Page 1

Migrating PanelView Enhanced Terminal Applications

Quick Start

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

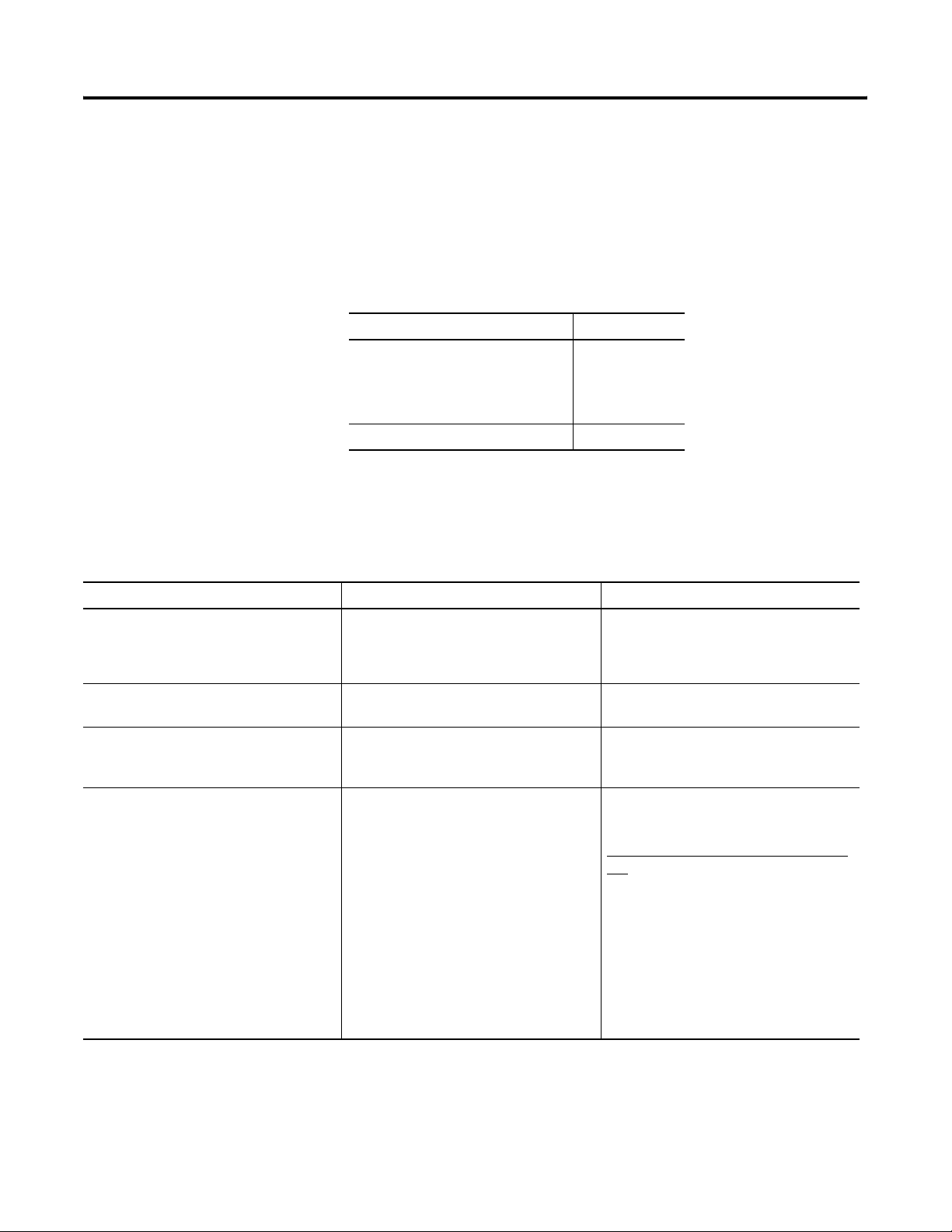

WARNING

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may reach dangerous

temperatures.

Allen-Bradley, CompactLogix, DH+, FactoryTalk, FactoryTalk View Machine Edition, FactoryTalk View ME, FactoryTalk Site

Edition, FactoryTalk View Studio, PanelBuilder, PanelView, PanelView e, PanelView Plus, PLC 5, Rockwell Automation, RSLinx,

RSLinx, RSLinx Lite, RSView, SLC, SLC 500, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

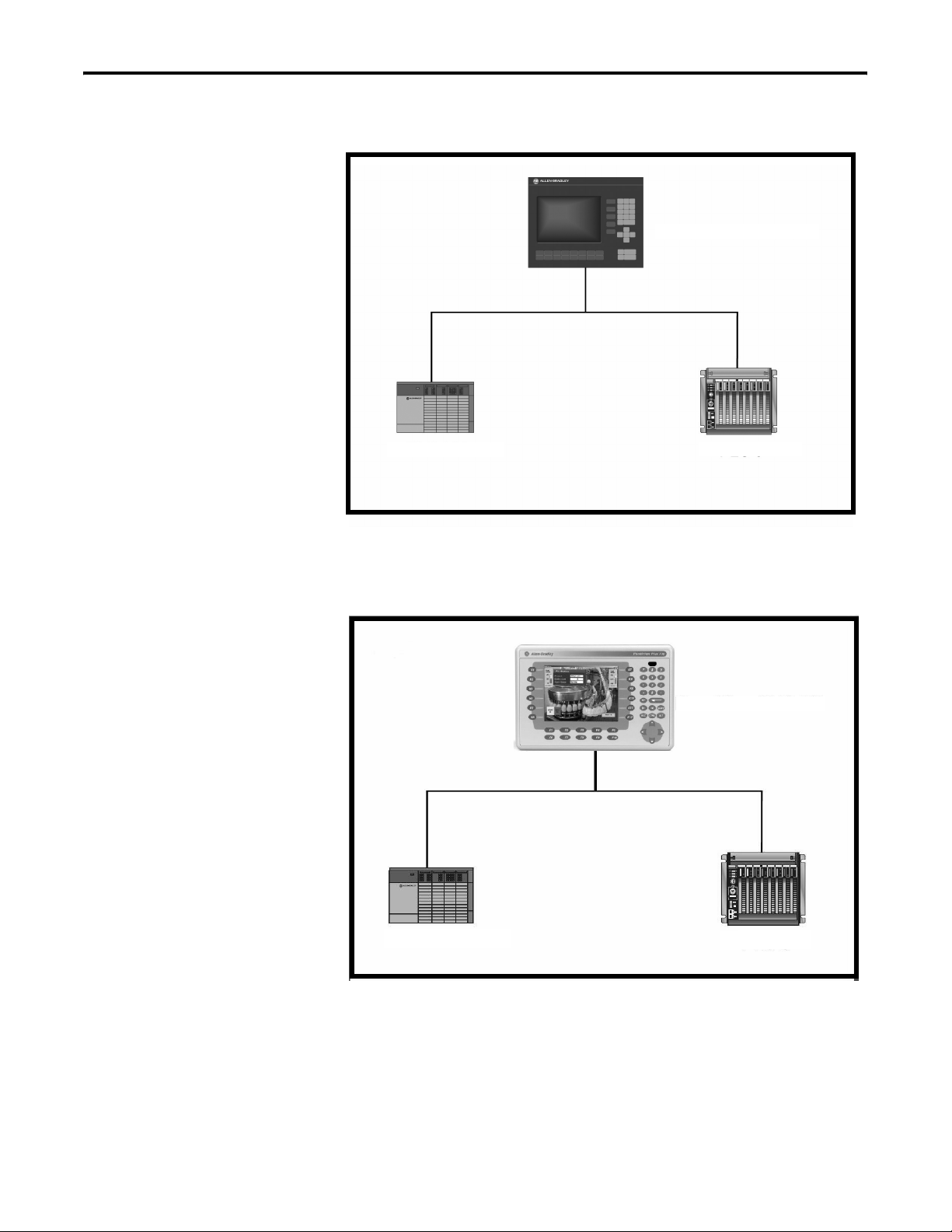

We Can Get You From Here...

Where to Start

PanelView 1400e Terminal

...To Here

SLC 500 Controller

PLC-5 Controller

PanelView Plus Terminal

SLC 500 Controller

3Publication 2711P-QS001A-EN-P - October 2007 3

L

C

P

o

l

l

e

5

-

r

o

C

n

r

t

Page 4

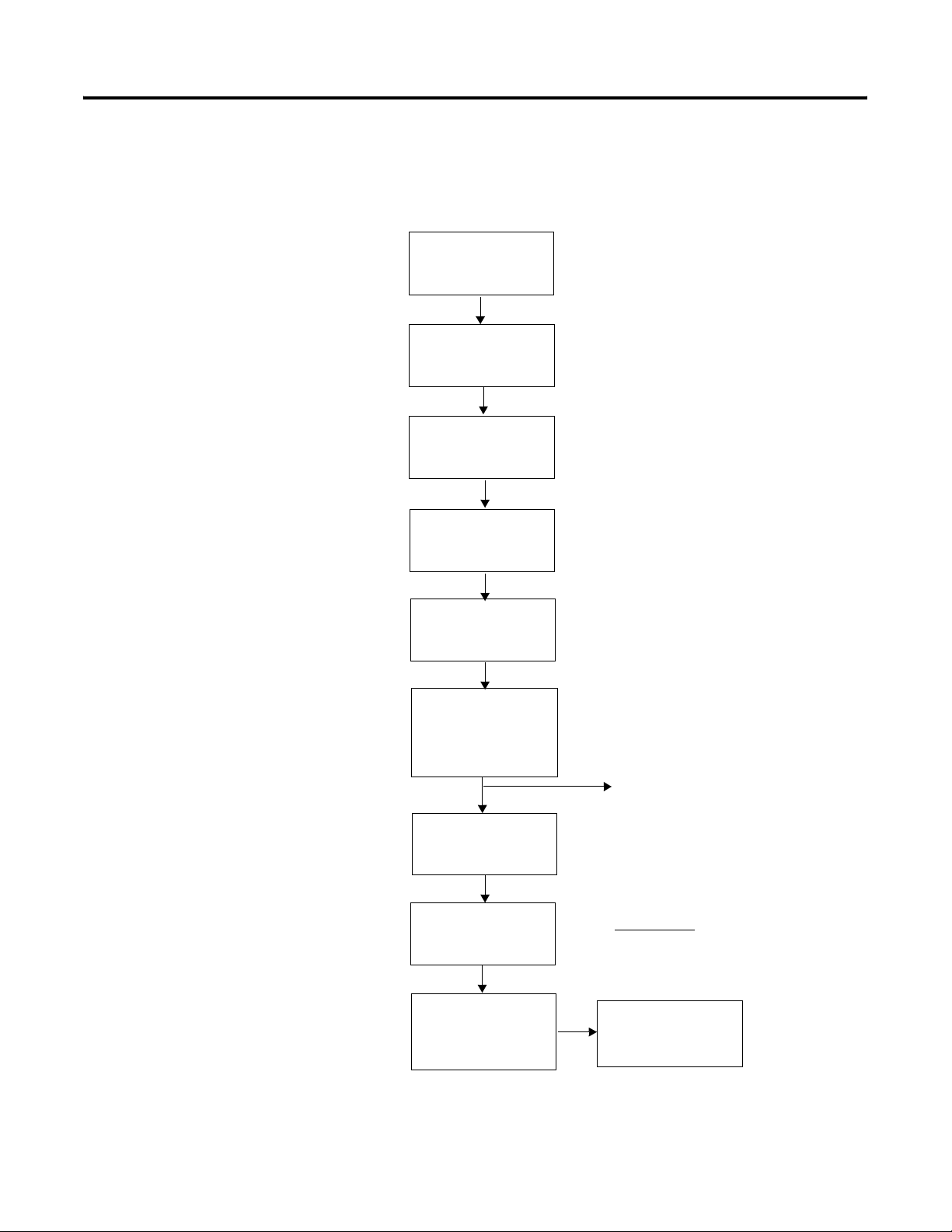

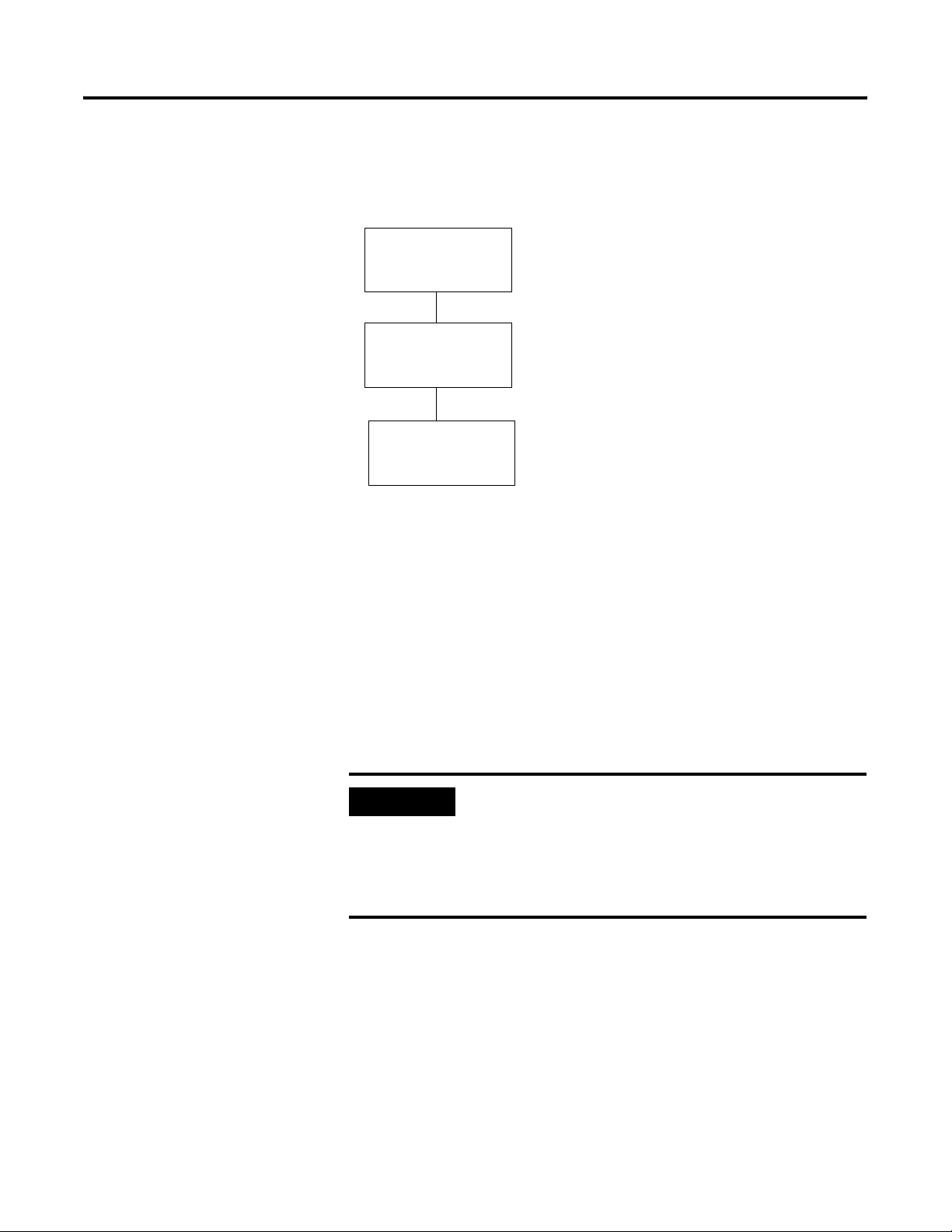

Where to Start

Follow this path to migrate your PanelView 1000e or 1400e terminal

and application to the PanelView Plus terminal platform.

Chapter 1

Migration Considerations

Chapter 2

Select a Terminal

Replacement

Chapter 3

Migrate Your Application

Chapter 4

Review the Application

Conversion Log

Chapter 5

Review Object Mapping

Chapter 6

Review Unsupported

Features and Implement

Workarounds for Migration

Issues

Chapter 7

Qualify the Runtime

Application

Chapter 8

Create the Runtime

Application

Chapter 9

Measure and Improve

Application Runtime

Performance

Before updating the migrated application,

review the conversion log details and the

remaining chapters. If you determine that

the conversion operation would not be

feasible, you can use the conversion

services provided by Rockwell

Automation. For more information, see

the Conversion Services, publication

GMSC10-PP016

Appendix A

Advanced Object Editing

.

4 Publication 2711P-QS001A-EN-P - October 2007

Page 5

Table of Contents

Preface

Migration Considerations

Select a Terminal Replacement

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Required Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Migration Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Migration Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Selecting a Terminal Replacement . . . . . . . . . . . . . . . . . . . . 16

Reviewing Terminal Comparisons . . . . . . . . . . . . . . . . . . . . 17

Installing a PanelView Plus Terminal . . . . . . . . . . . . . . . . . . 18

Migrate Your Application

Review the Application

Conversion Log

Review Object Mapping

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Import Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

About the Conversion Log. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Open the Conversion Log . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Review the Conversion Log . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Reviewing Object Mapping . . . . . . . . . . . . . . . . . . . . . . . . . 35

Reviewing and Modifying Expressions . . . . . . . . . . . . . . . . . 37

5Publication 2711P-QS001A-EN-P - October 2007 5

Page 6

Table of Contents

Review Unsupported Features and

Implement Workarounds for

Migration Issues

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Reviewing Unsupported Features. . . . . . . . . . . . . . . . . . . . . 41

Reviewing Common Migration Issues and Workarounds. . . . 46

Required Files and Utilities . . . . . . . . . . . . . . . . . . . . . . . . . 46

Replacing Scrolling List Objects . . . . . . . . . . . . . . . . . . . . . . 47

Replacing the Cursor List. . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Create a Piloted Control List Selector . . . . . . . . . . . . . . . 48

Retain Last State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Resize the Piloted Control List Selector . . . . . . . . . . . . . . 53

Assign Navigation Keys to Piloted Control List Selector . . 53

Assign Function Keys to a Piloted Control List Selector . . 55

Replacing the Multistate Indicator Object List . . . . . . . . . . . . 56

Create Multistate Indicators. . . . . . . . . . . . . . . . . . . . . . . 56

Resize and Align Multistate Indicators . . . . . . . . . . . . . . . 59

Replacing the Local Message Object List. . . . . . . . . . . . . . . . 60

Create Local Message Displays . . . . . . . . . . . . . . . . . . . . 60

Resize and Align the Local Message Displays . . . . . . . . . 63

Replacing the Numeric Data Display Object List . . . . . . . . . . 64

Create Numeric Displays . . . . . . . . . . . . . . . . . . . . . . . . 64

Resize and Align the Numeric Displays . . . . . . . . . . . . . . 67

Replacing the Set Bit Cursor Point Object. . . . . . . . . . . . . . . 68

Register the ActiveX Control on Your Computer. . . . . . . 68

Configure the Set Bit Cursor Point ActiveX Control . . . . . 71

Migrate the Set Bit Cursor Point Object . . . . . . . . . . . . . . 72

Provide Visual Feedback . . . . . . . . . . . . . . . . . . . . . . . . 76

Register the ActiveX Control on a PanelView CE Terminal 79

Bit Position Data Type Workaround. . . . . . . . . . . . . . . . . . . 80

PLC Controlled Decimal Point Workaround . . . . . . . . . . . . . 81

Fixed Position Decimal Point Workaround . . . . . . . . . . . . . . 82

Retain Last State Workaround . . . . . . . . . . . . . . . . . . . . . . . 83

Ladder Logic Updates to Support Visible States. . . . . . . . . . . 86

Chapter 7

Qualify the Runtime Application

6 Publication 2711P-QS001A-EN-P - October 2007

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Reviewing Diagnostic Lists. . . . . . . . . . . . . . . . . . . . . . . . . . 93

Configure the Runtime Diagnostic Display . . . . . . . . . . . . . . 94

Reviewing Error States for Graphic Objects . . . . . . . . . . . . . 95

Test Run Graphic Displays . . . . . . . . . . . . . . . . . . . . . . . . . 96

Page 7

Create the Runtime Application

Table of Contents

Test Run the Application . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Configuring Global Memory Connections. . . . . . . . . . . . . . . 99

Hardware Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Configure Global Connections . . . . . . . . . . . . . . . . . . . 100

Configuring Communication . . . . . . . . . . . . . . . . . . . . . . . 102

Remote I/O Communication. . . . . . . . . . . . . . . . . . . . . 102

Configure DH+ Communication . . . . . . . . . . . . . . . . . . 106

ControlNet Communications. . . . . . . . . . . . . . . . . . . . . 109

Chapter 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Create the Runtime Application . . . . . . . . . . . . . . . . . . . . . 113

Download the Runtime Application . . . . . . . . . . . . . . . . . . 114

Download Application Using Ethernet Connection . . . . 114

Download Application Using a CompactFlash Card . . . . 118

Run the Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Measure and Improve Runtime

Application Performance

Chapter 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Benchmarking Performance. . . . . . . . . . . . . . . . . . . . . . . . 123

Reviewing Tag Update Response . . . . . . . . . . . . . . . . . . . . 123

Scan Classes - PanelBuilder 1400E Software . . . . . . . . . 123

Tag Update Rate - FactoryTalk View ME Software . . . . . 124

Measure Performance of Display Changes . . . . . . . . . . . . . 125

Reviewing Background Updates . . . . . . . . . . . . . . . . . . . . 126

Global Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Data Log Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Information Messages. . . . . . . . . . . . . . . . . . . . . . . . . . 129

Optimize Tags for Communication Protocols . . . . . . . . . . . 129

About the Tag Converter Wizard . . . . . . . . . . . . . . . . . 130

Export the HMI Tag Database. . . . . . . . . . . . . . . . . . . . 131

Export Graphic Displays to XML File . . . . . . . . . . . . . . 133

Export Alarms to XML File . . . . . . . . . . . . . . . . . . . . . . 135

Run the Tag Converter Wizard . . . . . . . . . . . . . . . . . . . 137

Re-import the Display XML File . . . . . . . . . . . . . . . . . . 141

Re-import the Alarms XML File . . . . . . . . . . . . . . . . . . . 144

Publication 2711P-QS001A-EN-P - October 2007 7

Page 8

Table of Contents

Advanced Object Editing

Appendix A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Property Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Editing Multiple Objects . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Object Explorer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Tag Substitution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Index

8 Publication 2711P-QS001A-EN-P - October 2007

Page 9

Preface

Introduction

This document provides guidelines and procedures for migrating a

PanelView 1000e or 1400e terminal application to the PanelView Plus

terminal platform. The procedures and guidelines cover:

• selecting and optionally installing a PanelView Plus terminal

replacement.

• migrating your PanelView 1000e or 1400e application to

FactoryTalk View Machine Edition software.

• updating the migrated application and ladder logic, as

necessary, to verify compatibility with FactoryTalk View

Machine Edition software.

• reviewing and implementing workarounds for unsupported

features.

• verifying the correct operation of the migrated application on

the PanelView Plus terminal.

• measuring and improving performance of the migrated

application.

The procedures and guidelines are designed to make the migration

process as easy as possible.

The beginning of most chapters contains the following information.

Read these sections carefully before beginning work in each chapter.

• Before You Begin - This section lists the steps that must be

completed and decisions that must be made before starting the

chapter. The chapters in this quick start must be completed or

reviewed in the order in which they appear.

• What You Need - This section lists the items that are required to

complete the steps in the current chapter. This includes, but is

not limited, to hardware and software.

• Follow These Steps - This section illustrates the path or steps in

the current chapter.

Also note that the electronic version of this publication contains links

to other publications for easier navigation and reference.

9Publication 2711P-QS001A-EN-P - October 2007 9

Page 10

Preface Preface

Audience

This quick start was created to assist a user familiar with Rockwell

Automation HMI products on how to convert an existing application

for the PanelView Plus terminal platform.

Required Software

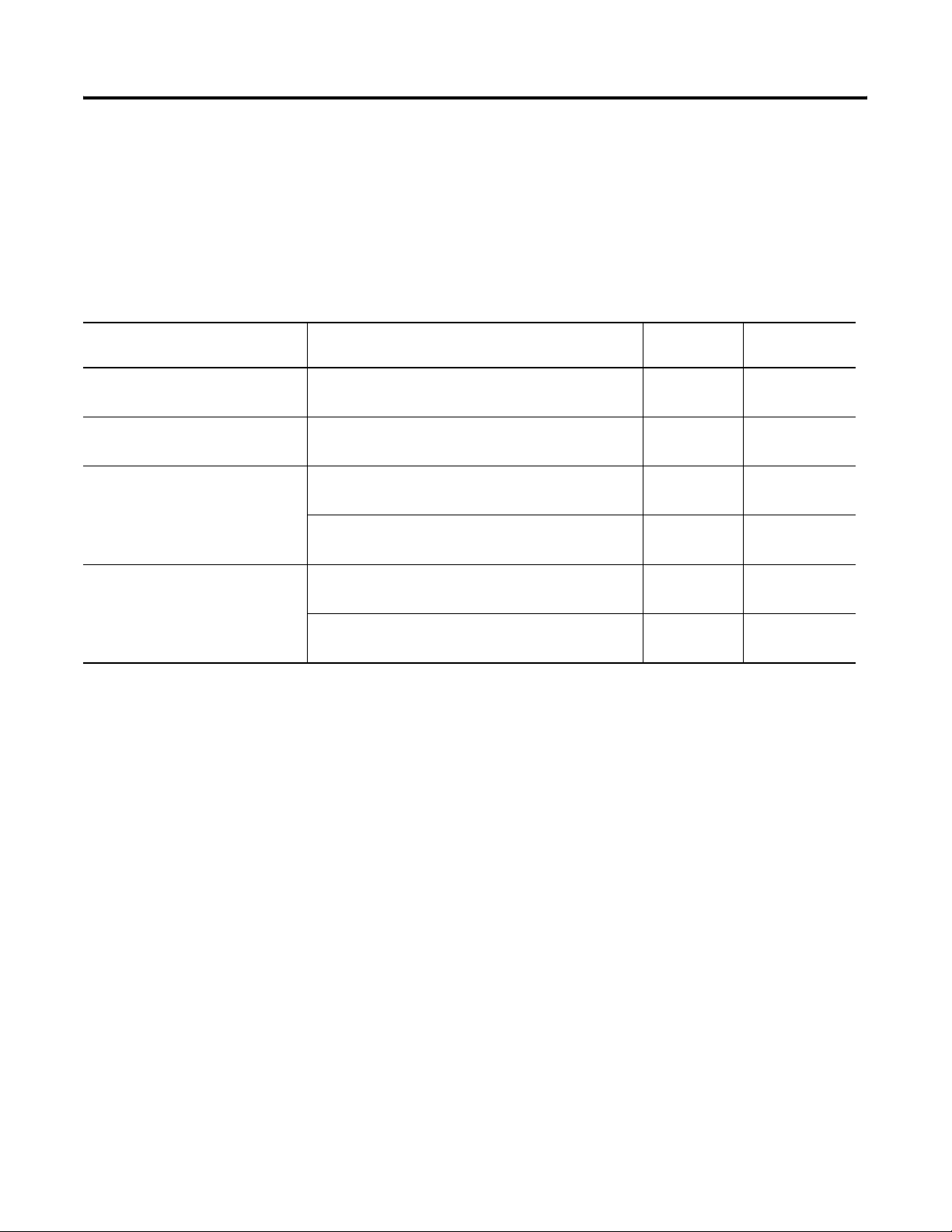

The table provides the software required to convert a PanelView

1000e or 1400e application to a PanelView Plus application.

Software Version

FactoryTalk View Studio, which

includes:

• FactoryTalk View Machine Edition

• RSLinx Enterprise

PanelBuilder 1400e Software Version 5.16

Version 5.0

Migration Services

This migration service Includes For more information

Step Forward Program Provides a credit for returned product.

• PanelView 1400e to PanelView 1000e

• PanelView Enhanced to PanelView Plus

PV1000e Migration Kits PV1000e terminal and adapter plate at a

reduced price

Consult your local distributor for details

Consult your local distributor for details

PanelView Plus Starter Kits PanelView Plus terminal and associated

software at a reduced price to help you get

started with a new product family.

Bundled Migration Services • PanelView Enhanced to PanelView Plus

terminal hardware conversion

• PanelView Enhanced to PanelView Plus

application file conversion

• Turnkey service including any ladder

logic changes required

• Delivered onsite by Rockwell

Automation service engineers

• Project supervision and conversion

engineering services

• Standardized service bundle

• Fixed price proposal

10 Publication 2711P-QS001A-EN-P - October 2007

Consult your local distributor for details

For more information on services, go to this

website:

http:\\rockwellautomation.com/services/on

site

Page 11

Preface Preface

Conventions

This manual uses the following conventions.

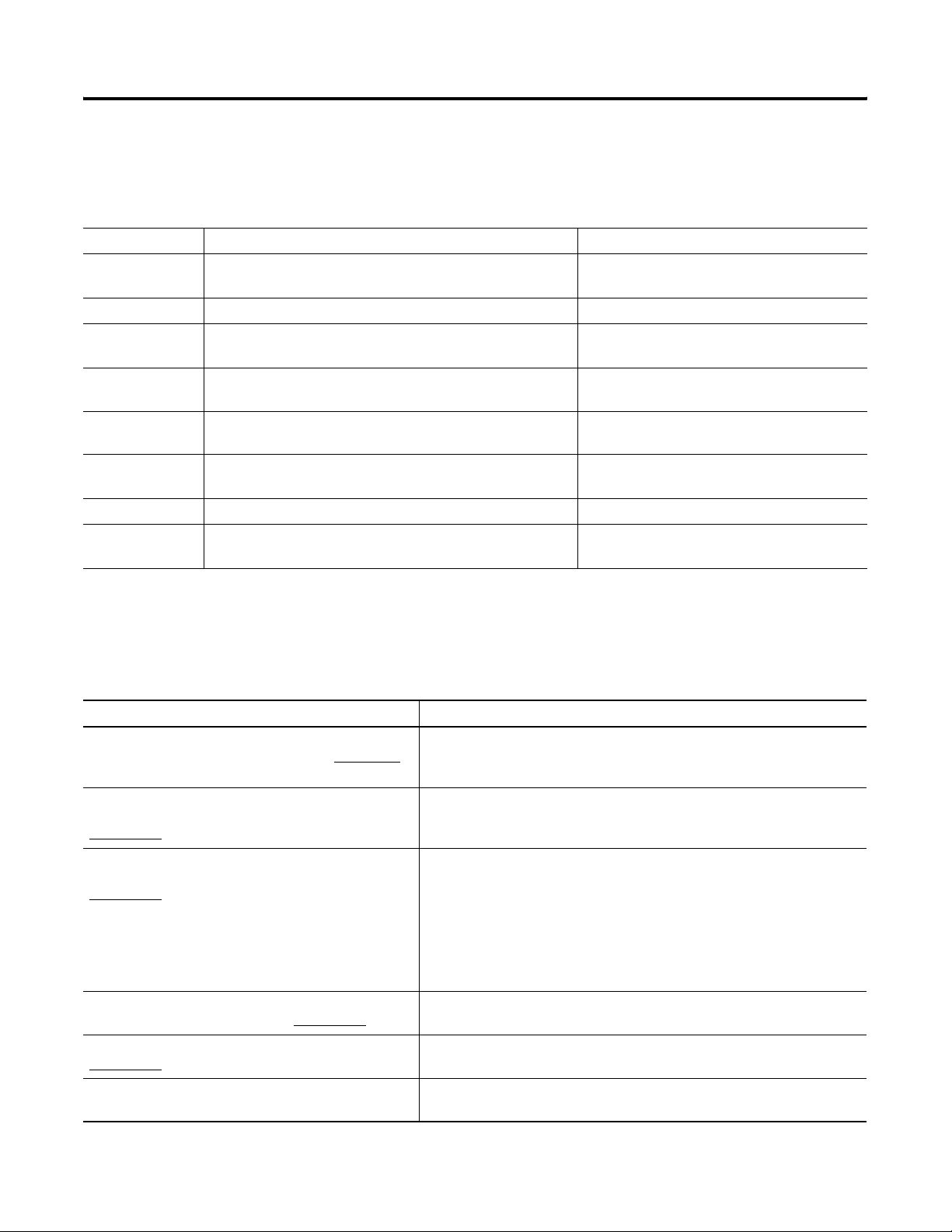

Convention Meaning Example

Courier

font

Check or uncheck Click to activate or deactivate a checkbox. Check the Disable Keying checkbox.

Click

Type or enter text exactly as shown. Type cmd.

Click the left mouse button once while the cursor is positioned

on object or selection.

Click Browse.

Double-click

Expand

Right-click

Select Click to highlight a menu item or list choice. Select the SBCP ActiveX file.

> Shows nested menu selections as menu name followed by menu

Click the left mouse button twice in quick succession while the

cursor is positioned on object or selection.

Click the + to the left of a given item /folder to show its

contents.

Click the right mouse button once while the cursor is positioned

on object or selection.

selection.

Double-click the application icon.

Expand HMI tags.

Right-click on Program Files.

Select Object>ActiveX Control.

Additional Resources

Resource Description

Adapter Kit for PanelView 1400e Touch Screen Terminal

Cutout Installation Instructions, publication 2711-IN023

Adapter Kit for PanelView 1200/1200e/1400e Keypad

Terminal Cutout installation instructions, publication

2711P-IN015

Provides details on how to use the cutout adapter kit, catalog number

2711P-RAT12E, to mount a PanelView Plus or PanelView Plus CE 1250 touch

screen terminal into an existing PanelView 1400e touch screen panel cutout.

Provides details on how to use the cutout adapter kit, catalog number

2711P-RAK12E, to mount a PanelView Plus or PanelView Plus CE 1250 keypad

terminal into an existing PanelView 1400e keypad panel cutout.

Adapter Kit for PanelView Standard or PanelView e

Terminal Cutouts Installation Instructions, publication

2711P-IN010

PanelView Plus Terminals and Display Modules

Installation Instructions, publication 2711P-IN001

Visualization Platforms Selection guide, publication

VIEW-SG001

FactoryTalk View Studio online help Provides information and procedures for creating and editing a FactoryTalk

Publication 2711P-QS001A-EN-P - October 2007 11

Provides details on how to use the:

• cutout adapter kit, cat. no. 2711P-RAK10, to mount a PanelView Plus or

PanelView Plus CE 1000 keypad terminal into an existing PanelView 1000e

keypad panel cutout.

• cutout adapter kit, cat. no. 2711P-RAT10, to mount a PanelView Plus or

PanelView Plus CE 1000 touch screen terminal into an existing PanelView

1000e touch screen, panel cutout.

Provides details on how to install the PanelView Plus 1250 or 1500 terminal in

a panel.

Provides catalog numbers for the PanelView Plus terminals.

View Machine Edition application and supported features.

Page 12

Preface Preface

12 Publication 2711P-QS001A-EN-P - October 2007

Page 13

Migration Considerations

Chapter

1

Introduction

Migration Considerations

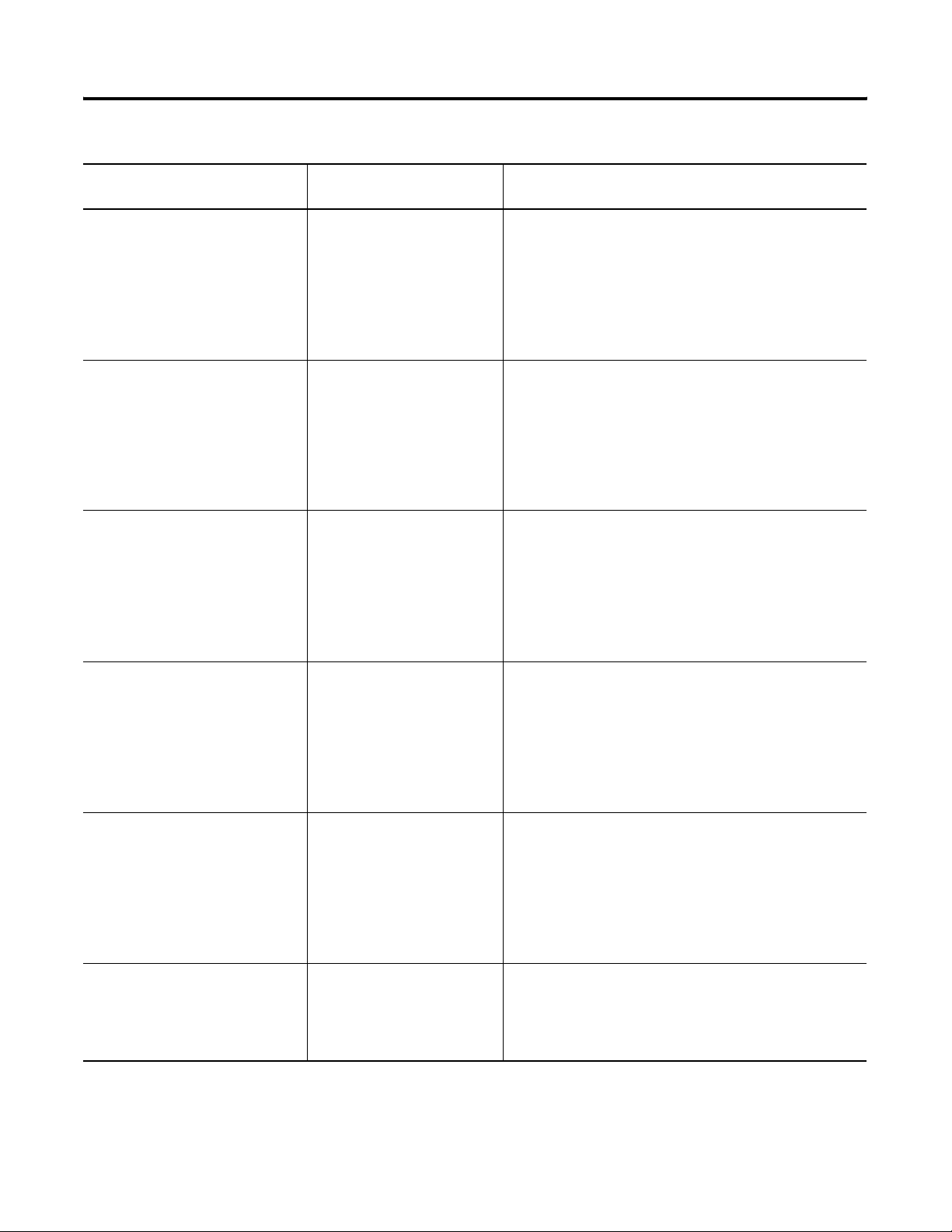

Migration Consideration Explanation For More Information

Application reuse? Do you need to reuse your PanelView 1000e or 1400e

Use multiple RIO racks? Does your application require more than one rack of discrete

Require relay or beeper? Does your application use a built-in alarm relay or beeper? The

This chapter covers considerations to address before migrating a

PanelView 1000e or 1400e application to the PanelView Plus platform.

The table provides an explanation of things to consider when

migrating an application.

Reviewing Object Mapping,

application and PLC ladder logic? If so, you can convert your

application for a PanelView Plus terminal using FactoryTalk

View Machine Edition (ME) software. The application and PLC

ladder logic may require updates because some objects or

features may not directly migrate to FactoryTalk View ME

software.

If you do not want to reuse your current application but instead

create a new one with FactoryTalk View ME software, you can

stop here.

Remote I/O? The PanelView Plus terminals support multiple

racks of discrete Remote I/O, depending on the scanner type.

PanelView Plus terminals do not support a built-in alarm relay

or beeper. However, you can use an external alarm relay.

page 35

Reviewing and Modifying

Expressions, page 37

Reviewing Unsupported

Features, page 41

Reviewing Terminal

Comparisons, page 17

13Publication 2711P-QS001A-EN-P - October 2007 13

Page 14

Chapter 1 Migration Considerations

Migration Consideration Explanation For More Information

Required enhanced features? Does your application require enhanced features? If so, you

can take advantage of the advanced features offered by the

PanelView Plus terminals.

• Functions: trending, data logging, alarming,

information and local messages, expressions, security,

language switching, recipes, global objects,

multiversion support, face plates, graphic libraries,

parameter files, rich graphics, and animation.

• Communication: Ethernet, ControlNet, DeviceNet,

DHPlus, Remote I/O, and third party PLC connectivity.

• Hardware: Analog resistive touchscreen, x86

processor, up to 128 MB of application memory,

modular display, communication, and logic

components, USB support, high-bright display, and

stainless steel bezel options.

• Remote connectivity: FTP, Web server, VNC, remote

desktop. Applies only to PanelView Plus CE terminals.

• Other: Adobe PDF, PowerPoint, Word, Excel, and MPEG

viewers, Internet Explorer (full-featured), various

ActiveX controls. Applies only to PanelView Plus CE

terminals.

What are the terminal

replacement options?

The terminal replacement options for the PanelView 1000e

and 1400e terminals are the PanelView Plus 1250 or 1500

Selecting a Terminal

Replacement, page 16

terminals.

The rest of this document steps you through the process of selecting a

replacement terminal, migrating, and testing the application.

14 Publication 2711P-QS001A-EN-P - October 2007

Page 15

Select a Terminal Replacement

Chapter

2

Introduction

Before You Begin

What You Need

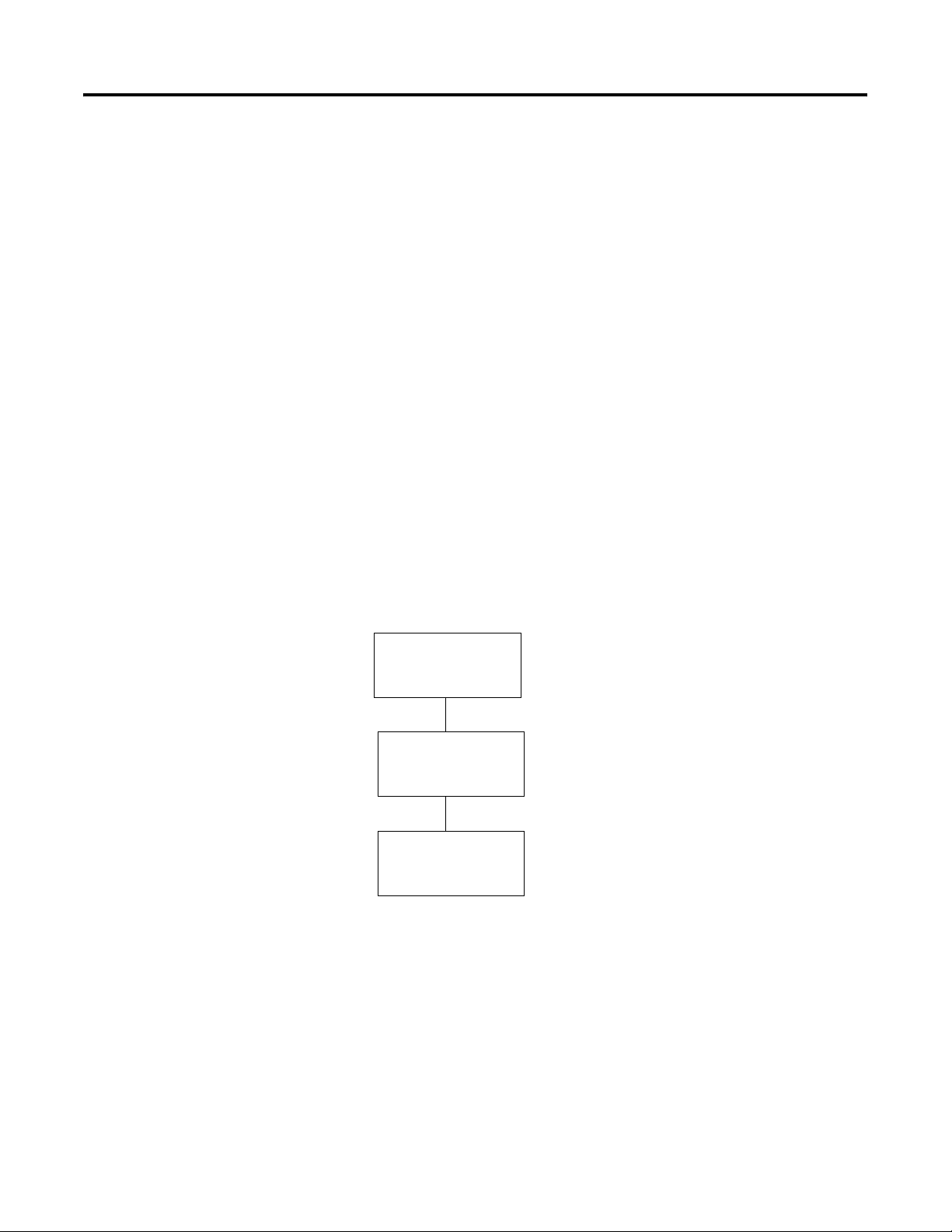

Follow These Steps

In this chapter, you will select and optionally install a PanelView Plus

terminal replacement for your PanelView 1000e or 1400e terminal.

Review the migration considerations table (chapter 1).

Nothing is required.

Follow these steps to select a PanelView Plus 1250 or 1500 terminal as

a replacement for your PanelView ‘e’ terminal.

Selecting a Terminal

Replacement

Page 16

Reviewing Terminal

Comparisons

Page 16

Installing a PanelView

Plus Terminal

Page 18

15Publication 2711P-QS001A-EN-P - October 2007 15

Page 16

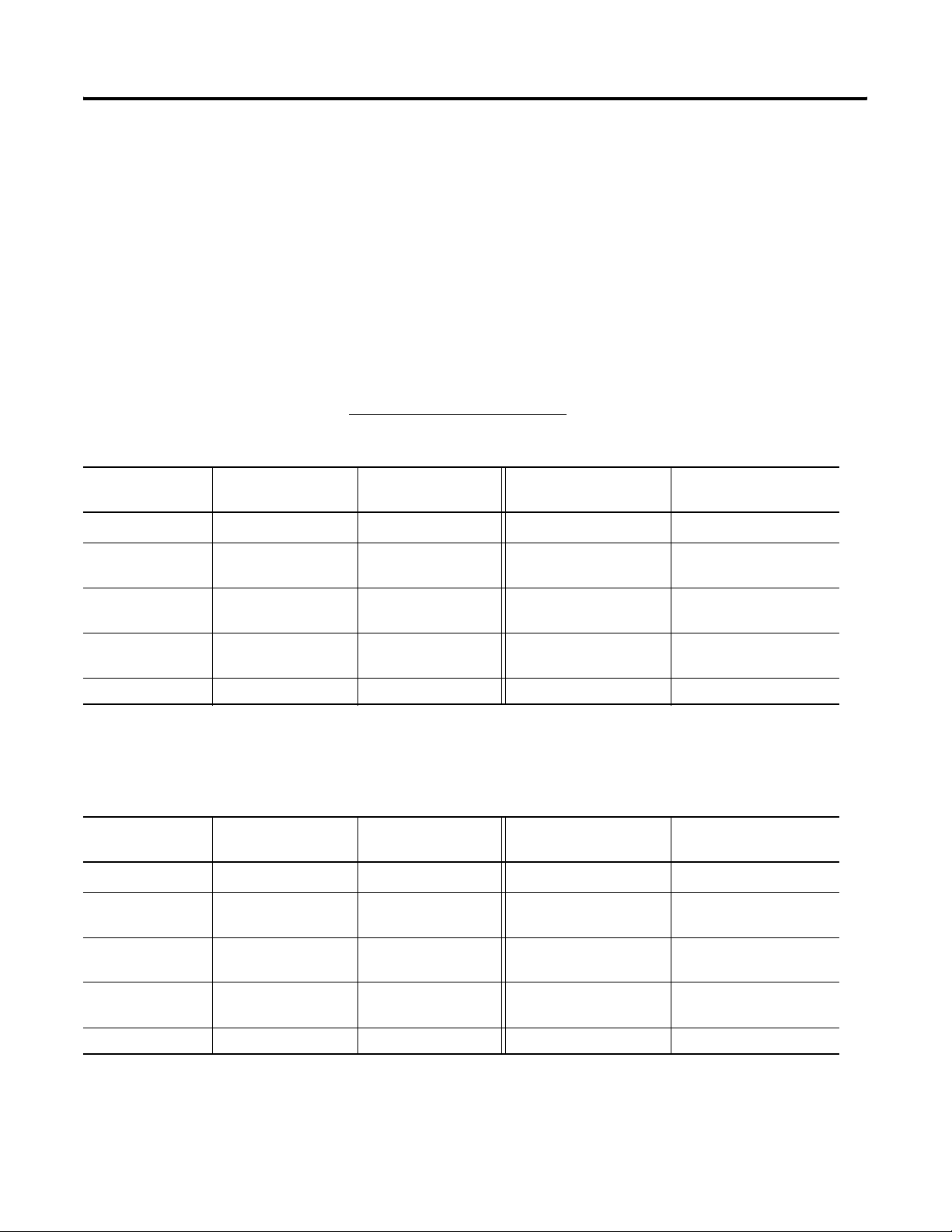

Chapter 2 Select a Terminal Replacement

Selecting a Terminal

Replacement options for the PanelView 1000e and 1400e terminals

include the PanelView Plus or PanelView Plus CE 1250 and 1500

Replacement

terminals. Some of the PanelView Plus terminals fit directly into the

existing panel cutout of the PanelView ‘e’ terminals; others will

require an adapter plate.

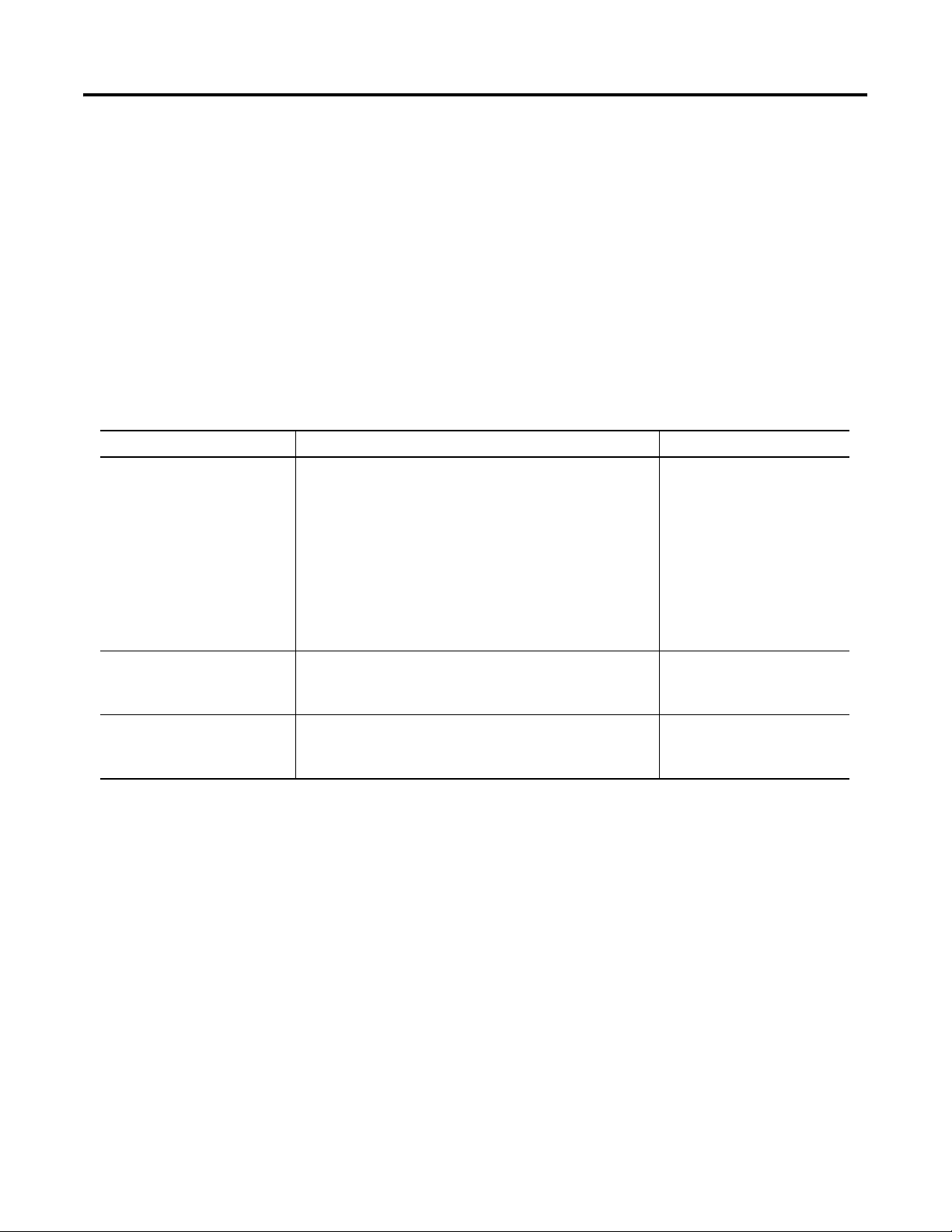

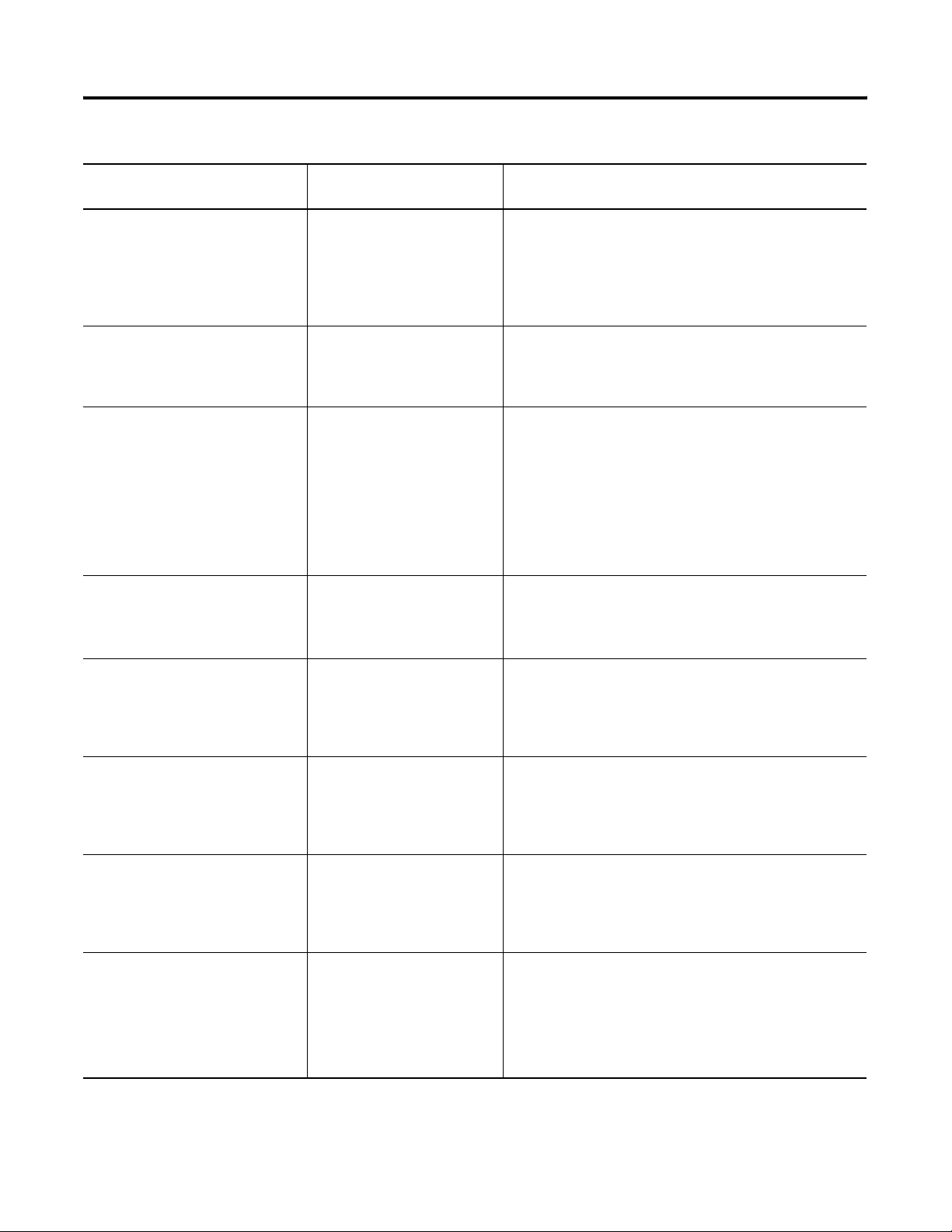

PanelView Plus Replacement Terminals

For this PanelView ‘e’ terminal Select one of these replacement terminals Adapter Plate

Required

PanelView 1000e touch screen PanelView Plus 1250 touch screen

PanelView Plus CE 1250 touch screen

(1)

PanelView 1000e keypad PanelView Plus 1250 keypad or keypad and touch

PanelView Plus CE 1250 keypad or keypad and touch

PanelView 1400e touch screen PanelView Plus 1250 touch screen

PanelView Plus CE 1250 touch screen

(1)

PanelView Plus 1500 touch screen

PanelView Plus CE 1500 touch screen

(1)

PanelView 1400e keypad PanelView Plus 1250 keypad or keypad and touch

PanelView Plus CE 1250 keypad or keypad and touch

PanelView Plus 1500 keypad or keypad and touch

PanelView Plus CE 1500 keypad or keypad and touch

(1)

The PanelView Plus CE terminal is required if your application requires the set bit cursor point function.

(2)

The PanelView Plus or PanelView Plus CE 1500 terminal will fit in the existing PanelView 1400e panel cutout. The adapter plate is required only to cover the stud

mounting holes.

No —

No —

(1)

Yes

(2)

Yes

Yes 2711P-RAK12E

(1)

(2)

Yes

(1)

Adapter Plate

Cat. No.

2711P-RAT12E

2711P-RAT15

2711P-RAK15

16 Publication 2711P-QS001A-EN-P - October 2007

Page 17

Select a Terminal Replacement Chapter 2

Reviewing Terminal

Review dimensions and other pertinent information comparing the

PanelView 1000e and 1400e keypad and touch terminals with the

Comparisons

equivalent PanelView Plus or PanelView Plus CE 1250 or 1500

terminals.

The PanelView Plus 1250 and 1500 terminals are available as

preconfigured units or separate modular components. The catalog

numbers of the preconfigured units are specific to operator input,

display size, communication, power, and memory requirements.

For a list of valid catalog numbers for preconfigured units or modular

components of the PanelView Plus terminals, refer to this website:

http://www.ab.com/catalogs/

Touch Screen Terminal Comparisons

Attribute PanelView 1000e

Cat. No. 2711e-T10C6

Depth, approx. 157 mm (6.18 in.) 404 mm (15.9 in.)

Panel cutout, H x W 257 x 338 mm

10.11 x 13.29 in.

Alarm relay 24V ac, 1 A

24V dc, 1 A

PanelView 1400e

Cat. No. 2711e-T14C6

326 x 391 mm

12.85 x 15.375 in.

250V ac, 18A

30V dc, 8 A

PanelView Plus 1250

Cat. No. 2711P-T12Cxxx

55 mm (2.18 in.)

257 x 338 mm

10.11 x 13.29 in.

Requires external relay Requires external relay

(1)

PanelView Plus 1500

Cat. No. 2711P-T15Cxxx

65 mm (2.55 in.)

305 x 391 mm

12.0 x 15.4 in.

(1)

Display 10.4 in. VGA

TFT flat panel display

Operator input Touch screen Touch screen Touch screen Touch screen

(1)

Optional add-on communication modules will increase the overall depth of the product.

Keypad Terminal Comparisons

Attribute PanelView 1000e

Cat. No. 2711e-K10C6

Depth, approx. 156 mm (6.15 in.) 404 mm (15.9 in.)

Panel cutout, H x W 257 x 390 mm

10.11 x 15.35 in.

Alarm relay 24V ac, 1 A

24V dc, 1 A

Display 10.4 in. VGA

TFT flat panel display

Operator input Keypad Keypad Keypad Keypad

(1)

Optional add-on communication modules will increase the overall depth of the product.

14.0 in. VGA/SVGA

CRT

PanelView 1400e

Cat. No. 2711e-K14C6

326 x 429 mm

12.85 x 16.90 in.

250V ac, 8 A

30V dc, 8 A

14.0 in. VGA/SVGA

CRT

12.1 in. SVGA

TFT flat panel display

PanelView Plus 1250

Cat. No. 2711P-K15Cxxx

55 mm (2.18 in.)

257 x 390 mm

10.11 x 15.35 in.

Requires external relay Requires external relay

12.1 in. SVGA

TFT flat panel display

(1)

15.1 in. SVGA

TFT flat panel display

PanelView Plus 1500

Cat. No. 2711P-K15xxx

65 mm (2.55 in.)

305 x 419 mm

12.0 x 16.5 in.

15.1 in. SVGA

TFT flat panel display

(1)

Publication 2711P-QS001A-EN-P - October 2007 17

Page 18

Chapter 2 Select a Terminal Replacement

Installing a PanelView Plus Terminal

Install the selected PanelView Plus 1250 or 1500 terminal into the

existing PanelView 1000e or 1400e panel cutout. You may need an

adapter plate depending on your terminal selection.

To assist you with the installation, refer to:

• PanelView Plus Terminals and Display Modules Installation

Instructions, publication 2711P-IN001

• Appropriate adapter plate installation instructions, if required.

.

18 Publication 2711P-QS001A-EN-P - October 2007

Page 19

Migrate Your Application

Chapter

3

Introduction

Before You Begin

What You Need

In this chapter, you will import your existing PanelBuilder 1400e

application into FactoryTalk View Machine Edition (ME) software.

Different software is used by each PanelView terminal platform to

develop applications.

• PanelView 1000e and 1400e terminals run applications created

with PanelBuilder 1400e configuration software.

• PanelView Plus terminals run applications created with

FactoryTalk View ME software.

• Review the migration considerations table (Chapter 1).

• Select a PanelView Plus terminal replacement and adapter plate,

if required (Chapter 2).

• Optionally install the PanelView Plus terminal replacement

(Chapter 2). You can install the terminal after migrating and

testing your application.

• FactoryTalk View Studio software

• PanelBuilder 1400e .pvc application file. The application file can

reside on your local hard drive or a CompactFlash card.

19Publication 2711P-QS001A-EN-P - October 2007 19

Page 20

Chapter 3 Migrate Your Application

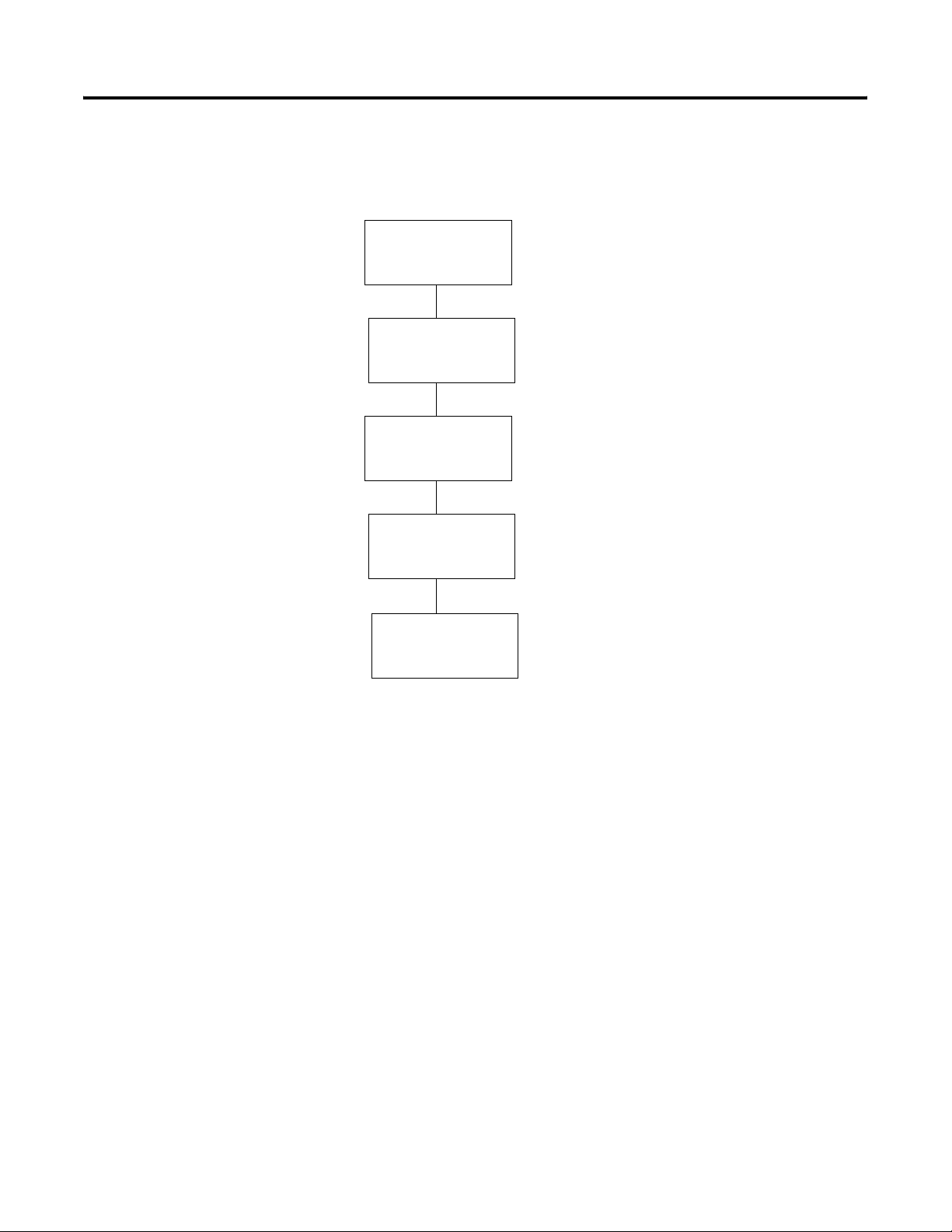

Follow These Steps

Follow these steps to import your PanelBuilder 1400e application into

FactoryTalk View Machine Edition software.

Launch FactoryTalk View

Machine Edition

Software

page 21

Create a New

Application Name

page 21

Select the PanelBuilder

1400e Application to

Migrate

page 22

Configure the Import

Options

page 23

Review Project Status

Dialog

page 24

20 Publication 2711P-QS001A-EN-P - October 2007

Page 21

Migrate Your Application Chapter 3

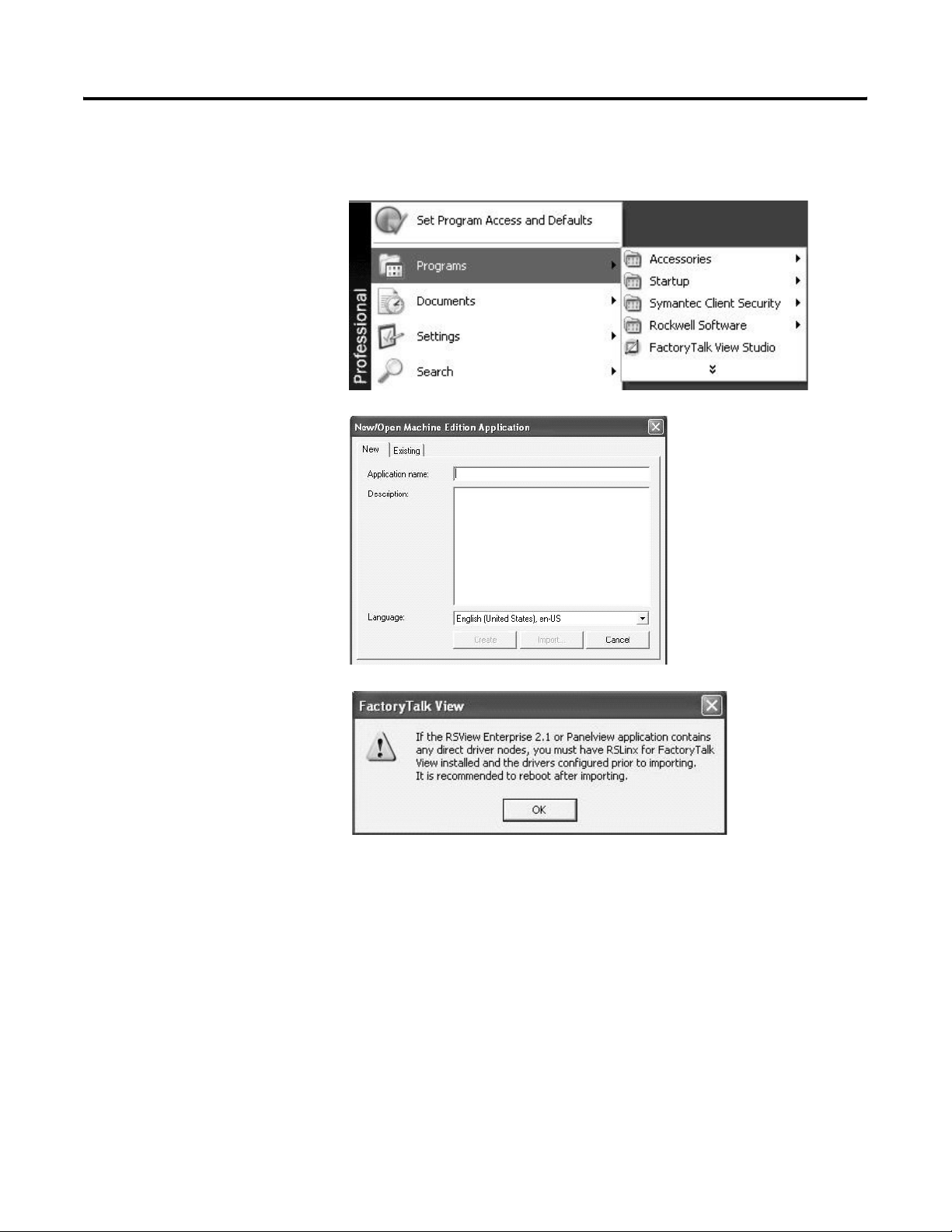

Import Application

1. Launch FactoryTalk View

Studio software.

2. Click the New tab.

3. Enter an Application name

and click Import.

Follow the steps in this procedure to migrate any PanelView 1000e or

1400e application into FactoryTalk View Machine Edition software.

4. Read the FactoryTalk View

dialogue and click OK.

RSLinx for FactoryTalk does

not need to be installed

prior to importing your

PanelBuilder 1400e

application.

Publication 2711P-QS001A-EN-P - October 2007 21

Page 22

Chapter 3 Migrate Your Application

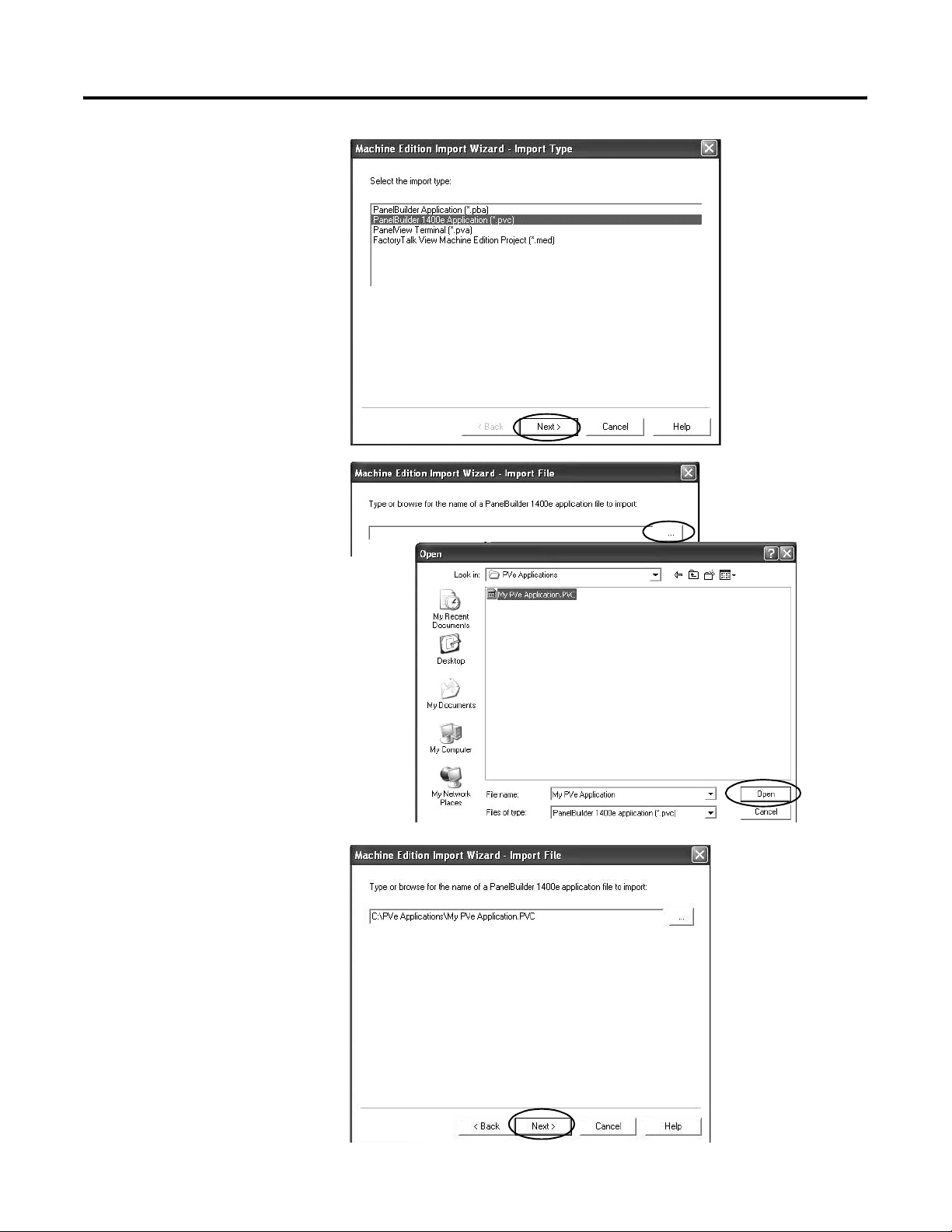

5. Select PanelBuilder 1400e

Application (*.pvc) and click

Next.

6. Click the ... button.

7. Browse to and select your

PanelBuilder 1400e .pvc

application and click Open.

8. Click Next.

22 Publication 2711P-QS001A-EN-P - October 2007

Page 23

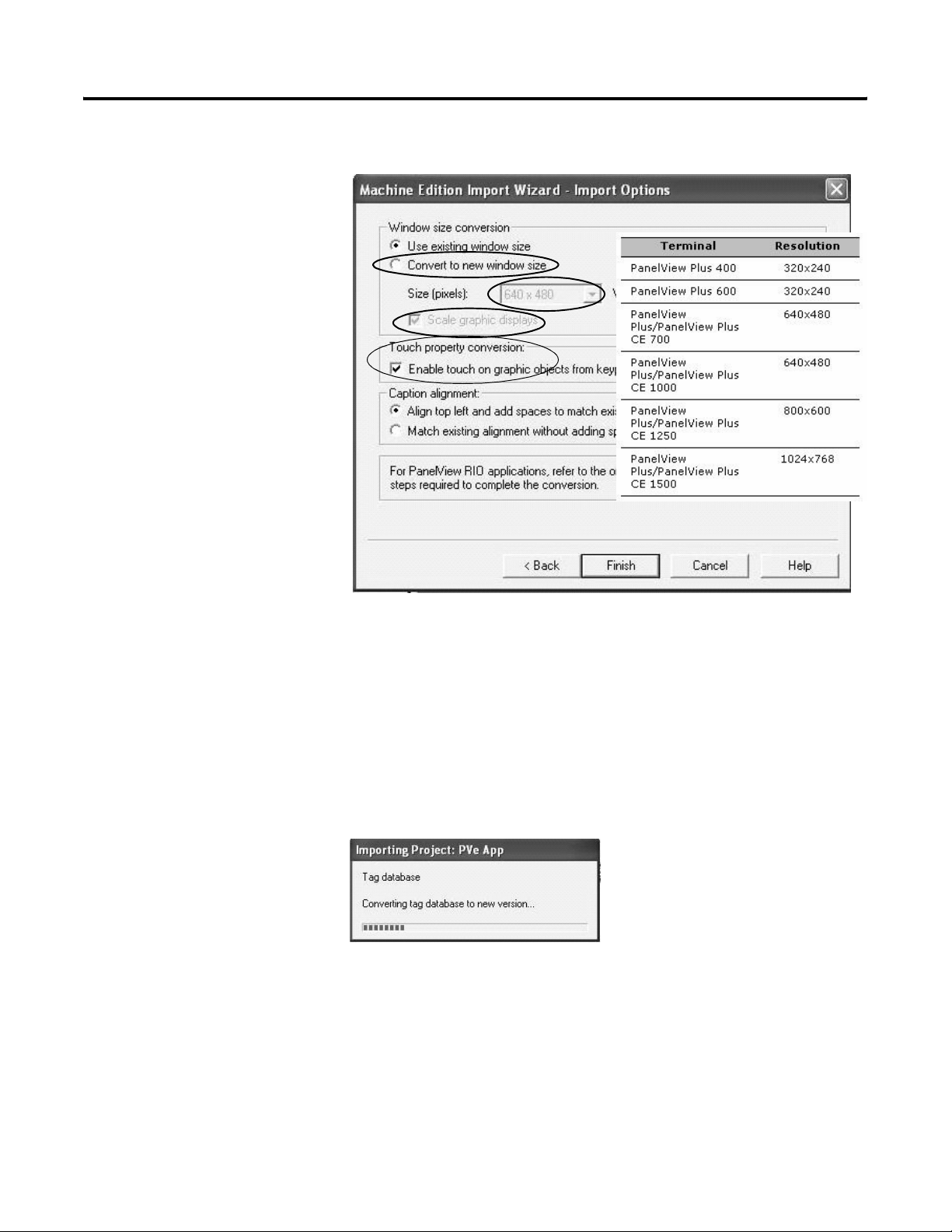

9. Configure the import

options based on your

replacement terminal.

Click Help at any time for

clarification of each dialog

option.

a. Check the Convert to

new window size

checkbox.

b. Select the size (in pixels)

of your PanelView Plus

terminal display as

shown in chart.

c. Check the Scale graphic

displays checkbox.

When selected, this

setting rescales all

displays.

d. If your original

PanelView e terminal

used a touch screen or

touch/keypad, check the

box under Touch

property conversion.

e. Click the Help button and

read the differences

between the caption

alignment options and

select an option for your

new application.

f. Click Finish.

Migrate Your Application Chapter 3

The Importing Progress

dialog shows the conversion

status. This process may

take a while, depending on

the size of your application.

When completed, you will

see the Project Status dialog

in the next step.

Publication 2711P-QS001A-EN-P - October 2007 23

Page 24

Chapter 3 Migrate Your Application

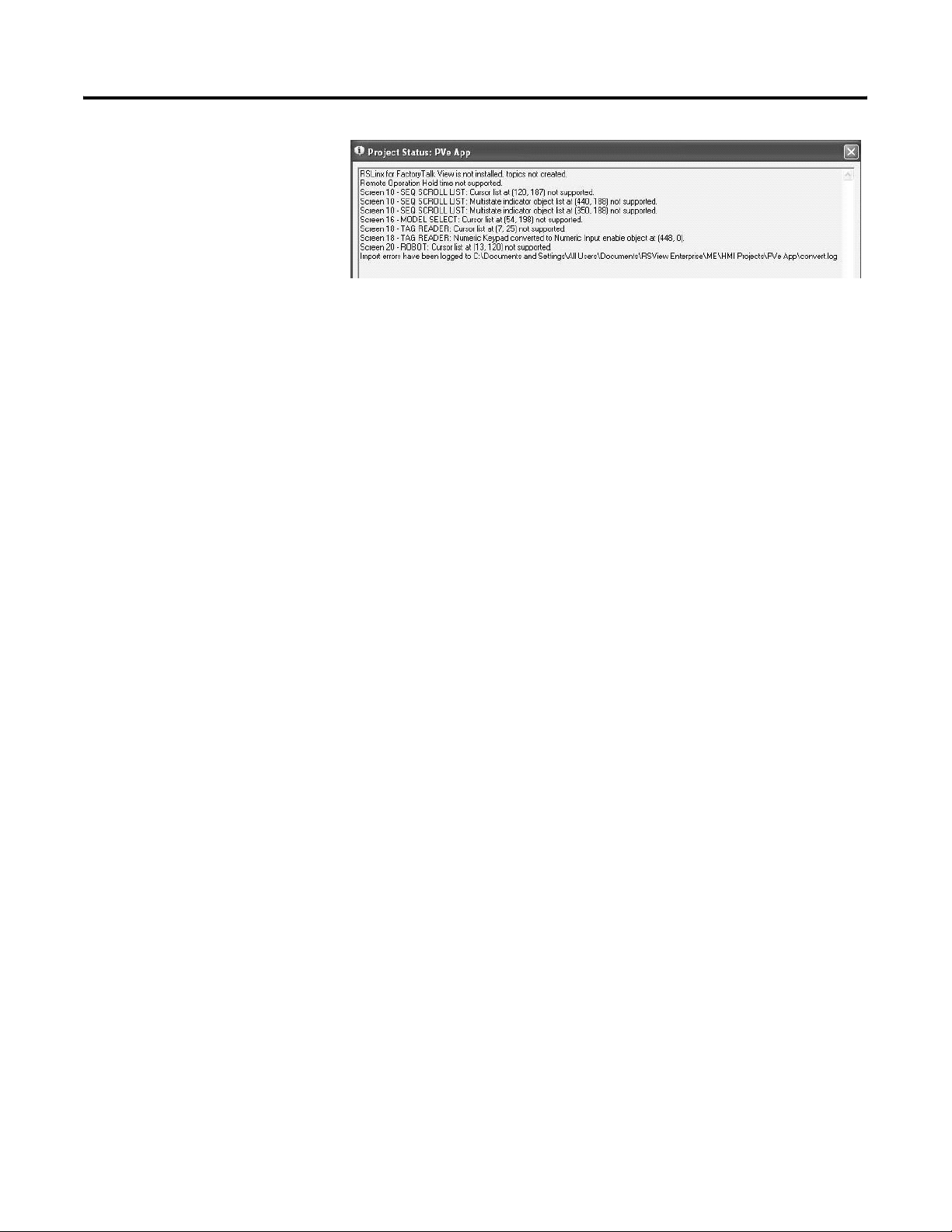

10. Review the Project Status

dialog and click OK.

11. Repeat steps 1 through 10

for each PanelBuilder 1400e

application you want to

migrate to FactoryTalk View

ME software.

24 Publication 2711P-QS001A-EN-P - October 2007

Page 25

Chapter

Review the Application Conversion Log

4

Introduction

Before You Begin

What You Need

In this chapter, you will review the conversion log generated by

FactoryTalk View Machine Edition (ME) software. The results of this

log will help you to determine what updates are required in your

converted application.

• Review migration considerations (Chapter 1).

• Select a PanelView Plus terminal replacement and adapter plate,

if required (Chapter 2).

• Install the PanelView Plus terminal in the existing PanelView

1000e or 1400e panel cutout (Chapter 2).

• Import your PanelBuilder 1400e .pvc application into

FactoryTalk View ME software (Chapter 3).

• A PanelBuilder 1400e application migrated into FactoryTalk

View ME software. This was done in Chapter 3.

• The new name given the migrated application in FactoryTalk

View ME software. This was done in Chapter 3.

• Conversion log generated by the FactoryTalk View ME import

wizard.

25Publication 2711P-QS001A-EN-P - October 2007 25

Page 26

Chapter 4 Review the Application Conversion Log

Follow These Steps

Follow this path to review changes that are required to your

FactoryTalk View ME application.

About the Conversion

Log

page 26

Open the Conversion

Log

page 27

Review the Conversion

Log

page 28

About the Conversion Log

The application conversion log is generated by the Import Wizard

when you import your PanelBuilder 1400e application into

FactoryTalk View ME software. This log provides detailed information

about objects or features that did not convert directly from your

PanelBuilder 1400e application. Use this log as a guide to update your

application accordingly. Modifications to the application are required

to verify that the application will operate correctly in FactoryTalk View

ME software.

IMPORTANT

It is important that you review each object and feature in the

converted application to verify that each will function as

expected. Because objects or features may not map directly

into FactoryTalk View ME software, you may need to update

your ladder logic to achieve the same operational results as

your PanelBuilder 1400e application.

26 Publication 2711P-QS001A-EN-P - October 2007

Page 27

Review the Application Conversion Log Chapter 4

Open the Conversion Log

1. Navigate to this folder

location.

2. Double-click the HMI

project folder that contains

the new application name

you created.

You entered this name in

the import wizard when

importing your PanelBuilder

1400e application into

FactoryTalk View ME

software.

The conversion log is stored with the new application that you

created when importing your PanelBuilder 1400e application into

FactoryTalk View ME software.

Follow these steps to locate the conversion log.

C:\Documents and Settings\All Users\Documents\RSView

Enterprise\ME\HMI projects\

TIP

All of your FactoryTalk View ME applications will be located in

this folder. This includes new or imported applications.

3. Double-click the convert.log

file generated by the import

wizard when you imported

your application.

Your convert.log file will

vary from the example

shown.

Publication 2711P-QS001A-EN-P - October 2007 27

Page 28

Chapter 4 Review the Application Conversion Log

Review the Conversion Log

The conversion log contains a list of messages from warnings, errors,

and unsupported features or objects in the converted application. You

can compare these messages to those in the table below for

information on why the message was logged.

Most conversion log messages identify these attributes for a

FactoryTalk View ME object:

• Display name

• Position (x,y) of the object

• New graphic object name

You can use this information to locate the object and make required

modifications. The description for a message may reference a

workaround in this document.

IMPORTANT

Some features or objects are no longer supported in FactoryTalk

View ME software. However, new features or objects are

available providing the same or enhanced functionality.

Match the messages in the conversion log with the messages in the

table. The Display Name, Object Name, and Position Text references

in the messages are unique for each application.

Conversion Log Messages

Message Applies to this

PanelBuilder 1400e object

Blinking wallpaper objects not

supported.

<Object Name> at <Position> on

<Display Name>.

Screen Select Keypad converted to a

default Display List Selector.

<Object Name> at <Position> on

<Display Name>.

Screen Keypad Enable converted to a

default Display List Selector.

<Object Name> at <Position> on

<Display Name>.

• Image

• Te xt

• Drawing

Screen Select Keypad A PanelBuilder 1400e display contained a Screen Select

Screen Select Keypad A PanelBuilder 1400e display contained a Screen Keypad

Description

A PanelBuilder 1400e object with blink set to true was

converted to wallpaper.

• At runtime, the PanelView ‘e’ object would blink.

• In FactoryTalk View ME software, the object will not blink

at runtime because wallpaper objects are disabled.

Keypad object.

FactoryTalk View ME software does not support a Screen

Select Keypad object so converts it to a default Display List

Selector, which needs to be configured.

Enable object.

FactoryTalk View ME software does not support a Screen

Keypad Enable object so converts it to a default Display List

Selector, which needs to be configured.

28 Publication 2711P-QS001A-EN-P - October 2007

Page 29

Conversion Log Messages

Review the Application Conversion Log Chapter 4

Message Applies to this

PanelBuilder 1400e object

"Fixed Position" decimal point display

option not supported.

• Numeric Input Cursor Point

• Numeric Data Display

<Object Name> at <Position> on

<Display Name>.

"PLC Controlled" decimal point

display option not supported.

• Numeric Input Cursor Point

• Numeric Data Display

<Object Name> at <Position> on

<Display Name>.

"Fixed Position" decimal point input

option not supported.

<Object Name> at <Position> on

<Display Name>.

• Numeric Input Cursor Point

• Numeric Keypad Enable

• Numeric Keypad object

Description

The object has its Decimal Point Display option set to Fixed

Position.

FactoryTalk View ME software does not support an option to

display a decimal point in a numeric value. You can achieve the

same result using an expression.

For information on a workaround, refer to page 82.

The object has its Decimal Point Display option set to PLC

Controlled.

FactoryTalk View ME software does not support an option to

display a decimal point in a numeric value. You can achieve the

same result using an expression.

For information on a workaround, refer to page 81.

The object has its Decimal Point Input option set to Fixed

Position.

FactoryTalk View ME software does not support an option to

input a decimal point in a numeric value. You can achieve the

same result using an expression.

"PLC Controlled" decimal point input

option not supported.

<Object Name> at <Position> on

<Display Name>.

"Decimal Key Controlled" decimal

point input option not supported.

<Object Name> at <Position> on

<Display Name>.

Numeric Keypad converted to a

Numeric Input Enable.

<Object Name> at <Position> on

<Display Name>.

For information on a workaround, refer to page 82.

• Numeric Input Cursor Point

• Numeric Keypad Enable

• Numeric Keypad

The object has its Decimal Point Input option set to PLC

Controlled.

FactoryTalk View ME software does not support an option to

input a decimal point in a numeric value. You can achieve the

same result using an expression.

For information on a workaround, refer to page 81.

• Numeric Input Cursor Point

• Numeric Keypad Enable

• Numeric Keypad

The object has its Decimal Point Input option set to Decimal

Key Controlled.

FactoryTalk View ME software does not support an option to

input a decimal point in a numeric value. You can achieve the

same result using an expression.

For information on a workaround, refer to page 81.

Numeric Keypad The display contains a Numeric Keypad object.

FactoryTalk View ME software does not support a Numeric

Keypad object so converts it to a Numeric Input Enable, which

needs to be configured.

Publication 2711P-QS001A-EN-P - October 2007 29

Page 30

Chapter 4 Review the Application Conversion Log

Conversion Log Messages

Message Applies to this

PanelBuilder 1400e object

Date labels not supported on Trend's

Trend A trend has one or more of its minimum, median or maximum

X-Axis.

<Object Name> at <Position> on

<Display Name>.

Blinking pens not supported by Trend.

Trend A trend had one or more of its pens configured to blink.

<Object Name> at <Position> on

<Display Name>.

Background screen plotting of pens

Trend A trend has one of its pens configured to use background

using expressions not supported by

Trend.

<Object Name> at <Position> on

<Display Name>.

Cursor List object at

Cursor List A display contains a Cursor List object.

<PV ‘e’ Position> on <Display Name>

not supported.

Description

date labels enabled.

The FactoryTalk View ME trend displays the current date in its

title. It does not display the minimum, median or maximum

date as part of its X-axis.

The FactoryTalk View ME trend does not allow any of its pens

to blink.

screen plotting and has an expression assigned to the Pen

Value control.

The FactoryTalk View ME trend supports background screen

plotting by adding the tags assigned to the Pen1 to Pen8

controls to a Data Log Model.

You cannot add expressions to a Data Log Model.

FactoryTalk View ME software does not support a Cursor List

object so does not convert it. See page 68 for a workaround.

Multistate Indicator Object List at

<PV ‘e’ Position> on <Display Name >

not supported.

Local Message Object List at

<PV ‘e’ Position> on <Display Name >

not supported.

Numeric Data Display Object List at

<PV ’e’ Position> on <Display Name >

not supported.

Multi-Line Alarm Window blinking

not supported by [ALARM] display.

Multistate Indicator Object List A display contains a Multistate Indicator Object List.

FactoryTalk View ME software does not support a Multistate

Indicator Object List so does not convert it. See page 56 for a

workaround.

Local Message Object List. A display contained a Local Message Object List.

FactoryTalk View ME software does not support a Local

Message Object List so does not convert it. See page 60 for a

workaround.

Numeric Data Display Object

A display contains a Numeric Data Display Object List.

List

FactoryTalk View ME software does not support a Numeric

Data Display Object List so does not convert it. See page 64 for

a workaround.

Alarm Configuration The Alarm Message Window is enabled with:

• Multi-line set.

• Blink enabled.

The multiline Alarm Window is converted to a FactoryTalk

View ME software [ALARM] display containing an Alarm List

object.

30 Publication 2711P-QS001A-EN-P - October 2007

Page 31

Conversion Log Messages

Review the Application Conversion Log Chapter 4

Message Applies to this

PanelBuilder 1400e object

"PLC Controlled Audio" alarm control

Alarm Configuration The PLC Controlled Audio control has a tag assigned.

not supported.

"PLC Controlled Relay" alarm control

Alarm Configuration The PLC Controlled Relay control has a tag assigned.

not supported.

Alarm message "Relay" option not

Alarm Message Configuration One or more relay flags has been enabled for alarm messages.

supported.

Only one hold time is used for

Alarm Configuration One or more of these controls has a tag assigned:

alarming. "Remote Alarm Operation

Hold Time" not supported.

Description

FactoryTalk View ME software does not support a PLC

Controlled Audio alarm control so does not convert it.

FactoryTalk View ME software does not support a PLC

Controlled Relay alarm control so does not convert it.

FactoryTalk View ME software does not support the triggering

of a relay when an alarm is triggered so will not convert this

feature.

• Silence Alarms to PLC

• Clear Window to PLC

• QTY/TIME Reset to PLC

• Message to PLC

FactoryTalk View ME software supports only one hold time for

alarming and this will be set to the value of the PanelView ’e’

Remote Alarm Ack Control Hold Time. The value of the

PanelView ’e’ Remote Alarm Operation Hold Time does not

convert.

"Remote Alarm Control Delay Time"

not supported.

Bit Acknowledging of alarms not

supported.

Screen security settings not

converted for <Display Name>.

RSLinx for FactoryTalk View is not

installed, topics not created.

<PanelView ’e’ Tag Name> converted

to memory tag, as its address is

blank.

Alarm Configuration These controls have a tag assigned:

• Acknowledge to PLC

• Acknowledge Control

• Message to PLC

In FactoryTalk View ME software, if the Ack control is assigned

to an alarm trigger, the terminal will immediately set the Ack

control without waiting for a delay time when the alarm is

acknowledged. The Remote Alarm Control Delay Time does not

convert.

Alarm Configuration The Alarm Acknowledge to PLC option is set to Bit and the

Acknowledge to PLC control has one or more tags assigned.

FactoryTalk View ME software does not support bit

acknowledging of alarms so does not convert the

Acknowledge to PLC tags.

Secure Screen Configuration A screen has one or more Authorize Operator settings enabled.

Screen security is not converted.

FactoryTalk View ME software does support display security.

Security is configured differently.

Communication You need to recreate the shortcut name to the PLC in RSLinx

Enterprise software under Communication Setup.

Any PanelView ’e’ Remote I/O tag with a blank address is

converted to an HMI memory tag.

Publication 2711P-QS001A-EN-P - October 2007 31

Page 32

Chapter 4 Review the Application Conversion Log

Conversion Log Messages

Message Applies to this

PanelBuilder 1400e object

<PanelView ’e’ Tag Name> converted

to memory tag, as its data type is not

supported.

<PanelView ’e’ Tag Name> converted

to memory tag, as the "Bit Position"

data type is not supported.

<PanelView ’e’ Tag Name> converted

to memory tag, as its addresses

references an undefined rack.

<PanelView ’e’ Tag Name> converted

to memory tag, as its addresses is

invalid.

Description

Any PanelView ’e’ Remote I/O tags with these data types are

converted to HMI memory tags.

• 1 Digit BCD

• 2 Digit BCD

• 3 Digit BCD

• 5 Digit BCD

• 6 Digit BCD

• 7 Digit BCD

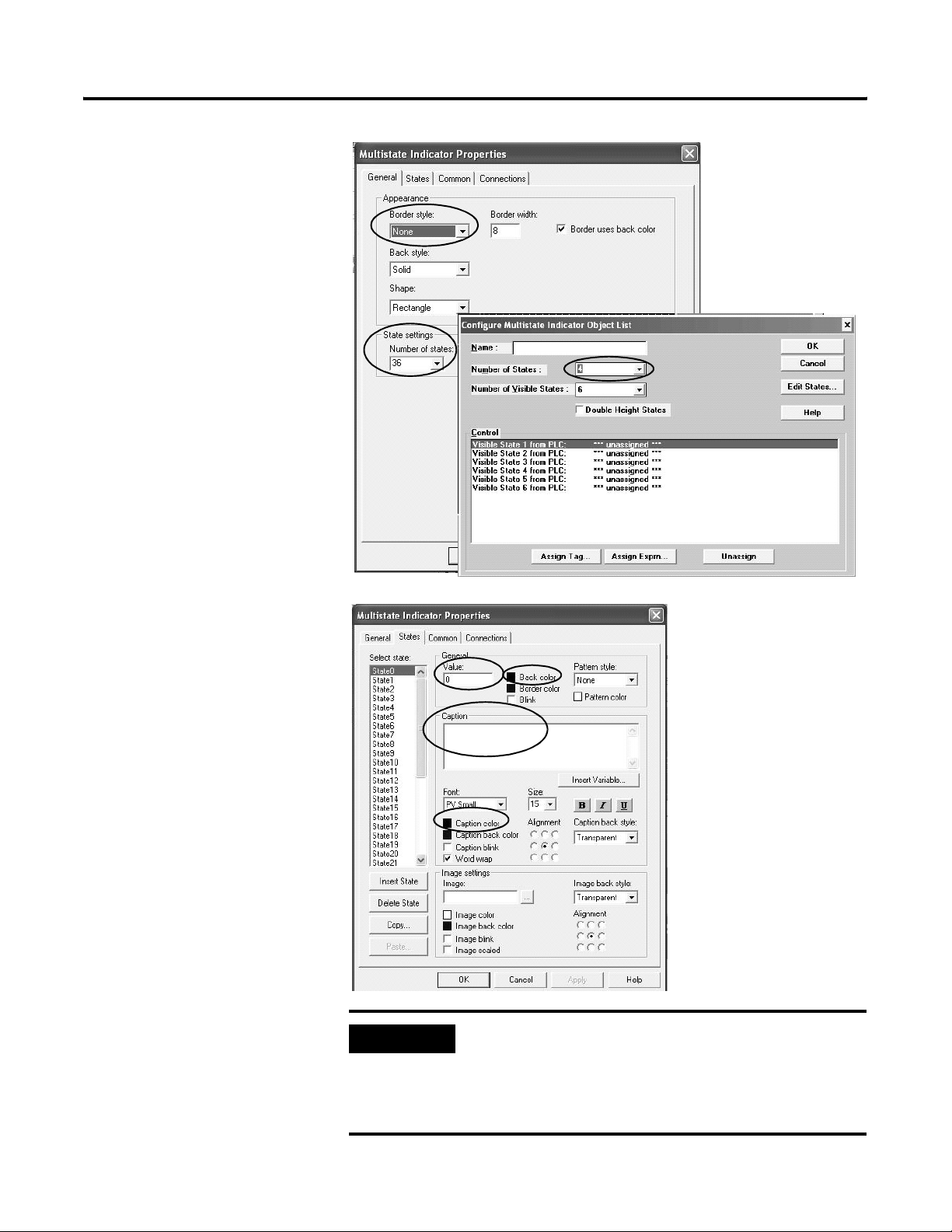

If the data type of a PanelView ’e’ Remote I/O tag is bit

position but the address does not reference a single bit, the

tag is converted to an HMI memory tag.

If a PanelView ’e’ Remote I/O tag has an address with an

undefined rack, the tag is converted to an HMI memory tag.

If a PanelView ’e’ Remote I/O tag does not have a valid I/O

address or block transfer address, the tag is converted to an

HMI memory tag.

32 Publication 2711P-QS001A-EN-P - October 2007

Page 33

Review Object Mapping

Chapter

5

Introduction

Before You Begin

What You Need

In this chapter, you will review how objects and expressions from

PanelBuilder 1400 software map to FactoryTalk View Machine Edition

(ME) software.

• Review migration considerations (Chapter 1).

• Select a PanelView Plus terminal replacement and adapter plate,

if required (Chapter 2).

• Optionally install the PanelView Plus terminal in the existing

PanelView 1000e or 1400e panel cutout (Chapter 2).

• Import your PanelBuilder 1400e .pvc application into

FactoryTalk View ME software (Chapter 3).

• Review the conversion log for your migrated application

(Chapter 4).

• A PanelBuilder 1400e application migrated into FactoryTalk ME

software.

• Conversion log generated by the FactoryTalk View ME Import

Wizard.

33Publication 2711P-QS001A-EN-P - October 2007 33

Page 34

Chapter 5 Review Object Mapping

Follow These Steps

Follow these steps to review how PanelBuilder 1400e objects and

expressions map to FactoryTalk View ME software. This information

will help you correct application errors listed in the conversion log.

Reviewing Object

Mapping

page 35

Reviewing and

Modifying Expressions

page 37

34 Publication 2711P-QS001A-EN-P - October 2007

Page 35

Review Object Mapping Chapter 5

Reviewing Object Mapping

This table identifies PanelBuilder 1400e graphic objects that migrate

into a FactoryTalk View ME application.

IMPORTANT

It is important that you verify the function of all objects after

importing your application to FactoryTalk View ME software.

New objects may not function as expected.

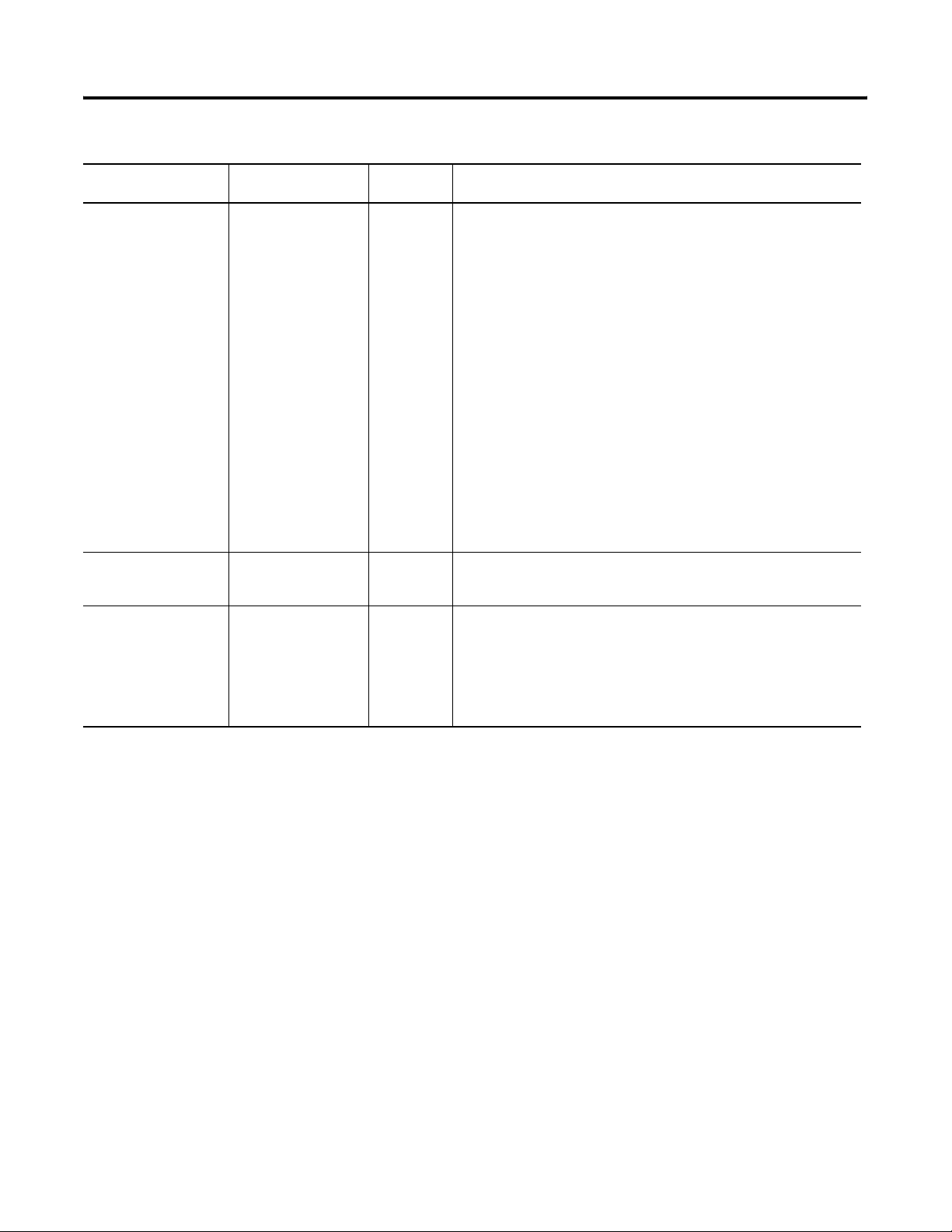

Mapping Objects Between PanelBuilder 1400e and FactoryTalk View ME Software

This PanelBuilder 1400e object Maps to this FactoryTalk View ME object Explanation

Increment Value Button Ramp Button

Decrement Value Button Ramp Button

Increment Value Button with Display Ramp Button and Numeric Display

Decrement Value Button with Display Ramp Button and Numeric Display

Small and Large ASCII Input String Input Enable

Arc with Fill Style set to Solid ME Arc and ME Line The PanelBuilder 1400e object is a closed

shape; the View ME object is not closed

between the arc of two points.

Screen List Selector Screen List Selector

Screen List Selector Enter Button Enter List Key

Screen List Selector

Down Cursor Button

Screen List Selector

Up Cursor Button

Control List Selector Control List Selector

Control List Selector Enter Button Enter List Key

Control List Selector

Down Cursor Button

Control List Selector

Up Cursor Button

Small and Large Screen

Select Keypad

Screen Keypad Enable Display List Selector You will need to configure this object to

Goto Screen Button Goto Display Button

Return to Previous Screen Button Return to Display Button

ASCII Display String Display

Numeric Keypad Enable Button Numeric Input Enable Button

Normally Open

Momentary Push Button

Move Down List Key

Move Up List Key

Move Down List Key

Move Up List Key

Display List Selector You will need to configure this object to

change to the appropriate displays.

change to the appropriate displays.

Momentary Push Button

Normally Closed

Momentary Push Button

Publication 2711P-QS001A-EN-P - October 2007 35

Momentary Push Button

Page 36

Chapter 5 Review Object Mapping

Mapping Objects Between PanelBuilder 1400e and FactoryTalk View ME Software

This PanelBuilder 1400e object Maps to this FactoryTalk View ME object Explanation

Multistate Indicators Multistate Indicators

Numeric Display Numeric Display

Screen Print Button Screen Print Button

Time Display Time and Date Display Set to show time only.

Date Display Time and Date Display Set to show date only.

Alarm History

Sort Alarms Button

Sort By Time/Sort By Value

Alarm Status Reset Qty/Time Button Reset Alarm Status Button

Alarm Panel Alarm Banner

Single Line Alarm Window Alarm Banner

Alarm Status Screen Alarm Status List

Local Messages Local Messages

Information Messages Information Messages

Bar Graphs Bar Graphs

Trend Trend

Text Text

Drawing Objects Drawing Objects

ISA Symbols ISA Symbols

Bitmaps, DXF Images Bitmaps, DXF Images

Digital and String Tag Types Bit and String Tag Types

Supported Analog Tag Types:

• Unsigned Integer

• Integer

• Long Integer

• Floating Point

• Byte

• 3-BCD, 4-BCD, 8-BCD

Supported Analog Tag Types:

• Unsigned Integer

• Integer

• Long Integer

• Floating Point

• Byte

• 3-BCD, 4-BCD

Supported communication:

• DH Plus

• Remote I/O multirack

• ControlNet

File transfers occur over DH+ or

ControlNet networks.

Supported communications:

• DH Plus

• Remote I/O multirack

• ControlNet

File transfers occur over DH+ or ControlNet

networks. No bridging network protocols.

File transfers use a memory card. File transfers use a CompactFlash card.

36 Publication 2711P-QS001A-EN-P - October 2007

Page 37

Review Object Mapping Chapter 5

Reviewing and Modifying Expressions

If any objects in your PanelView 1000e or 1400e application contain

expressions, you need to review the order of precedence in each

expression. The order of precedence may be different between

PanelBuilder 1400e software and FactoryTalk View ME software.

The table compares the order of precedence in expressions between

PanelBuilder 1400e and FactoryTalk View ME software.

IMPORTANT

The text "--check and reuse as needed--" precedes all migrated

expressions. Remove this text from each expression and verify

the order of precedence.

The conversion log does not indicate which objects contained

expressions with the “--check and reuse as needed--”” text. Refer to

Appendix A. Tag substitution provides a method of identifying if a

display contains expressions that require updates. The object explorer

section also describes how to highlight objects with expressions on

the display.

Expressions: Order of Precedence

PanelBuilder 1400e Software FactoryTalk View ME Software

( ) ( )

- (negation) NOT, ~ (tilde)

*, / (floating point division) *, /, MOD, %, **, AND, &&, &, >>, <<

\ (integer point division) +, -, OR, ||, | ^

MOD EQ, = =, NE, <>, LT, <, GT, >, LE, <=. GE. =>

+, - (subtraction) Unchanged

+, < >, < >, <=, >+ Unchanged

NOT Unchanged

And Unchanged

Or Unchanged

Xor Unchanged

Publication 2711P-QS001A-EN-P - October 2007 37

Page 38

Chapter 5 Review Object Mapping

38 Publication 2711P-QS001A-EN-P - October 2007

Page 39

Chapter

6

Review Unsupported Features and Implement

Workarounds for Migration Issues

Introduction

Before You Begin

What You Need

In this chapter, you will review unsupported features in FactoryTalk

View Machine Edition (ME) software and workarounds for common

migration issues. This will help you to resolve errors in the migrated

application.

• Review migration considerations (Chapter 1).

• Select a PanelView Plus terminal replacement and adapter plate,

if required (Chapter 2).

• Optionally install the PanelView Plus terminal in the existing

PanelView 1000e or 1400e panel cutout (Chapter 2).

• Import your PanelBuilder 1400e .pvc application into

FactoryTalk View ME software (Chapter 3).

• Review the conversion log for your migrated application

(Chapter 4).

• Review object and expression mapping (Chapter 5).

• A migrated PanelBuilder 1400 application into FactoryTalk ME

software.

• Conversion log generated by the FactoryTalk View ME Import

Wizard.

39Publication 2711P-QS001A-EN-P - October 2007 39

Page 40

Chapter 6 Review Unsupported Features and Implement Workarounds for Migration Issues

Follow These Steps

Follow this path to review unsupported features in FactoryTalk View

ME software and workarounds for common migration issues.

Reviewing Unsupported

Features

page 41

Reviewing Common

Migration Issues and

Workarounds

page 46

Replacing Scrolling List

Objects

page 47

Replacing the Cursor List

page 48

Bit Position Data Type

Workaround

page 80

Replacing the Multistate

Indicator Object List

Replacing the Local

Message Object List

Replacing the Numeric

Data Display Object List

Replacing the Set Bit

Cursor Point Object

page 56

page 60

page 64

page 68

PLC Controlled Decimal

Point Workaround

page 81

Fixed Position Decimal

Point Workaround

page 82

Retain Last State

Workaround

page 83

Ladder Logic Updates to

Support Visible States

page 86

40 Publication 2711P-QS001A-EN-P - October 2007

Page 41

Review Unsupported Features and Implement Workarounds for Migration Issues Chapter 6

Reviewing Unsupported

Some PanelBuilder 1400e objects or features are not supported in

FactoryTalk View Machine Edition software. Compare the conversion

Features

log with the information on unsupported features to assist with

updates to your migrated application. Additional information is

provided where it is possible to achieve the same result using another

option or work around in your migrated application.

Unsupported Objects or Features in FactoryTalk View Machine Edition

For this PanelBuilder 1400e object These features are unsupported

in FactoryTalk View ME software

Trend Blinking Pens

Date Labels on X-Axis Date is displayed in the trend title.

Background Screen Plotting You can plot tag values in the background by

Scrolling List Objects

• Cursor List

• Multistate Indicator Object List

• Local Message Object List

• Numeric Data Display Object List

Blank States For information on replacement objects in

Additional Information

assigning the tags to a data log model. Tags

configured for background screen plotting are

automatically assigned to a data log model on

conversion. However, data log models do not plot

expression values. Expressions configured for

background screen plotting are not converted.

FactoryTalk View ME software, refer to page 47.

Set Bit Cursor Point Object Not Supported For information on replacement objects , refer to ID:

44265 in the Knowledgebase and also to page 68.

Numeric Display Polarity If a PanelBuilder 1400e application was configured

with the polarity control requiring a negative number

to display the minus sign, the numeric display will

not work properly after the application is converted.

Implicit The implicit option in a PanelBuilder 1400e

application is converted to a fixed position in the

new object. Review these objects to verify that the

number of digits and decimal places are adequate

for displaying the correct value.

Numeric Input Cursor Point Fixed Position Decimal Fixed Position Decimal will convert correctly. You

need to remove the comments from the expressions.

PLC Controlled Decimal Display PLC Controlled Decimal Display may or may not

convert correctly. For information on a workaround in

FactoryTalk View ME software, refer to page 81.

Retain Cursor on Cancel

Goto Configure Mode Button Object not converted

Publication 2711P-QS001A-EN-P - October 2007 41

Page 42

Chapter 6 Review Unsupported Features and Implement Workarounds for Migration Issues

Unsupported Objects or Features in FactoryTalk View Machine Edition

For this PanelBuilder 1400e object These features are unsupported

Additional Information

in FactoryTalk View ME software

Wallpaper, Image, Text, Arc, Ellipse, Line,

Panel, Rectangle, Wedge

Blink Property If you want an object to blink at runtime, unlock the

wallpaper. In FactoryTalk View ME software, all of

the list objects except images and panels use color

animation to blink.

• Panels use the blink property to blink.

• Color images do not blink.

• Monochrome images use the blink property to

blink.

All Objects Object Names Object names are replaced with default object

names in FactoryTalk View ME software. The

PanelBuilder 1400e object name is used for the

object's description. You can view and edit the name

and description in the property panel.

Caption and Image Placement FactoryTalk View ME software supports one, three,

or nine positions for captions and images, depending

on the type of object. On conversion, captions and

images are positioned using the closest match.

Some captions might:

• overlap images.

• be truncated.

• be clipped to fit the object.

Realign or resize objects for best fit.

Multiple Image Labels FactoryTalk View ME software supports one image

label per object or state. If a PanelBuilder 1400e

object is configured to use multiple image labels,

only the top left image is converted. Create a single

image from multiple ones.

Text Overlap Change the border width or resize objects.

Expressions Expressions are converted without modification and

then commented.

• Warning text is placed at the beginning of the

first line of the expression.

• Exclamation marks (!) are placed at the beginning

of each subsequent line of the expression.

To enable the expression, you must remove the

warning text and exclamation marks, and revise the

syntax if necessary.

Expression Length The maximum length of expressions in FactoryTalk

View ME software is 1024 characters. If a

PanelBuilder 1400e expression contains more than

1024 characters, the excess characters are not

converted. Modify the expressions as needed.

42 Publication 2711P-QS001A-EN-P - October 2007

Page 43

Review Unsupported Features and Implement Workarounds for Migration Issues Chapter 6

Unsupported Objects or Features in FactoryTalk View Machine Edition

For this PanelBuilder 1400e object These features are unsupported

Additional Information

in FactoryTalk View ME software

All Displays Display Names In FactoryTalk View ME software, unsupported

characters in display names are replaced with the

underscore character.

Graphic Alignment The graphics may not line up and appear properly.

Resize graphics as needed.

Remote Alarm Ack Bit Array Data Types Workaround with ladder logic change by using the

ack value to indirectly change a tag in an array.

Alarming Controls Acknowledge To PLC Control

Remote Alarm Control Delay Time When an alarm is acknowledged in the FactoryTalk

View ME application, the Ack control, if assigned, is

set immediately, without waiting for a delay time.

Update the ladder logic to implement a delay timer

in PLC.

PLC Controlled Relay Control The terminal does not have a relay. Use the PLC

controller to turn on device.

PLC Controlled Audio Control The terminal does not have audio. Use the PLC

controller to turn on a horn.

Blinking Alarm Messages

Alarm Relays The terminal does not have a relay. Use the PLC

controller to turn on device.

Remote Alarm Operation Hold Time The PanelBuilder 1400e Remote Alarm Ack Control

Hold Time will be used for all alarm hold times. You

can change the hold time in the Advanced tab of the

Alarm Setup editor in FactoryTalk View ME software.

Alarm Handshaking

Message Handshake Control

Security Runtime Password Changes In the PanelBuilder 1400e software, user passwords

are set up in the configuration mode screens.

FactoryTalk View ME software requires the Change

Password button on a display.

Display Security Settings FactoryTalk View ME software uses a different

method to assign security to graphic displays. You

must reapply security. The software uses a logon

system of security similar to RSView32 software.

Once logged on, the operator does not need to

re-enter the password until manually logged off, or

optionally after an idle time.

Publication 2711P-QS001A-EN-P - October 2007 43

Page 44

Chapter 6 Review Unsupported Features and Implement Workarounds for Migration Issues

Unsupported Objects or Features in FactoryTalk View Machine Edition

For this PanelBuilder 1400e object These features are unsupported

Additional Information

in FactoryTalk View ME software

Communications (RIO) Passthrough Downloads Use an Ethernet connection or a CompactFlash card

to transfer files.

Remote I/O Connector Wiring The Remote I/O connector wiring for the PanelView

Plus terminal is reversed from the PanelView 1000e

and 1400e terminals.

Remote I/O Tag with Blank Address Remote I/O tags with blank addresses are converted

to HMI memory tags. An error is recorded in the

conversion log.

Data Types Bit Position If a bit position data type does not reference a single

bit, it is converted to an HMI memory tag. An error is

recorded in the conversion log.

• Create an expression to isolate the bits used to

drive the state of the display object, such as a

multistate indicator.

For information on how to implement this

workaround, refer to page 80.

• For write objects, such as push buttons, there is

no workaround except to change the ladder logic.

• For Remote I/O, you may need to change the

Rack/Block Transfer configuration.

• For DH+ and ControlNet, unscheduled tags with

the bit position data type are converted to HMI

analog tags with a data type of default.

Binary A binary tag is converted to an HMI memory tag if it

does not reference:

• a single bit.

• a single word.

• a length or range of 8 or 16 bits and does not

start at an offset of 0 or 8 (SLC controller) or 10

(PLC-5 controller).

An error is recorded in the conversion log.

• Create an expression to isolate the bits used to

drive the state of display object, such as a

multistate indicator.

• For write objects such as push buttons, there is

no workaround.

BCD BCD data types are not supported: 1-BCD, 2-BCD,

5-BCD, 6-BCD, 7-BCD, 8-BCD.

Tags that use this data type are converted to analog

tags with the default data type. The default data

type uses floating point values.

Byte If the byte address does not have a bit offset of 0 or

8, it is converted to an HMI memory tag. The error is

recorded in the conversion log

44 Publication 2711P-QS001A-EN-P - October 2007

Page 45

Review Unsupported Features and Implement Workarounds for Migration Issues Chapter 6

Unsupported Objects or Features in FactoryTalk View Machine Edition

For this PanelBuilder 1400e object These features are unsupported

Additional Information

in FactoryTalk View ME software

Data Types Block Tags Block tags monitor alarms in PanelBuilder 1400e

applications and are converted to bit arrays. An error

is recorded in the conversion log.

Analog Tags with One Bit Length PanelBuilder 1400e analog tags that are one bit in

length (0 is min, 1 is max) convert to analog tags in

FactoryTalk View ME software, but the value is

0 and -1 (all bits off, all bits on). This feature is

typically used for indicator objects with two states.

In a FactoryTalk View application, this results in an

incorrect state. Change analog tags to bit data types.

Important: No message appears in the conversion

log. Modify any analog tags that are one bit in

length.

File Transfers Transfer Inhibit These three controls are not necessary in FactoryTalk

View ME software because the transfer utility lets

you transfer the runtime project file while running a

project on the runtime terminal.

Transfer Request

Transfer Status

Design Time Features Tag Cross-Reference

Screen Captures

Application Validation

Application memory usage

calculation

Saving applications to a user

specified location

Tag Search and Replace Use tag substitution on each page or see

Default Object/Graphic Display

Settings

Power Up Options Write Last Terminal State to

Controller

Knowledgebase ID: 29942. RSView Graphic Tags

Search and Replace using Graphics XML Exported

Files

Publication 2711P-QS001A-EN-P - October 2007 45

Page 46

Chapter 6 Review Unsupported Features and Implement Workarounds for Migration Issues

Reviewing Common Migration Issues and Workarounds

Required Files and Utilities

Some graphic objects, data types, and other features do not migrate

directly into FactoryTalk View ME software. The most common

migration issues relate to these objects or features:

• Scrolling list objects

• Cursor list objects

• Set bit cursor point objects

• Bit position data type

• PLC controlled or fixed position decimal

• Retain last state

• Ladder logic updates to support visible states

FactoryTalkView ME software provides replacement objects and

workarounds that provide the same if not similar functionality.

The Rockwell Automation Knowledgebase document contains files

and utilities to simplify the migration process.

Document ID: 44265

Document Title: Migrating PanelView Enhanced Terminal Applications

Download the Migration Solutions.zip attachment containing the

required files and utilities. This file contains a Migration Solutions.apa

demo project, the tag converter wizard utility, and a set bit cursor

point ActiveX Control.

• Migration solutions demo project contains replacement

objects for the cursor list, local message list, multisate indicator

object list, numeric data display object list and the set bit cursor

point. You can import these displays into your converted

application, copy the objects, and then configure them.

To see how the set bit cusror point works, click the Display Test

Run button on the set bit cursor point display.

• Tag converter wizard utility optimizes tags in the converted

application. To improve performance, the utility converts HMI

tags to alias or direct reference tags.

• Set bit cursor point ActiveX control replaces the set bit

cursor point object in the converted application. To activate this

control, it needs to be registered on our computer and the

PanelView Plus CE terminal

46 Publication 2711P-QS001A-EN-P - October 2007

Page 47

Review Unsupported Features and Implement Workarounds for Migration Issues Chapter 6

Replacing Scrolling List

Scrolling list objects in PanelBuilder 1400e software consists of a

cursor list and one or more object lists. The operator can move

Objects

through a maximum of 999 items within these object lists.

Scrolling lists can multiplex PLC output data to the PanelView ‘e’

terminal, minimizing the ladder logic required to display and edit

large amounts of data.

FactoryTalk View ME software does not support scrolling list objects.

but does provide replacement objects to perform the same operations.

Replacement Objects for Scrolling List Objects

Replace this PanelView ‘e’ object With this FactoryTalk View ME object See

Cursor List • Piloted Control List Selector

• Key buttons

• Terminal function keys

Multistate Indicator Object List Multistate Indicator Page 56

Local Message Object List Local Message Page 60

Numeric Data Display Object List Numeric Data Display Page 64

• Page 48

• Page 53

• Page 55

Publication 2711P-QS001A-EN-P - October 2007 47

Page 48

Chapter 6 Review Unsupported Features and Implement Workarounds for Migration Issues

Replacing the Cursor List

1. Select

Objects>Advanced>Piloted

Control List Selector.

2. Draw and size the object on

your display.

Replacement objects for the cursor list object in FactoryTalk View ME

software are the piloted control list selector, key objects, and terminal

function keys.

• The piloted control list selector replaces the cursor list.

• The key objects provide on-screen navigation for the list such as