Rosemount 8732C User Manual

00809-0100-4725

Model 8732C

Integral Mount

Magnetic

Flowmeter System

English

Rev. BB

Product Manual

Model 8732C

Integral Mount Magnetic

Flowmeter System

NOTICE

Read this manual before working with the prod uc t. For perso nal and system

safety, and for optimum product performance, make sure you thoroughly

understand the conten ts before installing, using, or maintaining this product.

Within the United States, Rosemount Inc. ha s two tol l-free assistance numbers.

Customer Central: 1-800-999-9307 (

Technical support, quoting, and order-related questions.

North American 1-800-654-7768 (

Response Center: Equipment service needs.

For equipment s ervice or s upport n eeds outs ide th e United State s, cont act your

local Rosemount representative.

7:00 a.m. to 7:00 p.m. CST)

24 hours a day – Includes Canada)

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel 1-800-999-9307

Telex 4310012

Fax (612) 949-7001

© Rosemount Inc. 1997. All rights reserved.

http://www.rosemount.com

T

N

I

E

D

R

P

IN

U.

A.

S.

The products described in this document are NOT designed for nuclearqualified applications.

Using non-nuclear qua lifi ed products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Rosemount nucle ar-qualified products, contact you r local

Rosemount Sales Representative.

Rosemount, the Rosemount logotype, and SMART FAMILY are registered trademarks of Rosemount Inc.

HART is a registered trademark of the HART Communica tion Found atio n.

Cover Photo: 8732-002AB.

Fisher-Rosemount satisfies all obligations coming from legislation

to harmonize product requ ireme n ts in th e Euro pe a n Union.

SNF-0004

Table of Contents

IMPORTANT

Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to the

safety messages listed at the beginning of each section before performing

an operation preceded by this symb o l.

SECTION 1:

Introduction

SECTION 2:

Installation

Manual Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 1

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Identify Options and Configurations . . . . . . . . . . . . . . . . . . . . . . 2-2

Hardware Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Failure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Current Output Internally or Externally Powered . . . . . . . 2-2

Transmitter Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Changing Hardware Switch Settings . . . . . . . . . . . . . . . . . . 2-3

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Conduit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Transmitter Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

dc Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Important User Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Installation Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Supply Wire Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Disconnects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Transmitter Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

i

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Flowtube Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Upstream/Downstream Piping . . . . . . . . . . . . . . . . . . . . . . . 2-8

Flowtube Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Vertical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Horizontal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Flow Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Flange Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Model 8705 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Model 8711 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Model 8705 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Model 8711 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Install Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Options, Considerations, and Procedures . . . . . . . . . . . . . . . . . . . . .2-20

Connect 4–20 mA Loop External Power Source . . . . . . . . . . . . .2-20

Connect Pulse Output Power Source . . . . . . . . . . . . . . . . . . . . .2-21

Connect Auxiliary Output Control . . . . . . . . . . . . . . . . . . . . . . .2-22

Quick Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Installation Check and Guide . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Process Leak Protection (Model 8705 Only) . . . . . . . . . . . . . . . . . . .2-23

Process Leak Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Field-Removable Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

SECTION 3:

Local Operator Interface

The Local Operator Interface (LOI) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

LOI Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

LOI Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

LOI Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table Value Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Select Value Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

LOI Screen Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

ii

SECTION 4:

Transmitter Functions

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Review Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Check Output Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Process Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Line Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Tube Cal. Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Upper Range Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Special Units Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Volume Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Base Volume Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Conversion Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Base Time Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Flow Rate Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Analog Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Upper Range Value (URV) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Lower Range Value (LRV) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4–20 mA Output Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Loop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Auxiliary Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Totalizer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Totalizer Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Noise Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Coil Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Auto Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Low Flow Cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Signal Processing Control . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Number of Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Maximum Percent Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Time Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Gain (Electronics) Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Transmitter Information Configuration . . . . . . . . . . . . . . . . . . . . . .4-15

Transmitter Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Software Revision Number . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Descriptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Flowtube Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Flowtube Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Liner Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Electrode Typ e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Electrode Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Flange Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Flange Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Multidrop Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Auto Poll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Poll Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

iii

SECTION 5:

Troubleshooting

Basic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Advanced Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Process Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Software Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Loop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Pulse Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Transmitter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Flowtube Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . 5-5

Transmitter Removal Procedure . . . . . . . . . . . . . . . . . . . . . . 5-5

Transmitter Assembly Procedure . . . . . . . . . . . . . . . . . . . . . 5-5

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

SECTION 6:

Model 8732C

Specifications and

Reference Data

SECTION 7:

Model 8705 Specifications

and Reference Data

SECTION 8:

Model 8711 Specifications

and Reference Data

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Model 8732C Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

iv

APPENDIX A:

HART Communicator

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

HART Communicator Menu Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

HART Fast Key Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Connections and Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Basic Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Action Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Alphanumeric and Shift Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

HART Fast Key Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

HART Fast Key Example . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Menus and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Online Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

APPENDIX B:

Operation Planning

APPENDIX C:

Transmitter

Output Instability

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Flowtube Site Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Line Power Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Bypass Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Process Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Adequate Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Low-Noise Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Flowtube Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Upstream Piping Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Vertical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Horizontal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Magnetic Flowmeter Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Auto Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

How Does It Really Work? . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

When Should Signal Processing Be Used? . . . . . . . . . . . . . . C-4

APPENDIX D:

Magnetic Flow

Operating Principles

INDEX

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Primary and Secondary Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Series 8700 Magnetic Flowmeter Flowtube . . . . . . . . . . . . . . . . D-2

Series 8712 Magnetic Flowmeter Transmitter . . . . . . . . . . . . . . D-2

Electrical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Pulsed dc Field Coil Advantages . . . . . . . . . . . . . . . . . . . . . . . . . D-2

v

vi

Section

1 Introduction

MANUAL SCOPE

This manual provides instructions for installing, configuring,

operating, and troubleshooting the Rosemount Model 8732C

Integral Mount Magnetic Flowmeter System.

Section 2: Installation

provides step by step instructions for installing and starting-up the

Model 8732C Magnetic Flowmeter System.

Section 3: Local Operator Interface

introduces the Model 8732C local operator interface (LOI) and its

function in configuring the Model 8732C.

Section 4: Transmitter Functions

guides you through the software configuration functions for the Model

8732C. Basic configuration covers the functions that are necessary to

get the system up and running as well as special configuration.

Section 5: Troubleshooting

includes troubleshooting tables and software test procedures for

diagnosing and repairing problems with the Model 8732C.

Section 6: Model 8732 Specifications and Reference Data

provides functional, performance, and physical specifications for the

Model 8732C. It also includes ordering information and approvals.

Section 7: Model 8705 Specifications and Reference Data

provides functional, performance, and physical specifications for Model

8705 Flanged Magnetic Flowmeter Flowtubes. It also includes ordering

information and approvals.

Section 8: Model 8711 Specifications and Reference Data

provides functional, performance, and physical specifications for Model

8711 Wafer Magnetic Flowmeter Flowtubes. It also includes ordering

information and approvals.

Appendix A: Hart Communicator

is a detailed summary of the operational features of the HART

Communicator. It includes a menu tree, Fast Key Sequence table,

and other instructions.

Appendix B: Operation Planning

provides guidance for system planning when using a magnetic

flowmeter system.

Appendix C: Transmitter Output Instability

describes the problems of signal noise and the s ignal processing system

of the Rosemount Model 8732C Transmitter.

Appendix D: Magnetic Flow Operating Principles

explains the principles behind Series 8700 System operations,

functions, and design.

1-1

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

SYSTEM DESCRIPTION

SAFETY MESSAGES

A complete magnetic flowmeter system consists of two components: the

Rosemount Model 8732C microprocessor-based integral-mount magnetic

flowmeter transmitter, and a Rosemount Model 8705 or 8711 flowtube.

The flowtube is installed in-line with process piping, either vertically or

horizontally. Coils located on opposite sides of the flowtube create a

magnetic field, and conductive liquid moving through the magnetic

field generates a voltage that is detected by two electrodes.

The transmitter controls the generation of th e mag netic field and

senses the voltage detected by the electrodes. Base d on the se n sed

voltage, the transmitter calculates a flow rate and produces analog

and frequency output signals proportional to this flow rate.

Procedures and instructions in this manual may requ ire spe cial

precautions to ensure the safety of the perso nnel performi ng the

operations. Refer to the safety messages listed at the beginning of

each section before performing any operations.

1-2

Section

2 Installation

INTRODUCTION

SAFETY MESSAGES

Warnings

This section covers the installation procedures for the Model 8732C

Magnetic Flowmeter System.

Instructions and procedures in this section may require special

precautions to ensure the safety of the perso nnel performi ng

the operations. Information that raises potential s afety issues

is indicated by a warning symbol ( ). Please refer to the following

safety messages before performing an operation preceded by

this symbol.

Explosions could result in death or serious injury:

• Verify that the operating atmosphere of the flowtube and

transmitter is consistent with the appropriate hazardous

locations certifications.

• Do not remove the transmitter cover in explosive atmospheres

when the circuit is alive.

• Before connecting a HART-based communicator in an explosive

atmosphere, make sure the instruments in the loop are

installed in accordance with intrinsically safe or non-incendive

field wiring practices.

• Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

Failure to follow safe installation a nd servicing guide lines could res ult

in death or serious injury:

• Make sure only qualified personnel perform the installation.

• Do not perform any service other than those contained in this

manual unless qualified.

High voltage that may be present on leads co uld cause

electrical shock:

• Avoid contact with leads and terminals.

2-1

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

PRE-INSTALLATION

Identify Options

and Configurations

Hardware Switches

There are several pre-installation steps that make the installation process

easier. They include identifying the options and configurations that apply

to your application, setting the hardware switches if neces sary, and

consideration of m ech anic al , electr ical , and envir on mental req u iremen ts .

Please remember that the flowtube liner is vulnerabl e to handli ng

damage. Never place anything through the flowtube for the purpose of

lifting or gaining leverage. Liner damage can render the flowtube useless.

Standard application of the Model 8732C includes a 4–20 mA output

and control of the flowtube coils. Other applications may require

one or more of the following configurations or options:

• Multidrop Communications

• Auxiliary Output

• Pulse Output

Additional options may also apply. Be sure to identify the options and

configurations that apply to your situation, and keep a list of them

nearby during the installation and configuration procedures.

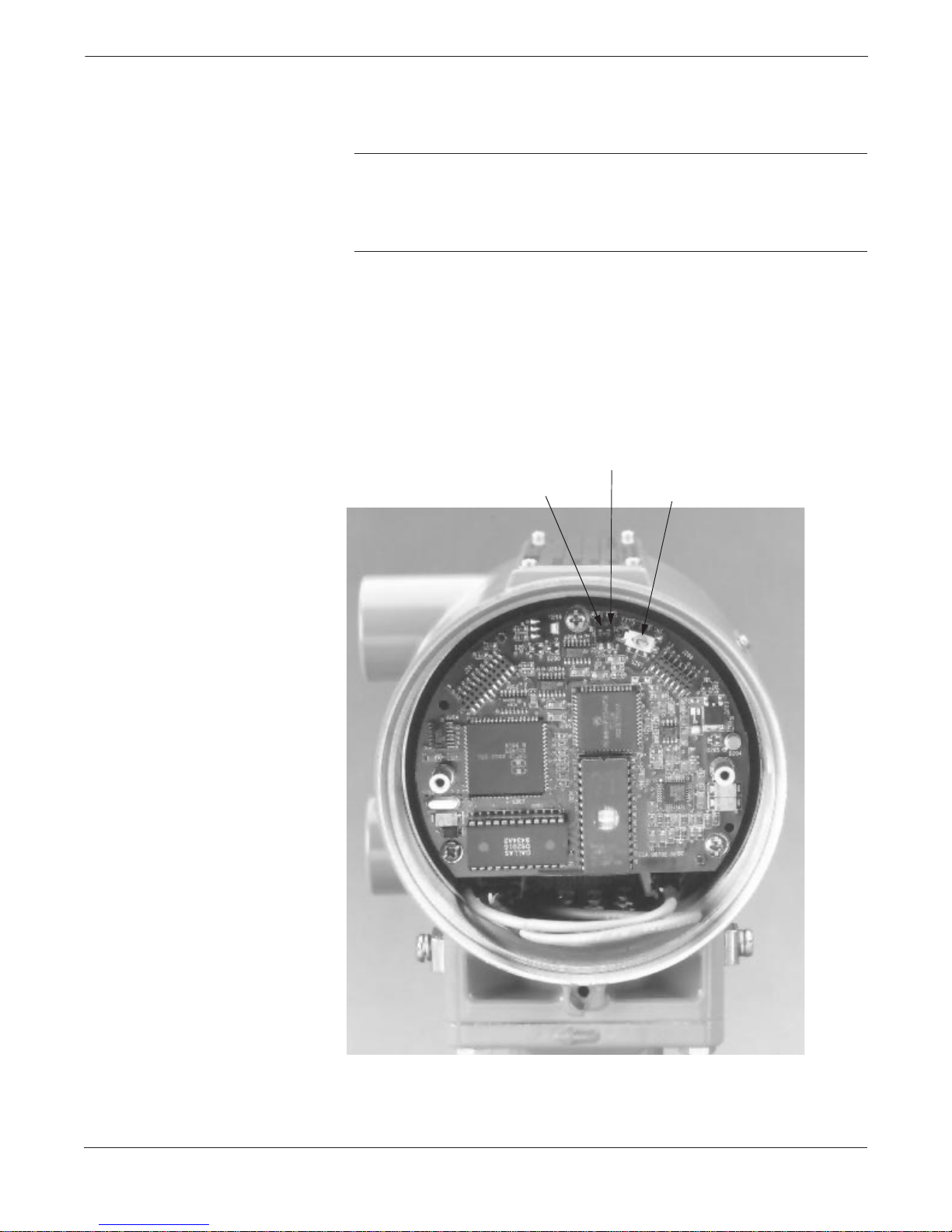

The Model 8732C electronics board is equipped with three user-selectable

hardware switches: Failure Alarm Mode, Output Power Source, and

Software Lockout Mode. The standard configurations for these switches

when shipped from the factory are as follows:

Failure Alarm Mode: High

Output Power Source: Internal

Software Lockout: Off

Definitions of these switches and their functions are provided below.

If you determine that the settings must be changed, see Changing

Hardware Switch Settings on page 2-3.

Failure Mode If the Model 8732C experiences a catastrophic failure in the electronics,

the current output can be driven high (22.50 mA) or low (3.75 mA). The

switch is set in the High position when it leaves the factory.

Current Output Internally or

Externally Powered

T ransmitter Security The Model 8732C has a switch that locks out any configuration changes

The Model 8732C 4–20 mA loop may be powered internally or by an

external power supply. The Internal/External power supply switch

determines the source of the 4–20 mA loop power. Transmitters leaving

the factory are set in the Internal position.

The external power option is required for multidrop communications

applications. A 10–30 V dc external supply is required, and the switch

must be reset. For further information on 4–20 mA external power, see

Connect 4–20 mA Loop External Power Source on page 2-20.

attempted on the transmitter. Any changes to the configuration are

disallowed whenever the switch is in the On position. Ho wever, the flow

rate indication and totalizer functions remain active.

With the switch in the On position, you may still access and review any

of the operating parameters and scroll through the available choices,

but no actual data changes are allowed.

The local operator interface (LOI) has a display lock function that will

restrict any changes to the configuration via the LOI only. (This

restriction applies to the totalizer functions as well.) This protection is

intended to prevent accidental activation of the optical LOI in the field.

Refer to page 3-5 for information about activating and deactivating the

display lock function. The display lock is not on when the Model 8732C

leaves the factory.

2-2

Installation

Changing Hardware

Switch Settings

FIGURE 2-1. Model 8732C

Electronics Board and Hardware Switches.

In most cases, it is not necessary to change the setting of the hardware

switches. If you need to change the switch settings, complete the steps

outlined below:

NOTE

The hardware switches are located under the cover opposite the terminal

block. Because changing their settings requires opening the electronics

housing, make every attempt possible to carry out these procedures away

from the plant environment to protect the electronics.

1. Disconnect power to the transmitter.

2. Unscrew and remove the electronics cover.

3. Identify the location of each switch (see Figure 2-1).

4. Change the setting of the desired switches with a small screwdriver.

5. Reinstall and tighten the electronics cover.

Hi/Lo Alarm

Software Lockout

On/Off

Internal External

Analog Power

8732-004AB

2-3

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

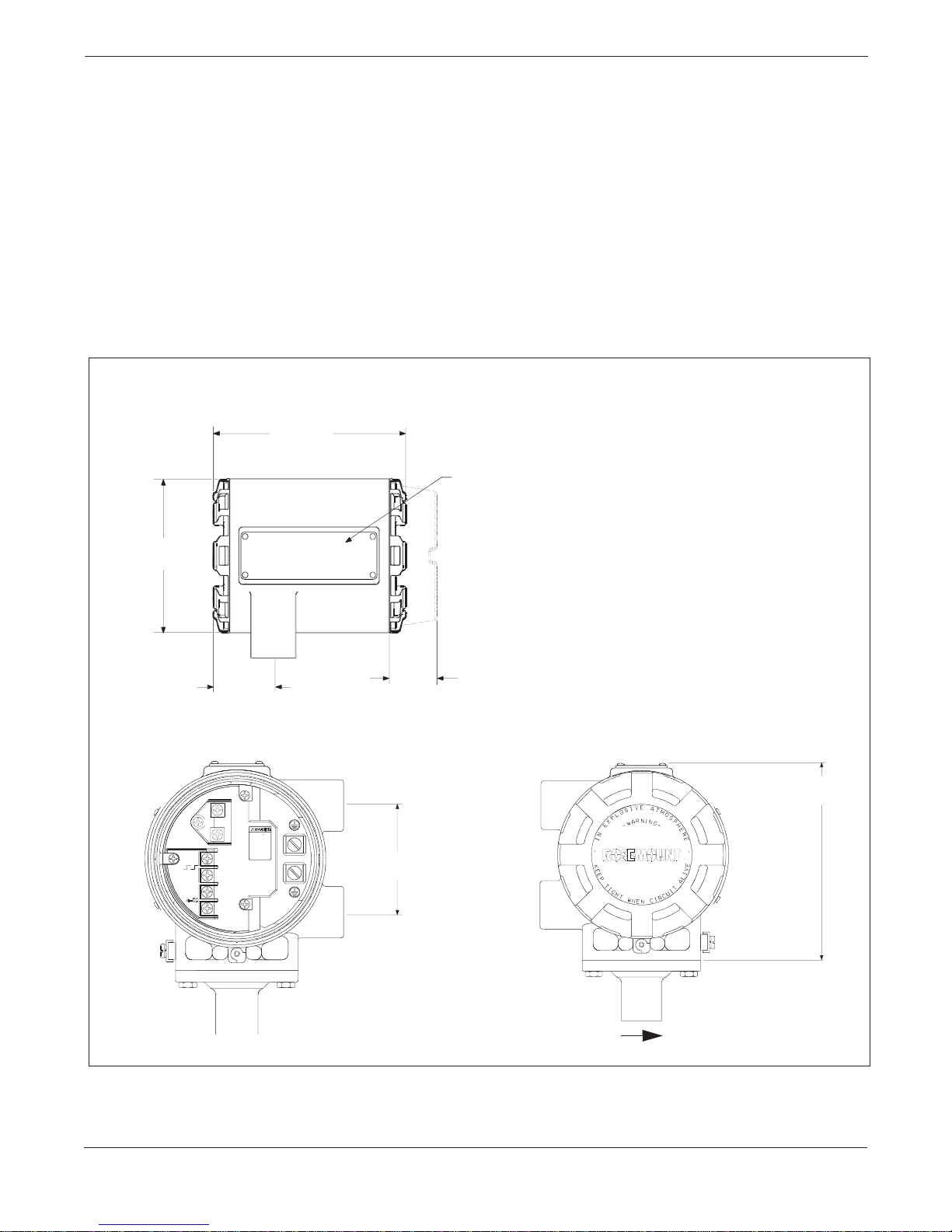

Mechanical Considerations

The mounting site for the Model 8732C Integral Mount Transmitter

should provide enough room for secure mounting, easy access to the

conduit ports, full opening of t he transmit ter covers, and eas y readability

of the local operator interface (LOI) screen (see Figure 2-2). The

electronics housing can be rotated on the flowtube in 90° increments.

This can be done by loosening the four mounting bolts on the bottom of

the housing, rotating the housing, and reinstalling the bolts. Be sure the

surface is clean and there is not a gap when returning the housing to its

original position.

The LOI can also b e ro tated i n 90 ° inc remen ts. Th is shou ld b e pe rf ormed

prior to installing the ma gnetic flowmeter system. Re fer to LOI Rotation

on page 3-3 for additional information.

FIGURE 2-2. Model 8732C Dimensional Drawin gs.

6.48 (165)

SST Tag

4.97

(126)

1.88

(47)

1.53

(39)

5.82

(148)

3.00

(76)

NOTE

Dimensions are in inches (millimeters).

2-4

FLOW

8732-1002A01B, 1002E01A, 1002G01A

Installation

Electrical Considerations

Before making any electrical connections to the Model 8732C, consider

the following standards and be sure to have proper power supply,

conduit, and other accessories.

Conduit Connections The Model 8732C Integral Mount Magnetic Flowmeter Transmitter

has two ¾–inch NPT conduit connections. If one of these ports is

not being used, it must be sealed with a conduit seal. In some

cases, conduits may also require drainage if moisture could build up in

the line.

Transmitter Input Power The Model 8732C Transmitter is designed to be powered by voltages

ranging from 90 to 250 V ac (50 to 60 Hz) or 15–30 V dc. Units powered

with an ac power supply should be connected to standard ac

connections for 90 V ac or 250 V ac. Units powered by a 15–30 V dc

power supply have special considerations.

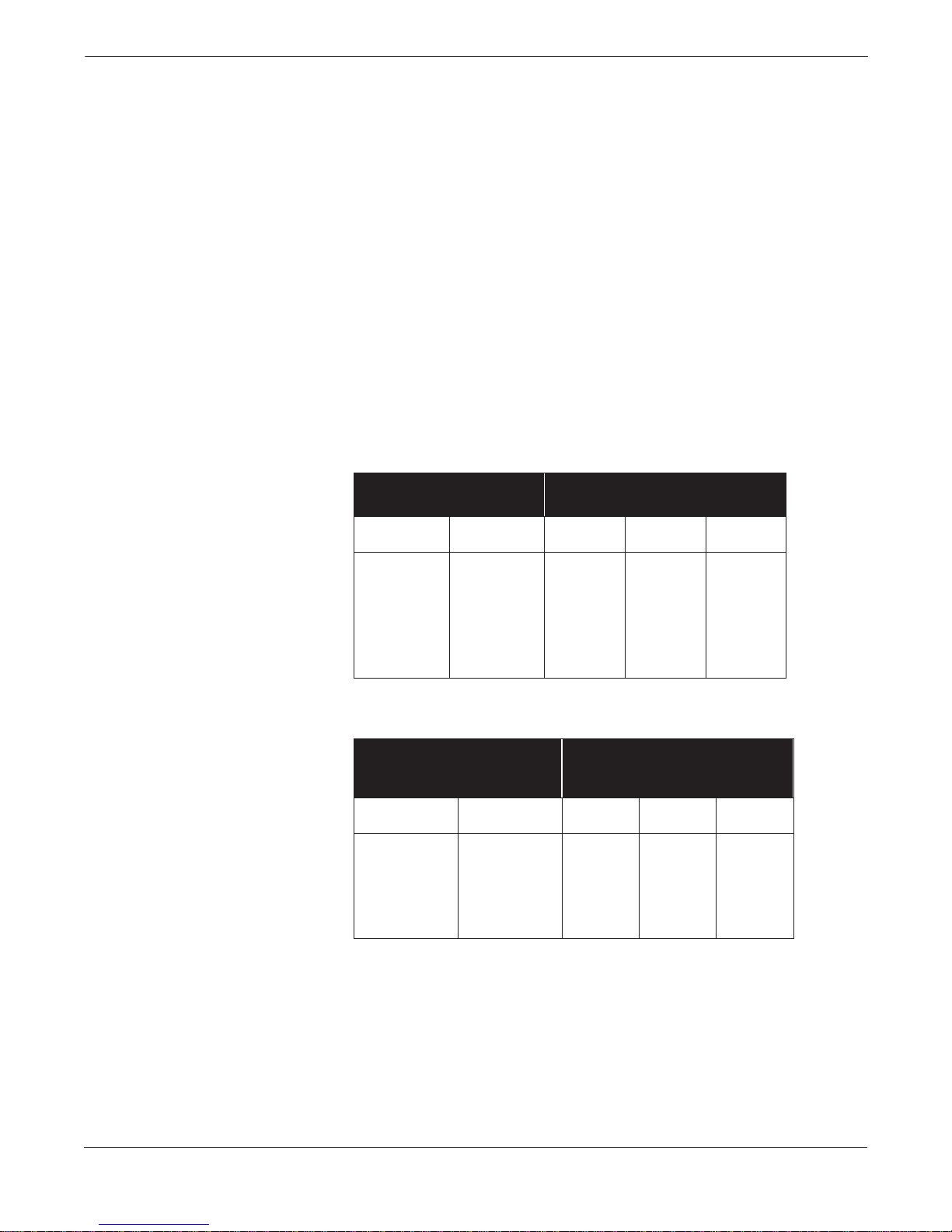

DC Power Requirements Units powered with 15–30 V dc may draw up to 2 amps of current. As a

result, the input power wire must meet certain gauge requirements.

Table 2-1 and Table 2-2 show the maximum wire length for

corresponding supply voltages, wire gauges, and wire type.

TABLE 2-1. Length of Annealed

Copper Wires.

Types of

Power Supply Wires

Wire Gauge Milliohms/ft

Annealed Cu

20 10.15 1,230 625 365

18 6.385 1,955 990 585

16 4.016 3,110 1,580 930

14 2.525 4,950 2,515 1,485

12 1.588 7,870 3,995 2,360

10 0.999 12,510 6,355 3,750

Maximum Length of the Wire for Each

Corresponding Pow er Sup p ly So u rc e

30 V

Supply (ft)

24 V

Supply (ft)

20 V

Supply (ft)

TABLE 2-2. Length of Hand-drawn

Copper Wires.

Types of

Power Supply Wires

Wire Gauge Milliohms/ft

Hand-drawn Cu

18 6.640 1,880 955 565

16 4.176 2,990 1,520 895

14 2.626 4,760 2,415 1,425

12 1.652 7,565 3,840 2,270

10 1.039 12,030 6,110 3,605

Maximum Length of the Wire for

Each Corresponding Power Supply

30 V

Supply (ft)

Source

24 V

Supply (ft)

20 V

Supply (ft)

2-5

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

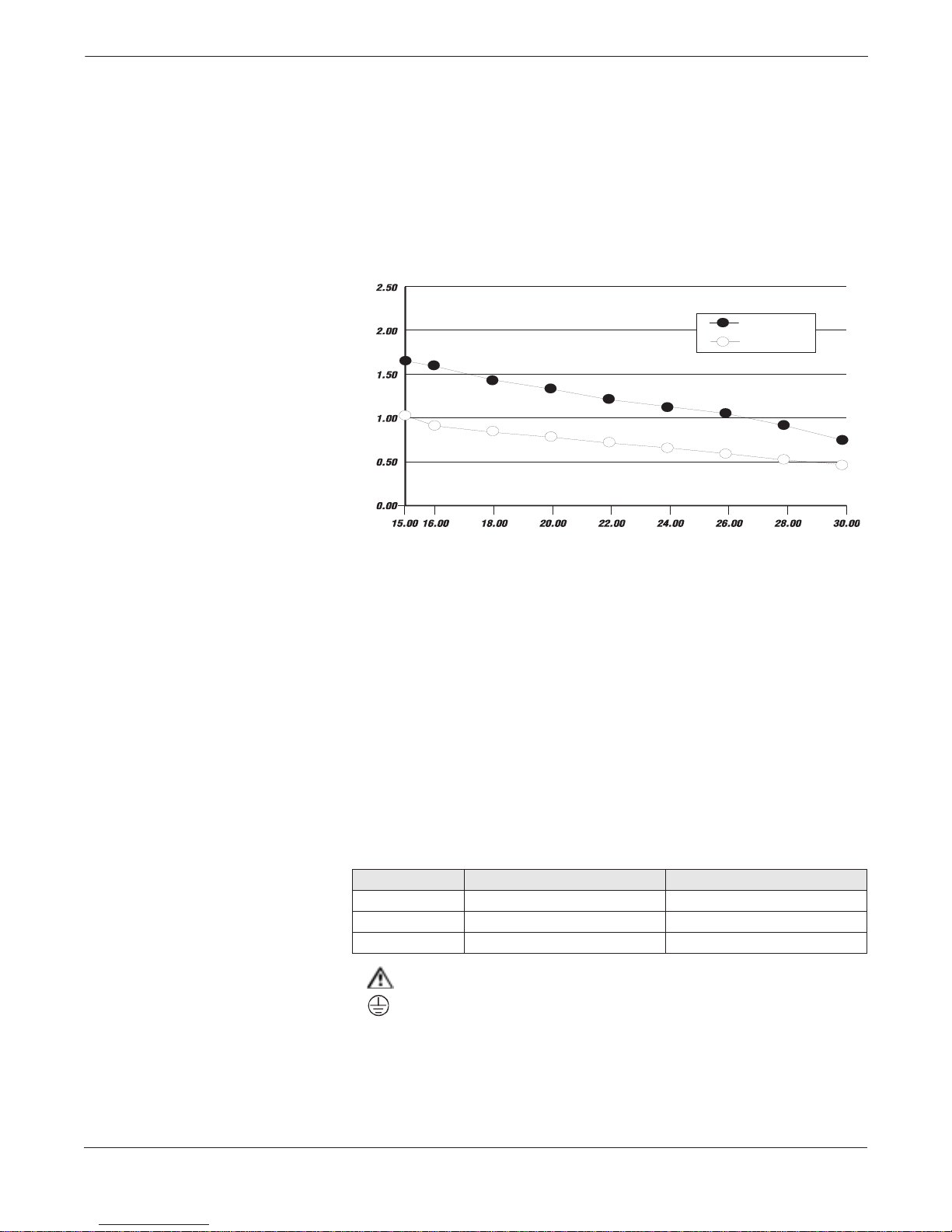

Figure 2-3 shows the surge current for each corresponding supply

voltage. For combinations not shown above, you can calculate the

maximum distance given the surge current, the voltage of the source,

and the minimum start-up voltage of the transmitter, 15 V dc using the

following equation:

Max. Resistance = (Supply Voltage –15 V dc) / Surge Current

Use Tables 2-1 and 2-2 to determine the maximum wire length

allowable for your power supply and maximum resistance.

FIGURE 2-3. Supply Current vs.

Input Voltage.

Supply Current (Amperes)

Surge

Nominal

IMPORTANT USER NOTES

Installation Category

Supply Wire Requirements

Disconnects

Overcurrent Protection

Transmitter Symbols

Input Voltage (Volts)

Installation (Overvoltage) Category II.

12- to 18-gauge wire. For connections in ambients in excess of 60° C

(140° F), use wire rated to at least 90° C (194° F).

The supply wires should be connected to the device through an external

disconnect or circuit breaker. The disconnect or circuit breaker should

be clearly labeled and located near the transmitter.

Model 8732 requires overcurrent protection of the supply lines.

Maximum rating of overcurrent devices are as follows:

Power System Fuse Rating Manufacturer

110 V ac 250 V; 1 Amp, Quick Acting Bussman AGCI or Equivalent

220 V ac 250 V;.5 Amp, Quick Acting Bussman AGCI or Equivalent

15 to 50 V dc 250 V; 3 Amp; Quick Acting Bussman AGCI or Equivalent

Caution Symbol — Check product documentation for details.

Protective conductor (grounding) terminal.

2-6

Installation

Environmental

Considerations

INSTALLATION

PROCEDURES

Handling

To ensure maximum transmitter life, avoid excessive heat and

vibration. Typical problem areas include high-vibration lines with

integrally mounted transmitters, warm-climate installations in direct

sunlight, and outdoor installations in cold climates.

Because the Model 8732C System requires external power, access to a

suitable power source must be ensured.

Overheating will damage the flowtube. Do not encapsulate the flowtube

with heating elements.

These installation tasks provide detailed mechanical and electrical

installation procedures.

All parts should be handled carefully to prevent damage. Whenever

possible, transport the system to the installation site in the original

shipping containers. The flowtube is shipped with end covers to protect

it from mechanical damage and normal unrestrained distortion. End

covers should not be removed until just before installation. Keep

shipping plugs in conduit connections until conduits are connected

and sealed.

All flowtube liners are vulnerable to handling damage. Never place

anything through the flowtube for the purpose of lifting or gaining

leverage. Liner damage can render the flowtube useless.

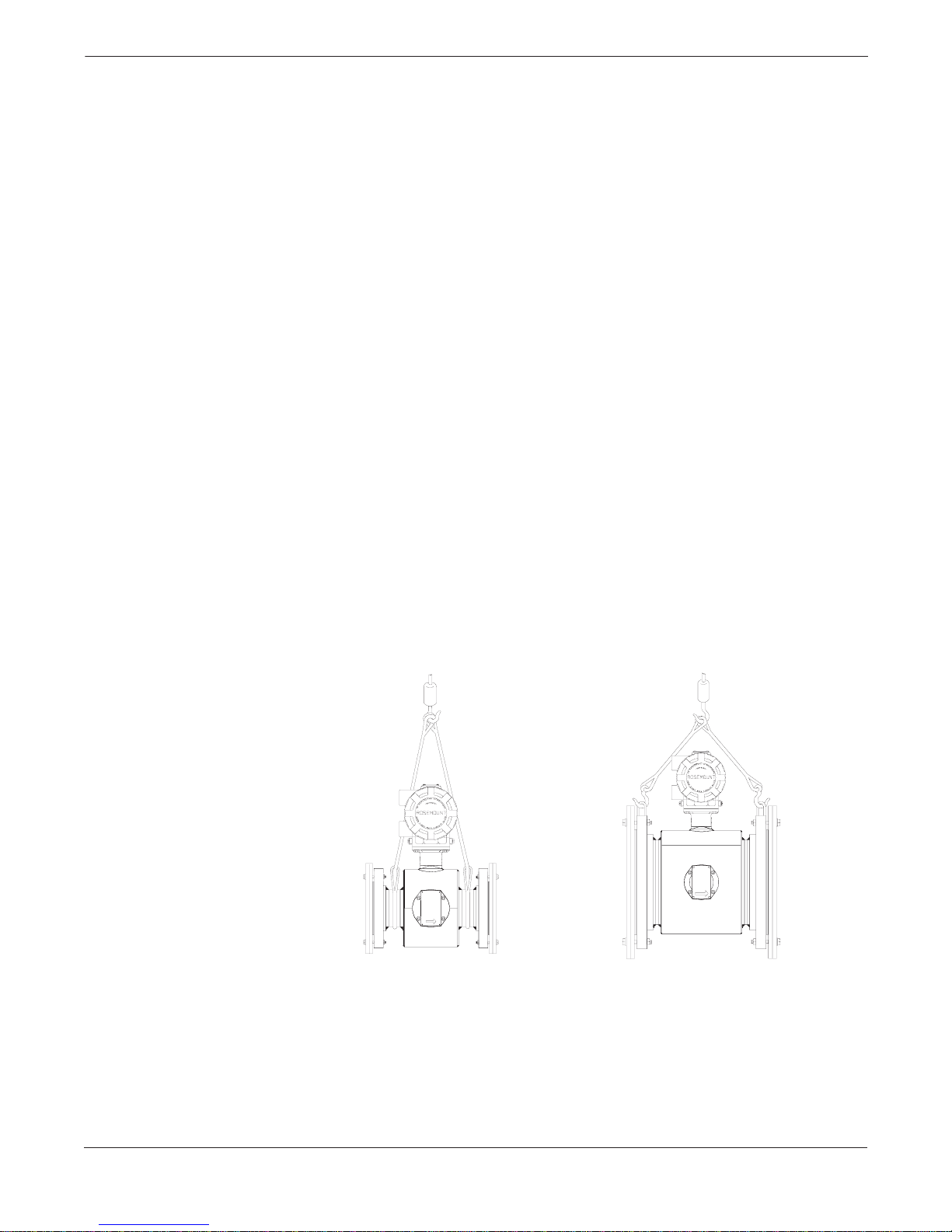

FIGURE 2-4. Model 8705

Flowtube Support for Handling.

Flanged flowtubes have different lifting and transportation guidance.

Refer to Figure 2-4 for correct handling techniques. Wafer style

flowtubes have no special lifting directions, however every precaution

should be taken to avoid liner damage.

½- to 4-Inch Flowtubes

6-Inch and

Larger Flowtubes

8732-0281B02A, C02A

2-7

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

Flowtube Mounting

Physical mounting of a flowtube is similar to installing a typical section

of pipe. Only conventional tools, equipment, and accessories (such as

bolts, gaskets, and grounding hardware) are required.

Calibration Rosemount magnetic flowmeter systems are wet-calibrated at the

factory and need no further calibration during installation.

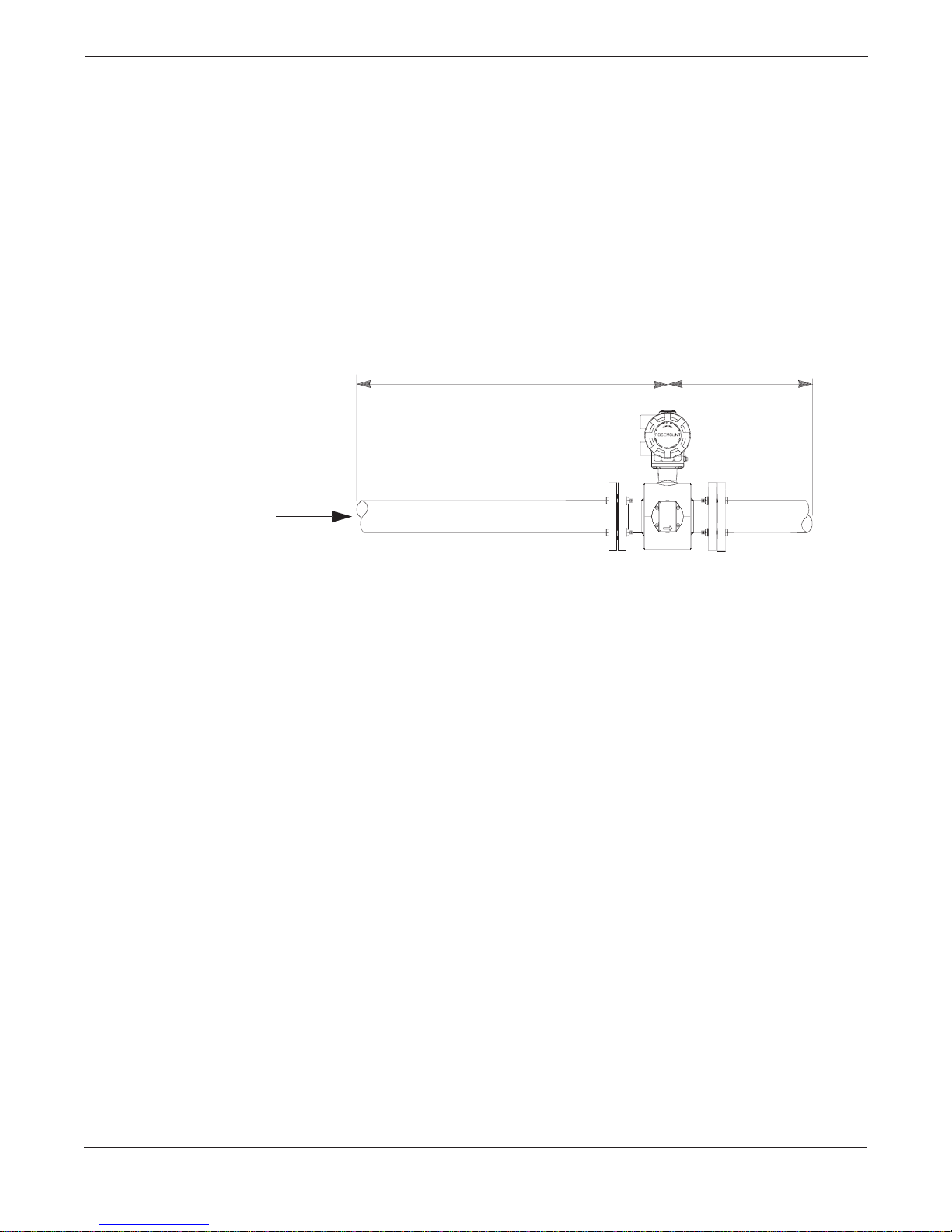

Upstream/Downstream Piping To ensure specific accuracy over widely varying process conditions,

install the flowtube with a minimum of five straight pipe diameters

upstream and two pipe diameters downstream from the electrode

plane, as shown in Figure 2-5. This flowtube placement is usually

adequate to allow for disturbances created by elbows, valves,

and reducers.

FIGURE 2-5. Upstream and

Downstream Straight Pipe Diameter.

5 Pipe Diameters 2 Pipe Diameters

Flow

8732-0281G01A

2-8

Installation

Flowtube Orientation

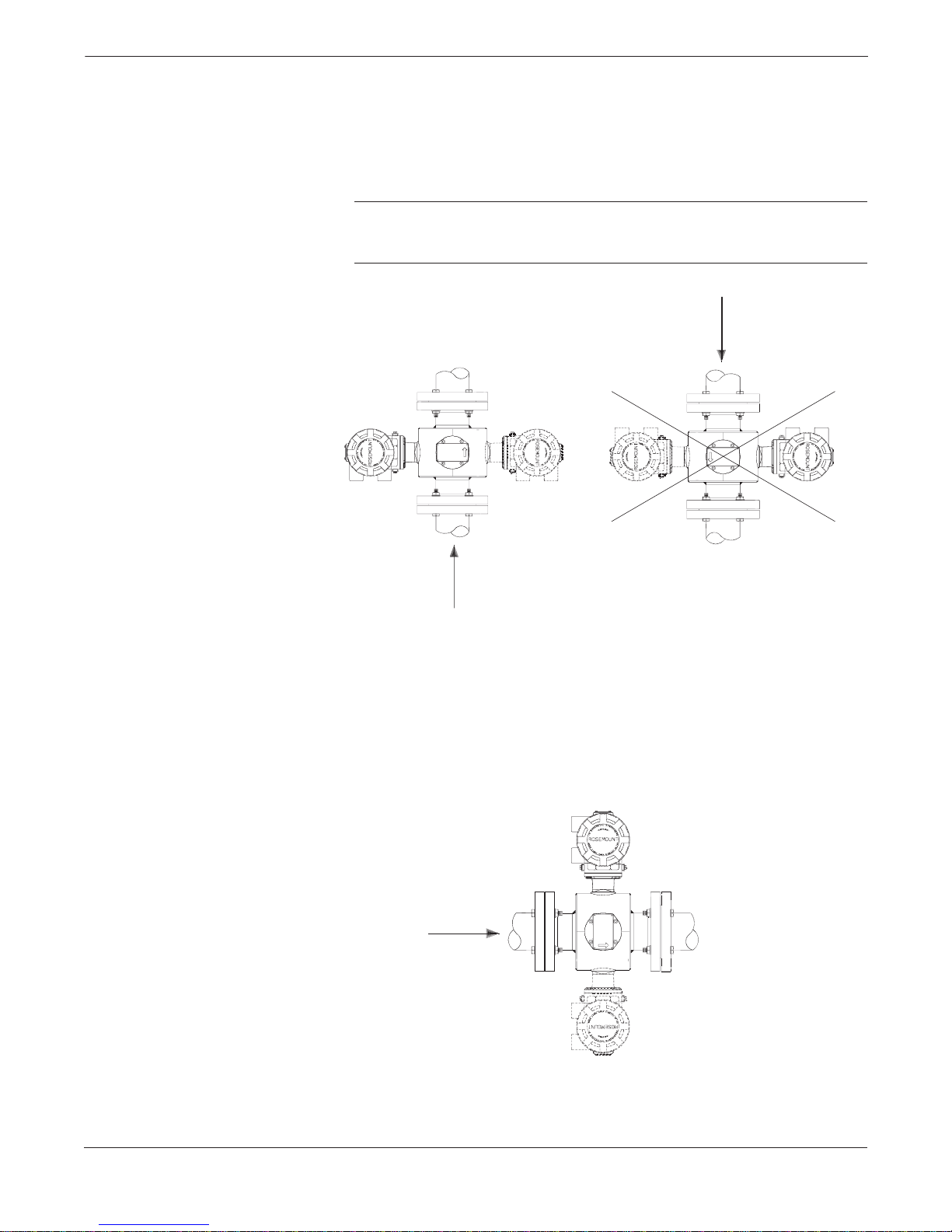

Vertical Installation Vertical installation allows upward process fluid flow and is generally

preferred. Upward flow keeps the cross-sectional area full, regardless

of flow rate. Orientation of the electrode plane is unimportant in

vertical installations.

NOTE

As shown in Figure 2-6, avoid downward vertical flows where back

pressure is inadequate to ensure that the flowtube remains full.

FIGURE 2-6. Vertical Flowtube Orientation.

Flow

Flow

B

Horizontal Installation Horizontal installation should be restricted to low piping sections that

are normally full. Orient the electrode plane to within 45 degrees of

horizontal in horizontal installations. A deviation of more than 45

degrees of horizontal would place an electrode at or near the top of the

flowtube–making it more susceptible to insulation by air or entrapped

gas at the top of the flowtube.

FIGURE 2-7. Horizontal Flowtube Orientation.

Flow

8705-0005A01A, 0005A01B

8705-0005A01C

2-9

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

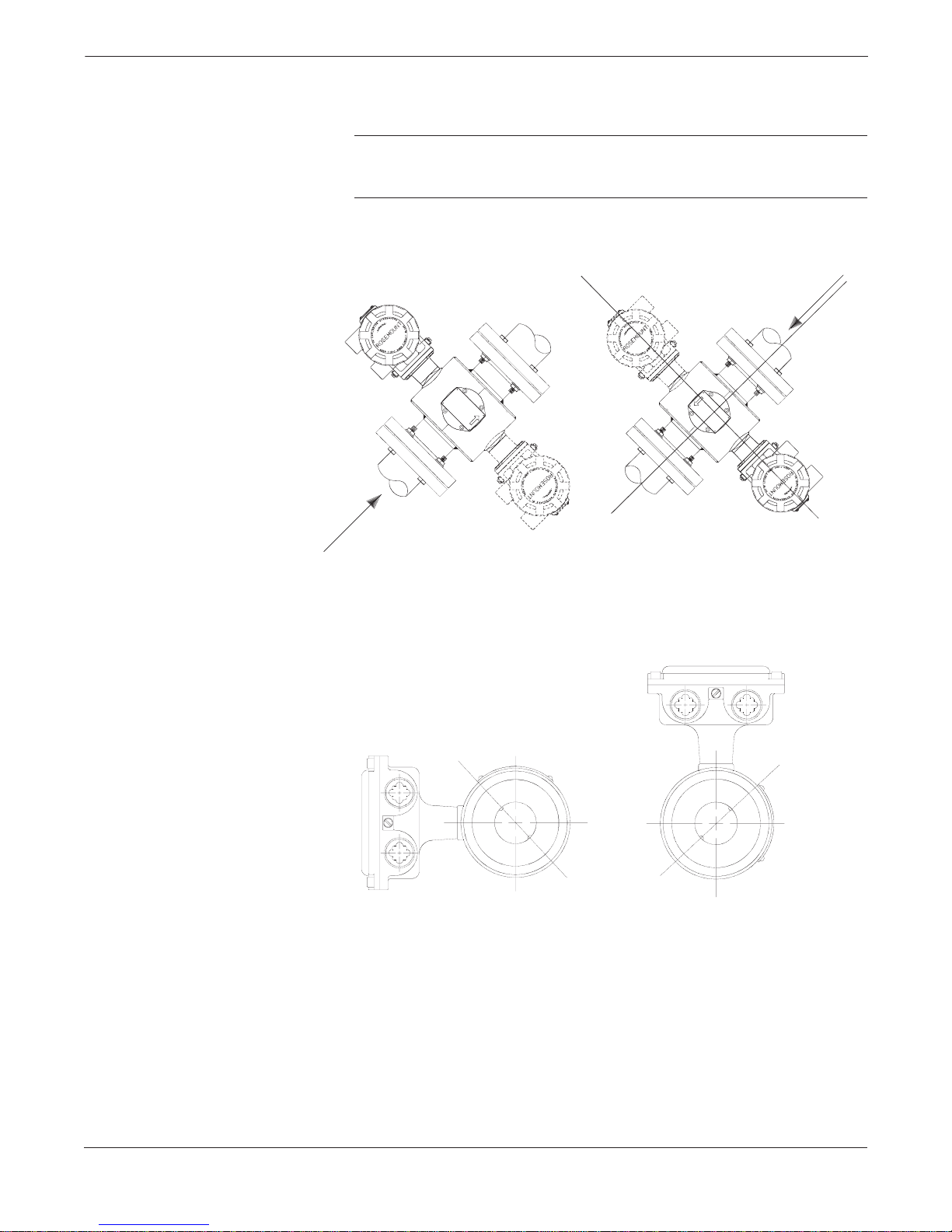

An inclined installation, as shown in Figure 2-8, is an acceptable

installation technique. This tends to keep the cross-sectional area full.

NOTE

As shown in Figure 2-8, avoid declining installations where back

pressure is inadequate to ensure that the flowtube remains full.

FIGURE 2-8. Incline or Decline Orientation.

Flow

Flow

B

8705-0005A01E, 0005A01F

The electrodes in the Model 8711 are properly oriented when the top

of the flowtube is either vertical or horizontal, as shown in Figure .

Avoid any mounting orientation that positions the top of the flowtube

at 45° from the vertical or horizontal position.

Model 8711 Mounting Position.

2-10

45° Electrode Plane

8711-8711E01A, 8711F01A

45° Electrode Plane

Installation

Flow Direction

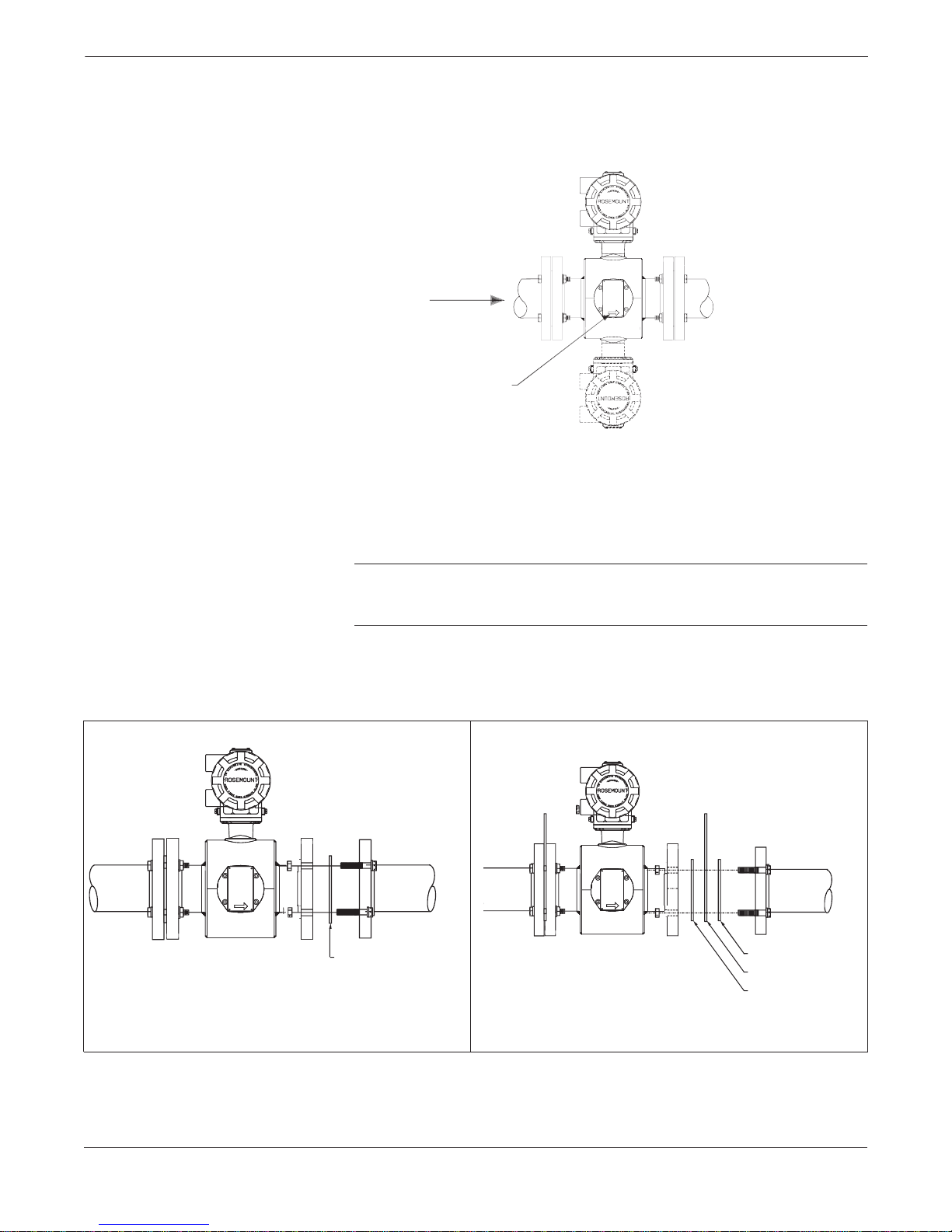

FIGURE 2-9. Flow Direction.

Gaskets

The flowtube should be mounted so that the FORWARD end of the flow

arrow, shown on the flowtube identification tag, points in the direction

of flow through the tube (see Figure 2-9).

Flow

Flow Direction Arrow

8705-0005G01A

The flowtube requires gaskets at each of its connections to adjacent

equipment or piping. The gasket material selected must be compatible

with the process fluid and operating conditions, and must not damage

the liner.

FIGURE 2-10. Model 8705 Flange Gaskets.

Gasket

FLANGE GASKETS FOR ALL OTHER

FLOWTUBES

NOTE

To avoid possible flowtube damage, do not use metallic or spiral

wound gaskets.

BA

Gasket

Grounding Ring

Gasket

FLANGE GASKETS WITH NON-ATTACHED

GROUNDING RINGS

8732-0040F, 0038F

2-11

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

Flange Bolts

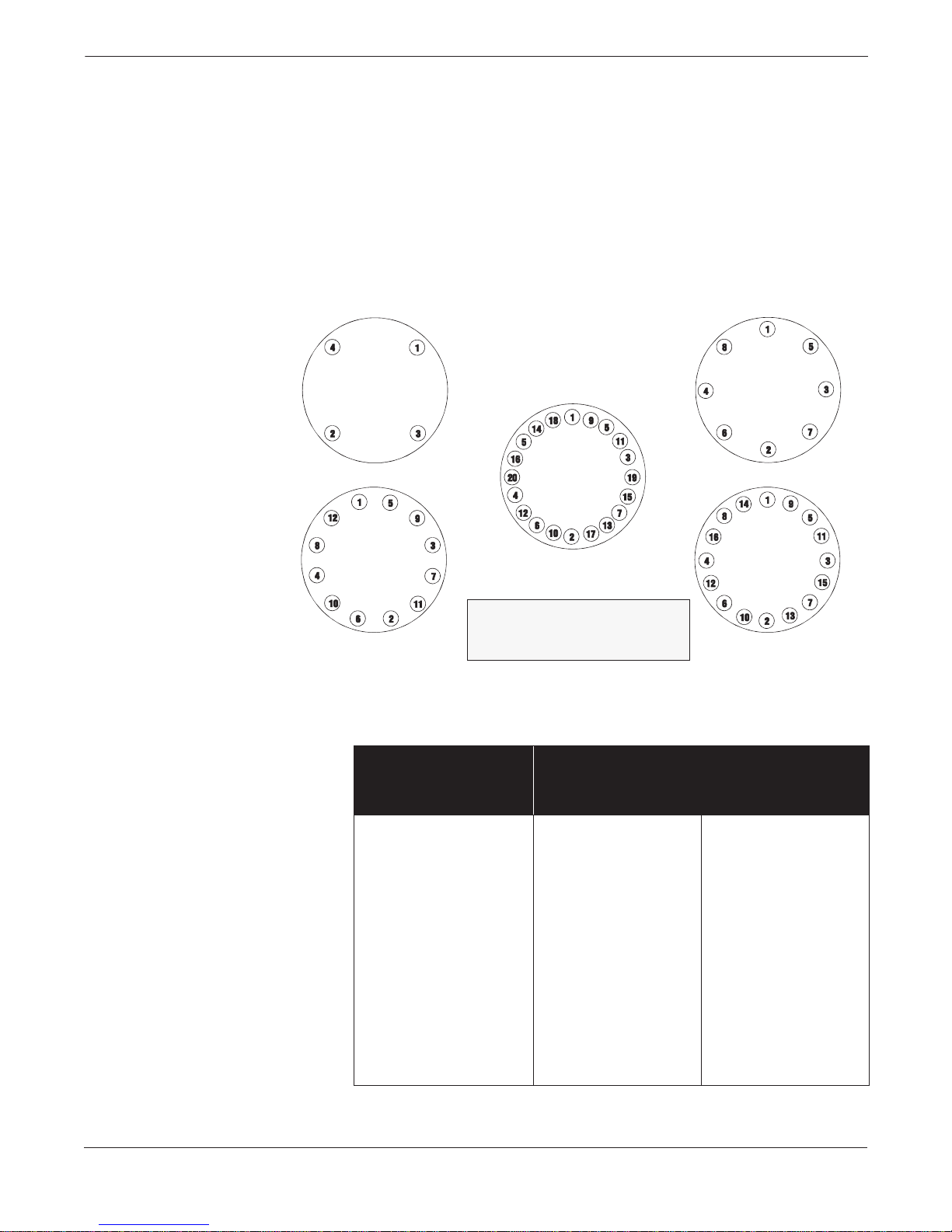

Flowtube sizes and torque values for Class 150 and Class 300 flanges

are listed in T able 2-3. Tighten flange bolts in the incremental sequence

shown in Figure 2-11.

Model 8705 Correct flange bolt tightening is crucial for proper flowtube operation and

life. All bolts must be tightened in the proper sequence to the specified

torque limits. Failure to observe these instructions could result in severe

damage to the flowtube lining and possible flowtube replacement.

Always check for leaks after tightening flange bolts. All flowtubes

require a second torquing 24 hours after initial flange bolt tightening.

FIGURE 2-11. Model 8705 Flange

Bolt Torquing Sequence.

4-Bolt

8-Bolt

TABLE 2-3. Model 8705 Flange Bolt

Torque Specifications.

12-Bolt

Nominal

Flowtube

Size (inches)

½

1

1½

2

3

4

6

8

10

12

14

16

18

20

24

30

36

20-Bolt

Torque the flange bolts

in increments according to

the above numerical sequence.

Flange Bolt Torque

Specifications in Foot-Pounds

Class 150 Flange Class 300 Flange

10

10

17

25

45

35

60

80

70

80

100

90

125

125

150

150

200

14-Bolt

8701-0589A

10

10

22

17

35

50

65

60

65

80

—

—

—

—

—

—

—

2-12

Installation

Model 8711 For Model 8711, the flowtube inside diameter should be centered with

respect to the inside diameter of the adjoining upstream and

downstream piping. This will ensure the flowmeter achieves its

specified accuracy. Mounting bolts supplied with 0.15 through 1-inch

(4–25 mm) line sizes are specifically sized to properly align these

flowtubes with the flange configurations specified. For 1.5 through

8-inch (40–200 mm) line sizes, two centering rings are supplied for

alignment purposes. Place the centering rings over the flowtube using

the following instructions as a reference. If you received two centering

sleeves, follow the steps described under Alignment with

Centering Sleeves.

Alignment with Centering Rings

1. Insert the two studs for the bottom side of the flowtube between

the pipe flanges.

2. Place the two centering rings over each end of the flowtube.

3. Place the flowtube between the flanges. Make sure that the

centering rings are properly placed in the studs. The

studs should be aligned with the markings on the rings that

correspond to the flange you are using.

4. Insert the remaining studs, and install the washers and nuts.

5. Tighten the nuts to the specifications listed in Table 2-4.

NOTE

On the 4- and 6-inch PN 10–16, the installer will need to insert the

flowtube with rings first and then insert the studs. The slots on this

ring scenario are located on the inside of the ring.

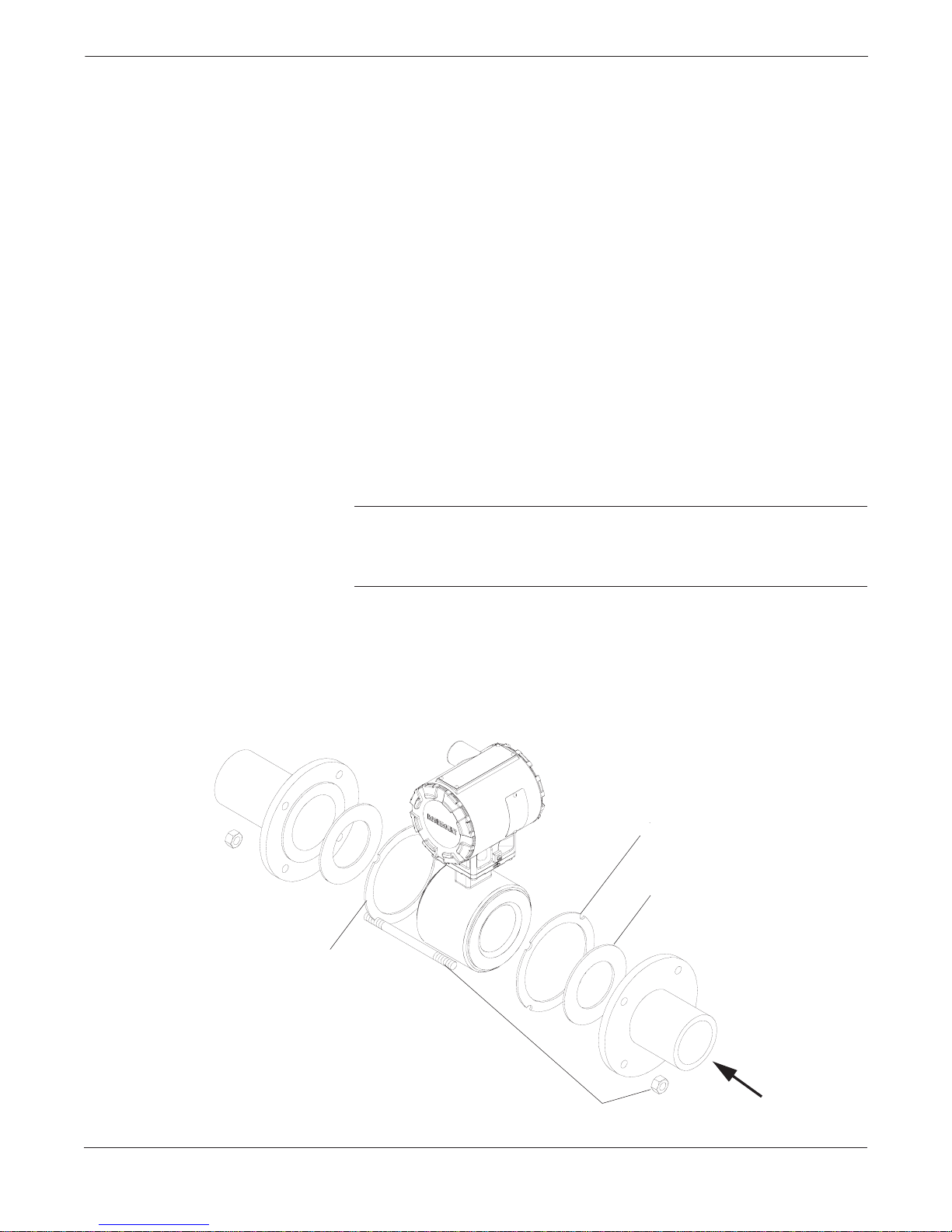

FIGURE 2-12. Alignment with Centering Rings.

Centering Ring

Centering Ring

Gasket for Tefzel/Teflon-lined

Flowtubes only

(Supplied by Customer)

Installation Stud s, Nut s, an d Washers

FLOW

2-13

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

Alignment with Centering Sleeves

Follow the instructions below for the 1.5- through 8-inch

(40 to 200 mm) line sizes if you received two centering

sleeves instead of centering rings:

1. Insert the two studs for the bottom side of the flowtube,

with the centering sleeves, between the pipe flanges.

2. Place the flowtube firmly against the two centering sleeves,

between the flanges.

3. Insert the remaining studs.

4. Install the washers and nuts.

5. Tighten the nuts to the specifications listed in Table 2-4.

TABLE 2-4. Flange Bolt

Torque Specifications.

Nominal Flowtube Size,

Inches (mm)

0.15 (4)

0.30 (8)

0.50 (15)

1 (25)

1.50 (40)

2 (50)

3 (80)

4 (100)

6 (150)

8 (200)

Applicable for Both Class 150 and 300 Flanges

Specifications in Foot-Pounds

Bolt Torque

5

5

5

10

15

25

40

30

50

70

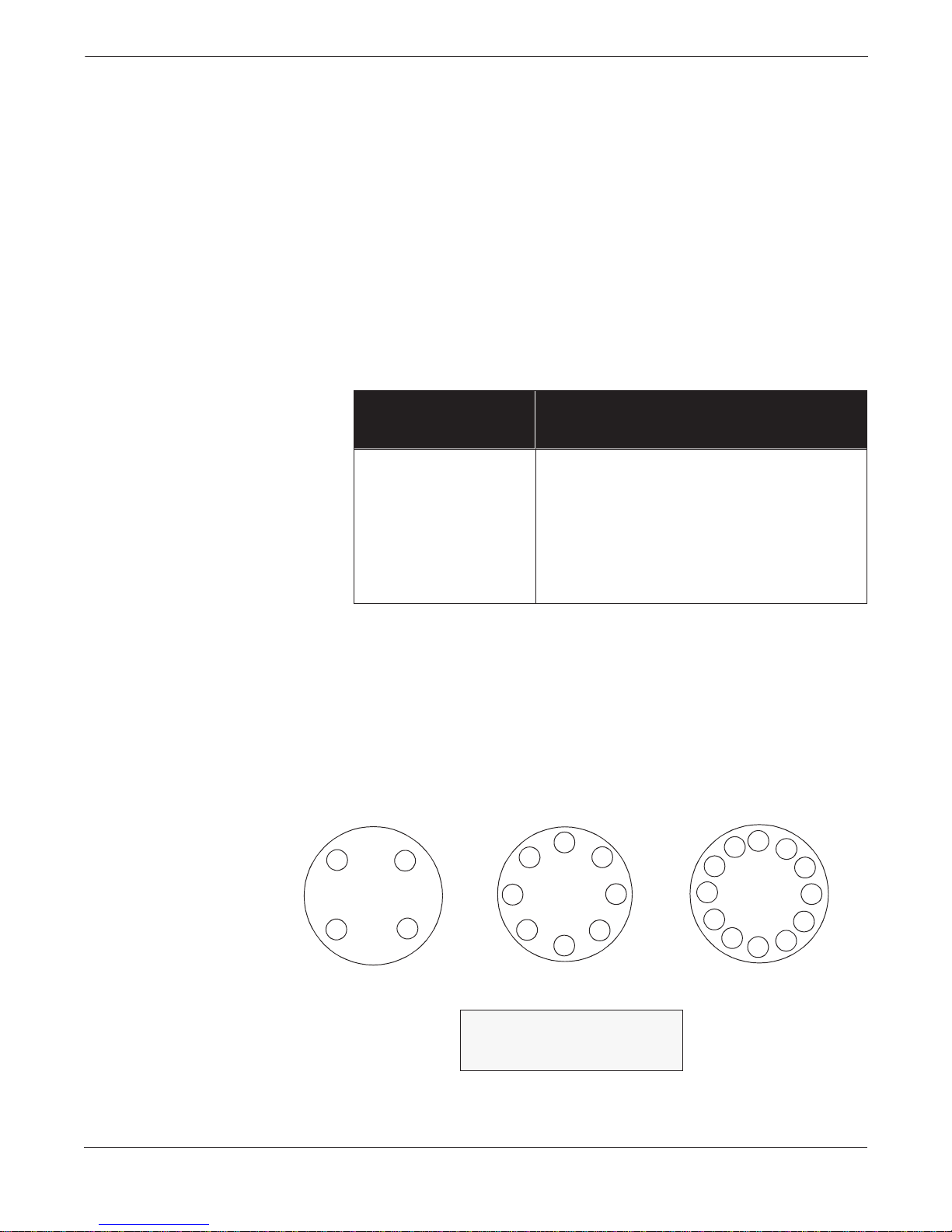

FIGURE 2-13. Model 871 1 Flange

Bolt Torquing Sequences.

2-14

1

1

4

4-Bolt 8-Bolt 12-Bolt

3

2

the above numerical sequence.

8

4

6

Torque the flange bolts

in increments according to

5

3

7

2

12

8

4

10

6

1

5

9

3

7

11

2

Installation

Grounding

Grounding the flowtube is one of the most important details of flowtube

installation. Proper grounding ensures that only the voltage induced in

the flowtubes magnetic field is measured.

Model 8705 Use Table 2-5 to determin e which grounding option figure to use for

proper installation.

NOTE

Consult factory for installations requiring cathodic protection or

situations where high currents or high potential exist in the process.

TABLE 2-5. Model 8705 Grounding Installation.

Grounding Options

Type of Pipe

Conductive Unlined Pipe See Figure 2-14 Not Required Not Required See Figure 2-15

Conductive Lined Pipe Insufficient Grounding See Figure 2-16 See Figure 2-14 See Figure 2-15

Non-conductive Pipe Insufficient Grounding See Figure 2-18 See Figure 2-19 See Figure 2-17

FIGURE 2-14. Model 8705 Grounding

for Conductive Unlined Pipe and

Grounding for Conductive Lin ed Pipe

with Grounding Electrodes.

No Grounding Opt ions Grounding Rings Grounding Electrode s Lining Protectors

FIGURE 2-15. Model 8705 Gro unding for

Conductive Unlined Pipe with Lining

Protectors and Grou nding for Con ductive

Lined Pipe with Lining Protectors.

Lining

Protector Tab

Lining

Protectors

Earth

Ground

0281A02A

Earth

Ground

8732-0281J02A

2-15

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

FIGURE 2-16. Model 8705

Grounding for Conductive Lined

Pipe with Grounding Rings.

Earth

Ground

FIGURE 2-17. Model 8705

Grounding for Non-Conductiv e

Pipe with Lining Protectors.

FIGURE 2-18. Model 8705

Grounding for Non-Conductive

Pipe with Grounding Rings.

Grounding Rings

Lining

Protector Tab

Lining

Protectors

8732C-0281F02A

Earth

Ground

8732-00281K02A

2-16

Grounding Rings

Earth

Ground

8732-0281L02A

Installation

FIGURE 2-19. Model 8705

Grounding for Non-Conducti ve

Pipe with Grounding Electrodes.

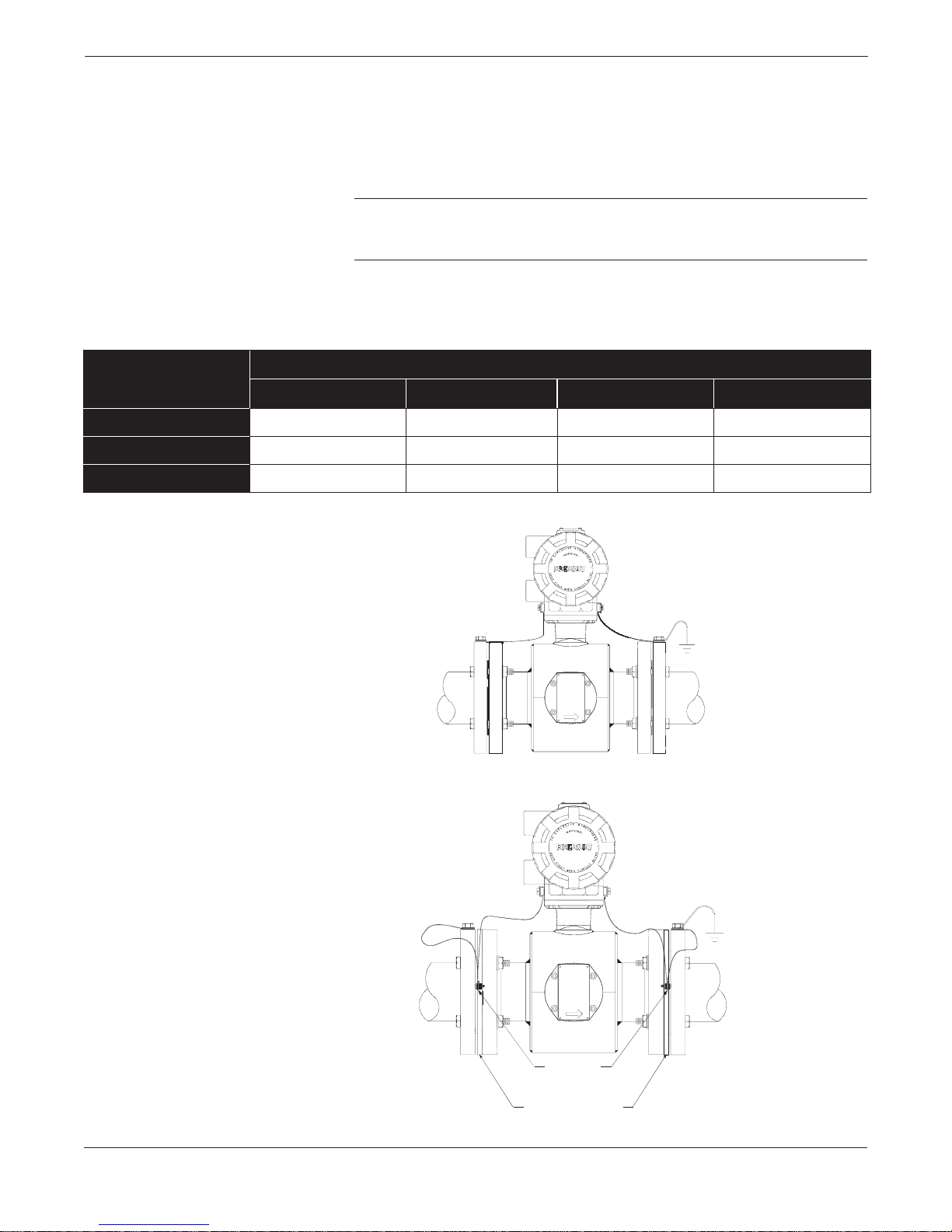

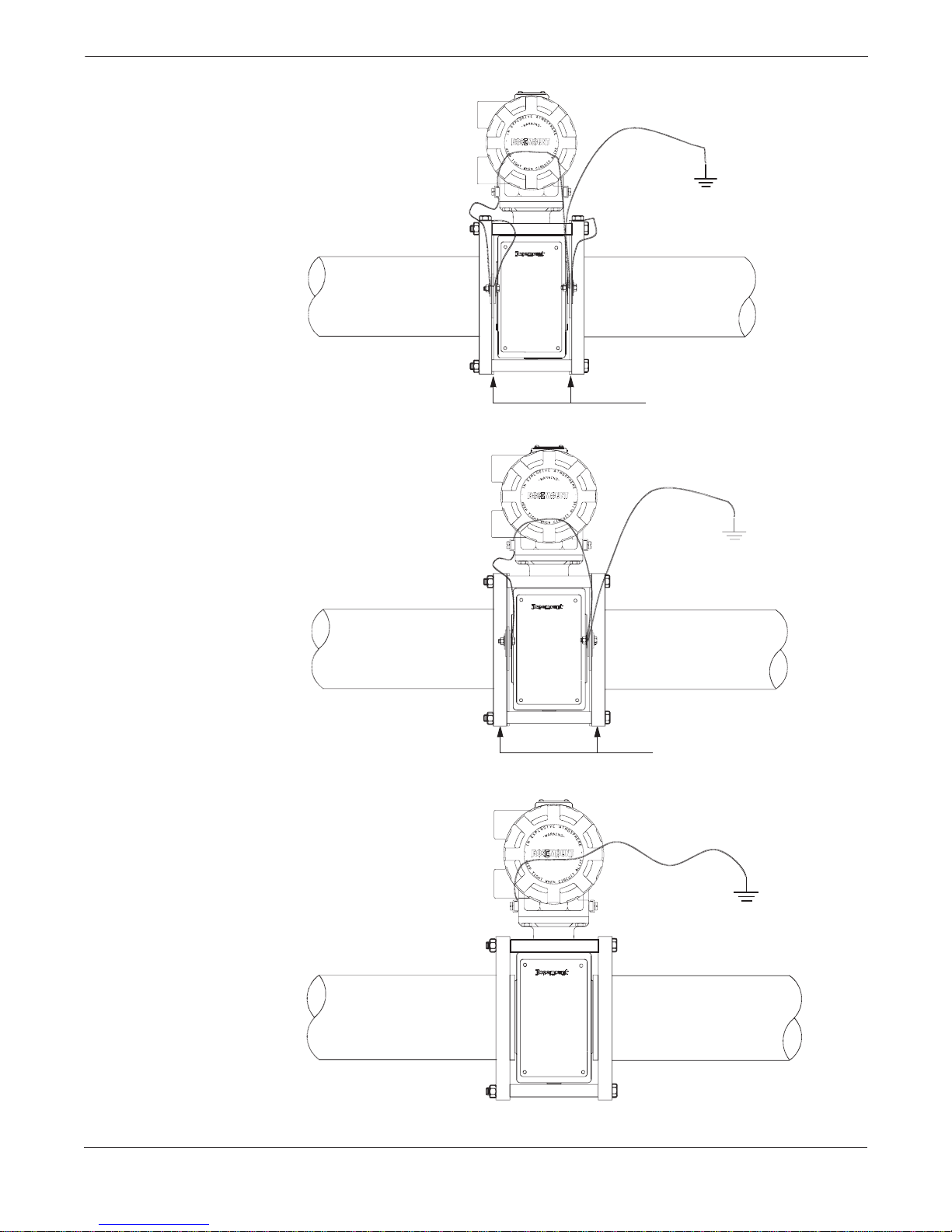

Model 8711 Use Table 2-6 to help determine the grounding option required for

proper operation.

TABLE 2-6. Model 8711

Grounding Installation.

Grounding Options

8732-0281M02A

Type of Pipe

Conductive Unlined Pipe

Conductive Lined Pipe

Non-conductive Pipe

FIGURE 2-20. Model 8711

Grounding for Conductive Unlined Pipe

and Grounding for Conductive Lined

Pipe with Groundin g Ele ct rode s.

No Grounding Opt ions Grounding Rings Grounding Electrode s

See Figure 2-20 Not Required Not Required

Insufficient Grounding See Figure 2-21 See Figure 2-20

Insufficient Grounding See Figure 2-22 See Figure 2-23

Earth

Ground

8711-0360A01C

2-17

Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

FIGURE 2-21. Model 8711

Grounding for Conductive Lined

Pipe with Grounding Rings.

Earth

Ground

FIGURE 2-22. Model 8711

Grounding for Non-Conductiv e

Pipe with Grounding Rings.

FIGURE 2-23. Model 8711

Grounding for Non-Conductive

Pipe with Grounding Electrodes.

Grounding Rin gs

Grounding Rings

8711-03660A01D

Earth

Ground

8711-03660a01B

2-18

Earth

Ground

8711-0368A01A

Loading...

Loading...