Page 1

R&S®RTB2000

Digital Oscilloscope

User Manual

(=Q@;2)

1333.1611.02 ─ 03

User Manual

Page 2

This manual describes the following R&S®RTB2000 models:

●

R&S®RTB2002 (1333.1005K02)

●

R&S®RTB2004 (1333.1005K04)

© 2017 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of their owners.

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol, e.g. R&S®RTB is indicated as

R&S RTB2000.

Page 3

Basic Safety Instructions

Symbol

Meaning

Symbol

Meaning

Notice, general danger location

Observe product documentation

ON/OFF Power

Caution when handling heavy equipment

Standby indication

Danger of electric shock

Direct current (DC)

Always read through and comply with the following safety instructions!

All plants and locations of the Rohde & Schwarz group of companies make every effort to keep the safety

standards of our products up to date and to offer our customers the highest possible degree of safety. Our

products and the auxiliary equipment they require are designed, built and tested in accordance with the

safety standards that apply in each case. Compliance with these standards is continuously monitored by

our quality assurance system. The product described here has been designed, built and tested in

accordance with the EC Certificate of Conformity and has left the manufacturer’s plant in a condition fully

complying with safety standards. To maintain this condition and to ensure safe operation, you must

observe all instructions and warnings provided in this manual. If you have any questions regarding these

safety instructions, the Rohde & Schwarz group of companies will be happy to answer them.

Furthermore, it is your responsibility to use the product in an appropriate manner. This product is designed

for use solely in industrial and laboratory environments or, if expressly permitted, also in the field and must

not be used in any way that may cause personal injury or property damage. You are responsible if the

product is used for any purpose other than its designated purpose or in disregard of the manufacturer's

instructions. The manufacturer shall assume no responsibility for such use of the product.

The product is used for its designated purpose if it is used in accordance with its product documentation

and within its performance limits (see data sheet, documentation, the following safety instructions). Using

the product requires technical skills and, in some cases, a basic knowledge of English. It is therefore

essential that only skilled and specialized staff or thoroughly trained personnel with the required skills be

allowed to use the product. If personal safety gear is required for using Rohde & Schwarz products, this

will be indicated at the appropriate place in the product documentation. Keep the basic safety instructions

and the product documentation in a safe place and pass them on to the subsequent users.

Observing the safety instructions will help prevent personal injury or damage of any kind caused by

dangerous situations. Therefore, carefully read through and adhere to the following safety instructions

before and when using the product. It is also absolutely essential to observe the additional safety

instructions on personal safety, for example, that appear in relevant parts of the product documentation. In

these safety instructions, the word "product" refers to all merchandise sold and distributed by the Rohde &

Schwarz group of companies, including instruments, systems and all accessories. For product-specific

information, see the data sheet and the product documentation.

Safety labels on products

The following safety labels are used on products to warn against risks and dangers.

1171.0000.42 - 09 Page 1

Page 4

Basic Safety Instructions

Symbol

Meaning

Symbol

Meaning

Caution ! Hot surface

Alternating current (AC)

Protective conductor terminal

To identify any terminal which is intended for

connection to an external conductor for

protection against electric shock in case of a

fault, or the terminal of a protective earth

Direct/alternating current (DC/AC)

Earth (Ground)

Class II Equipment

to identify equipment meeting the safety

requirements specified for Class II equipment

(device protected by double or reinforced

insulation)

Frame or chassis Ground terminal

EU labeling for batteries and accumulators

For additional information, see section "Waste

disposal/Environmental protection", item 1.

Be careful when handling electrostatic sensitive

devices

EU labeling for separate collection of electrical

and electronic devices

For additional information, see section "Waste

disposal/Environmental protection", item 2.

Warning! Laser radiation

For additional information, see section

"Operation", item 7.

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Indicates information considered important, but not hazard-related, e.g.

messages relating to property damage.

In the product documentation, the word ATTENTION is used synonymously.

Signal words and their meaning

The following signal words are used in the product documentation in order to warn the reader about risks

and dangers.

These signal words are in accordance with the standard definition for civil applications in the European

Economic Area. Definitions that deviate from the standard definition may also exist in other economic

areas or military applications. It is therefore essential to make sure that the signal words described here

are always used only in connection with the related product documentation and the related product. The

use of signal words in connection with unrelated products or documentation can result in misinterpretation

and in personal injury or material damage.

1171.0000.42 - 09 Page 2

Page 5

Basic Safety Instructions

Operating states and operating positions

The product may be operated only under the operating conditions and in the positions specified by the

manufacturer, without the product's ventilation being obstructed. If the manufacturer's specifications are

not observed, this can result in electric shock, fire and/or serious personal injury or death. Applicable local

or national safety regulations and rules for the prevention of accidents must be observed in all work

performed.

1. Unless otherwise specified, the following requirements apply to Rohde & Schwarz products:

predefined operating position is always with the housing floor facing down, IP protection 2X, use only

indoors, max. operating altitude 2000 m above sea level, max. transport altitude 4500 m above sea

level. A tolerance of ±10 % shall apply to the nominal voltage and ±5 % to the nominal frequency,

overvoltage category 2, pollution degree 2.

2. Do not place the product on surfaces, vehicles, cabinets or tables that for reasons of weight or stability

are unsuitable for this purpose. Always follow the manufacturer's installation instructions when

installing the product and fastening it to objects or structures (e.g. walls and shelves). An installation

that is not carried out as described in the product documentation could result in personal injury or

even death.

3. Do not place the product on heat-generating devices such as radiators or fan heaters. The ambient

temperature must not exceed the maximum temperature specified in the product documentation or in

the data sheet. Product overheating can cause electric shock, fire and/or serious personal injury or

even death.

Electrical safety

If the information on electrical safety is not observed either at all or to the extent necessary, electric shock,

fire and/or serious personal injury or death may occur.

1. Prior to switching on the product, always ensure that the nominal voltage setting on the product

matches the nominal voltage of the mains-supply network. If a different voltage is to be set, the power

fuse of the product may have to be changed accordingly.

2. In the case of products of safety class I with movable power cord and connector, operation is

permitted only on sockets with a protective conductor contact and protective conductor.

3. Intentionally breaking the protective conductor either in the feed line or in the product itself is not

permitted. Doing so can result in the danger of an electric shock from the product. If extension cords

or connector strips are implemented, they must be checked on a regular basis to ensure that they are

safe to use.

4. If there is no power switch for disconnecting the product from the mains, or if the power switch is not

suitable for this purpose, use the plug of the connecting cable to disconnect the product from the

mains. In such cases, always ensure that the power plug is easily reachable and accessible at all

times. For example, if the power plug is the disconnecting device, the length of the connecting cable

must not exceed 3 m. Functional or electronic switches are not suitable for providing disconnection

from the AC supply network. If products without power switches are integrated into racks or systems,

the disconnecting device must be provided at the system level.

5. Never use the product if the power cable is damaged. Check the power cables on a regular basis to

ensure that they are in proper operating condition. By taking appropriate safety measures and

carefully laying the power cable, ensure that the cable cannot be damaged and that no one can be

hurt by, for example, tripping over the cable or suffering an electric shock.

1171.0000.42 - 09 Page 3

Page 6

Basic Safety Instructions

6. The product may be operated only from TN/TT supply networks fuse-protected with max. 16 A (higher

fuse only after consulting with the Rohde & Schwarz group of companies).

7. Do not insert the plug into sockets that are dusty or dirty. Insert the plug firmly and all the way into the

socket provided for this purpose. Otherwise, sparks that result in fire and/or injuries may occur.

8. Do not overload any sockets, extension cords or connector strips; doing so can cause fire or electric

shocks.

9. For measurements in circuits with voltages V

> 30 V, suitable measures (e.g. appropriate

rms

measuring equipment, fuse protection, current limiting, electrical separation, insulation) should be

taken to avoid any hazards.

10. Ensure that the connections with information technology equipment, e.g. PCs or other industrial

computers, comply with the IEC 60950-1 / EN 60950-1 or IEC 61010-1 / EN 61010-1 standards that

apply in each case.

11. Unless expressly permitted, never remove the cover or any part of the housing while the product is in

operation. Doing so will expose circuits and components and can lead to injuries, fire or damage to the

product.

12. If a product is to be permanently installed, the connection between the protective conductor terminal

on site and the product's protective conductor must be made first before any other connection is

made. The product may be installed and connected only by a licensed electrician.

13. For permanently installed equipment without built-in fuses, circuit breakers or similar protective

devices, the supply circuit must be fuse-protected in such a way that anyone who has access to the

product, as well as the product itself, is adequately protected from injury or damage.

14. Use suitable overvoltage protection to ensure that no overvoltage (such as that caused by a bolt of

lightning) can reach the product. Otherwise, the person operating the product will be exposed to the

danger of an electric shock.

15. Any object that is not designed to be placed in the openings of the housing must not be used for this

purpose. Doing so can cause short circuits inside the product and/or electric shocks, fire or injuries.

16. Unless specified otherwise, products are not liquid-proof (see also section "Operating states and

operating positions", item 1). Therefore, the equipment must be protected against penetration by

liquids. If the necessary precautions are not taken, the user may suffer electric shock or the product

itself may be damaged, which can also lead to personal injury.

17. Never use the product under conditions in which condensation has formed or can form in or on the

product, e.g. if the product has been moved from a cold to a warm environment. Penetration by water

increases the risk of electric shock.

18. Prior to cleaning the product, disconnect it completely from the power supply (e.g. AC supply network

or battery). Use a soft, non-linting cloth to clean the product. Never use chemical cleaning agents such

as alcohol, acetone or diluents for cellulose lacquers.

Operation

1. Operating the products requires special training and intense concentration. Make sure that persons

who use the products are physically, mentally and emotionally fit enough to do so; otherwise, injuries

or material damage may occur. It is the responsibility of the employer/operator to select suitable

personnel for operating the products.

1171.0000.42 - 09 Page 4

Page 7

Basic Safety Instructions

2. Before you move or transport the product, read and observe the section titled "Transport".

3. As with all industrially manufactured goods, the use of substances that induce an allergic reaction

(allergens) such as nickel cannot be generally excluded. If you develop an allergic reaction (such as a

skin rash, frequent sneezing, red eyes or respiratory difficulties) when using a Rohde & Schwarz

product, consult a physician immediately to determine the cause and to prevent health problems or

stress.

4. Before you start processing the product mechanically and/or thermally, or before you take it apart, be

sure to read and pay special attention to the section titled "Waste disposal/Environmental protection",

item 1.

5. Depending on the function, certain products such as RF radio equipment can produce an elevated

level of electromagnetic radiation. Considering that unborn babies require increased protection,

pregnant women must be protected by appropriate measures. Persons with pacemakers may also be

exposed to risks from electromagnetic radiation. The employer/operator must evaluate workplaces

where there is a special risk of exposure to radiation and, if necessary, take measures to avert the

potential danger.

6. Should a fire occur, the product may release hazardous substances (gases, fluids, etc.) that can

cause health problems. Therefore, suitable measures must be taken, e.g. protective masks and

protective clothing must be worn.

7. Laser products are given warning labels that are standardized according to their laser class. Lasers

can cause biological harm due to the properties of their radiation and due to their extremely

concentrated electromagnetic power. If a laser product (e.g. a CD/DVD drive) is integrated into a

Rohde & Schwarz product, absolutely no other settings or functions may be used as described in the

product documentation. The objective is to prevent personal injury (e.g. due to laser beams).

8. EMC classes (in line with EN 55011/CISPR 11, and analogously with EN 55022/CISPR 22,

EN 55032/CISPR 32)

Class A equipment:

Equipment suitable for use in all environments except residential environments and environments

that are directly connected to a low-voltage supply network that supplies residential buildings

Note: Class A equipment is intended for use in an industrial environment. This equipment may

cause radio disturbances in residential environments, due to possible conducted as well as

radiated disturbances. In this case, the operator may be required to take appropriate measures to

eliminate these disturbances.

Class B equipment:

Equipment suitable for use in residential environments and environments that are directly

connected to a low-voltage supply network that supplies residential buildings

Repair and service

1. The product may be opened only by authorized, specially trained personnel. Before any work is

performed on the product or before the product is opened, it must be disconnected from the AC supply

network. Otherwise, personnel will be exposed to the risk of an electric shock.

1171.0000.42 - 09 Page 5

Page 8

Basic Safety Instructions

2. Adjustments, replacement of parts, maintenance and repair may be performed only by electrical

experts authorized by Rohde & Schwarz. Only original parts may be used for replacing parts relevant

to safety (e.g. power switches, power transformers, fuses). A safety test must always be performed

after parts relevant to safety have been replaced (visual inspection, protective conductor test,

insulation resistance measurement, leakage current measurement, functional test). This helps ensure

the continued safety of the product.

Batteries and rechargeable batteries/cells

If the information regarding batteries and rechargeable batteries/cells is not observed either at all or to the

extent necessary, product users may be exposed to the risk of explosions, fire and/or serious personal

injury, and, in some cases, death. Batteries and rechargeable batteries with alkaline electrolytes (e.g.

lithium cells) must be handled in accordance with the EN 62133 standard.

1. Cells must not be taken apart or crushed.

2. Cells or batteries must not be exposed to heat or fire. Storage in direct sunlight must be avoided.

Keep cells and batteries clean and dry. Clean soiled connectors using a dry, clean cloth.

3. Cells or batteries must not be short-circuited. Cells or batteries must not be stored in a box or in a

drawer where they can short-circuit each other, or where they can be short-circuited by other

conductive materials. Cells and batteries must not be removed from their original packaging until they

are ready to be used.

4. Cells and batteries must not be exposed to any mechanical shocks that are stronger than permitted.

5. If a cell develops a leak, the fluid must not be allowed to come into contact with the skin or eyes. If

contact occurs, wash the affected area with plenty of water and seek medical aid.

6. Improperly replacing or charging cells or batteries that contain alkaline electrolytes (e.g. lithium cells)

can cause explosions. Replace cells or batteries only with the matching Rohde & Schwarz type (see

parts list) in order to ensure the safety of the product.

7. Cells and batteries must be recycled and kept separate from residual waste. Rechargeable batteries

and normal batteries that contain lead, mercury or cadmium are hazardous waste. Observe the

national regulations regarding waste disposal and recycling.

8. Follow the transport stipulations of the carrier (IATA-DGR, IMDG-Code, ADR, RID) when returning

lithium batteries to Rohde & Schwarz subsidiaries.

Transport

1. The product may be very heavy. Therefore, the product must be handled with care. In some cases,

the user may require a suitable means of lifting or moving the product (e.g. with a lift-truck) to avoid

back or other physical injuries.

2. Handles on the products are designed exclusively to enable personnel to transport the product. It is

therefore not permissible to use handles to fasten the product to or on transport equipment such as

cranes, fork lifts, wagons, etc. The user is responsible for securely fastening the products to or on the

means of transport or lifting. Observe the safety regulations of the manufacturer of the means of

transport or lifting. Noncompliance can result in personal injury or material damage.

1171.0000.42 - 09 Page 6

Page 9

Instrucciones de seguridad elementales

3. If you use the product in a vehicle, it is the sole responsibility of the driver to drive the vehicle safely

and properly. The manufacturer assumes no responsibility for accidents or collisions. Never use the

product in a moving vehicle if doing so could distract the driver of the vehicle. Adequately secure the

product in the vehicle to prevent injuries or other damage in the event of an accident.

Waste disposal/Environmental protection

1. Specially marked equipment has a battery or accumulator that must not be disposed of with unsorted

municipal waste, but must be collected separately. It may only be disposed of at a suitable collection

point or via a Rohde & Schwarz customer service center.

2. Waste electrical and electronic equipment must not be disposed of with unsorted municipal waste, but

must be collected separately.

Rohde & Schwarz GmbH & Co. KG has developed a disposal concept and takes full responsibility for

take-back obligations and disposal obligations for manufacturers within the EU. Contact your

Rohde & Schwarz customer service center for environmentally responsible disposal of the product.

3. If products or their components are mechanically and/or thermally processed in a manner that goes

beyond their intended use, hazardous substances (heavy-metal dust such as lead, beryllium, nickel)

may be released. For this reason, the product may only be disassembled by specially trained

personnel. Improper disassembly may be hazardous to your health. National waste disposal

regulations must be observed.

4. If handling the product releases hazardous substances or fuels that must be disposed of in a special

way, e.g. coolants or engine oils that must be replenished regularly, the safety instructions of the

manufacturer of the hazardous substances or fuels and the applicable regional waste disposal

regulations must be observed. Also observe the relevant safety instructions in the product

documentation. The improper disposal of hazardous substances or fuels can cause health problems

and lead to environmental damage.

For additional information about environmental protection, visit the Rohde & Schwarz website.

1171.0000.42 - 09 Page 7

Page 10

Customer Support

Technical support – where and when you need it

For quick, expert help with any Rohde & Schwarz equipment, contact one of our Customer Support

Centers. A team of highly qualified engineers provides telephone support and will work with you to find a

solution to your query on any aspect of the operation, programming or applications of Rohde & Schwarz

equipment.

Up-to-date information and upgrades

To keep your instrument up-to-date and to be informed about new application notes related to your

instrument, please send an e-mail to the Customer Support Center stating your instrument and your wish.

We will take care that you will get the right information.

Europe, Africa, Middle East

North America

Latin America

Asia/Pacific

China

Phone +49 89 4129 12345

customersupport@rohde-schwarz.com

Phone 1-888-TEST-RSA (1-888-837-8772)

customer.support@rsa.rohde-schwarz.com

Phone +1-410-910-7988

customersupport.la@rohde-schwarz.com

Phone +65 65 13 04 88

customersupport.asia@rohde-schwarz.com

Phone +86-800-810-8228 /

+86-400-650-5896

customersupport.china@rohde-schwarz.com

1171.0200.22-06.00

Page 11

R&S®RTB2000

1.1 For Your Safety........................................................................................................... 13

1.2 Documentation Overview........................................................................................... 14

1.2.1 Manuals and Instrument Help....................................................................................... 14

1.2.2 Data Sheet and Brochure..............................................................................................15

1.2.3 Calibration Certificate....................................................................................................15

1.2.4 Release Notes and Open Source Acknowledgment..................................................... 16

1.3 Conventions Used in the Documentation.................................................................16

1.3.1 Typographical Conventions...........................................................................................16

1.3.2 Conventions for Procedure Descriptions.......................................................................16

1.3.3 Notes on Screenshots...................................................................................................17

Contents

Contents

1 Preface.................................................................................................. 13

2 Getting Started..................................................................................... 18

2.1 Preparing for Use........................................................................................................ 18

2.1.1 Unpacking and Checking the Instrument...................................................................... 18

2.1.2 Positioning the Instrument.............................................................................................18

2.1.3 Starting the Instrument..................................................................................................19

2.1.4 Replacing the Fuses..................................................................................................... 21

2.2 Instrument Tour...........................................................................................................22

2.2.1 Front Panel....................................................................................................................22

2.2.2 Rear Panel.................................................................................................................... 24

3 Operating Basics..................................................................................26

3.1 Display Overview........................................................................................................ 26

3.2 Selecting the Application........................................................................................... 27

3.3 Using the Touchscreen.............................................................................................. 27

3.3.1 Accessing Functionality Using the Main Menu..............................................................27

3.3.2 Accessing Functionality Using Shortcuts...................................................................... 29

3.3.3 Entering Data................................................................................................................ 29

3.3.4 Using Gestures............................................................................................................. 30

3.4 Front Panel Keys.........................................................................................................31

3.4.1 Action Controls..............................................................................................................31

3.4.2 Analysis Controls.......................................................................................................... 32

3User Manual 1333.1611.02 ─ 03

Page 12

R&S®RTB2000

3.5 Using the Toolbar........................................................................................................33

3.6 Getting Help.................................................................................................................34

4.1 Connecting Probes and Displaying a Signal............................................................36

4.2 Vertical Setup.............................................................................................................. 37

4.2.1 VERTICAL Controls...................................................................................................... 38

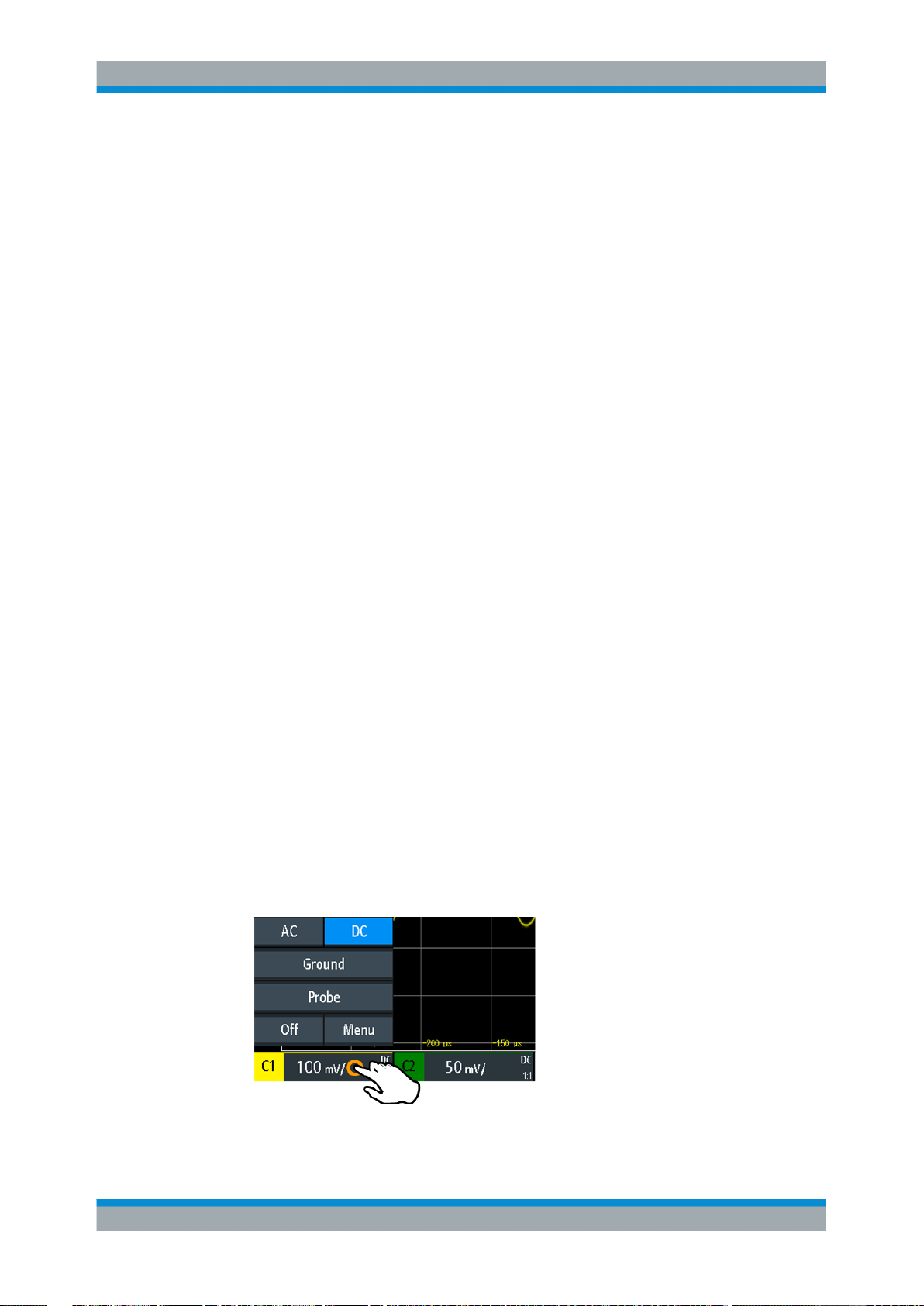

4.2.2 Short Menu for Analog Channels.................................................................................. 39

4.2.3 Vertical Settings............................................................................................................ 40

4.2.4 Probe Settings...............................................................................................................43

4.2.5 Threshold Settings........................................................................................................ 44

4.2.6 Label Settings............................................................................................................... 45

4.3 Horizontal Setup..........................................................................................................45

Contents

4 Waveform Setup...................................................................................36

4.3.1 HORIZONTAL Controls.................................................................................................46

4.3.2 Shortcuts for Horizontal Settings...................................................................................47

4.3.3 Horizontal Settings........................................................................................................ 48

4.4 Acquisition Setup........................................................................................................49

4.4.1 Shortcuts for Acquisition Settings................................................................................. 49

4.4.2 Acquisition Settings.......................................................................................................50

5 Trigger...................................................................................................53

5.1 Trigger Controls.......................................................................................................... 53

5.2 Shortcuts for Trigger Settings................................................................................... 55

5.3 General Trigger Settings............................................................................................ 56

5.4 Edge Trigger................................................................................................................ 58

5.5 Width Trigger...............................................................................................................59

5.6 Video Trigger............................................................................................................... 62

5.7 Pattern Trigger............................................................................................................ 64

5.8 Timeout Trigger...........................................................................................................66

6 Waveform Analysis..............................................................................69

6.1 Zoom............................................................................................................................ 69

6.1.1 Using the Zoom.............................................................................................................69

6.1.2 Zoom Settings............................................................................................................... 71

6.2 Mathematics................................................................................................................ 71

4User Manual 1333.1611.02 ─ 03

Page 13

R&S®RTB2000

6.2.1 Math Waveform Settings...............................................................................................72

6.3 Reference Waveforms................................................................................................ 74

6.3.1 Using References..........................................................................................................74

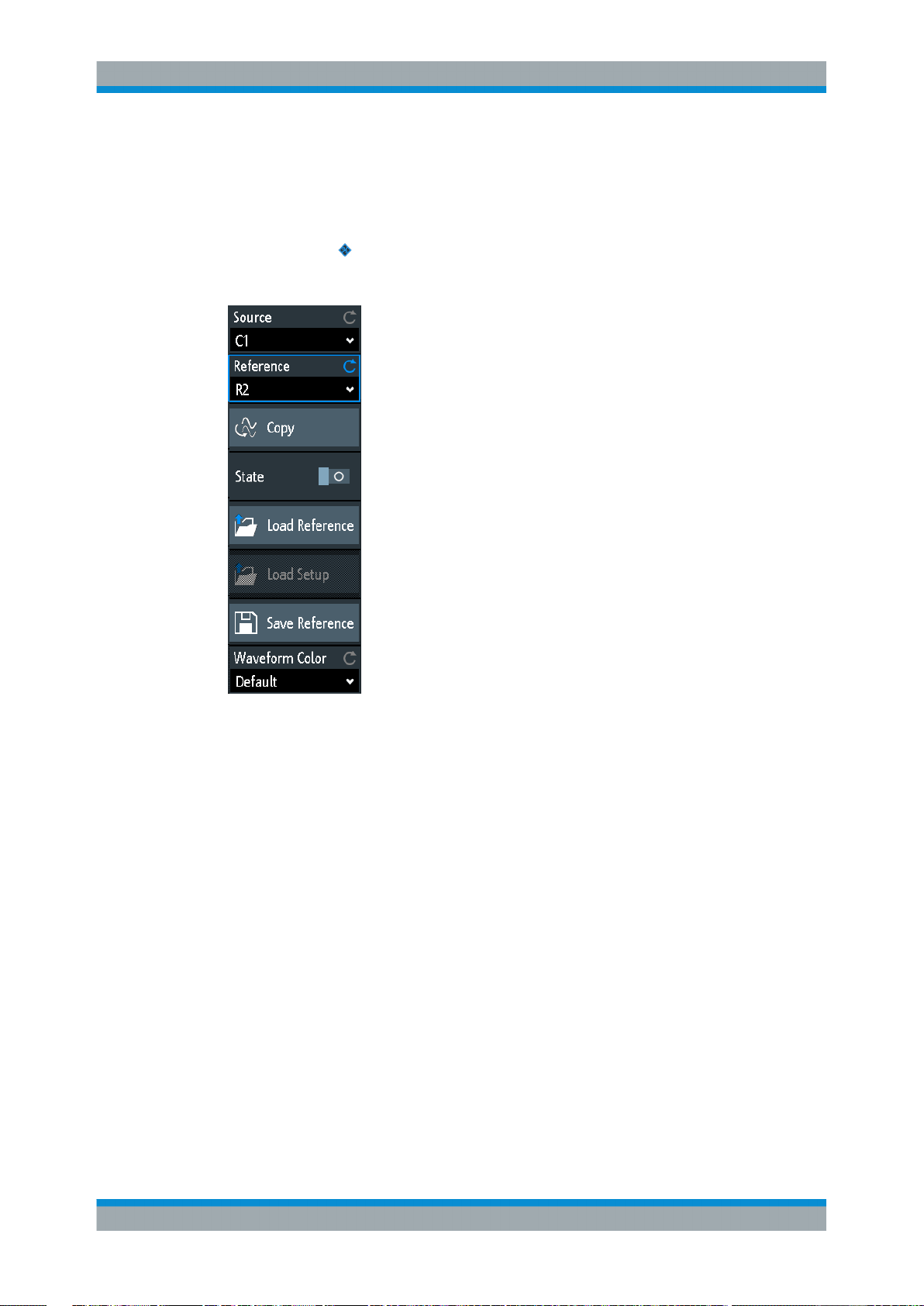

6.3.2 Settings for Reference Waveforms............................................................................... 76

6.4 History and Segmented Memory (Option R&S RTB-K15)....................................... 78

6.4.1 Segmented Memory......................................................................................................78

6.4.2 Segment Table..............................................................................................................79

6.4.3 Displaying History Segments........................................................................................ 80

6.4.4 Exporting History Data.................................................................................................. 81

6.5 Search.......................................................................................................................... 84

6.5.1 Search Conditions and Results.....................................................................................84

6.5.2 General Search Settings............................................................................................... 87

6.5.3 Edge Search................................................................................................................. 89

Contents

6.5.4 Width Search.................................................................................................................90

6.5.5 Peak Search..................................................................................................................91

6.5.6 Rise/Fall Time Search...................................................................................................91

6.5.7 Runt Setup.................................................................................................................... 93

6.5.8 Data2Clock....................................................................................................................94

6.5.9 Pattern Search.............................................................................................................. 96

7 Measurements......................................................................................99

7.1 Quick Measurements.................................................................................................. 99

7.2 Automatic Measurements........................................................................................ 100

7.2.1 Measurement Results................................................................................................. 100

7.2.2 Measurement Types................................................................................................... 101

7.2.3 Settings for Automatic Measurements........................................................................ 105

7.3 Cursor Measurements.............................................................................................. 107

7.3.1 Cursor Settings........................................................................................................... 109

8 Applications........................................................................................112

8.1 Mask Testing............................................................................................................. 112

8.1.1 About Masks and Mask Testing.................................................................................. 112

8.1.2 Using Masks................................................................................................................113

8.1.3 Mask Window..............................................................................................................115

8.1.4 Mask Menu..................................................................................................................116

5User Manual 1333.1611.02 ─ 03

Page 14

R&S®RTB2000

8.2 FFT Analysis..............................................................................................................118

8.2.1 FFT Display.................................................................................................................119

8.2.2 Performing FFT Analysis.............................................................................................120

8.2.3 FFT Setup................................................................................................................... 120

8.3 XY-Diagram................................................................................................................124

8.4 Digital Voltmeter........................................................................................................126

8.4.1 Using the Meter...........................................................................................................126

8.4.2 Meter Settings............................................................................................................. 127

8.5 Trigger Counter......................................................................................................... 128

9.1 Saving and Loading Instrument Settings............................................................... 131

9.2 Exporting Waveforms............................................................................................... 132

Contents

9 Documenting Results........................................................................ 130

9.2.1 Waveform Export Settings.......................................................................................... 133

9.2.2 Waveform File Formats...............................................................................................134

9.3 Annotations............................................................................................................... 136

9.4 Screenshots...............................................................................................................137

9.5 Quick Save with OneTouch......................................................................................139

9.6 Export and Import..................................................................................................... 140

10 General Instrument Setup................................................................. 142

10.1 Instrument Settings.................................................................................................. 142

10.2 Display Settings........................................................................................................ 145

10.3 Resetting the Instrument..........................................................................................148

10.4 Locking the Touchscreen.........................................................................................148

10.5 Performing a Self-Alignment....................................................................................148

10.6 Setting the Data, Time and Language..................................................................... 149

10.7 Adjusting Passive Probes........................................................................................ 150

10.8 Options.......................................................................................................................151

10.8.1 Activating Options....................................................................................................... 152

10.9 Updating the Firmware............................................................................................. 152

11 Network Connections and Remote Operation.................................154

11.1 LAN Connection........................................................................................................ 154

11.2 USB Connection........................................................................................................156

6User Manual 1333.1611.02 ─ 03

Page 15

R&S®RTB2000

11.3 Remote Access Using a Web Browser................................................................... 158

11.3.1 Accessing the Instrument Using a Web Browser........................................................ 158

11.3.2 Instrument Home.........................................................................................................158

11.3.3 Screenshot.................................................................................................................. 159

11.3.4 SCPI Device Control................................................................................................... 160

11.3.5 Save/Recall................................................................................................................. 161

11.3.6 Network Settings......................................................................................................... 162

11.3.7 Change Password.......................................................................................................163

11.3.8 Livescreen...................................................................................................................163

11.3.9 Remote Front Panel.................................................................................................... 163

12 Serial Bus Analysis............................................................................164

12.1 Basics of Protocol Analysis.....................................................................................164

Contents

12.1.1 Protocol - Common Settings....................................................................................... 165

12.1.2 Display Settings.......................................................................................................... 167

12.1.3 Bus Table: Decode Results.........................................................................................167

12.1.4 Bus Labels.................................................................................................................. 168

12.1.5 Label List.....................................................................................................................169

12.2 SPI/SSPI Bus (Option R&S RTB-K1)........................................................................172

12.2.1 The SPI Protocol......................................................................................................... 172

12.2.2 SPI/SSPI Configuration...............................................................................................173

12.2.3 SPI/SSPI Trigger.........................................................................................................176

12.2.4 SPI/SSPI Decode Results ..........................................................................................178

12.3 I²C (Option R&S RTB-K1)..........................................................................................179

12.3.1 The I²C Protocol.......................................................................................................... 180

12.3.2

12.3.3

12.3.4

I2C Configuration.........................................................................................................182

I2C Trigger...................................................................................................................183

I2C Decode Results ....................................................................................................186

12.3.5

12.4 UART / RS232 (Option R&S RTB-K2)...................................................................... 188

12.4.1 The UART / RS232 Interface...................................................................................... 189

12.4.2 UART Configuration.................................................................................................... 189

12.4.3 UART Trigger.............................................................................................................. 191

12.4.4 UART Decode Results ............................................................................................... 194

I2C Label List...............................................................................................................187

7User Manual 1333.1611.02 ─ 03

Page 16

R&S®RTB2000

12.5 CAN (Option R&S RTB-K3).......................................................................................195

12.5.1 CAN Configuration...................................................................................................... 195

12.5.2 CAN Trigger................................................................................................................ 197

12.5.3 CAN Decode Results.................................................................................................. 201

12.5.4 Search on Decoded CAN Data................................................................................... 203

12.5.5 CAN Label List............................................................................................................ 205

12.6 LIN (Option R&S RTB-K3).........................................................................................207

12.6.1 The LIN Protocol......................................................................................................... 207

12.6.2 LIN Configuration........................................................................................................ 209

12.6.3 LIN Trigger.................................................................................................................. 210

12.6.4 LIN Decode Results ................................................................................................... 214

12.6.5 Search on Decoded LIN Data..................................................................................... 215

12.6.6 LIN Label List.............................................................................................................. 217

Contents

13 Logic Analyzer (Option R&S RTB-B1, MSO)....................................220

13.1 Short Menu for Logic Channels...............................................................................220

13.2 Logic Analyzer Settings........................................................................................... 221

13.3 Triggering on Logic Channels................................................................................. 223

13.4 Analyzing Logic Channels....................................................................................... 223

13.5 Parallel Buses............................................................................................................224

13.5.1 Parallel Bus Configuration...........................................................................................224

13.5.2 Decode Results...........................................................................................................226

14 Signal Generation (Option R&S RTB-B6).........................................228

14.1 Function Generator...................................................................................................228

14.1.1 Basic Function Generator Settings............................................................................. 229

14.1.2 Sweep Settings........................................................................................................... 231

14.1.3 Modulation Settings.....................................................................................................232

14.1.4 Arbitrary Setup Settings.............................................................................................. 233

14.2 Pattern Generator......................................................................................................234

14.2.1 Pattern Selection.........................................................................................................234

14.2.2 Settings for Square Wave Pattern...............................................................................235

14.2.3 Settings for Counter Pattern........................................................................................236

14.2.4 Settings for Arbitrary Pattern.......................................................................................236

14.2.5 Settings for Manual Pattern.........................................................................................239

8User Manual 1333.1611.02 ─ 03

Page 17

R&S®RTB2000

14.2.6 Settings for Serial Buses.............................................................................................239

15 Remote Control Commands..............................................................240

15.1 Conventions used in Command Description......................................................... 240

15.2 Programming Examples........................................................................................... 241

15.2.1 Documenting Results.................................................................................................. 241

15.2.2 Firmware Update.........................................................................................................245

15.2.3 Search.........................................................................................................................246

15.2.4 Function Generator..................................................................................................... 247

15.3 Common Commands................................................................................................ 247

15.4 Waveform Setup........................................................................................................250

15.4.1 Automatic Setup..........................................................................................................250

15.4.2 Starting and Stopping Acquisition............................................................................... 250

Contents

15.4.3 Vertical Settings.......................................................................................................... 252

15.4.4 Probes.........................................................................................................................258

15.4.5 Horizontal Settings...................................................................................................... 258

15.4.6 Acquisition Settings.....................................................................................................260

15.4.7 Waveform Data........................................................................................................... 265

15.5 Trigger........................................................................................................................266

15.5.1 General Trigger Settings............................................................................................. 266

15.5.2 Edge Trigger............................................................................................................... 268

15.5.3 Width Trigger...............................................................................................................269

15.5.4 Video/TV Trigger......................................................................................................... 271

15.5.5 Pattern Trigger............................................................................................................ 272

15.5.6 Timeout Trigger...........................................................................................................275

15.6 Waveform Analysis................................................................................................... 276

15.6.1 Zoom........................................................................................................................... 276

15.6.2 Mathematics................................................................................................................277

15.6.3 Reference Waveforms................................................................................................ 278

15.6.4 Search.........................................................................................................................281

15.6.5 History (Option R&S RTB2000-K15)...........................................................................296

15.7 Measurements........................................................................................................... 306

15.7.1 Quick Measurements.................................................................................................. 306

15.7.2 Automatic Measurements........................................................................................... 307

9User Manual 1333.1611.02 ─ 03

Page 18

R&S®RTB2000

15.7.3 Cursor Measurements.................................................................................................317

15.8 Applications...............................................................................................................323

15.8.1 Mask Testing...............................................................................................................323

15.8.2 FFT Analysis............................................................................................................... 327

15.8.3 XY-Waveforms............................................................................................................ 334

15.8.4 Digital Voltmeter..........................................................................................................335

15.8.5 Trigger Counter........................................................................................................... 337

15.9 Documenting Results............................................................................................... 338

15.9.1 Transfer of Waveform Data.........................................................................................338

15.9.2 Waveform Data Export to File..................................................................................... 349

15.9.3 Screenshots................................................................................................................ 350

15.9.4 Instrument Settings: Mass MEMomory Subsystem.................................................... 352

15.10 General Instrument Setup........................................................................................ 359

Contents

15.10.1 Display Settings.......................................................................................................... 359

15.10.2 System Settings.......................................................................................................... 363

15.10.3 LAN Settings............................................................................................................... 367

15.10.4 USB Settings...............................................................................................................369

15.10.5 Trigger Out.................................................................................................................. 369

15.11 Serial Bus Analysis...................................................................................................370

15.11.1 General....................................................................................................................... 371

15.11.2 SPI and SSPI (Option R&S RTB-K1).......................................................................... 373

15.11.3 I²C............................................................................................................................... 384

15.11.4 UART (Option R&S RTB-K2)...................................................................................... 395

15.11.5 CAN.............................................................................................................................402

15.11.6 LIN (Option R&S RTB-K3).......................................................................................... 418

15.12 Mixed Signal Option (Option R&S RTB-B1)............................................................431

15.12.1 Logic Channels........................................................................................................... 431

15.12.2 Parallel Buses............................................................................................................. 437

15.13 Signal Generation (Option R&S RTB-B6)................................................................442

15.13.1 Function Generator..................................................................................................... 442

15.13.2 Pattern Generator....................................................................................................... 448

15.14 Status Reporting....................................................................................................... 454

15.14.1 STATus:OPERation Register......................................................................................454

10User Manual 1333.1611.02 ─ 03

Page 19

R&S®RTB2000

15.14.2 STATus:QUEStionable Registers............................................................................... 456

16 Maintenance....................................................................................... 460

16.1 Cleaning..................................................................................................................... 460

16.2 Storing and Packing................................................................................................. 461

16.3 Replacing the Fuses................................................................................................. 461

16.4 Data Security............................................................................................................. 462

A SCPI Command Structure................................................................. 463

A.1 Syntax for Common Commands............................................................................. 463

A.2 Syntax for Device-Specific Commands.................................................................. 464

A.2.1 Long and short form.................................................................................................... 464

A.2.2 Numeric Suffixes......................................................................................................... 465

Contents

Annex.................................................................................................. 463

A.2.3 Optional Mnemonics................................................................................................... 465

A.3 SCPI Parameters....................................................................................................... 466

A.3.1 Numeric Values...........................................................................................................466

A.3.2 Special Numeric Values.............................................................................................. 467

A.3.3 Boolean Parameters................................................................................................... 467

A.3.4 Text Parameters..........................................................................................................467

A.3.5 Character Strings........................................................................................................ 468

A.3.6 Block Data...................................................................................................................468

A.4 Overview of Syntax Elements.................................................................................. 468

A.5 Structure of a Command Line..................................................................................469

A.6 Responses to Queries.............................................................................................. 470

B Command Sequence and Synchronization..................................... 472

B.1 Preventing Overlapping Execution......................................................................... 472

C Status Reporting System.................................................................. 474

C.1 Structure of a SCPI Status Register........................................................................ 474

C.2 Hierarchy of status registers................................................................................... 475

C.3 Contents of the Status Registers............................................................................ 477

C.3.1 Status Byte (STB) and Service Request Enable Register (SRE)................................477

C.3.2 Event Status Register (ESR) and Event Status Enable Register (ESE)..................... 478

C.3.3 STATus:OPERation Register......................................................................................479

11User Manual 1333.1611.02 ─ 03

Page 20

R&S®RTB2000

C.3.4 STATus:QUEStionable Register................................................................................. 479

C.4 Application of the Status Reporting System.......................................................... 482

C.4.1 Service Request..........................................................................................................482

C.4.2 Serial Poll.................................................................................................................... 483

C.4.3 Query of an instrument status..................................................................................... 483

C.4.4 Error Queue................................................................................................................ 484

C.5 Reset Values of the Status Reporting System....................................................... 484

Contents

List of Commands..............................................................................486

12User Manual 1333.1611.02 ─ 03

Page 21

R&S®RTB2000

1 Preface

Preface

For Your Safety

1.1 For Your Safety

The R&S RTB2000 digital oscilloscope is designed for measurements on circuits that

are only indirectly connected to the mains or not connected at all. It is not rated for any

measurement category.

The instrument is intended for use in industrial areas. When used in residential areas,

radio disturbances caused by the instrument can exceed given limits. Additional shielding can be required.

The instrument must be controlled by personnel familiar with the potential risks of measuring electrical quantities. Applicable local or national safety regulations and rules for

the prevention of accidents must be observed.

Safety information is part of the product documentation. It warns you about the potential dangers and gives instructions how to prevent personal injury or damage caused

by dangerous situations. Safety information is provided as follows:

●

The "Basic Safety Instructions" in different languages are delivered as a printed

brochure with the instrument.

●

Throughout the documentation, safety instructions are provided when you need to

take care during setup or operation.

Risk of injury

The instrument must be used in an appropriate manner to prevent electric shock, personal injury, fire, or damage:

●

Do not open the instrument casing.

●

Do not use the instrument if the instrument casing, the display or any accessory

are damaged. If you detect or suspect any damage, have the instrument or accessory inspected by qualified service personnel.

●

Do not operate the instrument in wet, damp or explosive atmospheres. Make sure

that the instrument, cables and connectors are completely dry before connecting

the inputs.

●

Do not exceed the voltage limits given in Chapter 2.2.1.1, "Input Connectors",

on page 23.

13User Manual 1333.1611.02 ─ 03

Page 22

R&S®RTB2000

Preface

Documentation Overview

Risk of instrument damage

An unsuitable operating site or test setup can damage the instrument and connected

devices. Ensure the following operating conditions before you switch on the instrument:

●

Read and observe the "Basic Safety Instructions" brochure and the safety instructions in the manuals.

●

Observe the operating conditions specified in the data sheet. Note that the general

safety instructions also contain information on operating conditions.

●

Position the instrument as described in the following sections.

Make sure that all fan openings are unobstructed and the airflow perforations are

unimpeded. The minimum distance from the wall is 10 cm.

●

Signal levels at the input connectors are all within the specified ranges.

●

Signal outputs are correctly connected and are not overloaded.

Instrument damage caused by electrostatic discharge

Electrostatic discharge (ESD) can damage the electronic components of the instrument

and the device under test (DUT). Electrostatic discharge is most likely to occur when

you connect or disconnect a DUT or test fixture to the instrument's test ports. To prevent electrostatic discharge, use a wrist strap and cord and connect yourself to the

ground, or use a conductive floor mat and heel strap combination.

Electromagnetic interference (EMI) may affect the measurement results.

To suppress generated electromagnetic interference (EMI):

●

Use suitable shielded cables of high quality. For example, use double-shielded RF

and LAN cables.

●

Always terminate open cable ends.

●

Note the EMC classification in the data sheet.

1.2 Documentation Overview

This section provides an overview of the R&S RTB2000 user documentation.

1.2.1 Manuals and Instrument Help

You find the manuals on the product page at:

www.rohde-schwarz.com/manual/rtb2000

14User Manual 1333.1611.02 ─ 03

Page 23

R&S®RTB2000

Preface

Documentation Overview

Getting started manual

Introduces the R&S RTB2000 and describes how to set up the product. A printed English version is included in the delivery.

User manual

Contains the description of all instrument modes and functions. It also provides an

introduction to remote control, a complete description of the remote control commands

with programming examples, and information on maintenance and instrument interfaces. Includes the contents of the getting started manual.

The online version of the user manual provides the complete contents for immediate

display on the internet.

Instrument help

The help offers quick, context-sensitive access to the functional description directly on

the instrument.

Basic safety instructions

Contains safety instructions, operating conditions and further important information.

The printed document is delivered with the instrument.

Instrument security procedures manual

Deals with security issues when working with the R&S RTB2000 in secure areas.

Service manual

Describes the performance test for checking the rated specifications, module replacement and repair, firmware update, troubleshooting and fault elimination, and contains

mechanical drawings and spare part lists. The service manual is available for registered users on the global Rohde & Schwarz information system (GLORIS, https://

gloris.rohde-schwarz.com).

1.2.2 Data Sheet and Brochure

The data sheet contains the technical specifications of the R&S RTB2000. It also lists

the options with their order numbers and optional accessories. The brochure provides

an overview of the instrument and deals with the specific characteristics.

See www.rohde-schwarz.com/brochure-datasheet/rtb2000

1.2.3 Calibration Certificate

The document is available on https://gloris.rohde-schwarz.com/calcert. You need the

device ID of your instrument, which you can find on a label on the rear panel.

15User Manual 1333.1611.02 ─ 03

Page 24

R&S®RTB2000

Preface

Conventions Used in the Documentation

1.2.4 Release Notes and Open Source Acknowledgment

The release notes list new features, improvements and known issues of the current

firmware version, and describe the firmware installation. The open source acknowledgment document provides verbatim license texts of the used open source software.

See www.rohde-schwarz.com/firmware/rtb2000. The open source acknowledgment

documant can also be read directly on the instrument.

1.3 Conventions Used in the Documentation

1.3.1 Typographical Conventions

The following text markers are used throughout this documentation:

Convention Description

"Graphical user interface elements"

All names of graphical user interface elements on the screen, such as

dialog boxes, menus, options, buttons, and softkeys are enclosed by

quotation marks.

KEYS Key names are written in capital letters.

File names, commands,

program code

Input Input to be entered by the user is displayed in italics.

Links Links that you can click are displayed in blue font.

"References" References to other parts of the documentation are enclosed by quota-

1.3.2 Conventions for Procedure Descriptions

File names, commands, coding samples and screen output are distinguished by their font.

tion marks.

When operating the instrument, several alternative methods may be available to perform the same task. In this case, the procedure using the touchscreen is described.

Any elements that can be activated by touching can also be clicked using an additionally connected mouse. The alternative procedure using the keys on the instrument or

the on-screen keyboard is only described if it deviates from the standard operating procedures.

The term "select" may refer to any of the described methods, i.e. using a finger on the

touchscreen, a mouse pointer in the display, or a key on the instrument or on a keyboard.

16User Manual 1333.1611.02 ─ 03

Page 25

R&S®RTB2000

Preface

Conventions Used in the Documentation

1.3.3 Notes on Screenshots

When describing the functions of the product, we use sample screenshots. These

screenshots are meant to illustrate as much as possible of the provided functions and

possible interdependencies between parameters. The shown values may not represent

realistic usage scenarios.

The screenshots usually show a fully equipped product, that is: with all options installed. Thus, some functions shown in the screenshots may not be available in your particular product configuration.

17User Manual 1333.1611.02 ─ 03

Page 26

R&S®RTB2000

2 Getting Started

Getting Started

Preparing for Use

2.1 Preparing for Use

2.1.1 Unpacking and Checking the Instrument

1. Inspect the package for damage.

If the packaging material shows any signs of stress, notify the carrier who delivered

the instrument.

2. Carefully unpack the instrument and the accessories.

3. Check the equipment for completeness. See section "Delivery contents"

on page 18.

4. Check the equipment for damage.

If there is damage, or anything is missing, immediately contact the carrier as well

as your distributor. Make sure not to discard the box and packing material.

Packing material

Retain the original packing material. If the instrument needs to be transported or shipped later, you can use the material to protect the control elements and connectors.

Delivery contents

The delivery package contains the following items:

●

R&S RTB2000 digital oscilloscope

●

R&S RT-ZP03 probes (2x for R&S RTB2002; 4x for R&S RTB2004)

●

Country-specific power cable

●

Printed "Getting Started" manual

●

Printed "Basic Safety Instructions" brochure

2.1.2 Positioning the Instrument

The instrument is designed for use under laboratory conditions. It can be used in

standalone operation on a bench top or can be installed in a rack.

For standalone operation, place the instrument on a horizontal bench with even, flat

surface. The instrument can be used in horizontal position, or with the support feet on

the bottom extended.

18User Manual 1333.1611.02 ─ 03

Page 27

R&S®RTB2000

Getting Started

Preparing for Use

The instrument can be installed in a 19" rack mount using a rack mount kit. The order

number of the rack mount kit is given in the data sheet. The installation instructions are

part of the rack mount kit.

Risk of injury if feet are folded out

The feet can fold in if they are not folded out completely or if the instrument is shifted.

This can cause damage or injury.

●

Fold the feet completely in or out to ensure stability of the instrument. Never shift

the instrument when the feet are folded out.

●

When the feet are folded out, do not work under the instrument or place anything

underneath.

●

The feet can break if they are overloaded. The overall load on the folded-out feet

must not exceed 200 N.

F

max

Risk of instrument damage due to overheating

An insufficient airflow can cause the R&S RTB2000 to overheat, which can impair the

measurement results, disturb the operation, and even cause damage.

●

Ensure that all fan openings are unobstructed and that the airflow perforations are

unimpeded. The minimum distance to a wall is 10 cm.

●

When placing several instruments side by side, keep a minimum distance of 20 cm

between the instruments. Ensure that the instruments do not draw in the preheated

air from their neighbors.

●

When mounting the instrument in a rack, observe the instructions of the rack manufacturer to ensure sufficient airflow and avoid overheating.

2.1.3 Starting the Instrument

2.1.3.1 Powering On

The R&S RTB2000 can be used with different AC power voltages and adapts itself

automatically to it.

19User Manual 1333.1611.02 ─ 03

Page 28

R&S®RTB2000

Getting Started

Preparing for Use

The nominal ranges are:

●

100 V to 240 V AC at 50 Hz to 60 Hz

●

0.95 A to 0.5 A

●

max. 60 W

Risk of injury

Connect the instrument only to an outlet that has a ground contact.

Do not use an isolating transformer to connect the instrument to the AC power supply.

1. Connect the power cable to the AC power connector on the rear panel of the

R&S RTB2000.

2. Connect the power cable to the socket outlet.

3. Switch the main power switch at the rear of the instrument to position I.

The STANDBY key lights up. The key is located in the bottom left corner of the

front panel.

You can leave the main power switch on to preserve your last instrument settings. To

disconnect from power supply, power off the instrument.

2.1.3.2 Starting Up and Shutting Down

To start up the instrument

1. Make sure that the R&S RTB2000 is connected to the AC power supply and the

main power switch on the rear panel is in position I.

2. Press the STANDBY key. The key is located in the bottom left corner of the front

panel.

The instrument performs a system check and starts the firmware. If the previous

session was terminated regularly, the oscilloscope uses the last settings.

Table 2-1: Colors of the STANDBY key

Green Instrument is on: firmware is working

Yellow Standby: instrument is off, main power switch is on

Warm-up and prepare the instrument

Make sure that the instrument has been running and warming up before you start the

self-alignment and the measurements. The minimum warm-up time is about 20 min.

20User Manual 1333.1611.02 ─ 03

Page 29

R&S®RTB2000

Getting Started

Preparing for Use