Rotronic LOG-HC2 Specifications

Important measurement data

OverviewOverview

SoftwareSoftware

DatacenterDatacenter

Contract ModulesContract Modules

ServicesServices

DatasheetsDatasheets

AlarmingAlarming

HardwareHardware

Data securityData security

just a click away!

With the most

flexible continuous

Monitoring System

SaaS

50008E/2 018-12

1

Rotronic Monitoring System

Watch the short Explain-it MovieWatch the short Explain-it Movie

RMS – ROTRONIC MONITORING SYSTEM

The Rotronic continuous Monitoring System allows users to monitor anything from anywhere using an on-premise or

cloud (SaaS) solution.

Strongly regulated applications

• Fridges

• Cold rooms

• Freezers

• Transport with dry ice

• Cryogenics with nitrogen tanks

• Blood banks

• Clean rooms

• Warehouses

Less regulated applications such as:

• Museums

• Archives

• Storage areas

• And much more...

Customize your own RMS Architecture

2

Rotronic Monitoring System

Multiple parameter monitoring

RMS monitors various parameters to ensure that the environment meets the required specifications for any application.

1. Digital probes give acces to a complete audit trail and easy digital calibration thanks to the probe hot swap possibility:

• Relative humidity

• Temperature

• CO

2

• Differential pressure

2. Other inputs and outputs for third party devices (particle counters, air flow and other such parameters):

• 0/4…20mA for the integration of existing devices or other parameters

• 0…10V for the integration of existing devices or other parameters

• Digital inputs for door contacts, leak detectors, etc.

• Digital outputs to switch alarm beacons

– Webcams to enable a snap shot to add to automatically generated reports and see the application

in real time (mouse-over)

mA

V

Real time camera view (mouse over)

– Any 3rd party devices with a documented protocol

– LoRa devices via the API function

3

Rotronic Monitoring System

Find out more at www.rotronic.com/rmsFind out more at www.rotronic.com/rms

Wireless or wired secure data communication

1. Wireless:

• Data stored on the logger with a battery backup and 24V power supply

• Redundant or parallel operation with various gateways

• Decrease wiring costs

• No more looking for errors in cabling

• Projects accomplished faster due to no cable requirements

• Easy to relocated physical measuring points

• Fast and easy implementation of new measuring points

• Monitor mobile equipment

• 868 or 915 MHz

2. Wired:

• Data stored on the logger with a backup battery, PoE and 24V power supply

• No loss of communication for high risk applications

• Link up to the existing Ethernet network

Compliance

1. Validatable software (new releases on a 6 months basis)

2. FDA CFR 21 Part 11 compliant

3. EU Annex 11 compliant

4. Developed based upon the GAMP©5 recommendations

5. Complete GxP documentation and an IQ testing script (from the URS to the IQ/OQ/PQ)

Real time monitoring and alarming

The RMS software will inform you in real time via E-Mail, SMS and telephone call should a measurement point be out of

limits! Automatic reporting allow for a hassle free solution and a quick login via mobile phone, tablet, PC or laptop will

give you either a chart, table or a layout overview of the current situation, with short cuts to all events listed within the

audit trail.

4

Rotronic Monitoring System

MONITORING SOFTWARE

Main Software Features

• Alarm overview – see directly how many alarms are active and where they are coming from

• Receive alerts via interactive phone, SMS’s and E-Mails

• Audit trail to see exactly what happened and when

• Monitor multiple locations – one system for all your monitoring locations

• Input floor plans – get a real overview of the setup

• Scalable – prefect for single points in small installations to thousands of points in worldwide installations

• Automatic report generation

• Integration of Rotronic and any third party hardware – analog and digital

• Automatic validation scripts – for fast and effective OQ validation

• Continuously developing based around customer feedback

• Create custom dashboards per user

• FDA 21 CFR Part 11 & EU Annex 11 complaint

• GAMP©5 conform for GxP applications

Additional Features

• Calibrate all of your measuring points, possibility to adjust all of the Rotronic devices

• Archive all measuring points that are no longer needed, keeping access to the data for as long as necessary

• Save all your documents in the system: user manuals, data sheets, calibration certificates, SOP’s...

5

Rotronic Monitoring System

SaaS

SaaS

Main software benefits

• Compliance, audit and risk management

• Time saving with automatic data collection and report generation

• 24/7 real-time centralised monitoring of all operations

• All critical measurements in one system

• Real time alarming for critical measuring points

Software solutions

1. Fast & Easy with the Rotronic SaaS Cloud solution

Forget the hassle of having to maintain your IT infrastructure and focus only on what is crucial to your

application. You can setup multiple measurement points in various locations and access the data from

any device with a browser and internet connection. Setup alarms and notifications to be sure that you

are always informed of what is happening!

2. Remain compliant to GxP regulations with the Rotronic Exclusive SaaS Cloud solution

Hosted on a high security and redundant datacentre with your own virtual server, you can run the Rotronic category 4 software in the cloud throughout each and every GxP compliant facility. Equip your

worldwide facilities with the RMS hardware and access all of the data, including the audit trail, alarming and data analysis functions from a completely validated system.

3. Take advantage of your own IT infrastructure with the RMS on-premise solution

Hosted on a high security and redundant datacentre with your own virtual server, you can run the

Rotronic category 4 software in the cloud throughout each and every GxP compliant facility. Equip your

worldwide facilities with the RMS hardware and access all of the data, including the audit trail, alarming and data analysis functions from a completely validated system.

6

Rotronic Monitoring System

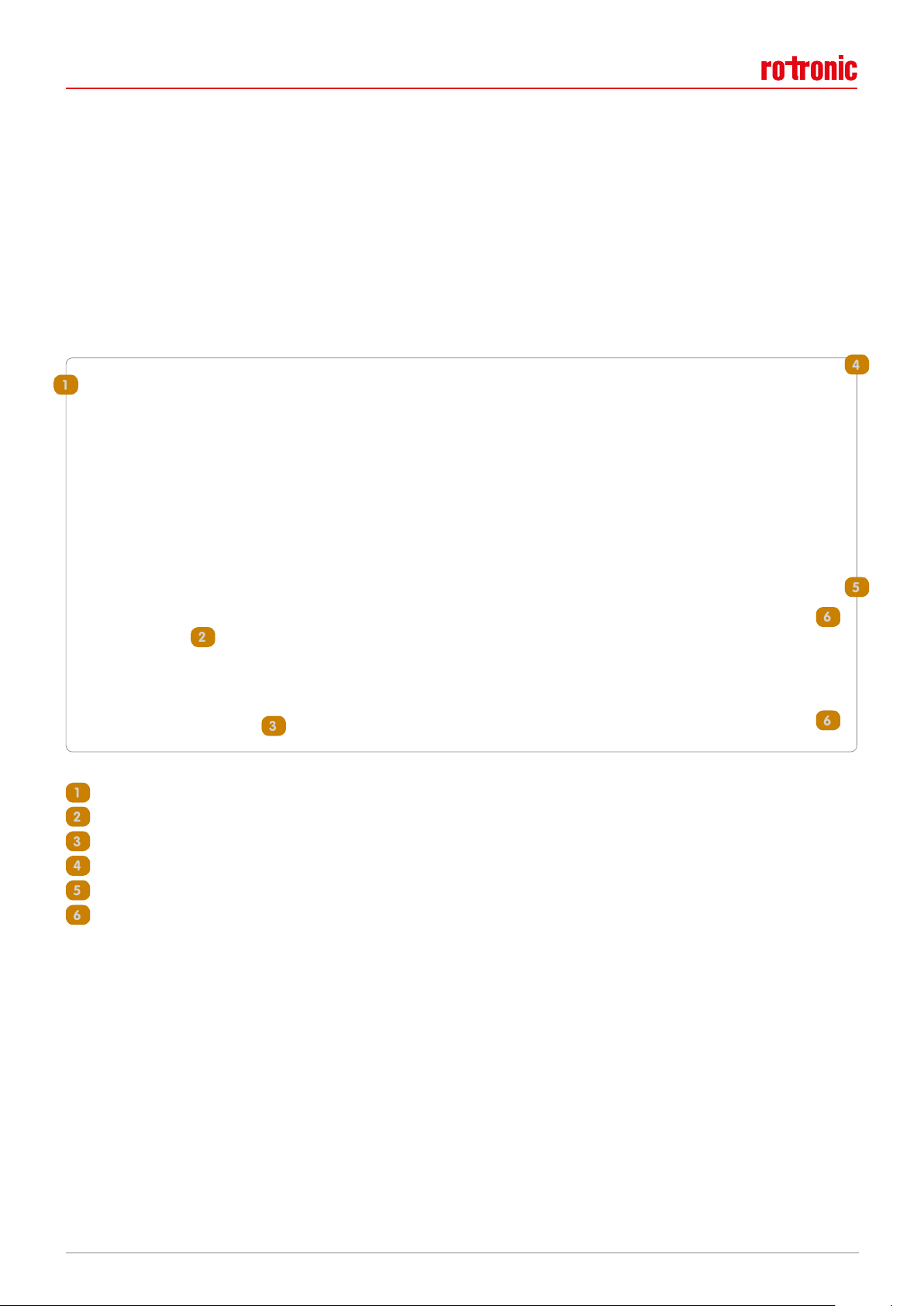

11

22

33

445566

66

112233

44

55

66

System Overview

RMS offers different views/tabs to present your system data, customised to your needs.

• Chart – measured values graphically and numerically and direct notification status

• Table – measured values numerically and various other data

• Layout – measured values numerically with placement in a room layout

• Dashboard – individual dashboard for each and every user

• Events – audit logs, alarms, warnings and system messages

Chart view

Upload your company logo

Group information by location, room…

Real-time measurement value and live status

Current logged on user, and notification overview

Historical overview

Alarms bands for a visual depicture of warnings and alarms

7

Rotronic Monitoring System

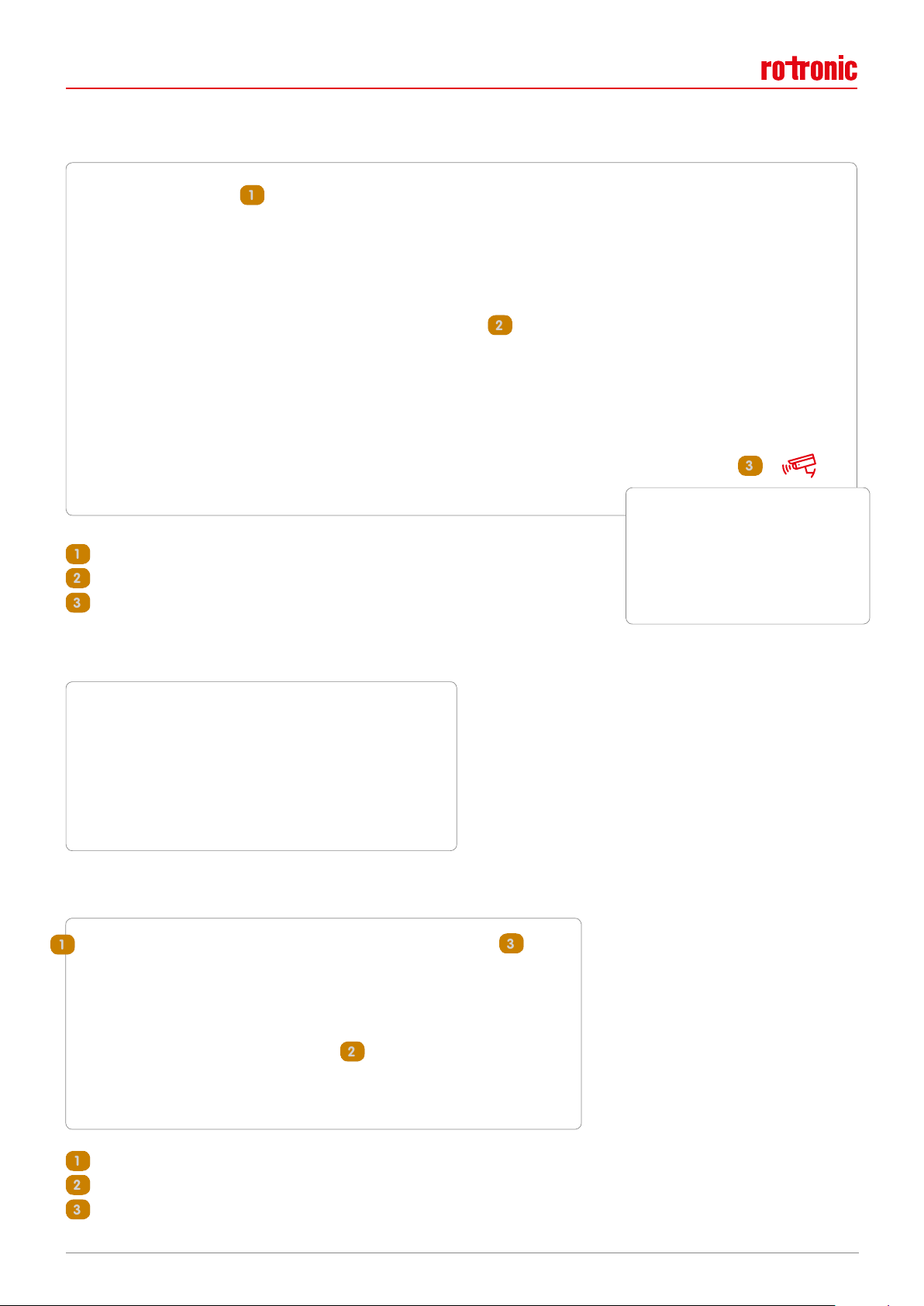

11

22

33

11

11

112222

22

33

33

33

Layout view

Real time camera view (mouse over)

Mouse over detailed measurement point

Standard measurement point overview

Mouse over IP camera for a snap shot of the current situation

Dashboard view: user defined

Events view (audit trail)

Define the notifications shown in the audit trail

See the actual status and user inputs of each individual event

Filter the audit trail based upon your requirements

8

Rotronic Monitoring System

IT risk

certified

DATACENTER

RMS Database Security

When purchasing the RMS SaaS solution, Rotronic works together with the company 4Net. They provide a virtual data

centre for the Rotronic Monitoring System server and database. 4Net uses the Interxion data centre. Interxion’s Zurich

data centre provides an ultra-secure, known location for storing and processing data in line with Swiss data protection

regulations. Like all Interxion data centres, Zurich operates in full accordance with the ITILv3 framework and has ISO

27001 and ISO 22301 certification. Their compliance with the FINMA circular 07/8 is externally audited.

Operational excellence:

• 99.999% availability SLA

• 2N or N+1 configurations for all critical systems

• 24x7 operation and monitoring

Sustainability:

• 100% renewable energy

• Carbon neutral, certified by myclimate

®

Security:

• Monitored 24x7 by CCTV and security patrols

Resilience and business continuity:

• 24x7 monitoring and alarms for ever y critical system

• Connectivity: quadruple-entr y fibre from separate carrier main routes and rapidly installed cross connects

• Power: secured grid supply from two sub-stations from two different power providers, two power feeds for all

equipment, each independently equipped with a power supply and generator backup with full load capacity for

indefinite running

• Environment: SLAs on temperature and humidity in line with ASHRAE recommendations, N+1 cooling, sophisticated

water and very early smoke detection systems, Inergen® gas fire suppression in line with local regulations and

designed for maximum safety and minimum damage

• Backups saved in a second data centre also located in Switzerland but 80 km away from the main one

9

Rotronic Monitoring System

ALARMING

Rotronic Monitoring System alarm protocols were set up to ensure that critical alarms cannot be missed. Notifications can

be triggered based upon the risk level.

Four levels of alarming are available, activation is based on the defined risk:

• Reminder for events that are non-urgent:

– Low battery (device)

– Simulator connected (measuring point)

– Reminder that a calibration is due

– Data gap after downloading missing measured values

• Warning for measured values that are out of limit (measuring point)

• Alarming for measured values that are out of limit (measuring point)

• Error for urgent hardware errors:

– Device timeout (device)

– Sensor error (measuring point)

An overview of the alarms can be seen once the user has logged into the system. The user only sees the alarms relevant

to his granted access rights. Each measuring point, if not conforming, will be attributed a different colour based upon the

alarm status:

Critical alarms can also be set up with a warning before alarms are activated. Hysteresis and a delay can be set up for the

warning, with upper and lower limits defined, as well as for the alarming.

All alarms are clearly shown in the audit trail indicating the unique ID for the event, the time and date of the alarm, information about what the alarm is, the target (the measuring point or device) as well as additional details.

Viewing the audit trail, it is easily possible to see if an alarm has been either acknowledged, or if it has ended. If an alarm

is acknowledged, the time, date, name of the user who acknowledged the alarm as well as the alarm details are also

saved and visible within the audit trail. Within the audit trail, it is also possible to close or inhibit an alarm.

10

Rotronic Monitoring System

Alarms can be set up based upon either the measuring point, or via an alarm scheme. For alarms based upon the measuring point the choice of options is limited. Within an alarm scheme the user has the possibility to set a condition such

as an active time as well as a warning. An action can be configured in both situations.

The various alarms can be notified in different ways and can be sent to just one or multiple users.

• E-Mail

• SMS *

• Telephone call *

• Switch relay

• Send data via TCP

* The user’s telephone number must be added to the system.

E-Mail alarm: When setting the system up with a TCP/IP based camera, a snap-shot can be added to the E-Mail with a

chart (either as a PDF or included in the body of the E-Mail).

SMS alarm: The alarm will be sent out in the language in which the software is configured.

Telephone call: Within the system settings, the user can decide the information stated during the telephone call, from the

device/measuring point ID to a measuring point comment. For the telephone call, if various users are selected, the system

will call the first user on the list and continue through the list. Only when one user inhibits the alarm via the telephone will

calling stop. The inhibition time from the telephone call is also set up within the system settings.

Switch relay: If a device with a relay is included in the system, then with the alarm scheme, it is possible to trigger that

alarm to action either a visual or audible alarm, or another type.

Send data via TCP: Data can be transmitted to a TCP/IP device to switch a device to either On or Off.

It is also possible to set up IF-THEN scripts to trigger actions on the basis of one or more defined pre-conditions.

11

Rotronic Monitoring System

HARDWARE

Lan and Wireless System

All RMS components are connected via a LAN or a wireless interface. All data is transmitted to the SQL database and

visualised via a web browser.

RMS Wall module

The RMS wall module is designed for applications where the module is visible to users:

simple and practicle. The module can be fixed

to the wall and easily wiped clean. The RMS

Wall module is available with either a LAN or

a wireless (868 or 915MHz) interface. The

module can be powered either via PoE (LAN

version only), 24V or battery and can store

44’000 data points.

Wall module devices:

• RMS-LOG-L / 868 / 915

• RMS-GW-868 / 915

The RMS Wall module also exists with display.

Wall module with display devices:

• RMS-D-L

The RMS Mini module

The RMS Mini module is only available with a

wireless interface (868 or 915MHz) and battery powered, with a storage of up to 12’000*

data points.

RMS Din Rail module

The RMS Din Rail module is for installation

where esthetiques are not crucial to the application. The RMS Din Rail module is available

with either a LAN or a wireless (868 or

915MHz) interface. The module can be powered either via PoE (LAN version only), 24V or

battery and can store 44’000 data points.

Din Rail module devices:

• RMS-DI-L-R

• RMS-DO-L-R

RMS Converter

The RMS Converter allows for integration of

digital third party devices with an Ethernet

connection. The converter will translate the

digital protocol and send it to the database,

the values are then visble via the web browser. The converter also has an onboard 7 day

memory** should the network go down. The

device is limited to 100 devices.

RMS converter:

• RMS-CONVERTER-100

Mini module devices:

• RMS-MLOG-T-868 / 915

• RMS-MLOG-T10-868 / 915

• RMS-MDI-868

• RMS-MLOG-B-868 / 915

• RMS-MADC-868-A / 915-A

• RMS-MADC-868-V

• RMS-MLOG-LGT-868

* Please check each device individually for the data storage possibilities.

** The converter should be on the same network as the third party device.

12

Rotronic Monitoring System

DATA SECURITY / -INTEGRITY / FDA CONFORMITY

Data security, data integrity, data availability: these three terms play a central role in monitoring systems. The RMS

reassuringly scores in all these fields.

Data Security

Data security means the data cannot be accessed by unauthorized persons. This is achieved through encryption during

data transfer and storage.

Data Security in RMS

The monitoring system provides encryption of the data during transfer. This means the data can neither be tapped or

manipulated by so-called retry attacks. The security of the stored database in RMS is ensured by the IT structure. The

Rotronic Cloud is protected by certified IT data centers. If the database is located in the customer’s server center, the

customer defines the security infrastructure. Rotronic then offers IT support.

FDA/GMP Requirements

Regulators in the pharmaceutical and food industries demand that all relevant events are recorded so they are traceable.

This is achieved through the electronic marking of all calibration measurements and verification processes. The so-called

“electronic recording” requires unique identification of certificates. This means that every calibration certificate with a

date and inspection stamp must be traceable such that the calibration chain can be verified.

Audit Trail

When a monitoring system is commissioned, it is calibrated and validated. In this way the operator assures his Quality

department that the system works correctly. During subsequent operation, all relevant changes must be recorded in full.

The audit trail guarantees recording of all changes in the system such as, for example, change in measurement probes,

user activities, battery change. This in turn ensures that all events can be tracked at a later date.

Data Availability

For some manufacturar’s systems, data availability can contradict data security because secure data are difficult to access. The user must authenticate themselves and use secure connections or verified platforms. Nevertheless, the trend

is clearly moving towards worldwide data accessibility allowing platform-independent viewing and evaluation.

Data Integrity

Ensuring data integrity means guaranteeing secure transmission and storage. A measured value must not change during

transmission because of disruptions. Data transmission and storage must therefore be safe from manipulation. This is

achieved with CRC checksums and intermediate storage during data transmission. In this way, faulty data communication

is recognized and the data stored in the buffer memory are sent again until the transmission has been finished.

All data in RMS are sent with CRC checksums and confirmed by the recipient after receipt. Faulty data transmission is thus

ruled out. Should the data not arrive with the recipient, they are stored intermediately by the logger and can then be

transmitted at a later point in time when the connection has been restored.

13

Rotronic Monitoring System

RMS Communications

14

Rotronic Monitoring System

RMS SERVICES

Project Procedure

The Rotronic Monitoring System (RMS) is a hardware and software solution adjustable to your requirements for a continuous monitoring system. The complete system conforms to GAMP5, Rotronic is well aware that our support is crucial to

your project, so we offer a complete solution. From the user requirement specifications to the IQ/OP/PQ with our detailed

documentation finishing off with tailor made training for your employees.

Furthermore the RMS software is delivered as a GAMP software category 4 system.Our main goal is to fully understand

your requirements and deliver the best continuous monitoring system for you and your company.

Review of the URS

Rotronic has designed a functional description document explaining each and every function

of the RMS software. This description will help you create your own URS, but it might also

help you adapt the one you already have striving to provide the best risk based approach to

compliant GxP computerised systems. Don’t know exactly how to build up your URS? No need

to worry, Rotronic have the knowledge and documentation required to help support you in

any case.

The continuous monitoring system RMS is a very flexible solution both on the hardware and

the software side (R&D and production in the Headquarters in Switzerland). You have a problem, let us work together to give you the perfect solution. A personal discussion is of the

upmost importance though, only when speaking to you can we really understand your requirements for a continuous monitoring system!

Design Concept

After fully understanding your requirements, a project is setup at Rotronic. Each and every

step is listed, costs evaluated and an initial time line defined. A crucial point is software adaptations, any adaptions are follow a stringent testing process within Rotronic, so project

timing is a key to a successful roll out of your continuous monitoring project.

Rotronic has the possibility to carry out the complete monitoring system project, from the

heat mapping of the various areas to the physical installation of the devices. Internally, the

project team needs to understand your requirements in order to deliver your solution based

upon your time line. Our main aim is an optimised communication based upon information

transfer to the entire team: sales, product management, inside sales, after sales, production

and R&D are all involved already in this initial process.

Conceptual Offer

Rotronic will give you an initial quotation based upon your URS and the project planning. This

initial quotation is rarely the final quotation, but a ball park figure that will help you to get a

feeling for the costs of a project. Products will be added and removed, services will be adapted… The initial quotation will help you get a feel for the market and already an understanding

of what working with Rotronic is like. We are more than happy to invest time in a project, so

that you get the best continuous monitoring solution possible!

15

Loading...

Loading...