Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

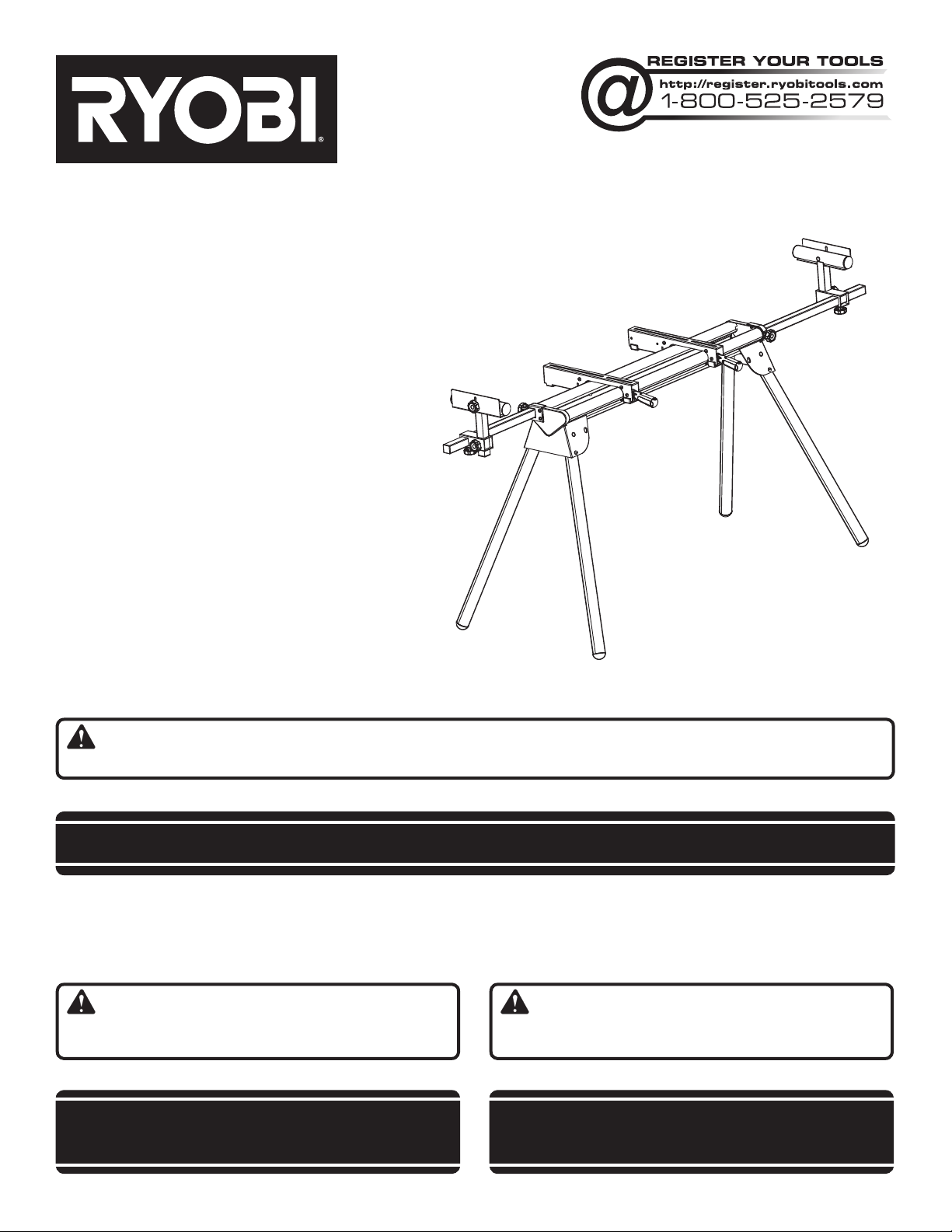

MITER SAW STAND

STAND POUR SCIE À ONGLETS

PEDESTAL PARA SIERRA

INGLETEADORA

RMS10SB

Your miter saw stand has been engineered and manufactured to our high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette stand pour scie à onglets a été conçue et fabriquée

conformément à nos strictes normes de fiabilité, simplicité

d’emploi et sécurité d’utilisation. Correctement entretenue, elle

vous donnera des années de fonctionnement robuste et sans

problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Merci de votre achat.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su pedestal para sierra ingleteadora de pintura ha sido diseñado

y fabricado de conformidad con nuestras estrictas normas para

brindar fiabilidad, facilidad de uso y seguridad para el operador.

Con el debido cuidado, le brindará muchos años de sólido y eficiente funcionamiento.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

Rules for Safe Operation ................................................................................................................................................. 2

Symbols ........................................................................................................................................................................... 3

Features ........................................................................................................................................................................... 4

Assembly ...................................................................................................................................................................... 5-8

Operation ......................................................................................................................................................................... 9

Maintenance .................................................................................................................................................................. 10

RULES FOR SAFE OPERATION

Safe operation of this accessory requires that you read and

understand this operator’s manual, the operator’s manual for

the table saw and all labels affixed to the tool.

READ ALL INSTRUCTIONS

Know your accessory. Read the operator’s manual care-

fully. Learn its applications and limitations, as well as the

specific potential hazards related to this accessory.

Keep the work area clean. Cluttered work areas and

work benches invite accidents.

Always wear safety glasses with side shields.

Everyday glasses have only impact resistant lenses. They

are NOT safety glasses.

This stand will accommodate many miter saws. How-

ever, it should never be used on any miter saw with a blade

diameter larger than 12 in. or with any slide miter saw with

a blade diameter larger than 10 in. Always confirm any

miter saw used is mounted securely and is stable before

plugging in the miter saw. Before turning on the saw,

perform a dry run of the cutting operation just to make

sure that no problems will occur when the cut is made.

WARNING:

Do not modify or use this stand for any purpose for

which it is not intended.

This stand is designed to be used on a flat stable

surface. Do not use the stand on an uneven surface. Be

sure to allow enough room to handle and properly support the workpiece.

Follow the tool mounting instructions carefully, and

ensure the tool is fastened securely.

Maximum weight of the miter saw and workpiece to-

gether must not exceed 300 pounds.

Do not apply an unbalanced load that could cause the

miter saw stand to tip over.

Save these instructions. Refer to them frequently and

use them to instruct others who may use this accessory.

If you loan someone this accessory, loan them these

instructions also to prevent misuse of the product and

possible injury.

This stand is designed for use with miter saws with a blade diameter not larger than 12 in., or a slide miter saw with a

blade diameter not larger than 10 in.

2 - English

Page 3

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL NAME

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Eye Protection

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

DESIGNATION/EXPLANATION

To reduce the risk of injury, user must read and understand operator’s manual before using this product.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

Wet Conditions Alert Do not expose to rain or use in damp locations.

Hot Surface

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

min Minutes Time

Alternating Current Type of current

n

o

.../min Per Minute Revolutions, strokes, surface speed, orbits, etc., per minute

No Load Speed Rotational speed, at no load

Class II Construction Double-insulated construction

To reduce the risk of injury or damage, avoid contact with any hot

surface.

3 - English

Page 4

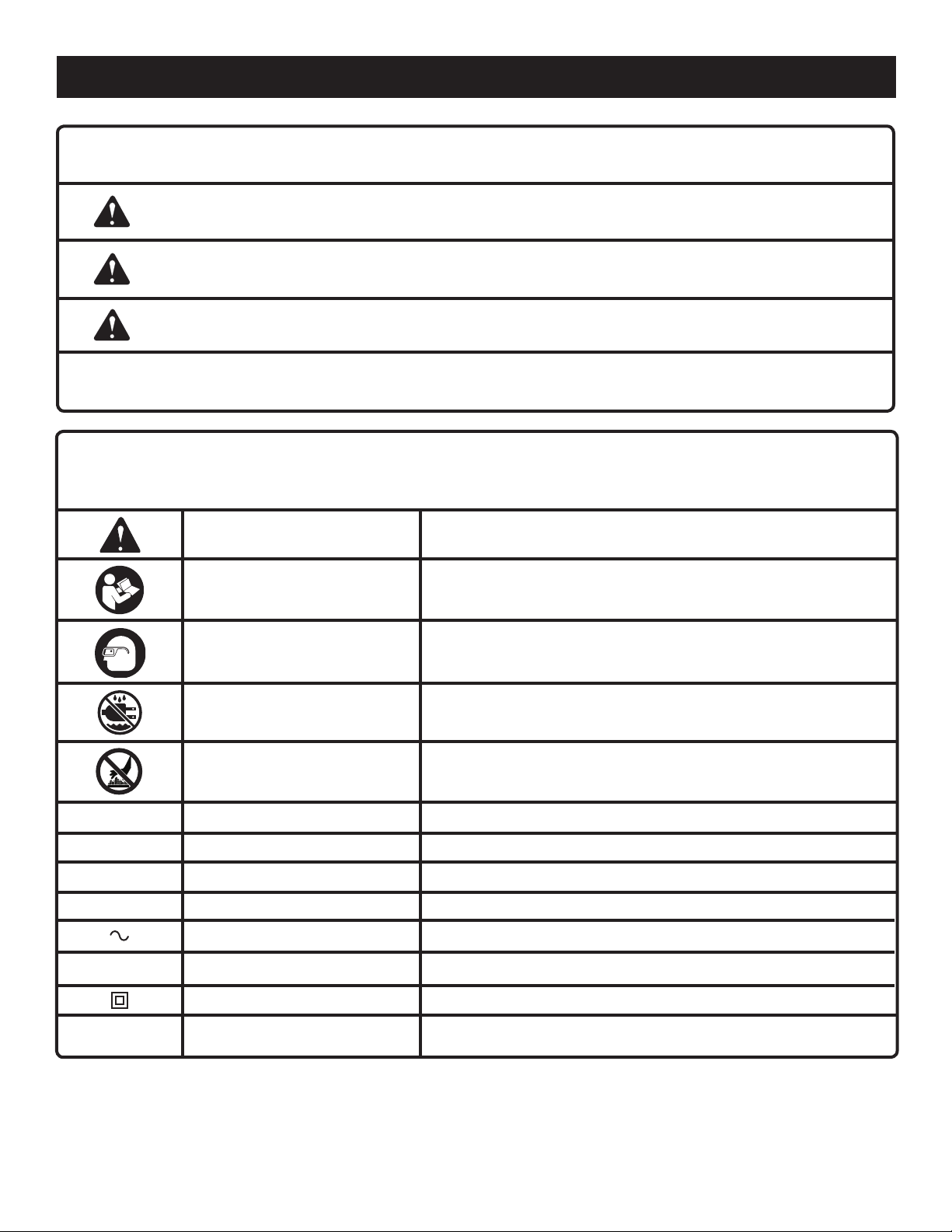

SAW MOUNTING

BRACKET

FEATURES

WORK

STOP

WORK

SUPPORT

WORK

STOP

EXTENSION

RAIL

WORK

SUPPORT

WORK

SUPPORT

MOUNTING

BRACKET

EXTENSION

RAIL

4 - English

Fig. 1

Page 5

ASSEMBLY

UNPACKING

This product requires some assembly.

Carefully remove the tool and any accessories from the

box. Make sure that all items listed in the packing list are

included.

WARNING:

Do not use this product if it is not completely assembled

or if any parts appear to be missing or damaged. Use of

a product that is not properly and completely assembled

could result in serious personal injury.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a

hazardous condition leading to possible serious personal

injury.

PACKING LIST

Miter Saw Stand

Saw Mounting Brackets (2)

Work Supports (2)

Work Support Mounting Brackets (2)

Work Stops (2)

Extension Adjustment Knobs (M8 x 24 mm) (2)

Length Adjustment Knobs (M8 x 18 mm) (2)

Height Adjustment Knobs (M8 x 18 mm) (2)

Work Stop Adjustment Knobs (2)

Carriage Bolts (M6 x 55 mm) (2)

Carriage Bolts (M8 x 45 mm) (4)

Carriage Bolts (M6 x 45 mm) (4)

Flat Washers (8)

Lock Washers (8)

Nuts (8)

Operator’s Manual

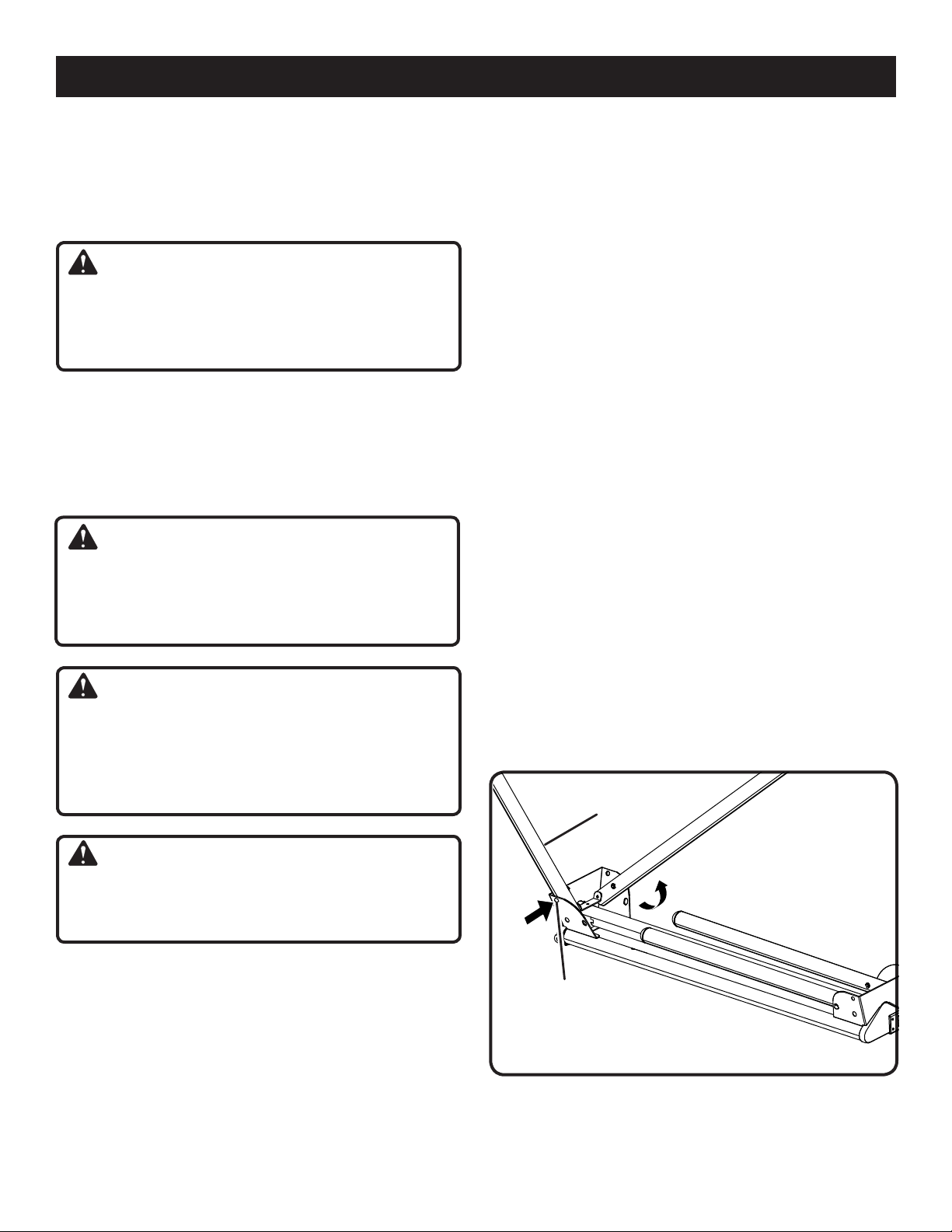

PREPARING THE STAND

See Figure 2.

Lay the stand’s top surface down on the floor with the

folded legs on top.

Push in a leg locking pin and rotate that leg up until the

locking pin clicks into place.

Repeat with the remaining three legs.

Lift the stand and place it in an upright position.

Check to ensure the stand is stable and all the legs have

the locking pins engaged.

LEG

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

5 - English

LOCKING

PIN

Fig. 2

Page 6

ASSEMBLY

ASSEMBLING AND INSTALLING MATERIAL

WORK SUPPORTS

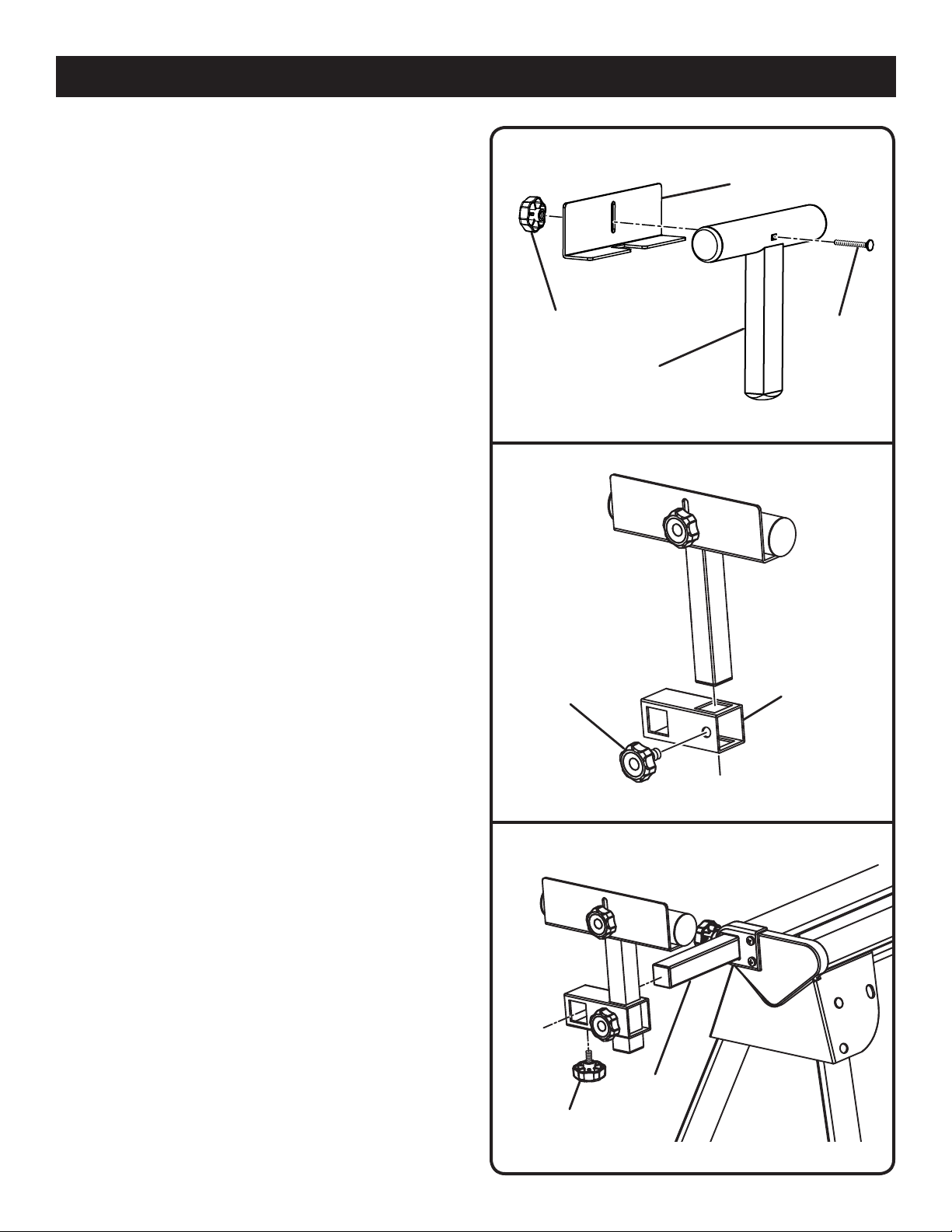

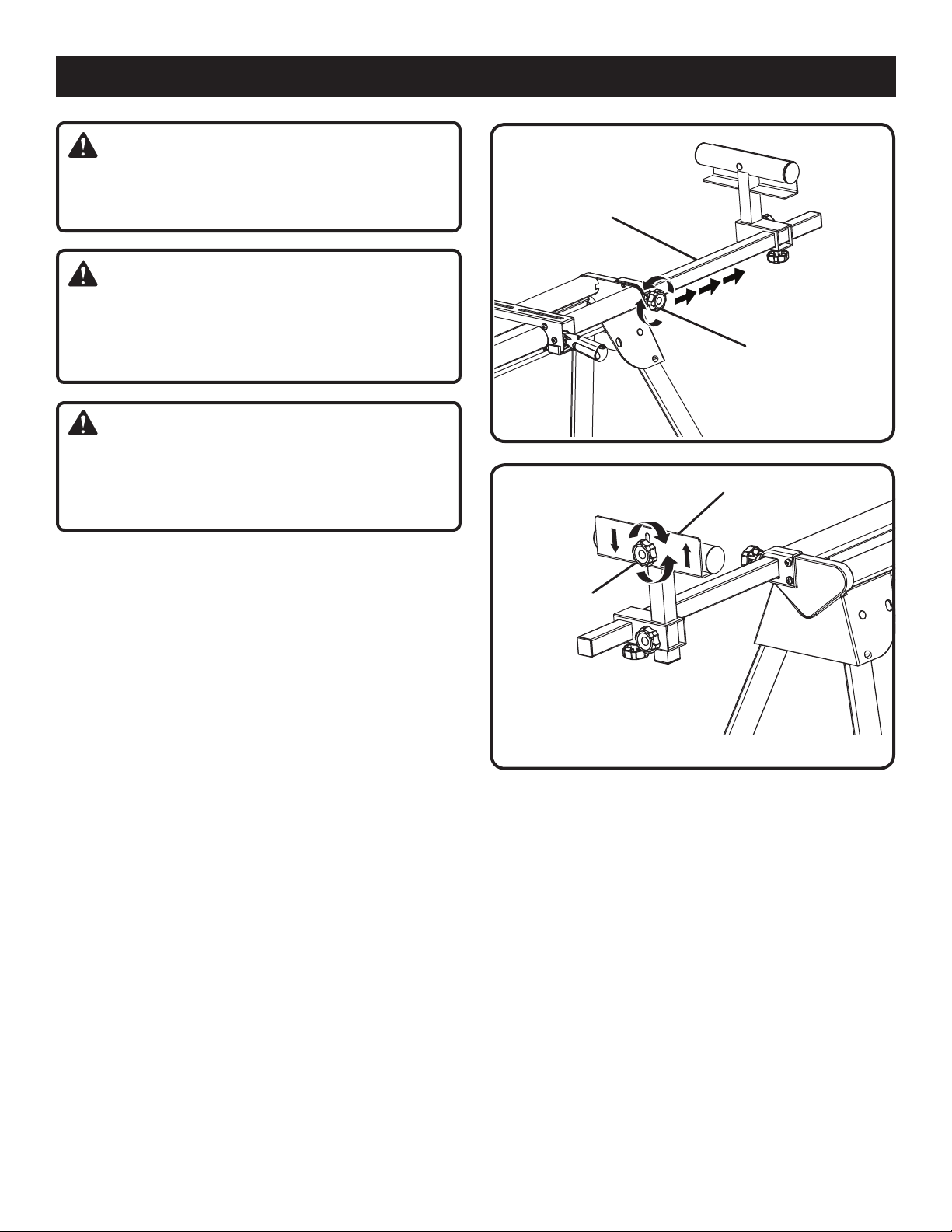

See Figures 3 - 5.

The material work supports help balance the workpiece

during cutting operations.

To assemble the work support:

Slide a carriage bolt (M6 x 55 mm) through the square

hole in the work support and extend through the other

side.

Place the work stop over the end of the bolt

Thread a work stop adjustment knob over the end of the

bolt and tighten to secure.

Slide the work support rail through the hole in the top of

the work support mounting bracket.

Insert the height adjustment knob through the small hole

on the side of the work support mounting bracket and

tighten to secure.

To install the work supports:

Slide the work support mounting bracket over the exten-

sion rail so that the extension rail extends through the

opening in the bracket. Position the work support at the

desired location on the extension rail.

Insert a length adjustment knob through the opening in

the bottom of the work support mounting bracket and

tighten to secure.

Repeat with the other support.

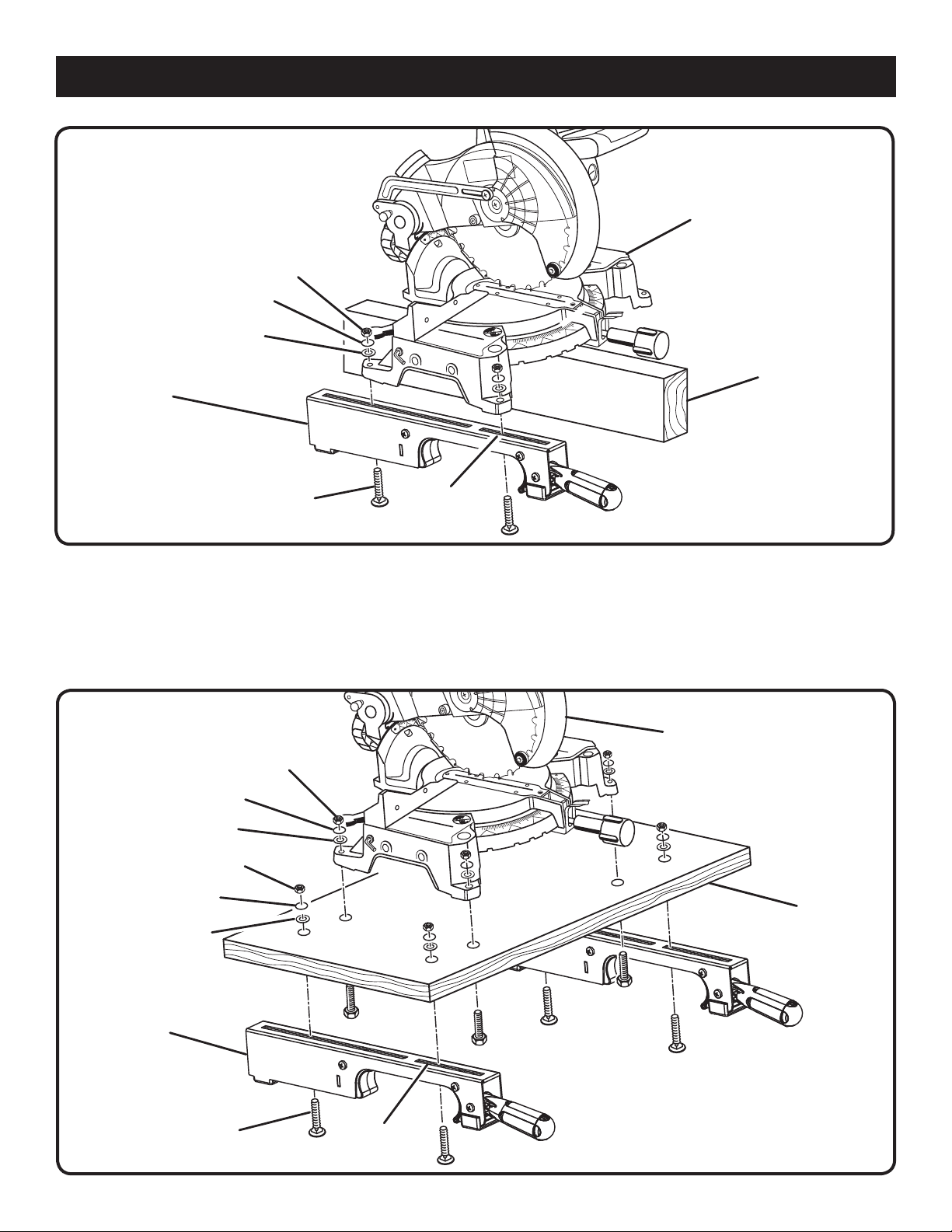

ATTACHING SAW MOUNTING BRACKETS

See Figures 6 - 7.

Always position the saw to achieve maximum balance and

stability. All four corners of the saw must be bolted to the

mounting brackets before use. Make sure bolts do not extend

above the table of the miter saw.

If the saw has holes that line up with the slots in the saw

mounting brackets:

Unplug the saw and lock the saw arm in the down

position.

Place a 2 x 4 or similar type of stable support underneath

the saw to raise the saw and allow access to the saw’s

mounting feet.

Place a saw mounting bracket underneath the raised side

of the saw, aligning the mounting holes on the miter saw

base with the slot in the top of the bracket.

Feed a carriage bolt up through both the bracket and a

mounting hole in the saw.

Secure in place using a flat washer, lock washer and

nut.

Repeat through the other end of the same bracket.

Place the second saw mounting bracket underneath the

other side of the saw, aligning the mounting holes on the

miter saw base with the opening in the bracket.

WORK STOP

ADJUSTMENT KNOB

SUPPORT

HEIGHT

ADJUSTMENT KNOB

LENGTH

ADJUSTMENT KNOB

WORK

STOP

CARRIAGE

BOLT

WORK

Fig. 3

WORK SUPPORT

MOUNTING

BRACKET

Fig. 4

EXTENSION

RAIL

Fig. 5

6 - English

Page 7

LOCK WASHER

FLAT WASHER

ASSEMBLY

MITER

SAW

NUT

SAW MOUNTING

BRACKET

CARRIAGE

BOLT

Install carriage bolts as previously described.

After making sure both brackets are parallel to each other,

finger tighten all four nuts to hold in position.

If the saw has holes that do not line up with the slots in

the saw mounting brackets:

Unplug the saw and lock saw arm in the down position.

NUT

LOCK WASHER

SLOT

2 x 4

Fig. 6

Mount the saw to a mounting surface at least 1/2 in.

thick using 5/16 hex head screws, washers, and nuts

(not included).

Drill holes in the mounting surface to match the slots in

the saw mounting brackets.

Proceed with installation as previously described.

MITER SAW

FLAT WASHER

LOCK WASHER

FLAT WASHER

SAW MOUNTING

BRACKET

CARRIAGE BOLT

NUT

MOUNTING

SURFACE

SLOT

Fig. 7

7 - English

Page 8

ASSEMBLY

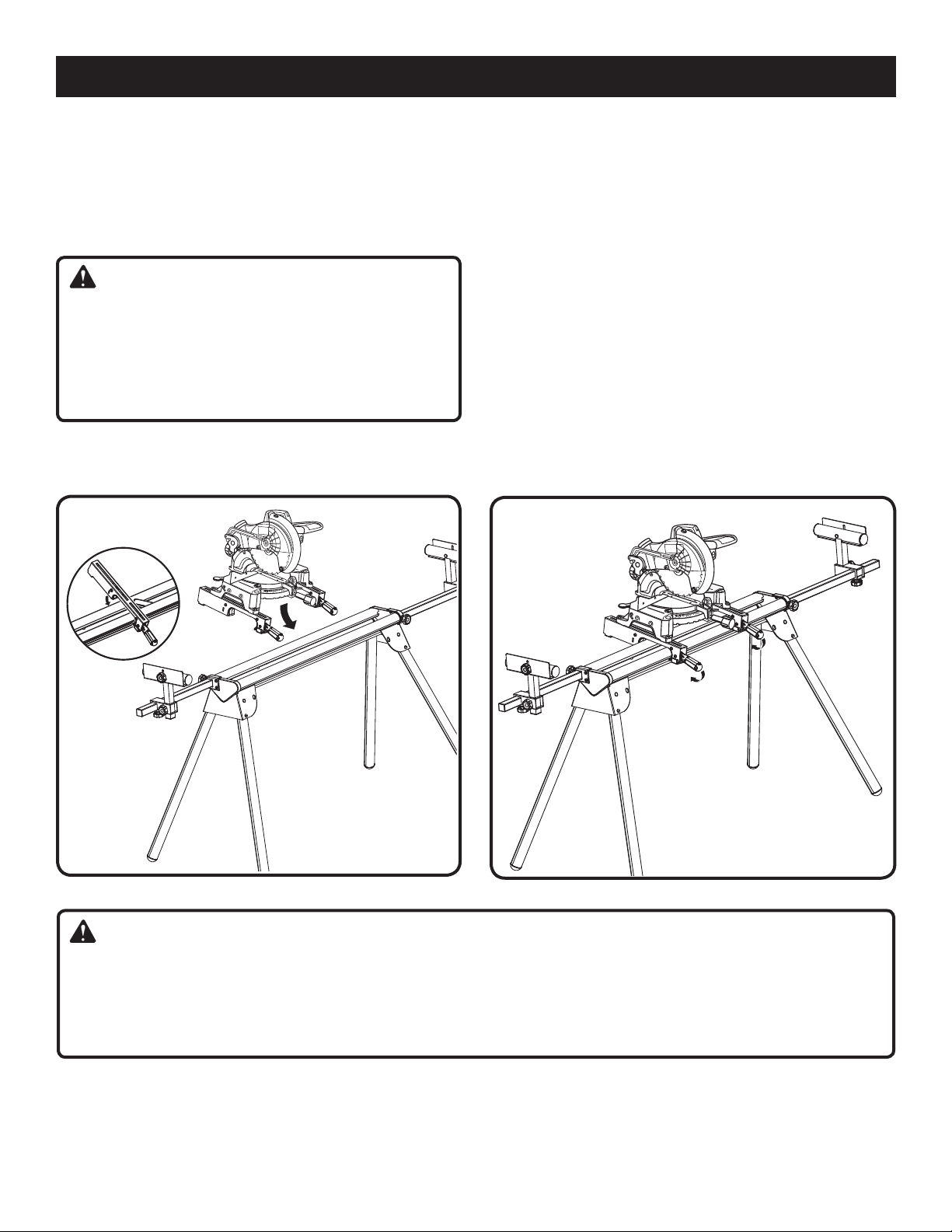

MOUNTING THE MITER SAW TO THE STAND

See Figures 8 - 9.

Lift the saw and bracket assembly, allowing the assembly

to tilt slightly toward your body.

While still tilted toward you, hook the front edge of the

bracket assembly onto the front rail of the stand.

WARNING:

To avoid serious personal injury, make sure the curved

front edge of the mounting brackets are securely seated

over the front rail before seating the other end of the

brackets. Failure to do so could cause you to lose control

of the saw mounting assembly, which could cause serious personal injury.

Lower the bracket assembly to allow the rear edge of the

bracket to seat fully over the rear rail.

Lock the brackets in position by lowering the locking

levers.

NOTE: Continue to hold the mounting bracket assembly

with one hand until both levers are securely locked.

Check position and adjust, if necessary, to make sure

the weight of the saw is evenly balanced over the rails

as shown in figure 9.

Ensure the saw is fully seated and locked in position, then

securely tighten the four nuts holding the saw to the saw

mounting brackets.

To remove saw from stand:

Raise the locking levers to unlock the saw and mounting

bracket assembly.

Lift away from the rear rail of the stand to disengage.

With the assembly tilted slightly toward you, lift the front

part of the assembly to disengage from the front rail of

the stand.

LOWER

LOCKING LEVERS

TO SECURE

TO STAND

Fig. 8

Fig. 9

WARNING:

The mounting brackets are designed to fit snugly over the stand rails. With the locking levers in the lowered (locked)

position, you should not be able to remove the saw and bracket assembly from the rails. If the mounting brackets will

not fit over the rails, or if the mounting brackets can be removed from the rails when the levers are locked, remove from

the saw and bracket assembly immediately and tighten the bracket adjustment screw as described in the Maintenance

section of this manual. Failure to heed this warning can result in serious personal injury.

8 - English

Page 9

OPERATION

WARNING:

Do not allow familiarity with tools to make you careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes resulting in possible

serious injury.

EXTENSION

RAIL

EXTENSION

ADJUSTMENT

KNOB

WARNING:

Do not use any attachments or accessories not recommended by the manufacturer of this tool. The use of attachments or accessories not recommended can result

in serious personal injury.

APPLICATIONS

You may use this tool for the following purpose:

To provide a stable, secure work surface for a miter

saw

USING THE EXTENSION RAILS

See Figure 10.

Use the extension rails when working with larger workpieces.

To extend the rails:

Loosen the extension adjustment knob.

Extend the rail to the desired position.

Tighten the extension adjustment knob.

USING THE WORK STOPS

See Figure 11.

Raise the work stops whenever you need to make repetitive

cuts of the same size. To avoid a greater risk of binding or

pinching, do not use both work stops at the same time.

To raise the work stops:

Loosen the work stop adjustment knob.

Raise the work stop to the desired position.

Tighten the work stop adjustment knob.

Fig. 10

WORK STOP

WORK STOP

ADJUSTMENT

KNOB

Fig. 11

9 - English

Page 10

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts can create a hazard or cause

product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes resulting in possible

serious injury.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

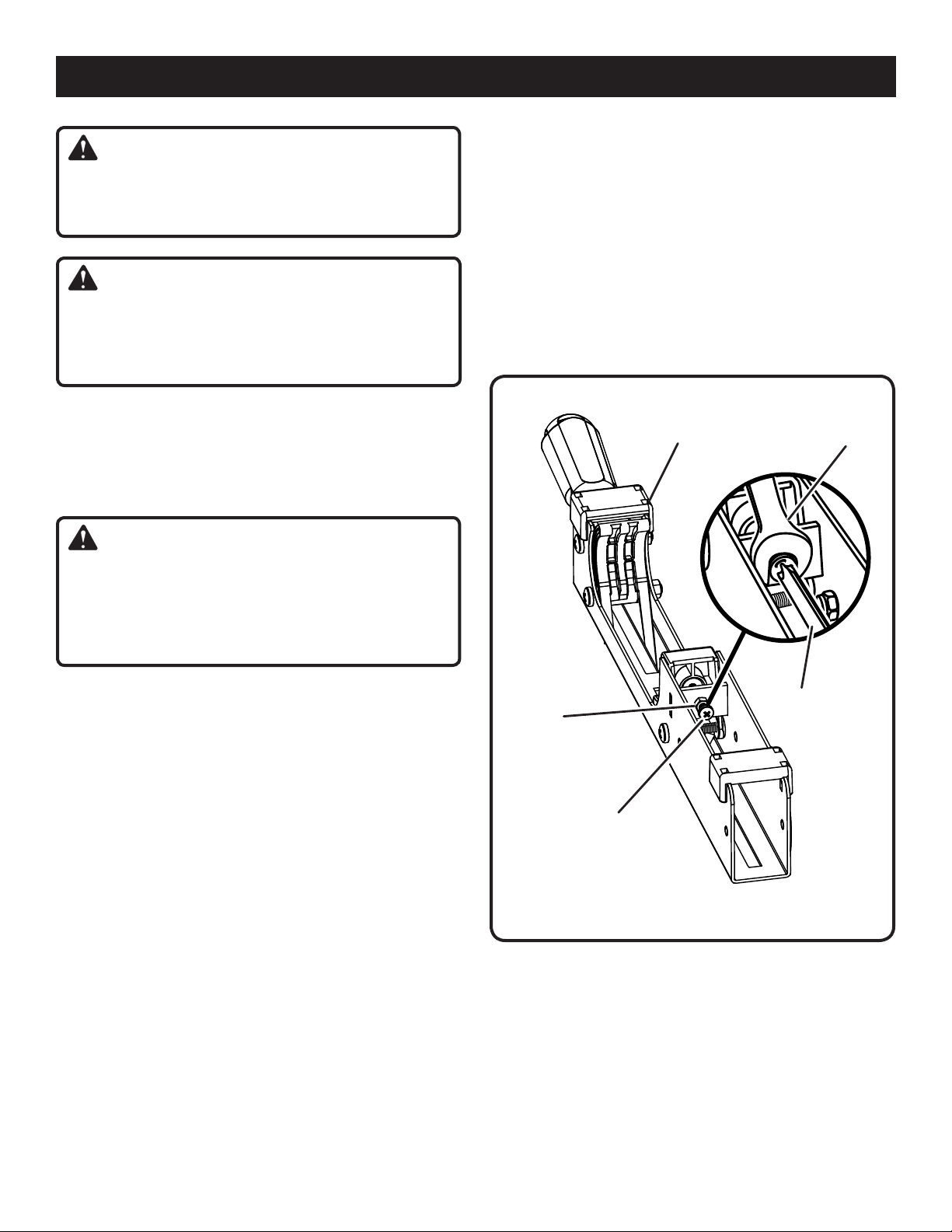

To adjust:

Use a wrench to slightly loosen the nut.

Turn the screw with a phillips screwdriver. Rotate clock-

wise if the bracket assembly needs to be tightened or

counterclockwise if the assembly needs to be loosened.

Install the bracket on the miter stand rails and lower the

locking lever to check the adjustment.

When the correct position is achieved, wrench tighten

the nut to secure.

Repeat with the second mounting bracket.

SAW

MOUNTING

BRACKET

WRENCH

WARNING:

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which can result in serious personal

injury.

BRACKET ADJUSTMENT SCREW

See Figure 12.

Mounting brackets are designed to fit snugly over the stand

rails. With the locking levers in the lowered (locked) position,

you should not be able to remove the saw and bracket assembly from the rails. If the saw and bracket assembly can

be removed from the rails when the levers are locked, the

bracket adjustment screws need to be tightened. If the saw

and bracket assembly will not fit over both rails, the bracket

adjustment screws needs to be loosened.

NOTE: The saw should be removed from the mounting

brackets before attempting to tighten or loosen the bracket

adjustment screws.

SCREWDRIVER

NUT

BRACKET

ADJUSTMENT

SCREW

Fig. 12

10 - English

Page 11

TABLE DES MATIÈRES

Règles pour la sécurité d’utilisation ...........................................................................................................................................2

Symboles ...................................................................................................................................................................................3

Caractéristiques .............................................................................................................................................................. 4

Assemblage ............................................................................................................................................................................ 5-8

Utilisation ....................................................................................................................................................................................9

Entretein ...................................................................................................................................................................................10

RÈGLES POUR LA SÉCURITÉ D’UTILISATION

La sécurité d’utilisation de cet accessoire exige que ce

manuel, le manuel d’utilisation de la scie circulaire à table

ainsi que tous les autocollants apposés sur l’outil soient lus

et bien compris.

LIRE TOUTES LES INSTRUCTIONS

Apprendre à connaître l’accessoire. Lire attentivement

le manuel d’utilisation. Apprendre les applications et les

limites de l’accessoire, ainsi que les risques spécifiques

relatifs à son utilisation.

Garder le lieu de travail propre. Un lieu de travail et un

établi encombrés sont propices aux accidents.

Toujours porter des lunettes de sécurité avec écrans

latéraux. Les lunettes de vue ordinaires sont munies

seulement de verres résistants aux impacts. Ce ne sont PAS

des lunettes de sécurité.

Ce stand peut être utilisé avec de nombreuses scies

à onglet. Toute fois, il ne doit jamais être utilisé pour

une scie à onglet de quelque type que ce soit à lame de

305 mm (12 po) ni pour une scie à onglet coulissante à

lame de 254 mm (10 po). Toujours vérifier que la scie à

onglet est solidement assujettie sur le stand avant de la

brancher. Avant de mettre la scie en marche, effectuer

un essai à vide, afin de s’assurer qu’aucun problème ne

se présentera lorsque la coupe est effectuée. Le respect

de cette règle réduira les risques de blessures graves.

Ne pas modifier le stand ou l’utiliser pour des applications

pour lesquelles il n’est pas conçu.

Ce stand est conçu pour être utilisé sur une surface

plane et stable. Ne pas l’utiliser sur une surface irrégulière.

Veiller à prévoir suffisamment d’espace pour pouvoir soutenir

correctement les pièces à couper et les manipuler.

Suivre les instructions de montage à la lettre et s’assurer

que l’outil est solidement assujetti.

Le poids total de la scie et de la pièce ne doit pas dépasser

136 kg (300 lb).

Ne pas appliquer une charge en déséquilibre sur le stand,

qui risquerait de le faire basculer.

Conserver ces instructions. Les consulter fréquemment

et les utiliser pour instruire les autres utilisateurs éventuels.

Si cet accessoire est prêté, il doit être accompagné de ces

instructions, afin d’éviter un usage incorrect et d’éventuelles

blessures.

AVERTISSEMENT :

Ce stand est conçu pour être utilize avec des scies à onglets ayant un diamètre de lame inférieur à 305 mm (12 po), ou

une scie à onglets coulissante ayant un diamètre de lame inférieur à 254 mm (10 po).

2 - Françias

Page 12

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à

l’utilisation de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

Indique une situation extrêmement dangereuse qui, si elle n’est pas

évitée, aura pour conséquences des blessures graves ou mortelles.

AVERTISSEMENT :

ATTENTION :

AVIS :

Certains des symboles ci-dessous peuvent être utilisés sur l’outil. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser l’outil plus efficacement et de réduire les risques.

SYMBOLE NOM

Symbole d’alerte de sécurité Indique un risque de blessure potentiel.

Lire le manuel d’utilisation

Protection oculaire

Avertissement concernant

l’humidité

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité) Indique une information importante

ne concernant pas un risque de blessure comme une situation pouvant

occasionner des dommages matériels.

DÉSIGNATION / EXPLICATION

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à

bien comprendre le manuel d’utilisation avant d’utiliser ce produit.

Toujours porter une protection oculaire avec écrans latéraux

certifiée conforme à la norme ANSI Z87.1.

Ne pas exposer à la pluie ou l’humidité.

Surface brûlante

V Volts Tension

A Ampères Intensité

Hz Hertz Fréquence (cycles par seconde)

min Minutes Temps

Courant alternatif Type de courant

n

o

.../min Par minute Tours, coups, vitesse périphérique, orbites, etc., par minute

Vitesse à vide Vitesse de rotation à vide

Construction de classe II Construction à double isolation

Pour éviter les risques de blessures ou de dommages, éviter tout

contact avec les surfaces bûlantes.

3 - Françias

Page 13

BUTÉE

CARACTÉRISTIQUES

BUTÉE

SUPPORT

DE TRAVAIL

SUPPORT DE

MONTAGE

DE LA SCIE

SUPPORT

DE TRAVAIL

ÉQUERRE

DE SUPPORT

DE PIÈCE

RAIL

D’EXTENSION

RAIL

D’EXTENSION

Fig. 1

4 - Françias

Page 14

ASSEMBLAGE

UNPACKING

Ce produit a été expédié complètement assemblé.

Avec précaution, sortir l’outil et les accessoires de la

boîte. S’assurer que toutes les pièces figurant sur la liste

de contrôle sont incluses.

AVERTISSEMENT :

Ne pas utiliser le produit s’il n’est pas complètement

assemblé ou si des pièces semblent manquantes ou

endommagées. Le fait d’utiliser un produit assemblé

de façon inadéquate ou incomplète peut entraîner des

blessures graves.

Examiner soigneusement l’outil pour s’assurer que rien

n’a été brisé ou endommagé en cours de transport.

Ne pas jeter les matériaux d’emballage avant d’avoir

soigneusement examiné l’outil et avoir vérifié qu’il

fonctionne correctement.

Si des pièces sont manquantes ou endommagées,

appeler le 1-800-525-2579.

AVERTISSEMENT :

Si des pièces manquent ou sont endommagées, ne pas

utiliser cet outil avant qu’elles aient été remplacées. Le

fait d’utiliser ce produit même s’il contient des pièces

endommagées ou s’il lui manque des pièces peut

entraîner des blessures graves.

AVERTISSEMENT :

Ne pas essayer de modifier cet outil ou de créer des

accessoires non recommandés pour l’outil. De telles

altérations ou modifications sont considérées comme un

usage abusif et peuvent créer des conditions dangereuses,

risquant d’entraîner des blessures graves.

PACKING LIST

Stand pour scie à onglets

Supports de montage de la scie (2)

Supports de pièce (2)

Équerre de support de pièce (2)

Butées (2)

Bouton de réglage d’extension (M8 x 24 mm) (2)

Bouton de réglage de longueur (M8 x 18 mm) (2)

Boutons de réglage de hauteur (M8 x 18 mm) (2)

Boutons de réglage de butée (2)

Boulon de carrossier (M6 x 55 mm) (2)

Boulons de carrossier (M8 x 45 mm) (4)

Boulons de carrossier (M6 x 45 mm) (4)

Rondelles plates (8)

Rondelles frein (8)

Écrous (8)

Manuel d’utilisation

PRÉPARATION DU STAND

Voir la figure 2.

Poser le stand à l’envers sur le sol, les pieds pliants dirigés

vers le haut.

Appuyer sur la goupille de verrouillage de l’un dés pieds

et relever ce pied jusqu’à ce que la goupille s’engage

dans son trou.

Répéter la procédure pour les trois autres pieds.

Soulever le stand et le mettre à l’endroit.

Vérifier que le stand est stable et que toutes les goupilles

de verrouillage des pieds sont engagées.

PIED

AVERTISSEMENT :

Ne pas brancher sur le secteur avant d’avoir terminé

l’assemblage. Le non respect de cet avertissement peut

causer un démarrage accidentel, entraînant des blessures

graves.

5 - Françias

AXE DE

BLOCAGE

Fig. 2

Page 15

ASSEMBLAGE

ASSEMBLAGE ET INSTALLATION DES

SUPPORTS DE PIÈCE

Voir les figures 3 à 5.

Les supports aident à maintenir l’équilibre des pièces

pendant la coupe.

Assemblage des supports de pièce :

Insérer un boulon de carrossier (M6 x 55 mm) dans le trou

carré du support de pièce et le faire ressortir de l’autre

côté.

Placer le support de pièce sur le boulon.

Visser un bouton de réglage de butée sur le boulon et le

serrer.

Glisser le rail du support de pièce dans le trou de son

support de montage.

Insérer le bouton de réglage de hauteur dans le petit trou

latéral du support de pièce et le serrer.

Installation des supports de pièce :

Glisser le support sur le rail d’extension, jusqu’à ce que

ce dernier dépasse du trou du support. Positionner le

support à l’endroit désiré du rail d’extension.

Insérer un bouton de réglage de longueur dans le petit

trou inférieur du support de pièce et le serrer.

Répéter l’opération pour l’autre support.

BOUTONS

DE RÉGLAGE

DE BUTÉE

BUTÉE

BOULON DE

CARROSSIER

SUPPORT

DE TRAVAIL

Fig. 3

INSTALLATION DES SUPPORTS DE

MONTAGE DE LA SCIE

Voir les figures 6 et 7.

Toujours positionner la scie de manière à obtenir un

maximum d’équilibre et de stabilité. Avant d’utiliser la scie,

les quatre coins de sa base doivent être boulonnés sur

les supports de montage. S’assurer que les boulons ne

dépassent pas de la table de la scie.

Si la scie comporte des trous qui s’alignent sur les fentes

des supports de montage :

Débrancher la scie et verrouiller le bras en position

abaissée.

Placer un morceau de montant 2 x 4 ou un objet similaire

au-dessous de la scie pour la soulever, afin de pouvoir

accéder à ses pieds de montage.

Placer un support de montage au-dessous du côté

soulevé de la scie, en alignant les trous de montage de

la base de la scie sur la fente du dessus du support.

Insérer un boulon de carrossier dans le support et un trou

de montage de la scie.

Assujettir le boulon avec une rondelle plate, une rondelle

frein et un écrou.

Répéter l’opération à l’autre extrémité du support.

Placer le second support de montage au-dessous de

l’autre côté de la scie, en alignant les trous de montage

de la base de la scie sur la fente du support.

Installer les boulons de carrossier comme décrit

précédemment.

Après avoir vérifié que les deux supports sont parallèles,

serrer les quatre boulons à la main, pour les maintenir en

place.

BOUTON

DE RÉGLAGE

DE HAUTEUR

D’EXTENSION

BOUTON DE RÉGLAGE

DE LONGUEUR

ÉQUERRE DE

SUPPORT DE PIÈCE

Fig. 4

RAIL

Fig. 5

6 - Françias

Page 16

RONDELLE FREIN

RONDELLE PLATE

ASSEMBLAGE

SCIE À

ONGLETS

ÉCROU

SUPPORT

DE MONTAGE

DE SCIE

BOULON DE

CARROSSIER

Si la scie comporte des trous qui ne s’alignent pas sur

les fentes des supports de montage :

Débrancher la scie et verrouiller le bras en position

abaissée.

ÉCROU

RONDELLE FREIN

FENTE

2 x 4

Fig. 6

Monter la scie sur une planche d’au moins 13 mm

(1/2 po) d’épaisseur au moyen de quatre vis hex. 5/16

po, rondelles et écrous à six pans (non inclus).

Percer des trous dans la planche, correspondant à ceux

du support de montage de la scie.

Monter la scie comme décrit précédemment.

SCIE À ONGLETS

RONDELLE PLATE

RONDELLE FREIN

RONDELLE PLATE

SUPPORT

DE MONTAGE

DE SCIE

BOULON DE

CARROSSIER

ÉCROU

SURFACE

DE MONTAGE

FENTE

Fig. 7

7 - Françias

Page 17

ASSEMBLAGE

MONTAGE DE LA SCIE À ONGLETS SUR LE

STAND

Voir les figures 8 et 9.

Soulever l’ensemble scie et support en le laissant basculer

légèrement vers soi.

L’ensemble étant toujours incliné vers soi, accrocher le

bord avant du support sur le rail avant du stand.

AVERTISSEMENT :

Pour éviter des blessures graves, s’assurer que le bord

incurvé des supports de montage est bien engagé sur

le rail avant, avant d’engager l’autre extrémité des

supports. Ne pas prendre cette précaution pourrait

causer la perte de contrôle de la scie, entraînant des

blessures graves.

Abaisser les leviers des supports pour les verrouiller en

place.

Abaisser le support de manière à ce que son bord arrière

s’engage complètement sur le rail arrière.

NOTE : Continuer de tenir le support de montage avec

une main jusqu’à ce que les deux leviers soient solidement verrouillés.

Vérifier la position et l’ajuster selon le besoin, pour

s’assurer que le poids de la scie est uniformément réparti

sur les rails, comme le montre la figure 9.

S’assurer que la scie est bien en place et verrouillée en

position, puis serrer fermement les quatre boulons de

fixation de la scie sur ses supports de montage.

Pour retirer la scie du stand :

Relever les leviers de verrouillage pour libérer l’ensemble

scie et supports de montage.

Soulever ce dernier pour le désengager du rail arrière.

L’ensemble étant toujours incliné vers soi, soulever l’avant

pour le désengager du rail avant du stand.

ABAISSER LES

LEVIERS DE

VERROUILLAGE

POUR ASSUJETTIR

SUR LE STAND

Fig. 8

Fig. 9

AVERTISSEMENT :

Les supports de montage sont conçus pour un ajustement serré sur les rails du stand. Lorsque les leviers de verrouillage

sont abaissés (position verrouillée) il ne devrait pas être possible de séparer la scie et le support des rails. Si les supports

de montage ne peuvent pas être engagés sur les rails ou s’ils peuvent en être retirés lorsque les leviers de verrouillage

sont abaissés, retirer immédiatement la scie et son support du stand et serrer la vis de réglage, comme décrit à la section Entretien de ce manuel. Le non respect de cet avertissement peut entraîner des blessures graves.

8 - Françias

Page 18

AVERTISSEMENT :

UTILISATION

Ne pas laisser la familiarité avec l’outil faire oublier la

prudence. Ne pas oublier qu’une fraction de seconde

d’inattention peut entraîner des blessures graves.

AVERTISSEMENT :

Toujours porter une protection oculaire certifiée conforme

à la norme ANSI Z87.1. Si cette précaution n’est pas

prise, des objets peuvent être projetés dans les yeux et

causer des lésions graves.

AVERTISSEMENT :

Ne pas utiliser d’outils ou accessoires non recommandés

pour cet outil. L’utilisation de pièces et accessoires non

recommandés peut entraîner des blessures graves.

APPLICATIONS

Cet outil peut être utilisé pour l’application ci-dessous :

Procurer un support stable et sûr pour les scies à

onglets

UTILISATION DES RAILS D’EXTENSION

Voir la figure 10.

Utiliser les rails d’extension pour le travail sur les pièces de

grande taille.

Extension des rails :

Desserrer le bouton de réglage d’extension.

Étendre le rail à la position désirée.

Resserrer le bouton de réglage d’extension.

RAIL

D’EXTENSION

BOUTON DE

RÉGLAGE

D’EXTENSION

Fig. 10

BUTÉE

BOUTON DE

RÉGLAGE DE

BUTÉE

Fig. 11

UTILISATION DES BUTÉES

Voir la figure 11.

Relever les butées pour effectuer des coupes répétitives à

la même dimension. Pour ne pas courir un plus grand risque

de grippage ou de pincement, ne pas utiliser les deux butées

en même temps.

Pour relever les butées :

Desserrer le bouton de réglage de butée.

Élever la butée à la position désirée.

Resserrer le bouton de réglage de butée.

9 - Françias

Page 19

ENTRETIEN

AVERTISSEMENT :

Utiliser exclusivement des pièces d’origine pour les

réparations. L’usage de toute autre pièce pourrait créer

une situation dangereuse ou endommager l’outil.

AVERTISSEMENT :

Toujours porter une protection oculaire certifiée conforme

à la norme ANSI Z87.1. Si cette précaution n’est pas

prise, des objets peuvent être projetés dans les yeux et

causer des lésions graves.

Réglage :

Desserrer légèrement l’écrou avec une clé.

Tourner la vis à l’aide d’un tournevis Phillips. Tourner vers

la droite pour serrer le support et vers la gauche pour le

desserrer.

Installer le support sur les rails du stand et abaisser le

levier de verrouillage pour vérifier le réglage.

Une fois la position correcte obtenue serrer l’écrou pour

maintenir le réglage.

Répéter la procédure avec le deuxième ensemble

support.

ENTRETIEN GÉNÉRAL

Éviter d’utiliser des solvants pour le nettoyage des

pièces en plastique. La plupart des matières plastiques

peuvent être endommagées par divers types de solvants

du commerce. Utiliser un chiffon propre pour éliminer la

saleté, la poussière, l’huile, la graisse, etc.

AVERTISSEMENT :

Ne jamais laisser de liquides tels que le fluide de freins,

l’essence, les produits à base de pétrole, les huiles

pénétrantes, etc., entrer en contact avec les pièces en

plastique. Les produits chimiques peuvent endommager,

affaiblir ou détruire le plastique, ce qui peut entraîner des

blessures graves.

VIS DE RÉGLAGE DU SUPPORT

Voir la figure 12.

Les supports de montage sont conçus pour un ajustement

serré sur les rails du stand. Lorsque les leviers de verrouillage sont abaissés (position verrouillée) il ne devrait pas être

possible de séparer la scie et le support des rails. Si la scie et

son support peuvent être retirés des rails lorsque les leviers

sont abaissés, la vis de serrage du support doit être serrée.

Si la scie et son support ne peuvent être engagés sur les

rails, la vis de serrage du support doit être desserrée.

REMARQUE : La scie doit être retirée des supports de

montage avant d’essayer de serrer ou desserrer la vis de

réglage du support.

ÉCROU

VIS DE

RÉGLAGE DU

SUPPORT

SUPPORT DE

MONTAGE

DE LA SCIE

CLÉ

TOURNEVIS

Fig. 12

10 - Françias

Page 20

ÍNDICE DE CONTENIDO

Reglas para el manejo seguro de la unidad ...............................................................................................................................2

Símbolos ....................................................................................................................................................................................3

Características ...........................................................................................................................................................................4

Armado ................................................................................................................................................................................... 5-8

Funcionamiento ..........................................................................................................................................................................9

Maintenimiento .........................................................................................................................................................................10

REGLAS PARA EL MANEJO SEGURO DE LA UNIDAD

Para manejar con seguridad este accesorio, se requiere la

lectura y la comprensión de este manual del operador, el

manual del operador correspondiente a la sierra de mesa, así

como de todas las etiquetas adheridas a la herramienta.

LEA TODAS LAS INSTRUCCIONES

Familiarícese con el accesorio. Lea cuidadosamente el

manual del operador. Aprenda sus usos y limitaciones, así

como los posibles peligros específicos de este accesorio.

Mantenga limpia el área de trabajo. Las áreas y mesas

de trabajo mal despejadas son causas comunes de

accidentes.

Siempre use gafas de seguridad con protección lateral.

Los anteojos comunes sólo tienen lentes resistentes a los

impactos. NO son anteojos de seguridad.

Este pedestal sirve para numerosas sierras

ingleteadoras. No obstante, nunca debe usarse con

ninguna sierra ingleteadora con una hoja de un diámetro

superior a 305 mm (12 pulg.), ni con ninguna sierra

ingleteadora deslizante con una hoja de un diámetro

superior a 254 mm (10 pulg.). Siempre confirme que

cualquiera que sea la sierra empleada, esté montada

firmemente y esté estable antes de conectarla. Antes de

encender la sierra, efectúe una simulación de la operación

de corte, sólo para asegurarse de que no suceda ningún

problema durante la operación de corte real. Con el

cumplimiento de esta regla se reduce el riesgo de lesiones

corporales serias.

No modifique este pedestal para ningún fin no

especificado aquí.

Este pedestal está diseñado para emplearse sobre una

superficie horizontal estable. No coloque el pedestal en

ninguna superficie desigual. Asegúrese de dejar suficiente

espacio para manejar y dar apoyo de forma adecuada a la

pieza de trabajo.

Siga con cuidado las instrucciones de montaje, y

asegúrese de dejar firmemente unida la herramienta.

El peso máximo de la sierra ingleteadora y la pieza de

trabajo juntos debe no ser superior a 136 kg (300 lb).

No aplique una carga desequilibrada que pudiera volcar

el pedestal de la sierra ingleteadora.

Guarde estas instrucciones. Consúltelas con frecuencia y

empléelas para instruir a otras personas que puedan utilizar

este accesorio. Si presta a alguien este accesorio, facilítele

también las instrucciones con el fin de evitar un uso indebido

del producto y posibles lesiones.

ADVERTENCIA:

Este banco está diseñado para emplearse con sierra ingleteadora con hoja de un diámetro menor a 305 mm (12 pulg.)

o con sierra ingleteadora deslizante con hoja de un diámetro menor a 254 mm (10 pulg.).

2 - Español

Page 21

SÍMBOLOS

Las siguientes palabras de señalización y sus significados tienen el objeto de explicar los niveles de riesgo relacionados

con este producto.

SÍMBOLO SEÑAL SIGNIFICADO

PELIGRO:

Indica una situación peligrosa inminente, la cual, si no se evita, causará la muerte

o lesiones serias.

ADVERTENCIA:

PRECAUCIÓN:

AVISO:

Es posible que se empleen en esta herramienta algunos de los siguientes símbolos. Le suplicamos estudiarlos

y aprender su significado. Una correcta interpretación de estos símbolos le permitirá utilizar mejor y de manera más segura

la herramienta.

SÍMBOLO NOMBRE

Alerta de seguridad Indica un peligro posible de lesiones personales.

Lea el manual del operador

Protección ocular

Indica una situación peligrosa posible, la cual, si no se evita, podría causar la

muerte o lesiones serias.

Indica una situación peligrosa posible, la cual, si no se evita, podría causar

lesiones menores o leves.

(Sin el símbolo de alerta de seguridad) Indica información importante no relacionada con ningún peligro de lesiones, como una situación que puede ocasionar

daños físicos.

DENOMINACIÓN/EXPLICACIÓN

Para reducir el riesgo de lesiones, el usuario debe leer y comprender

el manual del operador antes de usar este producto.

Siempre póngase protección ocular con protección lateral con

la marca de cumplimiento de la norma ANSI Z87.1.

Alerta de condiciones

húmedas

Superficie caliente

V Volts Voltaje

A Amperes Corriente

Hz Hertz Frecuencia (ciclos por segundo)

min Minutos Tiempo

Corriente alterna Tipo de corriente

n

o

.../min Por minuto

Velocidad en vacío Velocidad de rotación, en vacío

Fabricación Clase II Fabricación con doble aislamiento

No exponga la unidad a la lluvia ni la use en lugares húmedos.

Para reducir el riesgo de lesiones corporales o daños materiales

evite tocar toda superficie caliente.

Revoluciones, carreras, velocidad superficial, órbitas, etc., por

minuto

3 - Español

Page 22

TOPE DE LA

PIEZA DE

TRABAJO

SOPORTE DE

LA PIEZA DE

TRABAJO

CARACTERÍSTICAS

TOPE DE LA

PIEZA DE

TRABAJO

SOPORTE DE

LA PIEZA DE

TRABAJO

APOYO DE

MONTAJE DE LA

SIERRA

PLACAS DE

MONTAJE

DE LOS

SOPORTES

DE LA PIEZA

DE TRABAJO

RIEL DE

EXTENSIÓN

RIEL DE

EXTENSIÓN

Fig. 1

4 - Español

Page 23

ARMADO

DESEMPAQUETADO

Embarcamos este producto completamente armado.

Extraiga cuidadosamente de la caja la herramienta y los

accesorios. Asegúrese de que estén presentes todos los

artículos enumerados en la lista de empaquetado.

ADVERTENCIA:

No use este producto si no está totalmente ensamblado o

si alguna pieza falta o está dañada. Si utiliza un producto

que no se encuentra ensamblado de forma correcta y

completa, puede sufrir lesiones graves.

Inspeccione cuidadosamente la herramienta para

asegurarse de que no haya sufrido ninguna rotura o daño

durante el transporte.

No deseche el material de empaquetado hasta que haya

inspeccionado cuidadosamente la herramienta y la haya

utilizado satisfactoriamente.

Si hay piezas dañadas o faltantes, le suplicamos llamar

al 1-800-525-2579, donde le brindaremos asistencia.

ADVERTENCIA:

Si hay piezas dañadas o faltantes, no utilice esta

producto sin haber reemplazado todas las piezas. Usar

este producto con partes dañadas o faltantes puede

causar lesiones serias al operador.

ADVERTENCIA:

No intente modificar esta herramienta ni hacer accesorios

no recomendados para la misma. Cualquier alteración o

modificación constituye maltrato el cual puede causar

una condición peligrosa, y como consecuencia posibles

lesiones corporales serias.

LISTA DE EMPAQUETADO

Pedestal para sierra ingleteadora

Placas de montaje de la sierra (2)

Soportes de la pieza de trabajo (2)

Placas de montaje de los soportes de la pieza

de trabajo (2)

Topes de la pieza de trabajo (2)

Perillas de ajuste de extensión (M8 x 24 mm) (2)

Perillas de ajuste de longitud (M8 x 18 mm) (2)

Perillas de ajuste de altura (M8 x 18 mm) (2)

Perillas de ajuste de tope de pieza de trabajo (2)

Pernos de carruaje (M6 x 55 mm) (2)

Pernos de carruaje (M8 x 45 mm) (4)

Pernos de carruaje (M6 x 45 mm) (4)

Arandelas planas (8)

Arandelas de seguridad (8)

Tuercas (8)

Manual del operador

PREPARACIÓN DEL PEDESTAL

Vea la figura 2.

Coloque la superficie superior del pedestal en el piso,

con las patas dobladas.

Oprima el pasador de seguridad de una pata y voltee hacia

arriba ésta hasta que entre en su lugar el pasador.

Repita este procedimiento con las tres patas restantes.

Levante el pedestal y colóquelo en posición vertical.

Revise para asegurarse de que el pedestal esté estable

y todas las patas tengan enganchado el pasador de

seguridad.

PATA

ADVERTENCIA:

No conecte la unidad al suministro de corriente sin haber

terminado de armarla. De lo contrario la unidad puede

ponerse en marcha accidentalmente, con el consiguiente

riesgo de lesiones corporales serias.

5 - Español

PASADOR DE

SEGURIDAD

Fig. 2

Page 24

ARMADO

ARMADO E INSTALACIÓN DE LOS SOPORTES

DE LA PIEZA DE TRABAJO

Vea las figuras 3 y 5.

Los soportes de la pieza de trabajo equilibran la pieza de trabajo

durante las operaciones de corte.

Para montar el soporte de la pieza de trabajo:

Introduzca un perno de carruaje (M6 x 55 mm) por el agujero

cuadrado del soporte de la pieza de trabajo y páselo a través

del otro lado.

Coloque el tope de la pieza de trabajo en el extremo del

perno.

Enrosque una perilla de ajuste de tope de pieza de trabajo en el

extremo del perno y apriétela para asegurar todo el conjunto.

Pase el riel del soporte de la pieza de trabajo a través del agujero

situado en la parte superior de la placa de montaje del soporte

de la pieza de trabajo.

Introduzca la perilla de ajuste de altura por el agujero pequeño

del otro lado del apoyo de montaje del soporte de la pieza de

trabajo y apriétela para asegurar todo el conjunto.

Para instalar los soportes de la pieza de trabajo:

Deslice el apoyo de montaje del soporte de la pieza de trabajo

en el riel de extensión, de manera que éste sobresalga por la

abertura del apoyo. Coloque el soporte de la pieza de trabajo

en el lugar deseado del riel de extensión.

Introduzca una perilla de ajuste de longitud por la abertura

situada en la parte inferior del apoyo de montaje del soporte de

la pieza de trabajo y apriétela para asegurar todo el conjunto.

Repita este procedimiento con el otro soporte.

PERILLA DE AJUSTE

DE TOPE

DE PIEZA

DE TRABAJO

SOPORTES

DE LA PIEZA

DE TRABAJO

TOPE DE LA PIEZA

DE TRABAJO

PERNO DE

CARRUAJE

Fig. 3

COLOCACIÓN DE LOS APOYOS DE MONTAJE

DE LA SIERRA

Vea las figuras 6 y 7.

Siempre coloque la sierra de forma que logre el máximo equilibrio y

estabilidad. Las cuatro esquinas de la sierra deben estar atornilladas

a los apoyos de montaje antes de usar la unidad. Asegúrese de

que los pernos no sobresalgan arriba de la mesa de la sierra

ingleteadora.

Si la sierra tiene agujeros que se alinean con las ranuras de

los apoyos de montaje:

Desconecte la sierra y asegure el brazo de la sierra en la posición

inferior.

Coloque una tabla de 2 x 4 pulg., o un tipo similar de soporte

bajo la sierra para subirla y así poder tener acceso a los pies

de montaje de la sierra.

Coloque un apoyo de montaje bajo el lado elevado de la sierra,

alineando los agujeros de montaje de la base de la sierra con

la ranura de la parte superior del apoyo.

Introduzca un perno de carruaje a través del apoyo y del agujero

de montaje de la sierra.

Asegúrela en su lugar con una arandela plana, una arandela de

seguridad y una tuerca.n

Repita el procedimiento en el otro extremo del mismo apoyo.

Coloque el segundo apoyo de montaje bajo el otro lado de la

sierra, alineando los agujeros de montaje de la base de la sierra

con la abertura del apoyo.

Coloque los pernos de carruaje como se explicó

anteriormente.

Después de asegurarse de que ambos apoyos queden paralelos

entre sí, apriete a mano las cuatro tuercas para mantener todo

el conjunto en su lugar.

6 - Español

PERILLA

DE AJUSTE

DE ALTURA

RIEL DE

EXTENSIÓN

PERILLA DE AJUSTE

DE LONGITUD

PLACAS DE MONTAJE

DE LOS SOPORTES

DE LA PIEZA DE

TRABAJO

Fig. 4

Fig. 5

Page 25

TUERCA

ARANDELA DE SEGURIDAD

ARANDELA PLANA

ARMADO

SIERRA

INGLETEADORA

APOYO DE

MONTAJE DE LA

SIERRA

PERNO DE

CARRUAJE

Si la sierra tiene agujeros que no se alinean con las ranuras

de los apoyos de montaje:

Desconecte la sierra y asegure el brazo de la sierra en la posición

inferior.

Monte la sierra en una superficie de montaje de 13 mm (1/2

pulg.) de espesor por lo menos con tornillo de cabeza hex. de

RANURA

TUERCA

ARANDELA DE SEGURIDAD

2 x 4

Fig. 6

3/8 pulg., arandelas de seguridad y tuercas hexagonales (no

vienen incluidos).

Taladre unos agujeros en la superficie de montaje que coincidan

con las ranuras de los apoyos de montaje de la sierra.

Proceda con la instalación como se explicó anteriormente.

SIERRA

INGLETEADORA

ARANDELA PLANA

ARANDELA DE

SEGURIDAD

ARANDELA PLANA

APOYO

DE MONTAJE

DE LA SIERRA

DE CARRUAJE

TUERCA

PERNO

SUPERFICIE

DE MONTAJE

RANURA

Fig. 7

7 - Español

Page 26

ARMADO

MONTAJE DE LA SIERRA INGLETEADORA

EN EL PEDESTAL

Vea las figuras 8 y 9.

Levante el conjunto de la sierra y los apoyos, permitiendo

que se incline levemente hacia usted.

Mientras tiene aún inclinado hacia usted el conjunto,

enganche la parte frontal de los apoyos en el riel delantero

del pedestal.

ADVERTENCIA:

Para evitar lesiones graves, asegúrese de que el

borde curvo delantero de los apoyos de montaje estén

firmemente asentados en el riel delantero antes de

asentar el otro extremo de los apoyos. Si no lo hace así,

podría perder el control del conjunto de montaje de la

sierra, con lo cual podría causarse lesiones serias.

Asegure los apoyos en su lugar; para ello, baje las

palancas de aseguramiento.

Baje los apoyos para permitir que el borde trasero de los

mismos se asiente completamente en el riel trasero.

NOTA: Continúe sujetando el conjunto de la placa de

montaje con una mano hasta que estén firmemente

aseguradas ambas palancas.

Revise la colocación y ajústela si es necesario, para

asegurarse de que el peso de la sierra esté equilibrado

uniformemente en los rieles, como se muestra en

la figura 9.

Asegúrese de que la sierra esté bien asentada y

asegurada en su lugar, y después apriete firmemente las

cuatro tuercas encargadas de fijar la sierra en los apoyos

de montaje.

Para desmontar del pedestal la sierra:

Suba las palancas de aseguramiento para desasegurar

la sierra y los apoyos de montaje.

Levante éste del riel trasero del pedestal para

separarlos.

Teniendo el conjunto levemente inclinado hacia usted,

levante la parte delantera del conjunto para separarlo del

riel delantero del pedestal.

PARA FIJAR EL

CONJUNTO EN EL

BANCO, BAJE LAS

PALANCAS DE

ASEGURAMIENTO

Fig. 9

Fig. 8

ADVERTENCIA:

Los apoyos de montaje están diseñados para quedar ajustados en los rieles del banco. Teniendo las palancas de fijación

en la posición inferior (aseguramiento), debe imposibilitarse retirar de los rieles el conjunto de la sierra y los soportes.

Si los apoyos de montaje no quedan en los rieles, o si pueden retirarse de los rieles cuando se aseguran las palancas,

retírelos de la sierra de inmediato y apriete el tornillo de ajuste según se explica en la sección de mantenimiento de este

manual. La inobservancia de esta advertencia puede causar lesiones corporales serias.

8 - Español

Page 27

ADVERTENCIA:

FUNCIONAMIENTO

No permita que su familarización con las herramientas lo

vuelva descuidado. Tenga presente que un descuido de

un instante es suficiente para causar una lesión grave.

ADVERTENCIA:

Siempre póngase protección ocular con protección

lateral con la marca de cumplimiento de la norma ANSI

Z87.1. Si no cumple esta advertencia, los objetos que

salen despedidos pueden producirle lesiones serias en

los ojos.

ADVERTENCIA:

No utilice ningún aditamento o accesorio no recomendado

por el fabricante de esta herramienta. El empleo de

aditamentos o accesorios no recomendandos podría

causar lesiones serias.

APLICACIONES

Esta herramienta puede emplearse para el fin siguiente:

Proporcionar una superficie de trabajo estable y segura

para una sierra ingleteadora

RIEL DE

EXTENSIÓN

PERILLA DE

AJUSTE DE

EXTENSIÓN

Fig. 10

TOPE DE LA

PIEZA DE

TRABAJO

PERILLA DE

AJUSTE DEL

TOPE DE LA

PIEZA DE

TRABAJO

USO DE LOS RIELES DE EXTENSIÓN

Vea la figura 10.

Para trabajar con piezas de trabajo grandes, utilice los rieles

de extensión.

Para extender los rieles:

Afloje la perilla de ajuste de extensión.

Extienda el riel a la distancia deseada.

Apriete la perilla de ajuste de extensión.

USO DE LOS TOPES DE LA PIEZA DE TRABAJO

Vea la figura 11.

Cada vez que necesite efectuar cortes repetitivos del mismo

tamaño, suba los topes de la pieza de trabajo. Para evitar

un riesgo mayor de atoramiento o pellizcamiento, no utilice

ambos topes al mismo tiempo.

Para subir los topes de trabajo:

Afloje la perilla de ajuste del tope de la pieza de

trabajo.

Suba el tope de la pieza de trabajo a la posición

deseada.

Apriete la perilla de ajuste del tope.

Fig. 11

9 - Español

Page 28

MANTENIMIENTO

ADVERTENCIA:

Al dar servicio a la unidad, sólo utilice piezas de repuesto

idénticas. El empleo de piezas diferentes puede presentar

un peligro o causar daños al producto.

ADVERTENCIA:

Siempre póngase protección ocular con protección

lateral con la marca de cumplimiento de la norma ANSI

Z87.1. Si no cumple esta advertencia, los objetos que

salen despedidos pueden producirle lesiones serias en

los ojos.

MANTENIMIENTO GENERAL

Evite el empleo de solventes al limpiar piezas de plástico.

La mayoría de los plásticos son susceptibles a diferentes

tipos de solventes comerciales y pueden resultar dañados.

Utilice paños limpios para eliminar la suciedad, el polvo, el

aceite, la grasa, etc.

Para ajustar:

Con una llave de tuercas afloje levemente la tuerca.

Gire el tornillo con un destornillador Phillips. Si los apoyos

necesitan apretarse, gire a la derecha los tornillos; si

los apoyos necesitan aflojarss, gire a la izquierda los

tornillos.

Instale el apoyo en los rieles del banco y baje la palanca

de fijación para verificar el ajuste.

Cuando logre la posición correcta, apriete con la llave de

tuercas la tuerca para asegurar el montaje.

Repita el proceso con el otro apoyo de montaje.

APOYO DE

MONTAJE DE LA

SIERRA

LLAVE

ADVERTENCIA:

No permita en ningún momento que fluidos para

frenos, gasolina, productos a base de petróleo, aceites

penetrantes, etc., lleguen a tocar las piezas de plástico.

Las sustancias químicas pueden dañar, debilitar o

destruir el plástico, lo cual a su vez puede producir

lesiones corporales serias.

TORNILLO DE AJUSTE DEL APOYO

Vea la figura 12.

Los apoyos de montaje están diseñados para quedar

ajustados en los rieles del banco. Teniendo las palancas

de fijación en la posición inferior (aseguramiento), debe

imposibilitarse retirar de los rieles el conjunto de la sierra y los

soportes. Si el conjunto de la sierra y los apoyos de montaje

pueden retirarse de los rieles al estar puesta la palanca de

fijación, es necesario apretar los tornillos de ajuste de los

apoyos. Si el conjunto de la sierra y los apoyos no queda

en ambos rieles, es necesario aflojar los tornillos de ajuste

de dichos apoyos.

NOTA: Es necesario retirar de los apoyos de montaje la sierra

antes de intentar apretar o aflojar los tornillos de ajuste de

dichos apoyos.

DESTORNILLADOR

TUERCA

TORNILLO DE

AJUSTE DEL

APOYO

Fig. 12

10 - Español

Page 29

NOTES / NOTAS

11

Page 30

NOTES / NOTAS

12

Page 31

NOTES / NOTAS

13

Page 32

OPERATOR’S MANUAL / MITER SAW STAND

MANUEL D’UTILISATION / STAND POUR SCIE À ONGLETS

MANUAL DEL OPERADOR / BANCO PARA SIERRA INGLETEADORA

• PARTS AND SERVICE

Prior to requesting service or purchasing replacement parts, please obtain your model and serial number from the

product data plate.

• MODEL NUMBER ____________________

• SERIAL NUMBER ____________________

RMS10SB

• HOW TO OBTAIN REPLACEMENT PARTS:

Replacement parts can be purchased online at www.ryobitools.com or by calling 1-800-525-2579. Replacement

parts can also be obtained at one of our Authorized Service Centers.

• HOW TO LOCATE AN AUTHORIZED SERVICE CENTER:

Authorized Service Centers can be located online at www.ryobitools.com or by calling 1-800-525-2579.

• HOW TO OBTAIN CUSTOMER OR TECHNICAL SUPPORT:

To obtain Customer or Technical Support please contact us at 1-800-525-2579.

RYOBI® is a registered trademark of Ryobi Limited used under license.

• PIÈCES ET SERVICE

Avant de faire la demande de service ou l’achat de pièces de remplacement, veuillez obtenir le numéro de série du modèle à partir

de la plaque de données du produit.

• NUMÉRO DE MODÈLE _____________________

• NUMÉRO DE SÉRIE _____________________

RMS10SB

• COMMENT OBTENIR LES PIÈCES DE REMPLACEMENT :

Les pièces de remplacement peuvent être achetées en ligne sur le site www.ryobitools.com ou par téléphone au 1-800-525-2579.

Les pièces de remplacement peuvent être obtenues à un de nos centres de service autorisés.

• COMMENT TROUVER UN CENTRE DE SERVICE AUTORISÉ :

Les centres de service autorisés peuvent être localisés en ligne au www.ryobitools.com ou en téléphonant au 1-800-525-2579.

• COMMENT OBTENIR DE L’AIDE EN CONTACTANT LE SERVICE À LA CLIENTÈLE :

Pour contacter le service à la clientèle pour une question technique ou pour tout autre renseignement, veuillez nous téléphoner

au 1-800-525-2579.

Ryobi® est une marque déposée de Ryobi Limited utilisée sous licence.

• PIEZAS DE REPUESTO Y SERVICIO

Antes de solicitar servicio técnico o comprar piezas de repuesto, obtenga su modelo y número de serie de la placa de datos del

producto.

• NÚMERO DE MODELO ______________________

• NÚMERO DE SERIE ______________________

RMS10SB

• CÓMO OBTENER PIEZAS DE REPUESTO:

Las piezas de repuesto se pueden comprar en nuestro sitio en la red mundial, en la dirección www.ryobitools.com o llamando al

1-800-525-2579. Las piezas de repuesto también se pueden obtener en uno de nuestros Centros de Servicio Autorizados.

• CÓMO LOCALIZAR UN CENTRO DE SERVICIO AUTORIZADO:

Puede encontrar los Centros de Servicio Autorizados visitando nuestro sitio en la red mundial, en la dirección www.ryobitools.

com o llamando al 1-800-525-2579.

• CÓMO OBTENER SERVICIO O ASISTENCIA TÉCNICA AL CONSUMIDOR:

Para obtener Servicio o Asistencia Técnica al Consumidor, sírvase comunicarse con nosotros llamando al 1-800-525-2579.

Ryobi® es una marca comercial registrada de Ryobi Limited y es empleada mediante autorización.

990000154

8-2-12 (REV:02)

ONE WORLD TECHNOLOGIES, INC.

1428 Pearman Dairy Road, Anderson, SC 29625 • Phone 1-800-525-2579

États-Unis, Téléphone 1-800-525-2579 • USA, Teléfono 1-800-525-2579

www.ryobitools.com

Loading...

Loading...