Rosemount 3051S Specifications

Product Data Sheet

00813-0100-4801, Rev UL

July 2019

Rosemount™ 3051S Series of Instrumentation

Innovation reaching across your operation

With the Rosemount 3051S Series of Instrumentation, operations can be optimized in these critical areas:

production, quality, energy efficiency, and safety and environment. By leveraging the power of the scalable

Rosemount 3051S across the entire operation, you’ll be able to minimize process variability, gain greater

process insight, reduce maintenance and downtime, and meet regulatory demands. What’s more, it’s easy

to use, ensuring the full potential of the measurement investment is realized.

Overview

Rosemount 3051S SuperModule™ Platform

The most advanced pressure, flow, and level measurements

■

The all-welded hermetic SST design delivers the industry's highest field reliability.

■

Ultra performance provides up to ±0.025% accuracy and 200:1 rangedown.

■

Ultra for Flow performance provides up to ±0.04% of reading and 14:1 flow

turndown.

■

15-year stability and 15-year limited warranty

■

SIL3 Capable: IEC 61508 certified by an accredited 3rd party agency for use in

safety instrumented systems up to SIL 3 (minimum requirement of single use

[1oo1] for SIL 2 and redundant use [1oo2] for SIL 3).

■

IEC 61508 Functional Safety Specifications for 3051S are detailed at

Emerson.com/Rosemount/Safety.

July 2019

Contents

Overview........................................................................................................................................................................................... 2

Rosemount™ 3051S Coplanar™ Pressure Transmitter......................................................................................................................... 7

Rosemount™ 3051S In-line Pressure Transmitter............................................................................................................................. 17

Rosemount™ 3051S MultiVariable™ Transmitter.............................................................................................................................. 24

Rosemount™ 3051SF DP Flow Meters.............................................................................................................................................. 33

Rosemount™ 3051S Electronic Remote Sensor (ERS™) System......................................................................................................... 61

Rosemount™ 3051S Scalable™ Level Transmitter..............................................................................................................................78

Specifications................................................................................................................................................................................ 107

Product certifications ....................................................................................................................................................................138

Dimensional drawings................................................................................................................................................................... 164

Accessories....................................................................................................................................................................................178

2 Emerson.com/Rosemount

July 2019

Rosemount 3051S Series selection guide

Rosemount 3051S Coplanar™ Differential, Gage, or Absolute Transmitter

Ordering information: Table 1

■

Coplanar platform enables integrated manifold, primary element, and seal system solutions.

■

Dual-capacitance Saturn™ sensor technology corrects for overpressure and line pressure

effects.

■

Calibrated spans from 0.1 inH2O to 4000 psi (0,25 mbar to 276 bar).

■

Available with 316L SST, Alloy C-276, Alloy 400, Tantalum, gold-plated Alloy 400, or goldplated 316L SST process isolators

Rosemount 3051S In-line Gage or Absolute Transmitter

Ordering information: Table 2

■

Direct threaded connection, manifold or seal system solutions

■

Piezoresistive sensor technology allows calibrated spans from 0.3 to 10000 psi (20,7 mbar to

689 bar).

■

Available with 316L SST or Alloy C-276 process isolators

Rosemount 3051S MultiVariable™ Transmitter

Ordering information: Table 3

■

Combines Differential Pressure, Static Pressure, and Process Temperature measurements

along with Mass and Energy Flow in a single device.

■

Compensates for 25+ different variables providing accurate and repeatable flow readings.

■

Customize pressure and temperature compensation for any flow application.

■

Easily configure flow and device parameters with Engineering Assistant Software.

Emerson.com/Rosemount 3

Rosemount 3051SF DP Flow Meters

Ordering information: Table 4

■

Integrates the Rosemount 3051S with Rosemount’s industry leading primary elements to

create one complete flow meter assembly.

■

Fully assembled, configured and leak tested for out-of-the-box installation.

■

Reduce installed costs by replacing ten parts traditionally used for a DP Flow installation with

one flow meter.

■

Reduce straight pipe requirements, lower permanent pressure loss, and achieve accurate

measurement in small line sizes.

Rosemount 3051S Electronic Remote Sensor (ERS™) System

Rosemount 3051SAM Transmitter Ordering information: Table 8

Rosemount 3051SAL Transmitter Ordering information: Table 9

■

The industry’s first digital DP Level architecture consists of a single 4–20 mA HART® loop with

two Rosemount 3051S pressure sensors connected electronically.

■

Unique digital architecture enables stable and repeatable DP Level measurements on tall

vessels, towers, and applications with wide-varying temperatures.

■

Achieve increased process insight and diagnostics with multivariable measurements

including DP, pressure, and scaled variable for tank level or volume.

■

Simplify installations and maintenance by eliminating wet or dry legs, heat tracing, and

purge systems.

July 2019

Rosemount 3051S Level Transmitter

Ordering information: Table 10

■

Level transmitters combine world-class Rosemount 3051S Pressure Transmitters with direct

mount seals, all in a single integrated model number.

■

Connect to virtually any process with a comprehensive offering of seal types, sizes, fill fluids,

and diaphragm materials.

■

Combine with an Rosemount 1199 Remote Mount Seal to form a Tuned-System™ Assembly

for a cost effective, easy-to-install DP Level measurement solution.

4 Emerson.com/Rosemount

July 2019

Advanced functionality

WirelessHART® (IEC 62591) capabilities

Advanced diagnostic capabilities

The following functionality is available on coplanar, in-line, multivariable, DP flow

meters and level transmitters:

■

Quickly deploy new pressure, level and flow measurements in 70 percent less

time.

■

Eliminate wiring design and construction complexities to lower costs by 40–60

percent.

■

Reduce pipe penetrations and impulse piping with industry-leading multivariable

technology.

■

Extended range antenna capabilities provide access to remote locations.

■

Delivering over a decade of maintenance free performance with 15-year stability

and 10-year power module life.

The following functionality is available on coplanar, in-line, DP flow meters and level

transmitters:

■

Provides diagnostic coverage from the process to the transmitter to the host.

■

Prevent on-scale failures by diagnosing electrical loop issues with loop integrity

diagnostics.

■

Process intelligence detects abnormal process conditions enabling more

productive and safer operations.

■

Monitor for solids build-up or freezing in the process connection with the plugged

impulse line diagnostic.

■

Extend diagnostic coverage to Safety Instrumented Systems with IEC 61508 SIL

2/3 capable rating.

Remote display and interface

The following functionality is available on coplanar, in-line, DP flow meters, Electronic

Remote Sensors, and level transmitters:

■

Direct mount to the process and access transmitter capabilities and diagnostics at

grade.

■

Get access up to 100 feet (30 m) away from the process to ensure personnel

safety.

■

Eliminate the need for impulse lines for best practice installations.

Emerson.com/Rosemount 5

Rosemount instrument manifolds

Available on traditional, coplanar, and in-line transmitters:

■

Designed and engineered to provide optimal performance with Rosemount

3051S Transmitters.

■

Reduce cost and leak points with flangeless coplanar design.

■

Fully integrated manifold and transmitter assemblies come fully leak-checked,

calibrated, and assembled allowing for one purchase order to save time and cost.

■

Rosemount manifolds provide a wide variety of styles, materials, and

configurations to fit any process.

July 2019

6 Emerson.com/Rosemount

July 2019

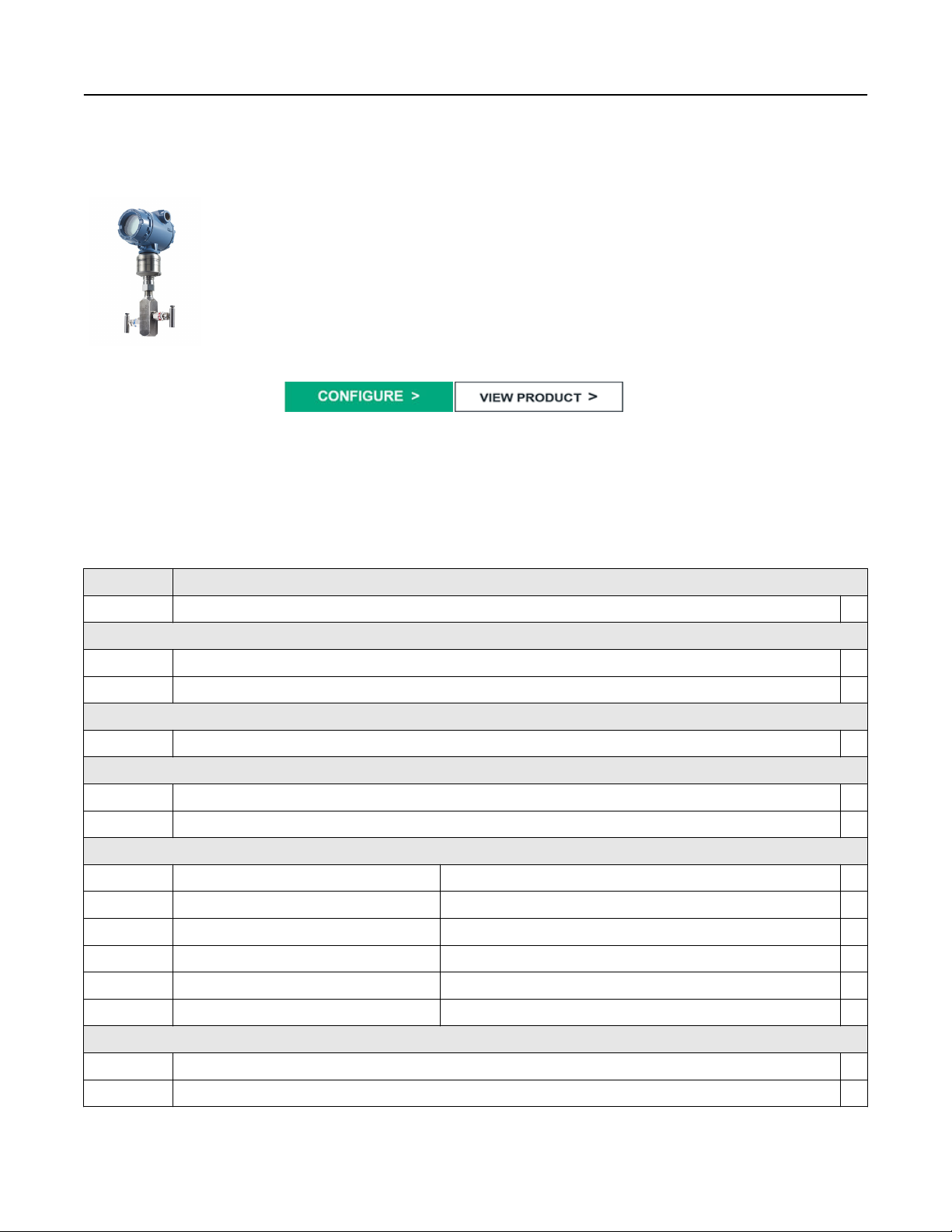

Rosemount™ 3051S Coplanar™ Pressure Transmitter

Rosemount 3051S Coplanar Pressure Transmitters are the industry leader for

Differential, Gage, and Absolute pressure measurement. The coplanar platform

allows seamless integration with manifolds, primary elements, and seal solutions.

Capabilities include:

■

Ultra, Ultra for flow, and classic performance

■

4–20 mA HART®, WirelessHART®, FOUNDATION™ Fieldbus protocols

■

Safety Certification (Option code QT)

■

Advanced diagnostics (Option code DA2)

■

Remote display and interface (Option code M7, M8, or M9)

Additional information: Specifications, Rosemount 3051S/3051SFx/3051S-ERS , Dimensional drawings

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment. See

Material selection for more information.

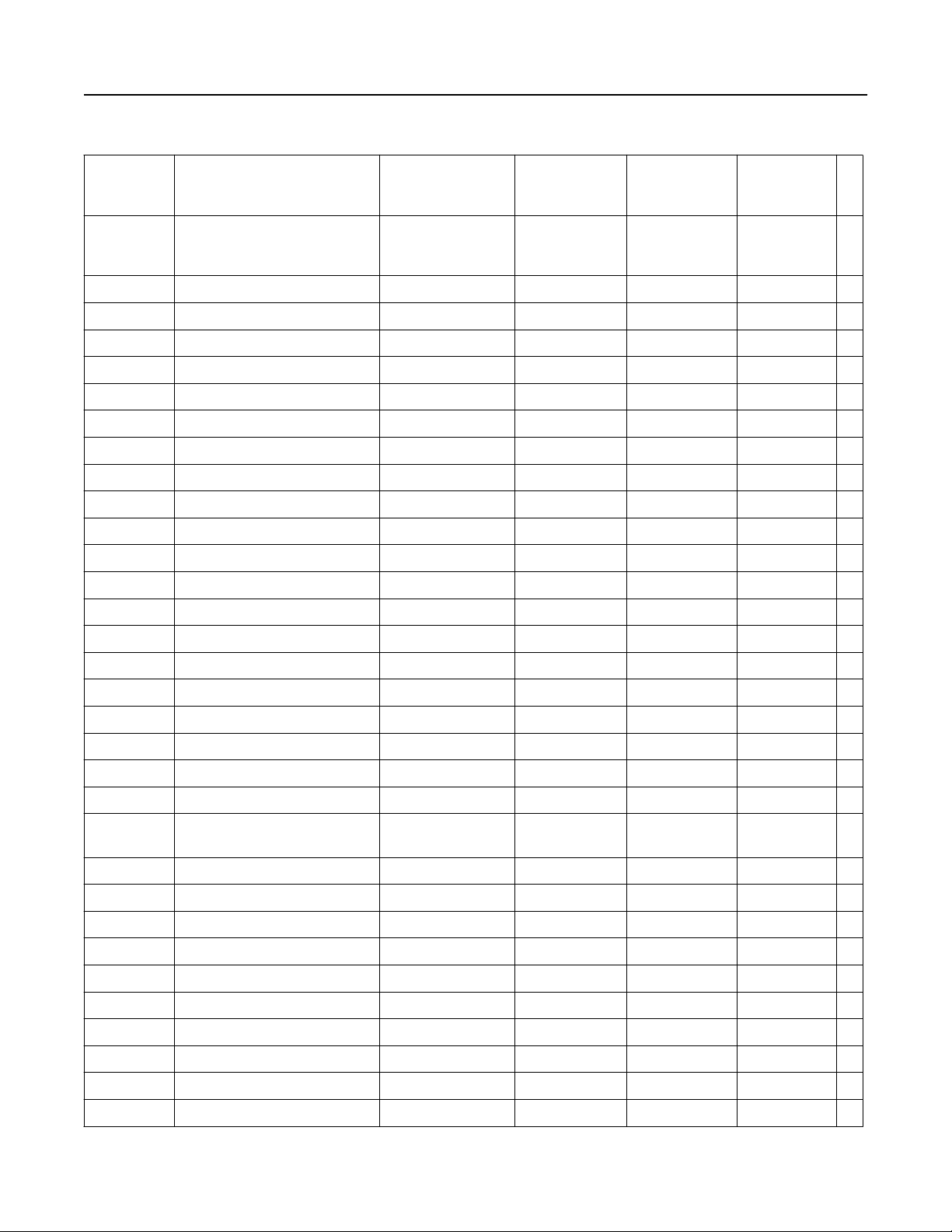

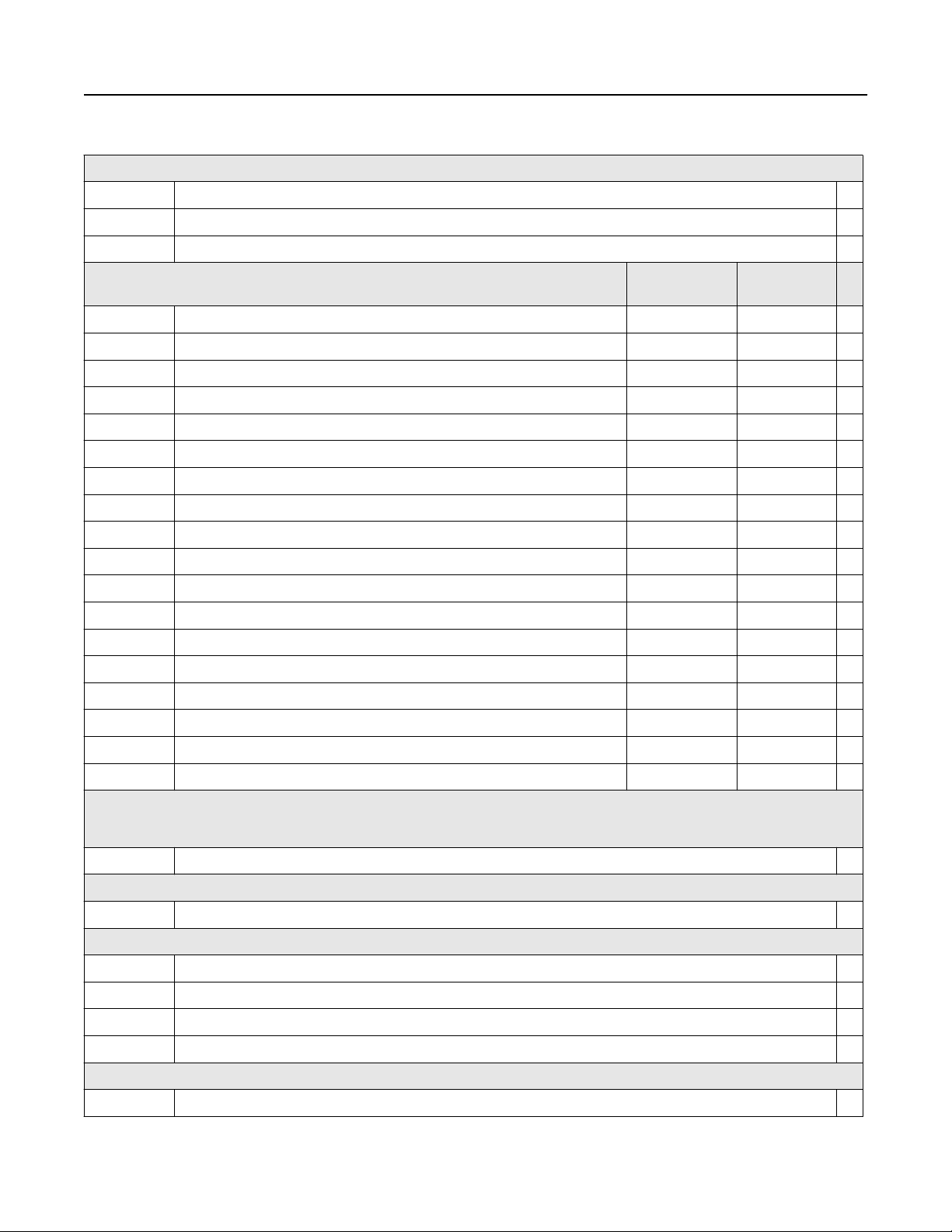

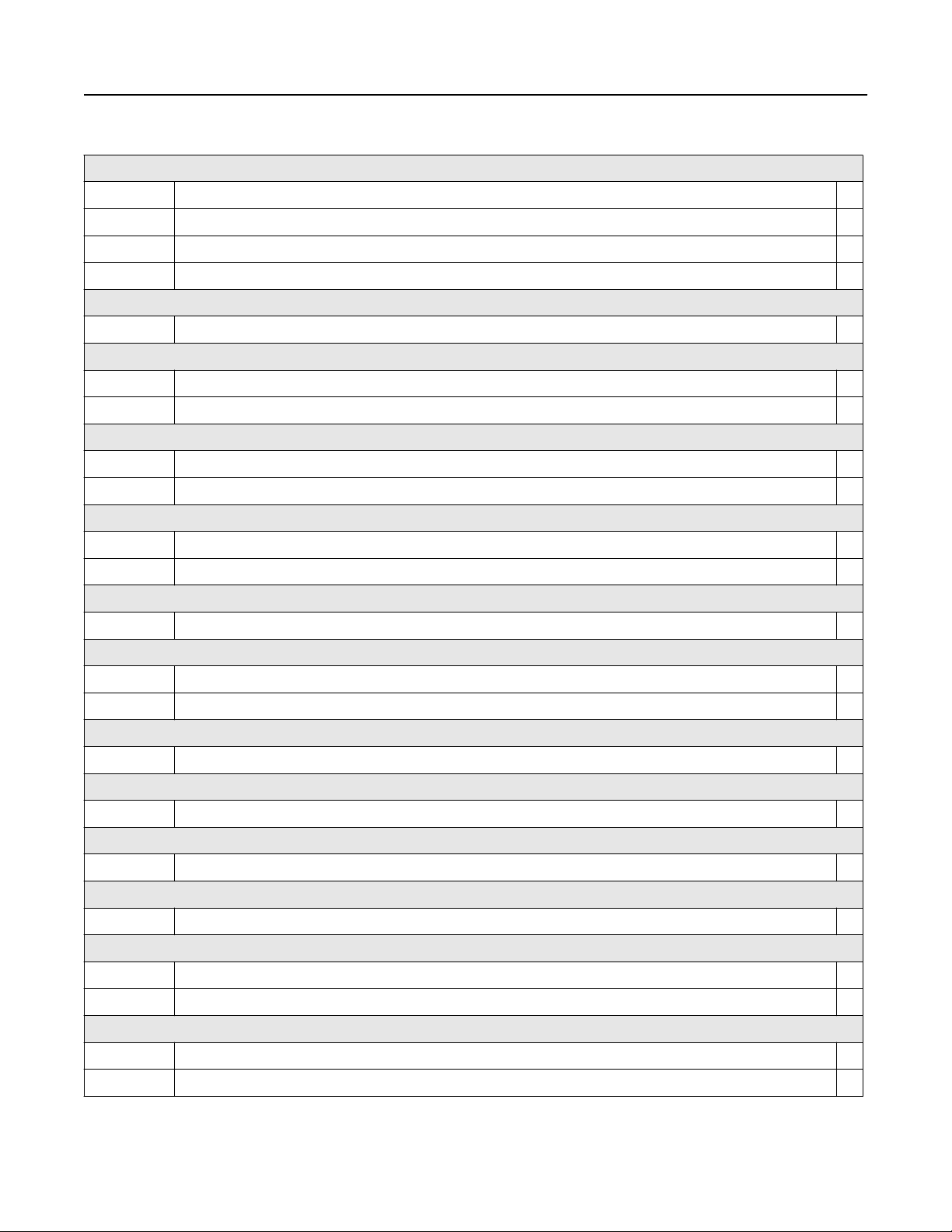

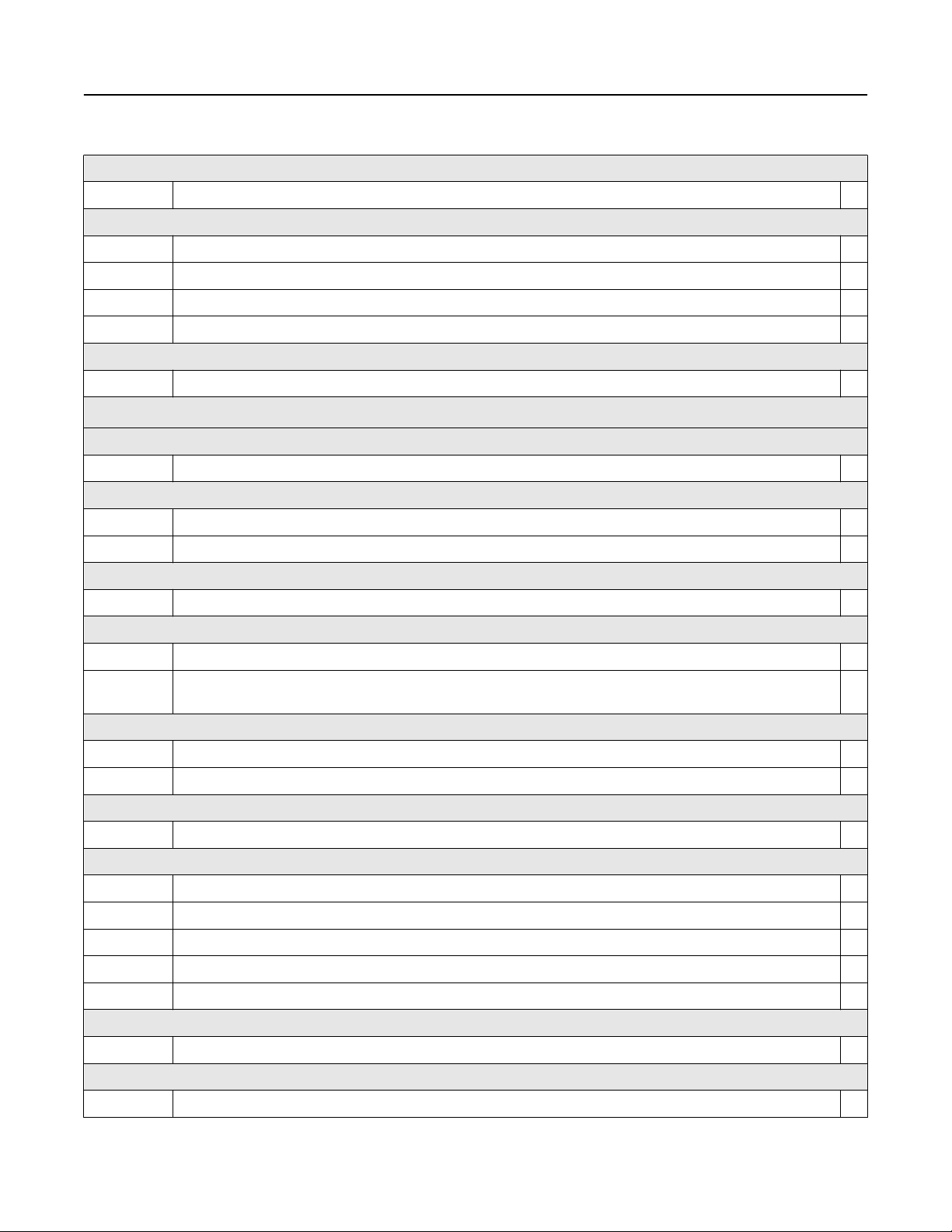

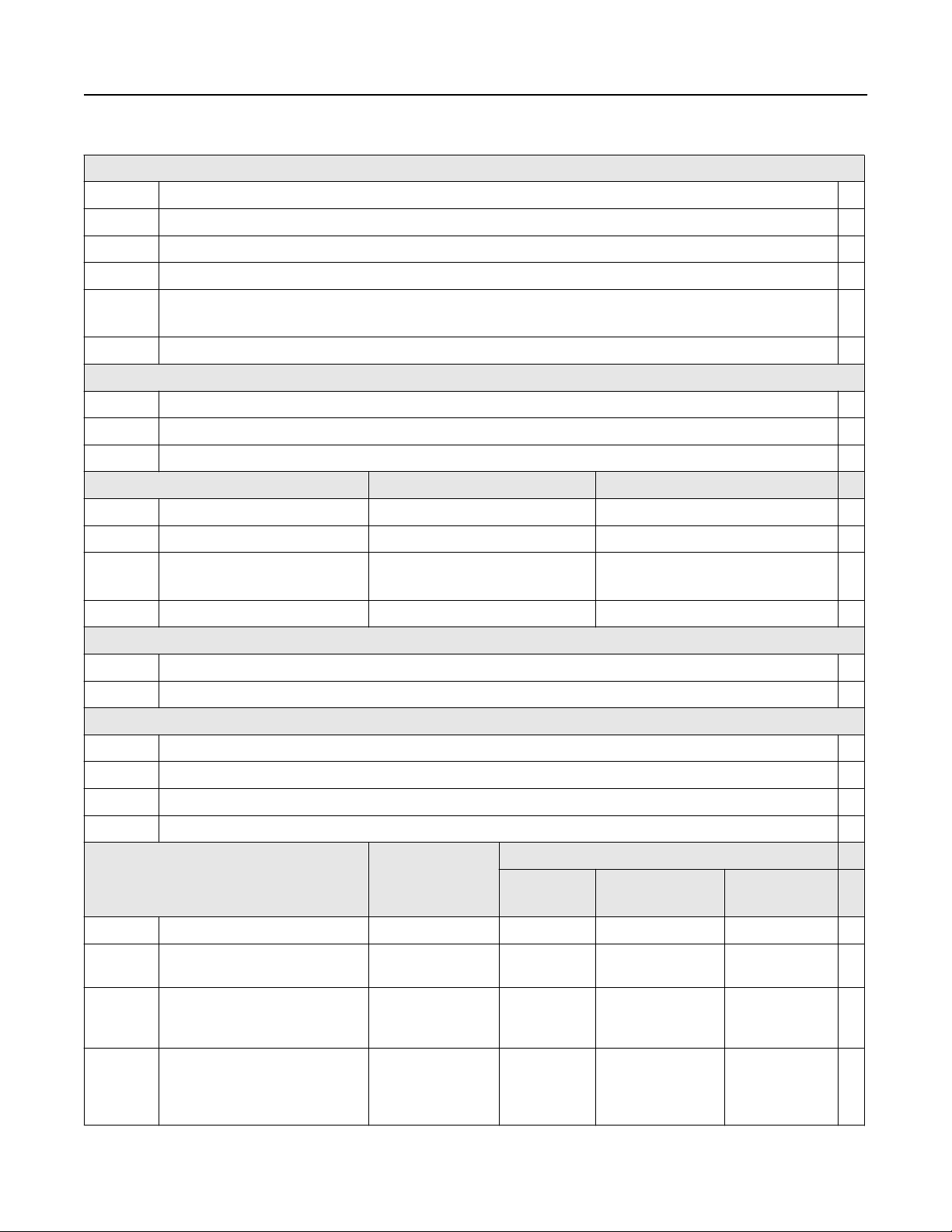

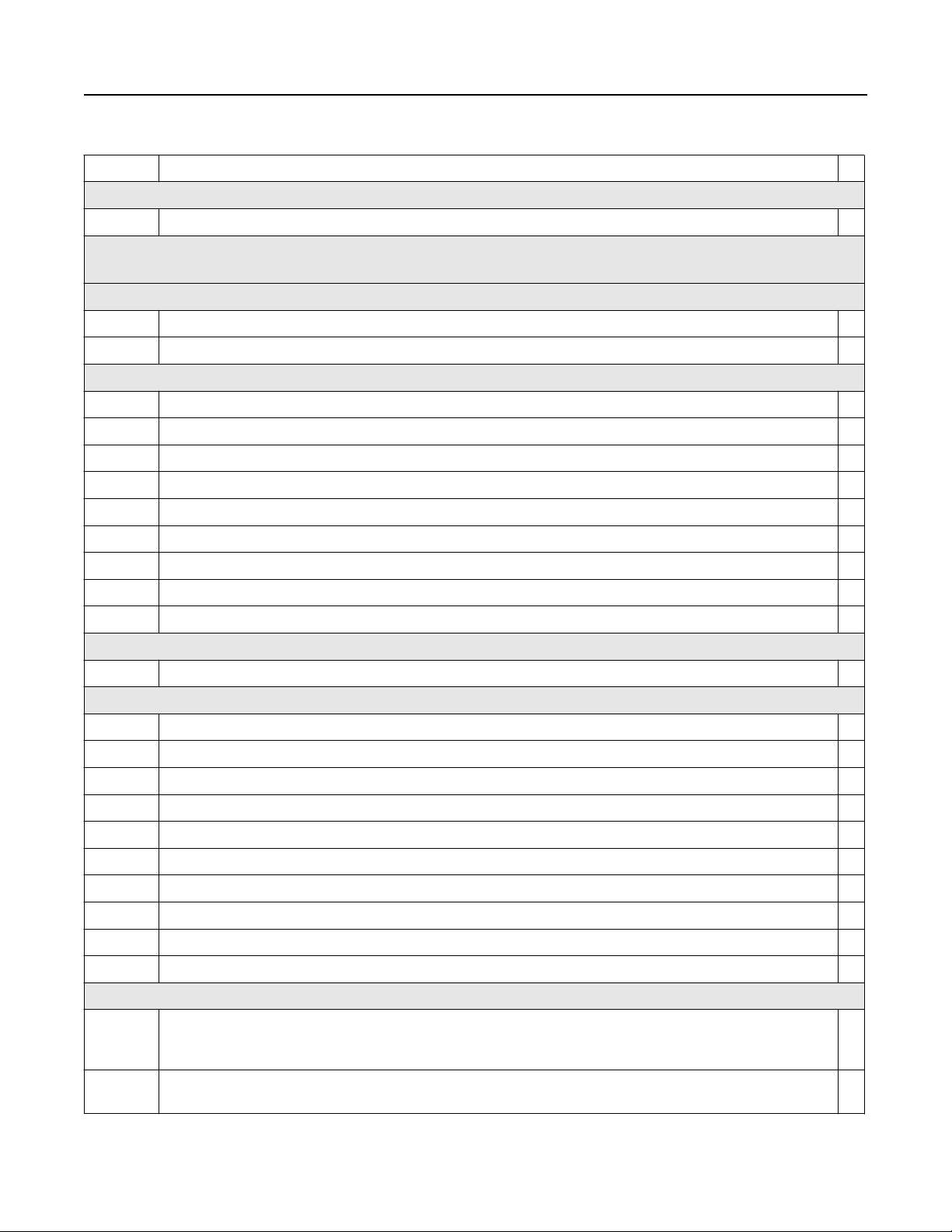

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Transmitter type

3051S Scalable pressure transmitter

Performance class

1 Ultra: 0.025% span accuracy, 200:1 rangedown, 15-yr stability, 15-yr limited warranty ★

(2)

3

2 Classic: 0.035% span accuracy, 150:1 rangedown, 15-yr stability ★

Connection type

C Coplanar ★

Measurement type

D Differential ★

G Gage ★

A Absolute

Pressure range

Differential Gage Absolute

1A –25 to 25 inH2O

2A –250 to 250 inH2O

(1)

Ultra for Flow: 0.04% reading accuracy, 200:1 turndown, 15-yr stability, 15-yr limited warranty ★

(3)

(–62,16 to 62,16 mbar)

(–621,60 to 621,60 mbar)

–25 to 25 inH2O

(–62,16 to 62,16 mbar)

–250 to 250 inH2O

(–621,60 to 621,60 mbar)

0 to 30 psia (0 to 2,07 bar) ★

0 to 150 psia (0 to 10,34 bar) ★

3A –1000 to 1000 inH2O

(–2,49 to 2,49 bar)

–393 to 1000 inH2O

(–0,97 to 2,49 bar)

0 to 800 psia (0 to 55,16 bar) ★

Emerson.com/Rosemount 7

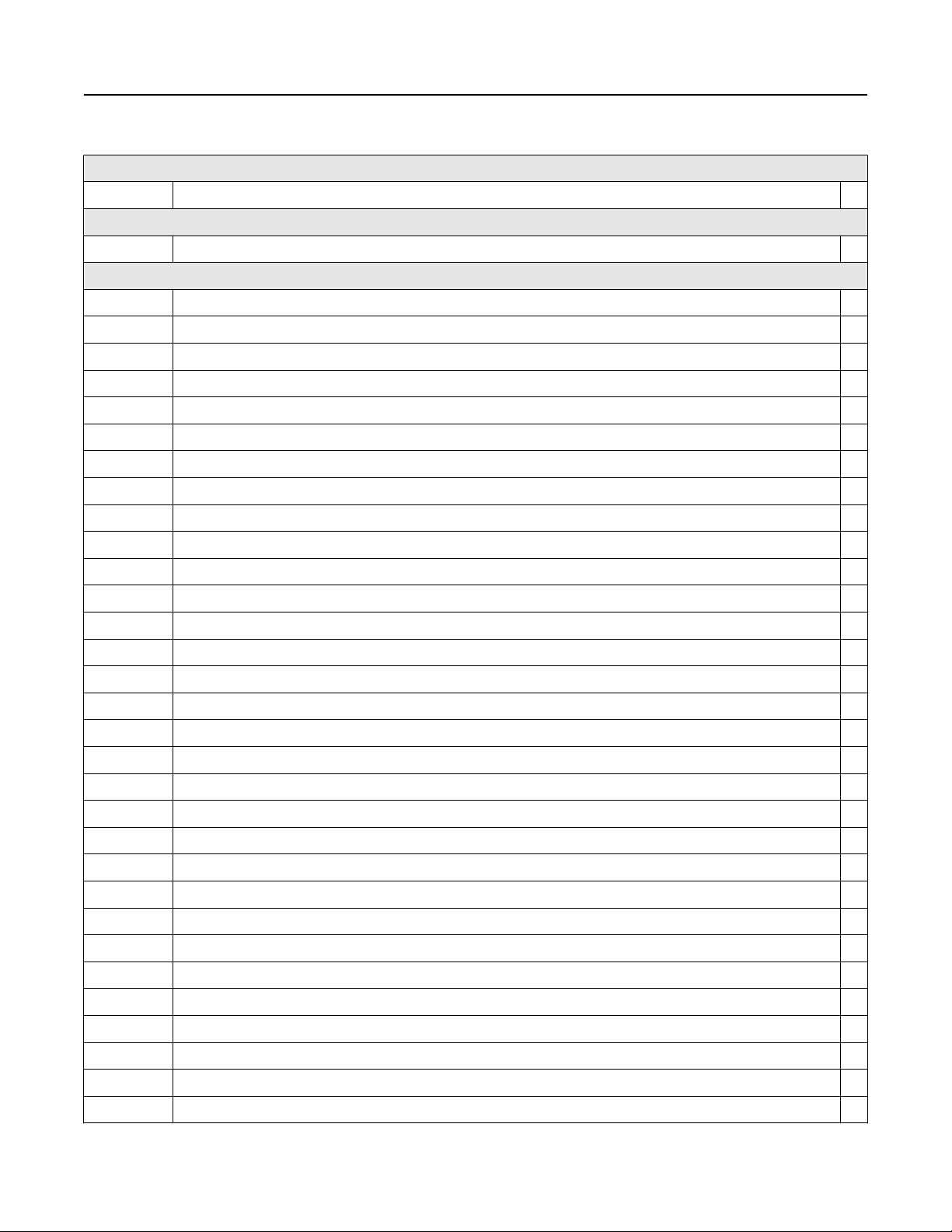

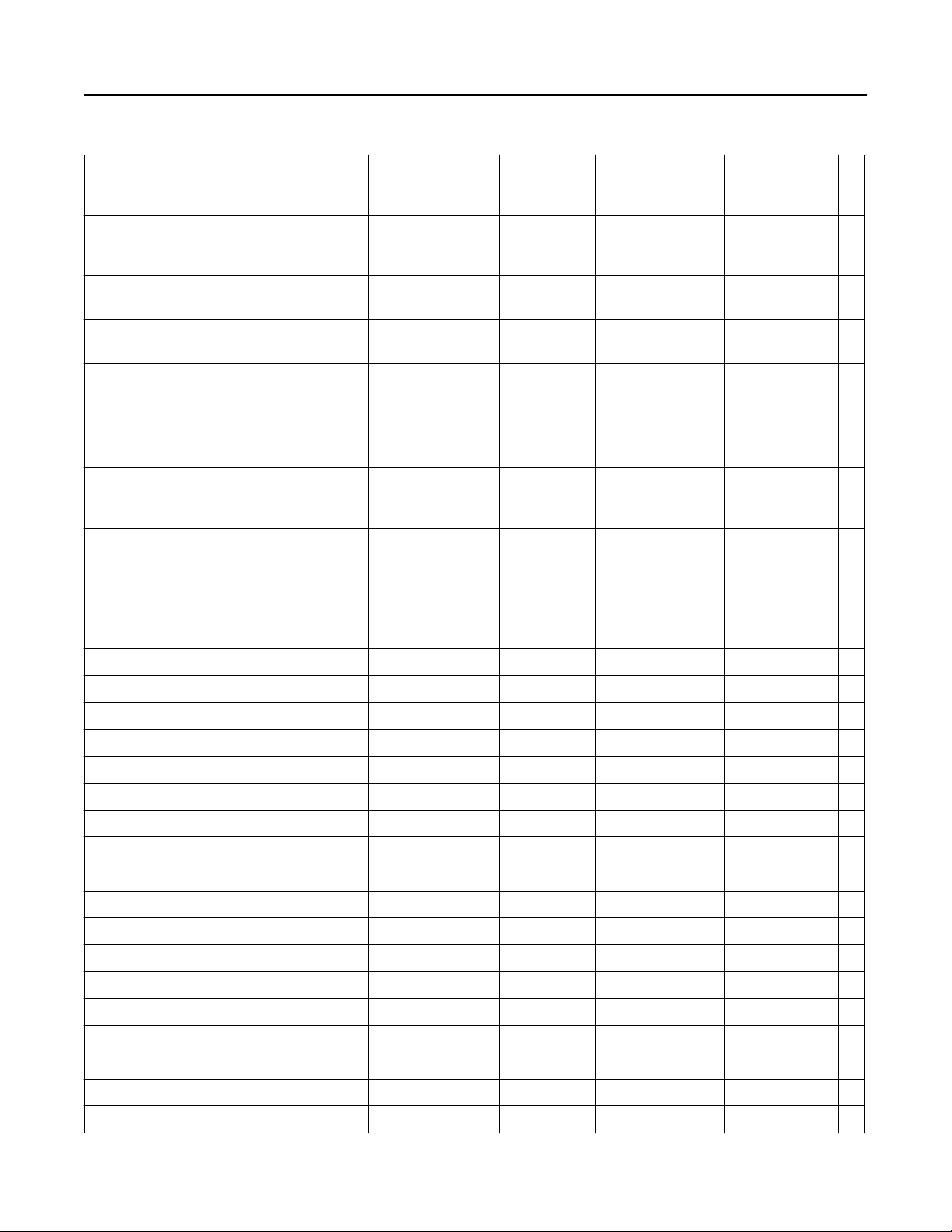

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

July 2019

4A –300 to 300 psi

(–20,68 to 20,68 bar)

5A –2000 to 2000 psi

(–137,89 to 137,89 bar)

(4)

0A

–3 to 3 inH2O

–14.2 to 300 psig

0 to 4000 psia (0 to 275,79 bar) ★

(–0,97 to 20,68 bar)

–14.2 to 2000 psig

N/A ★

(–0,97 to 137,89 bar)

N/A 0 to 5 psia (0 to 0,34 bar)

(–7,46 to 7,46 mbar)

Isolating diaphragm

(5)

2

(5)

3

(5)

4

(6)

5

(5)

6

(5)

7

316L SST ★

Alloy C-276 ★

Alloy 400

Tantalum

Gold-plated Alloy 400 (includes graphite-filled PTFE O-ring)

Gold-plated 316L SST

Process connection Size Materials of construction

Flange material Drain vent Bolting

000 None (no process flange) N/A N/A N/A N/A ★

(7)

A11

Assemble to Rosemount 305

N/A N/A N/A N/A ★

integral manifold

(7)

A12

Assemble to Rosemount 304 or

N/A N/A N/A N/A ★

AMF manifold and SST

traditional flange

A15 Assemble to Rosemount 304 or

AMF manifold to SST traditional

flange with Alloy C-276 drain

vents

(7)

A16

Assemble to 304 or AMF

manifold to DIN SST traditional

flange

A22 Assemble to Rosemount 304 or

AMF manifold to SST coplanar

flange

(7)(8)(9)

B11

Assemble to one Rosemount

1199 seal

(7)(8)(9)

B12

Assemble to two Rosemount

1199 seals

(7)

C11

Assemble to Rosemount 405C

or 405P primary element

(7)

D11

Assemble to Rosemount 1195

integral orifice and Rosemount

305 integral manifold

(7)

EA2

Assemble to Rosemount 485 or

405A Annubar™ primary

element with coplanar flange

N/A N/A N/A N/A ★

N/A N/A N/A N/A ★

N/A N/A N/A N/A ★

N/A SST N/A N/A ★

N/A SST N/A N/A ★

N/A N/A N/A N/A ★

N/A N/A N/A N/A ★

N/A SST 316 SST N/A ★

8 Emerson.com/Rosemount

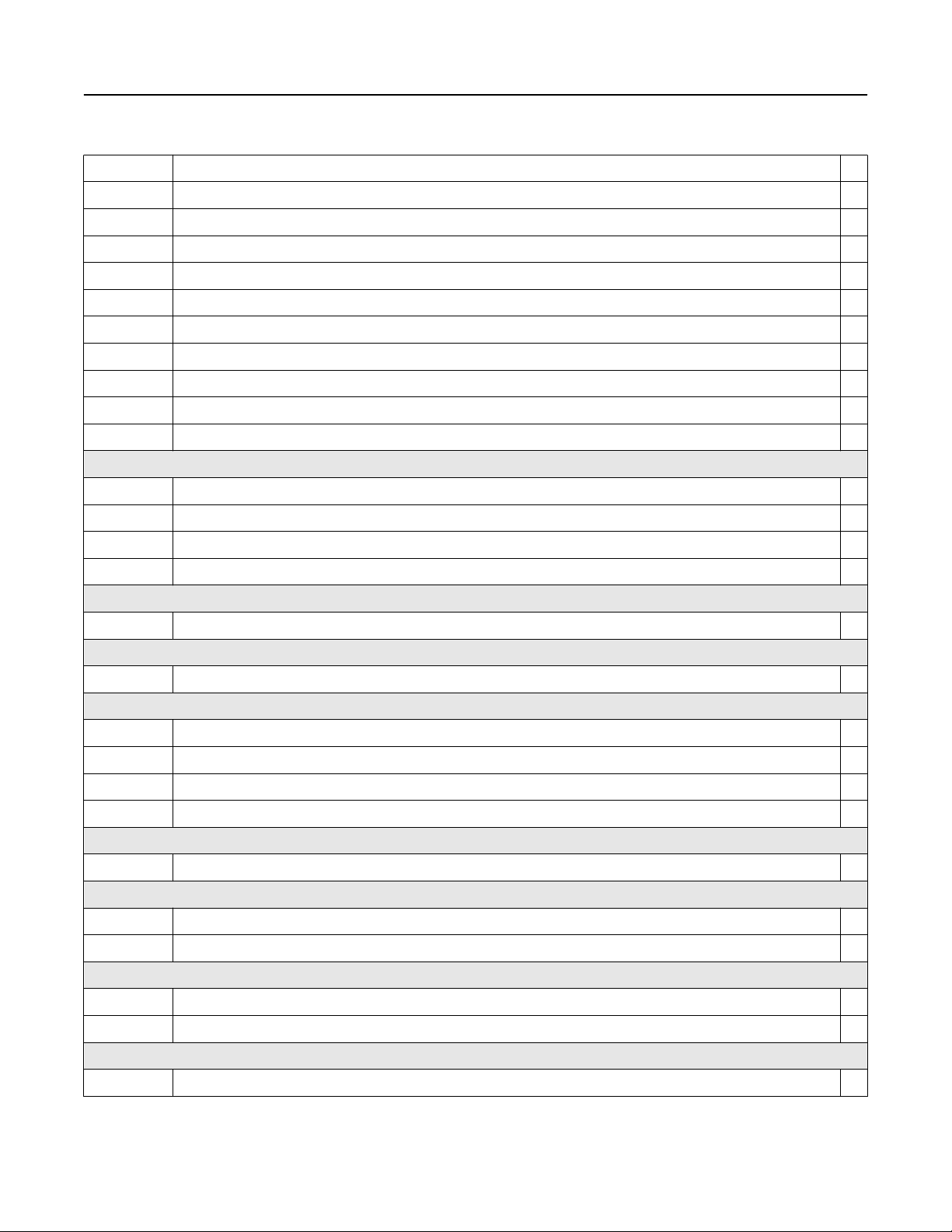

July 2019

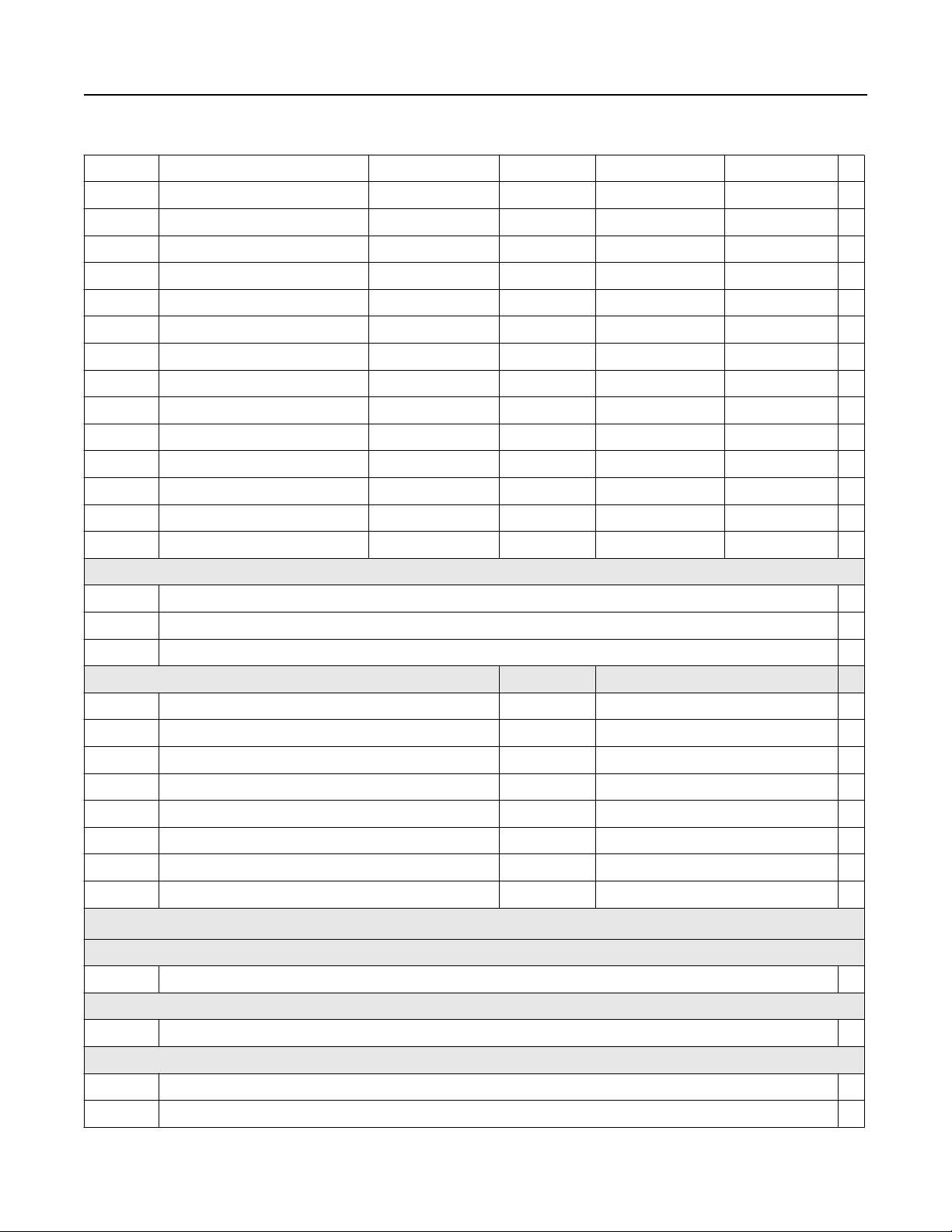

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

(7)

EA3

Assemble to Rosemount 485 or

N/A Cast C-276 Alloy C-276 N/A ★

405A Annubar primary element

with coplanar flange

(7)

EA5

Assemble to Rosemount 485 or

N/A SST Alloy C-276 N/A ★

405A Annubar primary element

with coplanar flange

E11 Coplanar flange ¼–18 NPT CS 316 SST N/A ★

E12 Coplanar flange ¼–18 NPT SST 316 SST N/A ★

(5)

E13

Coplanar flange ¼–18 NPT Cast C-276 Alloy C-276 N/A ★

E14 Coplanar flange ¼–18 NPT Cast Alloy 400 Alloy 400/K-500 N/A ★

(5)

E15

E16

(5)

Coplanar flange ¼–18 NPT SST Alloy C-276 N/A ★

Coplanar flange ¼–18 NPT CS Alloy C-276 N/A ★

E21 Coplanar flange RC ¼ CS 316 SST N/A ★

E22 Coplanar flange RC ¼ SST 316 SST N/A ★

(5)

E23

Coplanar flange RC ¼ Cast C-276 Alloy C-276 N/A ★

E24 Coplanar flange RC ¼ Cast Alloy 400 Alloy 400/K-500 N/A ★

(5)

E25

E26

(5)

Coplanar flange RC ¼ SST Alloy C-276 N/A ★

Coplanar flange RC ¼ CS Alloy C-276 N/A ★

F12 Traditional flange ¼–18 NPT SST 316 SST N/A ★

(5)

F13

Traditional flange ¼–18 NPT Cast C-276 Alloy C-276 N/A ★

F14 Traditional flange ¼–18 NPT Cast Alloy 400 Alloy 400/K-500 N/A ★

(5)

F15

Traditional flange ¼–18 NPT SST Alloy C-276 N/A ★

F22 Traditional flange RC ¼ SST 316 SST N/A ★

(5)

F23

Traditional flange RC ¼ Cast C-276 Alloy C-276 N/A ★

F24 Traditional flange RC ¼ Cast Alloy 400 Alloy 400/K-500 N/A ★

(5)

F25

Traditional flange RC ¼ SST Alloy C-276 N/A ★

F52 DIN-compliant traditional flange ¼–18 NPT SST 316 SST 7⁄16-in.

bolting

G11 Vertical mount level flange 2-in. ANSI Class 150 SST 316 SST N/A ★

G12 Vertical mount level flange 2-in. ANSI Class 300 SST 316 SST N/A ★

G21 Vertical mount level flange 3-in. ANSI Class 150 SST 316 SST N/A ★

G22 Vertical mount level flange 3-in. ANSI Class 300 SST 316 SST N/A ★

G31 Vertical mount level flange DIN- DN 50 PN 40 SST 316 SST N/A ★

G41 Vertical mount level flange DIN- DN 80 PN 40 SST 316 SST N/A ★

F32 Bottom vent traditional flange ¼–18 NPT SST 316 SST N/A

F42 Bottom vent traditional flange RC ¼ SST 316 SST N/A

★

F62 DIN-compliant traditional flange ¼–18 NPT SST 316 SST M10 bolting

F72 DIN-compliant traditional flange ¼–18 NPT SST 316 SST M12 bolting

Emerson.com/Rosemount 9

July 2019

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

Transmitter output

A 4–20 mA with digital signal based on HART protocol ★

(10)

F

(11)

X

FOUNDATION Fieldbus protocol ★

Wireless (requires wireless options and wireless Plantweb™ housing) ★

Housing style Material Conduit entry

size

00 None (SuperModule spare part, order output code A) N/A N/A ★

1A Plantweb housing Aluminum ½–14 NPT ★

1B Plantweb housing Aluminum M20 x 1.5 ★

1J Plantweb housing SST ½–14 NPT ★

1K Plantweb housing SST M20 x 1.5 ★

(12)

5A

5J

(12)

Wireless Plantweb housing Aluminum ½–14 NPT ★

Wireless Plantweb housing SST ½–14 NPT ★

2A Junction box housing Aluminum ½–14 NPT ★

2B Junction box housing Aluminum M20 x 1.5 ★

2J Junction box housing SST ½–14 NPT ★

2E Junction box housing with output for remote display and interface Aluminum ½–14 NPT ★

2F Junction box housing with output for remote display and interface Aluminum M20 x 1.5 ★

2M Junction box housing with output for remote display and interface SST ½–14 NPT ★

(13)

7J

Quick connect (A size mini, 4-pin male termination) SST N/A ★

1C Plantweb housing Aluminum G½

1L Plantweb housing SST G½

2C Junction box housing Aluminum G½

2G Junction box housing with output for remote display and interface Aluminum G½

Wireless options (requires option code X and wireless Plantweb housing)

Update rate

WA User configurable update rate ★

Operating frequency and protocol

3 2.4 GHz DSSS, IEC 62591 (WirelessHART) ★

Omni-directional wireless antenna

WK External antenna ★

WM Extended range, external antenna ★

WJ Remote antenna ★

WN High-gain, remote antenna

SmartPower™

(14)

1 Adapter for black power module (I.S. Power Module sold separately) ★

10 Emerson.com/Rosemount

July 2019

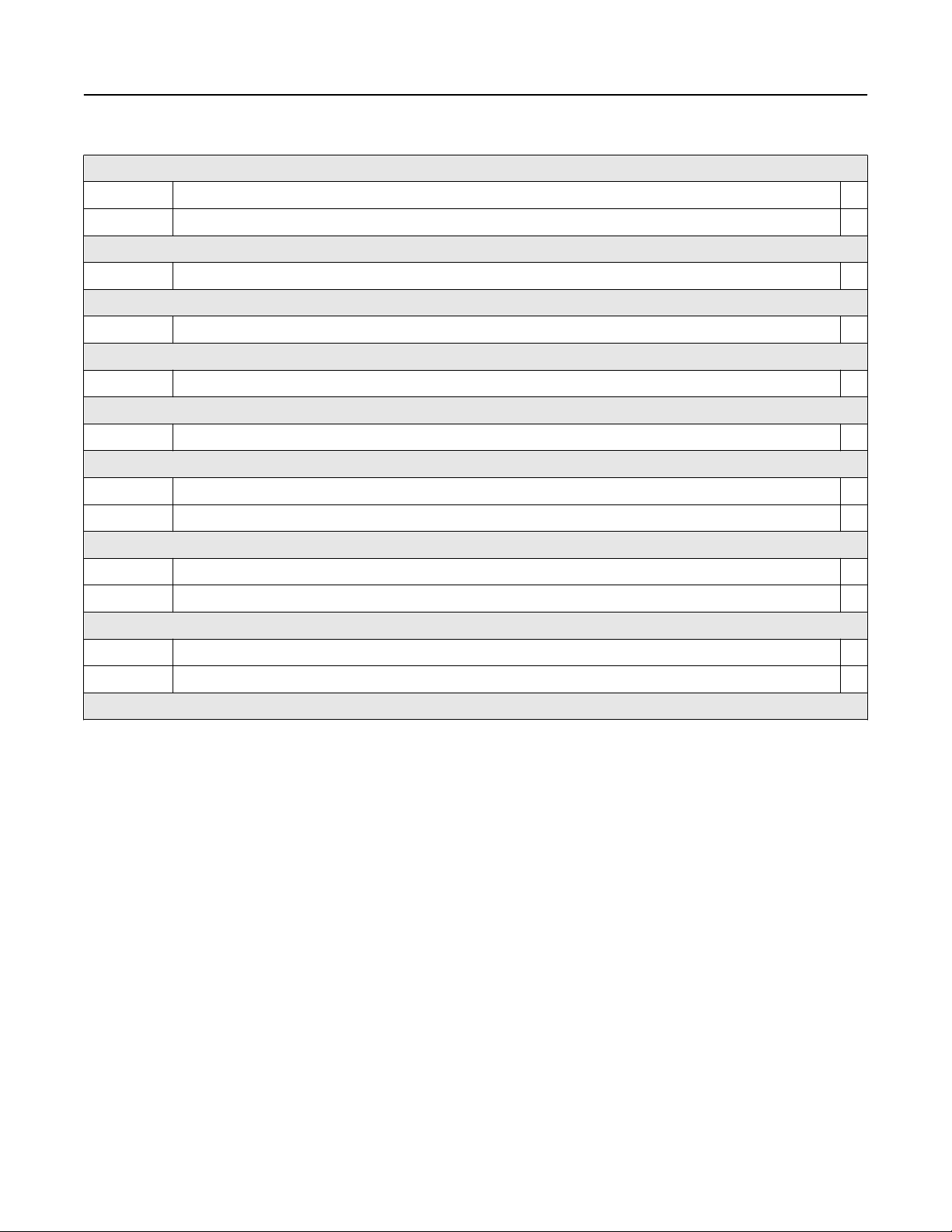

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

Other options (include with selected model number)

HART Revision configuration (requires HART Protocol output code A)

(15)

HR7 Configured for HART Revision 7 ★

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

Plantweb control functionality

A01 FOUNDATION Fieldbus advanced control function block suite ★

Diagnostics suite

D01 FOUNDATION Fieldbus diagnostics suite (Process Intelligence, Plugged Impulse Line diagnostic) ★

(16)

DA2

Advanced HART diagnostics suite (Process Intelligence, Loop Integrity, Plugged Impulse Line diagnostic,

Process Alerts, Service Alerts, Variable Log, Event Log)

Mounting bracket

(17)

B4 Coplanar flange bracket, all SST, 2-in. pipe and panel ★

★

B1 Traditional flange bracket, CS, 2-in. pipe ★

B2 Traditional flange bracket, CS, panel ★

B3 Traditional flange flat bracket, CS, 2-in. pipe ★

B7 Traditional flange bracket, B1 with SST bolts ★

B8 Traditional flange bracket, B2 with SST bolts ★

B9 Traditional flange bracket, B3 with SST bolts ★

BA Traditional flange bracket, B1, all SST ★

BC Traditional flange bracket, B3, all SST ★

BE 316SST B4-style bracket with 316SST bolting ★

Software configuration

(18)

C1

Custom software configuration (requires Configuration Data Sheet) ★

C2 Custom flow configuration (requires H01 and Configuration Data Sheet) ★

Gage pressure calibration

C3 Gage pressure calibration on Rosemount 3051S_CA4 only ★

Alarm limit

(18)(19)

C4 NAMUR alarm and saturation levels, high alarm ★

C5 NAMUR alarm and saturation levels, low alarm ★

C6 Custom alarm and saturation signal levels, high alarm (requires C1 and Configuration Data Sheet) ★

C7 Custom alarm and saturation signal levels, low alarm (requires C1 and Configuration Data Sheet) ★

C8 Low alarm (standard Rosemount alarm and saturation levels) ★

Hardware adjustments

(18)(19)(20)

D1 Hardware adjustments (zero, span, alarm, security) ★

Emerson.com/Rosemount 11

July 2019

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

Flange adapter

(21)

D2 ½-14 NPT flange adapter ★

D9 RC½ SST flange adapter

Custody transfer

(22)

D3 Measurement Canada accuracy approval ★

Ground screw

(23)

D4 External ground screw assembly ★

Drain/vent valve

(21)

D5 Delete transmitter drain/vent valves (install plugs) ★

D7 SST coplanar flange without drain/vent ports

Conduit plug

(24)

DO 316 SST conduit plug ★

Product certifications

(25)

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ★

IA ATEX FISCO Intrinsic Safety (FOUNDATION fieldbus protocol only) ★

N1 ATEX Type n ★

K1 ATEX Flameproof, Intrinsic Safety, Type n, Dust ★

ND ATEX Dust ★

E4 TIIS Flameproof ★

(12)

I4

TIIS Intrinsic Safety ★

E5 FM Explosion-proof, Dust Ignition-proof ★

I5 FM Intrinsically Safe; Nonincendive ★

IE FM FISCO Intrinsically Safe (FOUNDATION Fieldbus protocol only) ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

(26)

E6

CSA Explosion-proof, Dust Ignition-proof, Division 2 ★

I6 CSA Intrinsically Safe ★

IF CSA FISCO Intrinsically Safe (FOUNDATION Fieldbus protocol only) ★

(26)

K6

CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

E7 IECEx Flameproof, Dust ★

I7 IECEx Intrinsic Safety ★

IG IECEx FISCO Intrinsic Safety (FOUNDATION Fieldbus protocol only) ★

N7 IECEx Type n ★

K7 IECEx Flameproof, Dust, Intrinsic Safety, Type n ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

12 Emerson.com/Rosemount

July 2019

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

IB INMETRO FISCO Intrinsic Safety ★

K2 INMETRO Flameproof, Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

N3 China Type n ★

EP Korea Flameproof ★

IP Korea Intrinsic Safety ★

KP Korea Flameproof, Intrinsic Safety ★

EM Technical Regulations Customs Union (EAC) Flameproof ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety ★

IN Technical Regulations Customs Union (EAC) FISCO Intrinsic Safety ★

KM Technical Regulations Customs Union (EAC) Flameproof, Intrinsic Safety ★

(26)

KA

KB

(26)

ATEX and CSA Flameproof, Intrinsically Safe, Division 2 ★

FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

KC FM and ATEX Explosion-proof, Intrinsically Safe, Division 2 ★

(26)

KD

FM, CSA, and ATEX Explosion-proof, Intrinsically Safe ★

KG FM, CSA, ATEX and IECEx FISCO Intrinsic Safety ★

KQ USA, Canada, ATEX Intrinsic Safety Combination ★

KS USA, Canada, IECEx, ATEX Explosion Proof, Intrinsically Safe, Dust, Non-Incendive, Type-N, Division 2 ★

Shipboard approvals

SBS American Bureau of Shipping ★

SBV Bureau Veritas (BV) Type Approval ★

SDN Det Norske Veritas (DNV) Type Approval ★

SLL Lloyds Register (LR) Type Approval ★

Stainless steel tagging

Y2 316SST nameplate, top tag, wire-on tag, and fasteners ★

Sensor fill fluid

(27)

L1 Inert sensor fill fluid ★

O-ring

L2 Graphite-filled PTFE O-ring ★

Bolting material

(21)

L4 Austenitic 316 SST bolts ★

L5 ASTM A 193, Grade B7M bolts ★

L6 Alloy K-500 bolts ★

(28)

L7

ASTM A453, Class D, Grade 660 bolts ★

L8 ASTM A193, Class 2, Grade B8M bolts ★

Emerson.com/Rosemount 13

July 2019

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

Display type

(29)

M5 Plantweb LCD display ★

(19)(30)(31)

M7

(19)(30)

M8

(19)(30)

M9

Pressure testing

Remote mount LCD display and interface, Plantweb housing, no cable, SST bracket ★

Remote mount LCD display and interface, Plantweb housing, 50 feet (15 m) cable, SST bracket ★

Remote mount LCD display and interface, Plantweb housing, 100 feet (31 m) cable, SST bracket ★

(32)

P1 Hydrostatic testing with certificate

Special cleaning

(21)

P2 Cleaning for special services

P3 Cleaning for special services with testing for <1PPM chlorine/fluorine

Maximum static line pressure

(33)

P9

P0

(34)

4500 psig (310 bar) static pressure limit (Rosemount 3051S_CD only) ★

6092 psig (420 bar) static pressure limit (Rosemount 3051S2CD only) ★

Calibration certification

Q4 Calibration certificate ★

QP Calibration certificate and tamper evident seal ★

Material traceability certification

Q8 Material traceability certification per EN 10204 3.1 ★

Quality certification for safety

(35)

QS Prior-use certificate of FMEDA data ★

QT Safety-certified to IEC 61508 with certificate of FMEDA data ★

Transient protection

(36)(37)

T1 Transient terminal block ★

Drinking water approval

(38)

DW NSF drinking water approval ★

Surface finish certification

Q16 Surface finish certification for sanitary remote seals ★

Toolkit total system performance reports

QZ Remote seal system performance calculation report ★

Conduit electrical connector

(39)

GE M12, 4-pin, male connector (eurofast®) ★

GM A size mini, 4-pin, male connector (minifast®) ★

NACE® certificate

(40)

Q15 Certificate of compliance to NACE MR0175/ISO 15156 for wetted materials ★

Q25 Certificate of compliance to NACE MR0103 for wetted materials ★

14 Emerson.com/Rosemount

July 2019

Table 1: Rosemount 3051S Scalable™ Coplanar Pressure Transmitter Ordering Information (continued)

Cold temperature

(41)

BR5 -58 °F (-50 °C) cold temperature ★

BR6 -76 °F (-60 °C) cold temperature ★

Thread sealants

Z1 High temperature liquid thread sealant (-65 to 400 °F temperature rating) ★

Z2 Liquid thread sealant (-63 to 302 °F temperature rating) ★

Z3 Anaerobic PTFE paste ★

Typical model number: 3051S1CD 2A 2 E12 A 1A DA2 B4 M5

For details, see Specifications.

(1)

This option is only available with range codes 2A and 3A, 316L SST or Alloy C-276 isolating diaphragm and silicone fill fluid.

(2)

Performance Class code 3 is available with Measurement Type code D only.

(3)

3051S_CD0 is only available with SST traditional flange, 316L SST diaphragm material, and Bolting option L4.

(4)

Materials of Construction comply with metallurgical requirements highlighted within NACE MR0175/ISO 15156 for sour oil field production

(5)

environments. Environmental limits apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE

MR0103 for sour refining environments. Order with Q15 or Q25 to receive a NACE certificate.

Tantalum diaphragm material is only available for ranges 2A–5A, differential and gage.

(6)

“Assemble to” items are specified separately and require a completed model number. Process connection option codes B12, C11, D11, EA2, EA3,

(7)

and EA5 are only available on differential Measurement Type, code D.

Consult an Emerson representative for performance specifications.

(8)

Not available with Performance Class code 3.

(9)

Requires Plantweb housing.

(10)

Only intrinsically safe approval codes apply.

(11)

Only available with output code X.

(12)

Available with output code A only. Available approvals are FM Intrinsically Safe; Nonincendive (option code I5), CSA Intrinsically Safe (option code

(13)

I6), ATEX Intrinsic Safety (option code I1), or IECEx Intrinsic Safety (option code I7). Contact an Emerson representative for additional information.

Long-Life Power Module must be shipped separately, order Power Module 701PBKKF.

(14)

Option HR7 configures the HART output to HART Revision 7. This option requires the selection of the Advanced Diagnostics (DA2) option. The

(15)

device with this option can be field configured to HART Revision 5 or 7 if desired.

Requires Plantweb housing and output code A. Includes Hardware Adjustments as standard.

(16)

For process connection option code A11, the mounting bracket must be ordered as part of the manifold model number.

(17)

Not available with output code F.

(18)

Not available with output code X.

(19)

Not available with housing style codes 00, 2E, 2F, 2G, 2M, 5A, 5J, or 7J.

(20)

Not available with process connection option code A11.

(21)

Requires Plantweb housing and Hardware Adjustments option code D1. Limited availability depending on transmitter type and range. Contact an

(22)

Emerson representative for additional information.

This assembly is included with options EP, KP, E1, N1, K1, ND, E4, E7, N7, K7, E2, E3, KA, KC, KD, IA, IB, IE, IF, IG, KG, T1, K2, N3, EM, and KM.

(23)

Transmitter is shipped with 316 SST conduit plug (uninstalled) in place of standard carbon steel conduit plug.

(24)

Valid when SuperModule Platform and housing have equivalent approvals.

(25)

Not available with M20 or G½ conduit entry size.

(26)

Only available on differential and gage measurement types. Silicone fill fluid is standard.

(27)

Bolts are not considered process wetted. In instances where NACE MR0175/ISO 15156 and NACE MR0103 conformance is required for bolting, L7

(28)

is the recommended bolting option.

Not available with Housing code 7J.

(29)

Not available with output code F, option code DA2, or option code QT.

(30)

See the Rosemount 3051S Reference Manual for cable requirements. Contact an Emerson representative for additional information.

(31)

P1 is not available with 3051S_CA0.

(32)

When assembled to remote diaphragm seal system using B11 or B12process connections, the maximum working pressure of the system may be

(33)

limited by the rating of the Rosemount 1199 Seal System selected.

Requires 316L SST, Alloy C-276, or Gold-plated 316L SST diaphragm material, assemble to Rosemount 305 integral manifold or DIN-compliant

(34)

traditional flange process connection, and bolting option L8. Limited to Pressure Range (Differential), ranges 2A – 5A.

Not available with output code F or X. Not available with housing code 7J.

(35)

Not available with Housing code 00, 5A, 5J, or 7J.

(36)

The T1 option is not needed with FISCO Product Certifications; transient protection is included in the FISCO product certification codes IA, IB, IE, IF,

(37)

IG, and KG.

Emerson.com/Rosemount 15

Requires 316L SST diaphragm material, glass-filled PTFE O-ring (standard), and Process Connection code E12 or F12.

(38)

Not available with Housing code 00, 5A, 5J, or 7J. Available with Intrinsically Safe approvals only. For FM Intrinsically Safe; Nonincendive (option

(39)

code I5) or FM FISCO Intrinsically Safe (option code IE), install in accordance with Rosemount drawing 03151-1009. Suitable for use with all IS

approvals (I1, I2, I3, I5, I6, I7, IA, IB, IE, IF, IG, IP, IM, KG).

NACE compliant wetted materials are identified by footnote

(40)

Only available on pressure ranges 1-5, with silicone sensor fill fluid and SST or C-276 isolating diaphragms.

(41)

(5)

.

July 2019

16 Emerson.com/Rosemount

July 2019

Rosemount™ 3051S In-line Pressure Transmitter

Rosemount 3051S In-line Pressure Transmitters are the industry leader for Gage and Absolute

pressure measurement. The in-line, compact design allows the transmitter to be connected

directly to a process for quick, easy and cost effective installation. Capabilities include:

■

Ultra and Classic Performance

■

4–20 mA HART®, WirelessHART®, FOUNDATION™ Fieldbus protocols

■

Safety certification (Option code QT)

■

Advanced diagnostics (Option code DA2)

■

Remote display and Interface (Option code M7, M8, or M9)

Additional information: Specifications, Rosemount 3051S/3051SFx/3051S-ERS , Dimensional drawings

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment. See

Material selection for more information .

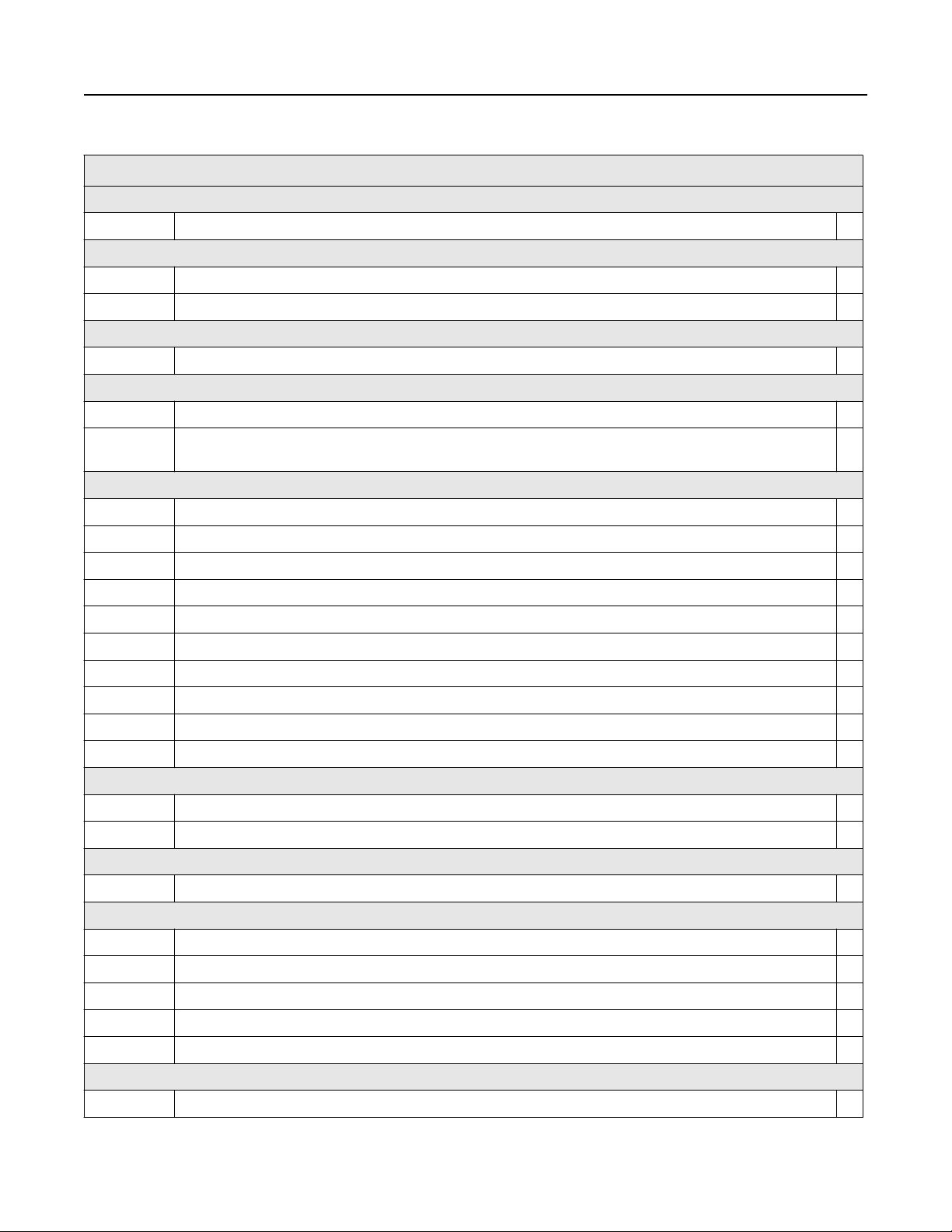

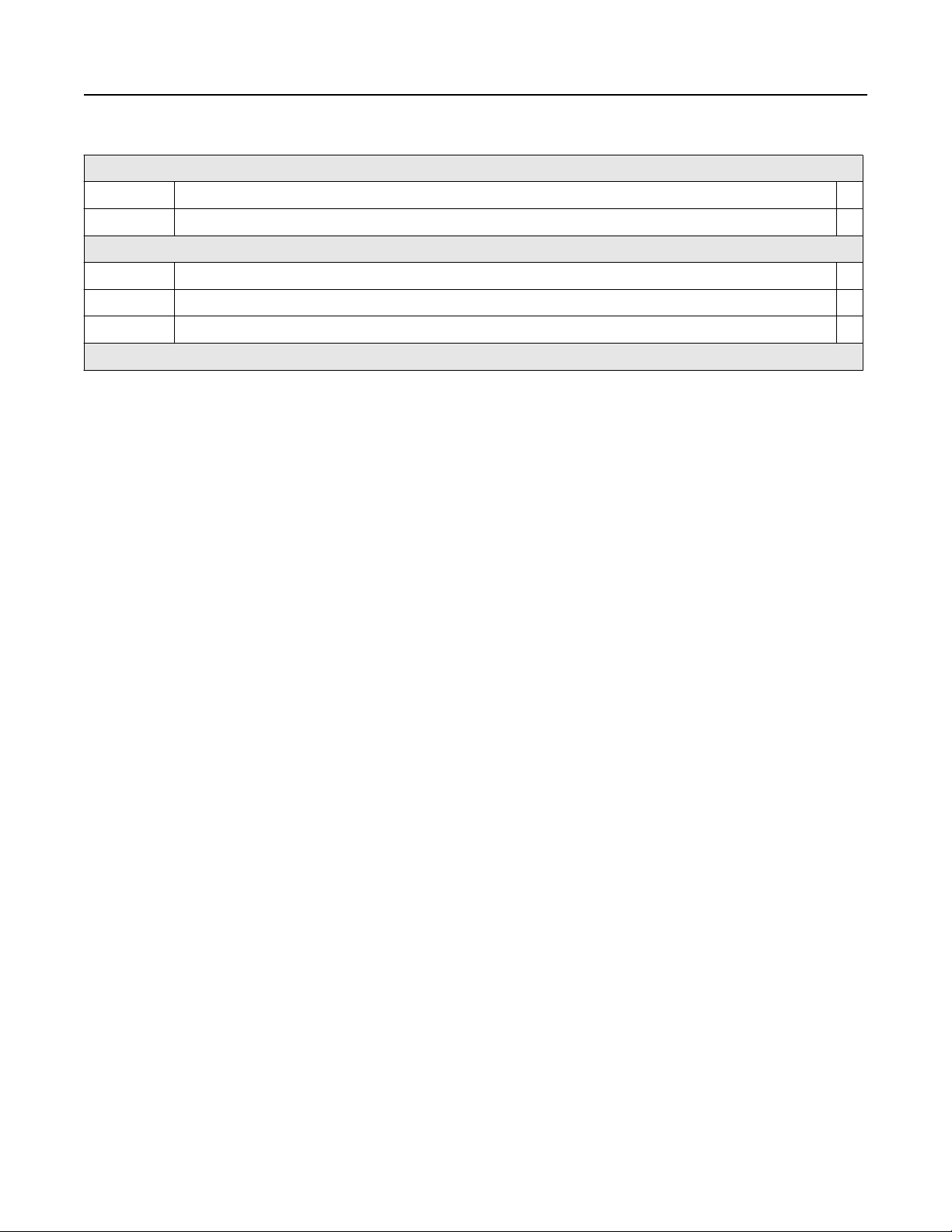

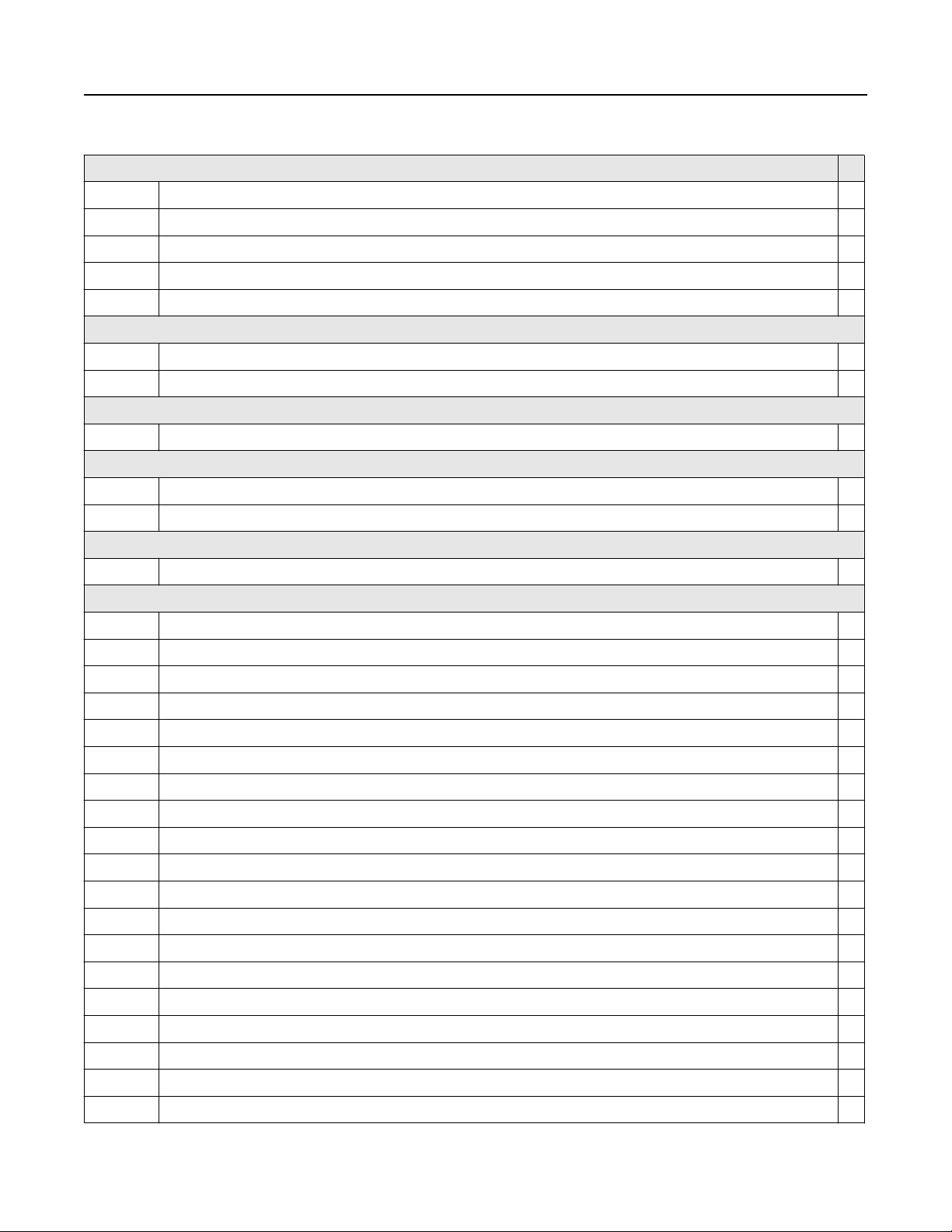

Table 2: Rosemount 3051S Scalable In-line Pressure Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Transmitter type

3051S Scalable pressure transmitter

Performance class

1 Ultra: 0.025% span accuracy, 200:1 rangedown, 15-yr stability, 15-yr limited warranty ★

2 Classic: 0.035% span accuracy, 150:1 rangedown, 15-yr stability ★

Connection type

T In-line ★

Measurement type

G Gage ★

A Absolute ★

Pressure range

Gage Absolute

1A –14.7 to 30 psi (–1,01 to 2,06 bar) 0 to 30 psia (2,06 bar) ★

2A –14.7 to 150 psi (–1,01 to 10,34 bar) 0 to 150 psia (10,34 bar) ★

3A –14.7 to 800 psi (–1,01 to 55,15 bar) 0 to 800 psia (55,15 bar) ★

4A –14.7 to 4000 psi (–1,01 to 275,79 bar) 0 to 4000 psia (275,79 bar) ★

5A –14.7 to 10000 psi (–1,01 to 689,47 bar) 0 to 10000 psia (689,47 bar) ★

Isolating diaphragm

(1)

(2)(3)

2 316L SST ★

3 Alloy C-276 ★

Emerson.com/Rosemount 17

July 2019

Table 2: Rosemount 3051S Scalable In-line Pressure Transmitter Ordering Information (continued)

Process connection

(4)

A11

B11

(4)(5)

Assemble to Rosemount 306 integral manifold ★

Assemble to one Rosemount 1199 seal ★

E11 ½–14 NPT female ★

G11 G½ A DIN 16288 male (range 1–4 only) ★

H11 Coned and threaded, compatible with autoclave type F-250-C (range 5A only)

F11 Non-threaded instrument flange (I-flange) (range 1–4 only)

Transmitter output

A 4–20 mA with digital signal based on HART protocol ★

(6)

F

(7)

X

FOUNDATION Fieldbus protocol ★

Wireless (requires wireless options and wireless Plantweb housing) ★

Housing style Material Conduit entry size

00 None (SuperModule spare part, order output code A) N/A N/A ★

1A Plantweb housing Aluminum ½–14 NPT ★

1B Plantweb housing Aluminum M20 x 1.5 ★

1J Plantweb housing SST ½–14 NPT ★

1K Plantweb housing SST M20 x 1.5 ★

(8)

5A

5J

(8)

Wireless Plantweb housing Aluminum ½–14 NPT ★

Wireless Plantweb housing SST ½–14 NPT ★

2A Junction box housing Aluminum ½–14 NPT ★

2B Junction box housing Aluminum M20 x 1.5 ★

2J Junction box housing SST ½–14 NPT ★

2E Junction box housing with output for remote display and

Aluminum ½–14 NPT ★

interface

2F Junction box housing with output for remote display and

Aluminum M20 x 1.5 ★

interface

2M Junction box housing with output for remote display and

SST ½–14 NPT ★

interface

(9)

7J

Quick Connect (A size mini, 4-pin male termination) SST N/A ★

1C Plantweb housing Aluminum G½

1L Plantweb housing SST G½

2C Junction box housing Aluminum G½

2G Junction box housing with output for remote display and

Aluminum G½

interface

Wireless options (requires option code X and wireless Plantweb housing)

Update rate

WA User configurable update rate ★

18 Emerson.com/Rosemount

July 2019

Table 2: Rosemount 3051S Scalable In-line Pressure Transmitter Ordering Information (continued)

Operating frequency and protocol

3 2.4 GHz DSSS, IEC 62591 (WirelessHART) ★

Omni-directional wireless antenna

WJ Remote antenna ★

WK External antenna ★

WM Extended range, external antenna ★

WN High-gain, remote antenna

SmartPower

(10)

1 Adapter for Black Power Module (I.S. Power Module sold separately) ★

Other options (include with selected model number)

HART revision configuration (requires HART Protocol output code A)

(11)

HR7 Configured for HART Revision 7 ★

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

Plantweb control functionality

A01 FOUNDATION Fieldbus advanced control function block suite ★

Diagnostics suite

D01 FOUNDATION Fieldbus diagnostics suite: Process Intelligence, Plugged Impulse Line diagnostic ★

(12)

DA2

Advanced HART diagnostics suite: Process Intelligence, Loop Integrity, Plugged Impulse Line diagnostic,

Process Alerts, Service Alerts, Variable Log, Event Log

Mounting bracket

B4 Bracket, all SST, 2-in. pipe and panel ★

BE 316SST B4-style bracket with 316SST bolting ★

Software configuration

(13)

C1 Custom software configuration (requires Configuration Data Sheet) ★

Alarm limit

(13)(14)

C4 NAMUR alarm and saturation levels, high alarm ★

C5 NAMUR alarm and saturation levels, low alarm ★

C6 Custom alarm and saturation signal levels, high alarm (requires C1 and Configuration Data Sheet) ★

C7 Custom alarm and saturation signal levels, low alarm (requires C1 and Configuration Data Sheet) ★

C8 Low alarm (standard Rosemount alarm and saturation levels) ★

Hardware adjustments

(13)(14)(15)

★

D1 Hardware adjustments (zero, span, alarm, security) ★

Custody transfer

(16)

D3 Measurement Canada accuracy approval ★

Emerson.com/Rosemount 19

July 2019

Table 2: Rosemount 3051S Scalable In-line Pressure Transmitter Ordering Information (continued)

Ground screw

(17)

D4 External ground screw assembly ★

Conduit plug

(18)

DO 316 SST conduit plug ★

Product certifications

(19)

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ★

IA ATEX FISCO Intrinsic Safety (FOUNDATION Fieldbus protocol only) ★

N1 ATEX Type n ★

K1 ATEX Flameproof, Intrinsic Safety, Type n, Dust ★

ND ATEX Dust ★

E4 TIIS Flameproof ★

(8)

I4

TIIS Intrinsic Safety ★

E5 FM Explosion-proof, Dust Ignition-proof ★

I5 FM Intrinsically Safe; Nonincendive ★

IE FM FISCO Intrinsically Safe (FOUNDATION Fieldbus protocol only) ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

(20)

E6

CSA Explosion-proof, Dust Ignition-proof, Division 2 ★

I6 CSA Intrinsically Safe ★

IF CSA FISCO Intrinsically Safe (FOUNDATION Fieldbus protocol only) ★

(20)

K6

CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

IG IECEx FISCO Intrinsic Safety (FOUNDATION Fieldbus protocol only) ★

N7 IECEx Type n ★

K7 IECEx Flameproof, Dust Ignition-proof, Intrinsic Safety, Type n ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

IB INMETRO FISCO Intrinsic Safety ★

K2 INMETRO Flameproof, Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

N3 China Type n ★

EP Korea Flameproof ★

IP Korea Intrinsic Safety ★

KP Korea Flameproof, Intrinsic Safety ★

20 Emerson.com/Rosemount

July 2019

Table 2: Rosemount 3051S Scalable In-line Pressure Transmitter Ordering Information (continued)

EM Technical Regulations Customs Union (EAC) Flameproof ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety ★

IN Technical Regulations Customs Union (EAC) FISCO Intrinsic Safety ★

KM Technical Regulations Customs Union (EAC) Flameproof, Intrinsic Safety ★

(20)

KA

KB

(20)

ATEX and CSA Flameproof, Intrinsically Safe, Division 2 ★

FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

KC FM and ATEX Explosion-proof, Intrinsically Safe, Division 2 ★

(20)

KD

FM, CSA, and ATEX Explosion-proof, Intrinsically Safe ★

KG FM, CSA, ATEX and IECEx FISCO Intrinsic Safety ★

KQ USA, Canada, ATEX Intrinsic Safety Combination ★

KS USA, Canada, IECEx, ATEX Explosion Proof, Intrinsically Safe, Dust, Non-Incendive, Type-N, Division 2 ★

Shipboard approvals

SBS American Bureau of Shipping ★

SBV Bureau Veritas (BV) Type Approval ★

SDN Det Norske Veritas (DNV) Type Approval ★

SLL Lloyds Register (LR) Type Approval ★

Stainless steel tagging

Y2 316SST nameplate, top tag, wire-on tag, and fasteners ★

Sensor fill fluid

(21)

L1 Inert sensor fill fluid ★

Display type

(22)

M5 Plantweb LCD display ★

(14)(23)(24)

M7

(14)(23)(24)

M8

(14)(23)(24)

M9

Remote mount LCD display and interface, Plantweb housing, no cable, SST bracket ★

Remote mount LCD display and interface, Plantweb housing, 50 feet (15 m) cable, SST bracket ★

Remote mount LCD display and interface, Plantweb housing, 100 feet (31 m) cable, SST bracket ★

Pressure testing

P1 Hydrostatic testing with certificate

Special cleaning

(25)

P2 Cleaning for special services

P3 Cleaning for special services with testing for <1PPM chlorine/fluorine

Calibration certification

Q4 Calibration certificate ★

QP Calibration certificate and tamper evident seal ★

Material traceability certification

Q8 Material traceability certification per EN 10204 3.1 ★

Emerson.com/Rosemount 21

July 2019

Table 2: Rosemount 3051S Scalable In-line Pressure Transmitter Ordering Information (continued)

Quality certification for safety

(26)

QS Prior-use certificate of FMEDA data ★

QT Safety-certified to IEC 61508 with certificate of FMEDA data ★

Transient protection

(27)(28)

T1 Transient terminal block ★

Drinking water approval

(29)

DW NSF drinking water approval ★

Surface finish certification

Q16 Surface finish certification for sanitary remote seals ★

Toolkit total system performance reports

QZ Remote seal system performance calculation report ★

Conduit electrical connector

(30)

GE M12, 4-pin, male connector (eurofast®) ★

GM A size mini, 4-pin, male connector (minifast®) ★

NACE certificate

(31)

Q15 Certificate of compliance to NACE MR0175/ISO 15156 for wetted materials ★

Q25 Certificate of compliance to NACE MR0103 for wetted materials ★

Cold temperature

(32)

BR5 -58 °F (-50 °C) cold temperature ★

BR6 -76 °F (-60 °C) cold temperature ★

Typical model number: 3051S1TG 2A 2 E11 A 1A DA2 B4 M5

For details, see Specifications.

(1)

Materials of Construction comply with metallurgical requirements highlighted within NACE MR0175/ISO 15156 for sour oil field production

(2)

environments. Environmental limits apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE

MR0103 for sour refining environments. Order with Q15 or Q25 to receive a NACE certificate.

Isolator diaphragm selection will dictate materials of construction for wetted parts.

(3)

“Assemble to” items are specified separately and require a completed model number.

(4)

Consult an Emerson representative for performance specifications.

(5)

Requires Plantweb housing.

(6)

Only intrinsically safe approval codes apply.

(7)

Only available with output code X.

(8)

Only available with output code A. Available approvals are FM Intrinsically Safe; Nonincendive (option code I5), CSA Intrinsically Safe (option code

(9)

I6), ATEX Intrinsic Safety (option code I1), or IECEx Intrinsic Safety (option code I7). Contact an Emerson representative for additional information.

Long-Life Power Module must be shipped separately, order Power Module 701PBKKF.

(10)

Option HR7 configures the HART output to HART Revision 7. This option requires the selection of the Advanced Diagnostics (DA2) option. The

(11)

device with this option can be field configured to HART Revision 5 or 7 if desired.

Requires Plantweb housing and output code A. Includes Hardware Adjustments as standard.

(12)

Not available with output code F.

(13)

Not available with output code X.

(14)

Not available with housing style codes 00, 01, 2E, 2F, 2G, 2M, 5A, 5J, or 7J.

(15)

Requires Plantweb housing and Hardware Adjustments option code D1. Limited availability depending on transmitter type and range. Contact an

(16)

Emerson representative for additional information.

This assembly is included with options EP, KP, E1, N1, K1, ND, E4, E7, N7, K7, E2, E3, KA, KC, KD, IA, IB, IE, IF, IG, KG, T1, K2, N3, EM, and KM.

(17)

Transmitter is shipped with 316 SST conduit plug (uninstalled) in place of standard carbon steel conduit plug.

(18)

Valid when SuperModule Platform and housing have equivalent approvals.

(19)

Not available with M20 or G½ conduit entry size.

(20)

22 Emerson.com/Rosemount

July 2019

Silicone fill fluid is standard.

(21)

Not available with Housing code 7J.

(22)

Not available with output code F, option code DA2, or option code QT.

(23)

See the Rosemount 3051S Reference Manual for cable requirements. Contact an Emerson representative for additional information.

(24)

Not available with process connection option code A11.

(25)

Not available with output code F or X. Not available with housing code 7J.

(26)

Not available with Housing code 00, 5A, 5J, or 7J.

(27)

The T1 option is not needed with FISCO Product Certifications; transient protection is included in the FISCO product certification codes IA, IB, IE, IF,

(28)

IG, and KG.

Requires 316L SST diaphragm material and Process Connection code E11 or G11.

(29)

Not available with Housing code 00, 5A, 5J, or 7J. Available with Intrinsically Safe approvals only. For FM Intrinsically Safe; Nonincendive (option

(30)

code I5) or FM FISCO Intrinsically Safe (option code IE), install in accordance with Rosemount drawing 03151-1009. Suitable for use with all IS

approvals (I1, I2, I3, I5, I6, I7, IA, IB, IE, IF, IG, IP, IM, KG).

NACE compliant wetted materials are identified by footnote

(31)

Only available on pressure ranges 1-5, with silicone sensor fill fluid and SST or C-276 isolating diaphragms.

(32)

(2)

.

Emerson.com/Rosemount 23

July 2019

Rosemount™ 3051S MultiVariable™ Transmitter

The Rosemount 3051S MultiVariable Transmitter delivers unprecedented performance and capabilities

by providing superior flow calculations including fully compensated mass or volume, energy, and

totalized flow. Specify the level of compensation that best matches the application:

■

Gas, natural gas, and steam measurement: Utilize full compensation (differential pressure, line

pressure, and temperature measurement)

■

Saturated steam: Utilize differential and line pressure, or differential pressure and temperature

measurement

■

Liquids: Utilize differential pressure and temperature measurement

■

Liquids at stable temperatures: Utilize differential pressure measurement

■

4–20 mA HART®, WirelessHART®, FOUNDATION™ Fieldbus protocols

Additional information: Specifications, Product certifications, Dimensional drawings

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment. See

Material selection for more information.

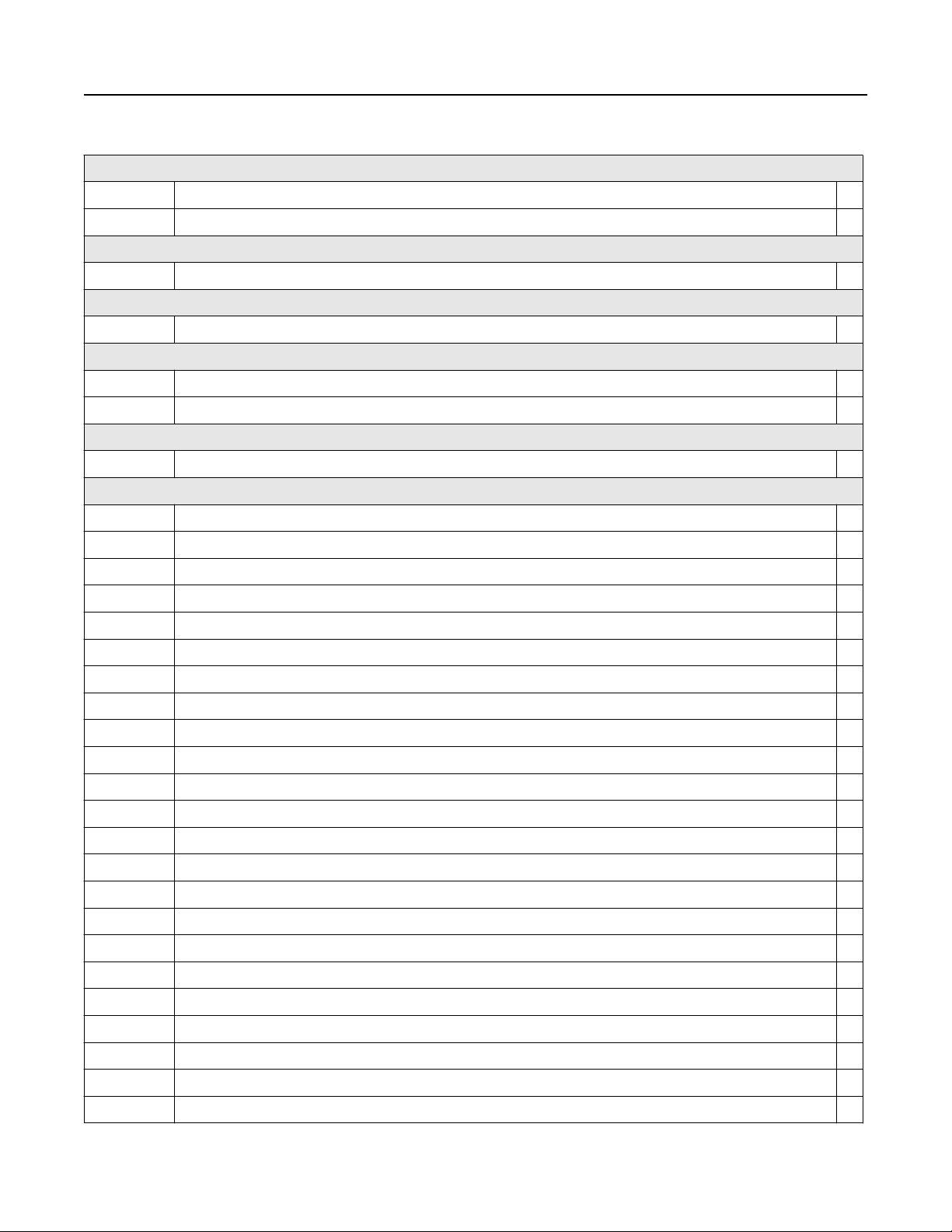

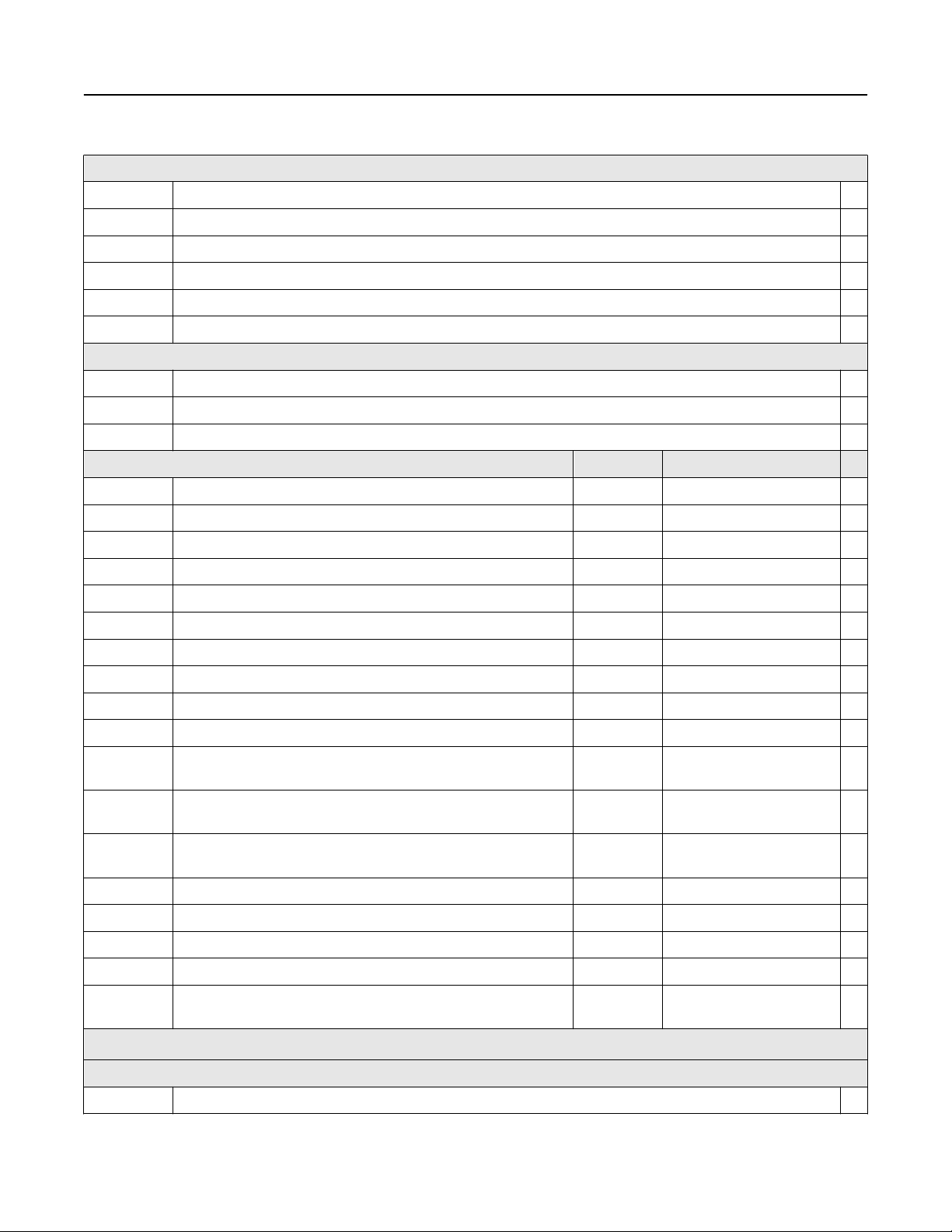

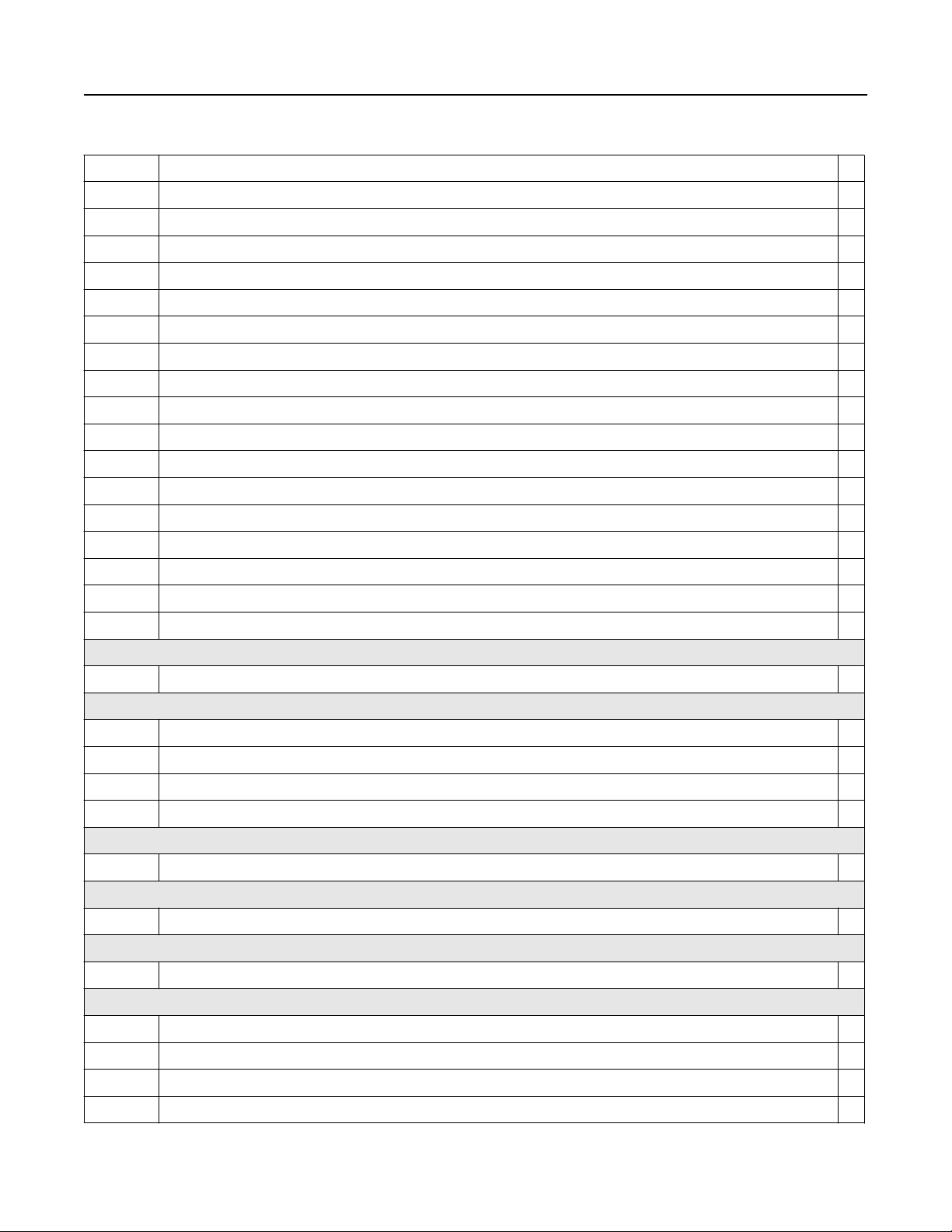

Table 3: Rosemount 3051S MultiVariable Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Transmitter type

3051SMV Scalable multivariable transmitter

Performance class

Measurement types 1 and 2

(2)

3

5 Classic MV: 0.04% span DP accuracy, 100:1 rangedown, 15-year stability ★

Measurement types 3 and 4

1 Ultra: 0.025% span DP accuracy, 200:1 rangedown, 15-year stability, 15-year limited warranty ★

2 Classic: 0.035% span DP accuracy, 150:1 rangedown, 15-year stability ★

(2)

3

Multivariable type

M Measurement with fully compensated mass and energy

P Measurement of process variables only (no flow calculations) ★

Measurement type

1 Differential pressure, static pressure, and temperature ★

2 Differential pressure and static pressure ★

3 Differential pressure and temperature ★

(1)

Ultra for Flow: 0.04% reading DP accuracy, 200:1 rangedown,15-year stability, 15-year limited warranty ★

Ultra for Flow: 0.04% reading DP accuracy, 200:1 rangedown,15-year stability, 15-year limited warranty ★

(3)

flow calculations ★

4 Differential pressure ★

24 Emerson.com/Rosemount

July 2019

Table 3: Rosemount 3051S MultiVariable Transmitter Ordering Information (continued)

Differential pressure range

(5)

0

–3 to 3 inH2O (–7,46 to 7,46 mbar) ★

(4)

1 –25 to 25 inH2O (–62,16 to 62,16 mbar) ★

2 –250 to 250 inH2O (–621,60 to 621,60 mbar) ★

3 –1000 to 1000 inH2O (–2,48 to 2,48 bar) ★

(6)

4

–150 to 150 psi (–10,34 to 10,34 bar) for measurement types 1 and 2;

–300 to 300 psi (–20,68 to 20,68 bar) for measurement types 3 and 4

(6)

5

–2000 to 2000 psi (–137,89 to 137,89 bar) ★

Static pressure type

(7)

N

None ★

A Absolute ★

G Gage ★

Static pressure range Absolute Gage

(7)

N

None N/A N/A ★

★

3 Range 3 0.5 to 800 psia (0,03 to 55,15 bar) –14.2 to 800 psig (–0,98 to 55,15 bar) ★

(8)

4

(9)(10)(11)

5

Range 4 0.5 to 3626 psia

(0,03 to 250,00 bar)

–14.2 to 3626 psig

(–0,98 to 250,00 bar)

Range 5 N/A –14.2 to 6092 PSI (420 bar) ★

Temperature input

(12)

N

(13)

R

None ★

RTD input (type Pt 100, –328 to 1562 °F [–200 to 850 °C]) ★

Isolating diaphragm

(14)

2

(14)

3

(15)

5

(14)

7

316L SST ★

Alloy C-276 ★

Tantalum

Gold-plated 316L SST

Process connection Size Material type

Flange

Drain vent Bolting

material

000 None (no process flange) N/A N/A N/A N/A ★

(16)

A11

Assemble to Rosemount

N/A N/A N/A N/A ★

305/306 integral manifold

(16)

A12

Assemble to Rosemount 304 or

N/A N/A N/A N/A ★

AMF manifold with SST

traditional flange

(16)

A15

Assemble to Rosemount 304 or

N/A N/A N/A N/A ★

AMF manifold to SST traditional

flange with Alloy C-276 drain

vents

★

Emerson.com/Rosemount 25

Table 3: Rosemount 3051S MultiVariable Transmitter Ordering Information (continued)

(16)

A16

Assemble to Rosemount 304 or

N/A N/A N/A N/A ★

AMF manifold to DIN SST

traditional flange

July 2019

A22 Assemble to Rosemount 304 or

N/A N/A N/A N/A ★

AMF manifold to SST coplanar

flange

(16)(17)

B11

Assemble to one Rosemount

N/A N/A N/A N/A ★

1199 seal

(16)(17)

B12

Assemble to two Rosemount

N/A N/A N/A N/A ★

1199 seals

(16)

C11

Assemble to Rosemount 405C or

N/A N/A N/A N/A ★

405P primary element

(16)

D11

Assemble to Rosemount 1195

N/A N/A N/A N/A ★

integral orifice and Rosemount

305 integral manifold

(16)

EA2

Assemble to Rosemount 485 or

N/A SST 316 SST N/A ★

405A Annubar primary element

with coplanar flange

(16)

EA3

Assemble to Rosemount 485 or

N/A Cast C-276 Alloy C-276 N/A ★

405A Annubar primary element

with coplanar flange

(16)

EA5

Assemble to Rosemount 485 or

N/A SST Alloy C-276 N/A ★

405A Annubar primary element

with coplanar flange

E11 Coplanar flange ¼–18 NPT Carbon steel 316 SST N/A ★

E12 Coplanar flange ¼–18 NPT SST 316 SST N/A ★

(14)

E13

Coplanar flange ¼–18 NPT Cast C-276 Alloy C-276 N/A ★

E14 Coplanar flange ¼–18 NPT Cast Alloy 400 Alloy 400/K-500 N/A ★

(14)

E15

E16

(14)

Coplanar flange ¼–18 NPT SST Alloy C-276 N/A ★

Coplanar flange ¼–18 NPT Carbon steel Alloy C-276 N/A ★

E21 Coplanar flange RC ¼ Carbon steel 316 SST N/A ★

E22 Coplanar flange RC ¼ SST 316 SST N/A ★

(14)

E23

Coplanar flange RC ¼ Cast C-276 Alloy C-276 N/A ★

E24 Coplanar flange RC ¼ Cast Alloy 400 Alloy 400/K-500 N/A ★

(14)

E25

E26

(14)

Coplanar flange RC ¼ SST Alloy C-276 N/A ★

Coplanar flange RC ¼ Carbon steel Alloy C-276 N/A ★

F12 Traditional flange ¼–18 NPT SST 316 SST N/A ★

(14)

F13

Traditional flange ¼–18 NPT Cast C-276 Alloy C-276 N/A ★

F14 Traditional flange ¼–18 NPT Cast Alloy 400 Alloy 400/K-500 N/A ★

(14)

F15

Traditional flange ¼–18 NPT SST Alloy C-276 N/A ★

F22 Traditional flange RC ¼ SST 316 SST N/A ★

(14)

F23

Traditional flange RC ¼ Cast C-276 Alloy C-276 N/A ★

26 Emerson.com/Rosemount

July 2019

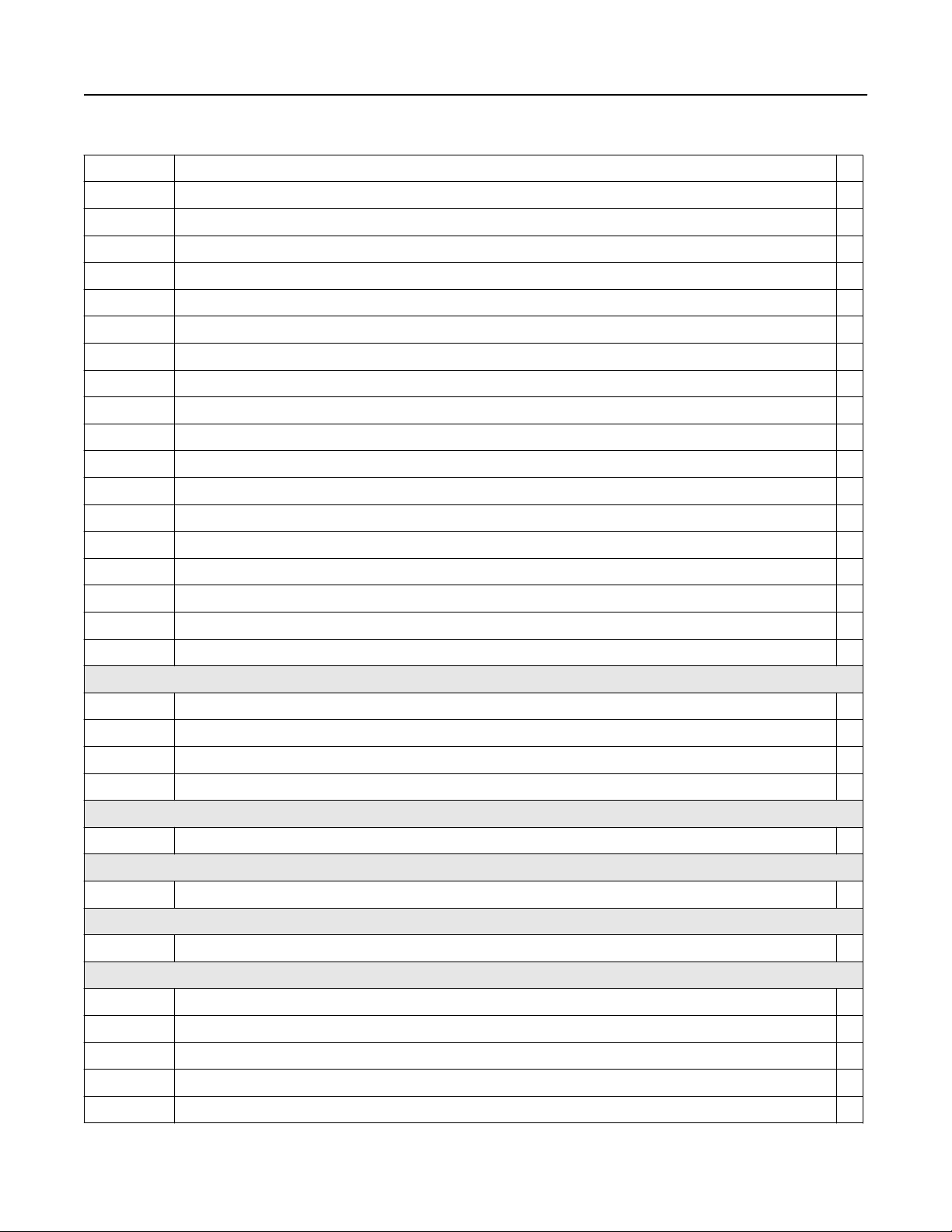

Table 3: Rosemount 3051S MultiVariable Transmitter Ordering Information (continued)

F24 Traditional flange RC ¼ Cast Alloy 400 Alloy 400/K-500 N/A ★

(14)

F25

Traditional flange RC ¼ SST Alloy C-276 N/A ★

F52 DIN-compliant traditional flange ¼–18 NPT SST 316 SST 7⁄16-in. bolting ★

G11 Vertical mount level flange 2-in. ANSI Class 150 SST N/A N/A ★

G12 Vertical mount level flange 2-in. ANSI Class 300 SST N/A N/A ★

(14)

G14

G15

(14)

Vertical mount level flange 2-in. ANSI Class 150 Cast C-276 N/A N/A ★

Vertical mount level flange 2-in. ANSI Class 300 Cast C-276 N/A N/A ★

G21 Vertical mount level flange 3-in. ANSI Class 150 SST N/A N/A ★

G22 Vertical mount level flange 3-in. ANSI Class 300 SST N/A N/A ★

G31 Vertical mount level flange DIN- DN 50 PN 40 SST N/A N/A ★

F32 Bottom vent traditional flange ¼–18 NPT SST 316 SST N/A

F42 Bottom vent traditional flange RC ¼ SST 316 SST N/A

F62 DIN-compliant traditional flange ¼–18 NPT SST 316 SST M10 bolting

F72 DIN-compliant traditional flange ¼–18 NPT SST 316 SST M12 bolting

G41 Vertical mount level flange DIN- DN 80 PN 40 SST N/A N/A

Transmitter output

A 4–20 mA with digital signal based on HART protocol ★

(18)

X

(19)(20)

F

Wireless (requires wireless options and wireless Plantweb housing) ★

FOUNDATION Fieldbus ★

Housing style Material Conduit entry size

1A Plantweb housing Aluminum ½–14 NPT ★

1B Plantweb housing Aluminum M20 x 1.5 ★

1J Plantweb housing SST ½–14 NPT ★

1K Plantweb housing SST M20 x 1.5 ★

(21)

5A

5J

(21)

Wireless Plantweb housing Aluminum ½–14 NPT ★

Wireless Plantweb housing SST ½–14 NPT ★

1C Plantweb housing Aluminum G½

1L Plantweb housing SST G½

Wireless options (requires option code X and wireless Plantweb housing)

Update rate

WA User configurable update rate ★

Operating frequency and protocol

3 2.4 GHz DSSS, IEC 62591 (WirelessHART) ★

Omni-directional wireless antenna

WK External antenna ★

WM Extended range, external antenna ★

Emerson.com/Rosemount 27

July 2019

Table 3: Rosemount 3051S MultiVariable Transmitter Ordering Information (continued)

WN High-gain, remote antenna ★

™

SmartPower

(22)

1 Adapter for Black Power Module (I.S. Power Module sold separately) ★

Other options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

RTD cable (RTD sensor must be ordered separately)

C12 RTD input with 12 feet (3,66 m) of shielded cable ★

C13 RTD input with 24 feet (7,32 m) of shielded cable ★

C14 RTD input with 75 feet (22,86 m) of shielded cable ★

C22 RTD input with 12 feet (3,66 m) of armored shielded cable ★

C23 RTD input with 24 feet (7,32 m) of armored shielded cable ★

C24 RTD input with 75 feet (22,86 m) of armored shielded cable ★

C32 RTD input with 12 feet (3,66 m) of ATEX/IECEx Flameproof cable ★

C33 RTD input with 24 feet (7,32 m) of ATEX/IECEx Flameproof cable ★

C34 RTD input with 75 feet (22,86 m) of ATEX/IECEx Flameproof cable ★

Plantweb control functionality

A01 FOUNDATION Fieldbus advanced control function block suite ★

Mounting brackets

(23)

B4 Coplanar flange bracket, all SST, 2-in. pipe and panel ★

B1 Traditional flange bracket, carbon steel, 2-in. pipe ★

B2 Traditional flange bracket, carbon steel, panel ★

B3 Traditional flange flat bracket, carbon steel, 2-in. pipe ★

B7 Traditional flange bracket, B1 with SST bolts ★

B8 Traditional flange bracket, B2 with SST bolts ★

B9 Traditional flange bracket, B3 with SST bolts ★

BA Traditional flange bracket, B1, all SST ★

BC Traditional flange bracket, B3, all SST ★

BE 316SST B4-style bracket with 316SST bolting ★

Software configuration

(24)

C1

Custom software configuration (Rosemount 3051SMV Configuration Data Sheet must be completed for HART

★

devices, Rosemount 3051SMV Wireless Configuration Data Sheet must be completed for WirelessHART

devices).

(25)

C2

Custom flow configuration (Rosemount 3051SMV Configuration Data Sheet for HART devices, and Rosemount

★

3051SMV Configuration Data Sheet for Fieldbus devices.)

28 Emerson.com/Rosemount

July 2019

Table 3: Rosemount 3051S MultiVariable Transmitter Ordering Information (continued)

Alarm limits

(24)(25)

C4 NAMUR alarm and saturation levels, high alarm ★

C5 NAMUR alarm and saturation levels, low alarm ★

C6 Custom alarm and saturation signal levels, high alarm ★

C7 Custom alarm and saturation signal levels, low alarm ★

C8 Low alarm (standard Rosemount alarm and saturation levels) ★

Flange adapter

(26)

D2 ½–14 NPT flange adapter ★

D9 RC ½ SST flange adapter

Ground screw

(27)

D4 External ground screw assembly ★

Drain/vent valve

(26)

D5 Delete transmitter drain/vent valves (install plugs) ★

D7 Coplanar flange without drain/vent ports

Conduit plug

(28)

DO 316 SST conduit plug ★

Product certifications

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ★

(29)

IA

ATEX FISCO Intrinsic Safety ★

N1 ATEX Type n ★

ND ATEX Dust ★

K1 ATEX Flameproof, Intrinsic Safety, Type n, Dust (combination of E1, I1, N1, and ND) ★

E4 TIIS Flameproof ★

E5 FM Explosion-proof, Dust Ignition-proof ★

I5 FM Intrinsically Safe; Nonincendive ★

(29)

IE

FM FISCO Intrinsic Safety ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 (combination of E5 and I5) ★

(30)

E6

CSA Explosion-proof, Dust Ignition-proof, Division 2 ★

I6 CSA Intrinsically Safe ★

(29)

IF

K6

(30)

CSA FISCO Intrinsic Safety ★

CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 (combination of E6 and I6) ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

(29)

IG

IECEx FISCO Intrinsic Safety ★

N7 IECEx Type n ★

Emerson.com/Rosemount 29

July 2019

Table 3: Rosemount 3051S MultiVariable Transmitter Ordering Information (continued)

K7 IECEx Flameproof, Dust Ignition-proof, Intrinsic Safety, and Type n (combination of E7, I7, and N7) ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

EM Technical Regulations Customs Union (EAC) Flameproof ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety ★

KM Technical Regulations Customs Union (EAC) Flameproof, Intrinsic Safety ★

(30)(31)

KA

KB

(30)(31)

ATEX and CSA Explosion-proof, Intrinsically Safe, Division 2 (combination of E1, E6, I1, and I6) ★

FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 (combination of E5, E6, I5, and I6) ★

KC FM and ATEX Explosion-proof, Intrinsically Safe, Division 2 (combination of E5, E1, I5, and I1) ★

(30)(31)

KD

KG

(29)

FM, CSA, and ATEX Explosion-proof, Intrinsically Safe (combination of E5, E6, E1, I5, I6, and I1) ★

ATEX, FM, CSA, and IECEx FISCO Intrinsic Safety (combination of IA, IE, IF, and IG) ★

K2 INMETRO Flameproof, Intrinsic Safety (Combination of E2 and I2) ★

EP Korea Flameproof ★

IP Korea Intrinsic Safety ★

KP Korea Flameproof, Intrinsic Safety ★

KS USA, Canada, IECEx, ATEX Explosion Proof, Intrinsically Safe, Dust, Non-Incendive, Type-N, Division 2 ★

Drinking water approval

(32)

DW NSF drinking water certification ★

Shipboard approvals

(24)

SBS American Bureau of Shipping ★

SBV Bureau Veritas (BV) Type Approval ★

SDN Det Norske Veritas (DNV) Type Approval ★

SLL Lloyds Register (LR) Type Approvals ★

Stainless steel tagging

Y2 316SST nameplate, top tag, wire-on tag, and fasteners ★

Sensor fill fluid

(33)(34)

L1 Inert sensor fill fluid (differential and gage sensors only) ★

O-rings

L2 Graphite-filled PTFE O-ring ★

Bolting material

(26)

L4

L5

L6

L7

(26)

(26)

(26)(35)

Austenitic 316 SST bolts ★

ASTM A193, Grade B7M bolts ★

Alloy K-500 bolts ★

ASTM A453, Class D, Grade 660 bolts ★

30 Emerson.com/Rosemount

Loading...

Loading...