Rosemount 755A Instruction Manual

Rosemount Analytical

M

ODEL

O

XYGEN ANALYZER

I

NSTRUCTION MANUAL

755A

245364-U

OTICE

N

The information contained in this document is subject to change without notice.

Teflon® is a registered trademark of E.I. duPont de Nemours and Co., Inc.

SNOOP® is a registered trademark of NUPRO Co.

Manual Part Number 245364-U

April 2000

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

C

ONTENTS

P

REF ACE

INTENDED USE STATEMENT............................................................................P-1

SAFETY SUMMARY ............................................................................................P-1

SPECIFICATIONS - GENERAL ...........................................................................P-3

SPECIFICATIONS - SAMPLE..............................................................................P-3

SPECIFICATIONS - ELECTRICAL.......................................................................P-4

SPECIFICATIONS - PHYSICAL...........................................................................P-5

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE......P-6

RETURNING PARTS TO THE FACTORY...........................................................P-6

TRAINING ........................................................................................................P-6

DOCUMENTATION..............................................................................................P-6

COMPLIANCES ...................................................................................................P-7

S

ECTION

1.1 OVERVIEW..............................................................................................1-1

1.2 OXYGEN RANGE ON FRONT PANEL DIGITAL DISPLAY .....................1-2

1.3 OXYGEN RANGES FOR RECORDER READOUT..................................1-2

1.4 RECORDER VOLTAGE AND CURRENT OUTPUTS..............................1-3

1.5 AUTOMATIC PRESSURE COMPENSATION..........................................1-3

1.6 ALARM (OPTION)....................................................................................1-3

1.7 CASE MOUNTING OPTIONS...................................................................1-3

1.8 ELECTRICAL POWER OPTIONS............................................................1-3

1. I

NTRODUCTION

SECTION 2. UNPACKING AND INSTALLATION

2.1 UNPACKING............................................................................................2-1

2.2 LOCATION...............................................................................................2-1

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

i

ONTENTS

C

SECTION 2. (CONTINUED)

2.2.1 Location and Mounting............................................................... 2-1

2.3 VOLTAGE REQUIREMENTS.................................................................. 2-1

2.4 ELECTRICAL CONNECTIONS................................................................ 2-2

2.4.1 Line Power Connections............................................................. 2-2

2.4.2 Recorder Connections................................................................ 2-2

2.4.3 Output Connections for Dual Alarm Option ................................ 2-5

2.5 CALIBRATION......................................................................................... 2-8

2.5.1 Zero Calibration Gas.................................................................. 2-8

2.5.2 Downscale Standard Gas........................................................... 2-8

2.5.3 Upscale Standard Gas ............................................................... 2-8

2.6 SAMPLE HANDLING............................................................................... 2-8

2.6.1 Sample Temperature Requirements...........................................2-8

2.6.2 Sample Pressure Requirements: General................................. 2-9

2.6.3 Normal Operation at Positive Gauge Pressures......................... 2-10

2.6.4 Operation at Negative Gauge Pressures.................................... 2-10

2.6.5 Sample Flow Rate...................................................................... 2-10

2.6.6 Corrosive Gases........................................................................ 2-11

2.7 LEAK TEST.............................................................................................. 2-11

2.8 PURGE KIT (OPTIONAL)........................................................................ 2-12

SECTION 3. INITIAL STARTUP AND CALIBRATION

3.1 SELECTION OF RECORDER OXYGEN RANGE................................... 3-1

3.1.1 Recorder Oxygen Range Selection Procedure........................... 3-1

3.1.2 Readout of Applied Zero-Suppression Voltage on

Digital Display............................................................... 3-5

3.2 STARTUP PROCEDURE......................................................................... 3-6

3.3 CALIBRATION......................................................................................... 3-7

3.3.1 Calibration Using Digital Readout for Oxygen Readout.............. 3-7

3.3.2 Calibration Using Recorder for Oxygen Readout ....................... 3-7

3.3.3 Calibration with Downscale and Upscale Standard Gases......... 3-8

3.3.4 Calibration of Automatic Pressure Compensation...................... 3-9

3.4 COMPENSATION FOR COMPOSITION OF BACKGROUND GAS........ 3-10

3.4.1 Oxygen Equivalent Values of Gases.......................................... 3-11

3.4.2 Computing Adjusted Settings for Zero and Span Controls......... 3-11

3.5 DUAL ALARM OPTION ........................................................................... 3-13

3.5.1 Inital Calibration and Selection of Setpoints for Alarms.............. 3-13

3.5.2 Selection of Deadband............................................................... 3-14

ii

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

SECTION 4. ROUTINE OPERATION

4.1 ROUTINE OPERATION ...........................................................................4-1

4.2 EFFECT OF BAROMETRIC PRESSURE CHANGES ON

INSTRUMENT READOUT............................................................4-1

4.3 CALIBRATION FREQUENCY..................................................................4-1

ONTENTS

C

S

ECTION

5.1 PRINCIPLES OF OPERATION................................................................5-1

5.2 VARIABLES INFLUENCING PARAMAGNETIC OXYGEN

5.3 ELECTRONIC CIRCUITRY......................................................................5-6

5. T

5.2.1 Pressure Effects..........................................................................5-5

5.2.2 Temperature Effects....................................................................5-5

5.2.3 Interferents.................................................................................5-6

5.2.4 Vibration Effects..........................................................................5-6

5.3.1 Detector/Magnet Assembly.........................................................5-7

5.3.2 Control Board and Associated Circuitry ......................................5-7

5.3.3 Case Board.................................................................................5-9

5.3.4 Isolated Current Output Board (Optional)....................................5-10

5.3.5 Alarm Option...............................................................................5-10

HEORY

MEASUREMENTS........................................................................5-5

SECTION 6. ELECTRONIC CIRCUIT ANALYSIS

6.1 OVERVIEW..............................................................................................6-1

6.2 ±15VDC POWER SUPPLY.......................................................................6-1

6.3 CASE HEATER CONTROL CIRCUIT ......................................................6-1

6.4 DETECTOR HEATER CONTROL CIRCUIT ............................................6-6

6.5 DETECTOR LIGHT SOURCE CONTROL CIRCUIT................................6-7

6.6 DETECTOR WITH FIRST STAGE AMPLIFIER A ND PRESSURE

COMPENSATION CIRCUITS.......................................................6-8

6.7 BUFFER AMPLIFIERS U10 AND ASSOCIATED ANTICIPATION

FUNCTION....................................................................................6-12

6.8 DIGITAL OUTPUT CIRCUIT.....................................................................6-12

6.9 ANALOG OUTPUT CIRCUITS FOR RECORDER AND ALARMS...........6-13

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

iii

ONTENTS

C

SECTION 7. ROUTINE SERVICE AND MAINTENANCE

7.1 INITIAL CHECKOUT W ITH STANDARD GASES.................................... 7-1

7.2 DETECTOR COMPONENT CHECKS..................................................... 7-2

7.2.1 Detector ..................................................................................... 7-2

7.2.2 Source Lamp.............................................................................. 7-2

7.2.3 Photocell..................................................................................... 7-2

7.2.4 Suspension................................................................................. 7-3

7.3 DETECTOR COMPONENT REPLACEMENT ......................................... 7-3

7.3.1 Detector Replacement................................................................ 7-3

7.3.2 Source Lamp Replacement........................................................ 7-5

7.3.3 Photocell Replacement and Adjustment..................................... 7-7

7.4 HEATING CIRCUITS............................................................................... 7-8

7.4.1 Case Heater Control Circuit........................................................ 7-8

7.4.2 Detector/Magnet Heating Circuit ................................................ 7-9

SECTION 8. REPLACEMENT PARTS

8.1 CIRCUIT BOARD REPLACEMENT POLICY........................................... 8-1

8.2 SELECTED REPLACEMENT PARTS ..................................................... 8-1

ENERAL PRECAUTIONS FOR STORING AND HANDLING HIGH PRESSURE GAS CYLINDERS

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

iv

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

FIGURES

1-1 Model 755A Oxygen Analyzer..................................................................1-1

1-2 Analyzer Components and Adjustments Locations..................................1-4

2-1 Electrical Connections..............................................................................2-3

2-2 Control Board...........................................................................................2-4

2-3 Connections for Potentiometric Recorder with Non-Standard Span.........2-4

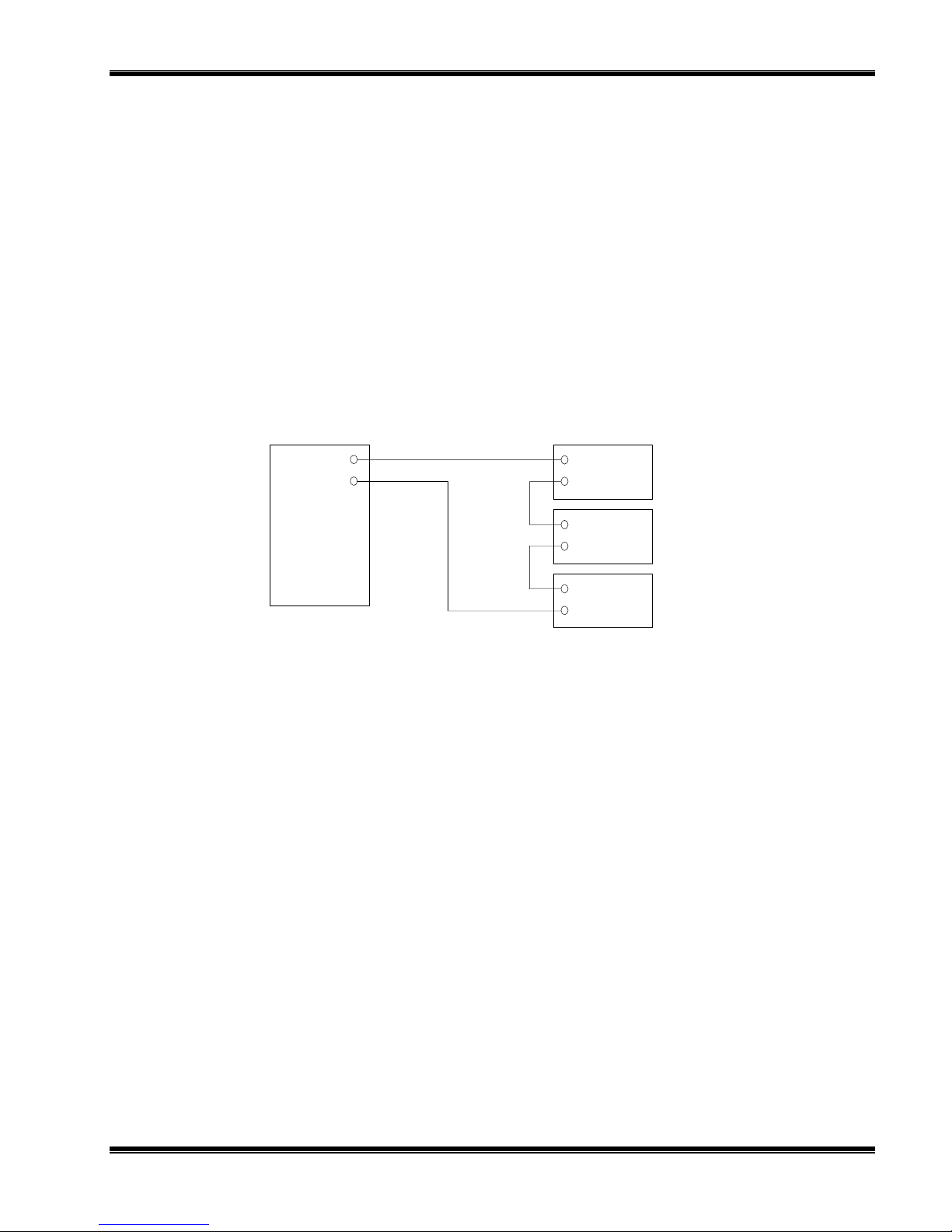

2-4 Analyzer Connected to Drive Several Current-Activated Output

Devices .........................................................................................2-5

2-5 Typical Alarm Settings..............................................................................2-7

2-6 Relay Terminal Connections for Typical Fail-Safe Application.................2-7

2-7 Connection of Typical Gas Selector Panel to Analyzer ............................2-9

2-8 Installation of Purge Kit (Optional)............................................................2-13

3-1 Front Panel Controls.................................................................................3-2

3-2 Internal Adjustments Locations.................................................................3-5

3-3 Calibration by Pressure Decrease Setup..................................................3-9

3-4 Schematic Circuit of Alarm Relay Assembly.............................................3-14

5-1 Spherical Body in Non-Uniform Magnetic Field........................................5-2

5-2 Functional Diagram of Paramagnetic Oxygen Measurement System ......5-3

5-3 Detector/Magnet Assembly.......................................................................5-4

6-1 Two-Comparator OR Circuit.....................................................................6-2

6-2 Ramp Generator.......................................................................................6-3

6-3 Case Heater Control Circuit......................................................................6-4

6-4 Case Heater Circuit..................................................................................6-5

6-5 Detector Heater Control Circuit.................................................................6-7

6-6 Detector Light Source Control Circuit.......................................................6-8

6-7 Detector with First Stage Amplifier and Pressure Compensation

Circuits..........................................................................................6-11

6-8 Pressure Signal and Reference Voltage Circuits......................................6-11

6-9 Buffer, Anticipation, and Digital Output Circuit..........................................6-12

6-10 Simplified Analog Output Circuit for Recorder (Showing Three

Ranges).........................................................................................6-15

7-1 Detector/Magnet Assembly.......................................................................7-4

7-2 Detector/Magnet Assembly Wiring ...........................................................7-5

7-3 Detector Adjustment.................................................................................7-5

7-4 Modifiication of 633689 Connector Board for Compatibility with

Replacement Lamp.......................................................................7-7

7-5 Lamp Alignment.........................................................................................7-7

ONTENTS

C

T

ABLES

3-1 Internal Adjustments.................................................................................3-4

3-2 Standard Gases Recommended for Calibration of Various Oxygen

Ranges on Analog Output.............................................................3-8

3-3 Oxygen Equivalents of Common Gases...................................................3-12

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

v

ONTENTS

C

DRAWINGS (LOCATED IN REAR OF MANUAL)

617186 Schematic Diagram, Master Board Assembly (Case)

617731 Pictorial Wiring Diagram, Model 755A

620434 Schematic Diagram, 0 to 20 mA or 4 to 20 mA Current Output

632349 Installation Drawing, Model 755A

652219 Schematic Diagram, Control Board

652222 Schematic Diagram, Transducer

vi

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

P

REFACE

I

NTENDED USE STATEMENT

The Model 755A is intended for use as an industrial process measurement device

only. It is not intended for use in medical, diagnostic, or life support applications, and

no independent agency certifications or approvals are to be implied as covering such

applications.

S

AFETY SUMMARY

To avoid explosion, loss of life, personal injury and damage to this equipment and

on-site property, all personnel authorized to install, operate and service the Model

755A Oxygen Analyzer should be thoroughly familiar with and strictly follow the

instructions in this manual. Save these instructions.

DANGER is used to indicate the presence of a hazard which will cause severe

personal injury, death, or substantial property damage if the warning is ignored

WARNING is used to indicate the presence of a hazard which can cause severe

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION is used to indicate the presence of a hazard which will or can cause minor

personal injury or property damage if the warning is ignored.

NOTE is used to indicate installation, operation, or maintenance information which is

important but not hazard-related.

WARNING: ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to

live parts which can cause death or serious injury. Refer servicing to qualified

personnel.

For safety and proper performance this instrument must be connected to a

properly grounded three-wire source of power.

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

P-1

REFACE

P

WARNING: POSSIBLE EXPLOSION HAZARD

This analyzer is of a type capable of analysis of sample gases which may be

flammable. If used for analysis of such gases, the instrument must be either in

an explosion-proof enclosure suitable for the gas, or, protected by a continuous

dilution purge system in accordance with Standard ANSI/NFPA-496-1086

(Chapter 8) or IEC Publication 79-2-1983 (Section Three).

If gases are introduced into this analyzer, the sample containment system must

be carefully leak-checked upon installation and before initial start-up, during

routine maintenance and any time the integrity of the sample containment

system is broken, to ensure the system is in leak-proof condition. Leak-check

instructions are provided in Section 2.7.

Internal leakage of sample resulting from failure to observe these precautions

could result in an explosion causing death, personal injury, or property damage.

CAUTION: PARTS INTEGRITY

Tampering or unauthorized substitution of components may adversely affect

safety of this product. Use only factory documented components for repair.

WARNING: HIGH PRESSURE GAS CYLINDERS

This analyzer requires periodic calibration with known zero and standard gases.

Refer to Sections 2.5 and 2.6. See also General Precautions for Handling and

Storing High Pressure Cylinders, in the rear of this manual.

P-2

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

SPECIFICATIONS - GENERAL

O

PERATING RANGE

0.00% to 100.0% oxygen

R

ECORDER RANGE

Selectable for 0% to 100% oxygen or for any desired span of 1%, 2%, 5%,

10%, 20% or 100% oxygen within the overall range.

R

ESPONSE TIME

(90% of fullscale) recorder output factory set for 20 seconds; adjustable from 5

to 25 seconds.

R

EPRODUCIBILITY (DIGITAL DISPLAY

±0.01% Oxygen ±2 counts.

A

MBIENT TEMPERATURE LIMITS

Maximum: 49°C (120°F) EXCEPT 38°C (100°F) for 99% to 100% oxygen.

Minimum: -7°C (20°F) EXCEPT 4°C (40°F) for 99% to 100% oxygen.

Z

ERO AND SPAN DRIFT

Within ±1% of fullscale (±2% of fullscale for 99% to 100% range) per 24 hours,

provided that ambient temperature does not change by more than 11.1°C

(20°F).

±2.5% of fullscale per 24 hours with ambient temperature change over entire

range.

1

REFACE

P

)

B

AROMETRIC PRESSURE COMPENSATION

Oxygen readout automatically corrected to within ±1% of fullscale for

barometric pressure variations within ±3% of target value and within ±2% of

fullscale for barometric pressure variations within ±5% of target value.

The target may be set anywhere within range of -2.7 to 3.3 psig ±3 psig (-18.6

to 22.8 kPa ±21 kPa).

Exhaust vented to atmosphere.

S

PECIFICATIONS

D

RYNESS

- S

AMPLE

Sample dewpoint below 43°C (110°F), sample free of entrained liquids.

T

EMPERATURE LIMITS

Maximum: 66°C (150°F)

Minimum: 10°C (50 °F)

1

Zero and span drift specifications based on following conditions: Operating pressure constant; ambient temperature

change from initial calibration temperature, less than 11.1 Celsius degrees (20 Fahrenheit degrees); deviation from set

flow held to within ±10% or ±20 cc/min, whichever is smaller.

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

P-3

REFACE

P

SPECIFICATIONS - SAMPLE (CONTINUED)

O

PERATING PRESSURE

Maximum: 69 kPa (10 psig).

Minimum: -13.1 kPa (-1.9 psig)

FLOW RATE

2

Maximum: 500 cc/min

Minimum: 50 cc/min

Recommended: 250 ±20 cc/min

M

ATERIALS IN CONTACT WITH SAMPLE GAS

316 stainless steel, glass, titanium, Paliney No. 7, epoxy resin, Viton-A,

platinum, nickel.

SPECIFICATIONS - ELECTRICAL

S

UPPLY VOLTAGE AND FREQUENCY

Standard: 115 VAC ±10 VAC, 50/60 Hz

Optional: 230 VAC ±10 VAC, 50/60 Hz

P

OWER CONSUMPTION

Maximum: 300 watts

Nominal: 75 watts

O

UTPUT

Standard: Field selectable voltage output of 0 to 10mV, 0 to 100mV, 0 to 1V,

or 0 to 5VDC

Optional: Isolated current output of 0 to 20mA or 4 to 20mA (with Current

Output Board)

A

LARM OPTION

High-Low Alarm

Contact Ratings:

5 amperes, 240V AC, resistive load

5 amperes, 120V AC, resistive load

5 amperes, 28V DC, resistive load

S

ETPOINT

Adjustable from 1% to 20% of fullscale

D

EADBAND

Adjustable from 1% to 20% of fullscale (Factory set at 10% of fullscale)

2

Deviation from set flow would be held to within ±10% or ±20 cc/min, whichever is smaller. If so, zero and span drift will

be within specifications, provided that operating temperature remains constant.

P-4

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

SPECIFICATIONS - PHYSICAL

M

OUNTING

Standard: Panel mount

Optional: Surface or stanchion mount accessory available

ENCLOSURE CLASSIFICATION

Meets requirements for NEMA 3R

Air Purge Option3: NFPA 496 (1989) Type Z purge

W

EIGHT

Approximately 32.5 lbs (14.74 Kg)

D

IMENSIONS

Height: 13.5 (343 mm)

Width: 11.5 (294 mm)

Depth: 7.12 (181 mm)

REFACE

P

3

When installed with user supplied components, meets requirements for Class I, Division 2 locations per National

Electrical Code (ANSI/NFPA 70) for analyzers sampling nonflammable gases. Analyzers sampling flammable gases

must be protected by a continuous dilution purge system in accordance with Standard ANSI/NFPA 496-1986, Chapter 8.

Consult factory for recommendations.

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

P-5

REFACE

P

CUST OMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

R

ETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call: Model Number, Serial Number, and Purchase Order Number or Sales Order

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sender, freight collect.

When returnin g any pro duct o r compon ent t hat has be en expo sed to a toxic, corrosi ve

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

TRAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the Current Operator and Service Training Schedule contact

the Technical Services Depart men t at:

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

D

OCUMENTATION

The following Model 755A Oxygen Analyzer instruction materials are available.

Contact Customer Service or the local representative to order.

245364 Instruction Manual (this document)

P-6

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

COMPLIANCES

The Model 755A Oxygen Analyzer (General Purpose Enclosure) has been designed to

meet the applicable requirements of the U.S. Occupational Safety and Health Act

(OSHA) of 1970 if installed in accordance with the requirements of the National

Electrical Code (NEC) of the United States in non-hazardous areas and operated and

maintained in the recommended manner.

This product may carry approvals from a certifying agency or may be in compliance

with EMC Directive. If so, the product will carry approval insignia, like those shown

here, on the product name rating plate.

®

REFACE

P

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

P-7

REFACE

P

NOTES

P-8

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

I

NTRODUCTION

1

1.1 OVERVIEW

The Model 755A Oxygen Analyzer provides digital readout of the oxygen content of a

flowing gas sample. Oxygen is strongly paramagnetic; other common gases, with only

a few exceptions, are weakly diamagnetic.

A front panel liquid crystal display provides direct digital readout of oxygen

concentration. In addition a field-selectable voltage output is provided as standard.

An isolated current output of 0 to 20 mA or 4 to 20 mA is obtainable with the optional

Current Output Board. Current and voltage output may be utilized simultaneously if

desired.

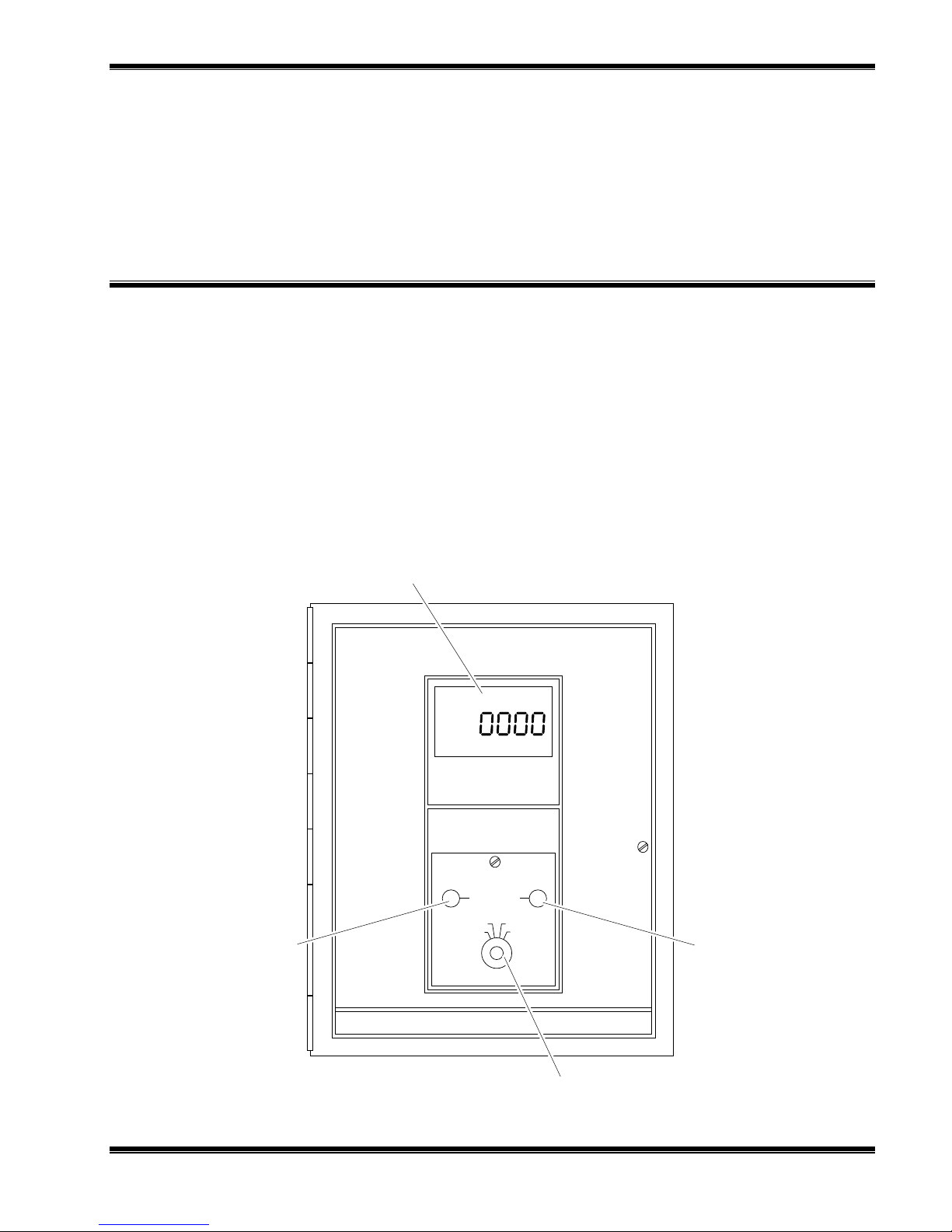

6 Digit LCD Display

ZERO Adjust

F

IGURE

245364-U Rosemount Analytical April 2000

1-1. M

ODEL

755A O

ZERO

PRESS CAL1 PR ESS CA L 2

NORM R EC OF FSET

Rosemount Analytical

XYGEN ANALYZER

Model 755A

Oxygen Analyzer

TEST Switch

SPAN Adjust

Model 755A Oxygen Analyzer

1-1

NTRODUCTION

I

The basic electronic circuitry is incorporated into two master boards: The Control

Board Assembly and the Case Circuit Board Assembly (see Figure 1-2). The Control

Board has a receptacle which accepts optional circuit boards, thus permitting inclusion

of such features as current output.

1.2 OXYGEN RANGE ON FRONT PANEL DIGITAL DISPLAY

The front panel LCD (liquid crystal display) provides direct readout of oxygen

concentration from 0.00% to 100.00%.

1.3 OXYGEN RANGES FOR RECORDER READOUT

If desired, the recorder output may be set for a fullscale range of 0 to 100% oxygen.

Alternatively, a desired portion of this overall range may be selected for fullscale

presentation on the recorder. The selection is made by an appropriate combination of

scale expansion and zero suppression.

CALE EXPANSION

S

Fullscale oxygen span for the recorder is switch selectable for 1%, 2%, 5%, 10%,

20%, or 100% oxygen.

ERO SUPPRESSION

Z

The desired zero suppression is obtained as the sum of (a) a jumper selectable fixed

value of 0%, 20%, 40%, 60% or 80% oxygen and (b) a continuously adjustable value

of 0% to 25% oxygen. Thus the electronic circuitry provides the capability of setting

the total zero suppression for any desired value from 0% up to a theoretical maximum

of 105% oxygen.

However, the maximum usable zero suppression is 99%, which is used in establishing

a range of 99% to 100%.

The effective zero suppression, in volts, may be read on the digital display by placing

the front panel TEST Switch in position 4 and the Reorder Oxygen Span Selection

Switch in 1 X gain position (i.e., 100% oxygen)

Example:

Desired oxygen range for recorder output: 99% to 100% oxygen.

Required span is 1% oxygen, obtained by jumper position.

Required zero suppression is 99% oxygen. Thus, fixed zero suppression of 80%

oxygen is selected by jumper position, and adjustable zero suppression is set for

19% oxygen.

1-2

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

1.4 RECORDER VOLTAGE AND CURRENT OUTPUTS

OLTAGE OUTPUTS (STANDA RD

V

Provided a standard is a jumper selectable voltage output of 0 to 10 mV, 0 to 100 mV,

0 to 1 V, or 0 to 5 V DC.

SOLATED CURRENT OUTPUT (OPTION

I

An isolated current output is obtainable with the optional Current Output Board, either

included with the Model 755A or added at a later date in the field.

This option provides a current output of either 0 to 20mA or 4 to 20mA for a maximum

of 850 ohms.

Refer to Section 8, Replacement Parts, for the part number of the Isolated Current

Output option.

)

)

NTRODUCTION

I

Note

Voltage and current outputs may be used simultaneously, if desired.

1.5 AUTOMATIC PRESSURE COMPENSATION

The oxygen readout is automatically corrected for pressure variations within 3% of the

target value, which may be set anywhere within the range of -2.7 to 3.3 psig ±3 psig (-

18.6 to 22.8 kPa ±21 kPa).

1.6 ALARM (OPTION)

The analyzer has an alarm relay assembly consisting of two single-pole, double-throw

relays, one each for the ALARM 1 and ALARM 2 contacts. These relays may be used

to drive external, customer-supplied alarm and/or control devices.

1.7 CASE MOUNTING OPTIONS

The analyzer is supplied, as ordered, with hardware for one of three mounting

arrangements: Panel, wall, or pipe stanchion.

1.8 ELECTRICAL POWER OPTIONS

The analyzer is supplied, as ordered, for operation on either 120 VAC, 50/60 Hz, or

240 VAC, 50/60 Hz.

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

1-3

NTRODUCTION

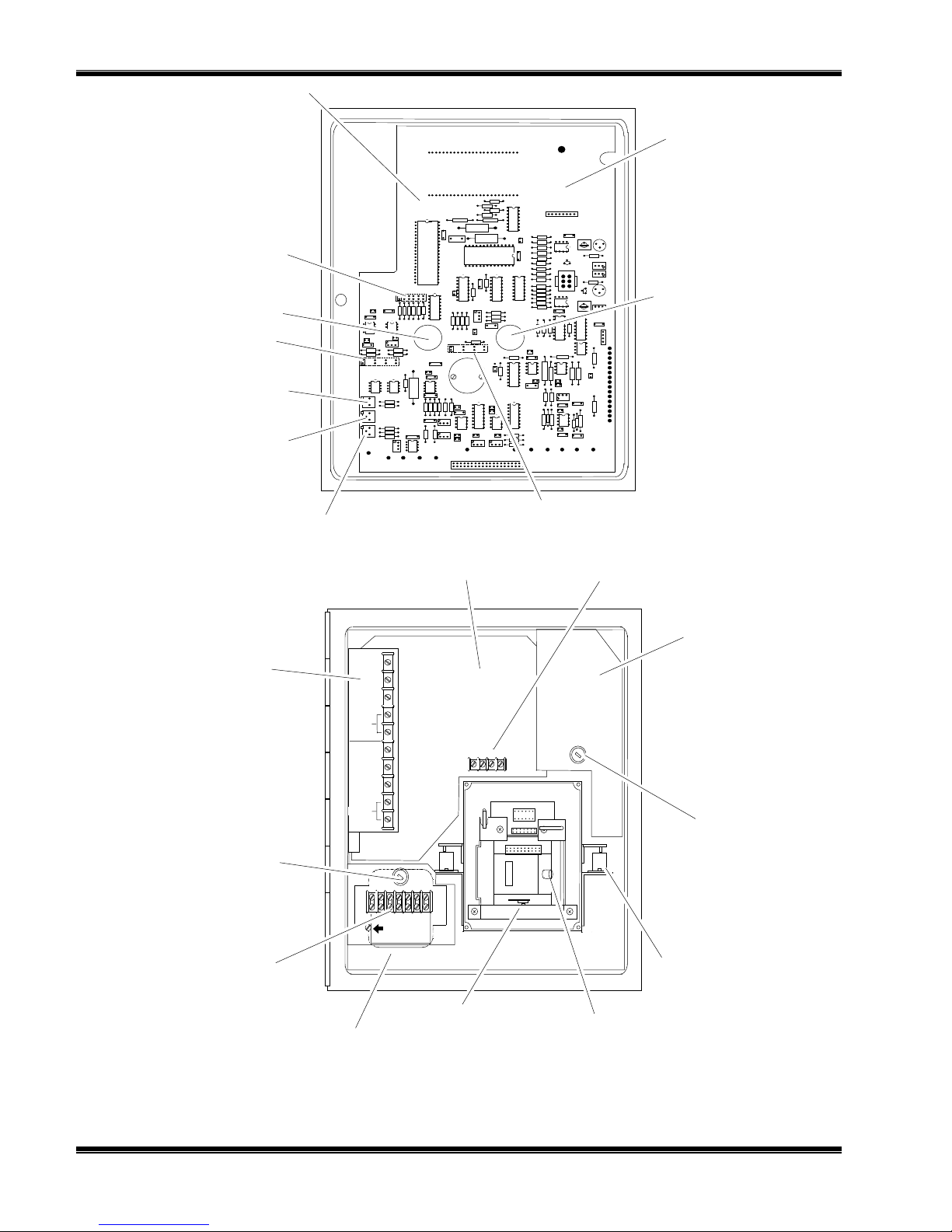

TB2

I

Control Board

Location for Optional

Current Output Board

Span Jumper Select

ZERO Control

SPAN Control

Recorder Output Jumper Select

Zero

Suppression

CAL2 Adjustment,

Pressure

Compensation

CAL1 Adjustment,

Pressure

Compensation

Alarm Relay Assembly

(Alarm Option)

Fuse

AC Power

NO. 1

RESE

NO. 2

RESET

COM

CO

Zero Offset Jumper Select

Recorder Output

Case Board

TB2

Case Heater

Assembly

NO

NC

NO

NC

-

+

HOT

Fuse

Case Heater

N

H

E

O

U

T

AC Power

TB1

Transformer, Power T1

(Behind TB1)

F

IGURE

1-2. M

ODEL

755A C

1-4

Detector/Magnet

Assembly Shock

Transducer

Mount

Detector/Magnet

Assembly

OMPONENTS AND ADJUSTMENTS LOCATIONS

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

U

NPACKING AND INSTALLATION

2

2.1 UNPACKING

Carefully examine the shipping carton and contents for signs of damage. Immediately

notify the shipping carrier if the carton or its contents are damaged. Retain the carton

and packing materials until the instrument is operational.

2.2 LOCATION

2.2.1 L

2.3 VOLTAGE REQUIREMENTS

OCATION AND MOUNTING

The analyzer is designed to meet NEMA 3R enclosure requirements and may be

mounted outdoors. Permissible ambient temperature range is 20°F to 120°F (-7°C to

49°C).

Avoid mounting outside in direct sunlight, or inside in a closed building, where ambient

temperature may exceed the allowable maximum.

Shock and mechanical motion can reduce instrument accuracy; therefore, mount the

instrument in an area that is as vibration free as possible

WARNING: ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to

live parts which can cause death or serious injury. Refer servicing to qualified

personnel.

For safety and proper performance this instrument must be connected to a

properly grounded three-wire source of power.

Note

Refer to Installation Drawing 642349 at the rear of this manual for recommended

cable conduit openings.

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

2-1

NPACKING AND INSTALLATION

U

CAUTION: ENCLOSURE INTEGRITY

With reference to Installation Drawing 642349, any unused cable conduit

openings must be securely sealed by permanent closures in order to provide

enclosure integrity in compliance with personnel safety and environmental

protection requirements. The plastic closures provided are for shipping

protection only.

Note

For NEMA 3R service, all conduit must be connected through approved fittings.

This instrument was shipped from the factory configured to operate on 115 VAC or

240 VAC, 50/60 Hz electric power. Verify that the power source conforms to the

requirements of the individual instrument, as noted on the name-rating plate.

2.4 ELECTRICAL CONNECTIONS

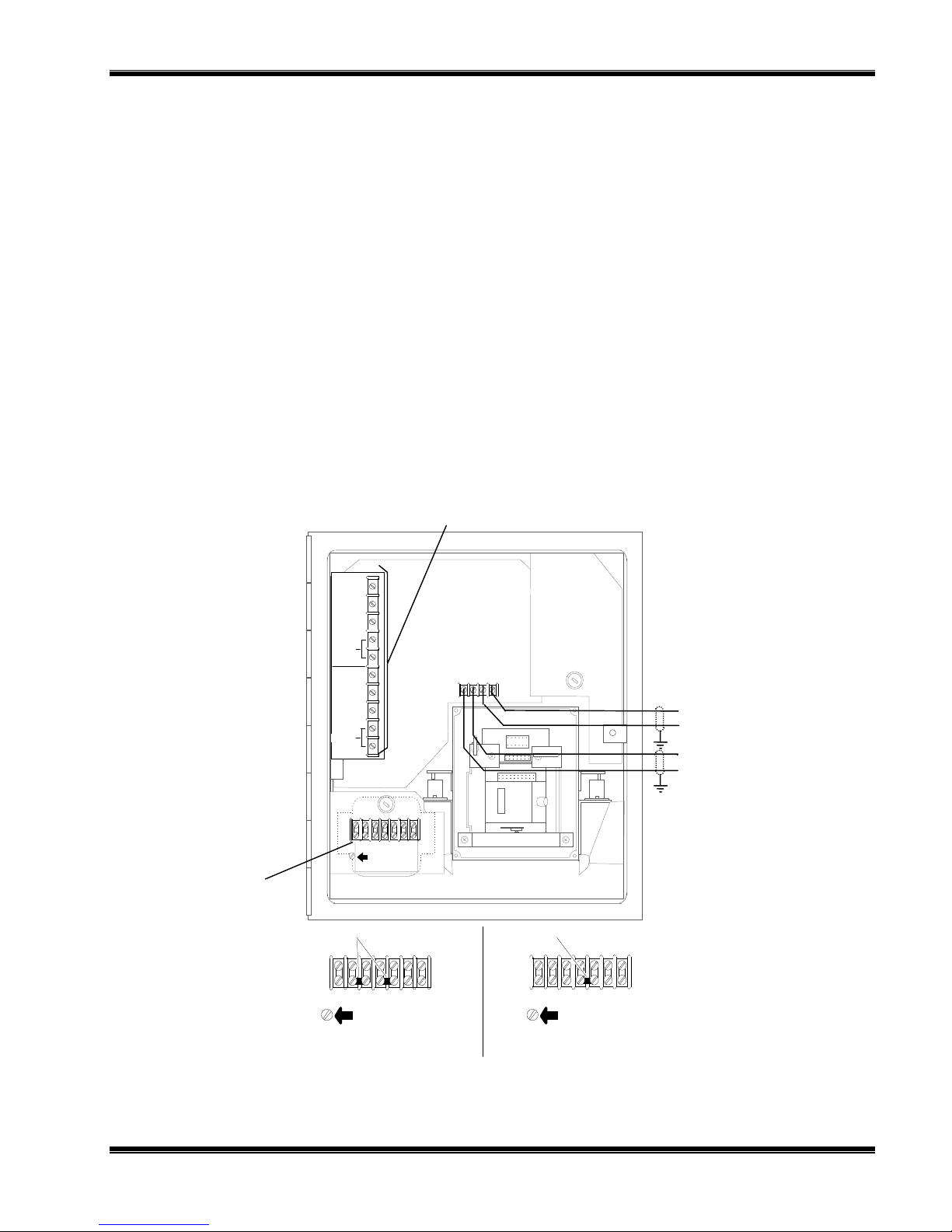

2.4.1 L

2.4.2 R

INE POWER CONNECTIONS

Electrical power is supplied to the analyzer via a customer-supplied, three-conductor

cable, type SJT, minimum wire size 18 AWG. Route power cable through conduit and

into appropriate opening in the instrument case (see Installation Drawing 642349).

Connect power leads to HOT, NEUT, AND GND terminals on TB1, see Figure 2-1.

Connect analyzer to power source via an external fuse, in accordance with local

codes.

Note

Do not draw power for associated equipment from the analyzer power cable.

ECORDER CONNECTIONS

Note

Route recorder cable through a separate conduit, not with power cable or alarm

output cable.

If a recorder, controller, or other output device is used, connector it to the analyzer via

a 24-22 AWG two-conductor shielded cable.

Route the cable through conduit to the analyzer and into the case through the

appropriate opening shown in Installation Drawing 642349. Connect the shield only at

the recorder or computer, if used.

Cable connections and output selection for potentiometric and current actuated

2-2

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

NPACKING AND INSTALLATION

GND

TB1

U

devices are explained in below.

OTENTIOMETRIC OUTPUT

P

Insert Recorder Output Selection Jumper, Figure 2-2, in position appropriate to the

desired output; 10 mV, 100 mV, 1V or 5V.

On TB2, Figure 2-1, connect leads of shielded recorder cable to "MV+" AND "COM"

terminals.

Connect free end of output cable to appropriate terminals of recorder or other

potentiometric device.

For device with a span of 0 to 10mV, 0 to 100mV, 0 to 1V, or 0 to 5V, connect cable

directly to input terminals of the device, making sure polarity is correct.

For device with intermediate span, i.e., between the specified values, connect cable to

device via a suitable external voltage divider, as shown in Figure 2-3.

Power Connections

(see below)

NO. 1

RESET

NO. 2

RESET

Jumpers

COM

COM

Optional Alarm Kit

NO

NC

NO

NC

N

H

E

O

U

T

T

COM

+ - +

TB2

Jumper

HOT

+

mV Recorder

-

+

mA Recorder

-

F

IGURE

2-1. E

LECTRICAL CONNECTIONS

245364-U Rosemount Analytical April 2000

TB1

N

GND GND

120 VAC CONFIGU RATION 240 VAC CONFIGU R AT ION

H

E

O

U

T

T

N

E

U

T

TB1

H

O

T

Model 755A Oxygen Analyzer

2-3

NPACKING AND INSTALLATION

U

Recorder Output Voltage

Selection Jumper

5V 1V 0.1V 0.01V

Control Board

R3

R4

R8

R9

CR2

1

2

3

4

C5

I

G

O

U5

I G O

I G O

R5

R6

U6

U3

U2

C4

C2

U4

C3 CR1 C1

R2 R1

U1

J1

Current Output

Board

F

IGURE

2-2. C

JP3

ONTROL BOARD

755A

Analyzer

Position of Recorder Output

Selector Plug

Voltage Divider

(Customer Supplied)

(Make sure polarity

is correct)

Minimum Permissible

Resistance for R1 + R2

10 mV 1K Ohm

100 mV 10K Ohm

1 V 100K Ohm

5 V 2K Ohm

Potentiometric

Recorder

Input

Terminals

F

IGURE

2-3. C

S

ONNECTIONS FOR POTENTIOMETRIC RECORDER WITH NON-STANDARD

PAN

2-4

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

NPACKING AND INSTALLATION

U

SOLATED CURRENT OUTPUT (OPTIONAL

I

)

1. Verify that the Current Output Board appropriate to desired output is properly in

place. See Figure 2-2. If originally ordered with analyzer, the board is factory

installed.

2. On TB2, Figure 2-1, connect leads of shielded recorder cable to "MA+" and "-"

terminals.

3. Connect free end of output cable to input terminals of recorder or other current

actuated device, making sure that polarity is correct. If two or more currentactuated devices are to be used, they must be connected in series as shown in

Figure 2-4.

Total resistance of all output devices and associated interconnection cable must not

exceed 850 ohms.

Current and voltage outputs may be utilized simultaneously, if desired.

+

Recorder

-

+

Controller

-

+

Indicator

Remote

F

IGURE

2.4.3 O

+

mA

-

755A

Analyzer

2-4. M

O

ODEL

UTPUT DEVICES

755A C

ONNECTED TO DRIVE SEVERAL CURRENT-ACTIVATED

UTPUT CONNECTIONS FOR DUAL ALARM OPTION

If so ordered, the analyzer is factory-equipped with alarm output. Alternatively, the

alarm feature is obtainable by subsequent installation of the 618083 Alarm Relay Kit.

LARM OUTPUT CONNECTIONS

A

The alarm output provides two sets of relay contacts for actuation of alarm and/or

process control functions. Leads from the (customer-supplied) external alarm system

connect to terminals on the 638254 Alarm Relay Assembly (see Figure 2-1).

Note the following recommendations:

1. A line fuse should be installed in the line between the (customer-supplied) power

supply and the alarm relay terminals on the Alarm Relay Assembly.

2. If the alarm contacts are connected to any device that produces radio frequency

interference (RFI), it should be arc-suppressed. Rosemount Analytical Arc

Suppression (PN 858728) is recommended.

3. If possible, the analyzer should operate on a different AC power source to avoid

RFI.

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

2-5

NPACKING AND INSTALLATION

U

4. Do not allow internal cable service loop to touch the detector assembly or

associated inlet and outlet tubing. This precaution ensures against possible

transmission of mechanical vibration through the cable to the detector, which can

cause loss of accuracy.

LARM RELAY CHARACTERISTICS

A

The ALARM 1 and ALARM 2. Outputs of the Alarm Relay Assembly are provided by

two identical single-pole double-throw relays. Relay contacts are rated:

5 amperes 240 VAC resistive

1 ampere 240 VAC inductive

5 amperes 120 VAC resistive

3 amperes 120 VAC inductive

5 amperes 30 VDC resistive

3 amperes 30 VDC inductive

Removal of AC power from the analyzer, as in a power failure, de-energizes both

relays, placing them in alarm condition. Switching characteristics of the ALARM 1 and

ALARM 2 relays are as follows:

ALARM 1 Relay - The ALARM 1 relay coil is de-energized when the meter needle

moves downscale through the value that corresponds to setpoint minus deadband.

This relay coil is energized when the needle moves upscale through the value that

corresponds to setpoint plus deadband. See Figure 2-5A.

ALARM 2 Relay - The ALARM 2 relay coil is de-energized when the meter needle

moves upscale through the value that corresponds to the setpoint plus deadband.

This relay coil is energized when needle moves downscale through the value that

corresponds to setpoint minus deadband. See Figure 2-5B.

Alarm Reset - Normally both the ALARM 1 and ALARM 2 functions incorporate

automatic reset. When the meter reading goes beyond the pre-selected limits, the

corresponding relay is de-energized. When the meter reading returns within the

acceptable range, the relay is automatically substituting an external pushbutton or

other momentary-contact switch for the jumper that normally connects the RESET

terminals on the Alarm Relay Assembly. If the corresponding relay is now deenergized, i.e., in alarm condition, the relay remains de-energized until the operator

momentarily closes the switch.

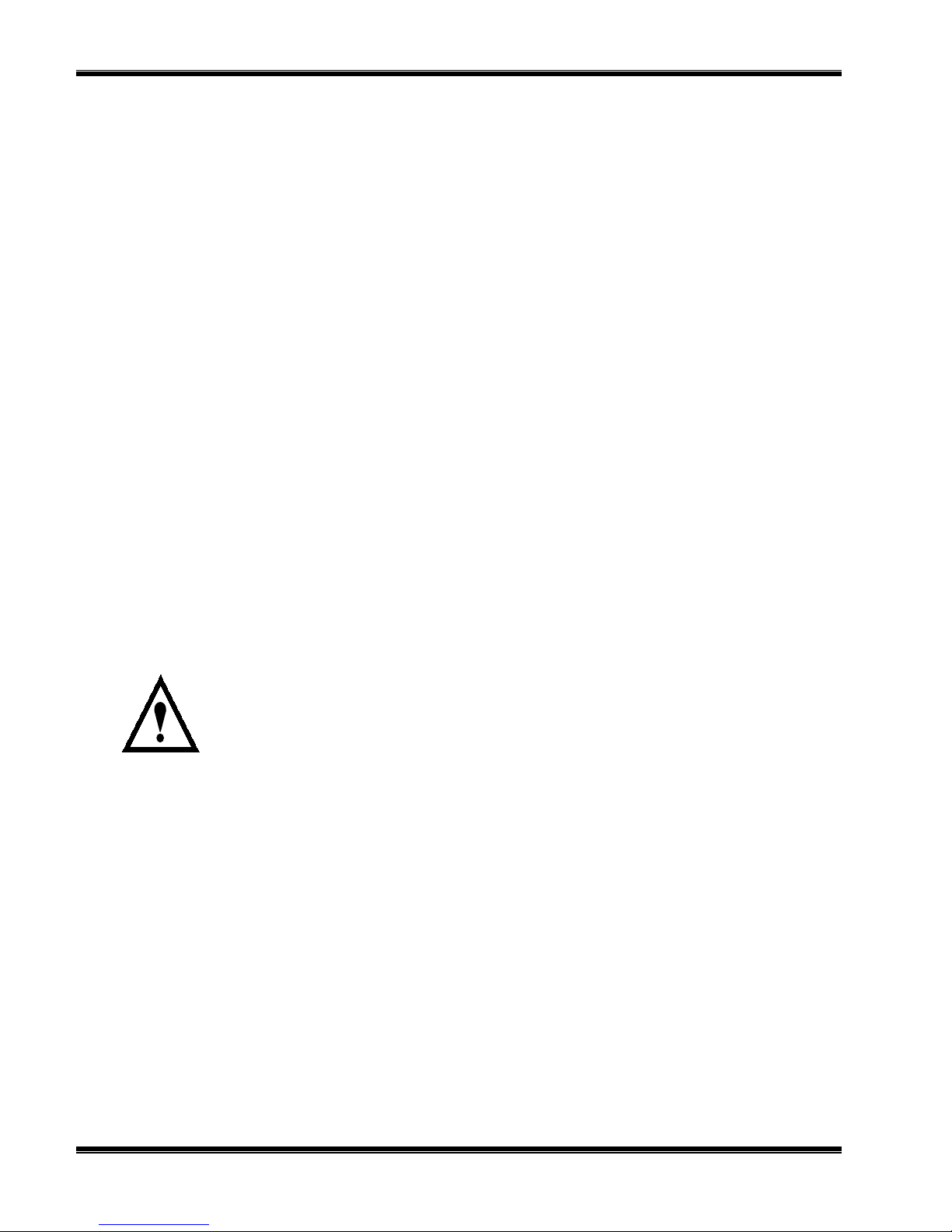

Fail-Safe Applications - By appropriate connection to the double-throw relay

contacts, it is possible to obtain either a contact closure or a contact opening for an

energized relay. Also, either a contact closure or a contact opening may be obtained

for a de-energized relay.

It is important that, for fail-safe applications, the user understand wheat circuit

conditions are desired in the event of power failure and the resultant relay deenergization. Relay contacts should then be connected accordingly. Refer to Figure

2-6.

2-6

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

NPACKING AND INSTALLATION

U

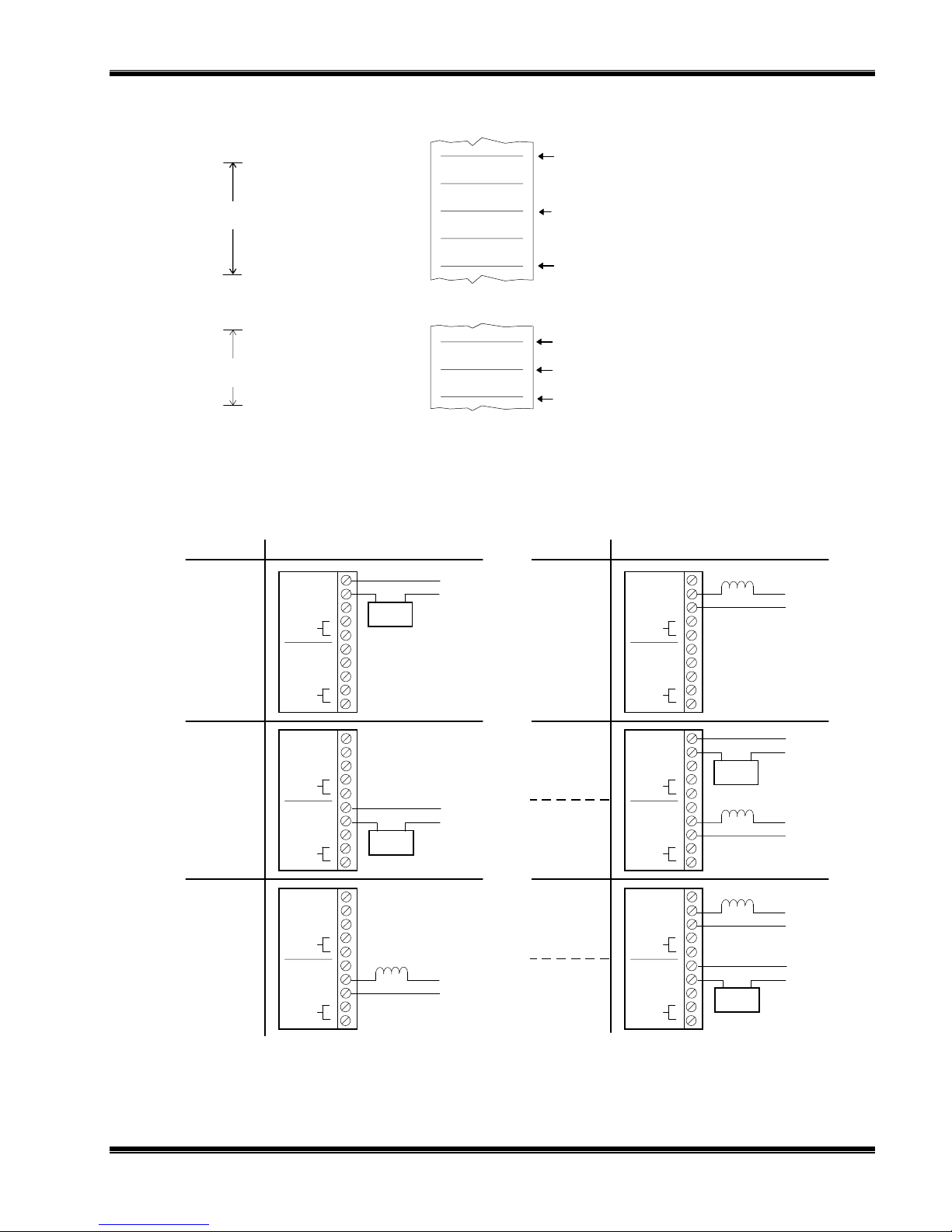

A. Typical ALARM 1 Setting

DEADBAND SET FOR

20% OF FULLSCALE

B. Typical ALARM 2 Setting

DEADBAND SET FOR

10% OF FULLSCALE

F

IGURE

2-5. T

Low Alarm,

Fail-Safe

40

INPUT SIGNAL

Percent of Fullscale

30

20

55

INPUT SIGNAL

Percent of Fullscale

50

45

YPICAL ALARM SETTINGS

No. 1

RESET

RESET

No. 2

COM

COM

NO

NC

NO

NC

Alarm Bell

or Lamp

115 VAC

N

H

When input signal moves upscale through this point, the coil of

ALARM 1 relay (K1) is energized, providing continuity between the

common and normally-closed contacts of the relay.

ALARM 1 Setpoint

When input signal moves downscale through this point, the coil of

ALARM 1 relay (K1) is de-energized, providing continuity between the

common and normally-open contacts of the relay.

When input signal moves upscale through this point, the coil of ALARM

2 relay (K2) is de-energized, providing continuity between the common

and normally-open contacts of the relay.

ALARM 2 Setpoint

When input signal moves upscale through this point, the coil of ALARM

2 relay (K2) is energized, providing continuity between the common

and normally-closed contacts of the relay.

REQUIREMENT TYPICAL CONNECTIONSREQUIREMENT TYPICAL CONNECTIONS

Solenoid

Valve

115 VAC

Low Control

Limit,

Fail-Safe

No. 1

RESET

RESET

No. 2

NO

COM

NC

NO

COM

NC

H

N

No. 1

NO

COM

NC

RESET

NO

COM

RESET

No. 2

No. 1

RESET

RESET

No. 2

NC

NO

COM

NC

NO

COM

NC

Alarm Bell

or Lamp

Solenoid

Valve

ELAY TERMINAL CONNECTIONS FOR TYPICAL FAIL-SAFE APPLICATION

F

IGURE

High Alarm,

Fail-Safe

Low Control

Limit,

Fail-Safe

2-6. R

245364-U Rosemount Analytical April 2000

115 VAC

115 VAC

No. 1

RESET

RESET

No. 2

No. 1

RESET

RESET

No. 2

COM

COM

COM

COM

NO

NC

NO

NC

NO

NC

NO

NC

Alarm Bell

or Lamp

Solenoid

Valve

Solenoid

Valve

Alarm Bell

or Lamp

Lower

Low Alarm

Indicator,

Fail-Safe

N

H

H

N

Low Control,

Fail-Safe

High Control,

Fail-Safe

Higher

High Alarm

Indicator,

Fail-Safe

Model 755A Oxygen Analyzer

115 VAC

115 VAC

115 VAC

115 VAC

N

H

H

N

H

N

N

H

2-7

NPACKING AND INSTALLATION

U

2.5 CALIBRATION GASES

2.5.1 Z

2.5.2 D

2.5.3 U

ERO CALIBRATION GAS

Zero-based range - Normally uses a oxygen-free gas, typically nitrogen.

Zero-suppressed range - Uses a blend consisting of a suitable percentage of oxygen

contained in a background gas, typically nitrogen.

OWNSCALE STANDA RD GAS

Digital Display - Typically, although not necessarily, the downscale standard gas will

be oxygen-free, such as nitrogen.

Recorder Readout - The downscale standard gas is selected to establish a

calibration point at or near the lower range limit.

PSCALE STANDA RD GAS

Digital Display - Typically, the upscale standard gas will be a readily obtained gas

such as dry air (20.93% oxygen) or 1005 oxygen.

Recorder Readout - A suitable upscale standard gas is required to establish a

calibration point at or near the upper range limit. If this range limit is 21% or

somewhat above 21%, the usual standard gas is dry air (20.93% oxygen).

2.6 SAMPLE HANDLING

CAUTION: PRESSURE LIMIT

Under no circumstances allow pressure to exceed 10 psig (69 kPa) as

irreparable damage to the detector may result.

Many different sample handling systems are available, depending on the requirements

of the individual user. Most sample handling systems have copper or brass

components; however, stainless steel components are available for applications

involving corrosive gases. With corrosive gases, complete drying of the sample is

desirable, as most of these gases are practically inert when totally dry.

For specific corrosive applications, consult the factory.

2.6.1 S

AMPLE TEMPERATURE REQUIREMENTS

Sample temperature at the analyzer inlet should be in the range of 50°V to 150°F

(10°C to 66°C). W ith a thoroughly dry sample, entry temperature can be as high as

150°F (66°C) without affecting readout accuracy. Normally, a maximum entry

temperature of 110°F (43°C) is recommended so that the sample temperature will rise

2-8

April 2000 Rosemount Analytical 245364-UModel 755A Oxygen Analyzer

NPACKING AND INSTALLATION

U

during passage of the sample through the analyzer. This precaution ensures against

cooling of the sample and possible condensation of moisture. Such condensation

should be avoided as it may damage the detector.

2.6.2. S

AMPLE PRESSURE REQUIREMENTS

: G

ENERAL

Operating pressure limits are the following: maximum, 10 psig (69 kPa gauge

pressure); minimum, -1.9 psig (-13.1 kPa).

CAUTION: OPERATIN G LI MITS

Operation outside the specified limits may damage the detector and will void the

warranty.

Oxygen readout is automatically corrected for atmospheric pressure variations within

±3% of the target value, which may be set anywhere within the range of -2.7 to 3.3

psig ±3 psig (-18.6 to 22.8 kPa ±21 kPa).

The basic rule for pressure of sample and standard gases supplied to the inlet is to

calibrate the analyzer at the same pressure that will be used during subsequent

operation and to maintain this pressure during operation. The arrangement required

to obtain appropriate pressure control will depend on the application. Refer to special

instructions included in Section 2.6.3, Normal Operation at Positive Gauge Pressures;

or Section 2.6.4, Operation at Negative Gauge Pressures.

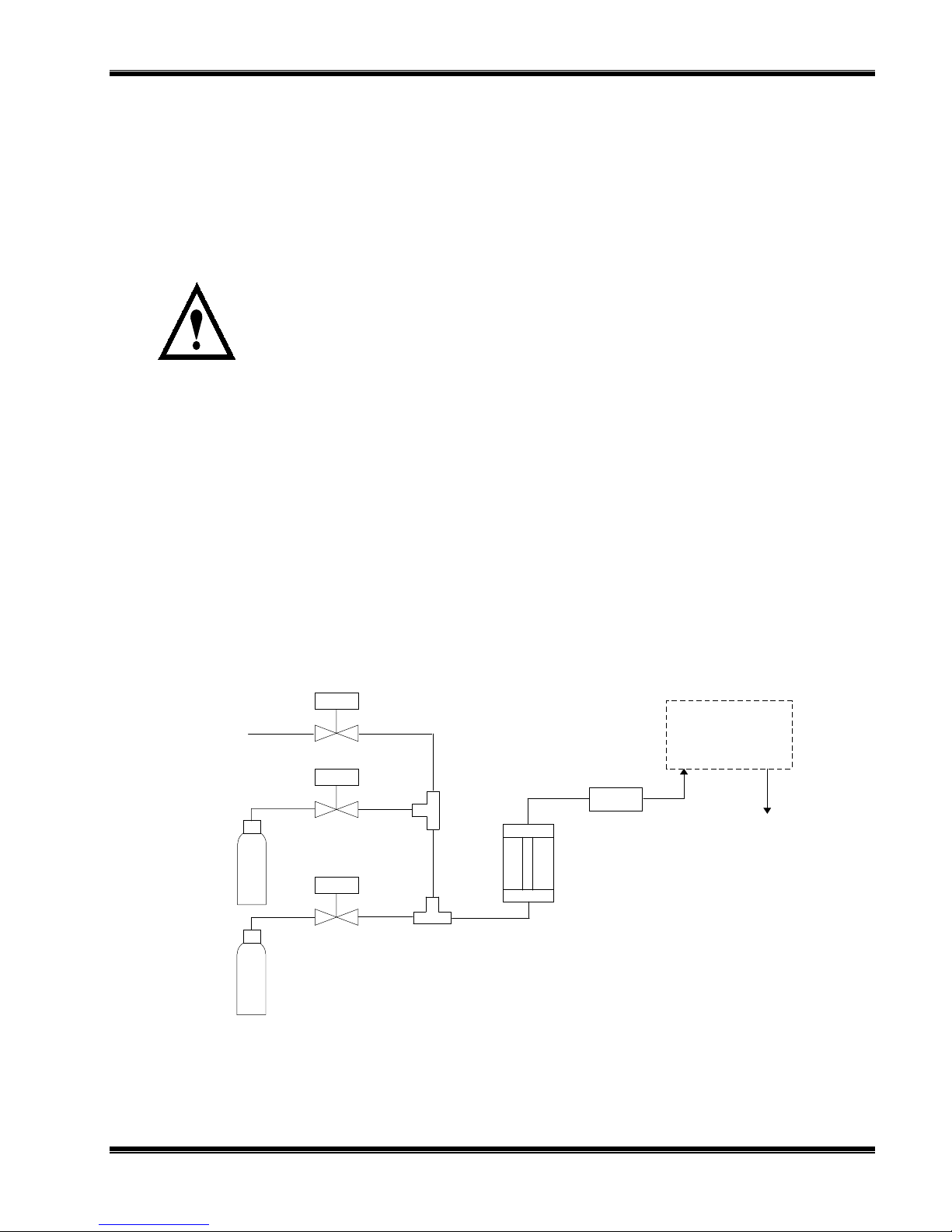

F

IGURE

Sample In

Downscale

Standard

Gas

Upscale

Standard

Gas

2-7. C

Needle

Valves

Two Micron

Flowmeter

Filter

Model 755A

Oxygen Analyzer

ONNECTION OF TYPICAL GAS SELECTOR PANEL TO MODEL

O

XYGEN ANALYZER

To Vent

755A

245364-U Rosemount Analytical April 2000

Model 755A Oxygen Analyzer

2-9

Loading...

Loading...