Page 1

ESS200RG / ESS280RG

1/3 SHEET SANDER

OWNER’S OPERATING MANUAL

ESS200RG

ESS280RG

Page 2

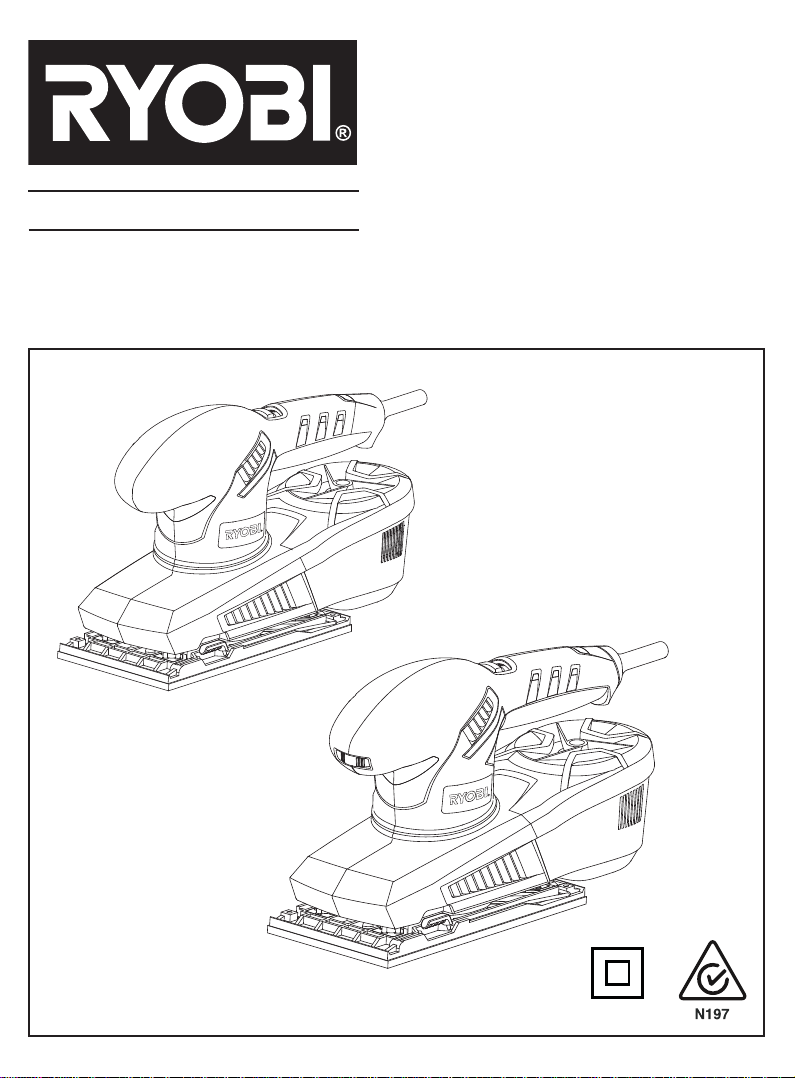

1. On/off trigger switch

2. Variable speed control selector

3. Overmold handle

4. Dust collection box

5. Sanding pad

DESCRIPTION

6. Paper clamp

7. Live tool indicator

8. Hook and loop sandpaper

9. Non-adhesive sandpaper

10. Paper punch

3

ESS200RG ESS280RG

1

6

7

2

4

5

1

6

7

3

4

5

Fig. 1

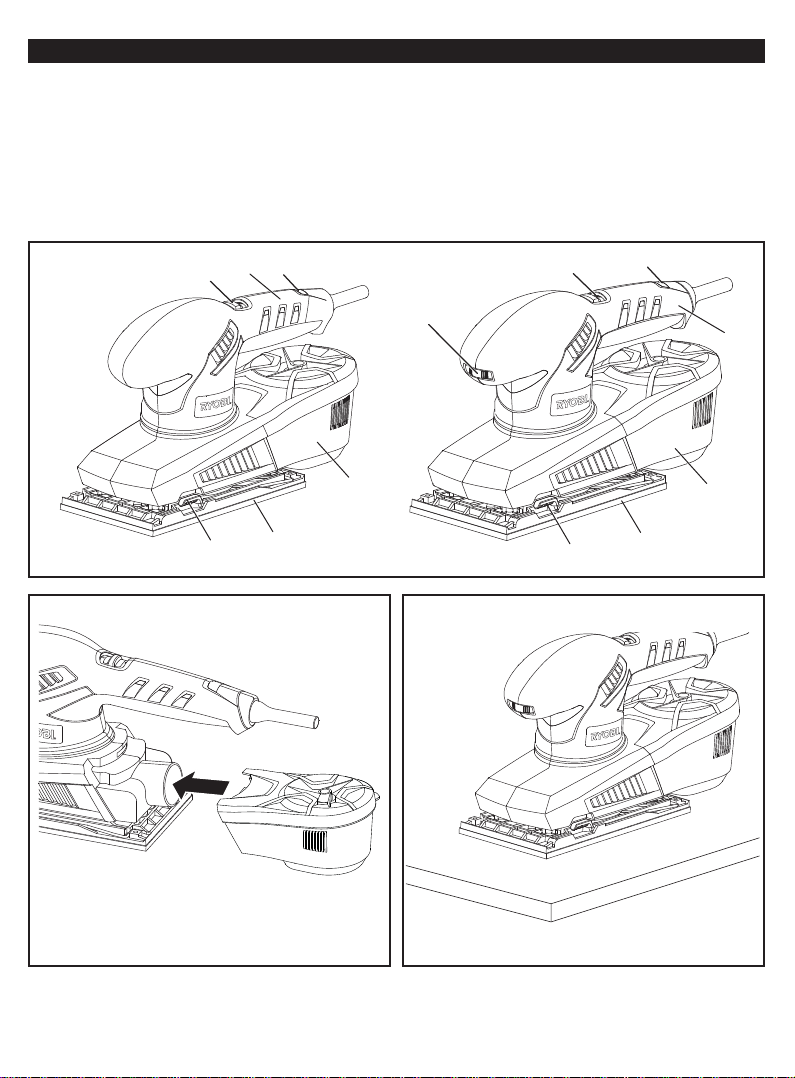

Fig. 2 Fig. 3

Page 3

5

8

Fig. 4 Fig. 5

6

5

9

9

10

Fig. 6 Fig. 7

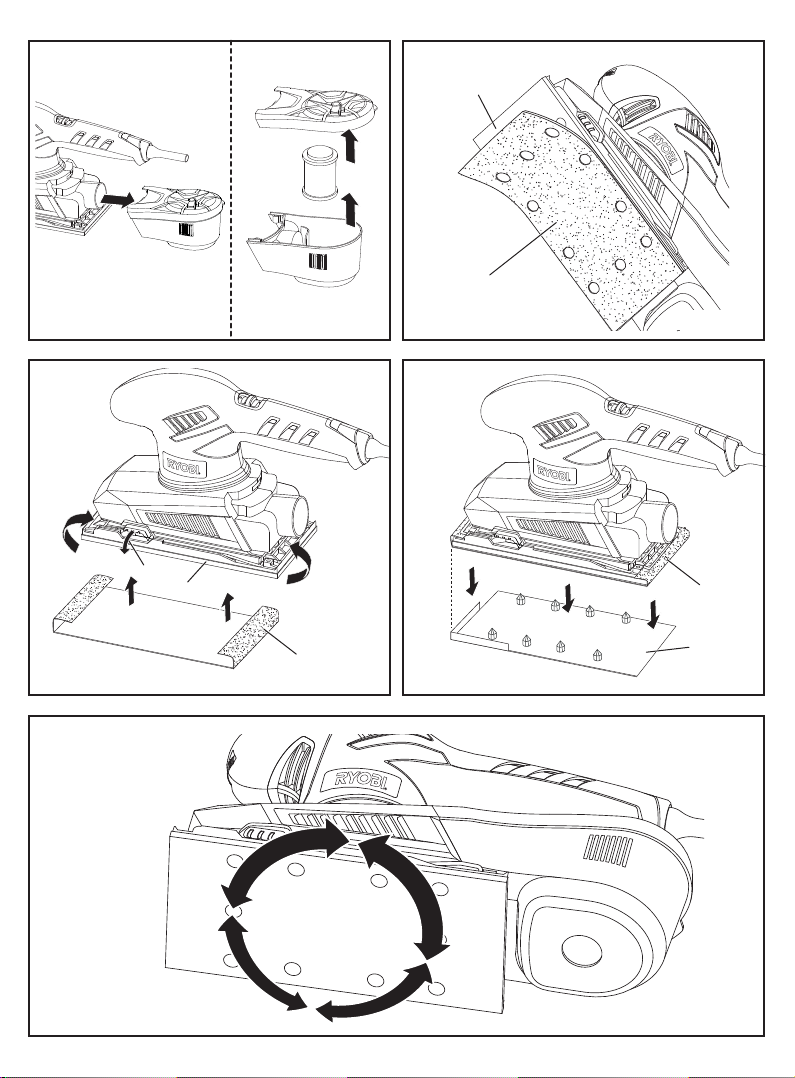

Fig. 8

Page 4

Important!

It is essential that you read the instructions in this manual before

operating this machine.

Subject to technical modifications.

Page 5

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result in electric

shock, fi re and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1. WORK AREA

a. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f. If operating power tools in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3. PERSONAL SAFETY

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your fi nger on the switch or energising power tools

that have the switch on invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

4. POWER TOOL USE AND CARE

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b. Do not use the power tool if the switch does not

turn it on and off. Any power tool that can not be

controlled with the switch is dangerous and must

be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

1

Page 6

English

e. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits

etc., in accordance with these instructions and

in the manner intended for the particular type

of power tool, taking into account the working

conditions and the work to be performed. Use

of the power tool for operations different from

intended could result in a hazardous situation.

5. SERVICE

a. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

SPECIAL SAFETY RULES

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance.

This appliance is not intended for use by young

children or infirm persons. Adequate supervision by a

responsible person must be provided to ensure that

they do not play with the appliance.

Keep children and visitors away. Visitors should

wear safety glasses and be kept a safe distance from

work area. Do not let visitors contact tool or extension

cord.

Complies with AS/NZS 60745.

Recommended for the use of a residual current device

with a rated residual current of 30 mA or less.

SPECIFIC SAFETY INSTRUCTIONS FOR

SANDERS

Always wear safety goggles and a dust mask when

sanding, especially sanding over-head.

The machine is not suitable for wet sanding.

Do not use sanding paper larger than needed.

Extra paper extending beyond the sanding pad can

also cause serious lacerations.

The dust collection box shall be equipped with the

tool. It should be emptied frequently. To connect dust

collection box, insert the adaptor of dust box to the

dust-collection opening on the rear end of the sander.

WARNING

Do not throw sanding dust on an open fi re because

materials in fi ne particle form may be explosive.

WARNING

A suitable breathing respirator must be worn while

sanding lead paint, some woods and metal to avoid

breathing the harmful/toxic dust or air.

SPECIFICATIONS

Model ESS200RG ESS280RG

Power 200 W 280W

-1

230 V - 240 V

50 Hz

7000-12000

-1

min

Voltage

No load speed 12000 min

Orbital diameter 2.0 mm 2.0 mm

Weight 1.5 kg 1.7 kg

230 V - 240 V

50 Hz

FEATURES

See Figure 1.

Your sander is suitable for sanding with coarse, medium

and fi ne grit sandpaper. It will produce a fi ne scratch

free fi nish when used to sand with the grain on wood

surfaces.

It has been designed so that fl ush corner sanding on three

sides of the sander is possible.

Your sander has a comfortable palm grip handle that

provides maximum one-hand comfort and reduces

operator fatigue during continuous sanding operations.

Before using this product, familiarize yourself with all

operating features and safety requirements. However, do

not let familiarity with the tool make you careless.

SWITCH

Electronic speed control (ESS280RG only)

The electronic speed control allows the operator to adjust

speed to meet a variety of sanding material from tough

heavy grained timber to delicate veneer.

Both ESS200RG and ESS280RG are equipped with a

2

Page 7

English

simple switch control. To turn the sander "On", slide the

switch to " I ". To turn the sander " Off ", slide the switch

to "O".

WARNING

Do not allow familiarity with your sander to make you

careless. Remember, a careless fraction of a second is

suffi cient to infl ict severe injury .

DUST COLLECTION BOX

The dust collection box attaches to the sander and keeps

dust to a minimum.

VARIABLE SPEED CONTROL (ESS280RG ONLY)

Your sander has advanced electronic features, designed

to assist you in getting the maximum use from your

sander. By making proper speed selections, your sander

can be adjusted to specifi c sanding needs.

The variable speed control allows the sander to develop a

no load speed that can be adjusted from 7,000 to 12,000

-1

. The variable speed control selector is conveniently

min

located on the front of the sander.

The electronic feature of your sander introduces the

fl exibility of adjusting the motor speed to required job

conditions. An electronic speed control module senses

the load applied to the motor and increases or decreases

motor voltage to compensate for and maintain desired

RPM. Speed can be set according to the sanding purpose

or work-piece's surface you will be using.

Select clockwise to increase speed for rough surfaces or

for quick removal of stock and anti-clockwise to decrease

speed for the smaller, delicate sanding applications.

ASSEMBLY

and fi ner grit will produce the best fi nish in all sanding

operations. The condition of the surface to be sanded

will determine which grit will do the job. If the surface is

rough, start with a coarse grit and sand until the surface

is uniform. Medium grit may then be used to remove

scratches left by the coarser grit and fi ner grit used for

fi nishing of the surface. Always continue sanding with

each grit until surface is uniform.

WARNING

Do not use sander without sandpaper, doing so will

damage the cushion.

Sheet/pad recommended use

80-grit sanding sheet Coarse sanding

120-grit sanding sheet Light sanding

150-grit sanding sheet Light sanding

ATTACHING THE DUST COLLECTION BOX

See Figure 2.

The dust collection box provides a dust collection system

for the sander. Sanding dust is drawn up through the holes

of the sanding disc and collected in the dust collection box

during sanding.

1. Unplug the sander.

2. Using a slight twisting motion, fi rmly slide the dust

collection box assembly in the blower exhaust on the

sander.

WARNING

Exercise caution when using this tool. Careless actions,

for even a fraction of a second, can result in serious

personal injury.

WARNING

The tool should never be connected to a power supply

when you are assembling parts, making adjustments,

cleaning, performing maintenance, or when the tool is

not in use. Disconnecting the tool will prevent accidental

starting that could cause serious injury.

SANDPAPER SELECTION

Selecting the correct size, grit and type of sand paper is

an extremely important step in achieving a high quality

sanded fi nish. Aluminum oxide, silicon carbide, and

other synthetic abrasives are best for power sanding.

Natural abrasives, such as fl int and garnet are too soft for

economical use in power sanding.

In general, coarse grit will remove the most material

APPLICATIONS

You may use the sander for the purposes listed below:

sanding on wood surfaces

removing rust from and sanding steel surfaces

polishing and scrubbing porcelain and metal

CAUTION

Keep the cord away from the sanding pad and position

the cord so that it will not be caught on lumber, tools, or

other objects during sanding.

3

Page 8

English

WARNING

Always wear safety goggles or safety glasses with side

shields when operating this tool. Failure to do so could

result in dust, shavings, or loose particles being thrown

into your eyes, resulting in possible serious injury.

OPERATION

INSTALLING ADHESIVE SANDP APER

Inspect sandpaper before installing. Do not use if broken

or defective.

INSTALLING ADHESIVE (HOOK AND LOOP) SANDPAPER

See Figure 5.

1. Unplug the sander.

2. Align holes in hook and loop type sanding disc with

holes in pad, then carefully press fuzzy side of sanding

disc against pad as tightly as possible.

NOTE: Hook and loop type sanding discs can be reused

for the life of the sanding abrasive. It is recommended that

you keep the sanding disc backing pad clean to provide for

best adhesion. Clean occasionally by brushing lightly with

a small brush.

WARNING

Failure to unplug the tool could result in accidental

starting causing possible serious injury.

INSTALLING NON-ADHESIVE SANDPAPER

See Figure 6.

1. Unplug the sander.

2. Release the paper clamp. Remove used sandpaper,

if any.

3. Insert the new sandpaper under the paper clamp.

4. Clamp the sandpaper in place.

PAPER PUNCH

See Figure 7.

A paper punch template has been supplied with your

sander for aligning and punching holes in sandpaper. The

punched holes must align with the holes in the sander

cushion.

1. Install sandpaper on your sander.

2. Align sander cushion over the paper punch.

3. Push down on the sander.

TURNING THE SANDER ON/OFF

See Figure 1.

Turn on the sander: Slide the switch to the '' I ''.

Turn off the sander: Slide the switch to the '' O ''.

OPERATING THE SANDER

See Figure 3.

1. Secure the workpiece to prevent it from moving under

the sander.

WARNING

Unsecured workpieces could be thrown towards the

operator, causing injury.

WARNING

Keep your head away from the sander and the sanding

area. Your hair could be drawn into the sander causing

serious injury.

2. Place the sander on the workpiece so that all of the

sanding disc surface is in contact with the workpiece.

CAUTION

Avoid damaging the motor from overheating, be careful

not to let your hand cover the air vents.

3. Turn on the sander and move it slowly over the

workpiece.

NOTE: Hold the sander in front and away from you,

keeping it clear of the workpiece. Start sander and let the

motor build to its maximum speed, then gradually lower

the sander onto the workpiece. Move the sander slowly

across the workpiece using small circular motions.

Do not force. The weight of the unit supplies adequate

pressure, so let the sanding disc and sander do the work.

Applying additional pressure only slows the motor, rapidly

wears sanding disc and greatly reduces sander speed.

Excessive pressure will overload the motor causing

possible damage from motor overheating and can result in

inferior work. Any fi nish or resin on wood may soften from

the frictional heat.

Do not allow sanding on one spot too long as the sander’s

rapid action may remove too much material, making the

surface uneven.

Extended periods of sanding may tend to overheat the

motor. If this occurs, turn sander off and wait until sanding

disc comes to a complete stop, unplug the sander, then

remove it from workpiece. Allow the tool to cool down.

EMPTYING THE DUST COLLECTION BOX

See Figure 4.

For more effi cient operation, empty the dust collection

4

Page 9

English

box when it is no more than half full. This will permit the

air to fl ow through the dust collection box better. Always

empty and clean the dust collection box thoroughly upon

completion of a sanding operation and before placing the

sander in storage.

WARNING

Collected sanding dust from sanding surface coatings

such as polyurethanes, linseed oil, etc., can self-ignite

in your sander dust collection box or elsewhere and

cause fi re. To reduce the risk of fi re always empty your

dust collection box frequently (10-15 minutes) while

sanding and never store or leave a sander without

totally emptying its dust collection box. Also follow the

recommendations of the coatings manufacturers.

1. Unplug the sander.

WARNING

Failure to unplug the tool could result in accidental

starting causing possible serious injury.

2. Remove the dust collection box from the sander.

3. Shake out the dust.

4. Reattach the dust collection box to the sander.

NOTE: For a more thorough cleaning of the dust collection

box, remove dust collection box from frame and shake out

dust. Replace dust collection box over frame then install

dust collection box assembly on sander.

ORBITAL MOTION

See Figure 8.

Orbital motion is ideal for fast cutting action when removing

old fi nishes, smoothing rough wood, cutting stock down to

required dimensions or for fi nishing surfaces to be painted.

The sandpaper moves in tiny circles at a very high speed,

allowing the sander to move easily.

MAINTENANCE

WARNING

The tool should never be connected to a power supply

when you are assembling parts, making adjustments,

cleaning, performing maintenance, or when the tool is

not in use. Disconnecting the tool will prevent accidental

starting that could cause serious injury.

WARNING

When servicing, use only identical Ryobi replacement

parts. Use of any other parts may create a hazard or

cause product damage.

GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to various types of commercial

solvents and may be damaged by their use. Use clean

cloths to remove dirt, carbon dust, etc.

WARNING

Do not at any time let brake fl uids, gasoline, petroleum-

based products, penetrating oils, etc., come in contact

with plastic parts. They contain chemicals that can

damage, weaken or destroy plastic.

Electric tools used on fi berglass material, wallboard,

spackling compounds, or plaster are subject to

accelerated wear and possible premature failure because

the fi berglass chips and grindings are highly abrasive to

bearings, brushes, commutators, etc. Consequently, we

do not recommended using this tool for extended work on

these types of materials. However, if you do work with any

of these materials, it is extremely important to clean the

tool using compressed air.

LIVE TOOL INDICATOR

This tool features a live tool indicator which illuminates as

soon as the tool is connected to the supply. This warns the

user that the tool is connected and will operate when the

switch is pressed.

WARNING

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing

dust. If operation is dusty, also wear a dust mask.

LUBRICATION

All of the bearings in this tool are lubricated with a suffi cient

amount of high grade lubricant for the life of the unit

under normal operating conditions. Therefore, no further

lubrication is required.

5

Page 10

English

CLEANING THE SANDING SHEETS

The sanding sheets that came with your sander are

made to be re-used. Therefore, it is important that they

be cleaned periodically to remove sanding residue and

foreign material that can accumulate over time.

One of the ways to clean sanding sheets is to rub the sheets

with a hard rubber block. You can also use the clean rubber

sole of a shoe.

WARNING

Always remove scrubbing or sanding pad from sander

before cleaning. Failure to do so could cause serious

personal injury.

SYMBOL

Safety Alert

V Volts

Hz

Hertz

Alternating Current

W

Watts

no

No-load speed

-

1

min

Revolutions or reciprocations per minute

Orbital Diameter

Conformity

Double insulation

Wear ear protection

Wear eye protection

Please read the instructions carefully before

starting the machine.

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

6

Page 11

7(&+7521,&,1'8675,(6$8675$/,$37</7'

/HYHO'RQFDVWHU5RDG

'RQFDVWHU9LFWRULD

$XVWUDOLD

7HO)D[1R

Loading...

Loading...