserted into the

self-sealing hose fittings of the controller sta

tion and fastened in place by mounting

screw.

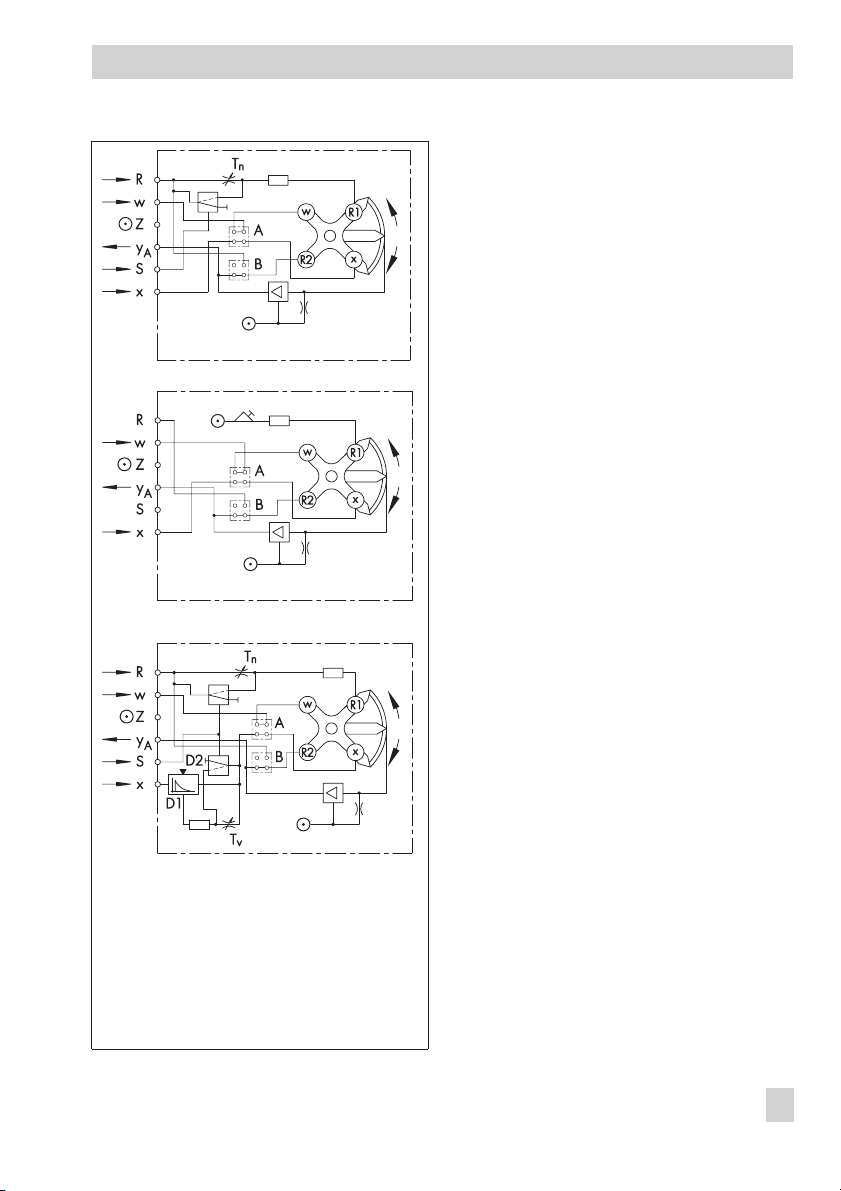

5.3.1 Type 3433 Controller

Modules

The controller modules consist of the com

parator equipped with four metal bellows

arranged in a square and the base plate

with plug-in connections. The base plate

contains the components necessary for the

corresponding function such as relays and

restrictors. The components can be exchanged or retrofitted to upgrade a device

(refer to section 9.1 for more details).

Type 3433-2 PI Controller (Fig. 7, top)

The controlled variable x (actual value) and

the reference variable w (set point) are

transmitted as pneumatic signals between

0.2 and 1 bar to metal bellows w und x

over the turnboard A. When x is greater

than w, the actual value bellows tilts the

swashplate at its pivot towards the set point

bellows. This causes the pressure to rise

downstream of the nozzle which is con

nected to the swashplate over a pin and, as

a result, the comparator increases the output

pressure y

. The output pressure is fed back

A

over turnboard B to the bellows R2 on the

swashplate.

The pressure and the position of the

swashplate continue changing until the dis

tance between the nozzle and flapper

achieve the initial value and the output pres

-

-

-

sure y

reaches the value related to the con

A

trolled variable x and the proportional-ac

tion coefficient K

Outside of the controller module, y

nected to R, meaning that the output pres

sure y

is also fed back to bellows R1 over

A

port R and the adjustable T

set at the screw.

p

restriction. As a

n

result, the effect caused by the pressures in

bellows R1 and R2 is balanced and system

deviation is eliminated.

Should a switching pressure exist at port S

after switching the controller station to man

ual mode, the T

start-up relay.

the T

n

restriction is bypassed by

n

Turnboard A determines the operating

action of the controller which can be

changed by turning the board. Refer to section 2.1.1.

Turnboard B determines the air supply to

the feedback bellows.

In delivered state, it is set to y

, i.e., the

A

output pressure is directly fed back to bellows R2, whereas, it is fed to bellows R1

over the manual control unit to port R. This

arrangement provides the controller with a

normal air supply and a damping of the out

put pressure.

Setting it to R results in the output pressure

being fed back to bellows R1 and R2

y

A

over port R which provides a higher air sup

ply.

This type of turnboard setting is suitable for

applications where the distance to the final

control element is long and the connected

volume is large as well as where controlled

systems react quickly. Refer to section 2.1.2

to set or change the air supply by turning

the turnboard B.

-

is con

A

-

-

-

-

-

-

-

14 EB 7030 EN

Page 15

0.2

Kp

20

0.2

Kp

20

Principle of operation

Type 3433-2 PI Controller Module

The following versions of the controller mod

ules are similar in most aspects to the

Type 3433-2 PI Controller Module, how

ever, they are fitted with, for example, an

operating point adjuster, derivative element,

or a selector switch, depending on the

application.

Type 3433-1 P Controller Module

corresponds to Type 3433-2.

An operating point adjuster is used in place

of the integral element.

-

R Feedback

R1/R2 Feedback bellows

Z = Supply air 1.4 bar

Output pressure

Y

A

S Switching pressure

Fig. 7 · Type 3433 Controller Modules

A Operating action

B Air supply

Turnboards

0.2

Kp

20

Type 3433-3 PID Controller Module

corresponds to Type 3433-2.

Additionally, it contains a derivative element

which produces the rate action with approx

imately ten times the gain in the input

branch of the controlled variable x. The rate

time can be adjusted at the T

restriction.

V

EB 7030 EN 15

-

Page 16

Principle of operation

Type 3433-4 PD Controller Module

corresponds to Type 3433-1.

Additionally, it contains a derivative element

which produces the rate action with approx

imately ten times the gain in the input

branch of the controlled variable x. The rate

time can be adjusted at the T

restriction.

V

Type 3433-5 P/PI Controller Module

with P/PI selector switch can optionally be

used as a P controller with operating point

adjustment or as a PI controller.

The structure is the same as that of the PI

and P controller module.

Type 3433-6 PD/PID Controller Module

with PD/PID selector switch can optionally

be used as a PD or PID controller.

0.2

-

Kp

20

0.2

Kp

20

Type 3433-9 P Controller Module

with set point-dependent operating point

corresponds to Type 3433-1 P Controller

Module, except that the operating point

shifts proportional to the set point w.

16 EB 7030 EN

0.2

Kp

20

Fig. 8 · Type 3433 Controller Modules

Page 17

Principle of operation

5.3.2 Type 3434 Controller

Modules

The controller modules have a round com

parator which operates according to the

force-balance principle.

The proportional-action coefficient K

be adjusted in the range between 1 and 25.

Type 3434-2 PI Controller Module (Fig. 9)

Controlled variable x and reference variable

w are transmitted as pneumatic excess pres

sures between 0.2 and 1 bar or 3 and

15 psi to the diaphragm chambers (R1 and

R2) over the turnboard A. When x is greater

than w, the force switch (23) lowers and the

plug opens. Supply air flows into the diaphragm chamber R2 and the output pressure y

ted over the T

increases. This pressure is transmit-

A

restriction (10) to the volume

n

of the 1:1 booster (24). Its output pressure is

fed back to the diaphragm chamber R1.

24

10

R

w

Z

y

A

S

A

T

n

-

can

p

9 8

K

p

The effect caused by the pressures in the di

aphragm chambers R1 and R2 is balanced.

The position of the force switch continues to

change until the controller output pressure

reaches a value which is related to the con

trolled variable x and the adjusted propor

tional-action coefficient K

i.e. until the sys

p,

tem deviation is eliminated.

The proportional-action coefficient K

justed at the restriction (9) and the reset time

at the restriction (10). The zero point ad

T

n

juster (8) is used to tune the device.

-

The turnboard A determines the controller’s

operating action which can be changed by

turning the board (section 2.1.1).

Type 3434-1 P Controller Module

The design and principle of operation are

the same in most aspects to Type 3434-2 PI

Controller Module.

However, a spring for an operating point

fixed at 0.6 bar is used instead of the feedback with T

restriction.

n

8 Zero point adjuster

9K

P

adjuster

10 T

n

21 Diaphragms

R1

23 Force switch

24 Booster

21

R2

R1 Diaphragm chamber

23

R2 Diaphragm chamber

A Turnboard for operating

action

adjuster

p

is ad

-

-

-

-

-

-

x

Fig. 9 · Type 3434-2 Controller Module

EB 7030 EN 17

Page 18

Principle of operation

5.4 Additional modules

5.4.1 Type 6112 i/p Converter

External reference variable w

and/or con

ext

trolled variable x can be issued as a current

signal of 4(0) to 20 mA or 1 to 5 mA and

converted by the i/p converter into a pneu

matic standardized signal of 0.2 to 1 bar.

The i/p additional module with one or two

converters is integrated into the controller

station and can only be used in conjunction

with the Type 3433 Controller Modules.

5.4.2 w

int/wext

selector switch

When used as a combination of fixed set

point controller and follower controller, the

controller is fitted with a w

int/wext

selector

switch.

The associated set point adjuster and differential pressure indicator allow a smooth

switchover when the indicator is at zero. Refer to section 3.3.

5.4.3 Supply pressure regulators

When a supply pressure regulator is

mounted onto the Type 3432 Controller Sta

tion, it is suitable for the connection to an

operating pressure of 2.0 to 12 bar.

The Type 3708-5003 Supply Pressure Regu

lator (Var.-ID 1023317) reduces and con

trols the operating pressure to the required

supply pressure of 1.4 bar.

-

-

-

Connecting plate with two i/p converters

for controlled variable x and external set point

Adjuster for internal set point

w

selector switch

-

int/wext

-

18 EB 7030 EN

Supply pressure regulator

Fig. 10 · Additional modules

Page 19

5.4.4 Inductive limit switches

The inductive limit switches indicate when

the controlled variable x exceeds and/or

falls below an adjustable limit value.

Two metal tags are mounted to the pointer

shaft of the controlled variable x which acti

vate associated proximity switches.

When the metal tag moves into the field of

the inductive pick-up, it is highly resistive

and when the metal tag moves outside of the

field, it is low resistive.

The proximity switches are located in adjust

able brackets. The required switching point

can be adjusted by turning the brackets. Refer to section 2.2 for more details.

Principle of operation

-

-

EB 7030 EN 19

Page 20

Installation

6 Installation

6.1 Mounting

The controller station is designed for mount

ing onto pipes, walls or in panels.

Refer to Figs. 11 and 12 for the correspond

ing dimensions.

Active sensor length

Air sensor

Ø19.5

Ø12

300

400

G¾

Type 3432 with Type 3436 Temperature Transmitter

300

425

Ø7

192

303130 30 16

26278/938

124

Pipe mounting

Mounting to vertical or horizontal 2" pipes

using a mounting part with bracket.

Required mounting kit:

Order no. 1400-6302.

Protective roof (accessories):

-

Order no. 1400-6311

Mounting plate

Bracket

Pipe 2”

Cable gland M 20x1.5

10

Protective roof

16069

40

2845

13

Ports:

26 x Controlled variable

27 wext Ext. set point

8/9 Supply air Z

38 y Manipulated variable

Fig. 11 · Installation dimensions of Type 3432 Controller Station

241

36

10

Process fluid connection

Type 3432 with Type 3435 Pressure Transmitter

29

5

26278/938

Tapped ports ISO 228/1-G 1/8

20 EB 7030 EN

Air connections

160

228 8 228 8

28

13

Page 21

Installation

Wall mounting

Mounting using three straps

Required mounting kit: Order no.1400-6301

Panel mounting

Mounting using four mounting elements

(DIN 43835).

Distance between centers to door approx.

235 mm.

Close arrangement in rows without door

acc. to DIN IEC 61554 (DIN 43700).

192

30 30 30 16

Pipe 2”

Cable glands

M20x1.5

Ø7

26278/9 38

124

Type 3432:

+1

Panel cut-out 188

x 255+1mm,

Required panel mounting kit:

Order no. 1400-6300.

Type 3431:

+1

Panel cut-out 188

x 138+1mm,

Required panel mounting kit:

Order no. 1400-6303

Protective roof (accessories):

Order no. 1400-6311

Mounting plate

Bracket

Pipe 2”

16069

10

Protective roof

2845

13

Ports:

26 x Controlled variable

27 wext Ext. set point

8/9 Supply air Z

38 y Manipulated variable

Fig. 12 · Installation dimensions of Type 3431 Controller Station

5

26278/9 38

241

10

Air connections

Tapped ports ISO 228/1-G 1/8

160

144 8 144 8

28

13

EB 7030 EN 21

Page 22

Installation

6.1.1 Changing scales

After unlocking the door (4, Fig. 4), the

scale can be removed from the back of the

display and, if necessary, replaced with a

special scale.

The scale division of the scale must match

the measuring range of the connected or in

tegrated transmitter.

Adhesive strips are attached to inside the

casing for tag labeling on the scale.

Cut the strips to size and stick them on

4

the scale.

6.2 Installing the temperature

sensor

Only applies to controller stations with

Type 3436 Transmitter Module

Bulb sensor Ø 12 mm, length 425 mm (ac

tive length 300 mm)

The bulb sensor can be installed in any

position. However, the entire length of the

sensor must be immersed in the medium to

be controlled.

Choose a point of installation where over

heating or noticeable time delays cannot oc

cur.

Run the capillary tube in such a way that the

large temperature deviations cannot occur

(ambient temperature approx. 20 °C) and

the tube cannot be damaged.

The smallest possible bending radius is

50 mm.

A sleeve with G ½ or G ¾ female thread at

the point of measurement is required to install the sensor. Screw or seal one of the

mounting parts shown in Fig. 13 into this

sleeve.

-

-

-

22 EB 7030 EN

Note!

The mounting parts are not included with the

sensor. They must be ordered separately.

Select which mounting parts are needed de

pending on the operating conditions at the

point of measurement.

-

Page 23

Installation

Mounting parts for bulb sensor Ø 12 mm, length

425 mm

Clamping flange

For wall mounting, e.g. pressureless containers or

ducts

Order no. 1090-9547

Mount flange to wall using two screws and attach

temperature sensor with two other screws in the

flange.

Screw gland (PN 10)

G ½ Order no. 1080-4881

G ¾ Order no. 1080-4882

Fill screw fitting with sealant. Insert sensor with screw

gland and coupling nut.

Tighten coupling nut.

Screw gland (PN 40) with clamping nut

G ½ Order no. 1080-4884

G ¾ Order no. 1080-4885

Install as described above. Tighten clamping nut

instead of coupling nut.

Thermowell with thread (PN 63)

G ½ Order no. 1080-4888

G ¾ Order no. 1080-4889

Use a thermowell when the nominal pressure is

exceeded, when corrosive media are involved or

when the plant is to continue to run while the sensor is

being replaced.

Insert sensor right to the bottom of the thermowell.

Tighten coupling nut.

32

8 Ø50

Ø26

G

G

Ø16

385

Ø21.3

Ø12

Ø9.5

G¾SW 32

SW 32

G¾

136

12

30

G SW 32

SW 32

55

75

Thermowell for welding (PN 63)

Order no. 1080-4890

Thermowell with flange

Order no. 1080-4891 (PN 40)

1080-4892 (PN 100)

Note: All wetted parts of the screw gland and thermo

wells are made of stainless steel 1.4571.

Fig. 13 · Mounting parts for bulb sensor

375

SW 32

-

Ø21.3

335 40

EB 7030 EN 23

Page 24

Connections

7 Connections

7.1 Pneumatic connections

The air connections underneath the device

are designed as bores with ISO 228/1G 1/8 thread. The customary fittings for

pipes or plastic hoses can be used.

Note!

The supply air must be dry and free from oil

and dust. The maintenance instructions for

upstream pressure reducing stations must be

observed.

Blow through all air tubes and hoses thoroughly prior to connecting them.

The connection designations with codes are

cast underneath the housing.

They can additionally be marked on the

back of the housing using the adhesive label

supplied with the controller station.

38 Output y – Manipulated variable,

Output signal of the controller to operate the

control valve or positioner.

8/9 Supply – Supply air ,

Supply air 1.4 ±0.1 bar or 2 to 12 bar for

the version with supply pressure regulator

(see section 5.4.3).

27 Input w

Closed with fixed set point controller and

open for the connected external set point

with follower controller.

26 Input x – Controlled variable,

Closed with pressure or temperature control

ler (controlled variable is recorded by the

transmitter module).

Open with standardized controllers.

– External reference variable,

ext

7.1.1 Typical applications

Controller for standardized signals

26MU8/9

Z

x

0.2...1 bar

Temperature controller (with Type 3436)

Sensor

Pressure controller (with Type 3435)

Process fluid connection

-

to measure pressure:

Connection to pipe,

pressure vessel, etc.

Fig. 14 · Standard applications

Supplyy0.2 ...1 bar

8/9

Z

Supplyy0.2 ...1 bar

8/9

Z

Supplyy0.2 ...1 bar

MU – Transmitter

STR – Positioner

38

STR

38

STR

38

STR

24 EB 7030 EN

Page 25

7.1.2 Adjusting the supply air for

version with supply pressure

regulator

Connections

Only applies to Type 3432 Controller Sta

tions with supply pressure regulator (1.9).

Hose connections for supply air are located

directly above the corners of the supply

pressure regulators on the bridge of the

connecting plate (inside housing). The con

nections are sealed by the hose end fittings.

Pull left end fitting off and use a hose to

4

connect it to a test pressure gauge.

Controller stations with a manual/auto

4

matic selector switch have a test connection (yellow) inside the indicating unit.

Use the enclosed test connector for this

version (Fig. 15).

Unscrew cap of the pressure controller.

4

Undo the lock nut on the spindle and adjust the spindle:

Turn the spindle clockwise to increase the

4

supply pressure and counterclockwise to

reduce it.

Secure the position of the spindle with

4

the lock nut and screw the cap back on

when the supply pressure at the test pres

sure gauge indicates a pressure of

1.4 ±0.1 bar (20 ±1.5 psi).

-

-

Fig. 15 · Test connection with test connector

-

-

EB 7030 EN 25

Page 26

Connections

7.2 Electrical connection

The electrical components only apply to

controller stations with i/p converter addi

tional modules for controlled variable x, ex

ternal reference variable wext and/or with

inductive limit switches.

Caution!

For electrical installation, you are re

quired to observe the relevant elec

trotechnical regulations and the acci

dent prevention regulations that ap

ply in the country of use. In Germa

ny, these are the VDE regulations

and the accident prevention regulations of the employers' liability insurance association.

The following standards apply for

assembly and installation in hazardous areas: EN 60079-14: 2003

(VDE 0165 Part 1/8.98) "Electrical

apparatus for explosive gas atmospheres" and EN 50281-1-2: 1999

(VDE 0165 Part 2/11.99) "Electrical

apparatus for use in the presence of

combustible dust".

For the interconnection of intrinsical

ly safe electrical equipment, the per

missible maximum values specified

in the EC type examination certifica

te apply (U

or C0, and Lior L0).

Note! The terminal assignment spe

cified in the Mounting and Opera

ting Instructions must be adhered to.

Reversing the assignment of the elec

trical terminals may cause the explo

sion protection to become ineffective.

Do not tamper with painted screws.

or U0; Iior I0; Pior P0; C

i

Note on the selection of cables and wires:

To install intrinsically safe circuits, observe

section 12 of the standard EN 60079-14:

-

2003 (VDE 0165 Part 1).

-

To run multi-core cables or lines with more

than one intrinsically safe circuit, section

12.2.2.7 of this standard applies.

Devices used at ambient temperatures down

to –40 °C must have metal cable entries.

-

-

The terminals on the base plate can be ac

-

cessed after unscrewing the front cover be

-

neath the display. For operation of the limit

-

switches, switching amplifiers which comply

with EN 60947-5-6 must be connected in

the output circuit.

Type 3432

Controller

Station

i/p converter

12 11 21 22 42 41 52 51

–+

+– –+ –+

w

x

ext

4(0)...20 mA

Sw. amplifier

-

-

Type 3431

Controller

Station

-

i

-

-

-

-

Fig. 16 · Connecting i/p converters and limit switches

+

–

+

–

Sw. amplifier

Limit switches

42 41 52 51

Limit switches

i/p converter

–

+

+

–

22 21 11 12

w

ext

4(0)...20 mA

-

-

x

26 EB 7030 EN

Page 27

Maintenance

Type 3438

–++

T

–

I

4...20 mA

+–

43

11 12 13

+

L

~

N

24V–

EEx i

–

PE

14

W

Y

H

Y

A

PID

I

X

P

Y38W

Z

8/9

Supply Output External

Setpoint

Sensor connection: No line compensation is required

ϑ

+–34

–

+

Safe area Ex zone 1

Fig. 17 · Electrical wiring of Type 3432 Controller Station with Type 3438 Transmitter Module

EEx i

–

+

Pt 100

8 Maintenance

with four-wire connection.

The resistance of the wires must be identical and the

permissible line resistance of 50Wper wire is not to be

exceeded.

The sensor lines are to be routed separately from relay

or contactor lines.

This filter needs to be cleaned or replaced

when the display for the controlled variable

8.1 Checking the air supply

The modules of the pneumatic controllers

normally do not require any maintenance.

However, the air supply should be checked

regular intervals.

The proper functioning of the device can

only be guaranteed when the compressed

air supplied to the device is always in a

clean condition.

Check the air filter and traps of the reducing

station at regular intervals. If necessary,

when the performance worsens, clean or re

place the appropriate filters.

Transmitter module:

A hose grommet fitted on the hose for sup

does not work (order no. 0550-0193).

Type 3433 Controller Module:

In case the controller module does not con

trol properly or there is no output signal, un

screw the restriction (7, Figs. 2 and 17) on

the left side underneath the comparator and

clean or replace it (order no.1390-0183).

Pull out the filter, if need be, and replace it

(order no. 0550-0193).

The hose connections of the controller mod

ule are also fitted with filters (order no.

0550-0186).

-

Additionally, the ports underneath the hous

ing are fitted with plastic-rimmed filters

which can be unscrewed and cleaned (order

no. 0550-0189).

-

ply air which includes a filter.

ext

27

-

-

-

-

EB 7030 EN 27

Page 28

Conversion

Undo bolts (3.3) and pull connecting

9 Conversion

4

plate (3.2) together with bolts and hex

9.1 Changing the controller

function

The controller function can be changed ei

ther by exchanging the entire module

(Type 3434-1 or Type 3434-2) or by up

grading or altering (Type 3433) components

such as adjusters, restrictions or differential

amplifier.

-

-

nuts off the controller module.

Detach and mount the corresponding

4

cover plates and adjusters by unfasten

ing the M3 hexagon socket head screws

inside the housing.

P into PI: Unscrew adjuster for operating

point (12) and replace it with T

restriction

n

(10).

P into P/PI: Unscrew adjuster for operating

Type 3433 Controller Module:

Unscrew the mounting screw (6) at the

4

controller module and pull it off the

self-sealing hose fittings. Remove it from

the controller station.

point (12) and replace it with a selector

switch with operating point adjuster (13)

restriction (10).

and T

n

P into PD: Unscrew cover plate (14.1). Take

out O-ring (14.3) and insert two O-rings

(14.4) in its place. Screw on differential

Part Quantity Designation Order no.

10

10.1

10.2

11

11.1

11.2

11.3

12

12

12.1

12.2

13

13.1

13.2

14

14.1

14.2

14.3

14.4

15 1 Plate with restriction for set point-dependent operating point 1590-1089

1

Tnrestriction

2

Screws M3x8

3

O-rings 1.78 x 1.02

1

Tvrestriction

1

Cover plate

2

Screws M3x8

4

O-rings 2 x 1.5

1

Operating point adjuster 1.4 bar

1

2

Screws M3x8

4

O-rings 1.78 x 1.02

1

Selector switch with operating point adjuster

2

Screws M3x30

4

O-rings 1.78 x 1.02

1

Differential amplifier

1

Cover plate

1

Screws M3x16

1

O-ring 14 x 1.5 for plate

4 (2)

O-rings 2 x 15

20 psi

1070-4584

8333-0479

8421-0010

1070-4585

0360-1597

8333-0479

8421-0023

1070-4583

1070-6413

8333-0479

8421-0010

1180-3615

8333-0482

8421-0010

1080-6924

0360-1598

8333-0476

8421-0070

8421-0023

-

28 EB 7030 EN

Page 29

Conversion

amplifier (14). Unscrew cover plate (11.1)

and mount T

restriction (11).

v

P into PID: Modify as described for P into

PD. Additionally, replace adjuster (12) with

restriction (10).

T

n

P controller with set point-dependent oper

ating point: Fasten the plate with restriction

P in PI

6

3.2

3.3

10

12

(15)

14.1, 14.2 11.1, 11.2

(15) in place of the adjuster for operating

point (12).

Note!

We recommend replacing old O-rings as

well as the filter in the restriction (7) with

-

new ones.

P/PI

14.1, 14.2 11.1, 11.2

P in PD

13

10

12

10

12

14

11

Filter

Restriction (7)

14.3 14.4 10.2

Fig. 18 · Changing the controller function of Type 3433

14.4 10.2

EB 7030 EN 29

Page 30

Conversion

9.2 Exchanging the transmitter

module

The Type 3435 and Type 3436 Transmitter

Module are fastened to the Type 3432 Con

troller Station over six screws.

The supply air x is connected over two sili

cone hoses.

The transmitter module can be replaced

when a measuring element is defective or

the measuring range is to be changed.

When you order a new module, you need to

provide information on the sensor version

and the required measuring range. In addi

tion, please state the specifications contained on the nameplate of the old transmitter module.

1 Unscrew the front plate located under-

neath the display. Unfasten the corresponding terminals for modules with

electrics.

2 Pull off the hoses for controlled variable

x and supply air Z on the housing

connecting plate.

3 Unfasten the six mounting screws on the

bottom of the controller station and re

move the transmitter module.

4 Mount the new transmitter in the reverse

order.

On attaching the hoses to ports x and Z,

it is important not to get them confused.

The supply air hose is fitted with a hose

grommet which contains a restriction

and filter.

-

-

-

Hose grommet

-

Controlled variable x Supply air Z

Fig. 19 · Connecting plate

9.3 Checking the controller

function

To check the controller, the controlled variable and the manipulated variable must be

bypassed at the ports x (26) and y (38) on

the bottom of the controller station.

Set the turnboard A to

34 increasing/decreasing,

restriction to “fully open” and

the T

n

restriction to “closed”.

the T

v

Change the reference variable at the set

4

point knob over the entire range. If the

controller works properly, the controlled

variable pointer (red) and the manipu

lated variable pointer (small pressure

gauge) follow the reference variable over

the whole display range.

-

30 EB 7030 EN

Page 31

Use in hazardous areas

10 Use in hazardous areas

The Type 3430 Controller Station is suitable

for use in potentially explosive atmospheres

in Zones 1 and 2, even though it does not

have its own EC-type examination certifi

cate. The controller station does not require

an EC-type examination certificate accord

ing to 94/9/EC (ATEX).

Conditions for use in hazardous areas:

The controller station is not marked as an

4

explosion-protected device with the cor

responding approval mark.

All installed explosion-protected modules

4

possess their own EC-type examination

certificate.

The maximum values specified in the as-

4

sociated EC-type examination certificate

apply to the connection to intrinsically

safe circuits.

The installation, wiring, terminals, cable

4

entry and other components relevant for

explosion protection comply with

DIN EN 50014, DIN EN 50020 and

DIN EN 60079-14 (VDE 0615).

The transparent door or window of the

4

controller station has a conductive

coating to prevent electrostatic charging.

The measuring circuit of the transmitter

4

model TTH200-E1H has a protection

level corresponding to “ia” and can be

connected to sensors which are routed

into Zone 0. The transmitter itself must

be installed in areas of Zone 1 or

Zone 2.

Caution!

Observe the following for installations in po

tentially explosive atmospheres: On install

ing and performing service work on the de

-

vice, ensure that no electrostatic charging

can arise due to the high surface resistivity

= 1012ohm).

(R

-

insul.

-

-

-

10.1 Servicing explosion-protected

devices

If a part of the apparatus on which the ex

plosion protection is based needs to be ser

viced, it must not be put back into operation

until an expert has inspected the device according to explosion protection requirements, has issued a certificate stating this or

given the device a mark of conformity.

Inspection by an expert is not required if the

manufacturer performs a routine check on

the device prior to putting it back into operation. The passing of the routine check must

be documented by attaching a mark of conformity to the device.

Explosion-protected components may only

be replaced by original, checked compo

nents from the manufacturer.

Devices that have already been used outside

of hazardous areas and are intended for

use in hazardous areas in future must com

ply with the safety demands placed on re

paired devices. Prior to operation, they must

be tested according to the specifications stip

ulated for "Repairing explosion-protected

devices".

-

-

-

-

-

-

EB 7030 EN 31

Page 32

Technical data

11 Technical data

Type 3432 and Type 3431 Controller Station

Actual value display Measuring range 0.2 to 1.0 bar (3 to 15 psi) · Accuracy class 1.6 · Scale length 212 mm

Set point adjustment Output 0.2 to 1.0 bar (3 to 15 psi) · Scale length 212 mm · Accuracy class 1.6

Adjuster for

manual mode

Limit switches

i/p converter

Output 0.2 to 1.0 bar (3 to 15 psi) · Max. 0.02 to 1.35 bar · Max. air supply: >1.5m

1 or 2 SC 3,5-NO-YE proximity switches acc. to DIN EN 60947-5-6 (NAMUR)

Type of protection II 2 G EEx ia IIC T6 (PTB 99 ATEX 2219 X)

Input 4 (0)...20 mA, output 0.2 to 1 bar or 3 to 15 psi for controlled variable x or

external set point w

ext

Upgradable with

Contr. Module Type 3434-1 3434-2 3433-1 3433-2 3433-3 3433-4 3433-5 3436-6 3433-9

Controller function P PI P PI PID PD P/PI PD/PID P

Proportional-action Kp= 1 to 20 Kp= 0.2 to 20 (0.4 to 40)

Reset time Tn[min] – 0.05...20 0.03 to 50

Rate time [min] – 0.01 to 10 · Derivative-action gain of x: approx. 10

Optionally with

Additional Module

Type

Signal Limiter

3437-1

Control Mode

Selector Switch

3437-2

Manual/auto Transfer Switch

3437-3

Output 0.2 to 1 bar (3 to 15 psi) · Max. 0.02 to 1.35 bar

Supply air

Air quality acc. to

ISO 8573-1

Standard version: Supply air 1.4 bar±0.1 bar (20 psi±1.5 psi)

Air consumption < 0.6 m

With supply pressure regulator: Operating air 2.0 to 12 bar (30 to 180 psi)

Air consumption < 0.75 m

With i/p converter: w

Max. particle size and density: Class 3 · Oil content: Class 2 · Pressure dew point: Class 3 or

at least 10 K beneath the lowest ambient temperature to be expected

: +0.13 m

ext

3

/h

n

3

/h

n

3

/h

n

Perm. ambient temp. –20 °C to +60 °C (–40 °C to +60 °C on request)

Degree of protection IP 40, IP 65 front with door

Total weight, approx. 6 kg

Type 3435 Transmitter Module for Pressure

Measuring range [bar]

(set point range)

0 to 1.6 0 to 2.5 0 to 4 0 to 6 0 to 16 0 to 25 0 to 40

Overloadable up to 1.25 times the upper measuring range value

Ultimate strength up to Double times the upper measuring range value (max. 63 bar at 0 to 40 bar)

Performance

Deviation from terminal-based linearity:£0.3 % with terminal-based conformity

Hysteresis:£0.5 % · Overloading to permissible value:£0.1 %

Ambient temperature:£0.04 %/°C

Influence

Supply air:£0.25 %/0.1 bar

Overload on permissible value£0.1 %

3

n

/h

32 EB 7030 EN

Page 33

Technical data

Type 3436 Transmitter Module for Temperature

Measuring span °C 50 100 150 200

Measuring limit °C

–40 to +200 or

150 to 300

Standard ranges °C –20 to +30 0 to 100 50 to 100 0 to 200

Overload limit 350 °C

Perm. pressure at sensor Without thermowell: PN 16 With thermowell PN 63 or PN 100

Supply air Supply air 1.4 ± 0.1 bar (20 ±1.5 psi)

Output 0.2...1.0 bar (3...15 psi)

Deviation from terminal-based

linearity

0.6 % with terminal-based conformity

Hysteresis < 0.25 %

Influence Supply air: < 0.25 %/0.1 bar

Pressure at sensor < 0.6 %/10 bar < 0.25 %/10 bar < 0.15 %/10 bar

Ambient temperature < 0.6 %/°C < 0.03 %/°C

Type 3438 Transmitter Module, consisting of Temperature Transmitter TTH200-E1H with Type 6112-22

i/p Converter Module

Electric Temperature Transmitter TTH200-E1H

Input Pt 100 resistance thermometer (RTD)

Measuring ranges

Connection Four-wire circuit, resistance per wire < 50 ohm

Measuring current < 0.3 mA

Output 4 to 20 mA, linear to temperature

Current consumption < 3.5 mA

Maximum output current 23.6 mA

Supply voltage Two-wire system: Power supply lines = Signal lines

Use in safe area U

Use in hazardous area U

Max. load R

B

Explosion protection II 2(1) G EEx [ia] ib IIC T6 acc. to ATEX

EC-type examination

certificate

–30 to 60 °C, 0 to 40 °C, 0 to 100 °C, 0 to 150 °C, 0 to 200 °C, 0 to 400 °C,

other ranges on request

= 16 to 30 V

S

= 16.5 to 28 (25) VDC, see EC-type examination certificates

S

The supply voltage USdetermines the max. load: RB<

PTB 05 ATEX 2017 X

–40 to +300

DC

(U 16.5 V)

S -

0.022 mA

EB 7030 EN 33

Page 34

Technical data

Electric Temperature Transmitter TTH200-E1H

Fault indication

Sensor breakage > 22 mA

Sensor short-circuit < 3.6 mA

Sensor wire breaking < 3.6 mA or > 22 mA

Supply voltage with reverse

poles

Deviation from terminal-based

0.1% or£0.2 K (whichever value is greater)

£

linearity

Influence of ambient

0.08 %/10 K for lower measuring range value and measuring span,

£

temperature

Influence of supply voltage < 0.5 %/10 V

Output signal refreshment rate 0.4 s when the input signal changes < 0.25 K/s

Electrical isolation (I/O) 3.5 kV

Long-term stability

0.05 % or 0.1 K per year (whichever value is greater)

£

(approx. 2.5 kVAC), 60 s, input/output

DC

Type 6112- … i/p Transmitter Module

Type 6112-02

without explosion protection

Type 6112-22

with explosion protection

1)

Intrinsically safe input circuit · Input impedance 200Wand ~ 0 mH

Input impedance 200Wand ~ 5.9 mH

Explosion protection II 2 G EEx ia IIC T6

EC-type examination certificate PTB 00 ATEX 2021

Input 4 to 20 mA or 0 to 20 mA

Output 0.2 to 1 bar or 3 to 15 psi

Supply air 1.4 bar ± 0.1 bar (20 psi ± 1.5 psi), air consumption < 0.1 m

Performance Characteristic: Output linear to input

Influence Hysteresis£0.3 % · Deviation from terminal-based linearity£0.1 % (fixed set point)

Supply air 0.1 %/0.1 bar

Ambient temperature < 0.03 %/K for lower measuring range value and measuring span, based on 20 °C

Perm. ambient temperature

range

1)

Refer to attached EC-type examination certificates for details (on permissible temperatures, effective internal

capacitance and inductance)

0 mA

based on 20 °C

–40 to +60 °C

3

/h

n

1)

34 EB 7030 EN

Page 35

EB 7030 EN 35

Page 36

36 EB 7030 EN

Page 37

EB 7030 EN 37

Page 38

38 EB 7030 EN

Page 39

EB 7030 EN 39

Page 40

40 EB 7030 EN

Page 41

EB 7030 EN 41

Page 42

42 EB 7030 EN

Page 43

EB 7030 EN 43

Page 44

44 EB 7030 EN

Page 45

EB 7030 EN 45

Page 46

46 EB 7030 EN

Page 47

EB 7030 EN 47

Page 48

48 EB 7030 EN

Page 49

EB 7030 EN 49

Page 50

50 EB 7030 EN

Page 51

EB 7030 EN 51

Page 52

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 7030 EN

S/Z 2010-11

Loading...

Loading...