Rosemount 8600 Specifications

Product Data Sheet

00813-0100-4860, Rev BC

Rosemount™ 8600 Series Utility™ Vortex Flowmeter

October 2016

The Rosemount 8600 Vortex delivers superior reliability for general purpose applications.

Rosemount reliability—the Rosemount 8600 Vortex improves reliability over traditional flow metering

technology.

Vibration immunity—mass balancing of the sensor system, and Adaptive Digital Signal Processing (ADSP)

provide vibration immunity.

Simplified Troubleshooting - Device Diagnostics enable field verification of Meter Electronics and meter

verification.

Rosemount 8600

October 2016

Rosemount™ 8600 MultiVariable™ Vortex reduces

installation costs, simplifies installation, and improves

performance in saturated steam

Multivariable vortex design

Incorporates temperature sensor into the vortex meter using

the shedder bar as a thermowell, which keeps the temperature

sensor isolated from process for easy verification and

replacement.

Temperature compensated capability for

saturated steam

Calculates density from measured process temperature and

uses the calculated density to provide a temperature

compensated mass flow.

Increased performance in saturated steam

Performance in saturated steam is improved due to the fact that

the electronics will be compensating for changes in the process

temperature.

Reduces installed costs

MultiVariable vortex eliminates the need for an external

thermowell and temperature sensor.

Output options

Remote mount electronics

Also available with remote mounted electronics up to 75 ft.

(23 m).

When you integrate the Multivariable vortex with a Rosemount

Flow Computer, you get:

Remote communications

Heat calculations

Remote totalization

Peak demand calculation

Datalogging capabilities

For more information on the Rosemount Flow Computer, see

the Rosemount Flow Computer Product Data Sheet

.

Can map independent variables to analog output, pulse output,

®

or HART

burst variables.

Available with flow computer for additional

functionality

Integrate the Multivariable vortex with a pressure transmitter

for full pressure and temperature compensation of superheated

steam and various gases.

Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Typical flow ranges . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . page 15

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . .page 20

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . page 24

2

Emerson.com/Rosemount

October 2016

R

D

VD

cp

----------- -=

36/

54/

36/

54/

90,000/ or 25

134,000/ or 7.6

90,000/ or 250

134,000/ or 76

Specifications

Rosemount 8600

The following specifications are for the Rosemount 8600 except

where noted.

Functional specifications

Process fluids

Liquid, gas, and steam applications. Fluids must be

homogeneous and single-phase.

Line sizes

Flanged style

1

/2, 2, 3, 4, 6, and 8 inches

1, 1

(DN 25, 40, 50, 80, 100, 150, and 200)

Pipe schedules

Process piping Schedules 10, 40, 80, and 160.

Note

The appropriate bore diameter of the process piping

must be entered using the Field Communicator or AMS

Device Manager. Meters will be shipped from the factory

at the Schedule 40 default value unless otherwise

specified.

Measurable flow rates

Capable of processing signals from flow applications which

meet the sizing requirements below.

To determine the appropriate flowmeter size for an application,

process conditions must be within the Reynolds number and

velocity limitations for the desired line size provided in Table 1,

Table 2, and Table 3.

Note

Consult your local sales representative to obtain a

computer sizing program that describes in greater detail

how to specify the correct flowmeter size for

an application.

™

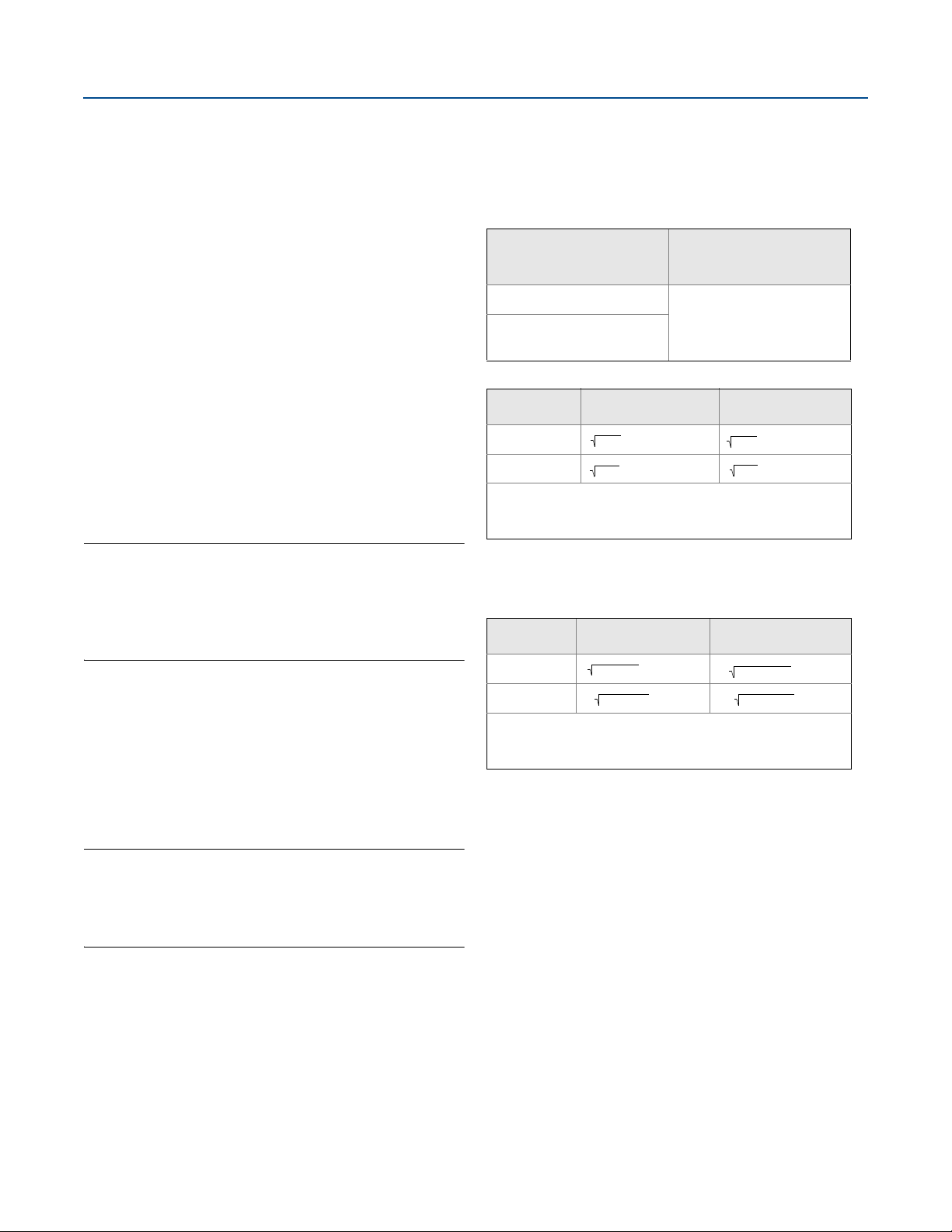

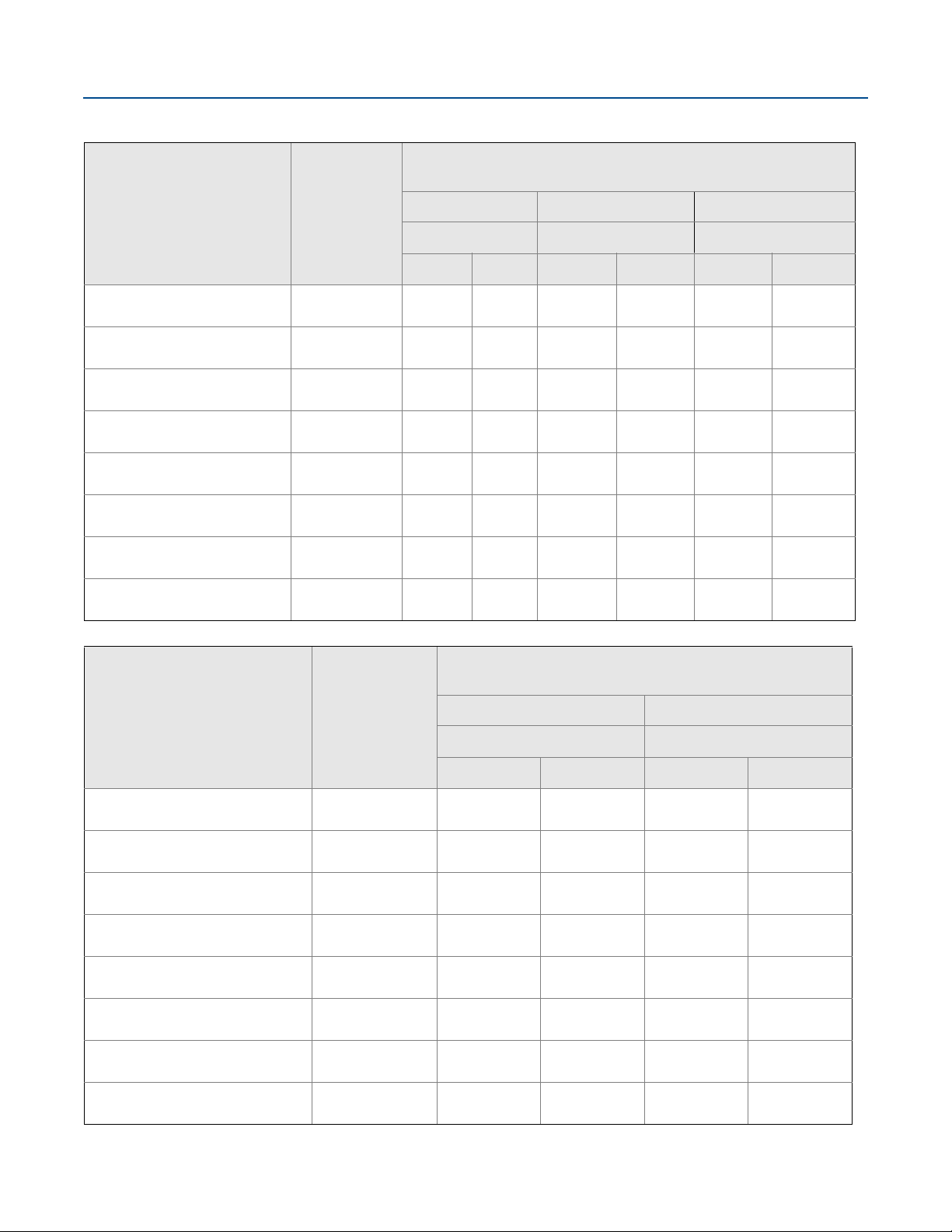

Table 1. Minimum Measurable Meter Reynolds

Numbers

Meter sizes

(Inches/DN)

1 through 4/25 through 100

6 through 8/150 through

200

Reynolds number

limitations

5000 minimum

Table 2. Minimum Measurable Meter Velocities

Feet per second Meters per second

Liquids

Gases

The is the process fluid density at flowing

conditions in lb/ft

1. Velocities are referenced to schedule 40 pipe.

Table 3. Maximum Measurable Meter Velocities

3

for ft/s and kg/m3 for m/s

(Use the smaller of the two values)

Feet per second Meters per second

Liquids

Gases

The is the process fluid density at flowing

conditions in lb/ft

1. Velocities are referenced to schedule 40 pipe.

3

for ft/s and kg/m3 for m/s

Process temperature limits

Standard

-58 to 482 °F (–50 to 250 °C)

Output signals

4–20 mA HART digital signal

(1)

(1)

The Reynolds number equation shown below combines the

effects of density (r), viscosity (m

and flow velocity (V).

Emerson.com/Rosemount

Superimposed on 4–20 mA signal

), pipe inside diameter (D),

cp

Optional scalable pulse output

0 to 10000 Hz; transistor switch closure with adjustable scaling

via HART communications; capable of switching up to 30 Vdc,

120 mA maximum.

3

Rosemount 8600

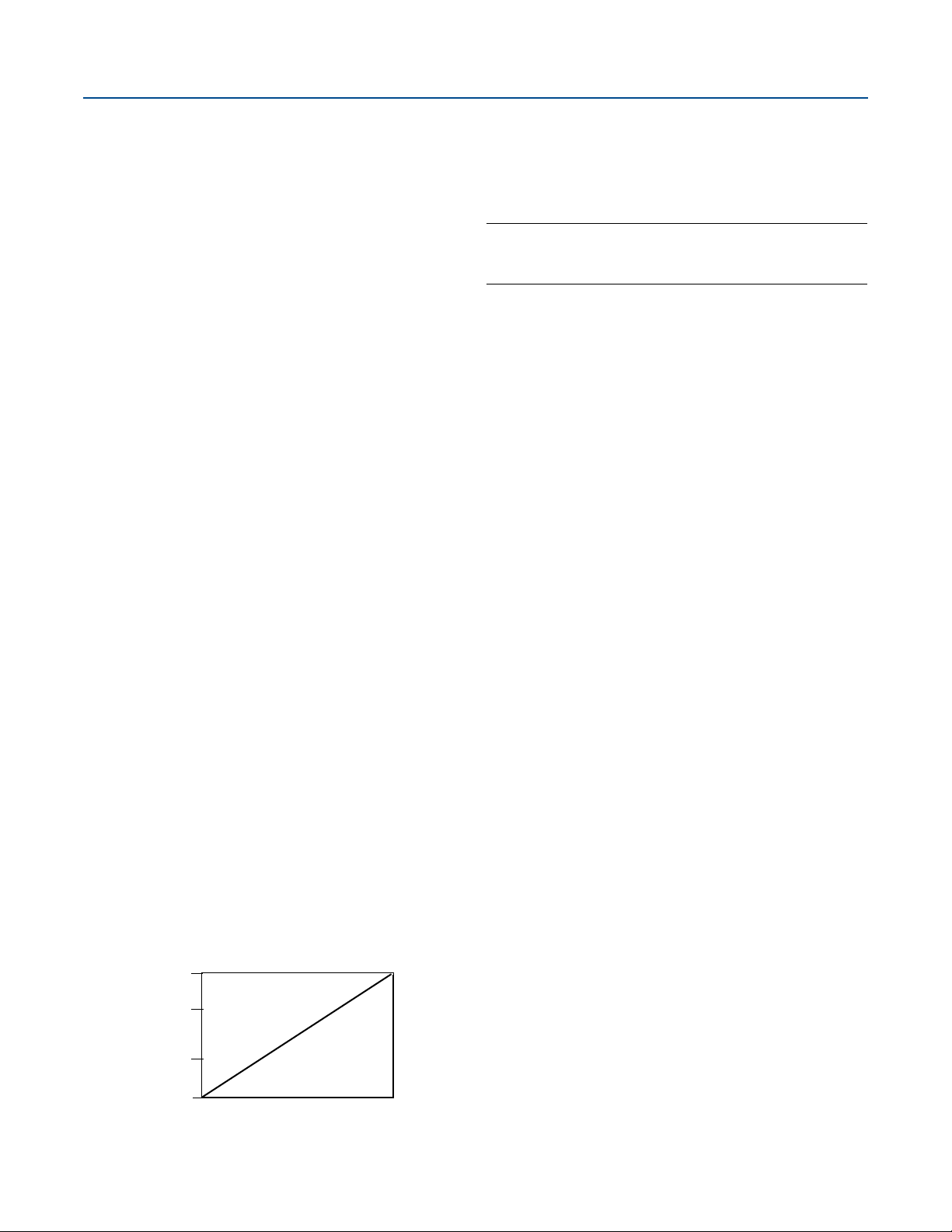

Power Supply (Volts)

Load (Ohms)

Operating

Region

1250

1000

500

0

10.8

42

PPL

A

f Q

2

D

4

----------------------------- -

=

October 2016

Analog output adjustment

Engineering units and lower and upper range values are

user-selected. Output is automatically scaled to provide 4 mA at

the selected lower range value, 20 mA at the selected upper

range value. No frequency input is required to adjust the range

values.

Scalable frequency adjustment

The scalable pulse output can be set to a specific velocity,

volume, or mass (i.e. 1 pulse = 1 lb). The scalable pulse output

can also be scaled to a specific rate of volume, mass, or velocity

(i.e. 100 Hz = 500 lb/hr).

Ambient temperature limits

Operating

–58 to 185 °F (–50 to 85 °C)

–4 to 185 °F (–20 to 85 °C) for flowmeters with local indicator

Storage

–58 to 250 °F (–50 to 121 °C)

–50 to 185 °F (–46 to 85 °C) for flowmeters with local indicator

Pressure limits

Flange style meter

Rated for ASME B16.5 (ANSI) Class 150, 300, EN 1092-1 PN 16

and 40.

Power supply

HART analog

External power supply required. Flowmeter operates on 10.8 to

42 Vdc terminal voltage (with 250-ohm minimum load required

for HART communications, 16.8 Vdc power supply is required).

Power consumption

One watt maximum

Load limitations (HART analog)

Maximum loop resistance is determined by the voltage level of

the external power supply, as described by:

R

= 41.7(Vps – 10.8)

max

= Power Supply Voltage (Volts)

V

ps

= Maximum Loop Resistance (Ohms)

R

max

Note

HART communication requires a minimum loop

resistance of 250 ohms.

Optional LCD display

The optional LCD display is capable of displaying:

Primary Variable

Velocity Flow

Volumetric Flow

Mass Flow

Percent of Range

Analog Output

Totalizer

Shedding Frequency

Pulse Output Frequency (if applicable)

Electronics Temperature

Process Temperature (MTA Option Only)

Calculated Process Density (MTA Option Only)

If more than one item is selected, the display will scroll through

all items selected.

Enclosure rating

FM Type 4X; IP66

Permanent pressure loss

The approximate permanent pressure loss (PPL) from the

Rosemount 8600 Flowmeter is calculated for each application in

the Vortex sizing software available from your local Rosemount

representative. The PPL is determined using the equation:

4

Emerson.com/Rosemount

October 2016

Rosemount 8600

where:

PPL = Permanent Pressure loss (psi or kPa)

Where:

= Density at operating conditions (lb/ft3 or kg/m3)

r

f

Q = Actual volumetric flow rate (Gas = ft

3

/min or m3/hr;

Liquid = gal/min or l/min)

D = Flowmeter bore diameter (in. or mm)

A = Constant depending on meter style, fluid type, and

flow units. Determined per the following table:

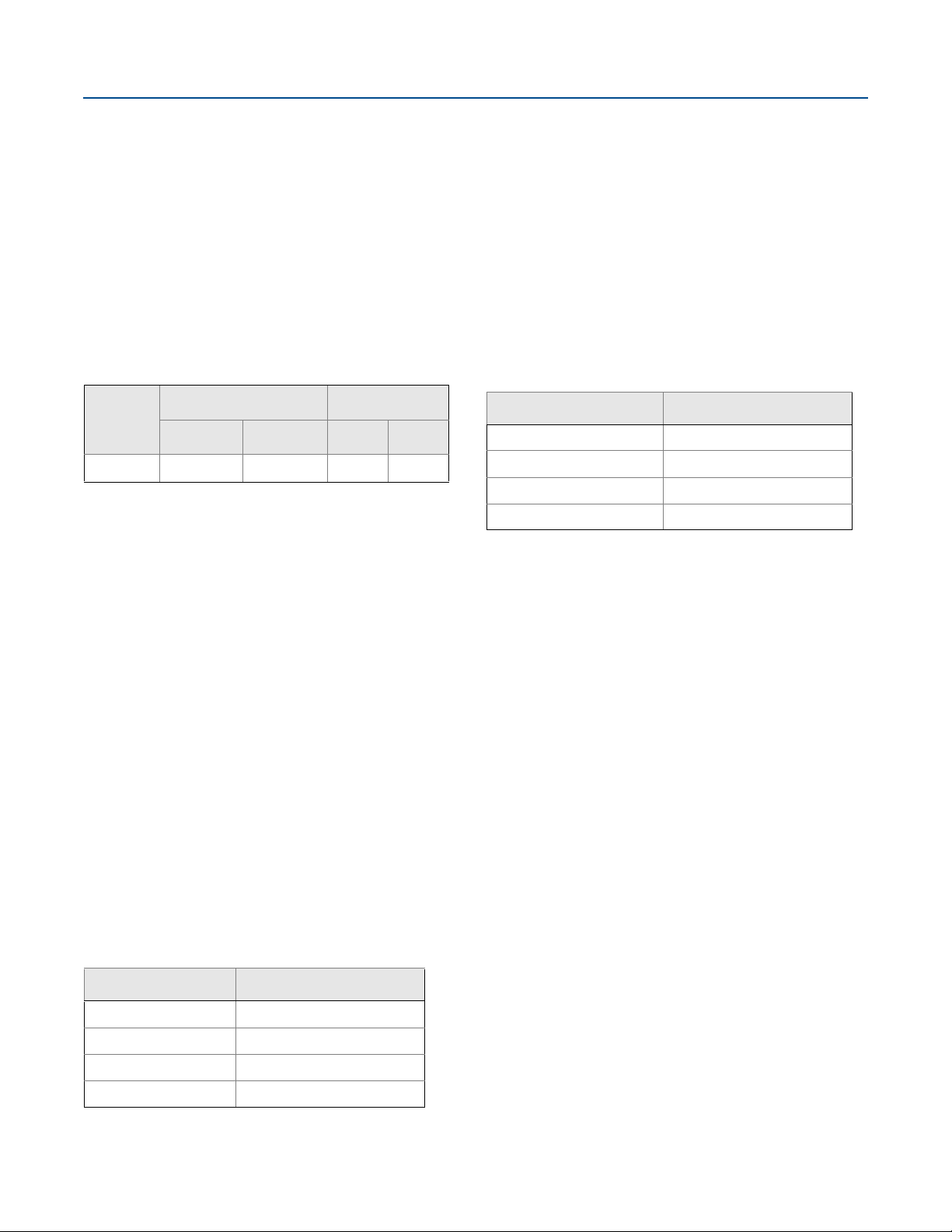

Table 4. Determining the PPL

Meter

style

8600 F 3.4 3 10

English units SI units

A

Liquid

-5

A

Gas

1.9 3 10

A

-3

0.425 118

Liquid

A

Gas

Minimum upstream pressure (liquids)

Flow metering conditions that would allow cavitation, the

release of vapor from a liquid, should be avoided. This flow

condition can be avoided by remaining within the proper flow

range of the meter and by following appropriate system design.

For some liquid applications, incorporation of a back pressure

valve should be considered. To prevent cavitation, the

minimum upstream pressure should be:

P = 2.9P + 1.3p

or P = 2.9P + pv + 0.5 psia (3.45

v

kPa) (use the smaller of the two results)

P = Line pressure five pipe diameters downstream of the

meter (psia or kPa abs)

P = Pressure loss across the meter (psi or kPa)

p

= Liquid vapor pressure at operating conditions (psia or

v

kPa abs)

Failure mode alarm

HART analog

If self-diagnostics detect a gross flowmeter failure, the analog

signal will be driven to the following values:

Signal Value

High or low alarm signal is user-selectable through the fail mode

alarm jumper on the electronics. NAMUR-compliant alarm limits

are available through the C4 or CN Option. Alarm type is field

configurable also.

Saturation output values

When the operating flow is outside the range points, the analog

output continues to track the operating flow until reaching the

saturation value listed below; the output does not exceed the

listed saturation value regardless of the operating flow.

The NAMUR-Compliant Saturation Values are available through

the C4 or CN option. Saturation type is field configurable.

Saturation Value

Low 3.9

High 20.8

NAMUR Low 3.8

NAMUR High 20.5

Damping

Flow Damping adjustable between 0.2 and 255 seconds.

Process Temperature Damping adjustable between 0.4 and

32.0 seconds (MTA Option Only).

Response time

Three vortex shedding cycles or 300 ms, whichever is greater,

maximum required to reach 63.2% of actual input with the

minimum damping (0.2 seconds).

Turn-on time

HART analog

Less than four (4) seconds plus the response time to rated

accuracy from power up (less than 7 seconds with the MTA

Option).

Transient protection

The optional transient terminal block prevents damage to the

flowmeter from transients induced by lightning, welding, heavy

electrical equipment, or switch gears. The transient protection

electronics are located in the terminal block.

Low 3.75

High 21.75

NAMUR Low 3.60

NAMUR High 22.6

Emerson.com/Rosemount

The transient terminal block meets the following specifications:

IEEE C62.41 - 2002 Category B

3 kA crest (8 3 20 s)

6 kV crest (1.2 3 50 s)

6 kV/0.5 kA (0.5 s, 100 kHz, ring wave)

5

Rosemount 8600

October 2016

Security lockout

When the security lockout jumper is enabled, the electronics

will not allow you to modify parameters that affect flowmeter

output.

Output testing

Current source

Flowmeter may be commanded to set the current to a specified

value between 4 and 20 mA.

Frequency source

Flowmeter may be commanded to set the frequency to a

specified value between 0 and 10000 Hz.

Low flow cutoff

Adjustable over entire flow range. Below selected value, output

is driven to 4 mA and zero pulse output frequency.

Humidity limits

Operates in 0–95% relative humidity under noncondensing

conditions (tested to IEC 60770, Section 6.2.11).

Overrange capability

HART analog

Analog signal output continues to 105 percent of span, then

remains constant with increasing flow. The digital and pulse

outputs will continue to indicate flow up to the upper sensor

limit of the flowmeter and a maximum pulse output frequency

of 10400 Hz.

Flow calibration

Meter bodies are flow-calibrated and assigned a unique

calibration factor (K-factor) at the factory. The calibration factor

is entered into the electronics, enabling interchangeability of

electronics and/or sensors without calculations or compromise

in accuracy of the calibrated meter body.

6

Emerson.com/Rosemount

October 2016

Rosemount 8600

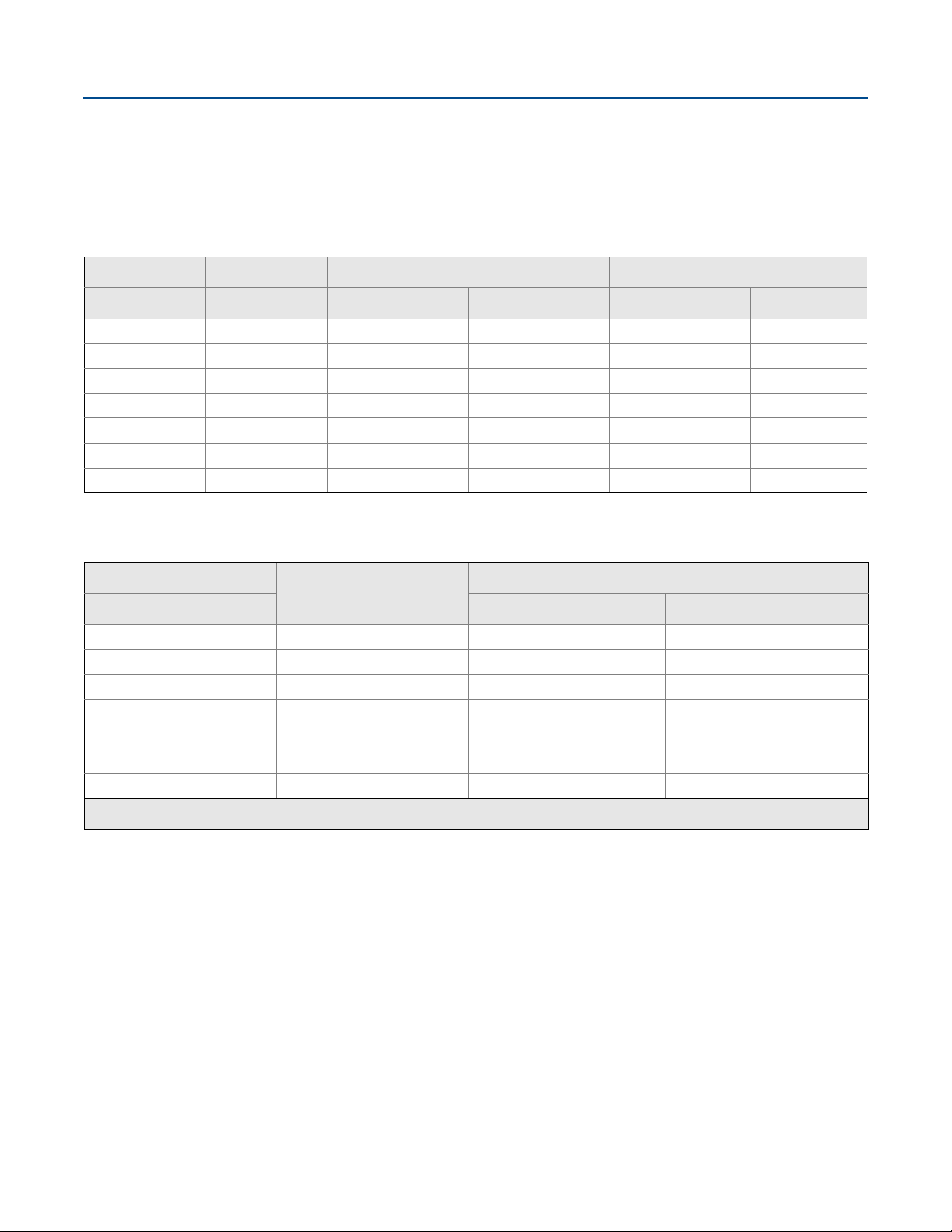

Typical flow ranges

Tables 5 through 9 show typical flow ranges for some common process fluids with default filter settings. Consult your local sales

representative to obtain a computer sizing program that describes in greater detail the flow range for an application.

Table 5. Typical pipe velocity ranges for 8600

Process line size Liquid velocity ranges Gas velocity ranges

(Inches/ DN) Vortex meter (ft/s) (m/s) (ft/s) (m/s)

1/ 25 8600F010 0.70 to 25.0 0.21 to 7.6 6.50 to 250.0 1.98 to 76.2

11/2 / 40 8600F015 0.70 to 25.0 0.21 to 7.6 6.50 to 250.0 1.98 to 76.2

2/ 50 8600F020 0.70 to 25.0 0.21 to 7.6 6.50 to 250.0 1.98 to 76.2

3/ 80 8600F030 0.70 to 25.0 0.21 to 7.6 6.50 to 250.0 1.98 to 76.2

4/ 100 8600F040 0.70 to 25.0 0.21 to 7.6 6.50 to 250.0 1.98 to 76.2

6/ 150 8600F060 0.70 to 25.0 0.21 to 7.6 6.50 to 250.0 1.98 to 76.2

8/ 200 8600F080 0.70 to 25.0 0.21 to 7.6 6.50 to 250.0 1.98 to 76.2

1. Table 5 is a reference of pipe velocities that can be measured for the standard Rosemount 8600. It does not consider density limitations, as described in Table

2

and 3. Velocities are referenced in schedule 40 pipe.

Table 6. Water Flow Rate Limits for the Rosemount 8600

Process line size

(Inches/ DN) Gallons/Minute Cubic Meters/Hour

1/ 25 8600F010 2.96 to 67.3 0.67 to 15.3

11/2 / 40 8600F015 4.83 to 158 1.10 to 35.9

2/ 50 8600F020 7.96 to 261 1.81 to 59.4

3/ 80 8600F030 17.5 to 576 4.00 to 130

4/ 100 8600F040 30.2 to 992 6.86 to 225

6/ 150 8600F060 68.5 to 2251 15.6 to 511

8/ 200 8600F080 119 to 3898 27.0 to 885

(1)

(1)

Minimum and maximum measurable water flow rates*

Vortex meter

*Conditions: 77 °F (25 °C) and 14.7 psia (1.01 bar absolute)

1. Table 6 is a reference of flow rates that can be measured for the standard Rosemount 8600. It does not consider density limitations, as described in Table 2 and

3.

Emerson.com/Rosemount

7

Rosemount 8600

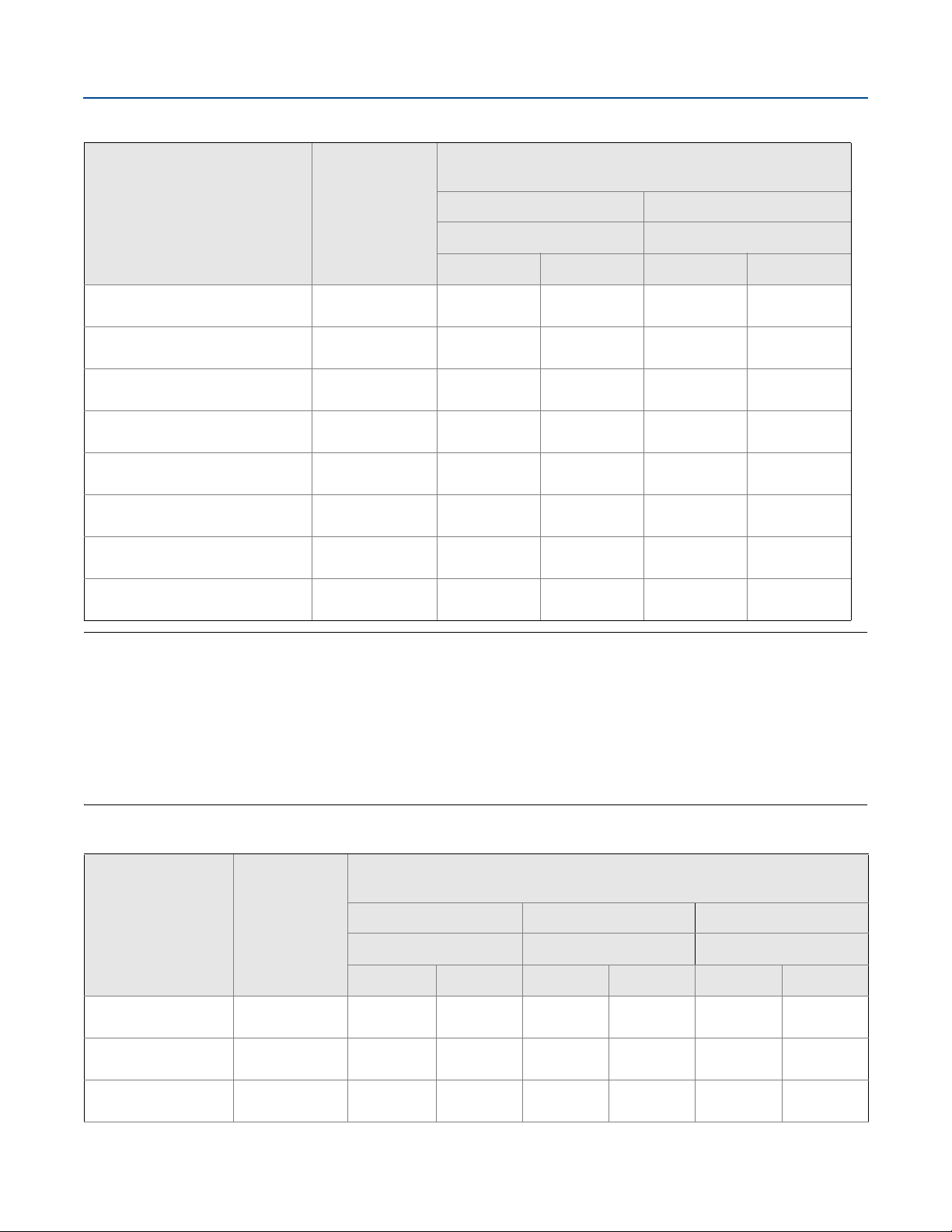

Table 7. Air Flow Rate Limits at 59 °F (15 °C)

October 2016

Minimum and maximum air flow rates

for line sizes 1-in./DN 25 through 2-in./DN 50

Process pressure Flow rate limits

0 psig (0 bar G)

50 psig (3.45 bar G)

100 psig (6.89 bar G)

150 psig (10.3 bar G)

200 psig (13.8 bar G)

300 psig (20.7 bar G)

400 psig (27.6 bar G)

500 psig (34.5 bar G)

Table 8.

Air Flow Rate Limits at 59 °F (15 °C)

max

min

max

min

max

min

max

min

max

min

max

min

max

min

max

min

1-in./DN 25 11/2-in./DN 40 2-in./DN 50

Rosemount 8600 Rosemount 8600 Rosemount 8600

ACFM ACMH ACFM ACMH ACFM ACMH

79.2

9.71

79.2

3.72

79.2

2.80

79.2

2.34

79.2

2.34

79.2

2.34

73.0

2.34

66.0

2.34

134

16.5

134

6.32

134

4.75

134

3.98

134

3.98

134

3.98

124

3.98

112

3.98

212

18.4

212

8.76

212

6.58

212

5.51

212

5.51

198

5.51

172

5.51

154

5.51

360

31.2

360

14.9

360

11.2

360

9.36

360

9.36

337

9.36

293

9.36

262

9.36

349

30.3

349

14.5

349

10.8

349

9.09

349

9.09

326

9.09

284

9.09

254

9.09

593

51.5

593

24.6

593

18.3

593

15.4

593

15.4

554

15.4

483

15.4

432

15.4

Process pressure Flow rate limits

0 psig (0 bar G)

50 psig (3.45 bar G)

100 psig (6.89 bar G)

150 psig (10.3 bar G)

200 psig (13.8 bar G)

300 psig (20.7 bar G)

400 psig (27.6 bar G)

500 psig (34.5 bar G)

max

min

max

min

max

min

max

min

max

min

max

min

max

min

max

min

Minimum and maximum air flow rates

for line sizes 3-in./DN 80 through 4-in./DN 100

3-in./DN 80 4-in./DN 100

Rosemount 8600 Rosemount 8600

ACFM ACMH ACFM ACMH

770

66.8

770

31.8

770

23.9

770

20.0

770

20.0

718

20.0

625

20.0

560

20.0

1308

114

1308

54.1

1308

40.6

1308

34.0

1308

34.0

1220

34.0

1062

34.0

951

34.0

1326

115

1326

54.8

1326

41.1

1326

34.5

1326

34.5

1237

34.5

1076

34.5

964

34.5

2253

195

2253

93.2

2253

69.8

2253

58.6

2253

58.6

2102

58.6

1828

58.6

1638

58.6

8

Emerson.com/Rosemount

October 2016

Table 9. Air Flow Rate Limits at 59 °F (15 °C)

Rosemount 8600

Minimum and maximum air flow rates

for line sizes 6-in./DN 150 through 8-in./DN 200

Process pressure Flow rate limits

0 psig (0 bar G)

50 psig (3.45 bar G)

100 psig (6.89 bar G)

150 psig (10.3 bar G)

200 psig (13.8 bar G)

300 psig (20.7 bar G)

400 psig (27.6 bar G)

500 psig (34.5 bar G)

max

min

max

min

max

min

max

min

max

min

max

min

max

min

max

min

6-in./DN 150 8-in./DN 200

Rosemount 8600 Rosemount 8600

ACFM ACMH ACFM ACMH

3009

261

3009

124

3009

93.3

3009

78.2

3009

78.2

2807

78.2

2442

78.2

2188

78.2

5112

443

5112

211

5112

159

5112

133

5112

133

4769

133

4149

133

3717

133

5211

452

5211

215

5211

162

5211

135

5211

135

4862

135

4228

136

3789

136

8853

768

8853

365

8853

276

8853

229

8853

229

8260

229

7183

229

6437

229

Notes

The Rosemount 8600 measures the volumetric flow under operating conditions (i.e. the actual volume at the

operating pressure and temperature—acfm or acmh), as shown above. However, gas volumes are strongly dependent

on pressure and temperature. Therefore, gas quantities are typically stated in standard or normal conditions (for

example: SCFM or NCMH). (Standard conditions are typically 59 °F and 14.7 psia. Normal conditions are typically 0 °C

and 1 bar abs.)

The flow rate limits in standard conditions are found using the equations below:

Standard Flow Rate = Actual Flow Rate X Density Ratio

Density Ratio = Density at Actual (Operating) Conditions/Density at Standard Conditions

Table 10. Saturated Steam Flow Rate Limits (Assumes Steam Quality is 100%)

Minimum and maximum saturated steam flow rates

for line sizes 1-in./DN 25 through 2-in./DN 50

Process pressure Flow rate limits

15 psig (1.03 bar G)

25 psig (1.72 bar G)

50 psig (3.45 bar G)

max

min

max

min

max

min

1-in./DN 25 11/2-in./DN 40 2-in./DN 50

Rosemount 8600 Rosemount 8600 Rosemount 8600

lb/hr kg/hr lb/hr kg/hr lb/hr kg/hr

342

34.8

449

39.9

711

50.1

155

15.8

203

18.1

322

22.7

917

82.0

1204

93.9

1904

118

Emerson.com/Rosemount

416

37.2

546

42.6

864

53.4

1511

135

1983

155

3138

195

685

61.2

899

70.2

1423

88.3

9

Loading...

Loading...