Rosemount 3051SFP Data sheet

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

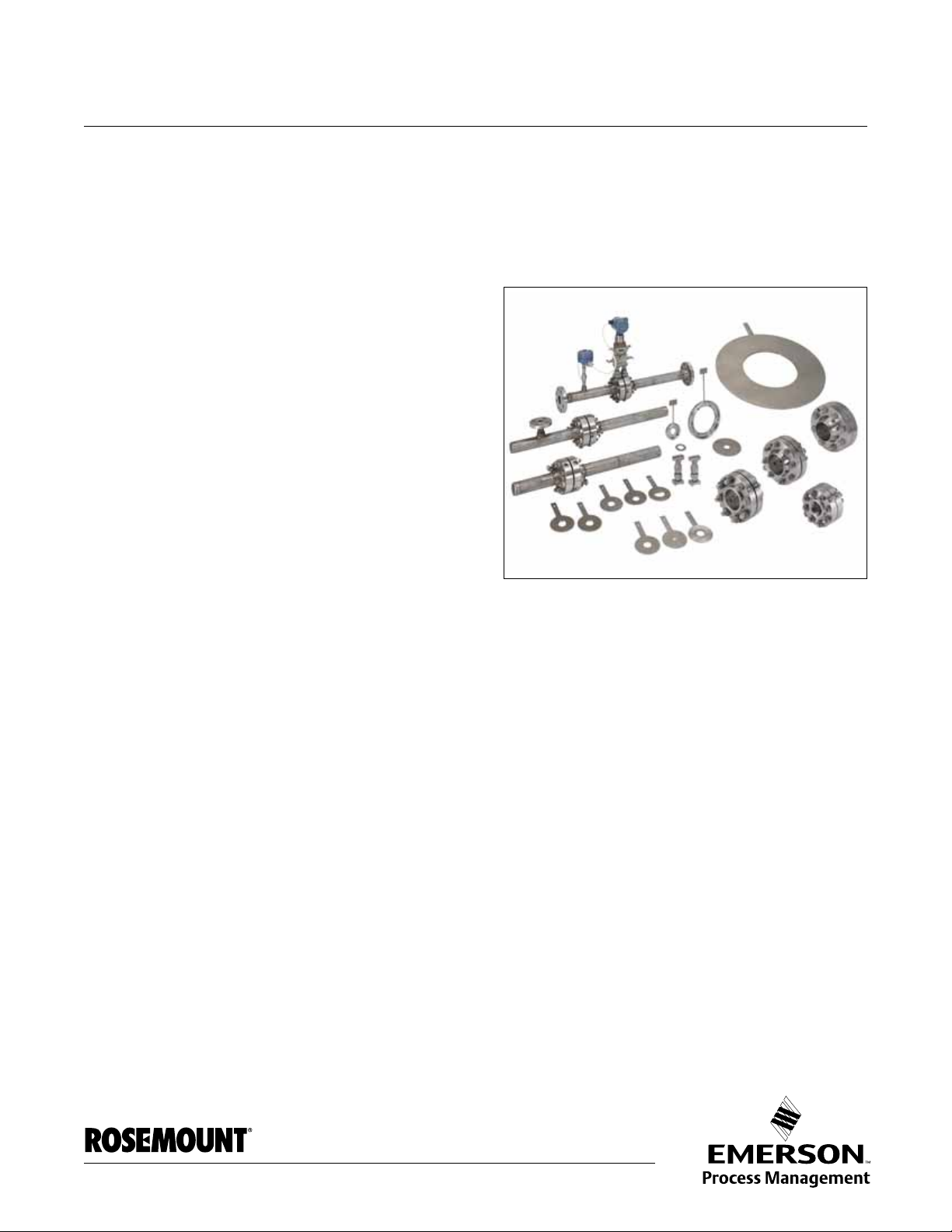

Rosemount 1495, 1496, and 1497

Rosemount 1495 Orifice Plate,

1496 Orifice Flange Union,

1497 Orifice Meter Section

• Comprehensive offering

• Easy to use, prove, and troubleshoot

• The Rosemount 1495 Orifice Plate is

compliant to ISO 5167, AGA Report No. 3 /

API 14.3.2 and ASME MFC-3M, making the

1495 ideal for custody transfer applications

• Suitable for most gas, liquid, and steam

applications

• Rosemount 1495 Restriction Orifice Plates

now available

Contents

The Rosemount 1495, 1496, and 1497. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Sizing and How to Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

1495 Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

1496 Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

1497 Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

1495 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

1496 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

1497 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Calculation Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

Configuration Data Sheet (CDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

www.rosemount.com

Rosemount 1495, 1496, and 1497

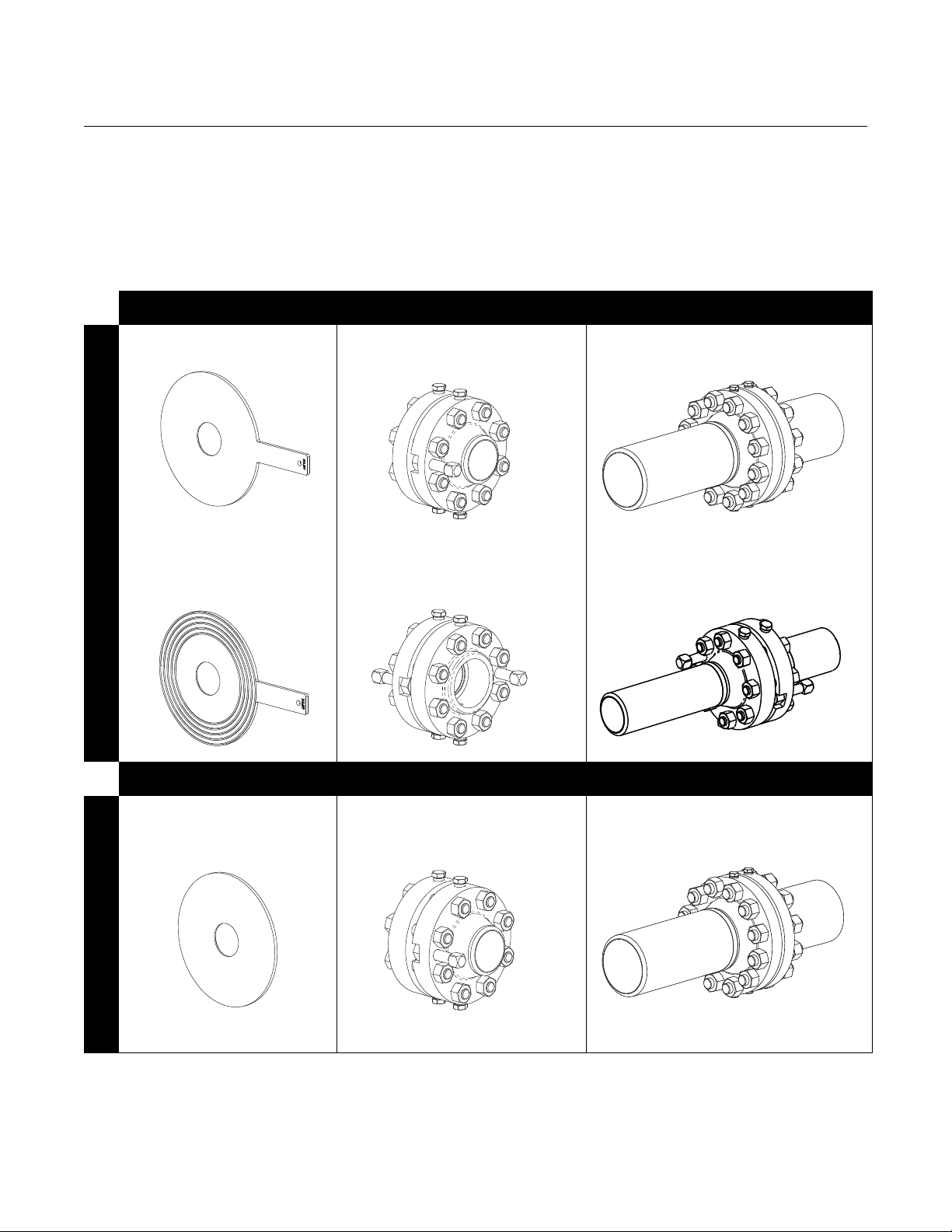

Shown with 1495 Orifice Plate (ordered separately).

Shown with 1495 Orifice Plate (ordered separately).

The Rosemount 1495, 1496, and 1497

Rosemount 1495 Orifice Plate

• The most common primary element in the world

with established manufacturing and installation

standards

• Reliable technology measurement due to known

historical flow data

• Easy to use, prove, and troubleshoot

• Compliant to ISO 5167, AGA Report No. 3 / API

14.3.2, and ASME MFC-3M, ensuring a precise

flow measurement.

• Ideal for custody transfer applications

• Additional bore types available per ISO TR 15377

as well as an unbeveled bore option for Restriction

Orifice applications

• Suitable for most gas, liquid, and steam as well as

high temperature and pressure applications

• Meets AGA, ASME, ISO, and API standards,

ensuring precision flow measurement

• Available for DIN 19206 Part 1

Rosemount 1496 Orifice Flange Union

• Cost effective flow measurement

• No on-site flange tap drilling required

• All hardware for complete assembly provided:

studs, nuts, jack screws, gaskets, and pipe plugs

• Meets high pressure and temperatures requirement

up to ANSI Class 2500#

• Meets ASME B16.36

• Flange unions available per DIN 19214 Part 1

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

FIGURE 1. 1495 Orifice Plate

FIGURE 2. 1496 Orifice Flange Union

Rosemount 1497 Flange Union Meter Section

• All the benefits of a 1496 Orifice Flange Union with

upstream and downstream piping provided

• Ease of installation with various piping connections

• Optional temperature and pressure taps available

Rosemount DP Flow Solutions

Annubar Flowmeter Series: Rosemount 3051SFA ProBar®, 3095MFA Mass ProBar, 485, and 285

The state-of-the-art, fifth generation Rosemount 485 Annubar

combined with the 3051S or 3095MV MultiVariable transmitter

creates an accurate, repeatable and dependable insertion-type

flowmeter. The Rosemount 285 provides a commercial product

offering for your general purpose applications.

Compact Orifice Flowmeter Series: Rosemount 3051SFC, 3095MFC, and 405

Compact Orifice Flowmeters can be installed between existing

flanges, up to a Class 600 (PN100) rating. In tight fit applications,

a conditioning orifice plate version is available, requiring only two

diameters of straight run upstream.

2

FIGURE 3. 1497 Orifice Meter Section

Integral Orifice Flowmeter Series: Rosemount 3051SFP ProPlate®, 3095MFP Mass ProPlate, and 1195

These integral orifice flowmeters eliminate the inaccuracies that

become more pronounced in small orifice line installations. The

completely assembled, ready to install flowmeters reduce cost and

simplify installation.

Orifice Plate Primary Element Systems: Rosemount 1495 and 1595 Orifice Plates, 1496 Flange Unions and 1497 Meter Sections

A comprehensive offering of orifice plates, flange unions and

meter sections that is easy to specify and order. The 1595

Conditioning Orifice provides superior performance in tight fit

applications.

Product Data Sheet

β2β

2

00813-0100-4792, Rev JA

March 2008

Rosemount 1495, 1496, and 1497

Specifications

FUNCTIONAL SPECIFICATIONS

Service and Flow Range

Liquid, gas or vapor turbulent flow, for pipe

Reynold’s Numbers greater than the following

AGA-3: 4,000

ASME MFC-3M

ISO-5167

(1) For flange tap applications.

(2) D = pipe I.D. in mm.

(2)

(2)

: 5,000 and 170 D

: 5,000 and 170 D

(1)

:

Orifice Plate Operating Limitations

Temperature Limit:

Based on flange rating per ANSI B16.5.

Maximum Working Pressure:

Based on flange rating per ANSI B16.5.

Service and Flow Range

Liquid, gas or vapor turbulent flow, for pipe Reynold’s Numbers

within ISO 5167, AGA Report No. 3/ API 14.3.2, and ASME

MFC-3M specifications.

PHYSICAL SPECIFICATIONS

Pipe Sizes

2-in. to 24-in. (50 mm to 600 mm). Contact Emerson Process

Management for pipe sizes less than 2-in. (50 mm) or greater than

24-in. (600 mm).

Rosemount 1497 Meter Section Pipe Length

(“D” is the inside diameter of the pipe)

Upstream

•10D

Downstream

• 5D (standard)

• 8D (if temperature tap is selected)

Custom

• Contact Emerson Process Management for more information

Operating Limits

1495 Temperature Range:

• –320 to 1200 °F (–196 to 649 °C)

1496 and 1497 Temperature Range:

• –320 to 1000 °F (–196 to 538 °C)

Standard Pipe Schedules

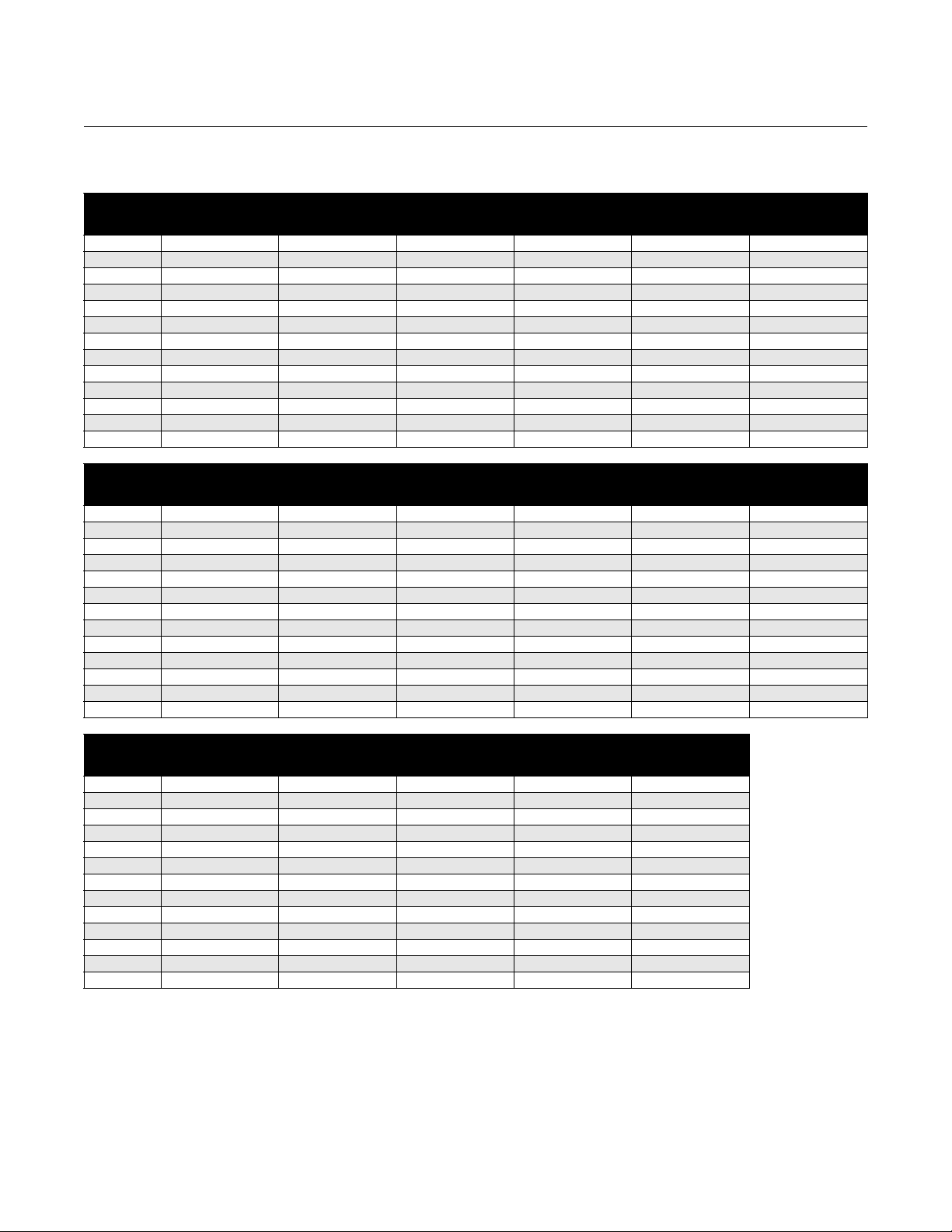

TABLE 1. Default Pipe Schedules for 1496 Orifice Flange Unions and 1497 Orifice Meter Sections

Pipe Size

2 (50.8) Standard Standard XS XS 160

2½ (63.5) Standard Standard XS XS

3 (76.2) Standard Standard XS

4 (101.6) Standard Standard XS

6 (152.4) Standard Standard XS

8 (203.2) Standard Standard

10 (254) Standard XS

12 (304.8) Standard XS

14 (355.6) Standard

16 (406.4) Standard

18 (457.2) Standard

20 (508) Standard

24 (609.6) XS

(1) Shaded gray areas represent no default schedule provided - customer must specify pipe schedule.

(2) Standard wall thickness for DIN weldneck flanges is per ISO EN 1092-1 (2002). Consult factory if different wall thickness is required.

(3) Measurement is in inches (millimeters).

(3)

ANSI 300#

(WN, TH, SO)

ANSI 600#

(WN, RJ)

ANSI 900#

(WN, RJ)

ANSI 1500#

(WN, RJ)

(1)(2)

ANSI 2500#

(WN, RJ)

NOTE

It is strongly encouraged to use the ordering codes to specify desired pipe schedule.

3

Rosemount 1495, 1496, and 1497

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

TABLE 2. Dimensions of Pipe Inner Diameter

Nominal

Pipe Size

2 (51) 2.245 (57.02) 2.157 (54.79) 2.157 (54.79) – – 2.067 (52.501)

2½- (64) 2.709 (68.81) 2.635 (66.93) 2.635 (66.93) – – 2.469 (62.71)

3 (76) 2.224 (56.49) 3.26 (82.80) 3.26 (82.80) – – 3.068 (77.93)

4 (102) 4.334 (110.08) 4.26 (108.20) 4.26 (108.20) – – 4.026 (102.26)

6 (152) 6.407 (162.74) 6.357 (161.47) 6.357 (161.47) – – 6.065 (154.05)

8 (203) 8.407 (213.54) 8.329 (211.56) 8.329 (211.56) 8.125 (206.38) 8.071 (205) 7.981 (202.72)

10 (254) 10.482 (266.24) 10.42 (264.67) 10.42 (264.67) 10.25 (260.35) 10.136 (257.45) 10.20 (254.51)

12 (305) 12.438 (315.93) 12.39 (314.71) 12.39 (314.71) 12.25 (311.15) 12.09 (307.09) 11.938 (303.23)

14 (356) – 13.5 (342.90) 13.624 (346.05) 13.376 (339.75) 13.25 (336.55) 13.124 (333.35)

16 (406) – 15.5 (393.70) 15.624 (396.85) 15.376 (390.55) 15.25 (387.35) 15.0 (381.0)

18 (457) – 17.5 (444.50) 17.624 (447.65) 17.376 (441.35) 17.126 (435.00) 16.976 (431.19)

20 (508) – 19.5 (495.30) 19.564 (496.93) 19.25 (488.95) 19.0 (482.60) 18.814 (477.88)

24 (610) – 23.5 (596.90) 23.5 (596.90) 23.25 (590.55) 22.876 (581.05) 22.626 (574.70)

Nominal

Pipe Size

2 (51) 2.067 (52.501) 2.067 (52.50) – 1.939 (49.25) 1.939 (49.25) 1.939 (49.25)

2½- (64) 2.469 (62.71) 2.469 (62.71) – 2.323 (59.0) 2.323 (59.0) 2.323 (59.0)

3 (76) 3.068 (77.93) 3.068 (77.93) – 2.90 (73.66) 2.90 (73.66) 2.90 (73.66)

4 (102) 4.026 (102.26) 4.026 (102.26) – 3.826 (97.18) 3.826 (97.18) 3.826 (97.18)

6 (152) 6.065 (154.05) 6.065 (154.05) – 5.761 (146.33) 5.761 (146.33) 5.761 (146.33)

8 (203) 7.981 (202.72) 7.981 (202.72) 7.813 (198.45) 7.625 (193.68) 7.625 (193.68) 7.625 (193.68)

10 (254) 10.02 (254.51) 10.20 (259.08) 9.75 (247.65) 9.564 (242.94) 9.75 (247.65) 9.75 (247.65)

12 (305) 12.0 (304.8) 12.00 (304.80) 11.626 (41.30) 11.376 (288.95) 11.75 (298.45) 11.75 (298.45)

14 (356) – 13.250 (336.55) 12.814 (325.48) 12.50 (317.50) – 13.0 (330.20)

16 (406) – 15.250 (387.35) 14.688 (373.08) 14.314 (363.58) – 15.0 (381.0)

18 (457) – 17.250 (438.15) 16.5 (419.10) 16.126 (409.60) – 17.0 (425.0)

20 (508) – 19.252 (488.95) 18.376 (466.75) 17.938 (455.63) – 19.0 (482.60)

24 (610) – 23.250 (590.55) 22.064 (560.43) 21.564 (547.73) – 23.0 (584.20)

5S 10 10S 20 30 40

40S Standard 60 80 80S XS

(1)

Schedule

Schedule

Nominal

Pipe Size

2 (51) – – – 1.689 (42.9) 1.503 (38.18)

2½- (64) – – – 2.125 (53.98) 1.771 (44.98)

3 (76) – – – 2.624 (66.65) 2.30 (58.42)

4 (102) – 3.624 (92.005) – 3.438 (87.33) 3.152 (80.06)

6 (152) – 5.501 (139.73) – 5.189 (131.80) 4.897 (124.38)

8 (203) 7.437 (188.90) 7.189 (157.15) 7.001 (177.83) 6.813 (173.05) 6.875 (174.63)

10 (254) 9.314 (236.58) 9.064 (230.23) 8.75 (222.25) 8.50 (215.90) –

12 (305) 11.064 (281.03) 10.75 (273.05) 10.5 (266.70) 10.126 (257.20) –

14 (356) 12.126 (308.00) 11.814 (300.08) 11.5 (37.50) 11.188 (284.18) –

16 (406) 13.938 (354.03) 13.564 (344.53) 13.124 (333.35) 12.814 (325.48) –

18 (457) 15.688 (398.27) 15.25 (387.35) 14.876 (377.85) 14.438 (366.73) –

20 (508) 17.44 (443.98) 17.0 (431.80) 16.5 (410.10) 16.064 (408.03) –

24 (610) 20.938 (531.83) 20.376 (517.55) 19.876 (504.85) 19.314 (490.58) –

(1) Measurement is in inches (millimeters).

4

100 120 140 160 XXS

Schedule

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

Materials of Construction

1495 Orifice Plate

304/304L or 316/316L Stainless Steel ASTM A240; DIN 1.4571

(316Ti SST)

ASTM B127.

Orifice Bore Sizes

Standard bore sizes are in 1/8-in. (3.2 mm) increments from ½-in.

(12.7 mm) to 4-in. (101.6 mm) and in

from 4

If required, Emerson Process Management can determine the

orifice bore. Basic flow data is required at the time of order, see

“Calculation Data Sheet” on page 1.

Bore tolerances are within AGA and ASME specifications.

Available options allow the user to have the Rosemount 1495

sized for specific operating conditions. The “Orifice Plate

Drawings” on page 6 specifies the physical parameters of the

orifice from a detailed sizing calculation.

1496 Flange Unions

Orifice Flanges (ANSI B16.36): Carbon Steel ASTM A105 / A350;

Stainless Steel ASTM A182; Hastelloy ASTM B564/575; or Monel

400 ASTM B564/127; DIN 1.4571 (316Ti SST)

(carbon steel)

(1)

; Hastelloy® C-276 ASTM B575; or Monel® 400

1

1

/4 to 6-in. (107.95 mm to 152.4 mm).

(1)

.

/4-in. (6.3 mm) increments

(1)

; DIN 1.0460

Rosemount 1495, 1496, and 1497

1497 Meter Section

• Pipe: Carbon Steel ASTM A106 Grade B; Stainless Steel

ASTM A312; Hastelloy ASTM B619 / B622, or Monel ASTM

B165

• Flanges (ANSI B16.5): Carbon Steel ASTM A105 / A350;

Stainless Steel ASTM A182; Hastelloy ASTM B564/575, or

Monel 400 ASTM B564/127

• See “Standard Pipe Schedules” and Table 2 on page 4.

Flange Mounting Hardware

• Studs: Carbon Steel ASTM A193 Grade B7M

• Nuts: Carbon Steel ASTM A194 Gr 2H

• Gaskets: Non-asbestos ring type, Durlon

Klingersil C4400, or equivalent

• Pipe Plugs: Match flange material

®

8500 Green,

Pressure Taps

Pressure tap connections are ½ -in. (12.7 mm) NPT and 180°

apart as standard. The tap hole diameter is ¼-in. (6.35 mm) for

2-in. (51 mm) and 2 ½ -in. (63.5 mm) size,

(76.2 mm) size, and ½-in. (12.7 mm) for 4-in. (101.6 mm) and

larger sizes.

3

/8-in. (9.6 mm) for 3-in.

(1) May not be available in all world areas.

5

Product Data Sheet

Paddle Type

Universal Type

00813-0100-4792, Rev JA

Rosemount 1495, 1496, and 1497

March 2008

Sizing and How to Order

When making a selection, move from left to right, selecting an option in Column 1 and/or either Column 2 or

Column 3.

Column 1 Column 2 Column 3

Orifice Paddle Type Flange Union Meter Section

1495 PC

Paddle, square edged, concentric

1495 PG

Paddle, square edged,

concentric, spiral finish

Orifice Universal Type Flange Union Meter Section

1496 WN

Raised Face (RF) Weld Neck

(for use with paddle type orifice plates)

1496 SO / TH

Raised Face (RF) Slip On / Threaded

(for use with paddle type orifice plates)

1497 WN

Raised Face (RF) Weld Neck

(for use with paddle type orifice plates)

1497 SO

Raised Face (RF) Slip On

(for use with paddle type orifice plates)

1495 UC

Universal, square edged,

concentric

6

1496 RJ

Ring Type Joint (RTJ) Weld Neck

(for use with universal orifice plates with

plate holder)

1497 RJ

Ring Type Joint (RTJ) Weld Neck (for use with

universal orifice plates with plate holder)

Continued on next page

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

Column 1 Column 2 Column 3

Orifice Plate Flange Union Meter Section

Choose Flange Rating:

ANSI Class 300#, 600#, 900#,

1500#, or 2500#

DIN flange ratings: PN10, PN16,

PN25, PN40, PN63, PN100

Rosemount 1495, 1496, and 1497

ANSI Class 300#, 600#, 900#, 1500#,

or 2500#

DIN flange ratings: PN10, PN16, PN25,

PN40, PN63, PN100

ANSI Class 300#, 600#, 900#, 1500#,

or 2500#

Material:

• SST 316/316L ASTM A240

• SST 304/304L ASTM A240

• SST 316Ti DIN 1.4571

• HASTELLOY C-276 ASTM

B575

• MONEL 400 ASTM B564

Choose Line Size:

• 2 to 24-in. (50 to 600 mm)

• Contact Emerson Process

Management for lines less

than 2-in. (51 mm) or greater

than 24-in. (600 mm)

Choose Plate Thickness:

• Default is 0.125-in. (3.2 mm)

for 2 to 6-in (50 to 150 mm)

line size

• Default is 0.250-in. (6.35 mm)

for 8 to 14-in (200 to 350 mm)

line size

• Default is 0.375-in. (9.53) for

16 to 20-in. (400 to 500 mm)

• Default is 0.500-in. (12.7 mm)

for 24-in (600 mm) line size

Choose Bore Diameter:

Refer to Instrument Toolkit

orifice plate sizing. Or, Emerson

Process Management will

calculate the bore diameter by

specifying option code BC in the

1495 ordering table. Include all of

the flowing conditions and pipe

information for the application on

the CDS. See the “Calculation

Data Sheet” for a detailed

sizing calculation.

™

for

• CS ASTM A105 (STANDARD)

• CS ASTM A350 LF2

(PED COMPLIANT - J6)

• SST 316/316L ASTM A182

• SST 304/304L ASTM A182

• SST 316Ti DIN 1.4571

• HASTELLOY C-276 ASTM B564

• MONEL 400 ASTM B564

• 2 to 24-in. (50 to 600 mm)

• Contact Emerson Process

Management for lines less than 2-in.

(51 mm) or greater than 24-in. (600

mm)

Choose Flange Union Type:

• Raised Face Weldneck (1496WN)

• Raised Face Threaded (1496TH)

• Raised Face Slip-On (1496SO)

• RTJ weldneck (1496RJ)

• Raised Face DIN Weldneck

(1496DN)

• CS ASTM A105 (STANDARD)

• CS ASTM A350 LF2

(PED COMPLIANT - J6)

• SST 316/316L ASTM A182

• SST 304/304L ASTM A182

• HASTELLOY C-276 ASTM B564

• MONEL 400 ASTM B564

• 2 to 24-in. (50 to 600 mm)

• Contact Emerson Process Management

for lines less than 2-in. (51 mm) or greater

than 24-in. (600 mm)

Choose Tap Type:

1

/2-in. NPT Flange Taps

•

1

/2-in. Socket Flange Taps

•

Choose Piping Connection:

• Beveled

• Flanged

7

Rosemount 1495, 1496, and 1497

Handle Width

Diameter

Handle

Length

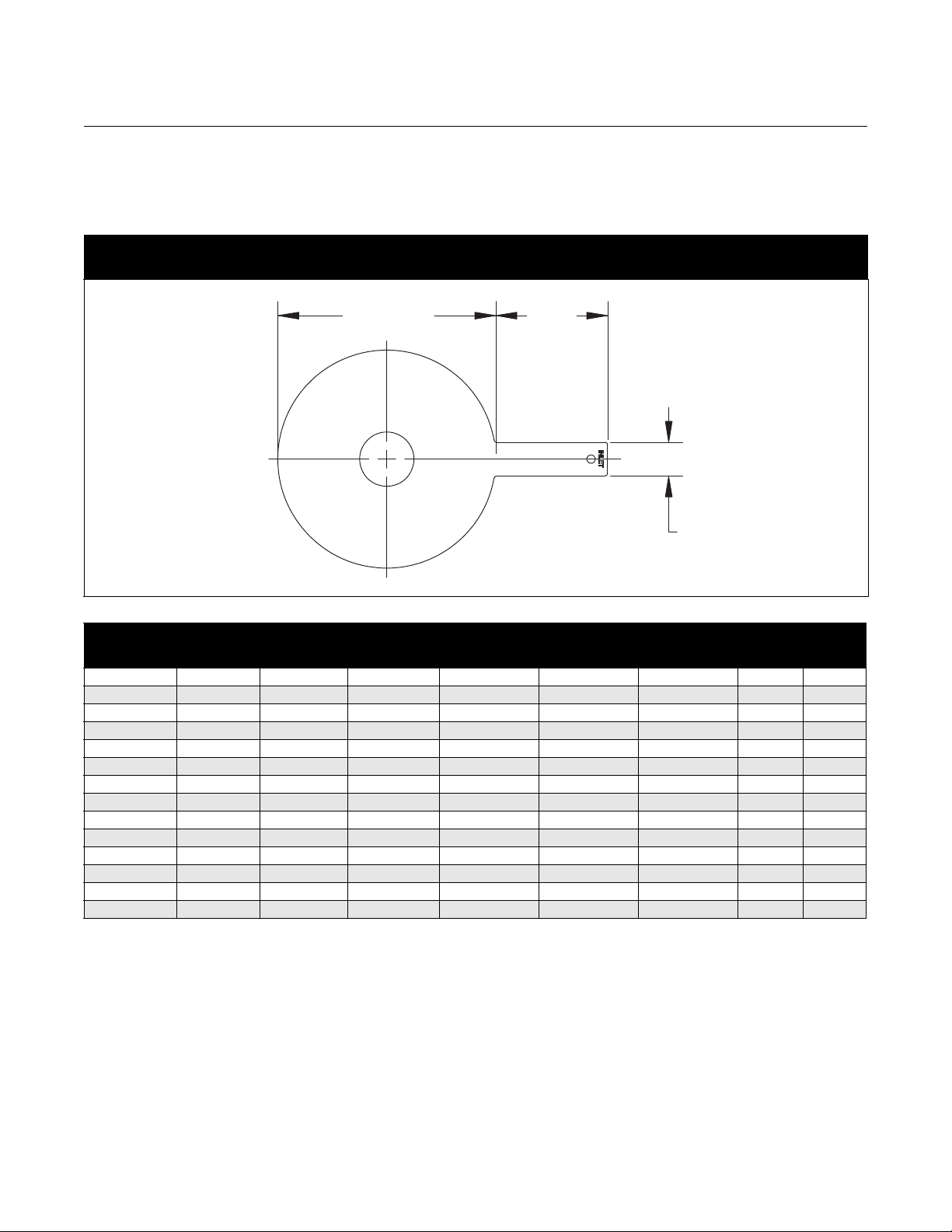

Dimensional Drawings

1495 DIMENSIONAL DRAWINGS

1495PC Paddle Type Orifice Plate

(DIN, Paddle, Square edged, Concentric)

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

TABLE 3. 1495 Orifice Plate Dimensions

DN

DN 50 4.21 (107) 4.21 (107) 4.21 (107) 4.21 (107) 4.45 (113) 4.69 (119) 1.5 (40) 6.3 (160)

DN 65 5 (127) 5 (127) 5 (127) 5 (127) 5.43 (138) 5.67 (144) 1.5 (40) 6.3 (160)

DN 80 5.6 (142) 5.6 (142) 5.6 (142) 5.6 (142) 5.82 (148) 6.06 (154) 1.5 (40) 6.3 (160)

DN 100 6.38 (162) 6.38 (162) 6.61 (168) 6.61 (168) 6.85 (174) 7.09 (180) 1.5 (40) 6.3 (160)

DN 125 7.56 (192) 7.56 (192) 7.64 (194) 7.63 (194) 8.27 (210) 8.54 (217) 1.5 (40) 6.3 (160)

DN 150 8.58 (218) 8.58 (218) 8.82 (224) 8.82 (224) 9.72 (247) 10.12 (257) 1.5 (40) 6.3 (160)

DN 200 10.74 (273) 10.74 (273) 11.18 (284) 11.42 (290) 12.17 (309) 12.76 (324) 1.5 (40) 6.3 (160)

DN 250 12.91 (328) 12.95 (329) 13.39 (340) 13.86 (352) 14.33 (364) 15.39 (391) 1.5 (40) 6.3 (160)

DN 300 14.88 (378) 15.11 (384) 15.75 (400) 16.42 (417) 16.69 (424) 18.03 (458) 1.5 (40) 6.3 (160)

DN 350 17.24 (438) 17.48 (444) 17.99 (457) 18.66 (474) 19.13 (486) 20.16 (512) 1.5 (40) 6.3 (160)

DN 400 19.25 (489) 19.49 (495) 20.24 (514) 21.49 (546) 21.38 (543) 22.52 (572) 1.5 (40) 6.3 (160)

DN 450 21.22 (539) 21.85 (555) 22.24 (565) 22.48 (571) Not Applicable Not Applicable 1.5 (40) 6.3 (160)

DN 500 23.39 (594) 24.29 (617) 24.57 (624) 24.72 (628) 25.87 (657) 27.72 (704) 1.5 (40) 8.0 (200)

DN 600 27.36 (695) 28.9 (734) 28.78 (731) 29.41 (747) 30.08 (764) 32.01(813) 1.5 (40) 8.0 (200)

(1) Measurement is in inches (millimeters)

PN 10 PN 16 PN 25 PN 40 PN 63/64 PN 100

(1)

Diameter (max) – by flange rating

Handle

Width

Handle

Length

8

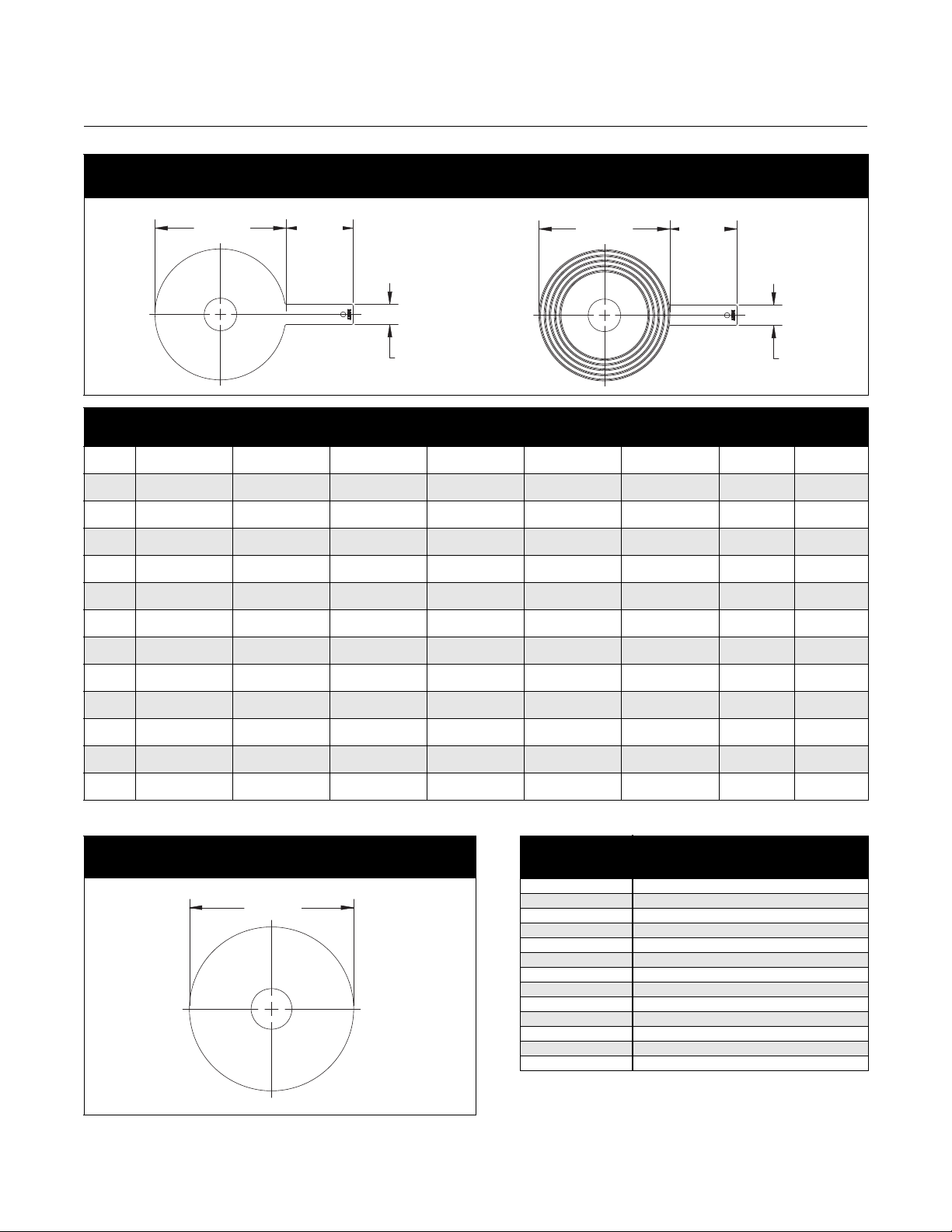

Product Data Sheet

Diameter Handle

Length

Handle

Width

Diameter Handle

Length

Handle

Width

Diameter

00813-0100-4792, Rev JA

March 2008

Rosemount 1495, 1496, and 1497

1495PC Orifice Paddle Type

(Paddle, Square edged, Concentric)

Line

Size

2-in. 4.125

21/2-in. 4.875

3-in. 5.375

4-in. 6.875

6-in. 8.750

8-in. 11 .00 0

10-in. 13.375

12-in. 16.125

14-in. 17.750

16-in. 20.250

18-in. 21.500

20-in. 23.750

24-in. 28.125

(1) Measurement is in inches (millimeters)

150# 300# 600# 900# 1500# 2500#

(104.78)

(123.82)

(136.53)

(174.63)

(222.25)

(279.4)

(339.73)

(409.58)

(450.85)

(514.35)

(546.1)

(603.25)

(714.375)

4.375

(111 .13)

5.125

(130.18)

5.875

(149.23)

7.125

(180.98)

9.875

(250.83)

12.125

(307.98)

14.250

(361.95)

16.625

(422.26)

19.125

(485.78)

21.250

(539.75)

23.375

(593.725)

25.625

(650.875)

30.375

(771.525)

Diameter for Paddle Type

4.375

(111 .13)

5.125

(130.18)

5.875

(149.23)

7.625

(266.7)

10.500

(266.7)

12.625

(320.675)

15.750

(400.05)

18.000

(457.2)

19.375

(339.725)

22.250

(565.15)

24.000

(609.6)

26.750

(679.45)

31.000

(787.4)

5.625

(142.875)

6.500

(165.1)

6.625

(168.275)

8.125

(206.375)

11. 375

(288.925)

14.125

(358.775)

17.125

(434.975)

19.625

(498.475)

20.500

(520.7)

22.625

(574.675)

25.000

(635.00)

27.375

(695.325)

32.875

(835.025)

1495PG Orifice Paddle Type

(Paddle, Square edged, Concentric, Spiral finish)

(1)

5.625

(142.875)

6.500

(165.1)

6.875

(174.625)

8.250

(209.55)

11. 125

(282.575)

13.875

(352.425)

17.125

(434.975)

20.500

(520.7)

22.750

(577.85)

25.250

(641.35)

27.625

(701.675)

29.625

(752.475)

35.500

(901.7)

5.750

(146.05)

6.625

(168.275)

7.750

(196.85)

9.250

(234.95)

12.500

(317.5)

15.250

(387.35)

18.750

(476.25)

21.625

(549.275)

—6.0

— 6.0

—6.0

— 6.0

—6.0

Handle

Length

4.0

(101.6)

4.0

(101.6)

4.0

(101.6)

4.0

(101.6)

4.0

(101.6)

6.0

(127)

6.0

(152.4)

6.0

(152.4)

(152.4)

(152.4)

(152.4)

(152.4)

(152.4)

Handle

Width

1.00

(25.4)

1.00

(25.4)

1.00

(25.4)

1.00

(25.4)

1.00

(25.4)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1495UC Orifice Universal Type

(Universal, Square edged, Concentric

(1) Measurement is in inches (millimeters)

Line Size Diameter for Universal Type

2-in. 2.437 (61.8998)

21/2-in. 2.812 (71.4248)

3-in. 3.437 (87.2998)

4-in. 4.406 (111.912)

6-in. 6.437 (163.5)

8-in. 8.437 (214.3)

10-in. 10.687 (271.45)

12-in. 12.593 (319.862)

14-in. 14.000 (355.6)

16-in. 16.000 (406.4)

18-in. 18.000 (457.2)

20-in. 20.000 (508)

24-in. 24.000 (609.6)

(1)

9

Rosemount 1495, 1496, and 1497

Y

A

B

1

1

R

O

Weld Neck

Y

1

C

0.06

0.94

1/2 NPT (1)

X

Q

B

R

G

O

Threaded

Y

1

F

Q

F

C

0.06

0.94

1/2 NPT (1)

1

X

B

2

Slip-On

Y

2

C

0.06

0.94

1/2 NPT (1)

1

See Note

(5)

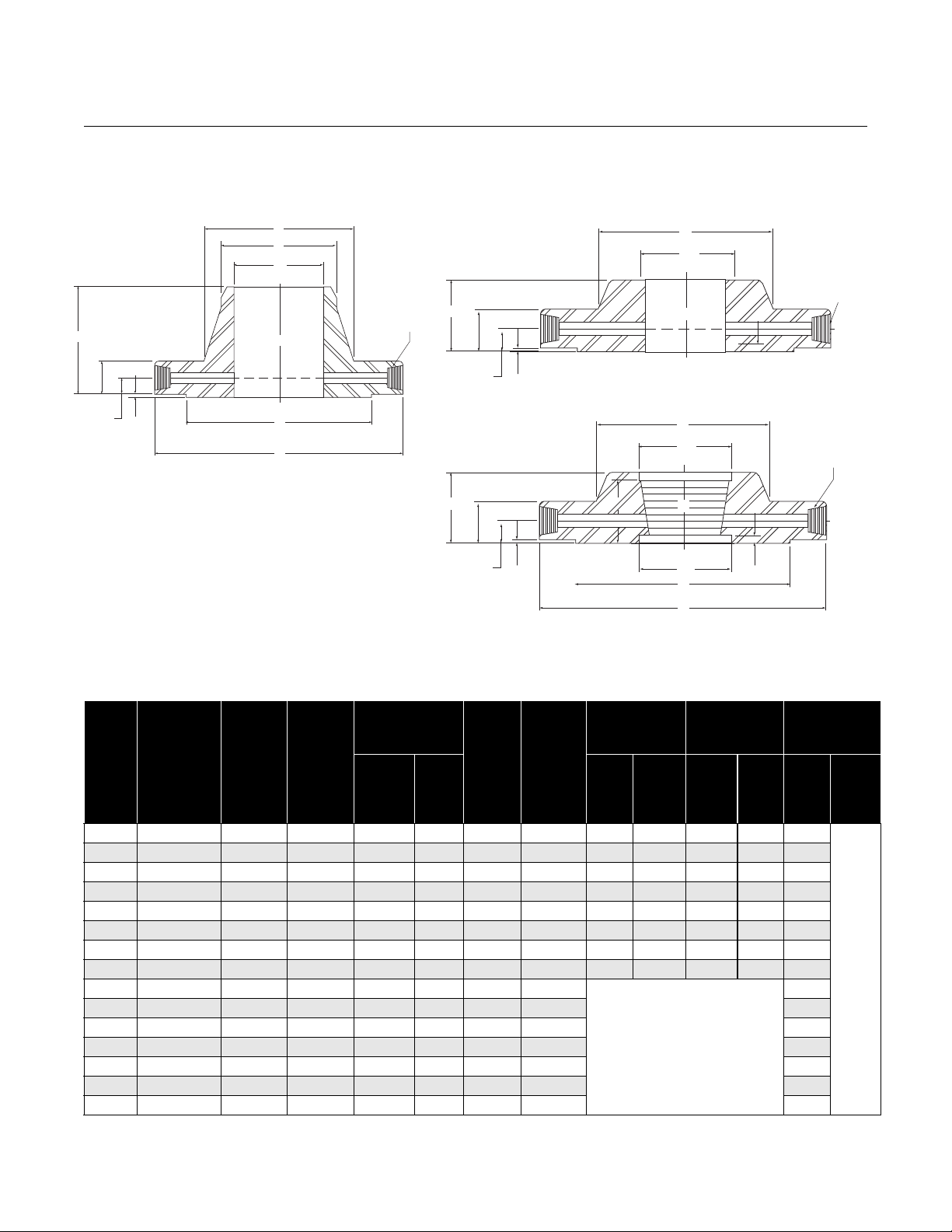

1496 DIMENSIONAL DRAWINGS

FIGURE 4. Class 300

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

ASME B16.36-1996

TABLE 4. Class 300 Orifice Flanges, Welding Neck, Slip-On, and Threaded

Length Through

Hub

Outside

Nominal

Pipe

Size

Diameter of

Raised Face

R

1 2.00 4.88 1.50 1.88 3.25 2.12 1.32 1.41 1.30 1.44 0.75 1.36

11/2 2.88 6.12 1.50 1.88 3.38 2.75 1.90 1.99 1.89 1.47 0.72 1.95

2 3.62 6.50 1.50 1.94 3.38 3.31 2.38 2.50 2.36 1.50 0.69 2.44

21/2 4.12 7.50 1.50 2.00 3.50 3.94 2.88 3.00 2.84 1.75 0.56 2.94

3 5.00 8.25 1.50 2.06 3.50 4.62 3.50 3.63 3.46 1.81 0.56 3.57

4 6.19 10.00 1.50 2.12 3.62 5.75 4.50 4.63 4.45 1.88 0.56 4.57

6 8.50 12.50 1.50 2.12 3.94 8.12 6.63 6.75 6.57 1.88 0.31 6.72

8 10.62 15.00 1.62 2.44 4.38 10.25 8.63 8.75 8.55 2.19 0.44 8.72

10 12.75 17.50 1.88 2.62 4.62 1262 10.75

12 15.00 20.50 2.00 2.88 5.12 14.75 12.75 12.88

14 16.25 23.00 2.12 3.00 5.62 16.75 14.00 14.14

16 18.50 25.50 2.25 3.25 5.75 19.00 16.00 16.16

18 21.00 28.00 2.38 3.50 6.25 21.00 18.00 18.18

20 23.00 30.50 2.50 3.75 6.38 23.12 20.00 20.20

24 27.25 36.00 2.75 4.19 6.62 27.62 24.00 24.25

Outside

Diameter

of Flange

O

Thickness

of Flange,

Min. C

Slip-On

and

Threaded

Y

2

Weld

Neck

Y

1

Diameter

of Hub X

(1)(2)

Hub

Diameter

Beginning

of

Chamfer

(W.N.) A

Diameter of

Counter-

bore

Back

Face Q

Q

B

F

See Note

Counter-

bore Depth

(From Face)

F G

(6)

.

Slip-

On B

10.88

Bore

2

Weld

Neck

B

1

10

Product Data Sheet

00813-0100-4792, Rev JA

March 2008

Rosemount 1495, 1496, and 1497

(1)(2)

Pipe

Size

1

11/2

2

21/2

3

4

6

8

10

12

14

16

18

20

24

Diameter of

Pressure

Connection

TT

1

/4 3.50 4 0.69

1

/4 4.50 4 0.81

1

/4 5.00 8 0.69

1

/4 5.88 8 0.81

3

/8 6.62 8 0.81

1

/2 7.88 8 0.81

1

/2 10.62 12 0.88

1

/2 13.00 12 1.00

1

/2 15.25 16 1.12 1 5.75 6.50

1

/2 17.75 16 1.25 11/8 6.25 7.00

1

/2 20.25 20 1.25 11/8 6.50 7.25

1

/2 22.50 20 1.38 11/4 7.00 7.75

1

/2 24.75 24 1.38 11/4 7.25 8.00

1

/2 27.00 24 1.38 11/4 7.50 8.50

1

/2 32.00 24 1.62 11/2 8.25 9.50

Bolt

Circle

Nominal

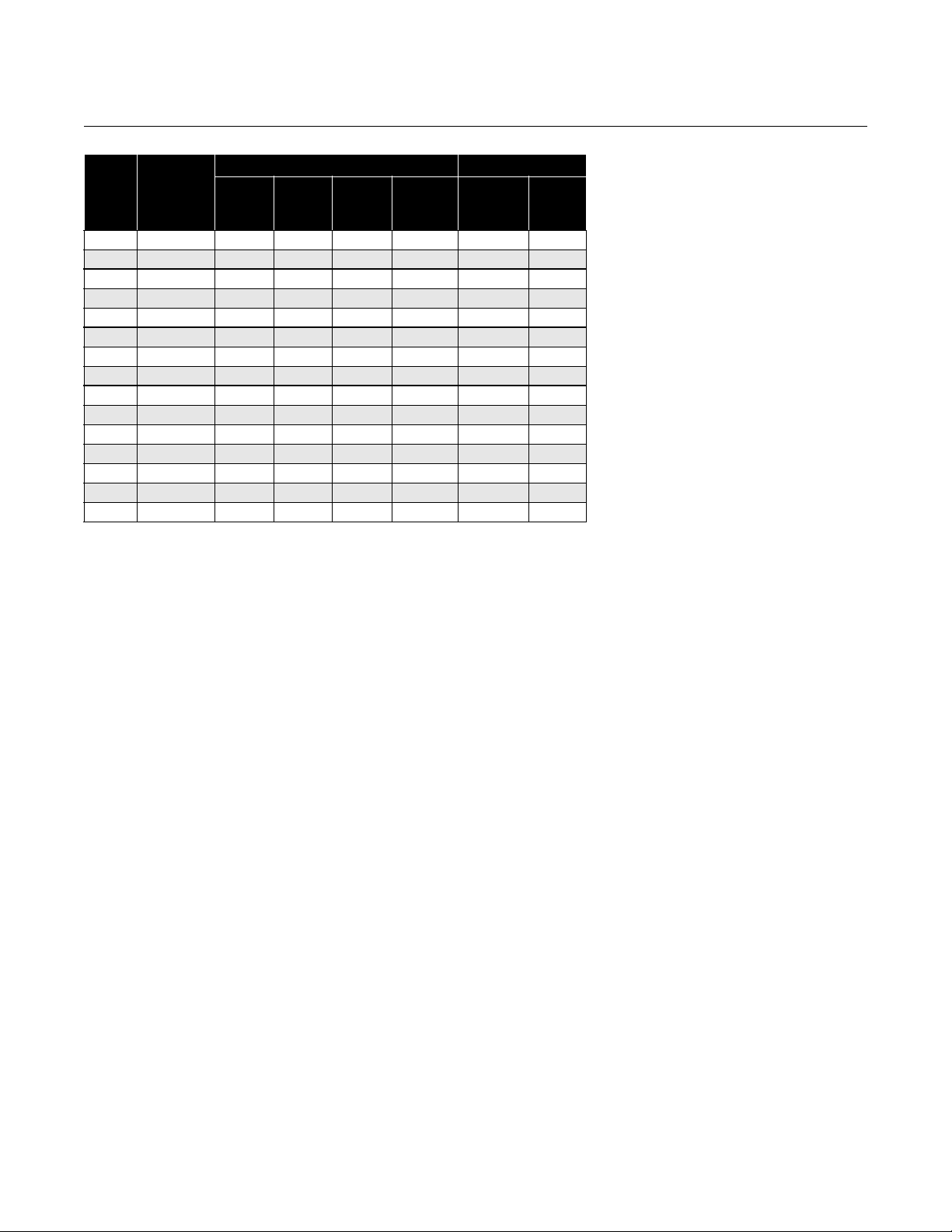

(1) Weld neck flanges NPS 3 and smaller are identical to Class 600 flanges and may be so marked.

(2) All other dimensions are in accordance with ASME B16.5.

(3) Bolt lengths include allowance for orifice and gasket thickness of 0.25 in. for NPS 1-12 and 0.38 in. for NPS 14-24.

(4) In conformance with ASME B16.5, stud bolt lengths do not include point heights.

(5) Threaded flanges are furnished in NPS 1-8 only.

(6) Bore diameter of weld neck flanges is to be specified by the purchaser.

Drilling Template Bolt Length

Number

of

Holes

Diameter

of Holes

Diameter

of Bolts

5

3

5

3

3

3

3

7

Machine

Bolts

/8 4.50 5.00

/4 4.75 5.25

/8 4.50 5.00

/4 4.75 5.25

/4 4.75 5.25

/4 4.75 5.25

/4 4.75 5.25

/8 5.00 5.75

(3)(4)

Stud

Bolts

(5)

(6)

11

Loading...

Loading...